Page 1

50cm Free Standing Gas Cooker

Instructions for installation and use

KD3G2/G

KD3G2S/IR

KD3G21/G

KD3G21S/IR

Page 2

Contents

Introduction 3

Installation 4

Safety Information 10

Features 12

Control Panel 13

Use of hotplates 14

Grilling 15

Oven 16

Oven cooking charts 17

Care and Cleaning 18

Cooking Results Not Satisfactory? 19

Something Wrong With Your Cooker? 20

If it Still Won’t Work... 21

Technical Characteristics 22

Key Contacts Back Cover

You must read these instructions prior to using your appliance and retain them

for future use.

2

Page 3

Introduction

Your new appliance is guaranteed* and will give lasting service. This guarantee is only applicable if the appliance

has been installed in accordance with the installation instructions detailed in this booklet.

To help make best use of your cooking equipment, please read this booklet carefully.

The cooker is designed specifically for domestic use and responsibility will not be accepted for use in any other

installation.

When the cooker is first used an odour may be emitted,

this will cease after a period of use.

When first using the cooker ensure that the room is well ventilated (e.g. open a window or use an extractor fan) and

that persons who may be sensitive to the odour avoid any fumes. It is suggested that any pets be removed from the

room until the smell has ceased. This odour is due to temporary finish on oven liners and elements and also any

moisture absorbed by the insulation.

* The guarantee is subject to the provisions that the appliance:

(a) Has been used solely in accordance with the Users Instruction Book.

(b) Has been properly connected to a suitable supply voltage as stated on the

rating plate attached to this equipment.

(c) Has not been subjected to misuse or accident or been modified or repaired by

any person other than the authorised employee or agent.

(d) Has been correctly installed.

1

This appliance is intended for nonprofessional use within the home.

2 These instructions are only for those countries whose symbols appear in the booklet and on the serial no. plate

of the appliance.

3 This owner’s manual is for a class 1 appliance (insulated) or class 2, subclass 1 appliances (installed

between two cabinets.

3

Page 4

Installation

The appliance must only be installed by a competent person. In the UK, CORGI registered installers undertake

to work to safe and satisfactory standards.

Before moving your cooker check that it is cool, and switch off at the cooker control unit. Movement of your cooker is

most easily achieved by lifting the front as follows:

Open the grill door sufficiently to allow a comfortable grip on the underside front edge of the oven roof, avoiding any

grill elements.

Note: Take care in moving the cooker as it is heavy. Take care to ensure that any floor covering is not damaged.

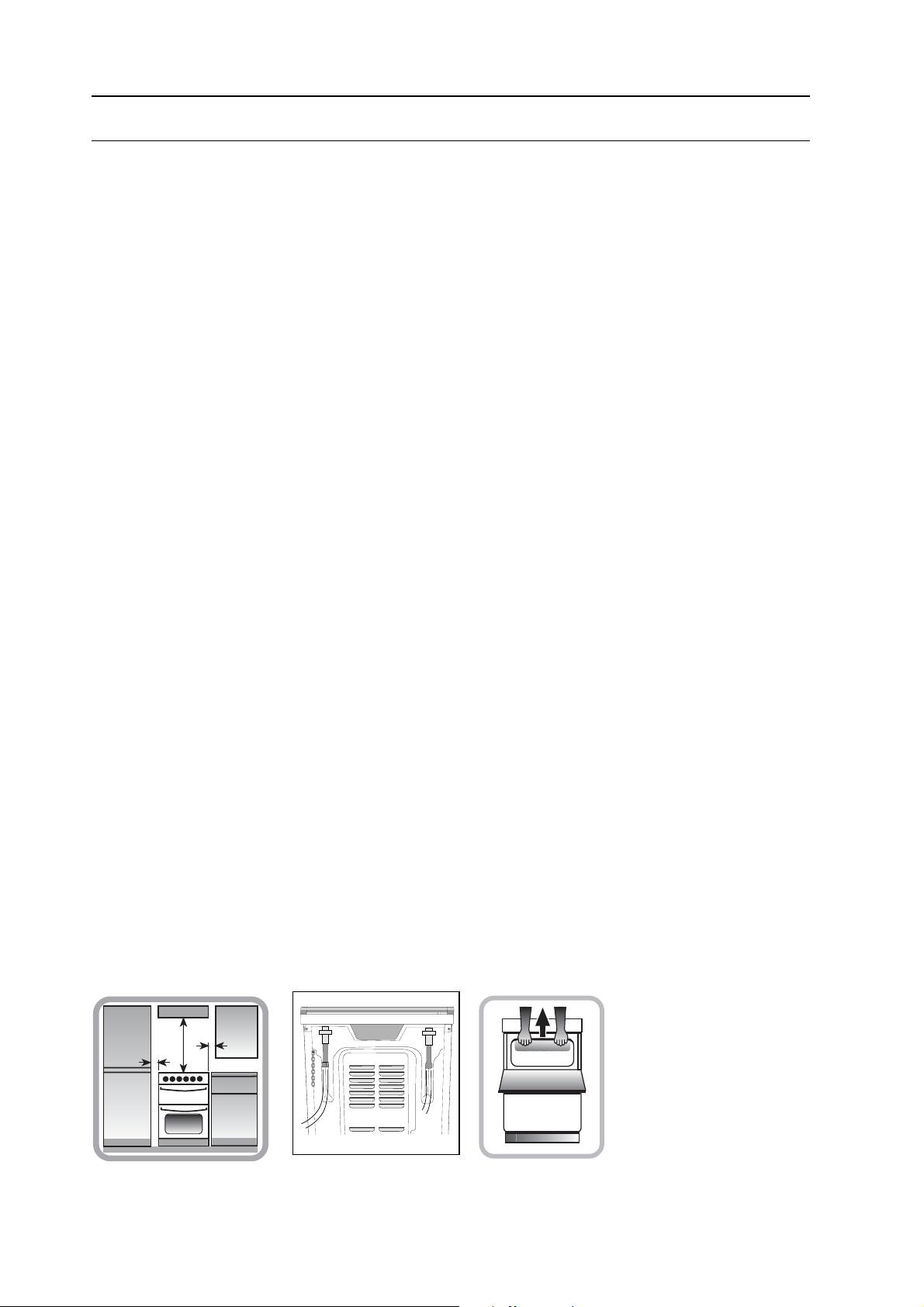

(FIG. C)

Splashplate optional, apply to Parts Department (see Back Cover for contact number.)

The following instructions should be read by a qualified technician to ensure that the appliance is installed,

regulated and technically serviced correctly in compliance with current regulations.

Important: remember to unplug the appliance from the mains before regulating the appliance or

carrying out any maintenance work.

Positioning

Important: this unit may be installed and used only in permanently ventilated rooms according to the British

Standards Codes Of Practice: B.S. 6172/B.S. 5440, Par. 2 and B.S. 6891 Current Editions. The following requirements

must be observed:

3

a) The cooker should not be installed in a bed sitting room with a volume of less than 20m

3

room of volume less than 5m

volume between 5m

3

and 10m3 a supplementary airvent area of 50cm2 is required, if the volume exceeds 11m

an air vent of effective area of 110cm2 is required, if it is installed in a room of

no airvent is required. However, if the room has a door or a window which opens directly to the outside no air

vent is required even when the volume is between 5m

3

and 11m3.

b) During prolonged use of the appliance you may consider it necessary to open a window to the outside to

improve ventilation.

c) If there are other fuel burning appliances in the same room, B.S.5440 Part 2 Current Edition, should, be

consulted to determine the requisite air vent requirements.

. If it is installed in a

3

Installation of the cooker

For a correct installation of the cooker the following precautions must be followed:

The height of the cooker can be adjusted by means of adjustable feet in the plinth (900mm - 915mm). Adjust the feet by

tilting the cooker from the side. Then install the product into position.

NOTE: This appliance must not be fitted on a platform.

The cooker is designed to fit between kitchen cabinets spaced 500mm apart. The space either side need only be sufficient

to allow withdrawal of the cooker for servicing. It can be used with cabinets one side or both as well as in a corner setting.

It can also be used free-standing.

Adjacent side walls which project above hob level, must not be nearer to the cooker than 150mm and should be protected

by heat resistant material. Any overhanging surface or cooker hood should not be nearer than 650mm. (Fig.A)

a) The cooker may be located in a kitchen, a kitonen/diner or bed sitting room, but not in a bathroom or

shower room.

b) The hoods must be installed according to the requirements in the hood handbook.

c) The wall in contact with the back of the cooker must be of flameproof material.

d) The cooker is fitted with a safety chain that must be attached to a hook, secured to the wall behind the

appliance.

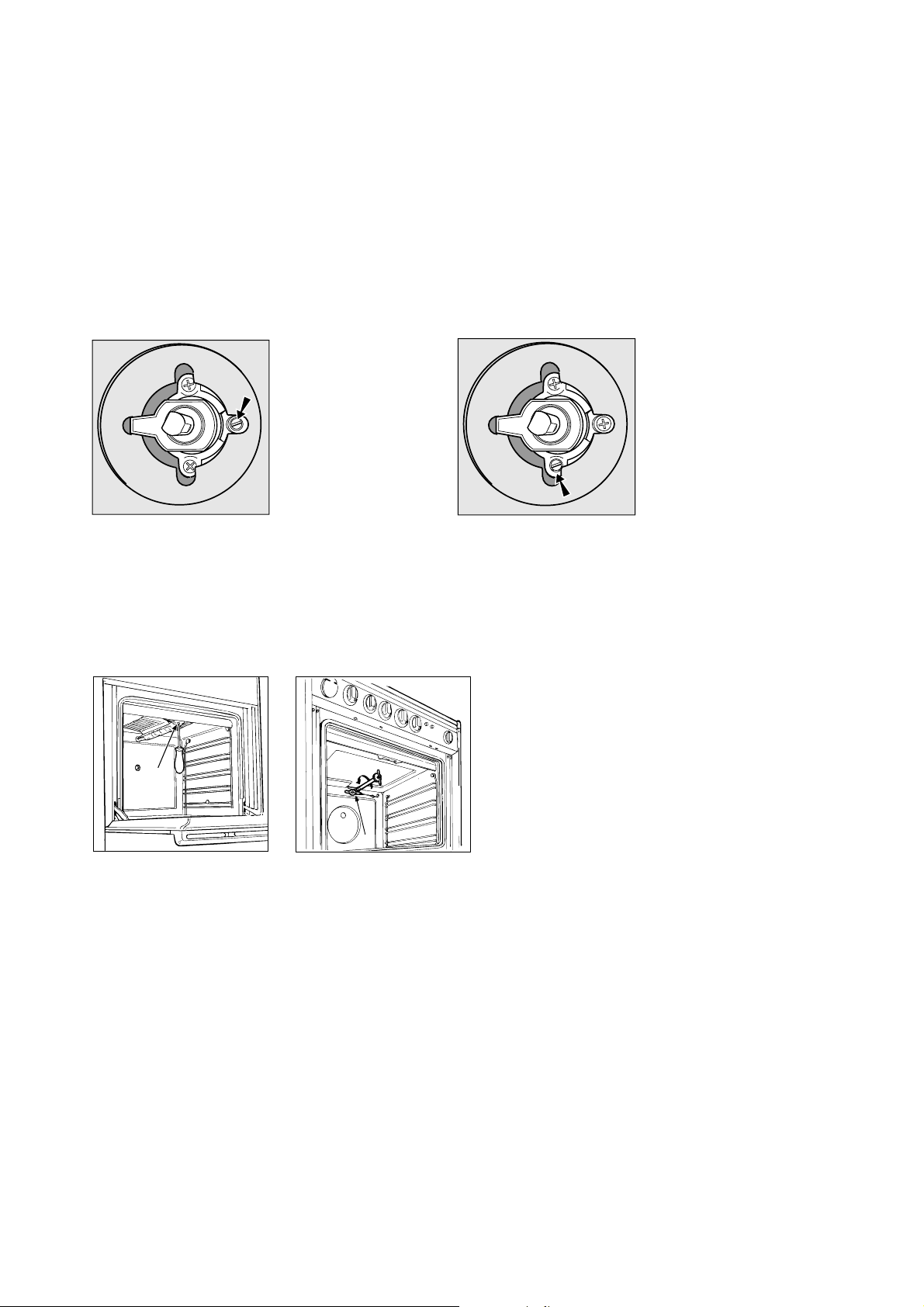

Note: some models can have their gas connection inverted. It is important to make sure the safety chain

is always situated on the side which corresponds to the hose holder (Fig. B).

150 mm

150 mm

650 mm

Fig. A Fig. B Fig. C

4

Page 5

Gas connection

The cooker should be connected to the gas-supply by a corgi registered installer. During installation of this

product it is essential to fit an approved gas tap to isolate the supply from the appliance for the convenience

of any subsequent removal or servicing. Connection of the appliance to the gas mains or liquid gas must be

carried out according to the prescribed regulation in force, and only after it is ascertained that it is adaptable

to the type of gas to be used. If not, follow the instructions indicated in the paragraph headed “Adaptation to

different gas types”. On some models the gas supply can be connected on the left or on the right, as

necessary; to change the connection, reverse the position of the hose holder with that of the cap and

replace the gasket (supplied with the appliance). In the case of connection to liquid gas, by tank, use

pressure regulators that conform to the regulation in force. The gas supply must be connected to the left of

the appliance. Be sure that the hose does not pass through the rear of the cooker touching hot parts.

HOT PARTS

600 mm

Important: make sure the supply pressure conforms with the values shown in the table entitled “Caracteristics of

the burners and nozzles”. When the cooker is installed between cabinets (recessed), the gas connection

must be effected by an approved flexible hose with bayonet fitting (BS 669 Current Edition). The gas inlet

for the cookers is a threaded G 1/2 gas female fitting.

Connecting the gas supply

To make the connection, a flexible hose should be used corresponding to the current gas regulations which are:

• the hose must never be at any point in its lenght in contact with the “hot” parts of the cooker;

• the hose must never be longer than 1,5 metre;

• the hose must not be subject to any tension or torsional stress and it must not have any excessively narrow

curves or bottlenecks;

• the hose must be easy to inspect along its entire length to check its condition;

• the hose must always be in good condition, never attempt to repair.

Important: the installation must comply with gas safety (installation and use) regulations 1984. In all cases for the

above, by low, a qualified, corgi approved engineer must be called for installation.

Important: Before using the oven, position the oven burner deflector "A" (provided with the appliance) in the

correct place by inserting the lower tab into the support slot (see figure).

A

5

Page 6

Electrial connection

Power supply voltage and frequency: 230-240V a.c. 50 Hz.

Note: the supply cable must be positioned so that it never reaches at any point a temperature 50°C higher than

the room temperature. The cable must be routed away from the rear vents. Should you require it, you may use a

longer cable, however, you must ensure that the cable supplied with the appliance is replaced by one of the same

specifications in accordance with current standards and legislation.

Your appliance is supplied with a 13 amp fused plug that can be plugged into a 13 amp socket for immediate use.

Before using the appliance please read the instructions below.

WARNING - THIS APPLIANCE MUST BE EARTHED.

THE FOLLOWING OPERATIONS SHOULD BE CARRIED OUT BY A QUALIFIED ELECTRICIAN.

Replacing the fuse:

When replacing a faulty fuse, a 13 amp ASTA approved fuse to BS 1362 should always be used, and the fuse

cover re-fitted. If the fuse cover is lost, the plug must not be used until a replacement is obtained.

Replacement fuse covers:

If a replacement fuse cover is fitted, it must be of the correct colour as indicated by the coloured marking or the

colour that is embossed in words on the base of the plug. Replacements can be obtained directly from your

nearest Service Depot.

Removing the plug:

If your appliance has a non-rewireable moulded plug and you should wish to remove it to add a cable extension

or to re-route the mains cable through partitions, units etc., please ensure that either:

• the plug is replaced by a fused 13 amp re-wireable plug bearing the BSI mark of approval.

or:

• the mains cable is wired directly into a 13 amp cable outlet, controlled by a switch, (in compliance with BS

5733) which is accessible without moving the appliance.

Please note: for appliances with a rating greater than 13 amp (eg: electric hob, double ovens and freestanding

electric cookers etc.) the mains cable must be wired into a cooker output point with a rating of 45 amp. In this case

the cable is not supplied.

Disposing of the plug:

Ensure that before disposing of the plug itself, you make the pins unusable so that it cannot be accidentally

inserted into a socket. Instructions for connecting cable to an alternative plug:

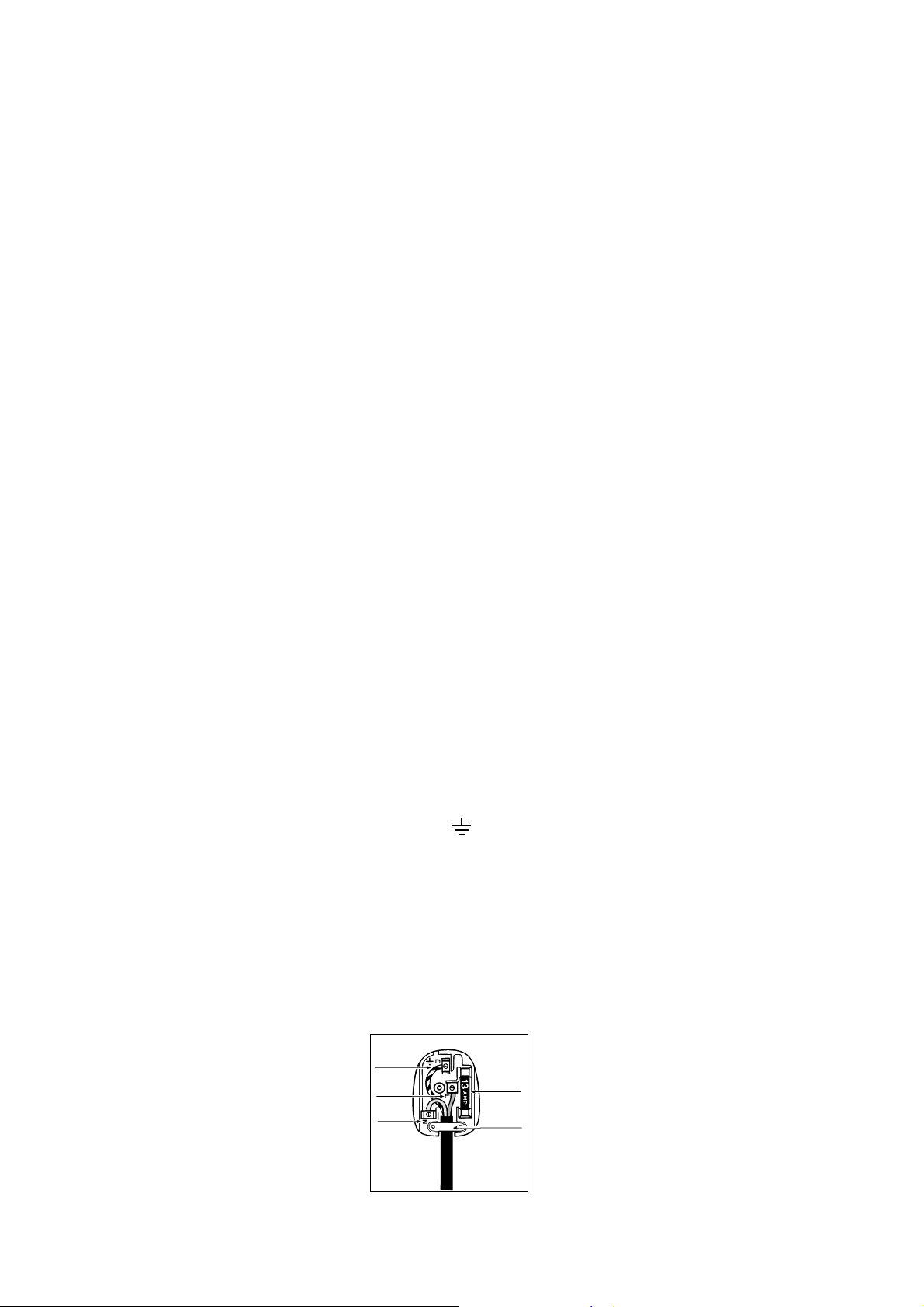

Important: the wires in the mains lead are coloured in accordance with the following code:

Green & Yellow - Earth

Blue - Neutral

Brown - Live

If the colours of the wires in the mains lead do not correspond with the coloured markings identifying the terminals

in your plug, proceed as follows:

Connect Green & Yellow wire to terminal marked “E” or

or coloured Green or Green & Yellow.

Connect Brown wire to terminal marked “L” or coloured Red.

Connect Blue wire to terminal marked “N” or coloured Black.

If a 13 amp plug (BS 1363) is used it must be fitted with a 13 amp fuse. A 15 amp plug must be protected by a 15

amp fuse, either in the plug or adaptor or at the distribution board. If you are in any doubt about the electrical supply

to your machine, consult a qualified electrician before use.

How to connect an alternative plug:

The wires in this mains lead are coloured in accordance with the following code:

BLUE “NEUTRAL” (“N”)

BROWN “LIVE” (“L”)

GREEN AND YELLOW “EARTH” (“E”)

GREEN &

YELLOW

BROWN

BLUE

13 amp fuse

CROSS-BAR

CORD GRIP

6

Page 7

Disposing of the appliance

When disposing of the appliance please remove the plug by cutting the mains cable as close as possible to the

plug body and dispose of it as described above.

Adapting the cooker to different types of gas

In order to adapt the cooker to a different type of gas with respect to the gas for which it was produced

(indicated on the label attached to the lid), follow these steps:

a) replace the hose holder mounted on the appliance with that supplied in the bag of “cooker accessories”.

b) Replacing the burner nozzles on the hob:

• remove the grids and slide the burners from their housings;

• unscrew the nozzles using a 7 mm socket spanner, and replace them with nozzles for the new type of

gas (see table 1 “Burner and nozzle characteristics”).

• replace all the components by repeating the steps in reverse order.

c) Minimum regulation of the hob burners:

•

turn the tap to minimum;

• remove the knob and adjust the regulation screw, which is positioned in or next to the tap pin, until the

flame is small but steady.

N.B.: in the case of liquid gas, the regulation screw must be screwed in to the bottom.

• check that the flame does not turn off when you turn the tap quickly from high to low.

d) Regulating the primary air of the burners:

The primary air of the burners requires no regulation.

Adapting to different types of gas

In order to adapt the oven to a different type of gas with respect to the gas for which it was manufactured

(indicated on the label), follow these simple steps:

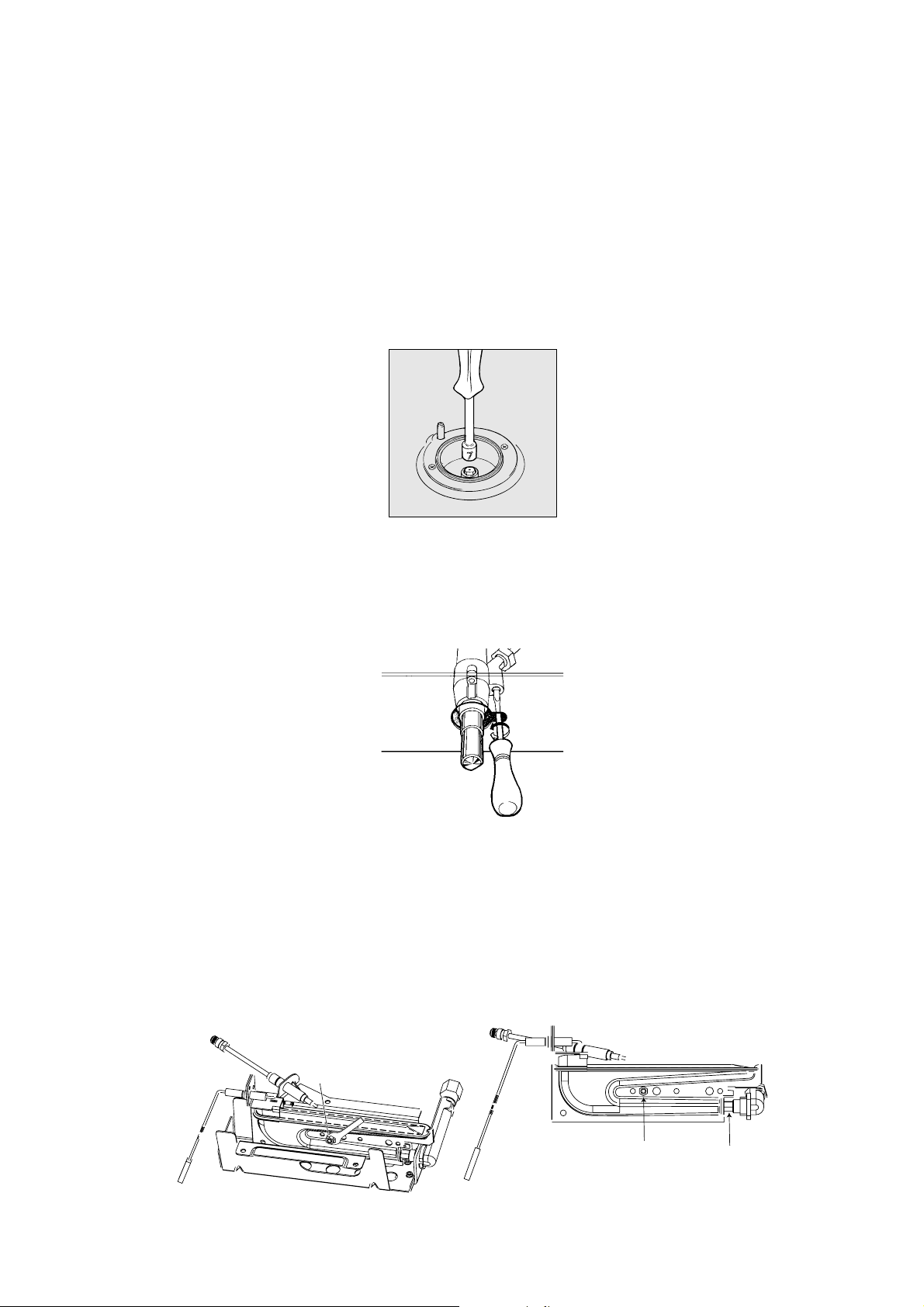

a) Replacing the oven burner nozzle

• open the oven door fully

• pull out the sliding oven bottom

• unscrew the burner fastening screws

V

V

Z

7

Page 8

• remove screw “V” and then the oven burner;

• Unscrew the oven burner nozzle using the socket spanner for the nozzles “Z”, or a 7 mm socket spanner,

and replace it with a nozzle suited to the new type of gas (see Table 1).

Take particular care handling the spark plug wires and the thermocouple pipes.

• Replace all the parts, following the steps described above in the reverse order.

b) Minimum regulation of the gas oven burner with thermostat:

• light the burner as described in the paragraph “the oven knob” of the instruction booklet.

• turn the knob to Max for about 10 minutes and then turn the knob to the Min setting;

• remove the knob;

• regulate the screw positioned outside the thermostat pin until the flame is small but steady.

N.B.: in the case of liquid gas, the regulation screw must be screwed in to the bottom.

• check that the burner does not turn off when you turn the knob from Max to Min and and when you open

and close the oven door quickly.

Adapting the gas grill to different types of gas

Replacing the nozzle of the grill burner:

• remove the screw and then slide out the grill burner “V” (see Fig. E);

• unscrew the grill burner nozzle using the special socket spanner for the nozzles (see Fig. F) or better still

a 7 mm socket spanner; replace the nozzle with a nozzle for the new type of gas (see table 1).

V

I

Fig. E Fig. F

Important

On completion of the operation, replace the old rating sticker with one indicating the new type of gas used.

This sticker is available from our Service Centres.

Note

Should the pressure of the gas used be different (or vary) from the recommended pressure, it is necessary to

fit a suitable pressure regulator onto the inlet pipe in compliance with current National Regulations relative to

“regulators for channelled gas”.

8

Page 9

Burner and Nozzle Specifications

Table 1 Liquid Gas Natural Gas

Burner Diameter

(mm)

Thermal Power

kW (p.c.s.*)

Nominal Reduced (mm) (mm) *** ** (mm)

By-Pass

1/100

Nozzle

1/100

Flow*

g/h

Nozzle

1/100

Flow*

l/h

Fast

(Large)(R)

Semi Fast

(Medium)(S)

Auxiliary

(Small)(A)

Oven - 2,60 0,6 36 75 189 186 123 248

Grill - 2,50 1,3 63 80 182 179 122 238

Supply

Pressures

100 3,00 0,7 41 87 218 214 128 286

75 1,90 0,4 30 70 138 136 104 181

51 1,00 0,4 30 52 73 71 76 95

Nominal (mbar)

Minimum (mbar)

Maximum (mbar)

28-30

20

35

37

25

45

20

17

25

* At 15°C and 1013 mbar- dry gas

** Propane P.C.S. = 50,37 MJ/Kg

*** Butane P.C.S. = 49,47 MJ/Kg

Natural P.C.S. = 37,78 MJ/m

S

S

R

A

3

KD3G2/G

KD3G2S/IR

KD3G21/G

KD3G21S/IR

9

Page 10

Safety Information

When used properly your appliance is completely safe but as with any electrical product there are certain

precautions that must be observed.

PLEASE READ THE PRECAUTIONS BELOW BEFORE USING YOUR APPLIANCE.

Always

l Remove all packing from inside the oven and grill compartments before switching on for the first time.

l Understand the controls prior to using the appliance.

l Keep children away from the appliance when grilling as the surfaces will get extremely hot during and after use.

l Turn controls off when you have finished cooking and when not in use.

l Stand back when opening an oven door to allow any build up of steam or heat to disperse.

l Use dry good quality oven gloves when removing items from the oven/grill.

l Place pans centrally over the hotplate making sure handles are kept away from the edge of the hob and cannot

become heated by other hotplate/pans.

l Take care to avoid heat/steam burns when operating the controls.

l Turn off the electricity supply at the wall switch before cleaning and allow the appliance to cool.

l Make sure the shelves are in the correct position before switching on the oven.

l Keep the oven and grill doors closed when the appliance is not in use.

l Take care when removing items from the grill when the lower oven is on as the contents will be hot.

l Keep the appliance clean, as a build up of grease or fat from cooking can cause a fire.

l Follow the basic principles of food handling and hygiene to prevent the possibility of bacterial growth.

l Keep ventilation slots clear of obstructions.

l Refer servicing to a qualified appliance service engineer.

l Take care to avoid touching heating elements inside the oven, as during use the oven becomes hot.

10

Page 11

Safety Information

Never

l Never line the interior of the oven with foil as this may cause the appliance to overheat.

l Never leave children unsupervised where a cooking appliance is installed as all surfaces will be hot during and

after its use.

l Never allow anyone to sit or stand on any part of the appliance.

l Never store items above the appliance that children may attempt to reach.

l Never leave anything on the hob surface when unattended and not in use.

l Never remove the oven shelves whilst the oven is hot.

l Never heat up unopened food containers as pressure can build up causing the container to burst.

l Never store chemicals/food stuffs, pressurised container in or on the appliance, or in cabinets immediately

above or next to the appliance.

l Never place flammable or plastic items on or near the hob.

l Never fill a deep fat frying pan more than 1/3 full of oil, or use a lid.

DO NOT LEAVE UNATTENDED WHILE COOKING.

l Never operate the grill with the grill door closed as this will cause the appliance to overheat.

l Never use the appliance as a room heater.

l Never use the grill to warm plates.

l Never dry any items on either the hob or oven doors.

l Never install the appliance next to curtains or other soft furnishings.

l Never use steam cleaners.

SAFETY ADVICE IN CASE OF A CHIP-PAN FIRE

In the event of a chip pan fire or any other pan fire.

1. TURN OFF THE COOKER APPLIANCE AT THE WALL SWITCH.

2. COVER THE PAN WITH A FIRE BLANKET OR DAMP CLOTH, this will smother the flames and extinguish the

fire.

3. LEAVE THE PAN TO COOL FOR AT LEAST 60 MINUTES BEFORE MOVING IT. Injuries are often caused by

picking up a hot pan and rushing outside with it.

NEVER USE A FIRE EXTINGUISHER TO PUT OUT A PAN FIRE as the force

of the extinguisher is likely to tip the pan over.

Never use water to extinguish oil or fat fires.

11

Page 12

Features

HOB VENTILATION SLOTS

GRILL/MEAT PAN

WITH REMOVABLE

HANDLE AND WIRE

FOOD SUPPORT

GRILL DOOR

REMOVABLE

INNER GLASS

DOOR

1900W

GRILL

1000W

1900W

3000W

CONTROL

PANEL

MAIN OVEN

WIREWORK

SHELF

SUPPORTS

MODEL & SERIAL

NUMBER

OVEN ROD

SHELVES

12

Page 13

Control Panel

TIMER*

ELECTRONIC*

INIECTION

BUTTON

Control Knobs

for the gas

burners

Electronic

Ignition

for the Gas Hob*

Models with Hob

Gas Burner Safety

Devices to Prevent

Leaks *

MAIN

GRILL

OVEN

The position of the gas burner controlled by each one of the knobs is shown by a solid ring •. To

light one of the burners, hold a lighted match or lighter near the burner and, at the same time,

press down and turn the corresponding knob counter clockwise to the maximum - setting. Each

burner can be operated at its maximum, minimum or intermediate power. Shown on the knob are

the different symbols for off • (the knob is on this setting when the symbol corresponds with the

reference mark on the control panel), for maximum - and minimum +. To obtain these settings,

turn the knob counter clockwise with respect to the off position. To turn off the burner, turn the

knob clockwise until it stops (corresponding again with the • symbol).

This device operates when a slight pressure is applied to the button marked with symbol. To

light a specific burner just press the button

and turning it counter-clockwise until it lights. For immediate lighting, first press the button and

then turn the knob.

Important: Should the burner flames accidentally go out, turn off the control knob and wait

at least 1 minute before trying to relight.

These models can be identified by the presence of the device itself.

Important: Since the hob burners are equipped with a safety device, you must hold the control knob in

for about 3 seconds after the burner has been lighted to allow the gas to pass until the safety

thermocouple has heated.

LEFT

FRONT

BURNER

LEFT

REAR

BURNER

while pushing the corresponding knob all the way in

RIGHT

REAR

BURNER

RIGHT

FRONT

BURNER

Timer *

* (only available on certain models)

To use the timer, the buzzer must be wound up by turning the knob one full turn clockwise; then turn it

back to the desired time so that the number of minutes on the knob matches the reference mark on

the panel.

13

Page 14

Use of Hotplates

Practical Advice on Using the Burners

To use the burners as efficiently as possible, some basic guidelines should be followed:

• Use cookware that is the right size for each burner (see table) in order to prevent the flame from spreading

beyond the bottom of the cookware.

• Only use cookware with flat bottoms.

• As soon as the boiling point is reached, turn the knob to the lowest setting.

• Always use lids with pots and pans.

Burner ø Cookware diameter (cm)

Fast (R) 24 - 26

Semi Fast (S) 16 - 20

Auxiliary (A) 10 - 14

N.B.: On models equipped with a reduction grid, the grid should only be used with the auxiliary burner when

cookware with a diameter of less than 12 cm is used.

1. Press the ignition button and then push in and turn the control knob of the chosen burner anti-clockwise

to the large flame symbol. Continue to press the ignition button until the sparks light the gas.

2. Turn the control knob anti-clockwise to the desired setting. Only turn the control knob between the large

flame symbol and the small flame symbol for adjusting the setting.

3. To turn off, turn the control knob fully clockwise to the symbol O.

DO NOT use the hotplate unless all pan supports are in position.

DO NOT use mis-shapen pans which may be unstable.

DO NOT use round base woks directly on the pan supports.

DO NOT use the glass lid (if fitted) as a working surface.

Each burner is fitted with a spark ignitor for lighting the gas. To ensure rapid lighting of the burners every time they

are used, the ignitors must be kept clean and dry. Remove any food spillage or cleaning materials from the

electrode using a small nylon brush such as a tooth brush. Access to the electrode can be achieved by lifting off the

loose burner parts carefully when the burners are cool.

When the hotplate burner bodies and caps are removed for cleaning, be careful not to drop any food particles or

cleaning materials into the burner bases, to avoid the possibility of blocking the gas jets.

If aluminium based pans are used, a silvery deposit may appear on the top edge of the pan support fingers. See

'Care and Cleaning' section for cleaning information.

SAFETY REQUIREMENTS FOR DEEP FAT FRYING

1. Never fill chip pans more than one third full with oil or fat.

2. Never leave oil or fat unattended during the heating or cooling period.

3. Never heat fat or fry with a lid on the pan.

4. Always dry food thoroughly before frying, and lower it slowly into the hot oil or fat. Frozen foods in

particular will cause frothing and spitting if added too quickly.

5. Always keep the outside of the pan clean and free from streaks of oil or fat.

HOW TO DEAL WITH A FAT FIRE

1. Do not move the pan.

2. Turn off the hotplate burners.

3. Smother the flames with a fire blanket or damp cloth to extinguish the fire. Do not use water or a fire

extinguisher as the force of it may spread the burning fat or oil over the edge of the pan.

4. Leave the pan for at least 60 minutes before moving it.

14

Page 15

Grilling

CAUTION: ACCESSIBLE PARTS WILL BECOME HOT WHEN THE GRILL

To operate the grill proceed as follows:

l Open the grill door and remove the grill pan.

l Press the ignition button and then push in and turn the grill control knob anti-clockwise to the large

flame symbol. Continue to press the ignition button until the spark lights the gas.

Grill Pan Handle

l Turn the control knob anti-clockwise to the desired setting. There is a delay of about six seconds

whilst the safety device operates before the burner comes on full. Only turn the control knob between

the large flame symbol and the small flame symbol when adjusting the setting.

l To turn off, turn the control knob fully clockwise to the symbol O

Important (only on a few models): when using the grill, the oven door must be left open by

positioning the deflector “B” between control panel and deflector “A” to prevent the cooker knobs from

overheating.

GRILLING MUST BE DONE WITH THE GRILL DOOR OPEN.

CONTROL KNOBS MAY BECOME HOT DURING GRILLING.

IS USED - CHILDREN SHOULD BE KEPT AWAY.

A

B

Slide the grill pan along the runner towards the rear of the grill compartment until it stops. An

odour may be noticed when first using the grill - this schould cease after a short period of use.

Grill can be started from cold but for the best result preheat for approximately five

minutes. Most cooking is done with the heat on full, but it may be necessary after sealing the

food to reduce the heat as required.

For au gratin dishes eg. Macaroni Cheese and meringue toppings eg. Baked Alaska place the

dish on the floor of the grill compartment. The base of the grill pan can be used for warming

fruit garnishes on the reduced setting.

DO NOT cover the grill pan or grid with aluminium foil as this can hold fat, intensify the heat and create a fire hazard.

Relighting‘

the burner

Fixing the Grill Pan

Handle

In the event of the burner flames being accidentally extinguished, turn off the burner control and do not

attempt to re-ignite the burner for at least one minute.

The grill pan handle is detachable from the pan, to facilitate cleaning and storage. Fix the grill pan

handle securely in position before use.

The handle fits onto the grill pan edge with the small recess, Fig.1.

Tilt the handle over the recess and slide it towards the centre, Fig.2.

Ensure the handle is fully located. Insert the washer and fixing screw and tighten fully to ensure handle

is secured, Fig.3.

Always hold the dripping pan handle in the highlighted zone marked "OK" in figure 4.

Recess

Fig. 1

Fig. 2

Always fit the screw prior to use.

Fig. 3

Fig. 4

NO

OK

The food to be cooked should be placed on the grill pan/grill pan food support.

Place the grill pan on the runners and push back to the stop position when the grill pan is

correctly positioned beneath the grill element.

Plates and dishes placed on the floor of the grill compartment will be heated when the oven is

in use.

15

Page 16

Oven

The oven has different heat zones - the thermostat settings refer to the temperature on the

middle shelf; above this shelf it is hotter and below it is cooler. Two shelves enable full use of

the temperatures inside the oven.

Each shelf has a safety stop to prevent if from being pulled out too far when attending to

food. Shelves are removed from the oven by pulling them out to the stop and then lifting

them at the front to withdraw.

The grill pan without the handle can be used in the oven. The maximum size of baking tray

that should be used is 300mm x 330mm (12" x 13").

TO USE THE OVEN 1. Place oven shelves in the chosen positions (refer to cooking charts).

2. Press the ignition button and then push in and turn the oven control knob fully anti-clockwise.

Continue to press the ignition button until the spark lights the gas.

3. Turn the control knob clockwise to the required setting (refer to cooking chart). There is a

delay of about six seconds whilst the safety device operates before the burner comes on full.

4. To turn off, turn the control knob fully clockwise the the symbol 0.

Never place dishes on the oven base over the burner.

An odour may be noticed when first using the oven - this should cease after a short period of

use.

5. The oven temperature control marking are gas marked 0 to 9.

The equivalent degrees Celsius (sometimes called Centigrade) and degrees Fahrenheit

are shown below as a guide.

MAIN OVEN

Gas Mark

1 120 250

2 150 300

3 175 350

4 195 385

(Centre Oven Temperature)

Celisus

°C

Fahrenheit °F

Gas Mark

5 210 410

6 220 430

7 230 445

8 235 455

9 240 465

MAIN OVEN

(Centre Oven Temperature)

Celisus

°C

Fahrenheit °F

RELIGHTING

THE BURNER

COLD START

COOKING

ROASTING OF

LARGE POULTRY

STORAGE AND

RE-HEATING

OF FOOD

‘COOK CHILL’

DISHES

In the event of the burner flames being accidentally extinguished, turn off the burner control

and do not attempt to re-ignite the burner for at least one minute

Anything requiring long slow cooking such as casseroles and rich fruit cakes can be put into

a cold oven. Satisfactory results can also be obtained with creamed mixture, rich pastries or

yeast mixtures, but for perfection we recommend preheating the oven for about 15 minutes.

The maximum weight of poultry that can be accommodated is 8kg (18 Ibs) of suitable shape.

It is important to check that the bird DOES NOT overhang the burner at the back of the oven.

It is vitally important to strictly adhere to the basic principles of food handling and hygiene to

prevent the possibility of bacterial growth.

1. If food is to be frozen or not served immediately, cool it in a clean container as quickly as

possible.

2. Completely thaw frozen food in the refrigerator before reheating.

3. Re-heat food thoroughly and quickly either on the hotplate or in a hot oven, Mk. 6, and

then serve immediately.

4. Only re-heat food once.

These should always be placed in a pre-heated oven ideally on the first or second shelf

position. Follow the packet instructions for cooking time.

ALUMINIUM FOIL If using Aluminium Foil:

1. Remember that it is important to increase the cooking time by one third.

2. Never allow the foil to touch the sides of the oven.

3. Never cover the oven interior with foil.

4. Never cover the oven shelves with foil.

16

Page 17

Oven Cooking Chart

The following times and setting are for guidance only. You may wish to alter the setting to give a result more to your

satisfaction. When a different setting to that shown below is given in a recipe, the recipe instructions should be

followed. Allow 15 minutes preheat for best results. Always turn the thermostat knob to Mark 9 before selecting the

appropriate gas Mark. Shelf position 1 is the highest.

Food Gas

Fish

Oily and white fish 3 or 4 4 25-60 mins. depending on recipe

Meat and Poultry

Beef 4 or 5 4 25-30 mins per 450g (1 Ib) + 25 mins. extra

Ham 5 4

Lamb 5 4 30 mins per 450g (1 Ib) + 30 mins extra

Pork 5 4 40 mins per 450g (1 Ib) + 40 mins extra

Chicken 5 4 25 mins per 450g (1 Ib) + 25 mins extra

Duckling & Goose 5 4 25 mins per 450g (1 Ib) + 25 mins extra

Turkey 4 or 5 4 or 5 15-20 mins per 450g (1 Ib) + 20 mins

Casseroles 3 3or4 2-6 hrs. depending on cut of meat

Vegetables

Baked jacket potatoes 4 or 5 3 1½ - 3 hrs. until soft, depending on size

Puddings

Milk Puddings (500ml/1 pt) 3 4

Baked Custard (500ml/1 pt) 3 4 45-60 mins. bain-marie

Baked Sponge Puddings 4 3 40-50 mins

Baked Apples 3 3 30-45 mins depending on type and size of apples

Meringue Topped Puddings 1 3or4 15 mins or until "tinged" with brown

Apple Tart (1 x205mm/8//) 6 2 45-60 mins

Fruit Crumble 5 2 35 -45 mins

Cakes, Pastries & Biscuits

Small Cakes 2 trays 5 2 and 4 15-25 mins.

1 tray 5 2 15-22mins.

Victoria sandwich (2 x 7") 4 2 and 4 20-30 mins

Swiss Roll (3 egg quantity) 5 2 15-20 mins.

Meringues 1 3 2-3 hrs

Christmas cake (1 x 205mm / 8") 2 3 Time depending on recipe

Madeira cake (1 x 180mm /

Rich Fruit cake (1 x 180mm /

Scones 7 1 and 3 10-20 mins.

Shortbread (1 x 180mm /

Biscuits 4 1 and 3 10-20 mins.

Shortcrust Pastry 6 2 15 - 60 mins depending on use.

Rich Short Crust 5 1 and 3 20-30 mins.

Flaky/Puff Pastry 7 2 10-30 mins.

Choux Pastry 6 2 20-30mins.

Yeast Mixtures

Bread - rolls 7 2 and 4 20-30 mins.

Miscellaneous

Yorkshire Pudding:- large 7 1 30-40 mins

individual 7 2 20-30mins

7")

7")

7")

Mark

4 4 1¼-1½ hrs.

2 4 Time depending on recipe

2 3 55 -65 mins.

Shelf

Position

Approx. Cooking Time and Comments

40 mins per 450g (1 Ib) covered in foil plus 40 mins.

extra

1¾-2½ stand dish on baking tray and started with

warm milk

When baking with two trays or tins on two levels, the top tray is removed first and the lower tray moved up to the top

position for a few minutes longer.

Soft Margarine -

Use the oven settings recommended by the margarine manufacturer and not those indicated on the cooking chart.

17

Page 18

Care and Cleaning

Grill

Control Panel

Decorative Trims

Doors

Remove the grill pan and the wire grid food support, it is best to wash these items immediately

after use to prevent stains from being burnt on when used again. Wipe out the Grill compartment,

use a fine steel wool soap pad to remove stubborn stains from the grill runners and the floor of the

compartment. Wipe over the control panel with a damp cloth and polish with a dry cloth.

Do not use cream cleaners, oven cleaners or aerosols, scouring pads or abrasive powder for

cleaning the plastic knobs as damage will occur.

It is advisable to clean the decorative trims regularly to prevent any build up of soiling. The

recommended method of cleaning is to wipe over the trims with a soft cloth wrung out in warm

water or mild non-abrasive cleaner. (If in doubt try the cleaner on a small area of trim which is not

noticeable in normal use). Then, after wiping with a cloth wrung out in clear water, dry with a soft

clean cloth.

Wipe over the outer door glass panels with a cloth wrung out in warm soapy water, then after

wiping with a cloth wrung out in clear water, dry with a soft clean cloth. Ensure that glass doors

are not subjected to any sharp mechanical blows.

Glass Inner Door Panel (where fitted) – open the door fully and unscrew the two screws securing

the glass panel, taking care not to allow the glass to fall. The glass panel may now be washed at

the sink. Stubborn stains can be removed by using a fine steel wool soap pad. Ensure the glass

panel is not subjected to any sharp mechanical blows. Take particular care not to damage the

inner surface which is coated with a heat reflective layer. After cleaning, rinse and dry with a soft

cloth. For slight soiling the inner glass panel may be cleaned, while still warm, without removing it

from the door.

Warning: Oven must not be operated with inner door glass removed.

Take care during cleaning not to damage or distort the door seals. Do not lift the door seal from

the oven chassis, if necessary remove the seal by carefully unhooking the corner clips.

Take care that the rating label edges are not lifted during cleaning, and furthermore that the

lettering is not blurred or removed.

Ovens

Oven Shelf

Supports

Oven Lamp

Replacement

Remove the rod shelves and grill pan. Use a fine steel wool soap pad to remove stubborn stains

from the rod shelves, grill pan and the floor of the oven.

The shelf supports are removable and dishwasher safe.

To remove hold the support at the front and pull away from the oven side, this can then be cleaned

in a sink or a dishwasher. When removed it allows access to the oven side, which can be cleaned

with warm soapy water.

To refit the support, insert the longer leg into the rear fixing hole and push in the front leg.

Open the oven door and remove the rod shelves. Using a suitable cloth to protect the fingers grip

the light glass dome, unscrew anti-clockwise and lift. Reach into the aperture with fingers, and

unscrew the lamp anticlockwise. Fit replacement lamp (15W 300°C rated SES), refit dome.

WARNING: To avoid electric shocks - please ensure that the electricity supply to the

appliance is switched off and the appliance is fully cold, before removing the lamp lens.

18

Page 19

Cooking Results Not Satisfactory?

Problem Check

Grilling

Uneven cooking front to

back

Fat splattering Ensure that the grill is not set to too high a

Ensure that the grill pan is positioned centrally below

the grill element.

temperature.

Oven Baking

Uneven rising of cake

Sinking of cakes The following may cause cakes to sink:

Over/Under cooking

Fast/Slow cooking

Uneven cooking of

cakes

Uneven rising of cake Ensure that the shelf is level (see above) and that the

Food is taking too long

to cook

Ensure that the oven shelves are level by using a

spirit level on the rod shelf and adjusting, using

suitable packing e.g. wood, under the feet of the

appliance. This should be checked both left to right

and front to back. Ensure that the food is positioned

centrally in the oven.

1. Cooking at too high a temperature.

2. Using normal creaming method with soft margarine.

Refer to the cooking times and temperatures given in

the oven temperature charts, however, it may be

necessary to increase or decrease temperatures by

10°C to suit personal taste.

Do not use utensils greater than 2¼ ins in height.

1. Too large baking sheet used. (See 'Cookery Notes')

2. Over loading of oven and always ensure even air

gaps around baking tins.

food is positioned centrally in the oven.

Only cook one item at a time to avoid overloading the

oven.

19

Page 20

Something Wrong with your Cooker?

Before contacting your nearest Service Centre/Installer, check the problem guide below; there may be nothing wrong

with your cooker.

Ignit ion does not wor k

Problem Check

Oven Cavit y Oven Bur ner

Ignitor Burner Port s

Top Cavity G rill Burner

Burner Ports Ignitor

Hotplate Bur ner

Hob Top

If all bur ners fail to ignite:

Chec k that s parks appear at the burners;

A c li cki ng nois e should be hear d.

If not

Chec k that t he plug is plug ged in to a

13am p El ectr ic s ocket and the s upply

is swi tched on.

If all burners still fail to ignite

Chec k and rep lace i f nece ssar y the 13amp fus e

If on ly one bur ner f ails to igni te

Check that the burner is dry and that spil lage of food or

cl eaning flu id rem ains are not affec ting the Ignit or or bur ner

port s.

Clean away any debri s with a dry nylon brush suc h as an

ol d dry t oothbrus h.

If a wir e wool pad has been us ed for c leani ng around the

burner ensure the Ignitor is fr ee from any stray str ands.

Any water on the bur ner s hould be dri ed wit h a cl oth or

kitchen towel.

On the hotplate make sure that all burner

part s are c orr ectl y seated

Oven or Grill will not stay lit

when the con tro l knob i s rele ased

Contr ol Panel Contr ol Knobs

Oven Tempe ratur e seems t oo

high or too low

Oven does not cook evenly.

Hotplates are slow to bo il or will

not simmer

Odour or smoke when usin g your n ew cooker

Condensation / Steam in the Oven Aft er Use

Cond ensation o n th e Wall at th e Rear of t he Cooker

Burner Ports Ignit or

For correct ignition of oven/grill burners press the ignition button

and then push in and turn c ontrol knobs anti -cl ock wise.

Continue t o press the i gni tion button u ntil the s park l ight s the gas .

Once al ight r eleas e the i gnition button and c onti nue to h old the

control knob i n for a fur ther 6 to 10 seconds.

Then release the control knob and set to the required temperature.

The f lame shoul d now st ay ali ght.

If the fl ame does not hol d and goes out wait 30 sec onds and try

agai n

Oven Control Grill Cont rol

Chec k that t he temper ature h as been s et in ac cord ance wi th

the temperature charts. It may be necessary to increase or

decr ease t he recom mended t emperat ure by 10 C to s uit y our

taste

Chec k the tem perat ure and shel f posi tion are as r ecom mended

in the temp eratur e chart s

Chec k that t he Utensi l bei ng use d in t he oven a ll ow suff icient

air fl ow around them.

Chec k that t he cook er is leve l.

Chec k that y our pans confor m to the rec omme ndati ons i n

these instructions.

Thi s is norma l and s hould c ease aft er a sho rt peri od.

Condensati on and s team is a by produc t of cooki ng food

wi th a wat er c ontent.

To hel p mi nimise al ways:

A) Try t o avoi d leav ing foo d in t he oven t o cool after b eing c ooked

B) Use a c oved Utens il whereve r poss ibl e

St eam and /or co ndensati on may appear f rom the v ent at th e rear of

the appl ianc e when usi ng an oven, par ti cul arly when coo ki ng foods

wi th a hi gh water content (Suc h as Ov en Chips or Chi cken ).

Thi s is norma l and any exce ss sho uld be wi ped off

20

Page 21

If It Still Won’t Work...

Contact the Service Office (0870 6070805)

If something is still wrong with your appliance after you have been through the ‘Something Wrong’ list:

1. Switch off and unplug the appliance from the mains.

2. Call your nearest Service Office or local importer.

When you contact us we will want to know the following:

1. Your name, address and postcode.

2. Your telephone number.

3. Clear and concise details of the fault.

4. The Model number and the Serial number of your appliance.

5. The date of purchase (please keep the receipt as evidence will be required when an engineer calls)

enter the date here:

.............................................................................

Please make sure you have all these details ready when you call.

Spare Parts

Please remember your new appliance is a complex piece of equipment.

‘DIY’ repairs or unqualified and untrained service people may put you in danger, could damage the appliance

and might mean you lose cover under the Parts Guarantee.

If you do experience a problem with the appliance don’t take risks, call in our Service Engineer. Our Parts are

designed exclusively to fit your appliance. Do not use them for any other purpose as you may create a safety

hazard.

Disposal of your product

To minimise the risk of injury to children please dispose of your product carefully and safely. Remove all doors

and lids. Remove the mains cable (where fitted) by cutting off flush with the appliance and always ensure that

no plug is left in a condition where it could be connected to the electricity supply.

To help the environment, Local Authority instructions should be followed for the disposal of your product.

21

Page 22

Technical Characteristics

Main Oven

Dimensions (HxWxD): 34x39x31 cm

Volume: 41 Litres

Voltage and Frequency

See data plate.

Burners:

Adaptable for use with all the types of gas indicated on the data plate.

This appliance conforms with the following European Economic Community directives:

- 73/23/EEC of 19/02/73 (Low Voltage) and subsequent modifications;

- 89/336/EEC of 03/05/89 (Electromagnetic Compatibility) and subsequent modifications;

- 90/396/EEC of 29/06/90 (Gas) and subsequent modifications (only for models which use gas);

- 93/68/EEC of 22/07/93 and subsequent modifications.

- 2002/96/EC

The European Directive 2002/96/EC on Waste Electrical and Electronic Equipment (WEEE), requires that old

household electrical appliances must not be disposed of in the normal unsorted municipal waste stream. Old

appliances must be collected separately in order to optimise the recovery and recycling of the materials they

contain and reduce the impact on human health and the environment. The crossed out “wheeled bin” symbol

on the product reminds you of your obligation, that when you dispose of the appliance it must be separately

collected.

Consumers should contact their local authority or retailer for information concerning the correct disposal of

their old appliance.

Mains frequency and voltage of the electric section and characteristics of the gas section

Model Gas section Electric section

Class

KD3G2/G

KD3G2S/IR

KD3G21/G

KD3G21S/IR

(1) The values in g/h refer to the capacities with liquid gas (Butane, Propane).

II2H3+

Rated power

kW (1)

12,90 (938 g/h - G30)

(921 g/h - G31)

230-240V~ 50/60Hz

Voltage

22

Page 23

Notes

23

Page 24

Key Contacts

Repair Service and Information Desk

UK: 0870 6070805

(Open 8am to 5.30pm Mon - Fri

9am to 5pm Sat

and 10am to 4pm Sun

Closed Bank Holidays)

Note: Our operators will require the following information:-

Model Number:

Serial Number:

Extended Warranty

To join: UK 0870 442 7661

(Open 8 to 8 Mon-Sun)

Genuine Parts & Accessories

Mail Order Hotline

To join: UK 0870 558 5850

(Open 8.30 to 5 Mon-Fri and 8.30 to 12 Sat).

All Services are offered as an extra benefit and do not affect your statutory rights.

Indesit Company UK Ltd, Morley Way, Peterborough, PE2 9JB

03/2007 - 195048072.06

Loading...

Loading...