现货库存、技术资料、百科信息、热点资讯,精彩尽在鼎好!

P-TO263

-7-2

Features

1 ... 3.3 V conversion:

phase PWM controller

P-TO220

-7-

230

Integrated Switch

Preliminary Data Sheet TDA21201

(MOSFET Driver and MOSFETs)

• Replaces with one part only the semiconductors of a DC/DC

power stage for a 12 V à

FET driver + High side FET + Low side FET

• Raises the efficiency by reducing static and dynamic losses

beyond 85 % due to optimized MOSFETs and Driver

• Reduces overall part count and board space consumption

• Simplifies and shortens the circuit design and the layout

P-TO220-7-3

• Eliminates the need for external bootstrap components

• Provides simplest overall output current scalability

• Protects the Driver and

the MOSFETs against over-

temperature and shoot-through problems Vcc à Gnd

• Achieves the lowest thermal resistance Rthjc and Rthja

• Uses the well-known, easy-to-assemble and robust

standard TO-220 and TO-263 (D²Pak) package

• Requires no separate supply voltage to operate except 12 V

• Three state input to enable a shut down mode to turn off

both MOSFETs

• Compatible with standard 2-, 3-, 4-, 6ICs

• Ideal for compact, highly-efficient, multi-phase voltage

regulators on motherboards and VRMs

7

1

Type Package Marking Ordering Code

TDA21201-P7 TO-220-7-3 21201P7 Q67042-S4100

TDA21201-S7 TO-220-7-230 21201S7 Q67042-S4101

TDA21201-B7 TO-263-7-2 21201B7 Q67042-S4099

Pin Configuration and Function

Pin number Pin name Pin description

1,2,3 GND Ground

4/tab V

Output voltage from common node of the MOSFETs

OUT

5 IN Input signal from PWM controller

6,7 VCC Supply voltage to MOSFETs and Driver IC

General Description

The Integrated Switch TDA21201 incorporates an intelligent MOSFET driver and two

Power MOSFETs in a single package to form a fully integrated and optimized power

stage of a DC/DC synchronous buck converter including the bootstrap components

for the high-side MOSFET.

The Power MOSFETs are optimized for lowest static and dynamic losses for a 12 V

to sub-3.5 V conversion and can handle up to 30 A output current. The TDA21201 is

manufactured in Infineon´s state-of-the-art multi-chip assembly using a low-Rth 7-Pin

Page 1 Apr-29, 2002

Preliminary Data Sheet TDA21201

TO-220 package or its associated SMD counterpart TO-263 and Infineon´s latest

chip technologies.

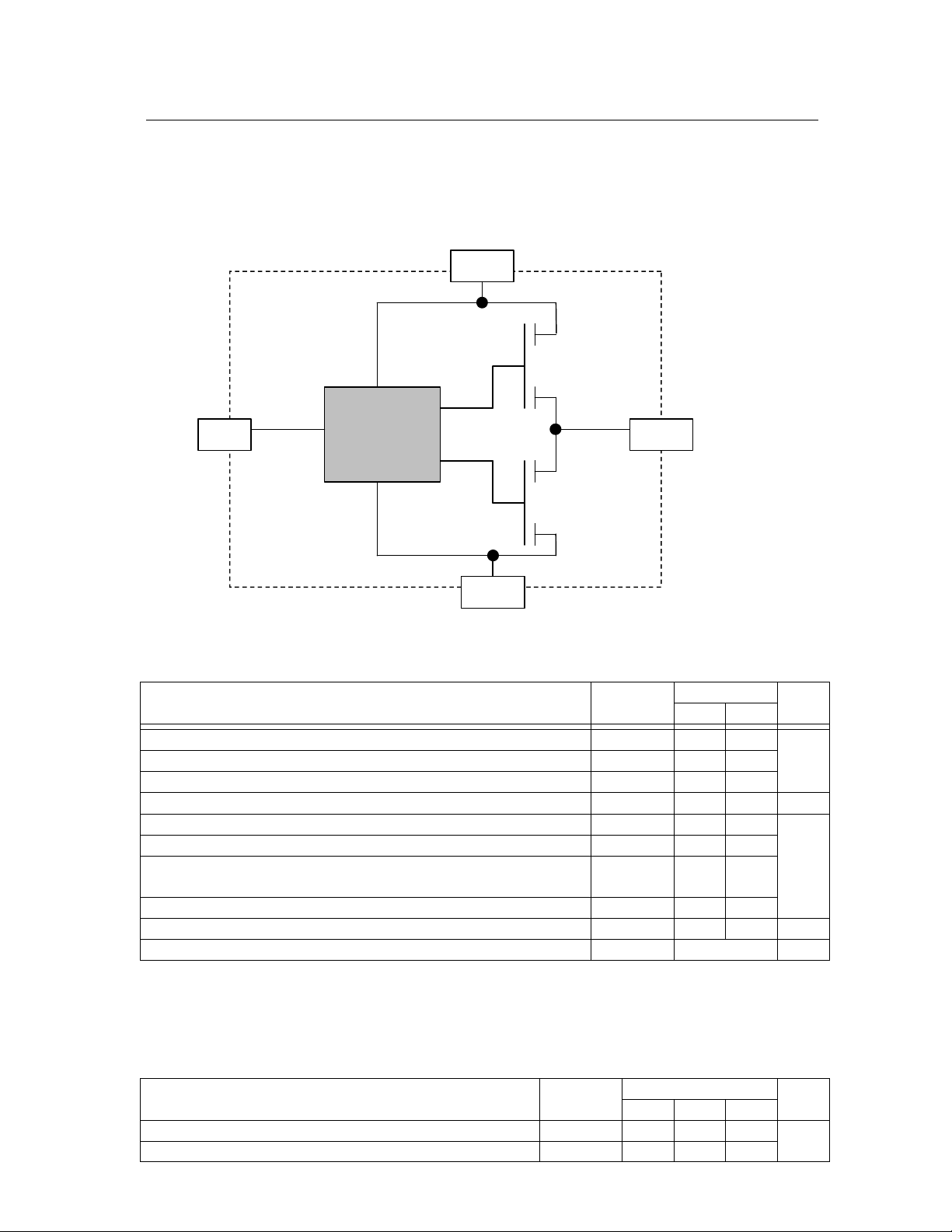

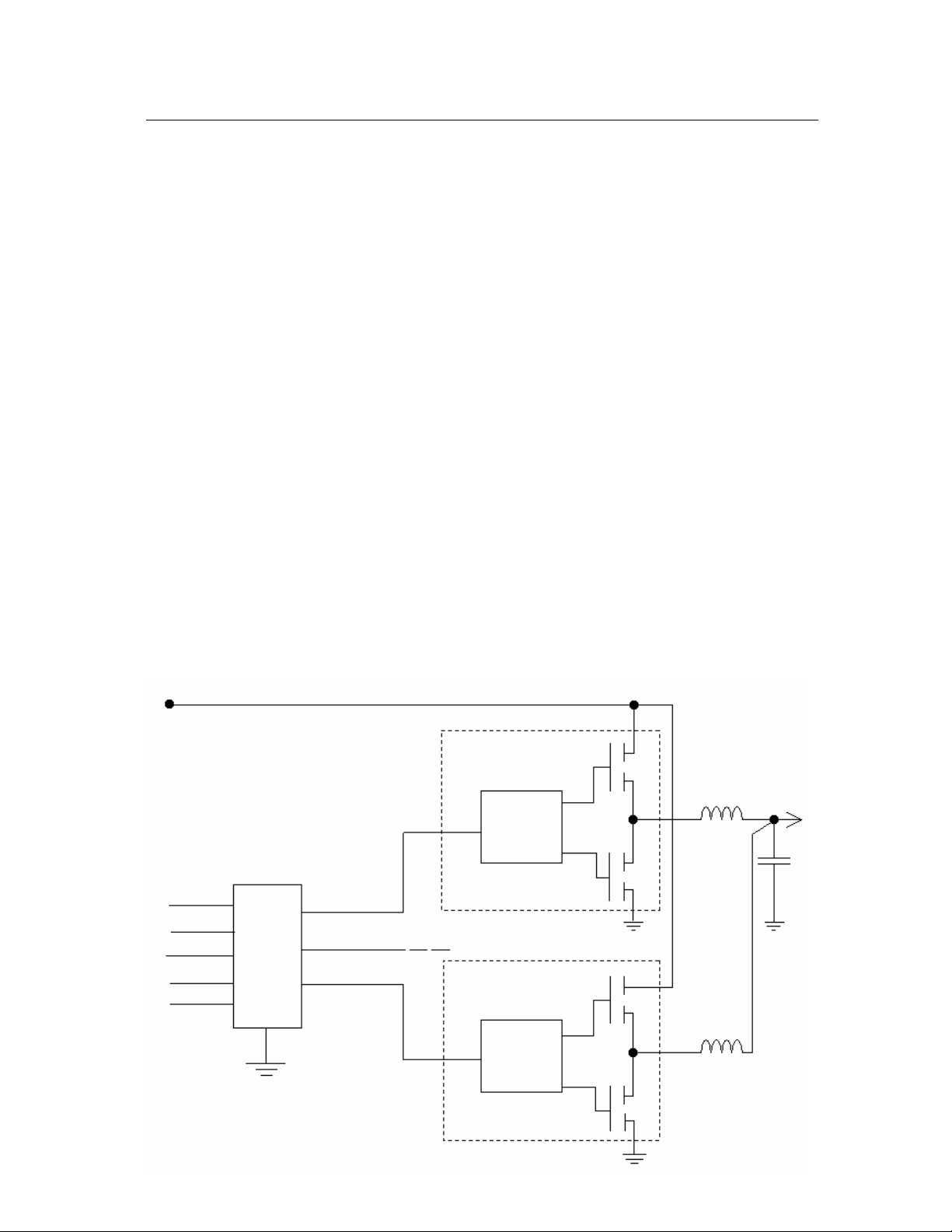

Block Diagram

VCC

= 12 V (Pin 6-7)

High side FET

VIN

FET Drive

Circuitry

V

OUT

to PWM IC

(Pin 5)

Low side FET

to output inductor

(Pin 4/tab)

GND

(Pin 1-3)

Absolute Maximum Ratings

At Tj = 25 °C, unless otherwise specified

Parameter Symbol

Value

Unit

Min. Max.

Peak voltage supplied to ‘VCC’ pins V

Peak voltage supplied to ‘IN’ pin, D

< 10 % VIN -5 10

IN_Peak

Peak voltage at ‘Vout’ pin to GND V

Maximum DC output current, VCC = 12 V, V

≤ 3.3 V

OUT

CC_PEAK

OUT_PK

I

OUT_MAX

Junction temperature TJ 150

Storage temperature TS -55 150

Lead temperature TO-263;

TL 225

20*

-5 20*

-10 30 A

°C

V

MSL1, IPC/JEDEC J-STD-020A

Lead temperature TO-220 (soldering, 10 seconds) TL 260

ESD rating (Human body model) ESD 2 k V

IEC climatic category; DIN EN 60068-1 55/150/56 -

* The positive peak voltage (= the voltage overshoot during switching transients) at the VCC pins and

the OUT pin/tab is limited by the Integrated Switch itself (pls., see the “Over-voltage protection of

VCC” paragraph

Thermal Characteristic

Values Parameter Symbol

Unit

Min. Typ. Max.

Thermal resistance, junctions-case 1.9

Thermal resistance, junctions-ambient, leaded 62.5

Page 2 Apr-29, 2002

K/W

SMD version, device on PCB:

@ min. footprint

@ 6 cm² cooling area

Preliminary Data Sheet TDA21201

62

40

Electrical Characteristics

At Tj = 25 °C, unless otherwise specified

Parameter Symbol

Conditions

Min.

Values

Typ. Max.

Unit

Input Characteristic (= MOSFET Driver)

Shut down window V

Shut down hold-off

IN_SHUT

t_

SHUT

t_

1.2 V ≤ V

> 1.5 µs 1.2 1.6 V

SHUT

≤ 1.6 V

IN

0.8 1.5 2.5 µs

time

Supply current during

shut down

Current into ‘IN’ pin,

during shut down

Current into ‘IN’ pin,

I

CC_SHUT

I

IN_SHUT

I

IN_LOW

1.2 V ≤ V

≤ 1.6 V

IN

10 16 22 mA

VCC = 12 V

VIN = 1.4 V -10 10

VIN = 0.4 V -2 -10 -50

µA

Low

Current into ‘IN’ pin,

I

IN_HIGH

VIN = 4.5 V 20 35 80

High

Static Characteristic (= High Side and Low Side MOSFET)

D-S Breakdown

Voltage High Side

D-S Breakdown

DS_HS

V

DS_LS

1.2 V ≤ V

I

D

≤ 1.6 V

IN

= 0.25 A

30

V

V

Voltage Low Side

D-S Leakage Current

High Side

D-S Leakage Current

High Side

Drain-Source on

Resistance High Side

Drain-Source on

Resistance Low Side

Drain-Source on

Resistance High Side

Drain-Source on

I

DSS_HS

I

DSS_LS

R

DSon_HS

R

DSon_LS

R

DSon_HS

R

DSon_LS

1.2 V ≤ V

V

CC

≤ 1.6 V

IN

= 12 V

I

= 15 A

OUT

Tj = 25 °C

I

= 15 A

OUT

Tj = 125 °C

0.1 1 µA

13.3

4.8

17.7

6.4

mΩ

Resistance Low Side

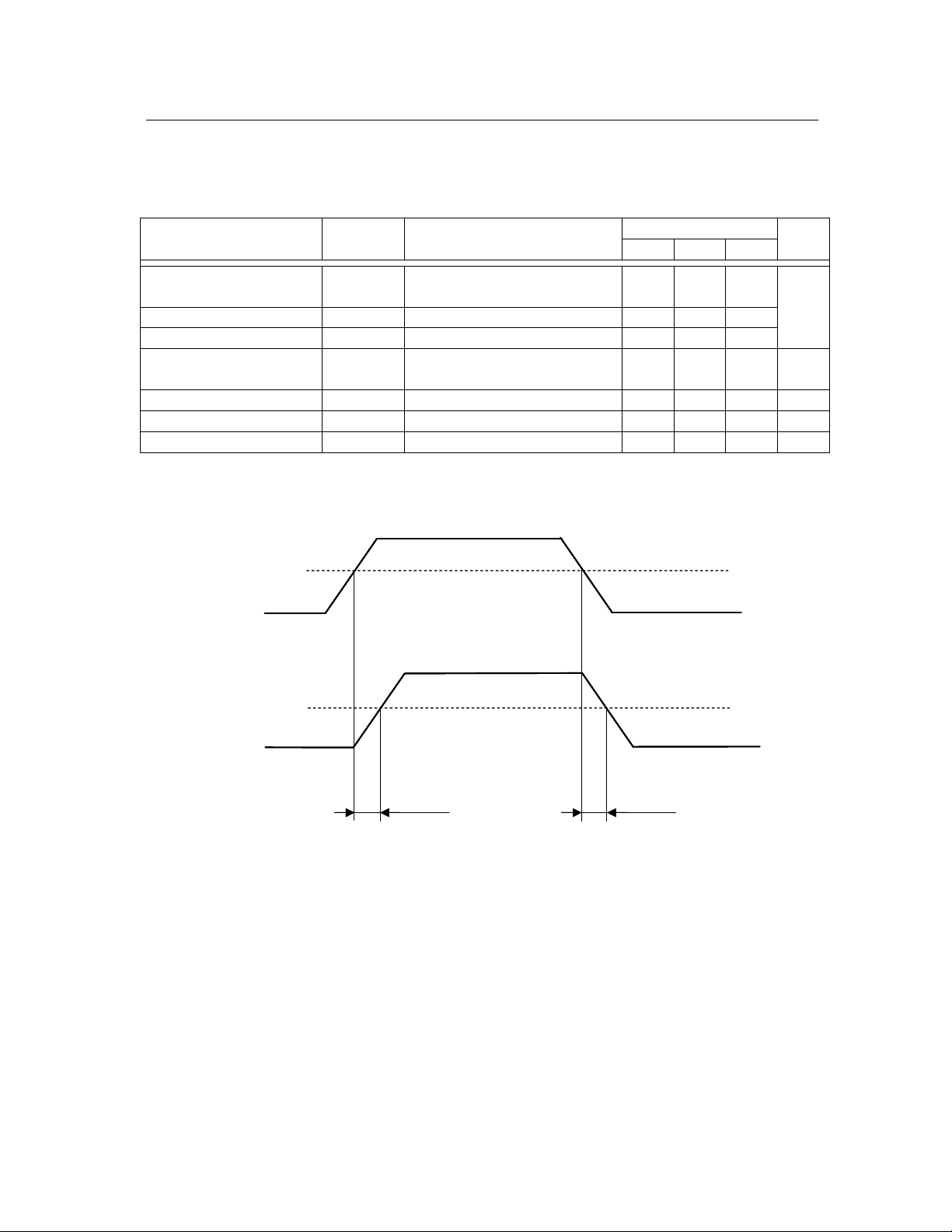

Dynamic Characteristic (= Integrated Switch)

IN to OUT delay time

L à H; 50 % to 50 %

IN to OUT delay time

H à L; 50 % to 50 %

OUT rise time; 20 %

t

110 150

d(ON)

= 15 A

t

70 100

d(OFF)

I

OUT

tr 10 25

(s. Timing Diagram)

ns

to 80 %

OUT fall time; 80 to

tf

10 30

20 %

Page 3 Apr-29, 2002

t

d(on)

t

d(off)

VIN

V

OUT

t

d(on)

t

d(off)

Preliminary Data Sheet TDA21201

Operating Conditions

At Tj = 25 °C, unless otherwise specified

Parameter Symbol

Voltage supplied to

VCC 9 15

‘VCC’ pins

Voltage ‘IN’ Low V

Voltage ‘IN’ High V

Input signal transition

-0.5 0.8

IN_L

2.1 5.5

IN_H

f 100 500 KHz

Conditions

Min.

Values

Typ. Max.

Unit

V

frequency

Pulse width Input t

Power dissipation P

90 ns

P_IN

10 W

TOT

Junction temperature TJ -25 125 °C

Timing Diagram

50%

50%

Typical application

A circuit designer will value the Integrated Switch TDA21201 as cost-optimized

power stage solution in high-density DC/DC conversion applications using a Vcc = 12

V input where efficiency and board space is an issue, e.g. in multi-phase

microprocessor supplies on motherboards, in VRMs and servers.

The TDA21201 can also be used to power Logic circuits, Memory banks etc. that

require higher voltages, e.g. 2.5 or 3.3 V. The efficiency of the Integrated Switch and

the overall efficiency of the converter will even go up at these elevated output

voltages compared to the 1.6 V efficiency given later on in this data sheet.

Page 4 Apr-29, 2002

PWM 1

1

N

N

C

Preliminary Data Sheet TDA21201

Designing a 12 V to sub-3.3 V converter using the TDA21201

General info

To design a multi-phase converter with a 12 V input simply use in each phase

just one TDA21201 instead of using a MOSFET driver, a high side MOSFET,

bootstrap components, and one or more low side MOSFETs. The entire

converter is completed by the input filter, the output filter and a multi-phase

PWM IC.

Input compatibility to standard PWM controllers / shut-down mode

The Integrated Switch TDA21201 has a high impedance input pin ‘IN’ to be

connected to PWM controller outputs ‘PWM1’, ‘PWM2’ etc. It sinks or sources

only a fraction of a mA from the controller’s output. The TDA21201 is

compatible to standard controller and driver signals in terms of the signal level

(5 V TTL) and in terms of the ‘Low’/’High’ relationship (’Low’ turns the low side

MOSFET on, ‘High` turns the High side MOSFET on).

The TDA21201 can be shut down (the high side MOSFET and the low side

MOSFET is turned off) by applying an input signal V

= 1.2 ... 1.6 V for more

IN

than 1.5 µs typical. This way the TDA21201 reduces the power dissipation by

saving the gate charges of both the high side and the low side MOSFET

during no load conditions. The shutdown state is terminated when V

moves

IN

into the ‘Low’ or ‘High’ threshold.

Typical Application: 12 V à 1.x V N-Phase Converter using the TDA21201

12 V

L1

1...2 V

FET

Driver

PWM

IC

PWM 2

PWM N

L

FET

Driver

Page 5 Apr-29, 2002

C

I I I

I

I

turn ON

turn ON

Integ

rated

Preliminary Data Sheet TDA21201

12 V

VCC

IN

TDA

L1

OUT

1...2 V

21201

PWM 1

PWM

IC

PWM 2

PWM N

GND

TDA

L

N

21201

Integrated Switch functionality vs. supply voltage Vcc

Switch

function

Low Side

FET can

Integrated Switch OFF

6 V 7.5 V 9 V 12 V 15 V Vcc

High Side

FET can

Integrated Switch fully

functional

The Integrated Switch reaches gradually its full functionality while the supply

voltage Vcc increases from 0 to its nominal value +12 V, e.g. during turn-on.

The same happens vice versa when the supply voltage decreases from its

nominal value +12 V to 0, e.g. during turn-off. The TDA21201 is very

insensitive to Vcc tolerances. It behaves properly in a wide Vcc range from 9

to 15 V. There is no distinct V

functionality or state changes abrupt while V

threshold at which the Integrated Switch’s

CC

increases or decreases. E.g.,

CC

there is no tight specified Under Voltage Lockout level. The TDA21201

changes smoothly its state, e.g., as the High Side and Low Side MOSFETs´

gate drive voltage increases while V

increases from 7.5 V to 9 V the Rds[on]

CC

of both the High Side MOSFET and the Low Side MOSFET decreases

gradually, rather than being fully Off at VCC slightly below a threshold level or

Page 6 Apr-29, 2002

Preliminary Data Sheet TDA21201

being fully On at a VCC level slightly greater than the threshold.

Bootstrapping

Turning on and off the High side MOSFET is done internally by the Driver. The

TDA21201 does not require any external bootstrap components such as a

capacitor or diode. Just apply GND, Vcc = 12 V, and the PWM signal of the

Controller to it and the Integrated Switch will operate.

Input filter / Output filter / Converter Stability

The Integrated Switch TDA21201 is a new solution to implement the power

semiconductor components in a DC/DC converter. It offers many advantages

to the user. However, the basic behavior with respect to the voltages, the

currents and the timing remains unchanged. Therefore, any of the rules and

procedures applied to design DC/DC converters using discrete MOSFETs and

Drivers apply in the same way to converters using the Integrated Switch –

except the worries regarding dead time control, lowest impedance in the AC

loop, elevated driver temperatures etc.

Current sense

Any of the commonly used current sense techniques are supported by the

Integrated Switch. For Low side sensing measure the voltage drop across the

GND pins and the OUT pin (or the tab when using the SMD version) during

the Low side switch’s On-time (Vin = Low). The High side MOSFET is sensed

across the Vcc and the OUT pin (or the tab when using the SMD version) of

the Integrated Switch during its On-time (Vin = High). Inductor sensing is

implemented outside of the integrated switch the usual way.

Resistor sensing using a separate resistor in the Input capacitor à High side

MOSFET (Vcc pin) path is possible but not recommended

. This current sense

approach introduces ample stray inductance in the AC current loop (+terminal

of the input capacitor à High side MOSFET à Low side MOSFET à GND à

-terminal of the input capacitor). This results in a very noisy Vcc line especially

during the switching period and a non-optimized switching behavior of the

Integrated Switch. This in turn, increases the switching losses and the device

temperature and lowers the efficiency.

Output current scalability

The converter output current can be chosen in a wide range by selecting the

appropriate number of phases. At a given number of phases the current per

phase (= current per TDA21201) and in turn the overall converter output

current is set by application requirements, e.g. the switching frequency, and by

environmental conditions, e.g. ambient temperature and the thermal

resistance of the TDA21201 to ambient. As a reference, one TDA21201

generates roughly 3.2 W @ 15 A RMS and 250 kHz (V

= 12 V, VO = 1.6 V).

CC

This amount of loss can be dissipated by the SMD version of the Integrated

Switch on a regular motherboard using proper thermal design techniques.

Greater phase currents result in higher losses; and higher switching

Page 7 Apr-29, 2002

Preliminary Data Sheet TDA21201

frequencies will also result in more losses. So, in modifying the thermal

environment and a switching frequency the phase current can be matched

your requirements; please, consult the efficiency curves in this Data Sheet to

choose the most suitable phase current and switching frequency per phase for

a particular design. To give a circuit designer more freedom in scaling the

phase current, the Integrated Switch is offered in a heat sink capable TO-220

version that allows better thermal coupling to ambient and a higher junction

temperature in the Integrated Switch as well - without violating the applicable

regulations.

Over temperature shut-down

The over temperature shut-down function of the Integrated Switch takes effect

@ 150 °C junction temperature typically and turns off the High side MOSFET

and the Low side MOSFET. Unlike as in discrete converter solutions the

MOSFETs and the Driver are thermally very well coupled. Therefore, this

function protects the Driver and

the MOSFETs. Once the Integrated Switch is

cooled down and the temperature shut-down is released the Integrated Switch

continues to operate by turning on one of the MOSFETs according to its PWM

signal present on the input.

Under Voltage Lockout / ∆ Vcc detection

The TDA21201 is fully functional at Vcc ≥ 9 V. However, the Low side

MOSFET can already be turned on at Vcc ≈ 6 V or greater when the input is

Low. The Integrated Switch is disabled and both MOSFETs are turned off at

lower Vcc, e.g. during power-up of the ATX supply.

The TDA21201 has two paralleled Vcc pins. The voltage applied to these pins

will be converted to a lower output voltage but it also serves as supply voltage

of the integrated gate drive circuit. Therefore, the voltage difference ∆ Vcc is

monitored for safety reasons. When ∆ Vcc ≥ 0.45 V for more than 2 µs

typically the Integrated Switch is disabled. This way it prevents the part itself

but it also protects the load

from inadequate behavior, e.g. due to a bad

soldering connection of the Vcc pins.

Layout guidelines

In general, the layout is simplified when using the Integrated Switch. However,

it should be kept in mind that the power density in the Integrated Switch is

higher than in a discrete solution. Therefore, proper thermal layout is very

critical in designs that employ the SMD version.

Another important aspect is a very low impedance path in the Vcc = 12 V à

TDA21201 à GND loop. It is recommended to place the capacitors of the

input filter as close to the GND and Vcc pins of the TDA21201 as possible.

Additional ceramic capacitors in parallel to the input capacitors help to reduce

the effect of stray inductance of the input capacitors and the PCB traces.

Reducing parasitic inductance will result in an optimized switching behavior

and lower switching losses. The arrangement of the output filter is of second

order importance.

Page 8 Apr-29, 2002

V

< 20

HS is turned off

Preliminary Data Sheet TDA21201

Over voltage protection of Vcc / Avalanche avoidance

The voltage at the Vcc pins of the TDA21201 rises above the nominal DC

value of the Vcc supply (= + 12 V) during the turn-off of the High Side

MOSFET. The voltage overshoots at the Vcc pins according to:

vcc(t) = Vcc + Lstray * di/dt

vcc (t) = instantaneous value of vcc; Vcc = +12 V DC; Lstray = stray

inductance of the PCB traces + the input capacitor’s ESL + the parasitic

inductance of the TDA21201 package itself; di/dt = slew rate of the High Side

current during its turn-off.

V

= +12 V

cc

TDA21201

L

stray

v

cc

HS C

L

D

z

Driver

in

out

LS

This equation reveals that Lstray should be made as small as possible (as

vcc(t) is limited by the breakdown voltage of the device, Vcc is given by the

application, di/dt should be as large as possible to reduce switching losses)

using proper layout techniques and low ESL capacitors, e.g. ceramics,

between the Vcc and GND pins of the Integrated Switch.

To protect the Integrated Switch from unallowable voltage spikes, the slew rate

of the High Side current di/dt is controlled in a way so that the overall voltage

(between Vcc pins to GND pins) does not exceed 20 V (measured between

the Vcc and GND pins at the PCB, this voltage will slightly exceed the 20 V

limit within the package/at the chips). As the MOSFETs have a Breakdown

voltage rating Vds = 30 V, it is made sure that they are never driven into

avalanche.

The slew rate control is implemented using the principal of the active zener

clamp technique: When vcc(t) rises during turn-off then the effective gate-drain

voltage of the High Side MOSFET rises, too. If, for what reason ever, the vcc(t)

overshoot approaches a value that possibly could damage the integrated

Page 9 Apr-29, 2002

t

Preliminary Data Sheet TDA21201

driver or the MOSFETs, the zener diode becomes conducting and reduces the

discharge speed of the High Side MOSFET´s gate within nanoseconds. This

will reduce slightly the turn-off slew rate of the High Side MOSFET´s current (=

di/dt). As a result the over voltage will be limited.

Power loss in the Integrated Switch TDA21201 / Heat sink estimation

The power loss in the Integrated Switch depends mainly on the current and

the switching frequency. Other conditions that impact the power loss are

increased junction temperature and the layout (e.g. very tight coupling of the

input capacitor to the V

and GND pins to reduce the PCB trace inductance).

CC

6

5

4

3

Pd [W]

2

Iphase =12 A Iphase =18 A

1

100 150 200 250 300 350 400 450

f_sw / phase [kHz]

6

f_sw = 100 kHz

5

4

Pd [W]

3

2

1

10 15 20 25

Iphase [A]

f_sw = 150 kHz

f_sw = 200 kHz

f_sw = 250 kHz

f_sw = 300 kHz

Using the above two diagrams the power loss (= the required power

dissipation Pd for thermally stable operation) can be estimated based on a

required phase current Iphase (= current in the Integrated Switch) an based on

the switching frequency per phase f_sw (= frequency of the Integrated Switch

in each phase).

Page 10 Apr-29, 2002

Pd

−

Efficiency [%]

Preliminary Data Sheet TDA21201

Having the power dissipation Pd of the Integrated Switch, the required thermal

resistance RthCA can be calculated. RthCA is the value of the heat sink

attached to the TO-220 version of the Integrated Switch. RthCA is the

“effective” thermal resistance (takes airflow etc. into account):

TATj

RthCA −

max_

≤

Rthjc

Wherein: R

CA = Thermal resistance from the package’s metal backside

th

(= lead frame) to ambient air that is required to operate the

Integrated Switch under given load and environmental

conditions without exceeding the maximum allowed

junction temperature; in [°C/W]

T

= Maximum allowed junction temperature of the Integrated

j_max

Switch; in [°C], use 110 °C for the SMD version of the

Integrated Switch, use 125 °C for the TO-220 version of

the Integrated Switch

TA = The ambient temperature; in [°C], usually this is the

maximum temperature of the surrounding air @ worst

case, e.g. 55 °C

Pd = The power loss generated in the Integrated Switch that

needs to be dissipated through the heat sink à air

(TO-220) or the PCB à air for thermal balance; in [W], use

one of the two diagrams Pd vs. Iphase or Pd vs. f_sw to

find the this value for your particular application

R

jc = Thermal resistance junction to case of the Integrated Switch;

th

in [K/W], use ≤ 2 K/W (s. also pg. 3 and 4 “Thermal

characteristic of the High side/Low side MOSFET” in this

data sheet; the majority of the losses are generated within

the MOSFETs, not in the driver)

Efficiency of a DC/DC converter using the Integrated Switch TDA21201

The following measurements were performed on a 4-phase Evaluation Board.

Phase 4 can be disabled so that the converter operates in a 3-phase mode.

Boundary Conditions: Vcc = 12 V, Vo = 1.6 V, TDA21201 as SMD

I 4-Phase Converter: Efficiency vs. Load current

95

90

85

80

75

70

65

0 20 40 60 80

Page 11 Apr-29, 2002

Load Current [A]

f_1 = 185 kHz

f_2 = 305 kHz

Efficiency [%]

Preliminary Data Sheet TDA21201

II 4-Phase Converter: Efficiency vs. Switching frequency

95

90

85

80

75

150 200 250 300 350

Frequency / Phase [kHz]

Io_1 = 25 A

Io_2 = 40 A

Io_3 = 55 A

Io_4 = 70 A

Ill 3- and 4-Phase Converter: Efficiency vs. Load current

95

90

85

80

Efficiency [%]

75

70

4 Phase @ 185 kHz

4 Phase @ 305 kHz

3 Phase @ 185 kHz

3 Phase @ 305 kHz

65

0 10 20 30 40 50 60

Load current [A]

It should be noted that the overall converter efficiency and the maximum converter

output power will increase as the output voltage increases, e.g. V

= 2.5 or 3.3 V.

O

Page 12 Apr-29, 2002

Preliminary Data Sheet TDA21201

Package Drawing TO-220-7-3 (straight leads)

Package Drawing TO-220-7-230 (staggered leads)

Page 13 Apr-29, 2002

Preliminary Data Sheet TDA21201

Package Drawing TO-263-7-2 (SMD)

Page 14 Apr-29, 2002

Published by

Infineon Technologies AG,

Bereichs Kommunikation

St.-Martin-Strasse 53,

D-81541 München

Infineon Technologies AG 1999

All Rights Reserved.

Attention please!

The information herein is given to describe certain components and shall not be considered as warranted

Characteristics.

Terms of delivery and rights to technical change reserved.

We hereby disclaim any and all warranties, including but not limited to warranties of non-infringement,

regarding circuits, descriptions and charts stated herein.

Infineon Technologies is an approved CECC manufacturer.

Information

For further information on technology, delivery terms and conditions and prices please contact your

nearest Infineon Technologies Office in Germany or our Infineon Technologies Representatives

worldwide (see address lists).

Warnings

Due to technical requirements components may contain dangerous substances.

For information on the types in question please contact your nearest Infineon Technologies Office.

Infineon Technologies Components may only be used in life-support devices or systems with the

express written approval of Infineon Technologies, if a failure of such components can reasonably be

expected to cause the failure of that life-support device or system, or to affect the safety or

effectiveness of that device or system Life support devices or systems are intended to be implanted in

the human body, or to support and/or maintain and sustain and/or protect human life. If they fail, it is

reasonable to assume that the health of the user or other persons may be endangered.

Preliminary Data Sheet TDA21201

Page 15 Apr-29, 2002

Loading...

Loading...