Indesit FDEF31111, FDEF51110, FDUD43133, FDUD44110, FDUD51110 Service Information

...

Indesit Company UK Ltd

© 2013 Reg. Office: Peterborough PE2 9JB Registered in London: 106725

Service

Information

Interim Manual

for

Hotpoint

Indesit

Hotpoint-Ariston

DISHWASHER

PLP2 Platform

Models Covered

FDEF31111

FDEF33121

FDEF51110

FDUD43133

FDUD44110

FDUD51110

LTB4M116

LTF11M1137

LTF11S1120

5407768 Issue 3 Oct. 2013

SM003785 ~ C00300571

2 of 20

Service Manual UK

Indesit Company

English

SAFETY NOTES & GENERAL SERVICING ADVICE

1. This manual is NOT intended as a comprehensive repair/maintenance guide to the appliance.

2. It should ONLY be used by suitably qualified persons having technical competence applicable product

knowledge and suitable tools and test equipment.

3. Servicing of electrical appliances must be undertaken with the appliance disconnected (unplugged)

from the electrical supply.

4. Servicing must be preceded by Earth Continuity, Earth Resistance and Insulation Resistance ch ecks.

5. Personal safety precautions must be taken to protect against accidents caused by sharp edges on

metal and plastic parts.

6. After Servicing the appliance must be rechecked for Electrical Safety. In the case of applian ces which

are connected to a water supply (i.e.: Washing Machines, Dishwashers & Food Centres etc.) checks

must be made for leaks from seals gaskets and pipe work and rectification carried out where

necessary.

7. It can be dangerous to attempt ‘DIY’ repairs / maintenance on complex equipment and the Compan y

recommends that any problem with the appliance is referred to its own Service Organisation.

8. Whilst the Company has endeavoured to ensure the accuracy of the data within this publication they

cannot hold themselves responsible for any inconvenience or loss occasioned by any error within.

INDEX

Safety Notes & General Servicing Advice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

General Information and Console Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 4

Virtual Sensors - Description and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 6

Additional Component Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Auto Test Cycle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 11

Fault Codes & Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 - 13

Thermistor Resistance Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

General Dishwashing Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 - 19

3 of 20

Indesit Company

Service Manual UK English

GENERAL INFORMATION

Programme Start Delay

AFTER ST ARTING A PROGRAMME THERE WILL BE A DELAY BEFORE THE CYCLE STARTS,

ALTHOUGH THE DISPLAY WILL BEGIN TO COUNT DOWN.

THIS DELAY CAN BE UPTO 5 MINUTES, THIS IS NOT A FAULT

WITH THE MACHINE and

CANNOT

BE CHANGED BY REPLACING P ARTS or REPROGRAMMING.

THERE MAY ALSO BE SHORT DELAYS DURING THE WASH PROGRAMMES.

Introduction

PLP2 Dishwashers are a New Innovation Version of the Current Dishwasher Range (EOS, 2007 to

current 2013).

These models have a DEA700 Module, with a BLAC Wash Pump and Drain Pump, Virtual Sensors

are used to monitor the quantity of water in the machine. The Pressure Switch has been eliminated.

Some Models also feature a Ozone Generator incorporated into the Dispenser.

A New Detergent/Rinse Aid Dispenser on some models incorporating an Ozone Generator.

The Ozone Generator prevents the formation of bacteria consequently minimizing unpleasant smells

inside the tub and generally improving hygiene conditions internally of the appliance.

Top End Models also have a Third Upper Cutlery Tray with a shower head in the roof of the

Dishwasher supplied by a continuation of the Upper Spray Arm Feed Pipe.

DEMO MODE

LCD Models Only

Activation:

1. Make certain the machine is Off at the Console with Mains power On.

2. Switch the machine On, then Off.

3. Press and hold the Start/Pause button, and at the same time (within 5 seconds), press and hold

On/Off for 10 seconds. A confirmatory "Beep" will be heard.

4. The message "DEMO ON" is displayed.

5. Demo Mode can be aborted by disconnecting the applia nce from the power su pply or follow the

Deactivation sequence below.

Deactivation:

1. With the machine Off at the Console, press and hold the Start/Pause button, and at the same

time - within 5 seconds - press and hold On/Off for 2 seconds.

2. A confirmatory "Beep" will be heard and the messa ge "DEMO OFF" is displayed.

3. Demo Mode can also be aborted by disconnecting the appliance from the power supply.

4 of 20

Service Manual UK

Indesit Company

English

CONSOLE PANELS (Dashboards) - PLP2 Platform

LED Type

LCD Display Type

5 of 20

Indesit Company

Service Manual UK English

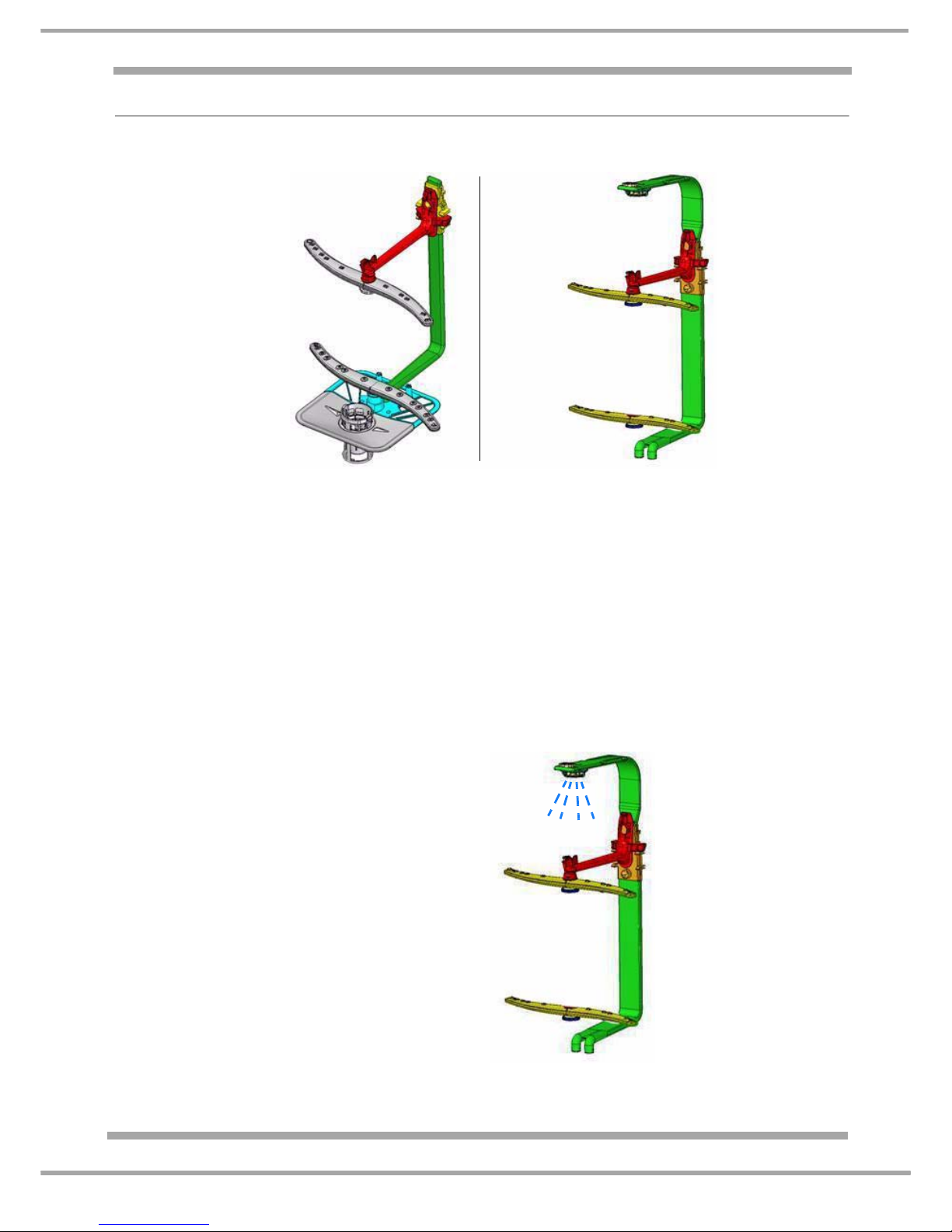

PLP2 Platform Hydraulics

Depending on the model, there are 2 type of PLP2 hydraulics.

"L" column type:

The "L" column system is similar to the classic two basket layout, similar to current Dishwasher

layouts, with the top basket lowered by a few centimetres and changes made to the "lift up" system

"C" column type:

Machines with this hydraulic system have three baskets: the two conventional baskets p lus a thi rd ,

at the top, used for washing cutlery.

A third spray outlet referred to as the Showerhead washes items in the third basket.

Machines with this arrangement also have an alternating wash motor with three delivery outlets and

a relative three-ported sump.

Third Basket - Cutlery Tray

Some PLP models have a third Upper Cutlery

Tray with a shower Head in the Roof. Fig. 3.

shows the Water Circuit.

Fig.1

"L" column type

Fig. 2

"C" column type

Fig. 3

6 of 20

Service Manual UK

Indesit Company

English

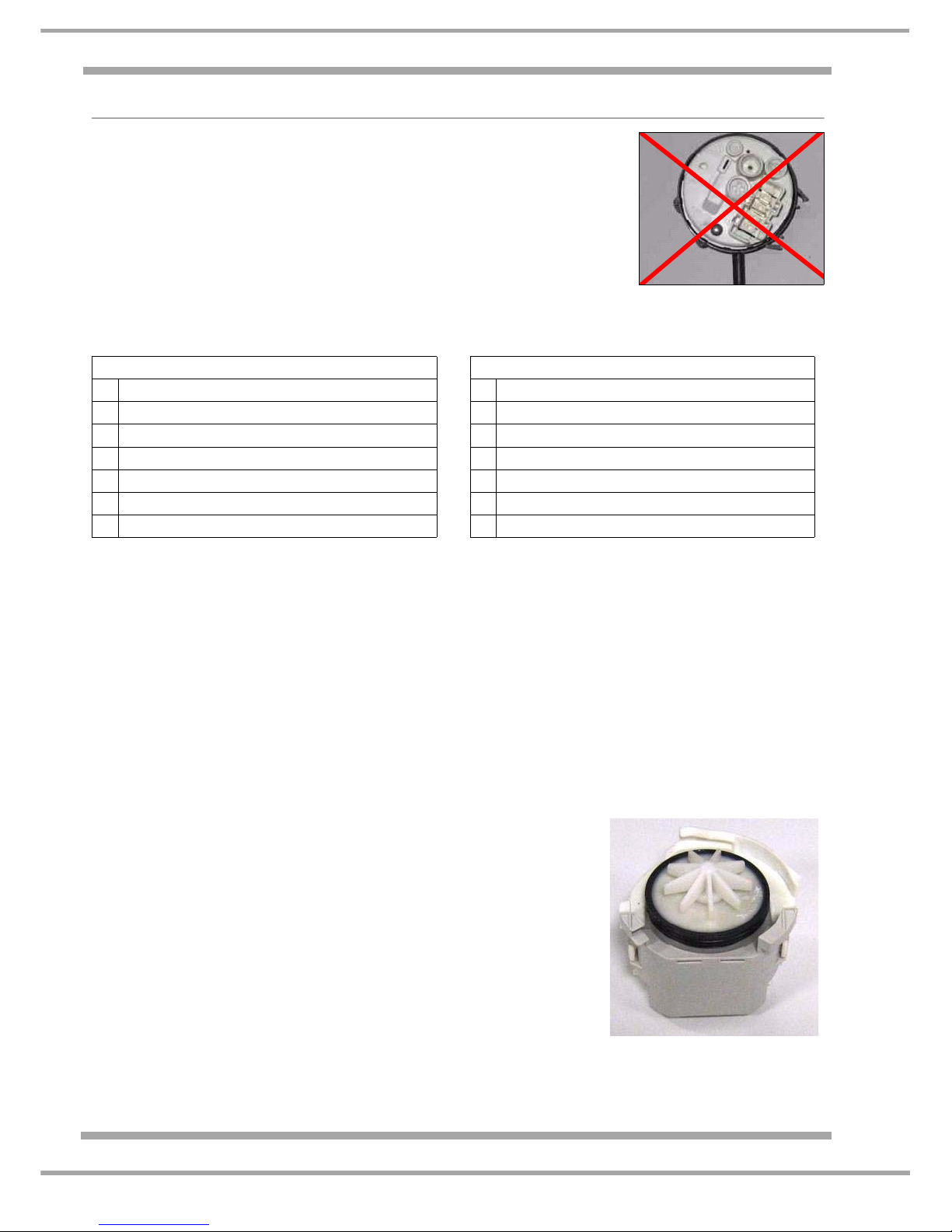

VIRTUAL SENSORS Description and Operation

Basic Description:.

The traditional pressure switch has been replaced by a system of "Virtual

Sensors" that will detect the presence or absence of water in the tub.

In practice, these sensors are the BLAC Wash Pump and the BLAC Drain

Pump.

The Virtual Sensors are able to detect full or empty conditions by

monitoring the operation of the BLAC wash pump and the BLAC drain

pump: By measuring the effort (energy consumption) expended power by

these motors, the Main Module can identify the exact operating situation.

See Tables below.

Virtual Sensor (BLAC WASH PUMP) Sensing Blocked Filter

If, during the wash cycle, the Wash Pump (functioning as Virtual Sensor) senses a Clogged Filters/

Suds situation, the main board will reduce the motor rpm by 20%.

If the situation stabilizes, the problem will b e identified as “Suds” an d the pump continues ope rating

at the new speed.

If the pump continues to struggle (condition 3: build-up of suds or filters clogged),

the speed will be reduced by a further 20% and the problem identified as “Clogged Filters”. If the

situation stabilizes, the pump will continue operating at the new speed.

If the problem persists, the machine will begin to top up with water until there are

5.5 litres in the tub or until the problem is over come (whichever occurs first).

If the problem still persists (even after 5.5 litres of water have entered), the machine

will drain and the program skips to the next step of the cycle.

Drain Pump

The new Drain Pump has a BLAC motor.

The speed of this pump is controlled by the Power Module in

response to the different conditions prevailing at any given moment.

The BLAC Drain Pump's main function is to drain water from the

machine.

In addition, the BLAC drain pump (in combination with the BLAC

Wash Pump) operate as a virtual sensors.

Anti Flood Device

Consisting of a polystyrene float and microswitch. An excess of water

in the base operates the float switch sending a signal to the control

module operating the drain pump and displaying a fault code on the console.

WASH PUMP DRAIN PUMP

0 Empty Sensor 0 Empty Sensor

1 Full Sensor to Wash 1 2 Full Sensor to activate Heating Element 2 Full Sensor

3 Dirty Filters/Foam (unsuitable situation) 3 4 Washing Pump Stopped 4 Drain Pump Stopped

5 Speed Reduction 5 6 State Transition 6 State Transition

Loading...

Loading...