impact SV005, SV007, SV008 User Manual

Electromagnetic Sieve Shakers

SV005, SV007, SV008

Impact Test Equipment Ltd

www.impact-test.co.uk & www.impact-test.com

User Guide

User Guide

Impact Test Equipment Ltd.

Building 21 Stevenston Ind. Est.

Stevenston

Ayrshire

KA20 3LR

T: 01294 602626

F: 01294 461168

E: sales@impact-test.co.uk

Test Equipment Web Site

www.impact-test.co.uk

Test Sieves & Accessories Web Site

www.impact-test.com

CONTENTS

Chapter 1 GENERAL INFORMATION

1.01 Warnings

1.02

1.03 Aim of the Instructions Manual

1.04 Modifications and enclosures of the Instructions Manual

1.05 Machine Identification Data

1.06 Usage

1.07 Operators

1.08 Storage

1.09 Transportation and Movement

1.10 Packaging removal

Chapter 2 TECHNICAL CHARACTERISTICS

2.01 General machine description

2.02 Dimension and weight

2.03 Electrical supply

2.04 Noise

Chapter 3 GENERAL SAFETY NORMS

3.01 General norms

3.02 Machine Safety devices and protection

Chapter 4 INSTALLATION INSTRUCTIONS

4.01 Location

4.02 Handling and movement

4.03 Electrical connection

WARNING and DANGER indications - SIGNS

Chapter 5 IN FUNCTION - USE

5.01 Machine calibration – Meters - Indicators

5.02 Placement

5.03 Equipping

5.04 Specimen positioning

5.05 Switching on the equipment

5.06 Operationg mode

5.07 Switching the appliance on

5.08 Normal stop

5.09 Emergency stop

5.10 Start up after emergency

5.11 Stop commanded by Safety circuit

5.12 Programming

5.13 Test start up

5.14 Practical example of usage

Chapter 6 MAINTENANCE

6.01 Ordinary Maintenance

6.02 Extraordinary Maintenance

6.03 Authorised maintenance centres

Chapter 7 GUIDE TO RECOGNISING DAMAGE AND ANOMALIES

Chapter 8 SPARE PARTS AND ACCESSORIES

Chapter 9 INACTIVITY

Chapter 10 DECOMMISSIONING THE MACHINE

Appendix CALIBRATING THE MACHINE

2

Chapter 1 GENERAL INFORMATION

1.01 WARNINGS

The manufacturer does not accept any responsibility for direct or indirect damage to people, things or animals and use

of the appliance in different conditions from those foreseen.

The manufacturer reserves the right to make changes to the documentary information or to the appliance without

advance notice.

Check the machine responds to the standards in force in the state in which it has been installed.

All operations necessary for maintaining machine efficiency before and throughout use are the operator’s responsibility

Carefully read the entire manual before operating the machine.

It is vital to know the information and limitations contained in this manual for correct machine use by the operator.

Interventions are only permitted if the operator is accordingly competent and trained.

The operator must be knowledgeable about machine operations and mechanisms.

The purchaser must ensure that operators are trained and aware of all the information and clarifications in the supplied

documentation.

Even with such certainty the operator or user must be informed and therefore aware of potential risks when operating

the machine.

Safety, reliability and optimum performance is guaranteed when using original parts.

Any tampering or modifying of the appliance (electrical, mechanical or other) which has not been previously authorised

in writing by the manufacturer is considered abusive and disclaims the constructor from any responsibility for any

resulting damage.

All necessary operations to maintain the efficiency of the machine before and throughout use are the responsibility of

the user.

1.02

WARNING AND DANGER INDICATIONS - SIGNS

The machine has been designed and constructed according to the current norms and consequently with mechanical

and electrical safety devices designed to protect the operator or user from possible physical damage. Residual risks

during use or in some intervention procedures on the device are however present. Such risks can be reduced by

carefully following manual procedures, using the suggested individual protection devices and respecting the legal and

safety norms in force.

This manual includes “Warning” and “Danger” indications in relevant chapters. These indications are shown with the

words “Danger” or “Warning” in bold font and uppercase to make them highly visible.

WARNING

DANGER

“DANGEROUS ZONE” indicates any zone inside or in the proximity of the appliance in which a person is exposed to the

risk of injury or damage to health.

1.03

AIM OF THE INSTRUCTIONS MANUAL

This manual has been edited with the aim of providing all machine operators with all the necessary information on

installation, use and maintenance from production to scrapping in as comprehensive and clear manner as possible.

All the procedures useful for any foreseeable emergency situations have been listed by the manufacturer and can be

verified during use.

Operators, for whom this manual has been written, due to their competence must give instructions or operate the

machine themselves.

The instructions manual must be carefully consulted by laboratory or site safety managers, equipment operators and

any internal and external maintenance workers.

The manual is integral to the product and refers to this appliance only.

The manual must be safeguarded and always kept near the equipment so that it can be easily consulted whenever

necessary.

IMPORTANT: The manual does not substitute the experience and technical training of the worker but must be

considered a guide for carrying out its functions.

Furthermore all the norms and rules the operator should be aware of or consult for correct use of the machine and/or

test performance can be found in the manual.

This responsibility is entrusted to the installer and Laboratory or Site Manager where the machine is installed.

The Constructor is available to provide further information.

indicates that machine damage could be caused should indications be ignored.

indicates that machine damage and/or injury to the worker could be caused should

indications be ignored.

3

1.04

MODIFICATIONS AND ENCLOSURES OF THE INSTRUCTIONS MANUAL

This manual reflects the state at the time of the launch of the machine on its market. If any modifications, improvements

or adjustments have been made since machine supply the Manufacturer does not have to intervene on the marketed

machine and will not consider the machine or the manual deficient or inadequate.

1.05

MACHINE IDENTIFICATION DATA

MODELS:

SV005

SV0047

SV008

PRODUCTION DATA : see EC declaration

1.06 USAGE

These sieving units have been developed for sieving tests on fine and wet materials.

This appliance is for the exclusive use which it has been conceived for.

Any other use is considered improper and therefore negligent.

Machine use is allowed only in places free from danger of explosion or fire.

During operation check for conditions of danger.

immediately stop the machine should it be working irregularly, and consult the authorised dealer’s Sales Service

department.

It is the Client’s responsibility to verify at the time of installation and use that no conditions of use arise which are

different to those indicated.

Refer to the Constructor when in doubt

1.07 OPERATORS

The use, transportation, installation, maintenance, demolition and

DANGER

WARNING

disposal of the appliance are only permitted to “QUALIFIED

PERSONNEL”.

This manual is exclusively aimed at “QUALIFIED PERSONNEL” and

contains the necessary information for machine use.

”QUALIFIED PERSONNEL” means people who, due to their training, experience and education, as well as knowledge

of the relevant standards, limitations and measures, have been authorised by the “PLANT SAFETY MANAGER” to carry

out any necessary activity and are able to recognise and avoid any possible danger.

The manufacturer recommends that the instructions, procedures and recommendations in this manual and the work

safety legislation in force be scrupulously adhered to, even with the use of appropriate protection devices (whether

individual or part of the machine).

Knowledge and respect of the instructions, safety warnings and danger in this manual are all necessary for installation,

operation, management and machine maintenance with a minimal risk.

The “PLANT SAFETY MANAGER” has the following responsibilities and duties:

- To know the machine functions, its commands, safety and protection devices, possible dangers of use and all the

information in this manual in detail. This knowledge can only be gleaned from detailed reading of this manual.

- To know the safety legislation in force in detail in order to operate the machine

- To recognise the “QUALIFIED PERSONNEL” for transportation, handling, installation, use, maintenance, disposal, etc.

4

- Correctly train and educate the “QUALIFIED PERSONNEL” before allowing them access to the machine. The

personnel must also be exhaustively trained with regards to the machine’s protection devices.

- Ensure the machine’s safety devices are not tampered with or removed and are checked on a daily basis. Provide the

operator appropriate individual protection devices according to the laws in force.

- The constructor is available for clarification, assistance and training and declines all responsibility for damage to things

or people resulting from improper, incorrect and negligent use by untrained personnel.

1.08 STORAGE

The appliance must be stored and conserved in the original packaging and in a closed

1.09

WARNING

TRANSPORTATION AND MOVEMENT

WARNING

environment, protected from atmospheric agents with a minimum temperature of -15C°,

and a maximum of +60C° and a maximum humidity of 70 %.

In order to avoid irreparable machine damage, move with care, do not overturn, protect

from rain, do not stack, protect the packaging and its contents from bumps and sources of

heat.

During transportation and movement it is important to avoid bumps, overloading with other packages, exposure to

freezing or heating atmospheric agents, or any other potentially harmful condition to the device, things or people.

Machine transportation and movement must be entrusted to Qualified Personnel who can ensure correct movement.

1.10

DANGER

WARNING

PACKAGING REMOVAL

Do not transport or move the product should it be impossible to respect the

conditions on the packaging or there be any doubts. Request information from

the constructor.

After removing the packaging check the machine is complete and that there are no visibly damaged parts.

DO NOT USE THE MACHINE and refer to the constructor when in doubt.

The components used for packaging (plastic bags, polystyrene, nails, screws, wood, etc)

DANGER

must be kept out of reach of children, as they are sources of danger. These components

should be placed in the appropriate containers.

In order to avoid bumps and overturn adopt the normal and logical precautions. Before

WARNING

disposing of the packaging check all machine components such as accessories, utensils,

instructions, documents etc have been removed.

5

Chapter 2 TECHNICAL CHARACTERISTICS

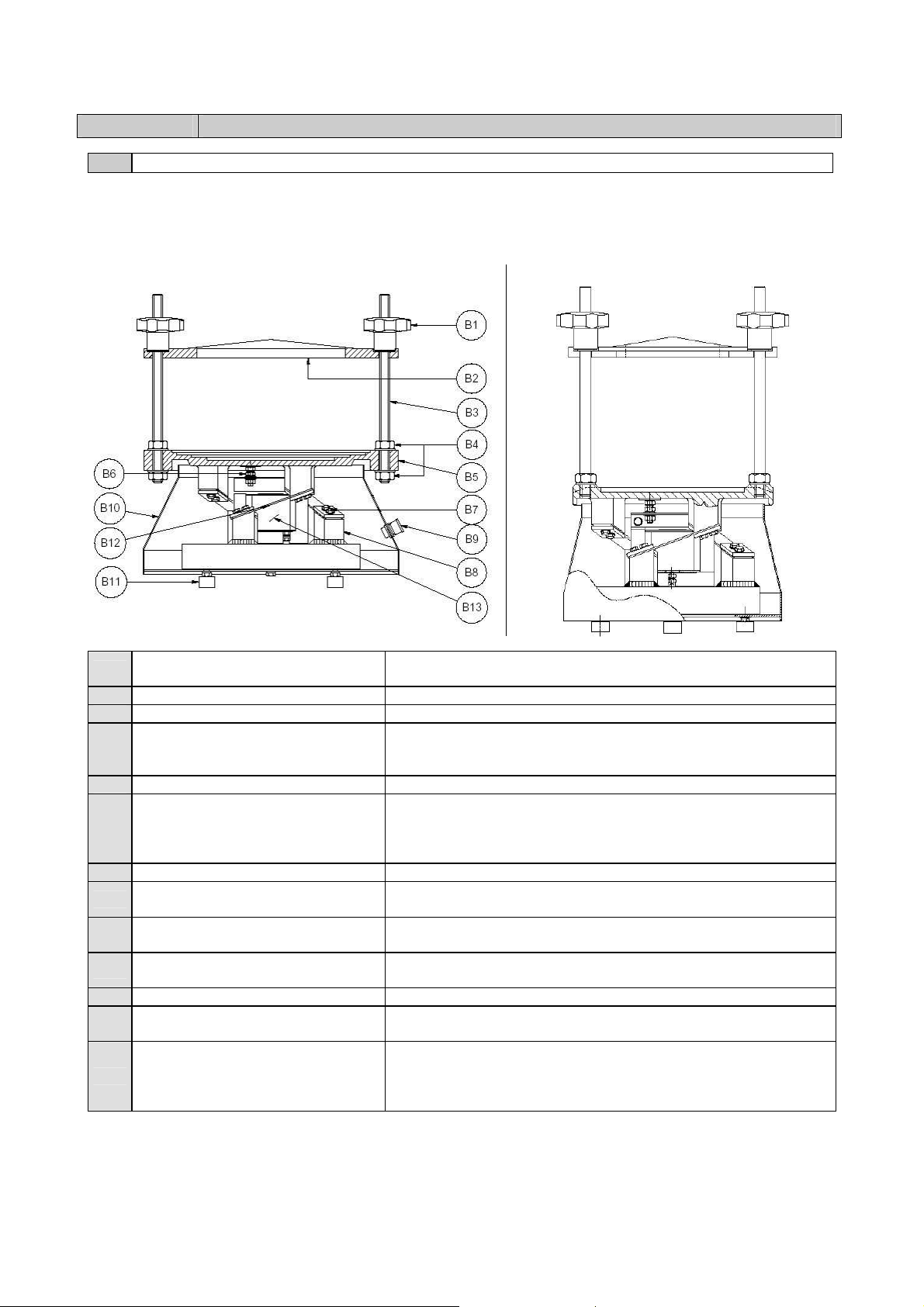

2.01

GENERAL MACHINE DESCRIPTION

The equipment is basically formed by a plate holder for specimens (B5). This is supported by springs (B12)

and is activated by electromagnetic impulses (B13). The sieves are subjected to a double vibrating action:

vertical and rotational.

A059-01 KIT

B10

B11

B12

B13

B1

BLOCKING KNOBS

B2

BAR It secures the sieves to the specimen receiver (B5).

B3

THREADED BARS They allow to regulate the bar height (B2).

They secure the upper bar (B2) to the sieves, blocking them

firmly to the receiver (B5).

They fix the threaded bars (B3) to the specimen receiver. In the

B4

FIXING NUTS

B5

SIEVE HOLDER It can hold several sieves according to the operator’s needs.

shaker A059-01 KIT is present only one pair of data and the bars

B2 are screwed into the sieve holder B5

They allow to fix and to adjust the specimen receiver (B5) to the

B6

ADJUSTMENT SCREWS

electromagnet (B13). In this way, the vibrations produced by the

electromagnet are transferred to the sieves placed on the

receiver (B5).

B7

FIXING SCREWS These screws fix the springs (B12) to the support columns (B8).

B8

SUPPORT COLUMN FOR SPRINGS

B9

CABLE FIXING DEVICE

GUARD

SUPPORTING FEET They allow laying the sieve shaker steadily on any surface.

SPRINGS

It allows connecting the base to the specimen receiver (B5) by

means of the springs (B12).

It fixes the feeling cable to the sieve shaker base, avoiding its

incidental pull during the normal working procedures.

It allows reaching the inside components of the sieve shaker

base. The guard is fixed to the base by some screws.

They transfer the vibrations from the electromagnet (B13) to the

specimen receiver (B5).

It generates the vibrations, which are necessary for a sieving

ELECTROMAGNET

test. Using the Control Panel (C) it is possible to modify the

vibrating intensity according to the user’s needs. (See Chapter

“USE” of this manual for further details).

6

Loading...

Loading...