Ingersoll-Rand 100-200 HP-75-160 KW, 125-200 HP-90-160 KW User Manual

Before installation or starting the compressor for the

first time, this manual should be studied carefully to

obtain a clear knowledge of the unit and of the duties

to be performed while operating and maintaining the

unit.

RET AIN THIS MANUAL WITH UNIT.

This Technical manual contains IMPORTANT SAFETY

DATA and should be kept with the air compressor at

all times.

125-200 HP/90-160 KW

SINGLE STAGE

AND

100-200 HP/75-160 KW

TWO STAGE UNITS

OPERATORS/

INSTRUCTION MANUAL

OPTIONS

FORM: APDD 738B

November 2002

More Than Air. Answers.

Online answers: http://www.air.irco.com

Phone: 1-800-526-3615

CCN: 80440415 REV: B

AIR COMPRESSOR GROUP

BONDED WARRANTY & REGISTERED START UP

Warranty

The Company warrants that the equipment manufactured b y it and deliv ered hereunder will be free of def ects in material

and workmanship for a period of twelve months (see extended airend warranty) from the date of placing the Equipment

in operation or eighteen months (see extended airend warranty) from the date of shipment from Davidson, NC, whichever

shall first occur.The Purchaser shall be obligated to promptly report any failure to conform to this warranty, in writing to

the Company in said period, whereupon the Company shall, at its option, correct such nonconformity, by suitable repair

to such equipment or, furnish a replacement part F.O.B.point of shipment, provided the Purchaser has stored, installed

maintained and operated such Equipment in accordance with good industry practices and has complied with specific

recommendations of the Company. Accessories or equipment furnished by the Company, but manufactured by others,

shall carry whatever warranty the manufacturers have conveyed to the Company and which can be passed on to the

Purchaser.The Company shall not be liable for any repairs, replacements, or adjustments to the Equipment or any costs

of labor performed by the Purchaser or others without Company’s prior written approval.

The effects of corrosion, erosion and normal wear and tear are specifically excluded.Perf ormance warranties are limited

to those specifically stated within the Company’s proposal.Unless responsibility for meeting such perf ormance warranties

are limited to specified tests, the Company’s obligation shall be to correct in the manner and for the period of time

provided above.

THE COMPANY MAKES NO OTHER WARRANTY OR REPRESENTATION OF ANY KIND WHATSOEVER,

EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE, ARE HEREBY DISCLAIMED.

Correction by the Company of nonconformities whether patent or latent, in the manner and for the period of time

provided above, shall constitute fulfillment of all liabilities of the Company for such nonconformities whether based on

contract, warranty negligence, indemnity, strict liability or otherwise with respect to or arising out of such Equipment.

The purchaser shall not operate Equipment which is considered to be defective, without first notifying the Company in

writing of its intention to do so. Any such Equipment will be at Purchaser’s sole risk and liability.

Note that this is Ingersoll-Rand’s standard warranty. Any warranty in force at the time of purchase of the compressor or

negotiated as part of the purchase order may take precendence over this warranty.

©INGERSOLL-RAND COMPANY

1

ROTARY SCREW AIR COMPRESSOR

This unit was purchased from:

_______________________________________________

_______________________________________________

_______________________________________________

Ingersoll-Rand Company reserves the right to make

changes or add improvements without notice and without

incurring any obligation to make such changes or add such

improvements to products sold previously.

Number of units on order: __________________________

Customer Order Number: __________________________

Ingersoll-Rand Company Order Number: ______________

For ready reference, record the serial number and

model number of your unit here:

Serial Number: ___________________________________

Model Number: ___________________________________

2

TABLE OF CONTENTS

0.0 SAFETY AND WARNINGS

0.1 safety instructions

0.2 safety precautions

0.3 decals

1.0 RECEIPT OF EQUIPMENT

1.1 inspection

1.2 unpacking and handling

1.3 tools

2.0 INSTALLATION

2.1 ventilation

2.2 foundation requirements

2.3 piping

2.4 electrical installation

2.5 outdoor sheltered

3.0 INTELLISYS

®

3.1 intellisys controls

3.2 display screen

3.3 current status

3.4 main menu

3.5 operator setpoints

3.6 options

3.7 sensor calibration

3.8 alarm history

3.9 warnings

3.10 alarms

4.0 SCHEDULED PREVENTATIVE MAINTENANCE

4.1 maintenance schedule

4.2 maintenance records

4.3 maintenance procedures

4.4 inlet air filter

4.5 coolant filter

4.6 coolant

4.7 separator tank scavenge screen/orifice

4.8 coolant separator element

4.9 cooler cores (cleaning)

4.10 motor lubrication

4.11 long term storage

4.12 coolant/lubricant changeout

4.13 intellisys removal

4.14 coolant hoses

4.15 fluid and vibration monitoring

4.16 coolant sampling procedure

5.0 SYSTEMS

5.1 general system information

5.2 air cooled compressors

5.3 coolant system

5.4 compressed air system

5.5 coolant/air separation system

5.6 electrical system

5.7 stepper motor inlet control

5.8 capacity control system

5.9 automatic start/stop control

5.10 remote start/sto

6.0 TROUBLESHOOTING

7.0 OPTIONS

7.1 power outage restart option

7.2 sequencer

7.3 low ambient

7.4 separator delta-p solenoid

7.5 separator delta-p sensor

7.6 high dust filter

7.7 lead/lag cycle length

7.8 schedule start/stop

7.9 remote load/unload

7.10 modbus

7.11 integral sequencing

8.0 REFERENCE DRAWINGS

8.1 electrical schematic, star delta

8.2 foundation plan, 125/150 HP, A/C - Single Stage

8.3 foundation plan, 200 HP, A/C - Single Stage

8.4 foundation plan, 125/150 HP,W/C - Single Stage

8.5 foundation plan, 200 HP,W/C - Single Stage

8.6 foundation plan, 125/150 HP, A/C - Two Stage

8.7 foundation plan, 200 HP, A/C - Two Stage

8.8 foundation plan, 125/150 HP,W/C - Two Stage

8.9 foundation plan, 200 HP,W/C - Two Stage

8.10 flow schematic, A/C - Single Stage

8.11 flow schematic,W/C-90°F (32°C) - Single Stage

8.12 flow schematic,W/C-115°F (46°C) - Single Stage

8.13 flow schematic, A/C - Two Stage

8.14 flow schematic,W/C-90°F (32°C) - Two Stage

8.15 flow schematic,W/C-115°F (46°C) - Two Stage

8.16 typical system flow diagrams

9.0 WATER QUALITY RECOMMENDATIONS

10.0 MAINTENANCE RECORD

Weight..............................See foundation plan, Section 8.0

Cooling Air Flow.............See foundation plan, Section 8.0

Ambient Temperature Limits..........................35°F to 115°F

...........................................................................((2°C to 46°C)

Coolant.............................Factory Filled SSR Ultra Coolant

Coolant Change ............................8000 hours or two years

............................................................whichever comes first

Coolant Capacity

125/200 HP (90-160 KW) -

Single Stage ...................................23.0 gallons (87.4 liters)

100 HP (75 KW) -

Two Stage.......................................22.0 gallons (83.3 liters)

125-200 HP (90-160 KW) -

Two Stage.....................................30.0 gallons (113.6 liters)

Discharge Temperature Limit.........................228°F (109°C)

Power Inlet Wiring .........................Recommended conduit:

............................metallic flexible Greenfield, or equivalent

Tools..............................................U.S. standard and metric

...................................are required to perform maintenance

3

0.0 SAFETY AND WARNINGS

0.1 SAFETY INSTRUCTIONS Before you install this air compressor you should take the time to carefully read all the instructions contained in this manual.

Electricity and compressed air have the potential to cause

severe personal injury or property damage.

Before installing, wiring, starting, operating or making any

adjustments, identify the components of the air

compressor using this manual as a guide.

The operator should use common sense and good

working practices while operating and maintaining this

unit. Follow all codes, pipe adequately, understand the

starting and stopping sequence. Check the safety devices

by following the procedure contained in this manual.

Maintenance should be done by qualified personnel,

adequately equipped with proper tools. Follow the

maintenance schedules as outlined in the operators

manual to ensure problem free operation after start up.

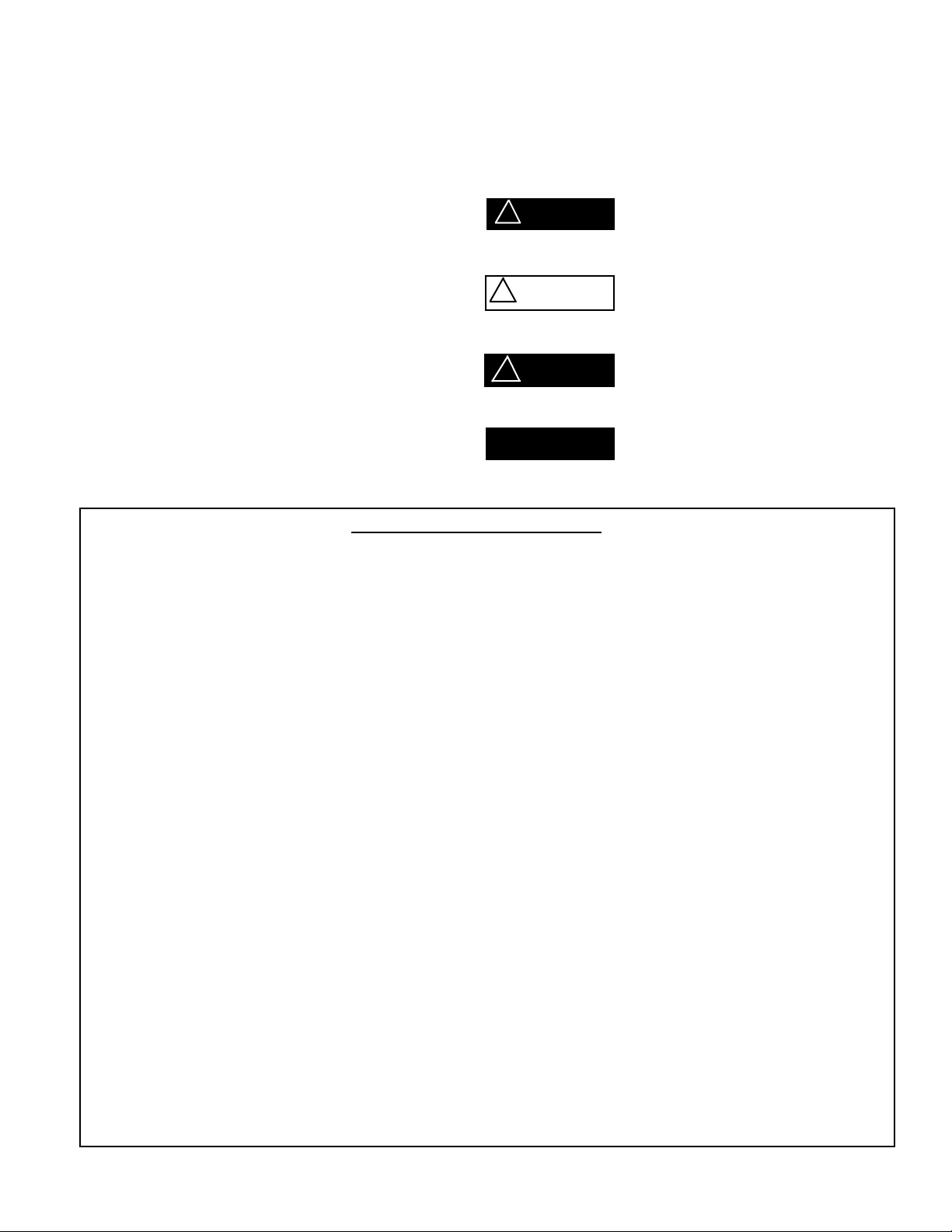

Safety instructions in the operators manual are bold-faced

for emphasis. The signal words DANGER, WARNING and

CAUTION are used to indicate hazard seriousness levels

as follows:

Danger is used to indicate the presence of

a hazard which will cause severe personal

injury, death, or substantial property

damage if the warning is ignored.

Warning is used to indicate the presence of

a hazard which can cause severe personal

injury, death, or substantial property

damage if the warning is ignored.

Caution is used to indicate the presence of

a hazard which will or can cause minor

personal injury or property damage if the

warning is ignored.

Notice is used to notify people of

installation, operation, or maintenance

information which is important but not

hazard-related.

D! DANGER

! WARNING

! CAUTION

NOTICE

WARNING

COMPRESSED AIR AND ELECTRICITY

ARE DANGEROUS.

BEFORE DOING ANY WORK ON THIS

UNIT,BE SURE THE ELECTRICAL SUPPLY

HAS BEEN CUT OFF–LOCKED & TAGGED

AND THE ENTIRE COMPRESSOR SYSTEM

HAS BEEN VENTED OF ALL PRESSURE.

1. Do not remove the covers, loosen or

remove any fittings, connections or

devices when this unit is in operation. Hot

liquid and air under pressure that are

contained within this unit can cause

severe injury or death.

2. The compressor has high and

dangerous voltage in the motor starter and

control box. All installations must be in

accordance with recognized electrical

codes. Before working on the electrical

system, be sure to remove voltage from

the system by use of a manualdisconnect-switch. A circuit breaker or

fuse safety switch must be provided in the

electrical supply line leading to the

compressor.

Those responsible for installation of this

equipment must provide suitable grounds,

maintenance clearance and lightning

arrestors for all electrical components as

stipulated in O.S.H.A. 1910.308 through

1910.329.

3. Do not operate the compressor at higher

discharge pressure than those specified

on the Compressor Nameplate or motor

overload will occur. This condition will

result in compressor motor shutdown.

4. Use only safety solvent for cleaning the

compressor and auxiliary equipment.

5. Install a manual shut off valve (isolation

type) in the discharge line. When a safety

valve is installed between the isolation

valve and the compressor, it must have

sufficient capacity to relieve the full

capacity of the compressor(s).

6. Whenever pressure is released through

the pressure relief valve, it is due to

excessive pressure in the system. The

cause for the excessive pressure should

be investigated immediately.

7. Before doing any mechanical work on

the compressor:

a.) Shut the unit down.

b.) Electrically isolate the compressor by

use of the manual disconnect switch in the

power line to the unit. Lock and tag the

switch so that it cannot be operated.

c.) Vent pressure from the compressor and

isolate the unit from any other source of

air.

8. There can be adverse effects if

compressor lubricants are allowed to enter

plant air systems.

Air line separators, properly selected and

installed, will minimize any liquid carryover.

The use of plastic bowls on line filters

without metal guards can be hazardous.

From a safety standpoint, metal bowls

should be used on any pressurized

system. Review of your plant air line

system is recommended.

9. When a receiver is installed, it is

recommended that occupational safety

and health standards as covered in the

Federal Register, Volume 36, number 105,

part 11, paragraph 1910.169 be adhered to

in the installation and maintenance of this

receiver.

10. Before starting the compressor, its

maintenance instructions should be

thoroughly read and understood.

11. After maintenance functions are

completed, covers and guards must be

replaced.

0.2 SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

BEFORE PROCEEDING, READ CAREFULLY BEFORE INSTALLING THE

COMPRESSOR OR PERFORMING ANY MAINTENANCE

4

WARNING

Failure to adhere to these recommendations can result in mechanical failure, property damage and serious injur y or death.

All air and water inlet, and air and water discharge pipework to and from the inlet and discharge port connections must take

into account vibration, pulsations, temperature, maximum pressure applied, corrosion and chemical resistance. In addition, it

should be noted that lubricated compressors will discharge some oil into the air stream; therefore, compatibility between

discharge piping, system accessories and software must be assured.

For the foregoing reasons, the use of plastic piping, soldered copper fittings and rubber hose as discharge piping is not

recommended. In addition, flexible joints and/or flex lines can only be considered for such purposes if their specifications fit

the operating parameters of the system.

It is the responsibility of the installer and owner to provide the appropriate service pipework to and from the machine.

WARNING

CHECK HIGH AIR TEMPERATURE

There is a high discharge air temperature shutdown function built into the Intellisys on each compressor. It is factory pre-set

at 228°F (109°C).This function should be checked at regular intervals for proper operation, once a month is recommended.

The procedure is:

1. Block off the cooling air discharge.

2. The compressor discharge temperature will rise at a rapid rate.Shutdown should occur when the discharge

temperature reaches the pre-set maximum discharge air temperature setting of the Intellisys.The display should

indicate “HIGH AIREND DISCH TEMP” and flash “ALARM”.

The actual temperature at which shutdown occurs should be recorded for comparison to the Intellisys set point and with

similar future test results.

SAFETY SHUTDO WN

“Ingersoll-Rand air compressors are not designed, intended, or approved for breathing air.Ingersoll-Rand does not approve

specialized equipment for breathing air application and assumes no responsibility or liability for compressors used for

breathing air services.”

39540174 Rev. 05

5

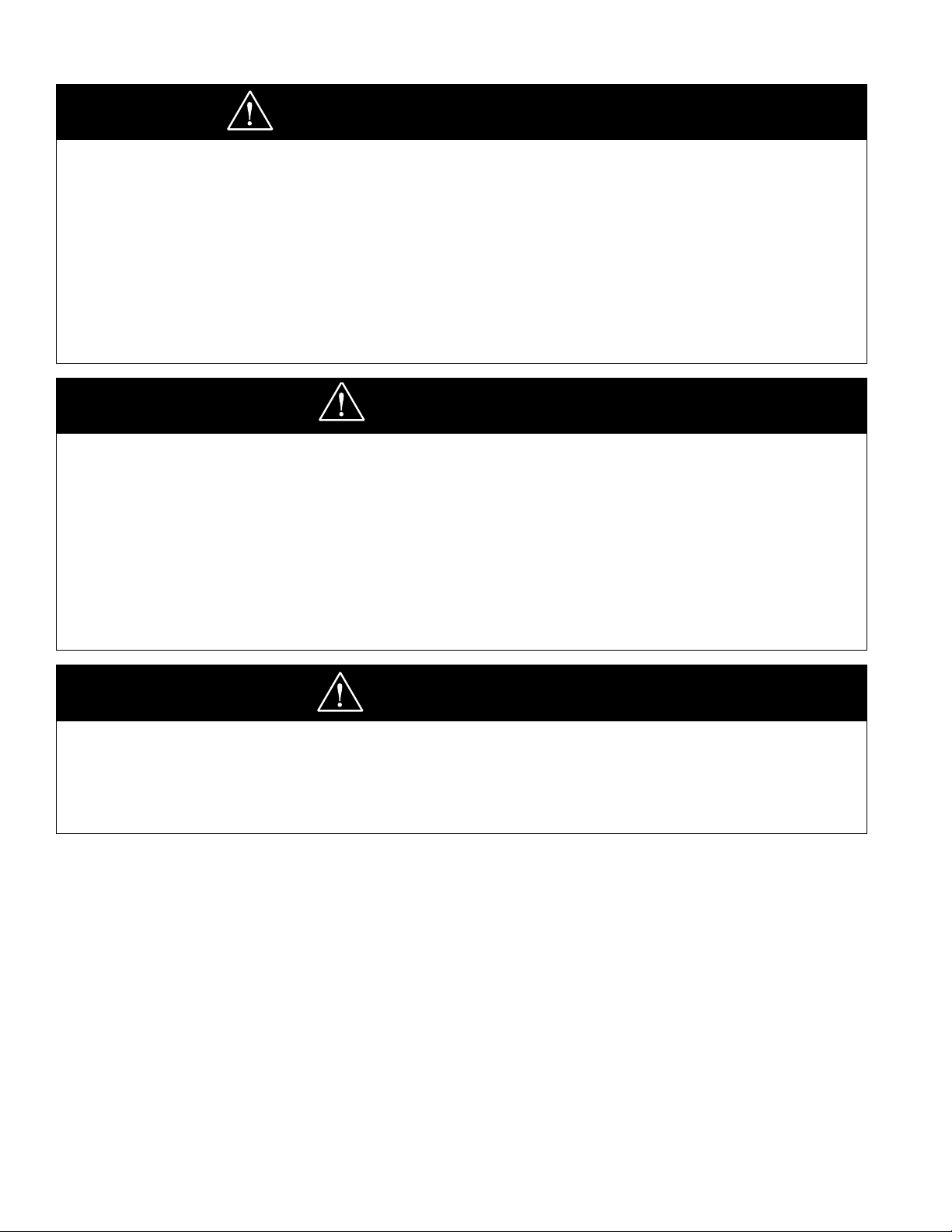

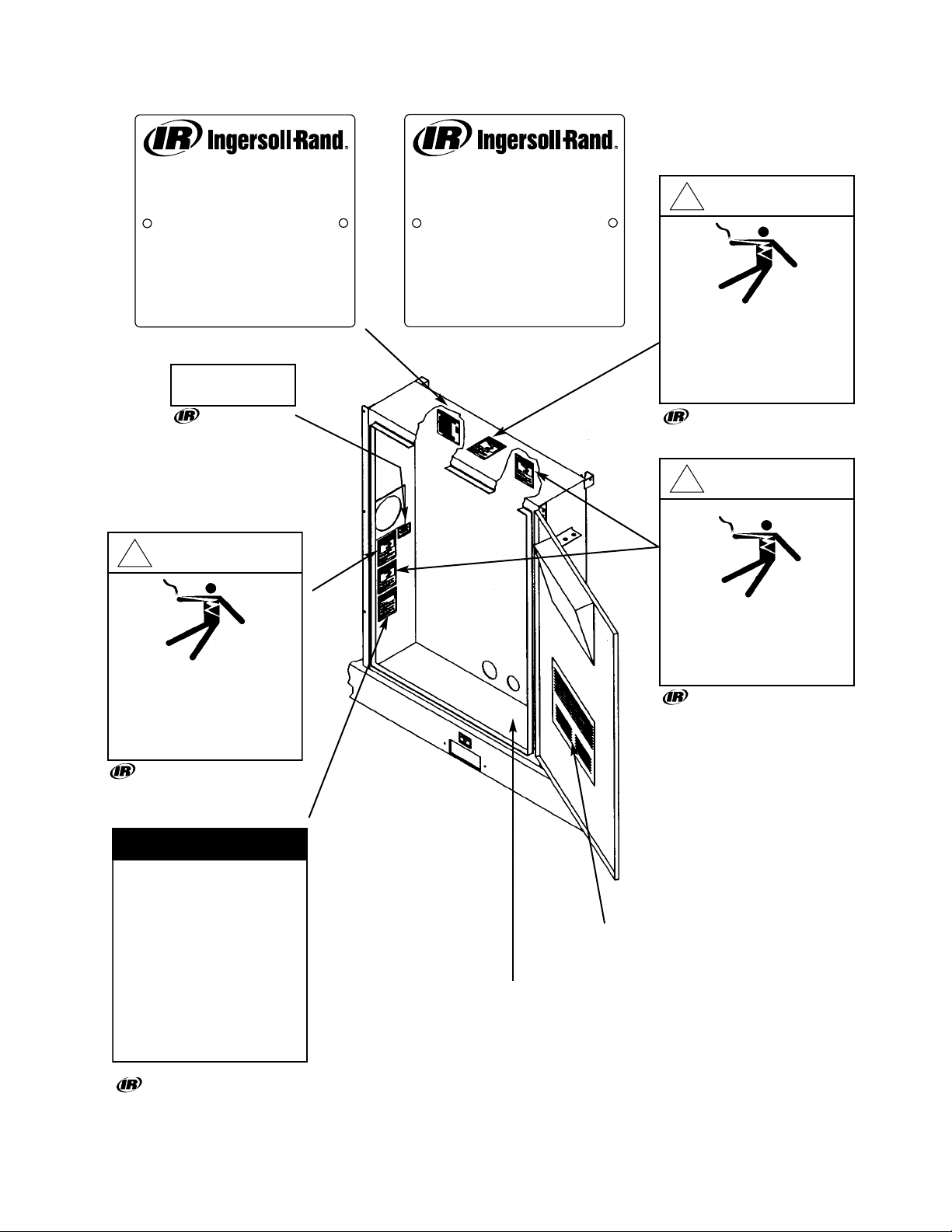

0.3 DECALS

This section contains representative examples of decals

which will be appearing throughout this manual and are

applied to the compressor unit. If for some reason a

decal is defaced, painted over, or parts are replaced, we

recommend that you obtain a replacement kit as listed in

the spare parts section of the Parts List Manual Form

APDD 735 for single stage and Form APDD 736 for two

stage units.

*PORO OPTION

39584529

*REMOTE START-

STOP OPTION

39547708

*FOOD GRADE

COOLANT OPTION

39568803

* FOOD GRADE COOLANT

OPTION 39568464

* FOOD GRADE COOLANT

OPTION ONLY

*ITEMS MARKED WITH * ARE OPTIONS THAT

ARE AVAILABLE

2 REQUIRED - BASE

VIEWED

FROM

FRONT

39541362 Rev. 04

39540240 Rev. 04

39544143 Rev. 03

39540224 Rev. 04

39543921 Rev. 03

39540265 Rev. 05

39540273 Rev. 04

39878657 Rev. 03

!

WARNING

Hazardous voltage. Can cause

severe injury or death.

Disconnect power before servicing.

Lockout/Tagout machine.

!

WARNING

Hot surface.

Can cause severe injury.

Do not touch. Allow to cool before

servicing.

!

WARNING

High pressure air.

Can cause severe injury or death.

Relieve pressure before removing filter

plugs / caps, fittings or covers.

CAUTION

Improper maintenance of

coolant filter can cause

compressor damage.

Change coolant filter after first

150 hours of operation and

every 2000 hours thereafter or

when coolant is changed.

Lift Here

Filler Cap.

Use only

recommended coolant.

Read instruction book

before servicing.

39543921

!

CAUTION

Use of incorrect coolant can cause

system contamination.

Use only SSR ULTRA COOLANT.

!

WARNING

Moving parts.

Can cause severe injury.

Do not operate with covers removed.

Service only with machine blocked to

prevent turn over.

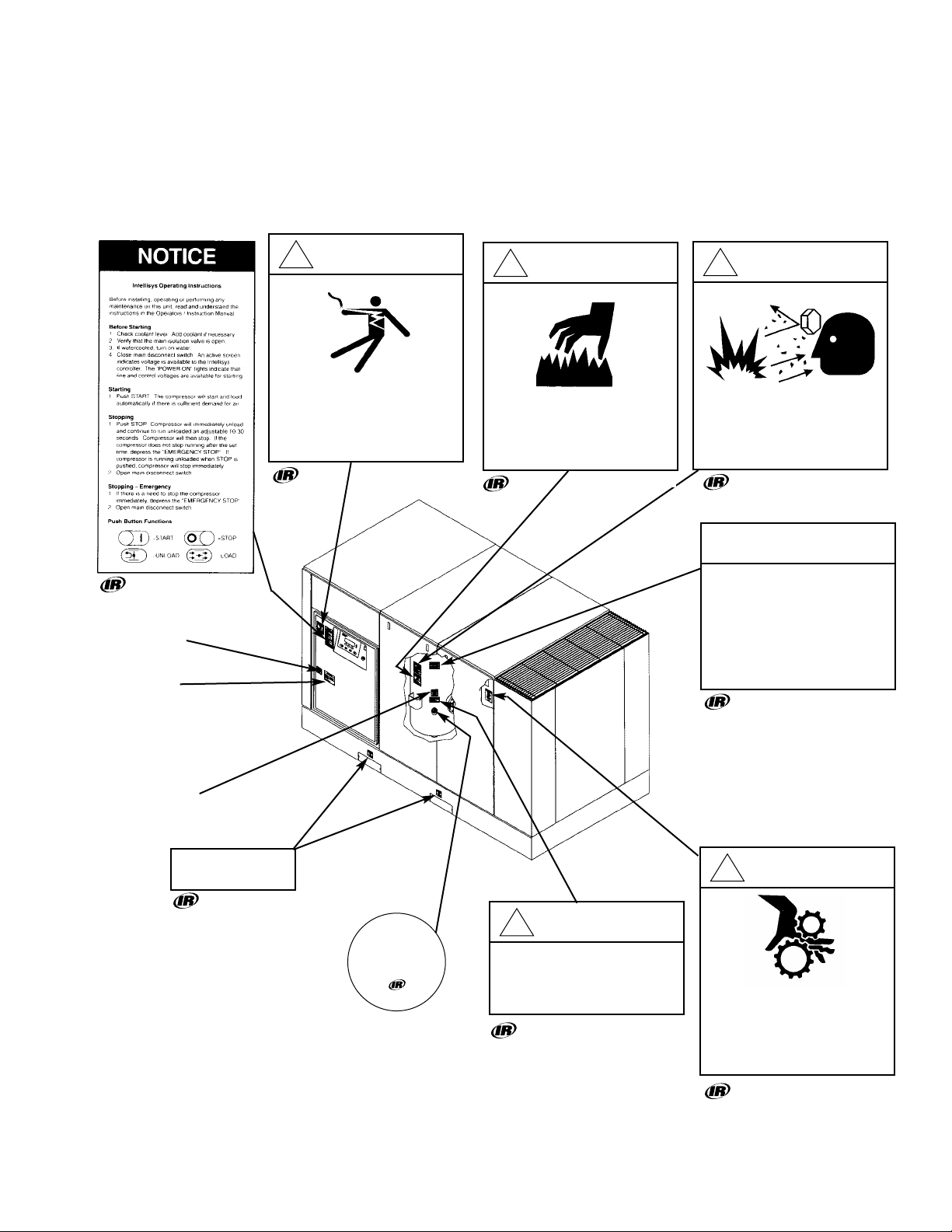

0.3 DECALS (continued)

6

39540224 Rev. 04

39540232 Rev.03

39544150 Rev. 03

39557095 Rev.05 (100-200 HP)

54425996 Rev.C (75-160KW)

39541354 Rev. 03

39540166 Rev. 06

39540257 Rev. 04

39541081 Rev. 04

39540273 Rev. 04

39541339 Rev. 03

39541321 Rev. 04

39541362 Rev. 04

39540182 Rev. 04

* WATERCOOLED UNITS ONLY

VIEWED

FROM

REAR

*

*

39540190 Rev. 04

39857552 Rev. 04

!

WARNING

!

WARNING

Compressor Package Data

COMPRESSOR MODEL...............................

CAPACITY......................................................

RATED OPERATING PRESSURE.................

MAX.DISCHARGE PRESSURE...................

MAX.MODULATE PRESSURE.....................

NOMINAL DRIVE MOTOR............................

NOMINAL FAN MOTOR................................

TOTAL PACKAGE AMPS...............................

VOLTS............................................................

PHASE / HERTZ............................................

CONTROL VOLTAGE.....................................

SERIAL NUMBER..........................................

CONTACTOR AMP.RATING.....................................

ASSEMBLY AMP.RATING........................................

LOCKED ROTOR AMP. RATING OF ASSY.............

AIR SOLUTIONS GROUP

DAVIDSON,NORTH CAROLINA 28036

WWW.AIR.INGERSOLL-RAND.COM

m3/MIN

BARG

BARG

BARG

KW

KW

54425996 Rev.C

Moving parts.

Can cause severe injury.

Do not operate with covers removed.

Service only with machine blocked to

prevent turn over.

!

WARNING

Hot surface.

Can cause severe injury.

Do not touch. Allow to cool before

servicing.

Water out.

Water in.

Exposed fan blade. Can cause severe

injury.

Do not operate with covers removed.

Disconnect power.Lock and tag.

Rotation.

Rotation.

Compressor Package Data

COMPRESSOR MODEL...............................

CAPACITY......................................................

RATED OPERATING PRESSURE.................

MAX.DISCHARGE PRESSURE...................

MAX.MODULATE PRESSURE.....................

NOMINAL DRIVE MOTOR............................

NOMINAL FAN MOTOR................................

TOTAL PACKAGE AMPS...............................

VOLTS............................................................

PHASE / HERTZ............................................

CONTROL VOLTAGE.....................................

SERIAL NUMBER..........................................

CONTACTOR AMP.RATING.....................................

ASSEMBLY AMP.RATING........................................

LOCKED ROTOR AMP. RATING OF ASSY.............

AIR SOLUTIONS GROUP

DAVIDSON,NORTH CAROLINA 28036

WWW.AIR.INGERSOLL-RAND.COM

CFM

PSIG

PSIG

PSIG

H.P.

H.P.

39557095 Rev.05

Air

Discharge

Electrical

power inlet.

Condensate

drain.

NOTICE

To obtain satisfactory compressor

operation and maintenance a minimum

of 3 feet clearance on 3 sides is

required 3-1/2 feet is required in front of

the control panel (or minimum required by

latest National Electrical code or

applicable local codes).

Refer to the Instruction / Operators

Manual before any maintenance.

Lift Here

CAUTION

!

Incorrect lifting of machine

can cause injury or property

damage.

Lift only from base channels.

!

DANGER

Discharge air.

Can contain carbon monoxide or

other contaminants.Will cause

severe injury or death.

Do not breathe this air.

Do not operate without enclosure

panels and forklift covers in place.

Enclosure panels will affect performance.

Motors must be greased periodically.

See Operators Manual for procedure.

0.3 DECALS (continued)

7

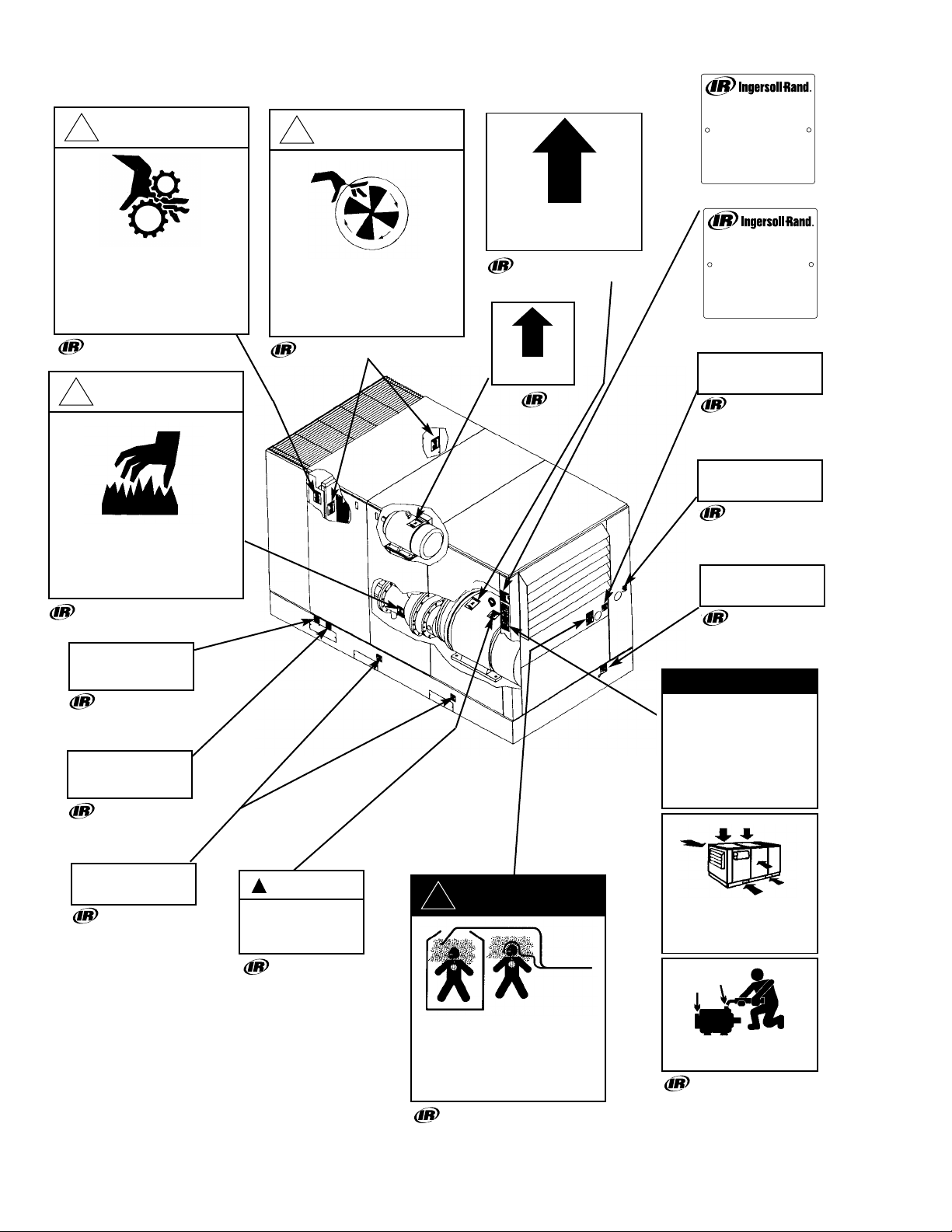

VOLTAGE DECAL OPTION

INSIDE STARTER BOX

ON RIGHT SIDE

SCHEMATIC DECAL

54425996 Rev. C (75-160 KW) - 2 REQUIRED

39543764 Rev. 04

39540174 Rev. 05

39541354 Rev 03

Instruction Manual.

39543764 Rev. 03

Instruction Manual.

39921804 Rev. B

39557095 Rev.05 (100-200 HP) - 2 REQUIRED

COMPRESSOR MODEL...............................

CAPACITY......................................................

RATED OPERATING PRESSURE.................

MAX. DISCHARGE PRESSURE...................

MAX. MODULATE PRESSURE.....................

NOMINAL DRIVE MOTOR............................

NOMINAL FAN MOTOR................................

TOTAL PACKAGE AMPS...............................

VOLTS............................................................

PHASE / HERTZ............................................

CONTROL VOLT A GE.....................................

SERIAL NUMBER..........................................

CONTACTOR AMP.RATING.....................................

ASSEMBLY AMP. RATING........................................

LOCKED ROTOR AMP. RATING OF ASSY. ............

DAVIDSON,NORTH CAROLINA 28036

WWW.AIR.INGERSOLL-RAND.COM

Compressor Package Data

AIR SOLUTIONS GROUP

m3/MIN

BARG

BARG

BARG

KW

KW

54425996 Rev.C

Electrical

power inlet.

!

WARNING

COMPRESSOR MODEL...............................

CAPACITY......................................................

RATED OPERATING PRESSURE.................

MAX. DISCHARGE PRESSURE...................

MAX. MODULATE PRESSURE.....................

NOMINAL DRIVE MOTOR............................

NOMINAL FAN MOTOR................................

TOTAL PACKAGE AMPS...............................

VOLTS............................................................

PHASE / HERTZ............................................

CONTROL VOLT A GE.....................................

SERIAL NUMBER..........................................

CONTACTOR AMP.RATING.....................................

ASSEMBLY AMP. RATING........................................

LOCKED ROTOR AMP. RATING OF ASSY. ............

DAVIDSON,NORTH CAROLINA 28036

WWW.AIR.INGERSOLL-RAND.COM

Compressor Package Data

AIR SOLUTIONS GROUP

CFM

PSIG

PSIG

PSIG

H.P.

H.P.

39557095 Rev.05

!

WARNING

Hazardous voltage. Can cause

severe injury or death.

Only use factory supplied inlet for

incoming power.See Operators/

Instruction manual.

!

WARNING

Hazardous voltage. Can cause

severe injury or death.

Only use factory supplied inlet for

incoming power.See Operators/

Instruction manual.

NOTICE

IEC Starter Overload Setting

1. Full-Voltage Starter (Main or Fan Motor):

Multiply MOTORnameplate amps by 1.11.

Star-Delta Starter (Main motors only):

Multiply MOTOR nameplate amps by 0.64.

2. Set corresponding overload relay at

this value.

3. Never exceed the following limits:

Full-Voltage Starter:125% of MOTOR

nameplate amps.

Star-Delta Starter: 72% of MOTOR

nameplate amps.

Hazardous voltage. Can cause

severe injury or death.

Disconnect power before servicing.

Lockout/Tagout machine.

8

1.0 RECEIPT OF EQUIPMENT

1.1 INSPECTION

When you receive the compressor please inspect it

closely. Any indication of careless handling by the carrier

should be noted on the delivery receipt especially if the

compressor will not be immediately uncrated. Obtaining

the delivery man’s signed agreement to any noted

damages will facilitate any future insurance claims.

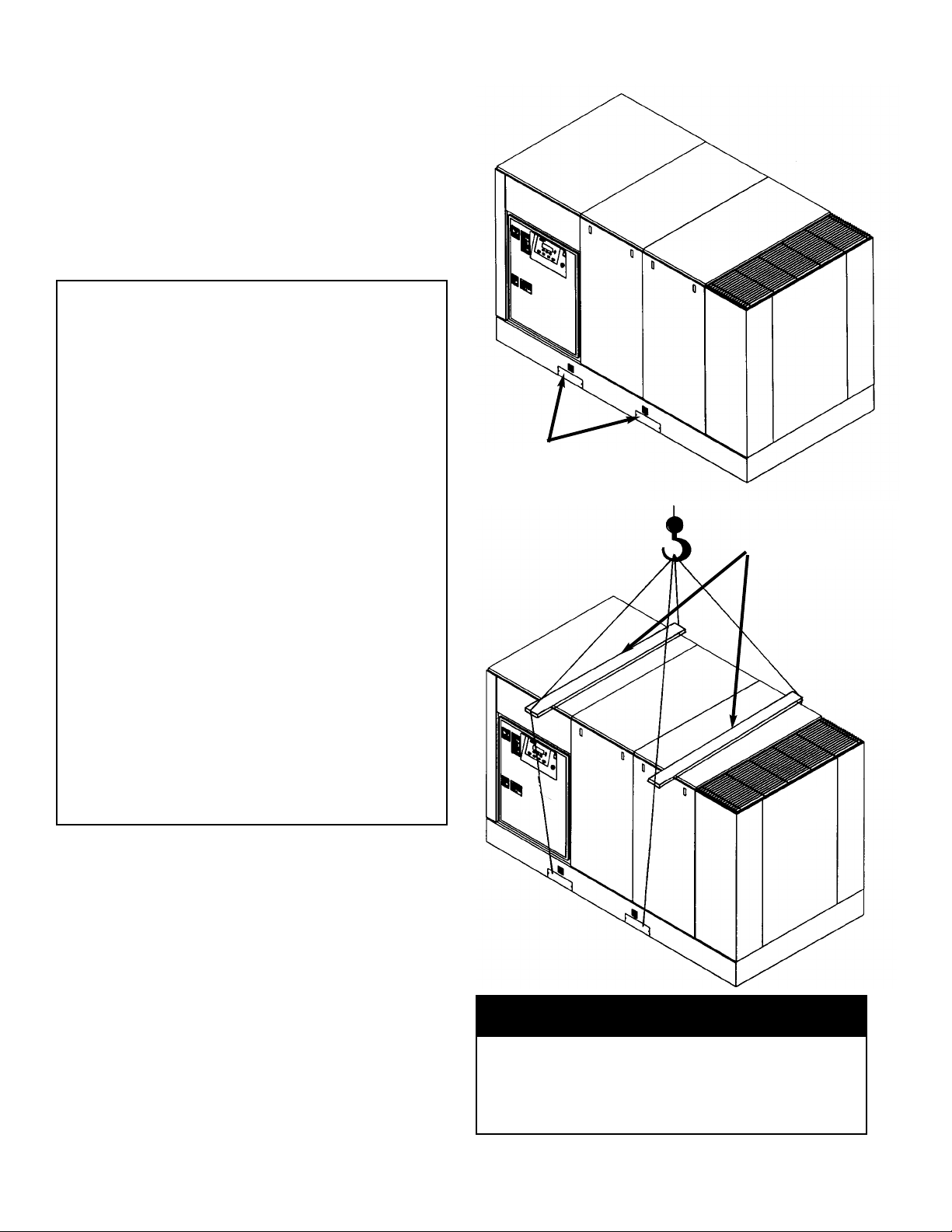

1.2 UNPACKING AND HANDLING

The compressor package has been mounted on a base

which provides for forklifting between the two side

channels to facilitate handling during shipment. Care in

positioning the forklifts is important because the location

of the center of gravity is strongly affected by the location

of the compression module and drive motor.

Slings can be used to lift the crates, but spreader bars

must be used to prevent the slings from exerting a force

against the sides of the crates.

1.3 TOOLS

Remove compressor unit from wooden skid.A crowbar

and hammer will be needed.

IMPORTANT

READ THIS

LOST OR DAMAGED GOODS

THOROUGHLY INSPECT THIS SHIPMENT

IMMEDIATELY UPON ARRIVAL

OUR RESPONSIBILITY FOR THIS SHIPMENT

CEASED WHEN THE CARRIER SIGNED

BILL OF LADING

If goods are received short or in damaged condition, it is important that

you notify the carrier and insist on a notation of the loss or damage

across the face of the freight bill.Otherwise no claim can be enforced

against the transportation company.

If concealed loss or damage is discovered, notify your carrier at once

and request an inspection.This is absolutely necessary.Unless you do

this the carrier will not entertain any claim for loss or damage.The agent

will make an inspection and grant a concealed damage notation.If you

give the transportation company a clear receipt for goods that have been

damaged or lost in transit, you do so at your own risk and expense.

WE, AT I-R, ARE WILLING TO ASSIST YOU IN EVERY POSSIBLE

MANNER TO COLLECT CLAIMS FOR LOSS OR DAMAGE, BUT THE

WILLINGNESS ON OUR PART DOES NOT MAKE US RESPONSIBLE

FOR COLLECTION OF CLAIMS OR REPLACEMENT OF MATERIAL.

THE ACTUAL FILING AND PROCESSING OF THE CLAIM IS YOUR

RESPONSIBILITY.

Ingersoll-Rand Company

Davidson, North Carolina

APDDGFO-99-79

Before starting this air compressor unit, the

shipping brace(s) must be removed.

Save the brace(s) for future use.

IMPORTANT

See tag in unit.

FORKLIFT PADDING

WILL REDUCE SCRATCHES

AND MARS

SPREADER

BARS

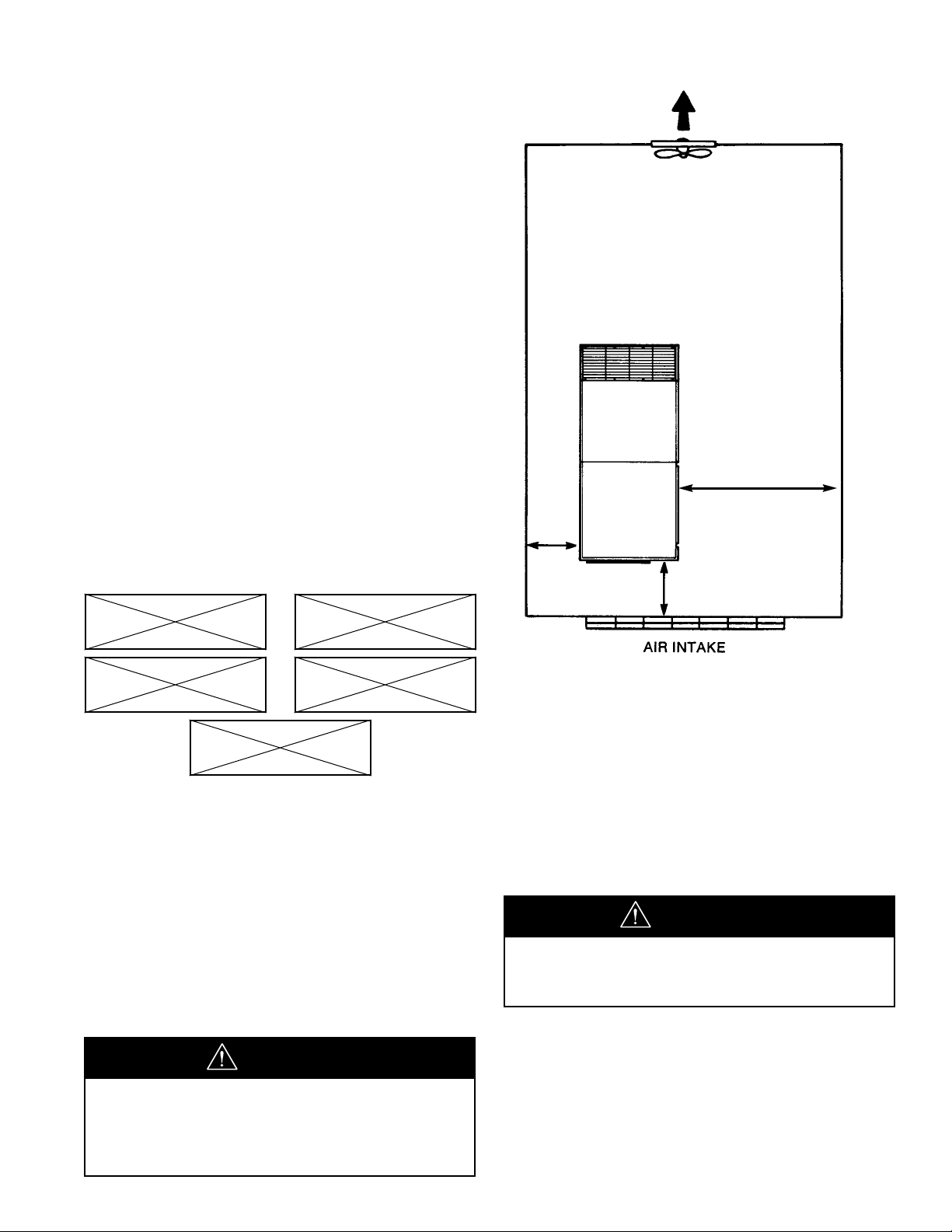

2.0 INSTALLATION

2.1 VENTILA TION

Oil flooded rotary air compressors produce large

amounts of heat. Because of this large heat production,

the compressor must be placed in a room with adequate

ventilation.

If heated air from the compressor exhaust is allowed to

recirculate back to the compressor, the compressor will

overheat and shut down.This heat must be exhausted

from the room.You should take this into consideration

when you decide where to place the compressor within

your plant. Consider that the required maintenance

clearance is 3 ft (.9 m) all around the compressor.

However 42” (1.06m), or minimum required by latest NEC

or applicable local codes, must be maintained in front of

control panel.

Ambient temperatures higher than 115°F (46°C)

should be avoided as well as areas of high humidity.

Consider also the environment surrounding or near

the compressor.The area selected for the location of

the compressor should be free of dust, chemicals,

metal filings, paint fumes and overspray.

2.2 FOUNDATION REQUIREMENTS

Refer to the foundation plan for the particular model

compressor to be installed. See Section 8.0.

The compressor can be installed on any level floor that is

capable of supporting it. Compressor weights are listed

on the foundation plans.

When sound transmission is of particular impor tance it is

often helpful to install a sheet of rubber-fabric-matting, or

cork under the compressor to reduce the possibility of

resonant sounds being transmitted or amplified through

the floor.

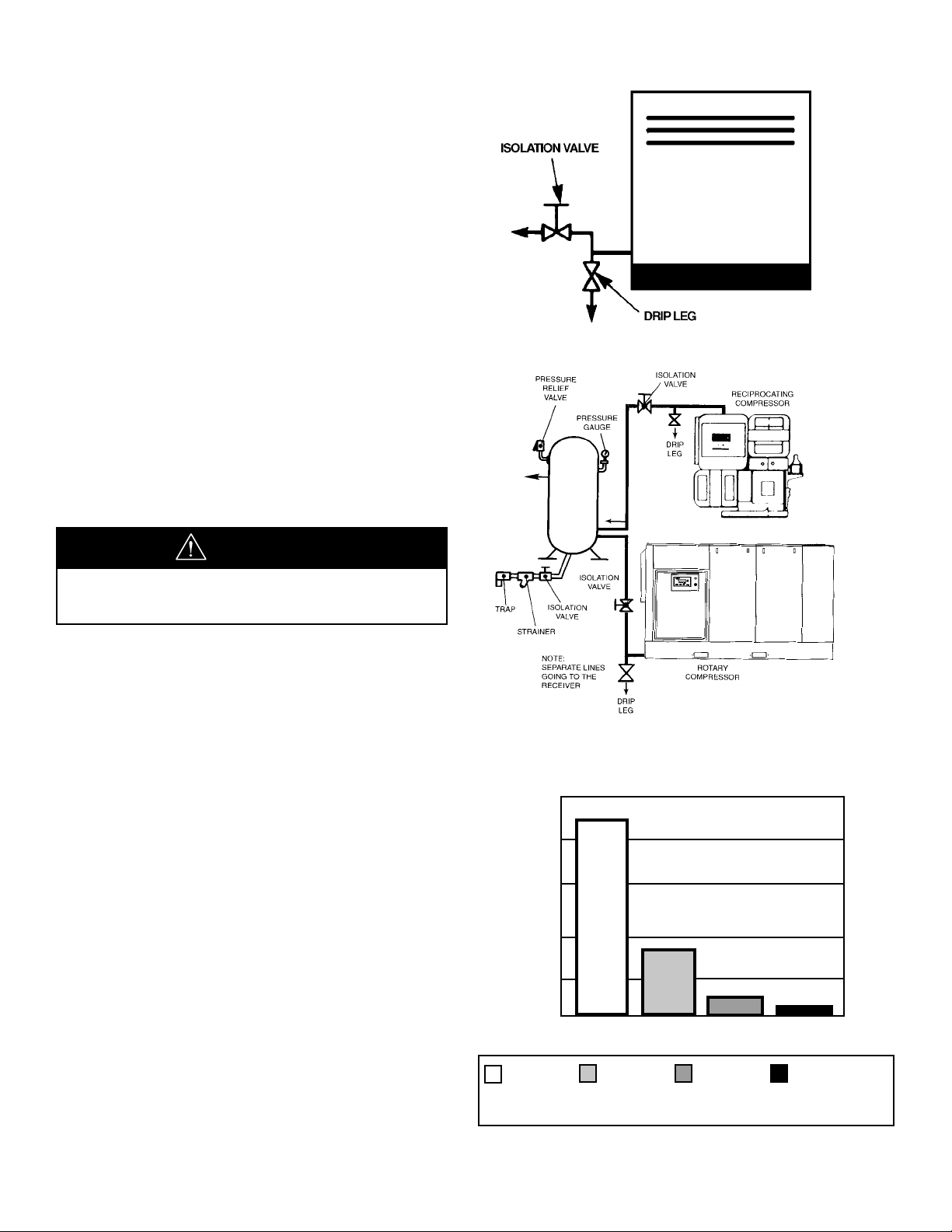

2.3 PIPING

The use of plastic bowls on line filters without metal

guards can be hazardous.Their safety can be affected by

either synthetic lubricants or the additives used in mineral

oil. From a safety standpoint, metal bowls should be used

on any pressurized system. Review of your plant air line

system is recommended.

The built-in aftercooler reduces the discharge air

temperature well below the dew point (for most ambient

conditions), therefore, considerable water vapor is

condensed.To remove this condensation, each

compressor with built-in aftercooler is furnished with a

combination condensate separator/trap.

DUST CHEMICALS

METAL

FILINGS

PAINT

SPRAY

OVERSPRAY

Do not use plastic pipe, soldered copper

fittings or rubber hose for discharge piping.

W ARNING

Never elevate the compressor unit

above the floor level.This may allow air

to enter the cabinet under the base.

Performance will be affected.

NOTICE

9

36”

(.9 m)

36” (.9 m)

42” (1.06m) OR

CODE MINIMUM

10

DISCHARGE PIPING WITH AFTERCOOLER

ROTARY-RECIP IN PARALLEL

Do not use the compressor

to support the discharge pipe.

Careful review of piping size from the compressor

connection point is essential. Length of pipe, size of pipe,

number and type of fittings and valves must be

considered for optimum efficiency of your compressor.

It is essential when installing a new compressor to review

the total plant air system.This is to ensure a safe and

effective total system.

Liquid water occurs naturally in air lines as a result of

compression. Moisture vapor in ambient air is

concentrated when pressurized and condenses when

cooled in downstream air piping.

Moisture in compressed air is responsible for costly

problems in almost every application that relies on

compressed air.Some common problems caused by

moisture are rusting and scaling in pipelines, clogging of

instruments, sticking of control valves, and freezing of

outdoor compressed air lines. Any of these could result in

partial or total plant shutdown.

Compressed air dryers reduce the water vapor concentration and prevent liquid water formation in

compressed air lines. Dryers are a necessary companion

to filters, aftercoolers, and automatic drains for improving

the productivity of compressed air systems.

NOTICE

2.3 PIPING (Continued)

A dripleg assembly and isolation valve should be

mounted near the compressor discharge. A drain line

should be connected to the condensate drain in the

base.

IMPORTANT :The drain line must slope downward from

the base to work properly.

NOTE: For ease of inspection of the automatic drain trap

operation, the drain piping should include an open funnel.

It is possible that additional condensation can occur if the

downstream piping cools the air even further and low

points in the piping systems should be provided with

driplegs and traps.

IMPORTANT :Discharge piping should be at least as

large as the discharge connection at the compressor

enclosure. All piping and fittings must be suitable for the

maximum operating temperature of the unit and, at a

minimum, rated for the same pressure as the compressor

sump tank.

MOISTURE CONTENT OF COMPRESSED AIR

200

160

120

80

40

0

DEW POINT

without

Aftercooling

100°F/38°C

(with

Aftercooler)

35°F /1.7°C

(Refrigerated

Dryer)

-40°F/-40°C

(Desiccant

Dryer)

Gallons of Water/24

hours/1000 acfm

11

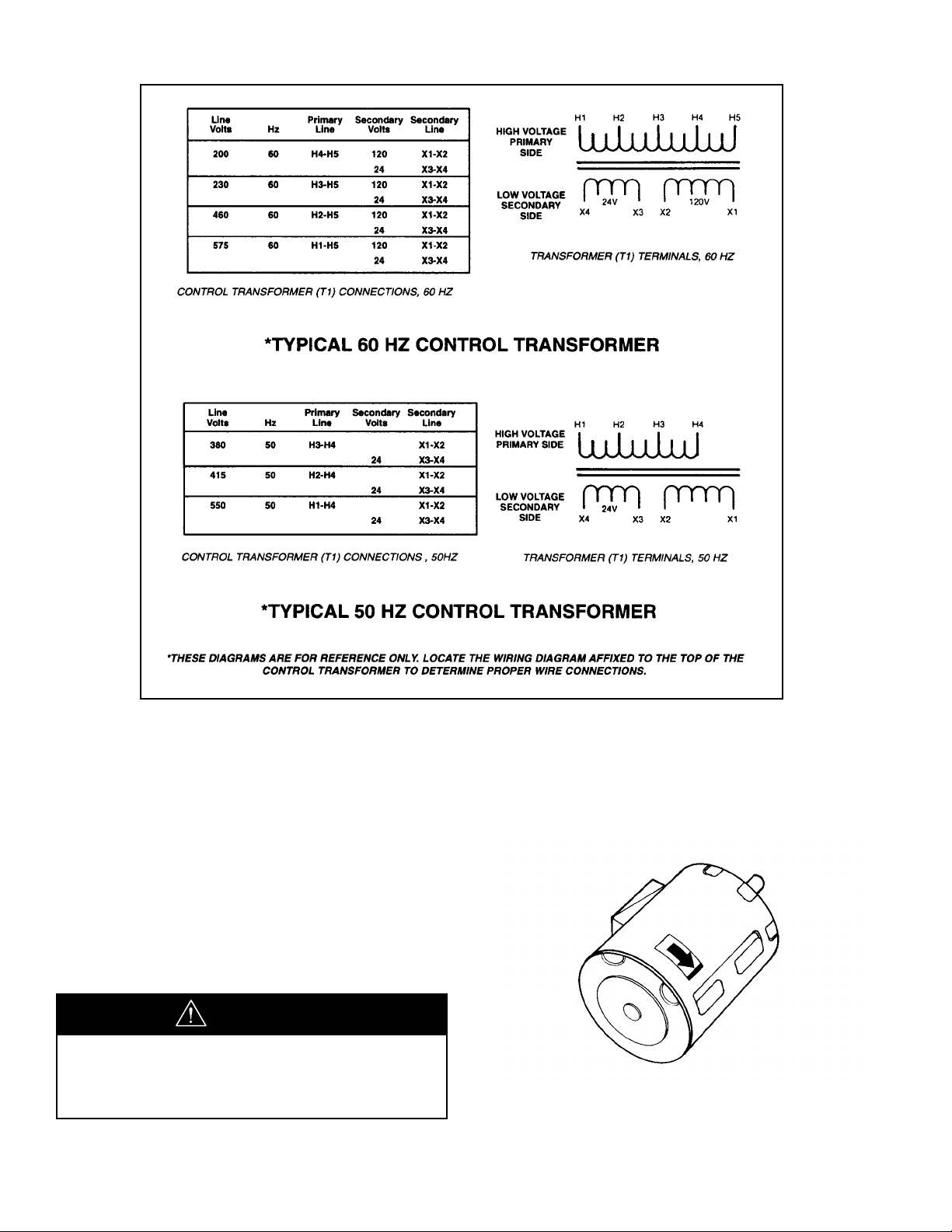

2.4 ELECTRICAL INSTALLATION

Before proceeding further, we recommend that you

review the safety data in the front of this manual.

Locate the compressor data plate on the side of the

cooler box or end of the unit.

The data plate lists the rated operating pressure, the

maximum discharge pressure and the electric motor

characteristics and power.

Confirm that the line voltage and compressor nameplate

voltage are the same and that the standard starter box

meets the intent of NEMA 1 guidelines.

Open the starter box door.Confirm that all electrical

connections are made and tightened. Confirm that the

control transformer is wired correctly for supply voltage.

See Figure 2.4-1 on next page for typical control

transformer wiring.

Two types of dr yers, refrigerated or desiccant, are used

to correct moisture related problems in a compressed air

system. Refrigerated dryers are normally specified where

compressed air pressure dew points of 33°F (1°C) to

39°F (4°C) are adequate. Desiccant dryers are required

where pressure dew points must be below 33°F (1°C).

Contact your local Ingersoll-Rand distributor for

assistance in selecting correct Ingersoll-Rand filtration or

drying products.

NOTE: Screw type compressors should not be installed

in air systems with reciprocating compressors without a

means of pulsation isolation, such as a common receiver

tank.We recommend both types of compressor units be

piped to a common receiver utilizing individual air lines.

When two rotary units are operated in parallel, provide an

isolation valve and drain trap for each compressor before

the common receiver.

ROTARY TWO COMPRESSOR SYSTEM

PRESSURE

RELIEF

VALVE

PRESSURE

GAUGE

54425996 Rev. C (75-160 KW)

39557095 Rev.05 (100-200 HP)

COMPRESSOR MODEL...............................

CAPACITY......................................................

RATED OPERATING PRESSURE.................

MAX. DISCHARGE PRESSURE...................

MAX. MODULATE PRESSURE.....................

NOMINAL DRIVE MOTOR............................

NOMINAL FAN MOTOR................................

TOTAL PACKAGE AMPS...............................

VOLTS............................................................

PHASE / HERTZ............................................

CONTROL VOLTAGE.....................................

SERIAL NUMBER..........................................

CONTACTOR AMP. RATING.....................................

ASSEMBLY AMP. RATING........................................

LOCKED ROTOR AMP. RATING OF ASSY. ............

DAVIDSON, NORTH CAROLINA 28036

WWW.AIR.INGERSOLL-RAND.COM

COMPRESSOR MODEL...............................

CAPACITY......................................................

RATED OPERATING PRESSURE.................

MAX. DISCHARGE PRESSURE...................

MAX. MODULATE PRESSURE.....................

NOMINAL DRIVE MOTOR............................

NOMINAL FAN MOTOR................................

TOTAL PACKAGE AMPS...............................

VOLTS............................................................

PHASE / HERTZ............................................

CONTROL VOLTAGE.....................................

SERIAL NUMBER..........................................

CONTACTOR AMP. RATING.....................................

ASSEMBLY AMP. RATING........................................

LOCKED ROTOR AMP. RATING OF ASSY. ............

DAVIDSON, NORTH CAROLINA 28036

WWW.AIR.INGERSOLL-RAND.COM

Compressor Package Data

AIR SOLUTIONS GROUP

Compressor Package Data

AIR SOLUTIONS GROUP

m3/MIN

BARG

BARG

BARG

KW

KW

54425996 Rev.C

CFM

PSIG

PSIG

PSIG

H.P.

H.P.

39557095 Rev.05

If the compressor is operated in the

opposite direction of rotation, airend damage

can result and is not warrantable.

CAUTION

12

ELECTRICAL INSTALLATION (Continued)

Inspect the motor and control wiring for tightness.

Close and fasten the starter box door.

ROTATION CHECK

Locate the rotation decal on each motor.

DRIVE MOTOR

The correct compressor drive motor rotation is

clockwise when viewed from the rear or non-drive

end of the motor.See Figure 2.4-2.

FIGURE 2.4-2 DRIVE MOTOR ROTATION

FIGURE 2.4-1 TYPICAL CONTROL TRANSFORMER WIRING

DRIVE

END

NON-DRIVE

END

110

110

110

110V

13

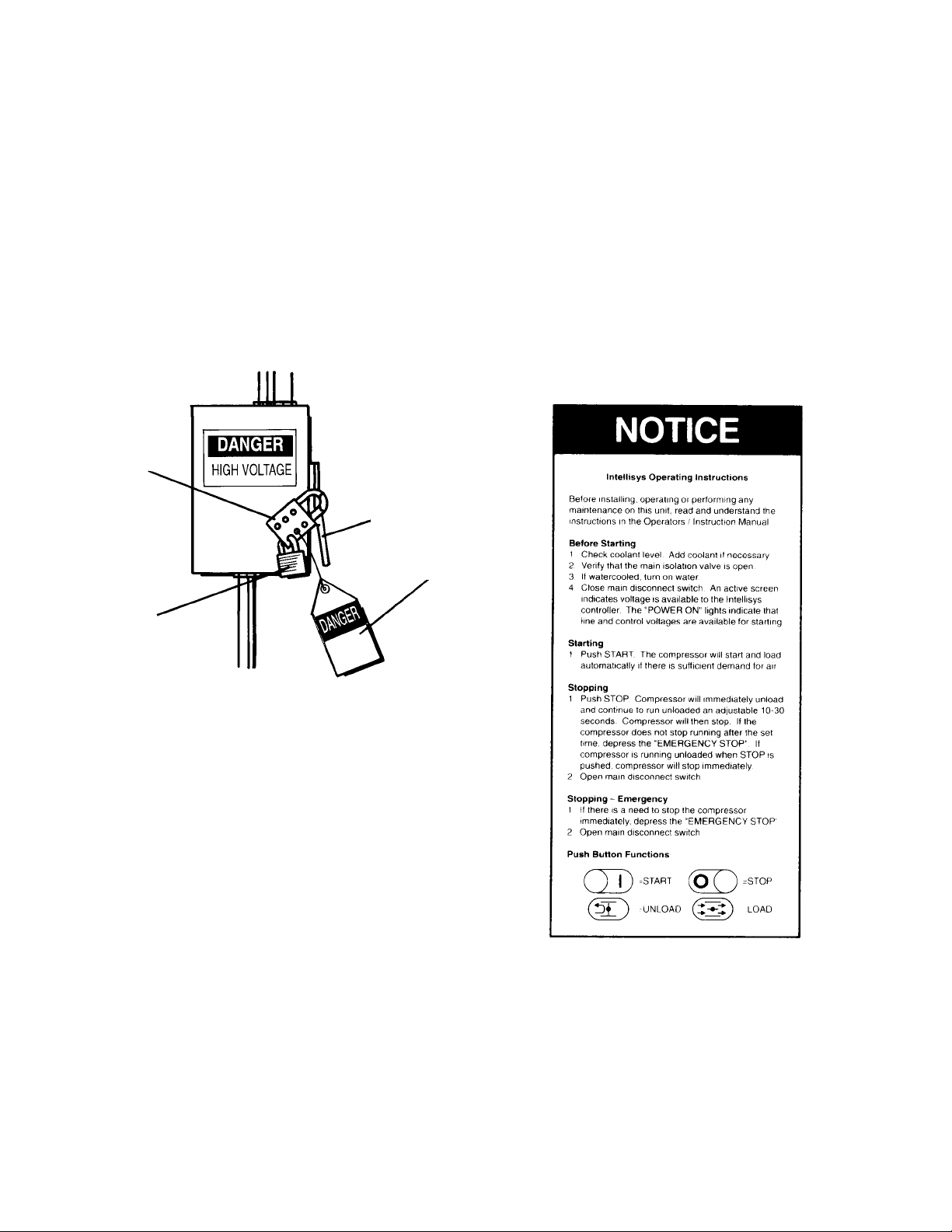

ELECTRICAL INSTALLATION (Continued)

The Intellisys will automatically shut the unit down if the

compressor rotation is incorrect, and the display will

indicate “CHECK MOTOR ROTATION” and will flash

“ALARM”.

For the compressor motor rotation check, the motor

jogging time must be as short as possible.

After depressing the start button, IMMEDIATELY

depress the “EMERGENCY STOP”button. Should the

motor rotation be incorrect, put main disconnect in

the OFF position, lock and tag. See Figure 2.4-3.

Fan motor rotation is clockwise when viewed from

the fan motor side.

INTELLISYS OPERATING INSTRUCTIONS

Read and understand the following Intellisys Operating

Instructions (See Figure 2.4-4) prior to operating the unit.

NOTE: These instructions are also contained on

the decal near the Intellisys panel of the unit.

FIGURE 2.4-3 MAIN DISCONNECT

LOCKED AND TAGGED

Open the starter box door.

Interchange any two line connections (L1, L2 or L3) at

the starter. Close and fasten the starter box door.

Recheck for correct rotation.

FAN MOTOR

Observe the compressor cooling fan.The rotation should

be in accordance with the fan rotation decal affixed to the

fan motor. Cooling air should exhaust through fan end of

compressor enclosure.

Should the motor rotation not be correct, put the main

disconnect in the OFF position, lock and tag.

Interchange any two fan motor leads at the fan motor

manual starter (MMS). Close and fasten the starter box

door.Recheck for correct rotation.

HASP

KEY

LOCK

LEVER

TAG

FIGURE 2.4-4 INTELLISYS

OPERATING INSTRUCTIONS

14

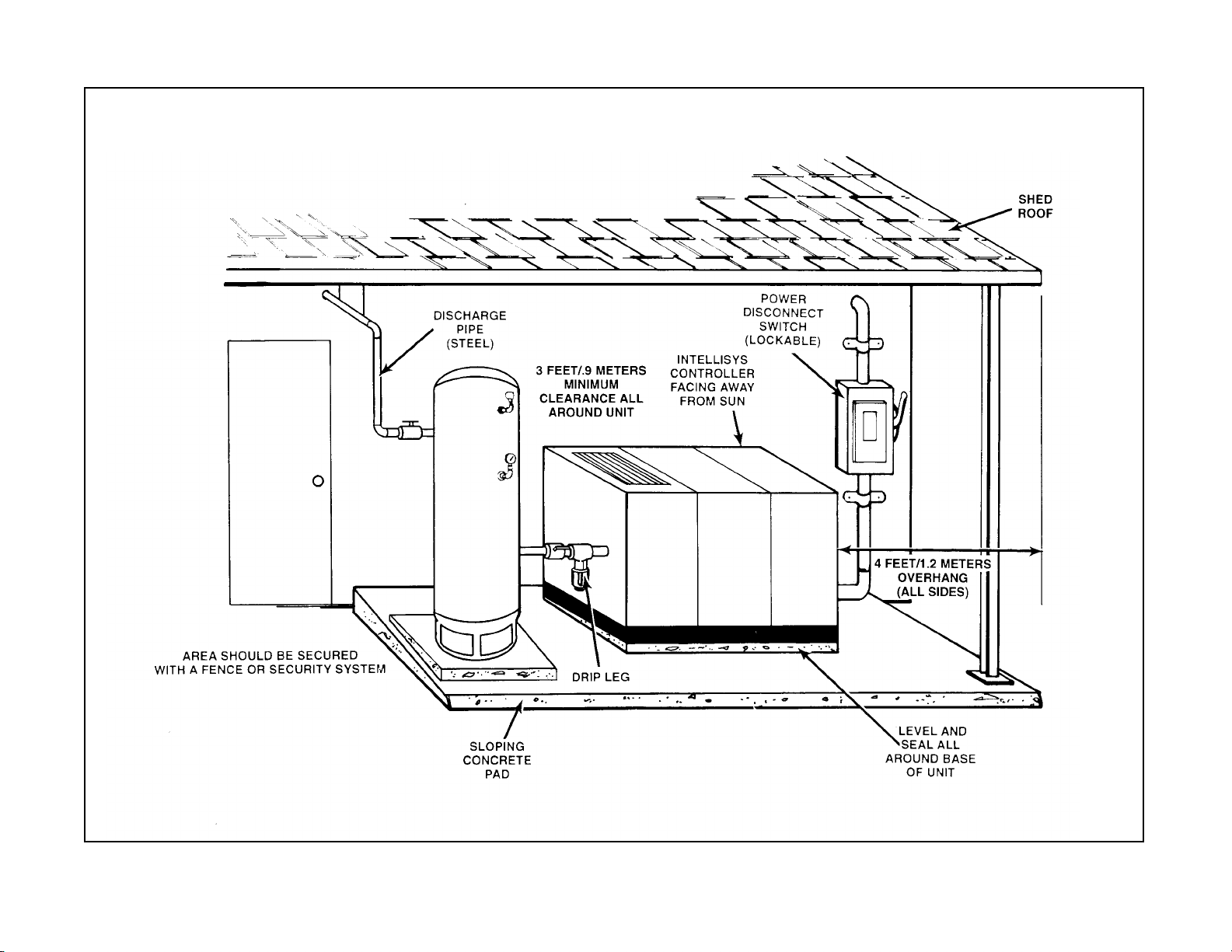

2.5 OUTDOOR SHELTERED INSTALLATION

Many times a compressor must be installed outside due

to jobsite conditions or limited space within a

manufacturing facility. When this occurs there are certain

items that should be incorporated into the installation to

help ensure trouble free operation.These items have

been listed below plus Figure 2.5-1 has been included to

show a typical outdoor sheltered installation.The unit

must be purchased with the Outdoor Modification Option

to provide NEMA 4 electrics and a cabinet exhaust on

the end of the unit rather than the top to prevent recirculation of cooling air.

■ The compressor should be on a concrete pad

designed to drain water away.If the concrete pad is

sloped, then the compressor must be leveled.In order

to properly pull cooling air through the aftercooler, the

base/skid must be sealed to the concrete pad.

■ The roof of the shelter should extend a minimum of

4 ft (1.2 m) around all sides of the compressor to prevent direct rain and snow from falling on the unit.

■ Air-cooled machines must be arranged under the

shelter in a way that prevents air recirculation (i.e.hot

exhaust back to the package inlet).

■ If the installation includes more than one compressor,

the hot air exhaust should not be directed towards the

fresh air intake of the second unit or an Air Dryer.

■ If a standard machine is to be installed outside, the

ambient temperature must never drop below 35°F

(1.7°C).

■ If ambient temperature drops below 35°F (1.7°C) to as

low as –10°F (–23°C) the unit must be supplied with

the Low Ambient Option. Installations below –10°F

(–23°C) ambient are not recommended.The Low

Ambient Option requires a separate power source to

operate internal heaters.

■ Arrange the machine with the Intellisys con-

troller/starter enclosure facing away from the sun as

radiant heat can affect starter/lntellisys performance.

Also direct sunlight and UV rays will degrade the

membrane touch panel.This is not a warrantable

situation.

■ Power disconnect switch should be within line of sight

and in close proximity to the unit.N.E.C.and local

electrical codes must be followed when installing the

power disconnect switch.

■ Condensate drains must never be allowed to dump on

the ground. Run to a suitable sump for future

collection and disposal or separation of lubricant and

water mixture.

■ Incoming power connections must use suitable

connectors for outdoor weather tight service.

■ A minimum of 3 ft (.9 m) clearance must be allowed

on all four sides of the unit for service access.If

possible, access by a forklift and/or an overhead beam

hoist should be kept in mind (for eventual service to

airend or motor).

■ If the area around the installation contains fine

airborne dust or lint and fibers etc., then the unit

should be purchased with the High Dust Filter Option

and TEFC motors.

■ If larger debris, such as leaves or trash, are blowing in

the area, the Inlet Panel Filter Accessory should be

purchased and added to the unit (ship loose item).

■ Some type of protection such as a fence or security

system, should be provided to prevent unauthorized

access.

FIGURE 2.5-1 TYPICAL OUTDOOR SHELTERED INSTALLATION

15

16

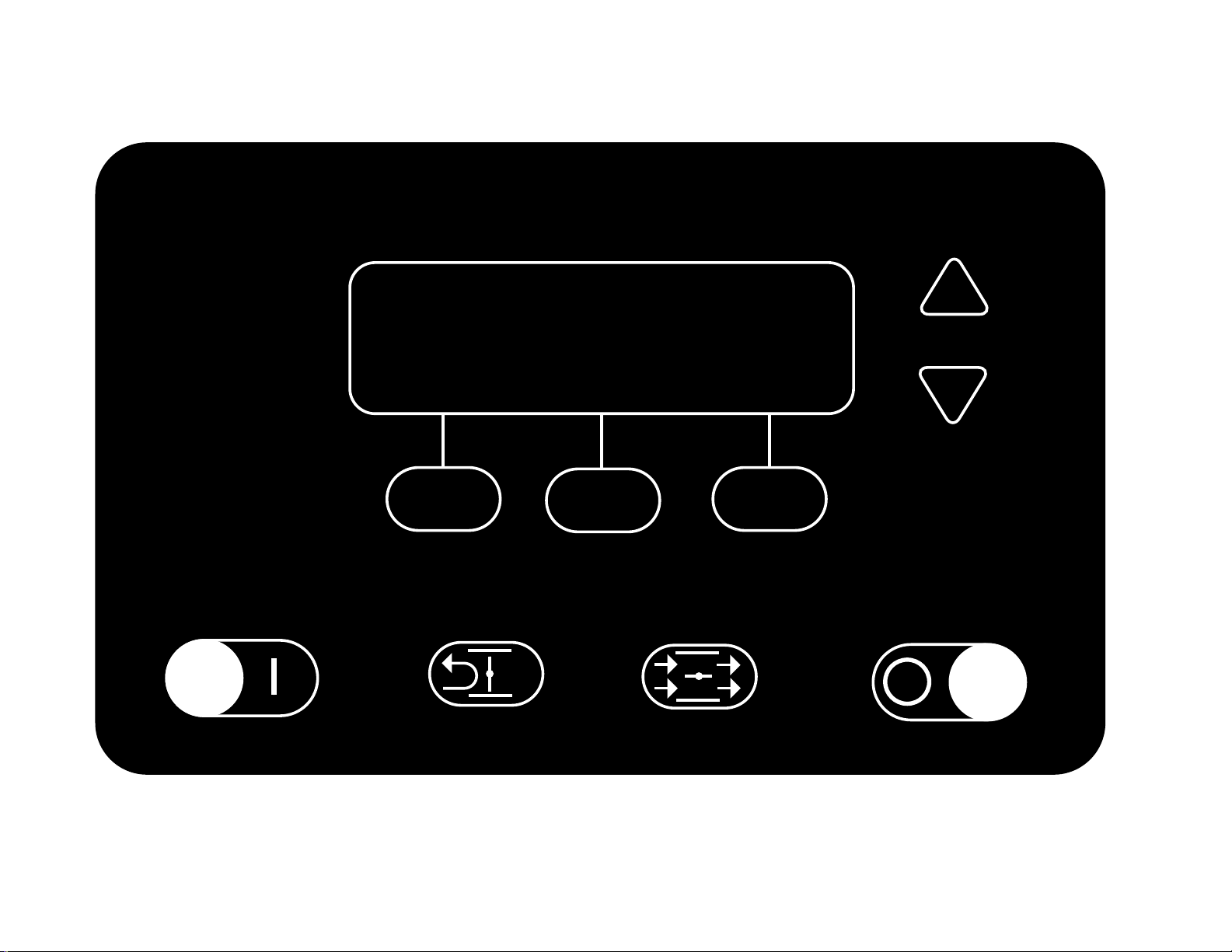

3.0 INTELLISYS

INTELLISYS CONTROLLER

INGERSOLLrAND

INTELLISYS

3.0 INTELLISYS

3.1 INTELLISYS CONTROLS

EMERGENCY STOP

Pressing this switch stops the compressor immediately.

The compressor can not be restarted until the switch is

manually reset.Turn the switch knob clockwise to

reset.

POWER ON LIGHT

This indicates the control voltage and the line voltage

are available for starting.

The operator panel is divided into two areas.The

bottom row of four buttons provides direct control over

the starting, stopping, unloading and loading of the

compressor.These are defined by the symbols printed

on the buttons themselves, as shown here.

START

Pressing this button will start the compressor if the

display shows “Ready To Start”. The compressor will

start and load if there is sufficient demand for air.

STOP

Pressing this button will activate the unloaded stop

sequence. If the compressor is running loaded, it will

unload and continue to run unloaded for an adjustable

10 to 30 seconds and then stop.If the compressor is

running unloaded, it will stop immediately.

UNLOAD

Pressing this button will cause the compressor to

unload and remain unloaded.The display will indicate

the machine is “Running Unloaded”, and “Mode:

UNLOAD”.

LOAD

Pressing this button will cause the compressor to load

if the compressor is running and if the “Discharge

Pressure” is less than the “Online Pressure”. This also

returns the machine to the operating mode that is

specified by the “Mode of Operation”set point.

The other five buttons provide access to various

operator-selectable functions and machine operating

conditions.The pur pose of each of these buttons is

defined by the display screen and the particular

function being performed at that time.

ARROWS

These up and down buttons have multiple functions

relating to the right half of the display screen.When

lists are presented, the buttons are used to move up or

down through the items on the list.The small arrow(s)

displayed in the upper right corner of the display

screen indicate when you can move up (designated by

arrow head pointing up) and/or down (designated by

arrow head pointing down) through the list.

When the value of a specific machine operating

parameter is highlighted on the display screen for the

purpose of changing that value, the buttons are used

to change the value itself.

DISPLAY BUTTONS

The functions of the three buttons below the display

screen change and are defined by the words

immediately above them in the bottom line of the

screen. Each function, such as MAIN MENU, STATUS,

SET, etc., is descr ibed in appropriate sections in this

manual.

17

EMEG

STOP

POWER

ON

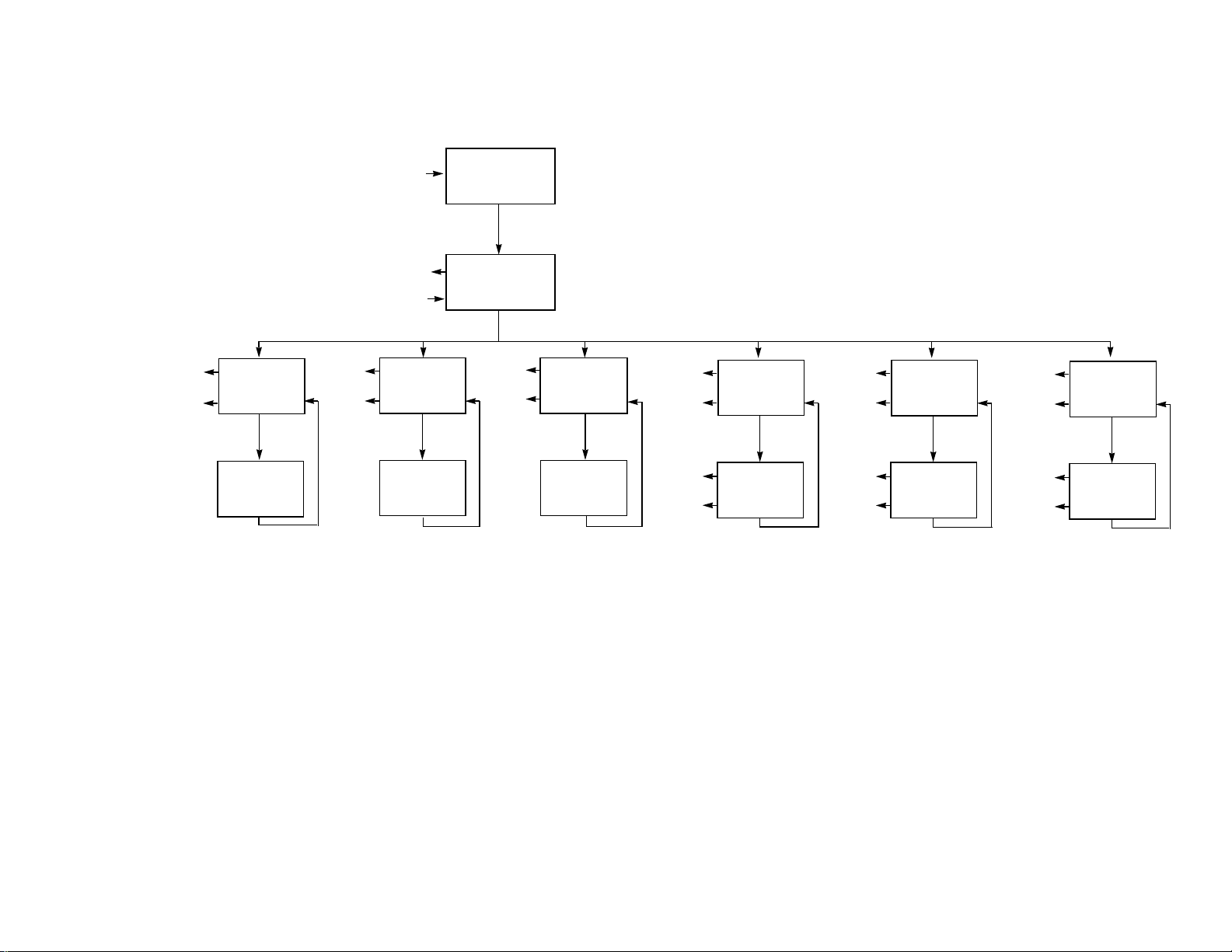

The display screen is divided into three functional

areas, as seen in the typical CURRENT STATUS

screen shown here.

The left side continuously shows the package

discharge pressure in large numbers, with the line

directly below the numbers showing the running

condition of the machine, and the line below that

showing the present mode of operation.

The right side shows various items or lists such as the

machine’s CURRENT STATUS readings, the MAIN

MENU, the OPERATOR SETPOINTS list, etc. Any of

the lists can be moved up or down by pressing the

arrow buttons to the right of the screen.The small

arrow(s) displayed in the upper right corner of the

screen indicate when you can move up (designated by

arrow head pointing up) and/or down (designated by

arrow head pointing down) through a list.The arrow

buttons are also used to change an individual item’s

value.At certain times, items and/or their values are

“highlighted”.This means they are displayed as light

characters on a dark background.

The bottom of the screen is divided into thirds with the

words in each small box showing the function of the

button directly beneath it.The words will change in

these boxes depending on what actions are permitted

at any particular time.The action resulting from

pressing each of these buttons is indicated in Figure

3.2.1, which can be used as a quick reference of how

to step the controller screen through any desired

function.

3.2 DISPLAY SCREEN

3.3 CURRENT STATUS

The CURRENT STATUS screen is considered the

“normal” display that the controller shows.

The following items and their present values can be

displayed on the right side of the screen by pressing

the up and down arrow buttons.

CURRENT STATUS Items

Discharge Temperature Inlet V acuum

Airend Discharge Temperature Inlet Filter

Injected Temperature Total Hours

Sump Pressure Loaded Hours

Separator Pressure Drop % Load Modulation

Unloaded Inlet Vacuum

Coolant Pressure

Time & Date

Coolant Filter Software Title

and V ersion

The controller automatically returns the display to this

CURRENT STATUS screen from other screens if no

buttons are pressed within 30 seconds.

The MAIN MENU screen can be accessed from the

CURRENT STATUS screen by pressing the MAIN

MENU button, identified by the words “MAIN MENU” in

the bottom line of the screen directly above the center

button.

Running Loaded

Mode: MOD/ACS

- CURRENT STATUS-

Package Discharge Temp

103°F

Airend Discharge Temp

193°F

MAIN MENU

Running Loaded

Mode: MOD/ACS

-CURRENT STATUS-

Package Discharge Temp

103°F

Airend Discharge Temp

193°F

MAIN MENU

18

1 0 0

P S I

1 0 0

P S I

19

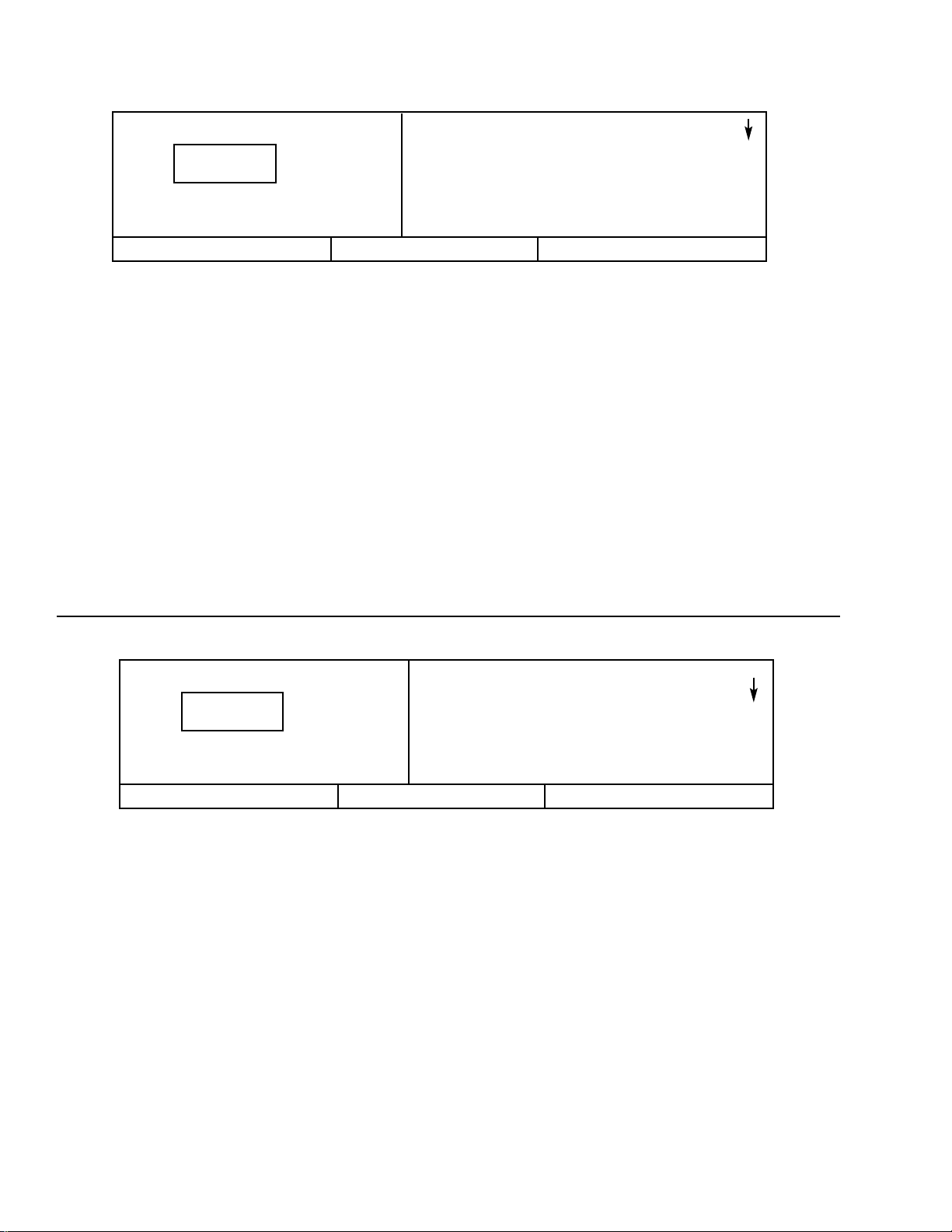

NOTE - Use the UP and DOWN arrows to move between selections.Items will be highlighted in inverse display mode.

* - Selecting the highlighted item will display the corresponding menu.

** - Selecting the highlighted item will place the value in edit mode.This is indicated by only the value being displayed in inverse display mode.

*** - The UP and DOWN arrows will alter the value. Depressing “Cancel” will exit the edit mode and leave the value unchanged. Depressing

“Set” will save the new value and flash the value to indicate acceptance.

**** - Depressing “Cancel” will exit calibration mode.Depressing “Calibrate” will calibrate selected sensor.

***** - Use UP and DOWN arrows to scroll through list of status items.

INTELLISYS

Operator Panel Flow Diagram

Figure 3.2.1

“Status”

“Alarm Hist.”

“Cancel ot Set”

“Cancel ot Set”

CURRENT STATUS

“Main Menu”

“Main Menu”

“Status”

OPERATOR

SETPOINTS**

“Select”

OPERATOR

SETPOINTS

ITEM***

“Cancel” or “Set” “Cancel” or “Set”

“Main Menu”

“Status”

“Status”

“Main Menu”

OPTIONS**

“Select” “Select”

OPTIONS

ITEM***

MAIN MENU*

“Select”

“Main Menu”

“Status”

CALIBRATION**

CALIBRATION

SENSOR

SENSOR

ITEM****

“Cancel” or “Calibrate”

“Main Menu”

“Status”

“Main Menu”

“Status”

ALARM

HISTORY**

“Select”

ALARM

HISTORY

ITEM*****

“Main Menu”

“Main Menu”

“Cancel” or “Set”

“Status”

“Status”

CLOCK

FUNCTIONS

“Select”

DATE AND

TIME

“Cancel” or “set”

“Main Menu”

“Status”

“Main Menu”

“Status”

INTEGRAL

SEQUENCING

“Select”

INTEGRAL

SEQUENCING

ITEM***

“Cancel” or “set”

3.4 MAIN MENU

The MAIN MENU screen is the point from which

various operator functions can be accessed. Refer to

the reference diagram in Figure 3.2.1.

Each of the functions can be chosen by using the up

and down arrows to highlight it on the screen.

The controller will go to the highlighted function if the

SELECT button is pressed or will return to the

CURRENT STATUS screen if the STATUS button is

pressed.

STATUS

SELECT

Ready To Start

-MAIN MENUOperator Setpoints

Options

Sensor Calibration

Alarm History

Clock Functions

3.5 OPERATOR SETPOINTS

STATUS

MAIN MENU

SELECT

Ready To Start

-OPERATOR SETPOINTSOffline Pressure

103 PSI

Online Pressure

93 PSI

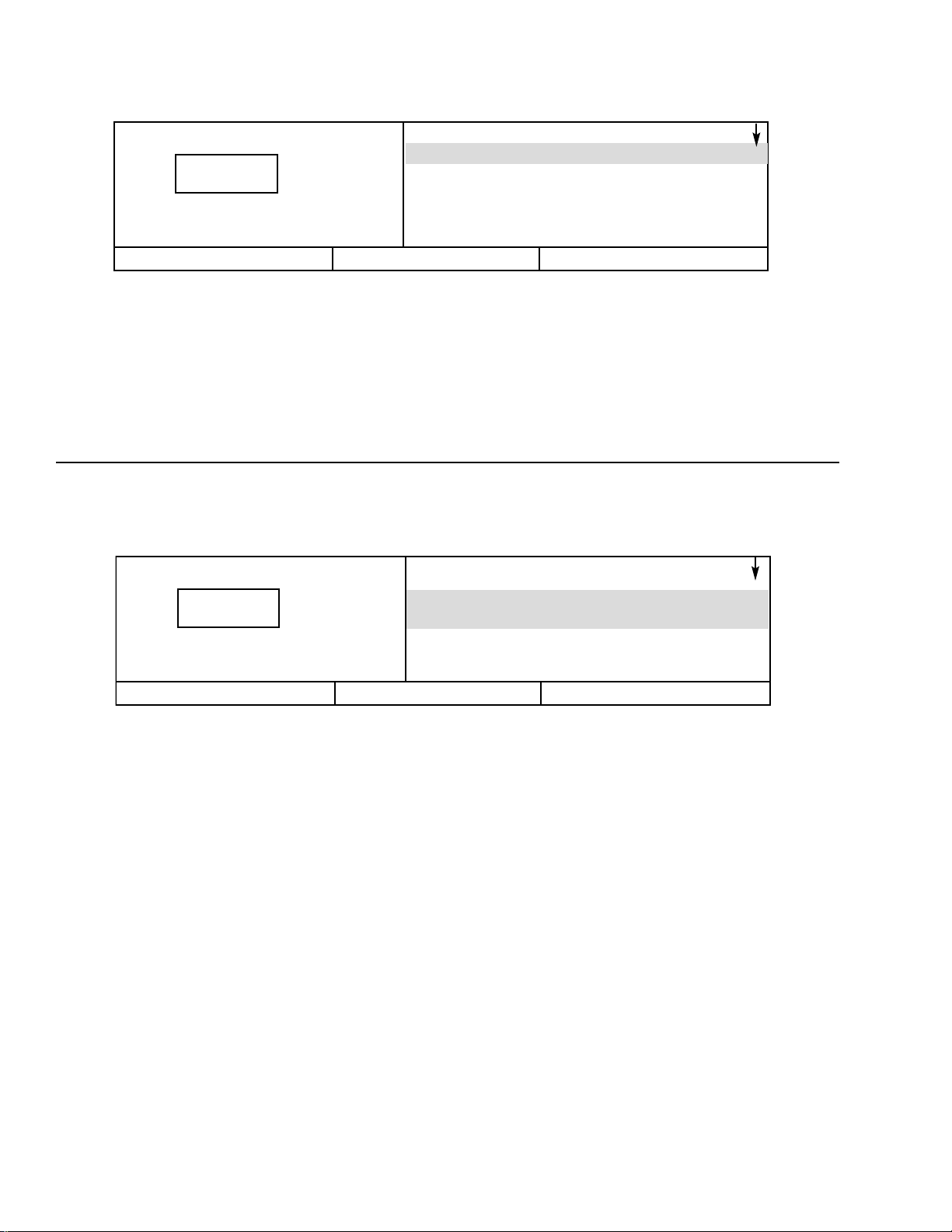

Setpoints are user-adjustable variables in the

controller logic that can be set using the OPERATOR

SETPOINTS screen.

The name and value of each of the setpoints listed

below can be seen on the screen by moving the list up

and down using the arrow buttons.

Setpoints associated with options are described in the

OPTIONS Section 3.6.

A setpoint’s value can be changed by first highlighting

the item and its value and pressing the SELECT

button to highlight just the value.When the value line is

highlighted by itself, the value can be adjusted using

the up and down arrow buttons.The CANCEL and

SET buttons appear at this time.Press the SET button

to enter the new value, or press the CANCEL button to

return to the value of the setpoint prior to using the

arrows.The displayed value will flash twice to indicate

it has been entered into the setpoint, and the pair of

setpoint item and value display lines will again be

highlighted together.

Operator set points can be exited by pressing the

STATUS or MAIN MENU buttons. If no buttons are

pressed within 30 seconds, the display will return to

the CURRENT STATUS screen.

OPERATOR SETPOINTS RANGE STEP UNIT

Lead/Lag Lead or Lag --- --Offline Pressure 75 to RATED +3 1 PSIG

Online Pressure 65 to OFFLINE - 10 1 PSIG

Lag Offset 0 to 45 1 PSIG

Mode of Operation MOD/ACS, ON/OFF LINE, --- ---

MODULATION ONLY

Max Modulation Pressure

Online + 10 to Offline + 7 1

PSIG

Stop Delay Time 10 to 60 1 SEC

Star-Delta Time* 5 to 20 1 SEC

(Screen) Contrast 0 to 10 1 ---

* Does not apply to automatic across the line starters.

20

1 0 0

P S I

1 0 0

P S I

3.5.1 Lead/Lag- This setpoint is used for setting lead

or lag operation. If set to lead, the controller will load

and unload the compressor by the online and offline

setpoints. If set to lag, the controller will subtract the

lag offset (see 3.5.4) from the online and offline set

points and operate the compressor at the lower

pressure range.

3.5.2 Offline Pressure- This setpoint is the pressure

the compressor will unload at if it is operating in on/off

line mode.

3.5.3 Online Pressure- This setpoint is the pressure

the compressor will load at.

3.5.4 Lag Offset- This setpoint is used with the

lead/lag operation. If the lead/lag set point is set to lag

(see 3.5.1), the value of the lag offset will be

subtracted from the online and offline setpoints.

3.5.5 Mode of Operation- This setpoint is used to

select the operating mode of the compressor.The

choices are MOD/ACS, ON/OFF LINE, and

MODULATION ONLY. See section 5.8 for more

information on these operating modes.

3.5.6 Max Modulation Pressure- This setpoint is the

pressure the compressor will unload at if it is

modulating. As the package discharge pressure rises

toward this value, the inlet valve will start to close.The

compressor will unload once the package discharge

reaches this value. See section 5.8 for more

information on modulation.

3.5.7 Stop Delay Time- This setpoint is the minimum

amount of time the compressor will run unloaded

before stopping.This period does not apply to alar ms

(shutdowns).

3.5.8 Star-Delta Time- This setpoint is only used with

star-delta starters. It is not used if the starter is full

voltage or a remote starter.This is the time period

between starting and star-delta transition.

3.5.9 Contrast- This setpoint is used to improve the

display on the Intellisys.

-OPTIONS-

Auto Restart

Off

Auto Restart Time

10 MINUTES

3.6 OPTIONS

Options are turned on or off and their associated

values are set using the OPTION screen.

Some options require additional machine hardware

and the proper “Option Module” to plug into the

Intellisys controller.Descriptions of the options

operations are in Section 7.0.The name and value of

each of the options listed in the right hand column can

be seen by moving the list up and down using the

arrow buttons.

An Option item’s value can be changed the same way

OPERATOR SETPOINTS values are changed. See

Section 3.5 for an explanation.

OPTIONS ITEMS RANGE STEP UNIT

Auto Restart On/Off --- --Auto Restart Time 2 to 60 1 MIN

Auto Restart Delay Time 0 to 60 1 SEC

Sequencer On/Off --- --Remote Start/Stop On/Off --- --Power Out Restart On/Off --- --Power Out Restart Time 10 to 600 1 SEC

Low Ambient On/Off --- --Min. Cooler Out Temp

30 to 150 1 Deg. F

Separator Delta-P Solenoid On/Off --- --Separator Delta-P Sensor On/Off --- --Lead/Lag Cycle Length 0-750 1 HRS

Scheduled Start

00:00 to 23:59

1 TIME

Scheduled Stop

00:00 to 23:59

1 TIME

High Dust Filter On/Off --- --Modbus Protocol On/Off/ICU --- --Modbus Address 1 to 247 1 ---

STATUS

MAIN MENU

SELECT

Ready To Start

21

1 0 0

P S I

22

3.6.1 Auto Restart- This setpoint is used to enable or

disable the auto restart option.

3.6.2 Auto Restart Time- This setpoint is the minimum

time period the compressor must run unloaded before

it can stop in the auto restart mode.

3.6.3 Auto Restart Delay Time- If the compressor is

stopped in auto restart, this setpoint is the number of

seconds the package discharge pressure must remain

below the online pressure setpoint before the

compressor will restart.

3.6.4 Sequencer- This setpoint is used to enable or

disable sequencer operation.

3.6.5 Remote Start/Stpop- This setpoint is used to

enable or disable the remote start/stop option.

3.6.6 Power Out Restart- This setpoint is used to

enable or disable the power out restart option, if it is

installed.

3.7.7 Power Out Restart Time- If the power out

restart option is installed and enabled, this setpoint is

time period between power returning to the

compressor and the compressor starting.

3.6.8 Low Ambient- This setpoint enables or disables

the low ambient option. If the low ambient option is

enabled, sensor 3CTT must be installed in the

compressor.

3.6.9 Minimum Cooler Out Temperature- When the

low ambient option is installed, this setpoint is the

minimum temperature to which the coolant must rise

before the compressor will load.

3.6.10 Separator Delta-P Solenoid- This setpoint

enables or disables the separator delta-p solenoid

option. Enabling this option will automatically disable

the Separator Delta-P Sensor option.

3.6.11 Separator Delta-P Sensor- This setpoint

enables or disables the separator delta-p sensor

option. Enabling this option will automatically disable

the Separator Delta-P Solenoid option.

3.6.12 Lead/Lag Cycle Length- This setpoint enables

the automatic cycling between lead and lag operation.

If it is set to a value greater than 0, the controller will

cycle between lead and lag operation.The value of this

set point is the cycle length in real time hours. A value

of 0 will disable the automatic cycling between lead

and lag.

3.6.13 Scheduled Start- If the scheduled start/stop

option is installed, this set point is the time of the day

(hour and minute) that the compressor will

automatically start. To disable this option, set it to the

same value as the scheduled stop (section 3.6.14).

3.6.14 Scheduled Stop- If the scheduled start/stop

option is installed, this setpoint is the time of the day

(hour and minute) that the compressor will

automatically stop.To disable this option, set it to the

same value as the scheduled start (section 3.6.13).

3.6.15 High Dust Filter- This option enables or

disables the high dust filter operation.

3.6.16 Modbus Protocol- This option is for IngersollRand service use only.

3.6.17 Modbus Address- This feature is used with the

Modbus Protocol and is for Ingersoll-Rand service use

only.

3.6 OPTIONS (CONTINUED)

3.7 SENSOR CALIBRATION

-SENSOR CALIBRATIONSensor 1AVPT

CALIBRATE

Sensor 3APT

CALIBRATE

STATUS

MAIN MENU

SELECT

Ready To Start

Pressure sensor calibration is done through the

SENSOR CALIBRATION screen. Sensor calibration

can only take place when the machine is stopped.

Calibration needs to be done only after a sensor has

been replaced or the Intellisys controller has been

replaced.

Each of the sensors listed below can be chosen by

using the up and down arrow buttons to highlight it on

the screen.

SENSOR CALIBRATION Items

Sensor 1AVPT

Sensor 3APT

Sensor 4APT

Sensor 5CPT

Sensor 6APT

Select the highlighted sensor by pressing the SELECT

button. Press the CALIBRATE button to start the

automatic calibration procedure, or press the CANCEL

button to not calibrate it and return to the sensor list.

The calibration screen can be exited by pressing either

the STATUS or MAIN MENU buttons. If no buttons are

pressed within 30 seconds, the display will return to

the CURRENT STATUS screen.

0

23

-ALARM HISTORYAlarm History 1

MOTOR OVERLOAD

Alarm History 2

HIGH AIREND DISCH TEMP

3.8 ALARM HISTORY

STATUS

MAIN MENU

SELECT

Ready To Start

Alarm History displays each of the Alarm messages

for the last 15 Alarms experienced by the machine.It

also gives access to displaying the machine operating

conditions that existed at the time of each Alarm.The

first one shown, “Alarm History 1”, was the most

recent Alarm to occur. Note that multiple, consecutive

EMERGENCY STOP Alarms are not recorded as

separate Alarms, only the first one will be shown.

Each of the last 15 Alarm messages can be seen by

moving the Alarm History list up and down using the

arrow buttons.Pressing the SELECT button when one

of the Alarms is highlighted will display the list of

machine values that existed at the time that particular

Alarm occurred.

1 0 0

P S I

1 0 0

P S I

24

-ALARM HISTORY 1-

Package Disch Pressure

199 PSI

Package Discharge Temp

103°F

STATUS

MAIN MENU

ALARM HISTORY

Ready To Start

The name and value of each of the items listed below

can be seen by moving the list up and down using the

arrow buttons.Pressing the ALARM HIST. button will

return the display to the ALARM HISTORY screen.

ALARM HISTORY Items

Discharge Pressure Coolant Filter

Discharge Temperature Inlet V acuum

Airend Discharge Temperature Inlet Filter

Injected Temperature Total Hours

Sump Pressure Loaded Hours

Separator Press. Drop % Load Modulation

Unloaded Inlet Vacuum

Coolant Pressure

Time & Date

Alarm histories can be exited by pressing either the

STATUS or MAIN MENU buttons. If no buttons are

pressed within 30 seconds, the display will return to the

CURRENT STATUS screen.

-CLOCK FUNCTIONSTime

01:15

Date

Jan 01, 00

3.9 CLOCK FUNCTIONS

The date and time for the real time clock is set through

the CLOCK FUNCTIONS screen. Use the up and

down arrows to highlight either TIME or DATE. Select

the highlighted setting by pressing SELECT.

If TIME is selected, first the hours will be highlighted.

Adjust the hours (00-23 hour clock) by using the up

and down arrows.Once the correct time is in the

display, press SET to highlight the minutes. Adjust the

minutes (00-59) and then press SET to complete

setting the time.

If DATE is selected, first the month will be highlighted.

Adjust the month by using the up and down arrows

and then press SET to highlight the date. Once the

correct date is displayed, press SET to highlight the

year. Once the correct year is displayed, press SET to

complete setting the date.

STATUS

MAIN MENU

SELECT

Ready To Start

1 0 0

P S I

1 0 0

P S I

25

-INTEGRAL SEQUENCINGLead Compressor

Off

Total Compressors

2

3.10 INTEGRAL SEQUENCING

Integral Sequencing is set up using the INTEGRAL

SEQUENCING screen. A description of integral is in

section 7.0.The name and value of each of the

integral sequencing setpoints as listed in the right

hand column can be seen by moving the list up and

down using the arrow buttons.

3.10.1 Lead Compressor- The choices for this

setpoint are On, Off, Always, and Never. On, means

the compressor is the lead unit. Off, means the

compressor is not the lead unit, but it could become

the lead unit. If Always is selected, the compressor is

the lead unit and it will not transfer the lead to another

compressor.Never, means the compressor is not the

lead unit and will never become the lead unit.The

operator must set one unit (and only one) to On or

Always to start integral sequencing.

3.10.2 T otal Compressors- This is the total number of

compressors in the integral sequence.This setpoint

must be set to the same number on each compressor.

3.10.3 Compressor Address- This is the address of

the compressor in the integral sequence.No two

compressors can have the same address.Two

compressors with the same address will cause

communication failures.

3.10.4 Load Delay Time- This is the number of

seconds the lead compressor will wait for the package

discharge pressure to start rising after issuing a load

command to another compressor.If the package

discharge pressure has not started rising at the end of

this time period, the lead compressor will load the next

compressor in the sequencer.

3.10.5 Lead Change - Hours- This is the number of

hours the compressor will operate as the lead unit.

Once a compressor has operated as the lead for this

number of hours, it will transfer the lead to the next

compressor in the sequence.This setpoint does not

apply to a unit where the lead compressor is set to

always or never. If this setpoint is set to 0, the next 2

setpoints will determine when the lead is transferred.

3.10.6 Lead Change - Day & Lead Change - Time-

These two setpoints are used together.If the Lead

Change - Hours setpoint is set to 0, these two

setpoints will be used to determine when the

compressor will transfer the lead to the next

compressor in sequence. Lead Change - Day is the

day of the week that the compressor will transfer the

lead. Lead Change - Time is the time of the day that

the compressor will transfer the lead.

STATUS

MAIN MENU

SELECT

Ready To Start

INTEGRAL SEQUENCING RANGE STEP UNIT

Lead Compressor On/Off/Always/Never --- --Total Compressors 2 to 4 1 --Compressor Address 1 to Total Compressors 1 --Load Delay Time 10 to 60 1 SEC

Lead Change - Hours 0 to 750 1 HRS

Lead Change - Day Sun to Sat, Daily, Week

1

DAY

Day, Week End

Lead Change - Time 00:00 to 23:59 1 TIME

1 0 0

P S I

Change Inlet Filter

Press RESET Twice

3.11 WARNINGS

STATUS

MAIN MENU

RESET

Running Unloaded

Mode: MOD/ACS

-CURRENT STATUS-

Package Discharge Temp

103°F

Airend Discharge Temp

193°F

WARNING

MAIN MENU

Running Unloaded

Mode: MOD/ACS

Pressing the WARNING button will return the display

to the WARNING screen and the RESET button.

A Warning needs to be reset by the operator by

pressing the RESET button twice.

The possible Warning messages are as follows.

AIREND DISCHARGE TEMP- This will occur if the

Airend Discharge (2ATT) exceeds 97% of the alarm

limit, 228°F (109°C), and is not adjustable.

CHANGE COOLANT FILTER- This warning will occur

if the high side pressure is 20 psig (1.4 bar) greater

than the low side pressure of 1 DPS, and the Injected

Coolant temperature (2CTT) is greater than

120°F (49°C).

CHANGE INLET FILTER- This will occur if the Inlet

Vacuum (1AVPT) is greater than 0.7 psig (.05 bar) and

the machine is fully loaded (inlet valve is completely

open).

CHANGE SEPR ELEMENT- This warning will occur if

the pressure on the Separator (3APT) is 12 psig

(.8 bar) greater than the pressure at the Package

Discharge (4APT), and the machine is fully loaded.

When a Warning occurs, a question mark will flash on

the display screen and appear in large letters as

shown above.The display message will indicate what

caused the warning.

If multiple Warnings exist, the small up/down arrows

will appear in the upper right corner of the display

screen.The multiple Warnings can be seen by

pressing the up and down arrow buttons.Pressing the

STATUS button will display the CURRENT STATUS

screen with the WARNING button indicating a Warning

still exists.

?

HIGH DISCHARGE PRESS- This can occur if the

machine’s loading function is being controlled by a host

device, such as a sequencer or an lSC.This warning

will occur when the package discharge pressure is

above the maximum offline pressure (rated pressure

plus 3 psig [.2 bar]) for more than 3 seconds.This

warning will cause the compressor to unload.The host

device will not be able to load the compressor until the

package discharge pressure falls to the rated pressure

of the machine.

SENSOR FAILURE 4ATT- This will occur if the

Package Discharge Temperature Sensor (4ATT) is

recognized as missing or broken.

AUXILIARY 1 (OR 2) - This warning will occur if either

of the auxiliary contacts closes.

HIGH SUMP/LINE DIF - This warning will occur if the

compressor is running loaded, the injected coolant

temperature is greater than or equal to 120 deg. F,

(49°C) the package discharge pressure is greater than

90 psig, (6.3 bar) the sump pressure is greater than the

compressor’s rated pressure, and the sump pressure is

25 psig (1.8 bar) or more above the package discharge

pressure.

26

1 0 0

1 0 0

P S I

P S I

Loading...

Loading...