Page 1

Page 2

Warning: Limitation of Liability

The ultimate responsibility of the consequences of use of toxic compounds

rests with the user. INFICON’s role is as a supplier of instrumentation to

assist in the early detection of hazardous conditions involving such

compounds.

It is vitally important to ensure that the 2020ppbPRO is maintained in

accordance with INFICON’s instructions and that proper calibration is

regularly performed.

As with any complex device, the 2020ppbPRO is subject to failure and, while

INFICON has taken, and continues to take, all possible precautions to (a)

reduce the possibility of failure, and (b) warn the user in the event of failure,

circumstances may occasionally occur in which there is a failure despite

such precautions on INFICON’s part. INFICON regrets that it cannot accept

liability for damages of any kind caused as a result of either failure of the

user to follow instructions or of the 2020ppbPRO to perform.

Customer Support

INFICON Inc.

2 Technology Place

East Syracuse, NY 13057-9714, U.S.A.

(315) 434-1100

www.inficon.com

reachus@inficon.com

Notices

The information contained in this manual is believed to be accurate and reliable. However,

INFICON assumes no responsibility for its use and shall not be liable for any special,

incidental, or consequential damages related to the use of this product.

Due to our continuing program of product improvements, specifications are subject to

change without notice.

Copyright Information

Copyright © 2012 INFICON Inc.

Reproduction or adaptation of any part of this document without permission is unlawful.

Trademarks

The trademarks of the products mentioned in this manual are held by the companies that

produce them.

INFICON® is a trademark of INFICON

All other brand and product names are trademarks or registered trademarks of their

respective companies.

ii ISP-074-576-P1D

Page 3

Contents

Contents ....................................................................................... iii

Figures ......................................................................................... vi

Tables ......................................................................................... vii

Notices and Warnings ................................................................. 2

FCC Warning ............................................................................... 3

The 2020ppbPRO Intrinsic Safety (I/S) Notice ............................ 3

ATEX Directive and EMC Directive ............................................. 8

EM Warnhinweis ........................................................................ 10

Hinweis zur Eigensicherheit (I/S) des 2020ppbPRO ................. 10

The 2020ppbPRO Intrinsic Safety (I/S) Notice .......................... 13

Avertissement Compatibilité électromagnétique ....................... 20

2020ppbPRO - Note de sécurité intrinsèque ............................. 20

Advertencia FCC ....................................................................... 24

Información sobre la seguridad intrínseca (I/S)

del 2020ppbPRO ....................................................................... 24

FCC Avvertenze ........................................................................ 27

The 2020ppbPRO Intrinsic Safety (I/S) Notice .......................... 27

Introduction ................................................................................ 29

About this Manual ...................................................................... 29

Warnings and Safety Practices .................................................. 31

Approved Models of the 2020ppbPRO ...................................... 31

Excessive Heat and Cold ........................................................... 31

2020ppbPRO Overview ............................................................. 32

General Operation ..................................................................... 33

Photoionization Detector ............................................................ 34

Unpacking Instrument ................................................................ 35

Support Equipment and Consumables ...................................... 35

Calibration ........................................................................... 35

Field Operation ................................................................... 36

Computer ............................................................................. 36

Using the 2020ppbPRO ............................................................. 37

................................................................................................... 38

Battery Charging ........................................................................ 38

Removing and Replacing the Battery Pack .................... 38

Charging the Battery Pack ................................................. 39

Sample Intake Conditioner Tube ............................................... 40

Display ....................................................................................... 40

Graphic Display .................................................................. 40

ISP-074-576-P1D iii

Page 4

Keys ........................................................................................... 43

Fixed Keys ........................................................................... 43

Soft Keys ............................................................................. 43

Beginning Operation .................................................................. 43

Turning the 2020ppbPRO On ............................................ 43

Operational Displays .......................................................... 43

Tube Life Time Display ...................................................... 45

Numeric Value, Duration, Time and Date Entry ............... 45

System Alerts and Alarms ................................................. 46

User Interface – Basic Menu ..................................................... 47

Operation Modes ....................................................................... 47

Logging Off Mode ............................................................... 47

Tag Mode ............................................................................. 47

Interval Mode ...................................................................... 48

Short-Term Exposure Limit (STEL) Mode ........................ 48

Time-Weighted Average (TWA) Mode .............................. 48

PEAK Mode ......................................................................... 49

Datalogger ................................................................................. 49

Interval Operation ............................................................... 49

Unit Setup Functions ................................................................. 51

Pump .................................................................................... 52

Backlight .............................................................................. 53

User Mode ........................................................................... 53

Date Format ......................................................................... 55

Language ............................................................................. 55

Units ..................................................................................... 55

Sample Collection Mode .................................................... 55

Response Factor Library ........................................................... 56

Response Factors and Memory Slots .............................. 57

Calibration Technical Description .............................................. 58

Calibrating the 2020ppbPRO ..................................................... 59

Calibration Introduction .............................................................. 59

Compressed Gases ............................................................ 60

Regulators for Compressed Gases .................................. 61

Calibration Gas ................................................................... 61

Calibration Using the Flow-Match Regulator ............................. 61

Connecting the Flow-Match Regulator to the Cylinder .. 61

Calibrating the 2020ppbPRO with the

Flow-Match Regulator ....................................................... 62

Calibration Using a Gas Bag ..................................................... 63

Preparing the Calibration Gas Bag and the

Zero Air Bag ........................................................................ 63

Calibrating the 2020ppbPRO with a Gas Bag .................. 64

Preparing for Field Operation .................................................... 65

Field Check List .................................................................. 65

Operational Check List ...................................................... 66

Connecting Accessories ........................................................... 67

Computer ................................................................................... 67

Pre-filter Tube Holder ................................................................ 69

Pre-filters and Sample Collection Tubes ................................... 70

iv ISP-074-576-P1D

Page 5

Sample Line ............................................................................... 70

Wrist Strap ................................................................................. 70

DC Power Cord .......................................................................... 71

Belt Clip Holster ......................................................................... 71

11.7 eV UV Lamp ...................................................................... 71

General Information ........................................................... 71

Limitations of Lithium Fluoride Lamp Window ............... 71

Using the 11.7 eV UV Lamp ............................................... 72

Off-Line Charger ........................................................................ 73

General Information ........................................................... 73

Charging from an AC Source ............................................ 73

Charging from a DC Source .............................................. 74

Routine Maintenance ................................................................. 75

Battery Charging ........................................................................ 75

Battery Pack Care ............................................................... 76

Maintenance of the UV Lamp .................................................... 77

Removing and Replacing the UV Lamp ........................... 77

Cleaning the Lithium Fluoride Window ............................ 80

Replacing the Sample Inlet Filter ............................................... 80

Troubleshooting ......................................................................... 82

General Information ................................................................... 82

Troubleshooting ......................................................................... 83

General Questions ..................................................................... 85

Appendices ................................................................................. 88

Specifications ............................................................................. 89

Warranty .................................................................................... 91

Contacting INFICON .................................................................. 92

Installing Alternate AC Plug on the Battery Charger ................. 93

Calibration Gas Supplier ............................................................ 93

Using the Gas Bag ..................................................................... 93

Presets and Response Factors ................................................. 94

References ................................................................................. 97

Index ............................................................................................ 98

ISP-074-576-P1D v

Page 6

Figures

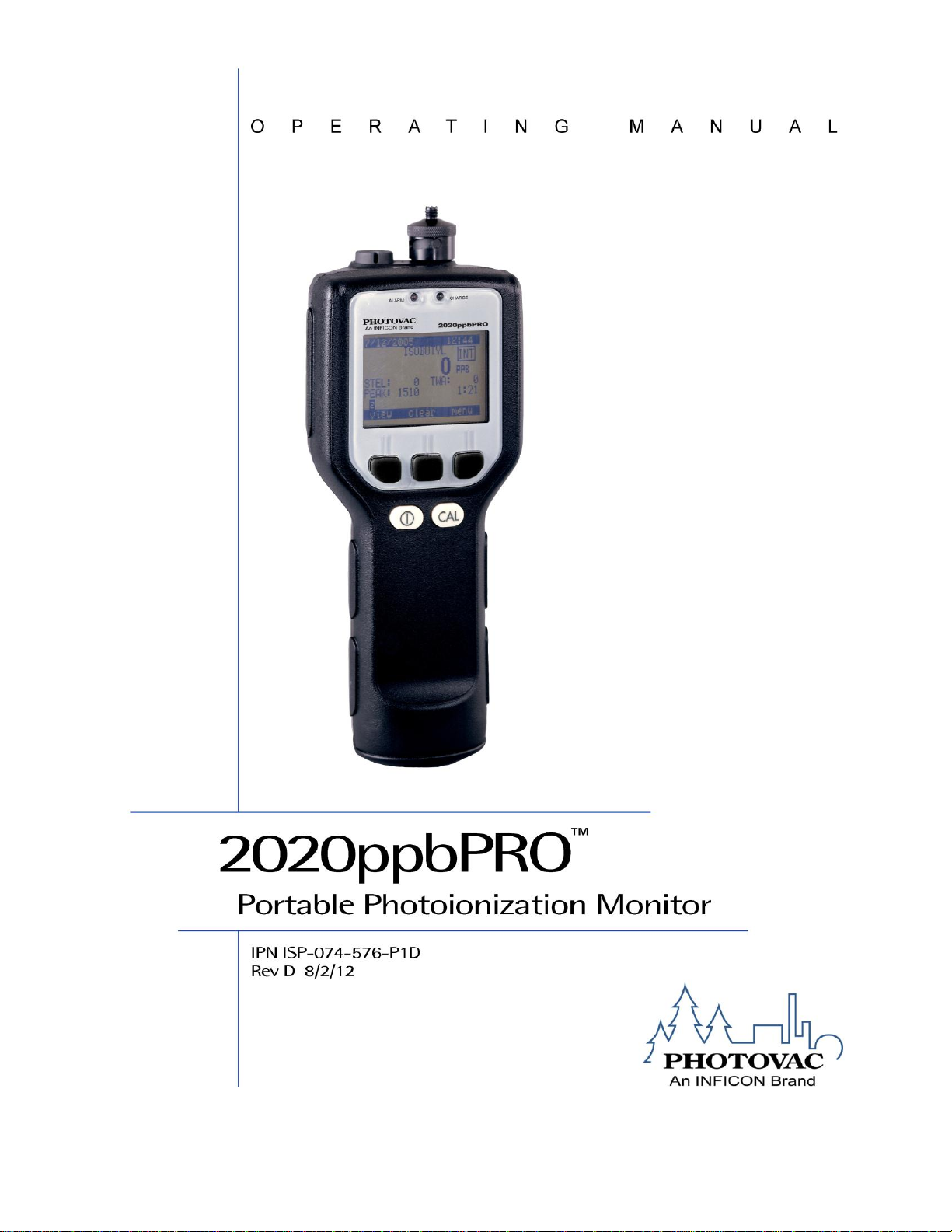

Figure 1. The 2020ppbPRO Instrument ........................................... 32

Figure 2. The 2020ppbPRO Block Diagram ................................... 33

Figure 3. Photoionization Detector ................................................... 34

Figure 4. Battery Pack Removal and Replacement ...................... 39

Figure 5. The 2020ppbPRO Display ................................................ 41

Figure 6. User Menu – Unit Setup .................................................... 42

Figure 7. User Menu – Data Log Options ....................................... 42

Figure 8. User Menu – Memory Slots .............................................. 43

Figure 9. Logging Off Mode Display ................................................ 44

Figure 11. Interval Mode Display ...................................................... 45

Figure 12. Interval time adjustment ................................ .................. 50

Figure 13. Unit Setup Map ................................................................ 52

Figure 14. Setting the Time .............................................................. 54

Figure 15. Sample Collection Mode ................................................. 56

Figure 16. Response Factor and Memory Slots ............................ 57

Figure 17. Calibration with Flow-Match ........................................... 62

Figure 18. Gas Bag Adapter ............................................................. 64

Figure 19. Tube Holder ..................................................................... 69

Figure 20. Dräger Pre-filter Tubes .................................................. 70

Figure 21. Removing the UV Lamp ................................ .................. 78

Figure 22. Replacing the Inlet Filter ................................................. 81

Figure 22. Using the Gas Bag........................................................... 94

vi ISP-074-576-P1D

Page 7

Tables

Table 1. System Alerts ........................................................................ 46

Table 2. Averaging Intervals and Period STEL, TWA,

and PEAK Operation ................................................................... 50

Table 3. Check List for Field Operation ........................................... 65

Table 4. Additional Field Items ......................................................... 65

Table 5. Contact Information ............................................................. 92

Table 6. Library Entries ...................................................................... 95

ISP-074-576-P1D vii

Page 8

Notices and Warnings

1

2 ISP-074-576-P1D

Page 9

FCC Warning

This equipment has been tested and found to comply with the limits for a Class B

Digital Device, pursuant to Subpart B, Class B of Part 15 of the FCC rules. These

limits are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment

generates, uses and can radiate radio frequency energy and if not installed and

used in accordance with the instruction manual, may cause harmful interference to

radio communications. Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be required to correct the

interference at their expense.

The 2020ppbPRO Intrinsic Safety (I/S) Notice

THE 2020ppbPRO IS CLASSIFIED FOR USE IN CLASS I, DIVISION 1, GROUPS

A, B, C, D HAZARDOUS LOCATIONS. T4 (135°C) RATING.

It has been listed by MET Laboratories, Inc., to comply with Underwriters

Laboratories® Inc. UL® 913 Standard for Intrinsically Safe Apparatus and

Associated Apparatus for use in Class I, Division 1, Groups A, B, C, D Hazardous

(Classified) Locations, Sixth Edition when powered by MX700010 or MX700011

Battery Pack. THE 2020ppbPRO IS NOT INTENDED TO DETECT COMBUSTIBLE

LEVELS OF GASES. THE 2020ppbPRO IS CLASSIFIED FOR USE IN

ATMOSPHERES CONTAINING COMBUSTIBLE LEVELS OF GASES.

These accessories are for use with the 2020ppbPRO in a hazardous location:

MX350006 Calibration Regulator

MX350007 Wrist Strap

MX750011 Belt-Clip Holster

MX700260 Carrying Case

M1760148 User’s Reference Card

MX380305 Long Sample Probe

MX395001 Short Sample Probe

A1790500 Tube Holder

F1760160 Dräger Tube, Carbon filter

F1760162 Dräger Tube, Intake sample conditioner

Do not use any other accessories with the 2020ppbPRO in a hazardous location.

Substitution of components may affect safety rating.

ISP-074-576-P1D 3

Page 10

WARNING

To reduce the risk of fire or injury to persons, read and

follow these instructions:

1. All calibration, maintenance and servicing of this

device, including battery charging, must be

performed in a safe area away from hazardous

locations. Disconnect all power before servicing.

2. There are no operator replaceable parts inside

the 2020ppbPRO except the battery pack, UV

lamp and sample inlet filter.

3. There are no operator serviceable parts inside

the 2020ppbPRO.

Do not use any other accessories with the 2020ppbPRO in a hazardous location.

Substitution of components may affect safety rating.

4 ISP-074-576-P1D

Page 11

CAUTION

1. For replacement battery pack use only Part No.

MX700010 or MX700011.

2. Do not dispose of the battery pack in a fire. The

cells may explode. The battery pack must be

disposed of properly. Check with local codes for

possible special disposal instructions.

3. Do not open or mutilate the battery pack. If the

2020ppbPRO is used in a manner not

specified, the protection provided by the

2020ppbPRO may be impaired.

4. Exercise care in handling battery packs in order

not to short the terminals with conducting

materials such as rings, bracelets and keys. The

battery or conductor may overheat and cause

burns.

5. Do not defeat proper polarity orientation

between the battery pack and battery

charger.

6. Charging the battery is only to be done in a nonhazardous area.

7. Charge the battery pack using the AC adapter

provided with or identified for use with this

product only in accordance with the instructions

and limitations specified in this manual. For AC

adapter use only Part No. MX350002 (115 Volts

AC), MX396013 (220 Volts AC). When using the

AC adapter do not block access to AC outlet in

use with adapter. AC adapter is not to be used

in a hazardous area.

ISP-074-576-P1D 5

Page 12

ATTENTION

Pour réduire le risque de feu ou blessures, lisez

attentivement ces directive:

1. Tout étalonnage et entretien, incluant le

chargement de la batterie, doit être fait dans un

endroit sécuritaire et non-explosif. L’alimentation

électrique doit être mis hors-service.

2. Aucune pièce ne peut être changée par

l’utilisateur à part la batterie.

3. Aucun entretien ne peut être fait par l’utilisateur.

ATTENTION

2020ppbPRO EST CLASSIFIÉ POUR USAGE DANS LES EMPLACEMENTS

DANGEREUX DE CLASSE I, DIVISION 1, GROUPES A, B, C, D. ÉVALUATION T4

(135ºC).

2020ppbPRO est conforme à la norme des Underwriters Laboratories Inc. UL 913

Standard for Intrinsically Safe Apparatus and Associated Apparatus for use in Class

I, Division 1, Groups A, B, C, D Hazardous (Classified) Locations. Quatrième

édition.

2020ppbPRO est conforme à la norme de CSA E79-0:1995 & CAS E79-11:1995:

Intrinsically Safe Equipment.

2020ppbPRO EST NE PAS INTENDER POUR DÉTECTER DES NIVEAUX DE

COMBUSTION DES GAZ. CET APPAREIL EST CLASSIFIÉ POUR USAGE DANS

DES ATMOSPHÈRES CONTENANT DES NIVEAUX DE COMBUSTION DES GAZ.

Les accessoires suivants peuvent également être utilisés avec l’appareil dans un

emplacement dangereux:

MX350006 Régulateur de calibration

MX350007 Sangle de poignet

MX750011 Étui de ceinture

MX700260 Étui de transport

M1760148 Carte de référence

MX380305 Gamme d’échantillons

MX395001 Petite Gamme d’échantillons

A1790500 Tube Holder

F1760160 Dräger Tube, Carbon filter

F1760162 Dräger Tube, Intake sample conditioner

Ne pas utiliser d’autres accessoires avec cet appareil dans un emplacement

dangereux. La substitution des composantes peut nuire à la sécurité d’emploi.

6 ISP-074-576-P1D

Page 13

ATTENTION

1. Utilisez seulement des batteries rechargeables de

type nickel cadmium avec un chargeur 12 Volts

DC (Pièce # MX700010 ou MX700011).

2. Ne jetez pas les batteries dans le feu. Elles

pourraient exploser Vérifiez avec la

réglementation locale avant d’en disposer.

3. Ne pas ouvrir ou briser la batterie. La protection

offerte par le 2020ppbPRO sera alors inutile.

4. La manutention de la batterie nécessite d’éviter

les produits conducteurs comme des anneaux,

bracelets ou clés pour éviter tout court- circuit La

batterie pourrait surchauffer et causer des

brûlures.

6. Ne pas modifier la polarité entre la batterie et le

chargeur.

7. Utilisez seulement l’adaptateur AC spécifié dans

le manuel. (Pièces # MX350002 (115 Volts AC),

MX396013 (220 Volts AC)). Ne pas bloquer la

sortie de l’adaptateur AC.

ISP-074-576-P1D 7

Page 14

ATEX Directive and EMC Directive

We INFICON, Inc.

2 Technology Place

East Syracuse, NY 13057 USA

declare that: Equipment: Photoionization Monitor

Model names: 2020PRO, 2020PROPlus, 2020ppbPRO,

2020gasPRO, and 2020ComboPRO

In accordance with the following directives:

94/9/EEC: ATEX Directive

2006/95/EC: Low Voltage Directive

2004/108/EC: The Electromagnetic Compatibility Directive

Has been designed and manufactured to the following standards:

Safety: EN61010-1:2004

EMC: EN61326-1:2006

Explosive Atmosphere: EN50014:1997/A2:1999 EN50020:2002

EC Type Examination Certificate #: TRL03ATEX21022X

II 2G EEx ib IIC T4, Tamb= 0ºC to +40ºC

ATEX Certified by TRaC Global Ltd. of Unit 1, Pendle Place, Skelmersdale,

West Lancashire, WN8 9PN, UK

I hereby declare that the equipment named above has been designed to

comply with the relevant sections of the above referenced standards and all

essential requirements of the Directives.

Signed by:

Name: Stephen Chabot

Title: Vice President of Operations and Quality

Done at East Syracuse, NY USA

On 1 May 2012

8 ISP-074-576-P1D

Page 15

WARNING

1. All calibration, maintenance and servicing of this device, including battery

charging, must be performed in a safe area away from hazardous locations.

2. Disconnect all power before servicing.

3. Do not open UV Lamp Cap when unit is energized.

4. Only use the AC Adapter in a safe area away from hazardous locations

5. Only use the Serial Port in a safe area away from hazardous locations.

CAUTION

To reduce the risk of fire or injury to persons, read and follow these instructions:

1. There are no operator replaceable parts inside the 2020ppbPRO except the

battery pack, UV lamp and sample inlet filter.

2. For replacement battery pack use only Part No. MX700010 or MX700011.

3. There are no operator serviceable parts inside the 2020ppbPRO.

4. Do not dispose of the battery pack in a fire. The cells may explode. The battery

pack must be disposed of properly. Check with local codes for possible special

disposal instructions.

5. Do not open or mutilate the battery pack. If the 2020ppbPRO is used in a

manner not specified, the protection provided by the 2020ppbPRO may be

impaired.

6. Exercise care in handling battery packs in order not to short the terminals with

conducting materials such as rings, bracelets and keys. The battery or

conductor may overheat and cause burns.

7. Do not defeat proper polarity orientation between the battery pack and battery

charger.

8. Charge the battery pack using the AC adapter provided with or identified for use

with this product only in accordance with the instructions and limitations

specified in this manual. For AC adapter use only Part No. MX350002 (115

Volts AC), MX396013 (220 Volts AC). When using the AC adapter do not block

access to AC outlet in use with adapter. AC adapter is not to be used in a

hazardous area.

ISP-074-576-P1D 9

Page 16

These optional accessories may be used with the 2020ppbPRO in a hazardous

location:

MX350006 Calibration Regulator

MX350007 Wrist Strap

MX750011 Belt-Clip Holster

MX700260 Carrying Case

M1760148 User’s Reference Card

MX380305 Long Sample Probe

MX395001 Short Sample Probe

A1790500 Tube Holder

F1760160 Dräger Tube, Carbon filter

F1760162 Dräger Tube, Intake sample conditioner

Do not use any other accessories with the 2020ppbPRO in a hazardous location.

EM Warnhinweis

Dieses Gerät wurde geprüft und die Einhaltung der Grenzwerte hinsichtlich der

Aussendung von elektromagnetischen Wellen für ein digitales Gerät der Klasse B

nach Subpart B, Klasse B von Teil 15 der EMV Richtlinie bestätigt. Diese

Grenzwerte sind so festgelegt, dass bei Verwendung des Geräts in einer IndustrieUmgebung Störungen weitestgehend ausgeschlossen sein sollten. Dieses Gerät

erzeugt und arbeitet mit Radiowellen und kann diese auch emittieren und somit

Störungen des Funkverkehrs hervorrufen, wenn es nicht gemäß der

Betriebsanleitung eingebaut und verwendet wird. In Wohngebieten können jedoch

Störungen durch den Betrieb dieses Gerätes nicht ausgeschlossen werden. In

diesem Fall liegt es in der Verantwortung des Anwenders diese Störungen auf seine

Kosten zu beseitigen.

Hinweis zur Eigensicherheit (I/S) des 2020ppbPRO

Das 2020ppbPRO IST KLASSIFIZIERT ZUR VERWENDUNG IN

ARBEITSBEREICHEN MIT EXPLOSIBLER ATMOSPHÄRE (=EX-ZONEN) DER

KLASSE I, ABSCHNITT 1, GRUPPEN A, B, C, D KlasseT4 (Zündtemperatur bis

135°C).

Es entspricht der Norm für zugelassene Geräte zur Verwendung in Ex-Zonen der

Klasse 1, Abschnitt 1, Gruppen A, B, C, D (Standard for Intrinsically Safe Apparatus

and Associated Apparatus for use in Class I, Division 1, Groups A, B, C, D

Hazardous (Classified) Locations) der Underwriters Laboratories® Inc. UL® 913, 6.

Ausgabe.

Das 2020ppbPRO IST NICHT ZUR MESSUNG VON BRENNBAREN GASEN

VORGESEHEN, SONDERN FÜR DEN EINSATZ IN UMGEBUNGEN, DIE BRENNBARE GASE ENTHALTEN KÖNNEN.

10 ISP-074-576-P1D

Page 17

Das nachfolgend aufgeführte Zubehör kann für das 2020ppbPRO in

VORSICHT

Um das Brandrisiko oder das Verletzungsrisiko für Personen zu

verringern, sind die folgenden Anweisungen aufmerksam zu

lesen und zu befolgen:

1. Jede Kalibrierung, Wartung und Instandhaltung dieses

Geräts, sowie das Laden des Akkus muss an einem

sicheren Ort außerhalb von explosionsgefährdeten

Bereichen (Ex-Zonen) ausgeführt werden. Vor und

während einer Wartung ist die Verbindung des Gerätes

zur Stromversorgung zu unterbrechen.

2. Die vom Anwender des 2020ppbPRO auszutauschenden Teile beschränken sich auf:

- den Akku, - die UV-Lampe und

- das Probenahmefilterplättchen.

3. Im Inneren 2020ppbPRO befinden sich keine Teile, die

vom Endanwender zu warten sind..

explosionsgefährdeten Bereichen (Ex-Zonen) verwendet werden:

MX350006 Kalibriergasdruckminderer (Kalibriergasregler)

MX350007 Handgelenksschlaufe

MX700260 Gürtelholster

MX700260 Gerätetragekoffer

M1760148 Karte mit Kurzbedienungsanleitung

MX395001 Probenahmesonde

In explosionsgefährdeten Bereichen (Ex-Zonen) darf keinesfalls anderes Zubehör

des 2020ppbPRO eingesetzt werden.

Der Austausch von Bauteilen kann Ihre Sicherheit beeinträchtigen.

ISP-074-576-P1D 11

Page 18

WARNUNG

1. Als Ersatz-Akku nur das Originalersatzteil (Ni/Cd- Akku mit der TeileNr. MX700010 oder MX700011 ) verwenden.

2. Den Akku nicht in offenes Feuer werfen. Die Zelle kann explodieren.

Der Akku muss ordnungsgemäß entsorgt werden. Vor Ort nach den

Regelungen zur Entsorgung erkundigen

3. Den Akkupack nicht öffnen und nicht verändern. Manipulationen am

Akku haben den Verlust der Ex-Zulassung und erhebliche

Sicherheits-Risiken zur Folge.

4. Vorsichtig mit dem Akku umgehen und sicherstellen, dass die

Batteriekontakte nicht mit leitenden Materialien wie Ringen,

Armbändern oder Schlüsseln in Berührung kommen. Der Akku kann

überhitzen und Verbrennungen verursachen.

6. Auf richtige Zuordnung der Polarität zwischen Akku und Ladegerät

achten.

7. Den Akku mit dem mitgelieferten Netzgerät nur gemäß den in dieser

Betriebsanleitung spezifizierten Anweisungen und Einschränkungen

laden. Nur Original-Netzgerät (Teile-Nr:MX396013) verwenden. Bei

Verwendung des Netzgeräts, den Zugang zur Wechselstromsteckdose nicht versperren.

8. Der Akku darf nur außerhalb von explosionsgefährdeten Bereichen

geladen werden.

WARNUNG

1. Jede Kalibrierung, Wartung und Instandhaltung dieses Geräts, sowie

das Laden des Akkus muss an einem sicheren Ort außerhalb von

explosionsgefährdeten Bereichen (Ex-Zonen) ausgeführt werden.

Vor der Wartung sind alle elektrischen Verbindungen zu trennen.

Keinesfalls den Zugang zur UV Lampe öffnen, während das Gerät

aufgeladen wird.

Das Netzgerät nur außerhalb von explosionsgefährdeten Bereichen (Ex-

Zonen) einsetzen.

2. Die serielle Schnittstelle (RS232C) nur außerhalb von

explosionsgefährdeten Bereichen (Ex-Zonen) verwenden.

12 ISP-074-576-P1D

Page 19

VORSICHT

Um die Gefahr eines Brandes oder die Verletzung von Personen zu

reduzieren, lesen und befolgen Sie die folgenden Anweisungen:

1. Die vom Anwender des 2020ppbPRO auszutauschenden Teile

beschränken sich auf:

- den Akku, - die UV-Lampe und

- das Probenahmefilterplättchen.

2. Als Ersatz-Akku nur das Originalersatzteil (Ni/Cd- Akku mit der

Teile-Nr. MX700010 oder MX700011) verwenden

3. Den Akku nicht in offenes Feuer werfen. Die Zelle kann

explodieren. Der Akku muss ordnungsgemäß entsorgt werden. Vor

Ort nach den Regelungen zur Entsorgung erkundigen

4. Den Akkupack nicht öffnen und nicht verändern. Manipulationen am

Akku haben den Verlust der Ex-Zulassung und erhebliche

Sicherheits-Risiken zur Folge.

5. Vorsichtig mit dem Akku umgehen und sicherstellen, dass die

Batteriekontakte nicht mit leitenden Materialien wie Ringen,

Armbändern oder Schlüsseln in Berührung kommen. Der Akku

kann überhitzen und Verbrennungen verursachen.

6. Auf richtige Zuordnung der Polarität zwischen Akku und Ladegerät

achten.

7. Den Akku mit dem mitgelieferten Netzgerät nur gemäß den in

dieser Betriebsanleitung spezifizierten Anweisungen und Einschränkungen laden. Nur Original-Netzgerät (Teile-Nr. MX396013)

verwenden. Bei Verwendung des Netzgeräts, den Zugang zur

Wechselstromsteckdose nicht versperren.

Das nachfolgend aufgeführte Zubehör für das 2020ppbPRO kann in

explosionsgefährdeten Bereichen (Ex-Zonen) verwendet werden

MX350006 Kalibriergasdruckminderer (Kalibriergasregler)

MX350007 Handgelenksschlaufe

MX700260 Gürtelholster

MX700260 Gerätekoffer

M1760148 Karte mit Kurzbedienungsanleitung

MX395001 Probenahmesonde

MX395001 Probenahmeschlauch

Verwenden Sie für das 2020ppbPRO kein anderes Zubehör in explosions

gefährdeten Bereichen.

The 2020ppbPRO Intrinsic Safety (I/S) Notice

THE 2020ppbPRO IS CLASSIFIED FOR USE IN CLASS I, DIVISION 1, GROUPS

A, B, C, D HAZARDOUS LOCATIONS. T4 (135°C) RATING.

It has been listed by MET® to comply with Underwriters Laboratories® Inc. UL® 913

Standard for Intrinsically Safe Apparatus and Associated Apparatus for use in Class

I, Division 1, Groups A, B, C, D Hazardous (Classified) Locations, Sixth Edition

when powered by MX700010 or MX700011 Battery Pack. THE 2020ppbPRO IS

NOT INTENDED TO DETECT COMBUSTIBLE LEVELS OF GASES. THE

2020ppbPRO IS CLASSIFIED FOR USE IN ATMOSPHERES CONTAINING

COMBUSTIBLE LEVELS OF GASES.

ISP-074-576-P1D 13

Page 20

BEMÆRK

For minimering af risiko for brand samt skade på personer læs

og følg denne instruktion:

1. Kalibrering, vedligeholdelse, service, batteriskift og

opladning af batterier må ikke foretages i EXklassificeret område.

2. Det er kun batteripakke, UV lampe og sample filter,

som skiftes af burger.

3. Der er indvendig i 2020ppbPRO ikke udskiftelige

servicedele for bruger.

Dette tilbehør må anvendes med 2020ppbPRO i EX- klassificeret område i henhold

til ovenfor beskrevet:

MX350006 Kalibreringsgas Regulator

MX350007 Håndrem

MX700260 Bæltetaske

MX700260 Field kit taske.

M1760148 Bruger reference kort

MX395001 Kort sampleprobe

Anvend ikke andet tilbehør til 2020ppbPRO i EX-klassificeret område.

Anvendes ikke originale komponenter kan det påvirke

sikkerhedsklassificeringen.

14 ISP-074-576-P1D

Page 21

ADVARSEL

1. For erstatnings batteripakke anvend kun Part Nr.

MX700010 eller MX700011

2. Følge den lokale ordning for afskaffelse af batterier.

Batterier kan eksplodere ved brand.

3. Åben eller beskadig ikke batteripakken. Hvis

2020ppbPRO ikke anvendes som specificeret

bliver sikkerheden forringet.

4. Udøv forsigtighed med batteripakken. Pas på med

ringe, armbånd, nøgler m.m. disse ting kan

kortslutte batteripakken og overophede denne,

således den bryder i brand.

5. Forhindre ikke korrekt polarisering mellem

batteripakken og oplader.

6. Opladning må ikke ske i Ex-klassificeret område.

7. Opladning af instruments batteripakke eller brug af

220V AC oplader skal ske i overensstemmelse

med instruktion og begrænsninger, som beskrevet i

denne manual. Anvend kun oplader MX396013

(220V AC). Oplader må ikke anvendes i Exklassificeret område.

ADVARSEL

1. Al kalibrering, vedligeholdelse og service af instrument,

dette inkludere opladning, må ske i ikke Ex-klassificeret

område.

2. Service må ikke foretages under opladning eller med

startet/tændt instrument.

3. Fjern ikke dæksel til uV-lampe mens denne er tændt.

4. Opladning må kun ske udenfor Ex-klassificeret område..

5. Anvend kun instruments serielle udgang udenfor Exklassificeret område.

BEMÆRK

For minimering af risiko for brand samt skade på personer læs og følg denne

instruktion:

1. Det er kun batteripakke, UV lampe og sample filter, som skiftes af burger.

2. For erstatnings batteripakke anvend kun Part Nr. MX700010 eller MX700011

3. Der er indvendig i 2020ppbPRO s ikke udskiftelige servicedele for bruger.

ISP-074-576-P1D 15

Page 22

4. Følge den lokale ordning for afskaffelse af batterier. Batterier kan eksplodere

ved brand.

5. Åben eller beskadig ikke batteripakken. Hvis 2020ppbPRO ikke anvendes som

specificeret bliver sikkerheden forringet.

6. Udøv forsigtighed med batteripakken. Pas på med ringe, armbånd, nøgler m.m.

disse ting kan kortslutte batteripakken og overophede denne, således den bryder i

brand.

7. Forhindre ikke korrekt polarisering mellem batteripakken og oplader

8. Opladning af instruments batteripakke eller brug af 220V AC oplader skal ske i

overensstemmelse med instruktion og begrænsninger, som beskrevet i denne

manual. Anvend kun oplader MX396013 (220V AC). Oplader må ikke anvendes i

Ex-klassificeret områd.e

Dette tilbehør må anvendes med 2020ppbPRO i EX- klassificeret område i henhold

til ovenfor beskrevet:

MX350006 Kalibrerings Regulator

MX350007 Håndrem

MX700260 Bæltetaske

MX700260 Field kit taske.

M1760148 Bruger reference kort

MX395001 Kort sampleprobe

16 ISP-074-576-P1D

Page 23

FCC Waarschuwing

VOORZICHTIG Lees en volg deze instructies op om het risico op brand of

verwonding van personen te reduceren: 1. Alle kalibratie, onderhoud en

servicewerkzaamheden aan dit apparaat, inclusief het opladen van de

batterij, moet altijd plaats vinden in een veilige zone, uit de buurt van

explosiegevaarlijke gebieden. Ontkoppel alle voeding voordat u

servicewerkzaamheden uitvoert. 2. Er zijn geen onderdelen in de

2020ppbPRO die door de operator vervangen kunnen worden, behalve

het batterij

Deze apparatuur is getest en er is geconcludeerd dat deze voldoet aan de

grenswaarden voor een Class B Digital Device, conform Subpart B, Class B van

Part 15 van de FCC regels. Deze grenswaarden zijn bedoeld om een redelijke

bescherming te bieden tegen schadelijke interferentie wanneer deze apparatuur

wordt gebruikt in een commerciële omgeving. Deze apparatuur, genereert, gebruikt

en kan radiofrequentie-energie uitstralen. Indien niet juist geïnstalleerd en gebruikt

in overeenstemming met de gebruikershandleiding, kan dit leiden tot schadelijke

interferentie met radiocommunicatie. Bediening van deze apparatuur in een

woonwijk kan leiden tot schadelijke interferentie, in welk geval de gebruiker de

interferentie op eigen kosten moet verhelpen.

De 2020ppbPRO intrinsiekveilig (I/S) mededeling

DE 2020ppbPRO IS GOEDGEKEURD VOOR GEBRUIK IN CLASS I, DIVISION 1,

GROUPS A, B, C, D EXPLOSIEGEVAARLIJKE GEBIEDEN. T4 (135°C)

CLASSIFICATIE. Het is geregistreerd door MET® als instrument dat voldoet aan de

Standard for Intrinsically Safe Apparatus and Associated Apparatus for use in Class

I, Division 1, Groups A, B, C, D Hazardous (Classified) Locations, Sixth Edition van

Underwriters Laboratories® Inc. UL® 913 indien gevoed door een MX700010 or

MX700011 batterij-pack. DE 2020ppbPRO IS NIET BEDOELD VOOR DETECTIE

VAN ONTBRANDBARE GASNIVEAUS.DE 2020ppbPRO IS GECLASSIFICEERD

VOOR GEBRUIK IN ATMOSFEREN DIE ONTBRANDBARE GASNIVEAUS

BEVATTEN.

Deze accessoires zijn bedoeld voor gebruik met de 2020ppbPRO in een

explosiegevaarlijk gebied::

MX350006 Kalibratieregelaar

MX350007 Polsband

MX700260 Riem clip-holster

MX700260 Draagkoffer

M1760148 Gebruikers referentiekaart

MX395001 Korte monsternameslang

Gebruik geen andere accessoires in combinatie met de 2020ppbPRO in een

explosiegevaarlijke locatie. Vervanging van componenten kan invloed hebben op de

veiligheidsclassificatie.

ISP-074-576-P1D 17

Page 24

WAAR-SCHUWING

1. Gebruik als vervangend batterij-pack uitsluitend artikelnr.Part No.

MX700010 of MX700011.

2. Gooi het batterij-pack niet in een vuur. De cellen kunnen exploderen. Het

batterij-pack moet correct worden afgevoerd. Verifieer de lokale regelgeving voor

instructies voor de afvoer van dergelijk afval.

3. Open of beschadig het batterij-pack niet. Wanneer de 2020ppbPRO wordt

gebruikt op een wijze die niet is gespecificeerd, dan kan de bescherming die wordt

geboden door de 2020ppbPRO gevaar lopen.

4. Wees voorzichtig met het omgaan met batterij-pack. Let er op dat de

contacten niet kortsluiten met geleidende materialen zoals ringen, armbanden en

sleutels. De batterij of geleider kan oververhit raken en brandwonden veroorzaken.

5. Let op de juiste polariteit tussen het batterij-pack en de lader.

6. De batterij mag uitsluitend worden geladen in een niet explosiegevaarlijk

gebied.

7. Laad het batterij-pack met de meegeleverde AC-adapter, of speciaal voor

dit product aangewezen adapter, uitsluitend conform de instructies en beperkingen

die worden gespecificeerd in deze handleiding. Gebruik voor AC-adapter uitsluitend

artikelnr.. MX396013 (220 Volt AC). bij het gebruik van de AC-adapter niet de

toegang tot de AC wandcontactdoos die wordt gebruikt voor de adapter. De ACadapter mag niet worden gebruikt in een explosiegevaarlijk gebied.

Waarschuwing

1. Alle kalibratie, onderhoud en servicewerkzaamheden aan dit apparaat,

inclusief het opladen van de batterij, moet altijd plaats vinden in een veilige zone, uit

de buurt van explosiegevaarlijke gebieden.

2. Ontkoppel alle voeding voordat u servicewerkzaamheden uitvoert.

3. Open de UV Lamp kap niet wanneer de eenheid is ingeschakeld.

4. Gebruik de AC-adapter uitsluitend in een veilig gebied, uit de buurt van

explosiegevaarlijke gebieden.

5. Gebruik de Seriële poort uitsluitend in een veilig gebied, uit de buurt van

explosiegevaarlijke gebieden.

Voorzichtig

Lees en volg deze instructies op om het risico op brand of verwonding van personen

te reduceren:

1. Er zijn geen onderdelen in de 2020ppbPRO die door de operator vervangen

kunnen worden, behalve het batterij-pack, de UV lamp en monsterinlaatfilter.

Gebruik als vervangend batterij-pack uitsluitend artikelnr. MX700010 of

MX700011.

18 ISP-074-576-P1D

Page 25

2. Er zijn geen onderdelen binnenin de 2020ppbPRO s die door de operator kunnen

worden onderhouden.

3. Gooi het batterij-pack niet in een vuur. De cellen kunnen exploderen. Het batterij-

pack moet correct worden afgevoerd. Verificeer de lokale regelgeving voor

instructies voor de afvoer van dergelijk afval.

4. Open of beschadig het batterij-pack niet. Wanneer de 2020ppbPRO wordt

gebruikt op een wijze die niet is gespecificeerd, kan de bescherming die wordt

geboden door de 2020ppbPRO gevaar lopen.

5. Wees voorzichtig met het omgaan met batterij-pack. Let er op dat de contacten

niet kortsluiten met geleidende materialen zoals ringen, armbanden en

sleutels. De batterij of geleider kan oververhit raken en brandwonden

veroorzaken.

6. Let op de juiste polariteit tussen het batterij-pack en de lader.

7. Laad het batterij-pack met de meegeleverde AC-adapter, of speciaal voor dit

product aangewezen adapter, uitsluitend conform de instructies en

beperkingen die worden gespecificeerd in deze handleiding. Gebruik voor ACadapter uitsluitend artikelnr, MX396013 (220 Volt AC). Blokkeer, bij het gebruik

van de AC-adapter niet de toegang tot de AC wandcontactdoos die wordt

gebruikt voor de adapter. De AC-adapter mag niet worden gebruikt in een

explosiegevaarlijk gebied.

Deze accessoires zijn bedoeld voor gebruik met de 2020ppbPRO in een

explosiegevaarlijk gebied::

MX350006 Kalibratieregelaar

MX350007 Polsband

MX700260 Riem clip-holster

MX700260 Draagkoffer

M1760148 Gebruikers referentiekaart

MX395001 Korte monsternameslang

Gebruik geen andere accessoires in combinatie met de 2020ppbPRO in een

explosiegevaarlijke locatie. Vervanging van componenten kan invloed hebben op de

veiligheidsclassificatie.

ISP-074-576-P1D 19

Page 26

Avertissement Compatibilité électromagnétique

Cet équipement a été testé et reconnu conforme aux limitations de la Classe B des

équipements numériques, conformément au sous-paragraphe B, Classe B du

paragraphe 15 des règles FCC. Ces limites sont conçues pour fournir une protection

raisonnable à l’encontre des interférences nuisibles lorsque l’équipement est utilisé

dans un environnement industriel.

Cet équipement génère, utilise et peut émettre de l’énergie sous forme de

fréquences radio et, si non installé et utilisé en conformité avec les instructions de

ce manuel, peut entraîner des interférences nuisibles aux communications radio.

L’utilisation de cet appareil dans une zone résidentielle peut entraîner des

interférences nuisibles auquel cas, l’utilisateur sera obligé de corriger les

interférences à ses propres frais.

2020ppbPRO - Note de sécurité intrinsèque

LE 2020ppbPRO EST CLASSIFIE POUR UN USAGE EN ZONES DANGEREUSES

DE CLASSE I, DIVISION I, GROUPES A, B, C, D. T4 EVALUTATION (135 °C).

Le 2020ppbPRO est conforme à la norme des Underwriters Laboratories Inc. UL

913 Standard for Intrinsically Safe Apparatus and Associated for use in Class I,

Division I, Groups A, B, C, D Hazardous (Classified) Locations. Quatrième édition.

Le 2020ppbPRO est conforme à la norme CSA E79-0:1995 & CAS E79-11:1995:

Intrinsically Safe Equipment.

LE 2020ppbPRO N’EST PAS PREVU POUR DETECTER DES NIVEAUX DE

COMBUSTION DE GAZ. LE 2020ppbPRO EST CLASSE POUR ETRE UTILISE EN

ATMOSPHERES CONTENANT DES NIVEAUX DE COMBUSTION DE GAZ.

Les accessoires suivants peuvent également être utilisés avec le 2020ppbPRO en

zone dangereuse :

MX350006 Régulateur d’étalonnage.

MX350007 Dragonne.

MX700260 Etui de ceinture

MX700260 Valise de transport

M1760148 Carte de référence utilisateur

MX395001 Sonde d’échantillonnage courte

N’utilisez aucun autre accessoire avec le 2020ppbPRO en zone dangereuse.

L’échange de composants peut altérer le niveau de sécurité.

AVERTISSEMENT

Pour réduire le risque d’incendie ou de blessure aux personnes, lisez et suivez les

instructions ci-dessous.

1. Tout étalonnage, maintenance ou entretien de cet équipement, y compris la

recharge des batteries, doit être réalisé dans une zone de sécurité et éloignée

de toutes zones dangereuses. Déconnecter toute source d’alimentation avant

toute intervention de maintenance.

2. Exceptés la batterie, la lampe UV et le filtre d’entrée d’échantillonnage, aucune

autre pièce du 2020ppbPRO ne peut être remplacée par l’opérateur.

3. Le2020ppbPRO ne contient aucune pièce réparable par l’utilisateur.

20 ISP-074-576-P1D

Page 27

ATTENTION

1. Pour le remplacement de la batterie, n’utilisez que la batterie référence

MX700010 ou MX700011.

2. Ne jetez pas le bloc batterie au feu. Les cellules peuvent exploser. Le bloc

batterie doit être jeté conformément à la réglementation locale. Vérifiez la

présence de contraintes locales spécifiques éventuelles.

3. N’ouvrez ni ne désagrégez la batterie. Si le 2020ppbPRO est utilisé d’une

façon non prévue, la protection fournie par le2020ppbPRO peut être altérée.

4. Soyez prudent lors de la manipulation des blocs batterie de manière à ne pas

court-circuiter les bornes avec des objets tels que bague, bracelets ou clefs. La

batterie ou le conducteur peut surchauffer et engendrer des brûlures.

5. Ne pas inverser les polarités entre la batterie et son chargeur.

6. La recharge de la batterie ne devra être effectuée que dans une zone non

dangereuse.

7. Chargez le bloc batterie en utilisant l’adaptateur pour courant alternatif fourni

ou identifié pour l’utilisation pour ce produit uniquement, en conformité avec les

instructions et limitations spécifiées dans ce manuel. Pour l’adaptateur pour

courant alternatif, n’utiliser que le produit référencé MX396013 (220 V AC).

Lors de l’utilisation de l’adaptateur pour courant alternatif, ne pas bloquer

l’accès à la sortie alternative en utilisation avec l’adaptateur. L’adaptateur pour

courant alternatif ne peut pas être utilisé dans une zone dangereuse.

ATTENTION

1. Tout étalonnage, maintenance et entretien de cet équipement, y compris la

recharge du bloc batterie, doit être réalisé dans une zone de sécurité

éloignée de toutes zones dangereuses.

2. Déconnecter toute source d’alimentation avant d’effectuer l’entretien.

3. Ne pas ouvrir le cache de la lampe UV avant d’avoir débrancher l’appareil.

4. N’utiliser un adaptateur pour courant alternatif que dans une zone de

sécurité éloignée de toutes zones dangereuses.

5. N’utiliser le port série que dans une zone de sécurité éloignée de toutes

zones dangereuses.

ISP-074-576-P1D 21

Page 28

ATTENTION

2020ppbPRO EST CLASSIFIÉ POUR USAGE DANS LES

EMPLACEMENTS DANGEREUX DE CLASSE I, DIVISION 1,

GROUPES A, B, C, D. ÉVALUATION T4 (135ºC).

2020ppbPRO est conforme à la norme des Underwriters

Laboratories Inc. UL 913 Standard for Intrinsically Safe

Apparatus and Associated Apparatus for use in Class I,

Division 1, Groups A, B, C, D Hazardous (Classified)

Locations. Quatrième édition.

2020ppbPRO est conforme à la norme de CSA E79-0:1995 &

CAS E79-11:1995: Intrinsically Safe Equipment.

2020ppbPRO EST NE PAS INTENDER POUR DÉTECTER

DES NIVEAUX DE COMBUSTION DES GAZ. CET

APPAREIL EST CLASSIFIÉ POUR USAGE DANS DES

ATMOSPHÈRES CONTENANT DES NIVEAUX DE

COMBUSTION DES GAZ.

Les accessoires suivants peuvent également être utilisés avec

l’appareil dans un emplacement dangereux:

MX350006 Régulateur de calibration

MX350007 Sangle de poignet

MX700260 Étui de ceinture

MX700260 Étui de transport

M1760148 Carte de référence

MX395001 Petite Gamme d’échantillons

Ne pas utiliser d’autres accessoires avec cet appareil dans un

emplacement dangereux.

La substitution des composantes peut nuire à la sécurité

d’emploi.

ATTENTION

Pour réduire le risque de feu ou blessures, lisez attentivement ces directive:

1. Tout étalonnage et entretien, incluant le chargement de la batterie, doit

être fait dans un endroit sécuritaire et non-explosif. L’alimentation électrique

doit être mis hors-service.

2. Aucune pièce ne peut être changée par l’utilisateur à part la batterie.

3. Aucun entretien ne peut être fait par l’utilisateur.

ATTENTION

1. Utilisez seulement des batteries rechargeables de type nickel cadmium

avec un chargeur 12 Volts DC (Pièce # MX700010 ou MX700011).

2. Ne jetez pas les batteries dans le feu. Elles pourraient exploser Vérifiez

avec la réglementation locale avant d’en disposer.

3. Ne pas ouvrir ou briser la batterie. La protection offerte par le 2020ppbPRO

sera alors inutile.

22 ISP-074-576-P1D

Page 29

4. La manutention de la batterie nécessite d’éviter les produits conducteurs

comme des anneaux, bracelets ou clés pour éviter tout court- circuit La

batterie pourrait surchauffer et causer des brûlures.

5. Ne pas modifier la polarité entre la batterie et le chargeur.

6. Utilisez seulement l’adaptateur AC spécifié dans le manuel. (Pièces #

MX396013 (220 Volts AC)). Ne pas bloquer la sortie de l’adaptateur AC.

ISP-074-576-P1D 23

Page 30

Advertencia FCC

Este equipo ha sido probado y se ha comprobado que cumple con los límites para

la clase B de los equipos digitales, en conformidad con la sub-parte B, clase B de la

parte 15 de las reglas FCC. Estos límites han sido determinados para proveer una

protección razonable contra interferencias cuando el equipo es operado en una

zona comercial. Este equipo genera, usa y puede radiar energía de radio frecuencia

y si no es usado de acuerdo con las instrucciones de este manual puede causar

interferencia para una radio de comunicación. La operación de este equipo en una

zona residencial probablemente causará interferencias que deben ser eliminadas

por cuenta del usuario.

Información sobre la seguridad intrínseca (I/S) del 2020ppbPRO

El 2020ppbPRO 2 ESTA CLASIFICADO PARA SER USADO EN ZONAS

PELIGROSAS DE LA CLASE I, DIVISIÓN 1, GRUPOS A, B, C, D. CLASE T4

(135°C).

Ha sido probado por MET® para cumplir con los estándares de seguridad de

Underwriters Laboratories® Inc. UL® 913 para aparatos intrínsicamente seguros y

aparatos asociados para su utilización en zonas (clasificadas ) de peligro en la

clase I, División 1, Grupos A, B, C, D, Sexta Edición cuando sea alimentado por un

paquete de baterías MX700010 o MX700011. EL 2020ppbPRO NO ESTA

DISEÑADO PARA DETECTAR NIVELES COMBUSTIBLES DE GASES. EL

2020ppbPRO ESTA CLASIFICADO PARA UTILIZARLO EN ATMÓSFERAS QUE

CONTENGA NIVELES COMBUSTIBLES DE GASES.

Los siguientes accesorios son utilizados con el 2020ppbPRO en zonas

clasificadas:

MX350006 Regulador de calibración

MX350007 Correa de mano

MX700260 Funda con clip para correa

MX700260 Maleta

M1760148 Tarjeta de referencia del usuario

MX395001 Sonda de toma de muestras.

No usar otros accesorios con el 2020ppbPRO en zonas peligrosas

La sustitución de componentes puede afectar el grado de seguridad.

CUIDADO

Para reducir el riesgo de incendios y daños personales, leer y seguir las siguientes

instrucciones:

1. La calibración, mantenimiento y servicio de este aparato, incluyendo el

cambio de baterías deben ser realizados en un área segura lejos de la zona de

peligro. Desconectar la alimentación de energía antes de empezar con los

trabajos de mantenimiento.

2. El 2020ppbPRO no cuenta con partes que deben ser reemplazadas por el

operador a excepción del paquete de baterías, la lámpara UV y el filtro de

entrada de la muestra.

3. El 2020ppbPRO 2 no cuenta con partes que deben ser mantenidas

directamente por el operador.

24 ISP-074-576-P1D

Page 31

ADVERTENCIA

1. Para reemplazar el paquete de baterías usar sólo la pieza nº. MX700010 o

MX700011.

2. No tirar el paquete de baterías en el fuego. Estas pueden explotar. El paquete

de baterías debe ser desechado adecuadamente. Averiguar si existen instrucciones

locales especiales como residuos.

3. No abrir o mutilar el paquete de baterías. Si el 2020ppbPRO se utiliza de una

manera no especificada, puede afectar la protección provista para el 2020ppbPRO.

4. Manipular el paquete de baterías con cuidado y asegúrese que los terminales

de ésta no entren en contacto con materiales conductores tales como anillos,

brazaletes y llaves. La batería o el conductor se pueden sobrecalentar y causar un

incendio.

5. No confundir la polaridad apropiada entre el paquete de baterías y el cargador.

6. La carga de la batería sólo debe realizarse en un área no peligrosa.

7. Cargar el paquete de baterías usando el adaptador AC suministrado o

señalado para ser usado sólo con este producto de acuerdo con las instrucciones y

limitaciones especificadas en este manual. Para el adaptador AC usar sólo la pieza

Nº. MX396013 (220 Voltios AC). Cuando se use el adaptador AC no bloquear el

acceso de la salida AC en uso con el adaptador. No usar el adaptador AC en áreas

peligrosas.

ADVERTENCIA

8. La calibración, mantenimiento y servicio de este aparato incluyendo el

cambio de baterías deben ser realizados en un área segura lejos de la zona

de peligro.

9. Desconectar la alimentación de energía antes de empezar con los trabajos

de mantenimiento.No abrir la cubierta de la lámpara UV cuando la unidad

está conectada a la alimentación de energía.

10. Utilizar el adaptador AC sólo en una zona segura lejos de zona peligrosas.

11. Utilizar el puerto serie sólo en una zona segura lejos de zonas peligrosas.

CUIDADO

Para reducir el riesgo de incendios y daños personales, leer y seguir las siguientes

instrucciones:

12. El 2020ppbPRO no cuenta con partes que puedan ser reemplazadas por el

operador a excepción del paquete de baterías, la lámpara UV y el filtro de

entrada de muestras.

13. Para reemplazar el paquete de baterías usar sólo la pieza original

nº. MX700010 o MX700011.

14. El 2020ppbPRO no cuenta con partes que deben ser reparadas

directamente por el operador.

15. No colocar el paquete de baterías en el fuego. Estas pueden explotar. El

paquete de baterías debe ser desechado adecuadamente. Averiguar si

existen instrucciones locales especiales como residuos.

ISP-074-576-P1D 25

Page 32

16. No abrir o mutilar el paquete de baterías. Si el 2020ppbPRO s es utilizado

de una manera no especificada la protección provista para el 2020ppbPRO

puede dañarse.

17. Manipular el paquete de baterías con cuidado y asegúrese que los

terminales de ésta no entren en contacto con materiales conductores

tales como anillos, brazaletes y llaves. La batería o el conductor se puede

sobrecalentar y causar un incendio.

18. No confundir la polaridad apropiada entre el paquete de baterías y el

cargador. Cargar el paquete de baterías usando el adaptador AC

suministrado o señalado para ser usado sólo con este producto de

acuerdo con las instrucciones y limitaciones especificadas en este

manual. Para el adaptador AC usar sólo la pieza Nº. MX396013 (220

Voltios AC). Cuando se use el adaptador AC no bloquear el acceso de la

salida AC en uso con el adaptador. No usar el adaptador AC en áreas

peligrosas.

Los siguientes accesorios son utilizados con el 2020ppbPRO en zonas

clasificadas:

MX350006 Regulador de calibración

MX350007 Correa de mano

MX700260 Funda con clip para correa

MX700260 Maleta

M1760148 Tarjeta de referencia del usuario

MX395001 Sonda de toma de muestras.

No usar otros accesorios con el 2020ppbPRO en zonas peligrosas

La sustitución de componentes puede afectar el grado de seguridad.

26 ISP-074-576-P1D

Page 33

FCC Avvertenze

FCC avverte che questa apparecchiatura è stata esaminata ed è idonea per

aderire ai limiti per un dispositivo del codice categoria B Digital, conforme a Subpart

B, codice categoria B della parte 15 delle regole del FCC. Questi limiti sono destinati

ad assicurare la protezione minima contro interferenza nociva quando

l'apparecchiatura è utilizzata in un ambiente commerciale. Questa apparecchiatura

genera, e può irradiare energia di frequenza radiofonica e se non usata in

conformità con il manuale d'istruzione, può causare interferenze alle comunicazioni

radio. L'impiego di queste attrezzature in una zona residenziale può causare

interferenze ed i relativi danni causati saranno totalmente a carico dell’utilizzatore .

The 2020ppbPRO Intrinsic Safety (I/S) Notice

Il 2020ppbPRO è certificato per usi in classe I, divisione 1, gruppi A, B, C, D luoghi

con rischio di esplosione . T4 (135°C).

È stato elencato da MET® per aderire al campione dei Underwriters Laboratories®

Inc. UL® 913 per l'apparecchio di per sè sicuro e l'apparecchio associato per uso

nel codice categoria I, divisione 1, gruppi A, B, C, posizioni (classificate) pericolose

di D, sesta edizione una volta alimentato dal pacco batteria.

IL 2020ppbPRO NON È INTESO PER RILEVARE I LIVELLI COMBUSTIBILI DEI

GAS.

IL 2020ppbPRO È CLASSIFICATO PER USO IN ATMOSFERA CHE

CONTENGONO I LIVELLI COMBUSTIBILI DEI GAS.

Questi accessori possono essere usati con il 2020ppbPRO in zona pericolosa:

MX350006 Adattatore di calibrazione

MX350007 Wrist Strap

MX700260 Cinghia - Clip

MX700260 Valigetta di trasporto

M1760148 Reference Card

MX395001 Sonda di campionamento

Non usare altri accessori con il 2020ppbPRO in zone pericolose . La sostituzione

dei componenti può avere effetti negativi sull’utilizzo dello stesso in completa

sicurezza.

CAUTELA

Per ridurre il rischio di infortuni e incidenti , leggere e seguire le seguenti istruzioni:

1. Tutti le calibrazioni, mantenimento ed assistenza di questo dispositivo, compreso

la verifica della batteria carica/ scarica , devono essere effettuati in una zona sicura.

Durante qualsiasi manutenzione lo strumento non deve essere alimentato.

2. Non ci sono parti sostituibili dell'operatore all'interno del 2020ppbPRO tranne il

pacchetto della batteria, la lampada UV ed il filtro all'ingresso del campione.

3. Non ci sono parti utili dell'operatore all'interno del 2020ppbPRO.

ISP-074-576-P1D 27

Page 34

Avvertenze

1. Per cambiare il pacco batteria usare solo il part number MX700010 o MX700011.

2. Non mettere il pacco batteria sul fuoco. Le celle possono esplodere. Le batterie

devono essere rottamate . Controllare I codici locali di rottamazione per possible

speciali istruzioni.

3. Non aprire o mutilare il pacco batteria . Un uso non corretto può alterare la

sicurezza dello strumento.

4. Prestare attenzione nel maneggiare la batteria al fine di non mettere in corto i

contatti . La batteria può scaldarsi toccare con cautela.

5. Non invertire le polarità della batteria .

6. Caricare le batterie solo in zone sicure .

7. Caricare la batteria solo con l’alimentatore in dotazione o utilizzare alimentatori

che rispettino i dati indicati sul manuale d’istruzione. Usare part number MX396013

( 220 Volts AC ). L’alimentatore non deve essere usate in zone pericolose.

28 ISP-074-576-P1D

Page 35

Introduction

2

ISP-074-576-P1D 29

Page 36

WARNING

A warning indicates an operation that could cause personal injury if

precautions are not followed.

CAUTION

A caution indicates an operation that could cause instrument

damage if precautions are not followed.

About this Manual

This manual provides detailed instructions for setup, operation and maintenance of

the 2020ppbPRO Portable Photoionization Monitor.

Before unpacking the instrument, please read Warnings and Safety Practices on

pages 4 and 5. This section describes possible hazards that might injure the user,

damage the instrument or compromise its operation. Some general safety

information is also provided.

To help you learn to use the 2020ppbPRO quickly, this manual is organized by tasks

beginning with:

Using the 2020ppbPRO in Chapter 3

Calibrating the 2020ppbPRO in Chapter 4

Accessories are covered in Chapter 5

Routine maintenance is covered in Chapter 6

Troubleshooting techniques are covered in Chapter 7

The 2020ppbPRO manual uses a few conventions for key names on the keypad and

for text that is shown on the display.

UPPERCASE Fixed key names are denoted by uppercase text.

“Display Text” Text that appears on the 2020ppbPRO status display is

in quotation marks.

Soft key names are also shown in quotation marks.

In the text you will find various warnings and notes.

NOTE: A note indicates significant information.

30 ISP-074-576-P1D

Page 37

Warnings and Safety Practices

WARNING

If the 2020ppbPRO you are using is not specifically identified as

intrinsically safe with a label on the 2020ppbPRO, do not use it in a

location where flammable concentrations of gases and vapors may

exist.

Please read the Notices and Warnings section of this user’s manual before

operating the 2020ppbPRO.

Approved Models of the 2020ppbPRO

This manual provides operational information for all models of the 2020ppbPRO.

The 2020ppbPRO is intrinsically safe and approved for use in hazardous locations.

Refer to the Notices and Warnings section of this manual for details of each

approval.

Throughout the manual, notes are provided to inform you of any limitations of usage

for the 2020ppbPRO models.

Excessive Heat and Cold

Do not expose the instrument to intense sunlight for prolonged periods.

Exposure to excessive heat or cold may result in erroneous readings.

ISP-074-576-P1D 31

Page 38

2020ppbPRO Overview

Figure 1. The 2020ppbPRO Instrument

The 2020ppbPRO measures the concentration of airborne gases and vapors that

can be ionized by a photoionization detector. The 2020ppbPRO automatically

displays and can record these concentrations. The 2020ppbPRO does not

distinguish between individual compounds. The reading displayed represents

the total concentration of all photoionizable chemicals present in the sample. The

2020ppbPRO displays concentrations in units of ppb as well as ppm and Mg/M3.

The 2020ppbPRO operates automatically. The 2020ppbPRO display updates itself

once per second. You can read concentrations directly from the display.

The 2020ppbPRO will perform short-term exposure limit (STEL), time-weighted

average (TWA) and PEAK calculations when it is in INTERVAL mode. You can view

any of these results in INTERVAL mode.

The 2020ppbPRO has two datalogging options, Tag and Interval mode. Tag mode

allows the user to manually tag and store readings during a walkthrough. Interval

mode allows the user to datalog at selectable intervals of 1 second to 999 seconds.

In Interval mode, the STEL, PEAK and TWA are calculated. If you select Interval

mode, these values are automatically recorded in the 2020ppbPRO’s memory. The

2020ppbPRO can log up to 12,000 entries.

32 ISP-074-576-P1D

Page 39

In Tag mode operation, the 2020ppbPRO prompts you to locate a site and then to

Inlet

Filter

Photoionization

Detector

Sample In

Sample Out

Display and

I/O Connector

Keypad

Microprocessor

Power

Supply

Electrical Connections

Gas Connections

Pump

record a background and sample readings for the site. You can record up to 12,000

manual entries. There is no averaging of data in Tag mode.

Recorded data can be reviewed on the display or downloaded to a computer. Data

are recorded by date and time.

The 2020ppbPRO has 5 keys for instrument operation. The keys are used to set up

and calibrate the 2020ppbPRO. All information entered with the keys and stored in

the 2020ppbPRO’s memory is retained when the instrument is switched off. The

clock and calendar continue to operate and do not need to be reset when the

2020ppbPRO is turned on.

General Operation

The 2020ppbPRO is a microprocessor-controlled air monitor for measuring the

presence of photoionizable compounds in air at parts-per-billion levels. The block

diagram in Figure 2 shows the main components of the 2020ppbPRO.

Figure 2. The 2020ppbPRO Block Diagram

The microprocessor controls the components of the instrument and interprets and

records the signal generated by the photoionization detector (PID). Recorded data

and setup information entered into the microprocessor’s memory are retained when

the 2020ppbPRO is turned off.

A pump continuously pulls the air under test through the 2020ppbPRO’s PID. The

PID converts the concentration of photoionizable compounds in the sample into an

electrical signal. The microprocessor subtracts any background from the signal and

divides this signal by a sensitivity obtained by calibrating with a standard gas of

known concentration. This concentration appears on the 2020ppbPRO’s display

and, depending on the values entered through the 2020ppbPRO’s keypad, an alarm

status may be displayed and an audio signal may be heard.

The 2020ppbPRO can detect thousands of different types of airborne gases and

vapors and its response depends on the characteristics as well as the concentration

of each compound.

The 2020ppbPRO does not distinguish one type of compound from another,

but displays a number indicating the total concentration of all photoionizable

compounds in the sample.

ISP-074-576-P1D 33

Page 40

M

M

M

M

M

M

e

+

-

++h

Lamp Power

Supply

Lamp Driver

Circuit

Microprocessor

Light Sensor

Electrometer

+125 Volts

Sample In

Detector Cell

UV Lamp

Lampholder

High Voltage

Plates

Sample Out

UV Lamp

UV Light

Sample

Ionized Molecule

Collector Electrode

Repeller Electrode

A standard of isobutylene at a known concentration may be used for setting the

sensitivity. If the 2020ppbPRO is calibrated with isobutylene, it displays

concentrations in units equivalent to ppm of isobutylene. If isobutylene were the only

photoionizable chemical in the sample, then the 2020ppbPRO would display its

concentration directly.

The 2020ppbPRO responds more or less readily to other chemicals than it does to

isobutylene. Because it has a medium sensitivity to isobutylene, this gas has been

chosen as a reliable means of reporting an average concentration of total ionizable

compounds present.

Gases other than isobutylene can be used to calibrate the 2020ppbPRO. However,

all response factors are based on an isobutylene calibration.

Photoionization Detector

The 2020ppbPRO’s PID is shown in Figure 3. The PID measures the concentration

of photoionizable chemicals in the gas stream from the sample inlet and produces

an electrical signal for the microprocessor.

A UV lamp generates photons which ionize specific molecules in the gas stream.

The permanent air gases (argon, carbon dioxide, nitrogen, oxygen, water vapor,

etc.) require a relatively high energy for ionization, and are not ionized by the UV

photons. Many of the compounds considered pollutants, including most

hydrocarbons, are ionized.

The gas stream is directed into the PID through a small port at the center of the UV

lamp window and through a series of larger ports around the perimeter of the lamp

window. This arrangement permits a high sample flow rate and short response time.

Figure 3. Photoionization Detector

The ionized molecules in the detector cell are subjected to a continuous electric field

between the repeller electrode and the collector electrode. The ions move in the

electric field, generating a current which is proportional to the concentration of the

34 ISP-074-576-P1D

Page 41

ionized molecules in the detector cell. An electrometer circuit converts the current to

a voltage which is then fed to the microprocessor.

The UV lamp is operated by a high voltage lamp driver circuit which delivers high

voltage energy to the lamp through plates in the lamp holder. The lamp driver power

supply is controlled by the microprocessor based on a feedback signal from a light

sensor on the driver circuit board.

Unpacking Instrument

Remove the 2020ppbPRO from its shipping box. The following accessories are

included with the 2020ppbPRO:

1. Sample Probe

2. Instrument Manual (on CD)

3. Multi-Tool

4. AC Adapter or AC Adapter with AC Line Cord

5. Replacement Sample Inlet Filters (10 pieces)

6. Reference Card

7. Water-trap Filter

8. INFICON filter tube holder

9. Intake sample conditioner tubes

Ensure that all of these accessories have been included with the instrument. If any

items are missing or damaged, contact INFICON immediately.

Support Equipment and Consumables

Calibration

For normal operation these items are required:

1. Calibration Gas Regulator (Part No. MX350006).

2. Calibration gas containing 10 ppm isobutylene (Part No. MX350025).

Other concentrations of the calibration gas may be required. This will

depend on your application.

3. Zero air (clean dry air without any organic impurities)

There are several alternatives for clean or zero air calibration: you can

use a bottle of clean air (certified as having not more than 0.1 ppm total

hydrocarbons) connected directly to the instrument; the clean air can be

transferred to a Tedlar bag which can then be connected to the

instrument; clean, ambient air without detectable contamination; or,

ambient air run through the charcoal filter (F1760160).

If you will be using large tanks of gas, specify a single stage, high purity

regulator with a CGA 590 connection at the inlet. The regulator should

also have a 1/8” parallel, compression fitting with which to connect the

regulator to the gas bag adapter. The delivery pressure must be

adjustable to between 5 psig (34.5 kPa). You may require a gas bag

and gas bag adapter (Part No. MX380014).

ISP-074-576-P1D 35

Page 42

4. If compound threshold limit values (TLVs) are exceeded, you should use

a gas bag for sampling and calibration.

To determine the TLV of the compounds contained in the calibration gas,

refer to the Material Safety Data Sheet (MSDS) supplied with your

calibration gas cylinder.

If you will be using a gas bag for calibration, see Calibration Using a

Gas Bag on page 63 for instructions.

Field Operation

For field operation, the 2020PRO series Field Kit (Part No. MX750080) is available.

The field kit includes a cable kit, a carrying case and a calibration regulator, and a

spare battery pack.

Refer to the check list in on page 65 to ensure you have all the necessary accessories

and equipment before beginning field operation.

Computer

The 2020ppbPRO may also be connected to a computer. The computer must be a

Windows-based PC. Use the cable kit (Part No. MX750120) to connect the

2020ppbPRO to the computer.

NOTE: The 2020ppbPRO is not classified for use in hazardous locations when connected to

a computer.

36 ISP-074-576-P1D

Page 43

Using the

2020ppbPRO

3

ISP-074-576-P1D 37

Page 44

Battery Charging

Before beginning operation of the 2020ppbPRO, the battery pack must be charged.

You can also remove the battery pack and replace it with a fully charged spare

battery pack (Part No. MX700010 or MX700011).

NOTE: You must use the 220 V battery charger (Part No. MX396013) in order to comply

with the requirements of the applicable Council Directives.

Removing and Replacing the

Battery Pack

NOTE: Do not remove or recharge the battery pack in a hazardous location.

To remove the battery pack:

1. If the 2020ppbPRO has been turned on, turn it off by pressing the

ON/OFF key for five seconds and then releasing it.

NOTE: If you do not turn the 2020ppbPRO off before removing the battery pack, you will

reset the instrument and you will lose all logged data and setup parameters.

2. Locate the battery hatch on the back of the instrument. See Figure 4.

3. Loosen the two Phillips screws in the top of the battery hatch.

4. The battery hatch can now be removed.

5. Lift the battery pack out of the case and carefully disconnect the battery

pack connector from the 2020ppbPRO.

6. Attach the connector from the charged battery pack to the

2020ppbPRO.

NOTE: The connector is polarized. It will only fit one way. Do not force the connection.

7. Place the battery pack in the 2020ppbPRO case. Ensure the battery

wires are not pinched or strained.

8. Ensure the wrist strap ring is in proper position. This ring holds the wrist

strap in place.

9. Replace the battery hatch and then replace the two screws. Do not

over-tighten the screws as you will damage the case.

38 ISP-074-576-P1D

Page 45

Charging the Battery Pack

NOTE: Only use the AC adapter specified for use with the 2020ppbPRO. Using another AC

adapter will result in damage to the battery pack, the 2020ppbPRO or the adapter

itself.

To charge the battery pack:

1. Plug the AC adapter into the jack located on the bottom of the

2020ppbPRO.

2. Plug the AC adapter into an AC outlet. If you are using the European AC

adapter, ensure the correct plug is installed on the line cord . If it is not

correct for the wall outlet in your area, then it must be replaced.

3. The Charge LED on the 2020ppbPRO indicates the charge state. Red

indicates the battery is being charged. Green indicates the battery is

fully charged and ready for use.

It is normal for a fully charged battery to indicate it is charging (red light)

when first plugged in. The Charge LED will turn green within a few

minutes to indicate the battery is fully charged.

4. When the battery pack is fully charged, remove the AC adapter first

from the wall outlet and then from the 2020ppbPRO.