Imperial Brown Walk-In Freezer Owner’s Manual

Walk-In Coolers and Freezers Installation and Maintenance

Release Date: 10-2015

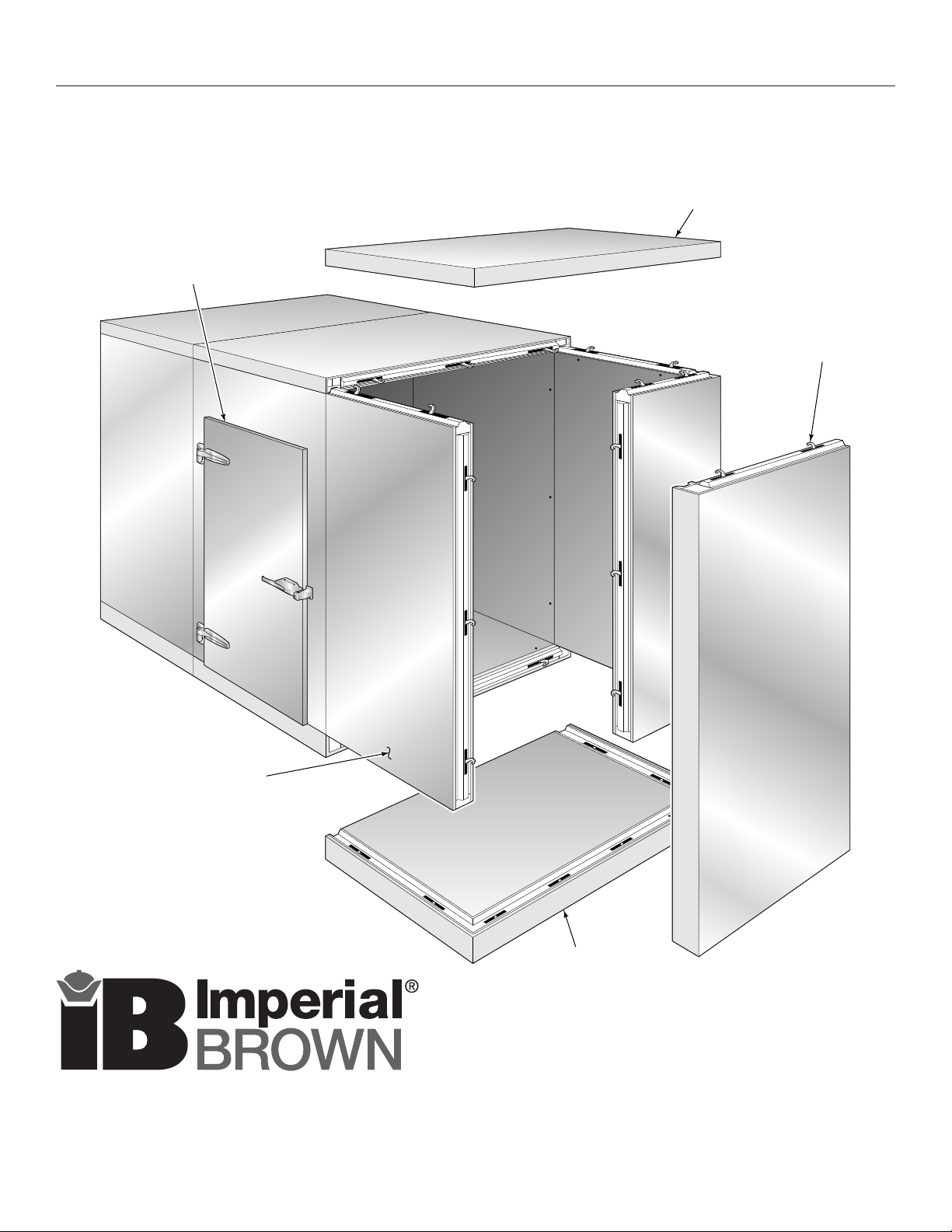

Ceiling Panel

Swing Door

Cam Lock

Fastener

Wall Panel

Floor Panel

Imperial Brown

west coast facility east coast facility

2271 NE 194th Avenue • Portland, OR 97230 209 Long Meadow Drive • Salisbury, NC 28147

Toll Free (800) 238-4093 • Local (503) 665-5539 Toll Free (800) 438-2316 • Local (704) 636-5131

Walk-In Coolers and Freezers Installation and Maintenance

Table of Contents

Page

Important Things You Should Know ....................................................................... 4-5

Shipping and Packaging ..................................................................................... 4

Product Storage .................................................................................................. 4

Permits and Engineering ..................................................................................... 4

Electrical Requirements ...................................................................................... 4

Inside Safety Release ......................................................................................... 4

Ceiling or Roof Loads ......................................................................................... 5

Structural Engineering and Seismic Restraint .................................................... 5

Construction Details ............................................................................................ 5

Penetrations ........................................................................................................ 5

Installation Over Fresh Concrete ........................................................................ 5

Installation Next To Existing Buildings ................................................................ 5

Installation Outside ............................................................................................. 5

Installation Above Ground ................................................................................... 5

Service Hot Line .................................................................................................. 5

Getting Started ....................................................................................................... 6

Tools Required .................................................................................................... 6

Locate the Parts Box ........................................................................................... 6

Shop Prints ........................................................................................................ 6

Shipping List ....................................................................................................... 7

Cam Lock Fasteners ........................................................................................... 7

Assembling Panels Together ............................................................................... 8

Floor Installation ..................................................................................................... 9

Prefabricated Insulated Floors ............................................................................ 9

Insulated Pit Floors ............................................................................................. 11

Wall Panel Preparation ........................................................................................... 13

Installing the Wall Panels ........................................................................................ 15

Installing the Ceiling Panels ................................................................................... 16

Lag-Down Ceilings .............................................................................................. 16

Cam Lock Ceilings .............................................................................................. 17

Doors and Other Add-On Items .............................................................................. 18

Swing Doors with Flat Frames ............................................................................ 18

Horizontal Sliding Doors ..................................................................................... 18

Vertical Lift Doors ................................................................................................ 18

Trafc Doors ........................................................................................................ 19

Glass Doors and Windows .................................................................................. 19

Strip Curtain and Flexible Doors ......................................................................... 19

Shelving .............................................................................................................. 19

Finish Work ............................................................................................................. 20

Snap Caps .......................................................................................................... 20

Tie-Downs and Cove Base ................................................................................. 20

Door Angles ........................................................................................................ 20

Wainscoting ......................................................................................................... 20

Finish Caulk ........................................................................................................ 20

Ceiling Trim ......................................................................................................... 20

Refrigeration Installation ......................................................................................... 21

Periodic Maintenance ............................................................................................. 22

Troubleshooting ...................................................................................................... 23

2

© Imperial Brown, Inc. 2015

Walk-In Coolers and Freezers Installation and Maintenance

IMPORTANT

1. Read all instructions!

2. Please review all illustrations and Shop Prints before installing the structure.

3. Manuals for third-party equipment, such as refrigeration or alarm devices, are included with each item. If

an item is pre-mounted on the Walk-In, the item documentation is included with the Walk-In information

package. e latest Imperial Brown Cooler and Freezer Manual can be found at http://imperial-brown.com.

4. Inspect and report any damage and/or missing parts, before installing. Imperial Brown will not be

responsible for costs of installing or removing damaged parts.

Warnings and Cautions

We provide many important safety messages in this manual about your Walk-In. Always read and obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill, injure, or damage equipment.

All safety messages will follow the safety alert symbol and either the word “Warning” or “Caution.”

These words mean:

WARNING You can be killed or seriously injured if you don’t follow instructions.

CAUTION Equipment can be damaged or destroyed if you don’t follow instructions.

Important Safety Instruction—Read Prior to Installation

All safety messages will tell you how to proceed to reduce the chance of death, injury, or damage to the Walk-In.

To reduce the risk of re, electrical shock, injury, death, or damage when installing or repairing a Walk-In, follow basic

precautions, including the following:

WARNING: During installation, make sure that

equipment does not exceed oor rating. Note that oor

rating might be less than nished product rating until oor

installation is complete (for example, until wear surface is eld

installed). Plywood sheeting should be used to spread the load.

WARNING: Remove children and unnecessary adults

from the area when installing or servicing the Walk-In.

WARNING: Panel lifting methods and panel lifting

equipment must meet OSHA approved guidelines for the

designed loads and lifting methods intended.

WARNING: Temporary support of panels during

assembly is the responsibility of the general contractor

or the onsite installation contractor. Temporary support should

only be attempted by trained individuals familiar with the safest

methods possible for securing loose or otherwise unsupported

panels. Stacking, leaning or blocking of panels when not

permanently supported may result in hazardous conditions.

Personnel injury or panel damage may result.

WARNING: Improper wiring or lack of proper ground can

result in re, electrical shock, injury or death. Disconnect

power to the Walk-In before performing any electrical repairs.

Field wiring or electrical repair should be done by a licensed

professional electrician. Follow all local building codes and laws

for electrical installation.

WARNING: In case of electrical re, disconnect the

power supply. Do not use water on electrical res. Smother

the re with an extinguisher rated for C-class res.

CAUTION: Per NEC 300-7, all raceways passing from

different temperatures shall be sealed with putty or other

method to stop the travel of moisture. Furthermore, all junction

box cover plates shall be sealed. Verify these seals are in place

and functioning properly after performing any service on the unit.

WARNING: Walking, climbing, or standing on non-

permanently supported panels may result in hazardous

conditions including falling. Personnel injury or panel damage may

result.

© Imperial Brown, Inc. 2015

3

Turn to Release Door.

Walk-In Coolers and Freezers Installation and Maintenance

Important Things You Should Know

Shipping and Packaging

Upon receiving freight, check the bill of lading for

the correct number of pallets and check the product

for any shipping damage. Take photos of damaged

goods. Report issues to both the trucking company

and Imperial Brown, Inc. Contact the freight company

directly, at time of delivery, to le a claim.

Product Storage

If panels are to be stored for any length of time

before installation, make sure that they are protected

from moisture, sunlight, and temperature extremes.

Exposure to sunlight or excessive temperature will

make protective plastic sheeting difcult to remove

and labels may dry out and peel off. Moisture trapped

between panels can cause corrosion, such as white

rust.

Permits and Engineering

Imperial Brown is not responsible for obtaining any

permit, unless otherwise noted on the Sales Order.

Specic local building code, engineering, or regulatory

requirements are to be communicated to Imperial

Brown when placing the order.

Electrical Requirements

Electrical requirements for each electrical component

are identied on the Shop Print. Component

instructions and electrical wiring information for

specic components is supplied along with each

component. Component instructions may also be

found online by searching for the component brand

and model number.

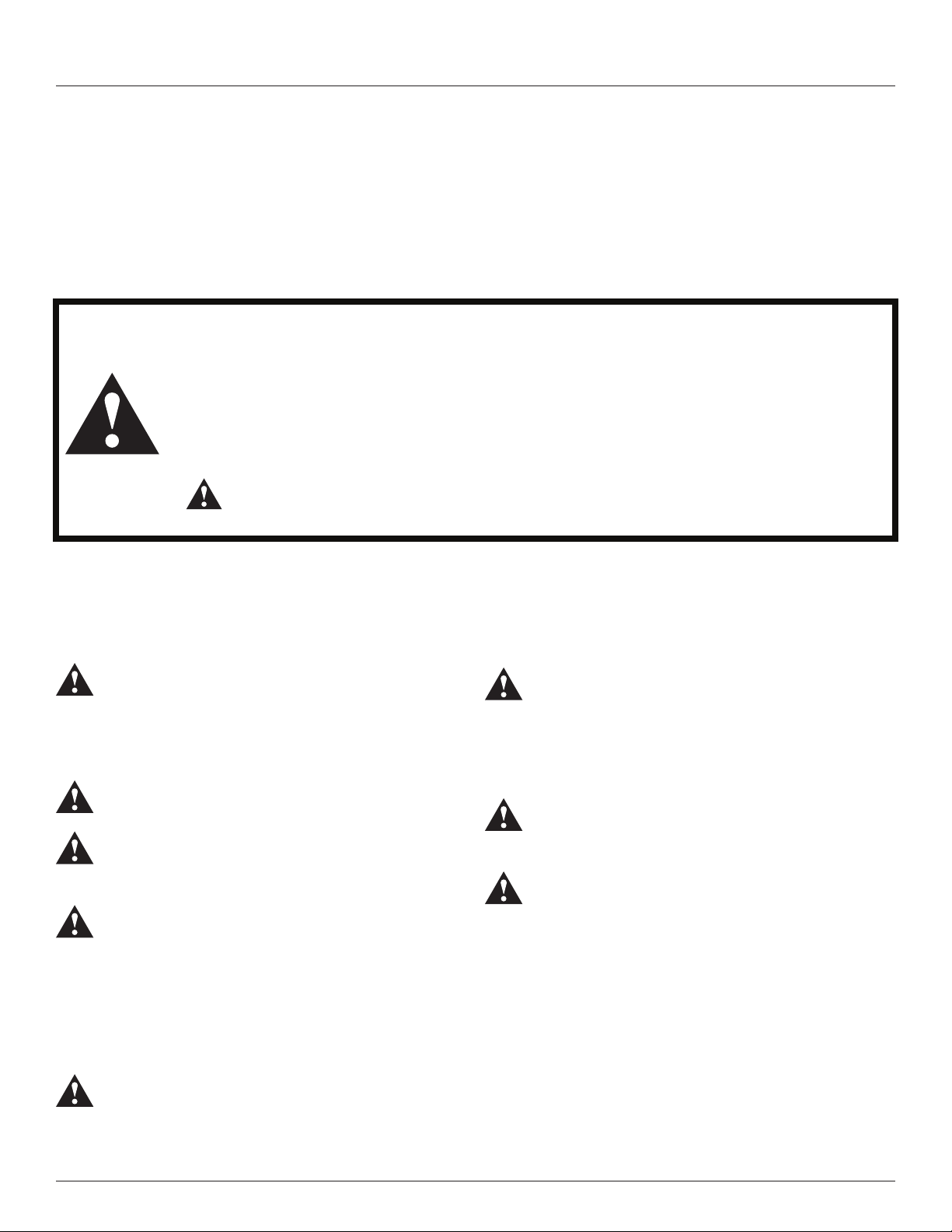

Inside Safety Release

Check to make sure the inside safety release on

the door works correctly and that all personnel

understand how to use it.

Swing Doors—All swing doors equipped with a

positive latch or lockable non-positive latch include an

inside safety release mechanism. The safety release

allows an occupant to open a latched or locked door

from the inside. Push or turn the knob to release

the door. Follow the directions printed on the safety

release label. This includes padlock hasps and fullwidth removable locking bars.

Sliding Doors—All electrically-driven doors have a

Manual Release mechanism that allows the manual

operation of the door. This can be used by turning the

inside release handle to disconnect the door from the

drive. The door can then be slid open and close.

Sliding Door with Padlock Hasp—Sliding doors

equipped with padlock hasp locking devices have an

inside release knob. Turn the knob to unscrew the

lock hasp system from the wall, in order to let the door

open.

Push to

Open

473934

Swing Doors

Slide Door Open.

473933

Sliding Doors

Unscrew Knob. Pull Out.

Slide Door Open.

473935

Doors with padlock hasp or deadbolt locking device

4

© Imperial Brown, Inc. 2015

Walk-In Coolers and Freezers Installation and Maintenance

Important Things You Should Know

Ceiling or Roof Loads

Each unit is designed to meet certain intended loads.

Specic load rating for each unit is indicated on the

Shop Print.

Live Loads—Limit number of workers on ceiling.

Workers should be evenly spread out across the

ceiling. Maintain perimeter loading in lieu of center

(mid-span) loading whenever possible. Do not exceed

maximum loading (see Shop Print).

Environmental Loads – Outdoor Walk-Ins are

designed for specic environmental loads like snow

loads, wind loads, etc. Walk-In must be installed at its

intended location or environmental load requirements

might not be met.

Equipment Loads—The Imperial Brown Design

Department requires review of all equipment,

including refrigeration, re sprinkler, air handling,

and others, before it is installed or attached to ceiling

panels. Failure to submit a list of equipment for review

will void any warranty and may lead to structure

failure.

Installation Outside

Design Loads —These units are designed for wind

load, snow load, and snow drift. Erecting another

structure near the unit location may affect the load

requirements, as loads and drifts may change.

Drainage – Make sure that rain drains away from the

unit.

Installation Above Ground

Installing a unit above ground, such as on the second

story of a building, always requires an insulated oor.

See Floor Installation.

Service Hot Line

800.238.4093

Construction Details

Tie-downs, hold-downs and other requirements must

be installed or performed exactly as shown in the

Shop Print, with no substitutions for fastener size,

spacing or embedment. Variations require permission

of the Imperial Brown Design Department.

Penetrations

Be aware that electrical or mechanical penetrations

through the Walk-In may need to be addressed as

the Walk-In is being erected, prior to losing access to

these items.

Installation Over Fresh Concrete

Out-gassing from curing concrete may cause damage

to the metal nish. To avoid, ensure proper ventilation

(i.e. an open door).

Installation Next To Existing Walls

Two inches of clearance is recommended for air ow

and to allow for wall surface irregularity.

© Imperial Brown, Inc. 2015

5

Walk-In Coolers and Freezers Installation and Maintenance

Getting Started

Tools Required

Minimum required tool set includes:

• Tape measure • Construction hammer

• Chalk line • Drill and electric screwdriver

• Pry-bar • Carpenters bubble level

• Caulking gun • Cam lock wrench (provided)

• Tin snips

Locate the Parts Box

The parts box(es) is generally a cardboard box

located in one of the pallets. It contains this

Installation Instruction, the Shop Prints of the Walk-In,

a Shipping List, and supplies such as fasteners, cam

lock wrench and caulk.

Shop Prints

Enclosed with the unit is a Shop Print showing proper

location of all panels. Before placing any panel into

position, check the print for proper location.

NOTE: This Installation Instruction Manual is provided

to make the installation process as easy as possible,

but it does not show every application available.

Some illustrations and details may not apply to your

unit. Please note any differences between the unit

illustrated and your actual unit.

Make sure that you understand the prints, notes,

and details in the Shop Prints (Parts Box) before

beginning. See Table 1.

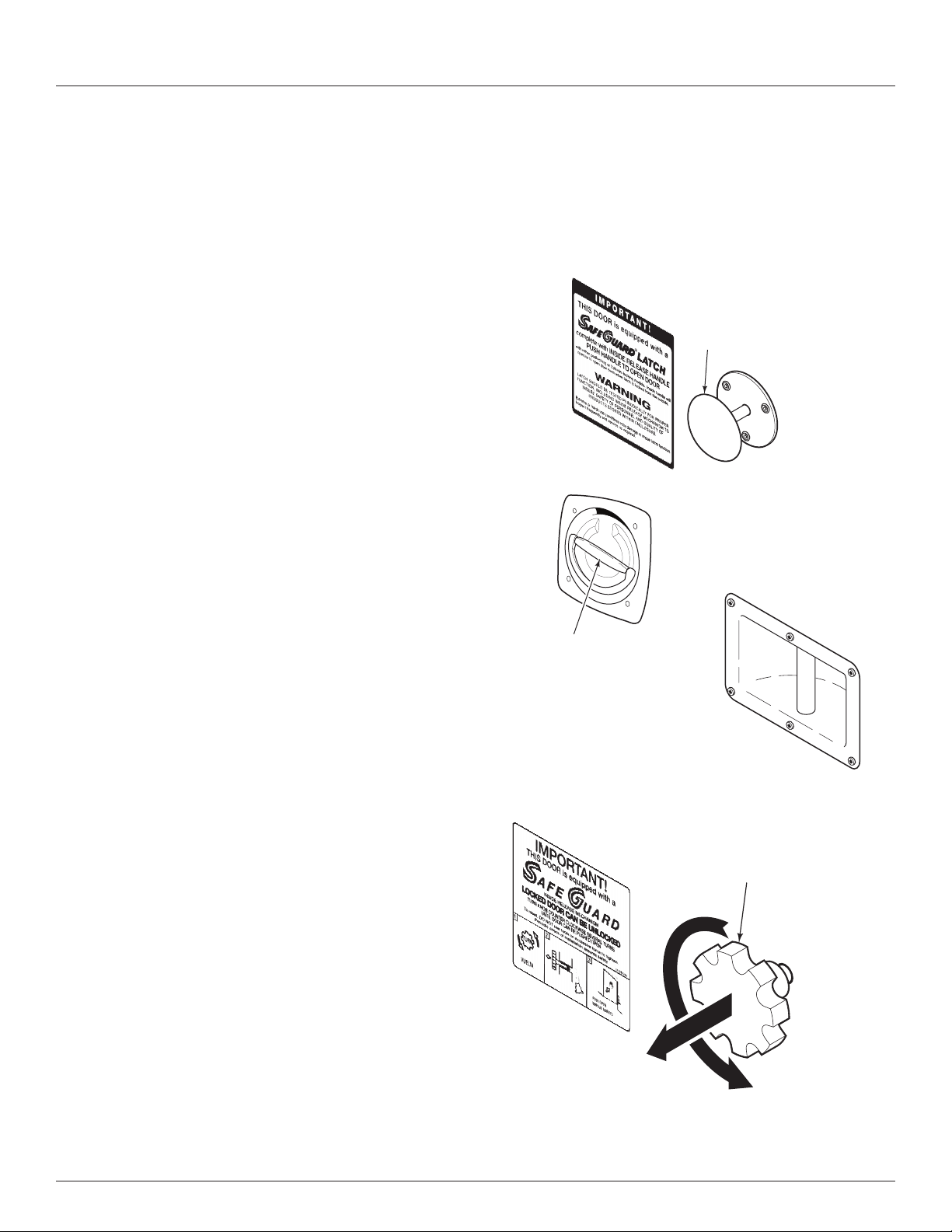

Identifying marks appear on all panels. These marks

guide the installer to the proper location for each

individual panel. See Figure 1 and Table 2.

Panels with the same part number (See Figure 1) can

be interchanged.

Symbol

AFF

BKG

CL Centerline

DC Double Cam

DP Double Pin

HIC Height In Clear (clear/nished opening height)

ID Inside Dimension

MCA Maximum Current Amperage

MOPD Maximum Overage Protection Device (Circuit Breaker)

NBI Not By Imperial Brown

NIC Not In Contract

NTS Not To Scale

O/C On Center

OD Outside Dimension

RC Reverse Cam

SIM. Similar

SPL

TYP Typical

WIC Width In Clear (clear/nished opening width)

Symbol Meaning

W1 Wall panel #1

C1 Ceiling panel #1

F1 Floor panel #1

S1 Screed panel #1

U1 Floor Spline #1

[A] Door or opening [A]

V1.A Valance #1 above opening [A]

B1.A Base #1 below opening [A]

T Thermometer

$ Single-pole switch

$

3

$

4

Meaning

Above Floor Finish

Backing

Special (panel has special features or

non-standard cam/pin layout)

Table 1. Common Drawing Abbreviations on Shop Print

A valance panel goes above a window or an opening.

Valance layout is best shown on elevation views.

A base panel goes below a window or an opening. Base

layout is best shown on elevation views.

3-way switch

4-way switch

Table 2. Sample Panel Numbers

6

W1

40

W2

47

W2 A

46546-01

Int. SS04 / Ext. SS04 (NSF Foam Gasket)

4" x 47" x 96"

Panel

Number

Par t

Number

W2 A

4" x 47" x 96"

473902

Description

Figure 1. Panel Label

© Imperial Brown, Inc. 2015

Label

46546-01

Short Job

Number

Int. SS04 / Ext. SS04 (NSF Foam Gasket)

Walk-In Coolers and Freezers Installation and Maintenance

Shipping List

The Shipping List included in the Parts Box identies

every item shipped and indicates in what parcel (pallet

or box) it is located. It also indicates if a parcel is

located in another parcel (for example, the Parts Box

being in a pallet).

Panels are stacked in the best way possible to

minimize the risk of shipment damage. They are not

stacked in order of panel numbers. Use the Shipping

List to easily locate panels and hardware.

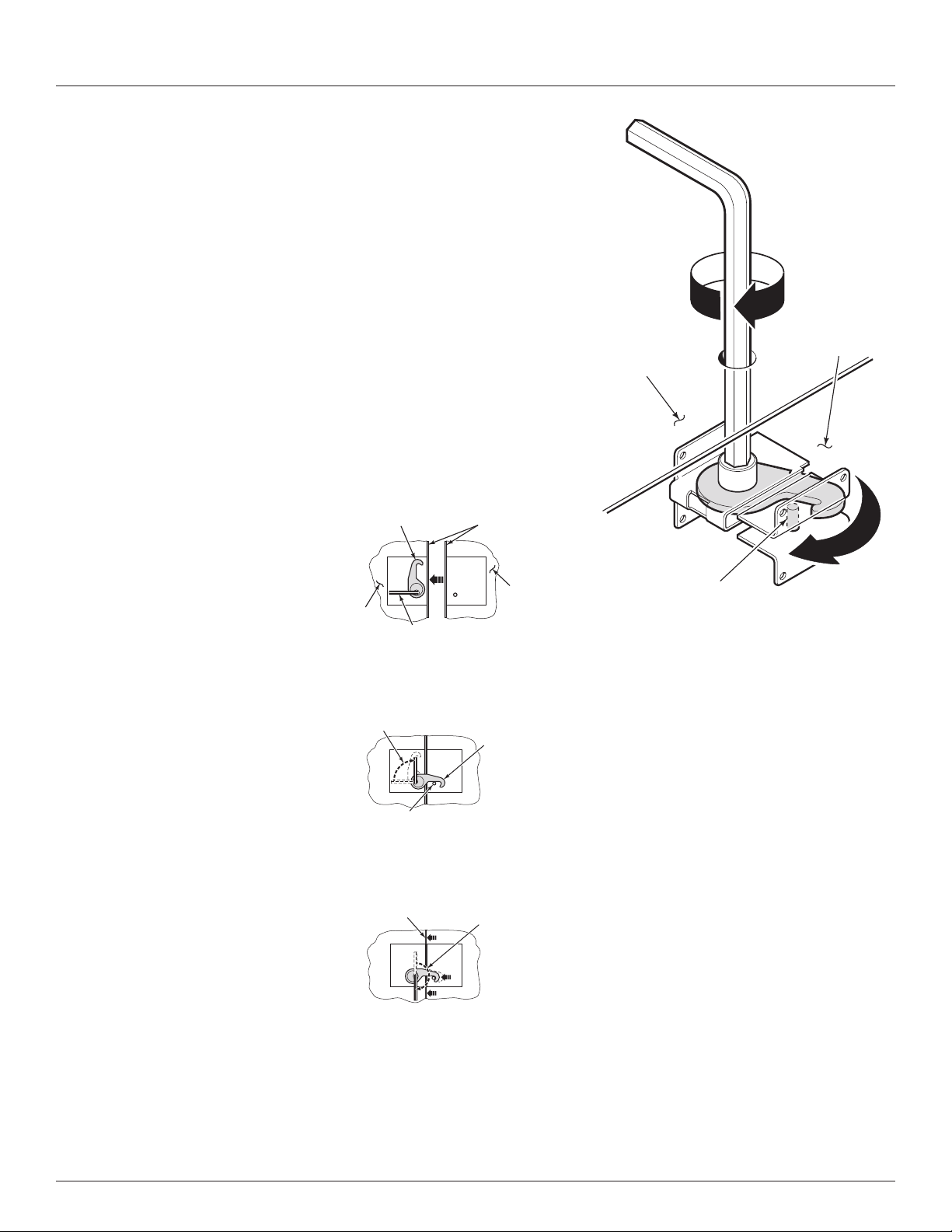

Cam Lock Fasteners

Panels are joined, using a 3/8” hex wrench (supplied)

on a cam lock device. Imperial Brown cam lock

fasteners must be fully understood before assembling

prefabricated panels. All cam locks must be in the

Open position before placing

panels together. Fasten the cam

locks as follows:

Cam Lock

Hook

Panel

Gaskets

Inside Surface

of Panel

473905

Inside Surface

of Panel

1. With the cam locks of the rst

panel in the fully Open position,

place the second panel

into position.

It should be tight along the matig

surface and ush at the edges. See

Figure 2.

2. Turn the cam lock clockwise 1/4

turn until the lock is engaged with

the hinging pin. Do not tighten yet.

See Figure 3.

3. Check that the panels are still

tight and properly aligned, then turn

the cam lock 1/2 turn to the fully

locked position. This will draw the

panels tightly together. Install cam

hole covers. See Figure 4.

Panel

Hex Wrench

Figure 2. Open Position

1/4 Turn

Hinging Pin

Figure 3. Engaged Position

Compressed

Gaskets

Figure 4. Locked Position

473918

Cam Lock

Hook

473919

1/2 Turn

Fully

Locked

473920

Panel

to

Hinging Pin

Figure 5. Cam Lock Fastener

© Imperial Brown, Inc. 2015

7

Walk-In Coolers and Freezers Installation and Maintenance

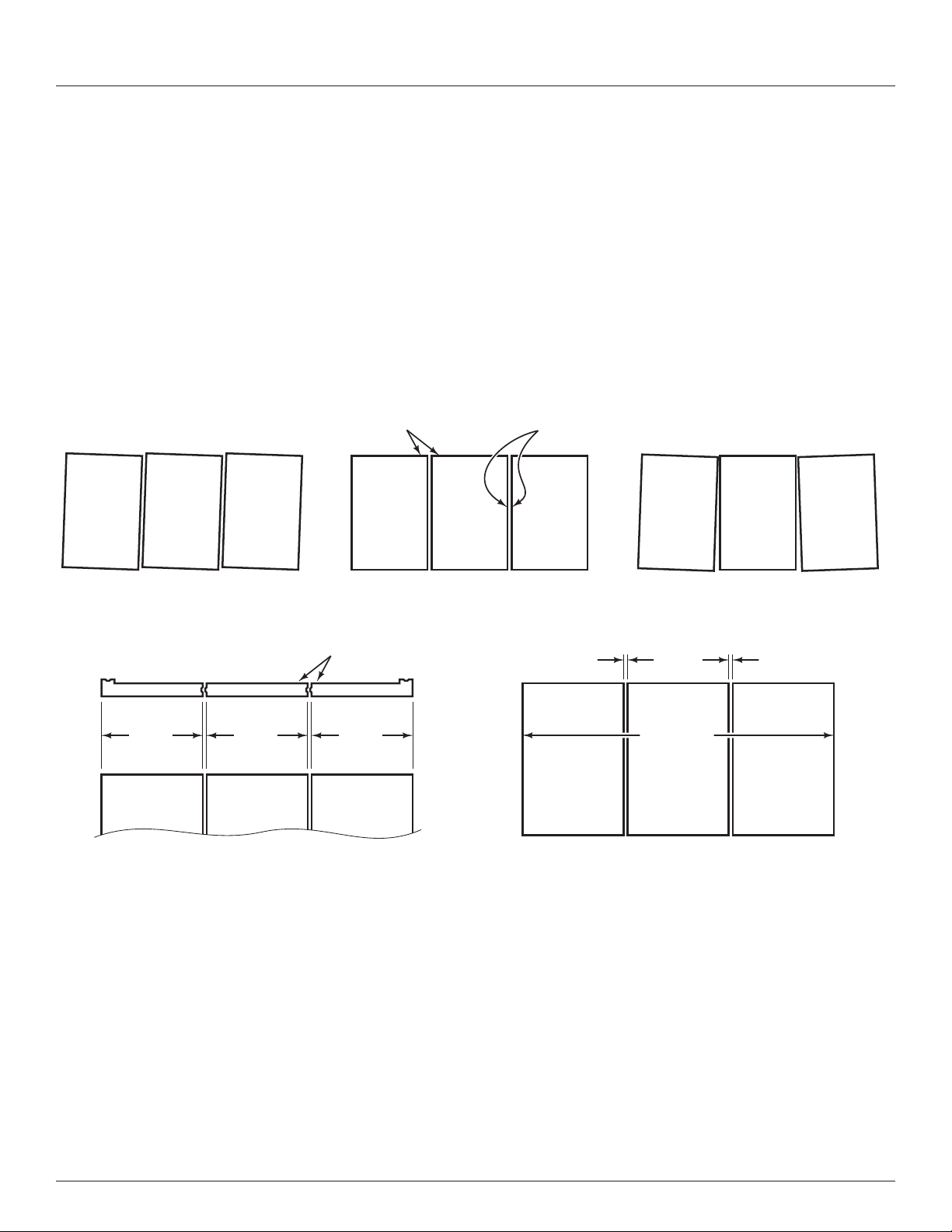

Assembling Panels Together

Panel widths are shown along each panel on the

plan views. See the Shop Print. Standard joint width is

1/16” between panels. This width may be different for

certain special joint types. Verify actual joint size on

the Shop Print. When fastening panels together, be

certain that dimensions are respected. For example,

irregular or loose tightening of the cam locks may

cause overall wall width to increase. See Figure 6.

Proper Alignment

No Yes

Proper Joint Size

40"

Panel

Figure 6. Assembling Panels

Panel

40"

Flush

40"

Panel

=

ParallelFlush

No

⁄" Joint ⁄" Joint

120 "

Overall

473903

8

© Imperial Brown, Inc. 2015

Loading...

Loading...