IMP Pumps NMTC module User Manual

NMTC module

Functional profile and user manual

preliminary, 7340055, v4

2

3

Contents

1 Symbols and conventions used in this

document ........................................................4

1.1 Abbreviations and conventions .........4

2 Introduction.............................................5

2.1 System diagram ................................5

2.2 Specifications ...................................5

3 Module layout .........................................7

3.1 Connection considerations ...............8

3.2 Connecting the module wiring ..........9

3.3 Connection examples ..................... 11

4 Control modes and priorities ................. 12

4.1 Priority of settings .......................... 12

4.2 Control variables............................. 13

4.3 Module mode selection .................. 13

4.4 Mode 1 ........................................... 14

4.4.1 Digital (switch) control ............ 15

4.4.2 Analog control ........................ 17

4.5 Mode 2 ........................................... 18

5 Relay output .......................................... 20

6 Ethernet................................................. 21

6.1 Bus topology ...................................21

6.2 Connecting to pump ad-hoc with a

cross over cable .........................................22

6.3 Connecting to pump via router .......26

6.4 Pump configuration over Ethernet ..27

7 Modbus .................................................31

7.1 Modbus related interface ...............31

7.2 Bus topology ...................................31

7.3 Connection to Modbus ...................32

7.4 Speed, parity and address ...............32

7.5 Termination ....................................32

7.6 Register block overview ..................33

7.7 NMTC Configuration register block .33

7.8 NMTC Status register block .............34

7.9 Pump control register block ............34

7.10 Pump status register block ..............36

7.11 Pump data register block ................38

7.12 Modbus telegrams and function

codes 39

8 Fault finding ...........................................39

8.1 Error codes .....................................39

8.2 Communication faults .....................41

WARNING!

Prior to installation and commissioning, read these instructions first. Installation and operation must

comply with local regulations.

WARNING!

Installation and use of this product requires experience and knowledge of this or similar products.

Persons with reduced physical, mental or sensory capabilities must not use this product, unless

properly instructed and supervised. Children must not be allowed to play with this product.

4

1 Symbols and conventions used in this document

WARNING!

Denotes that a failure to observe those instructions might cause damage to equipment or pose danger

to the user.

NOTE: - Gives additional tips or instructions that might ease the job and ensure proper operation.

1.1 Abbreviations and conventions

Abbreviation

Description

Baud, Baud rate

Serial communication speed, in bits per second including start, parity and stop bits.

CRC

Cyclic Redundancy Check, additional bytes used to confirm valid data transmission.

Ethernet

IEEE 802.3, mostly referring to 10BASE-T RJ-45 connector present on board.

H

Differential pressure, often called Head.

LED

Light Emitting Diode.

Modbus

A serial communication protocol used for device automation and remote access.

NMTC

NMT pump Communication module.

Q

Pump flow or flow rate.

RTU

Remote Terminal Unit.

RS-485

Multi drop serial network wiring, used to transfer Modbus data.

For Modbus use, this manual assumes that the reader is familiar with commissioning and configuring of

Modbus devices. It is also assumed that an existing Modbus RTU network on RS-485 wiring with

Modbus master is present.

For Ethernet and web interface use, this manual assumes that the reader knows how to configure or

already has preconfigured Ethernet network.

For use of analog signals and relay output signals, external controller needs to be configured and used.

Proper operating mode must also be selected for the module.

NOTE:

• Data in this document are subject to change.

• Actual implementation might differ by pump model and software revision.

• Make sure you are using the right manual for your product.

• Verify proper operation in the final system.

• Manufacturer cannot be held responsible for problems caused either directly or indirectly by

the use of information in this manual.

5

2 Introduction

This manual describes the NMTC module for NMT range of pumps that is either integrated or separately

available. This module is used for various remote control applications, including:

• Remote on/off

• Analog 0..10V voltage control

• Modbus remote control

• Status relay feedback

• Web access over Ethernet

It is suitable for medium size NMT pumps, 90-440W of rated power.

2.1 System diagram

There are several possible connection configurations. Not all functions can be used simultaneously.

…

2.2 Specifications

The table below is an overview of NMTC specifications. For details, please refer to appropriate

sections of this manual.

General data

Ambient humidity

<95 % relative, non-

condensing

Also see appropriate pump data for other

ambient specifications.

Dimensions

[∅

x H]

112 mm x 32 (45) mm Dimensions without glands.

Power supply and

connection

5V@500mA supplied

by the pump

6-pin connector further extended for display.

on/off + 0..10V + relay output

Modbus RTU + Relay output

Ethernet + on/off + 0..10V

Modbus RTU + Ethernet

Ethernet + on/off + relay output

6

Modbus specifications

Data protocol Modbus RTU

Modbus connector Screwless terminals

2+1 pins. See section 7.3 “

Connection to

Modbus

”.

Modbus connection

type

RS-485

Modbus wire

configuration

Two-wire + common

Conductors: A, B and COM (Common).

See section 7.3 “

Connection to Modbus

”.

Communication

transceiver

Integrated, 1/8 of

standard load

Connect either via passive taps or daisy chain.

Maximum cable

length

1200 m See section 7.5 “

Termination

”.

Slave address 1-247

Default is 245, settable over Modbus. See

section 7.4 “

Speed, parity and address

”.

Line termination Not present

Line termination is not integrated. For low

speed/short distance, termination can be

omitted. Otherwise, terminate the line

externally on both ends.

Supported

transmission speeds

1200, 2400, 4800,

9600, 19200, 38400

baud

Settable over Modbus register [default=19200].

Start bit 1 Fixed.

Data bits 8 Fixed.

Stop bits 1 or 2

1 stop bit minimum, up to 2 when parity not

enabled [default=1]

Parity bit Even/odd/none [default=Even]

Modbus visual

diagnostics

LED2

Flashing yellow when data reception detected.

Combined (OR) with Ethernet ACT function.

Maximum number of

Modbus devices

247

Limited by possible Modbus addresses to 247.

1/8 nominal load enables 256 devices.

Maximum Modbus

packet size

256 bytes Including address (1) and CRC (2) bytes.

Isolation

Common ground

(COM) with SET1,

SET2 and SET3.

Modbus shares common ground with other

signals.

Ethernet specifications

Ethernet connector RJ-45 10BASE-T, 10Mbit/s connection.

Connection type and

services

-

Web server (port 80)

-

Firmware update over web interface

-

Optional Modbus RTU over TCP/IP

Default IP address 192.168.0.245 192.168.0.246 for right twin pump.

Ethernet visual

diagnostics

LED1 / LINK

Slowly blinking when module is powered,

permanently lid when link established.

LED2 / ACT

Flashing yellow when data reception detected.

Combined (OR) with Modbus data reception

indication.

7

Mode selection switch

Adjustment

10 position rotary

switch

Position read at power-on.

Used for relay configuration and module

configuration reset.

Analog signals (SET1, SET2, SET3)

Input voltage range -1..32VDC When used as input.

Output voltage

range

0..12V

When used as output. 5mA max. load allowed

per output.

Input resistance ~100k 0.5mA load is added for most configurations.

Output current sink

range

0..33mA (4-20mA) Current sink to COM if configured as output.

Relay specifications

Connection type Screwless terminals

Rating

- 230 VAC, 3 A, AC1

-

32 VDC, 3 A

Potential free changeover contact.

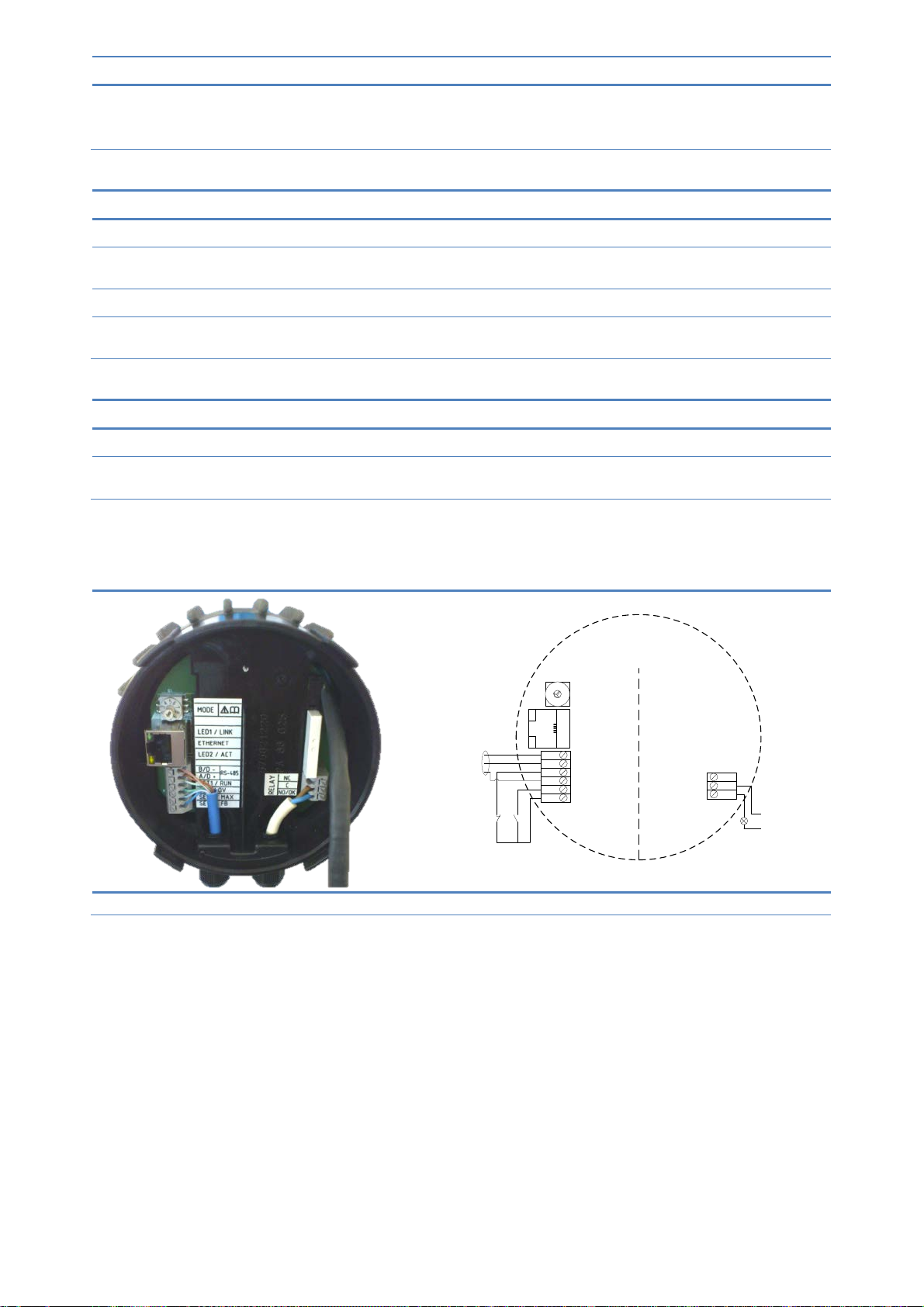

3 Module layout

Modbus signal

SET3 / FB

SET2 / MAX

COM / 0V

SET1 / RUN

A/D +

B/D -

NC

C

NO

RS-485

LED2 / ACT

LED1 / LINK

ETHERNET

MODE

2

1

3

4

5

6

7

8

9

0

MAX

RUN

ALARM

Figure 1: Typical module connection

8

Terminal

Designation

Description

MODE

Mode selection rotary switch. Used to configure mode of operation for the circuit. See

section 4.3 “Module mode selection”.

LED1 / LINK

Slowly blinking when module is powered.

Blinking fast when Modbus Error

Permanently lid when Ethernet link established.

Ethernet

10BASE-T RJ-45 connector.

LED2 / ACT

Indicates Ethernet activity or Modbus activity.

B/D-

RS-485 negative data signal for Modbus.

A/D+

RS-485 positive data signal for Modbus.

SET1 / RUN

Control signal 1.

COM / 0V

RS-485 common and analog input common (ground).

SET2 / MAX

Control signal 2.

SET3 / FB

Control signal 3.

NC

Normally closed relay contact. Opens when relay is active.

C

Relay common contact.

NO / OK

Normally open relay contact. Closes when relay is active.

3.1 Connection considerations

• All cables connected must be heat-resistant to at least +85°C.

• All cables connected must be installed in accordance with EN 60204-1.

• All wires to the communications module must be connected to the terminals or cut. No loose wiring

permitted.

• If voltages over 24VAC/DC are possible on NO, C, NC terminals:

WARNING!

• Wires should be routed so no wire crosses the center barrier.

• Relay cable (NO, C, NC) must be separated from all other wiring with reinforced

insulation. Cable outer layer must not be stripped longer than 15mm. See “Cabling

preparation” below.

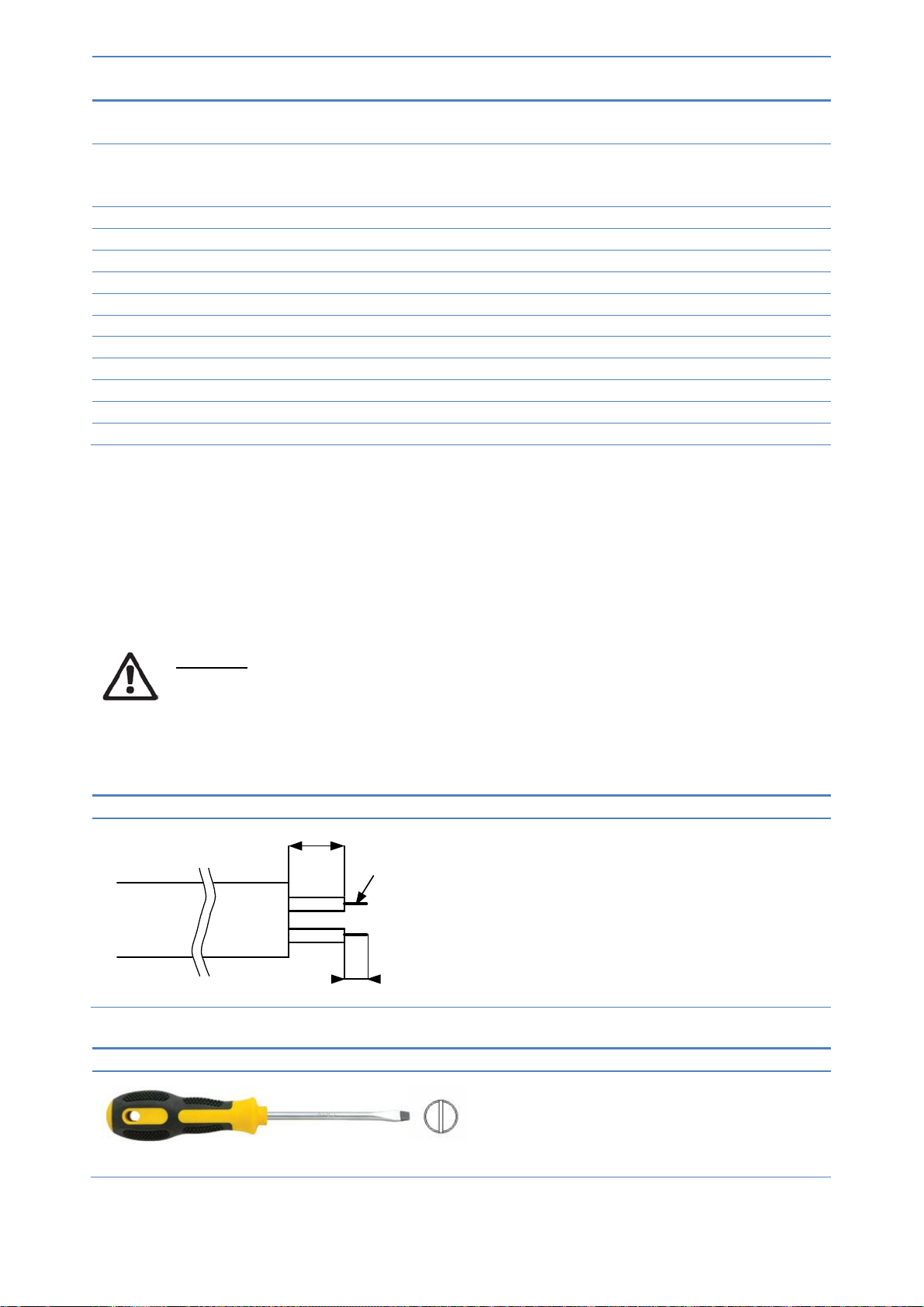

Cabling preparation

max. 15

mm

8(7-

10)mm

0.

25 - 1 mm

2

Cable for the screwless terminals should

be prepared as shown on the left.

Tools

2.4mm wide flat-bladed screwdriver is

needed to press the terminal spring

while inserting the cable.

Same tool is also used to rotate the

Mode switch.

9

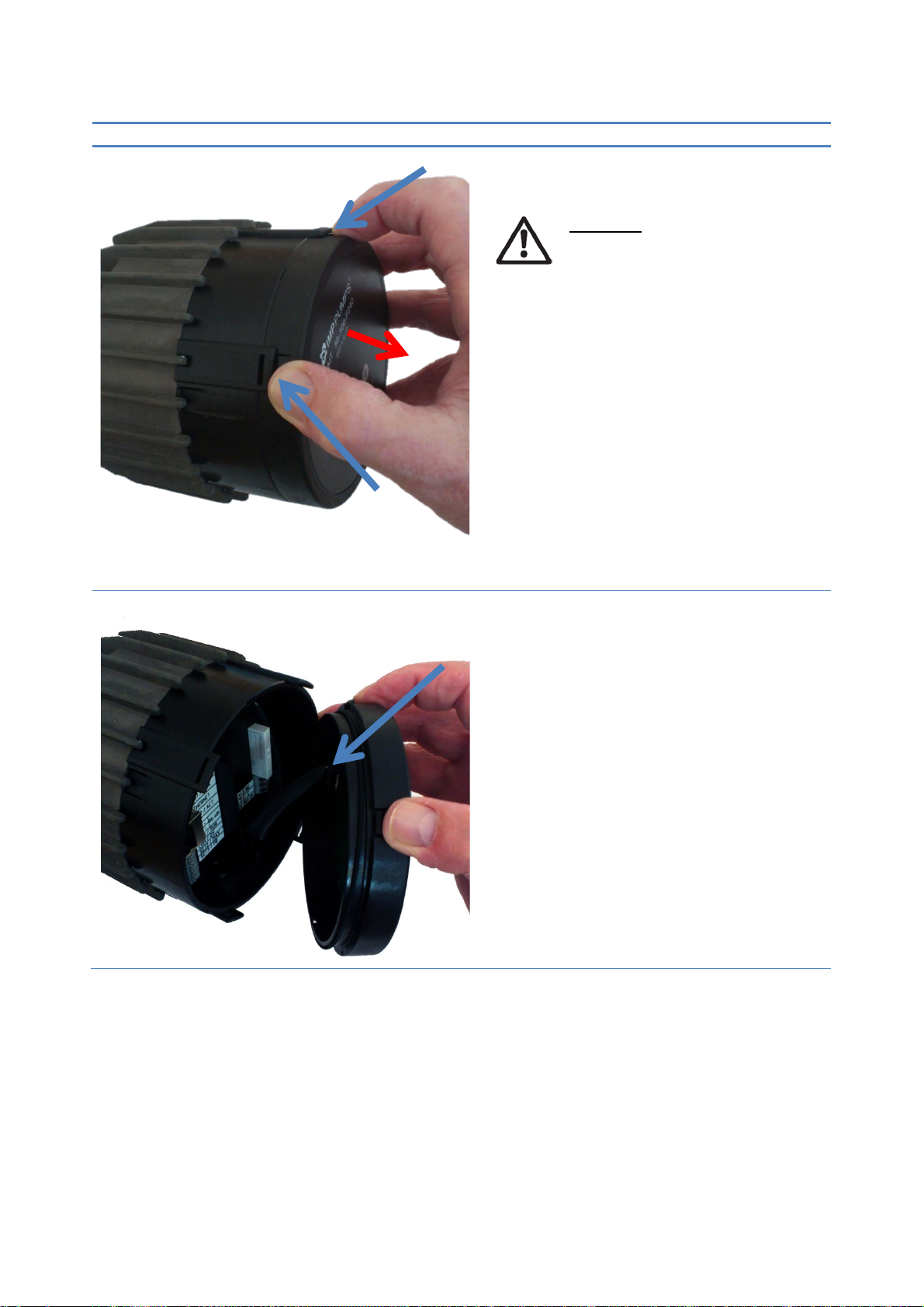

3.2 Connecting the module wiring

Opening the cover

WARNING!

Before performing any work on

the module, make sure that the

pump and module electricity

supply has been switched off and

that it cannot be accidently

switched on.

1) Press two top hooks on the display

panel. Use flat tip screwdriver if

needed.

2) Simultaneously pull display panel away

from the pump.

3) Disconnect display panel cable to ease

access to the module wiring. Wiring can

now be connected.

1.

1.

2.

3.

10

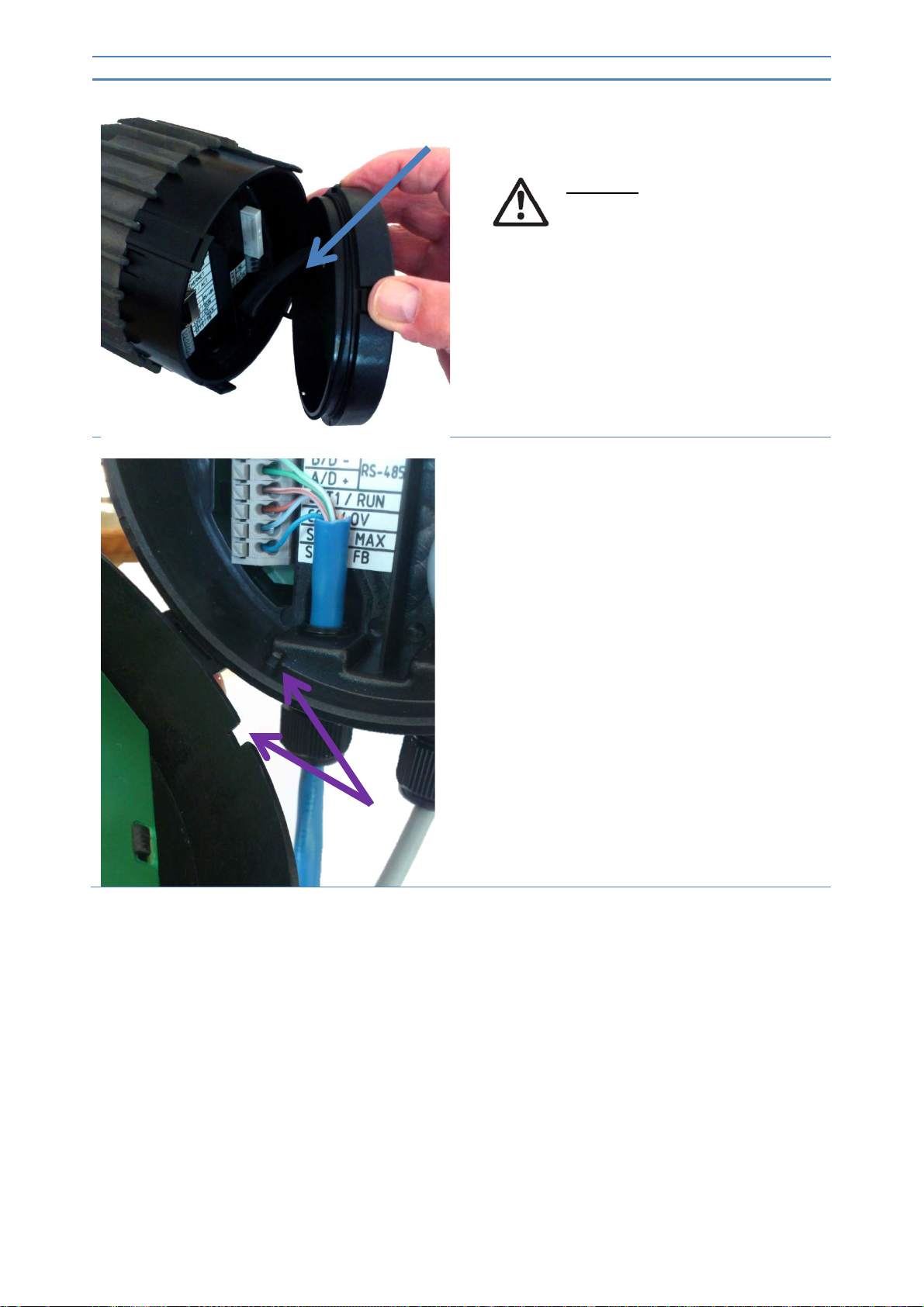

Closing the cover

WARNING!

Before performing any work on the

module, make sure that the pump

and module electricity supply has

been switched off and that it

cannot be accidently switched on.

4) Reconnect display panel cable.

5) Make sure that the position tab and

position slot are aligned.

5.

4.

11

Closing the cover

6) Make sure that the hooks are aligned.

7) Push the display back to the NMTC

module.

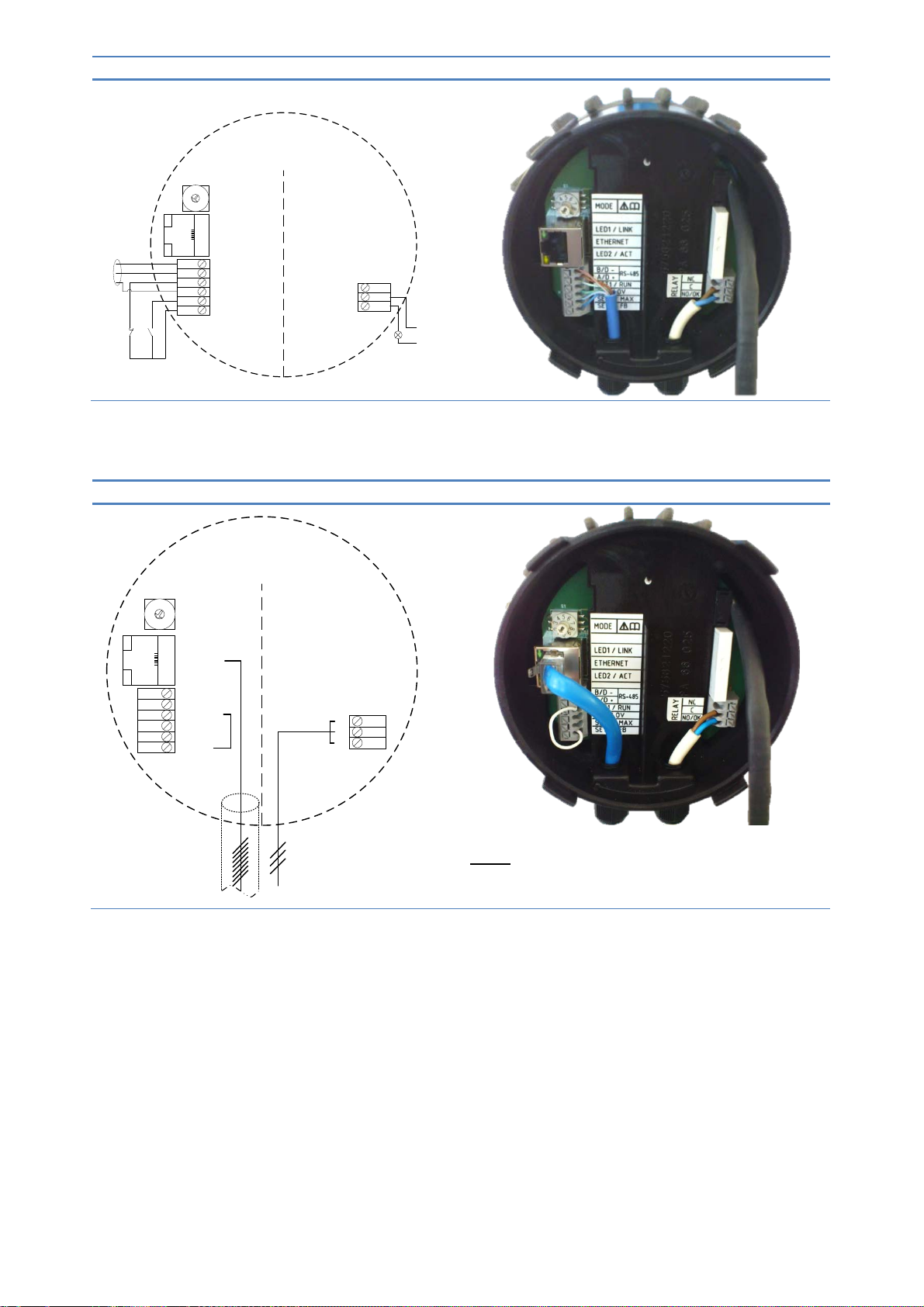

3.3 Connection examples

Default (factory) configuration

SET3/

FB

SET2 / MAX

COM / 0V

SET1 / RUN

A/D +

B/D -

NC

C

NO

RS-

485

LED2 / ACT

LED1 / LINK

ETHERNET

MODE

2

1

3

4

5

6

7

8

9

0

6.

7.

12

Relay and Modbus connection

Modbus signal

SET3 / FB

SET2 / MAX

COM / 0V

SET1 / RUN

A/D +

B/D -

NC

C

NO

RS-485

LED2 / ACT

LED1 / LINK

ETHERNET

MODE

2

1

3

4

5

6

7

8

9

0

MAXRUN

ALARM

Relay and Ethernet connection

SET3/ FB

SET2 / MAX

COM / 0V

SET1 / RUN

A

/D +

B/D -

NC

C

NO

RS

-485

LED2 / ACT

LED1

/ LINK

ETHERNET

MODE

2

1

3

4

5

6

7

8

9

0

NOTE: To maintain pump IP protection, the

network cable should be pulled through the gland

inlet and then crimped to a connector.

4 Control modes and priorities

4.1 Priority of settings

Several signals will influence the pump operation. For this reason, settings have priorities as shown in

the table below. If two or more functions are active at the same time, the one with highest priority will

take precedence.

13

Priority

Pump control panel &

Ethernet settings

External signals

1

Modbus control

1

Stop (OFF)

2

Night mode active

2

3

Max. RPM (Hi)

4

Min. curve

4

5

Stop (Run not active)

6

Max. curve

4

Stop

3

7

Setpoint setting

4

Setpoint setting

3

8

Setpoint setting

4

Examples:

• Stop on the pump display panel will stop the pump, regardless of external setpoint.

• If External Run input is inactive, the pump cannot be started over Modbus, but can be set to max

RPM on the display panel.

4.2 Control variables

Pump will respond to external controls according to selected pump operating mode. Consult proper

pump operating manual for explanation.

Symbol

Regulation mode

Module setpoint controls:

Auto mode

-

(RUN only)

Proportional pressure Maximum head

Constant pressure Maximum head

Constant speed

Speed

(RPM)

Free

5

-

(Web interface only)

Night mode

6

-

(RUN only)

4.3 Module mode selection

1

Not all inputs are available in all modes.

2

External and Modbus Stop signals become active in night mode. Due to possible confusion, use of night mode is

discouraged while using external control.

3

Only available when pump is bus controlled.

4

Not available when pump is bus controlled.

5

Multiple limits can be set. Not available on all pumps.

6

Night mode is not independent regulation mode.

A

Loading...

Loading...