Page 1

AN2018

-

13

IM393 Application note

IM393 IPM Technical Description

About this document

Scope and purpose

The scope of this application note is to describe the IM393 product family and the basic requirements for

operating the products in a recommended mode. This includes integrated components, such as IGBT,

bootstrap functionality or gate drive IC, as well as the design of the necessary external circuitry, interfacing and

application use.

Intended audience

Power electronics engineers who want to design reliable and efficient motor drive application with IM393 IPM

family.

Table of contents

About this document ....................................................................................................................... 1

Table of contents ............................................................................................................................ 1

1 Introduction .......................................................................................................................... 3

1.1 Product line-up ........................................................................................................................................ 4

1.2 Nomenclature .......................................................................................................................................... 5

2 Internal components and package technology .......................................................................... 6

2.1 Power transistor and diode technology ................................................................................................. 6

2.2 Control IC – Six-channel gate driver IC ................................................................................................... 6

2.3 Thermistor ............................................................................................................................................... 7

2.4 Package technology ................................................................................................................................ 8

3 Product overview and pin description ...................................................................................... 9

3.1 Internal circuit and features ................................................................................................................... 9

3.2 Maximum electrical rating .................................................................................................................... 10

3.3 Description of the input and output pins ............................................................................................. 10

3.4 Outline drawings ................................................................................................................................... 15

4 Interface circuit and layout guide ........................................................................................... 17

4.1 Input/output signal connection ............................................................................................................ 17

4.2 Input/output signal connection ............................................................................................................ 19

4.3 Recommended circuit current of power supply .................................................................................. 20

4.4 Recommended layout for over-current protection (OCP) and short-circuit protection (SCP)

functions ................................................................................................................................................ 21

4.5 Recommended wiring of shunt resistor and snubber capacitor ......................................................... 21

4.6 Pin and screw hole coordinates for IM393-XX footprint ...................................................................... 23

5 Function and protection circuit ............................................................................................... 25

5.1 Over-current protection ........................................................................................................................ 25

5.1.1 Timing chart of over-current protection (OCP) ............................................................................... 25

5.1.2 Selecting current-sensing shunt resistor ........................................................................................ 26

5.1.3 Delay time ......................................................................................................................................... 27

Application Note Please read the Important Notice and Warnings at the end of this document V 1.0

www.infineon.com page 1 of 53 2019-04-01

Page 2

IM393 Application note

IM393 IPM Technical Description

Introduction

5.2 Fault output and auto-clear function ................................................................................................... 27

5.3 Undervoltage lockout (UVLO) ............................................................................................................... 29

5.4 Over-temperature protection ............................................................................................................... 31

6 Bootstrap circuit ................................................................................................................... 33

6.1 Bootstrap circuit operation .................................................................................................................. 33

6.2 Initial charge of bootstrap capacitor .................................................................................................... 34

6.3 Bootstrap capacitor selection .............................................................................................................. 34

6.4 Charging and discharging of the bootstrap capacitor during PWM inverter operation ..................... 35

7 Thermal design ..................................................................................................................... 37

7.1 Introduction ........................................................................................................................................... 37

7.2 Power losses .......................................................................................................................................... 38

7.2.1 Conduction losses ............................................................................................................................ 38

7.2.2 Switching losses ............................................................................................................................... 39

7.3 Thermal impedance .............................................................................................................................. 39

7.4 Temperature rise considerations and calculation example ................................................................ 40

7.5 Heat sink selection guide ...................................................................................................................... 42

7.5.1 Required heat sink performance ..................................................................................................... 42

7.5.2 Heat sink characteristics .................................................................................................................. 43

7.5.2.1 Heat transfer from heat source to heat sink .............................................................................. 43

7.5.2.2 Heat transfer within the heat sink .............................................................................................. 43

7.5.2.3 Heat transfer from heat sink surface to ambient ....................................................................... 43

7.5.3 Selecting a heat sink ........................................................................................................................ 45

7.6 Online simulation tool .......................................................................................................................... 45

8 Heat sink mounting and handling guidelines ............................................................................ 47

8.1 Heat sink mounting ............................................................................................................................... 47

8.1.1 General guidelines ........................................................................................................................... 47

8.1.1.1 Recommended tightening torque .............................................................................................. 47

8.1.1.2 Screw tightening to heat sink ..................................................................................................... 48

8.2 Handling guideline ................................................................................................................................ 49

8.3 Storage guideline .................................................................................................................................. 50

8.3.1 Recommended storage conditions ................................................................................................. 50

9 References ........................................................................................................................... 51

Revision history............................................................................................................................. 52

Application Note 2 of 53 V 1.0

2019-04-01

Page 3

IM393 Application note

IM393 IPM Technical Description

Introduction

1 Introduction

With the global emphasis on energy efficiency, there are ever stricter requirements on the efficiency of motor

drive circuits. CIPOS™ Integrated Power Modules (IPMs) are becoming more popular in the home appliance and

industrial motor-drive applications, because of their higher efficiency, smaller size, easier assembly and shorter

development time.

The next generation of CIPOS™ IPM from Infineon Technologies has been developed with a focus on improving

module efficiency and long-term reliability. The combined benefits of advanced trench IGBT technology and

optimized package design have enabled us to achieve higher efficiency and improved reliability, along with

minimized module system costs. Integrating discrete power semiconductors and drivers into one package

allows designers to reduce the time and effort spent on design. To meet the strong demand for small size and

higher power density, Infineon has developed a new family of highly integrated intelligent power modules that

contain nearly all of the semiconductor components required to drive electronically controlled variable-speed

electric motors.

This advanced IPM is a combination of Infineon’s newest low V

best trade-off between conduction and switching losses, and the industry benchmark three-phase high voltage,

high-speed driver (3.3 V-compatible) in a fully isolated thermally enhanced package. A built-in high precision

temperature monitor and over-current protection feature, along with the short-circuit rated IGBTs and

integrated undervoltage lockout function, deliver a high level of protection and fail-safe operation. Using a dual

or single in-line package with full transfer molded structure resolves the isolation problem to the heat sink.

The application note concerns the following products:

− IM393-S6E

− IM393-S6F

− IM393-M6E

− IM393-M6F

− IM393-L6E

− IM393-L6F

− IM393-X6E

− IM393-X6F

IM393-XX is part of CIPOS™ Tiny family of intelligent power modules which are designed for motor drives in

household appliances covering a wide range of power from 100 W up to 1500 W with products such as:

− Washing machines

− Dish washers

− Refrigerators

− Air conditioning compressors

− Pumps

trench IGBT technology optimized for the

CE(ON)

Application Note 3 of 53 V 1.0

2019-04-01

Page 4

IM393 Application note

IM393 IPM Technical Description

Introduction

1.1 Product line-up

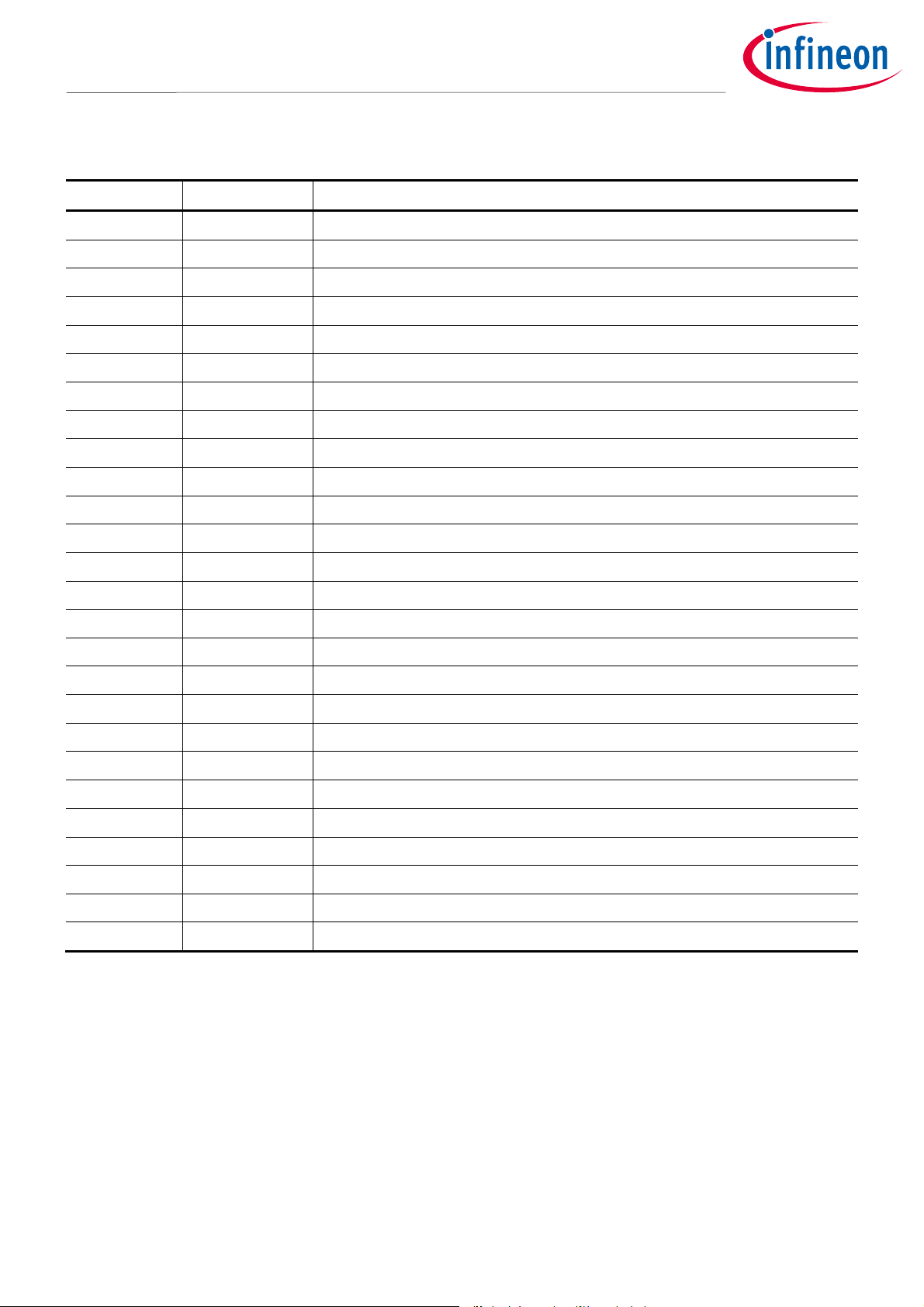

Table 1 IM393-XX Products

Rating

Part Number

Current

(A)

Voltage

(V)

Internal

Circuit

Package

Isolation

voltage (V

RMS

Main applications

)

Refrigerator

IM393-S6E(F) 6 A

E(Fully

Dryer

Dish washer

molded

Washing

machine

Dryer

Elevator door

Washing

machine

Air conditioner

Elevator door

IM393-M6E(F) 10 A

IM393-L6E(F) 15 A

600 V

3 ф Bridge

Open

emitter

DIP

Module)

F(Fully

molded

SIP

Module)

2000 V

RMS

sinusoidal,

1min.

IM393-X6E(F) 20 A Air conditioner

Fan

Pump

GPI

Application Note 4 of 53 V 1.0

2019-04-01

Page 5

IM393 Application note

IM393 IPM Technical Description

Introduction

1.2 Nomenclature

Application Note 5 of 53 V 1.0

2019-04-01

Page 6

IM393 Application note

IM393 IPM Technical Description

Internal components and package technology

2 Internal components and package technology

2.1 Power transistor and diode technology

IM393-XX IPM products are based on new Infineon IGBT6 TRENCHSTOP™ technology [1]. This new IGBT

generation is based on trench and field-stop technology, and offers significant improvements in terms of loss

reduction. It features the well-known properties of robustness of Infineon’s IGBT, including short-circuitwithstand capability and maximum-junction temperature. Moreover, all the advantages of this technology are

maintained in order to achieve the highest efficiency and power density. The features include very low static

parameters such as the saturation voltage of the IGBT or the forward voltage of the diode. Excellent dynamic

parameters such as turn-off energy of the IGBT or the reverse-recovery charge of the diode are also valuable

features. The forward diodes are ultrafast with very soft recovery characteristics that lead to a reduction in

reverse-recovery and turn-on energy losses.

2.2 Control IC – Six-channel gate driver IC

The driver is a high-voltage, high-speed IGBT gate driver with three high-side and three low-side referenced

output channels for three-phase applications. The IC is designed to be used with low-cost bootstrap power

supplies. The bootstrap diode functionality has been integrated into this device to reduce the component

count on the PCB. Proprietary HVIC and latch-up immune CMOS technologies have been implemented in a

rugged monolithic structure. The floating logic input is compatible with standard CMOS and LSTTL output

(down to 3.3 V logic). A current-trip function which terminates all six outputs can be done by an external current

sense resistor. Enable functionality is available to terminate all six outputs simultaneously. An open-drain

FAULT signal is provided to indicate that a fault has occurred. Fault conditions are cleared automatically after a

delay programmed externally via an RC network connected to the RCIN input. The output drivers feature a

high-pulse current buffer stage designed for minimum driver cross conduction. Shoot-through protection

circuitry and a minimum dead-time circuitry have been integrated into this IC. Propagation delays are matched

to simplify the HVIC’s use in high-frequency applications.

The HVIC technology uses proprietary monolithic structures integrating bipolar, CMOS and lateral DMOS

devices [2]. Using this mixed-signal HVIC technology, both high-voltage, level-shifting circuits, and low-voltage

analog and digital circuits can be implemented. This technology places high-voltage circuits in a ‘well’ formed

by polysilicon rings which can float 600 V within the same silicon, away from the low-voltage circuitry, as shown

in Figure 1.

These HVIC gate drivers with floating switches are well-suited for topologies requiring high-side and bridge

configuration.

Figure 1 Structure and cross section of the HVIC

Application Note 6 of 53 V 1.0

2019-04-01

Page 7

IM393 Application note

IM393 IPM Technical Description

Internal components and package technology

2.3 Thermistor

All IM393-XX IPMs have internal thermistors to sense the module temperature. Figure 2 shows the correlation

between NTC temperature (TTH) and the thermistor output voltage which can be used to set the threshold for

over-temperature protection.

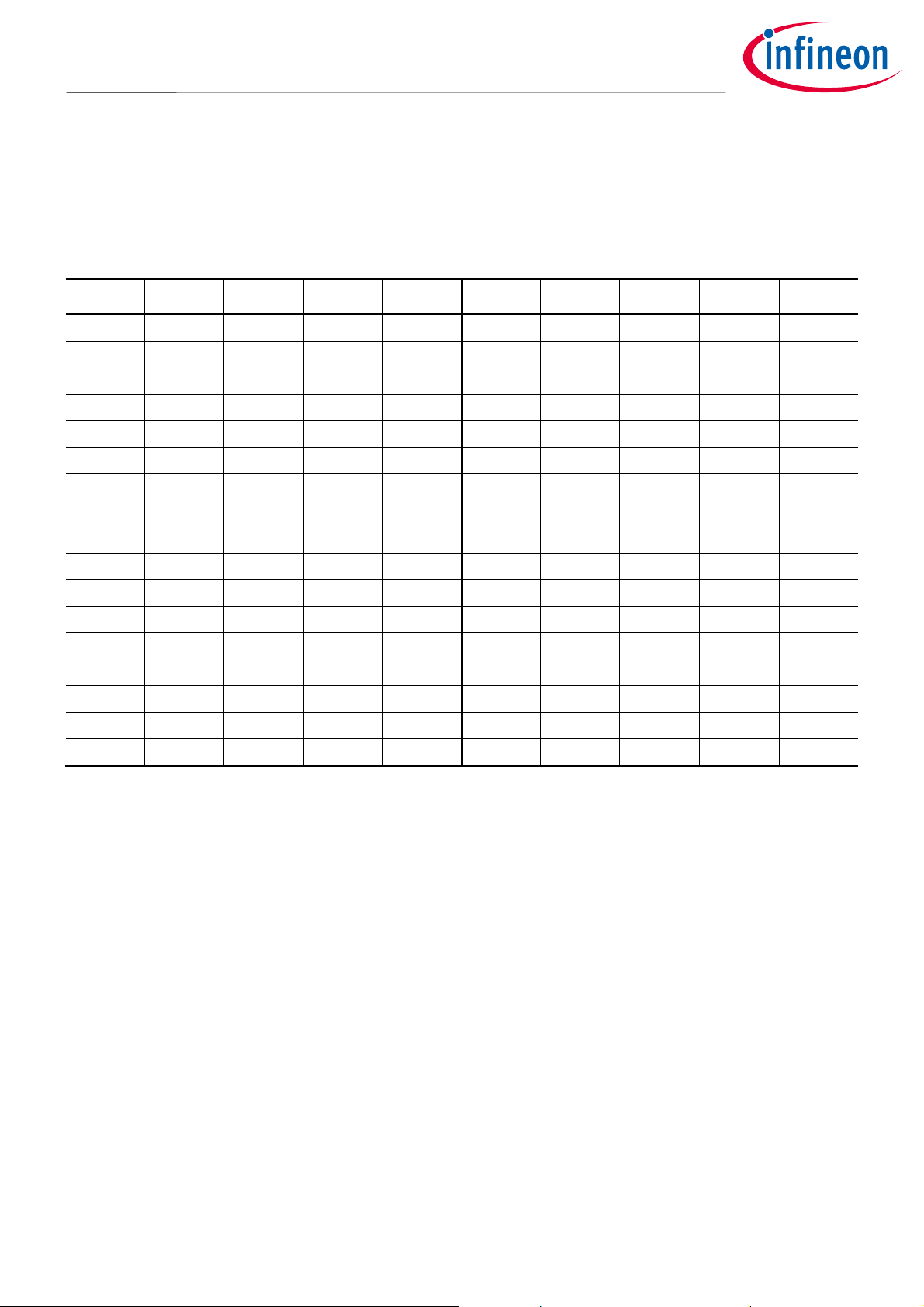

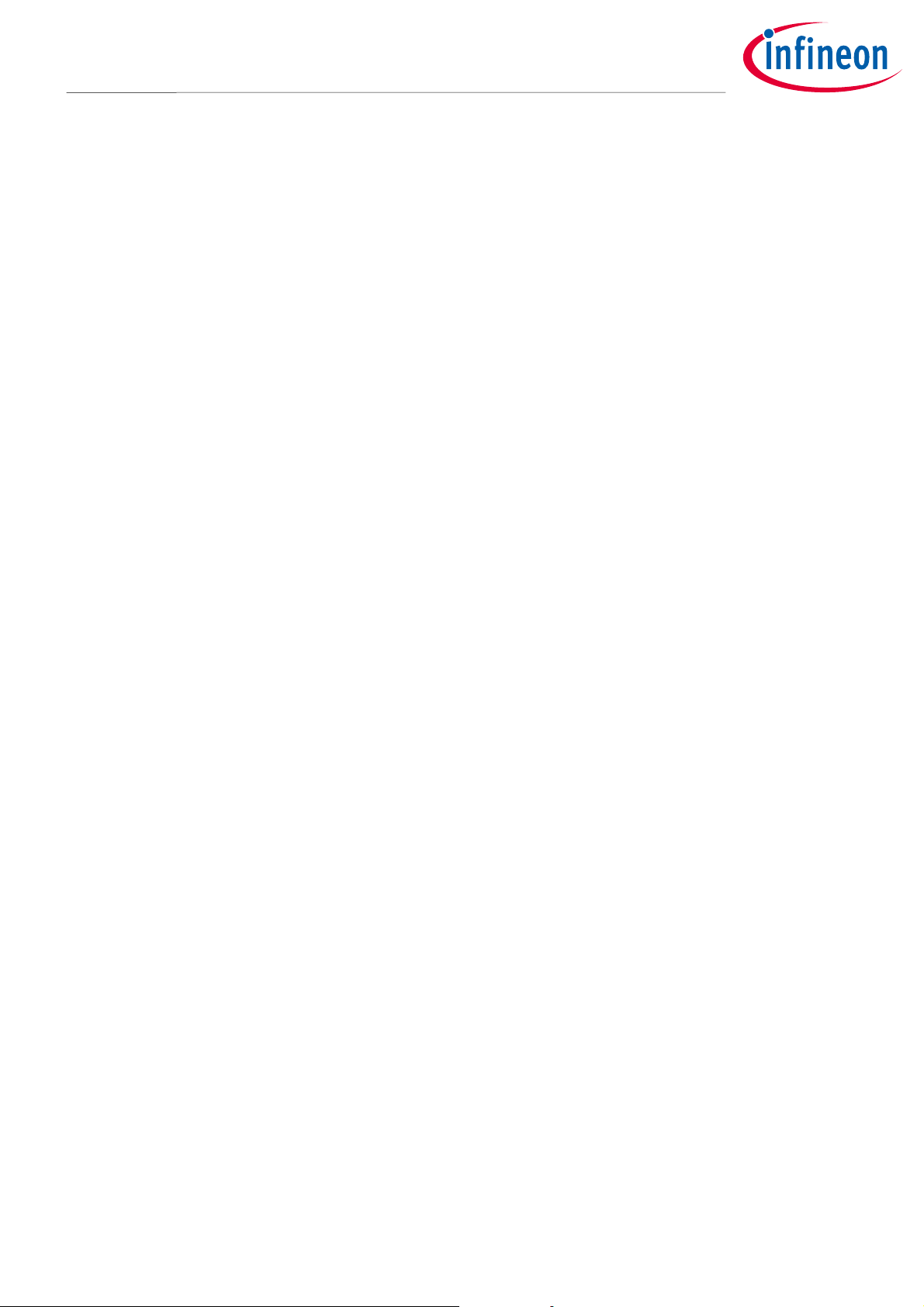

Table 2 Raw data of the thermistor used in IM393-XX

T [℃] R

[kΩ] R

min

[kΩ] R

typ

max

[kΩ]

Tol [%]

T [℃] R

[kΩ] R

min

[kΩ] R

typ

max

[kΩ]

Tol [%]

-40 1438.40 1568.15 1705.34 8.7% 45 18.930 20.097 21.282 5.9%

-35 1040.65 1130.82 1225.73 8.4% 50 15.448 16.432 17.436 6.1%

-30 761.64 825.03 891.47 8.1% 55 12.695 13.531 14.385 6.3%

-25 563.53 608.58 655.58 7.7% 60 10.4830 11.1942 11.9238 6.5%

-20 421.23 453.57 487.16 7.4% 65 8.6961 9.3033 9.9279 6.7%

-15 317.53 340.93 365.14 7.1% 70 7.2454 7.7652 8.3016 6.9%

-10 241.62 258.72 276.33 6.8% 75 6.0619 6.5084 6.9703 7.1%

-5 185.51 198.10 211.02 6.5% 80 5.0922 5.4767 5.8755 7.3%

0 143.62 152.98 162.53 6.2% 85 4.3017 4.6342 4.9800 7.5%

5 112.35 119.37 126.51 6.0% 90 3.6482 3.9366 4.2372 7.6%

10 88.440 93.740 99.109 5.7% 95 3.1056 3.3565 3.6186 7.8%

15 70.033 74.055 78.112 5.5% 100 2.6533 2.8721 3.1012 8.0%

20 55.770 58.837 61.918 5.2% 105 2.2748 2.4661 2.6669 8.1%

25 44.650 47.000 49.350 5.0% 110 1.9567 2.1245 2.3009 8.3%

30 35.772 37.737 39.711 5.2% 115 1.6886 1.8360 1.9913 8.5%

35 28.801 30.449 32.110 5.5% 120 1.4616 1.5915 1.7287 8.6%

40 23.298 24.682 26.084 5.7% 125 1.2690 1.3837 1.5050 8.8%

Thermistor temperature (or voltage reading) can then be linked to the IGBT junction temperature. The VTH can

be used as a microcontroller input to monitor IGBT junction temperature during operation.

Figure 2 IGBT junction temperature vs. internal thermistor temperature for IM393-L6E

Application Note 7 of 53 V 1.0

2019-04-01

Page 8

IM393 Application note

IM393 IPM Technical Description

Internal components and package technology

Figure 2 is valid only for the following conditions:

- V

= 300 V

DC

- PWM sinusoidal modulation

- I

- F

- F

phase = 5 A

rms

= 16 kHz

sw

= 50 Hz

mod

- MI = 0.8

- PF = 0.6

- Heat sink R

For different application conditions, the difference between TJ and T

less heat. Also in the extreme case of zero current, TJ and T

= 1.25 °C/W

th

will be smaller if the module dissipates

TH

will be identical. In any case, it should be ensured

TH

for safety reasons that the absolute maximum junction temperature is not reached.

Please note that an over-temperature event in the IGBT will only be visible in the NTC readings after a certain

time, which depends significantly on the application conditions.

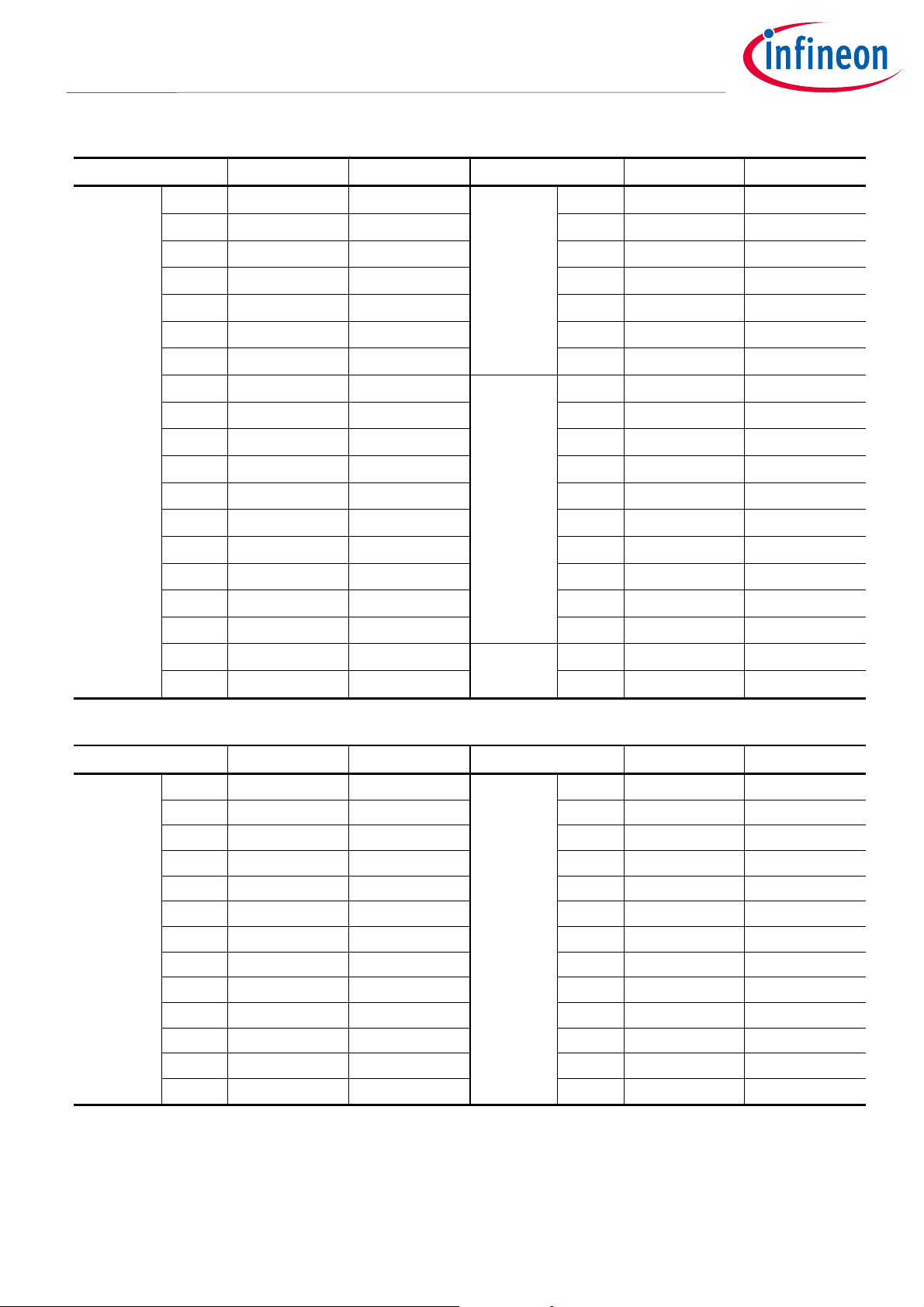

2.4 Package technology

IM393-XX offers the smallest size while providing high-power density up to 600 V and 20 A by employing

TRENCHSTOP™ IGBT and emitter-controlled diodes with a six-channel gate drive IC. It contains all power

components such as IGBTs, and isolates them from each other and from the heat sink. All low-power

components such as the gate drive IC and thermistor are assembled on a lead frame.

The electric insulation is provided by the mold compound, which is simultaneously the thermal contact to the

heat sink. In order to further decrease the thermal impedance, the internal lead-frame design has been

optimized [3]. Figure 3 shows the external view of the IM393-XX package.

(a) Dual in-line package (b) Single in-line package

Figure 3 External view of IM393-XX

Application Note 8 of 53 V 1.0

2019-04-01

Page 9

IM393 Application note

IM393 IPM Technical Description

Product overview and pin description

3 Product overview and pin description

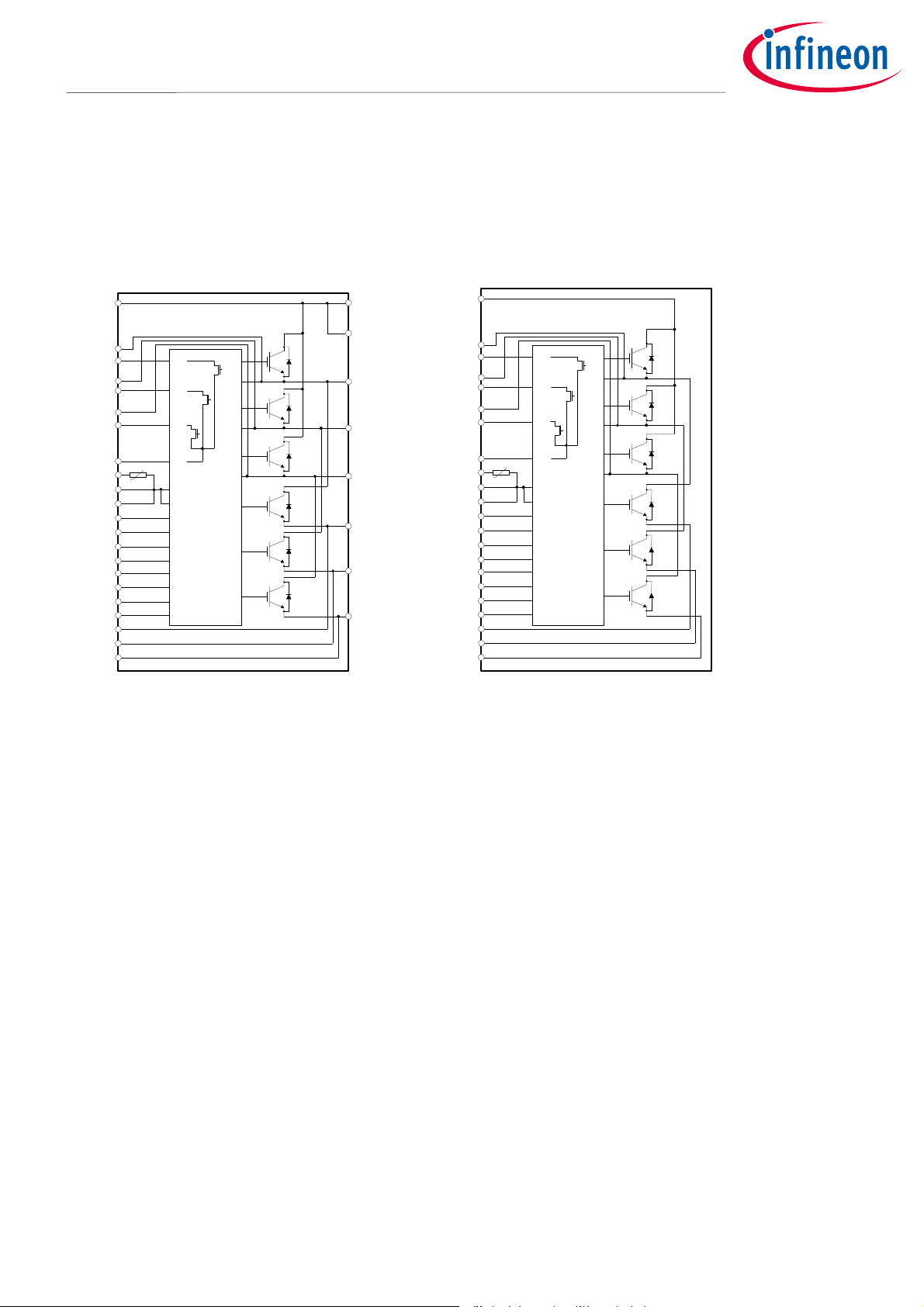

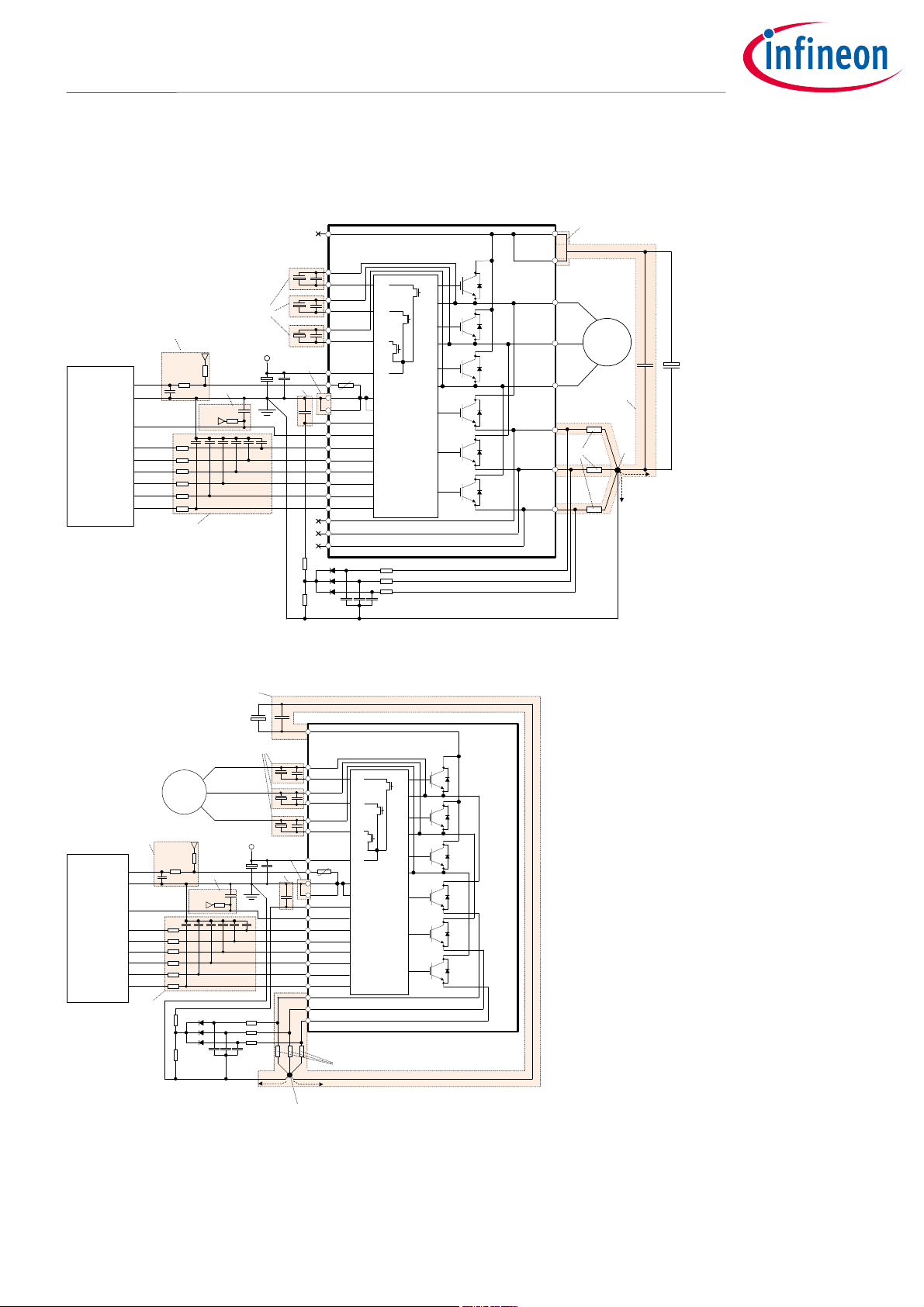

3.1 Internal circuit and features

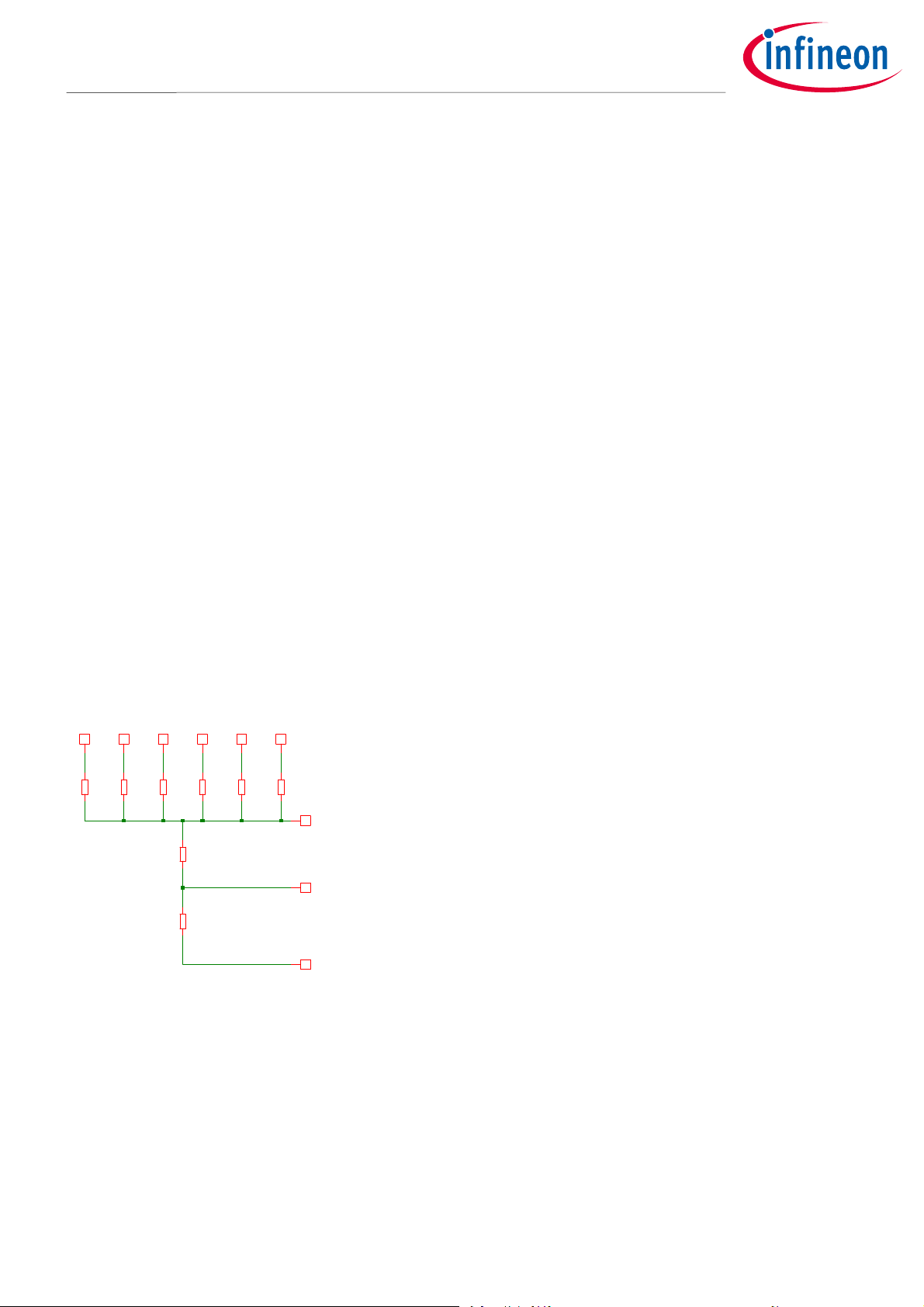

Figure 3 illustrates the internal block diagram of the IM393-XX. It consists of a three-phase IGBT inverter circuit

and a driver IC with control functions. The detailed features and integrated functions of IM393-XX are described

as follows:

(1) P

(35) P

(1) P

(3) VS(W)

(4) VB(W)

(6) VS(V)

(7) VB(V)

(9) VS(U)

(10) VB(U)

(12) VDD

(13) VTH

(14) COM

(15) COM

(16) ITRIP

(17) RFE

(18) HIN(U)

(19) HIN(V)

(20) HIN(W)

(21) LIN(U)

(22) LIN(V)

(23) LIN(W)

(24) N(W)

(25) N(V)

(26) N(U)

(33) P

VB3

VB2

VB1

VDD

-t°

COM

VSS

ITRIP

RFE

HIN1

HIN2

HIN3

LIN1

LIN2

LIN3

HO3

HO2

HO1

VS3

VS2

VS1

LO3

LO2

LO1

(32) W

(31) V

(30) U

(29) N(W)

(28) N(V)

(27) N(U)

(3) VS(W)

(4) VB(W)

(6) VS(V)

(7) VB(V)

(9) VS(U)

(10) VB(U)

(12) VDD

(13) VTH

(14) COM

(15) COM

(16) ITRIP

(17) RFE

(18) HIN(U)

(19) HIN(V)

(20) HIN(W)

(21) LIN(U)

(22) LIN(V)

(23) LIN(W)

(24) N(W)

(25) N(V)

(26) N(U)

VB3

VB2

VB1

VDD

-t°

COM

VSS

ITRIP

RFE

HIN1

HIN2

HIN3

LIN1

LIN2

LIN3

HO3

VS3

HO2

VS2

HO1

VS1

LO3

LO2

LO1

(a) Dual in-line package (b) Single in-line package

Figure 4 Internal circuit

Features

− 600 V / 6 A to 20 A rating in one physical package size (mechanical layouts are identical)

− Motor power range from 100 W to 1.5 kW

− Fully isolated dual in-line package (DIP) and single in-line package (SIP) molded module

− Infineon low- V

− Undervoltage lockout for all channels

− Rugged gate driver technology with stability against transients and negative voltage

− Integrated bootstrap functionality

− Matched delay times of all channels / Built-in deadtime

− Over-current protection

− Lead-free terminal plating; RoHS-compliant

− 3.3 V Schmitt triggered input logic

− Cross conduction preventing logic

− Low-side emitter pins accessible for current monitoring

− Active high input signal logic

− Isolation 2000 V

− High operating case temperature, T

− Temperature monitor

TRENCHSTOP™ IGBTs with separate freewheeling diode

CE(ON)

min and CTI>600

RMS

= 125°C

Cmax

Application Note 9 of 53 V 1.0

2019-04-01

Page 10

IM393 Application note

IM393 IPM Technical Description

Product overview and pin description

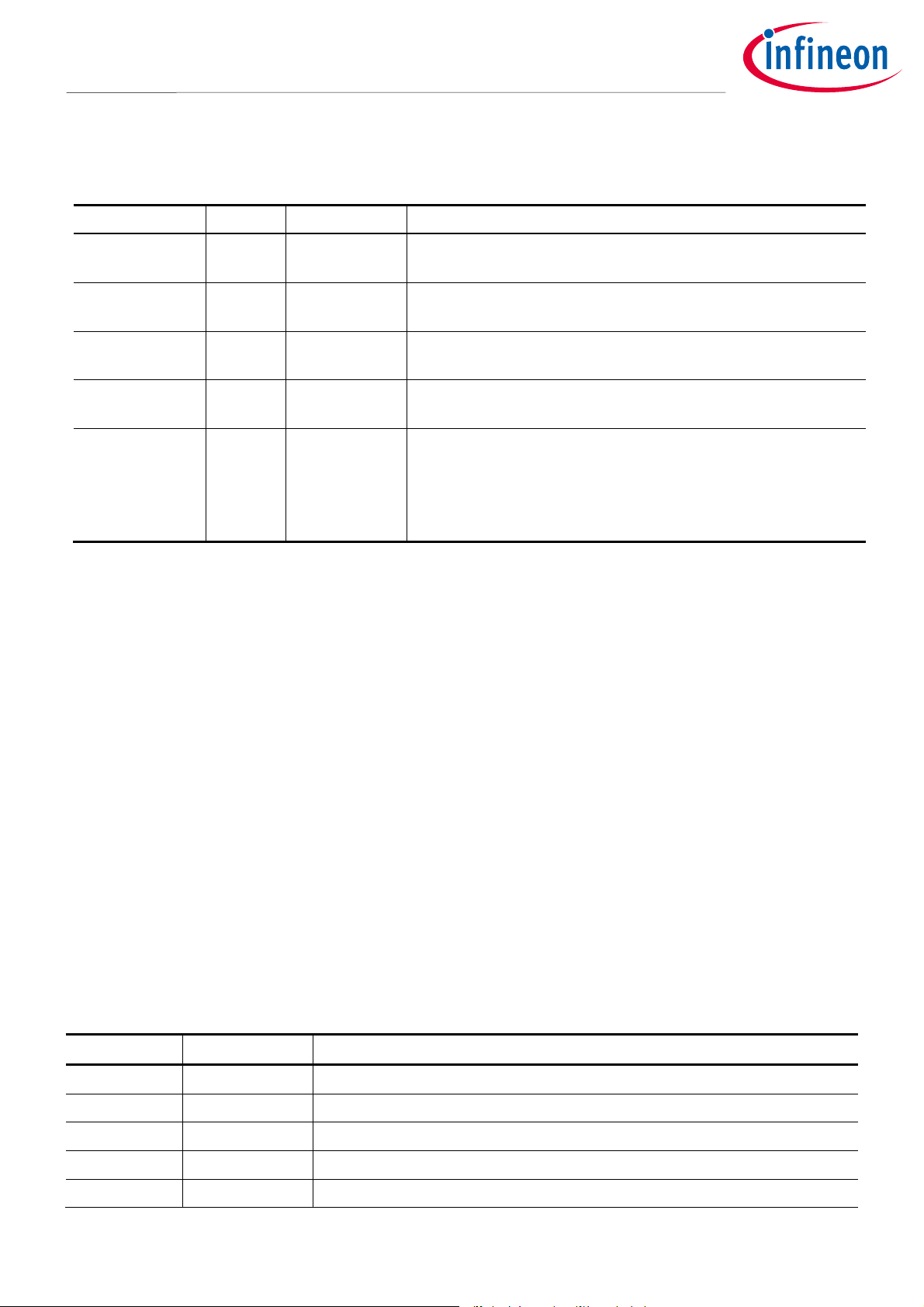

3.2 Maximum electrical rating

Table 3 Detailed description of absolute maximum ratings (IM393-M6E/F case)

Item Symbol Rating Description

Max. blocking

voltage

Output RMS

current

Output peak

current

Junction

temperature

Operating case

temperature

range

V

I

Peak

T

T

CES

I

600 V The sustained collector-emitter voltage of internal IGBTs

C

10 A

15 A

J

-40 ~ 150°C

The allowable RMS IGBT collector current at steady state and

Tc = 25 °C.

The allowable peak IGBT collector current at Tc = 25°C

Considering temperature ripple on the power chips, the

maximum junction temperature rating of IM393-XX is 150°C.

Tc (case temperature) is defined as a temperature of the

package surface underneath the specified power chip. Please

C

-40 ~ 125°C

mount a temperature sensor on a heat-sink surface at the

defined position in Figure 5 so as to get accurate temperature

information.

Figure 5 TC measurement point

3.3 Description of the input and output pins

The following tables define the DIP type of IM393-XX input and output pins. The detailed functional descriptions

are as follows:

Pin Name Description

1 P Positive bus input voltage

2 N/A None

3 VS(W) W-phase high side floating supply offset voltage

4 VB(W) W-phase high side floating supply voltage

5 N/A None

Application Note 10 of 53 V 1.0

2019-04-01

Page 11

IM393 Application note

IM393 IPM Technical Description

Product overview and pin description

6 VS(V) V-phase high side floating supply offset voltage

7 VB(V) V-phase high side floating supply voltage

8 N/A None

9 VS(U) U-phase high side floating supply offset voltage

10 VB(U) U-phase high side floating supply voltage

11 N/A None

12 VDD Low side control supply

13 VTH Temperature monitor

14 COM Low side control negative supply

15 COM Low side control negative supply

16 ITRIP Over current protection input

17 RFE RCIN / Fault / Enable

18 HIN(U) U-phase high side gate driver input

19 HIN(V) V-phase high side gate driver input

20 HIN(W) W-phase high side gate driver input

21 LIN(U) U-phase low side gate driver input

22 LIN(V) V-phase low side gate driver input

23 LIN(W) W-phase low side gate driver input

24 N(W) W-phase low side emitter

25 N(V) V-phase low side emitter

26 N(U) U-phase low side emitter

27 N(U) U-phase low side emitter (DIP only)

28 N(V) V-phase low side emitter (DIP only)

29 N(W) W-phase low side emitter (DIP only)

30 U U-phase output (DIP only)

31 V V-phase output (DIP only)

32 W W-phase output (DIP only)

33 P Positive bus input voltage (DIP only)

34 N/A None

35 P Positive bus input voltage (DIP only)

36 N/A None

Application Note 11 of 53 V 1.0

2019-04-01

Page 12

IM393 Application note

IM393 IPM Technical Description

Product overview and pin description

The following tables define the SIP type of IM393-XX input and output pins. The detailed functional descriptions

are as follows:

Pin Name Description

1 P Positive bus input voltage

2 N/A None

3 VS(W) / W W-phase high side floating supply offset voltage / W-phase output

4 VB(W) W-phase high side floating supply voltage

5 N/A None

6 VS(V) / V V-phase high side floating supply offset voltage / V-phase output

7 VB(V) V-phase high side floating supply voltage

8 N/A None

9 VS(U) / U U-phase high side floating supply offset voltage / U-phase output

10 VB(U) U-phase high side floating supply voltage

11 N/A None

12 VDD Low side control supply

13 VTH Temperature monitor

14 COM Low side control negative supply

15 COM Low side control negative supply

16 ITRIP Over current protection input

17 RFE RCIN / Fault / Enable

18 HIN(U) U-phase high side gate driver input

19 HIN(V) V-phase high side gate driver input

20 HIN(W) W-phase high side gate driver input

21 LIN(U) U-phase low side gate driver input

22 LIN(V) V-phase low side gate driver input

23 LIN(W) W-phase low side gate driver input

24 N(W) W-phase low side emitter

25 N(V) V-phase low side emitter

26 N(U) U-phase low side emitter

Application Note 12 of 53 V 1.0

2019-04-01

Page 13

IM393 Application note

IM393 IPM Technical Description

Product overview and pin description

High-side bias voltage pins for driving the IGBT

Pins: VB(U) – VS(U) , VB(V) – VS(V), VB(W) – VS(W)

• These pins provide the gate drive power to the high-side IGBTs.

• The ability to utilize a bootstrap circuit scheme for the high-side IGBTs eliminates the need for external power

supplies.

• Each bootstrap capacitor is charged from the V

IGBT or the freewheeling state of the low-side freewheeling diode.

• In order to prevent malfunctions caused by noise and ripple in the supply voltage, a good quality (low ESR,

low ESL) filter capacitor should be mounted very close to these pins.

Low-side bias voltage pin

Pin: VDD

• This is the control supply pin for the internal IC.

• In order to prevent malfunctions caused by noise and ripple in the supply voltage, a good quality (low ESR,

low ESL) filter capacitor should be mounted very close to this pin.

supply during the ON-state of the corresponding low-side

DD

Low-side common supply ground pin

Pin: COM

• This pin connects the control ground for the internal IC.

Signal Input pins

Pins: HIN(U), HIN(V), HIN(W), LIN(U), LIN(V), LIN(W)

• These are pins to control the operation of the internal IGBTs.

• They are activated by voltage input signals. The terminals are internally connected to a Schmitt trigger circuit

composed of 5 V-class CMOS.

• The signal logic of these pins is active-high. The IGBT associated with each of these pins will be turned ON

when a sufficient logic voltage is applied to these pins.

• The wiring of each input should be as short as possible to protect the IM393-XX against noise influences.

• To prevent signal oscillations, an RC coupling is recommended as illustrated in Figure 4.1.

Over-current detection pin

Pin: ITRIP

• The current-sensing shunt resistor should be connected between the pin N (emitter of low-side IGBT) and the

power ground to detect short-circuit current (refer to Figure 4.3). An RC filter should be connected between

the shunt resistor and the pin ITRIP to eliminate noise.

• The integrated comparator is triggered if the voltage V

selected to meet this level for the specific application. In case of a trigger event, the voltage at pin RFE is pulled

down to LOW.

• The connection length between the shunt resistor and ITRIP pin should be minimized.

Application Note 13 of 53 V 1.0

is higher than 0.49 V. The shunt resistor should be

ITRIP

2019-04-01

Page 14

IM393 Application note

IM393 IPM Technical Description

Product overview and pin description

RCIN/Fault/Enable input pin

Pin: RFE

• In case of an over-current event, the FLT/EN pin will get low with the turning ON of the open-drain MOSFET.

This pin is used to post I

• There are two situations in which the fault is reported via the RCIN/FLT/EN pin.

• The first is an undervoltage condition of V

pin will get low with the turning ON of the open-drain MOSFET.

• When the fault has been removed, the fault clear timer is started, and the length of the fault clear time period

is determined by the external capacitor value. (see section 5.2)

Temperature-monitoring output pin

Pin: VTH

• The VTH pin provides a voltage linked to NTC temperature. (see section 5.4)

to switch turn-OFF clear time. (see section 5.2)

TRIP

, the second is an over-current event condition, and the FLT/EN

DD

Positive DC-link pin

Pin: P

• This is the DC-link positive power supply pin of the IM393-XX IPM.

• It is internally connected to the collectors of the high-side IGBTs.

• In order to suppress the surge voltage caused by the DC-link wiring or PCB-pattern inductance, connect a

smoothing filter capacitor close to this pin. (Typically metal film capacitors are used.)

Negative DC-link pins

Pins: N(U), N(V), N(W)

• These are the DC-link negative power supply pins (power ground) of the inverter.

• These pins are connected to the low-side IGBT emitters of the each phase.

Inverter power output pins

Pins: U, V, W

• Inverter output pins for connecting to the inverter load (e. g. motor).

Application Note 14 of 53 V 1.0

2019-04-01

Page 15

IM393 Application note

IM393 IPM Technical Description

Product overview and pin description

3.4 Outline drawings

Figure 6 DIP version (IM393-X6E)

Figure 7 DIP version (IM393-X6E2)

Application Note 15 of 53 V 1.0

2019-04-01

Page 16

IM393 Application note

IM393 IPM Technical Description

Product overview and pin description

Figure 8 DIP version (IM393-X6E3)

Figure 9 SIP version (IM393-X6F)

Application Note 16 of 53 V 1.0

2019-04-01

Page 17

IM393 Application note

IM393 IPM Technical Description

Interface circuit and layout guide

4 Interface circuit and layout guide

4.1 Input/output signal connection

The following shows the I/O interface circuit between microcontroller and IM393-XX. Because the IPM input

logic is active-high with internal pull-down resistors, pulled-up resistors are not required. The RFE output is

open-drain MOSFET configured. Thus this signal should be pulled up to the positive side of 5 V or 3.3 V external

logic power supply with a resistor. The resistor should be carefully chosen to limit current (e.g. 1.2 MΩ). In case

of over-current, the RFE pin will get low as the MOSFET turns ON. When the over-current condition is over, the

MOSFET will then turn OFF, however, all the IGBTs will remain OFF until the fault is cleared (see section 5.3).

5V-Line (or 3.3V-Line)

CIPOSTM Tiny

HIN / LIN

RFE

COM

Micro

Controller

1nF

1kΩ

1.2MΩ

100Ω

1nF

1nF

Figure 10 Recommended microcontroller I/O interface circuit

Table 4 Maximum rating of input and RFE pin

Item Symbol Condition Rating Unit

Module supply voltage V

DD

Applied between

VDD – COM

Applied between

Input voltage V

IN

HIN(U), HIN(V), HIN(W) – COM

LIN(U), LIN(V), LIN(W) – COM

-0.3 ~ 20 V

-0.3 ~ 20 V

Fault output supply voltage RFE Applied between RFE – COM -0.3 ~ 20 V

The input and fault output maximum rating voltages are listed in Table 4. It is recommended to use 5 V logic

supply, which is the same for the input signals of the fault output. Bypass capacitors should be mounted as

close as possible to the RFE pin to avoid any noise that might switch the open-drain MOSFET ON.

Application Note 17 of 53 V 1.0

2019-04-01

Page 18

IM393 Application note

IM393 IPM Technical Description

Ω

≈

Ω

≈

Interface circuit and layout guide

CIPOSTM Tiny

HIN

k4

LIN

k4

Input

Noise

Filter

Deadtime &

Shoot

Through

Prevention

Input

Noise

Filter

Figure 11 Internal structure of signal input terminals

Because IM393-XX employs active-high input logic, the power sequence restriction between the control supply

and the input signal during start-up or shut-down operation does not exist. Therefore it makes the system failsafe. In addition, pull-down resistors are built into each input circuit. This reduces the required external

component count. Input Schmitt-trigger, noise filter, deadtime and shoot-through prevention functions

provide beneficial noise rejection to short input pulses. Furthermore, by lowering the turn ON and turn OFF

threshold voltage of the input signal as shown in Table 4.2, a direct connection to 3.3 V-class microcontroller or

DSP is possible.

Level shift

circuit

Delay

Gate driver

Gate driver

Table 5 Input threshold voltage (at VDD = 15 V and TJ = 25°C)

Item Symbol Condition Min. Typ. Max. Unit

Logic "1" input voltage V

Logic "0" input voltage V

IN,TH+

IN,TH-

LIN, HIN, RFE

2.5 - - V

- - 0.8 V

As shown in Figure 11, IM393-XX input signal integrates a 4 kΩ (typical) pull-down resistor. Therefore, when

using an external filtering resistor between the microcontroller output and IM393-XX input, attention should be

paid to the signal voltage drop at the IPM input terminal to satisfy the turn ON threshold voltage requirement.

For instance, R = 100 Ω and C = 1 nF for the parts shown in Figure 10.

Application Note 18 of 53 V 1.0

2019-04-01

Page 19

IM393 Application note

IM393 IPM Technical Description

Interface circuit and layout guide

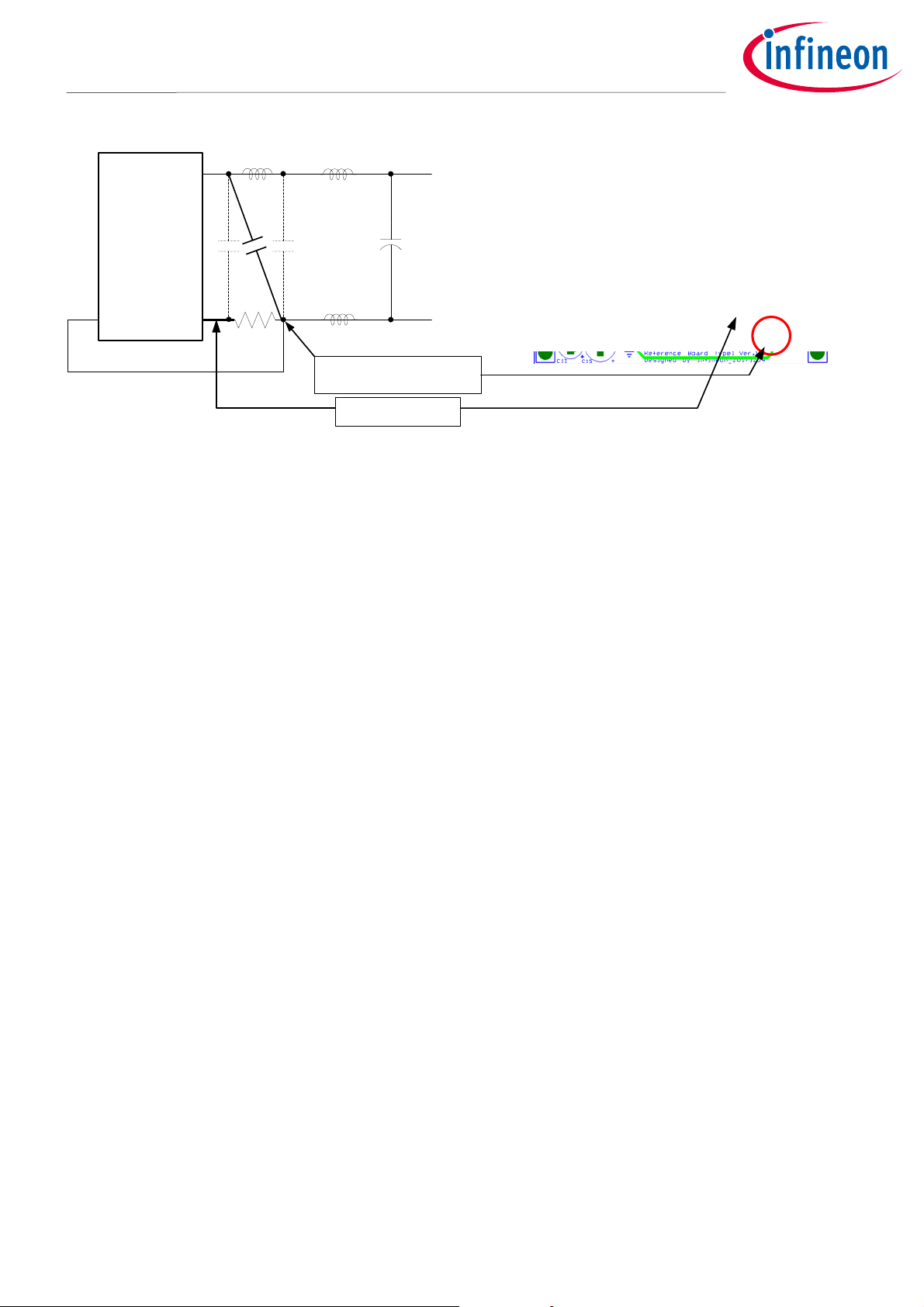

4.2 Input/output signal connection

Figure 4.3 and 4.4 show a typical application circuit interface schematic with control signals connected directly

to the microcontroller.

P (35)

P (33)

W (32)

V (31)

U (30)

#10

3-ph AC

Motor

#5

#6

#7

Power GND

Control GND

Micro

Controller

(1) P

(3) VS(W)

(4) VB(W)

VB3

(6) VS(V)

(7) VB(V)

#4

#3

5 or 3.3V

15V

#8

#9

#2

5 or 3.3V

#1

(9) VS(U)

(10) VB(U)

(12) VDD

(13) VTH

-t°

(14) COM

(15) COM

(16) ITRIP

(17) RFE

(18) HIN(U)

(19) HIN(V)

(20) HIN(W)

(21) LIN(U)

(22) LIN(V)

(23) LIN(W)

(24) N(W)

(25) N(V)

(26) N(U)

VB2

VB1

VDD

COM

VSS

ITRIP

RFE

HIN1

HIN2

HIN3

LIN1

LIN2

LIN3

HO3

VS3

HO2

VS2

HO1

VS1

LO3

LO2

LO1

N(W) (29)

N(V) (28)

N(U) (27)

Figure 12 Example of application circuit (DIP package)

#5

(1) P

#4

(3) VS(W)

(4) VB(W)

VB3

VB2

VB1

VDD

COM

VSS

ITRIP

RFE

HIN1

HIN2

HIN3

LIN1

LIN2

LIN3

HO3

VS3

HO2

VS2

HO1

VS1

LO3

LO2

LO1

Micro

Controller

3-ph AC

Motor

5 or 3.3V

#3

15V

#9

5 or 3.3V

#1

(6) VS(V)

(7) VB(V)

(9) VS(U)

(10) VB(U)

#8

(12) VDD

(13) VTH

#2

-t°

(14) COM

(15) COM

(16) ITRIP

(17) RFE

(18) HIN(U)

(19) HIN(V)

(20) HIN(W)

(21) LIN(U)

(22) LIN(V)

(23) LIN(W)

(24) N(W)

(25) N(V)

(26) N(U)

#6

Control GND

Power GND

#7

Figure 13 Example of application circuit (SIP package)

Application Note 19 of 53 V 1.0

2019-04-01

Page 20

IM393 Application note

IM393 IPM Technical Description

Interface circuit and layout guide

Notes:

1. Input circuit

- RC filter can be used to reduce input signal noise. (100 Ω, 1 nF)

- The capacitors should be located close to CIPOS™ Tiny (to COM terminal especially).

2. Itrip circuit

- To prevent a malfunctioning of the protection function, an RC filter is recommended.

- The capacitor must be located close to Itrip and COM terminals.

3. VTH circuit

- This terminal should be pulled up to the bias voltage of 5 V/3.3 V by a proper resistor to define suitable

voltage for temperature monitoring.

- It is recommended that the RC filter be placed close to the controller.

4. VB-VS circuit

- Capacitors for high-side floating supply voltage should be placed close to VB and VS terminals.

- Additional high-frequency capacitors, typically 0.1 μF, are strongly recommended.

- Overlap of pattern-to-motor and pattern-to-bootstrap capacitors should be minimized. (SIP only)

5. Snubber capacitor

- The wiring between CIPOS™ Tiny, snubber capacitor and shunt resistors should be as short as possible.

6. Shunt resistor

- SMD-type shunt resistors are strongly recommended to minimize internal stray inductance.

7. Ground pattern

- Pattern overlap of power ground and signal ground should be minimized. The patterns should be

connected at the common end of the shunt resistors only, for the same potential.

8. COM pattern

- In the case of a DIP package, pins 24, 25 and 26 must be left unconnected, as COM is connected to pin 29, 28

and 27 by the shunt resistor.

- It is highly advisable to connect both pins 14 and 15 together.

9. RFE circuit

- To set up R and C parameters for fault-clear time, please refer to Figure 5.

- For normal operation, RFE (pin 17) should always be pulled up to 5 V or 3.3 V via the pull resistor.

- This R is also mandatory for fault reporting function, as it is an open-drain structure.

10. P pattern

- In the case of a DIP package, pin 1 can be left unconnected, as positive bus voltage is connected by pins 35

and 33 that are internally connected to pin 1.

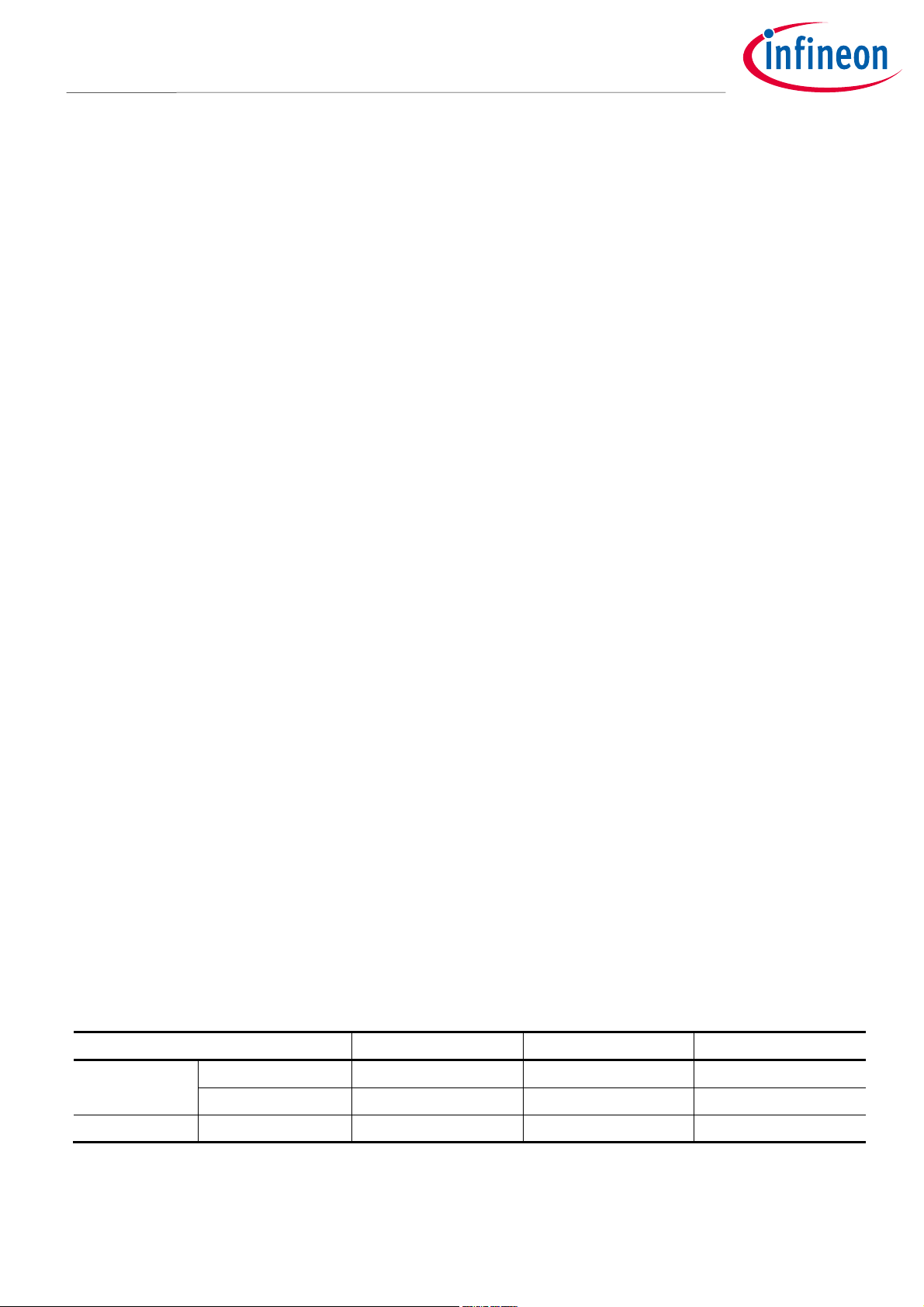

4.3 Recommended circuit current of power supply

Control and gate driver power for the IM393-XX is normally provided by a single 15 V supply that is connected to

the module VDD Pin. The circuit current of VDD control supply of IM393-L6E is shown in below Table 6.

Table 6 The circuit current of control power supply of IM393-L6E (Unit:[mA])

Item Static (Typ.) Dynamic (Typ.) Total (Typ.)

V

= 15 V

DD

V

= 20 V FSW = 20 kHz 8.03 4.08 12.11

DD

And the circuit current of the 5 V logic power supply (VTH, RFE and input terminal) is about 20 mA.

Finally, the recommended minimum circuit currents of power supply considering margins are shown in Table 7.

Application Note 20 of 53 V 1.0

FSW = 5 kHz 4.02 0.26 4.28

FSW = 15 kHz 4.02 0.78 4.83

2019-04-01

Page 21

IM393 Application note

IM393 IPM Technical Description

Interface circuit and layout guide

Table 7 The recommended minimum circuit current of control power supply (Unit:[mA])

Item The circuit current of +15 V control supply The circuit current of +5 V logic supply

VDD ≤ 20 V,

FSW ≤ 20 kHz

90 45

4.4 Recommended layout for over-current protection (OCP) and shortcircuit protection (SCP) functions

It is recommended to make the I

ITRIP filter capacitor should be connected to the COM pin directly without overlapping ground pattern. The

signal ground and power ground should be as short as possible and connected at only one point via the filter

capacitor of VDD line. The I

function combined with the external shunt resistor can be used to detect over-

TRIP

current events in the ground path that will result in damages to the IPM. The internal HVIC gate driver

continuously monitors the voltage on ITRIP pin. If this voltage exceeds the reference voltage (typ. 0.49 V), a

fault signal will be generated on the RFE pin and all six IGBTs will be turned OFF.

VDD line

Micro

Controller

5 or 3.3V line

filter capacitor connections to the IM393-XX pins as short as possible. The

TRIP

CIPOSTM Tiny

(12) VDD

(14,15) COM

(16) ITRIP

(1) P

(17) RFE

(18~23) HIN/LIN

(24~26) Nx

Figure 14 Example of layout pattern for OCP and SCP functions

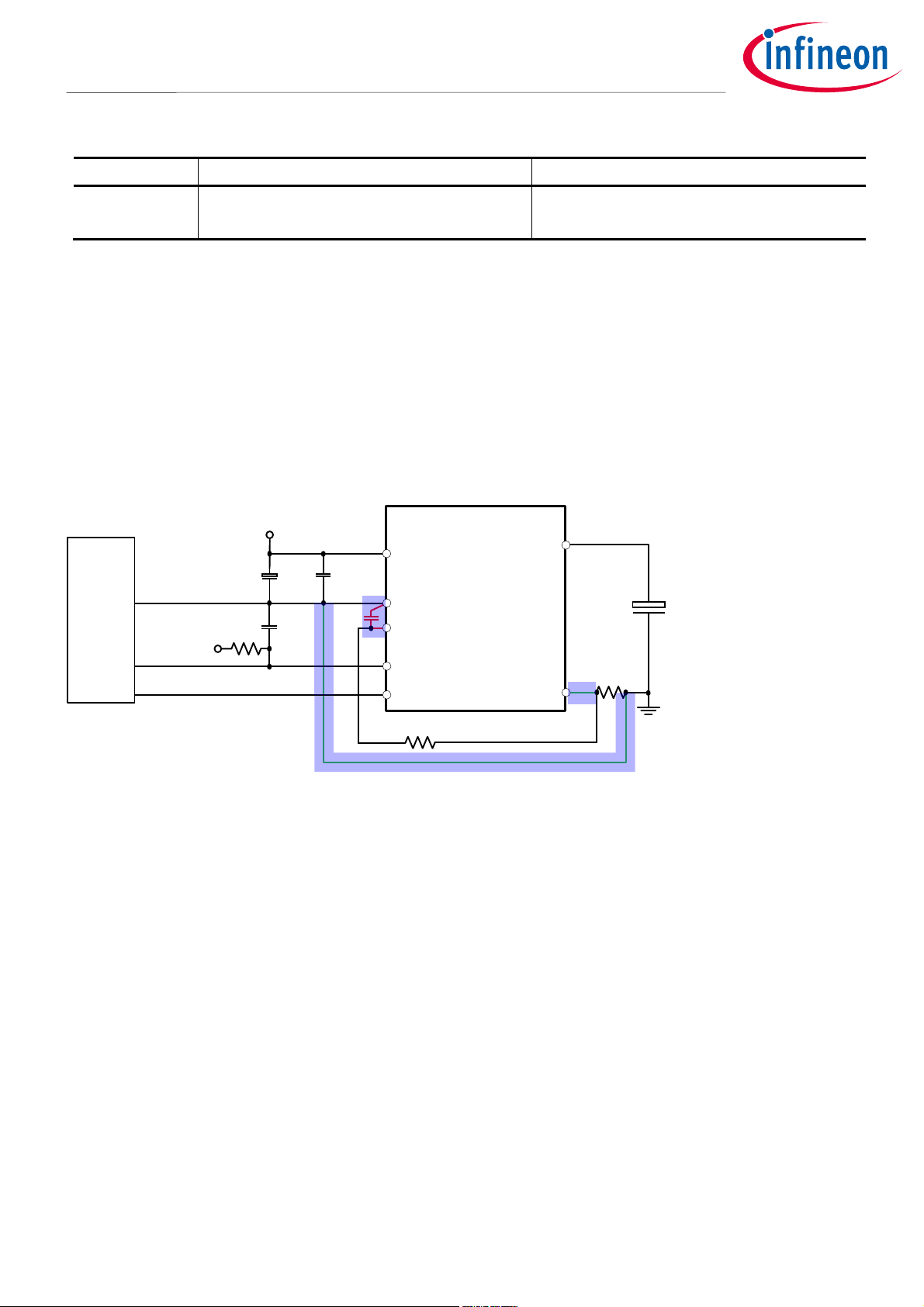

4.5 Recommended wiring of shunt resistor and snubber capacitor

External current-sensing resistors are applied to detect over-current of phase currents. A long wiring pattern

between the shunt resistors and IM393-XX will cause excessive surges that might damage the IPM-internal IC

and current-detection components. This may also distort the sensing signals that may lead to loss of control

when driving a motor. To decrease the pattern inductance, the wiring between the shunt resistors and the

IM393-XX should be as short as possible, and any loop should be avoided.

As shown in Figure 15, snubber capacitors should be installed in the right location so as to suppress surge

voltages effectively. Generally a high-frequency, non-inductive capacitor of around 0.1 ~ 0.22 µF is

recommended. If the snubber capacitor is installed in the wrong location, ‘1’ as shown in Figure 15, the snubber

capacitor cannot suppress the surge voltage effectively. If the capacitor is installed in location ‘2’, the charging

and discharging currents generated by wiring inductance and the snubber capacitor will appear on the shunt

resistor. This will impact the current-sensing signal, and the SC protection level will be a little lower than the

calculated design value. The “2” position surge suppression effect is greater than in locations ‘1’ or ‘3’. The ‘3’

position is a reasonable compromise with better suppression than in location ‘1’ without impacting the

current-sensing signal accuracy. For this reason, location ‘3’ is generally used.

Application Note 21 of 53 V 1.0

2019-04-01

Page 22

IM393 Application note

IM393 IPM Technical Description

Interface circuit and layout guide

CIPOS

TM

P

3

12

Wiring Leakage

NVSS

Shunt

Resistor

Inductance

Please make the one point connection

point as close as possible to the GND

terminal of shunt resistor

Wiring inductance should

be less than 10nH

Capacitor

Bank

PCB layout example - CIPOSTM Reference Board

Figure 15 Recommended wiring of shunt resistor and snubber capacitor

General suggestions and summary:

• PCB traces should be designed as short as possible and the area of the circuit (power or signal) should be

minimized to avoid any noise.

• Make sure there is a good distance between switching lines with high di/dt and dV/dt and the signal lines, as

they are very sensitive to electrical noise. Specifically, the trace of each phase OUT carrying significant fast

current and voltage transition should be separated from the logic lines and analog sensing circuit (R

SHUNT

, I

TRIP

RFE).

• Place shunt resistors as close as possible to the low-side pins of the IPM. Parasitic inductance should be as

low as possible. Use of a low-inductance SMD resistor is highly advisable.

• Avoid any ground loop. Only a single path must connect to COM.

• Place each RC filter as close as possible to the IPM pins to increase its efficiency.

• Fixed voltage traces such as GND and high voltage lines can be used to shield the logic and analog lines from

electrical noise produced by the switching lines.

,

Application Note 22 of 53 V 1.0

2019-04-01

Page 23

IM393 Application note

IM393 IPM Technical Description

Interface circuit and layout guide

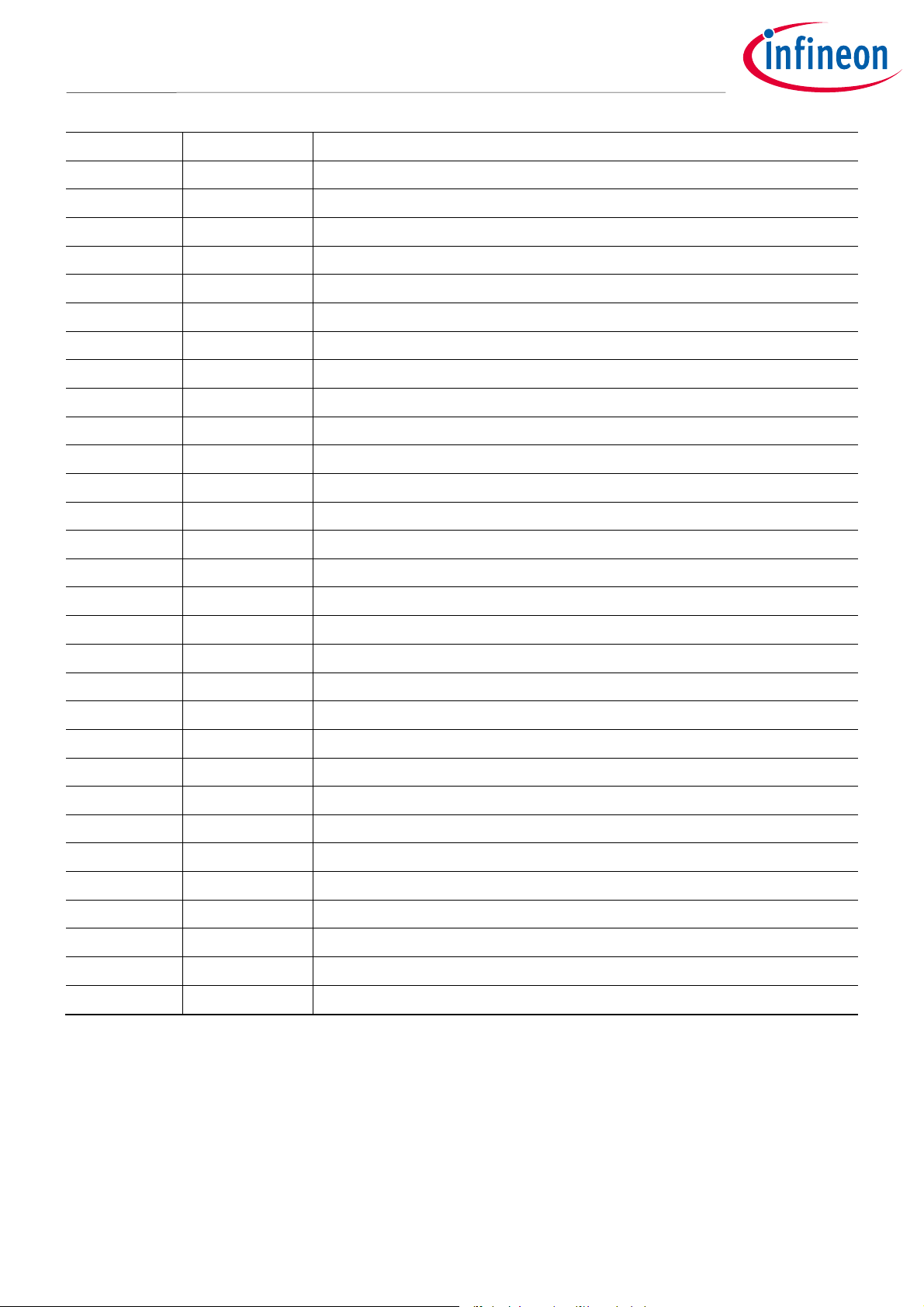

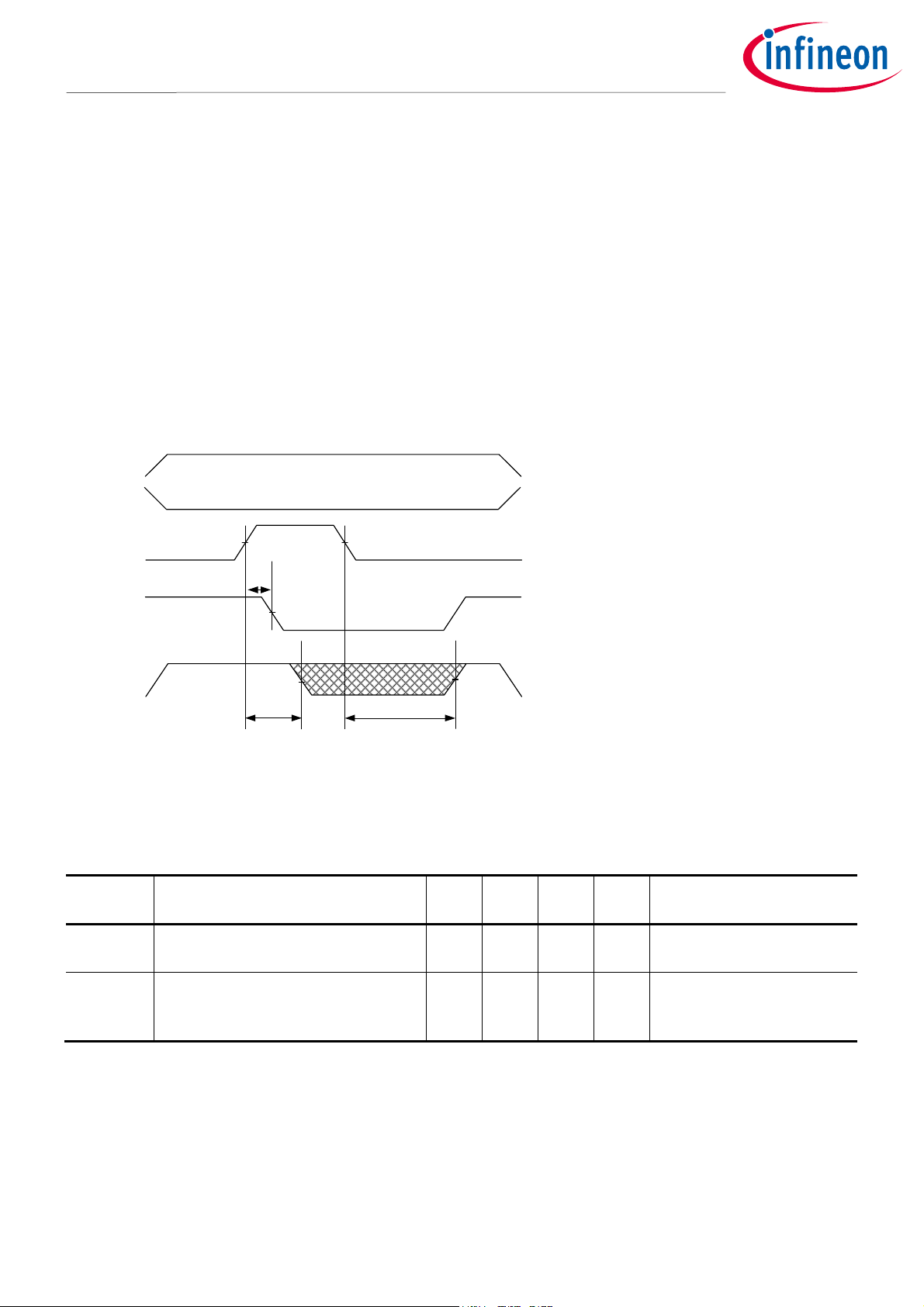

4.6 Pin and screw hole coordinates for IM393-XX footprint

Figure 16 shows IM393-XX position on the PCB to indicate center coordinates of each pin and screw hole in

Table 8 and Table 9.

(a) Dual in-line package

(b) Single in-line package

Figure 16 IM393-XX positions on PCB

Application Note 23 of 53 V 1.0

2019-04-01

Page 24

IM393 Application note

IM393 IPM Technical Description

Interface circuit and layout guide

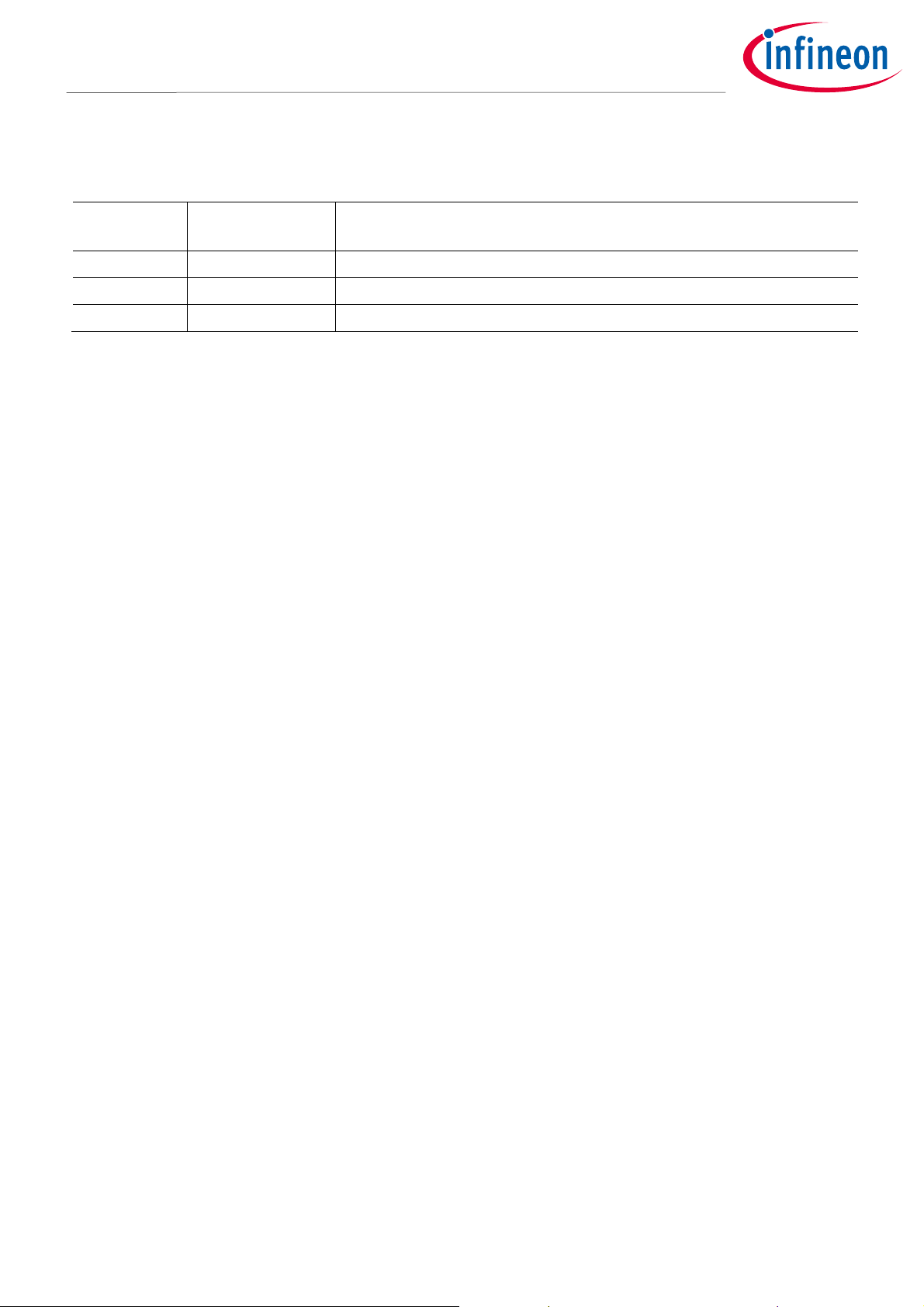

Table 8 Pin and screw hole coordinates for DIP package (Unit:[mm])

Pin Number X Y Pin Number X Y

Signal pin

1 0.00 0.00

20 24.13 3.00

2 N/A N/A 21 25.40 0.00

3 2.54 3.00 22 26.67 3.00

4 3.81 0.00 23 27.94 0.00

Signal pin

5 N/A N/A 24 29.21 3.00

6 6.35 3.00 25 30.48 0.00

7 7.62 0.00 26 31.75 3.00

8 N/A N/A

27 30.48 -19.00

9 10.16 3.00 28 27.94 -19.00

10 11.43 0.00 29 25.40 -19.00

11 N/A N/A 30 21.59 -19.00

12 13.97 3.00 31 17.78 -19.00

Power pin

13 15.24 0.00 32 13.97 -19.00

14 16.51 3.00 33 10.16 -19.00

15 17.78 0.00 34 N/A N/A

16 19.05 3.00 35 2.54 -19.00

17 20.32 0.00 36 N/A N/A

18 21.59 3.00

19 22.86 0.00 2 -0.13 -9.50

Screw

hole

1 31.87 -9.50

Table 9 Pin and screw hole coordinates for SIP package (Unit:[mm])

Pin Number

1 0.00 0.00

X Y

Pin Number

14 16.51 -3.00

2 N/A N/A 15 17.78 0.00

3 2.54 -3.00 16 19.05 -3.00

4 3.81 0.00 17 20.32 0.00

5 N/A N/A 18 21.59 -3.00

6 6.35 -3.00 19 22.86 0.00

Signal pin

7 7.62 0.00 20 24.13 -3.00

Signal pin

8 N/A N/A 21 25.40 0.00

9 10.16 -3.00 22 26.67 -3.00

10 11.43 0.00 23 27.94 0.00

11 N/A N/A 24 29.21 -3.00

12 13.97 -3.00 25 30.48 0.00

13 15.24 0.00 26 31.75 -3.00

X Y

Application Note 24 of 53 V 1.0

2019-04-01

Page 25

IM393 Application note

IM393 IPM Technical Description

Function and protection circuit

5 Function and protection circuit

5.1 Over-current protection

IM393-XX is equipped with an I

input pin. Together with an external shunt resistor, this functionality can be

TRIP

used to detect over-current events in the negative DC bus. The internal HVIC gate driver will continuously

monitor the voltage on the I

pin. Whenever this voltage exceeds the reference voltage (typ. 0.49 V), a fault

TRIP

signal will be generated on the RFE pin, and all six IGBTs will be turned OFF. Typically, the maximum shortcircuit current magnitude is gate-dependent. A higher gate voltage results in a larger short-circuit current. In

order to avoid this potential problem, the maximum over-current trip level is generally set below twice the

nominal rated collector current.

5.1.1 Timing chart of over-current protection (OCP)

HIN(U, V, W)

LIN(U, V, W)

I

TRIP

RFE

U, V, W

50%

T

FLT

50%

50%

50%

50%

T

ITRIP

T

FLT-CLR

Figure 17 Timing chart of over-current protection function

The threshold of over-current protection can be determined by V

directly connected to I

pin. The following table shows the delay time of fault reporting and I

TRIP

ITRIP+

/ R

, if a single bus shunt is used, and is

SHUNT

shutdown:

TRIP

Table 10 Dynamic electrical characteristics

Symbol Description Min. Typ. Max. Unit conditions

T

T

FLT

ITRIP

I

to fault propagation delay 400 600 800 ns V

TRIP

I

to six switches turn OFF

TRIP

propagation delay

- - 1.5 μs IC = 5 A, V

= 0 V or 5 V, V

IN

= 300 V

DC

ITRIP

= 5 V

In the case of a short-circuit, the current level will rise very quickly to the saturation current of the IGBT. It is

critical to ensure that all IGBTs are turned OFF as soon as possible. Since the IGBTs in IM393-XX are short-circuit

rated (see Table 11), the safe operating of the IPM is guaranteed by minimizing the delay of the external currentsensing circuit, and ensuring its delay plus T

is less than the IGBT short-circuit rating time. Because IGBT short

ITRIP

circuit rating depends a lot on the gate voltage that is influenced by VDD and junction temperature, it is important

to consider all possible conditions.

Application Note 25 of 53 V 1.0

2019-04-01

Page 26

IM393 Application note

IM393 IPM Technical Description

0.8

Function and protection circuit

Table 11 IGBT short-circuit ratings

Item Symbol Condition Value Unit

Short-circuit withstand time T

SC

TJ < 150 °C, VDC = 360 V, VDD = 15 V 3 μs

5.1.2 Selecting current-sensing shunt resistor

The value of the current-sensing resistor is calculated by the following equation:

V

THIT,

R

=

SH

Where

V

OC detection level.

The maximum value of the OC protection level should be set lower than the repetitive peak collector current in

the datasheet considering the tolerance of the shunt resistor.

For example, the maximum peak collector current of IM393-L6E/F is 22.5 A

value of the shunt resistor is calculated as

()

For the power rating of the shunt resistor, the following list should be considered:

• Maximum load current of inverter (I

• Shunt resistor value at Tc = 25°C (R

• Power derating ratio of shunt resistor at T

• Safety margin

+

I

OC

is the ITRIP positive-going threshold voltage of IM393-XX. It is typically 0.49 V. IOC is the current of

+THIT,

, and thus, the recommended

peak

0.49

=

22.5

= 0.022 Ω

SH

RMS

)

)

= 100°C according to the manufacturer’s datasheet

SH

(1)

The shunt resistor power rating is calculated by the following equation:

2

SH

rms

=

P

SH

marginRI

××

ratioderating

For example with IM393-L6E/F and RSH = 22 mΩ:

• Max. load current of the inverter : 6 A

• Power derating ratio of shunt resistor at T

• Safety margin : 30 %

2

P

=

SH

1.30.0225

××

W0.9

=

RMS

=100°C : 80 %

SH

A proper power rating of shunt resistor should then exceed 1 W, e.g. 1.5 W.

Based on the previous equations, conditions, and calculation method, the minimum shunt resistance and

resistor power according to IM393-XX products have been introduced and are listed in Table 12.

Note that a proper resistance and power rating, which is higher than the minimum value, should be chosen

considering the over-current protection level required in the application.

(2)

Application Note 26 of 53 V 1.0

2019-04-01

Page 27

IM393 Application note

IM393 IPM Technical Description

Function and protection circuit

Table 12 Minimum RSH and P

Product Maximum peak current

IM393-X6E/F 30 A

IM393-L6E/F 22.5 A

IM393-M6E/F 15 A

IM393-S6E/F 9 A

SH

Minimum shunt resistance,

R

SH

16 mΩ

22 mΩ

33 mΩ

54 mΩ

Minimum shunt resistor

power, P

SH

3 W

2 W

1.5 W

1 W

5.1.3 Delay time

The RC filter is necessary in the over-current sensing circuit to prevent malfunction of OC protection caused by

noise. The RC time constant is determined by applying time of noise and the withstand time capability of IGBT.

When the sensing voltage on the shunt resistor exceeds I

applied to the ITRIP pin of the IM393-XX via the RC filter. Table 13 shows the specification of the OC protection

reference level. The filter delay time (T

rises to the I

positive threshold voltage during T

TRIP

) is caused by RC filter time constant, and the input voltage of I

FILTER

FILTER

In addition there is the shutdown propagation delay of I

Table 13 Specification of OC protection reference level ‘V

positive-going threshold (V

TRIP

.

. Please refer to Table 14.

TRIP

’

IT,TH+

), this voltage is

IT,TH+

TRIP

pin

Item Min. Typ. Max. Unit

I

positive going threshold V

TRIP

IT,TH+

0.44 0.49 0.54 V

Table 14 Internal delay time of OC protection circuit

Item Condition Min. Typ. Max. Unit

Shut down

propagation

delay (T

ITRIP

)

IM393-X6E/F I

IM393-L6E/F I

IM393-M6E/F I

IM393-S6E/F I

= 10 A, from V

out

= 7.5 A, from V

out

= 5 A, from V

out

= 3 A, from V

out

IT,TH+

IT,TH+

IT,TH+

IT,TH+

to 10 % I

to 10 % I

to 10 % I

to 10 % I

out

out

out

out

- - 1.5 μs

- - 1.5 μs

- - 1.5 μs

- - 1.5 μs

Therefore the total time from over-current event to shut down of all six IGBTs is:

T

= T

TOTAL

Shut-down propagation delay is inversely proportional to the current range; therefore the T

FILTER

+ T

ITRIP

is reduced at

ITRIP

(3)

higher current conditions than those in Table 14. The recommended total delay is less than the 3 μs of safety

operation. Thus, the RC time constant should be set in the range of 1~1.5 µs. Recommended values for the filter

components are R = 1.5 kΩ and C = 1 nF.

5.2 Fault output and auto-clear function

As described in the previous section, in the event of an over-current, the RFE pin will get low as the I

high when the open-drain MOSFET is turned on. When over-current conditions end, the open-drain MOSFET will

be turned off, as illustrated in Figure 18. However, all IGBTs will remain off until RFE voltage can reach a positivegoing threshold. This is called the fault auto-clear function, and is shown as T

Application Note 27 of 53 V 1.0

in Figure 19.

FLT-CLR

pin gets

TRIP

2019-04-01

Page 28

IM393 Application note

IM393 IPM Technical Description

Function and protection circuit

HIN(X)

HIN(X)

LIN(X)

LIN(X)

COM

COM

Input

Noise

filter

Input

Noise

filter

Deadtime &

Shoot-Through

Prevention

VDD

Under-

voltage

detection

To Microcontroller

ITRIP

ITRIP

+3.3V

R

RCIN

C

RCIN

RFE

Noise

filter

ITRIP

Noise

filter

Figure 18 Internal block diagram of IM393-XX

HIN(U, V, W)

LIN(U, V, W)

I

TRIP

50%

T

FLT

50%

RFE

U, V, W

T

Figure 19 Input-output timing chart during short-circuit event

The T

can be determined by the below formula.

FLT-CLR

In the case of 3.3 V,

V

(t) = 3.3 V * (1 – e

RFE

T

= - R

FLT-CLR

RCIN

For example, if R

Application Note 28 of 53 V 1.0

-t/RC

) (4)

* C

* ln (1-V

RCIN

is 1.2 MΩ and C

RCIN

50%

ITRIP

50%

50%

T

FLT-CLR

/3.3 V) (5)

IN_TH+

is 1 nF, the T

RCIN

is about 1.7 ms with V

FLT-CLR

IN_TH+

of 2.5 V.

2019-04-01

Page 29

IM393 Application note

IM393 IPM Technical Description

Function and protection circuit

It is also important to note that C

needs to be minimized in order to make sure it is fully discharged in the

RCIN

event of over-current. Since the ITRIP pin has a 350 ns input filter, it is appropriate to ensure that C

discharged below V

V

(t) = 3.3 V * e

RFE

C

< 350 ns / (- ln (V

RCIN

Considering V

-t/RC

IN_TH-

by the open-drain MOSFET, after 350 ns. Therefore, the max C

IN_TH-

< V

IN_TH-

/ 3.3 V) * R

IN_TH-

of 0.8 V and R

RFE_ON

) (7)

RFE_ON

of 50 Ω, C

should be less than 4.9 nF.

RCIN

can be calculated as:

RCIN

In the case of 5 V,

V

(t) = 5 V * (1 – e

RFE

T

= - R

FLT-CLR

RCIN

For example, if R

The max C

V

RFE

C

RCIN

RCIN

(t) = 5 V * e

< 350 ns / (- ln (V

-t/RC

) (8)

* C

* ln (1-V

RCIN

is 1.2 MΩ and C

RCIN

IN_TH+

can be calculated as:

-t/RC

< V

IN_TH-

/ 5 V) * R

IN_TH-

/5 V) (9)

is 1 nF, the T

RCIN

) (11)

RFE_ON

is about 0.8 ms with V

FLT-CLR

IN_TH+

of 2.5 V.

will be

RCIN

(6)

(10)

Considering V

As far as R

RCIN

interfere with the discharging of C

of 0.8 V and R

IN_TH-

RFE_ON

of 50 Ω, C

should be less than 3.8 nF.

RCIN

is concerned, it should be selected to achieve the desired T

in the case of over-current. Also it cannot be too high in order to ensure

RCIN

. Its value should not be too low to

FLT-CLR

proper biasing of the RFE pin during normal operation. A resistor value between 0.5 MΩ and 2 MΩ is suggested to

have a fault-clear time in the range of 1 ms.

It is critical that the PWM generator be disabled within the fault duration to guarantee a shutdown of the system,

and the over-current condition must be cleared before resuming operation.

5.3 Undervoltage lockout (UVLO)

IM393-XX HVIC provides undervoltage lockout protection on both the V

supply and the V

(high-side circuitry) power supply. Figure 20 is used to illustrate this concept. V

BS

plotted over time, and as the waveform crosses the UVLO threshold (V

protection is enabled or disabled.

Upon power-up, should the V

VDD voltage decreases below the V

voltage fail to reach V

DD

threshold during operation, the undervoltage lockout circuitry will

DDUV-

threshold, the IC will not turn on. Additionally, if the

DDUV+

recognize a fault condition, and shut down the high and low-side gate drive outputs. The RFE pin will then go to

the low state to inform the controller of the fault condition.

Upon power-up, should the V

the V

voltage decreases below the V

BS

voltage fail to reach the V

BS

threshold during operation, the undervoltage lockout circuitry will

BSUV-

threshold, the IC will not turn on. Additionally, if

BSUV+

recognize a fault condition, and shut down the high-side gate drive outputs of the IC.

(logic and low-side circuitry) power

DD

or VBS is

DD

DDUV+/-

or V

), the undervoltage

BSUV+/-

The UVLO protection ensures that the IC drives the power devices only when the gate supply voltage is

sufficient to fully enhance the power devices. Without this feature, the power switch could be driven with a low

gate voltage which results in excessive losses, as it conducts current while the channel impedance is high.

When conduction losses are too high within the power switch, it could lead to power switch failure.

Application Note 29 of 53 V 1.0

2019-04-01

Page 30

IM393 Application note

IM393 IPM Technical Description

V

Fault Output Signal

V

Fault Output Signal

Function and protection circuit

V

DDUV-

(or V

)

BSUV-

UVLO Protection

(Gate Dr ive Outpu ts Dis abled)

Normal

Operation

Figure 20 UVLO protection

DDUV+

Control

Supply Voltage

V

DDUV+

(or V

)

BSUV+

Time

Normal

Operation

V

DDUV-

HINx

LINx

HOx

LOx

Figure 21 Timing chart of low-side undervoltage protection function

BSUV+

Control

Supply Voltage

V

BSUV-

HINx

LINx

HOx

LOx

High-level (no fault output)

Figure 22 Timing chart of high-side undervoltage protection function

Table 15 IM393-XX functions versus control power supply voltage

Control voltage range [V] IM393-XX function operations

0 ~ 4

Application Note 30 of 53 V 1.0

Control IC is not operating. Undervoltage lockout function is not working and

fault output signal is not provided.

2019-04-01

Page 31

IM393 Application note

IM393 IPM Technical Description

Function and protection circuit

4 ~ 11.2

As the undervoltage lockout function is activated, control input signals are

blocked, and a fault signal VFO is generated.

IGBTs will be operated in accordance with the control gate input. Driving

11.2 ~ 13.5

voltage is below the recommended range, so V

will be larger than under normal conditions. High-side IGBTs cannot operate

after VBS initial charging, as VBS cannot reach V

13.5 ~ 16.5 for VDD

12.5 ~ 17.5 for VBS

Normal operation. This is the recommended operating condition.

VDD of 15 V is recommended when only integrated bootstrap circuitry is used.

IGBTs are still in operation. Because driving voltage is above the

16.5 ~ 20 for VDD

17.5 ~ 20 for VBS

recommended range, IGBTs’ switching is faster. It causes increased system

noise. And peak short-circuit current might be too large for proper operation

of the short-circuit protection.

Over 20 Control circuit in the IM393-XX might be damaged.

5.4 Over-temperature protection

and the switching losses

CE(sat)

.

BSUV+

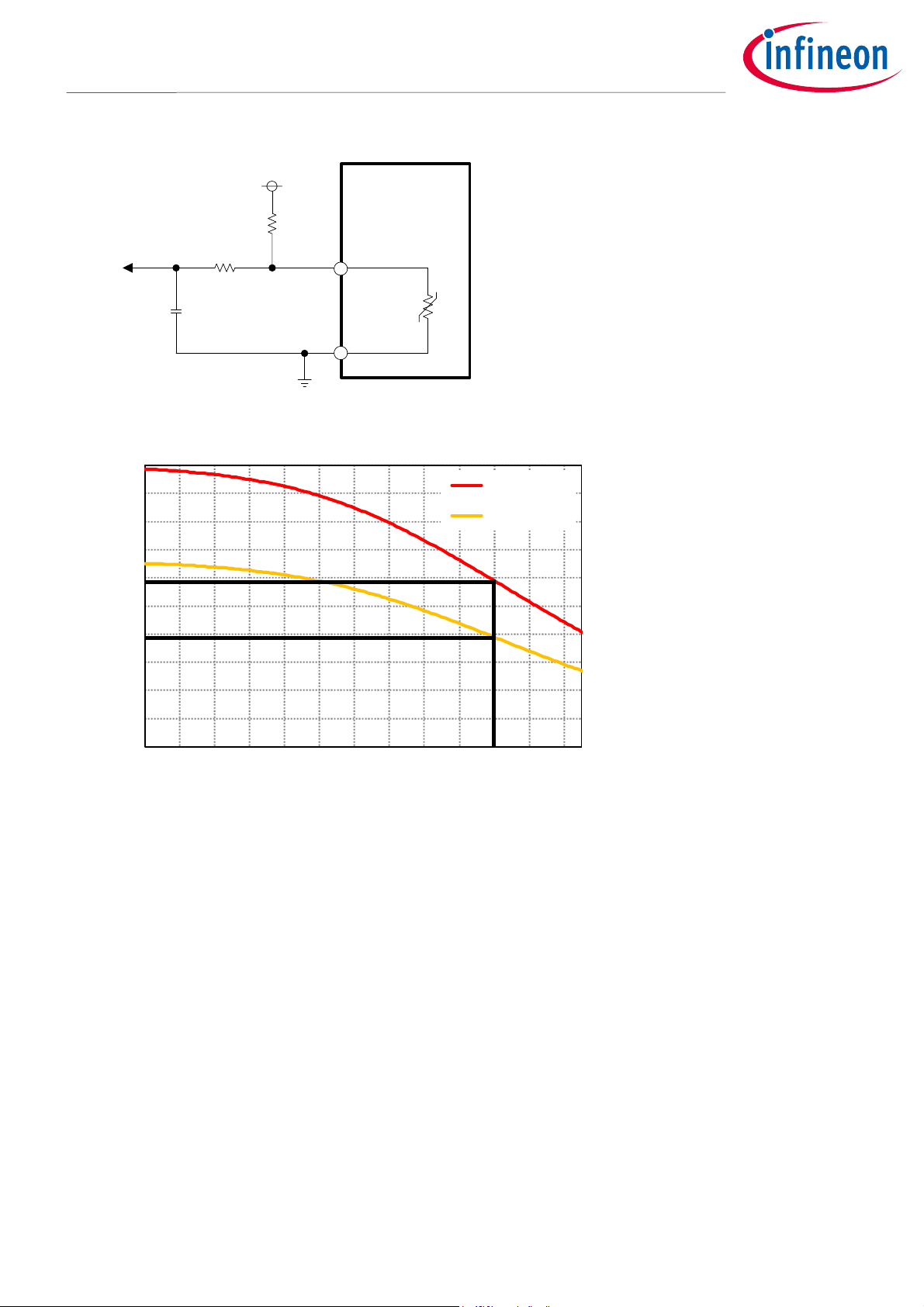

IM393-XX have VTH pins for temperature-sensing. Figure 23 shows internal thermistor-resistance characteristics

according to the thermistor temperature. For over-temperature protection, a circuitry is introduced in this

section. As shown in Figure 24, the VTH pin is connected directly to the ADC terminal of the microcontroller. This

circuit is very simple, and the six IGBTs have to be shut down by a command issued from the microcontroller.

Figure 23 Internal thermistor-resistance characteristics according to thermistor temperature

NTC resistance can be translated to a voltage that can be read by the microcontroller using external resistance

R1. For example, when R1 is 2 kΩ, then VFO at about 100°C of the thermistor temperature is 2.95 V

and 1.95 V at V

Application Note 31 of 53 V 1.0

= 3.3 V, as shown in Figure 25.

ctr

typ

at V

= 5 V

ctr

2019-04-01

Page 32

IM393 Application note

IM393 IPM Technical Description

℃ : 2.95 V at Vctr = 5 V

℃ : 1.95 V at Vctr = 3.3 V

Function and protection circuit

Vctr

R1

CIPOSTM Tiny

ADC

VTH

Thermistor

COM

Figure 24 Circuit proposals for over-temperature protection

5.0

Vctr = 5 V

Vctr = 3.3 V

[V]

V

TH

4.5

4.0

3.5

3.0

2.5

2.0

1.5

1.0

OT set 100

OT set 100

0.5

0.0

0 10 20 30 40 50 60 70 80 90 100 110 120

Thermistor temperature [℃]

Figure 25 Voltage of VTH pin according to thermistor temperature

Application Note 32 of 53 V 1.0

2019-04-01

Page 33

IM393 Application note

IM393 IPM Technical Description

Bootstrap circuit

6 Bootstrap circuit

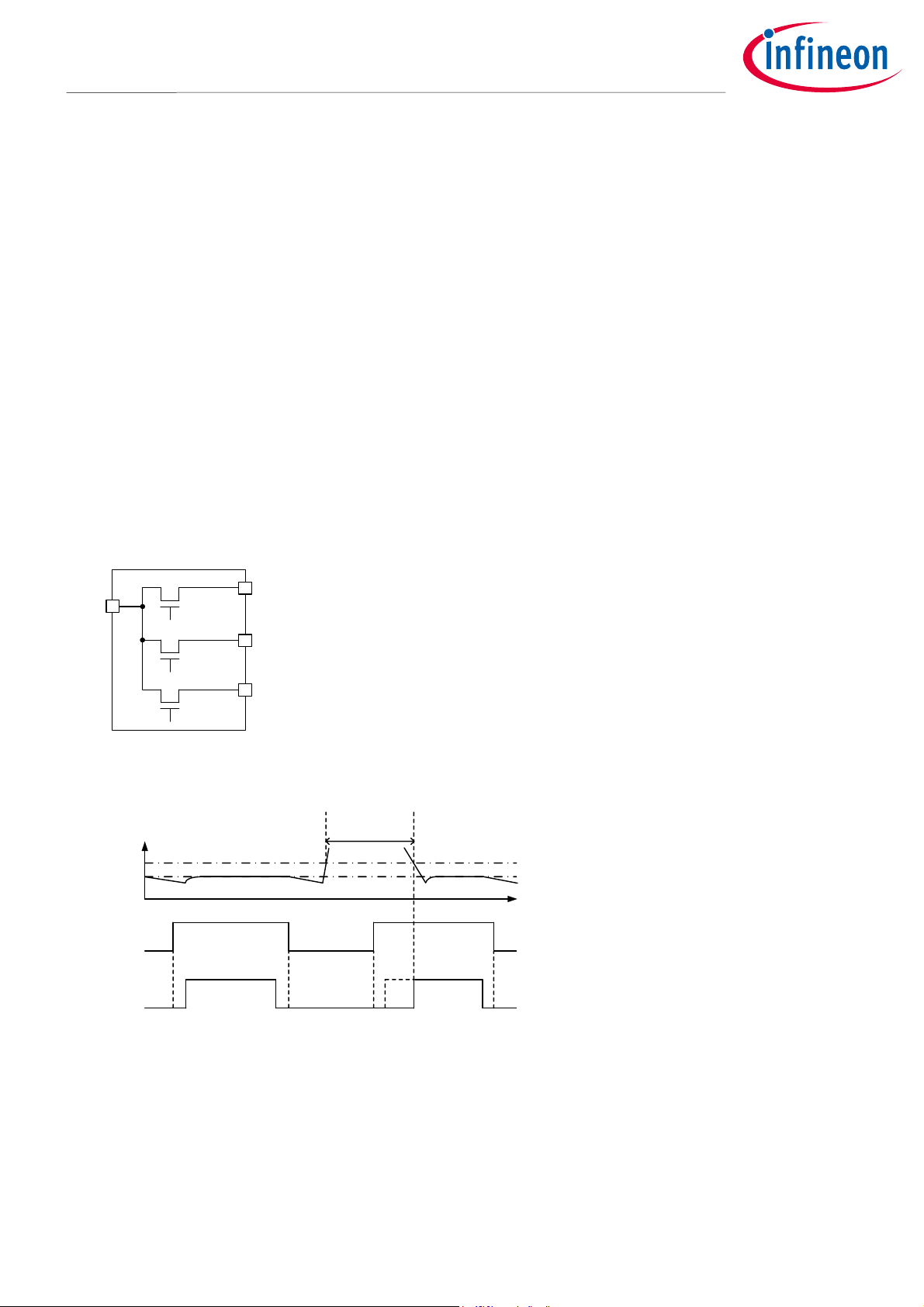

6.1 Bootstrap circuit operation

The VBS voltage, which is the voltage difference between V

B (U, V, W)

and V

, provides the supply to the IC

S (U, V, W)

within the IM393-XX. This supply voltage must be in the range of 12.5~17.5 V to ensure that the IC can fully drive

the high side IGBT. IM393-XX includes an under-voltage detection function for the VBS to ensure that the IC does

not drive the high-side IGBT if the VBS voltage drops below a specified voltage (section 5.3).

Internal bootstrap circuitry is integrated inside the HVIC. It consists of three high-voltage MOSFETs that

eliminate the need for an external circuitry (diodes + resistors). There is one MOSFET for each high-side output

channel, which is connected between the VDD supply and its respective floating supply (V

B(U)

, V

B(V)

, V

B(W)

), as

shown in Figure 26. The integrated bootstrap MOSFET is turned ON only when the low-side output (LO) is

“HIGH”, and has a limited source-current due to RBS. The VBS voltage will be charged each cycle depending on

the time of LO and the value of the CBS capacitor, the collector-emitter drop of external IGBT and the low-side

freewheeling diode drop.

The bootstrap MOSFET of each channel follows the state of respective low-side output stage unless the V

voltage is higher than approximately 110% of V

In that case, the bootstrap MOSFET is designed to remain OFF

DD.

B

until VB returns below that threshold. This concept is illustrated in Figure 27.

V

B(U)

V

DD

V

B(V)

V

B(W)

Figure 26 Internal bootstrap MOSFET connections

Bootstrap

MOSFET

disabled

Time

OFF

Vth ~1.1(VDD)

VDD=15V

Bootstrap

MOSFET

state

V

LO

BS

ON ON

Figure 27 Bootstrap MOSFET state diagram

A bootstrap MOSFET is suitable for most of the PWM modulation schemes, and can be used either in parallel

with an external bootstrap network or as a replacement of it. The use of the integrated bootstrap as a

replacement of the external bootstrap network may have some limitations however. An example of this

limitation may arise when this functionality is used in non-complementary PWM schemes and at very high PWM

duty cycle. In these cases, superior performance can be achieved by using an external bootstrap diode and

resistor in parallel with the internal bootstrap network.

Application Note 33 of 53 V 1.0

2019-04-01

Page 34

IM393 Application note

IM393 IPM Technical Description

ΔV

×

Bootstrap circuit

Table 16 Electrical characteristics of internal bootstrap parameters

Item Symbol

Unit

Min. Typ. Max.

Value

Bootstrap resistance R

BS

- 200 -

Ω

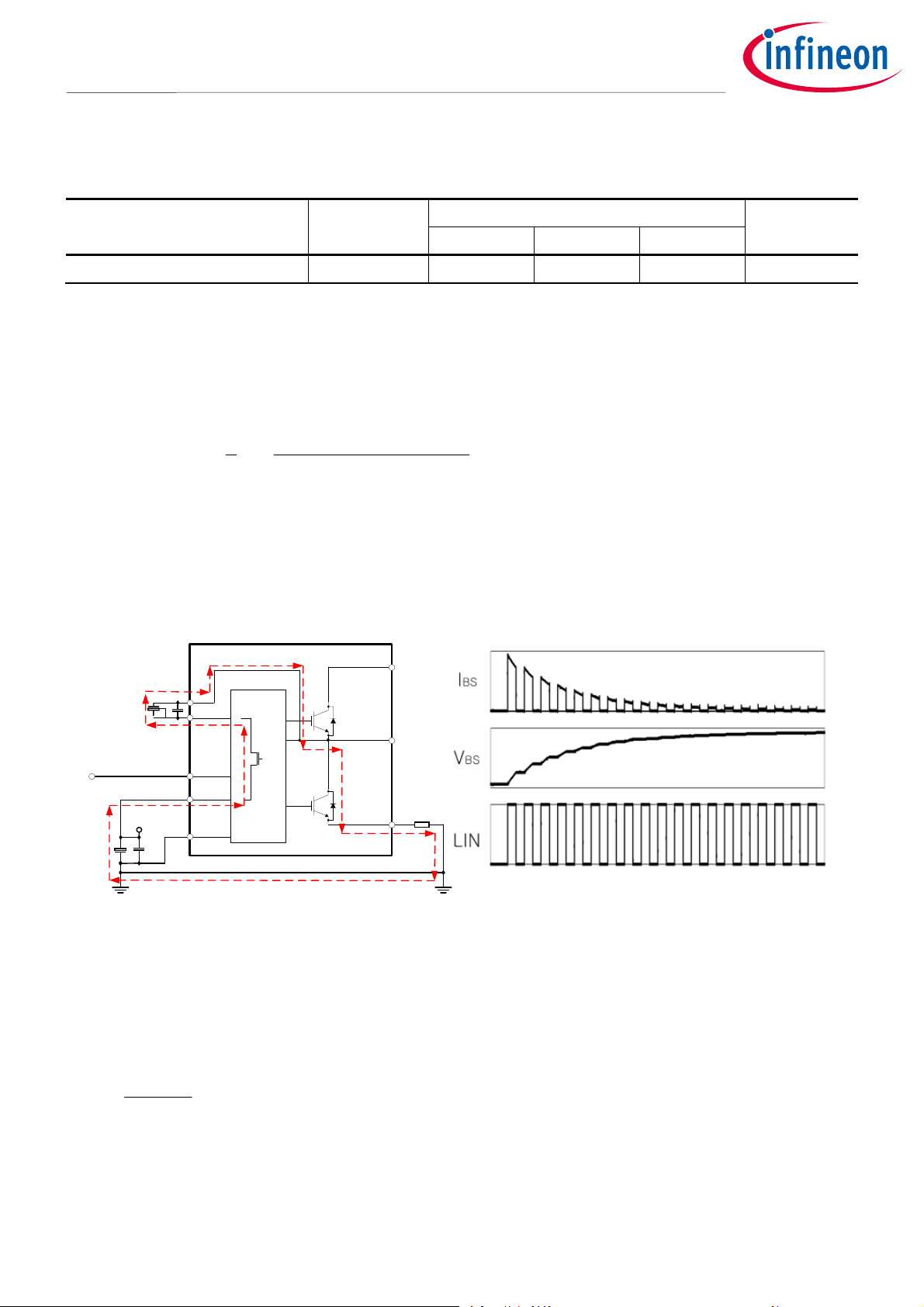

6.2 Initial charge of bootstrap capacitor

Adequate on-time duration of the low-side IGBT to fully charge the bootstrap capacitor is required for initial

bootstrap charging. The bootstrap capacitor needs to be pre-charged in order to limit peak current and power

through the resistor. The initial charging time (t

1

RCt

BSBScharge

• V

= Forward voltage drop across the bootstrap diode

FD

• V

• V

= The minimum value of the bootstrap capacitor voltage

BS(min)

= Voltage drop across the low-side IGBT

LS

ln(

×××≥

δ

• δ = Duty ratio of PWM

CIPOSTM Tiny

C

BS

VS

VB

VB

HO

VS

V

DD

U, V, W

P

U

) can be calculated with the following equation:

charge

)

VVVV

−−−

LSFDBS(min)DD

(12)

LIN

VDD

COM

LIN

VDD

LO

VSS

N

LIN

15V line

(a) Bootstrap circuit (b) Timing chart of initial bootstrap charging

Figure 28 Bootstrap circuit operation and initial charging

6.3 Bootstrap capacitor selection

The bootstrap capacitance can be calculated by:

ΔtI

C

BS

• Whereby,

• Δt = maximum ON pulse width of high-side IGBT

• ΔV = the allowable discharge voltage of the C

leak

=

.

BS

(13)

Application Note 34 of 53 V 1.0

2019-04-01

Page 35

IM393 Application note

IM393 IPM Technical Description

≥4.

7×

200Ω×

1

0.5

×

ln

15

15−12.

5−0.

1

≅3.

4

Bootstrap circuit

• I

= maximum discharge current of the CBS mainly via the following mechanisms:

leak

− Gate charge for turning on the high-side IGBT

− Quiescent current to the high-side circuit in the IC

− Level-shift charge required by level shifters in the IC

− Leakage current in the bootstrap diode

− C

capacitor leakage current (ignored for non-electrolytic capacitors)

BS

− Bootstrap diode reverse-recovery charge

In practice, a leakage current of 1mA is recommended as a calculation basis for IM393-XX. By taking into

consideration dispersion and reliability, the capacitance is generally selected to be 2 to 3 times higher than the

calculated one. The CBS is only charged when the high-side IGBT is off, and the VS voltage is pulled down to

ground. Therefore, the on-time of the low-side IGBT must be sufficient to ensure that the charge drawn from

the CBS capacitor can be fully replenished. Hence, there is inherently a minimum on-time of the low-side IGBT

(or off-time of the high-side IGBT).

The bootstrap capacitor should always be placed as close to the IM393-XX pins as possible. At least one low ESR

capacitor should be used to provide good local de-coupling. For example, a separate ceramic capacitor close to

IM393-XX is essential, if an electrolytic capacitor is used for the bootstrap capacitor. If the bootstrap capacitor is

either a ceramic or tantalum type, it should be adequate for local decoupling.

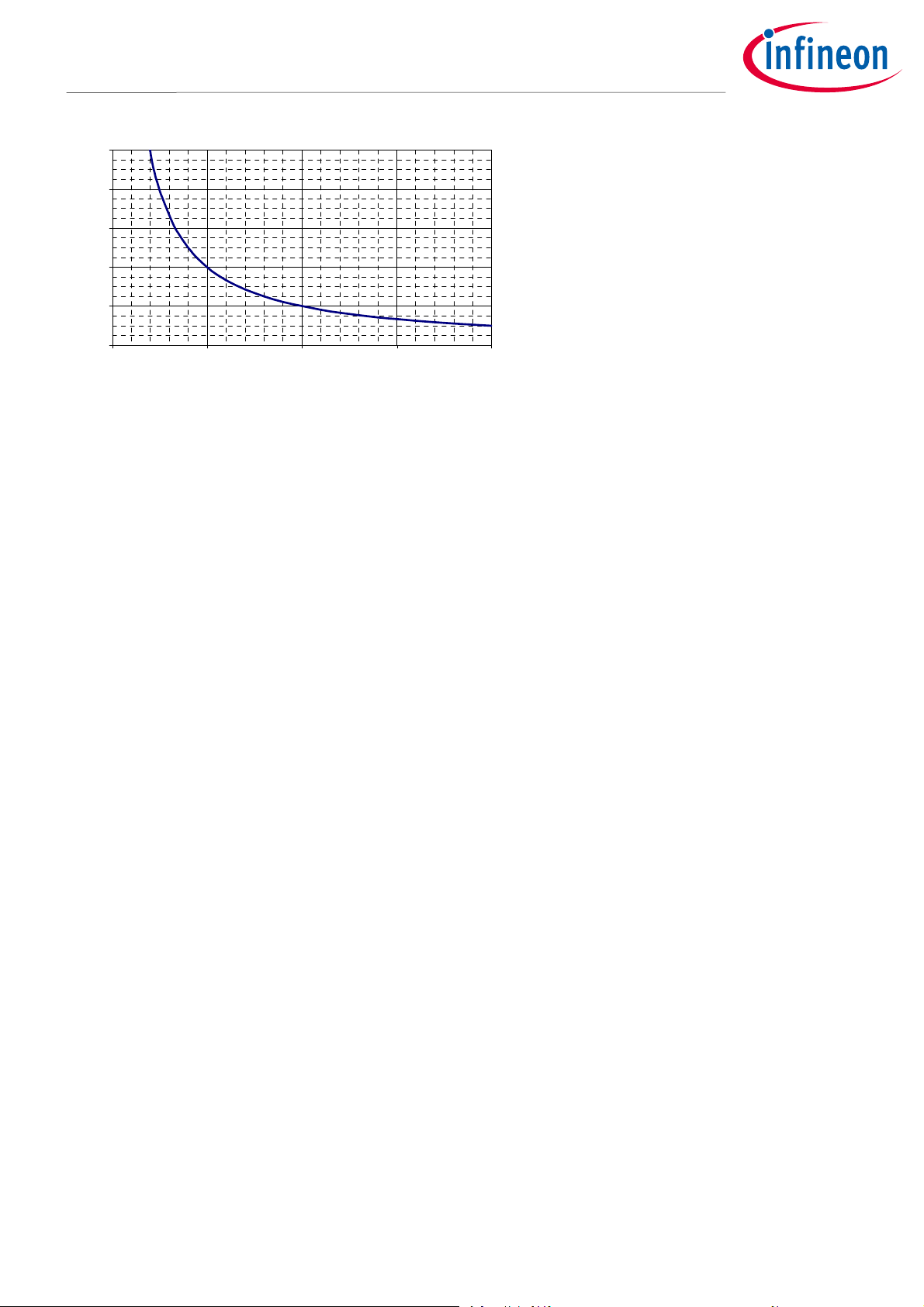

6.4 Charging and discharging of the bootstrap capacitor during PWM

inverter operation

The bootstrap capacitor CBS charges through the bootstrap MOSFET from the VDD supply when the high-side

IGBT is off, and the VS voltage is pulled down to ground. It discharges when the high-side IGBT or diode are on.

Example: Selection of the initial charging time

An example of the calculation of the minimum value of the initial charging time

Conditions:

• C

= 4.7 µF, RBS = 200 Ω, Duty Ratio (δ)= 0.5, VDD = 15 V,

BS

• V

•

In order to ensure safety, it is recommended that the charging time be at least three times longer than the

calculated value.

Example 2: The minimum value of the bootstrap capacitor

Conditions:

= 12.5 V, VLS = 0.1 V

BS (min)

ΔV=0.1 V, I

Application Note 35 of 53 V 1.0

=1 mA

leak

2019-04-01

Page 36

IM393 Application note

IM393 IPM Technical Description

Bootstrap circuit

5

4

3

[uF]

BS

2

C

1

0

0 5 10 15 20

f

[kHz]

PWM

Figure 29 Bootstrap capacitance as a function of the switching frequency

Figure 29 shows the curve for a continuous sinusoidal modulation. If the voltage ripple is 0.1 V, the

recommended bootstrap capacitance is therefore in the range of 4.7 µF for most switching frequencies. In case

of other PWM method like a discontinuous sinusoidal modulation, the t

the low-side IGBT off-state.

must be set to the longest period of

charge

Note that this result is only an example. It is recommended that the system design considers the actual control

pattern and lifetime of the used components.

Application Note 36 of 53 V 1.0

2019-04-01

Page 37

IM393 Application note

IM393 IPM Technical Description

T_Heatsink

TJ,chip

Rth,J

TJ,chip

TJ,chip6T_Case

T_Ambient

Thermal design

7 Thermal design

7.1 Introduction

Thermal design is a key issue for the IM393-XX that is to be built into in electronic systems such as drives. In

order to avoid overheating and/or to increase reliability, two design criteria are of importance:

• Low power losses

• Low thermal resistance from junction to ambient

The first criterion has already been fulfilled if users have chosen IM393-XX as an intelligent power module for

their application. To get the most out of the system, the selection of a proper heat sink is also necessary. A good

thermal design allows users to maximize the power or increase the reliability of the system by reducing the

maximum temperature. This application note gives a short introduction to power losses and heat sinks, helping

users to understand the mode of operation and to find the right heat sink for their specific application.

For the thermal design, the user requires the following data:

• The maximum power losses P

• The maximum junction temperature T

• The junction-to-ambient thermal impedance Z

is sufficient. This thermal resistance comprises the junction-to-case thermal resistance R

A

datasheets, the case-to-heat sink thermal resistance R

of each power switch

sw,i

of the power semiconductors

J,max

th,J-A

. For steady-state conditions, static thermal resistance R

as provided in

th,J-C

accounting for the heat flow through the thermal

th,C-HS

interface material between heat sink and the power module, and the heat sink-to-ambient thermal resistance

R

. Each thermal resistance can be extended to its corresponding thermal impedance by adding the

th,HS-A

thermal capacitances.

• The maximum allowable ambient temperature T

• Furthermore all heat flow paths need to be identified.

1

TJ,chip2

TJ,chip3

Rth,J-C

Rth,J-C

TJ,chip4

Rth,J-C

Rth,C-HS

Rth,HS-A

5

-C

Rth,J-C

Rth,J-C

A,max

th,J-

Figure 30 Simplified thermal equivalent circuit