Infranor CD1-k-230/2.25, CD1-k-230/10.5, CD1-k-230/16.5, CD1-k-400/1.8, CD1-k-400/2.7 Installation Manual

...

CD1-k – Installation Guide

gb

CD1-k

Installation Guide

CANopen

amplifier

INFRANOR®

CD1-k 1

CD1-k- Installation guide

WARNING

This is a general manual describing a series of servo amplifiers having output capability suitable for driving AC

brushless sinusoidal servo motors.

Please see CD1-k User Guide for the operation of the amplifier (commissioning, configuration, ...).

For the CANopen communication, see manual CD1-k – CANopen Communication Profile.

Instructions for storage, use after storage, commissioning as well as all technical details require the

MANDATORY reading of the manual before getting the amplifiers operational.

Maintenance procedures should be attempted only by highly skilled technicians having good knowledge

of electronics and servo systems with variable speed (EN 60204-1 standard) and using proper test

equipment.

The conformity with the standards and the "CE" approval is only valid if the items are installed according to the

recommendations of the amplifier manuals. Connections are the user's responsibility if recommendations and

drawings requirements are not met.

INFRANOR does not assume any responsibility for any physical or material damage due to improper handling or

wrong descriptions of the ordered items.

Any intervention on the items, which is not specified in the manual, will immediately cancel the warranty.

Infranor reserves the right to change any information contained in this manual without notice.

Any contact with electrical parts, even after power down, may involve physical damage.

Wait for at least 5 minutes after power down before handling the amplifiers (a residual voltage of several

hundreds of volts may remain during a few minutes).

ESD INFORMATION (ElectroStatic Discharge)

INFRANOR amplifiers are conceived to be best protected against electrostatic discharges. However,

some components are particularly sensitive and may be damaged if the amplifiers are not properly

stored and handled.

STORAGE

- The amplifiers must be stored in their original package.

- When taken out of their package, they must be stored positioned on one of their flat metal

surfaces and on a dissipating or electrostatically neutral support.

- Avoid any contact between the amplifier connectors and material with electrostatic potential

HANDLING

ELIMINATION

In order to comply with the 2002/96/EC directive of the European Parliament and of the Council of

27 January 2003 on waste electrical and electronic equipment (WEEE), all INFRANOR devices

have got a sticker

the 2002/96/EC Directive

This symbol indicates that INFRANOR devices must be eliminated by selective disposal and not

with standard waste.

(plastic film, polyester, carpet…).

- If no protection equipment is available (dissipating shoes or bracelets), the amplifiers must

be handled via their metal housing.

-

symbolizing a crossed-out wheel dustbin as shown in Appendix IV of

.

© INFRAN

!

O

August 2008. All rights reserved.

R,

Issue: 5.

7

2

CD1-k- Installation guide

CD1-k – Installation Guide

Content

PAGE

CONTENT ............................................................................................................................................... 3

CHAPTER 1 – GENERAL DESCRIPTION............................................................................................. 5

- INTRODUCTION............................................................................................................................. 5

1

- DESCRIPTION / COMPLIANCE WITH THE STANDARDS............................................................ 5

2

2.1 - GENERAL DESCRIPTION.......................................................................................................5

2.2 - REFERENCE TO THE STANDARDS: "CE" CERTIFICATION ............................................... 6

2.3 - REFERENCE TO THE STANDARDS: "UL" LISTING ............................................................. 6

3

- OTHER DOCUMENTS REQUIRED FOR THE COMMISSIONING................................................ 6

CHAPTER 2 – SPECIFICATIONS.......................................................................................................... 7

1

- MAIN TECHNICAL DATA................................................................................................................ 7

1.1 - CD1-k-230/I SINGLE-AXIS AMPLIFIER .................................................................................. 7

1.2 - CD1-K-400/I SINGLE-AXIS AMPLIFIER.................................................................................. 7

1.3 - COMMON SPECIFICATIONS TO THE CD1-k-230/I AND CD1-k-400/I AMPLIFIER TYPES. 8

2

- DIMENSIONS................................................................................................................................ 11

2.1 - CD1-k-230/I AMPLIFIER…..................................................................................................... 11

2.2 - CD1-k-400/1.8 TO 7.2 A AMPLIFIER..................................................................................... 11

2.3 - CD1-k-400/14 A AMPLIFIER.................................................................................................. 11

2.4 - CD1-k-400/30/45/70 AND 90 A AMPLIFIER.......................................................................... 11

2.5 - BRAKING RESISTOR dp 100/100, dp 200/100, dp 50/200, dp33/280 AND EF 400V.......... 12

3

- FASTENING.................................................................................................................................. 13

3.1 - CD1-k-230/I AMPLIFIER…..................................................................................................... 13

3.2 - CD1-k-400/1.8 TO 7.2 A AMPLIFIER..................................................................................... 13

3.3 - CD1-k-400/14 A AMPLIFIER….............................................................................................. 13

3.4 - CD1-k-400/30/45/70 AND 90 A AMPLIFIER.......................................................................... 13

4

- MULTIAXIS CABINET MOUNTING .............................................................................................. 14

4.1 - CD1-k-230/I AMPLIFIER…..................................................................................................... 14

4.2 - CD1-k-400/1.8 TO 7.2 A AMPLIFIER..................................................................................... 14

4.3 - CD1-k-400/14 A AMPLIFIER.................................................................................................. 14

4.4 - CD1-k-400/30/45/70 AND 90 A AMPLIFIER.......................................................................... 14

CHAPTER 3 – INPUTS-OUTPUTS ......................................................................................................15

1

- CONNECTORS LOCATION ......................................................................................................... 15

1.1 - SINGLE-AXIS AMPLIFIERS CD1-k-230-I AND CD1-k-400-I ................................................ 15

1.2 - CD1-k-400/30/45/70 AND 90 AMPLIFIER ............................................................................. 15

2

- LED DISPLAY ............................................................................................................................... 16

2.1 - IDENTIFICATION OF THE LEDs........................................................................................... 16

3

- AMPLIFIER ADDRESSING: SELECTION OF THE TRANSMISSION SPEED............................. 17

4

- X1 CONNECTOR: RESOLVER SENSOR ....................................................................................... 18

5

- X2 CONNECTOR: INPUTS-OUTPUTS ........................................................................................ 18

5.1 - SPECIFICATION OF THE LOGIC INPUTS: INHIBIT, FC+, FC-, INDEX, CAPTURE, LOW

SPEED............................................................................................................................................ 19

5.2 - SPECIFICATION OF THE LOGIC OUTPUT "AOK" ON RELAY........................................... 19

5.3 - SPECIFICATION OF THE LOGIC OUTPUTS ....................................................................... 19

5.4 - SPECIFICATION OF THE ANALOG INPUTS ....................................................................... 19

6

- X3 CONNECTORS: ENCODER.................................................................................................... 20

6.1 - X3 CONNECTOR FOR TTL INCREMENTAL ENCODER & HES INPUT (Sub D 25 pins

female)............................................................................................................................................ 20

6.2 - X3 CONNECTOR FOR SinCos INCREMENTAL ENCODER & HES INPUT (Sub D 25 pins

female)............................................................................................................................................ 21

6.3 – X3 CONNECTOR FOR ABSOLUTE SINGLE-TURN SinCos ENCODER (Sub D 25 pins

female)............................................................................................................................................ 22

6.4 - X3 CONNECTOR FOR "PULSE / DIRECTION" INPUTS (Sub D 25 pins female)................ 23

3

Content

CD1-k- Installation Guide

6.5 - X3 CONNECTOR FOR ENCODER OUTPUT (Sub D 25 pins female) ................................. 24

7

- X6 AND X7 CONNECTORS: CAN-OPEN ...................................................................................... 24

8

- X5 CONNECTOR: RS-232............................................................................................................ 24

9

- X8 CONNECTOR: AUXILIARY SUPPLY AND BRAKE ................................................................ 25

10

- X9 CONNECTOR: POWER........................................................................................................ 25

CHAPTER 4 - CONNECTIONS............................................................................................................ 26

- CONNECTION DIAGRAMS.......................................................................................................... 26

1

1.1 - CD1-k-230/I AMPLIFIER ........................................................................................................ 26

1.2 - CD1-k-400/I AMPLIFIER ........................................................................................................ 27

1.3 - CONNECTION OF THE SERIAL LINK .................................................................................. 28

1.4 - CONNECTION OF A BACKUP BATTERY ............................................................................ 28

1.5 - CONNECTION FOR A MULTIAXIS APPLICATION .............................................................. 28

2

- WIRING RECOMMENDATIONS................................................................................................... 29

2.1 - GROUND CONNECTIONS AND GROUNDING.................................................................... 29

2.2 - SHIELD CONNECTION OF THE CONNECTORS ................................................................ 30

2.3 - CONNECTION VUE OF CD1-K-400/30/45/70 AND 90......................................................... 31

2.4 - MOTOR, RESOLVER AND ENCODER CABLES ................................................................. 31

2.5 - SERIAL LINK AND CAN COMMUNICATION CABLES......................................................... 32

2.6 - CONNECTION CABLES OF THE BRAKING RESISTOR..................................................... 32

3

- FIRST POWERING OF THE AMPLIFIER ..................................................................................... 33

3.1 - VERY IMPORTANT................................................................................................................ 33

3.2 - SWITCHING ON THE 24 Vdc SUPPLY................................................................................. 33

3.3 - SWITCHING ON THE POWER SUPPLY (230 Vac or 400 Vac according to the

amplifier type) ................................................................................................................................. 33

3.4 - COMMISSIONING.................................................................................................................. 33

4

- REQUIREMENTS FOR THE COMPLIANCE WITH THE UL STANDARDS ................................. 33

4.1 - CONNECTION BY MEANS OF A FASTON SOCKET........................................................... 33

4.2 - 24 V SUPPLY ......................................................................................................................... 33

4.3 - POWER SUPPLY AND UL FUSE RATING ........................................................................... 34

4.4 - CD1-k-230/I AMPLIFIER: CONNECTION DIAGRAM WITH PROTECTIONS BY

"UL" FUSES.................................................................................................................................... 35

4.5 - CD1-k-400/I AMPLIFIER: CONNECTION DIAGRAM WITH PROTECTIONS BY

"UL" FUSES.................................................................................................................................... 36

4.6 - CONNECTION EXAMPLE FOR A UL COMPLIANT MULTIAXIS APPLICATION ............... 37

.................................................................................................................... 38

CHAPTER 5 - APPENDIX

1

- HARDWARE ADJUSTMENTS OF THE LOGIC BOARD.............................................................. 38

2

- ADJUSTMENT TO VARIOIUS RESOLVER TYPES..................................................................... 39

- USE OF THE "AOK" OUTPUT ...................................................................................................... 39

3

4

- ENERGY RECUPERATION VIA A BRAKING RESISTOR ................................................................. 40

- ORDER CODE .............................................................................................................................. 40

5

4

Content

CD1-k – Installation Guide

Chapter 1 – General description

1 - INTRODUCTION

CD1-k all-digital amplifiers with sinusoidal PWM control are servo amplifiers that provide the control of brushless

AC motors with a position sensor.

The CD1-k amplifier is a stand-alone single-axis block including power supply unit and mains filters. It is available

in both 230 VAC and 400/480 VAC mains operated voltages.

2 - DESCRIPTION / COMPLIANCE WITH THE STANDARDS

2.1 - GENERAL DESCRIPTION

The CD1-k amplifier directly controls the motor torque and speed by means of the information provided by a high

resolution position sensor (resolver or encoder). The sinusoidal current commutation based on this high resolution

position sensor provides very smooth motor torque/force control.

The CD1-k amplifier can be configured for the feedback of various position sensor types. The appropriate position

sensor configuration is selectable by software and saved in the amplifier.

- With a resolver sensor feedback, the motor absolute position value over one revolution is available and the

servo motor can immediately be enabled after the amplifier power up.

- With a "SinCos tracks" sensor which provides two analog Sin and Cos signals electrically compliant with the

SinCos encoder signals and which period is equal to the motor pole pitch, the servo-motor can be immediately

enabled after the powering of the drive.

- With an absolute single-turn SinCos encoder feedback (Heidenhain ERN 1085 or compliant), the servo

motor can also immediately be enabled after the amplifier power up.

- With an incremental encoder only, a motor phasing procedure (Phasing) must be executed at each amplifier

power up before the motor enabling.

- With an incremental encoder + Hall Effect Sensors (HES) feedback, the motor phasing procedure is no more

necessary and the servo motor can immediately be enabled after the amplifier power up.

- With an absolute single-turn, multi-turn or linear encoder using the ENDAT or HIPERFACE communication

protocols and fitted with incremental SinCos outputs, the servo-motor can also be immediately enabled after the

powering of the drive.

Series CD1-k amplifiers have their own DC/DC converter to provide appropriate logic voltage to the modules. An

auxiliary 24VDC +/- 15 % supply is generally available on all machines and supplies a DC/DC converter with all

logic supplies required by the amplifier. The auxiliary supply allows to keep the logic board on, after the power

supply has been switched off, in order to keep the position output and to avoid initializing the machine all over

again. A 24 VDC battery supply with specific wiring allows to keep the position even after switching off the

auxiliary 24 VDC supply. This wiring can be used for "absolute" operation with the CD1-k amplifier (see chapter 4:

Connections).

The power supply is depending on the amplifier type:

• CD1-k-230/I: 230 VAC single-phase mains operation power supply or three-phase via a transformer or

an auto-transformer or three-phase mains operation if there are three-phase mains available in 200 to

230 VAC.

• CD1-k-400/I: 400 to 480 VAC three-phase mains operated power supply.

A soft start system of the power supply allows to limit the inrush current at power on.

The very small dimensions of the CD1-k amplifier allow an optimum integration in 300 mm deep cabinets

(connectors included).

Chapter 1 - General description

5

CD1-K- Installation Guide

2.2 - REFERENCE TO THE STANDARDS: "CE" CERTIFICATION

Series CD1-k amplifiers have been approved with regard to their conformity with the Electromagnetic Compatibility

standards concerning the power servos referenced in the EN 61800-3:2004 standard "Electrical variable speed

power servo systems":

- EN 55011, group 1, C3 category, regarding radiated radioelectric disturbances,

- EN 61000.4-2-3-4-5 regarding immunity.

Standard to be applied to the electrical equipment of industrial machines: EN 60204-1.

These items have been "CE" marked since year 2000.

2.3 - REFERENCE TO THE STANDARDS: "UL" LISTING

CD1-k series have been «

This product was evaluated to:

- the Third Edition of UL508C, the UL Standard for Power Conversion Equipment, dated May 2002 for the UL

Listing (USL),

- the CSA Standard for Industrial Control Equipment, C22.2 N° 14-95, dated August 1995 for the Canadian UL

Listing (CNL) except for CD1-k-400/70 and 90 drives.

Providing that the manual is specifying that the end user has to provide an isolated power supply, for 24 VDC

auxiliary input protected by a 4 A UL Listed fuse, the power board is considered within a limited voltage/current

circuit per section 31.4 of UL508C. Therefore, spaces on the power board are not required to be evaluated per

section 31.2 of UL508C and were evaluated according to UL 840.

Per UL 840 (Second Edition, dated May 20, 1993) requirements, spaces are limited to 2.5 mm assuming pollution

degree 2 environment.

Ground connection is fixed in the frame of the device by a rivet, Avibulb masse, BN10-5168. The connector

complies with standard dimensions given in table 6.2 of UL 310, the standard for Electrical Quick connect

terminals.

» listed according to UL508C and UL840 regarding the insulator.

cULus

3 - OTHER DOCUMENTS REQUIRED FOR THE COMMISSIONING

CD1-k User Guide,

CANopen communication protocol for CD1-k amplifiers.

"CD1-a/CD1-k SinCos track feedback" application note regarding the use of motors equipped with

"SinCos tracks" position sensors.

"CD1-a/CD1-k absolute encoders feedback" application note regarding the use of absolute single-turn,

multi-turn or linear encoders using the ENDAT or HIPERFACE Communication protocols.

6

Chapter 1 - General description

CD1-k – Installation Guide

Chapter 2 – Specifications

1 - MAIN TECHNICAL DATA

1.1 – CD1-k-230/I SINGLE-AXIS AMPLIFIER

Mains operated power supply voltage 230 Vac +10 % / -15 % single-phase or 3-phase

50 to 60 Hz

Isolated auxiliary logic and motor brake supply voltage 24 Vdc +/-15 % - 320 mA without brake

Motor phase-phase output voltage 200 Vrms

Integrated braking system External resistor 100 Ohm / 100 W (dp 100/100)

Minimum resistance: 50 Ohm

Minimum inductance between phases 1 mH

OUTPUT CURRENT RATINGS (at a maximum room temperature of 40°C)

Amplifier type

CD1-k-230/2.25 2.25 1.1 25 1.1 6 A 5 kA yes

CD1-k-230/4.5 4.5 2.25 30 2.25 6 A 5 kA yes

CD1-k-230/7.5 7.5 3.75 44 3.75 6 A 5 kA yes

CD1-k-230/10.5 10.5 5.25 55 5.25 6 A 5 kA yes

CD1-k-230/16.5 16.5 8.25 66 8.25 9 A 5 kA yes

1.2 - CD1-K-400/I SINGLE-AXIS AMPLIFIER

Mains operated power supply voltage 400 to 480 Vac +10 % / -15 % 3-phase, TN or TT

50 to 60 Hz (phase-earth voltage must be

Auxiliary logic and motor brake supply voltage 24 Vdc +/-15 % - 320 mA without brake

Motor phase-phase output voltage 380 to 460 Vrms depending on the mains

Integrated braking system CD1-k-400/1.8 to 7.2 A:

External resistor: 200 Ohm / 100 W (dp 200/100)

Minimum resistor value: 150 Ω/100 W

CD1-k-400/14 A:

External resistor: 50 Ohm / 200 W (dp 50/200)

CD1-k-400/30 and 45 A:

External resistor : 33 Ω/280 W (dp 33/280)

CD1-k-400/70 and 90 A:

External resistor: 16.5 Ω/560 W (EF 400V)

Minimum inductance between phases 2 mH

Max. output

current (Arms)

for 1 sec.

+/- 5 %

(230 VAC)

Rated

output

current

(Arms)

(230 VAC)

Power

losses

(W)

Rated input

current (Arms)

(230 VAC,

60 Hz)

Max. protection

fuses for line

circuit

RK5 listed

(Bussman /

Littelfuse)

system with earthed neutral point

balanced)

Shortcircuit

power of

the mains

UL listed

Chapter 2 - Specifications

7

CD1-K- Installation Guide

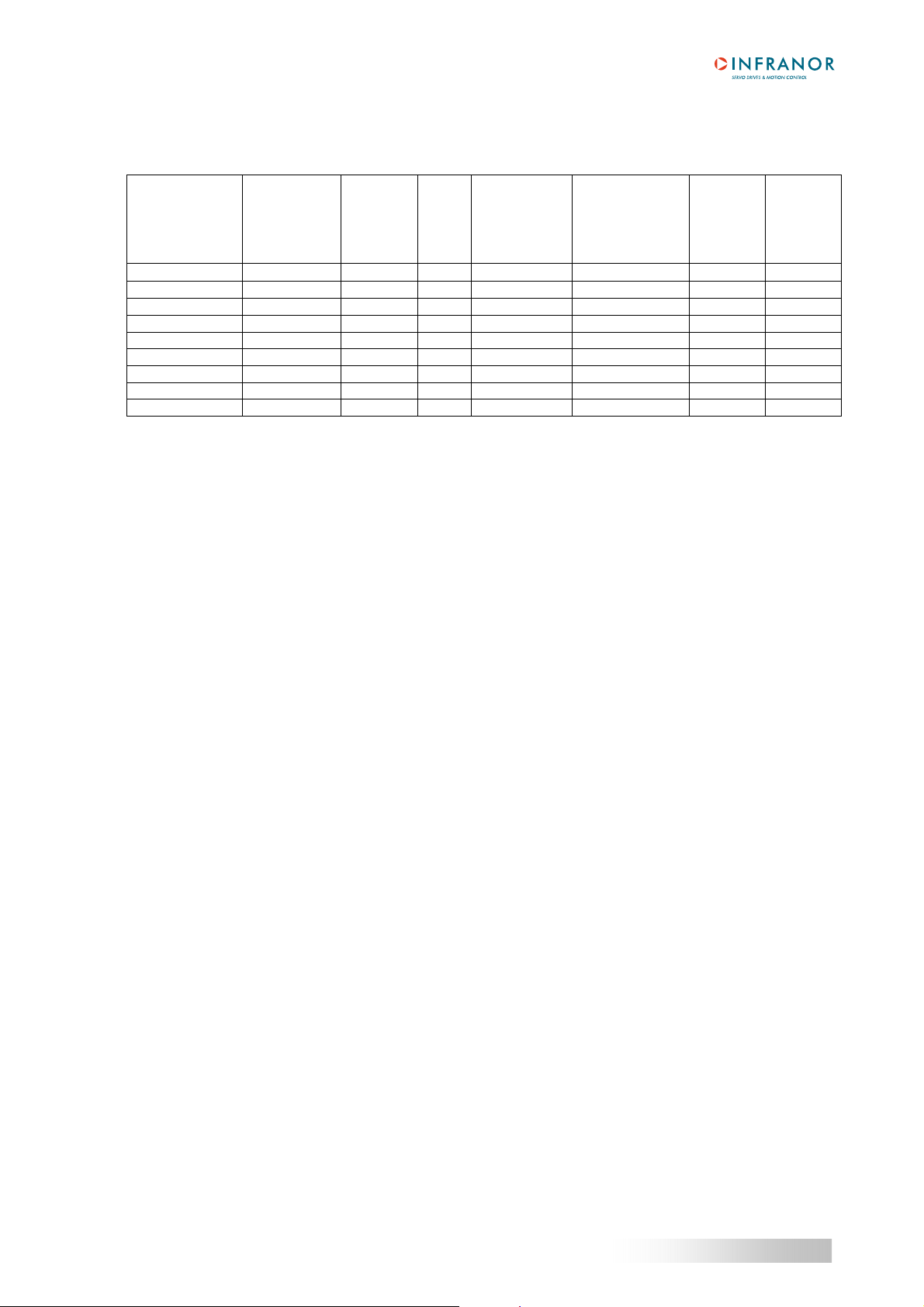

OUTPUT CURRENT RATINGS (at a maximum room temperature of 40°C)

Output voltage range for 400-480 VAC (rms) three-phase mains

Output current range: 1.8 A, 2.7 A, 5.1 A, 7.2 A, 14 A, 30 A, 45 A, 70 A, 90 A (rms)

Amplifier type

Max. output

current (Arms)

for 1 sec.

+/- 5 % (480

VAC)

Rated

output

current

(Arms)

(480 VAC)

Power

losses

(W)

Rated input

current (Arms)

(480 VAC,

60 Hz)

Max. protection

fuses for line

circuit

RK5 or A60Q40

for 400/70 and 90

listed

Shortcircuit

power of

the mains

UL listed

CD1-k-400/1.8 1.8 0.9 35 0.9 2 A 5 kA yes

CD1-k-400/2.7 2.7 1.35 43 1.35 2 A 5 kA yes

CD1-k-400/5.1 5.1 2.55 71 2.55 4 A 5 kA yes

CD1-k-400/7.2 7.2 3.6 93 3.6 4 A 5 kA yes

CD1-k-400/14 14 7 200 7 8 A 5 kA yes

CD1-k-400/30 30 15 400 15 20 A 5 kA yes

CD1-k-400/45 45 20 560 20 20 A 5 kA yes

CD1-k-400/70 70 35 650 35 40 A 5 kA

CD1-k-400/90 90 35 650 35 40 A 5 kA

In progress

In progress

1.3 – COMMON SPECIFICATIONS TO THE CD1-k-230/I AND CD1-k-400/I AMPLIFIER TYPES

Servo loops: current, speed and position Digital

Mains filter on power supply Integrated in the amplifier

Common mode filter on auxiliary supply Integrated in the amplifier

Common mode filter on motor brake supply Integrated in the amplifier

Position sensor Transmitter resolver

Absolute single-turn encoder (ERN1085 or compliant)

Incremental encoder (TTL or SinCos signals)

Incremental encoder + Hall Effect Sensors

Power stage protections See table of the main protections in the CD1-k User Guide

Motor brake control 1.5 A maximum with 24 Vdc.

PWM switching frequency 8 kHz

Minimum inductance between phases 1 mH pour 230 V / 2 mH pour 400 V

Digital current regulator (PI) Adjustable

Current loop bandwidth Cut-off frequency for 45° phase shift: 1000 Hz

Internal current limitation Imax: 20 % to 100 % and I rated: 20 % to 50 %

Authorized Imax duration = 1 second

Digital speed and position regulators Sampling period = 0.5 ms

Anti-wind-up system of the integrator

Adjustable digital gains

Speed loop bandwidth Selectable cut-off frequency for 45° phase shift:

50 Hz, 75 Hz or 100 Hz

Max. motor speed Adjustable from 100 rpm to 25 000 rpm

Resolver input Resolution : 65536 ppr (16 bit)

Excitation frequency: 8 kHz

Transformation ratio: 0.3 to 0.5 (other values need factory

adjustment)

8

Chapter 2 – Specifications

CD1-k – Installation Guide

Encoder input Software selectable:

Quadrature signals A & B with Z marker pulse

RS 422 line receiver

Maximum pulse frequency: 1 MHz

Resolution: 500 to 10

6

ppr

Incremental Sin/Cos encoder

Heidenhain 1Vcc Sin/Cos type or compliant

Maximum signal frequency: 200 kHz

Resolution: 500 to 10

6

ppr

Interpolation factor : 1024

Absolute single-turn Sin/Cos encoder

Heidenhain ERN 1085 or compliant

Maximum signal frequency: 200 kHz

Resolution: 2048 or 512 ppr

Interpolation factor : 1024

Pulse & Direction input Re-configuration of the encoder input for stepper motor

emulation:

Line receiver RS-422

Maximum pulse frequency: 1 MHz

Resolution: 200 to 10

6

pitch/revolution

Hall sensors input Software selectable: 120° or 60° HES type

5 V or 12 V supply voltage

HES sequence error detection

Logic inputs INHIBIT

FC+ and FC- limit switches

INDEX

CAPTURE

LOW SPEED

Logic outputs 4 logic outputs activated by bus

Relay outputs Relay contact: open if error

Umax = 50 V, Imax = 100 mA, Pmax = 10 W

Open collector output protected against load

Motor brake coil with 24 VDC/1.5 A

short-circuit

Analog inputs Re-configuration of the logic outputs by means of jumpers:

+/- 10 V, resolution = 14 bits

Encoder position output Re-configuration of the TTL encoder input via CANopen:

Two A and B channels in quadrature + 1 marker pulse per

revolution

RS 422 line driver

Programmable resolution: 64 ppr to 16384 ppr (according to

the maximum motor speed)

Arc minute accuracy = (8 + 5400/Resolution)

Note

: The total position accuracy must take into account the

accuracy of the resolver used.

CAN interface CANopen protocol (DS 301 – DSP 402)

Error display LEDs on front panel + diagnostic via serial link RS 232 +

diagnostic via CANopen.

Motor and application parameter setting Serial link RS 232 or

bus interface with CANopen protocol

Automatic functions Amplifier adjustment to the motor (AUTO-PHASING)

Servo control adjustment (AUTO-TUNING)

Chapter 2 - Specifications

9

CD1-K- Installation Guide

Compliance with the standards: CE certification.

360° shield connection, equipotentiality according

to the wiring rules.

CD1-400/70 and 90 A with mains filtre F-40070/90.

Conformity with the standards:

UL listing

"360°" shield; equipotentiality according to the

wiring rules.

EMC standards:

- immunity: EN 61000.4-2-3-4-5

- conducted and radiated disturbances: EN 55011, Group 1,

C3 category

Electrical standards for industrial machines:

- EN 60204-1: insulator 1500 Vac / 1 mn

leakage current > 30 mA (EMI filters).

CD1-k series have been “

” listed according to UL508C

cULus

and UL840 regarding the insulator.

This product was evaluated to:

- the Third Edition of UL508C, the UL Standard for Power

Conversion Equipment, dated May 2002 for the UL Listing

(USL),

- the CSA Standard for Industrial Control Equipment, C22.2

N° 14-95, dated August 1995 for the Canadian UL Listing

(CNL) except for CD1-k-400/70 and 90 drives.

Temperature

- storage: -20° C to +70° C

- operation: +5° C to +40° C

From 40° C, the rated currents must be reduced of

3 % per additional Celsius degree

Max. temperature: 50° C

Altitude 1000 m

Moisture < 50% at 40° C and < 90% at 20° C: EN 60204-1 standard

Condensation prohibited (storage and operation)

Cooling Forced air (fan integrated in the CD1-k amplifier)

Check for free ventilation and no upper or lower obstruction of

the air admissions

Mounting position Vertical

Environment Open chassis to be mounted in a housing protecting the

amplifier from conducting dust and condensation (pollution

degree 2 environment)

Mounting location Closed cabinet without any conducting and/or corroding

agents and according to the environment conditions

requirements

Condensation prohibited

Weight CD1-k-230/I: about 1 kg

CD1-k-400/1.8 to 7.2 A: about 1.5 kg

CD1-k-400/14: about 3 kg

CD1-k-400/30 and 45: about 4.8 kg

CD1-k-400/70 and 90: about 5.3 kg

10

Chapter 2 – Specifications

CD1-k – Installation Guide

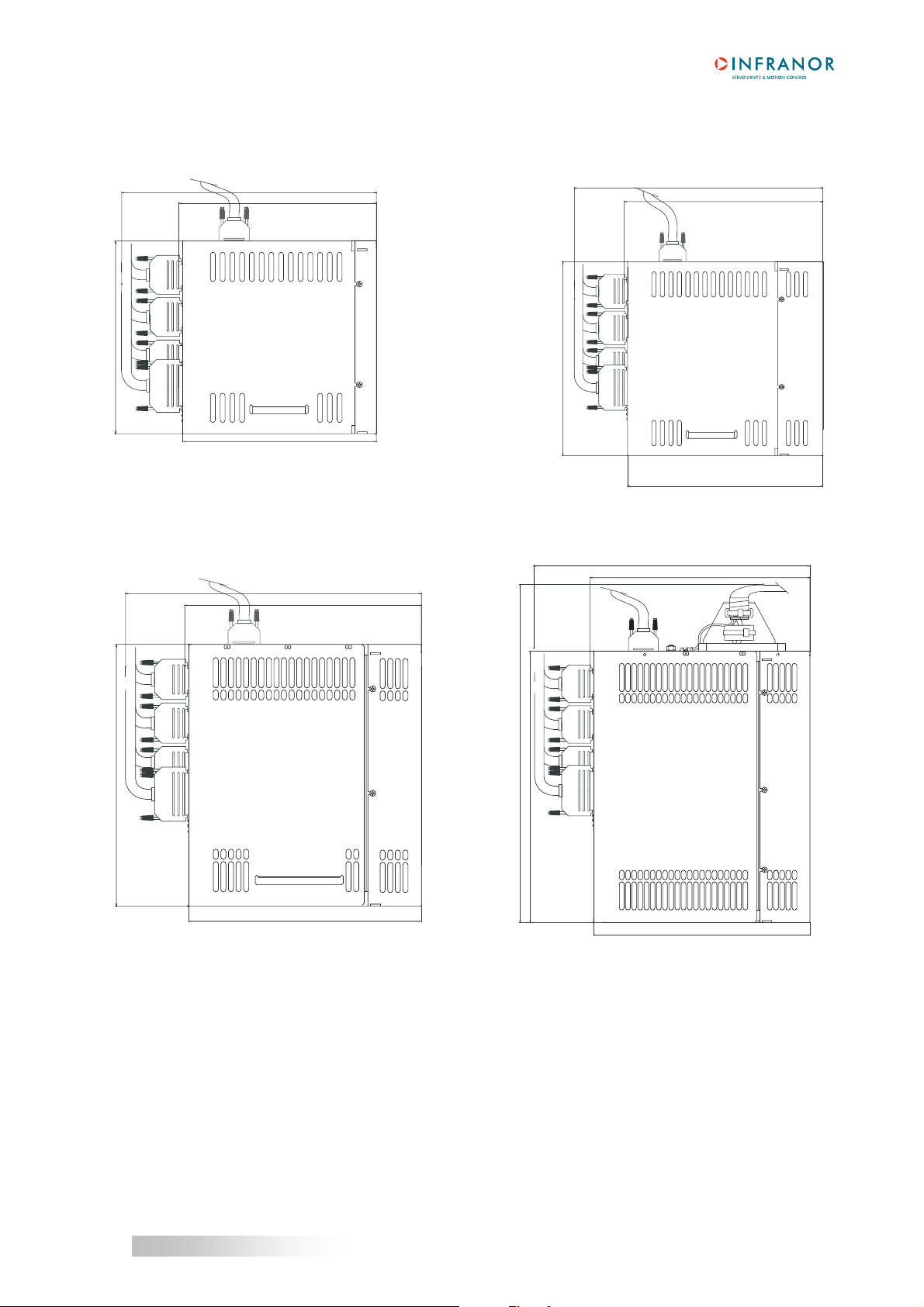

2 - DIMENSIONS

2.1 - CD1-k-230/I AMPLIFIER 2.2 - CD1-k-400/1.8 TO 7.2 A AMPLIFIER

260

203

293

234

200

228

199

230

2.3 - CD1-k-400/14 A AMPLIFIER 2.4 - CD1-k-400/30/45/70 AND 90 A AMPLIFIER

293

234

293

234

258

UV

W

381

288

230

230

Chapter 2 - Specifications

11

CD1-K- Installation Guide

2.5 - BRAKING RESISTOR dp 100/100, dp 200/100, dp 50/200, dp33/280 AND EF 400V

A

B

7

7

83

40

C

DIMENSIONS dp 50/200, dp 100/100 and dp 200/100 dp 33/280, EF 400V

A 157 mm 290 mm

B 145 mm 278 mm

C 52 mm 57 mm

12

Chapter 2 – Specifications

Loading...

Loading...