Page 1

MRS

™

MAXIMUM RADIATING SURFACE

FLAT-PANEL TRANSDUCER

THE CHALLENGE

The requirements for designing and building loudspeakers are dramatically

different from what they were even a decade ago and present several new

challenges, both technical and aesthetic.The days of monolithic loudspeakers

requiring a large percentage of a room’s floor space are gone.Today’s customers

are demanding architecturally friendly designs that will blend with and even

isappear into their homes. However, at the same time, the loudspeakers are being

d

asked to do more and more. Today, a speaker system is not only expected to play

usic from a CD, but also is typically used for movies,TV and video games.

m

Customers also want to connect their portable music devices such as the iPod

to play through their home loudspeakers. This produces an interesting conundrum

in the marketplace. Consumers are demanding that their loudspeakers do more –

nd often appreciate improved performance – but, on the other hand, want them

a

o only minimally intrude into their living spaces.

t

The challenge for Infinity is to introduce attractive loudspeakers that easily blend

into a wide range of home décors while not compromising Infinity’s hallmark

sonic performance in any way. The Infinity Cascade

result of this unique challenge. Each Cascade model is designed to be slim and

legant, while delivering superlative sonic performance.

e

™

series is the first, beautiful

®

aluminum coil etched on its surface, suspended between sets of powerful samarium

cobalt magnets.As electrical current flows through the coil, the induced magnetic

field interacts with the stationary magnetic field created by the magnets.This

auses the diaphragm to move and energize the air around it.The essential

c

feature of Infinity’s EMI tweeter (EMIT

flat radiating diaphragm is uniformly driven across its surface. This causes all

points on the diaphragm surface to vibrate in phase, thus reducing the propensity

f the diaphragm to exhibit resonances or breakup modes.

o

EMI devices are able to meet the “thin”goal but fall short when held to the

“no compromise in sonic performance”goal.Although innovative at one time,

MI transducers have some performance limitations.They are inherently

E

inefficient devices and are incapable of making the mechanical excursions

necessary to reproduce lower frequencies with adequate acoustic output and

low distortion. EMI devices also suffer from having coils with low thermal mass,

aking them prone to thermal-induced compression and failure.

m

MERGING CONVENTIONAL-CONE AND EMI TECHNOLOGIES

Since EMI devices meet our “thin”goal and conventional-cone transducers meet

our “performance”goal, the natural question was how we could combine the two

echnologies in order to achieve both goals.

t

The most logical approach was to combine the flat diaphragm aspect of the

EMI transducers with a variation on conventional loudspeaker motor technology.

eplacing the more familiar cone-shaped diaphragm with a flat diaphragm

R

reduces the depth of the device. However, using conventional motor technology

has allowed us to overcome the mechanical excursion and thermal limitations

inherent in the EMI device.

™

) and EMI midrange (EMIM™) was that a

Once again, Infinity

is changing the shape

of sound by applying

innovative

technology

in loudspeakers

that deliver superb

performance from

™

The result is the patent-pending Maximum Radiating Surface

transducer, which offers the strengths of both technologies with the weakness

of neither. Our engineers were able to combine the two technologies and add

™

a few more to truly optimize the performance of the new device.

(MRS™) flat-panel

attractive, slender

and striking

designs.

THE TECHNOLOGY

Typically, new technical developments have influenced the final visual design

wly developed driver was 6" in depth,

if a ne

,

xample

or e

F

of a loudspeaker

the enclosure was designed around the driver’s requirements. We employed

a slightly differ

the thinnest possible dr

our engineering team began development of a radical new transducer design

that would be far thinner than pr

mance

or

perf

• Very thin form factor

• Flat br

• Unifor

• Delivery of high output levels with a minimum of breakup and power compression

.

ent approach. Knowing that any future designs would require

k with slimmer and mor

s to wor

er

v

i

evious designs and would also offer improved

The key requirements of this driver were…

.

oadband frequency response

m dispersion,

both on- and off-axis

e compact enclosures,

DEVELOPING THE MAXIMUM RADIATING SURFACE™(MRS™)

T

LA

-PANEL TRANSDUCER

F

CONVENTIONAL-CONE TRANSDUCERS

We began by examining the advantages as well as the disadvantages of

conventional-cone transducers. Conventional-cone drivers use the force from

a tubular voice coil immersed in a static radial magnetic field to energize a coneshaped diaphragm.The static magnetic field is maintained by a magnetic loop

driven by permanent magnets. As current from the amplifier flows through the voice

coil wire, a magnetic field that interacts with the static magnetic field is generated,

causing a mechanical force along the axis of the voice coil. The direction of current

ough the coil deter

low thr

f

entional-cone tr

v

Con

a good reason for this.

drivers is a fairly well-established process, allowing loudspeaker designers to

e specified performance goals in a reasonable amount of time and at a

v

achie

easonable cost.

r

mance standar

or

perf

surround, as well as the stacking of the motor components, causes this type of

ice to f

v

de

ELECTROMAGNETIC INDUCTION TRANSDUCERS

xt, we revisited Infinity’s vintage electromagnetic induction (EMI) transducers.

Ne

his driver design utilized a thin, rectangular sheet of plastic with a flat,

T

Con

all shor

mines the dir

ansducers have been around for a long time and there’s

he design and manuf

T

entional-cone tr

v

ed.

equir

ds r

t of the depth requirements.

ection of the mechanical force.

e of conventional-cone-type

actur

ansducer

Howe

s can certainly meet the high

er, the height of the cone diaphragm and

v

ABOUT

There is no question that there were many factors that influenced the decision to

pursue a flat radiating diaphragm for our new transducer. But, again, the primary

antage of the flat diaphragm is that it allows us to reduce the overall depth

v

ad

and mounting requirements of the transducer relative to a comparably performing

conventional-cone driver, with respect to radiating surface area.

BETTER-SOUNDING

A further advantage to using a flat-panel diaphragm is that its rectangular shape

allows us to maximize the useful sound-radiating area on the front of the speaker

losur

enc

mounted on them are circular.This leaves a lot of “wasted,”or dormant, space on

the baffle which, while contributing to how big and boxy the speaker looks in your

room, actually does very little to contribute useful sound. Maximizing the ratio of

radiating surface area to baffle area allows higher levels of sonic performance

from enclosures that do not dominate your room.

MRS™FLAT-PANEL DRIVER

TTRACTIVE, TOO

A

MORE

AND

e.While most loudspeaker baffles are basically rectangular, the radiators

HE

T

250 Crossways Park Drive, Woodbury, NY 11797 USA • 516.674.4INF (4463)

ax 516.682.3523 • www

F

All rights reserved. Printed 7/05 Part No.MRSWHTPAPER7/05

inity and CMMD ar

Inf

EMIT and EMIM are trademarks,of Harman International Industries, Incorporated.

iPod is a registered trademark of Apple Computer, Inc.

edited and digitally pr

Designed,

Woodbury,NY.

inity continually strives to update and improve existing products, as well as create new ones.

Inf

T

he specifications and construction details herein are therefore subject to change without notice.

.infinitysystems.com

ed tr

egister

e r

oduced by Har

© 2005 Harman International Industries, Incorporated.

Maximum Radiating Surface (MRS),

ademar

and Cascade

,

ks

man Consumer Gr

,

keting & Design Center

oup Mar

,

Page 2

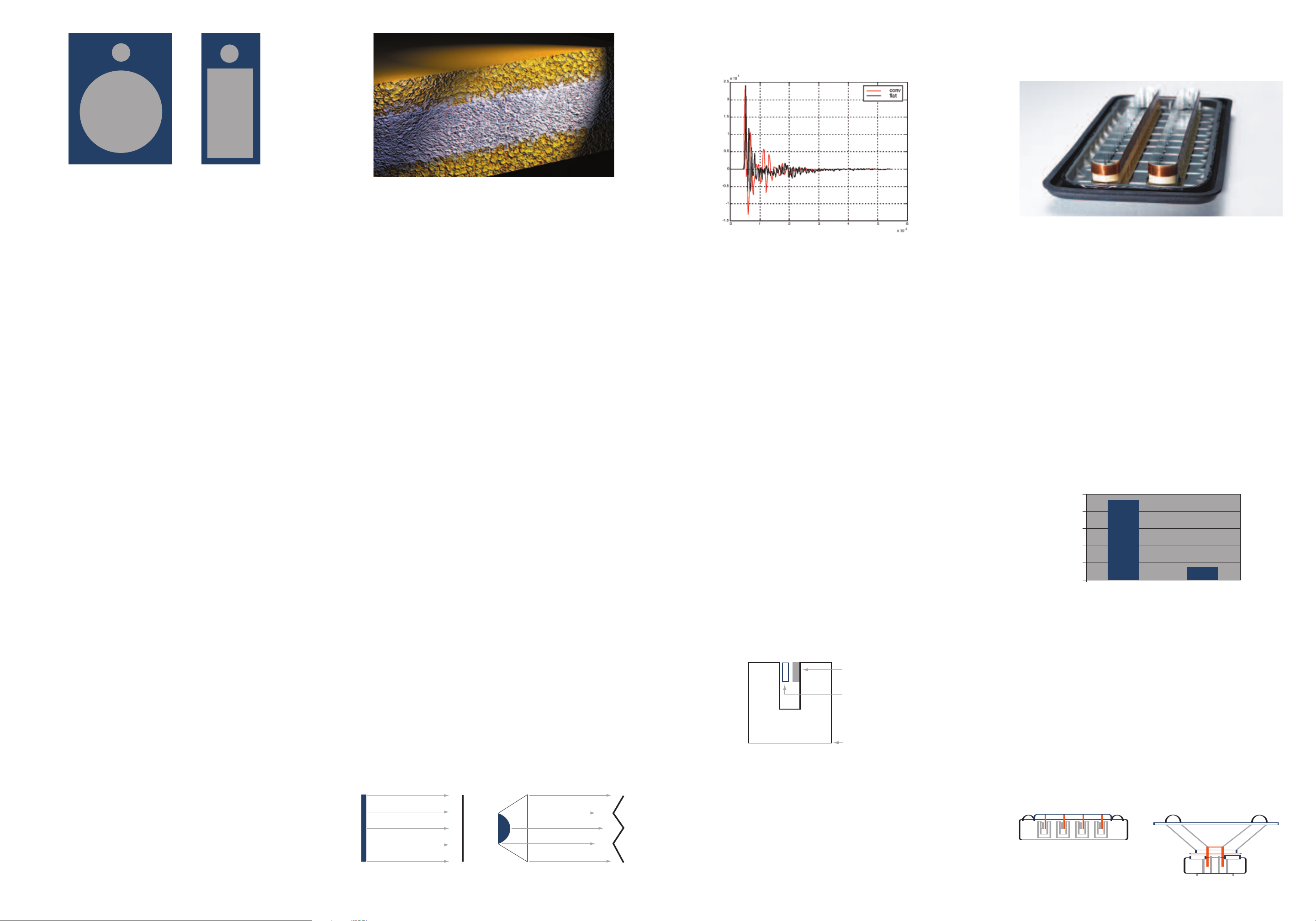

MRS™DRIVER CONVENTIONAL-CONE DRIVER

INFINITY MRS

™

COMPETITOR

VOICE COIL SURFACE AREA

SURFACE AREA (SQUARE INCHES)

10

8

6

4

2

0

27%

INFINITY MRS

FLAT-PANEL TRANSDUCER

CONVENTIONAL CONE

STEEL RAIL

VOICE COIL

NEODYMIUM MAGNET

asted Baffle Area

W

Useful Sound-Radiating Surface

CONTROLLED DIRECTIVITY

As with nearly all decisions related to loudspeaker design, each design choice

made for one parameter may influence other parameters. While choosing a

diaphragm shape that makes the speaker system’s appearance more aesthetically

leasing is a good thing, it will often have consequences related to how the

p

speaker sounds.The shape of a loudspeaker cone or diaphragm is a major factor

in defining the directional characteristics of a transducer. Putting a physics

lecture aside, it can be simply stated that in most cases, at a given operating

requency, a smaller diaphragm will have a wider radiating pattern than a larger

f

diaphragm.This is one of the reasons why high-quality loudspeakers use multiple

drivers (woofers, midranges and tweeters).A large-diameter woofer would not

be suitable for mid- or high-frequency use, due to its propensity to become too

directional at these frequencies.

™

The aspect ratio of the Infinity MRS

small with respect to width and larger with respect to height. While having the

same radiating surface area of a round 6-1/2" woofer, the MRS driver has a

horizontal radiating pattern, similar to a 3-1/2" midrange.This contributes a very

wide and smooth radiating pattern in the horizontal plane, providing exceptional

imaging and soundstage presentation to listeners throughout the room.The height

of the flat-panel transducer tends to project a narrow vertical radiating pattern

into the listening room, which reduces the detrimental effects of floor and ceiling

reflections.The result is exceptional imaging and soundstage presentation across

a large listening area, from a compact loudspeaker.

THE DIAPHRA

Optimizing the parameters of a flat-panel diaphragm in a loudspeaker presents

quite an engineering challenge. Conventional-cone-shaped loudspeaker

diaphragms are typically energized by the force generated by a cylindrical

voice coil interacting with a static magnetic field. The voice coil is constrained

around its perimeter by a corrugated diaphragm (spider) which limits its axial

movement at the extremes, and also ensures that the coil stays well centered

in the magnetic gap. Mechanical force generated by the coil is applied to the

apex of the cone.

T

he f

while the other end interacts with the restoring force provided by the surround.

Interaction with the sur

cone toward the voice coil.

will be some mechanical standing waves or interference pattern distributed along

the w

the speaker.

anomalies which act to color the sound of a loudspeaker.

GM MATERIAL

orce from the voice coil alternately pushes and pulls one end of the cone,

ound can cause r

r

he net eff

T

alls of the cone.

T

These in turn produce unwanted acoustical anomalies from

ect is called

his eff

flat-panel diaphragm makes the diaphragm

eflected waves to travel back down the

ect of the

“cone br

eakup” and causes frequency response

<10%

“outgoing”

and “incoming” waves

CMMD cones consist of a stiff aluminum core, deep-anodized on both sides

(alumina) for increased strength and rigidity. Naturally, no “real world”material

as zero mass or infinite stiffness, but by optimizing the tradeoff between

h

diaphragm thickness (mass) and strength through strategic use of ribbing and

gussets along the diaphragm surface, our engineers were able to achieve the

best balance of electro-acoustic efficiency and reliability.The stiffness in this

arrangement is so high that it pushes the lowest frequency breakup mode outside

f the flat-panel transducer’s region of operation, thereby making it inaudible.

o

SHAPE MATTERS

Aside from providing directivity and baffle size advantages, the shape and size of

he diaphragm used in the flat-panel transducers help to reduce cone breakup or

t

flexing. Reduced cone breakup results in a driver with significantly lower distortion.

The shape of the venerable “cone” transducer results in a certain amount of

stiffness.The shallower a cone-shaped diaphragm is, the more likely its walls will

lex and bend when force is applied to its apex.This is readily demonstrated by

f

using the tip of your finger to push the center of a sheet of paper. Compare this

to pushing at the apex of the same sheet of paper rolled like a cone.This would

indicate that the use of a flat diaphragm could be problematic. The solution was to

increase the area of contact between the edge of the voice coil and the radiating

agm.This was done by adopting a variation on conventional loudspeaker

diaphr

motor design to energize our new flat diaphragm. Our engineers utilized two

large, elliptically shaped voice coils to uniformly couple and distribute motor

force to the surface of the new flat diaphragm. Distributing the mechanical

driving force over a larger area over the diaphragm produces a more uniform

application of motor force across the surface of the diaphragm and greatly aids

in overcoming the inertial effects of the distributed mass of the diaphragm.

To further decrease the likelihood of diaphragm breakup, gussets and raised

ribs were added to the diaphragm. The ribs increase stiffness along the length

from which they are drawn. They further help to distribute and decouple energy

from the voice coils on the rear of the diaphragm.The gussets reinforce the

edge along the outer perimeter of the cone to the point at which the surround

is attached. Both the ribs and the gussets are placed along the height of the

diaphragm at non-harmonically related distances, in order to distribute the

effects of any flexural tendencies to different frequencies, rather than one.

The net result is that the diaphragm moves very nearly like an ideal pistonic

radiator, with all points moving together and in phase.

CORRECT TIME ALIGNMENT

er so that

v

Another method used to combat cone br

it is “uniformly driven,”meaning the panel receives the electrical signal across

.

its entire r

adiating surf

ace

eakup is to engineer the dr

i

Differences in path length related to cone geometry (between signals arriving

from the center and outer edges of the cone) cause a “smearing” of the arrivals

in the time domain (see plot).

This can be seen by noting the width of the impulse response. Note that the flat-

anel diaphragm results in a more concentrated pocket of arrivals compared to

p

that of a cone diaphragm.This helps the Infinity MRS transducer deliver exceptional resolution and detail when compared to conventional transducer systems.

USPENDING THE DIAPHRAGM

S

While developing our low-profile transducer, our transducer engineers needed to

think beyond the traditional geometries that have existed between the cone, spider

and surround.

An examination of a force diagram for conventional-cone/spider/surround

geometry shows that the location of the interface between the outer edge of the

cone and the surround, in relation to the point of application of force from the

voice coil, acts as a ‘fulcrum’ to amplify differential force distributions resulting

from small differences in mass distribution. This instability can cause the cone to

rock back and forth when it moves. This phenomenon resembles a cork riding on a

series of waves in a pond. Ultimately, this can cause the voice coil to scrape the

top plate and buzz. Given that typical production tolerances in materials, as well

as the manufacturing process, contribute to small differences in the distribution

of mass around the moving assembly, this can present audible problems.

Infinity engineers recognized and designed a means (patent pending) to minimize

. By moving the interface between the cone and surround into the same plane

this

as the driving force from the voice coil, the mechanical instability – as well as the

cone’s tendency to rock – is minimized.

This new innovation is so effective that Infinity’s MRS flat-panel transducer

does not need the conventional spider to keep the voice coil centered in the

gap.The same-plane surround limits excursion at the extremes, as well as

keeping the cone and coils well centered at all times.

THE MO

Our primary design goals placed two primary constraints on the choice of motor for

the MRS f

ibutor to the depth of the transducer

contr

of producing relatively high mechanical excursion with minimal distortion and

thermal compression.

ASSEMBL

TOR

lat-panel transducer. First, the motor structure could not be a significant

Y

Second, the motor needed to be capable

.

THE ELLIPTICAL VOICE COIL

The use of elliptically shaped voice coils allows for maximum contact area

between the coils and the diaphragm, as well as placing more wire in the static

agnetic field.

m

As a point of comparison, a typical system using a 6-1/2" woofer might have a

1-1/2"-diameter cylindrical voice coil with 4-11/16 linear inches of voice coil

dge contacting the cone.The unique, elliptically shaped voice coils used in each

e

Infinity flat-panel transducer have a voice coil edge-to-diaphragm contact length

of nearly 30 linear inches – more than 6x that of a typical cone transducer. The

combination of greatly improved diaphragm-to-motor coupling and use of our

atented CMMD diaphragm ensures that the Infinity MRS driver functions more like

p

a true flat piston.This results in crystal-clear sound and resonance-free operation

throughout the operational range.

The advantages offered by our dual elliptical voice coils go beyond the diaphragm

to include motor coupling.The dual elliptical design provides a greatly increased

coil surface area over conventional designs. It is important to note that the

surface area of a transducer’s voice coil is directly related to how much electrical

power can be dissipated. When power is applied to a transducer voice coil, heat

is generated. Most consumer loudspeakers operate with electrical-to-acoustic

efficiencies of less than 5%.This means that for every 100 watts of electrical

power your amplifier produces, your speakers will dissipate 95 watts as heat.

As a voice coil’s temperature increases, thermal compression sets in. As a result,

the dynamic range capability of a speaker system is dramatically reduced.

he MRS design yields 9 squar

T

1-1/2 square inches in a conv

surface area and helping to keep the coil cooler at a given operational level.The

esult is impro

r

than what is found in tr

and movie soundtracks with more clarity and dynamics, as well as less distortion.

ved transient response and dramatically less thermal compression

e inches of v

entional dr

aditional designs

oice coil surf

allowing a large power-dissipating

,

er

v

i

t,

In shor

.

ace area, as opposed to

the MRS driver reproduces music

Selection of an appr

surround interface is the first step to controlling the unwanted “breakup”problem.

The theoretically ideal choice for a diaphragm would be a material that possesses

o mass and infinite stiffness. Zero mass would allow the highest electro-

er

z

acoustic efficiency (the most sound out of your speaker for each watt of amplifier

power) and infinite stiffness would prohibit cone breakup. These considerations

made Infinity’s patented Ceramic Metal Matrix Diaphragm (CMMD

natural choice f

iate diaphr

opr

lat-panel diaphr

or our f

gm material and optimizing the diaphragm/

a

®

) material a

agm.

A transducer diaphragm where all points move together and in phase results

“time domain smear”

in less

when compared to conventional-cone transducers.

as a natural choice for the magnet structure. A neodymium-based

ymium w

Neod

motor structure offers high magnetic energy in a compact, lightweight package.

Neodymium is also inherently magnetically shielded and does not require

additional bucking magnets or shielding cans in order to be safely used near

a video monitor.

The rectangular neodymium slugs are located along the inside of the top edge

of low-carbon steel

frame.The combination of this motor geometry, neodymium magnets and lowcarbon steel rails results in very high magnetic circuit efficiency. Furthermore,

the o

verall height of the magnetic circuit is minimized and is engineered to fit

within the str

“U-channel”

ucture of the transducer frame.

rails mounted vertically within the transducer’s

TS

RESUL

A comparison of cross sections of an MRS flat-panel transducer and a conventionalcone transducer, with similar radiating area, is shown below.The reduced depth

of the Inf

Goal number one (“thin”) has been achiev

driver in visually striking loudspeaker designs. Most important, measurements and

listening evaluations confirm that all the sonic goals have been met, resulting in

unsurpassed sonic perf

inity MRS tr

ansducer relative to a conventional device is clearly shown.

his allows the use of the MRS

ed.T

.

mance

or

Loading...

Loading...