Page 1

C

over Page

OPERATING MANUAL

3000 Micro GC

Gas Analyzer

PN 074-519-P1C

Page 2

Page 3

www.inficon.com reachus@inficon.com

©2013 INFICON

Title P

age

OPERATING MANUAL

3000 Micro GC

Gas Analyzer

PN 074-519-P1C

Page 4

Trademarks

The trademarks of the products mentioned in this manual are held by the companies that

produce them.

3000 Micro GC™, Bring the Lab to the Sample™, EZ IQ™ and INFICON® are trademarks of INFICON GmbH

Genie® (filter) is a registered trademark of A+ Corporation, LLC

Luer-Lok® is a registered trademarks of Becton Dickinson.

Stabilwax® is a registered trademark of Restek Corporation.

Swagelok® is a registered trademark of Swagelok Co.

Teflon® is a registered trademarks of E. I. du Pont de Nemours and Company or its affiliates.

Tygon® is a registered trademark of Saint-Gobain Performance Plastics.

Windows®, Microsoft® are registered trademarks of Microsoft Corporation.

All other brand and product names are trademarks or registered trademarks of their respective companies.

Disclaimer

The information contained in this manual is believed to be accurate and reliable. However, INFICON assumes

no responsibility for its use and shall not be liable for any special, incidental, or consequential damages related

to the use of this product.

Due to our continuing program of product improvements, specifications are subject to change without notice.

Copyright

©2013 All rights reserved.

Reproduction or adaptation of any part of this document without permission is unlawful.

Page 5

DECLARATION

OF

CONFORMITY

This is to certify that this equipment manufactured by:

INFICON Instruments ( Shanghai ) Co., Ltd

Section B, 1/F, No.11 Building, 201 Min Yi Road

Shanghai, 201612,

China

Design Control Authority

INFICON Inc.

Two Technology Place

East Syracuse, NY 13057

USA

Meets the essential safety requirements of the European Union and is placed on the market accordingly. It has

been constructed in accordance with good engineering practice in safety matters in force in the Community and

does not endanger the safety of persons, domestic animals or property when properly installed and maintained and

used in applications for which it was made.

In addition, this is to certify that this equipment has also been designed and manufactured; having regard to the

state of the art, to ensure complies with the Protection Requirements of EMC Directive 2004/108/EC.

A Technical Documentation File is also available for review by competent authorities and will be maintained for a

period of ten years after the date on which the equipment was last manufactured. In additional to this file,

technical, installation, maintenance and application information concerning this equipment can also be found in the

Operating Manual(s) for this product or product family.

Equipment Description: INFICON 3000 Micro Gas Chromatograph, INFICON 3000 Natural Gas Analyzer.

Including all standard options and accessories.

Applicable Directives: Low Voltage Directive 2006/95/EC

EMC Directive 2004/108/EC

Applicable Standards:

Safety: IEC 61010-1:2001 / EN 61010-1:2001

EMC: IEC 61326-1:2005 EN 61236-1:2006

Standard Limit

CISPR11:2003 EN55011:1998+A1:1999+A2:2002

CE Implementation Date: 17 November 2009

Authorized Representative: Jerry Wander Stephen Chabot

2)

1)

______________________________ ____________________________

INFICON Inc. INFICON Inc.

Business Line Manager, ISS Vice President, Operations

ANY QUESTIONS RELATIVE TO THIS DECLARATION OR TO THE SAFETY OF INFICON'S PRODUCTS SHOULD BE DIRECTED, IN

WRITING, TO THE QUALITY ASSURANCE DEPARTMENT AT THE ABOVE ADDRESS.

Revised 2010/06/17 (Rev A)

Page 6

Page 7

Warranty

WARRANTY AND LIABILITY - LIMITATION: Seller warrants the products

manufactured by it, or by an affiliated company and sold by it, and described on

the reverse hereof, to be, for the period of warranty coverage specified below, free

from defects of materials or workmanship under normal proper use and service.

The period of warranty coverage is specified for the respective products in the

respective Seller instruction manuals for those products but shall not be less than

two (2) years from the date of shipment thereof by Seller. Seller's liability under

this warranty is limited to such of the above products or parts thereof as are

returned, transportation prepaid, to Seller's plant, not later than thirty (30) days

after the expiration of the period of warranty coverage in respect thereof and are

found by Seller's examination to have failed to function properly because of

defective workmanship or materials and not because of improper installation or

misuse and is limited to, at Seller's election, either (a) repairing and returning the

product or part thereof, or (b) furnishing a replacement product or part thereof,

transportation prepaid by Seller in either case. In the event Buyer discovers or

learns that a product does not conform to warranty, Buyer shall immediately notify

Seller in writing of such non-conformity, specifying in reasonable detail the nature

of such non-conformity. If Seller is not provided with such written notification,

Seller shall not be liable for any further damages which could have been avoided if

Seller had been provided with immediate written notification.

THIS WARRANTY IS MADE AND ACCEPTED IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, WHETHER OF MERCHANTABILITY OR

OF FITNESS FOR A PARTICULAR PURPOSE OR OTHERWISE, AS BUYER'S

EXCLUSIVE REMEDY FOR ANY DEFECTS IN THE PRODUCTS TO BE SOLD

HEREUNDER. All other obligations and liabilities of Seller, whether in contract or

tort (including negligence) or otherwise, are expressly EXCLUDED. In no event

shall Seller be liable for any costs, expenses or damages, whether direct or

indirect, special, incidental, consequential, or other, on any claim of any defective

product, in excess of the price paid by Buyer for the product plus return

transportation charges prepaid.

No warranty is made by Seller of any Seller product which has been installed,

used or operated contrary to Seller's written instruction manual or which has been

subjected to misuse, negligence or accident or has been repaired or altered by

anyone other than Seller or which has been used in a manner or for a purpose for

which the Seller product was not designed nor against any defects due to plans or

instructions supplied to Seller by or for Buyer.

This manual is intended for private use by INFICON® Inc. and its customers.

Contact INFICON before reproducing its contents.

NOTE: These instructions do not provide for every contingency that may arise in

connection with the installation, operation or maintenance of this equipment.

Should you require further assistance, please contact INFICON.

www.inficon.com reachus@inficon.com

Page 8

Page 9

Chapter 1

1.1 About the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Definition of Notes, Warnings and Cautions. . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.3 Safety Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.3.1 Cleaning 3000 Micro GC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.4 Electromagnetic Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.5 Sound Emission Certification for

3000 Micro GC Operating Manual

Table Of Contents

Trademarks

Disclaimer

Copyright

Declaration Of Conformity

Warranty

Introduction

Federal Republic of Germany. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Chapter 2

Specifications

2.1 3000 Micro GC Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Environmental Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.3 Instrument Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.3.1 Sample Inlet Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.3.2 Sample Injector Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.3.3 Column Heater Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.3.4 TCD Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.3.5 Repeatability. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

PN 074-519-P1C

2.3.6 Carrier Gas Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.3.7 Portable 3000 Micro GC Carrier Gas Specifications . . . . . . . . . . . . . . . . . .2-3

2.3.8 External Input/Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.3.9 Portable 3000 Micro GC Onboard Battery . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.3.10 Safety and Regulatory Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Chapter 3

Overview

3.1 Overview of 3000 Micro GC Instrument and Accessories . . . . . . . . . . . . . . 3-1

3.2 3000 Micro GC Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3.2.1 1,2-Channel Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

TOC - 1

Page 10

3000 Micro GC Operating Manual

3.2.2 3,4-Channel Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.2.3 Portable Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.3 The 3000 Micro GC Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.3.1 Principle of 3000 Micro GC Module Operation. . . . . . . . . . . . . . . . . . . . . . . 3-5

3.3.2 Injector Flow Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.3.3 Injectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.3.3.1 Variable Injector (Timed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.3.3.2 Variable Large Volume Injector (Timed). . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.3.3.3 Fixed Injector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.3.3.4 Backflush Injector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.3.4 Columns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.3.5 Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.3.6 D-Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.3.6.1 Enhanced D-Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.3.6.2 Standard D-Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.3.7 Module Cases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

3.3.7.1 Standard Module Case. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

3.3.7.2 Modbox Module Case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

3.4 3000 Micro GC Chassis Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.4.1 Inlet Tubing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.4.2 C-Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

3.4.3 OBC Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

3.4.4 Sample Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

3.4.5 Carrier Gas Weldment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3.4.6 Carrier Gas Inlet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

3.4.7 Vents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

3.4.8 Remote Control Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

3.5 Sample Conditioners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

3.6 EZ IQ Chromatography Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

3.7 Product Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

3.7.1 1,2-Channel and Portable 3000 Micro GC Part Numbering . . . . . . . . . . . . 3-24

3.7.2 3,4-Channel 3000 Micro GC Part Numbering . . . . . . . . . . . . . . . . . . . . . . 3-25

3.7.3 Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

3.7.4 Identification Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

Chapter 4

4.1 Site Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.1 List of Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.2 Tubing and Fitting Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

PN 074-519-P1C

Installation

TOC - 2

Page 11

3000 Micro GC Operating Manual

4.1.3 Site Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

4.1.3.1 Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.1.3.2 Space and Venting Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.1.4 computer Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

4.1.5 Gas and Regulator Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.1.5.1 Carrier Gas and Regulator Requirements . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.1.5.2 Calibration Gas and Regulator Requirements . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.2 Instrument Hardware Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

4.2.1 Unpacking the Instrument. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.2.2 Shipping Kit Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

4.2.2.1 Shipped with Every Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.2.2.2 Configuration Dependent Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.2.2.2.1 1,2-Channel and 3,4-Channel 3000 Micro GC Specific Parts . . . . . . . . . . . 4-5

4.2.2.2.2 Portable 3000 Micro GC Specific Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

4.2.2.2.3 Sample Inlet Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.2.2.2.4 Gas Inlet Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.2.2.2.5 GC Module Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

4.2.2.2.6 Power Cords - Country Dependent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

4.2.3 Making Carrier Gas and Sample Inlet Connectors. . . . . . . . . . . . . . . . . . . . 4-6

4.2.4 Connecting the Carrier Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.2.4.1 Gas Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.2.4.2 Connecting the Carrier Gas Particulate Filter. . . . . . . . . . . . . . . . . . . . . . . . 4-9

4.2.4.3 Setting the Gas Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

4.2.4.4 Purge the Carrier Gas Line. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4.2.4.5 Connecting the Carrier Gas to the 3000 Micro GC. . . . . . . . . . . . . . . . . . . 4-11

4.2.4.6 Using the Onboard Carrier Gas Cylinder

(Portable 3000 Micro GC only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

4.2.5 Installing the Sample Inlet Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

PN 074-519-P1C

4.2.5.1 Sample Inlet Filter Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

4.2.5.2 Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

4.2.5.3 Sample Inlet Filter Assembly Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

4.2.6 Power and Communication Cable Setup . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

4.3 Instrument Configuration Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

4.3.1 Turn on 3000 Micro GC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

4.3.2 IP Address Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

4.3.3 Ping the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

4.3.4 Carrier Gas Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17

4.4 Chromatography Software Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18

TOC - 3

Page 12

3000 Micro GC Operating Manual

Chapter 5

Accessory Installation

5.1 Sample Conditioners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1.1 List of Sample Conditioners and IPNs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1.2 Installing the 10 Micron Sample Inlet Filter . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.1.3 Installing the Genie Filter Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.1.3.1 Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.1.3.2 User Supplied Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.1.3.3 Installation Instructions for the Genie Filter Assembly . . . . . . . . . . . . . . . . . 5-4

5.1.4 Installing the Pressure Reducer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.1.4.1 Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.1.4.2 User Supplied Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.1.4.3 Installation Instructions for the Pressure Reducer . . . . . . . . . . . . . . . . . . . . 5-9

5.1.5 Installing the Pressure Reducer and Genie Filter Assembly . . . . . . . . . . . 5-12

5.1.5.1 Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

5.1.5.2 User Supplied Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

5.1.5.3 Installation Instructions for the Pressure Reducer and

Genie Filter Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

5.1.6 Installing Heated Sample Introduction Accessories . . . . . . . . . . . . . . . . . . 5-17

5.1.6.1 Heated Regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

5.1.6.1.1 Target Analytes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

5.1.6.1.2 Heated Regulator Accessory Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

5.1.6.2 Heated Vaporizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

5.1.6.2.1 Heated Vaporizer Accessory Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

5.1.6.3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

5.1.6.3.1 Tools and Supplies Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

5.1.6.3.2 User Supplied Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

5.1.6.3.3 Prepare the 3000 Micro GC and Sample Introduction Accessory . . . . . . . 5-22

5.1.6.3.4 Installing the Transfer Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

5.1.6.3.5 Mounting the Heated Sample Conditioners . . . . . . . . . . . . . . . . . . . . . . . . 5-24

5.1.6.3.6 Install the Vent Tubing and Connect to Power . . . . . . . . . . . . . . . . . . . . . . 5-26

5.1.6.4 Installation for 3,4-Channel 3000 Micro GCs . . . . . . . . . . . . . . . . . . . . . . . 5-27

5.1.6.5 Heated Regulator/Vaporizer Part Numbers . . . . . . . . . . . . . . . . . . . . . . . . 5-28

5.2 The Remote Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-30

5.2.1 EZ IQ Operation to Activate Remote Start/Cancel Function . . . . . . . . . . . 5-32

5.3 Multi-Position Valve Installation and Setup . . . . . . . . . . . . . . . . . . . . . . . . 5-33

5.3.1 Valve Hardware/Software Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . 5-33

5.3.2 Valve Hardware Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-34

5.3.3 Valve Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-34

PN 074-519-P1C

TOC - 4

Page 13

Chapter 6

6.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1.1 Determine Basic 3000 Micro GC Configuration . . . . . . . . . . . . . . . . . . . . . .6-1

6.1.2 Determining 3000 Micro GC Advanced Configuration . . . . . . . . . . . . . . . . .6-3

6.2 Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6

6.2.1 Check GC Module Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6

6.2.2 Check the Duty Cycle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7

6.3 Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7

6.3.1 Set Date/Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6.3.2 Restart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

6.3.3 Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

6.3.4 Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

6.3.5 Remove or Replace a GC Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

6.3.6 Change GC Module Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

6.4 Change Carrier Gas Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

6.5 Change IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-13

6.5.1 IP Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

6.5.2 Access the Embedded Web Page Via a Fixed IP Address . . . . . . . . . . . . 6-16

3000 Micro GC Operating Manual

Instrument Setup Through

Embedded Web Page Operation

Chapter 7

Basic EZ IQ Operation

7.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.2 Connecting EZ IQ with 3000 Micro GC . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

7.3 Configuring EZ IQ to Use a Valco (VICI) Valve . . . . . . . . . . . . . . . . . . . . . . 7-4

7.3.1 Configuring a Valco (VICI) Switching Valve . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

7.3.2 Configuring a Valco (VICI) Sampling Valve . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

7.4 Navigating EZ IQ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

PN 074-519-P1C

7.5 EZ IQ Workflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-11

7.6 Basic Method Development . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

7.6.1 Creating a New Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

7.6.2 Opening a Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-16

7.6.3 Downloading a Method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

7.6.4 View Instrument Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

7.7 Run a Sample . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

7.8 Basic Sequencing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

7.9 Scheduling Runs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-20

7.10 Integrating the Chromatogram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-21

7.10.1 About Integration Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-21

TOC - 5

Page 14

3000 Micro GC Operating Manual

7.10.2 Common Integration Events. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-22

7.10.2.1 Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-22

7.10.2.2 Threshold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-22

7.10.2.3 Integration Off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

7.10.3 Add or Edit Integration Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

7.10.3.1 Manually Add or Edit Integration Events . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

7.10.3.2 Graphically Programming Integration Events. . . . . . . . . . . . . . . . . . . . . . . 7-25

7.11 Qualify Peaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-26

7.11.1 Annotate a Chromatogram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-26

7.11.2 Adding Peak and Group Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-28

7.11.2.1 Manually Add Peak Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-28

7.11.2.2 Define Peaks Graphically . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

7.11.2.3 Adding Groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-33

7.11.3 Adjust Peak Windows. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-34

7.12 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-36

7.12.1 Obtain Preliminary Data for Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-36

7.12.2 Enter Concentration Amounts in the Peaks/Groups Table. . . . . . . . . . . . . 7-36

7.12.3 Perform A Single Level Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-37

7.12.4 Perform a Multiple Level Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-40

7.12.5 Review Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-41

7.13 Generate Standard Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-42

7.13.1 Method Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-42

7.13.1.1 Customize a Method Report. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-42

7.13.1.1.1 Custom Method Report Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-43

7.13.1.1.2 Importing a Template File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-44

7.13.1.2 Save a Custom Method Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-45

7.13.1.3 View or Print a Custom Method Report . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-46

7.13.2 External Standard (ESTD) Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-47

7.13.2.1 Customize an ESTD Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-47

7.13.2.2 Save a Customized ESTD Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-47

7.13.2.3 View and Print an ESTD Report. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-48

7.14 EZ IQ Operation to Activate Remote Start/Cancel Function . . . . . . . . . . . 7-49

7.15 Apply the Valco Valve Program to EZ IQ Method . . . . . . . . . . . . . . . . . . . 7-52

7.15.1 Valco Valve Setup in EZ IQ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-52

7.15.2 Running a Sample with a Valco Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-53

7.15.3 Running a Sequence with a Valco Valve . . . . . . . . . . . . . . . . . . . . . . . . . . 7-54

TOC - 6

PN 074-519-P1C

Page 15

3000 Micro GC Operating Manual

Chapter 8

Instrument Operations

8.1 Routine Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

8.1.1 System Bakeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.1.2 Shutdown/Restart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-3

8.1.3 Standby . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

8.2 Remove and Replace a 3000 Micro GC Module . . . . . . . . . . . . . . . . . . . . .8-5

8.2.1 Types of Replacement Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

8.2.2 Performance Enhanced GC Module vs. Standard GC Module . . . . . . . . . .8-5

8.2.3 Update the Instrument Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-6

8.2.4 Decommission a Standard GC Module . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-7

8.2.5 Remove a GC Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-11

8.2.6 Install a GC Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-16

8.2.7 Commission a New Standard GC Module . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

8.2.8 Enable the Instrument in EZ IQ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-22

8.3 Sample Conditioners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-23

8.3.1 Sample Conditioner Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-23

8.3.1.1 Connections for Sample Inlet Filter (PN G2801-60900),

Pressure Reducer (PN G2815A),

Pressure Reducer and Genie Filter Assembly (PN G2816A), and

Genie Filter Assembly (PN G2817A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-23

8.3.1.2 Connections for the Heated Regulator

(PN G2818A-X/G2845A-X/G2857A-X). . . . . . . . . . . . . . . . . . . . . . . . . . . .8-23

8.3.1.3 Connections for the Heated Vaporizer

(PN G2819A-X/G2846A-X/G2858A-X). . . . . . . . . . . . . . . . . . . . . . . . . . . .8-23

8.3.2 Running a Low Pressure, Clean Gas Sample . . . . . . . . . . . . . . . . . . . . . . 8-24

8.3.3 Running a Low Pressure, Liquid/Particulate Containing Gas Sample . . . .8-25

8.3.4 Running a High Pressure Gas Sample without Liquids/Particulates . . . . . 8-26

8.3.5 Running a High Pressure Gas Sample with Liquids/Particulates . . . . . . . . 8-27

PN 074-519-P1C

8.3.6 Running a High Pressure Gas Sample Containing C6+ Components . . . . 8-28

8.3.6.1 Using a Sample Vessel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-28

8.3.6.2 Using a Transfer Line or Other Continuous Sample Source . . . . . . . . . . . 8-30

8.3.7 Running a High Pressure Liquid Petroleum Gas Sample. . . . . . . . . . . . . .8-32

8.4 Consumable Replacement Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-35

8.4.1 Replacing the External 10 Micron Sample Inlet Filter Disk. . . . . . . . . . . . .8-35

8.4.2 Replacing the 2 Micron Filter in the Heated Vaporizer

(PN G2819A-X/G2846A-X/G2858A-X). . . . . . . . . . . . . . . . . . . . . . . . . . . .8-36

8.4.3 Replacing the 7 Micron Filter in the Heated Regulator

(PN G2818A-X/G2845A/G2857A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-37

8.5 Portable 3000 Micro GC Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-38

8.5.1 General Information and Cautions of the Portable 3000 Micro GC . . . . . . 8-38

TOC - 7

Page 16

3000 Micro GC Operating Manual

8.5.2 Battery Usage Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-38

8.5.2.1 To View the Battery Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-39

8.5.2.2 Charging the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-39

8.5.2.3 Replace the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-40

8.5.3 Onboard Carrier Gas Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-42

8.5.3.1 Refill Onboard Carrier Gas Cylinder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-43

8.5.3.2 Before Turning Off the Carrier Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-46

Chapter 9

Troubleshooting

9.1 Symptom, Cause, and Remedy Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.1.1 Common Chromatographic Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.1.2 Common Software Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

9.1.3 Common Connection Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

9.1.4 Common Hardware Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

9.2 Common Chromatographic and Method Problems . . . . . . . . . . . . . . . . . . 9-10

9.2.1 Chromatographic Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

9.2.1.1 Baseline Symptoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

9.2.1.1.1 Baseline Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

9.2.1.1.2 Baseline Wander and Drift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

9.2.1.1.3 Baseline Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

9.2.1.1.4 Baseline Spiking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

9.2.1.2 Retention Time Symptoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-13

9.2.1.2.1 Retention Time Drift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-13

9.2.1.2.2 Retention Time Wander (Reproducibility) . . . . . . . . . . . . . . . . . . . . . . . . . 9-13

9.2.1.3 Peak Symptoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-14

9.2.1.3.1 No Peaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-14

9.2.1.3.2 Inverted Peaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-14

9.2.1.3.3 Extra Peaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-15

9.2.1.4 Deformed peaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-16

9.2.1.4.1 Peak Fronting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-16

9.2.1.4.2 Peak Tailing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-16

9.2.1.4.3 Deformed Peak Apex . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-17

9.2.1.4.4 Split Peak Apex . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-17

9.2.2 Method Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-18

9.2.2.1 Column and Detector Bakeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-18

9.2.2.2 Correcting Instrument Parameter Settings . . . . . . . . . . . . . . . . . . . . . . . . . 9-18

9.2.2.2.1 Adjusting Column Head Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-18

9.2.2.2.2 Recalibrating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-18

PN 074-519-P1C

TOC - 8

Page 17

3000 Micro GC Operating Manual

Chapter 10

Service and Technical Support

10.1 How to Contact Customer Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

10.2 Returning 3000 Micro GC to INFICON. . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

10.3 Warranty Extension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

10.4 Service Contract. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-2

Chapter 11

Replacement Parts and Gases

11.1 Power Cables and Converters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-1

11.2 GC Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-3

11.2.1 Description of GC Module Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-3

11.2.1.1 Reference Number on Top of GC Module . . . . . . . . . . . . . . . . . . . . . . . . . 11-3

11.2.1.2 New Module Part Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-3

11.2.1.3 Refurbished Module Part Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-3

11.2.1.4 New Module Replacement Part Number: . . . . . . . . . . . . . . . . . . . . . . . . . .11-3

11.2.2 Standard Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-4

11.2.3 Standard Modules Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-5

11.2.4 Performance Enhanced Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-9

11.2.5 Performance Enhanced Modules Table . . . . . . . . . . . . . . . . . . . . . . . . . . 11-10

11.2.6 Discontinued Module Replacement IPNs . . . . . . . . . . . . . . . . . . . . . . . . .11-14

11.3 Sample Accessories and Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-15

11.3.1 Sample Conditioners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-15

11.3.2 Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-16

11.3.3 Other Support Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-16

11.4 Checkout Gases. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-17

11.4.1 Universal Checkout Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-17

11.5 NGA Checkout Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-18

11.5.1 RGA Checkout Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-19

PN 074-519-P1C

TOC - 9

Page 18

3000 Micro GC Operating Manual

This page is intentionally blank.

TOC - 10

PN 074-519-P1C

Page 19

This operating manual describes the use and maintenance of the INFICON 3000

Micro Gas Chromatograph (GC).

3000 Micro GC can be used to analyze alternative fuels such as natural gas,

syngas, biogas, and landfill gas. Additional applications include: refinery gases,

mine gas, furnace gas, custody transfer, well logging, environmental screening,

storage tank analysis, scrubber analyses, and monitoring volatile organic

compounds (VOC).

3000 Micro GC in combination with EZ IQ data handling and instrument control

software provides a comprehensive, easy-to-use gas analysis system.

1.1 About the Instrument

3000 Micro GC self-contained GC modules consist of an injector using

Microelectromechanical Systems (MEMS) technology, analytical and reference

columns, electronic pressure control, and a thermal conductivity detector (TCD)

also using MEMS technology.

3000 Micro GC Operating Manual

Chapter 1

Introduction

NOTE: When installed in a 3000 Micro GC chassis, a module is referred to as a

channel. When standalone, it is referred to as a module.

Routine replacement of parts such as septa, ferrules, or columns is not required.

This eliminates the need for frequent leak testing.

®

Samples are introduced through a 1/16 in. Swagelok

3000 Micro GC front panel. This design eliminates the need for traditional

hypodermic syringe injection through septa. The inlet pressure can be nearly

atmospheric because an internal vacuum pump connected to the column exit

eliminates column back pressure. See Table 1-1 for a summary of external

PN 074-519-P1C

connections.

connection to inlet(s) on the

1 - 1

Page 20

3000 Micro GC Operating Manual

Table 1-1 Summary of connections

Connection Notes

Input fitting(s) 1/16 in. Swagelok

Input pressure range

Recommended range

0 to 172 kPa (0 to 25 PSI)

35 to 69 kPa (5 to 10 PSI)

Sample filtration External 10 micron particle trap standard (not used with

accessories G2816A, G2817A, G2818A, G2819A-X

G2845A-X

1

Where X is the country specific power cord number:

1

, or G2846A-X1, G2857A-X1, G2858A-X1)

1

,

1: China

2: Europe

3: US

4: Japan

5: UK/HK/SG/MY

6: Australia/NZ

7: Korea

Instrument control EZ IQ software

Carrier gas inlet fitting 1/8 in. Swagelok

Vent gas fitting 1/8 in. Luer-Lok

®

Only clean gases or vapors should be introduced to 3000 Micro GC. Avoid

aerosols, condensable vapors, liquids and solid particles. Install an appropriate

sample filter or conditioner. An external 10 micron filter (PN G2801-60900) is

shipped with every 3000 Micro GC. This filter must be used unless it is replaced by

another filter or sample conditioner. Contact INFICON for details on available

accessories.

1 - 2

3000 Micro GC can be controlled by a personal computer (computer) through a

standard RJ-45 connection, either directly from a computer using a cross-over

cable connection or through a Local Area Network (LAN) connection. EZ IQ

software controls all experimental settings, data collection, and data analysis.

PN 074-519-P1C

Page 21

3000 Micro GC Operating Manual

CAUTION

WARNING

WARNING - Risk Of Electric Shock

1.2 Definition of Notes, Warnings and Cautions

When using this manual, please pay attention to the Notes, Cautions, and

Warnings found throughout. For the purposes of this manual they are defined as

follows:

NOTE: Pertinent information that is useful in achieving maximum 3000 Micro GC

efficiency when followed.

Failure to heed these messages could result in

damage to 3000 Micro GC.

Failure to heed these messages could result in

personal injury.

Dangerous voltages are present which could result in

personal injury.

PN 074-519-P1C

1 - 3

Page 22

3000 Micro GC Operating Manual

WARNING

WARNING

WARNING

WARNING

WARNING

1.3 Safety Overview

3000 MicroGC meets IEC (International Electro-technical Commission)

classifications: Safety Class III, Transient Overvoltage Category II, Pollution

Degree 2.

3000 Micro GC has been designed and tested in

accordance with recognized safety standards and is

designed for indoor use.

If 3000 Micro GC is used in a manner not specified by the

manufacturer, the protection provided by 3000 Micro GC

may be impaired.

Whenever the safety protection of 3000 Micro GC has

been compromised, disconnect 3000 Micro GC from all

power sources and secure 3000 Micro GC against

unintended operation.

Refer servicing to qualified service personnel.

Substituting parts or performing any unauthorized

modification to the instrument may result in a safety

hazard.

PN 074-519-P1C

1 - 4

Page 23

3000 Micro GC Operating Manual

WARNING

WARNING

WARNING

WARNING - Risk Of Electric Shock

WARNING

WARNING

3000 Micro GC has inlets which can be heated to 140°C.

Touching the inlets once they are at operating

temperatures can result in injury. Extreme care should be

taken to avoid touching the inlets.

Do not operate in an explosive environment or in the

presence of flammable gases or fumes. Operation of any

electrical instrument in such environments constitutes a

safety hazard.

Use only the INFICON supplied power source. Use of any

other power supply could result in catastrophic failure of

the electrical system and may cause personal injury.

Always disconnect the power supply before replacing or

touching any components.

PN 074-519-P1C

Hot surfaces. Many parts of 3000 Micro GC operate at

temperatures high enough to cause serious burns. These

parts include, but are not limited to: the inlet port, the

inlet manifold, the GC module, the column nuts attaching

the module to an inlet or a vent. Extreme care should be

taken to avoid touching these heated surfaces.

Do not operate the instrument with the GC module

disassembled. Column temperatures can reach 180°C.

1 - 5

Page 24

3000 Micro GC Operating Manual

CAUTION - Static Sensitive Device

WARNING

WARNING

Electrostatic discharge (ESD) is a threat to electronics.

Electrostatic discharge can damage the circuit boards in

the instrument. Do not handle the circuit boards.

Hydrogen (H2) gas is flammable and can present an

explosion hazard. Leaks, when confined in an enclosed

space, may create an ignition or explosion hazard. In any

application using hydrogen, leak test all plumbing

connections before operating 3000 Micro GC. Always

turn off the hydrogen supply at its source and disconnect

the tubing before servicing the instrument. Do not flow

hydrogen through a disassembled GC module. Vent

exhaust gases safely.

Never fill the Portable 3000 Micro GC internal gas

cylinder with hydrogen. A hydrogen leak inside the

instrument can present an explosion hazard.

NOTE: The pressure in the Portable 3000 Micro GC internal carrier gas tank

should not exceed 12,405 kPa (1800 PSI). If this pressure is exceeded, the

relief valve on the Cylinder Recharge Kit will open. A loud startling noise

will commence and continue until the internal carrier pressure drops to

12,405 kPa (1800 PSI).

NOTE: The Portable 3000 Micro GC refillable carrier gas cylinder is United States

Department of Transportation rated at a 12,405 kPa (1800 PSI) maximum

with a five year Hydrostatic approval.

1.3.1 Cleaning 3000 Micro GC

To clean the exterior of 3000 Micro GC, disconnect the power and wipe down with

a slightly damp, lint-free cloth.

PN 074-519-P1C

1 - 6

Page 25

1.4 Electromagnetic Compatibility

3000 Micro GC complies with the requirements of CISPR 11 and EN 61326.

Operation is subject to the following conditions:

This device may not cause harmful interference

This device must accept any interference received, including interference that

may cause undesired operation

If 3000 Micro GC causes harmful interference to radio or television reception when

turned on or off, try one or more of the following measures:

Relocate the radio or television antenna

Move the device away from the radio or television

Plug the device into a different electrical outlet, so that the device and the radio

or television are on separate electrical circuits

Ensure all peripheral devices are also certified

Ensure appropriate cables are used to connect the device to peripheral

equipment

3000 Micro GC Operating Manual

If none of above measures reduce the interference, contact INFICON.

Changes or modifications not expressly approved by INFICON could void the

user’s authority to operate the equipment

This ISM device complies with Canadian ICES-001

1.5 Sound Emission Certification for Federal Republic of Germany

Sound pressure level Lp <65 dB(A)

During normal operation

PN 074-519-P1C

At the operator position

According to ISO 7779 (Type Test)

1 - 7

Page 26

3000 Micro GC Operating Manual

This page is intentionally blank.

1 - 8

PN 074-519-P1C

Page 27

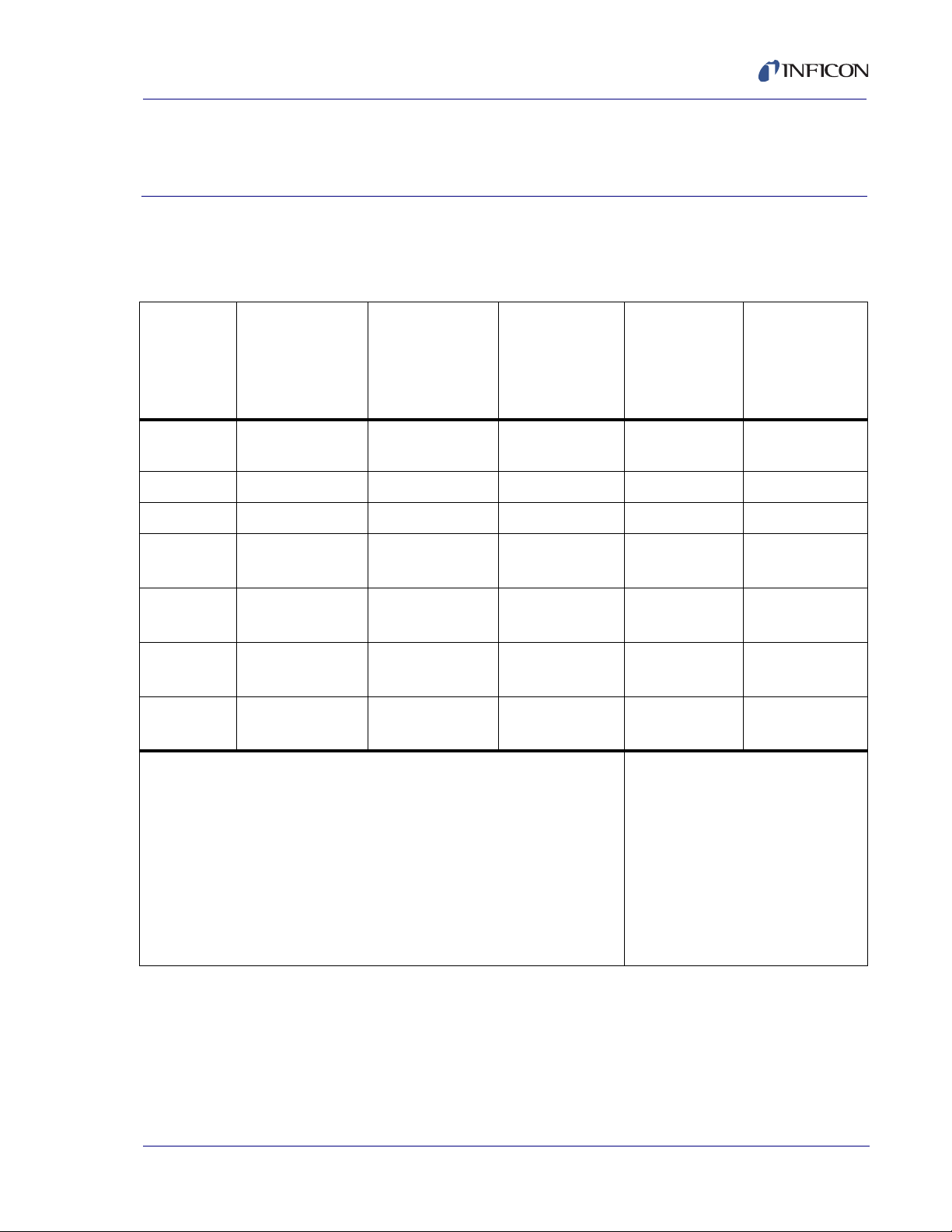

2.1 3000 Micro GC Specifications

Table 2-1 Specifications

3000 Micro GC Operating Manual

Chapter 2

Specifications

1 or 2-channel

3000 Micro GC

Main

voltage

Power 100 VA 130 VA 130 VA 1.2/0.6 A 1.2/0.6 A

Frequency 50-60 Hz 50-60 Hz 50-60 Hz 50-60 Hz 50-60 Hz

Height 15 cm

Width 25 cm

Depth 41 cm

Weight 8.2 kg

* Does not include mounting bracket

PN 074-519-P1C

100-240 V (ac) 100-240 V (ac) 100-240 V (ac) 115/230 V (ac) 115/230 V (ac)

(6 in.)

(10 in.)

(16.5 in.)

(18.0 lb.)

3 or 4-channel

3000 Micro GC

15.5 cm

(6.1 in.)

48 cm

(18.5 in.)

42 cm

(16.5 in.)

11.2 kg

(24.8 lb.)

Portable

3000 Micro GC

15.5 cm

(6.1 in.)

36.4 cm

(14.3 in.)

41.3 cm

(16.3 in.)

16.6 kg

(36.5 lb.)

Heated

Vaporizer

(PN G2819A-X

/ G2846A-X1/

G2857A-X

15 cm

(6 in.)

12.5 cm

(5 in.)

9 cm

(3.5 in.)

1.4 kg

(3.1 lb.)*

1

Where X is the country specific

power cord number:

1

1

)

1: China

2: Europe

3: US

4: Japan

5: UK/HK/SG/MY

6: Australia/NZ

7: Korea

Heated

Regulator

(PN G2818A-X

G2845A-X

G2858A-X

15 cm

(6 in.)

12.5 cm

(5 in.)

9 cm

(3.5 in.)

1.65 kg

(3.64 lb.)*

1

1

1

/

/

)

2 - 1

Page 28

3000 Micro GC Operating Manual

2.2 Environmental Conditions

The following specifications are applicable to the 3000 Micro GC Heated Regulator

and Heated Vaporizer sample conditioners.

Operating temperature range. . . . . . 0 to 50°C

Relative humidity . . . . . . . . . . . . . . . 5 to 95% (non-condensing)

Altitude . . . . . . . . . . . . . . . . . . . . . . . 4572 m (15000 ft.)

Usage location . . . . . . . . . . . . . . . . . Temperature controlled environment

2.3 Instrument Specifications

2.3.1 Sample Inlet Specifications

Sample type . . . . . . . . . . . . . . . . . . . Gas

Maximum sample pressure . . . . . . . <172 kPa (25 PSI)

Recommended sample pressure . . . Ambient to 69 kPa (ambient to 10 PSI)

2.3.2 Sample Injector Specifications

Injector types

Variable volume/timed, heated

Variable volume/large loop, heated

Fixed volume, heated

Backflush to vent, heated

Injection volume

1 to 10 μL for variable volume/timed

1 to 30 μL for variable volume/large loop

1 μL for fixed volume injector and backflush injector with fixed mode

2.3.3 Column Heater Specification

Isothermal Operation . . . . . . . . . . . . Ambient plus 15 to 180°C

2.3.4 TCD Specifications

PN 074-519-P1C

2 - 2

Internal Volume . . . . . . . . . . . . . . . . 240 nL

Detection Limit . . . . . . . . . . . . . . . . . Low ppm to 100%

6

Linear Dynamic Range. . . . . . . . . . . 10

±10%

Page 29

2.3.5 Repeatability

Typical results for Relative Standard Deviation (RSD) at constant temperature and

pressure (for C

3000 Micro GC Operating Manual

to C6 components at % level) are shown below for peak areas.

1

Injector Type

Peak Area Repeatability

Variable volume . . . . . . . . . . . . . . . . <1% RSD

Fixed volume . . . . . . . . . . . . . . . . . . <0.2% RSD

Backflush (timed mode) . . . . . . . . . . <1% RSD

Backflush (fixed mode). . . . . . . . . . . <0.5% RSD

2.3.6 Carrier Gas Specifications

Connection to 3000 Micro GC . . . . . 1/8 in. Swagelok fittings

External source . . . . . . . . . . . . . . . . Helium

Hydrogen

Nitrogen

Argon

Carrier gas purity . . . . . . . . . . . . . . . 99.995 to 99.9995%

Input pressure . . . . . . . . . . . . . . . . . 552 to 566 kPa (80 to 82 PSI)

2.3.7 Portable 3000 Micro GC Carrier Gas Specifications

Onboard cylinder source . . . . . . . . . Helium

Nitrogen

Argon

Onboard cylinder capacity . . . . . . . . 12,410 kPa (1800 PSI)

Onboard cylinder usage . . . . . . . . . . 35-40 hours, application dependent

2.3.8 External Input/Output

PN 074-519-P1C

RJ-45 based LAN

Power supply input connector

Remote start

2.3.9 Portable 3000 Micro GC Onboard Battery

The 3000 Micro GC onboard battery will operate the instrument up to two hours,

depending on the application.

2 - 3

Page 30

3000 Micro GC Operating Manual

2.3.10 Safety and Regulatory Standards

Conforms to the following safety standards:

CSA/National Recognized Test Laboratory (NRTL) UL61010-1

International Electrotechnical Commission (IEC) 61010-1

Canadian Standards Association (CSA) C22.2 No. 61010-1

EuroNorm (EN) 61010-1

Conforms to the following regulations on Electromagnetic Compatibility (EMC) and

Radio Frequency Interface (RFI):

CISPR I1/EN 55011 Group 1 Class A IEC/EN 61326

Declaration of Conformity available

2 - 4

PN 074-519-P1C

Page 31

3000 Micro GC Operating Manual

Chapter 3

Overview

3.1 Overview of 3000 Micro GC Instrument and Accessories

3000 Micro GC is a gas analyzer with applications ranging from fixed gases

(H

, O2, N2, CO, CO2, etc.) to light hydrocarbons (methane, ethane, ethylene,

2

propane, butanes, and pentanes) and volatile organic compounds (methanol,

ethanol, benzene, etc.). 3000 Micro GC contains from 1 to 4 channels that perform

analysis in seconds. For many applications, hydrocarbons between the C

boiling range can be detected at mid-to-high ppm concentrations.

NOTE: When installed in a 3000 Micro GC chassis, a module is referred to as a

channel. When standalone, it is referred to as a module.

®

Samples can be introduced manually by a gas tight syringe, Tedlar

sample cylinder such as a summa canister. Samples can also be interfaced to

3000 Micro GC with appropriate INFICON supplied sample conditioners to

facilitate on-line analysis from bench scale or pilot plant reactors, or directly from a

process line. See Chapter 5, Accessory Installation for information on sample

conditioners.

bag, or a

- C10

6

3000 Micro GC is a ready to use solution combining speed of analysis, simplicity,

and small size. Since 3000 Micro GC is a gas chromatographic instrument, all

principles of GC operation and calibration apply.

3000 Micro GC is used in combination with INFICON EZ IQ chromatography

software for instrument control and chromatography analysis.

PN 074-519-P1C

3 - 1

Page 32

3000 Micro GC Operating Manual

Sample Inlet

RS-232 Port

RJ-45 LAN Port

Power Supply Connector

Ven ts

3.2 3000 Micro GC Chassis

There are three types of 3000 Micro GC chassis that house GC modules:

1,2-Channel Chassis, see section 3.2.1 on page 3-2

3,4-Channel Chassis, see section 3.2.2 on page 3-3

Portable Chassis, see section 3.2.3 on page 3-4

3.2.1 1,2-Channel Chassis

The 1,2-channel chassis can accept one or two channels. The carrier gas and

power for a 1,2-channel system must be supplied externally. See Figure 3-1 and

Figure 3-2.

Figure 3-1 Front panel of the 1,2-channel 3000 Micro GC

Figure 3-2 Rear panel of the 1,2-channel 3000 Micro GC

PN 074-519-P1C

3 - 2

Page 33

3.2.2 3,4-Channel Chassis

Sample Inlet

RS-232 Port

RJ-45 LAN Port

Power Supply Connector

Vents

The 3,4-channel chassis can accept three or four channels. The carrier gas and

power for a 3,4-channel system must be supplied externally. See Figure 3-3 and

Figure 3-4.

Figure 3-3 Front panel of the 3,4-channel 3000 Micro GC

Figure 3-4 Rear panel of the 3,4-channel 3000 Micro GC

3000 Micro GC Operating Manual

PN 074-519-P1C

3 - 3

Page 34

3000 Micro GC Operating Manual

Sample Inlet

Onboard carrier

gas control knob

Vents

Power supply

connector

RS-232 Port

RJ-45 LAN Port

3.2.3 Portable Chassis

Portable 3000 Micro GC is a completely self-contained, miniaturized gas

chromatograph specifically designed for fast, accurate analysis in the field. Each

instrument contains one or two GC channels and an internal carrier gas cylinder.

Rechargeable battery packs and automobile power cable options are available for

alternative power sourcing. See Figure 3-5, Figure 3-6, and Figure 3-7.

Figure 3-5 Front panel of the Portable 3000 Micro GC

Figure 3-6 Rear panel of the Portable 3000 Micro GC

3 - 4

Figure 3-7 Onboard carrier gas cylinder (battery installed underneath)

Portable 3000 Micro GC has an internal, refillable carrier gas tank. When full, it can

support 35 to 40 hours of operation, application dependent.

Portable 3000 Micro GC also contains an optional internal, rechargeable lead-acid

battery pack that supports instrument operation without external power.

PN 074-519-P1C

Page 35

3.3 The 3000 Micro GC Module

Channel

A (1)

Channel

Channel

Channel

B (2)

C (3)

D (4)

3000 Micro GC utilizes a modular GC platform, which can simultaneously analyze

samples from one to four independent 3000 Micro GC channels. Each channel (or

module) is a self-contained GC that performs sample injection, separation, and

detection on a set of target components.

When installed in a 3000 Micro GC chassis, a module is referred to as a channel.

When standalone, it is referred to as a module.

Modules may be referred to as Channel A, B, C, D or 1, 2, 3, 4 from left to right.

See Figure 3-8.

Figure 3-8 Modules installed in a 4-channel 3000 Micro GC

3000 Micro GC Operating Manual

PN 074-519-P1C

3.3.1 Principle of 3000 Micro GC Module Operation

The major functions of the 3000 Micro GC module operation are: injection,

separation, and detection.

1 Injection: Gaseous sample is injected into 3000 Micro GC through the heated

inlet manifold. The manifold regulates the sample temperature and directs it

into the 3000 Micro GC injector flow assembly on a module. The sample is

drawn by vacuum pump through the injector sample loop and is released onto

the column.

3 - 5

Page 36

3000 Micro GC Operating Manual

Sample

Flow

Ref

Flow

E

R

V

V

S

i

vOut

rS

I

E

+

-

Sample

Flow

Ref

Flow

rR

2 Separation: As the sample gas enters the column, its component gases are

separated based on their retention or adsorption property with the column

stationary phase material. The longer the component gas is retained by the

column, the later it will elute from of the column for detection. Components may

be separated based on size, polarity, or boiling point, depending on the column.

3 Detection: After column separation, the sample gas enters the Thermal

Conductivity Detector (TCD). 3000 Micro GC employs a

Microelectromechanical systems (MEMS) TCD which operates on a

Wheatstone bridge circuit. The carrier gas enters the TCD via two pathways,

the reference path and the analytical path. The reference path contains only

carrier gas. The analytical path contains carrier gas and sample gas. The TCD

measures the difference in thermal conductivity between the carrier gas

reference and the sample gas components.

For example, the thermal conductivity of helium carrier gas at 300 K is

157 mW/m K. The thermal conductivity of methane sample gas at 300 K is

34 mW/m K.This difference is picked up by the Wheatstone bridge circuit,

generating signal response to the sample component eluted. See Figure 3-9.

Figure 3-9 Wheatstone bridge circuit

PN 074-519-P1C

3 - 6

Page 37

3.3.2 Injector Flow Assembly

The injector flow assembly (see Figure 3-10) consists of:

MEMS injector chip—micro-machined miniature chip that injects sample into

the GC column

Injector Pilot Solenoid Valve—on/off valve that directs carrier gas to drive

diaphragm valves within the MEMS injector chip

Electronic Pressure Control (EPC) Valve—regulates the column head

pressure

Sample Manifold Plate—provides interface between the EPC valve and the

Injector Pilot Solenoid valve to the MEMS injector

Figure 3-10 Injector flow assembly

3000 Micro GC Operating Manual

PN 074-519-P1C

3 - 7

Page 38

3000 Micro GC Operating Manual

3.3.3 Injectors

Depending on application requirements, 3000 Micro GC supports four different

types of injectors. These MEMS based injector “wafers” contain sample loops

etched into the wafer and micro-diaphragm valves used to direct sample and

carrier gas flow. The sample volume is controlled in EZ IQ by the Inject Time in

milliseconds (ms). The Injector Temperature can be set from 40-100

turned off.

3.3.3.1 Variable Injector (Timed)

The variable injector allows the injection volume to be changed by the user. An

inject time of 0 ms results in no injection.

Valid settings are between 10-100 ms. No significant difference in inject volume is

achieved after 100 ms.

The typical setpoint is 25 ms. Values less than 10 ms may result in repeatability

issues.

The higher the setting, the more sample is injected which results in higher

sensitivity. Actual injection volumes are on the order of a few microliters (µL) of gas.

°C or be

Variable injectors will show the matrix effect as the sample density varies with

compositional changes.

3.3.3.2 Variable Large Volume Injector (Timed)

Similar to the Variable Injector, the Large Volume Injector can be programmed to

inject a large volume. Variable Large Volume Injectors should only be used when

low sensitivity (1-10 ppm) is required. An Inject Time of 0 ms results in no injection.

Valid settings are between 10-400 ms. No significant difference in inject volume is

achieved after 400 ms.

Values less than 10 ms may result in repeatability issues.

PN 074-519-P1C

3 - 8

Page 39

3.3.3.3 Fixed Injector

Fixed Injectors are unique to 3000 Micro GC. Fixed Injectors provide the best

accuracy and precision for 0.2% levels and higher.

Valid settings are between 0-50 ms. An inject time of 0 ms results in no injection.

A typical setpoint is 30 ms. No significant difference in inject volume is achieved

from inject times between 15-50 ms. Values less than 15 ms may result in

repeatability issues.

Actual injection volumes are typically 1-2 µL of gas.

Fixed volume injectors should not be used for trace levels (<200 ppm).

Fixed injectors minimize any matrix effects as sample density varies with

compositional changes.

3000 Micro GC Operating Manual

PN 074-519-P1C

3 - 9

Page 40

3000 Micro GC Operating Manual

3.3.3.4 Backflush Injector

The backflush assembly consists of:

a backflush injector

a precolumn

an analytical capillary column

The precolumn is a short section of column, whereas the analytical column is

usually longer. The precolumn and analytical column are connected in series.

The precolumn functions to prevent contaminants from entering the analytical

column. The sample first travels through the precolumn and then through the

analytical column. After components of interest enter the analytical column, the

flow is reversed through the precolumn, flushing the unwanted components to vent.

This backflushing of the precolumn prevents these contaminants from entering the

analytical column and causing deactivation or ghost peaks.

The backflush injector has two method parameters in EZ IQ software: Backflush

Time (in seconds) and Inject Time (in milliseconds). The Backflush Time

parameter on the Instrument Setup window can be changed to suit analysis

needs. Valid settings for the Backflush Time are between 0-240 s. Recommended

settings for the Backflush Time are between 6-12 s. Valid settings for the Inject

Time are between 0-250 ms.

The backflush injector can also function in a semi-fixed mode. An Inject Time of

0 ms results in a fixed volume injected and is best used for component levels from

0.1% and higher. This will result in higher precision.

The backflush injector can function in a variable volume mode. An Inject Time

greater than 10 ms will result in a higher injection volume. This used for component

levels below 0.1%.

Actual inject volumes are typically a few microliters of gas. For better sensitivity, set

a higher Inject Time, however, accuracy and precision will be negatively impacted.

Backflush times vary with column and setpoints and must be optimized for every

3000 Micro GC module.

PN 074-519-P1C

3 - 10

Page 41

3.3.4 Columns

Porous Layer Open Tube

(PLOT)

Wall Coated Open Tube

(WCOT)

Open (Capillary)

3000 Micro GC utilizes capillary columns for separation. Two types of capillary

columns are used: Porous Layer Open Tubular (PLOT) and Wall Coated Open

Tubular (WCOT). The capillary columns are wound into a column can, which is

installed into a module and can be heated up to 180°C. Columns are connected to

the injector on one end and the TCD on the other end using small dead-volume

fittings. Typical column flow rates range from 0.4 to 4 mL/min (cc/min) depending

on column dimensions.

PLOT columns have small particles embedded on the surface of the column. See

Figure 3-11. PLOT column separation is based on gas-solid partitioning. The most

popular PLOT columns are Molecular Sieve 5A (MolSieve), PLOT Q, PLOT U and

Alumina. PLOT columns separate according to compound polarity. Typical lengths

are 4 to 30 m with an internal diameter of 0.32 mm.

WCOT columns have a chemical stationary phase bonded to the internal surface

of the column. (See Figure 3-11.) WCOT separation based on gas-liquid

partitioning. OV-1 is a commonly used WCOT column, which separates

compounds according to boiling point. Typical lengths are 4 to 14 m, with an

internal diameter of 0.15 mm. Stationary phase thicknesses of 1.2 or 2 µm are used

for the OV-1. Other columns are also used in 3000 Micro GC, such as Stabilwax

OV-1701, etc.

3000 Micro GC Operating Manual

®

,

Figure 3-11 PLOT and WCOT columns

PN 074-519-P1C

Separation may be optimized by varying the column coating type and thickness,

column length and diameter, and carrier gas type. EZ IQ can further optimize

separation by adjusting column head pressure and column temperature.

3 - 11

Page 42

3.3.5 Detector

3000 Micro GC uses a MEMS based TCD, which has a 240 nL internal cell volume.

(See Figure 3-12.) The small volume provides for excellent sensitivity. For some

components, a detection limit of 1 ppm can be achieved.

NOTE: TCD sensitivity is matrix, carrier gas, and component dependent.

The TCD uses a Wheatstone bridge design and has a sample and reference

channel. The TCD detects the difference in thermal conductivity of the gas traveling

through the reference side (pure carrier gas) versus the gas traveling through the

sample side (carrier gas plus the sample gas). When ON, the TCD filament is hot.

3000 Micro GC monitors the column pressure. If carrier gas flow is turned off, the

TCD will automatically turn off.

Figure 3-12 MEMS TCD detector

3000 Micro GC Operating Manual

3.3.6 D-Board

A Detector board, also known as a D-board, is attached to the side of each module.

The D-Board controls the module conditions and communicates module

information and setpoints to the Communications Board (C-Board, see section

3.4.2 on page 3-15). 3000 Micro GC supports two types of D-board: Enhanced and

Standard.

3.3.6.1 Enhanced D-Board

Enhanced D-Board circuitry significantly reduces solvent peak tailing, resulting in

better chromatography and improved sensitivity of peaks eluting after the solvent

peak (e.g., air). This feature is most useful for applications that involve low ppm

trace analysis in a solvent gas.

3.3.6.2 Standard D-Board

The Standard D-Board circuitry is for general purpose applications with a

mid-to-high ppm analysis requirement.

PN 074-519-P1C

3 - 12

Page 43

3.3.7 Module Cases

3000 Micro GC supports two types of module cases, a standard module case and

a Modbox module case.

3.3.7.1 Standard Module Case

The standard module case is used for most column types. MolSieve modules are

an exception. See Figure 3-13.

Figure 3-13 Standard module

3000 Micro GC Operating Manual

3.3.7.2 Modbox Module Case

The Modbox module allows the column to be wound in a larger diameter. The

MolSieve column benefits from this design because the column is vulnerable to

breakage when winding into a small diameter. See Figure 3-14.

Figure 3-14 Modbox module

PN 074-519-P1C

3 - 13

Page 44

3000 Micro GC Operating Manual

To c olum n

To column

Sample inlet

Sample inlet

3.4 3000 Micro GC Chassis Components

3000 Micro GC modules are installed into the 3000 Micro GC chassis. The

components that are integrated into the chassis are:

Inlet Tubing, see section 3.4.1 on page 3-14

C-Board, see section 3.4.2 on page 3-15

OBC Board, see section 3.4.3 on page 3-15

Sample Pump, see section 3.4.4 on page 3-16

Carrier Gas Weldment, see section 3.4.5 on page 3-17

Carrier Gas Inlet, see section 3.4.6 on page 3-18

Vents, see section 3.4.7 on page 3-19

Remote Control Module, see section 3.4.8 on page 3-20

3.4.1 Inlet Tubing

The inlet tubing is enclosed in a heated compartment which contains a short piece

of 1/16 in. OD tubing. One side of the tubing is connected to the sample fitting on

the front panel. The other side of the tubing connects to one or more modules.

Depending on instrument configuration, the tubing is split to each module.

Temperatures can be set from 45-140

The inlet temperature can also be turned off. The internal surface of the tubing is

deactivated to ensure the surfaces of the tubing are inert.

°C. Typical setpoints are between 80-100°C.

Figure 3-15 Inlet tubing of a 2-Channel 3000 Micro GC with two inlets

PN 074-519-P1C

3 - 14

Page 45

3.4.2 C-Board

The Communications Board, also known as the C-board is internally mounted on

the side of 3000 Micro GC. It controls the inlet zone heater and communicates with

the D-boards and onboard computer.

3.4.3 OBC Board

The onboard computer (OBC) is internally mounted on the back of 3000 Micro GC.

It is the main processor which communicates with the C-board and the external

control system. OBC has an internal flash memory which stores 3000 Micro GC

configuration information. See Figure 3-16.

Figure 3-16 Onboard computer (OBC)

3000 Micro GC Operating Manual

The OBC provides a RJ-45 based LAN interface. 3000 Micro GC can be connected

to a LAN network or directly to an external control system (i.e., EZ IQ software) via

a RJ-45 LAN connection.

Figure 3-17 LAN connection on rear side of 3000 Micro GC

PN 074-519-P1C

3 - 15

Page 46

3000 Micro GC Operating Manual

3.4.4 Sample Pump

One or two sample pumps are installed internally in 3000 Micro GC. There is no

flow through the sample path until the pump turns on. When the sample pump turns

on, the sample is drawn through the sample inlet tubing and the sample injectors

open for the time specified in the acquisition method. Set pump time at a minimum

of 20 seconds. If sufficient sample gas is available, increase the pump time to 60

seconds. The sample pump draws at a rate of 10 mL/min.

NOTE: For specific applications, there is a mode of operation called continuous

where the pumps can be turned off and sample gas flows continuously

through the internal tubing. Continuous operation can only be used with

variable and fixed volume injectors.

Backflush injectors cannot be used in continuous mode. In continuous

mode, the sample valve always remains on (open) and sample gas can

flush the sample inlet lines and injector.

Figure 3-18 Sample pump

3 - 16

PN 074-519-P1C

Page 47

3.4.5 Carrier Gas Weldment

Base plate

The carrier gas weldment connects the carrier gas to each module. It consists of a

base plate and stainless steel tubing. Base plates align to each module.

NOTE: See section 8.2, Remove and Replace a 3000 Micro GC Module, on page

8-5 for more information about how to align a module.

Figure 3-19 Carrier gas weldment

3000 Micro GC Operating Manual

PN 074-519-P1C

3 - 17

Page 48

3000 Micro GC Operating Manual

3.4.6 Carrier Gas Inlet

One or two carrier gases can be configured with the carrier gas inlets located on

the rear of 3000 Micro GC. See Figure 3-20, Figure 3-21, and Figure 3-22.