Ingersoll-Rand 4RSERIES Operation And Maintenance Manual

03534809

OPERATION AND MAINTENANCE MANUAL

for

SERIES 4R SCREWDRIVERS

Form P6782

Edition 5

January, 1994

IMPORTANT SAFETY INFORMATION ENCLOSED.

READ THIS MANUAL BEFORE OPERATING TOOL.

FAILURE TO OBSERVE THE FOLLOWING WARNINGS COULD RESULT IN INJURY.

l

Always operate, inspect and maintain this tool in

accordance with American National Standards

Institute Safety Code for Portable Air Tools

(ANSI B186.1).

l

For safety, top performance and maximum

durability of parts, operate this tool at 90 psig

(6.2 bar/620 kPa) maximum air pressure at the

inlet with 1/4” (6 mm) inside diameter air supply

hose.

l

Air powered tools can vibrate in use. Vibration,

repetitive motions or uncomfortable positions may

be harmful to your hands and arms. Stop using any

tool if discomfort, tingling feeling or pain occurs.

Seek medical advice before resuming use.

l

Always turn off the air supply and disconnect the

The use of other than genuine Ingersoll-Rand replacement parts may result in safety hazards, decreased tool

performance, and increased maintenance, and may invalidate all warranties.

Ingersoll-Rand is not responsible for customer modification of tools for applications on which Ingersoll-Rand was not

consulted.

Repairs should be made only by authorized trained personnel. Consult your nearest Ingersoll-Rand Authorized

Servicenter.

It is the responsibility of the employer to place the information in this manual into the hands of the operator.

air supply hose before installing, removing or

adjusting any accessory on this tool, or before

performing any maintenance on this tool.

l

Keep hands, loose clothing and long hair away

from rotating end of tool.

l

Anticipate and be alert for sudden changes in

motion during start up and operation of any power

tool.

l

Tool accessory may continue to rotate briefly after

throttle is released.

l

Do not lubricate tools with flammable or volatile

liquids such as kerosene, diesel or jet fuel.

l

Do not remove any labels. Replace any damaged

label.

l

Use accessories recommended by Ingersoll-Rand.

Refer All Communications to the Nearest

Ingersoll-Rand Office or Distributor.

© Ingersoll-Rand Company 1994

Printed in U.S.A.

WARNING LABEL IDENTIFICATION

FAILURE TO OBSERVE THE FOLLOWING WARNINGS COULD RESULT IN INJURY.

A WARNING

Always wear eye protection

when operating or performing maintenance on this

tool.

e, WARNING

Always turn off the air

supply and disconnect the

air supply hose before

installing, removing or

adjusting any accessory on

this tool, or before performing any maintenance on this

tool.

A WARNING

Do not carry the tool by

the hose.

I

A WARNING

Always wear hearing

protection when operating

this tool.

A WARNING

Air powered tools can

vibrate in use. Vibration,

repetitive motions or uncomfortable positions may be

harmful to your hands and

arms. Stop using any tool if

discomfort, tingling feeling

or pain occurs. Seek medical advice before resuming

use.

pI WARNING

I

Do not use damaged, frayed

or deteriorated air hoses

and fittings.

A WARNING

Keep body stance balanced

and firm. Do not overreach

when operating this tool.

A WARNING

Operate at 90 psig

(6.2 bar/620 kPa)

Maximum air pressure.

2

PLACING TOOL IN SERVICE

LUBRICATION

Ingersoll-Rand No. 10 Ingersoll-Rand No. 28

Ingersoll-Rand No. 67

Always use an air line lubricator with these tools.

We recommend the following Filter-Lubricator-Regulator

Unit:

For USA - No. C05-02-G00

For International -No. C01-C2-T29

Before starting the tool and after each eight hours of

operation, unless an air

few drops of Ingersoll-Rand No. 10 Gil into the air inlet.

The cavity around outside of Rear Rotor Bearing (42) in

Motor Housing (1) should be filled 50 to 75 percent

capacity with Ingersoll-Rand No. 28 Grease.

Gearing

For models

with L gearing, inject approximately 6 to

8 cc of Ingersoll-Rand No. 28 Grease into the Grease

Fitting (5 1) in the Gear Case (50) after each 50 000 cycles

or 100 hours of operation, whichever comes first.

For models with M, N or P gearing,

approximately 10 to 12 cc of Ingersoll-Rand No. 28

Grease into the Grease Fitting (5 1) in the Gear Case (50)

after each 50 000 cycles or 100 hours of operation,

whichever comes first.

Clutch

Lubricate the 4C15, 4C17 or 4Sl Adjustable Clutch with 6

to 8 cc of Ingersoll-Rand No. 67 Grease after each 50 000

cycles or each 100 hours of operation, whichever occurs

first. Lubricate the Clutches as follows:

line lubricator is used, inject a

inject

clockwise

for the 4C15 and

counterclockwise

for the

4S1 until there is no compression on the Clutch

spring (112 or 261).

For 4C17,

insert the Clutch Adjusting Key into the

hole in the Clutch Adjusting Nut and, while holding

the Nut against rotation and pushing against the Bit

Holder to engage the clutch jaws, rotate the Bit

Holder counterclockwise until them is no compression

on the Clutch Spring (209).

Using a wrench on the flats of the Gear Case and an

4.

adjustable spanner wrench in the slot of the Clutch

Housing, unscrew the Clutch Housing from the Gear

Case.

This is a left-hand thread; turn clockwise to

remove.

For 4C15, using

5.

snap ring pliers, remove the Sleeve

Spring Retainer (119) from the Bit Holder. Slide the

Retaining Sleeve Spring (118) and Bit Retaining

Sleeve (117) from the Bit Holder and remove the Bit

Retaining Ball (116).

Withdraw the assembled clutch from the Clutch

6.

Housing and lubricate all bearing surfaces, bearings

and balls with the recommended grease.

Do not get your fingers between the clutch

components.

To reassemble the Clutch, perform steps 3 through 6

7.

in Changing the Clutch Spring.

CLUTCH ADJUSTMENT

Turn off the air supply and disconnect the air supply

hose at the tool before performing any maintenance.

1. Rotate the Adjusting Hole Cover (103,219 or 252) to

expose the slot in the Clutch Housing (101,201 or

250).

2.

For 4C15 or 4S1,

insert a l/4” Allen Wrench into the

Bit Holder (106 or 270) and rotate the Bit Holder until

the hole in the Clutch Adjusting Nut (113 or 256) is

aligned with the slot in the Clutch Housing.

For 4C17,

insert a l/4” Allen Wrench into the Bit

Holder (217) and, while pushing against the Bit

Holder to engage the clutch jaws, rotate the Bit

Holder until the hole in the Clutch Adjusting Nut

(214) is aligned with the slot in the Clutch Housing.

3.

For 4C15 or 4S1,

insert the Clutch Adjusting Key

into the hole in the Clutch Adjusting Nut and, while

holding the Nut against rotation, rotate the Bit Holder

The 4C15, 4C17 and 4Sl clutches can be externally

adjusted within a certain range to ratchet when a

predetermined torque has been delivered. To adjust the

clutch, proceed as follows:

1.

Turn off the air supply and disconnect the air

supply hose at the tool before proceeding.

2. Rotate the Adjusting Hole Cover (103,219 or 252) to

expose the slot in the Clutch Housing (101,201 or

250).

3.

For 4C15 or 4S1, insert

a l/4”

Allen

Wrench into

the Bit Holder (106 or 270) and rotate the Bit Holder

until the hole in the Clutch Adjusting Nut (113 or

256)

is aligned with the slot in the Clutch Housing.

For 4C17,

insert a l/4” Allen Wrench into the Bit

Holder (217) and, while pushing against the Bit

Holder to engage the clutch jaws, rotate the Bit

Holder until the hole in the Clutch Adjusting Nut

(214) is aligned with the slot in the Clutch Housing.

PLACING TOOL IN SERVICE

4.

For 4C15 or 4S1,

into the hole in the Clutch Adjusting Nut and, while

holding the Nut against rotation, rotate the Bit Holder

to adjust the torque output.

For 4C17,

hole in the Clutch Adjusting Nut and, while holding

the Nut against rotation and pushing against the Bit

Holder to engage the clutch jaws, rotate the Bit

Holder to adjust the torque output.

5. Rotating the Bit Holder clockwise increases the

compression on the Clutch Spring (112,209 or 261)

and raises the torque at which the clutch will ratchet.

The most satisfactory adjustment is usually

obtained by use of the tool on the actual

application, and increasing or decreasing the

delivered torque until the desired setting is

reached. In any event, it is recommended that the

final adjustment be made by gradual progression.

These clutches, when equipped with a Heavy

Spring, can he set beyond the torque capacity of

the tool, in which case the tool will stall before the

clutch ratchets. Do not adjust the clutch beyond

the torque capacity of the tool.

- CHANGING THE CLUTCH SPRING -

Additional Clutch Springs are available for these clutches

which allow the tools to be used when the desired torque

does not fall within the torque range of the furnished

Spring. To change a Clutch Spring (112,209 or 261)

proceed as follows:

1. Withdraw the assembled clutch from the Clutch

Housing (101,201 or 250) after performing steps 1

through 6 as described in the section

Lubrication.

2. To change the Clutch Spring in the 4C15 Clutch,

proceed as follows:

a. Grasp the spline of the Clutch Shaft Support

(120) in leather-covered or copper-covered vise

jaws with the Bit Holder (106) upward.

b. Using snap ring piers, remove the Bit Holder

stop (115).

c. Using a wrench and keeping pressure against the

Spring Seat (110) to prevent the Clutch Balls

(108) from falling out of position, unscrew and

remove the Clutch Adjusting Nut (113).

insert the Clutch Adjusting Key

insert the Clutch Adjusting Key into the

Clutch

This is a left-hand thread; turn clockwise to

remove.

d. Lift off the Adjusting Nut Lock (114) and the

Clutch Spring.

e. Install the new Clutch Spring and replace the

Adjusting Nut Lock.

f. Thread the Clutch Adjusting Nut onto the Bit

Holder and replace the Bit Holder Stop.

g. Remove the assembled clutch from the vise.

3. To change the Clutch Spring in the 4C17

Clutch, proceed as follows:

Carefully grasp the Front Clutch Jaw (204) in

a.

leather-covered or copper-covered vise jaws

with the Clutch Adjusting Nut (214) upward.

Using a wrench on the flats of the Clutch

b.

Adjusting Nut (214), loosen and remove the Nut.

With the assembly in the vise and while applying

C.

slight downward pressure to the Clutch Ball Seat

(208), remove the Adjusting Nut Lock (213),

Spring Seat Bearing (212), Clutch Spring Seat

(211) and the Clutch Spring from the Clutch

Driver (203).

Thoroughly grease the Bearing and Adjusting Nut

d.

Lock, and in the order named, slide the following

over the Clutch Driver: the new Clutch Spring,

the Clutch Spring Seat, the Spring Seat Bearing

and the Adjusting Nut Lock, indented side

trailing.

e.

Start the Clutch Adjusting Nut, detent side first,

onto the Clutch Driver and run it finger tight

against the compression of the Spring. With a

wrench, tighten the Nut an additional one or two

turns.

f.

Remove the assembled clutch from the vise.

4. To change the Clutch Spring in the 4Sl Clutch,

proceed as follows:

a Grasp a l/4” Allen Wrench in vise jaws with a

section of the hex pointing upward. Position the

Bit Holder (270) on the Allen Wrench so that the

splined end of the Clutch Driver (253) is upward

b. Remove the Clutch Return Spring (254) and

Return Spring Collar (255) from the Clutch

Driver.

c. Using snap ring pliers, remove the Spring Seat

Stop (260) from the threaded section of the

Clutch Driver.

d. Using a wrench, unscrew and remove the Clutch

Adjusting Nut (256).

PLACING TOOL IN SERVICE

e.

Lift off the Adjusting Nut Lock (257), the Thrust

Bearing (258), the Clutch Spring Seat (259) and

the Clutch Spring from the Clutch Driver.

f.

Thoroughly grease the Bearing and Adjusting Nut

Lock, and in the order named, slide the following

over the Clutch Driver: the new Clutch Spring,

the Clutch Spring Seat, the Thrust Bearing and

the Adjusting Nut Lock, indented side trailing.

Start the Clutch Adjusting Nut, detent side first,

onto the Clutch Driver and run it finger tight

against the compression of the Spring. With a

wrench, tighten the Nut an additional one or two

turns.

h.

Using snap ring pliers, install the Spring Seat

Stop on the Clutch Driver.

i.

Place the Return Spring Collar, concave end

trailing, and the Clutch Return Spring on the

splined end of the Clutch Driver.

Remove the assembled clutch from the Allen

j.

Wrench and the wrench from the vise.

5.

Insert the assembled clutch, Bit Holder end first, into

the Clutch Housing.

6.

For 4C15, insert the Bit Retaining Ball into the hole

in the Bit Driver. Install the Bit Retaining Sleeve on

the hub of the Bit Holder against the Bit Retaining

Sleeve Stop (123). Install the Retaining Sleeve

Spring on the Bit Holder and inside the Sleeve. Using

snap ring pliers and compressing the Spring, install

the Sleeve Spring Retainer in the external groove near

the output end of the Bit Holder.

7.

Thread the assembled Clutch onto the Gear Case.

This is a left-hand thread; turn clockwise to

remove.

lighten the Clutch Housing between 2 to 5 ft-lb

(3 to 7 Nm) torque.

8. Adjust the Clutch as directed in the section Clutch

Adjustment.

INSTALLATION

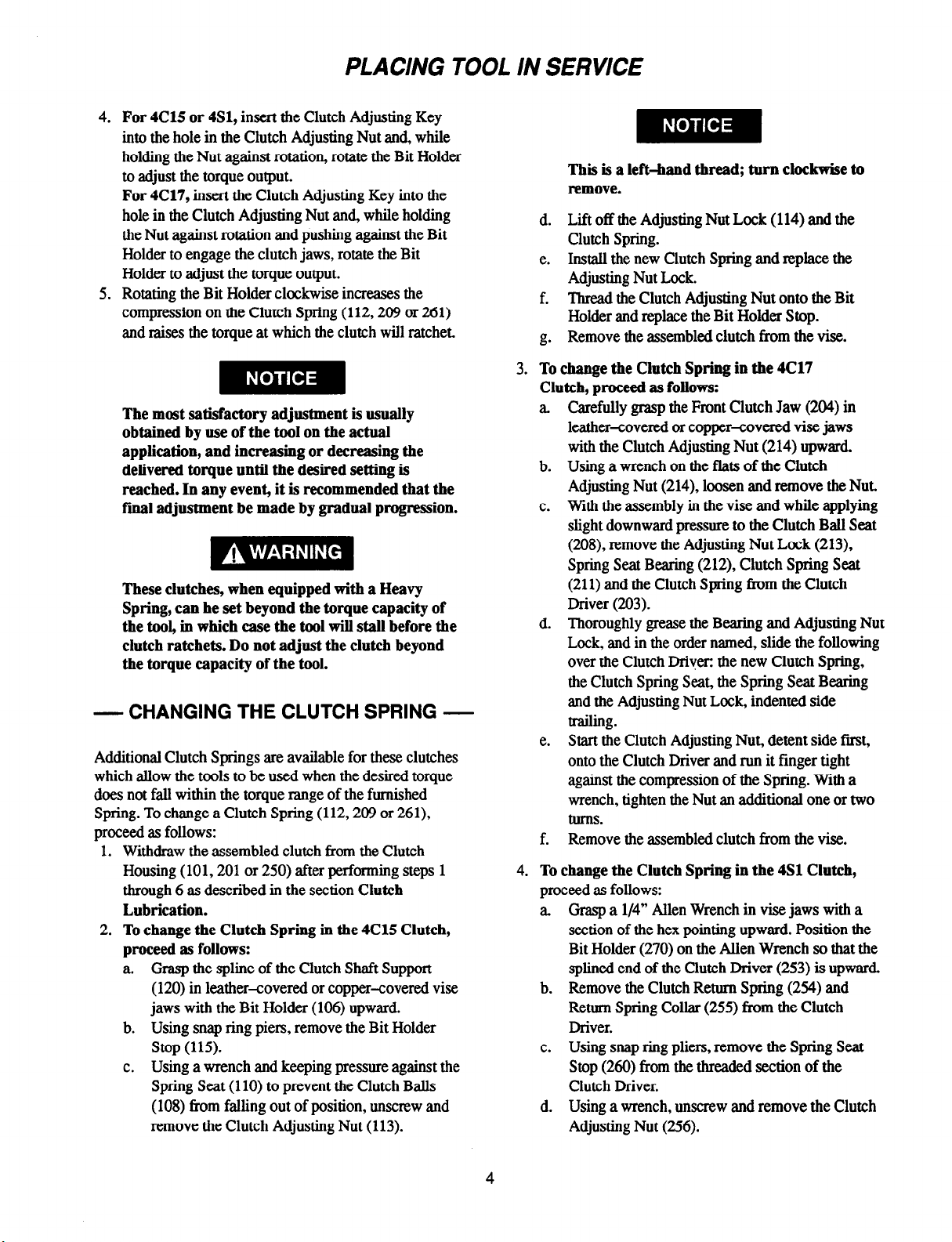

Air Supply and Connections

Always use clean dry air. Dust, corrosive fumes and/or

excessive moisture can ruin the motor of an air tool. An

air line filter can greatly increase the live of an air tool.

The filter removes dust and moisture. Low pressure (under

90 psig; 6.2 bar/620 kPa) reduces the speed of all air tools.

Low air pressure not only wastes time, but also costs

money. High air pressure (over 90 psig; 6.2 bar/620 kPa)

raises performance beyond the rated capacity of the tool

and could cause injury. Be sure all hoses and fittings ate

the correct size and are tightly secured.

See Dwg. TPD905-1 for a typical piping arrangement.

MAIN LINES 3 TIMES

AIR TOOL INLET SIZE

TO

AIR

AIR TOOL INLET SIZE

DRAIN REGULARLY

COMPRESSOR

(Dwg. TPD905-1)

The Model 4R Screwdriver is &signed

electronic and aerospace industries and

for

fastening applications in automotive and appliance assembly, the

for

woodworking.

HOW TO ORDER A SCREWDRIVER

REVERSIBLE WITH PISTOL GRIP HANDLE AND ADJUSTABLE CUSHION CLUTCH

Torque Range (Soft Draw)

Model

.-----

4RAMCl

4RANCl

4RAPCl

I

in-lb

-- .-

15-65

20-80

20-105

5

Nm

-.. ..-

l-7-7.4

2.3-9.1

2.3-11.9

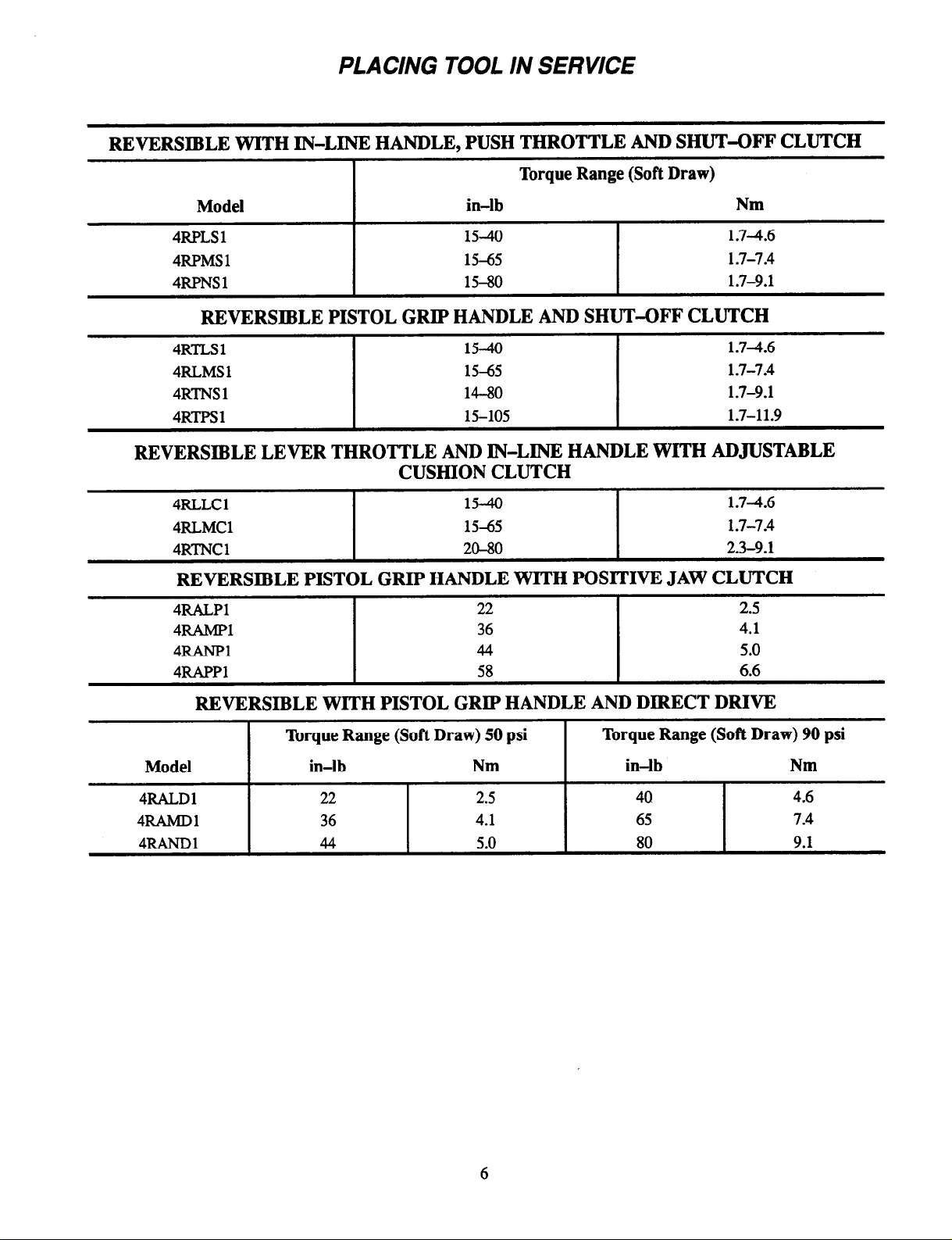

PLACING TOOL IN SERVICE

REVERSIBLE WITH IN-LINE HANDLE, PUSH THROTTLE AND SHUT-OFF CLUTCH

Torque Range (Soft Draw)

Model

4RPLS1

4RPMS1

4RPNS1

in-lb Nm

15-40

15-65

15-80

1.7-4.6

1.7-7.4

1.7-9.1

REVERSIBLE PISTOL GRIP HANDLE AND SHUT-OFF CLUTCH

4RTLS1

4RLMSl

4RTNS1

4RTPSl

15-40

15-65

14-80

15-105

1.74.6

1.7-7.4

1.7-9.1

1.7-11.9

REVERSIBLE LEVER THROTTLE AND IN-LINE HANDLE WITH ADJUSTABLE

CUSHION CLUTCH

4RLLCl

4RLMCl

4RTNCl

15-40

15-65

20-80

1.74.6

1.7-7.4

2.3-9.1

REVERSIBLE PISTOL GRIP HANDLE WITH POSITIVE JAW CLUTCH

4RALPl

4FAMPl

4FANPl

4RAPPl

I

22

36

44

58

2.5

4.1

5.0

I

6.6

REVERSIBLE WITH PISTOL GRIP HANDLE AND DIRECT DRIVE

Model

4RALDl

4RAMDl

4RANDl

Torque Range (Soft Draw) 50 psi Torque Range (Soft Draw) 90 psi

in-lb

22

36

44

Nm

2.5

4.1

5.0

in-lb

40

65

80

Nm

4.6

7.4

9.1

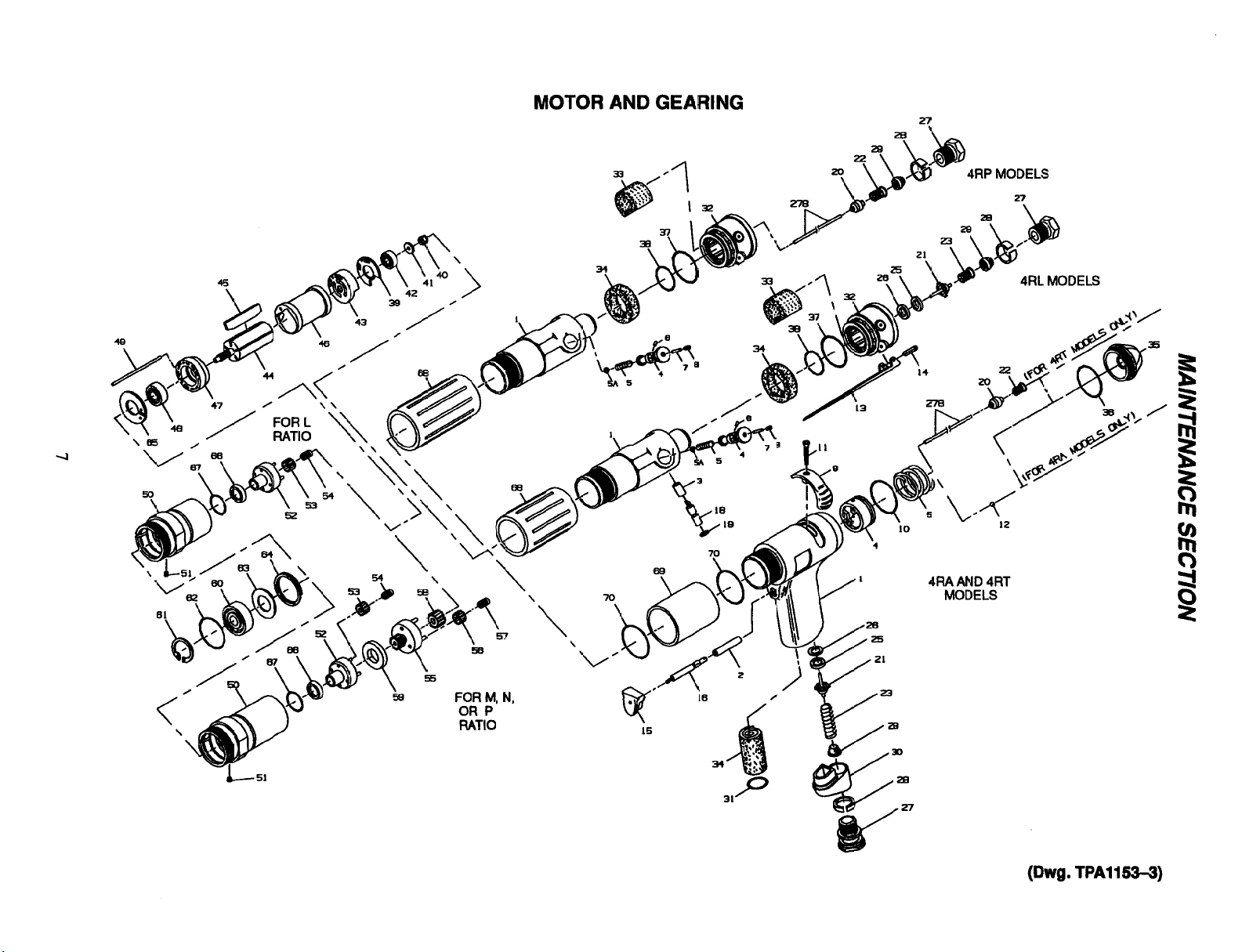

MAINTENANCE SECTION

PART NUMBER FOR ORDERING

PART NUMBER FOR ORDERING --

t

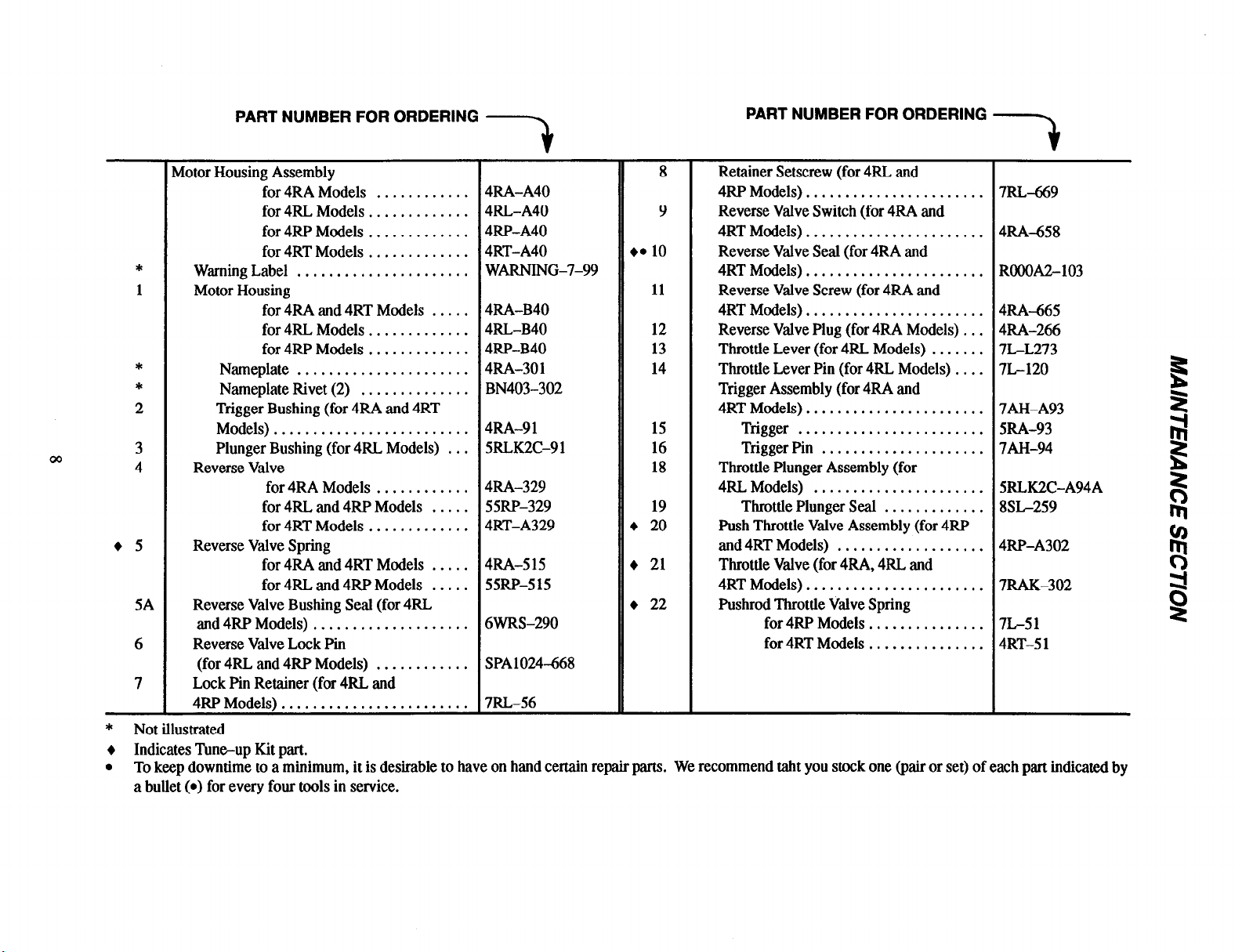

Motor Housing Assembly

for 4RA Models ............

for 4RL Models .............

for 4RP Models .............

for 4RT Models .............

*

1

Warning Label ......................

Motor Housing

for 4RA and 4RT Models .....

for 4RL Models .............

for 4RP Models .............

*

*

2

Nameplate ......................

Nameplate Rivet (2) ..............

Trigger Bushing (for 4RA and 4RT

Models) .........................

3

4

Plunger Bushing (for 4RL Models) ...

Reverse Valve

for 4RA Models ............

for 4RL and 4RP Models .....

for 4RT Models .............

l

5

Reverse Valve Spring

for 4RA and 4RT Models .....

for 4RL and 4RP Models .....

5A

Reverse Valve Bushing Seal (for 4RL

and 4RP Models) ....................

6

7

Reverse Valve Lock Pin

(for 4RL and 4RP Models)

............

Lock Pin Retainer (for 4RL and

4RP Models) . . . . . . . . . . . . . . . . . . . . . . . .

4RA-A40

4RL-A40

4RP-A40

4RT-A40

WARNING-7-99

4RA-B40

4RL-B40

4RP-B40

4RA-301

BN403-302

4RA-91

5RLK2C-91

4RA-329

55RP-329

4RT-A329

4RA-515

55RP-515

6WRS-290

SPA1024668

7RL-56

8

9

l

a 10

11

12

13

14

15

16

18

19

+ 20

+ 21

l

22

Retainer Setscrew (for 4RL and

4RP Models) .......................

Reverse Valve Switch (for 4RA and

4RT Models) .......................

Reverse Valve Seal (for 4RA and

4RT Models) .......................

Reverse Valve Screw (for 4RA and

4RT Models) .......................

Reverse Valve Plug (for 4RA Models) ...

Throttle Lever (for 4RL Models) .......

Throttle Lever Pin (for 4RL Models) ....

Trigger Assembly (for 4RA and

4RT Models) .......................

Trigger ........................

Trigger Pin .....................

Throttle Plunger Assembly (for

4RL Models) ......................

Throttle Plunger Seal .............

Push Throttle Valve Assembly (for 4RP

and 4RT Models) ...................

Throttle Valve (for 4RA, 4RL and

4RT Models) .......................

Pushrod Throttle Valve Spring

for 4RP Models ...............

for 4RT Models ...............

7RL-669

4RA-658

ROOOA2-103

4RA-665

4RA-266

7L-L273

7L-120

7AH-A93

5RA-93

7AH-94

5RLK2C-A94A

8SL-259

4RP-A302

7RAK-302

7L-51

4RT-51

t

* Not illustrated

Indicates Tune-up Kit part.

l

To keep downtime to a minimum, it is desirable to have on hand certain repair parts. We recommend taht you stock one (pair or set) of each part indicated by

a bullet (•) for every four tools in service.

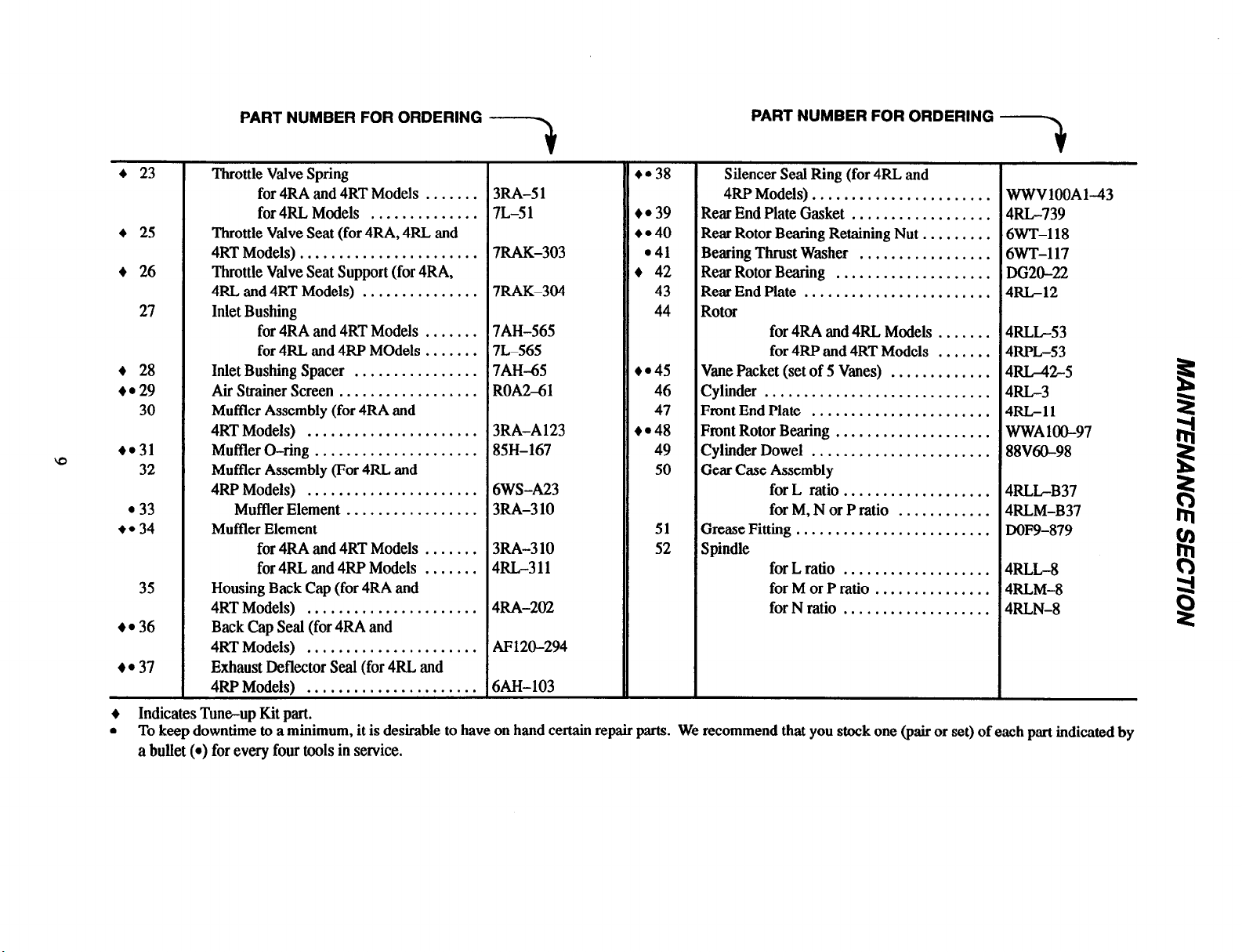

PART NUMBER FOR ORDERING

Silencer Seal Ring (for 4RL and

4RP Models)

.......................

..................

.........

.................

....................

........................

for 4RA and 4RL Models

for 4RP and 4RT Models

.......

.......

.............

.............................

....................

.......................

for L ratio

for M, N or P ratio

...................

............

.........................

for L ratio

for M or P ratio

for N ratio

...................

...............

...................

WWVlOOA1-43

4RL-739

6WT-118

6WT-117

DG20-22

4RL-12

4RLL-53

4RPL-53

4RL-42-5

4RL-3

4RL-11

WWAlOO-97

88V60-98

4RLL-B37

4RLM-B37

DOF9-879

4RLL-8

4RLM-8

4RLN-8

l

l

*34

23

25

26

27

28

29

30

31

32

33

35

36

37

PART NUMBER FOR ORDERING

Throttle Valve Spring

for 4RA and 4RT Models .......

for 4RL Models ..............

Throttle Valve Seat (for 4RA, 4RL and

4RT Models) .......................

Throttle Valve Seat Support (for 4RA,

4RL and 4RT Models) ...............

Inlet Bushing

for 4RA and 4RT Models .......

for 4RL and 4RP Models.. .....

Inlet Bushing Spacer

................

Air Strainer Screen ..................

Muffler Assembly (for 4RA and

4RT Models) ......................

Muffler O-ring .....................

Muffler Assembly (For 4RL and

4RP Models)

......................

Muffler Element .................

Muffler Element

for 4RA and 4RT Models .......

for 4RL and 4RP Models .......

Housing Back Cap (for 4RA and

4RT Models)

......................

Back Cap Seal (for 4RA and

4RT Models)

......................

Exhaust Deflector SeaI (for 4RL and

4RP Models) ......................

t

3RA-51

7L-51

7RAK-303

7RAK-304

7AH-565

7L-565

7AH-65

ROA2-61

3RA-A123

85H-167

6WS-A23

3RA-310

3RA-310

4RL-311

4RA-202

AF120-294

6AH-103

38

em 39

•41

42

43

44

45

46

47

48

49

50

51

52

Rear End Plate Gasket

Rear Rotor Bearing Retaining Nut

Bearing Thrust Washer

Rear Rotor Bearing

Rear End Plate

Rotor

Vane Packet (set of 5 Vanes)

Cylinder

Front End Plate .......................

Front Rotor Bearing

Cylinder Dowel

Gear Case Assembly

Grease Fitting

Spindle

Indicates Tuneup Kit part.

l

To keep downtime to a minimum, it is desirable to have on hand certain repair parts. We recommend that you stock one (pair or set) of each part indicated by

a bullet (•) for every four tools in service.

Loading...

Loading...