G

B

All the parts included in this document are the property of Indesit Company S.p.A.

All rights reserved. This document and the information it contains are supplied without liability for possi-

ble errors or omissions; no part of this document can be reproduced, used or copied without written

permission or without being authorised by the terms of a contract clause.

Service Manual

New Electronic Cold Platform 2005

Edition

2005.03.25

Language

English

SERVICE MANUAL

New Electronic Cold

Platform 2005.

SERVICE MANUAL

New Electronic Cold

Platform 2005.

G

B

2

Service Manual

New Electronic Cold Platform 2005

Edition

2005.03.25

Language

English

CONTENTS OF THE MANUAL: NOTE FOR THE ENGINEER

This manual is a supporting document for technical personnel. It contains a description of the various

product types, the general operating principle, and indications concerning assistance.

Technical personnel should anyway consult the specific model on

(www.servicenet.indesitcompany.com) to access data and updates of electrical diagrams, techni-

cal bulletins, and spare parts.

G

B

3

Service Manual

New Electronic Cold Platform 2005

Edition

2005.03.25

Language

English

CONTENTS

1. PRODUCT TYPE 4-6

Key 4

nterface 4

Energy Label 6

2. OPERATING LOGIC 7-29

Instructions for settings and operation 7-25

Thermodynamics 26-29

3. COMPONENTS 30-38

4. WIRING DIAGRAMS 39-47

Main PCB circuit diagram 39-41

Sensors diagram 42-46

Freezer wiring diagram 47

5. ASSISTANCE 48-63

Demo Mode 48

Auto Test (Testing / Running-in) 48

Faults and solutions 50-52

Troubleshooting 53

Removing No Frost Electronic Thermostat 54-60

Disassembling the Standard or Evolution Electronic Static Fridge-Freezer 61-63

6. EXPLODED VIEWS 64-72

7. APPENDICES73

Table of Sensors (Temperature / Impedance) 73

Table of Compressors 73

T

YPE

G

B

4

Service Manual

New Electronic Cold Platform 2005

Edition

2005.03.25

Language

English

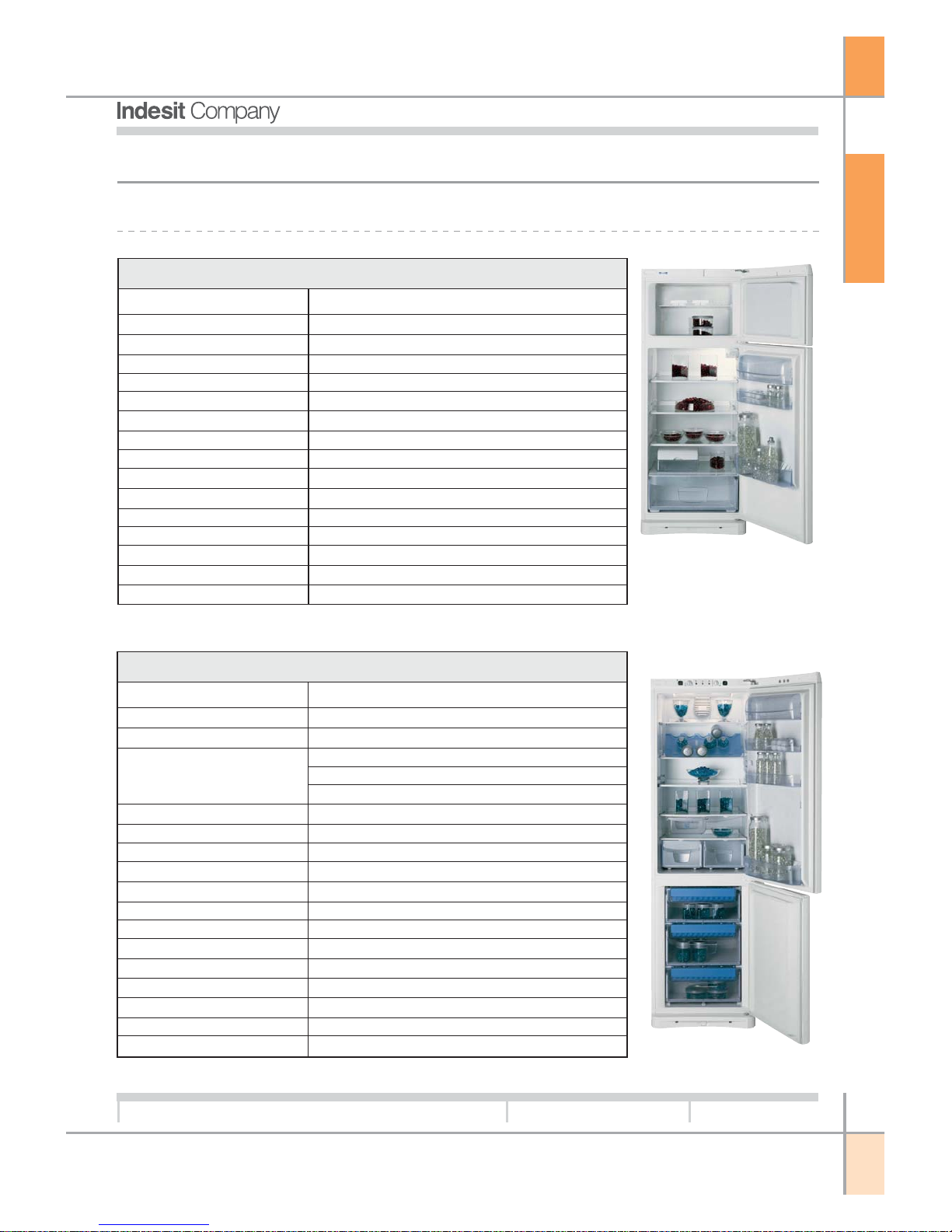

FRIDGE-FREEZER:

B Bottom freezer

B - A - AA - AAA Efficiency class

N New Platform

1st number 1= 1 compressor

2= 2 compressors

3= 1 compressor + Solenoid Valve or 1 compressor + Electronics

2nd number Height (0 =150, 2 =175, 3 =187, 4 =200)

3rd number only for 4-drawer freezer

4 levels in freezer

V Ventilated (also DGT for electronic models)

T Colour Teak

S Colour Silver

X Colour Stainless Steel

I Isobutane Gas (for classes A , B , C )

NF Full no frost

W Grilles

P Playzone

L Lock

G Graffiti

Final letters (EU,F, etc..) Intended markets

1. PRODUCT TYPE:

1.1. KEY TO INDESIT PRODUCTS:

DOBLE DOOR:

T Top freezer

B - A - AA - AAA Efficiency class

1st number only for NF Type NF ( 1= mechanical , 3= electronic)

number ( 2 - 25 - 3 - 4 ) Height (2 =150, 25 =167, 3 =175, 4 =187)

N New Platform

T Colour Teak

S Colour Silver

X Colour Stainless Steel

I Isobutane Gas (for classes A , B , C )

NF Full no frost

W Grilles

P Playzone

L Lock

V Ventilated

G Graffiti

Final letters (EU,F, etc..) Intended markets

T

YPE

G

B

5

Service Manual

New Electronic Cold Platform 2005

Edition

2005.03.25

Language

English

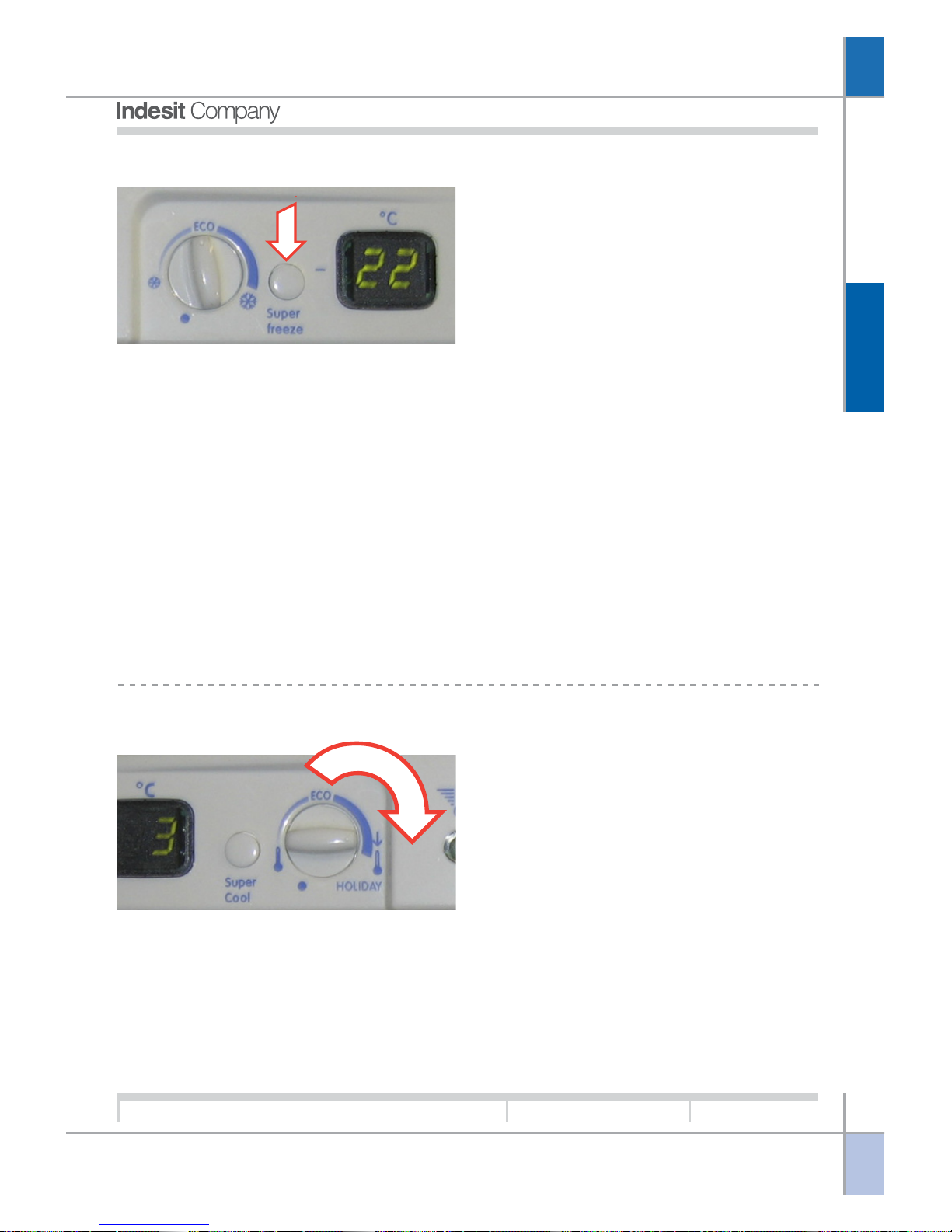

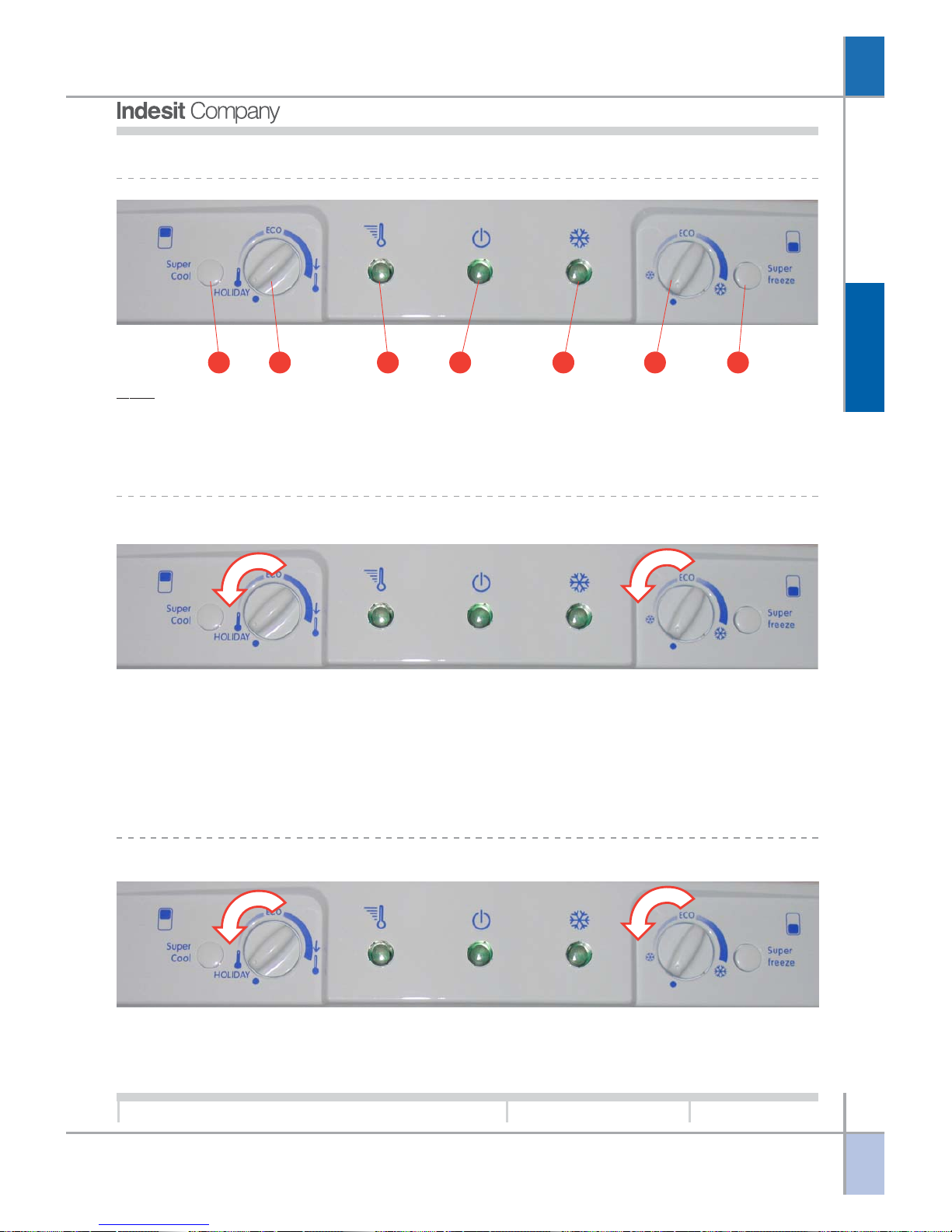

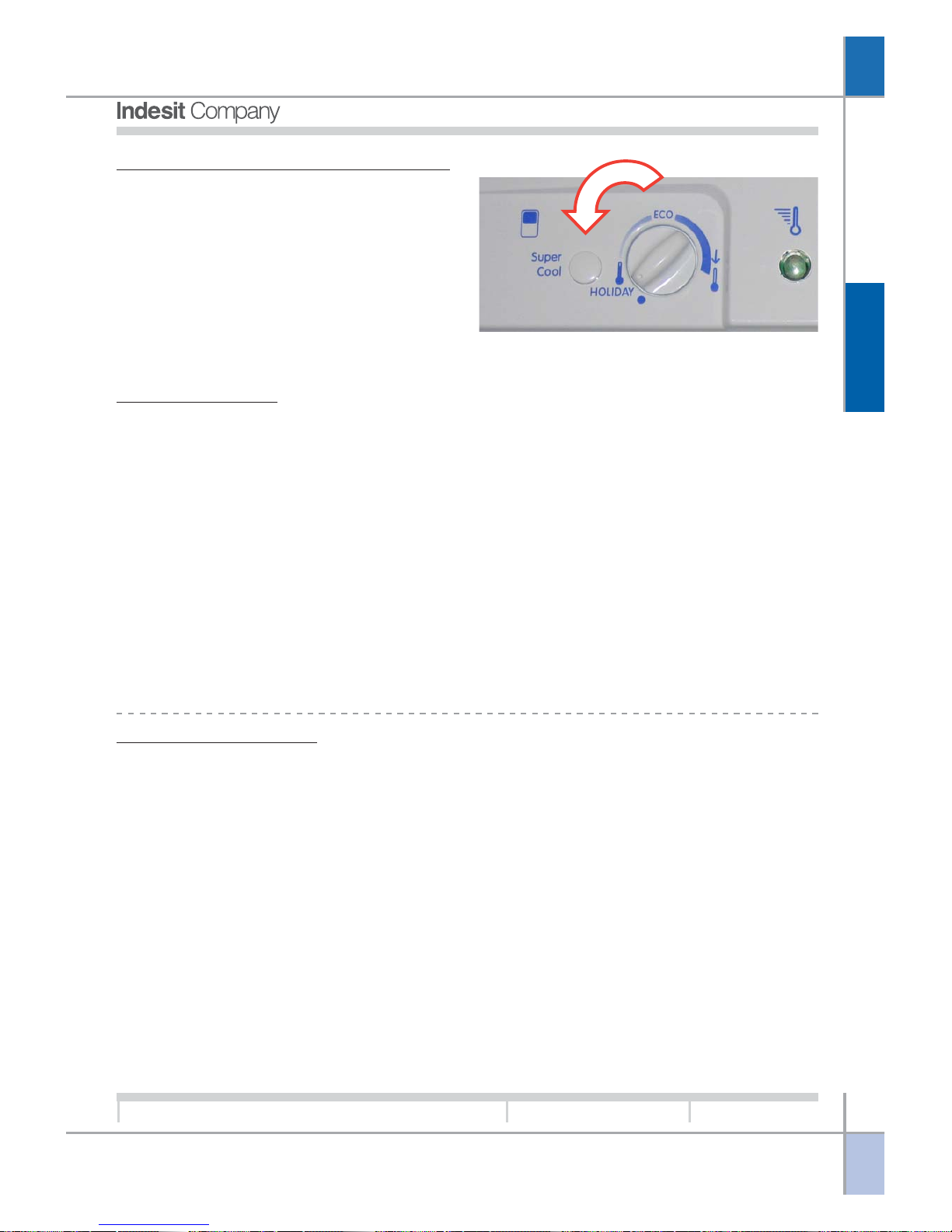

1.2. INTERFACE:

No Frost Fridge-freezer and Electronic Thermostat Double Door.

Basic Electronic Static Fridge-Freezer.

Evolution Electronic Static Fridge-Freezer.

Basic Electronic No Frost Fridge-Freezer.

T

YPE

G

B

6

Service Manual

New Electronic Cold Platform 2005

Edition

2005.03.25

Language

English

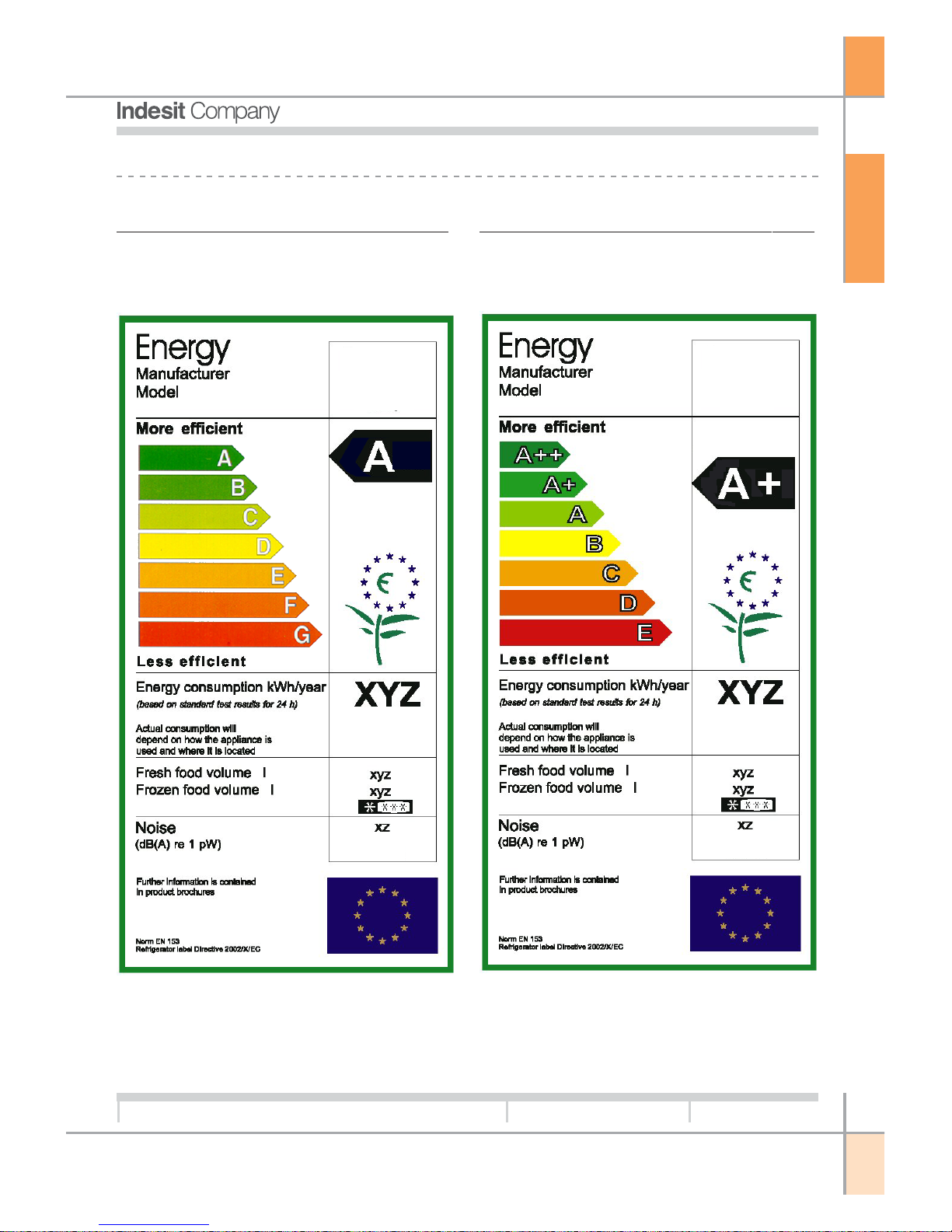

1.3. ENERGY LABEL:

Energy Label for products BAN or TAN:

Class “A” energy label

Energy Label for products BAAN or TAAN:

Class “A+” energy label

Indesit

BAN e TAN

2005

Indesit

BAAN e TAAN

2005

O

PERATION

G

B

7

Service Manual

New Electronic Cold Platform 2005

Edition

2005.03.25

Language

English

2. PRODUCT TYPE:

NO FROST FRIDGE-FREEZER AND ELECTRONIC THERMOSTAT DOUBLE DOOR.

The user interface is located on the fridge cabinet in Fridge-Freezer models and on the freezer

cabinet in Double Door models.

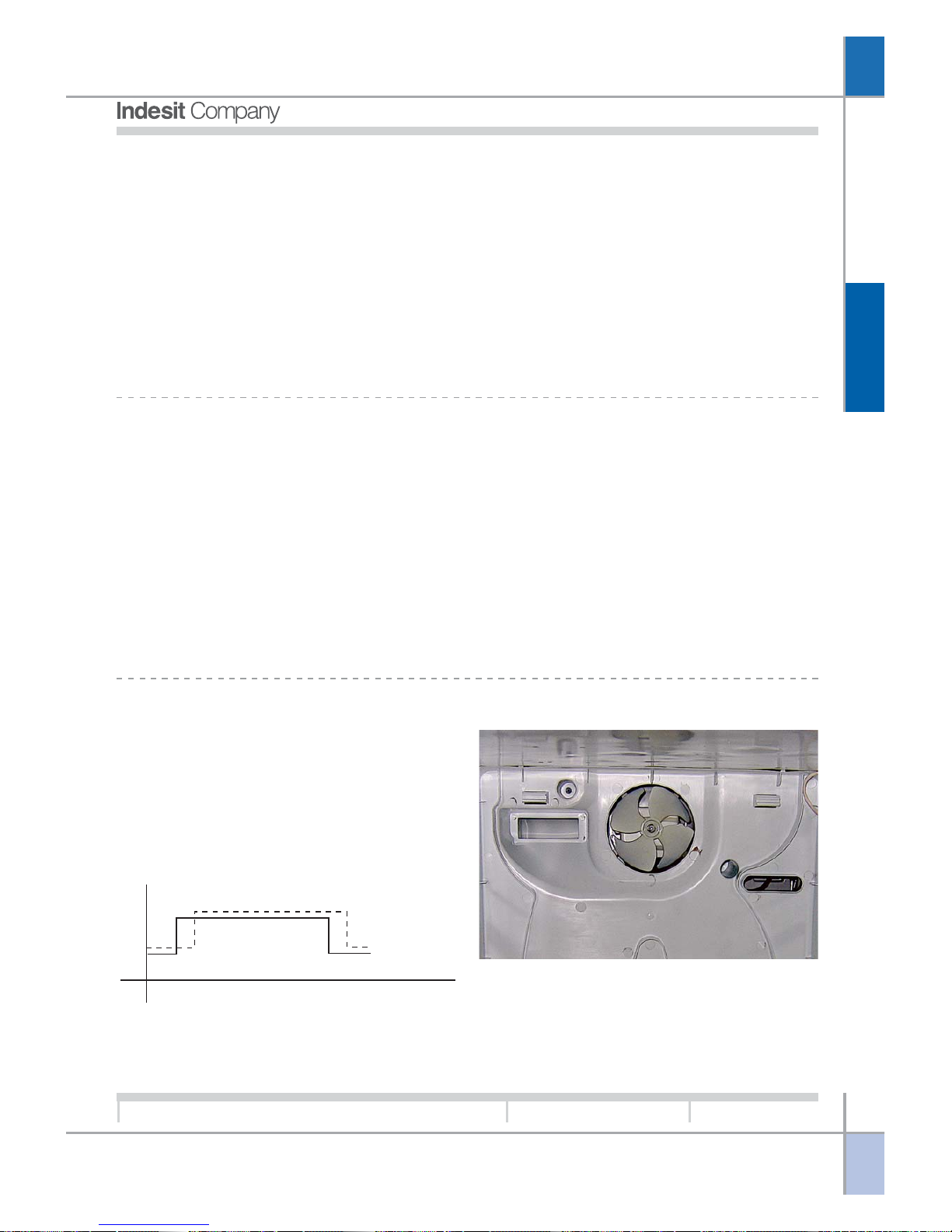

COMPRESSOR OPERATION:

The compressor serves to compress the gas in the

thermodynamic circuit in order to generate the necessary cooling capacity to chill the appliance compartments.

The compressor is managed by the Main PCB with

the aid of a relay and a triac that trips, in parallel

with the relay, only at the time of compressor poweron and power-off to protect the relay from electrical

arcing when the contact is opened and closed. The

compressor

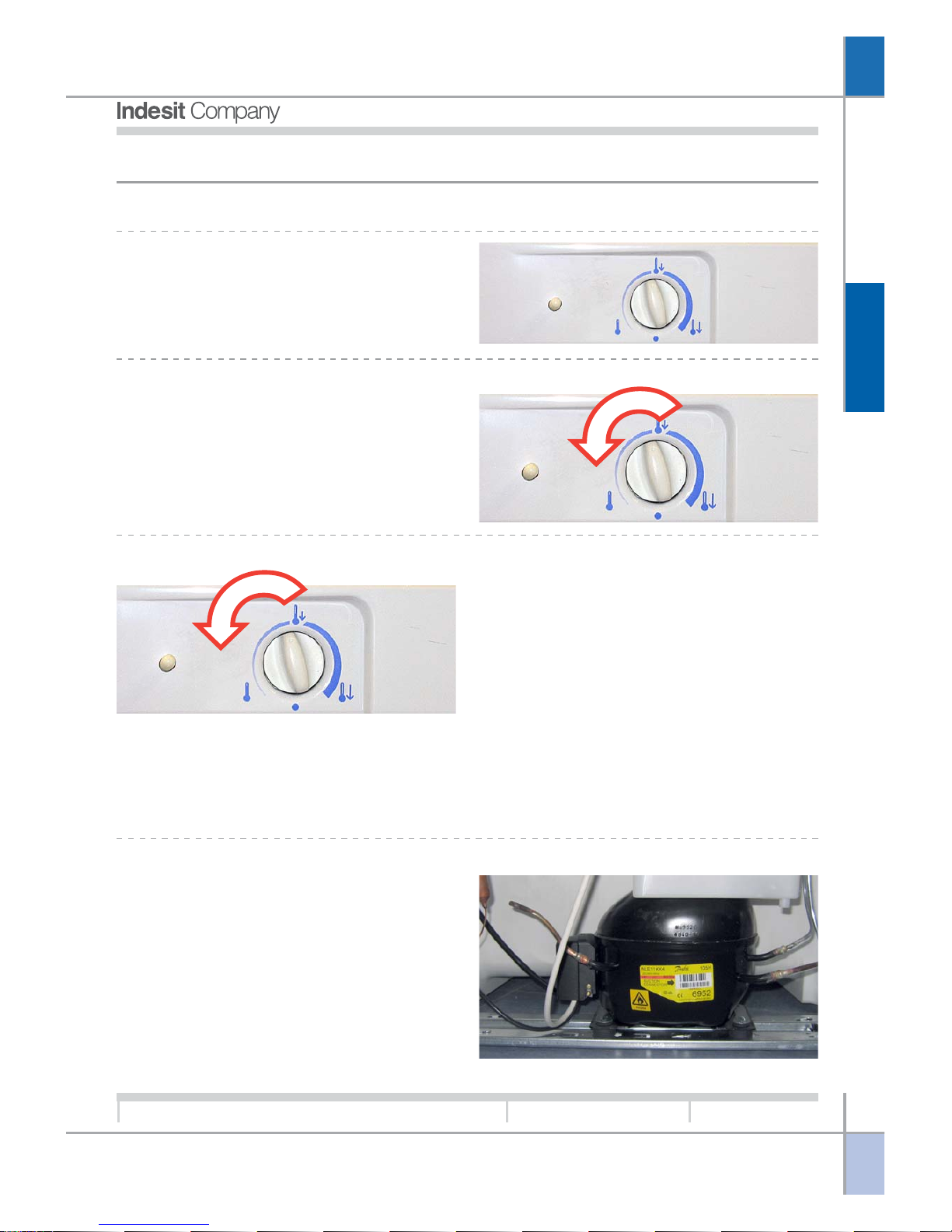

SWITCHING THE APPLIANCE OFF AND ON:

The appliance is switched Off when the knob is set

to Minimum. To switch on the appliance turn the knob

clockwise away from the Minimum position (appliance OFF). Turn the knob counterclockwise to the

Minimum position to switch off the appliance.

TEMPERATURE ADJUSTMENT:

ture. The refrigerator compartment temperature is

controlled by a mechanical damper located on the

multiflow unit. The damper enables cold air from the

evaporator coil to cool the refrigerator compartment.

Temperature adjustment is performed in accordance

with specific rules if the following conditions occur:

• Temperature detected by PCB sensor (on the

board) is between two values parameterised in

the EEPROM memory;

• The time that has elapsed from the last time the

door was opened is greater than the relative parameter stored in the EEPROM memory;

• The compressor power-on time is lower than the

parameter stored in the EEPROM;

The freezer compartment temperature is adjusted

by the electronic PCB. To set a lower temperature

turn the knob clockwise, turning the knob

counterclockwise gives a higher temperature. The

refrigerator compartment temperature depends on

the adjustment of the freezer compartment tempera-

O

PERATION

G

B

8

Service Manual

New Electronic Cold Platform 2005

Edition

2005.03.25

Language

English

OFF

ON

Ventola Freezer

Compressore

FREEZER FAN OPERATION:

The freezer van is located in front of the evaporator

coil and is designed to distribute the cold air produced by the evaporator coil uniformly inside the

freezer compartment.

The freezer fan is managed by the PCB and is

switched on/off after a preset time interval that is

parameterised in the EEPROM after a compressor

start/stop.

The defrost procedure is preceded by activation of

the fan for a time interval that is parameterised in

the EEPROM memory.

switches on whenever a demand for cooling is received.

There are situations of cooling demand in which the

compressor remains off. These are as follows:

1. Compressor protection: the compressor switches

on once a minimum safety time lag has elapsed

since the last power-off, thereby allowing gas

pressure to reach a point of equilibrium in the

refrigerant circuit. The same minimum safety time

is observed in the event of a mains power interruption (voluntary or involuntary). This compressor protection strategy is observed only after the

product has been operating continuously for the

number of hours defined in the EEPROM memory.

This facilitates the execution of factory tests.

2. Long periods of activity: if the compressor remains

on for more than a value set in EEPROM memory

it is switched off, even in the presence of a cooling demand.

3. Pause after defrost: at the end of the defrost cycle the compressor observes a protection time

parameterised in the EEPROM so that the water

formed during the defrost can be completely

drained.

DEFROST AND DRIP TRAY HEATING ELEMENTS:

There are two defrost heating elements connected

in parallel and controlled by the Main PCB:

The defrost heating element, which serves to melt

any ice that has formed on the evaporator coil that

could have a negative effect on the thermal exchange

between the evaporator and surrounding air.

The drip tray heating element, which is designed to

melt any ice that detaches from the evaporator.

In addition, the drip tray heating element prevents

blockage of the pipe that transfers the water from

the drip tray to the drain tube.

During the defrost cycle the compressor is switched

off, even in the presence of a cooling demand from

the freezer compartment. The heating elements are

switched off by means of a thermal protection (closed

when the appliance is cold and open when it is hot).

The parameters utilised to start the defrost cycle are

as follows:

1. Compressor ON time since last defrost cycle.

2. Duration of last defrost cycle; if the duration of

the last defrost cycle was short, the next defrost

cycle will be longer, and vice versa.

3. Duration of doors open condition.

After the defrost cycle the fan starts after a time interval following a compressor start, also this interval

is parameterised in the EEPROM memory;

thi}Ëinterval is different from the interval programmed

for normal operating conditions.

O

PERATION

G

B

9

Service Manual

New Electronic Cold Platform 2005

Edition

2005.03.25

Language

English

FRIDGE LAMP OPERATION:

FAULT MANAGEMENT:

The refrigerator lamp is located inside the multiflow

unit. The Fridge-Freezer appliance has one lamp

while the Double Door appliance has two lamps. The

lamps are controlled by a triac on the PCB, and

switch on when the fridge door is open (assuming

the appliance is switched on). If the door remains

open for a time period that is greater than the time

interval stored in the EEPROM memory, the lamp

will start flashing and continue until the door is

closed.

The appliance is designed to recognise faults, specifically those relative to the temperature sensors and the

EEPROM memory.

For faults of this type there are various alternative operating modes that can be activated to allow the

appliance to continue to function normally.

Normal operation of the appliance will resume after mains power has been disconnected and reconnected

(if the problem persists the appliance will resume alternative mode operation).

FRIDGE DOOR OPEN:

If the door remains open for a prolonged time period the fridge lamp flashes at regular intervals. Close the

door to reset the alarm.

FREEZER AIR SENSOR FAULT:

In the event of a fault of the freezer air sensor, the

appliance will no longer be able to execute thermostatic control with the parameters set in the EEPROM

memory.

The appliance will continue to function controlled by

the main PCB, which assumes timer control of operation in accordance with the temperature set by

the user and parameters stored in the EEPROM

memory.

O

PERATION

G

B

10

Service Manual

New Electronic Cold Platform 2005

Edition

2005.03.25

Language

English

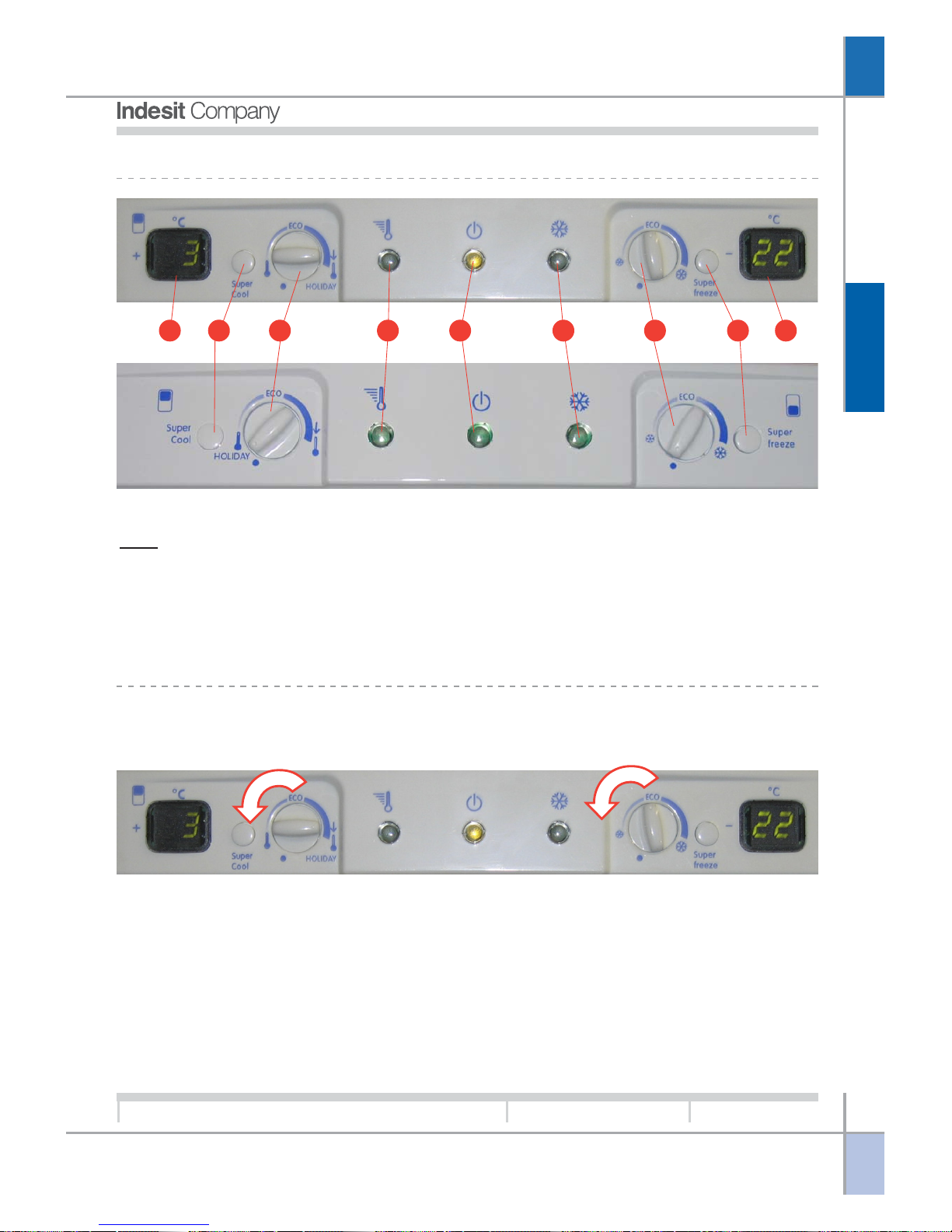

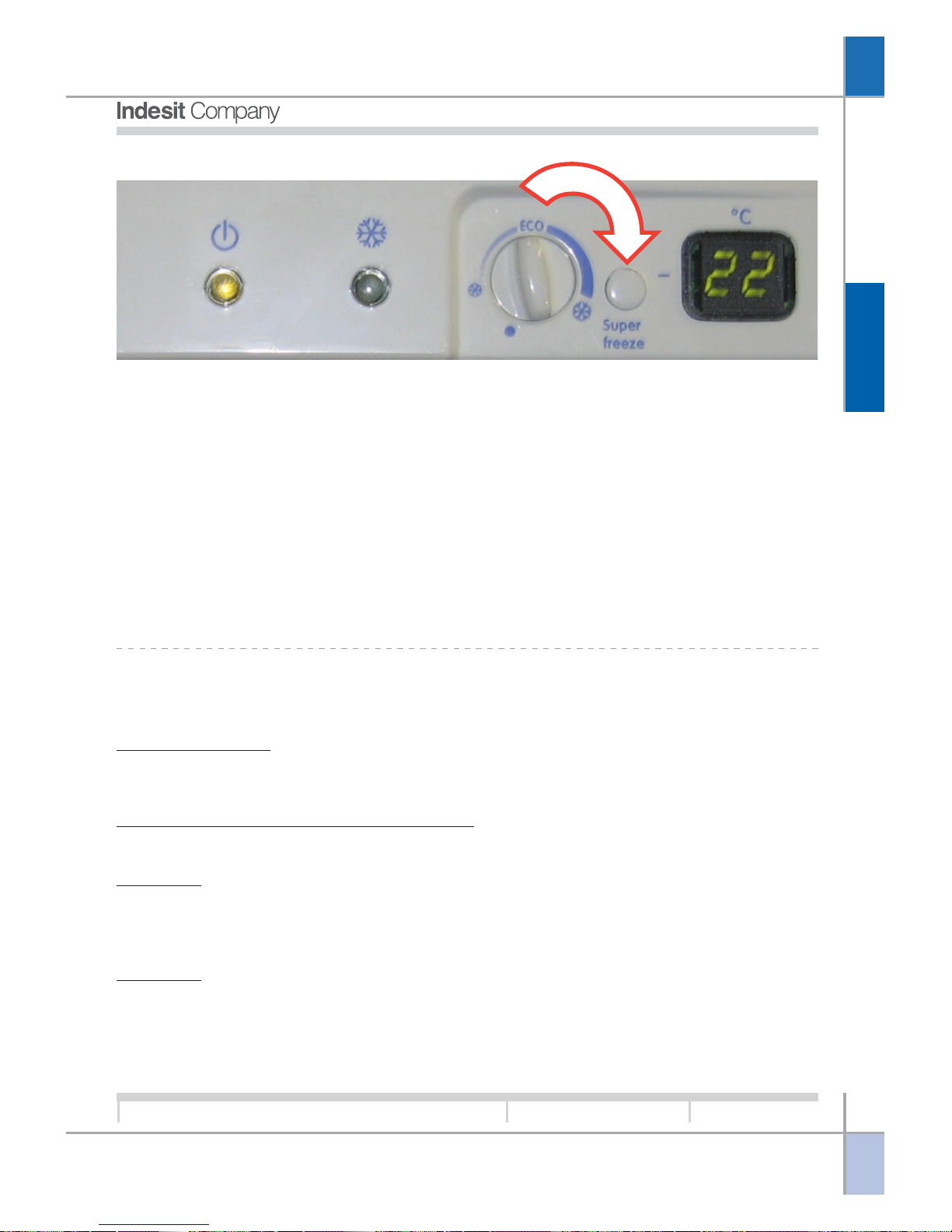

BASIC ELECTRONIC STATIC FRIDGE-FREEZER AND EVOLUTION MODEL.

Key:

1. SUPER FRIDGE button.

2. FRIDGE knob.

3. SUPER FRIDGE LED.

4. Power indicator LED.

5. SUPER FREEZER LED.

6. FREEZER knob.

7. SUPER FREEZER button.

8. FRIDGE temperature display. (7-segment)

9. FREEZER temperature display. (7-segment)

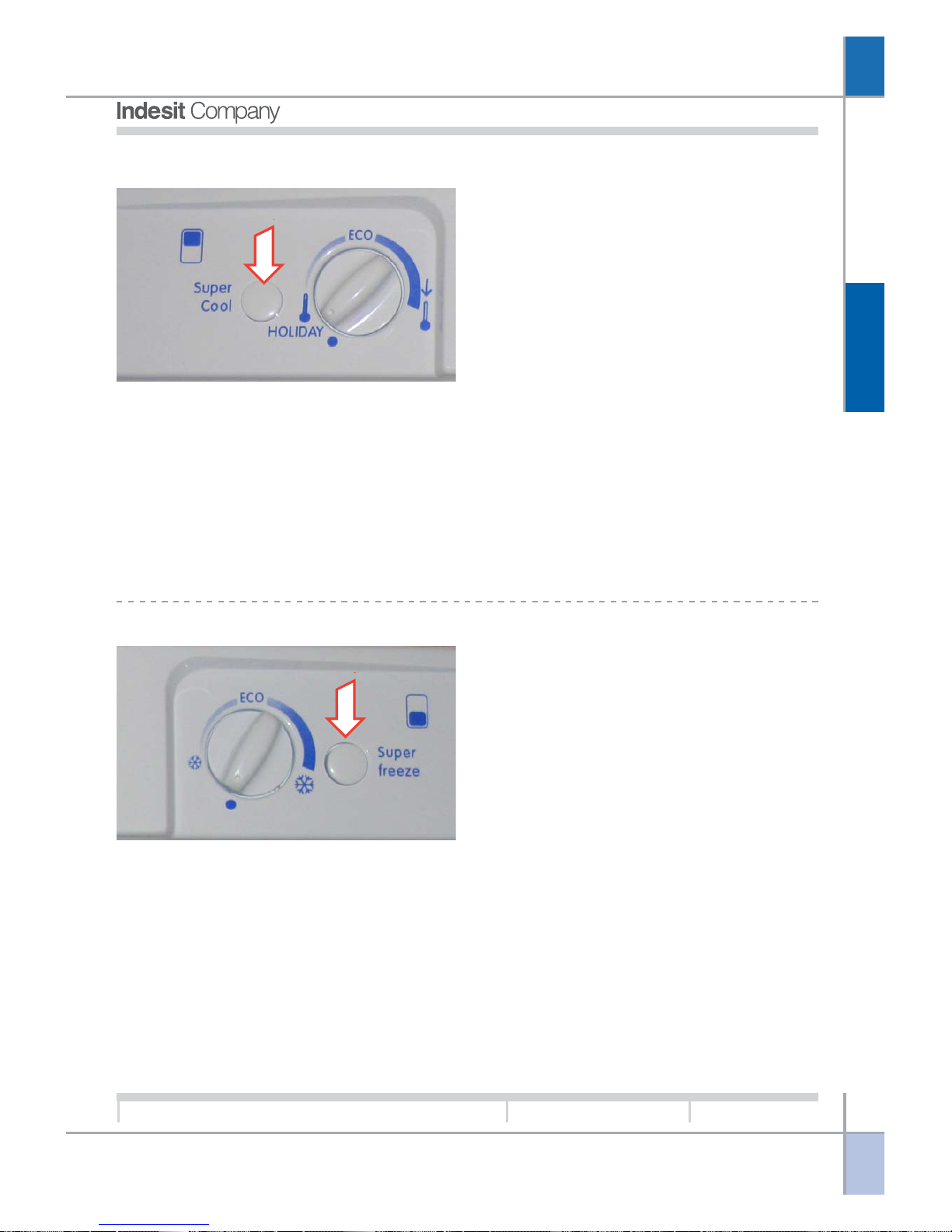

SWITCHING THE APPLIANCE OFF AND ON:

The appliance is Off when the freezer compartment

knob (6) is set to Minimum.

To switch the appliance on turn the freezer knob

clockwise, away from the Minimum position.

To switch it off turn the knob counterclockwise to the

Minimum position. All active functions are deactivated when the appliance is switched off. If the appliance is On and the refrigerator compartment knob

(2) is set to minimum, the refrigerator compartment

is Off.

To switch on the refrigerator compartment, turn the

knob clockwise away from the Minimum position; to

switch it off turn the knob counterclockwise to the

Minimum position. If the SUPER COOL function is

active it will be automatically deactivated by switching the refrigerator compartment off.

1 2 3 4 5 6 78 9

O

PERATION

G

B

11

Service Manual

New Electronic Cold Platform 2005

Edition

2005.03.25

Language

English

TEMPERATURE SETTING:

Turn the refrigerator knob (2) or freezer knob (6)

clockwise to decrease the temperature or

counterclockwise to increase the temperature until

reaching the minimum position; when the refrigera-

tor knob is set to minimum the refrigerator compartment will be switched off, while setting the freezer

knob to minimum switches off the entire appliance.

“SUPER COOL” FUNCTION:

TEMPERATURE DISPLAYS (7–SEGMENT):

The displays serve to show the user temperature

setting for the refrigerator compartment and the

freezer compartment in accordance with the position of the knob. Freezer compartment temperature

is from -18°C to -26°C, while refrigerator compartment temperature is from +3°C to +8°C. If either the

refrigerator or freezer is switched off, the display (7–

segment) will remain blank.

This function allows optimal chilling of large quantities of food in the refrigerator compartment by altering the refrigerator On and Off set-points in accordance with parameters stored in the EEPROM

memory.

Activating this function forces the fridge fan, which

starts after a time parameterised in the EEPROM

memory, to run continuously to obtain the maximum

cooling capacity in the refrigerator compartment. The

SUPER COOL function cannot be activated if either

of the two freezer temperature alarm conditions is

active. Activation of an alarm mode or switching off

the appliance or only the refrigerator compartment

automatically causes this function to be deactivated.

Press button (1) to activate the function. In the case

of the basic interface LED (3) will illuminate confirming activation of the function. Deactivation of the

SUPER COOL function can be performed by the

user pressing the relative button again, or will occur

automatically at the end of the procedure (number

of cycles) as defined in the EEPROM memory.

If the appliance is equipped with the Digit interface,

the relative 7-segment display will show temperature 1 until deactivation of the function, at which point

the display will return to the temperature value set

on the freezer knob. The user can also activate the

ECO or HOLIDAY functions, which will become operational as soon as the SUPER COOL function has

been deactivated The SUPER COOL function cannot be selected if the HOLIDAY function is active. In

case of electrical power failures the function is resumed automatically when power is restored, completing the remaining cycles except in the presence

of a temperature alarm

O

PERATION

G

B

12

Service Manual

New Electronic Cold Platform 2005

Edition

2005.03.25

Language

English

This function provides optimal freezing of food in the

freezer compartment, conserving properties of texture and flavour.

Activating this function forces the compressor run

continuously thereby obtaining maximum freezing

power in the freezer compartment.

There are two modes: SUPER FREEZE 24h, which

is used for freezing small quantities of food (this function should ideally be activated immediately before

before placing the food in the compartment).

The SUPER FREEZE function is activated by pressing button (7); this will cause LED (5) to illuminate to

confirm that the function is active. The second mode

is SUPER FREEZE 48h, which is activated by holding down button (7); this function is used for freez-

ing large quantities of food (should be activated 24h

before placing the food in the compartment). In this

case LED (5) will flash for the first 24 h and then

remain steadily illuminated for the second 24 h period. If the appliance is equipped with the Digit inter-

face, the temperature of -35 °C will be displayed on

the 7-segment display until the function is deactivated, at which point the LED will extinguish and the

value set on the freezer knob will be shown on the

display.

The function cannot be activated in the presence of

alarm signals. Activation of an alarm mode or switching off the appliance automatically causes this function to be deactivated. This mode can be deactivated

by pressing the relative button again. The function is

deactivated automatically when the maximum time

has elapsed (24 or 48 hours) or, in the case of 24 h

mode, once a given temperature has been reached

and maintained for a time interval parameterised in

the EEPROM memory.

The ECO or HOLIDAY functions can be selected,

although they will only become operational when the

SUPER FREEZER function has terminated.

In case of electrical power failures the function will

be reactivated automatically when power is restored,

completing the remaining hours, unless a temperature alarm occurs in this interval.

SUPER FREEZER FUNCTION:

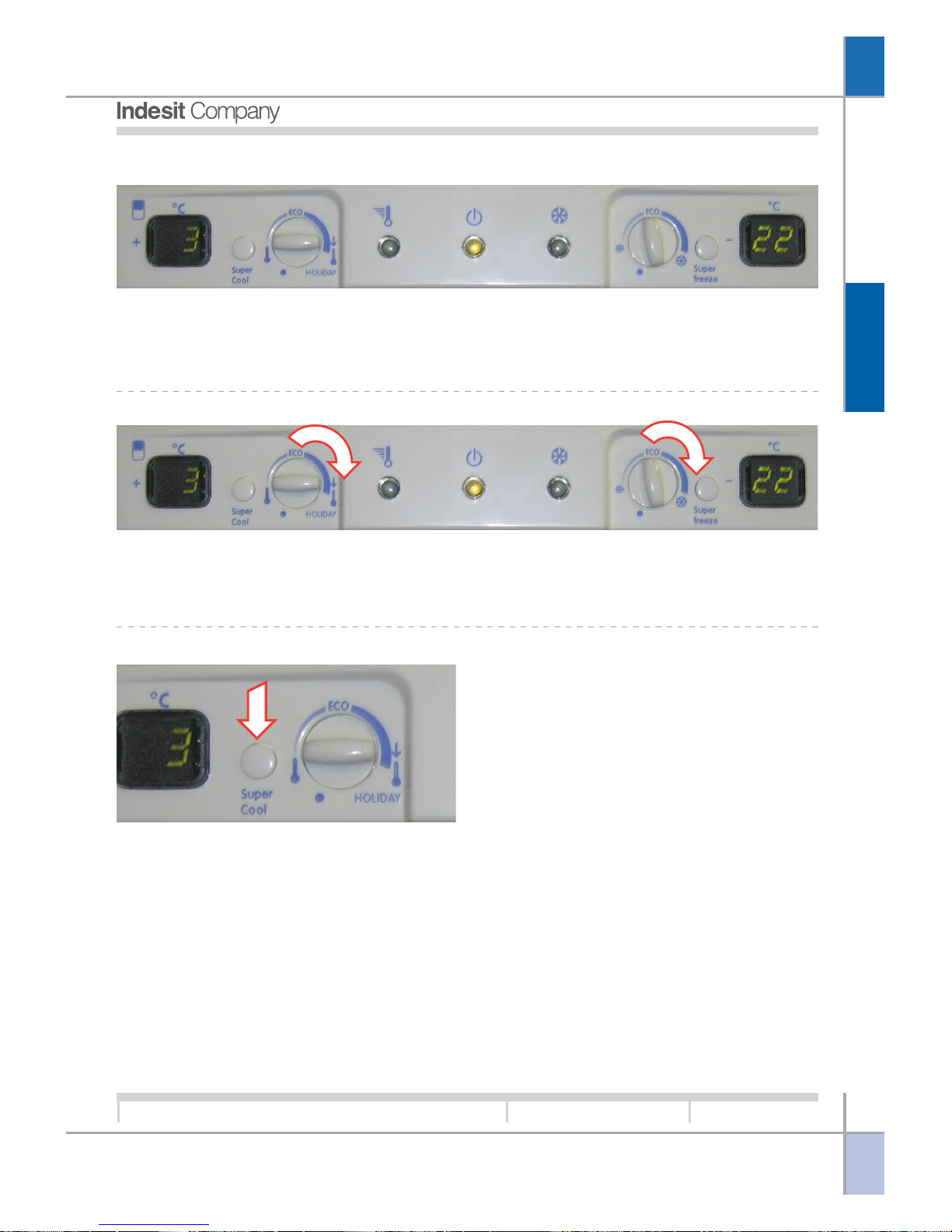

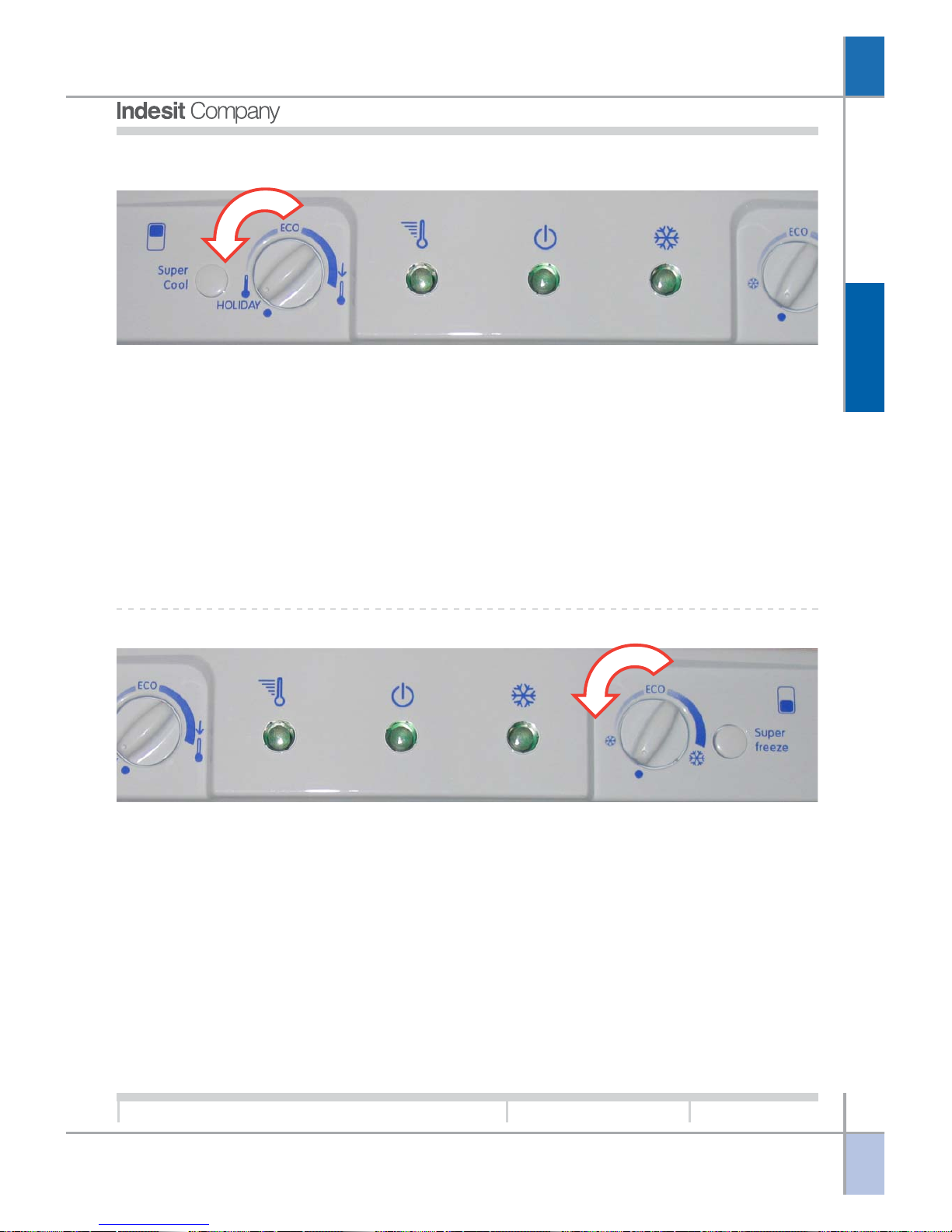

HOLIDAY FUNCTION:

In case of minimum use of the refrigerator compartment this function makes it possible to store food

while reducing power consumption to the minimum

(E.g. during holiday periods the freezer can remain

full and the refrigerator empty). The function is activated by turning the refrigerator knob (2) to the

HOLIDAY setting (a double beep will sound to indi-

cate that the function is active). To deactivate the

function move the knob away from the HOLIDAY

position (the appliance will emit a single beep) or

switch off the refrigerator compartment or the entire

appliance. The HOLIDAY function cannot be activated when alarms are present. Since the two functions are not compatible it is not possible to select

the SUPER COOL or SUPER FREEZER functions

if the knob is set to HOLIDAY. If these two functions

are already active when the HOLIDAY function is

selected, SUPER COOL and SUPER FREEZER will

be terminated normally, after which the HOLIDAY

function will start. If one or more of the sensors is

faulty, the function will be controlled by the main PCB

utilising alternative parameters. In case of electrical

power failures the function will be reactivated automatically when power is restored.

O

PERATION

G

B

13

Service Manual

New Electronic Cold Platform 2005

Edition

2005.03.25

Language

English

ECO FUNCTION:

ALARMS MANAGEMENT:

Alarms serve to notify the user of specific conditions such as: prolonged opening of fridge door; excessively

high temperature in freezer compartment.

Door Open Alarm:

If the fridge door is kept open for a time longer than that defined by a parameter set in EEPROM memory,

an audible signal is emitted and the fridge lamp flashes at regular intervals. Close the door to reset the

alarm.

Freezer Compartment Temperature Alarm:

There are two types of alarms that can be generated if the freezer compartment temperature rises excessively:

Alarm A1:

In this case it is still possible to recover the food in the freezer by cooking it immediately and either consuming it or re-freezing it once cooked.

LEDs 3 and 5 flash on the appliance control panel to indicate the presence of the alarm (if the refrigerator

is equipped with the Digit interface the message A1 is displayed on the freezer temperature display).

Alarm A2:

In this case the food in the freezer compartment must be discarded. LEDs 3, 4 and 5 flash on the appliance

control panel to indicate the presence of the alarm (if the refrigerator is equipped with the Digit interface the

message A2 is displayed on the freezer temperature display).

At the same time an audible signal is emitted by the beeper during both alarm modes.

This function allows storage of food with the lowest

possible power consumption while ensuring excellent results. The ECO function can be activated by

turning the refrigerator (2) and freezer (6) knobs to

the ECO setting. To deactivate the function simply

turn one of the two knobs away from the ECO setting. The compressor starts in the presence of a

cooling demand from either of the two compartments.

To optimise operation of the appliance there is a fixed

time setting for operation of the freezer at the end of

a refrigerator cooling demand by means of a switch

over of the relative solenoid valve without having to

disconnect the compressor.

Normally, the ECO function adjustment corresponds

to the adjustment utilised to calculate power consumption in compliance with European regulations.

The function cannot be activated in the presence of

alarm signals.

The SUPER FREEZER and SUPER FRIDGE functions can be activated when the ECO function is set.

These functions will assume priority over the ECO

function. The appliance returns to ECO function

mode once the conditions are met to deactivate the

priority procedure. If one or more of the sensors is

faulty, the appliance will be controlled by the main

PCB utilising alternative parameters. In case of electrical power failures the function will be reactivated

automatically when power is restored.

O

PERATION

G

B

14

Service Manual

New Electronic Cold Platform 2005

Edition

2005.03.25

Language

English

In alarm status the appliance forces operation utilising specific On / Off parameters that control the temperature in the freezer compartment at specific values depending on the type of alarm. To reset the alarm

and restore normal operation, the appliance must be set to LOGICAL OFF (freezer knob set to minimum).

Control of freezer compartment temperature is continuous during operation of the appliance, by means of

the freezer air temperature sensor; this control will proceed even if the appliance is in one of the two

available alarm conditions. In the event of a freezer air sensor fault, the alarms will no longer be displayed.

Temperature control is not performed for a time parameterised in the EEPROM memory to prevent false

alarms both during the testing process and at the time of power-on immediately after the appliance has

been purchased.

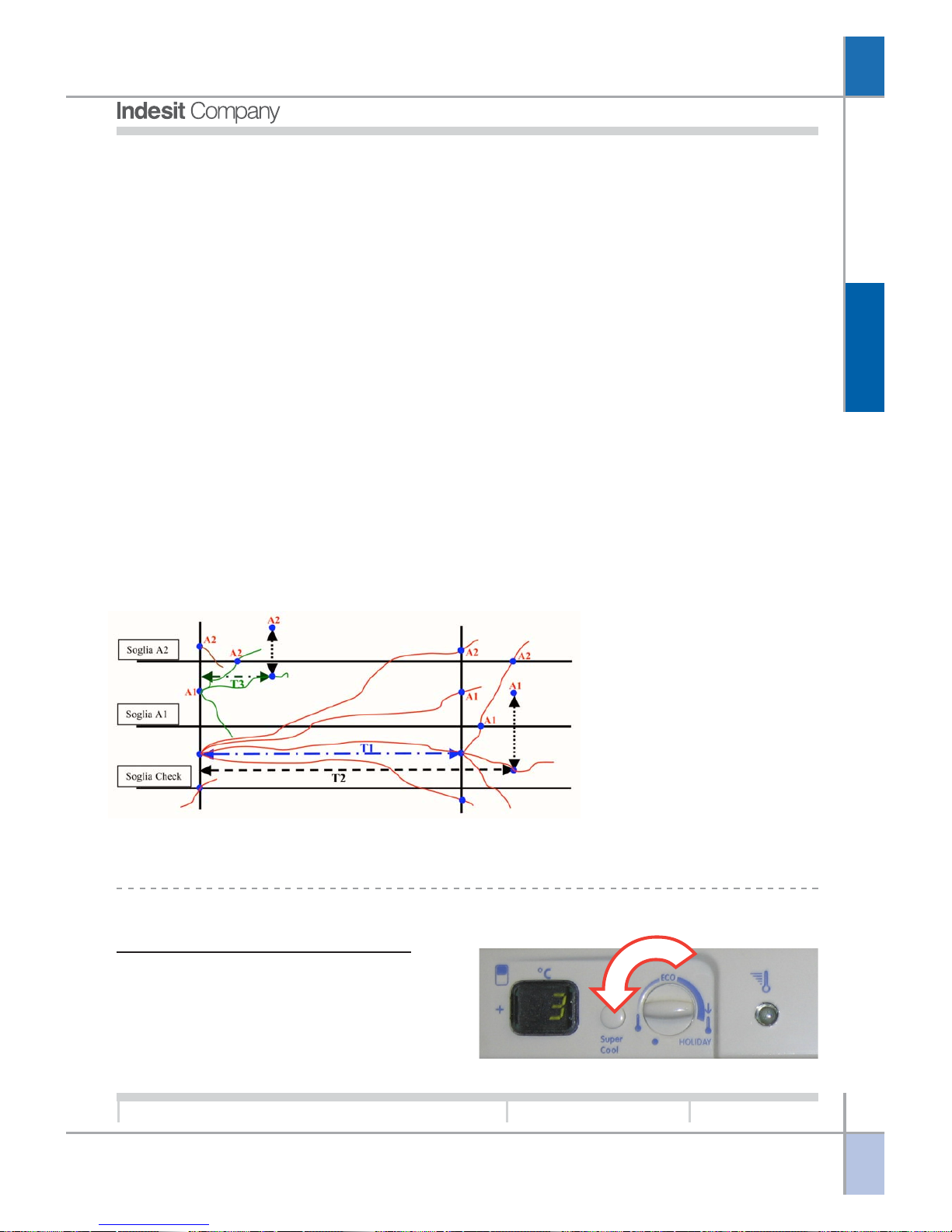

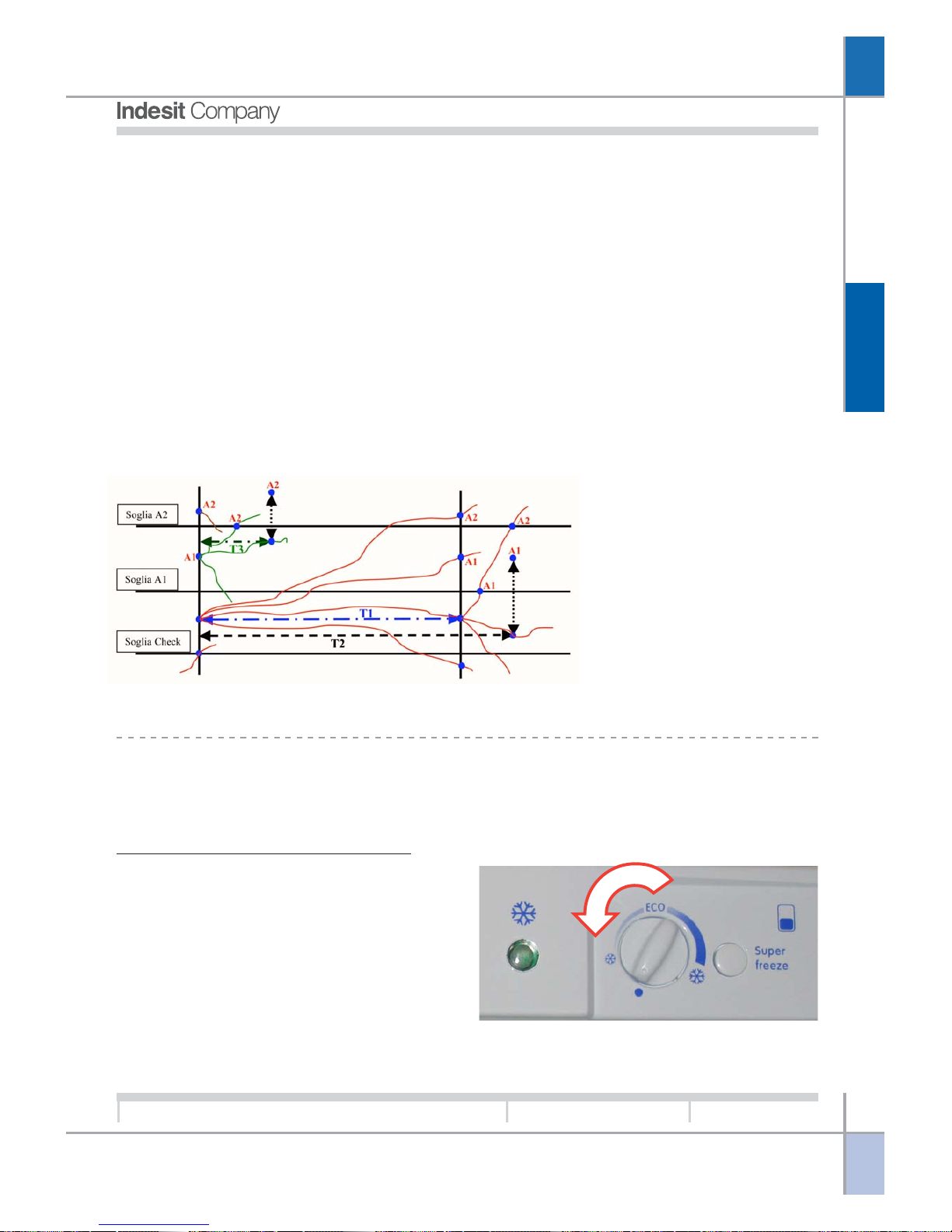

Temperature control and alarm signalling are managed by means of three thresholds: Check Threshold

(the control strategy becomes more intensive when this threshold is exceeded); Threshold A1: when exceeded, alarm A1 is activated; Threshold A2: when exceeded, alarm A2 is activated. The values of the three

thresholds are parameterised in the EEPROM memory.

If the control temperature exceeds the Check Threshold but does not exceed the A1 Alarm threshold, a

delay time T1 is activated (parameterised in the EEPROM) before performing the next control, to prevent

the generation of alarm signals when the placement of large quantities of warm food in the freezer compartment near the freezer air sensor causes unreliable transient temperature readings. At the same time another time interval T2 is activated (parameterised on the EEPROM) after which, if the temperature is constantly maintained between the Check Threshold and the Alarm A1 Threshold, alarm A1 is forced because

the persistence of a temperature in this range for this period of time is anyway a symptom of faulty operation

and constitutes a risk for the correct preservation of the food.

At the time of activation of alarm A1 also a time interval T3 is activated (parameterised in the EEPROM)

after which, if an alarm reset has not been executed, alarm A2 is forced, since in the situation of alarm A1

the freezer compartment is set to a temperature that may not be the same as the temperature selected by

the user. This time interval is reset also when power is restored after a mains power failure.

THERMOSTAT CONTROL.

The temperature adjustments in both the compartments are independent from each other and set individually by the relative knobs.

Freezer Compartment Adjustment:

8°C

-6°C

2°C

T1 = 2 1/2 Hours

T2 = 24 Hours

T1 = 120 Hours

N. B.: The time and temperature values shown in this graph are EEPROM parameters and as such they are subject to modification

Freezer temperature is managed by the PCB utilising

the value detected by the freezer air sensor to switch

the compressor on/off.

The On / Off threshold is detected by the EEPROM

and it depends on the user setting.on the interface.

O

PERATION

G

B

15

Service Manual

New Electronic Cold Platform 2005

Edition

2005.03.25

Language

English

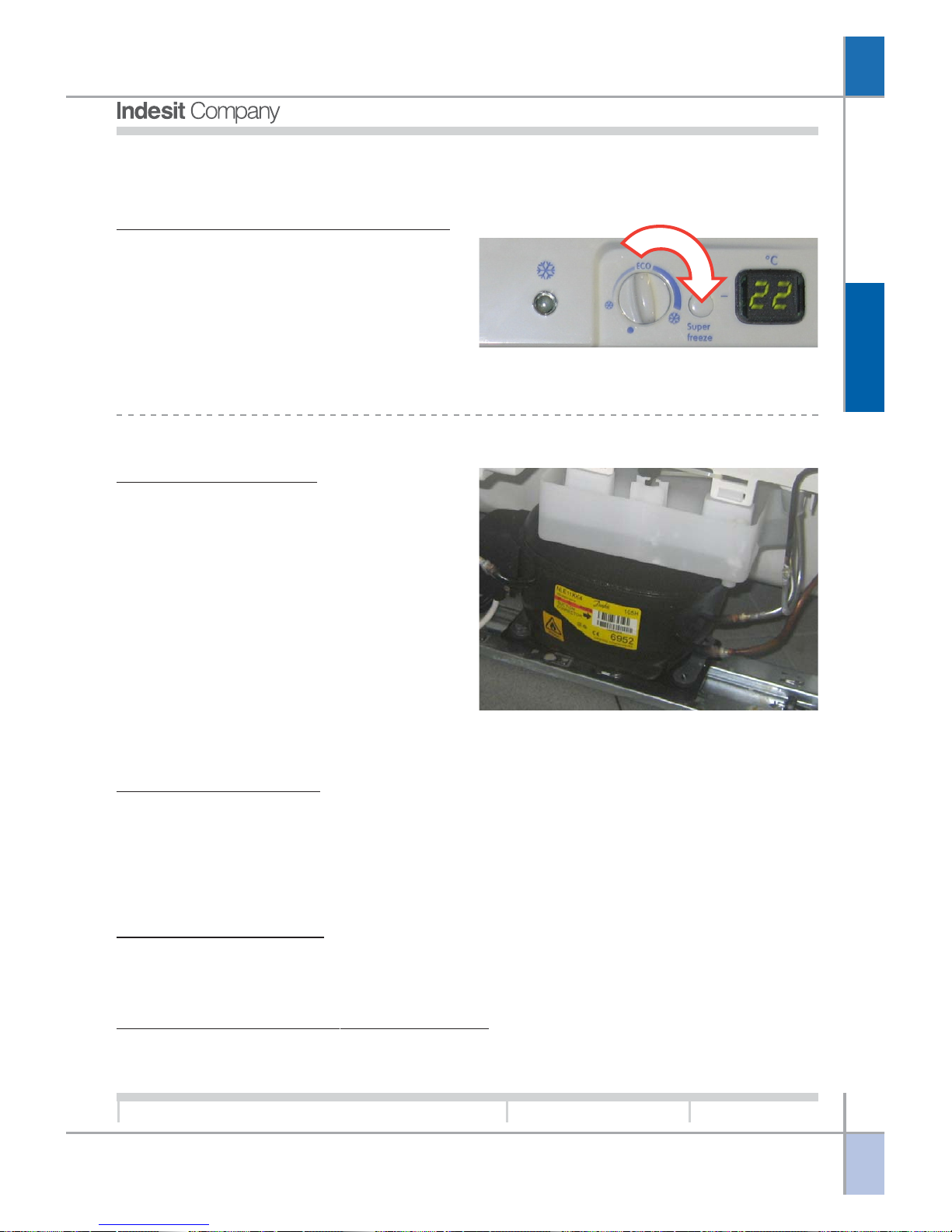

Compressor Operation:

The compressor serves to compress the gas in the

thermodynamic circuit in order to generate the necessary cooling capacity to chill the appliance compartments.

The compressor is managed by the Main PCB with

the aid of a relay and a triac that trips, in parallel with

the relay, only at the time of compressor power-on

and power-off to protect the relay from electrical arcing when the contact is opened and closed, otherwise the compressor is powered exclusively via the

relay when it is running.

The compressor is started whenever a cooling demand is received.

In certain conditions the compressor will remain stopped despite the presence cooling demands; these

situations are as follows:

Compressor protection:

The compressor switches on once a minimum safety time interval (parameterised in the EEPROM) has

elapsed since the last power off, thereby allowing the pressure of gas to reach a point of equilibrium in the

refrigerant circuit. The same minimum safety time is observed in the event of a mains power interruption

(voluntary or involuntary). This compressor protection strategy is observed only after the product has been

operating continuously for a number of hours defined in the memory. This facilitates the execution of factory

tests.

Long periods of activity:

If the compressor runs for a time greater than a value defined in the EEPROM memory, it is switched off

even in the presence of a cooling demand from either or both compartments. This feature is designed to

protect the compressor.

Fridge Fan Operation: (only in Digit models)

The fan is designed to distribute cold air uniformly inside the fridge compartment. The fan is controlled by

If the temperature measured by the freezer air sensor is above the On threshold a cooling demand is

activated thereby starting the compressor; on the contrary, if the freezer air sensor detects a temperature

lower than the Off temperature, the cooling demand is deactivated.

Refrigerator Compartment Adjustment:

Refrigerator temperature control is managed by the

PCB according to the temperature measured by the

refrigerator air sensor in relation to the user settings

on the interface.

If the temperature measured by the refrigerator air

sensor is above the On threshold, a cooling demand

is activated thereby starting the compressor and the refrigerator fan (if present); on the contrary, if the

refrigerator air sensor detects a temperature lower than the Off temperature, the cooling demand is deactivated.

LOADS MANAGEMENT:

O

PERATION

G

B

16

Service Manual

New Electronic Cold Platform 2005

Edition

2005.03.25

Language

English

the PCB and it starts on receipt of a refrigerator compartment cooling demand after a time interval

parameterised in the EEPROM following start-up of the compressor.

It may occur that the fan is kept switched off, even though the compressor is running.

This occurs in the event that the fridge door is open.

In order to check that the refrigerator fan is functioning correctly “door closed” conditions must be simulated

by applying a magnet.

Fridge Lamp Operation:

Housed in a light fixture, the fridge lamp serves to

illuminate the refrigerator compartment. The lamp is

controlled by a triac on the PCB and it switches on

when the door is opened and switches off when it is

closed.

If the door is kept open for more than a time interval

parameterised on the PCB, the lamp will flash until

the door is closed.

O

PERATION

G

B

17

Service Manual

New Electronic Cold Platform 2005

Edition

2005.03.25

Language

English

1 2 3 4 5 6 7

BASIC ELECTRONIC NO FROST FRIDGE-FREEZER.

Key:

1. SUPER FRIDGE button.

2. FRIDGE knob.

3. SUPER FRIDGE LED.

4. Power indicator LED.

5. SUPER FREEZER LED.

6. FREEZER knob.

7.

SUPER FREEZER button.Accensione/Spegnimento del prodotto:

SWITCHING THE APPLIANCE OFF AND ON:

TEMPERATURE SETTING:

Turn the refrigerator knob (2) or freezer knob (6) clockwise to

decrease the temperature or counterclockwise to increase the

temperature until reaching the minimum position; when the re-

frigerator knob is set to minimum the refrigerator compartment

will be switched off, while setting the freezer knob to minimum

switches off the entire appliance.

The appliance is Off when the freezer compartment

knob (6) is set to Minimum.

To switch the appliance on turn the freezer knob

clockwise, away from the Minimum position. To switch

it off turn the knob counterclockwise to the Minimum

position. All active functions are deactivated when

the appliance is switched off.

If the appliance is On and the refrigerator compart-

ment knob (2) is set to minimum, the refrigerator

compartment is Off. To switch on the refrigerator

compartment, turn the knob clockwise away from

the Minimum position; to switch it off turn the knob

counterclockwise to the Minimum position. If the

SUPER COOL function is active it will be automatically deactivated by switching the refrigerator compartment off.

O

PERATION

G

B

18

Service Manual

New Electronic Cold Platform 2005

Edition

2005.03.25

Language

English

SUPER FREEZER FUNCTION:

This function provides optimal freezing of food in the

freezer compartment, conserving properties of texture and flavour.

Activating this function forces the compressor run

continuously thereby obtaining maximum freezing

power in the freezer compartment.

The fan starts after a time interval parameterised in

the EEPROM memory from the compressor ON

time, thereby displacing the cold air from the evaporator coil and allowing the freezer compartment to

be chilled.

The function cannot be activated in the presence of

alarm signals. Activation of an alarm mode or switching off the appliance automatically causes this function to be deactivated.

This function is deactivated in the following cases:

pressing the relative button again; automatically,

when the maximum activation time (24 hours) is

reached; when the freezer air temperature sensor

detects a temperature below a value parameterised

in the EEPROM for a time parameterised in the

memory.

When the function is deactivated the appliance

resumes the operating mode defined previously by

the user. The ECO or HOLIDAY functions can be

selected, although they will only become operational

when the SUPER FREEZER procedure has terminated.

In the case of a faulty freezer air sensor this function is timer controlled.

In case of electrical power failures the function will

be reactivated automatically when power is restored,

completing the remaining hours, unless a temperature alarm occurs in this interval.

SUPER COOL FUNCTION:

When the SUPER COOL function is inhibited the

appliance returns to the setting that was active before the SUPER COOL function was selected.

The user can also activate the ECO or HOLIDAY

functions, which will become operational as soon as

the SUPER COOL function has been deactivated. The

SUPER COOL function cannot be activated if the HOLI-

DAY function is active. In the case of a faulty refrigerator air sensor, this function is timer controlled.

In case of electrical power failures the function is

resumed automatically when power is restored, completing the remaining cycles, except in the presence

of a temperature alarm.

This function allows optimal chilling of large quantities of food in the refrigerator compartment by altering the refrigerator On and Off set-points in accordance with parameters stored in the EEPROM

memory and it is maintained for the number of cycles stored in the memory. The cold air transferred

by the fan via the damper serves to chill the refrigerator compartment.

The SUPER COOL function cannot be activated if

either of the two alarm modes is active.

Activation of an alarm mode or switching off the appliance or only the refrigerator compartment automatically causes this function to be deactivated.

Activation of the SUPER COOL function can be performed by the user pressing button (1) in which case

LED (3) will illuminate to confirm the function is active; the function is deactivated by the user pressing

the button again, or it will be deactivated automatically at the end of the procedure (number of cycles)

as defined in the EEPROM memory.

O

PERATION

G

B

19

Service Manual

New Electronic Cold Platform 2005

Edition

2005.03.25

Language

English

HOLIDAY FUNCTION:

alarms are present. Since the two functions are not

compatible it is not possible to select the SUPER

COOL or SUPER FREEZER functions if the knob is

set to HOLIDAY. If these two functions are already

active when the HOLIDAY function is selected, SUPER COOL and SUPER FREEZER will be terminated normally, after which the HOLIDAY function

will start. If one or more of the sensors is faulty, the

function will be controlled by the main PCB utilising

alternative parameters. In case of electrical power

failures the function will be reactivated automatically

when power is restored.

In case of minimum use of the refrigerator compartment this function makes it possible to store food

while reducing power consumption to the minimum

(E.g. during holiday periods the freezer can remain

full and the refrigerator empty).

The function is activated by turning the refrigerator knob

(2) to the HOLIDAY setting (a double beep will sound

to indicate that the function is active)., To deactivate

the function move the knob away from the HOLIDAY

position (the appliance will emit a single beep) and the

appliance will resume normal operation.

The HOLIDAY function cannot be activated when

ECO FUNCTION:

This function allows storage of food with the lowest

possible power consumption while ensuring excellent results.

The function can be activated by turning the fridge

(2) and freezer (6) knobs to the ECO setting.

To deactivate the function simply turn one of the two

knobs away from the ECO setting.

The compressor starts in the presence of a cooling

demand from either of the two compartments. To

optimise operation of the appliance there is a fixed

time setting for operation of the freezer at the end of

a refrigerator cooling demand; this interval can vary

in accordance with the temperature read by the

freezer sensor. Normally, the ECO function adjustment corresponds to the adjustment utilised to calculate power consumption in compliance with European regulations. The SUPER FREEZER and SUPER FRIDGE functions can be activated when the

ECO function is set. These functions will assume

priority over the ECO function. The appliance returns

to ECO function mode once the conditions are met

to deactivate the priority procedure. If one or more

of the sensors is faulty, the appliance will be controlled by the main PCB utilising alternative parameters.

In case of electrical power failures the function will

be reactivated automatically when power is restored.

O

PERATION

G

B

20

Service Manual

New Electronic Cold Platform 2005

Edition

2005.03.25

Language

English

ALARMS MANAGEMENT:

Alarms serve to notify the user of specific conditions such as: prolonged opening of fridge door; excessive

temperature in freezer compartment.

Door Open Alarm:

If the fridge door is kept open for a time longer than that defined by a parameter set in EEPROM memory,

an audible signal is emitted and the fridge lamp flashes at regular intervals. Close the door to reset the

alarm.

Freezer Compartment Temperature Alarm:

There are two types of alarms that can be generated if the freezer compartment temperature rises excessively:

Alarm A1:

In this case it is still possible to recover the food in the freezer by cooking it immediately and either consuming it or re-freezing it once cooked. LEDs 3 and 5 flash on the appliance control panel to indicate the

presence of the alarm, while a beeper signal is emitted at the same time.

Alarm A2:

In this case the food in the freezer compartment must be discarded. LEDs 3, 4 and 5 flash on the appliance

control panel to indicate the presence of the alarm, while a beeper signal is emitted at the same time.

In alarm status the appliance inhibits all functions or adjustments to force a specific operating mode with

specific On/ Off thresholds that set the freezer compartment temperature to given values in relation to the

type of alarm (A1 or A2); the new On / Off thresholds for the two alarm types are parameterised in the

EEPROM memory. During alarm status forced defrost cycles are executed, activated once the number of

hours parameterised in the EEPROM memory have elapsed, as in normal operation. To reset the alarm and

restore normal operation, the appliance must be set to LOGICAL OFF (freezer knob set to minimum).

The beeper can be muted by opening and closing the refrigerator door. When alarm status is reset the

timer-controlled defrost cycles are deactivated, but if the alarm reset occurs during a defrost cycle, the

alarm is reset but the current defrost cycle continues to its natural conclusion. If the appliance is set to

logical OFF with A1 or A2 active, and then switched on again after a fixed number of minutes as parameterised

in the EEPROM memory, a defrost cycle is forced after which the appliance will resume operation in accordance with the settings that were present before the alarm.

Once the appliance has entered alarm status it is not possible to quit except by means of a reset procedure

(the only possible change is the transition from alarm A1 to alarm A2). In the event of a power failure, the

state present at the time of interruption is resumed when power is restored.

Control of freezer compartment temperature, performed by means of the freezer air temperature sensor, is

executed continuously during appliance operation. In the event of a freezer air sensor fault, the alarms will

no longer be displayed.

Temperature control does not start for a time parameterised in the EEPROM memory from the first poweron of the appliance, thus avoiding the possible occurrence of alarms during the testing phases at the first

power-on at the user’s home.

When the appliance is ON, the temperature control is inhibited for a given time interval parameterised in the

EEPROM memory in order to give the compartment time to cool without generating any superfluous alarms.

After a mains power failure the freezer compartment temperature is checked immediately, since prolonged

absence of electrical power is the main cause for heating of the appliance.

O

PERATION

G

B

21

Service Manual

New Electronic Cold Platform 2005

Edition

2005.03.25

Language

English

8°C

-6°C

2°C

Temperature control and alarm signalling are managed by means of three thresholds: Check Threshold

(the control strategy becomes more intensive when this threshold is exceeded); Threshold A1: when exceeded, alarm

A1 is activated; Alarm threshold A2: when exceeded, alarm A2 is activated. The values of the three thresholds are parameterised in the EEPROM memory..

If the control temperature exceeds the Check Threshold but does not exceed the A1 Alarm threshold, a

delay time T1 is activated (parameterised in the EEPROM) before performing the next control, to prevent

the generation of alarm signals when the placement of large quantities of warm food in the freezer compartment near the freezer air sensor causes unreliable transient temperature readings. At the same time another time interval T2 is activated (parameterised on the EEPROM) after which, if the temperature is constantly maintained between the Check Threshold and the Alarm A1 Threshold, alarm A1 is forced because

the persistence of a temperature in this range for this period of time is anyway a symptom of faulty operation

and constitutes a risk for the correct preservation of the food.

At the time of activation of alarm A1 also a time interval T3 is activated (parameterised in the EEPROM)

after which, if an alarm reset has not been executed, alarm A2 is forced, since in the situation of alarm A1

the freezer compartment is set to a temperature that may not be the same as the temperature selected by

the user. This time interval is reset also when power is restored after a mains power failure.

THERMOSTAT CONTROL.

The temperature adjustments in both the compartments are independent from each other and set individually by the relative knobs.

Freezer Compartment Adjustment:

Freezer temperature is managed by the PCB utilising the value detected by the freezer air sensor to

switch the compressor on/off.

The On / Off threshold is detected by the EEPROM

and it depends on the setting

selected by the user on the interface.

If the temperature measured by the freezer air sen-

sor is above the On threshold, a cooling demand is

activated thereby starting the compressor, the fan, and opening the damper; on the contrary, if the freezer

air sensor detects a temperature lower than the Off temperature, the cooling demand is deactivated.

T1 = 2 1/2 Hours

T2 = 24 Hours

T3 = 120 Hours

N. B.: The time and temperature values shown in this graph are EEPROM parameters and as such they are subject to modification

O

PERATION

G

B

22

Service Manual

New Electronic Cold Platform 2005

Edition

2005.03.25

Language

English

Refrigerator Compartment Adjustment:

Refrigerator temperature control is managed by the

PCB according to the temperature measured by the

refrigerator air sensor in relation to the user settings

on the interface. If the temperature measured by the

refrigerator air sensor is above the On threshold, a

cooling demand is activated thereby starting the

compressor and the refrigerator fan and opening the

damper; on the contrary, if the refrigerator air sensor detects a temperature lower than the Off temperature, the cooling demand is deactivated.

Special Conditions

Optimisation of power consumption: Temperature adjustment follows different rules if the following conditions occur:

· Only ECO ON

· Temperature detected by PCB sensor (on the PCB) between two values parameterised in the EEPROM

memory.

· Time since the last time the door was opened greater than the parameters stored in the EEPROM

memory.

· Duration of last compressor On cycle less than a parameter stored in the EEPROM memory.

If these conditions are all met, with every cooling demand from the refrigerator compartment, because of

the rise in the relative temperature above the set On threshold, also the freezer compartment is forced to

transmit a cooling demand.

Cancellation of this situation can occur if at least one of the previous conditions is no longer detected, or

because the condition persists for a time greater than the relative parameter set in the EEPROM memory.

LOADS MANAGEMENT:

Compressor Operation:

The compressor serves to compress the gas in the thermodynamic circuit in order to generate the necessary cooling capacity to chill the appliance compartments.

The compressor is managed by the Main PCB with the aid of a relay and a triac that trips, in parallel with the

relay, only at the time of compressor power-on and power-off to protect the relay from electrical arcing when

the contact is opened and closed, otherwise the compressor is powered exclusively via the relay when it is

running.

The compressor is started whenever a cooling demand is received from either of the two compartments.

When both compartments no longer require cooling, the compressor will be switched off.

In certain conditions the compressor will remain stopped despite the presence cooling demands; these

situations are as follows:

Compressor protection: the compressor switches on once a minimum safety time interval (parameterised

in the EEPROM) has elapsed since the last power off, thereby allowing the pressure of gas to reach a point

of equilibrium in the refrigerant circuit. The same minimum safety time is observed in the event of a mains

power interruption (voluntary or involuntary). This compressor protection strategy is observed only after the

product has been operating continuously for a number of hours defined in the memory. This facilitates the

execution of factory tests.

O

PERATION

G

B

23

Service Manual

New Electronic Cold Platform 2005

Edition

2005.03.25

Language

English

Long periods of activity: if the compressor runs for a time greater than a value defined in the EEPROM

memory, it is switched off even in the presence of a cooling demand from either or both compartments. This

feature is designed to protect the compressor.

Pause after defrost: at the end of every defrost cycle the compressor observes a number of protection

minutes parameterised in the EEPROM memory to allow the defrost water to drain completely.

DEFROST HEATING ELEMENTS AND DRIP TRAY:

Connection of the defrost and drip tray heating elements occurs when a defrost cycle is required; this event

is controlled by the PCB by means of a procedure that considers that total compressor run time since the

last defrost cycle, the duration of the last defrost cycle, and the duration of door open times. The purpose of

the defrost heating element is to melt any ice on the evaporating coil. This ice compromises the heat

exchange between the evaporator and the air, reducing the refrigeration properties in the two compartments of the appliance. The drip tray heating element melts any ice that detaches from the evaporator and

falls into the drip tray, and also prevents blockage of the tube that transfers defrost water from the drip tray

to the drain pipe.

The defrost and drip tray heating elements are connected in parallel and controlled by the PCB. When these

heating elements are switched on, the compressor remains switched off, even in presence of cooling demands from either of the two compartments.

Deactivation of the heating elements is managed by the freezer evaporator sensor. When the temperature

detected by the evaporator sensor reaches the value parameterised in the EEPROM memory, the defrost

and drip tray heating elements are switched off. A defrost cycle cannot last more than a given time

parameterised in the EEPROM memory.

At the end of each defrost cycle the number of hours is calculated that the compressor needs to run before

starting the next defrost cycle. This calculation is performed on the basis of the duration of the defrost cycle

that has just been terminated; specifically, if said duration is greater than an ideal value stored in the

memory, for each fixed number of extra minutes parameterised in the memory one hour is deducted from

the ideal value of compressor run hours parameterised in the memory; on the contrary, if the duration is less

than the ideal value, for each fixed number of minutes below the ideal number an hour is added to the ideal

value of compressor run hours.

This control makes it possible to anticipate the next defrost cycle if the defrost cycle that has just ended

lasted too long, and vice versa. The duration of the defrost cycle can be related to the presence of ice on the

evaporator coil, because a long defrost cycle means that an excessive amount of ice has accumulated on

the coil. The duration of door open times between two defrost cycles contributes to reducing the number of

compressor run hours that must be accumulated before the next defrost cycle. Specifically, each fixed

number of minutes in which the door is open, as parameterised in the EEPROM memory, serves to reduce

by one unit the number of compressor run hours that must be accumulated before the next defrost cycle.

Finally, the time that elapses between two defrost cycle can never be greater than a value parameterised in

the EEPROM memory or lower than another value parameterised in the EEPROM; the first strategy serves

to guarantee a defrost cycle at least every number of preset hours, while the second serves to avoid

excessively frequent defrost cycles. If the last defrost cycle was interrupted according to timer control, the

minimum time between defrost cycles is equal to another value parameterised in the EEPROM memory.

Special conditions in which a defrost cycle can occur:

1. If the SUPER FREEZE function is activated, there may be an immediate defrost cycle if the accumulated

compressor run hours are more than a parameter set in the EEPROM memory, otherwise the function

proceeds as specified.

Loading...

Loading...