Page 1

Service Guide for the

X1

Page 2

Table of Contents

Table of Contents.......................................................................................................... 2

Safety Precautions........................................................................................................ 3

Important Precautions .................................................................................................. 3

Important Safety Instructions ...................................................................................... 4

Parts Replacement ........................................................................................................ 5

Removable Parts Hierarchy ..................................................................................................5

Remove and Replace the Ballast/Power Supply ECA ..........................................................6

Remove and Replace the Bottom EMI Shield.....................................................................10

Remove and Replace the Chassis......................................................................................12

Remove and Replace the Color Wheel Shield....................................................................17

Remove and Replace the Controller ECA........................................................................... 19

Remove and Replace the Elevator .....................................................................................22

Remove and Replace the Optical Engine ...........................................................................24

Remove and Replace the Cooling Fans .............................................................................27

Remove and Replace the Focus and Zoom Rings .............................................................30

Remove and Replace the Front Bezel ................................................................................32

Remove and Replace the I/O ECA .....................................................................................35

Remove and Replace the Keypad ......................................................................................37

Remove and Replace Lamp Module...................................................................................42

Remove and Replace the Lamphouse................................................................................45

Remove and Replace the Leveling Foot .............................................................................48

Remove and Replace the Rear Bezel.................................................................................49

Remove and Replace the Rubber Feet...............................................................................51

Remove and Replace the Top Case ...................................................................................52

Remove and Replace the Speaker .....................................................................................54

Functional Tests.......................................................................................................... 56

Required equipment............................................................................................................56

Before beginning .................................................................................................................57

Perform the following tests..................................................................................................57

Troubleshooting.......................................................................................................... 60

Power and Start-up Problems .............................................................................................61

Image Problems ..................................................................................................................67

Keypad Problems................................................................................................................71

Remote Problems ...............................................................................................................72

Audio Problems...................................................................................................................73

Block Diagram.....................................................................................................................74

Prepare for Power Up with Top Case Removed ................................................................. 80

Check Controller Voltages ..................................................................................................81

Check the Color Wheel and Reseat the Cable ...................................................................84

Check the Thermal Switch ..................................................................................................86

Check fan operation ............................................................................................................87

Check Ballast/Power Supply Voltages and Signals ............................................................88

Check I/O ECA Voltages and Signals .................................................................................90

Parts Lists.................................................................................................................... 93

Parts Exploded View ...........................................................................................................93

FRUs by alphabetic listing...................................................................................................94

X1 Service Guide 2

Page 3

SAFETY PRECAUTIONS

WARNING: TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE THIS

CAUTION: Laser beam is emitted when the laser button of the remote control is press ed. Do not

APPLIANCE TO RAIN OR MOISTURE. DANGEROUS HIGH VOLTAGES ARE

PRESENT INSIDETHE ENCLOSURE. DO NOT OPEN THE CABINET. REFER

SERVICING TO QUALIRED PERSONNEL ONLY.

look from the front of the remote control. Do not face toward a person or to a mirror.

The lightning flash with arrowhead

symbol, within an equilateral triangle,

is intended to alert the user to the

presenc e of uninsulated "dangerous

voltage" within the product's

enclosure that may be of sufficient

magnitude to constitute a risk of

electric shock to persons.

The exclamation point within an

equilateral triangle is intended to

alert the user to the presence of

important operating and

maintenance (servic ing) instructions

in the literature accompanying the

appliance.

FCC Radio Frequency Interferenc e Statement

Note: This equipment has been tested and found to comply with the limits for a Class A

WARNING: Changes or modifications made to this equipment, not expressly approved by

Notice: This Class A digital apparatus c omplies with Canadian ICES-003.

IMPORTANT PRECAUTIONS

Save Original Packing Materials

The original shipping carton and packing materials will come in

handy if you ever have to ship your LCD projector. For maximum

protection, repack the set as it was originally packed at the factor y.

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiates radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communic ations.

Operation of this equipment in a residential area is likely to caus e harmful

interference in whic h case the user will be r equired to correct the interferenc e at his

own expens e.

Toshiba, or parties authorized by Toshiba, could void the user's authority to operate

the equipment.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du

Canada.

In the spaces provided below, record the Model and Serial No. Iocated

at the rear of your LCD projector.

Mode No. Serial No.

Retain this information for future reference.

Avoid Volatile Liquid

Do not us e volatile liquids, such as an insect spray, near the unit.

Do not leave rubber or plastic pr oducts touching the unit for a long

time. They will mar the finish.

Moisture Condensation

Never operate this unit immediately after moving it from a cold

location to a warm location. When the unit is exposed to such a

change in temperature, moisture may condense on the crucial

internal parts. To prevent the unit from possible damage, do not use

the unit for at least 2 hours when there is an extr eme or sudden

change in temperature.

LP280/LP290 Service Manual 4

Page 4

IMPORTANT SAFETY INSTRUCTIONS

CAUTION: PLEASE READ AND OBSERVE

ALLWARNINGS AND

INSTRUCTIONS GIVEN IN THIS

OWNER'S MANUAL AND THOSE

MARKED ON THE UNIT. RETAIN

THIS BOOKLET FOR FUTURE

REFERENCE.

This set has been designed and manuf actured

to assure personal safety. Improper use can

result in electric shock or fire hazard. The

safeguards incorporated in this unit will protect

you if you observe the following procedures for

installation, use and servicing. This unit is fully

transistorized and does not contain any parts

that can be repaired by the user.

DO NOT REMOVE THE CABINET COVER, OR

YOU MAY BE EXPOSED TO DANGEROUS

VOLTAGE. REFER SERVICING TO

QUALIFIED SERVICE PERSONNEL ONLY.

1. Read Owner's Manual

After unpacking this product, read the

owner's manual carefully, and follow all

the operating and other instructions.

2. Power Sources

This product should be operated only from

the type of power source indicated on the

marking label. If you are not s ure of the

type of power supply to your home,

consult your product dealer or local power

company.

For products intended to operate from

battery power, or other sources, refer to

the operating instructions.

3. Source of Light

Do not look into the lens while the lamp

is on. The strong light from the lamp may

cause damage to your eyes or sight.

4. Ventilation

Openings in the cabinet ar e provided for

ventilation and to ensure reliable

operation of the product and to protect it

from overheating, and these openings

must not be blocked or covered. The

openings should never be blocked by

placing the product on a bed, sofa, rug or

other similar surface. This product should

not be placed in a built-in installation such

as a bookcase or rack unless proper

ventilation is provided or the

manufacturer's instructions have been

adhered to.

IMPORTANT SAFETY INSTRUCTIONS

5. Heat

The product should be situated away from

heat sources such as radiators heat

registers, stoves, or other products

(including amplifiers) that produce heat.

6. Water and Moisture

Do not use this product near water - for

example, near a bath tub, wash bowl,

kitchen sink, or laundry tub; in a wet

basement ; or near a swimming pool and

the like .

7. Cleaning

Unplug this product from the wall outlet

before cleaning. Do not use liquid cleaners

or aerosol cleaners. Use a damp cloth for

cleaning.

8. Power-Cord Protection

Power-supply cords should be routed so

that they ar e not likely to be walked on or

pinched by items placed upon or against

them, paying particular attention to cords

at plugs, convenienc e receptacles, and

the point where they exit from the product.

9. Overloading

Do not overload wall outlets; extension

cords, or integral convenience

receptacles as this can result in a risk of

fire or electric shock.

10. Lightning

For added pr otection for this product

during storm, or when it is left unattended

and unused for long periods of time,

unplug it from the wall outlet.

This will prevent damage to the product

due to lightning and power-line surges.

Page 5

Parts Replacement

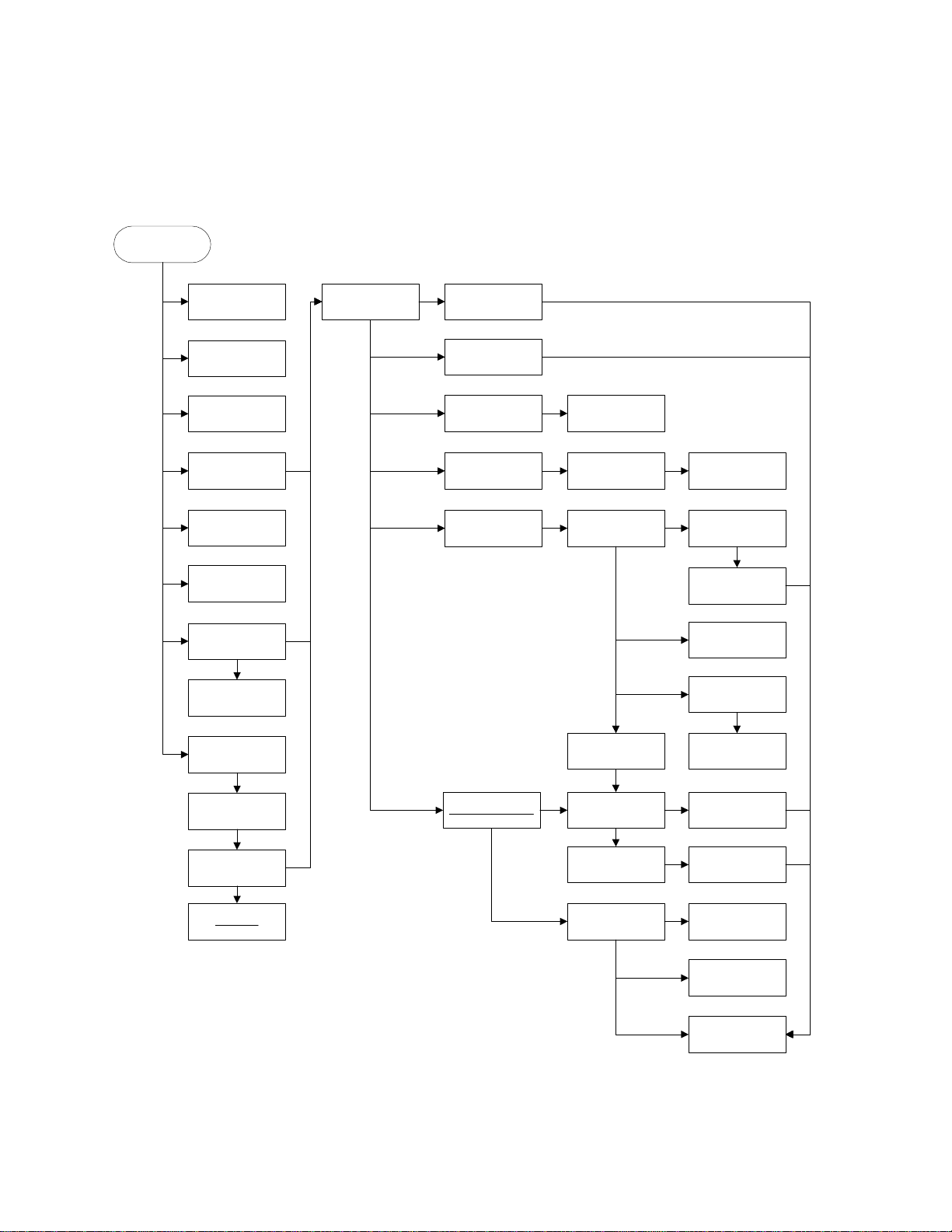

Removable Parts Hierarchy

Start

Certification label

Nameplate label

I/O panel label

Rear b ezel

Lens cap

Rubber foot

Lamp d oor

Lamp module

Focus ring

Top case Elevator shaft

Leveling foot

Speaker Speaker grill

Keypad ECA Key set LED cover

Ballast/power

supply ECA

Controller ECA

I/O EMI shieldChassis

I/O ECA

Ground spring

Retainer studs

Ballast/power

supply insulator

Zoom ring

Front bezel

Inner grill

Color wheel shield

Optical engine

Bottom EMI shield

Elevator sprin gElevator actuator

80mm fanLamphouse

60mm fan

Bottom case

X1 Service Guide 5

Page 6

Remove and Replace the Ballast/Power Supply ECA

The ballast/power supply ECA (520-0114-xx) fastens to the chassis. It converts 100-240 VAC supply

voltage to various low voltage DC levels required internally by the projector. The power supply directly

interfaces with the ballast to control lamp strike and operation. The ballast steps up voltage from the

power supply to ignite the lamp module. The ballast/power supply ECA also interfaces with the controller

ECA to provide DC power and exchange control signals.

Audio amplification and takes place on the ballast/power supply ECA.

Fuses on the ballast/power supply ECA protect against internal shorts or supply surges. The fuses are

not available as FRU parts as a blown fuse usually indicates circuit damage and the need for ECA

replacement.

DANGER Do not attempt to measure the output voltage from the ballast when the lamp strikes. High

voltage produced by the ballast to strike the lamp can ruin test instruments as well as cause

personal injury.

1. Remove the following items:

Lamp module (page 42)

Focus ring (page 30)

Zoom ring (page 30)

Front bezel (page 32)

Rear bezel (page 49)

Top case (page 52)

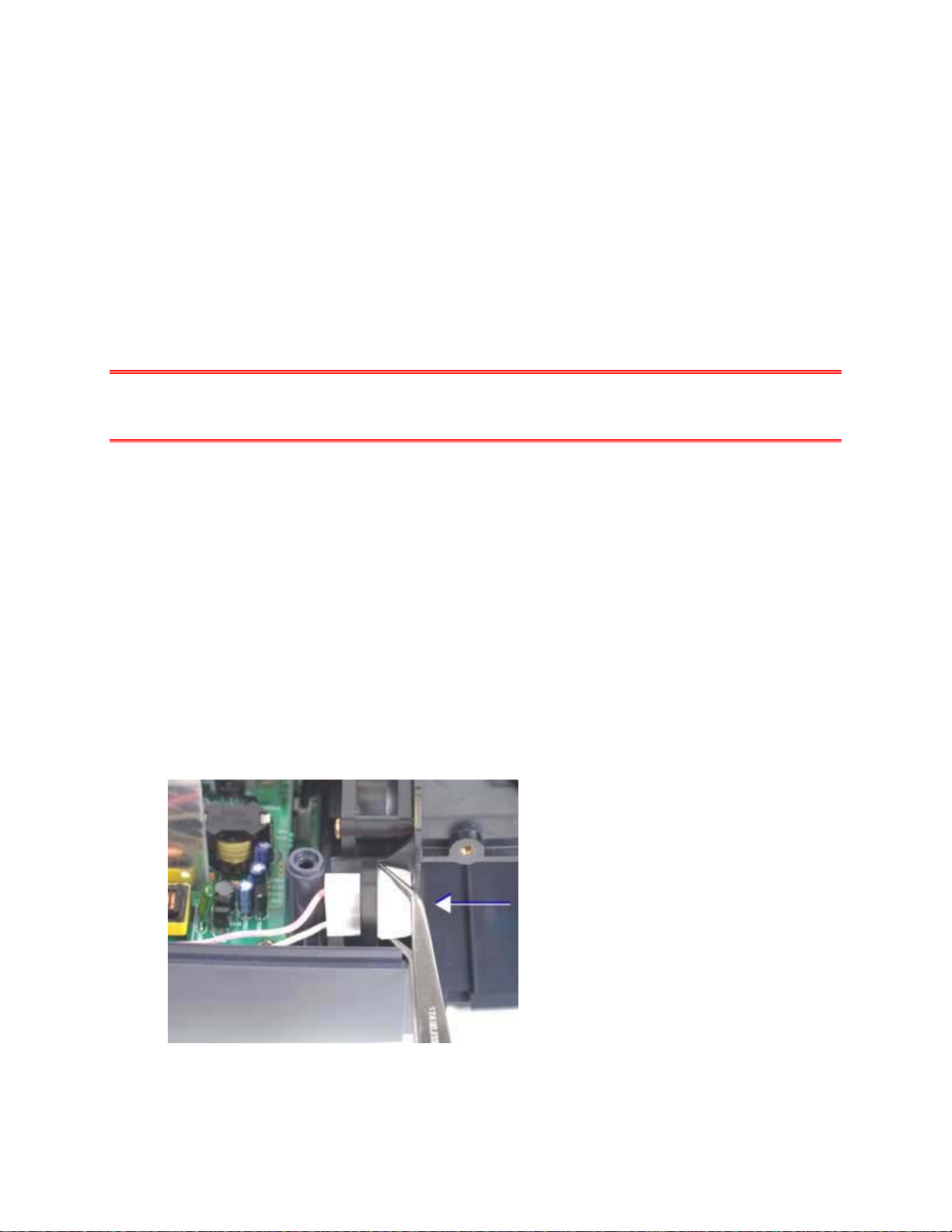

2. Detach the lamp cable connector from the side of the lamphouse. Squeeze the two tabs on the

side of the connector and slide it rearward through the retainer on the lamphouse.

X1 Service Guide 6

Page 7

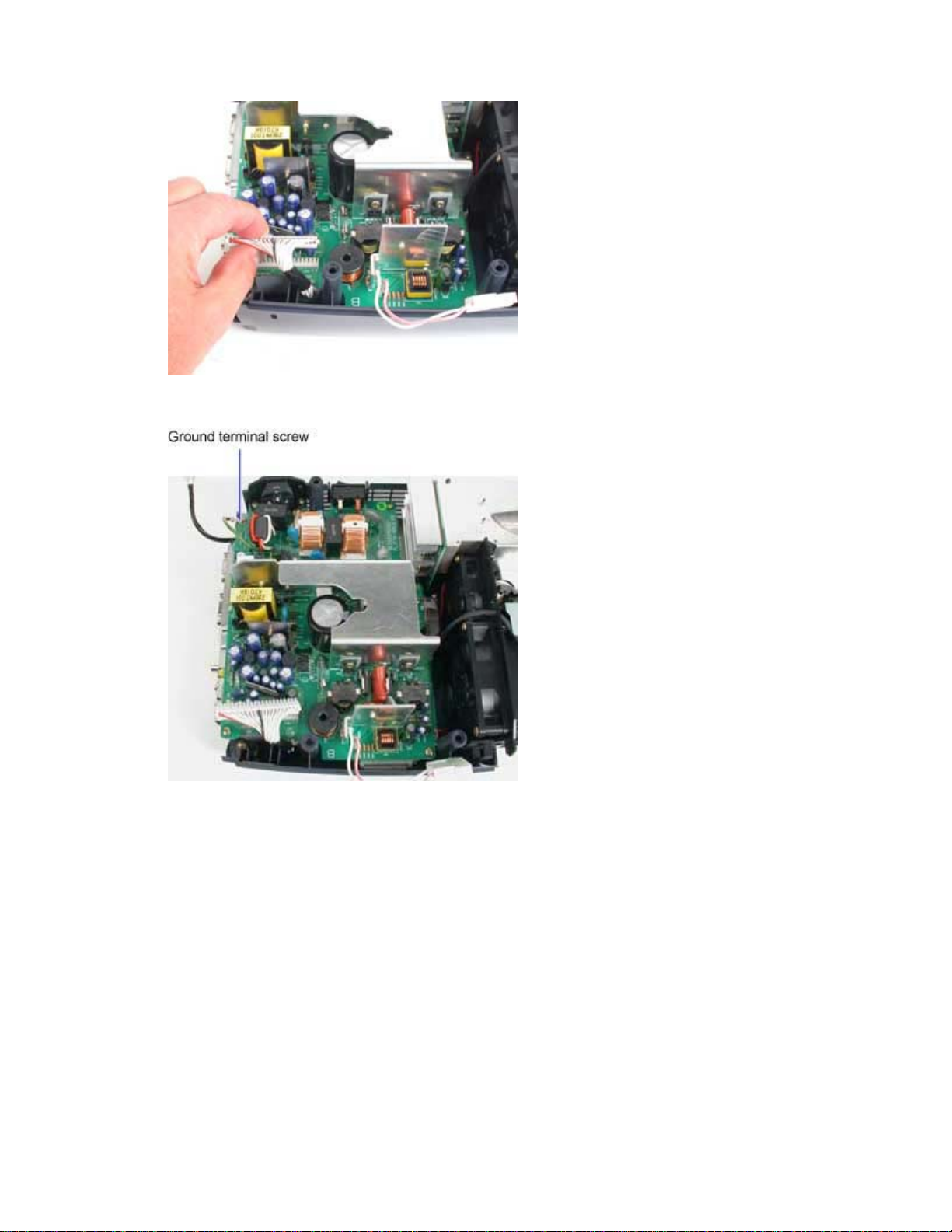

3. Unplug the power supply/controller ECA cable from the ballast/power supply ECA

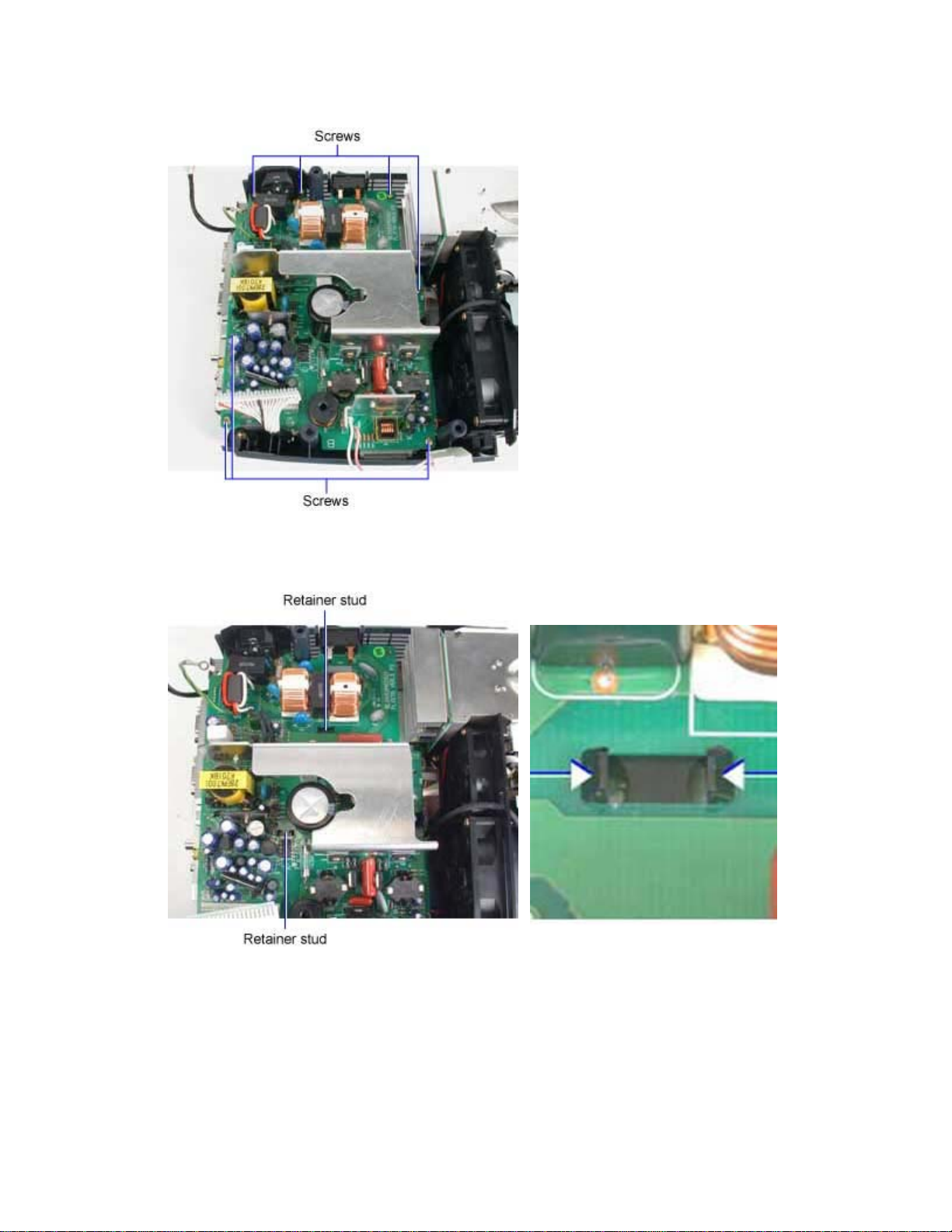

4. Remove the M4x6 Phillips screw that fastens the ground terminal to the chassis.

X1 Service Guide 7

Page 8

5. Remove the seven M3x12 Plastite Phillips screws that fasten the ballast/power supply ECA to the

chassis.

6. Squeeze the tabs on each of the two retainer studs that secure the ballast/power supply ECA to

the chassis. Then lift the ECA away from the chassis.

X1 Service Guide 8

Page 9

Assembly Notes

♦ Ensure that the two retainer studs on the chassis engage the slots in the ballast/power supply ECA.

Press down on the ECA to lock the retainers into the slots.

♦ Tighten the seven M3x12 Plastite Phillips screws securely. Do not overtighten the screws.

♦ Connect the ground terminal to the chassis. Tighten the M4x6 Phillips screw securely.

♦ Connect the power supply/controller ECA cable to CN651 on the ballast/power supply ECA.

♦ Insert the lamp cable connector into the slot on the side of the lamphouse. Ensure that the slot for the

connector lock faces outward.

X1 Service Guide 9

Page 10

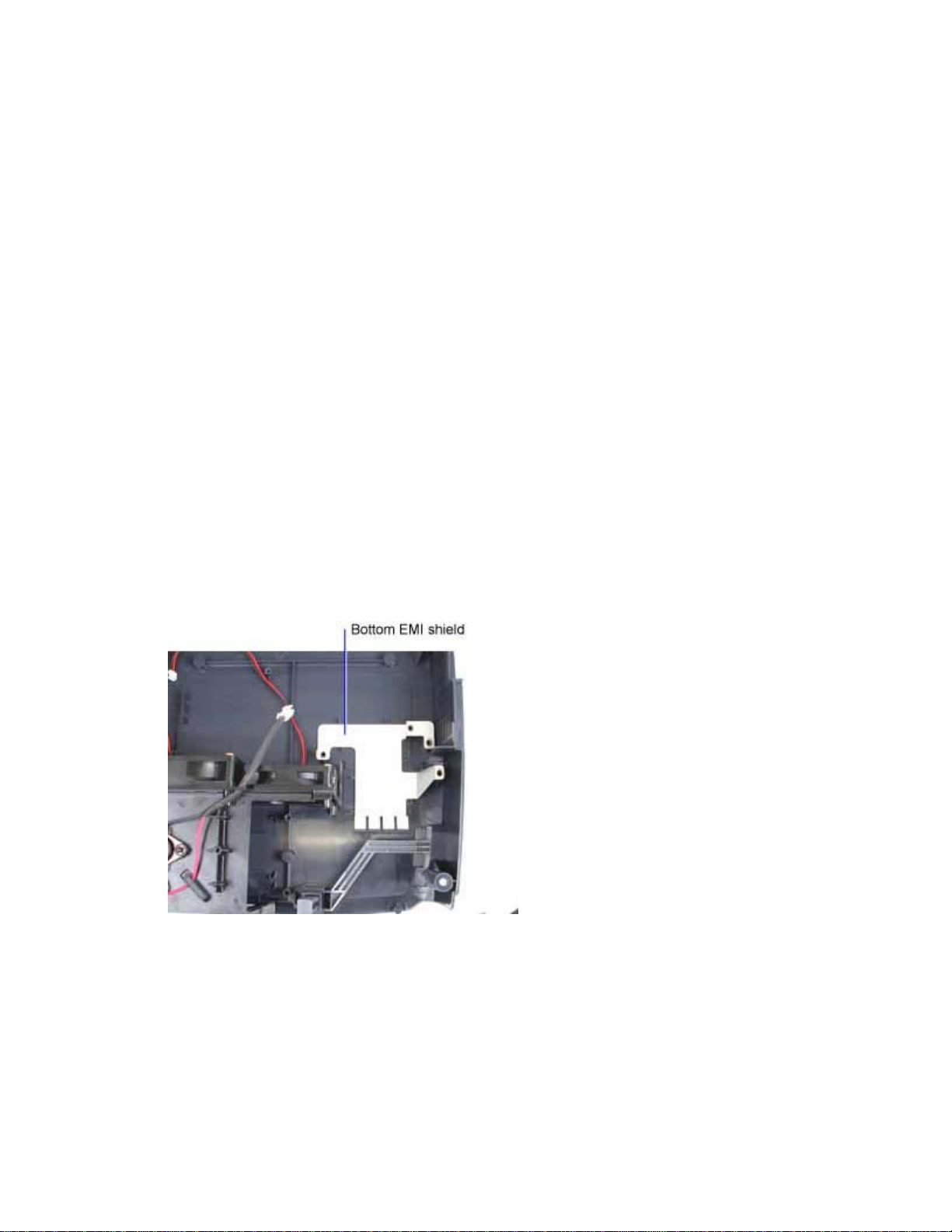

Remove and Replace the Bottom EMI Shield

The bottom EMI shield (330-0965-xx) lies in the bottom case. It provides ground continuity between the

optical engine and the chassis.

1. Remove the following items:

Lamp module (page 42)

Focus ring (page 30)

Zoom ring (page 30)

Front bezel (page 32)

Rear bezel (page 49)

Top case (page 52)

Ballast/power supply ECA (page 6)

Chassis (page 12)

Controller ECA (page 19)

Color wheel shield (page 17)

Optical engine (page 24)

2. Lift the bottom EMI shield away from the bottom case.

X1 Service Guide 10

Page 11

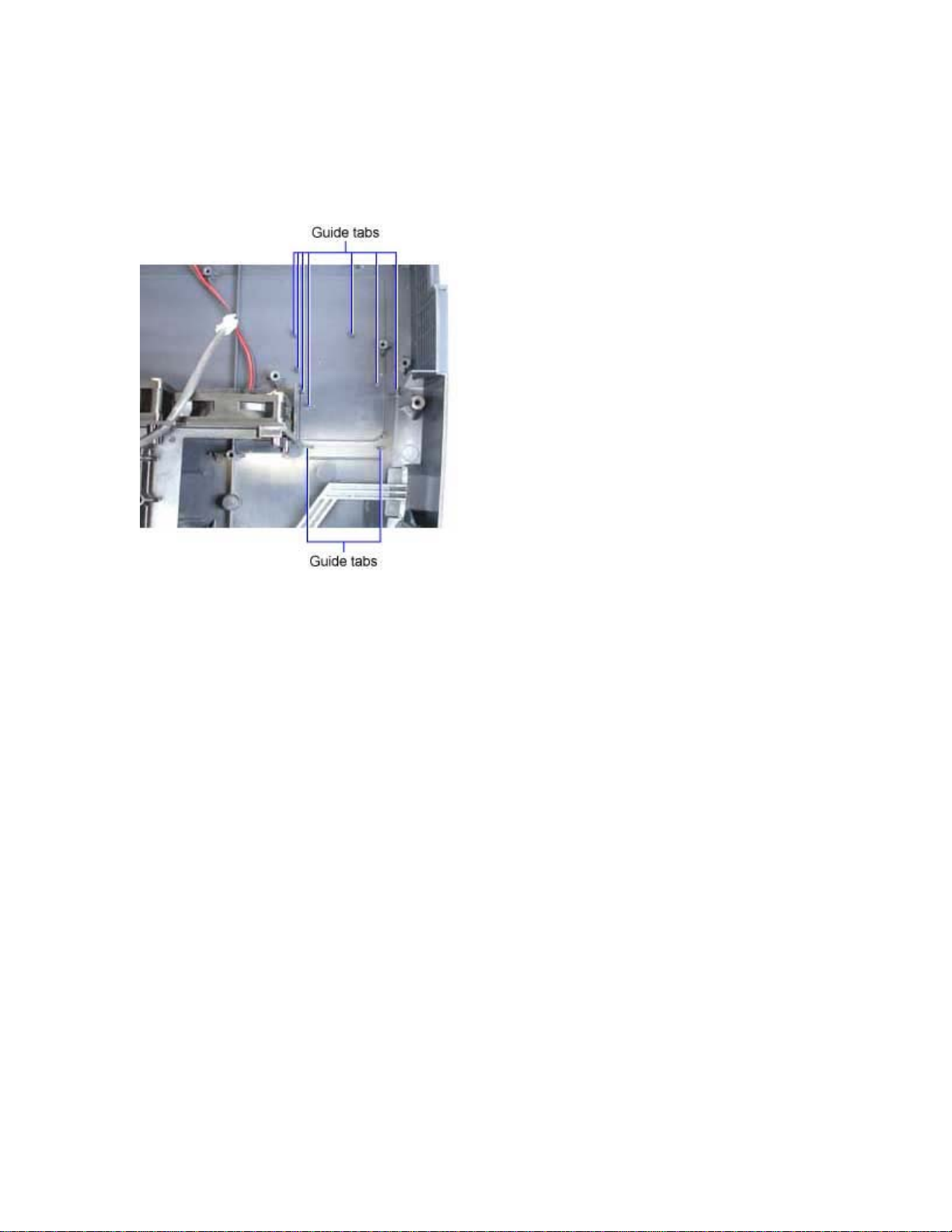

Assembly Notes

♦ Make sure the shield isn't bent and that the fingers on the shield will contact the bottom housing on

the optical engine when it's replaced.

♦ Position the bottom EMI shield between the guide tabs on the bottom case. Then press the shield into

position to secure it in the bottom case.

X1 Service Guide 11

Page 12

Remove and Replace the Chassis

The metal chassis (330-0963-xx) provides the necessary rigidity for the projector’s internal components

without adding much overall weight. The ballast/power supply ECA fastens to the chassis. The ground

spring (321-0218-xx) attaches to the chassis and provides ground continuity to the optical engine.

The ballast/power supply insulator (329-0433-xx) also fastens to the chassis. It provides electrical

insulation between the chassis and components on the ECA. Two retainer studs (340-1115-xx) fasten

the insulator to the chassis.

A new chassis does not include the ground spring, ballast/power supply insulator, or retainer studs.

If you're removing the chassis to access other FRUs in the projector, you don't need to remove the

ground spring or ballast/power supply insulator.

Remove the Chassis and Ground Spring

1. Remove the following items:

Lamp module (page 42)

Focus ring (page 30)

Zoom ring (page 30)

Front bezel (page 32)

Rear bezel (page 49)

Top case (page 52)

Ballast/power supply ECA (page 6)

X1 Service Guide 12

Page 13

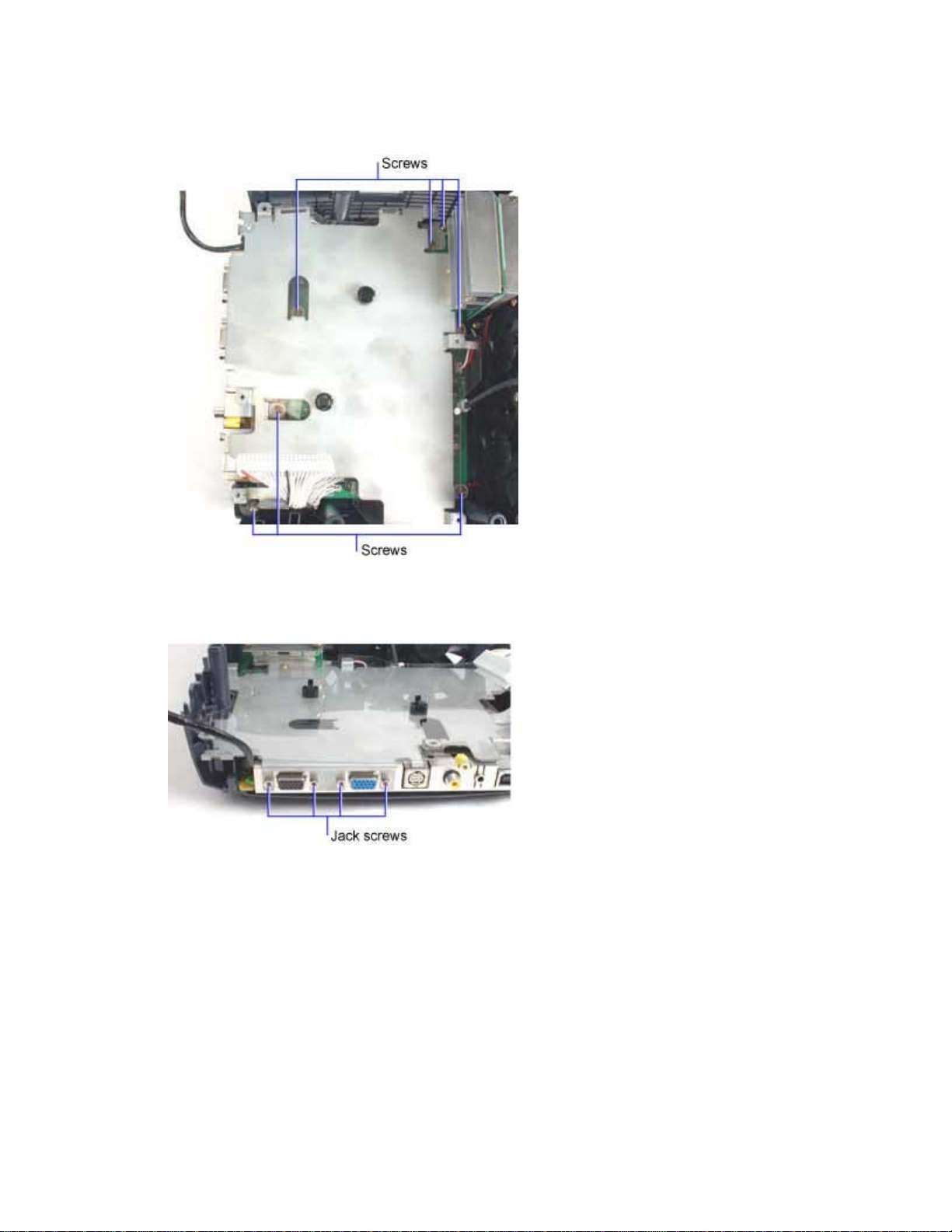

2. Remove the seven M3x10 Plastite Phillips screws that fasten the chassis to the bottom case. You

need to lift the ballast/power supply insulator to reach the two screws near the center of the

chassis.

3. Remove the four #4-40 jack screws that fasten the chassis around the 15-pin D-sub connectors

on the I/O panel.

X1 Service Guide 13

Page 14

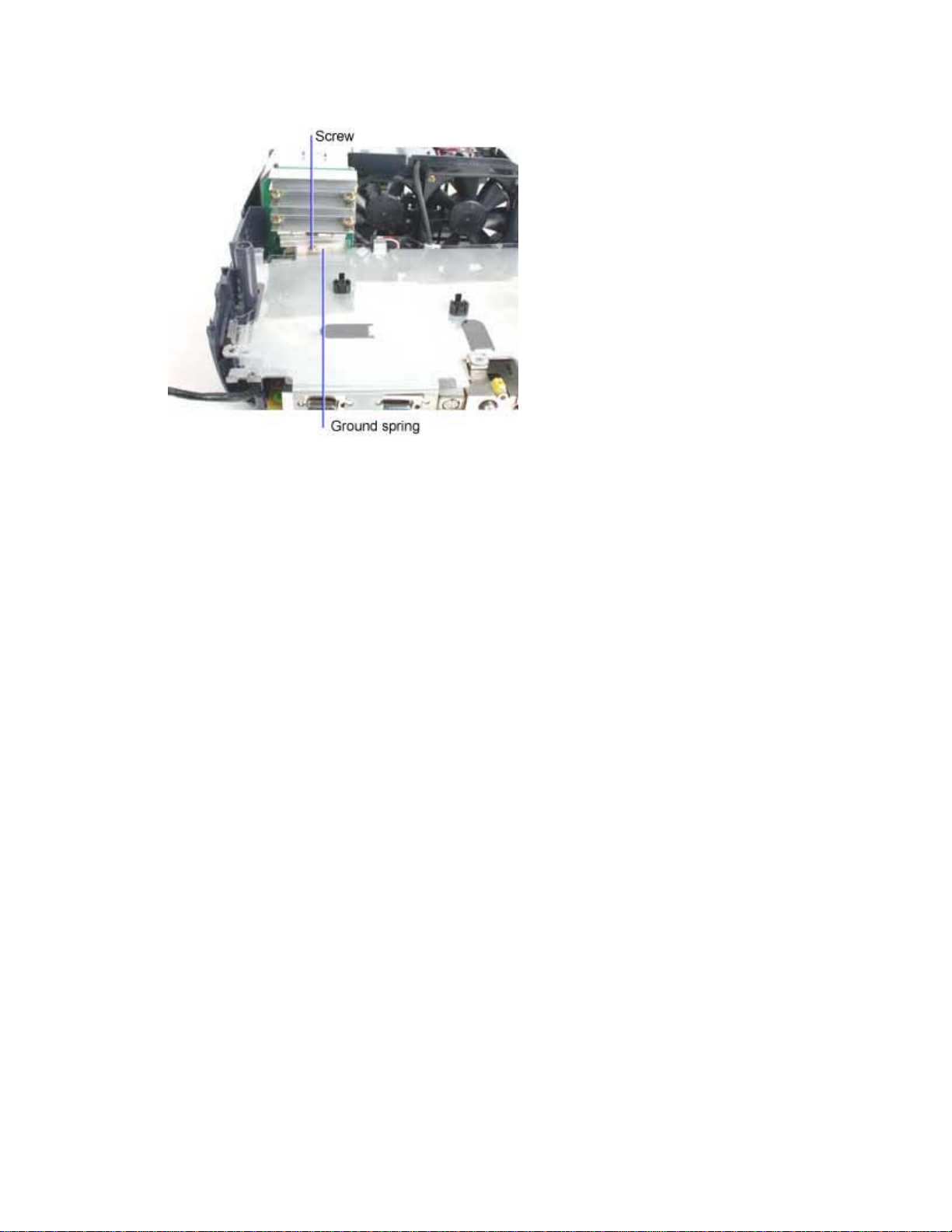

4. Lift the chassis near the rear of the projector, then slide the chassis rearward to disengage the

ground spring from the bottom side of the DMD heat shield on the optical engine.

5. Lift the chassis away from the projector.

6. If you need to remove the ground spring, lift the ballast/power supply insulator and remove the

M3x8 Plastite Phillips screw that fastens the ground spring to the chassis.

Assembly Notes

♦ Ensure that the ground spring is in proper position on the chassis to provide ground continuity to the

optical engine.

♦ Place the chassis into the projector, then slide the chassis forward to engage the ground spring

against the bottom side of the DMD heat shield on the optical engine.

♦ Press down on the chassis to position it over the two 15-pin D-sub connectors on the I/O panel.

Replace the four jack screws and torque them to 2 in-lbs (.226 Nm).

♦ Replace and tighten the seven M3x10 Plastite Phillips screws securely. Do not overtighten the

screws.

X1 Service Guide 14

Page 15

Remove the Ballast/Power Supply Insulator

1. Place the chassis upside down on the work surface.

2. Squeeze the tabs on each of the two retainer studs that secure the ballast/power supply insulator

to the chassis. Remove the studs from the chassis.

3. Turn the chassis over. Then lift the insulator away from the chassis.

Assembly Notes

♦ Place the triangular hole in the ballast/power supply insulator over the mounting tab on the chassis.

Then lay the insulator flat against the chassis.

X1 Service Guide 15

Page 16

♦ Insert the two retainer studs into the chassis slots. Then place the four tabs on the insulator into the

corresponding slots on the chassis.

X1 Service Guide 16

Page 17

Remove and Replace the Color Wheel Shield

The color wheel shield (330-0968-xx) fastens to the lamphouse and the optical engine. The shield

provides protection to the fragile color wheel and bracing for the lamphouse which is otherwise open to

the optical engine.

1. Remove the following items:

Lamp module (page 42)

Focus ring (page 30)

Zoom ring (page 30)

Front bezel (page 32)

Rear bezel (page 49)

Top case (page 52)

2. Remove the two M3x10 Plastite Phillips screws that fasten the color wheel shield to the top of

the lamphouse and the optical engine.

X1 Service Guide 17

Page 18

3. Carefully lift the color wheel shield straight upward and out of the projector.

CAUTION The shield is very close to the color wheel. Don't allow the shield to scrape the color wheel

and break or damage it.

Assembly Notes

♦ Be careful as you replace the color wheel shield. Don't allow it to contact the color wheel.

♦ Make sure that the holes in the color wheel shield align properly with the two pins on the lamphouse.

♦ Replace and tighten the two M3x10 Plastite Phillips screws securely. Do not overtighten the screws.

X1 Service Guide 18

Page 19

Remove and Replace the Controller ECA

The controller ECA (510-1773-xx) mounts beneath the metal chassis and ballast/power supply ECA and

behind the optical engine. It fastens to the bottom case with seven screws and connects to the DMD ECA

through two connectors at the front side of the controller.

A new controller ECA includes the keypad and ballast/power supply cables. These cables

permanently connect to the controller ECA. Do not attempt to remove them.

WARNING Be sure to take proper ESD precautions while working near the controller ECA. It can be

easily damaged by static electricity. ECAs damaged by static electricity require replacement.

1. Remove the following items:

Lamp module (page 42)

Focus ring (page 30)

Zoom ring (page 30)

Front bezel (page 32)

Rear bezel (page 49)

Top case (page 52)

Ballast/power supply ECA (page 6)

Chassis (page 12)

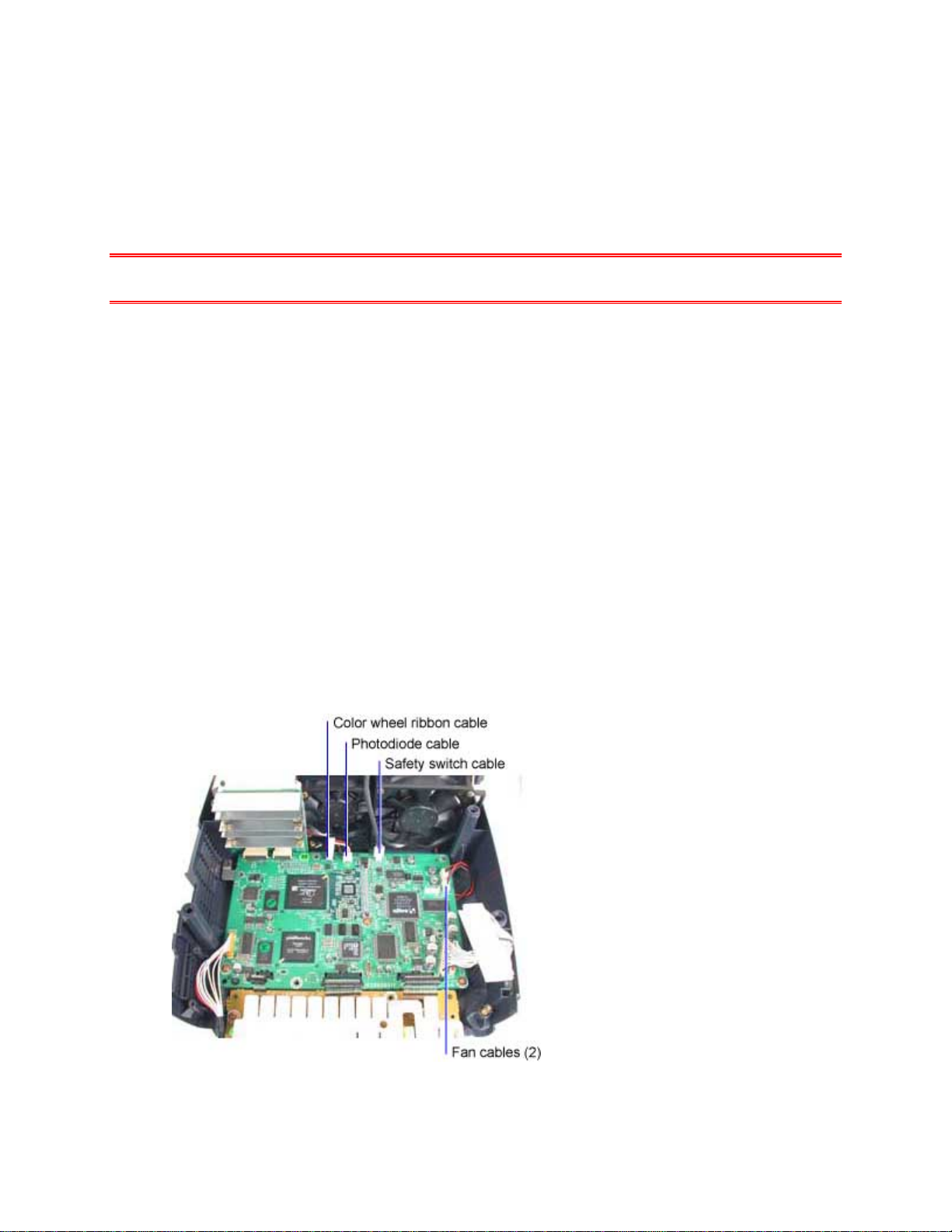

2. Unplug the safety switch cable, the two fan cables, the color wheel ribbon cable, and the

photodiode cable from the controller ECA.

X1 Service Guide 19

Page 20

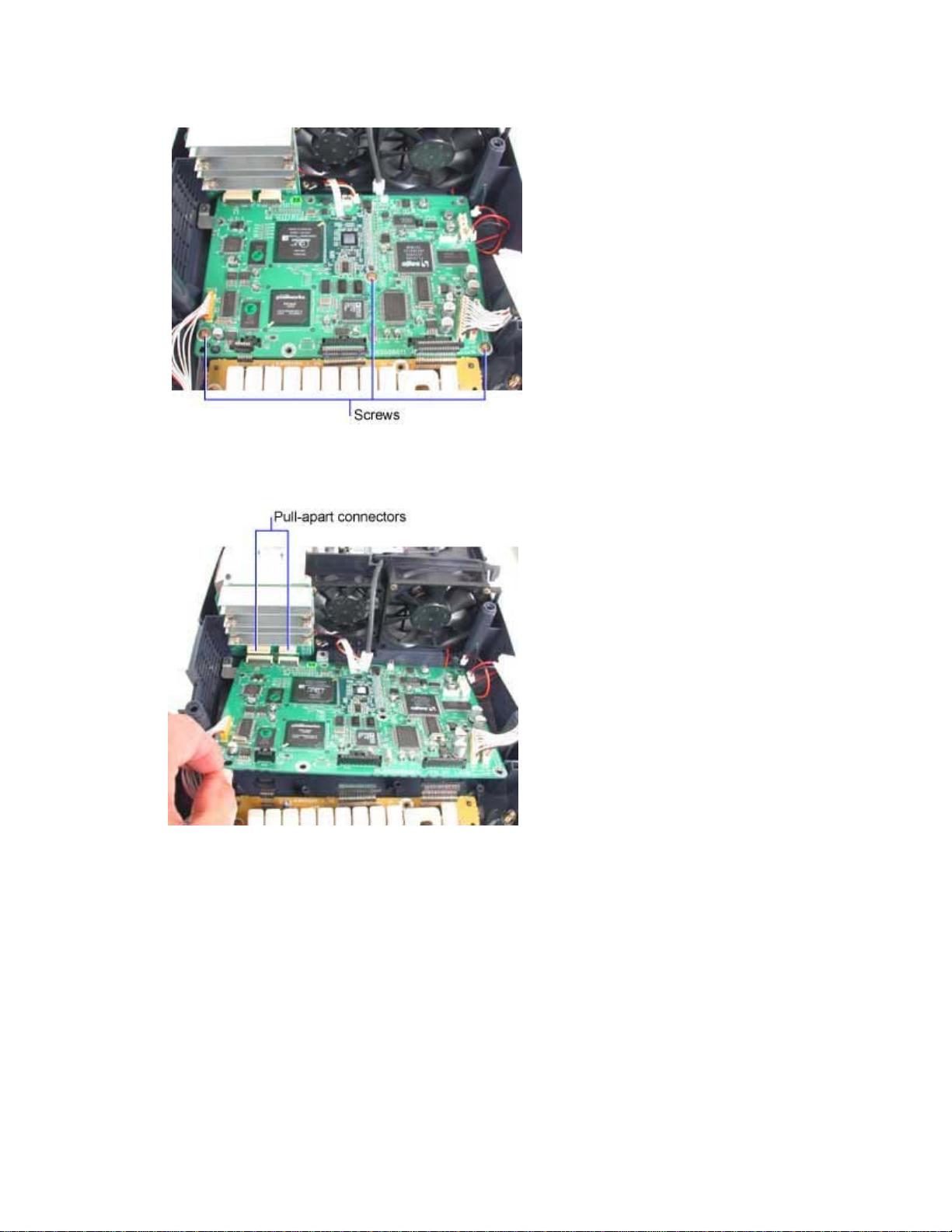

3. Remove the three M3x10 Plastite Phillips screws that fasten the controller ECA to the bottom

case.

4. Lift the rear of the controller ECA away from the bottom case. Then gently pull the controller

rearward to separate the two connectors at the DMD ECA.

5. Lift the controller ECA away from the projector.

Store the controller ECA in a static-free container while it is removed from the projector.

X1 Service Guide 20

Page 21

Assembly Notes

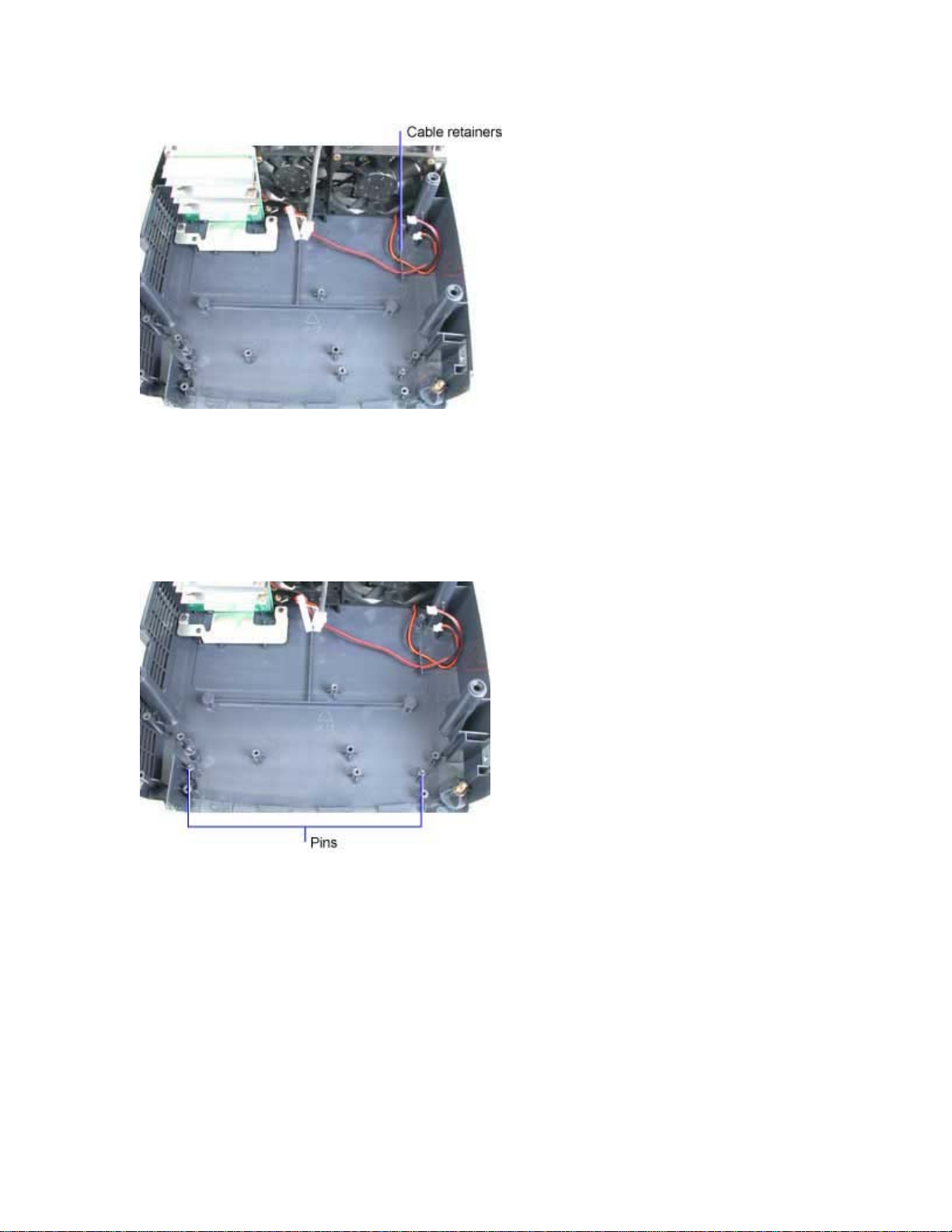

♦ Ensure that the cables from the 60mm and 80mm fans route through the retainers in the bottom case.

♦ Place the controller ECA into the projector, then slide it forward to engage the two connectors at the

DMD ECA.

♦ Make sure that the holes in the controller ECA align properly with the two pins on the bottom case.

Gently press down on the controller ECA to ensure that it is in proper position over the pins on the

bottom case.

♦ Connect the following cables to the controller ECA:

- Safety switch cable to CN708

- Photodiode cable to CN300

- Color wheel cable to CN301

- 60mm fan cable to CN704

- 80mm fan cable to CN705

♦ Replace and tighten the three M3x10 Plastite Phillips screws securely. Do not overtighten the screws.

X1 Service Guide 21

Page 22

Remove and Replace the Elevator

The elevator is comprised of the elevator spring (321-0107-xx), elevator actuator (340-1119-xx) and

elevator shaft (340-1120-xx). The elevator shaft includes a molded foot. The actuator allows the shaft to

extend or retract and adjust the level of the projected image. The elevator housing is molded into the

bottom case. Except for the housing, each part can be replaced separately.

Remove the Elevator Shaft

1. Remove the following items:

Lamp module (page 42)

Focus ring (page 30)

Zoom ring (page 30)

Front bezel (page 32)

Rear bezel (page 22)

Top case (page 52)

2. Fully extend the elevator shaft. Then use a small flat-blade screwdriver to gently depress the stop

on the elevator shaft. This allows the elevator shaft to pass through the housing and out of the

bottom case.

3. Depress the elevator actuator as you pull the elevator shaft out from the bottom side of the

projector.

Assembly Note

♦ Make sure that the grooves on the elevator shaft face the lamphouse. Then depress the elevator

actuator and replace the elevator shaft in the bottom case.

X1 Service Guide 22

Page 23

Remove the Elevator Actuator and Spring

1. Remove the elevator shaft, then remove the:

Ballast/power supply ECA (page 6)

Chassis (page 12)

Controller ECA (page 19)

Color wheel shield (page 17)

Optical engine (page 24)

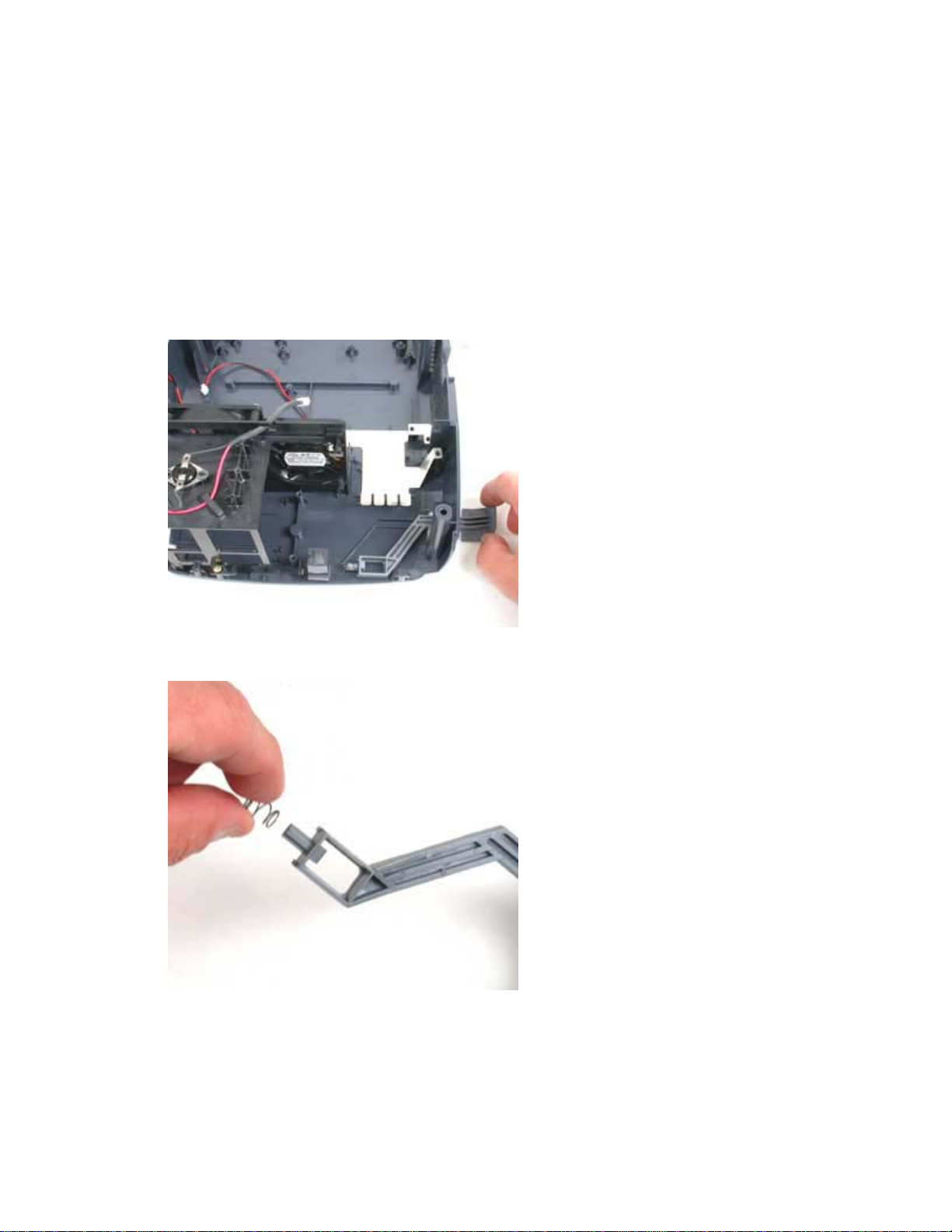

2. Gently slide the elevator actuator out of the bottom case.

3. Slide the elevator spring off of the end of the actuator.

Assembly Note

♦ Replace the elevator spring on the end of the actuator. Then replace the elevator actuator in the

bottom case.

X1 Service Guide 23

Page 24

Remove and Replace the Optical Engine

The optical engine (505-1506-xx) fastens to the bottom case. It produces the projected image by

directing focused light from the lamp module through the color wheel and onto the Digital Micromirror

Device (DMD). The optical engine contains a formatter ECA that processes the image signal from the

controller ECA before the the signal is delivered to the DMD.

It also comprises other elements in the light path, including the:

♦ Light tunnel

♦ Photodiode

♦ Projection lens

CAUTION The color wheel is unprotected on the side of the optical engine. Avoid touching the color

wheel. The edge of the glass wheel is sharp and can cause personal injury. Touching the color

wheel can break it or leave smudges that degrade the image.

1. Remove the following items:

Lamp module (page 42)

Focus ring (page 6)

Zoom ring (page 30)

Front bezel (page 32)

Rear bezel (page 49)

Top case (page 52)

Ballast/power supply ECA (page 6)

Chassis (page 12)

Controller ECA (page 19)

Color wheel shield (page 17)

X1 Service Guide 24

Page 25

2. Remove the two M3x10 Plastite Phillips screws that fasten the optical engine to the bottom case.

3. Fully extend the elevator shaft to minimize its interference as you remove the optical engine.

4. Grasp the optical engine around the body behind the lens barrel. Carefully lift it up and forward.

The photodiode and color wheel ribbon cables pass through a retainer guide beneath the

lamphouse. As you lift the optical engine, gently pull these cables through the retainer guide and

out from beneath the lamphouse.

CAUTION Avoid touching or damaging the color wheel.

5. Lift the optical engine away from the projector.

6. Place the engine on a soft, static-free surface or in an ESD-protected container.

X1 Service Guide 25

Page 26

Assembly Notes

♦ Fully extend the elevator shaft to minimize its interference as you replace the optical engine.

♦ As you lower the optical engine into the projector, route the photodiode and color wheel ribbon cables

through the retainer guide beneath the lamphouse.

♦ Replace and tighten the two M3x10 Plastite Phillips screws securely. Do not overtighten the screws.

X1 Service Guide 26

Page 27

Remove and Replace the Cooling Fans

Two fans provide all the cooling air necessary for the projector. The 80mm fan (526-0152-xx) provides

primary cooling for the lamp module and lamphouse. The 60mm fan (526-0153-xx) cools the color wheel

and optical engine. Both fans draw cool air across the electronic components in the projector and exhaust

heated air through the front bezel. The fans fasten to the rear side of the lamphouse.

1. Remove the following items:

Lamp module (page 42)

Focus ring (page 30)

Zoom ring (page 30)

Front bezel (page 32)

Rear bezel (page 49)

Top case (page 52)

Ballast/power supply ECA (page 6)

Chassis (page 12)

Controller ECA (page 19)

Color wheel shield (page 17)

Lamphouse (page 45)

Removing the 60mm Fan

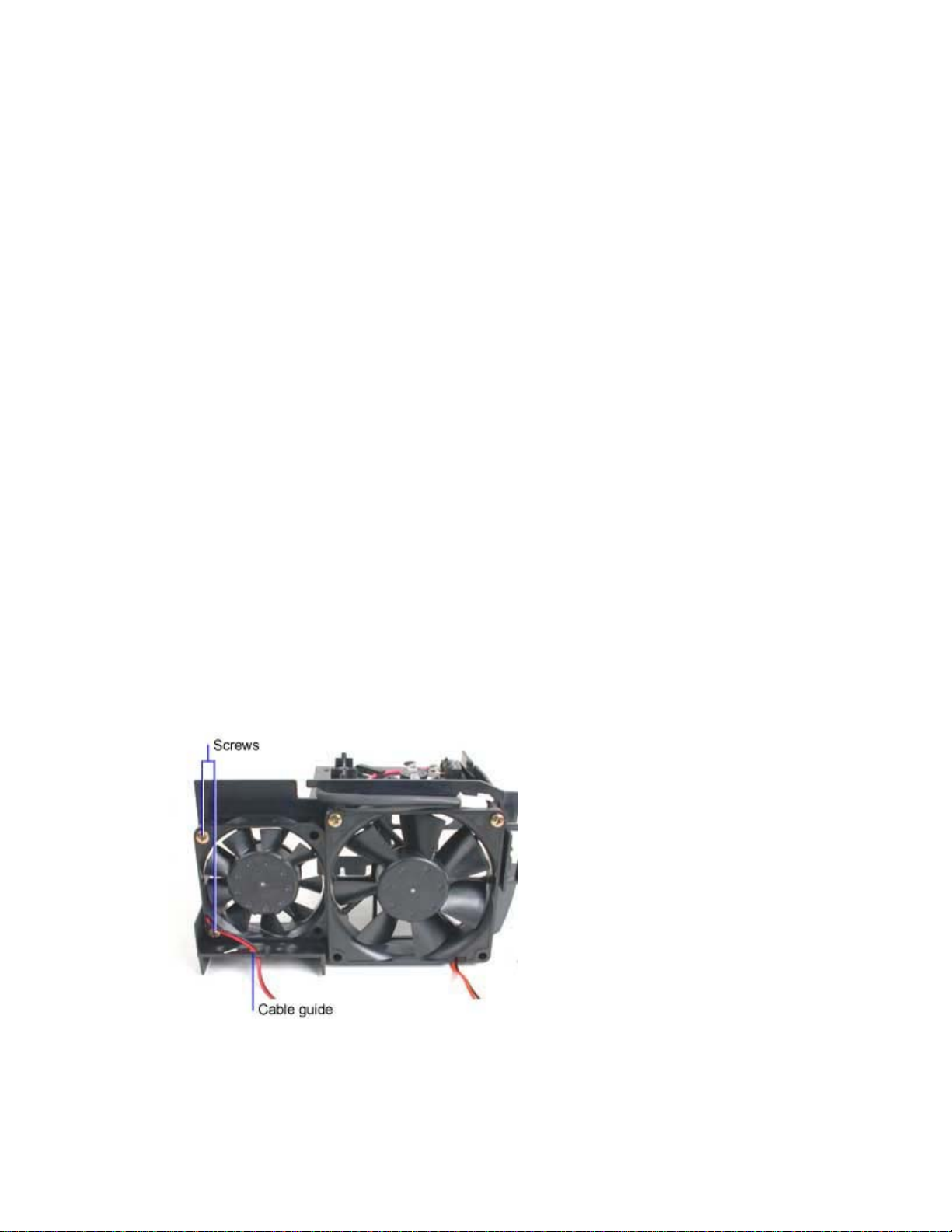

1. Remove the two M3x25 Plastite Phillips screws that fasten the fan to the lamphouse. Then

remove the fan cables from the retainer guide on the lamphouse.

2. Lift the fan away from the lamphouse.

X1 Service Guide 27

Page 28

Assembly Notes

♦ Position the fan against the lamphouse with fan label facing the lamphouse and the cable recess at

the left lower side. The cables should exit the fan at the recess on the side opposite the label.

♦ Replace and tighten the two M3x25 Plastite Phillips screws. Do not overtighten the screws.

♦ Make sure that the cables are clear of the fan blades.

Removing the 80mm Fan

1. Remove the two M3x30 Plastite Phillips screws that fasten the fan to the lamphouse.

2. Lift the fan away from the lamphouse.

X1 Service Guide 28

Page 29

Assembly Notes

♦ Position the fan against the lamphouse with fan label facing the lamphouse and the cable recess at

the bottom right side. The cables should exit the fan at the recess on the side opposite the label.

♦ Replace and tighten the two M3x30 Plastite Phillips screws. Do not overtighten the screws.

♦ Make sure that the cables are clear of the fan blades.

X1 Service Guide 29

Page 30

Remove and Replace the Focus and Zoom Rings

The focus ring (340-1117-xx) fits around the front of the projection lens. The zoom ring (340-1116-xx) is

behind the focus ring. The lens cap (505-1247-xx) snaps onto the focus ring.

Both the focus ring and the zoom ring snap into place on the lens barrel. They can be replaced without

removing any other projector parts.

Three retainer tabs inside the zoom ring engage the outside of the lens. Three retainer tabs on the focus

ring engage the inner lens barrel.

1. Place the projector right side up on a soft work surface. Then remove the lens cap.

2. Grasp the focus ring and pull it off of the lens barrel. The retainer tabs disengage from the lens

ring.

3. Grasp the zoom ring and pull it off of the lens barrel. The retainer tabs disengage from the lens

barrel.

X1 Service Guide 30

Page 31

Assembly Notes

♦ When you replace the zoom ring, push it as far as it will go onto the lens barrel. The lens barrel fits

snugly against the collar inside the zoom ring. Rotate the zoom ring to ensure that the alignment tab

properly engages one of the slots on the lens barrel.

♦ Press the focus ring onto the lens. Then rotate the ring to ensure that the retainer tabs engage to lock

it in place on the inner lens barrel.

♦ Place the lens cap over the focus ring.

X1 Service Guide 31

Page 32

Remove and Replace the Front Bezel

The front bezel (505-1509) covers the front of the projector and helps to secure the top case to the

bottom case. Two screws at the bottom and two tabs and a slotted receiver on the top of the front bezel

hold it in place on the projector. The front bezel includes the front IR lens.

Remove the Front Bezel

1. Remove the following items:

Focus ring (page 30)

Zoom ring (page 30)

2. Place the projector upside down on a soft work surface.

3. Remove the two M3x10 Plastite Phillips screws that fasten the front bezel to the bottom case.

4. Turn the projector right side up on the work surface. Gently pull the top of the front bezel away

from the projector. The two tabs and slotted receiver on the front bezel disengage from the

projector. You may need to use a small flat-blade screwdriver to depress the slotted receivers on

the top case to get them to disengage from the tabs on the front bezel.

X1 Service Guide 32

Page 33

CAUTION Don't pry the front bezel to remove it.

5. Pull the front bezel away from the projector.

Remove the Inner Grill

1. Remove the two M3x8 Plastite Phillips screws that fasten the inner grill to the front bezel.

X1 Service Guide 33

Page 34

2. Lift the inner grill away from the front bezel.

Assembly Notes

♦ Lay the front grill in position inside the front bezel. Replace and tighten the two M3x8 Plastite Phillips

screws securely. Do not overtighten the screws.

♦ Align the front bezel against the front of the projector. Press the bezel into position to lock the two

tabs and slotted receiver against the top case.

♦ Tighten the two M3x10 Plastite Phillips screws securely. Do not overtighten the screws.

X1 Service Guide 34

Page 35

Remove and Replace the I/O ECA

The I/O ECA (510-1800-xx) contains the connectors for interfacing the projector with external devices.

Ribbon cables carry the I/O signals into and out of the controller ECA where all signal processing takes

place. The I/O ECA is located at the backside of the projector behind the controller ECA

1. Remove the following items:

Lamp module (page 42)

Focus ring (page 30)

Zoom ring (page 30)

Front bezel (page 32)

Rear bezel (page 49)

Top case (page 52)

Ballast/power supply ECA (page 6)

Chassis (page 12)

2. Unplug the connectors at the ends of the three ribbon cables that connect the I/O ECA to the

controller ECA.

X1 Service Guide 35

Page 36

3. Remove the M3x10 Plastite Phillips screws that fastens the I/O ECA to the bottom case.

Assembly Notes

♦ Avoid sharply bending the ribbon cables that connect the I/O ECA to the controller ECA. When you

replace the I/O ECA, ensure that the connectors on the cables fully engage connectors CN702,

CN700 and CN701 on the controller ECA.

♦ Make sure that the holes in the I/O ECA align properly with the two pins on the bottom case.

♦ Replace and tighten the M3x10 Plastite Phillips screw securely. Do not overtighten the screw.

X1 Service Guide 36

Page 37

Remove and Replace the I/O EMI Shield

The I/O EMI shield (330-0964-xx) fits over the I/O connectors on the rear of the I/O ECA. The shield lies

behind the chassis. The I/O EMI shield and chassis fasten to the I/O ECA with four jack screws.

1. Remove the following items:

Lamp module (see page 42)

Focus ring (see page 30)

Zoom ring (see page 30)

Front bezel (see page 32)

Rear bezel (see page 49)

Top case (see page 52)

Ballast/power supply ECA (see page 6)

Chassis (see page 12)

2. Pull the I/O EMI shield off of the connectors on the I/O ECA. Take care not to bend the shield or

the contact fingers as you work the shield off.

Assembly Notes

♦ Make sure the shield and contact fingers aren't bent and that the shield contacts the I/O connectors.

X1 Service Guide 37

Page 38

Remove and Replace the Keypad

The keypad fastens to the inside of the top case. The keypad consists of the keypad ECA (510-1774-xx),

the key set (505-1515-xx), and the LED cover (340-1123-xx. The keypad ECA permanently connects to

the front IR receiver ECA. A ribbon cable extends between them. The LED cover nests in the recess

between the keypad ECA and the top case. It focuses light from the power LED on the keypad ECA

through a hole in the top case.

1. Remove the following items:

Lamp module (page 42)

Focus ring (page 30)

Zoom ring (page 30)

Front bezel (page 32)

Rear bezel (page 49)

Top case (page 52)

2. Place the top case face down on a soft work surface.

3. Remove the four M3x10 Plastite Phillips screws that fasten the keypad to the top case. Then then

lift the keypad ECA out of the top case.

X1 Service Guide 38

Page 39

4. Lift the key set out of the top case.

5. Lift the LED cover out of the top case.

6. Remove the M3x10 Plastite Phillips screw that fastens the front IR receiver ECA to the top case.

X1 Service Guide 39

Page 40

7. Remove the front IR receiver cable from the retainer in the top case.

8. Lift the front IR receiver ECA out of its recess in the top case.

Assembly Notes

♦ The keypad ECA, the front IR receiver ECA, the key set and the LED cover fit only one way in the top

case.

♦ Make sure that the alignment holes in the LED cover fit over the pins in the top case.

♦

♦ Position the key set in the top case such that the holes in the key set frame fit over the pins in the top

case.

X1 Service Guide 40

Page 41

♦ Position the front IR receiver ECA between the retainers in the top case.

♦ Route the IR receiver cable beneath the retainer near the mounting location of the IR receiver ECA.

♦ Replace and tighten the M3x10 Plastite Phillips screws securely. Do not overtighten the screws.

X1 Service Guide 41

Page 42

Remove and Replace Lamp Module

The lamp door (505-1513-xx) fits over the lamp cavity in the projector. A pin on the lamp door closes the

safety switch on top of the lamphouse when the door is shut.

The lamp module (SP-LAMP-009) consists of a metal housing and enclosed reflector assembly and arc

tube. Air flow from the 80 mm fan passes through openings on two sides of the lamp module. Screens

over these openings provide air filtration and contain quartz fragments in the event of lamp rupture.

CAUTION The lamp module gets very hot during operation. Allow the lamp to cool for 30 minutes before

handling it.

1. To remove the lamp door, insert a small flat-blade screwdriver into one of the recesses at the top

of the door. Gently pry the top of the door away from the projector. The door detaches from the

projector.

2. Squeeze the locking tab on the lamp cable connector and unplug it from the connector inside the

lamphouse.

X1 Service Guide 42

Page 43

3. To remove the lamp, loosen the two captive screws that secure it in the projector.

4. Slide the lamp module straight out of the lamphouse.

X1 Service Guide 43

Page 44

Assembly Notes

♦ Check the screens over the openings on the sides of the lamp module to make sure they're clean.

Vacuum away any dust on the screens so cooling air can flow freely through the lamp module.

♦ Slide the lamp module straight into the lamphouse. The alignment pins on the innermost side of the

lamp module engage holes on the optical engine.

♦ Gently tighten the two captive screws on the lamp module to secure it in the projector.

♦ Plug the cable on the lamp module into the connector inside the lamphouse. Ensure that the locking

tab securely holds the connector halves together.

♦ Place the two tabs on the bottom side of the lamp door in their respective slots on the projector. Then

press the top of the door against the projector to engage the alignment pin and the two upper tabs

that secure the lamp door in position.

♦ If you installed a new lamp module, follow the directions below to reset the lamp timer.

♦ Press the Menu button and navigate to the Main Menu>Settings>Service menu. Select Lamp Reset

to reset the lamp timer.

After you reset the lamp timer, read the timer value to make sure it was reset. Navigate to the About

screen from the Main Menu, then view the Lamp Hour value. It should show 0 hours.

X1 Service Guide 44

Page 45

Remove and Replace the Lamphouse

The lamphouse (505-1514-xx) fastens to the bottom case. It provides an alignment mechanism for the

lamp module to ensure precise beam focus into the optical path.

The lamphouse includes the safety switch and thermal switch.

Two cooling fans fasten to the rear side of the lamphouse. If you need to replace a fan, refer to Remove

and Replace the Cooling Fans on page 27. If you're removing the lamphouse to access another FRU,

you don't need to remove the fans.

1. Remove the following items:

Lamp module (page 42)

Focus ring (page 30)

Zoom ring (page 30)

Front bezel (page 32)

Rear bezel (page 49)

Top case (page 52)

Ballast/power supply ECA (page 6)

Chassis (page 12)

Controller ECA (page 19)

Color wheel shield (page 17)

X1 Service Guide 45

Page 46

2. Remove the fan cables from their retainers in the bottom case.

3. Remove the two M3x10 Plastite Phillips screws that fasten the lamphouse to the bottom case.

X1 Service Guide 46

Page 47

4. Carefully lift the lamphouse up and out of the projector. The photodiode and color wheel ribbon

cables pass through a retainer guide on the rear side of the lamphouse. As you lift the

lamphouse, remove these cables from the retainer guide.

CAUTION The lamphouse is very close to the color wheel. Avoid touching the color wheel. The edge of

the glass wheel is sharp and can cause personal injury. Touching the color wheel can break it

or leave smudges that degrade the image.

Assembly Notes

♦ Be careful as you replace the lamphouse. Don't allow it or your fingers to contact the color wheel.

♦ As you lower the lamphouse into the projector, route the photodiode and color wheel ribbon cables

through the retainer guide. Make sure that the lamphouse aligns properly with the two pins on the

bottom case.

♦ Replace and tighten the two M3x10 Plastite Phillips screws securely. Do not overtighten the screws.

X1 Service Guide 47

Page 48

Remove and Replace the Leveling Foot

The leveling foot (340-1118-xx) consists of the leveling foot and shaft, and a retainer. Rotating the

leveling foot extends or retracts it in the bottom case. The shaft threads through the bottom case from the

outside. A circular retainer stops the leveling foot at its maximum extension.

1. Remove the following items:

Lamp module (page 42)

Focus ring (page 30)

Zoom ring (page 30)

Front bezel (page 32)

Rear bezel (page 49)

Top case (page 52)

2. Rotate the leveling foot to fully retract it in the bottom case.

3. Remove the retainer from the groove at the top of the leveling foot shaft.

4. Rotate the leveling foot to extend it until it detaches from the bottom case.

Assembly Notes

♦ Insert the leveling foot shaft into the bottom side of the projector. Rotate the foot until it's fully

retracted in the bottom case.

♦ Replace the retainer in the groove at the top of the leveling foot shaft. Make sure the retainer fully

seats in the groove.

♦ Adjust the leveling foot to be level with the bottom of the projector.

X1 Service Guide 48

Page 49

Remove and Replace the Rear Bezel

The rear bezel (505-1510-xx) fastens to the rear of the projector and surrounds the I/O ports. The I/O

panel label (020-1775-xx) adheres to the outside of the rear bezel.

If you replace the rear bezel, you need a replacement I/O panel label. You cannot remove the label from

the rear bezel.

1. Place the projector upside down on a soft work surface.

2. Remove the two M3x10 Plastite Phillips screws that fasten the rear bezel to the bottom case.

3. Remove the M2.6x10 Plastite Phillips screw that fastens the rear bezel to the chassis.

X1 Service Guide 49

Page 50

4. Turn the projector right side up on the work surface. Three tabs on the rear bezel engage slotted

receivers on the top case. While firmly pulling the top of the rear bezel away from the projector,

carefully insert the tip of a flat blade screwdriver into the space between the rear bezel and top

case. Position the screwdriver blade at the location of one of the slotted receivers and press

down to release it.

You may need to repeat this step, pressing down on one of the other two tabs in order to release

the rear bezel from the top case.

5. Pull the rear bezel away from the projector.

Assembly Notes

♦ Align the rear bezel against the rear of the projector. Press the bezel into position to lock the three

tabs against the top case.

♦ Tighten the two M3x10 and the M2.6x10 Plastite Phillips screws securely. Do not overtighten the

screws.

When you install a new rear bezel:

♦ Adhere a new I/O panel label to the outside of the bezel.

X1 Service Guide 50

Page 51

Remove and Replace the Rubber Feet

The rubber foot (328-0155-xx) adheres to the bottom case at the rear of the projector, opposite the

leveling foot.

If you need to remove an old rubber foot, gently pry it away from the bottom case. To replace the rubber

foot, peel the protective paper from the replacement foot. Then press the foot into the recess in the

bottom case.

X1 Service Guide 51

Page 52

Remove and Replace the Top Case

The top case (505-1508-xx) covers the top half of the half of the projector. Once you remove the top

case, you have access to FRUs inside the projector. When you replace the top case, you need to adhere

a new nameplate (020-1118-xx) to the top case.

1. Remove the following items:

Lamp module (see page 42)

Focus ring (see page 30)

Zoom ring (see page 30)

Front bezel (see page 32)

Rear bezel (see page 49)

2. Place the projector upside down on a soft work surface. Remove the four M4x18 Plastite Phillips

screws from the bottom case.

3. Holding the top case against the bottom case, turn the projector over and place it right side up on

the work surface.

X1 Service Guide 52

Page 53

4. At the rear of the projector, unplug the keypad cable from the keypad ECA and the speaker cable

from the power supply ECA.

5. Slowly lift the top case away from the projector.

If you're replacing the top case with a new one, remove the keypad (page 38) and remove the speaker

(page 54) from the old one.

Assembly Notes

♦ If you're replacing the top case with a new one, install any top case parts that you removed from the

old one.

♦ Adhere a new nameplate to the top case.

♦ Connect the keypad cable at the keypad ECA and the speaker cable at the power supply ECA.

♦ Make sure that the top case fits flush over the bottom case.

♦ Tighten the four M4x18 Plastite Phillips screws securely. Do not overtighten the screws.

X1 Service Guide 53

Page 54

Remove and Replace the Speaker

The speaker (526-0151-xx) fastens to the top case. The speaker grill (330-0967-xx) protects the

speaker from damage by objects that could pass through the holes in the top case.

1. Remove the following items:

Lamp module (page 42)

Focus ring (page 30)

Zoom ring (page 30)

Front bezel (page 32)

Rear bezel (page 49)

Top case (page 52)

2. Place the top case face down on a soft work surface.

3. Remove the three M3x10 Plastite Phillips screws that fasten the speaker to the top case. Then lift

the speaker away from the top case.

4. Lift the speaker grill away from the top case.

X1 Service Guide 54

Page 55

Assembly Notes

♦ Position the speaker grill in the top case. The recesses in the grill align with ribs and mounting studs

in the top case.

♦ Position the speaker in the top case with the leads facing toward the rear of the projector. Tighten the

three M3x10 Plastite Phillips screws securely. Do not overtighten the screws.

X1 Service Guide 55

Page 56

Functional Tests

You perform the functional tests after you’ve repaired the projector to make sure all components of the

projector operate properly. You can also perform the functional tests if you’re having trouble determining

what is wrong with the projector. For additional help in diagnosing trouble with the projector, see

Troubleshooting on page 60.

Required equipment

Equipment Notes

Composite video DVD player

with S-video capability

Commercially produced video to

test S-video, composite video,

and audio.

Video cables

Computer cables

Make sure the video player has an S-video Out port and cables. The

player should also have a Composite video output port (RCA).

InFocus strongly suggests you use a DVD player to test the video

quality. DVD players reproduce colors better and project sharper

images. The least preferable is a VCR. If you must use a VCR, make

sure you use a commercially produced recording, not one recorded

from a broadcast source. The VCR must include an S-video connector

in addition to a composite connector.

You'll need the video in DVD, laser disc, or videocassette format.

InFocus strongly suggests you use Video Essentials, Optimizing Your

Audio/Video System (DVD International, 1997) available at

http://www.infocus.com/service/asc/lp530/english/tests_ve.asp

S-video, RCA composite, component video to S-Video adapter cable,

and RGB component with RGB to SCART adapter

HD15 VESA cable for analog video

Audio cable

RGB test screens in a

PowerPoint presentation

PC

Remote control

Projection screen

X1 Service Guide 56

3.5 mm mono audio cable

We recommend that you use test patterns you can download from the

InFocus web site to check image quality.

(http://www.infocus.com/service/software/downloads/test_screens.exe)

The computer must have a CD-ROM and a standard VESA connector

for analog output.

Ensure that the remote has fresh AA batteries.

Use a flat screen, not a curved one.

Page 57

Before beginning

Make sure the work surface where you perform the functional tests is level and clean. Place the projector

on a soft surface (such as an anti-static mat) when running the tests.

Connect the following to the I/O panel on the projector:

♦ DVD player through component video, composite video and S-video ports

♦ Computer through VESA cable

Perform the following tests

Test Verification

Power Up

Connect AC power, and turn

the unit on.

Cosmetics and mechanicals

Adjust the projector so that the

image is square. Make sure

the lens is at a 90° angle to

the wall.

Component video from DVD

player

1. Press the Source

button on the keypad

to select a video

source.

2. Connect the

component video

adapter cable and to

the projector.

3. Disconnect any other

video sources.

Composite video from DVD

player

1. Connect the

composite video cable

to the projector.

2. Disconnect any other

video sources.

Verify that the proper splash (logo) screen appears.

Verify image quality.

Verify that the elevator and leveling foot are functional.

Verify that the focus and zoom rings operate properly.

Verify cosmetics.

Verify that the video automatically synchronizes.

Verify there is no distortion, noise or other abnormalities.

Verify that the video automatically synchronizes.

Verify there is no distortion, noise or other abnormalities

S-Video from DVD player

1. Disconnect any other

video sources.

2. Connect the S-video

cable to the projector.

X1 Service Guide 57

Verify that the video automatically synchronizes.

Verify there is no distortion, noise or other video abnormalities.

Page 58

Audio from DVD player

Connect the audio cable to the

projector.

Software Version / Keystone

/ Reset All

1. Press and hold the

Keystone up and

Keystone down

button on the keypad.

2. Press the Menu

button. Navigate to

the Settings menu.

Select Service. In

Service menu, select

Service Info. In the

About message box,

check the software

version.

3. Return to the Service

menu. Select Factory

Reset. Press the

menu button to close

the menus.

Verify that the audio system produces clear sound.

Verify that the volume controls function properly

Verify the keys function properly and are not sticky.

Verify that the lamp hours are well within normal life range.

Verify that the projector uses the current software version.

The next step is to observe 3

computer images. These will

confirm that the computer

input works properly, and will

test image quality.

On the keypad, press the

Source Select button to

select Computer.

Image #1: Focus Test Image

Turn off any local light.

Turn the zoom ring to make

the smallest image.

Focus the image so the middle

icon is clearly focused.

Focus the image on the 4

green squares.

After focusing on the green

squares on the middle

icon, turn the zoom ring to

make the largest image, then

repeat the focus tests.

Verify that the images project synchronize properly through both of the

following inputs:

M1 Analog

M1 Digital

Verify that all four corner icons have clear resolution

Verify that the white space is visible on all 5 bar/line icon areas (between

green).

Verify that the image focuses through the full zoom range.

Verify that the image remains in focus when the Image Shift knob is

turned.

X1 Service Guide 58

Page 59

Image #2: Color Ramp

Project the Color Ramp

image.

Image #4: SMPTE133

Project the SMPTE133 image.

Verify there are no missing parts of the ramp.

Verify that the bars are not flashing.

Verify that the transitions from light to dark are smooth and gradual.

On the keypad, press Menu.

On the Display menu, select

Reset All.

Power Down

After all tests are complete,

turn the power off and

disconnect all cables. Attach

the lens cap.

Verify that there are no noise, tint, duplicating columns, or other general

image abnormalities present

Verify that the image synchronizes.

Verify unit is powered off before disconnecting cables.

X1 Service Guide 59

Page 60

Troubleshooting

You use the Troubleshooting section to diagnose problems with the projector. In this section, you will find

troubleshooting flowcharts for a variety of symptoms. Each flowchart leads you through a series of steps

that will ultimately result in a solution. The solutions begin with the most simple and progress to the most

complex.

In this section, you will find troubleshooting flowcharts for a variety of symptoms. Each flowchart leads

you through a series of steps that will ultimately result in a solution. The solutions begin with the most

simple and progress to the most complex.

What do you want help solving?

Power problems, including lamp issues, partial power up, shutdown and no power (page 61)

Image problems, including no image, bad color, dim image and other picture distortions (page

67)

Keypad problems (page 71)

Remote problems (page 72

Audio problems (page 73)

Check Internal Voltages and Signals

In addition to the troubleshooting flowcharts, you can also check internal voltages and signals to diagnose

a defective part.

This section includes diagrams of internal voltages and signals that should be present at locations on the

controller ECA, ballast/power supply ECA, and the I/O ECA. You can use this section to verify a problem

that you diagnose from the troubleshooting flowcharts, or you can perform voltage checks as a starting

point for diagnosis.

What do you want to check?

♦ The controller ECA (page 19)

♦ The ballast/power supply ECA (page 6)

♦ The I/O ECA (page 35)

X1 Service Guide 60

Page 61

Power and Start-up Problems

The projector communicates its status via an LED located on the keypad. When this status LED is green,

you know that the projector is working properly. When the status LED is solid red or flashing red, you

know there are lamp, power or startup problems. The frequency with which the status indicator blinks red

indicates one of several error codes. These error codes provide crucial information about projector

malfunctions.

Go to the next page to begin the power diagnosis sequence.

Below is a table that shows the meaning the various LED states.

NOTE We strongly suggest that you follow the entire power diagnosis sequence, which begins on the

next page.

LED Status

LED flashes green

LED is solid green

LED flashes red once The lamp will not strike after five tries (2 1/2 minutes).

LED flashes red two times

LED flashes red three times Lamp failure. Projector shuts down.

LED is solid red Undiagnosed error. Projector shuts down.

The projector is starting up after the Power button was pressed, or the

projector is shutting down after the Power button was pressed.

The projector is ready to light the lamp when the Power button is

pressed. Or the lamp is lit and the projector is operating properly.

The lamp has more than 2,980 hours of use. Requires replacement.

Projector shuts down.

X1 Service Guide 61

Page 62

Power Diagnostics, part 1

Plug the projector into a good power source

with a known good power cor d.

Check the power supply

fuse and replace if with

a T2.5A 250V if

necessary

Solve the

problem?

No

Replace

power supply

(page 6)

Confirm that unit is

good by starting again.

Note

A solid green LED

means the projector

is either waiting for a

command or is

operating normally.

No, the fans

did not

start and

the LED

did not light.

solid green

Go to Power

Diagnostics, part 2

(page 63)

This is the

normal

condition.

Do the fans run

briefly and the

LED light?

Yes

LED light

green or red?

This is the normal condition.

No, the fans

started but

the LED

did not light

Red

Go to Error

Codes

(page 64)

Confirm that unit is

good by starting again.

Conf irm t hat the keypad

cable is plugged in.

Chec k the voltages at

the controller/power

No Voltages OK?

Replace

power supply

(page 6)

Replace cont roller E CA

Yes

(page 37)

supply connector.

(page 88)

Yes

(page 19)

Solve the

problem?

No

A flashing green

LED means the

projector is either

attempting to light

the lamp or is

shutting down.

Replace keypad ECA

(page 37)

X1 Service Guide 62

Page 63

Power Diagnostics, part 2

Note

A solid green LED

means the projec tor

is either waiting for a

command or is

operati ng normally.

A flashing green

LED means the

projec tor is either

attempting to light

the lamp or is

shutting down.

Pres s the Power button on the keypad

The Startup tone sounds.

The fans spin up, then slow.

The color wheel spins up.

This assumes you have plugged the power

cord in and that the LED is solid green. If

not, go back to Part 1 (page 62).

The lamp attempts to strike five times at 30-

second intervals. After 2 1/2 minutes, the

projector no longer tries to strike the lamp and

the LED begins flashing red.

No. The lamp does

not light, and the LED

begins blinking red.

Go to Error Codes

(page 6 4)

Is the LED

flashing

green?

Yes

The LED continues flashing

green until the lamp lights.

Did the lamp light

and the LED turn

solid green?

Yes

Run the projector long enough to ensure

that the problem is solved. If the lamp

goes out and the LED turns red, go to

error codes (page 64).

No, the LED

remains

solid green.

Yes

Pres s the Power

button again.

The LED remains solid green

after pressing the Power button

twic e. The lamp does not light.

Replace keypad ECA

(pag e 37)

Solve the

problem?

No

Replace contr oller ECA

(pag e 19)

Repeat process to conf irm the

problem fixed.

X1 Service Guide 63

Page 64

Power Diagnostics, Error Codes

Steady

Interpret

red LED

behavior

Is the LED steady or

flashing?

Flashing

Red LED flashes have

2-second intervals

between series of

flashes. For example,

the LED may flash 4

times, the pause for 2

seconds, the flash 4

times again.

On

Off

1 flash

The lamp failed to strike after

five attempts.

Diagnose lamp strike failure.

(page 65)

An internal error occurred that

the projector cannot identify.

Diagnose the error.

(page 62)

On

Off

2 flashes

The lamp timer registers

lamp use of 2000 hours

or more.

Replace the lamp.

(page 42)

What is the

flashing pattern?

On

Off

3 flashes

The projector detected an

internal error and shutdown

the lamp.

Diagnose lamp shutdown.

(page 66)

X1 Service Guide 64

Page 65

LED flashes single red

The lamp won't strike after five attempts. The status

LED flashes a repeated red single-flash sequence.

Ensure that the lamp door

is present and shut.

Can you hear the

safety switch open

and close?

Yes

Replace the lamp

module. (page 42)

Ens ure that the color wheel

cable is connected to the

controller ECA. (page 84)

Ensure that the safety switch cable is

connected to the power supply. Also, ohm out

the interlock switch and the thermal switch to

make sure they are good. If not, replace the

lamp house. (page 45)

Voltages good

at power supply/

controller

connector?

(page 88)

No

No

Replace the lamp

house.

(page 45)

Verify the repair by

restarting the Power

Diagnosis process.

(page 62)

Replace the ballast/

power supply ECA.

(page 6)

Solve the

Yes

Replace cont roller

ECA (page 19)

problem?

No

Verify the repair by

restarting the Power

Diagnosis process.

(page 62)

X1 Service Guide 65

Page 66

LED repeats 3 flash sequence

The lamp was operating but shut down. Fans are

running. The status LED flashes a repeated

red three-flash sequence.

Open the lamp door and

check the lamp calble

connector to make sure

it's fully seated.

Run the projector long

enough to ensure that the

problem is solved.

Replace the ballast/

power supply ECA.

(page 6)

Yes

No

Solve the

problem?

Replace the lamp.

(page 42)

Solve the

problem?

Repeat the diagnostic

proc ess to ensure that

the problem is solved.

(page 62)

No

Yes

If the projector fails to start properly, you

may see the status LED flas h a repeated

single-flash sequence indicating that the

lamp won't strike. Go to page xxx to solve

failure to strike problems.

X1 Service Guide 66

Page 67

Image Problems

The image is not correct.

The projector starts and runs normally.

The menus are accessible. The lamp is lit.

Flas h the projector

with the latest software.

No image at all.

Vertical or horizontal

lines.

Sparkley picture.

Clusters of dark pixels.

(page 68)

Confirm that all image

adjustments are set to the

factory defaults.

Conf irm that the c ables and

the s ource s ignals are good.

What is the problem?

Bad or missing tint or color

Missing logo, VG A, composite video, or S-

video Distorted image, noisy, rolling, torn,

frozen, 'plaid', r epeated, or shif ted image

(page 69)

Select Factory Reset from

the Settings>Service menu.

If in doubt, feed the signal

to a good projector.

Dim image

(page 70)

X1 Service Guide 67

Page 68

No image

No image.

Vertical lines. Horizontal lines.

Sparkly picture. Clusters of dark pixels.

Replace the controller ECA.

(page 19)

Is the image

correct?

No

Replace the optical engine.

(page 24)

X1 Service Guide 68

Page 69

Bad image

Bad or missing tint or color.

Missing startup screen, VGA, composite video or S-video.

Distorted image, excess noise, rolling image, torn image, frozen image, 'plaid' image,

repeated single image, or shifted image.

Make sure cables are good.

Is the image

correct?

No

Replace the c ontroller ECA.

(page 19)

X1 Service Guide 69

Page 70

Dim image

Dim image

The lamp takes about 90

seconds to achieve full

brightness.

Substitute known

good lamp (page 42)

Is the image

brighter?

No

Substitute a known good

controller ECA.

(page 19)

Is the image

brighter?

No

Replace the optical engine.

(page 24)

Yes

Yes

Replace the lamp.

Replace the controller ECA.

X1 Service Guide 70

Page 71

Keypad Problems

Keypad does not respond to key presses

Replace the keypad ECA

(page 37)

Yes

The IR ECA mounts permanently

to the keypad ECA. You replace

both parts at the same time.

Does the

remote control

work?

No

For this test, make sure that you

point the remote control directly at

the IR receiver on the front of the

projector.

Replace the controller ECA.

(page 19)

X1 Service Guide 71

Page 72

Remote Problems

Use known good batteries in the remote.

Infrared remote problem

Does the

remote work?

No

Replace the remote.

Does the

remote work?

No

Replace the keypad ECA.

(page 37)

Does the remote

work?

No

Replace the controller ECA.

(page 19)

Make sure that you aim the

remote directly at the IR

receiver on the f ront of the

projector.

X1 Service Guide 72

Page 73

Audio Problems

No audio or sound is scratchy or distorted.

Make sure the s peaker cable is

connected to the controller ECA.

Is there sound?

Yes

Is there sound

from both s peakers?

Yes

Problem solved.

No

only

one

Replace the controller ECA.

No,

A shorted speaker can damage the stereo

Run the projector with audio for 30 minutes.

(page 19)

Replace the top case. (page 52)

But note:

audio amp on the c ontroller ECA.

If the problem returns, replace both the

controller ECA and the top case if the

resistanc e across either speaker coil no

longer measur es approximately 16 ohms.

X1 Service Guide 73

Page 74

Block Diagram

The diagram below illustrates the projector's electrical architecture.

This section also contains information about:

♦ Controller ECA functions (page 75)

♦ System memory (page 75)

♦ System states (page 76)

♦ Remote control features and functions (page 79)

X1 Service Guide 74

Page 75

Controller ECA Functions

A Pixelworks PW164B processor is responsible for control of the entire system as well as processing of

the graphics and video data, including GUI insertion and rescaling to the DMD’s native SVGA resolution.

The processor consists of an Intel 80C186 core CPU with on-chip peripherals including GPIO, Timers,

UART, IR receiver logic, interrupt controller, and a 16-bit memory interface. The PW164B also includes

video input and graphic input ports, a synchronization decoder and automatic image optimizer. The image

data is processed and fed to an on-board frame buffer. The data is then scaled and the on-screen display

information is laid over the image. The processor also supports color lookup-tables, color-space

expansion, and keystone correction. The processor outputs all timing and image data required for the TI

DLP driver logic. The processor's internal vertical and horizontal image scaler is bypassed; a Faroudja

FLI2200 deinterlacer performs scaling. A voltage-controlled amplifier controls audio volume and balance.

System Memory

The Pixelworks processor is interfaced to a single 8Mbit word-wide FLASH memory for code storage, and

a 32kbit serial EEPROM for unit-specific and dynamic data storage. The FLASH is attached to the

PW164B’s word-wide memory interface. An EEPROM is also located on the DMD board. This EEPROM

stores DMD and engine-specific data.

X1 Service Guide 75

Page 76

System States

The projector always operates in one of the following states:

♦ Boot up

Condition: the power switch is ON but the LED is OFF and all user input is ignored. Boot-up takes

approximately 2 seconds. The projector moves to the Startup state automatically when boot-up is

complete

♦ Off

The projector skips the OFF state when it is first booted. Off state can be entered via the Power key

on the IR remote or by the Power Save feature. In the OFF state, the LED is steady green. The lamp

is off and no source is selected but the software is booted up and the projector can communicate or

be powered on via USB. The Power key on the remote or any key on the projector keypad can also

power up the projector. A power up command from any of these sources causes the projector to

move to the Startup state.

♦ Startup

Startup begins when boot-up is complete or when a power-on command is received during the Off

state. Power-on commands can be generated by the power key on the IR remote, any key on the

projector keypad, or via USB. Startup can also be entered from the Power Save state if a signal is

detected before Power Save shuts down the projector. The lamp strikes during the Startup state.

During this time, the LED slowly flashes green and all external control of the projector is locked out

(no keys active). If Auto Source is enabled, the currently selected Startup Logo displays as the lamp

brightens. When Startup is complete, the projector moves to the Search state. If Auto Source is not

enabled, the currently selected Startup Logo still displays, but only briefly before the projector moves

to the Setting Up Image state.

♦ Search

In Search State, the currently selected Startup Logo continues to be displayed, the LED is steady green,

and all user input is accepted. Source selection is determined by a combination of the settings for Default

Power Up Source and Auto Source. If Auto Source is enabled, the projector begins searching for a source,

and the Searching message displays. Audio is disabled at this time. If Auto Source is disabled, the source

name displays and audio is enabled. If no active source is detected, the projector remains in Search state

and continues to display the Startup Logo

for a preset amount of time. If no source is detected and no keys

are pressed during this preset time, the projector goes to either the Screen Save state or the Power Save

state. If a source is detected, the projector goes to the Setting Up Image state.

♦ Image setup

Auto Image runs during this time, the logo continues to be displayed and the LED is steady green. All user

input is accepted. The selected source (either auto or manually selected) displays, with the Setting Up

Image message below it. If the source is locked, the projector switches to the Display state. If the source is

locked but then lost, the projector switches to the Search state. If a signal is detected but cannot be

X1 Service Guide 76

Page 77

resolved, the Signal out of Range message displays. When the projector leaves the Setting Up Image state,

the logo no longer displays; this would include a change to either Display state or Menu state.

♦ Display

This is the projector's primary mode of operation and the one the user spends the most time in. The

LED is steady green and the projector displays an image from the selected source. If the source is

lost, the projector goes to the Search State.

♦ Menu

The user interacts with the projector through configuration of on-screen menus. The menus are rendered in

an overlay memory that becomes visible on top of the current image during menu mode. The Menu state

provides access to parameters not accessible directly through the keypad. The Menu state can be

executed from the Zoom state, Search state, Setting Up Image state, Screen Saver state, or Display state.

The Menu state can be enabled or disabled via the infrared remote (except the Executive remote) or

projector keypad. The LED remains steady green.

♦ Power save

When more than 20 minutes has elapsed since a source was locked or a key was pressed, and Power

Save is enabled, the lamp is extinguishes and a one-minute cool-down period begins. If a source is

detected or the Power key is pressed during the cool-down period, the projector will not react immediately

but switches to the Startup state at the end of the cool-down period. The LED slow flashes green during

cool-down. At the end of cool-down, the LED changes to a slow blip green and the projector enters the

Power Save state. The Power Save state lasts for 10 minutes. If there is no activity during this 10 minutes,

the projector switches to the Off state. If a source is detected or the IR remote power key is pressed or any

key on the projector keypad is pressed during this 10 minutes, the projector immediately switches to Startup

state.

♦ Screen save

When more than the preset time has elapsed since a source was locked or a key was pressed, and Power

Save is not enabled, the projector switches to a black screen that prevents damage to the DMD. The

projector remains in the Screen Save state until a key is pressed, a source is detected, or the projector is

shut down. The projector will respond to any key by switching from Screen Save to the Search mode. Note

that key-presses are not processed other than to exit Screen Save mode. The LED flashes a slow blip

green. Screen Save is always enabled, except when Power Save is enabled.

♦ Power down confirm

The LED lights solid green and the projector displays a blank curtain screen. Only the Power key is active.

If it is not pressed in less than 3 seconds, power down is cancelled. The projector displays the message

“Powering down. Press Power to confirm.”

X1 Service Guide 77

Page 78

♦ Cool down

The lamp cool-down state provides 1 minute of cooling time, beginning when the lamp is extinguished,

before the lamp can be re-struck. The fans continue to run during this time. All projector control is disabled

for of the 1-minute cool-down period. The LED changes to slow flashing green during cool-down.

♦ Error

A flashing red LED indicates an error condition (see Troubleshooting Power Problems). The lamp is

turned off and the projector ignores any user input. Only a hard reset exits this state.

♦ Freeze

Freeze Mode halts, or “freezes”, the incoming external source image. This feature can be used to freeze a

frame of TV video or an image from a computer, allowing other operations to be performed that are not

visible to the audience. Freeze can be executed only from Display mode. Freeze can only be enabled or

disabled via the infrared remotes, using the Effect key. The LED remains steady green.

♦ Blank

Blank, as the name implies, blanks the screen. Blank can be executed from the Search state, Display