现货库存、技术资料、百科信息、热点资讯,精彩尽在鼎好!

j

j

AR

t

j

g

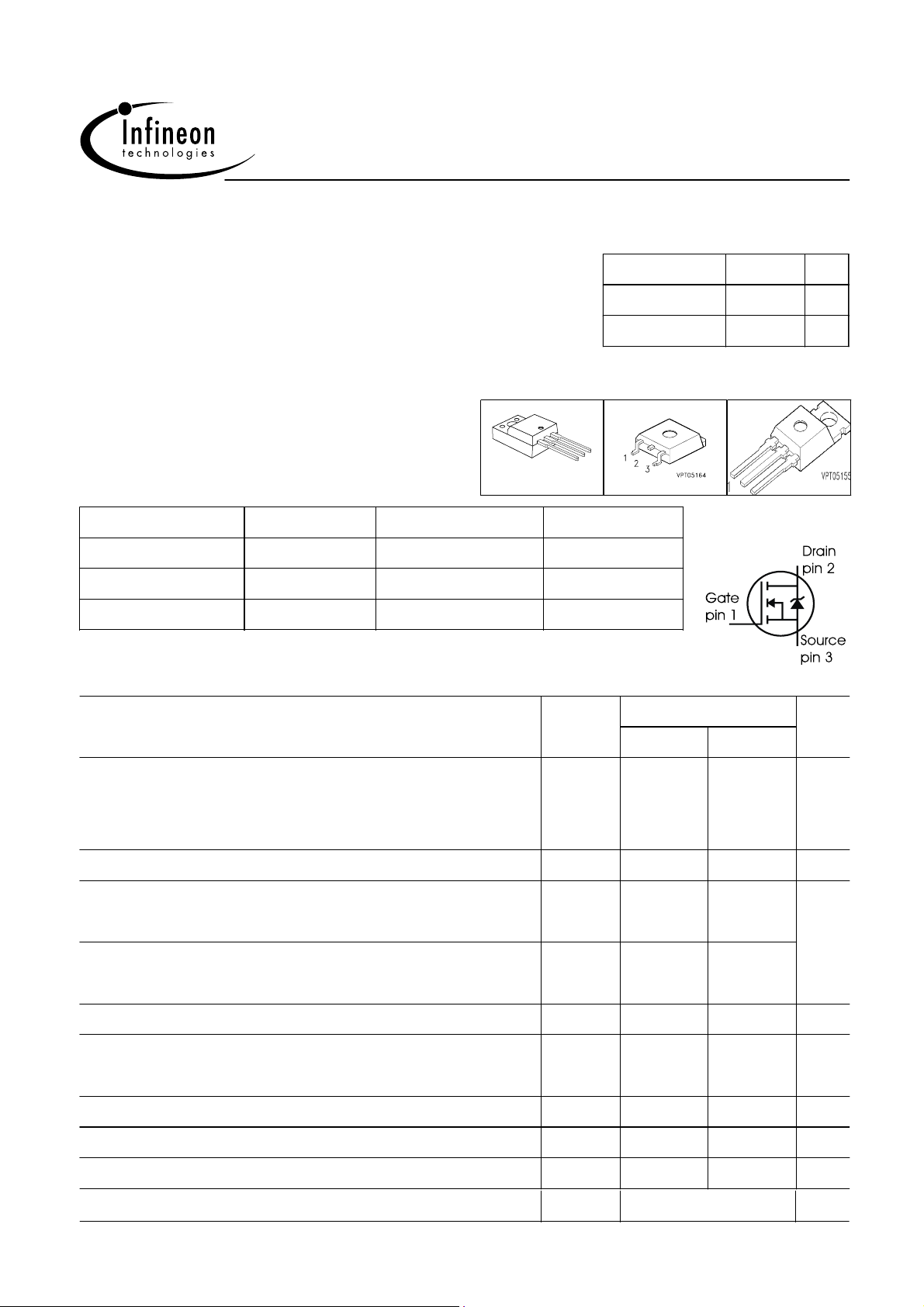

Cool MOS™ Power Transistor

Final data

SPP20N60C2, SPB20N60C2

SPA20N60C2

Feature

• New revolutionary high voltage technology

• Worldwide best R

DS(on)

in TO 220

• Ultra low gate charge

• Periodic avalanche rated

• Extreme dv/dt rated

P-TO220-3-31 P-TO220-3-1P-TO263-3-2

• Ultra low effective capacitances

P-TO220-3-31

Type Package Ordering Code

SPP20N60C2 P-TO220-3-1 Q67040-S4320

SPB20N60C2 P-TO263-3-2 Q67040-S4322

SPA20N60C2 P-TO220-3-31 Q67040-S4333

Maximum Ratings

Product Summary

V

R

I

3

2

1

Marking

20N60C2

20N60C2

20N60C2

@ T

DS

DS(on)

D

jmax

650 V

0.19 Ω

20 A

Parameter Symbol Value Unit

SPA

1)

20

1)

13

A

Continuous drain current

T

= 25 °C

C

T

= 100 °C

C

Pulsed drain current, tp limited by T

max

Avalanche energy, single pulse

I

=10A, VDD=50V

D

Avalanche energy, repetitive tAR limited by T

I

=20A, VDD=50V

D

Avalanche current, repetitive tAR limited by T

Reverse diode dv/dt

I

= 20 A, V

S

< VDD, di/dt=100A/µs, T

DS

jmax

=150°C

jmax

max

2)

I

I

E

E

I

dv/dt 6 6 V/ns

Gate source voltage V

Gate source voltage AC (f >1Hz) V

Power dissipation, T

= 25°C P

C

D

D puls

AS

AR

GS

GS

to

SPP_B

20

13

40 40 A

690 690 mJ

1 1

20 20 A

±20 ±20 V

±30 ±30

208 34.5 W

Operating and storage temperature T

Page 1

T

,

st

-55...+150 °C

2002-08-12

SPP20N60C2, SPB20N60C2

A

Final data

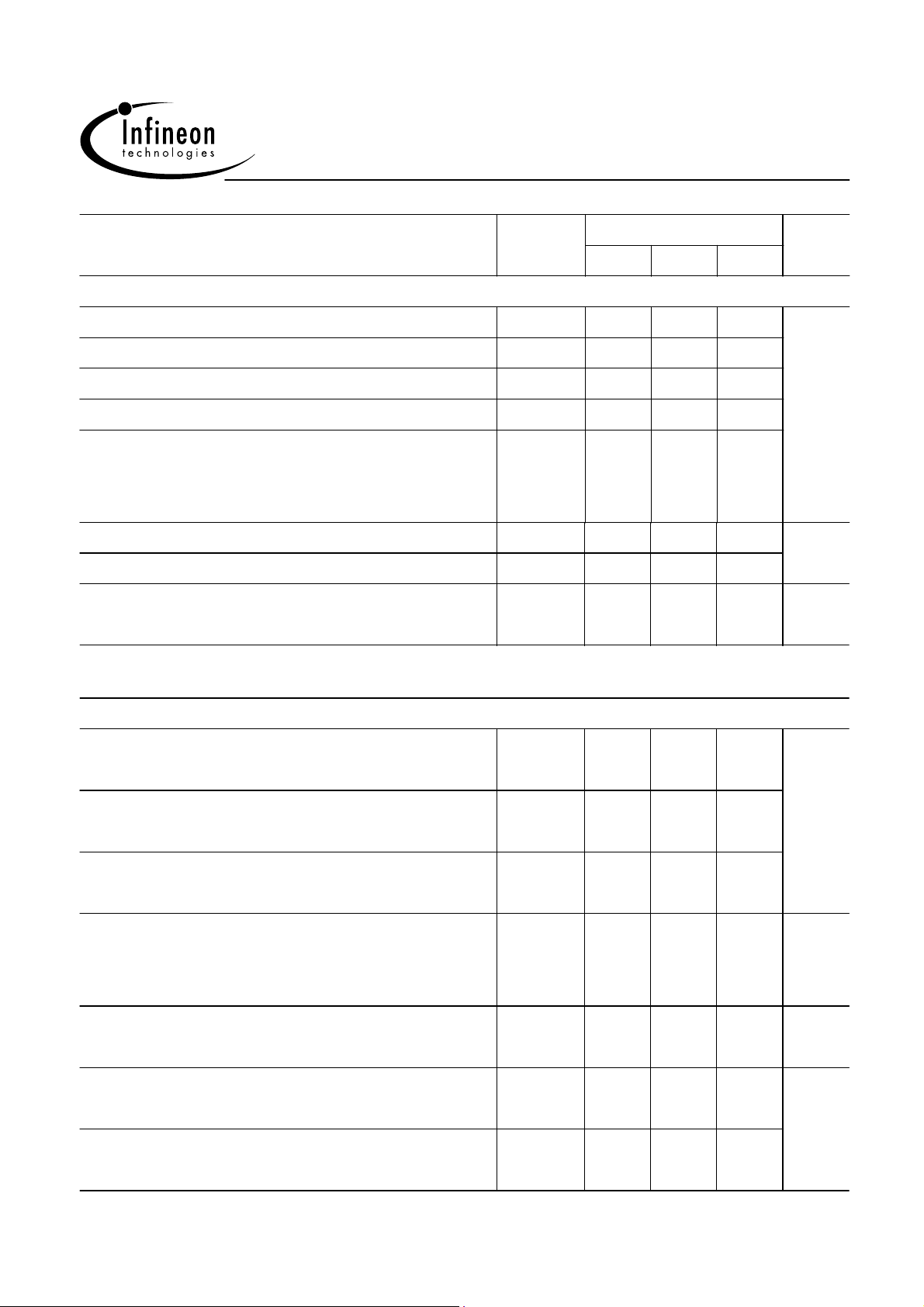

Thermal Characteristics

Parameter Symbol Values Unit

min. typ. max.

Characteristics

SPA20N60C2

Thermal resistance, junction - case R

Thremal resistance, junction - case, FullPAK R

Thermal resistance, junction - ambient, leaded R

Thermal resistance, junction - ambient, FullPAK R

SMD version, device on PCB:

R

@ min. footprint

@ 6 cm

2

cooling area

3)

Linear derating factor

thJC

thJC_FP

thJ

thJA_FP

thJA

- - 0.6 K/W

- - 3.6

- - 62

- - 80

-

-

-

-

35

-

62

-

1.67

Linear derating factor, FullPAK - - 0.28

Soldering temperature,

T

sold

- - 260 °C

1.6 mm (0.063 in.) from case for 10s

Electrical Characteristics, at Tj = 25 °C, unless otherwise specified

Static Characteristics

Drain-source breakdown voltage

VGS=0V, ID=0.25mA

V

(BR)DSS

600 - - V

W/K

Drain-source avalanche breakdown voltage

VGS=0V, ID=20A

Gate threshold voltage, VGS = V

I

=1mA

D

DS

Zero gate voltage drain current

VDS = 600 V, VGS = 0 V, Tj = 25 °C

= 600 V, VGS = 0 V, Tj = 150 °C

V

DS

Gate-source leakage current

VGS=20V, VDS=0V

Drain-source on-state resistance

VGS=10V, ID=13A, Tj=25°C

Gate input resistance

f = 1 MHz, open drain

Page 2

V

(BR)DS

V

GS(th)

I

DSS

I

GSS

R

DS(on)

R

G

- 700 -

3.5 4.5 5.5

-

-

0.1

-

1

100

- - 100 nA

- 0.16 0.19

- 0.54 -

2002-08-12

µA

Ω

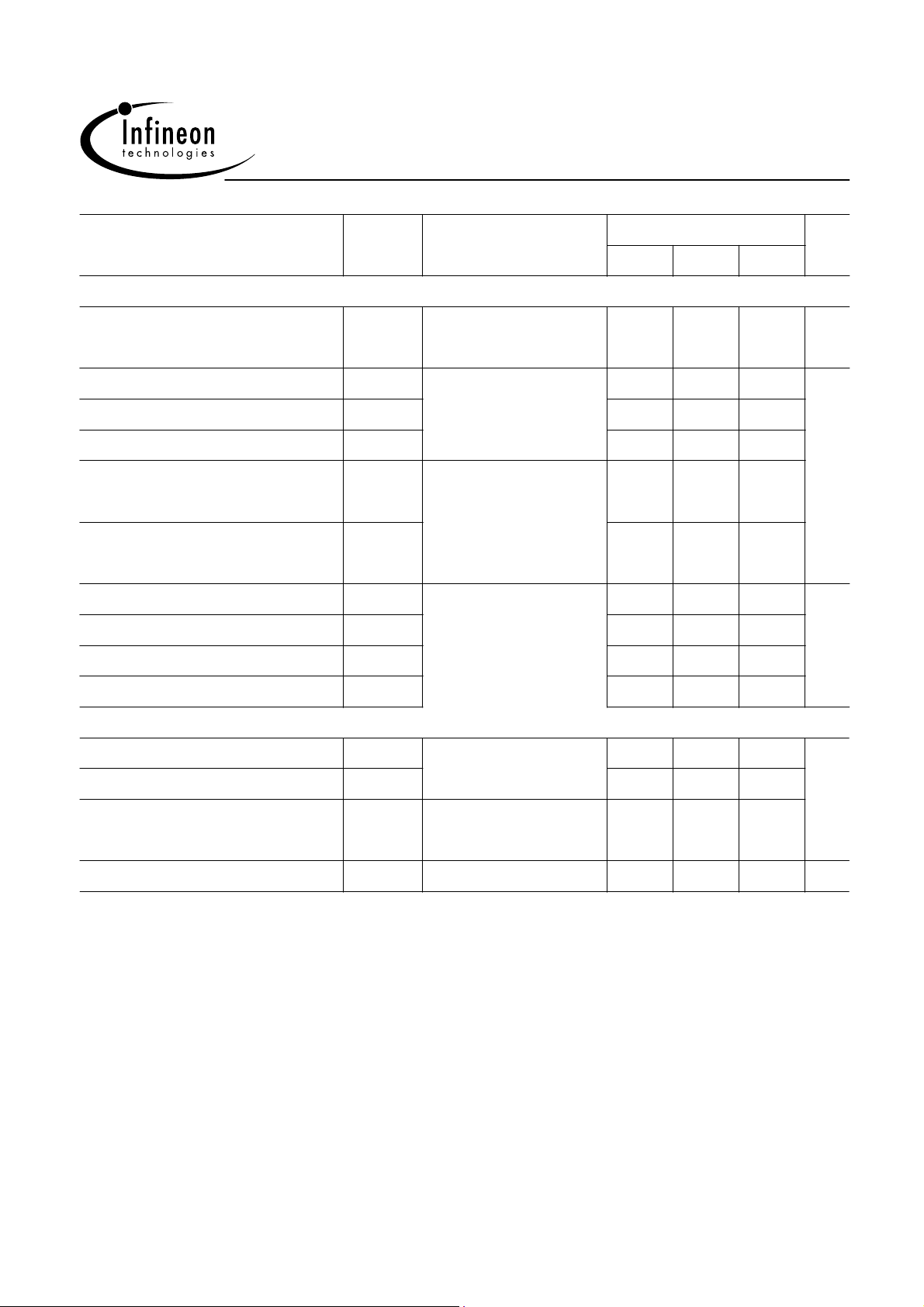

Electrical Characteristics

)

)

f

Final data

SPP20N60C2, SPB20N60C2

SPA20N60C2

Parameter

Symbol Conditions Values Unit

Characteristics

Transconductance g

Input capacitance C

Output capacitance C

Reverse transfer capacitance C

Effective output capacitance,

4)

C

energy related

Effective output capacitance,

5)

C

time related

Turn-on delay time t

Rise time t

Turn-off delay time t

Fall time t

fs

iss

oss

rss

o(er)

o(tr)

d(on

r

d(off

V

≥2*I

DS

D*RDS(on)max

=13A

I

D

VGS=0V, VDS=25V,

f=1MHz

VGS=0V,

=0V to 480V

V

DS

VDD=380V, VGS=0/13V,

=20A,

I

D

=3.6Ω, Tj=125°C

R

G

,

min. typ. max.

- 12 - S

- 3000 - pF

- 1170 -

- 28 -

- 83 -

- 160 -

- 21 - ns

- 51 -

- 56 84

- 6 9

Gate Charge Characteristics

Gate to source charge

Gate to drain charge Q

Gate charge total Q

Gate plateau voltage V

1

Limited only by maximum temperature

2

Repetitve avalanche causes additional power losses that can be calculated as P

3

Device on 40mm*40mm*1.5mm epoxy PCB FR4 with 6cm² (one layer, 70 µm thick) copper area for drain

connection. PCB is vertical without blown air.

4

C

is a fixed capacitance that gives the same stored energy as C

o(er)

5

is a fixed capacitance that gives the same charging time as C

C

o(tr)

Q

gs

gd

g

(plateau)

VDD=350V, ID=20A - 21 - nC

- 46 -

VDD=350V, ID=20A,

=0 to 10V

V

GS

VDD=350V, ID=20A - 8 - V

while VDS is rising from 0 to 80% V

oss

while VDS is rising from 0 to 80% V

oss

- 79 103

AV=EAR

*f.

DSS

DSS

.

.

Page 3

2002-08-12

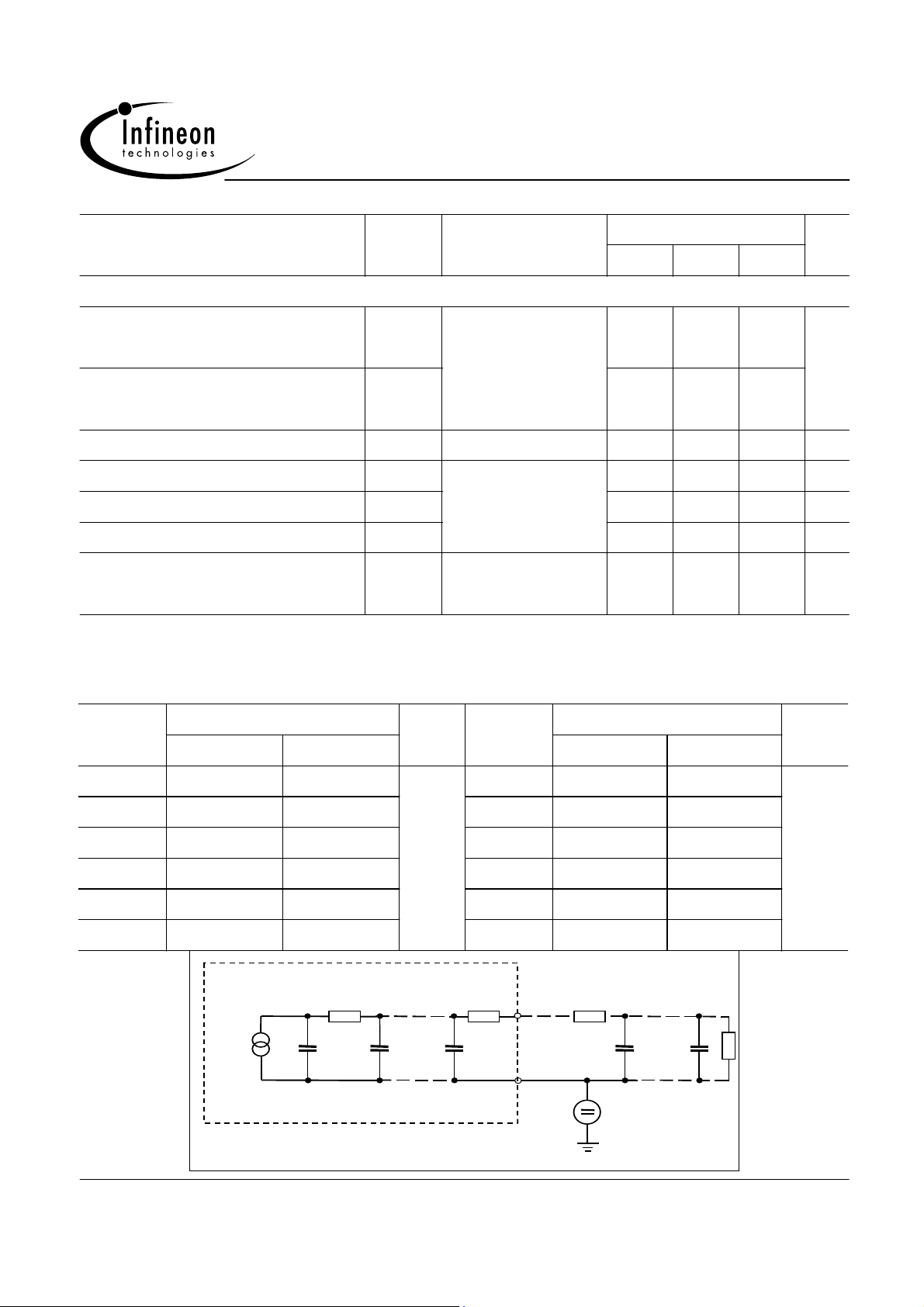

Electrical Characteristics

Final data

SPP20N60C2, SPB20N60C2

SPA20N60C2

Parameter

Symbol Conditions Values Unit

Characteristics

Inverse diode continuous

I

forward current

Inverse diode direct current,

I

pulsed

Inverse diode forward voltage V

Reverse recovery time t

Reverse recovery charge Q

Peak reverse recovery current I

Peak rate of fall of reverse

dirr/dt

recovery current

S

SM

SD

rr

rr

rrm

min. typ. max.

TC=25°C - - 20 A

- - 40

VGS=0V, IF=IS - 1 1.2 V

VR=350V, IF=IS ,

di

/dt=100A/µs

F

- 610 1040 ns

- 12 - µC

- 48 - A

Tj=25°C - 1500 - A/µs

Typical Transient Thermal Characteristics

Symbol

Value Unit Symbol Value Unit

SPA SPA

R

R

R

R

R

R

th1

th2

th3

th4

th5

th6

0.007416 0.077 K/W C

0.016 0.015 C

0.021 0.022 C

0.06 0.063 C

0.083 0.214 C

0.038 2.479 C

T

R

j T

th1

P

(t)

tot

C

th1

C

th2

SPP_BSPP_B

th1

th2

th3

th4

th5

th6

R

th,n

C

th,n

0.0004409 0.000376 Ws/K

0.001462 0.00141

0.0024 0.00192

0.003031 0.00332

0.02 0.019

0.146 0.412

External Heatsink

T

case

amb

Page 4

2002-08-12

Final data

SPP20N60C2, SPB20N60C2

SPA20N60C2

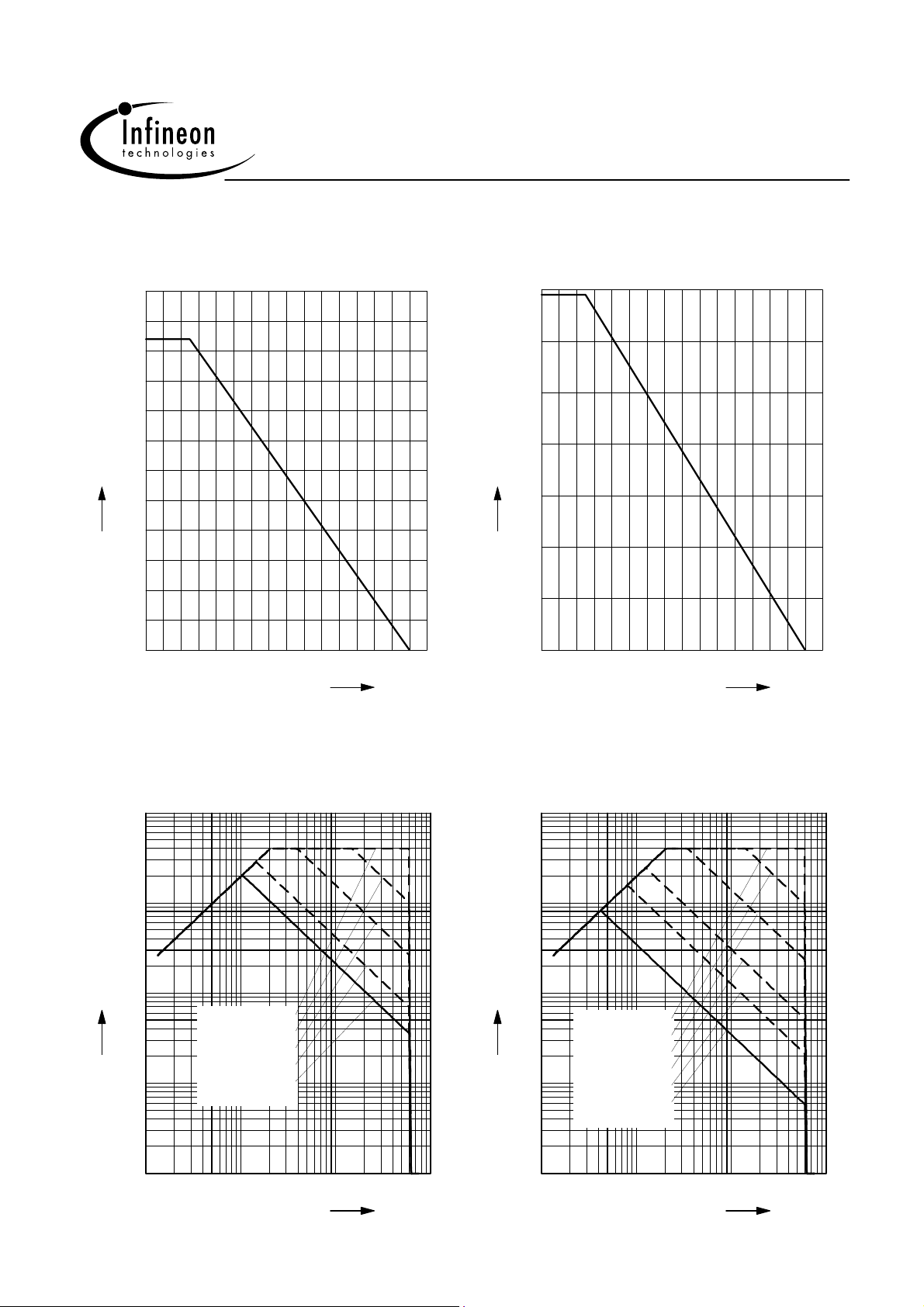

1 Power dissipation

= f (TC)

P

tot

SPP20N60C2

240

W

200

180

160

tot

P

140

120

100

80

60

40

20

0

0 20 40 60 80 100 120

°C

2 Power dissiaption FullPAK

= f (TC)

P

tot

35

W

25

tot

P

20

15

10

5

160

T

C

0

0 20 40 60 80 100 120

°C

T

160

C

3 Safe operating area

= f ( VDS )

I

D

parameter : D = 0 , T

2

10

A

1

10

D

I

0

10

tp = 0.001 ms

tp = 0.01 ms

tp = 0.1 ms

tp = 1 ms

DC

0

10

10

-1

-2

10

10

C

1

=25°C

10

4 Safe operating area FullPAK

= f (VDS)

I

D

parameter: D = 0, T

2

10

A

1

10

D

I

0

10

tp = 0.001 ms

tp = 0.01 ms

tp = 0.1 ms

tp = 1 ms

-1

10

2

V

V

DS

10

3

10

-2

10

tp = 10 ms

DC

0

10

C

1

= 25°C

10

2

V

V

DS

10

3

Page 5

2002-08-12

Final data

SPP20N60C2, SPB20N60C2

SPA20N60C2

5 Transient thermal impedance

= f (tp)

Z

thJC

parameter: D = t

0

10

K/W

-1

10

thJC

Z

-2

10

-3

10

-4

10

-7

10

10

/T

p

D = 0.5

D = 0.2

D = 0.1

D = 0.05

D = 0.02

D = 0.01

single pulse

-6

-5

-4

10

10

10

-3

10

6 Transient thermal impedance FullPAK

= f (tp)

Z

thJC

parameter: D = t

1

10

K/W

0

10

thJC

Z

-1

10

-2

10

-3

-2

s

t

0

10

p

10

10

-6

10

/t

p

D = 0.5

D = 0.2

D = 0.1

D = 0.05

D = 0.02

D = 0.01

single pulse

-5

-4

-3

-2

10

10

10

10

-1

s

t

1

10

p

7 Typ. output characteristic

= f (VDS); Tj=25°C

I

D

parameter: t

75

A

60

55

50

D

I

45

40

35

30

25

20

15

10

5

0

0 5 10 15 20

= 10 µs, V

p

20V

15V

12V

11V

GS

10V

9V

8V

7V

V

V

DS

30

8 Typ. output characteristic

= f (VDS); Tj=150°C

I

D

parameter: t

35

A

25

D

I

20

15

10

5

0

0 5 10 15

= 10 µs, V

p

GS

20V

12V

10V

V

9V

8.5V

8V

7.5V

7V

6.5V

6V

V

25

DS

Page 6

2002-08-12

Final data

SPP20N60C2, SPB20N60C2

SPA20N60C2

9 Typ. drain-source on resistance

R

DS(on)

parameter: T

R

=f(ID)

=150°C, V

j

1.5

Ω

1.3

1.2

1.1

DS(on)

1

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0 5 10 15 20 25 30

GS

6V

6.5V

7V

7.5V

8V

8.5V

9V

10V

12V

20V

A

I

D

40

10 Drain-source on-state resistance

R

DS(on)

parameter : I

= f (Tj)

= 13 A, VGS = 10 V

D

SPP20N60C2

1.1

Ω

0.9

0.8

DS(on)

0.7

R

0.6

0.5

0.4

0.3

0.2

0.1

0

-60 -20 20 60 100

98%

typ

°C

180

T

j

11 Typ. transfer characteristics

= f ( VGS ); V

I

D

DS

≥ 2 x I

D

x R

DS(on)max

parameter: tp = 10 µs

70

A

60

55

50

45

D

I

40

35

30

25

20

15

10

5

0

0 5 10

25°C

150°C

V

V

GS

20

12 Typ. gate charge

V

= f (Q

GS

parameter: I

SPP20N60C2

16

V

12

GS

10

V

8

6

4

2

0

0 20 40 60 80

)

Gate

= 20 A pulsed

D

0,2

V

DS max

0,8 V

nC

DS max

Q

Gate

120

Page 7

2002-08-12

Final data

SPP20N60C2, SPB20N60C2

SPA20N60C2

13 Forward characteristics of body diode

= f (VSD)

I

F

parameter: Tj , t

2

SPP20N60C2

10

A

1

10

F

I

0

10

-1

10

0 0.4 0.8 1.2 1.6 2 2.4

p = 10 µs

Tj = 25 °C typ

Tj = 150 °C typ

Tj = 25 °C (98%)

Tj = 150 °C (98%)

3

V

V

SD

14 Typ. switching time

t = f (I

par.: V

), inductive load, Tj=125°C

D

=380V, VGS=0/+13V, RG=3.6Ω

DS

3

10

ns

2

10

t

t

d(on)

1

10

0

10

0 5 10 15 20 25 30 35 40

t

r

t

d(off)

t

f

50

A

I

D

15 Typ. switching time

t = f (R

par.: V

t

), inductive load, Tj=125°C

G

=380V, VGS=0/+13V, ID=20A

DS

3

10

ns

t

d(off)

2

10

1

10

0

10

0 5 10 15 20 25 30

16 Typ. switching losses

1)

E = f (ID), inductive load, Tj=125°C

par.: V

mWs

t

d(on)

t

r

t

f

40

Ω

R

G

E

=380V, VGS=0/+13V, RG=3.6Ω

DS

1.6

*) Eon includes SDP06S60 diode

commutation losses.

1

This chart helps to estimate

the switching power losses.

The values can be different

under other operating conditions.

1.2

1

0.8

0.6

Eon*

0.4

E

off

0.2

0

0 5 10 15 20 25 30 35

A

45

I

D

Page 8

2002-08-12

Final data

SPP20N60C2, SPB20N60C2

SPA20N60C2

17 Typ. switching losses

1)

E = f(RG), inductive load, Tj=125°C

par.: V

mWs

E

=380V, VGS=0/+13V,ID=20A

DS

1

*) Eon includes SDP06S60 diode

commutation losses.

1

This chart helps to estimate

the switching power losses.

The values can be different

0.8

under other operating conditions.

0.7

0.6

0.5

0.4

0.3

0.2

0.1

Eon*

E

off

18 Avalanche SOA

= f (tAR)

I

AR

par.: T

AR

I

≤ 150 °C

j

20

A

10

5

(START)

T

j

=125°C

(START)

T

j

=25°C

0

0 5 10 15 20 25 30

19 Avalanche energy

= f (Tj)

E

AS

par.: I

= 10 A, VDD = 50 V

D

750

mJ

600

550

500

AS

E

450

400

350

300

250

200

150

100

50

0

20 40 60 80 100 120

°C

Ω

R

T

0

-3

-2

40

G

10

10

-1

10

10 0 10 1 10

2

µs

t

AR

10

4

20 Drain-source breakdown voltage

V

(BR)DSS

(BR)DSS

V

160

j

= f (Tj)

SPP20N60C2

720

V

680

660

640

620

600

580

560

540

-60 -20 20 60 100

°C

180

T

j

Page 9

2002-08-12

Final data

SPP20N60C2, SPB20N60C2

SPA20N60C2

21 Avalanche power losses

= f (f )

P

AR

parameter: E

500

W

AR

P

300

200

100

0

4

10

AR

=1mJ

10

5

Hz

22 Typ. capacitances

C = f (V

parameter: V

10

pF

10

10

C

10

10

6

10

f

10

)

DS

=0V, f=1 MHz

GS

5

4

C

iss

3

C

2

C

1

0

rss

0 100 200 300 400

oss

V

V

600

DS

23 Typ. C

=f(VDS)

E

oss

14

µJ

12

11

10

oss

9

E

8

7

6

5

4

3

2

1

0

0 100 200 300 400

stored energy

oss

V

V

600

DS

Page 10

2002-08-12

Final data

Definition of diodes switching characteristics

SPP20N60C2, SPB20N60C2

SPA20N60C2

Page 11

2002-08-12

P-TO-220-3-1

±0.4

10

±0.2

3.7

SPP20N60C2, SPB20N60C2

Final data

B

4.44

A

±0.13

1.27

SPA20N60C2

±0.6

±0.2

2.8

0.05

15.38

±0.5

C

±0.9

5.23

13.5

3x

±0.1

0.75

±0.22

1.17

2.54

2x

M

BA0.25

C

All metal surfaces tin plated, except area of cut.

Metal surface min. x=7.25, y=12.3

P-TO-263-3-1 (D2-PAK)

±0.2

0...0.3

±0.3

1

±0.2

9.25

(15)

0...0.15

10

8.5

A

1)

1)

7.55

±0.1

0.75

1.05

2.54

1.27

B

±0.5

4.7

8

˚

±0.1

0.1

2.4

±0.3

2.7

MAX.

4.4

0.5

0.5

2.51

±0.

±0.48

9.98

±0.1

±0.2

0.05

1

5.08

M

BA0.25

1)

Typical

All metal surfaces: tin plated, except area of cut.

Metal surface min. x=7.25, y=6.9

Page 12

0.1

B

2002-08-12

P-TO-220-3-31 (FullPAK)

±0.005

10.5

Final data

SPP20N60C2, SPB20N60C2

SPA20N60C2

4.7

±0.005

±0.005

9.68

±0.005

3.3

±0.005

±0.005

15.99

14.1

±0.001

1.5

±0.005

12.79

±0.002

6.1

123

±0.005

2.7

±0.005

˚

7

13.6

1.28

+0.003

-0.002

0.7

+0.003

-0.002

2.57

±0.002

0.5

+0.005

-0.002

2.54

Please refer to mounting instructions (application note AN-TO220-3-31-01)

Page 13

2002-08-12

SPP20N60C2, SPB20N60C2

Final data

Published by

Infineon Technologies AG,

Bereichs Kommunikation

St.-Martin-Strasse 53,

D-81541 München

© Infineon Technologies AG 1999

All Rights Reserved.

Attention please!

The information herein is given to describe certain components and shall not be considered as warranted

characteristics.

Terms of delivery and rights to technical change reserved.

We hereby disclaim any and all warranties, including but not limited to warranties of non-infringement,

regarding circuits, descriptions and charts stated herein.

Infineon Technologies is an approved CECC manufacturer.

Information

For further information on technology, delivery terms and conditions and prices please contact your nearest

Infineon Technologies Office in Germany or our Infineon Technologies Reprensatives worldwide (see address list).

Warnings

Due to technical requirements components may contain dangerous substances.

For information on the types in question please contact your nearest Infineon Technologies Office.

Infineon Technologies Components may only be used in life-support devices or systems with the express

written approval of Infineon Technologies, if a failure of such components can reasonably be expected to

cause the failure of that life-support device or system, or to affect the safety or effectiveness of that device

or system Life support devices or systems are intended to be implanted in the human body, or to support

and/or maintain and sustain and/or protect human life. If they fail, it is reasonable to assume that the health

of the user or other persons may be endangered.

SPA20N60C2

Page 14

2002-08-12

Loading...

Loading...