Page 1

Model type:

W63TK

Commercial code:

F024761

Page 2

General notes

Technical Documentation guidelines

----------------------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------

You can find herewith some generic information to simplify cunsulting of technical documentation:

1. Models of same range share the same exploded views, which report the richest set of spare parts:generally, a model does not

necessarly have a related spare part for each particular shown on exploded views.

2. Some spare parts can not be represented directly on the exploded views (instruction booklets, specific kit, etc...). You can find

those codes in the spare parts list with the same reference of particular where spares are installed or with references 099, 999.

Instruction booklets, once managed, appear with 000 reference.

3. On the higher right site of each exploded view there is a serial number which indicates the beginning of the production of

certain range:some models might have more than an exploded view for a given category, each distinguished by a different serial

no.and linked to another spare parts list, In this case, serial no. is required to supply the right spare part code. Exploded view to be

considered is the one with a more recent serial no. but previous than the one of the model that needs assistance.

4.Exploded views might require further updates even after publishing. Addition of new spares will go on following the already

existing numeration references. Revision number of an exploded view is shown into last four digits of serial number into upper

right hand corner.

5.The spare parts list associated to an exploded view shows related codes of spares managed for a certain model; for each spare

part other informations are available:

REF: reference no of spare into a table; SUBSTITUTE: list of spare(s) which can replace a code but that keeps same functional

characteristics

INDUSTRIAL CODE: list of variables of a model (shown into model label) where such spare is used; NOTICE: code of

information(s) to refer to complete technical intervention, track for changes or to find correct spare part code.

6. Some notices, into a same section are generic therefore cannot be directly linked to a spare part. In order to assist a model in

the best way as possible, it is helpful to pay attention to all notices and constantly verify documentation updates

7.Technical documentation cover shows model name and its commercial codes

mod.W63TK page 2

Page 3

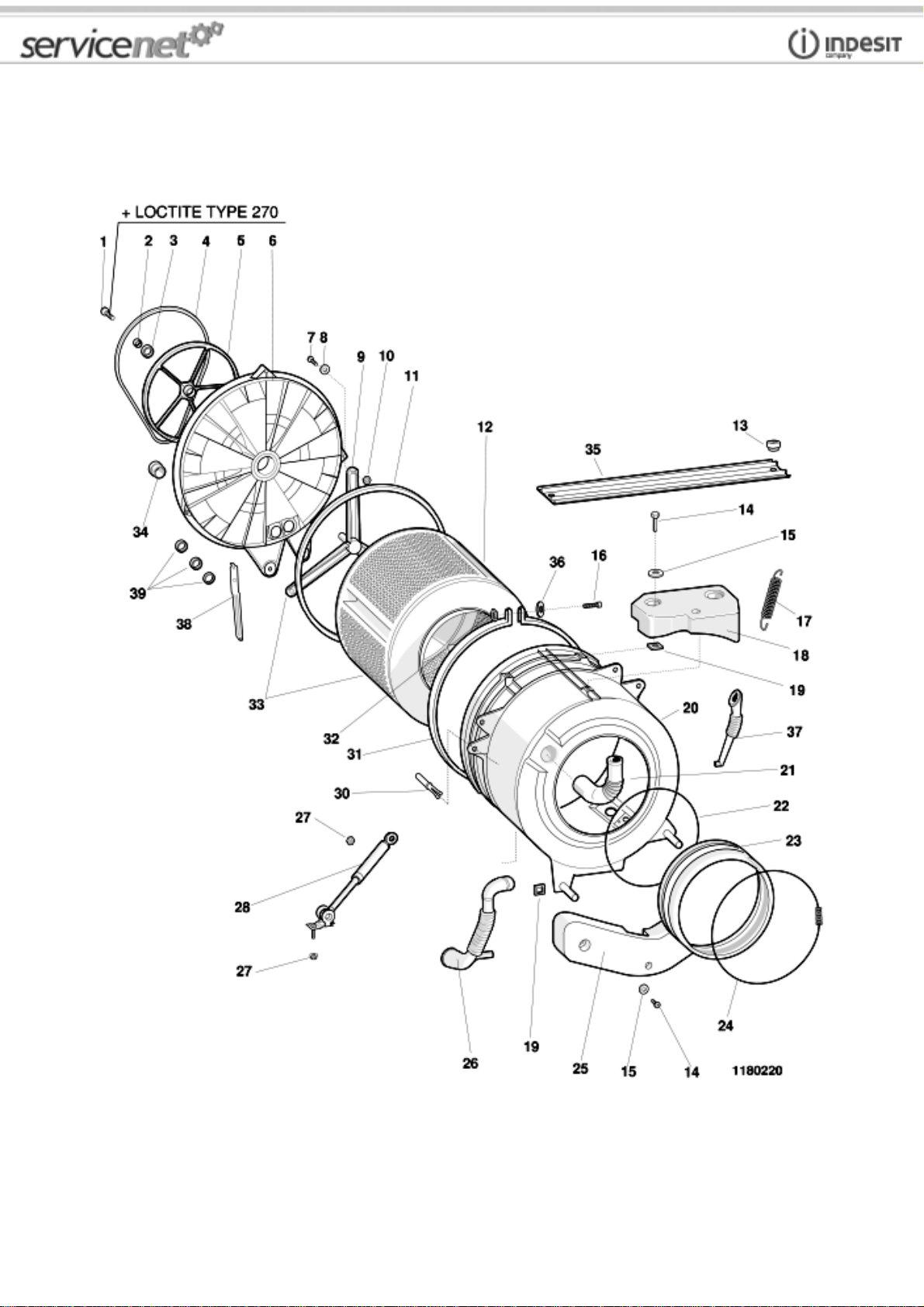

1180110 Exploded views

mod.W63TK page 3

Page 4

1180110 Spare parts list

Ref. Code С сер.№ По Substitute Description Notice Industrial

000 C00078841 user instructions booklet tk

002 C00075420

(488000075420)

003 C00075417

(482000076386)

003 C00083796

(482000076908)

004 C00078839 dashboard + handle

005 C00075317

(482000027327)

007 C00075319

(482000027328)

008 C00075320

(482000022681)

008 C00081890

(482000022709)

009 C00075323

(482000022682)

1 x C00090583

(482000077532)

колпачок электромагн. клапана n1040200

верх в сборе

белая тумба n1040200

белая клавиша

рукоятка белого таймера

дверца люка в сборе n1040213

дверца люка в сборе

ручка люка в сборе

n1040276

010 C00075418

(482000027331)

011 C00050320

(482000070430)

012 C00059869

(482000027089)

013 C00075325

(482000070083)

014 C00002497

(482000072582)

014 C00019846

(482000072833)

8 x C00309312

(488000309312)

2 x C00096210

(482000022792)

1 x C00255430

(482000023037)

белый плинтус

регулируемая опора m 8 h = 41

mm

пружина ножки d =11 mm h =

21 mm

петля смотрового 3.5 mm indesit

гайка m4x3,2x7

винт t 1/2 t m4x12

mod.W63TK page 4

Page 5

014 C00057568

(482000070059)

015 C00044085 заглушка для мебели

1 x C00065185

(482000022669)

bolt kfr

016 C00064755

(482000027172)

017 C00046924

(482000074303)

019 C00076402 panel paraspray

099 C00040932

(482000073863)

099 C00044115

(482000074165)

099 C00056932 bolt

099 C00058925

(482000027062)

099 C00065878 bracket

099 C00065879

(482000027217)

самоконтрящаяся гайка m6

прокладка упаковки l = 34 mm

прокладка упаковочная бака

хомут

панель задняя белая 27

пластмассовая

винт бака пластмас.

mod.W63TK page 5

Page 6

1180220 Exploded views

mod.W63TK page 6

Page 7

1180220 Spare parts list

Ref. Code С сер.№ По Substitute Description Notice Industrial

001 C00034335

(482000073494)

винт крепежный ведомого

шкива m10

n1040259

002 C00034337

(482000068675)

002 C00058039

(482000075058)

004 C00056443

(482000022651)

005 C00055043

(482000026924)

006 C00056949

(482000026983)

006 C00081781

(482000070067)

009 C00038453

(482000070062)

1 x C00038358

(482000026357)

1 x C00089642

(482000027789)

1 x C00034335

(482000073494)

1 x C00038358

(482000026357)

1 x C00089734

(482000027794)

шайба 10,5 x 21 n1040259

шайба 10,5 x 25 x 3

ремень j4 1279/80/85 mm n1040305

ведомый шкив d= 280 mm n1040259

крышка пласт. ванны 800-1000-

2f

крышка бака пластм. без

отверстий th

крестовина барабана 600-800

об(20406)

n1040193

n1040259

n1040259

011 C00040897

(482000026412)

012 C00036059

(482000073589)

013 C00047133

(482000026642)

014 C00014342

(482000072693)

014 C00055019 винт m8x60 te

014 C00081630 винт самонарезающийся l 60 /

1 x C00089735

(482000077409)

уплотнительная резина

барабан 400-600-800-1000 obg

зажимн.кольцо пружины бел.

винт m8x75 te n1040184

n1040235

n1040235

56 mm x 9,5

mod.W63TK page 7

Page 8

015 C00034336

(482000068425)

шайба d33xd9xsp2 n1040184

n1040235

015 C00055018

(482000074893)

016 C00058677

(482000070056)

017 C00055017

(482000026920)

018 C00065959

(482000070289)

019 C00055038 пластинка n1040235

020 C00066420

(482000071375)

020 C00081216

(482000027495)

021 C00066183

(482000027226)

1 x C00014855

(482000072700)

1 x C00066615

(482000075486)

1 x C00066421

(482000027234)

коническая зубчатая шайба m8 n1040184

n1040235

bolt m8x8,8x90

пружина ванны

upper counterweight

пластмас. ванна без сбора

моющ.средства

втулка стальная комплект d=10

mm l=10 mm

сильфон загрузки

моющ.средства

n1040179

n1040235

n1040179

022 C00041843

(482000073980)

022 C00057933

(482000027016)

023 C00057932

(482000027015)

024 C00064546

(482000027165)

025 C00054768

(482000074866)

1 x C00081633

(482000076733)

шайба плоская 8,5x17x1,5

пружинное кольцо бака

прокладка смотрового окна

пружинное кольцо

front counterweight 9,8 kg. n1040184

mod.W63TK page 8

Page 9

1180220 Spare parts list

Ref. Code С сер.№ По Substitute Description Notice Industrial

025 C00081633

(482000076733)

передний противовес 9,8 кг. n1040235

026 C00054777

(482000074868)

027 C00065152

(482000075376)

028 C00055039

(482000026922)

030 C00055037

(482000026921)

031 C00042410

(482000074042)

032 C00040935 гайка m8 самоконтрящаяся

033 C00038450

(482000070379)

034 C00014917

(482000025959)

034 C00020181

(482000026014)

035 C00055397

(482000026932)

1 x C00089735

(482000077409)

сильфон слива

гайка romob m6x22x1,5

амортизатор 120 n

расширитель

кольцо бака, пластик

drum + spider assembly 600-800-

1000 rpm

прокладка термостата

пробка отверстия термостата

поперечина корпуса

036 C00058676

(482000070061)

038 C00066597 earth plate n1040297

039 C00066691

(482000075492)

099 C00057566

(482000075020)

1 x C00041843

(482000073980)

1 x C00090555

(482000027827)

шайба 8,4x14x1,6

подшипники пласт.ванны n1040259

винт hi-lo 4 x10

mod.W63TK page 9

Page 10

1180310 Exploded views

mod.W63TK page 10

Page 11

1180310 Spare parts list

Ref. Code С сер.№ По Substitute Description Notice Industrial

001 C00064563

(482000075318)

кабель питания 3x1 schuko 1,5 m

002 C00019902

(482000072836)

003 C00027466

(482000026108)

005 C00058465

(482000027042)

005 C00058466

(482000075091)

005 C00063971

(482000027138)

006 C00065987

(482000075427)

007 C00065975

(482000027221)

009 C00075456

(482000027333)

012 C00050186

(482000074520)

016 C00075352

(482000042989)

1 x C00143383

(482000029761)

1 x C00097732

(482000022797)

опора спиральн. сливн. шланга

сливной шланг длина 1860 mм

двухполюсный выключатель

вкл-выкл

разм. выключатель

однополюсный выключатель

вкл-выкл

шумопоглощающий фильтр

таймер elbi 0748/1.a/2.a n1040178

красная сигнальная лампочка f.

опора реле давления

прямой ящик моющего средства

n1040251

017 C00057877

(482000075049)

018 C00075351

(482000070267)

019 C00034325

(482000069524)

020 C00019755

(482000026008)

022 C00103883

(482000028372)

023 C00015856

(482000025963)

1 x C00097732

(482000022797)

1 x C00097835

(482000022799)

1 x C00103833

(482000078920)

реле давления 1 уровня 225 /

110

воронка

pressure switch hose l 560 mm

устройство вибропоглощающее

воздухоуловитель 1-ход. 117

mm

термостат 1t 87ø c nc n1040193

mod.W63TK page 11

Page 12

024 C00020181

(482000026014)

пробка отверстия термостата

025 C00011140

(482000025944)

027 C00045023

(482000022622)

027 C00045025

(482000022623)

027 C00045027

(482000022624)

028 C00044998

(482000026549)

028 C00085618

(482000070222)

029 C00052497

(482000070064)

030 C00104675

(482000028397)

031 C00040931

(482000073862)

033 C00050187

(482000026722)

1 x C00119307

(482000022889)

1 x C00082723

(482000076853)

устройство блокировки двери

рукоятка фильтра askoll/plaset

прокладка фильтра

насосный фильтр askoll/plaset

асинхр. самоочищ. насос 240

в/50 гц с фильтром

асинхр.самоочищ. насос без

сбора моющ.средства "idc"

оцинков.винт m6 x 30

втулка штифта двигателя

опорный штырь двигателя

пластмас.ванны

бел.пласт.маточная гайка

n1040223

034 C00066247 двигатель 2/16 полюсов 220 в

037 C00055036 защита нагревательного

038 C00066284

(482000070356)

038 C00082601

(482000027556)

041 C00074643

(482000070847)

1 x C00086357

(482000027685)

1 x C00087885

(482000027743)

1 x C00045957

(482000026580)

предохран. 1800 вт/230 в+земля

нагреватель с стермопредохр.

конденсатор + скоба 16

50 гц

элемента

сопротивление с тепл.

1800w

n1040193

mod.W63TK page 12

Page 13

1180310 Spare parts list

Ref. Code С сер.№ По Substitute Description Notice Industrial

046 C00075812

(482000076422)

крышка воронки 1 ev

047 C00064534

(482000022667)

047 C00074586

(482000027297)

048 C00005572

(482000025916)

049 C00005781

(482000025917)

050 C00003070

(482000022577)

052 C00078840 wiring + timer elbi 0748/1.a

054 C00047069

(482000070270)

056 C00082616

(482000076838)

1 x C00314116

(484000001132)

1 x C00097834

(482000022798)

прокладка воронки

электроклапан ie2u 7 lt.

прокладка заливочного шланга

фильтр заливочного шланга

залив.шланг 1500 mm

крышка присадок

термостат для сопротивления 1t

87шc nc

mod.W63TK page 13

Page 14

Notices

n1040178: Timer ELBI 0748 green label specifically for the SAT.

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

The timer code 065975 that is forwarded as a spare part, is used exclusively for After Sales Service.

This particular item is handled in place of the five timers used in production, and differs not only aesthetically but also in function

as it combines all the operations.

Please be aware of the following, in the employment of the timer Code 065975 - Timer Elbi 0748 Green Label for SAT :

1) Do not rotate the wiring harness connectors at 180° during the connection;

2) The connectors must be inserted in respect to their correspondence to the letters noted on the lower right side of the timer,

without respecting the terminals.

3) The SAT timer is mounted without any modification performed on apparatus that employ a timer without a distribution lever.

Rationalized Elbi Timers.

The SAT timer, is used in place of the following timers:

ELBI 0748/1.A (yellow label) the distribution lever is not employed;

ELBI 0748/2.A (blue label) the distribution lever is not employed;

ELBI 5000 0678.A Rationalized (white label);

ELBI 5000 0698.A Rationalized (red label);

ELBI 5000 0698/3.A Rationalized (white label with red band).

n1040179: Kit of Small Steel Sleeves for spring eyelets on plastic tubs.

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

If on the apparatus' with plastic tubs with registration number previous to 81001.0001, the wearing of the spring eyelet shows

(caused by an anomalous rubbing of the spring on the plastic), a Kit of small steel bushes been realized (Diameter 10 mm X

Length 10 mm) Code 081216.

The two small sleeves that are part of the kit have to be inserted in interference to the spring eyelets (see Letter A in following

figure)when signs that these have being used are visible. The solution is effective even if the ring is completely cut.

mod.W63TK page 14

Page 15

n1040184: Modification of counterweight fixing on front plastic tubs.

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

From the registration no. 10320.0001, the front counterweight fixing system has been modified, on Washing machines with

plastic tubs produced in the Teverola factory plant, that now is achieved via the use of three self-tapping screws code 081630.

This modification has affected the following items :

Tubs code 066420 and 066530.

The modified tubs retain the same SAT pre-modification code and will be handled until stock depletion and are equipped with

the respective fixing screws;

Pre-modified tubs equipped with the following items:

Qty. 3 Screws code 014342;

Qty. 3 Conical washers code 055018;

Qty. 3 Plain washers code 034336.

Modified tubs, equipped with the following items:

Qty. 3 Self-tapping screws code 081630.

Front counterweight.

The modified front counterweight code 081633 may be used in place of the pre-modification counterweight code 054768 but not

vice versa, the pre-modification counterweight will continue to be handled until stock depletion.

Each time in a modified tub it is necessary to unscrew the self-tapping screws that stop the front counterweight , effecting again

the fixing and avoiding a possible loosening in time of the tub and consequently its break , it has to be used screws code 014342,

conical washers code 055018, plain washers code 034336 and plates code 055038.

n1040193: Probe perforation / thermostat from the tub cover has been eliminated.

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Rom the registration no. 10401.0001 the Washing machines produced in the Teverola factory Plant, involving the present

notification, the perforation for housing the temperature / adjustable thermostat / probe on the plastic tub cover has been

eliminated and has been realized directly on the connector.

Common Items involved in this modification are :

Code 081653 - Temperature probe

Code 081780 - Connector with thermo fusible + probe perforatio 1700 W 230 V;

mod.W63TK page 15

Page 16

Code 082462 - Connector with thermo fusible + probe perforation 1700 W 240V;

Code 081781 - Plastic tub cover without probe perforation;

Cod. 082616 - Thermostat for heating 1T87°C NC;

Code 081939 - Adjustable thermostat;

Code 082601 - Heating element + termal cut -out 1800W 230V.

The new items are not singularly interchangeable with the pre-modification items that will continue to be handled.

The introduction date of modification especifically for each model, it is visible on the plate of EPROM's description SAT code,

which is inserted on the model's documentation Xpartfinder

n1040200: Electrovalve drill hole plug for Teverola production cabinets.

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

From the registration no. 10601.0001 on all Washing machines produced in the Teverola plant have been using cabinets with two

electrovalve drill holes.

If the model produced provides for one only electrovalve, then one drill hole is capped by using the appropriate plug code

083796.

The cabinets handled by After Sales Service with two electrovalve drill holes where used on models with one only electrovalve

should use the plug.

n1040213: Use of the porthole code 081890.

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

All the washing machines produced in the Teverola Plant that use the porthole code 075320, should be replaced with the

porthole code 081890 when an intervention occurs.

n1040223: Discharge pump "RAST5" for Teverola washing machines

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

From the registration no. 11022.0001, the Teverola produced washing machines involved by the present Notice, will use new

discharge pumps code 085618 and 085617 in substitution respectively to the preceding codes: 044998 and 050334.

The new pumps may be used in place of the preceding pumps ensuring that the terminals are equipped with faston covers.

The pre-modification pumps will be handled regularly until stock depletion.

n1040235: Restored the fixing of the anterior counterweight with platelets inserted in the tub

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

From the 11105.0001 registration number on the washing machines with plastic tubs produced in the Teverola factory, the fixing

mod.W63TK page 16

Page 17

of the anterior counterweight is restored with platelets inserted in the tub instead of those realised with self-threading screws, the

system described in Notice N1040184.

The tubs maintain the same SAT code and are provided with the following particulars:

N° 3 Screws code cod. 014342;

N° 3 Conical washer cod. 055018;

N° 3 Plain washer cod. 034336.

Whenever the necessity may arise on a tub, proceed with diverting the self-threading screws that block the anterior

counterweight., as it's compulsory to execute the fixing again avoiding in time a possible loosening and thus the breaking of the

tub by utilising the registered screws (cod. 014342), the conical washers (cod. 055018), the plain washers (cod. 034336) and the

platelets (cod. 055038).

n1040251: Induction motors NO On/Off switch

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

From serial number 20304.0001, the NO On/Off switch code 063971 replaces the NO + NO double On/Off switch code 058465

on all the washing machines with induction motor produced in the Teverola factory.

Both switches are regularly managed, therefore in case of repair the serial number of the unit must be taken into consideration.

mod.W63TK page 17

Page 18

Electric schemes and links

Cod. ce014100

mod.W63TK page 18

Page 19

Legend

Legend: ce014100

AQS Aquastop electrovalve Mzbn/MTA zbn timer motor

B Buzzer N Neutral or Terminal Board

BC Blocco Cesto NC Spin cycle exclusion

BF Terminal board contact, motor fan and dryer P Pressure switch

BP Buzzer P1 1st level pressure cut-off switch

C Condensator P2 2nd level pressure cut-off switch

CA Condensator PA High speed potentiometer

DV Switching device PB Low speed potentiometer

EF/CL Electro-Valve Cold Water / Bleach PL Pure Wool

EF/L Electro-Valve Cold Water / Wash PM Motor Thermoprotector

EF/P Electro-Valve Cold Water / Prewash PR Timer programmer or Pressure switch

ER Exclude Heating Element PS Drain pump

ET Thermostat disactivation R Heating element

EV Electrovalve RE Relay

EVA Dryer electrovalve RR Heating element

EVC Hot water electrovalve RV Speed regulator

EVF Elettrovalvola acqua fredda Ras/RA Dryer heating element

EVL Wash electrovalve S LED

EVP Pre Wash electrovalve SL Line LED

FA Antijamming filter SO Door LED

FD Delicate drying cycle thermostat SR Heating LED

FE Strong drying cycle thermostat ST Temperature selector

FRT Thermofusible Heating Element SV Speed Selector for Spin

I Inverter T Timer contacts

I1..2..3.. Switches/switching devices TA Drying timer contacts

IA Switch On/Off TB Low Temperature Thermostat

IC Switch N.C. - 1/2 Load TC Spider wheel earth

ID Switch display TFL Flange earth

IE Water Saving Device TG Main earth

IF Switch - Spin Reduction TH Thermostat

IP Door switch TH1 1st temperature thermostat

IR Line switch TH2 2nd temperature thermostat

IS Water-stop TH3 3rd temperature thermostat

mod.W63TK page 19

Page 20

L Line or Lamp THF Operating thermostat

LB Low Level THR Adjustable thermostat

LN Normal Level TM Motor earth

LS Pilot lamp TMB Main cabinet earth

M Earth-symbol TMP Motor thermal protector

MC Spin cycle motor TMS Thermostop

MI MOTOR WITH PULLEY TP Thermal protector

ML Wash cycle motor TPS Drain pump earth

MO Terminal Board TR Heating element earth

MP Door dip-switch TS Safety thermostat

MR Thermal Lock TT Timer earthing connection

MT Timer motor TTH Earthing Thermostat

MV Motor fan TV Tank earth

MV -Ras Dryer heating element ZBN Timer

mod.W63TK page 20

Page 21

Electric schemes and links

Cod. lg001400

mod.W63TK page 21

Page 22

Legend

Legend: lg001400

AQS Aquastop electrovalve Mzbn/MTA zbn timer motor

B Buzzer N Neutral or Terminal Board

BC Blocco Cesto NC Spin cycle exclusion

BF Terminal board contact, motor fan and dryer P Pressure switch

BP Buzzer P1 1st level pressure cut-off switch

C Condensator P2 2nd level pressure cut-off switch

CA Condensator PA High speed potentiometer

DV Switching device PB Low speed potentiometer

EF/CL Electro-Valve Cold Water / Bleach PL Pure Wool

EF/L Electro-Valve Cold Water / Wash PM Motor Thermoprotector

EF/P Electro-Valve Cold Water / Prewash PR Timer programmer or Pressure switch

ER Exclude Heating Element PS Drain pump

ET Thermostat disactivation R Heating element

EV Electrovalve RE Relay

EVA Dryer electrovalve RR Heating element

EVC Hot water electrovalve RV Speed regulator

EVF Elettrovalvola acqua fredda Ras/RA Dryer heating element

EVL Wash electrovalve S LED

EVP Pre Wash electrovalve SL Line LED

FA Antijamming filter SO Door LED

FD Delicate drying cycle thermostat SR Heating LED

FE Strong drying cycle thermostat ST Temperature selector

FRT Thermofusible Heating Element SV Speed Selector for Spin

I Inverter T Timer contacts

I1..2..3.. Switches/switching devices TA Drying timer contacts

IA Switch On/Off TB Low Temperature Thermostat

IC Switch N.C. - 1/2 Load TC Spider wheel earth

ID Switch display TFL Flange earth

IE Water Saving Device TG Main earth

IF Switch - Spin Reduction TH Thermostat

IP Door switch TH1 1st temperature thermostat

IR Line switch TH2 2nd temperature thermostat

IS Water-stop TH3 3rd temperature thermostat

mod.W63TK page 22

Page 23

L Line or Lamp THF Operating thermostat

LB Low Level THR Adjustable thermostat

LN Normal Level TM Motor earth

LS Pilot lamp TMB Main cabinet earth

M Earth-symbol TMP Motor thermal protector

MC Spin cycle motor TMS Thermostop

MI MOTOR WITH PULLEY TP Thermal protector

ML Wash cycle motor TPS Drain pump earth

MO Terminal Board TR Heating element earth

MP Door dip-switch TS Safety thermostat

MR Thermal Lock TT Timer earthing connection

MT Timer motor TTH Earthing Thermostat

MV Motor fan TV Tank earth

MV -Ras Dryer heating element ZBN Timer

mod.W63TK page 23

Page 24

Electric schemes and links

Cod. se050300

mod.W63TK page 24

Page 25

Legend

Legend: se050300

AQS Aquastop electrovalve Mzbn/MTA zbn timer motor

B Buzzer N Neutral or Terminal Board

BC Blocco Cesto NC Spin cycle exclusion

BF Terminal board contact, motor fan and dryer P Pressure switch

BP Buzzer P1 1st level pressure cut-off switch

C Condensator P2 2nd level pressure cut-off switch

CA Condensator PA High speed potentiometer

DV Switching device PB Low speed potentiometer

EF/CL Electro-Valve Cold Water / Bleach PL Pure Wool

EF/L Electro-Valve Cold Water / Wash PM Motor Thermoprotector

EF/P Electro-Valve Cold Water / Prewash PR Timer programmer or Pressure switch

ER Exclude Heating Element PS Drain pump

ET Thermostat disactivation R Heating element

EV Electrovalve RE Relay

EVA Dryer electrovalve RR Heating element

EVC Hot water electrovalve RV Speed regulator

EVF Elettrovalvola acqua fredda Ras/RA Dryer heating element

EVL Wash electrovalve S LED

EVP Pre Wash electrovalve SL Line LED

FA Antijamming filter SO Door LED

FD Delicate drying cycle thermostat SR Heating LED

FE Strong drying cycle thermostat ST Temperature selector

FRT Thermofusible Heating Element SV Speed Selector for Spin

I Inverter T Timer contacts

I1..2..3.. Switches/switching devices TA Drying timer contacts

IA Switch On/Off TB Low Temperature Thermostat

IC Switch N.C. - 1/2 Load TC Spider wheel earth

ID Switch display TFL Flange earth

IE Water Saving Device TG Main earth

IF Switch - Spin Reduction TH Thermostat

IP Door switch TH1 1st temperature thermostat

IR Line switch TH2 2nd temperature thermostat

IS Water-stop TH3 3rd temperature thermostat

mod.W63TK page 25

Page 26

L Line or Lamp THF Operating thermostat

LB Low Level THR Adjustable thermostat

LN Normal Level TM Motor earth

LS Pilot lamp TMB Main cabinet earth

M Earth-symbol TMP Motor thermal protector

MC Spin cycle motor TMS Thermostop

MI MOTOR WITH PULLEY TP Thermal protector

ML Wash cycle motor TPS Drain pump earth

MO Terminal Board TR Heating element earth

MP Door dip-switch TS Safety thermostat

MR Thermal Lock TT Timer earthing connection

MT Timer motor TTH Earthing Thermostat

MV Motor fan TV Tank earth

MV -Ras Dryer heating element ZBN Timer

mod.W63TK page 26

Loading...

Loading...