Ingersoll-Rand 650409-X User Manual

OPERATOR’S MANUAL 650409-X

SPECIFICATIONS, SERVICE KITS, G ENERAL INFORMATION, TROUBLESHOOTING

INCLUDE MANUALS: 65106-X Lower Pump End (pn 97999-578), 6544X-X AirMotor (pn 97999-64) & S-632 General Information Manual (pn 97999-624).

4-1/4” AIR MOTOR

9:1 RATIO

4” STROKE

TWO-BALL PUMP SERIES

650409-X

STAINLESS STEEL

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

RELEASED: 05-28-93

REVISED: 6-1-10

(REV. C)

SERVICE KITS

• Use only genuine AROR replacement parts to assure compatible

pressure rating and longest service life.

• 61268 for repair of air motor section.

• 637010 for repair of 65106 lower pump ends.

637010-4

637011

for repair of 65106-4 lower pump ends.

for replacement of lower ball check.

SPECIFICATIONS

Model Series (refer to option chart) 650409-X........

Type Air Operated, Two-ball.........................

Ratio 9:1.........................

Air Motor

650409 65444-B....................

650409-1 65444-2-B...................

650409-4 65444-B...................

Motor Repair Kit 61268...............

Motor Diameter 4-1/4” (10.795 cm)...............

Stroke (Double Acting) 4” (10.16 cm)..........

Air Inlet (female) 1/2 - 14 N.P.T.F. - 1...............

Air Exhaust (female) 1-1/4 - 11-1/2 N.P.T.F. - 1............

Lower Pump End Series

650409 65106....................

650409-1 65106-4...................

650409-4 65106-4...................

Lower Pump Repair Kit 637010-X.........

Material Inlet (female) 1-1/4 - 11-1/2 N.P.S.M............

Material Outlet (female) 3/4 - 14 N.P.T.F. - 1.........

Weight 45 lbs (20.4 kgs)........................

PERFORMANCE

Air Inlet Pressure Range 0 - 150 p.s.i. (0 - 10.3 bar)..........

Fluid Pressure Range 0 - 1350 p.s.i. (0 - 93.1 bar)............

Maximum Rec’d Cycles / Minute 60....

Displacement In

Volume / Cycle 6.1 oz. (180.2 ml)..................

Cycles Per Gallon 21...............

Flow @ 60 Cycles / Minute 2.9 g.p.m. (10.8 l.p.m.).........

Noise Level @ 60 p.s.i. - 40 c.p.m. 80.0 db(A)

Tested with 91790 muffler installed. The pump sound pressure level has been updated

to an Equivalent Continuous Sound Level (L

13-1971, CAGI-PNEUROP S5.1 using four microphone locations.

3

Per Cycle 11. 0........

...

) to meet the intent of ANSI S1.

Aeq

PUMP DATA

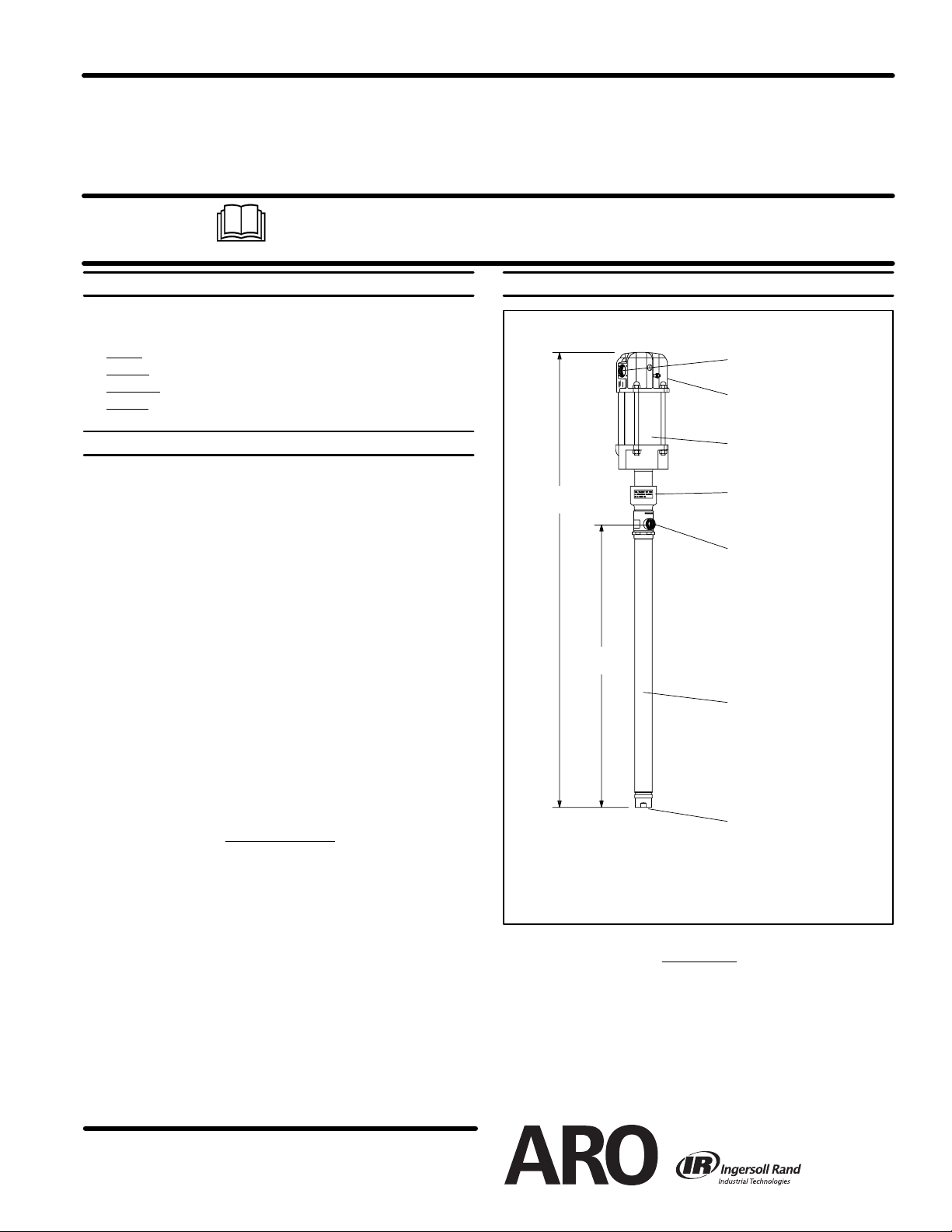

MODEL 650409-X

Air Exhaust (female)

1-1 / 4 - 11- 1 /2 N.P. T.F. - 1

Air Inlet (female)(not shown)

1/2 - 14 N.P.T.F. - 1

Air Motor 65444-X-B

(see manual 6544X-X)

55-3/16”

(1401 mm)

34-11/32”

(872 mm)

Figure 1

NOTE: Dimensions are shown in inches and (mm), supplied for reference only.

Accessories: 66100 wall mount bracket, 91790 silencer.

IMPORTANT

This is one of the four documents which support the pump. Replacement copies of these forms are available upon request.

= 650409-X Model Operator’s Manual (pn 97999-581)

- General Information - Industrial Piston Pumps (pn 97999-624)

- 65106-X Lower Pump End Operator’s Manual (pn 97999-578)

- 6544X-X Air Motor Operator’s Manual (pn 97999-64)

Spacer Section

(see figure 2)

Material Outlet (female)

3/4 - 14 N.P.T.F. - 1

Lower Pump 65106-X

(see manual 65106-X)

Material Inlet (female)

1-1/4 - 11-1/2 N.P.S.M.

INGERSOLL RAND COMPANY

209 NORTH MAIN STREET-BRYAN, OHIO 43506

(800) 495--0276 D FAX (800) 892--6276

www.ingersollrandproducts.com

E2010 CCN 81690570

PUMP OPTION DESCRIPTION CHART

650409 - X

DESCRIPTION

GENERAL DESCRIPTION

WARNING

mumoperating pressure of 1,350 p.s.i. (93 bar) at 150 p.s.i. (10.3

bar) inlet air pressure.

INLET PRESSURE TO PUMP MOTOR

Pump ratio is an expression of the relationship between the pump motor area and the

lower pump end area. EXAMPLE: When 150 p.s.i. (10.3 bar) inlet pressure is supplied

to the motor of a 9:1 ratio pump it will develop a maximum of 1,350 p.s.i. (93 bar) fluid

pressure (at no flow) - as the fluid control is opened, the flow rate will increase as the

motor cycle rate increases to keep up with the demand.

WARNING

safety precautions and important information.

• The two-ball design provides for easy priming of the lower foot valve.

The double acting feature is standard in all ARO industrial pumps.

Material is delivered to the pump discharge outlet on both the up and

down stroke.

• The motor is connected to the lower pump end with a spacer tube

and solvent cup. This allows for lubrication of the upper packing

gland and to prevent air motor contamination because of normal

wear and eventual leakage through the material packing gland.

Pump problems can occur in either the air motor section or the lower

pump end section. Use these basic guidelines to help determine which

section is affected. Be sure to eliminate any possible non-pump problems before suspecting pump malfunction.

Pump will not cycle.

• No pressure to the motor. See motor manual.

• Restricted return lines. Clean obstruction.

• Damaged motor. Service motor

HAZARDOUS PRESSURE. Do not exceed maxi-

PUMP RATIO X MAXIMUM PUMP

= FLUID PRESSURE

Refer to general information sheet for additional

TROUBLE SHOOTING

DESCRIPTION

PTFE Packing / Plain Rod & Tube, Standard Motor

1 UHMW-PE Packing / Plain Rod & Tube, Counter Motor

4 UHMW-PE Packing / Plain Rod & Tube, Standard Motor

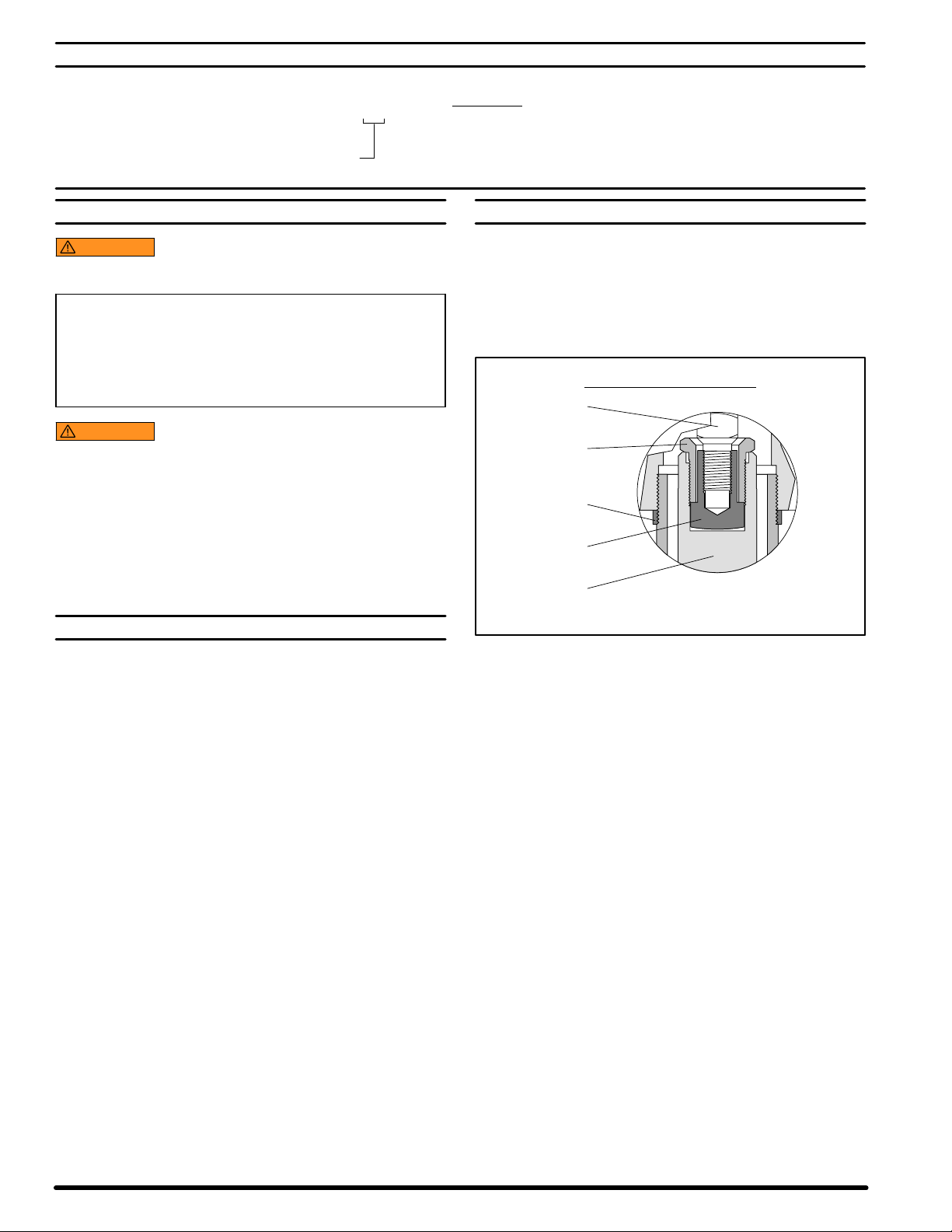

PUMP CONNECTION - UPPER / LOWER

NOTE: All threads are right hand.

1. Loosen (90606) lock nut and unscrew entire pump from the air motor. This will expose (90609) retaining screw (see figure 2).

2. Unscrew (90609) retaining screw to remove pump assembly from

the air motor.

3. Remove (90608) shoulder nut to remove (90609) retaining screw.

PUMP CONNECTOR DETAIL

Pump Motor

Piston Rod

Retaining Screw

90609

Lock Nut

(90606) Ref.

Shoulder Nut

90608

Lower Pump

Plunger

Figure 2

REASSEMBLY

1. Slide (90609) retaining screw over air motor rod (see figure 2).

2. Screw (90608) shoulder nut to air motor rod.

3. Apply Loctite 242 to threads of (90609) retaining screw and screw

(90609) retaining screw into lower pump plunger.

4. Screw the lower pump assembly to the air motor.

5. Position air motor exhaust port approximately 90_ from lower pump

outlet.

6. Screw (90606) lock nut against air motor base and tighten to 50 - 65

ft lbs (67.8 - 88.1 Nm).

No material at the outlet (pump continually cycles).

• Check the material supply, disconnect or shut off the air supply and

replenish the material, reconnect.

Material on one stroke only (fast downstroke).

• The lower check may not be seating in the foot valve (see lower

pump disassembly). Remove the check from the foot valve, clean

and inspect the valve seat area. If check or foot valve are damaged,

replace.

Material on one stroke only (fast upstroke).

• The middle packings may be worn (see lower pump disassembly).

Replace the seals as necessary.

Material leakage out of the solvent cup or material appears on the

pump plunger rod.

• Tighten the solvent cup until leakage discontinues. If this procedure

does not aid in stopping the leakage problem, the upper packings

may be worn (see lower pump disassembly). Replace the seals as

necessary.

PN 97999-581

650409-XPage2of2