Page 1

0473

Patient Warming Systems

Service Manual

Inditherm Medical

Houndhill Park

Bolton Road

Rotherham

S63 7LG

Tel: +44 (0) 1709 761000

Fax: +44 (0) 1709 761066

e-mail: info@indithermplc.com

www.inditherm.com/medical

©Inditherm plc 2007

Page 2

Inditherm Service Manual

Contents:

Page

Warnings 3

Introduction 4

Product Range 5

System Description 6

Fault Finding 8

Repairs 11

Mattress/Blanket

Mattress/Blanket connector 11

Control cable

Control cable connectors 11

Control Unit 14

Clamp assembly 14

Display PCB 14

Case upper half 14

Output fuse 15

Control PCB assembly 15

Transformer assembly 15

Power on/off switch 16

Mains power cable 16

Control Cable 17

Case lower half 19

Testing

Control Unit 20

Mattress/Blanket 21

System Test 22

Spare Parts List 23

Technical Specification 25

© Inditherm plc, 2007

Copyright: All rights reserved. No part of this handbook may be reproduced, stored in a retrieval system

or transmitted in any form or by any means electronic, mechanical, photocopying, recording or otherwise,

without the prior permission of Inditherm plc.

Patient Warming Systems Page 2 of 25 Rev 1.5; 21-09-07

Page 3

Inditherm Service Manual

WARNINGS:

Any person carrying out repairs or service should have received adequate

training and be competent to carry out the work.

The control unit should be disconnected from the mains supply before the

covers are removed.

All work should be carried out with the equipment disconnected from the

mains supply wherever possible.

This Service Manual should be read in conjunction with the Operating

Instructions for the system.

It is recommended that the unit is cleaned and decontaminated prior to

handling, unless a decontamination certificate or statement that the system is

free of hazard is supplied.

Patient Warming Systems Page 3 of 25 Rev 1.5; 21-09-07

Page 4

Inditherm Service Manual

INTRODUCTION:

This Service Manual is for use by qualified engineers and technicians only. Servicing carried out

by any person other than authorised Inditherm engineers will invalidate any warranty on the system.

The Inditherm Patient Warming Systems are designed for use in the operating room, recovery room,

anaesthetic room and accident & emergency department. They provide safe and controlled

warming to assist patients to maintain normal body temperature. The warming medium is available

as:

• A mattress for use under a patient

• A recovery blanket or operating room blanket to be placed over a patient on a bed or trolley.

Different sizes and models of mattress and blanket are available for various procedures and

situations. Mattresses are sealed to prevent ingress of fluids and allow cleaning. Integral straps are

provided to ensure mattresses can be securely fastened to the operating table or trolley.

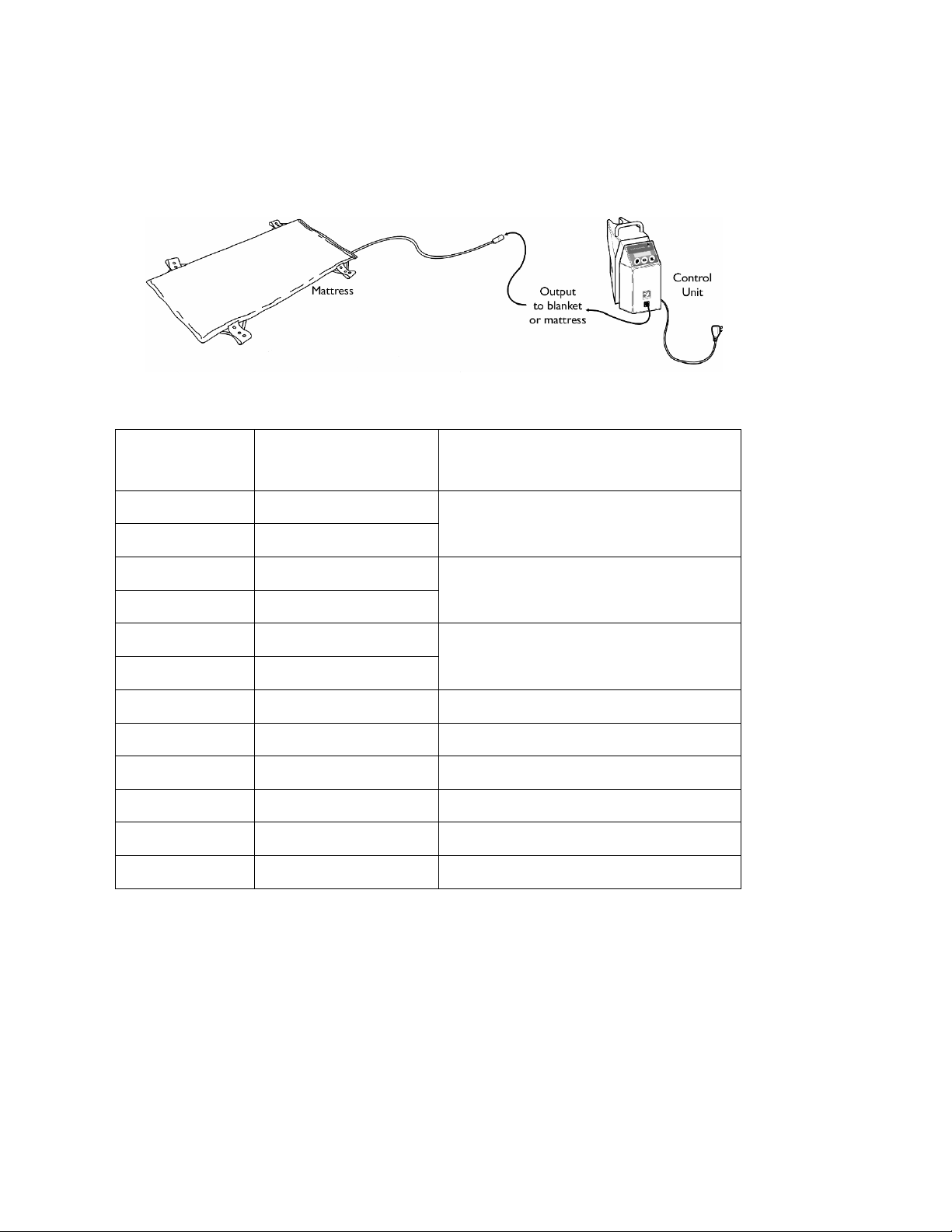

The system is powered and controlled by an electronic control unit. The mattresses and blankets

are powered at low voltage, ensuring safety for patients and operators. The temperature is

controlled automatically to user-selected level. An over-temperature safety cut-out is integrated

into each mattress and blanket.

The control unit is powered from a standard mains supply input and produces a nominal working

output of 24Vac to the mattress or blanket. The system has 4 pre-set operating temperatures of 37,

38, 39 and 40°C and is designed to be operated continuously, maintaining a uniform heat under the

patient.

Patient Warming Systems Page 4 of 25 Rev 1.5; 21-09-07

Page 5

Inditherm Service Manual

PRODUCT RANGE:

Note: Any mattress or blanket can be used with any control unit, but is limited to only one mattress

or blanket per unit.

Model

Size Description

OTM1 1900 x 585 x 40 mm

Operating Room Mattress, Full Length

OTM1-N 1900 x 535 x 40 mm

OTM2 1200 x 585 x 40 mm

Operating Room Mattress, ¾ Length

OTM2-N 1200 x 535 x 40 mm

GTM1 1070 x 585 x 40 mm

Operating Room Gynaecology Mattress

GTM1-N 1070 x 535 x 40 mm

PTM1 560 x 500 x 40 mm Operating Room Paediatric Mattress

OTB1 500 x 1070 x 40 mm Operating Room Blanket

OTB2 500 x 870 x 40 mm Operating Room Blanket

RB1 1660 x 800 x 40 mm Recovery Room Blanket

RB2 1660 x 1200 x 40 mm Recovery Room Blanket

MECU1 160 x 240 x 230 mm Electronic Control Unit

Patient Warming Systems Page 5 of 25 Rev 1.5; 21-09-07

Page 6

Inditherm Service Manual

SYSTEM DESCRIPTION:

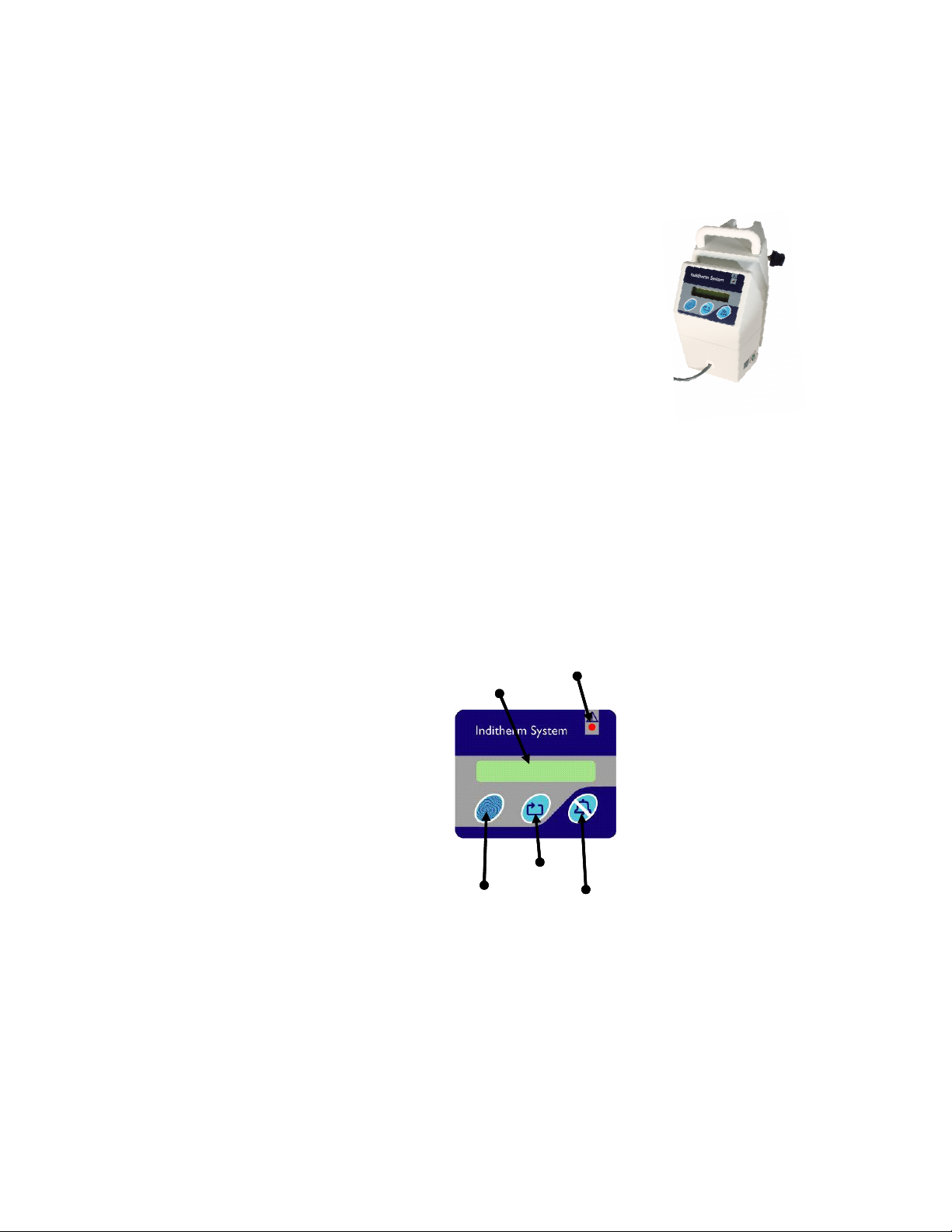

Control Unit

The control unit is a precision temperature controller to be

used in conjunction with an Inditherm warming mattress or

blanket.

The control unit comprises a single case, with integral clamp,

containing mains power inlet, mains fuse, transformer,

control PCB, display and controls.

On the front of the unit is a display and control panel from

which all the functions can be accessed, there are three

control buttons, and an LCD display. A captive cable for

connection to the mattress or blanket is hard wired through

the front face of the unit.

The control unit provides a 24Vac supply to the mattress or blanket and receives temperature

information back. The control unit output is protected by a 1600mA fuse, which is accessible from

the base of the unit. The controller automatically adjusts to the type of mattress or blanket

connected.

The control unit takes signals from the temperature sensor in the mattress or blanket and the

readings are used to control the power output and alert the user to over and under temperature

faults.

Control panel layout is

as shown. For function

of controls, and display

parameters, please see

Operating Instructions

LCD Screen

LCD Screen

Enable Button

Enable Button

Warning Indicator

Warning Indicator

Scroll Button

Scroll Button

Alarm Cancel /

Alarm Cancel /

Reset Button

Reset Button

Patient Warming Systems Page 6 of 25 Rev 1.5; 21-09-07

Page 7

Inditherm Service Manual

Mattresses

Mattresses are available in various sizes

and are only designed to operate under the

patient. The mattress provides an even

temperature over the whole surface and is

extremely flexible.

The basic construction of the mattresses

remains the same throughout the range.

The mattresses are water and solvent

resistant and have been tested for biocompatibility to allow skin contact during

use. All seams are fully sealed by RF

welding.

The internal patented Inditherm carbon

polymer material provides the heat source,

and internal temperature sensor provides the

output to the control unit for temperature

control. The mattress has a thermal cut-out

that will not allow the mattress to overheat.

A pressure relief pad is integrated into the mattress, underneath the flexible warming surface. This

prevents pressure sores without any attenuation of the warming performance.

Straps are used to retain the mattress in-situ and it is important that the mattress is securely fastened

to the operating table or trolley.

Blankets

Blankets are designed to operate over the

patient. There are two types of blanket

available, one for the operating room and the

other for areas such as recovery room,

intensive care unit, etc. The operating room

blankets are constructed in the same manner as

the mattresses, but without the pressure relief

pad. The recovery blanket has lighter outer

material and stitched seams.

Patient Warming Systems Page 7 of 25 Rev 1.5; 21-09-07

Page 8

Inditherm Service Manual

FAULT FINDING:

General Performance

On initial start up, if the ambient temperature is low, the mattress/blanket will take longer to achieve

the desired temperature. If the desired temperature is not achieved within 40 minutes the alarm will

sound. Should this happen select the reset/alarm button and the unit will restart and the system will

allow another 20 minutes for the desired temperature to be achieved.

The control unit will power the mattress/blanket and monitor temperature performance. Once the

mattress/blanket reaches the desired temperature the control unit will adjust power input to ensure

the desired temperature is maintained. If the maximum allowed temperature is achieved the over

temperature alarm will sound. If the alarm is activated select reset/alarm button and the unit will

restart. An internal safety cut-out temperature management system will ensure the mattress/blanket

will never achieve a temperature greater than 43°C under any fault condition.

When the system is powered on it should follow the cycle below. In case of any error messages or

other faults, refer to the Fault Finding chart.

Display Screen Readout

Bleep will be heard on switch on

Inditherm

V2.03E

English UK

>>>> to change language

Language

English UK

Bleep will be heard

System Check

Bleep will be heard

System OK

Bleep will be heard

Alarm Check

Bleep will be heard

Alarm OK

Bleep will be heard

∧∧∧∧ 37 °C ∧∧∧∧

>>>> 37 °C <<<<

∨∨∨∨ 37 °C ∨∨∨∨

Action Required

None

Option to change Language

See Control Instructions

Bleep will be heard

None Screen Indicates Language

None Automatic system test

None

None Automatic test of alarm sound

None User indication that alarm ok

User can change temperature set

User can change temperature set

User can change temperature set

Information

First screen indicating initialisation

started

For UK users, take no action and

system will automatically continue

User indication that system is OK

Display showing temperature setting.

Arrows will point upwards whilst

heating up to set temperature.

Display showing temperature setting.

Arrows point horizontal to indicate

that set temperature is reached.

Display showing temperature setting.

Arrows will point downwards to

indicate cooling to set temperature.

Patient Warming Systems Page 8 of 25 Rev 1.5; 21-09-07

Page 9

Inditherm Service Manual

Fault Finding / Troubleshooting

Fault or Error Message

General Procedure:

Alarm & Error Message:

“Connect mattress/blanket”

Alarm & Error Message:

“Mattress Fault” (A number will

show after message, this is for

Inditherm indication only)

Diagnostic Checks

• In most cases the fastest fault diagnosis is achieved by carrying out

substitution tests as follows:

- Replace mattress/blanket from faulty system with known working

mattress/blanket

- Replace control unit from faulty system with known working

control unit

- When faulty component is identified, substitute it back and check

it is still not working, then proceed as described in Repair section

• Check mattress is plugged in correctly. Verify that orientation of

plugs/sockets are correct

• Check for any visible damage to cable and connectors

• Unplug connectors and check that pins on plugs show no sign of

being damaged or bent

• If none of the above are applicable call supplier for advice

• Check 6.3A fuse on Control PCB has not blown (see diagram in

Repairs section)

• If fuse is intact, return mattress to supplier

• Ensure none of the control buttons is stuck, by pressing each button

in turn and checking that there is a positive tactile feel and that a

click is heard

Mattress/Blanket warms up but

does not reach temperature set

“Low Temperature Detected”

• Ensure the fault does not only occur when the mattress does not

have a patient on. The system may not reach target temperature if

the mattress is uncovered and the ambient temperature is low

• Place the mattress/blanket on a flat surface that is not cold and

cover upper surface with a standard blanket. Turn on the system

and check that temperature is reached within 15 minutes. If this

works then system is functioning normally and fault is due to local

operating conditions, such as ambient temperature or cold surface

• Reduce set temperature to 37°C, cover mattress with a blanket and

check that temperature is reached within 15 minutes. Increase

temperature setting to required level and check temperature is

reached. If this works then system is functioning normally and

fault is due to local operating conditions, such as ambient

temperature or cold surface

• Run unit in Test mode (see section Testing the System) and check

that the temperature is increasing

• If problems persist, contact supplier and advise operating

conditions, including ambient temperature from Test Mode

Patient Warming Systems Page 9 of 25 Rev 1.5; 21-09-07

Page 10

Inditherm Service Manual

Fault Finding / Troubleshooting

Fault or Error Message

Mattress/Blanket does not warm

up at all

Control Unit display is blank

Diagnostic Checks

• Check control unit is on and there are no error messages

• Disconnect the mattress/blanket from the control unit and check

there is an output of 23Vac ±6% from inside the control unit

between the two black wires (0V & 24Vac) on the transformer

connector to the PCB. (see diagram in Repair section).

• If there is no 23V output, check cable as described in Repair

section.

• If cable is not faulty carry out diagnostic checks as described below

for “Control Unit display is blank”

• Run unit in Test mode (see section Testing the System) and check

that the temperature is increasing.

• If problems persist, contact supplier and advise operating

conditions, including ambient temperature from Test mode

• Check control unit switch is set to On and is illuminated. If switch

not illuminated check fuse in mains plug (if fitted). If fuse not

blown check mains input wiring as described in Repair section

• Check 1600mA external fuse on bottom of unit (see diagram in

Repairs section)

• Check transformer connector is correctly installed onto Control

PCB (see diagram in Repairs section)

• Check output voltage of transformer is 23Vac ±6%. If output is

correct check input to transformer is at mains voltage.

• Check transformer connector is correctly fitted onto Control PCB

• Check ribbon cable connector is correctly fitted onto Control PCB

• Ensure none of the control buttons is stuck, by pressing each button

in turn and checking that there is a positive tactile feel and that a

click is heard

Patient Warming Systems Page 10 of 25 Rev 1.5; 21-09-07

Page 11

Inditherm Service Manual

REPAIRS:

Mattress/Blanket Plug (PS3):

3

Please follow sequence shown for assembling socket

2

once wires have been connected as per Diagram 1.

1

Note: individual cable insulation is numbered.

Front face

Diagram 1: Connections for PS3

Study how the connector is assembled before attempting to replace it. Diagram 3 shows how the

connector parts are assembled.

Each connector has multiple components to it, thus making it imperative that each piece is

correctly put together. Failure to do so may cause damage to the mattress/blanket or control unit.

Due to improvements in design, not all systems are the same. Identify the build type of your system

to ascertain which of these instructions are applicable.

Connector Socket (PS5)

3

Please follow sequence below for assembling socket

once wires have been connected as per Diagram 2.

2

Note: individual cable insulation is numbered.

1

Rear view

Diagram 2: Connections for PS5

Study how the connector is assembled before attempting to replace it. Diagram 4 shows how the

connector parts are assembled.

Each connector has multiple components to it, thus making it imperative that each piece is

correctly put together. Failure to do so may cause damage to the mattress/blanket or control unit.

4

5

6

Rear view

4

5

6

Front face

3

2

1

3

2

1

Patient Warming Systems Page 11 of 25 Rev 1.5; 21-09-07

Page 12

hand tight.

grip up to the plug insert.

cable.

plug to be assembled correctly.

casing.

up to the grey cable grip.

Ensure all the parts are assembled in the

correct order as shown above.

Screw

The cable grip has a locating pin which

should be sat in the top grove of the plug

insert. The keyed part of the plug should

be at the bottom, meaning the locating

pin and screw are in line with each

other. Tighten the screw to grip the

Keyed part of plug

to bottom

Once the insert is inside

the housing, slide the

blue ring down the cable

Screw the collet to the

plug housing until

Inditherm Service Manual

Diagram 3: Assembly for PS3

Once the 5 wires are soldered &

insulated correctly, slide the grey cable

Locating Pin

Slide the grey

washer ring up to

the blue ring.

Tighten up using

the collet spanner.

White Arrows

The screw and the locating pin should

be in line with the white arrows on the

plug housing. Push the plug insert into

the housing until a “click” is heard.

This means it is in place correctly. This

must stay in place for the rest of the

Grey Cable Grip

Screw

Locating Pin

Slide the collet up

to meet the black

The plug is now

complete

Patient Warming Systems Page 12 of 25 Rev 1.5; 21-09-07

Page 13

of the socket is underne

ath.

down the cable.

the grey cable grip.

and screw into housing.

the blue ring.

housing.

Please note correct order of

parts for complete assembly.

Tighten the

screw so the

cable is gripped

tight.

Next slide the grey

washer up to the blue

ring.

Using a multipurpose

silicon lubricant,

lightly spray around

Inditherm Service Manual

Diagram 4: Assembly for PS5

Once the wires

are soldered and

insulated

correctly, slide

the grey piece

Notch

Inlet

Place the socket insert

into the outer shell

housing, fit the housing

so that the small notch

fits into the inlet as

shown.

Ensuring all parts are held

together slide over the collet

Now slide the outer

case over the blue ring

and screw to the front

Screw

Cut out

Ensure the grey cable grip is

pushed up to the socket insert

and that no wires are visible.

Ensure the screw is facing

upwards and the cut out part

Holding all parts together

slide the blue ring up to

Once hand tight use the

collet spanner to tighten.

The socket is now

complete, if required

tighten outer casing with

a suitable sized spanner.

Patient Warming Systems Page 13 of 25 Rev 1.5; 21-09-07

Page 14

Inditherm Service Manual

plate

Control unit repairs

Ensure power is switched off & unplugged before opening the case

Open the case by removing five cross-head

(Pozidriv) screws on underside of case as shown.

Lift upper half of case upwards to separate from

lower half. Remove connector that connects

Case

securing

screws

ribbon cable from Display PCB (located in upper

case half) to Control PCB (in lower case half) at

the left side of the Control PCB. This separates the

upper and lower case halves.

Disconnect

ribbon cable

connector

Note: of the five screws, the top screw as pointed out

above is shorter than the other four and requires a long

nose screw drive (Pozidriv)

Replacing Clamp (MA4):

Clamp

mechanism

When the upper case half has been removed, the

clamp mechanism may simply be lifted out from the

upper case housing. When replacing the upper or

lower case half, the clamp mounting plate must also

be removed.

Replacing Display PCB Assembly (EA4):

Remove the four screws retaining the Display PCB into

the case upper half. Observing anti-static precautions

when handling the circuit board, remove it from the case.

Replace by reversing the above procedure.

Retaining

screws

Replacing Case Upper Half (MA2):

To replace the case upper half, remove clamp, clamp

mounting plate, unscrew handle and Display PCB as

described above, and re-fit components to new case.

Short screw

Case

securing

screws

Clamp

mounting

Patient Warming Systems Page 14 of 25 Rev 1.5; 21-09-07

Page 15

Inditherm Service Manual

Replacing Control Board Output Fuse (FU1):

The output fuse, FU1, can be replaced without removing

the Control PCB from the case lower half. Remove the

fuse from the plastic holder and replace with same rating.

Replacing Control PCB Assembly (EA3):

Disconnect the transformer and the output cable from the

PCB by un-plugging the two connectors. Observing antistatic precautions when handling the circuit board, slide it

upwards in the guide slots to remove it from the case.

Replace by reversing the above procedure.

Replacing Transformer Assembly (TR1):

Disconnect the transformer from the Control PCB by

removing the transformer connector as shown above.

Remove the four retaining screws, noting the position and

orientation of the mounting insulators under the lower rear

side of the transformer for later re-assembly.

Lift the transformer from its mountings and place carefully

beside the case, ensuring there is no strain on the

connecting wires, as shown.

Remove the cable loom plastic spiral binding, after noting

how the cables are retained for later re-assembly.

Remove the transformer input connections from the mains

on/off switch by pulling the crimp connectors off, taking

note of the cable orientation.

Replace by reversing the above procedure, taking care to

ensure connection orientations are correct, the cable loom

binding is replaced and the mounting insulators are

correctly positioned.

Fuse

holder

Transformer

connector

Output cable

connector

Mounting

insulators

Retaining

screws

Mounting

insulators

Mains switch

connections

Patient Warming Systems Page 15 of 25 Rev 1.5; 21-09-07

Page 16

Inditherm Service Manual

Replacing Power On/Off Switch (SW1):

Remove the transformer as described above.

Remove the remaining connections from the mains on/off switch by pulling the crimp connectors

off, taking note of the cable orientation.

Press down and hold the retaining tab on the top of the switch and push the switch outward through

the case.

Replace by reversing the above procedure, taking care to ensure connection orientations are correct.

Replacing Mains Power Cable (EA1):

Remove the transformer as described above.

Remove the input connections from the mains on/off

switch and the fuse holder by pulling the crimp connectors

off, taking note of the cable connections.

Cable

retention

Cable entry

Cut off the crimp terminals and lift the cable from the

retention slots to allow the cable to be pulled out through

the cable entry. Remove the cable.

Pass the new cable through the entry in the bottom of the

case. Strip back the outer insulation and prepare the wires.

Note that the system is double insulated and patient

isolated Type BF, therefore the earth connector is not used

and should be cut off flush with the outer insulation.

Crimp on the terminals and attach them in the same

locations as the removed cable. Pull any excess cable

back through the entry and retain the cable in the slots

provided, as shown.

Fuse holder

Patient Warming Systems Page 16 of 25 Rev 1.5; 21-09-07

Page 17

Inditherm Service Manual

Replacing Control Cable (EA6):

Open the case by removing the 5 screws underneath the control unit

as per Control Unit Repairs Section.

Remove the top half of the case by disconnecting the display

board ribbon cable from the main printed circuit board (PCB).

Remove the transformer by removing the 4 screws as per

Replacing the Transformer Section.

Slide out the PCB and remove it from the bottom half of the

case completely.

Using a pair of sharp side cutters, cut off the end of the hardwire

cable inside the case, so that the plastic housing is removed.

Make sure the plastic housing is discarded as this will be

replaced with a new one accompanied with the hardwire kit.

Patient Warming Systems Page 17 of 25 Rev 1.5; 21-09-07

Page 18

Inditherm Service Manual

Using a pair of long nose pliers, squeeze together the side tabs

on the inside of the plastic insert as shown.

This will enable the insert to “pop” out, thus enabling the rest of

the hardwire cable to be pulled through, and out of the case.

Pull the entire cable out of the case.

Using the new moulded insert from the kit, push into the front

of the case until flush with the front of the case, and the 2

prongs have clicked into position inside the case so it cannot be

pushed out.

Shown on the right is the correct way of how the insert should

look once inserted.

PULL

PUSH

INSERT LEGS IN PLACE

Patient Warming Systems Page 18 of 25 Rev 1.5; 21-09-07

Page 19

Inditherm Service Manual

plate

Once the insert is pushed in correctly, push the new hard wire

cable through the hole and route the wire left, around the

internal fuse as shown.

Each individual core (numbered 1-4 and earth) will need to be

pushed through the hole separately in order for the whole cable

to fit through.

Pull the cable through so that the start of the sheathing can touch

the back of the case.

Holding the plug housing, lip faced down; push the wires in

through the back slots from left to right, numbered 2, 1, 4, 3 and

earth in that order left to right respectively.

Once they are inserted, the one way barb should stop the crimp

being able to be pulled back out. This is fitted correctly.

Slide the PCB back into the case groves and connect the hard

wire plug housing to the board, lip face down.

NB. Make sure the plug housing is lined up correctly with the

pins on the PCB.

Wire 2 should be on HTR1, wire 1 on HTR2, then 4 on NTC1

and 3 on NTC2. The earth wire should be on the RB pin.

The installation of the hard wire kit is now complete.

The unit can be reassembled and tested to make sure that it

works correctly.

Once tested as being correct, screw the unit back together and

place back into service for use.

Replacing Case Lower Half (MA3):

To replace the case lower half, remove transformer,

Control PCB, Power on/off switch, output connector and

mains power cable as described above. Remove fuse

holder and clamp mounting plate and re-fit components to

new case.

Clamp

mounting

Patient Warming Systems Page 19 of 25 Rev 1.5; 21-09-07

Page 20

Inditherm Service Manual

TESTING THE SYSTEM:

Control Unit Tests:

Equipment required:

Inditherm mattress or blanket that is known to be working correctly.

Control cable (units without integral cable only).

Test Procedure:

Inspect the outside of the case, power cable and mains plug for any sign of damage. If any damage

is found, replace parts as appropriate.

With NO mattress or blanket connected, turn on the control unit. Check that the following occur:

• Power switch illuminates

• Display illuminates and a short beep sounds

• Display shows: “INDITHERM Vx.xxn” where “x.xxn” must be “2.03E” or later

• Unit cycles through checks (see Fault Finding section for details)

• Unit halts displaying “Connect Mattress/Blanket”

• Red alarm indicator illuminates

• A constant beep sounds

Connect a mattress or blanket that is known to be working. Check that the following occur:

• Message “Connect Mattress/Blanket” disappears

• Alarm indicator is no longer illuminated

• Continuous beep stops sounding

• Unit completes check cycle (see Fault Finding section for details)

• Display shows last temperature set with ^ to indicate warming up (e.g. ^ 40 C ^)

Press and hold Enable and Scroll buttons together and whilst holding press and release Alarm

Cancel/Reset button. The unit will re-start in Test Mode.

Allow the unit to cycle through the test sequence to the main menu.

Remove the mattress/blanket connector. Check the following occur:

• Unit halts displaying “Connect Mattress/Blanket”

• Red alarm indicator illuminates

• A constant beep sounds

Reconnect the mattress/blanket and check that the following occur:

• Message “Connect Mattress/Blanket” disappears

• Alarm indicator is no longer illuminated

• Continuous beep stops sounding

Patient Warming Systems Page 20 of 25 Rev 1.5; 21-09-07

Page 21

Inditherm Service Manual

Mattress/Blanket Test:

This testing procedure will establish that the mattress/blanket is functioning correctly. It is not

possible for the user to make accurate temperature measurements by any other means than the

procedure below, as these relate to the heating surface itself, which is sealed inside the

mattress/blanket. This accurate heating surface measurement is checked during manufacture and at

any time the mattress is serviced by Inditherm.

Test Procedure:

Press and hold Enable and Scroll buttons together and whilst holding press and release Alarm

Cancel/Reset button. The unit will re-start in Test Mode.

Ensure that Page 1 (Temperature Data) of Test Mode is selected; there are four pages as follows:

• Page 1 Temperature Data (This is the only page relevant for temperature testing)

• Page 2 Bad Data

• Page 3 Rail Data

• Page 4 Safety Timers

To move to the correct page if the unit has not defaulted to Page 1; whilst holding Enable button,

press and hold Scroll button until the page changes, continue until Page 1 Temperature Data is

shown.

Set Temperature

Actual Temperature

To check the actual temperature of the mattress / blanket against the temperature set there will be

two temperatures shown on the screen as follows:

• Top right hand corner is the set temperature

• Bottom right hand corner is the actual temperature of the mattress / blanket

Check that the temperature reading at the bottom right hand corner increases steadily until set

temperature has been achieved with a tolerance of ±1ºC.

Please Note: Whilst in Test Mode, when selecting set temperature, if scroll button is held for too

long the Test Mode page will change to Page 2, if this happens follow instructions above to return

to Page 1. Also when Test Mode is first selected the temperature will default to the lowest within

the range, to change the temperature press and hold enable button and select scroll button in the

normal way.

Patient Warming Systems Page 21 of 25 Rev 1.5; 21-09-07

Page 22

Inditherm Service Manual

System Test:

Connect mattress or blanket to control unit. Turn control unit power switch to On. Check that the

system performs start up checks correctly (see Fault Finding section).

Disconnect mattress or blanket and check error message is displayed and alarm sounds.

Re-connect mattress or blanket and check alarm stops sounding, error message is removed and

display shows temperature setting.

Perform an insulation breakdown and enclosure leakage (touch current) test and ensure results meet

regulation for Class II equipment.

Patient Warming Systems Page 22 of 25 Rev 1.5; 21-09-07

Page 23

Spares - Patient Warming Range

Product Description

Spares for Medical Control Unit & Cable

Case assembly, complete MA1

Case assembly, Top MA2

Case assembly, Bottom MA3

Clamp assembly MA4

Handle assembly MA6

Cable, mains power – United Kingdom EA1 (UK)

Cable, mains power – United States EA1(US)

Cable, mains power - Australia EA1(AU)

Cable, mains power – Japan EA1(JP)

Cable, mains power - Europe EA1(EU)

Inditherm Service Manual

Product

Code

Control cable assembly, complete EA2

Control PCB assembly EA3

Display PCB assembly EA4

Black connector & captive cable, hard wire kit EA6

Black connector for control cable PS5

Fuse Holder, mains power PS8

Power switch SW1

Fuse, T6.3A, control board FU1

Fuse, T1600mA, mains power FU2

Transformer assembly TR1

MECU1 front label LA1

Fuse label LA4

Serial Number / Address / CE label LA5

Power switch label LA6

Spares for Operating Room Warming Mattresses

Connector black plug for mattress PS3

Factory re-cover of OTM1 mattress SV1

Factory re-cover of OTM2 or GTM1 mattress SV2

Factory re-cover of PTM1 mattress SV3

Spares for Operating Room & Recovery Blankets

Connector black plug for blanket PS3

Factory re-cover of RB1 blanket SV4

Patient Warming Systems Page 23 of 25 Rev 1.5; 21-09-07

Page 24

Inditherm Service Manual

label)

EA1(UK)

MA6

EA1(JP)

(Power

EA1(US)

(Power

EA1(AU)

New Zealand)

EA1(EU)

LA

4

(Fuse

LA

6

MA2 (Case assembly, Top)

MA1 (Case assembly, complete)

MA3 (Case assembly, Bottom)

LA1

(Front

(Handle

EA3 (Control PCB assembly)

MA4 (Clamp assembly)

TR1 (Transformer assembly)

EA4 (Display PCB assembly)

(Power

switch label)

PS8 (Fuse holder)

EA6 (Hard wire kit)

SW1 (Power switch)

Cable - UK)

(Power

PS3 (Connector, plug)

PS5 (Connector, socket)

(Power

Cable – USA /

Canada)

Cable - Australia /

Cable - Japan)

(Power)

Cable - Europe)

Patient Warming Systems Page 24 of 25 Rev 1.5; 21-09-07

Page 25

Technical Specification:

Inditherm Service Manual

Mattress Construction:

Temperature Range:

Power: Control Unit:

Mattresses & Blankets:

Dimensions: Control Unit:

Mattresses & Blankets:

Cable Length:

Compliance:

Environmental:

Ambient Temperature (Operating):

Ambient Temperature (Storage):

Relative Humidity:

Inditherm® flexible polymer heating sheet, with 18mm viscoelastic

foam pressure relief pad under and 205g.m-2 expanded polyester

comfort lining over.

Encapsulated in latex-free, nylon fabric cover, with non-microporous

polyurethane coating, fully sealed with RF welded seams.

In-built temperature sensor and over-temperature thermal cut-out.

Connection cable, 20 cm long, with strain relief, fully sealed entry

grommet and IP61 rated waterproof connector.

Sensors and cables let into pressure relief pad for patient comfort.

37°C to 40°C (99°F to 104°F) in steps of 1°C (2°F)

Over-temperature safety cut-out at 43°C (109°F)

230 Vac, ±6%, 50Hz, or 110 Vac, ±6%, 60Hz

75 W

24 Vac (nom.)

25 W to 65 W, depending on size

160 x 240 x 230 mm

Type

OTM1

OTM2

GTM1

PTM1

OTB

RB1

Standard

1900 x 585 x 40 mm

1200 x 585 x 40 mm

1070 x 585 x 40 mm

560 x 500 x 40 mm

1070 x 500 x 40 mm

1660 x 800 x 40 mm

Narrow

1900 x 535 x 40 mm

1200 x 535 x 40 mm

1070 x 535 x 40 mm

Other dimensions available on request

4 m

EN60601-1, Class IIa, Type BF

EN60601-2

93/42/EEC, EEC Medical Devices Directive

73/23/EEC, EEC Low Voltage Devices Directive

15°C to 40°C (59°F to 104°F)

-10°C to 55°C (14°F to 131°F)

30% to 70%

Patient Warming Systems Page 25 of 25 Rev 1.5; 21-09-07

Loading...

Loading...