Page 1

MAINTENANCE

GI

CONTENTS

PRECAUTIONS ...............................................................2

Precautions for Supplemental Restraint System

(SRS) ″AIR BAG″ and ″SEAT BELT

PRE-TENSIONER″......................................................2

PREPARATION ...............................................................3

Special Service Tool....................................................3

Commercial Service Tool.............................................3

GENERAL MAINTENANCE............................................4

PERIODIC MAINTENANCE ............................................6

Schedule 1...................................................................7

EMISSION CONTROL SYSTEM MAINTENANCE

CHASSIS AND BODY MAINTENANCE

Schedule 2...................................................................9

EMISSION CONTROL SYSTEM MAINTENANCE

CHASSIS AND BODY MAINTENANCE

RECOMMENDED FLUIDS AND LUBRICANTS...........11

Fluids and Lubricants ................................................11

SAE Viscosity Number ..............................................11

GASOLINE ENGINE OIL

Anti-freeze Coolant Mixture Ratio .............................12

ENGINE MAINTENANCE..............................................13

Checking Drive Belts.................................................13

Changing Engine Coolant..........................................14

- DRAINING ENGINE COOLANT -

- REFILLING ENGINE COOLANT -

- FLUSHING COOLING SYSTEM -

Checking Fuel Lines..................................................16

Changing Air Cleaner Filter .......................................17

VISCOUS PAPER TYPE

Changing Engine Oil..................................................17

..........................................11

...........................................17

........................8

......................10

............................14

...........................15

............................16

.........7

.........9

SECTION

Changing Oil Filter.....................................................18

Changing Spark Plugs...............................................18

Checking EVAP Vapor Lines.....................................20

CHASSIS AND BODY MAINTENANCE.......................21

Checking Exhaust System.........................................21

Checking A/T Fluid ....................................................21

Changing A/T Fluid....................................................22

Balancing Wheels (Bonding Weight Type)................22

REMOVAL

WHEEL BALANCE ADJUSTMENT

Tire Rotation..............................................................24

Checking Brake Fluid Level and Leaks.....................24

Checking Brake Lines and Cables............................24

Checking Disc Brake.................................................24

ROTOR

CALIPER

PAD

Checking Steering Gear and Linkage.......................25

STEERING GEAR

STEERING LINKAGE

Checking Power Steering Fluid and Lines................25

Lubricating Locks, Hinges and Hood Latches...........26

Checking Seat Belts, Buckles, Retractors,

Anchors and Adjusters...............................................26

SERVICE DATA AND SPECIFICATIONS (SDS).........27

Engine Maintenance..................................................27

BELT DEFLECTION AND TENSION

SPARK PLUG

Chassis and Body Maintenance................................27

WHEEL BALANCE

...............................................................22

...................................................................24

.................................................................25

........................................................................25

..........................................................27

MA

............................22

....................................................25

...............................................25

..........................27

...................................................27

EM

LC

EC

FE

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

Page 2

PRECAUTIONS

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT BELT PRE-TENSIONER”

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT

PRE-TENSIONER”

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELTPRE-TENSIONER” used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS system composition which is available to INFINITI I30 is as follows (The composition varies according to optional equipment.):

I For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steering wheel), front passenger air bag module (located on the instrument panel on passenger side), seat belt

pre-tensioners, a diagnosis sensor unit, crash zone sensor, warning lamp, wiring harness and spiral cable.

I For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), satellite sensor, diagnosis sensor unit (one of components of air bags for a frontal collision), wiring

harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in the RS section of this Service Manual.

WARNING:

I To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be performed by an authorized INFINITI dealer.

I Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

I Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified with yellow harness connector (and with

yellow harness protector or yellow insulation tape before the harness connectors).

NHMA0034

MA-2

Page 3

PREPARATION

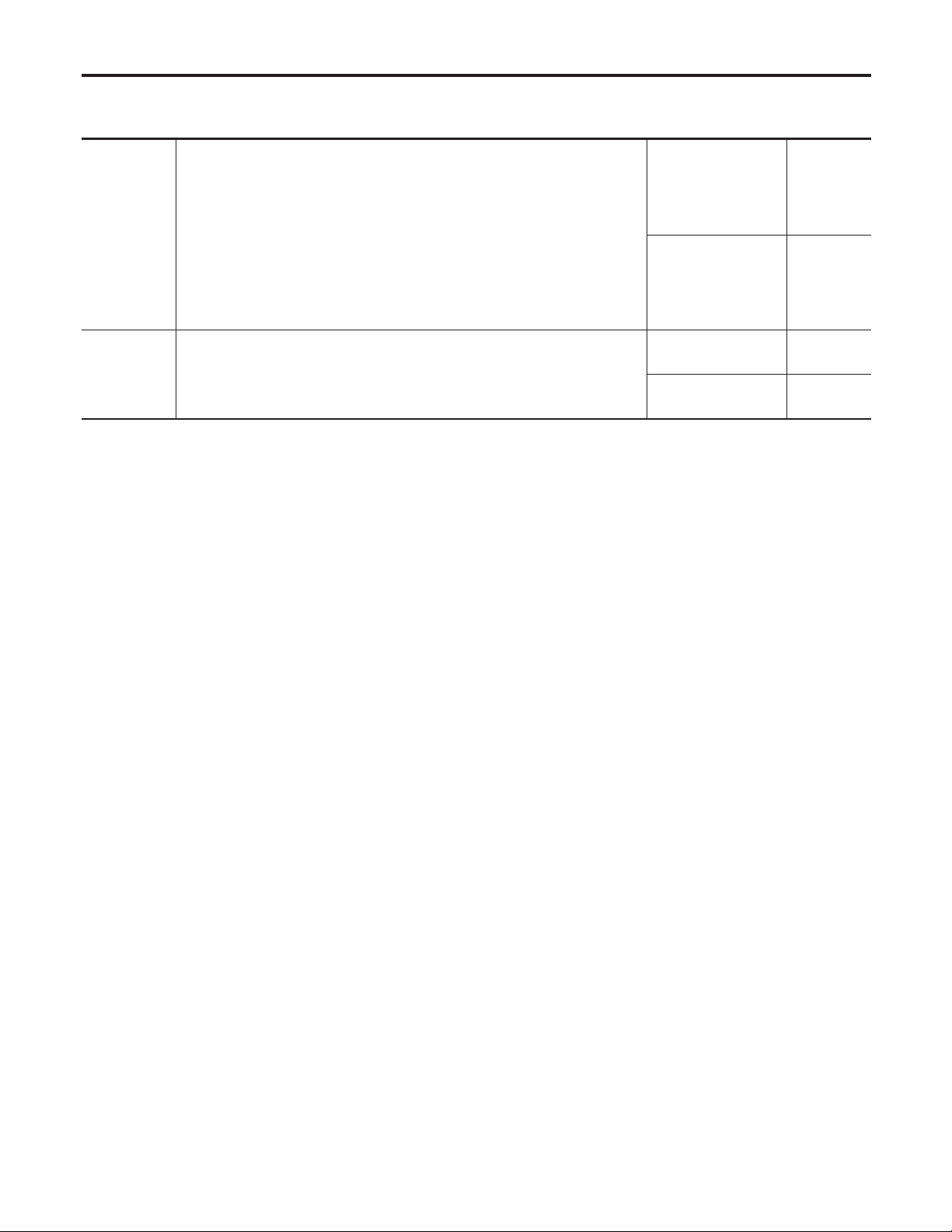

Special Service Tool

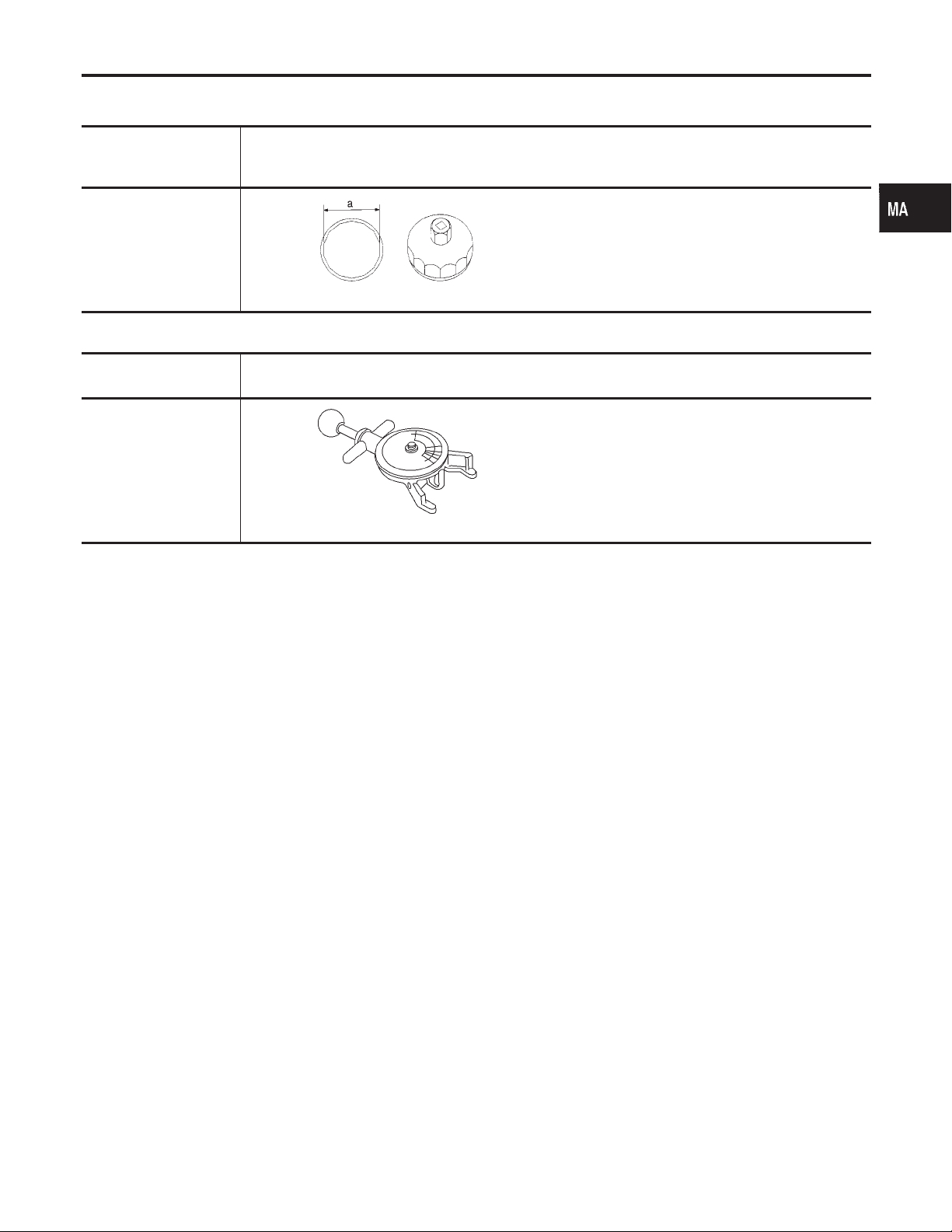

Special Service Tool

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool name

KV10115801

(J38956)

Oil filter cap wrench

Description

Removing oil filter

a: 64.3 mm (2.531 in)

NT375

Commercial Service Tool

Tool name

(Kent-Moore No.)

Belt tension gauge

(BT3373-F)

Description

Checking drive belt tension

AMA126

NHMA0002

GI

EM

LC

NHMA0003

EC

FE

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

MA-3

Page 4

NHMA0004

GENERAL MAINTENANCE

General maintenance includes those items which should be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform

checks and inspections themselves or have their INFINITI dealers do them.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

Item Reference page

Tires Check the pressure with a gauge periodically when at a service station,

including the spare, and adjust to the specified pressure if necessary. Check

carefully for damage, cuts or excessive wear.

—

Wheel nuts When checking the tires, make sure no nuts are missing, and check for any

loose nuts. Tighten if necessary.

Tire rotation Tires should be rotated every 12,000 km (7,500 miles). MA-24

Wheel alignment and

balance

Windshield wiper

blades

Doors and engine

hood

Lamps Make sure that the headlamps, stop lamps, tail lamps, turn signal lamps, and

If the vehicle pulls to either side while driving on a straight and level road, or

if you detect uneven or abnormal tire wear, there may be a need for wheel

alignment. If the steering wheel or seat vibrates at normal highway speeds,

wheel balancing may be needed.

Check for cracks or wear if they do not wipe properly. —

Check that all doors and the engine hood operate smoothly as well as the

trunk lid and back hatch. Also make sure that all latches lock securely. Lubricate if necessary. Make sure that the secondary latch keeps the hood from

opening when the primary latch is released.

When driving in areas using road salt or other corrosive materials, check

lubrication frequently.

other lamps are all operating properly and installed securely. Also check

headlamp aim.

SU-7, “Preliminary

—

MA-22,

Inspection”

MA-26

—

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the

vehicle, etc.

Item Reference page

Warning lamps and

chimes

Windshield wiper and

washer

Windshield defroster Check that the air comes out of the defroster outlets properly and in suffi-

Steering wheel Check that it has the specified play. Be sure to check for changes in the

Seats Check seat position controls such as seat adjusters, seatback recliner, etc. to

Seat belts Check that all parts of the seat belt system (e.g. buckles, anchors, adjusters

Accelerator pedal Check the pedal for smooth operation and make sure the pedal does not

Brakes Check that the brake does not pull the vehicle to one side when applied. —

Make sure that all warning lamps and chimes are operating properly. —

Check that the wipers and washer operate properly and that the wipers do

not streak.

cient quantity when operating the heater or air conditioner.

steering condition, such as excessive play, hard steering or strange noises.

Free play: Less than 35 mm (1.38 in)

make sure they operate smoothly and that all latches lock securely in every

position. Check that the head restrains move up and down smoothly and that

the locks (if equipped) hold securely in all latched positions. Check that the

latches lock securely for folding-down rear seatbacks.

and retractors) operate properly and smoothly and are installed securely.

Check the belt webbing for cuts, fraying, wear or damage.

catch or require uneven effort. Keep the floor mats away from the pedal.

RS-9, “Seat Belt

—

—

—

—

MA-26

Inspection”

—

MA-4

Page 5

GENERAL MAINTENANCE

Item Reference page

Brake pedal and

booster

Parking brake Check that the lever has the proper travel and make sure that the vehicle is

Automatic transaxle

“Park” mechanism

Check the pedal for smooth operation and make sure it has the proper distance under it when depressed fully. Check the brake booster function. Be

sure to keep floor mats away from the pedal.

held securely on a fairly steep hill when only the parking brake is applied.

Check that the lock release button on the selector lever operates properly

and smoothly. On a fairly steep hill check that the vehicle is held securely

with the selector lever in the “P” position without applying any brakes.

BR-13, “Brake Pedal

and Bracket” and

BR-21, “Brake Booster”

BR-37, “Parking Brake

Control”

—

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically (e.g. each time you check the engine oil or refuel).

Item Reference page

Windshield washer

fluid

Engine coolant level Check the coolant level when the engine is cold. MA-15

Radiator and hoses Check the front of the radiator and clean off any dirt, insects, leaves, etc.,

Brake fluid level Make sure that the brake fluid level is between the “MAX” and “MIN” lines on

Battery Check the fluid level in each cell. It should be between the “MAX” and “MIN”

Check that there is adequate fluid in the tank. —

that may have accumulated. Make sure the hoses have no cracks,

deformation, deterioration or loose connections.

the reservoir.

lines.

—

MA-24

—

GI

EM

LC

EC

FE

AT

AX

SU

Engine drive belts Make sure that no belt is frayed, worn, cracked or oily. MA-13

Engine oil level Check the level on the dipstick after parking the vehicle on a level spot and

turning off the engine.

Power steering fluid

level and lines

Automatic transaxle

fluid level

Exhaust system Make sure there are no loose supports, cracks or holes. If the sound of the

Underbody The underbody is frequently exposed to corrosive substances such as those

Fluid leaks Check under the vehicle for fuel, oil, water or other fluid leaks after the

Check the level on the dipstick with the engine off. Check the lines for

improper attachment, leaks, cracks, etc.

Check the level on the dipstick after putting the selector lever in “P” with the

engine idling.

exhaust seems unusual or there is a smell of exhaust fumes, immediately

locate the trouble and correct it.

used on icy roads or to control dust. It is very important to remove these

substances, otherwise rust will form on the floor pan, frame, fuel lines and

around the exhaust system. At the end of winter, the underbody should be

thoroughly flushed with plain water, being careful to clean those areas where

mud and dirt can easily accumulate.

vehicle has been parked for a while. Water dripping from the air conditioner

after use is normal. If you should notice any leaks or gasoline fumes are

evident, check for the cause and correct it immediately.

MA-17

MA-25

MA-21

MA-21

—

—

BR

ST

RS

BT

HA

SC

EL

IDX

MA-5

Page 6

NHMA0005

PERIODIC MAINTENANCE

Two different maintenance schedules are provided, and should be used, depending upon the conditions in

which the vehicle is mainly operated. After 60,000 miles (96,000 km) or 48 months, continue the periodic

maintenance at the same mileage/time intervals.

Schedule 1

Schedule 2

Follow Periodic Maintenance Schedule 1 if the driving habits frequently

include one or more of the following driving conditions:

I Repeated short trips of less than 5 miles (8 km).

I Repeated short trips of less than 10 miles (16 km) with outside tempera-

tures remaining below freezing.

I Operating in hot weather in stop-and-go “rush hour” traffic.

I Extensive idling and/or low speed driving for long distances, such as

police, taxi or door-to-door delivery use.

I Driving in dusty conditions.

I Driving on rough, muddy, or salt spread roads.

I Towing a trailer, using a camper or a car-top carrier.

Follow Periodic Maintenance Schedule 2 if none of driving conditions shown

in Schedule 1 apply to the driving habits.

Emission Control

System Maintenance

Chassis and Body

Maintenance

Emission Control

System Maintenance

Chassis and Body

Maintenance

MA-7

MA-8

MA-9

MA-10

MA-6

Page 7

PERIODIC MAINTENANCE

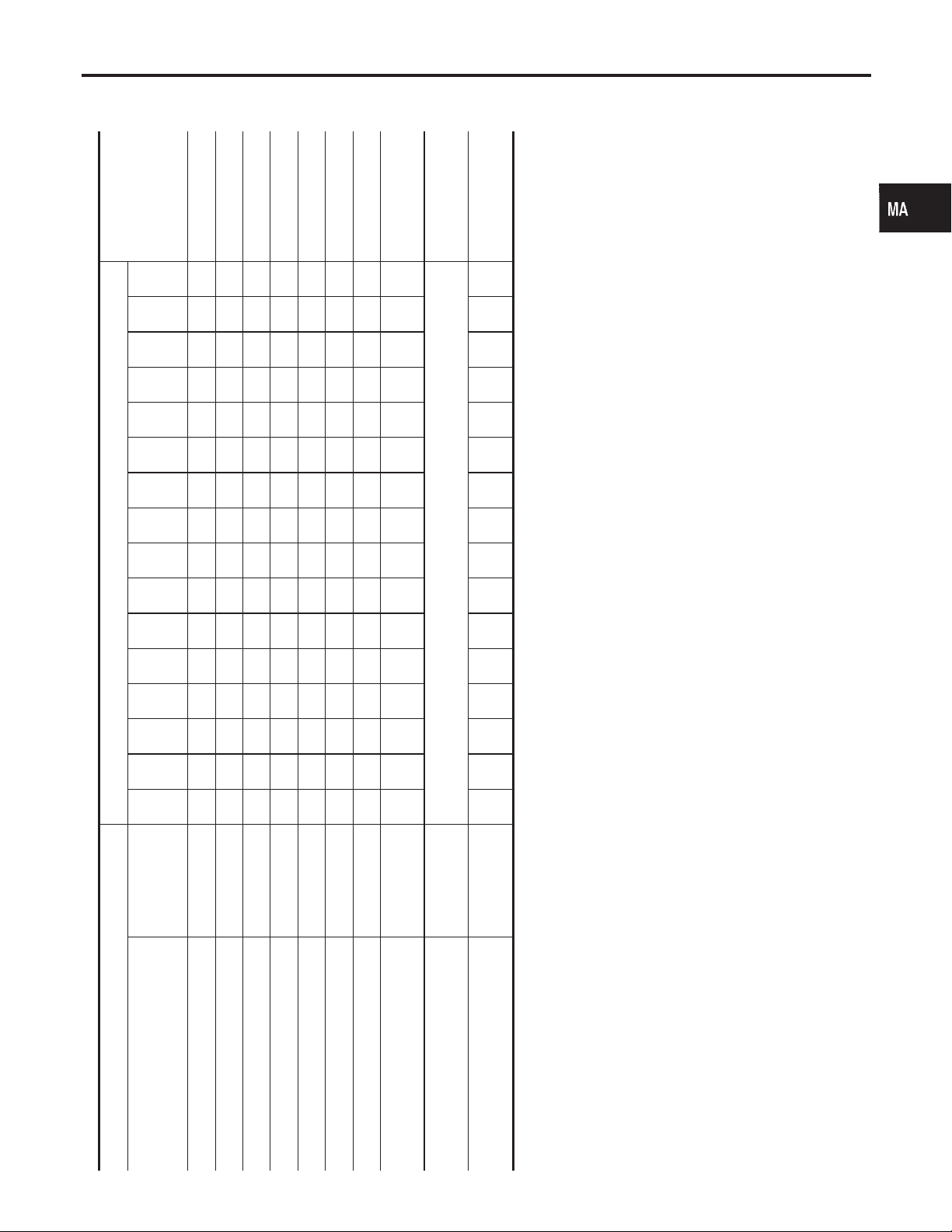

Schedule 1

Schedule 1

EMISSION CONTROL SYSTEM MAINTENANCE

or

- Page

60

56.3

52.5

48.8

45

41.3

37.5

33.8

- Content Title

(96)

(90)

(84)

(78)

(72)

(66)

(60)

(54)

48

45

42

39

36

33

30

27

Reference Section

NHMA0005S01

NHMA0005S0101

GI

Clearance”

EM-51, “Valve

EM

LC

EC

FE

AT

AX

Abbreviations: R = Replace. I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

30

(48)

(42)

26.3

(36)

22.5

(30)

18.8

15

(24)

(18)

11.3

7.5

(12)

(6)

3.8

(km x 1,000)

Miles x 1,000

24

21

18

15

12

9

6

3

Months

SU

BR

Replace every 105,000 miles (169,000 km). MA-18

ST

RS

BT

RRRRRRRRRRRRRRRR MA-18

HA

SC

EL

IDX

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform at number of miles, kilome-

ters or months, whichever comes

first.

Drive belts NOTE (1) I* MA-13

Air cleaner filter NOTE (2) [R] [R] MA-17

EVAP vapor lines I* I* MA-20

Fuel lines I* I* MA-16

Fuel filter NOTE (3)

Engine coolant NOTE (4) R* MA-15

Engine oil RRRRRRRRRRRRRRRR MA-17

Engine oil filter (Use part No. 15208-

31U00 or equivalent.)

Spark plugs (PLATINUM-TIPPED

type)

Intake & exhaust valve clearance* NOTE (5)

MA-7

NOTE:

(1) After 60,000 miles (96,000 km) or 48 months, inspect every 15,000 miles (24,000 km) or 12 months.

(2) If operating mainly in dusty conditions, more frequent maintenance may be required.

(3) Maintenance-free item. For service procedures, refer to FE section.

(4) After 60,000 miles (96,000 km) or 48 months, replace every 30,000 miles (48,000 km) or 24 months.

(5) If valve noise increases, inspect valve clearance.

★ Maintenance items and intervals with “*” are recommended by INFINITI for reliable vehicle operation. The owner need not perform such maintenance in order to maintain the

emission warranty or manufacturer recall liability. Other maintenance items and intervals are required.

Page 8

Schedule 1 (Cont’d)

PERIODIC MAINTENANCE

CHASSIS AND BODY MAINTENANCE

Abbreviations: R = Replace, I = Inspect. Correct or replace if necessary.

or

- Page

Section

Reference

60

(96)

(90)

56.3

(84)

52.5

(78)

48.8

45

(72)

(66)

41.3

(60)

37.5

(54)

33.8

30

(48)

- Content Title

48

45

42

39

36

33

30

27

24

MA-25

NOTE (3)

SHAFT”

AX-4, “DRIVE

nance Items”

RS-19, “Mainte-

tion Air Filter”

HA-123, “Ventila-

CHECK”

EL-297, “ASCD

ACTUATOR/PUMP

NHMA0005S0102

(42)

26.3

(36)

22.5

(30)

18.8

15

(24)

(18)

11.3

7.5

(12)

(6)

3.8

(km x 1,000)

Miles x 1,000

21

18

15

12

9

6

3

Months

IIIIIIII

NOTE (2)

Tire rotation NOTE (4) MA-4

Front drive shaft boots IIIIIIII

Exhaust system IIIIIIIIMA-21

Supplemental air bag system and

supplemental side air bag systems

Brake lines & cables IIIIMA-24

Brake pads & rotors IIIIIIIIMA-24

Automatic transaxle fluid NOTE (1) IIIIMA-21

Steering gear & linkage, axle & sus-

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform at number of miles, kilome-

ters or months, whichever comes

first.

pension parts

Ventilation air filter IRIRIRIR

ASCD vacuum hoses IIII

NOTE:

(1) If towing a trailer, using a camper or a car-top carrier, or driving on rough or muddy roads, change (not just inspect) oil at every 30,000 miles (48,000 km) or 24 months.

(2) Inspect the supplemental air bag systems 10 years after the date of manufacture noted on the FMVSS certification label.

(3) Refer to SU-6, “Front Suspention Parts”, SU-19, “Rear Suspention Parts”, AX-3, “Front Axle Parts” and AX-18, “Rear Axle Parts”.

(4) Refer to “Tire rotation” under the “General maintenance” heading earlier in this section.

MA-8

Page 9

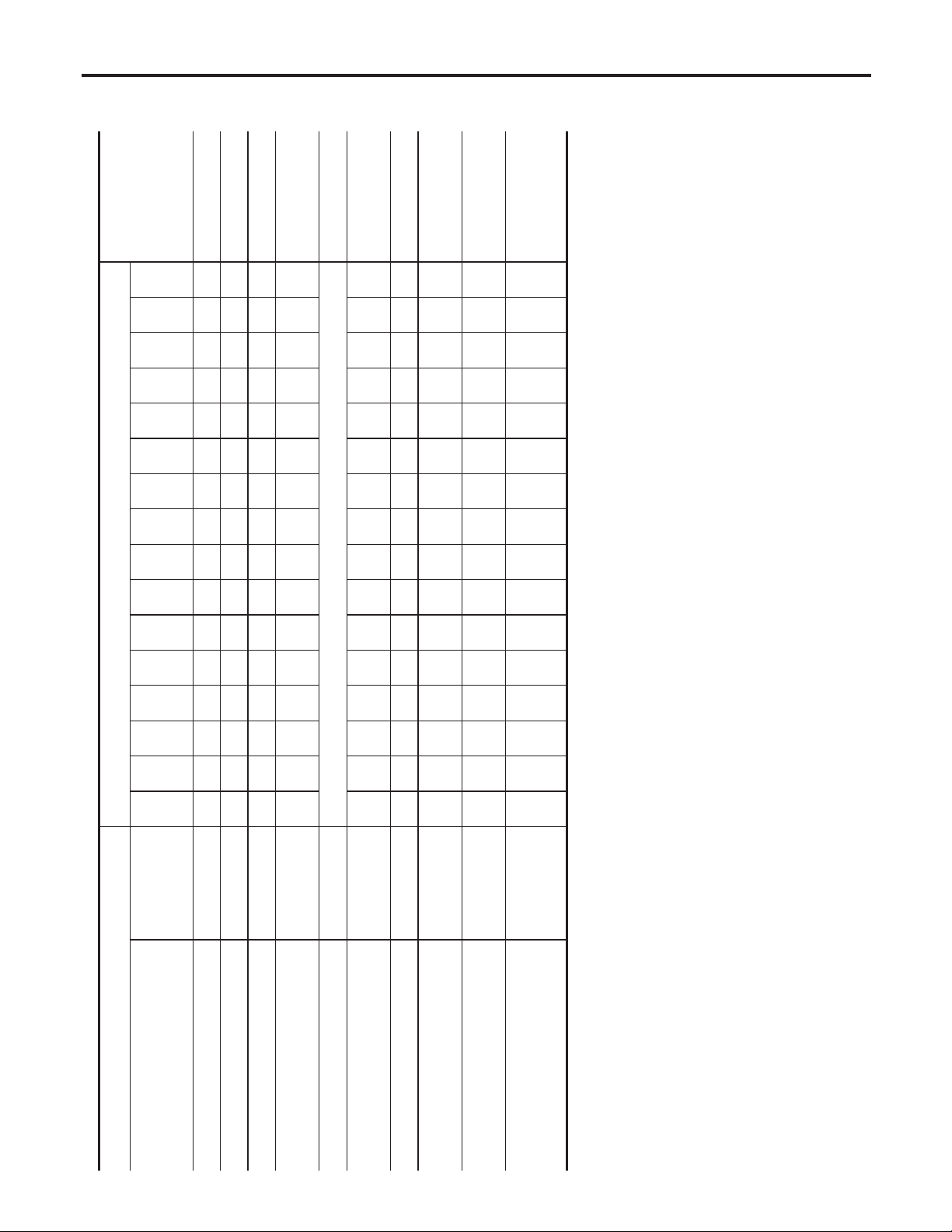

PERIODIC MAINTENANCE

Schedule 2

Schedule 2

EMISSION CONTROL SYSTEM MAINTENANCE

or

- Page

60

52.5

45

37.5

- Content Title

(96)

(84)

(72)

(60)

48

42

36

30

Reference Section

ance”

EM-51, “Valve Clear-

NHMA0005S02

NHMA0005S0201

GI

EM

LC

EC

FE

AT

AX

Abbreviations: R = Replace. I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

30

(48)

(36)

22.5

15

(24)

7.5

(12)

(km x 1,000)

Miles x 1,000

24

18

12

6

Months

RRRRRRRR MA-18

SU

BR

ST

RS

BT

HA

SC

EL

IDX

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform at number of miles, kilometers

or months, whichever comes first.

Drive belts NOTE (1) I* MA-13

Air cleaner filter [R] [R] MA-17

EVAP vapor lines I* I* MA-20

Fuel lines I* I* MA-16

Fuel filter NOTE (2)

Engine coolant NOTE (3) R* MA-15

Engine oil RRRRRRRR MA-17

Engine oil filter (Use part No. 15208-

31U00 or equivalent.)

Spark plugs (PLATINUM-TIPPED type) Replace every 105,000 miles (169,000 km). MA-18

MA-9

Intake & exhaust valve clearance* NOTE (4)

NOTE:

(1) After 60,000 miles (96,000 km) or 48 months, inspect every 15,000 miles (24,000 km) or 12 months.

(2) Maintenance-free item. For service procedures, refer to FE section.

(3) After 60,000 miles (96,000 km) or 48 months, replace every 30,000 miles (48,000 km) or 24 months.

(4) If valve noise increases, inspect valve clearance.

★ Maintenance items and intervals with “*” are recommended by INFINITI for reliable vehicle operation. The owner need not perform such maintenance in order to maintain the

emission warranty or manufacturer recall liability. Other maintenance items and intervals are required.

Page 10

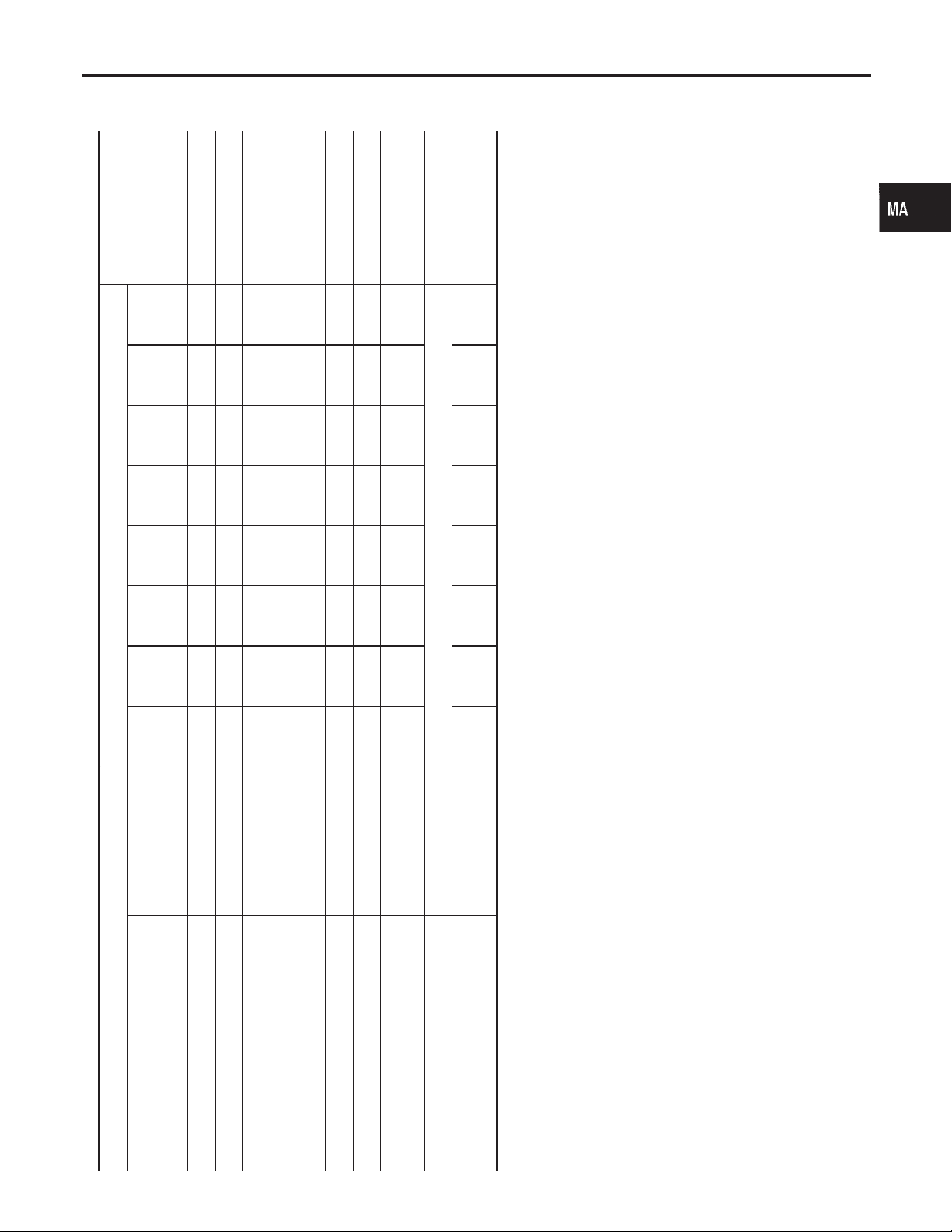

Schedule 2 (Cont’d)

PERIODIC MAINTENANCE

CHASSIS AND BODY MAINTENANCE

- Page

Reference Section

60

52.5

45

37.5

or

- Content Title

(96)

(84)

(72)

(60)

48

42

36

30

MA-25

NOTE (2)

Filter”

Items”

RS-19, “Maintenance

HA-123, “Ventilation Air

CHECK”

EL-297, “ASCD

ACTUATOR/PUMP

NHMA0005S0202

Abbreviations: R = Replace, I = Inspect. Correct or replace if necessary.

30

(48)

(36)

22.5

15

(24)

7.5

(12)

(km x 1,000)

Miles x 1,000

24

18

12

6

Months

II

NOTE (1)

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform at number of miles, kilometers

or months, whichever comes first.

Brake lines & cables IIIIMA-24

Brake pads & rotors IIIIMA-24

Automatic transaxle fluid IIIIMA-21

Steering gear & linkage, axle & suspen-

sion parts

Tire rotation NOTE (3) MA-4

Front drive shaft boots IIIIAX-4, “Drive Shaft”

Exhaust system I I MA-21

Supplemental air bag system and

supplemental side iar bag systems

Ventilation air filter RRRR

ASCD vacuum hoses IIII

NOTE:

(1) Inspect the supplemental air bag systems 10 years after the date of manufacture noted on the FMVSS certification label.

(2) Refer to SU-6, “Front Suspention Parts”, SU-19, “Rear Suspension Parts”, AX-3, “Front Axle Parts” and AX-18, “Rear Axle Parts”.

(3) Refer to “Tire rotation” under the “General maintenance” heading earlier in this section.

MA-10

Page 11

RECOMMENDED FLUIDS AND LUBRICANTS

NHMA0006

Fluids and Lubricants

Fluids and Lubricants

Capacity (Approximate)

US measure Imp measure Liter

With oil filter

Engine oil

Drain and refill

Dry engine (engine overhaul) 5-1/8 qt 4-1/4 qt 4.8

Cooling system

Automatic transaxle fluid

Power steering fluid — — — Genuine NISSAN PSF II or equivalent*4

Brake fluid — — —

Multi-purpose grease — — — NLGI No. 2 (Lithium soap base)

*1: For further details, see “SAE Viscosity Number”.

*2: Dexron

ership for more information regarding suitable fluids, including recommended brand(s) of Dexron

sion Fluid.

*3: Available in mainland U.S.A. through your INFINITI dealer.

*4: Genuine Nissan PSF, Canada NISSAN Automatic Transmission Fluid, Dexron

TM

change

Without oil filter

change

With reservoir 8-1/8 qt 6-3/4 qt 7.7

Reservoir 3/4 qt 5/8 qt 0.7

RE4F04B/

RE4F04W

III/MerconTMor equivalent may also be used. Outside the continental United States and Alaska contact an INFINITI deal-

4-1/4 qt 3-1/2 qt 4.0

3-7/8 qt 3-1/4 qt 3.7

10 qt 8-1/4 qt 9.4

TM

III/MerconTM, or equivalent ATF may also be used.

Recommended Fluids/Lubricants

I API Certification Mark*1

I API grade SG/SH, Energy Conserving I &

II or API grade SJ, Energy Conserving*1

I ILSAC grade GF-I & GF-II*1

Genuine Nissan Anti-freeze coolant or

equivalent

Nissan Matic “D” (Continental U.S. and

Alaska) or Canada NISSAN Automatic Transmission Fluid*2

Genuine Nissan Brake Fluid*3 or equivalent

DOT 3 (US FMVSS No. 116)

TM

III/MerconTMAutomatic Transmis-

NHMA0006S01

GI

EM

LC

EC

FE

AT

AX

SU

SAE Viscosity Number

GASOLINE ENGINE OIL

NHMA0006S02

NHMA0006S0203

SAE 5W-30 viscosity oil is preferred for all temperatures. SAE

10W-30 and 10W-40 viscosity oil may be used if the ambient temperature is above −18°C (0°F).

BR

ST

RS

BT

HA

SC

EL

IDX

MMA117AA

MA-11

Page 12

RECOMMENDED FLUIDS AND LUBRICANTS

Anti-freeze Coolant Mixture Ratio

SMA947CA

Anti-freeze Coolant Mixture Ratio

NHMA0006S03

The engine cooling system is filled at the factory with a high-quality,

year-round, anti-freeze coolant solution. The anti-freeze solution

contains rust and corrosion inhibitors. Therefore, additional cooling

system additives are not necessary.

CAUTION:

When adding or replacing coolant, be sure to use only Genuine Nissan anti-freeze coolant or equivalent with the proper

mixture ratio of 50% anti-freeze and 50% demineralized water/

distilled water.

Other types of coolant solutions may damage your cooling

system.

MA-12

Page 13

ENGINE MAINTENANCE

Checking Drive Belts

Checking Drive Belts

NHMA0007

GI

EM

LC

EC

FE

AT

AX

Belt deflection and tension:

With air conditioner compressor

Alternator

Without air conditioner compressor

Limit

7 (0.28)

10 (0.39)

1. Inspect belts for cracks, fraying, wear and oil. If necessary,

replace.

2. Inspect drive belt deflection or tension at a point on the belt

midway between pulleys.

I Check belt tension using belt tension gauge (BT 3373-F or

equivalent).

I Inspect drive belt deflection or tension when engine is

cold.

Adjust if belt deflection exceeds the limit or if belt tension is

not within specifications.

I Drive belt tension can also be checked at other points on

the belts.

Deflection adjustment

Unit: mm (in)

Used belt

After adjust-

ment

4.2 - 4.6

(0.165 - 0.181)

6.3 - 6.9

(0.248 - 0.272)

New belt

3.7 - 4.1

(0.146 - 0.161)

5.6 - 6.0

(0.220 - 0.236)

Used belt

Limit

294 (30, 66)

294 (30, 66)

Tension adjustment*1

Unit: N (kg, lb)

After adjust-

ment

730 - 818

(74.5 - 83.5,

164 - 184)

730 - 818

(74.5 - 83.5,

164 - 184)

SU

SMA804CB

BR

ST

RS

BT

HA

SC

EL

New belt

IDX

838 - 926

(85.45 - 94.43,

188.4 - 208.2)

838 - 926

(85.45 - 94.43,

188.4 - 208.2)

MA-13

Page 14

Checking Drive Belts (Cont’d)

ENGINE MAINTENANCE

Deflection adjustment

Unit: mm (in)

Used belt

Limit

Power steering oil pump 11 (0.43)

Applied pushing force 98 N (10 kg, 22 lb) —

*1: If the belt tension gauge cannot be installed at check points shown, check drive belt tension at a different location on the belt.

After adjust-

ment

7.3 - 8 (0.287 -

0.315)

New belt

6.5 - 7.2

(0.256 - 0.283)

Limit

196 (20, 44)

Changing Engine Coolant

Tension adjustment*1

Unit: N (kg, lb)

Used belt

After adjust-

ment

495 - 583

(50.5 - 59.5,

111 - 131)

New belt

603 - 691

(61.5 - 70.5,

136 - 155)

NHMA0008

WARNING:

To avoid the danger of being scalded, never change the coolant when the engine is hot.

SMA032D

SMA033D

— DRAINING ENGINE COOLANT —

NHMA0008S01

1. Set air conditioning system as follows to prevent coolant from

remaining in the system.

a. Turn ignition switch ON and set temperature controller to maxi-

mum hot position.

b. Wait 10 seconds before turning ignition switch OFF.

2. Open radiator drain plug at the bottom of radiator, and remove

radiator filler cap.

3. Remove reservoir tank, drain coolant, then clean reservoir

tank.

I Be careful not to allow coolant to contact drive belts.

MA-14

Page 15

ENGINE MAINTENANCE

4. Remove drain plugs on both sides of cylinder block and air

relief plug.

5. Check drained coolant for contaminants such as rust, corrosion or discoloration. If contaminated flush engine cooling

system, refer to “FLUSHING COOLING SYSTEM”, MA-16.

SMA034D

Changing Engine Coolant (Cont’d)

GI

EM

LC

EC

FE

AT

SMA953CA

— REFILLING ENGINE COOLANT —

1. Install reservoir tank, and radiator drain plug.

2. Close and tighten cylinder block drain plugs securely.

I Apply sealant to the thread of cylinder block drain plugs.

: 60 - 66 N·m (6.1 - 6.7 kg-m, 44 - 48 ft-lb) Left side

: 18 - 22 N·m (1.8 - 2.2 kg-m, 13 - 16 ft-lb) Right side

3. Fill radiator slowly with coolant until coolant spills from the air

relief plug, then install air relief plug.

Air relief plug:

: 6.9 - 7.8 N·m (0.7 - 0.8 kg-m, 61 - 69 in-lb)

I Use genuine Nissan anti-freeze coolant or equivalent

mixed with water (distilled or demineralized).

NHMA0008S02

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

MA-15

Page 16

Changing Engine Coolant (Cont’d)

ENGINE MAINTENANCE

Refer to “RECOMMENDED FLUIDS AND LUBRICANTS”,

MA-11.

Engine coolant capacity (With reservoir tank):

7.7 (8-1/8 US qt, 6-3/4 Imp qt)

Reservoir tank capacity:

0.7 (3/4 US qt, 5/8 Imp qt)

I Pour coolant through coolant filler neck slowly to allow air

in system to escape.

4. Fill radiator and reservoir tank to specified level.

SMA182B

SMA412B

5. Warm up engine to normal operating temperature without

radiator cap installed.

I If coolant overflows radiator filler hole, install filler cap.

6. Run engine at 2,500 rpm for 10 seconds and return to idle

speed with radiator cap installed.

I Repeat two or three times.

Watch coolant temperature gauge so as not to overheat the

engine.

7. Stop engine and cool it down.

I Cool down using a fan to reduce the time.

I If necessary, refill radiator up to filler neck with coolant.

8. Refill reservoir tank to MAX level line with coolant.

9. Repeat steps 5 through 8 two or more times with radiator cap

installed until coolant level no longer drops.

10. Check cooling system for leaks with engine running.

11. Warm up engine, and check for sound of coolant flow while

running engine from idle up to 3,000 rpm with heater temperature controller set at several positions between COOL and

WARM.

I Sound may be noticeable at heater water cock.

12. If sound is heard, bleed air from cooling system by repeating

steps 5 through 8 until coolant level no longer drops

I Clean excess coolant from engine.

SMA803A

— FLUSHING COOLING SYSTEM —

NHMA0008S03

1. Open air relief plug.

2. Fill radiator with water until water spills from the air relief hole,

then close air relief plug. Fill radiator and reservoir tank with

water and reinstall radiator cap.

3. Run engine and warm it up to normal operating temperature.

4. Rev engine two or three times under no-load.

5. Stop engine and wait until it cools down.

6. Drain water.

7. Repeat steps 1 through 6 until clear water begins to drain from

radiator.

Checking Fuel Lines

NHMA0009

Inspect fuel lines and tank for improper attachment, leaks, cracks,

damage, loose connections, chafing or deterioration. If necessary,

repair or replace faulty parts.

MA-16

Page 17

ENGINE MAINTENANCE

CAUTION:

Tighten high-pressure rubber hose clamp so that clamp end is

3 mm (0.12 in) from hose end.

Tightening torque specifications are the same for all rubber

hose clamps.

Ensure that screw does not contact adjacent parts.

MMA104A

Checking Fuel Lines (Cont’d)

GI

EM

SMA037D

SMA038D

Changing Air Cleaner Filter

VISCOUS PAPER TYPE

The viscous paper type filter does not need cleaning.

Changing Engine Oil

WARNING:

I Be careful not to burn yourself, as the engine oil is hot.

I Prolonged and repeated contact with used engine oil may

cause skin cancer; try to avoid direct skin contact with

used oil. If skin contact is made, wash thoroughly with

soap or hand cleaner as soon as possible.

1. Warm up engine, and check for oil leakage from engine components.

2. Stop engine and wait more than 10 minutes.

3. Remove drain plug and oil filler cap.

4. Drain oil and refill with new engine oil.

Oil specification and viscosity:

I API Certification Mark

I API grade SG/SH, Energy ConservingI&IIorAPIgrade

SJ, Energy Conserving

I ILSAC grade GF-I & GF-II

I Refer to “RECOMMENDED FLUIDS AND LUBRICANTS”,

MA-11.

Oil capacity (Approximate):

Unit: liter (US qt, Imp qt)

With oil filter change 4.0 (4-1/4, 3-1/2)

Drain and refill

Without oil filter

change

3.7 (3-7/8, 3-1/4)

NHMA0011

NHMA0011S01

NHMA0012

LC

EC

FE

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

Dry engine (engine overhaul) 4.8 (5-1/8, 4-1/4)

CAUTION:

I Be sure to clean drain plug and install with new washer.

Oil pan drain plug:

: 29 - 39 N·m (3.0 - 4.0 kg-m, 22 - 29 ft-lb)

MA-17

Page 18

Changing Engine Oil (Cont’d)

ENGINE MAINTENANCE

I The refill capacity depends on the oil temperature and

drain time. Use these specifications for reference only.

Always use the dipstick to determine when the proper

amount of oil is in the engine.

I Never pull out level gauge while filling engine oil.

5. Warm up engine and check area around drain plug and oil filter for oil leakage.

6. Stop engine and wait more than 10 minutes.

7. Check oil level.

SMA954C

SMA039D

SMA010

Changing Oil Filter

NHMA0013

1. The oil filter is a small full-flow cartridge type and is provided

with a relief valve.

Refer to LC-7, “Oil Filter”.

2. Remove oil filter with Tool or suitable tool.

WARNING:

Be careful not to burn yourself, as the engine and the engine

oil are hot.

3. Clean oil filter mounting surface on cylinder block. Coat rubber

seal of new oil filter with engine oil.

4. Screw in the oil filter until a slight resistance is felt, then tighten

additionally 2/3 turn.

5. Add engine oil.

Oil filter:

: 14.7 - 20.5 N·m (1.5 - 2.1 kg-m, 11 - 15 ft-lb)

Refer to “Changing Engine Oil”, MA-17.

SMA229B

SMA040D

Changing Spark Plugs

NHMA0014

1. Remove left side rocker cover ornament.

2. Disconnect ignition coil harness connectors.

3. Loosen ignition coil fixing bolts and pull out coil from intake

manifold connector.

MA-18

Page 19

ENGINE MAINTENANCE

Changing Spark Plugs (Cont’d)

4. Remove spark plugs with suitable spark plug wrench.

Spark plug (Platinum-tipped type):

Make NGK

Standard type PFR5G-11

Hot type PFR4G-11

Cold type PFR6G-11

GI

SEM294A

Use standard type spark plug for normal condition.

The hot type spark plug is suitable when fouling may occur with the

standard type spark plug such as:

I frequent engine starts

I low ambient temperatures

The cold type spark plug is suitable when spark knock may occur

with the standard type spark plug such as:

I extended highway driving

I frequent high engine revolution

Gap (Nominal): 1.1 mm (0.043 in)

: 20 - 29 N·m (2.0 - 3.0 kg-m, 14 - 22 ft-lb)

I Do not use a wire brush for cleaning.

I If plug tip is covered with carbon, spark plug cleaner may

be used.

Cleaner air pressure:

Less than 588 kPa (6 kg/cm

Cleaning time:

Less than 20 seconds

2

, 85 psi)

EM

LC

EC

FE

AT

AX

SU

BR

ST

SMA773C

SMA806C

I Checking and adjusting plug gap is not required.

RS

BT

HA

SC

EL

IDX

MA-19

Page 20

Checking EVAP Vapor Lines

ENGINE MAINTENANCE

SMA041D

Checking EVAP Vapor Lines

NHMA0015

1. Visually inspect EVAP vapor lines for improper attachment and

for cracks, damage, loose connections, chafing and deterioration.

2. Inspect fuel tank filler cap vacuum relief valve for clogging,

sticking, etc.

Refer to EC-32, “Evaporative Emission System”.

MA-20

Page 21

CHASSIS AND BODY MAINTENANCE

Checking Exhaust System

SMA211A

SMA053D

SMA051D

Checking Exhaust System

Check exhaust pipes, muffler and mounting for improper

attachment, leaks, cracks, damage, chafing or deterioration.

Checking A/T Fluid

1. Warm up engine.

2. Check for fluid leakage.

3. Before driving, fluid level can be checked at fluid temperatures

of 30 to 50°C (86 to 122°F) using “COLD” range on A/T fluid

level gauge.

a. Park vehicle on level surface and set parking brake.

b. Start engine and move selector lever through each gear posi-

tion. Leave selector lever in “P” position.

c. Check fluid level with engine idling.

d. Remove A/T fluid level gauge and wipe clean with lint-free

paper.

e. Re-insert A/T fluid level gauge into charging pipe as far as it

will go.

f. Remove A/T fluid level gauge and note reading. If reading is

at low side of range, add fluid to the charging pipe.

Do not overfill.

4. Drive vehicle for approximately 5 minutes in urban areas.

5. Re-check fluid level at fluid temperatures of 50 to 80°C (122

to 176°F) using “HOT” range on A/T fluid level gauge.

CAUTION:

Firmly fix the A/T fluid level gauge to the A/T fluid charging

pipe using a stopper attached.

NHMA0016

NHMA0020

GI

EM

LC

EC

FE

AT

AX

SU

BR

ST

RS

SMA853B

6. Check fluid condition.

I If fluid is very dark or smells burned, refer to AT section for

checking operation of A/T. Flush cooling system after repair of

A/T.

I If A/T fluid contains frictional material (clutches, bands, etc.),

replace radiator and flush cooler line using cleaning solvent

and compressed air after repair of A/T.Refer to LC-17, “Radiator”.

MA-21

BT

HA

SC

EL

IDX

Page 22

Changing A/T Fluid

CHASSIS AND BODY MAINTENANCE

SMA052D

Changing A/T Fluid

NHMA0021

1. Warm up A/T fluid.

2. Stop engine.

3. Drain A/T fluid from drain plug and refill with new A/T fluid.

Always refill same volume with drained fluid.

Fluid grade:

Nissan Matic “D” (Continental U.S. and Alaska) or

Canada NISSAN Automatic Transmission Fluid

Refer to “RECOMMENDED FLUIDS AND

LUBRICANTS”, MA-11.

Fluid capacity (With torque converter):

RE4F04B/RE4F04W

9.4 (10 US qt, 8-1/4 Imp qt)

Drain plug:

: 29 - 39 N·m (3.0 - 4.0 kg-m, 22 - 29 ft-lb)

4. Run engine at idle speed for five minutes.

5. Check fluid level and condition. Refer to “Checking A/T Fluid”.

If fluid is still dirty, repeat step 2. through 5.

Balancing Wheels (Bonding Weight Type)

REMOVAL

NHMA0022

NHMA0022S01

1. Remove inner and outer balance weights from the road wheel.

CAUTION:

Be careful not to scratch the road wheel during removal procedures.

2. Using releasing agent, remove double-faced adhesive tape

from the road wheel.

CAUTION:

I Be careful not to scratch the road wheel during removal.

I After removing double-faced adhesive tape, wipe clean

traces of releasing agent from the road wheel.

WHEEL BALANCE ADJUSTMENT

NHMA0022S02

I If a tire balance machine has adhesion balance weight mode

settings and drive-in weight mode setting, select and adjust a

drive-in weight mode suitable for road wheels.

1. Set road wheel on wheel balancer using the center hole as a

guide. Start the tire balance machine.

2. When inner and outer unbalance values are shown on the

wheel balancer indicator, multiply outer unbalance value by 1.6

to determine balance weight that should be used. Select the

outer balance weight with a value closest to the calculated

value above and install it to the designated outer position of,

or at the designated angle in relation to the road wheel.

CAUTION:

I Do not install the inner balance weight before installing

the outer balance weight.

I Before installing the balance weight, be sure to clean the

mating surface of the road wheel.

MA-22

Page 23

CHASSIS AND BODY MAINTENANCE

Balancing Wheels (Bonding Weight Type) (Cont’d)

Indicated unbalance value × 1.6 = balance weight to be

installed

Calculation example:

23 g (0.81 oz) × 1.6 = 38.33 g (1.35 oz) = 40 g (1.41 oz) balance weight (closer to calculated balance weight value)

Note that balance weight value must be closer to the calculated balance weight value.

Example:

37.4 = 35 g (1.23 oz)

37.5 = 40 g (1.41 oz)

SMA054D

a. Install balance weight in the position shown in the figure at left.

b. When installing balance weight to road wheels, set it into the

grooved area on the inner wall of the road wheel as shown in

the figure at left so that the balance weight center is aligned

with the wheel balancer indication position (angle).

CAUTION:

I Always use genuine Nissan adhesion balance weights.

I Balance weights are unreusable; always replace with new

ones.

I Do not install more than three sheets of balance weight.

GI

EM

LC

EC

FE

AT

SMA055D

SMA056D

c. If calculated balance weight value exceeds 50 g (1.76 oz),

install two balance weight sheets in line with each other (as

shown in the figure at left).

CAUTION:

Do not install one balance weight sheet on top of another.

3. Start wheel balancer again.

4. Install drive-in balance weight on inner side of road wheel in

the wheel balancer indication position (angle).

CAUTION:

Do not install more than two balance weights.

5. Start wheel balancer. Make sure that inner and outer residual

unbalance values are 10 g (0.35 oz) each or below.

I If either residual unbalance value exceeds 10 g (0.35 oz),

repeat installation procedures.

Wheel balance (Maximum allowable unbalance):

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

Maximum allowable

unbalance

MA-23

Dynamic (At rim flange) 10 g (0.35 oz) (one side)

Static 20 g (0.71 oz)

Page 24

Tire Rotation

CHASSIS AND BODY MAINTENANCE

SMA829C

Tire Rotation

NHMA0023

Do not include the T-type spare tire when rotating the tires.

Wheel nuts:

: 98 - 118 N·m (10.0 - 12.0 kg-m, 72 - 87 ft-lb)

Checking Brake Fluid Level and Leaks

NHMA0024

If fluid level is extremely low, check brake system for leaks.

Checking Brake Lines and Cables

NHMA0025

Check brake fluid lines and parking brake cables for improper

attachment, leaks, chafing, abrasions, deterioration, etc.

SBR389C

SMA260A

Checking Disc Brake

ROTOR

Check condition and thickness.

Unit: mm (in)

Front Rear

Brake model CLZ25VC CL9HB

Standard thickness 26 (1.02) 9 (0.35)

Maximum runout 0.07 (0.0028) 0.07 (0.0028)

Minimum thickness

(Wear limit)

24.0 (0.945) 8.0 (0.315)

NHMA0026

NHMA0026S01

MA-24

Page 25

CHASSIS AND BODY MAINTENANCE

Checking Disc Brake (Cont’d)

SMA922A

SMA847B

CALIPER

NHMA0026S02

Check for leakage.

PAD

NHMA0026S03

Check for wear or damage.

Unit: mm (in)

Brake model CLZ25VC CL9HB

Standard thickness 11 (0.43) 10 (0.39)

Minimum thickness

(Wear limit)

Checking Steering Gear and Linkage

STEERING GEAR

2.0 (0.079) 1.5 (0.059)

NHMA0027

NHMA0027S01

I Check gear housing and boots for looseness, damage and

grease leakage.

I Check connection with steering column for looseness.

STEERING LINKAGE

NHMA0027S02

Check ball joint, dust cover and other component parts for

looseness, wear, damage and grease leakage.

GI

EM

LC

EC

FE

AT

AX

SU

BR

ST

SMA654C

SST850C

SST851C

Checking Power Steering Fluid and Lines

NHMA0028

Check fluid level in reservoir tank with engine off.

Use “HOT” range at fluid temperatures of 50 to 80°C(122 to 176°F)

or “COLD” range at fluid temperatures of 0 to 30°C (32 to 86°F).

CAUTION:

I Do not overfill.

I Recommended fluid is Genuine NISSAN PSF II or equiva-

lent.

Refer to “RECOMMENDED FLUIDS AND LUBRICANTS”,

MA-11.

I Check lines for improper attachment, leaks, cracks, damage,

loose connections, chafing and deterioration.

I Check rack boots for accumulation of power steering fluid.

RS

BT

HA

SC

EL

IDX

MA-25

Page 26

CHASSIS AND BODY MAINTENANCE

Lubricating Locks, Hinges and Hood Latches

Lubricating Locks, Hinges and Hood Latches

NHMA0029

SMA081D

Checking Seat Belts, Buckles, Retractors, Anchors and Adjusters

NHMA0030

MA-26

SMA042DA

Page 27

SERVICE DATA AND SPECIFICATIONS (SDS)

Engine Maintenance

Engine Maintenance

BELT DEFLECTION AND TENSION

Deflection adjustment

Unit: mm (in)

Used belt

Limit After adjustment Limit After adjustment

With air conditioner

compressor

Alternator

Without air conditioner compressor

Power steering oil pump 11 (0.43)

Applied pushing force 98 N (10 kg, 22 lb) —

*1: If the belt tension gauge cannot be installed at check points shown, check drive belt tension at a different location on the belt.

7 (0.28)

10 (0.39)

4.2 - 4.6

(0.165 - 0.181)

6.3 - 6.9

(0.248 - 0.272)

7.3-8

(0.287 - 0.315)

New belt

3.7 - 4.1

(0.146 - 0.161)

5.6 - 6.0

(0.220 - 0.236)

6.5 - 7.2

(0.256 - 0.283)

294 (30, 66)

294 (30, 66)

196 (20, 44)

Tension adjustment*1

Unit: N (kg, lb)

Used belt

730 - 818

(74.5 - 83.5,

164 - 184)

730 - 818

(74.5 - 83.5,

164 - 184)

495 - 583

(50.5 - 59.5,

111 - 131)

(85.45 - 94.43,

188.4 - 208.2)

(85.45 - 94.43,

188.4 - 208.2)

NHMA0031

New belt

838 - 926

838 - 926

603 - 691

(61.5 - 70.5,

136 - 155)

GI

EM

LC

EC

FE

SPARK PLUG

Platinum tipped type

Make NGK

Standard PFR5G-11

Hot PFR4G-11

Type

Cold PFR6G-11

Plug gap (Nominal) 1.1 mm (0.043 in)

Chassis and Body Maintenance

WHEEL BALANCE

Dynamic (At rim flange) 10 g (0.35 oz) (one side)

Maximum allowable unbalance

Static 20 g (0.71 oz)

NHMA0032

NHMA0033

AT

AX

SU

BR

ST

RS

BT

HA

SC

MA-27

EL

IDX

Page 28

NOTES

Loading...

Loading...