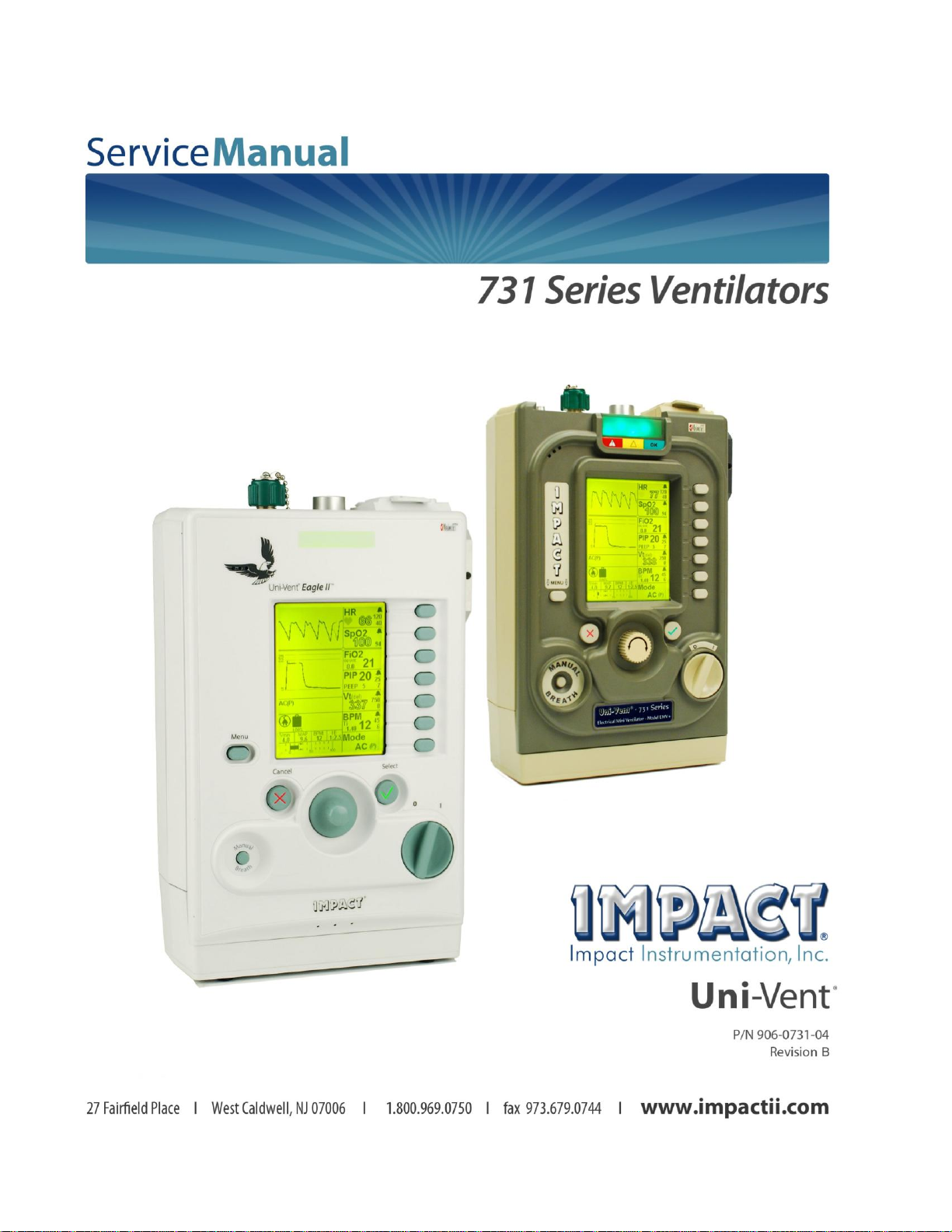

Page 1

906-0731-04 Rev. B Sept. 2012 Page 1 of 68

Page 2

Table of Contents

INTRODUCTION ............................................................................................................................................. 3

Conventions ................................................................................................................................................... 3

Terminology and Abbreviations..................................................................................................................... 3

General Warnings .......................................................................................................................................... 4

Cautionary Note ............................................................................................................................................. 4

Helpful Hints .................................................................................................................................................. 4

Limited Copyright Release ............................................................................................................................ 4

Warranty ........................................................................................................................................................ 5

Masimo Pulse Oximeter ................................................................................................................................. 5

WARNINGS AND CAUTIONS REGARDING USE....................................................................................... 6

731Series and Pulse Oximeter ....................................................................................................................... 6

Pulse Oximeter Specific Warnings And Cautions.......................................................................................... 7

MAINTENANCE .............................................................................................................................................. 9

Routine Inspections ........................................................................................................................................ 9

Cleaning ..................................................................................................................................................... 9

Storage Information ..................................................................................................................................10

Post-Contaminated Environment Cleaning ...............................................................................................10

Removable Foam Filter Replacement .......................................................................................................11

Fresh Gas/Emergency Air Intake Disk Filter Replacement ......................................................................11

Battery Capacity, Care and Recharging ....................................................................................................12

Preventive Maintenance (PM) .......................................................................................................................13

Periodic Maintenance Check (PMC) .........................................................................................................13

Troubleshooting and Repairs ............................................................................................................................15

Service Kits ...................................................................................................................................................15

Service Kit Listing ....................................................................................................................................16

Replacement Instructions ..........................................................................................................................17

Membrane Panel Kit 712-0731-01 / 712-EGL2-01 ...............................................................................17

SPM Kit 712-0731-02 / 712-EGL2-02 ..................................................................................................21

Battery Compartment Kit 712-0731-03 / 712-EGL2-03 .......................................................................25

Outer Air Intake Kit 712-0731-04 / 712-EGL2-04 ...............................................................................26

Bezel Assembly Kit 712-0731-05 / 712-EGL2-05 / 712-AEV1-01 ......................................................27

Power Knob Kit 712-0731-06 / 712-EGL2-06 ......................................................................................29

USB Connector Plate Kit 712-0731-07 / 712-EGL2-07 .......................................................................31

Front Case Assembly Kit 712-0731-08 / 712-EGL2-08 / 712-AEV1-02 ..............................................34

Battery Case Bottom Cover Kit 712-0731-09 / 712-EGL2-09 ..............................................................36

EMV Chassis Kit 712-0731-10 / 712-EGL2-10 ....................................................................................37

Connector Panel Kit 712-0731-11 / 712-EGL2-11 ...............................................................................41

Back Case Kit 712-0731-12 / 712-EGL2-12 .........................................................................................45

PIM Board Kit 702-0731-02 .................................................................................................................46

CPU/UIM & SPO2 Stack Kit 712-0731-14 ..........................................................................................49

USB Connector Kit 712-0731-15 ..........................................................................................................52

Gas Output Kit 712-0731-16 .................................................................................................................54

Power Input Kit 712-0731-17 ...............................................................................................................55

Oxygen Inlet Fitting Kit 712-0731-18...................................................................................................59

Selector Knob Kit 712-0731-19 / 392-0066-00.....................................................................................60

Troubleshooting ............................................................................................................................................62

Alarm Category .........................................................................................................................................62

Service Codes ............................................................................................................................................63

HiPot Testing ....................................................................................................................................................68

906-0731-04 Rev. B Sept. 2012 Page 2 of 68

Page 3

INTRODUCTION

A/C- Assist/Control

LED - Light Emitting Diode

ACLS- Advanced Cardiac Life Support

LPM - Liters per Minute

ALS- Advanced Life Support

ml - Milliliters

ATLS- Advanced Trauma Life Support

mm - Millimeter

ACV- Assist-Control Ventilation

NPPV – Noninvasive Positive Pressure

Ventilation

ATPD - Atmospheric Temperature and Pressure, Dry

O2 - Oxygen

BPM - Breaths per Minute

Paw - Airway Pressure

B/V - Bacterial/Viral Filter

PEEP - Positive End Expiratory Pressure

cm H2O - Centimeters of Water

PIP - Peak Inspiratory Pressure

CPR - Cardiopulmonary Resuscitation

psig - Pounds per Square Inch Gage

DISS - Diameter Index Safety System

USP - United States Pharmacopeia

FIO

2 -

Fraction of Inspired Oxygen

VAC - Volts AC

HME - Heat and Moisture Exchanger

VDC - Volts DC

HME/BV - Heat and Moisture Exchanger/Bacterial

Viral filter combined

VT - Tidal Volume

Hz – Hertz (as in frequency, cycles per second)

WOB – Work of Breathing

ID - Internal Diameter

L - Liters

Conventions

WARNING!

A WARNING statement identifies conditions or information that could have an adverse effect upon the

patient or operator which if not avoided, could result in death or serious injury.

CAUTION!

A CAUTION statement provides important information about a potentially hazardous situation which if not

avoided may result in minor or moderate injury to the patient, operator or damage to the equipment or

other property.

NOTE:

A NOTE provides additional information intended to avoid inconvenience during operation.

Terminology and Abbreviations

906-0731-04 Rev. B Sept. 2012 Page 3 of 68

Page 4

General Warnings

The design and intended use of 731 series ventilators requires that the operation of the product be

restricted to trained medical professionals. US federal law restricts this device for sale by or on the order of

a physician.

The information contained herein is restricted for use by personnel certified by Impact Instrumentation, Inc.

in the care and servicing of this product. Impact does not authorize or assume any obligations resulting

from unauthorized servicing of its products nor will it be held liable for any injuries or damages incurred

therefrom.

This device has been classified "life supporting" and "life sustaining" by the United States Food & Drug

Administration. If you have not been trained and certified by Impact Instrumentation, Inc in the care and

servicing of this product, DO NOT attempt to service this device. Should factory based servicing become

necessary, or technical assistance is required, please have the device’s Model and Serial Number available

and contact the Impact service team. All service requests, including requests to schedule service training,

may be addressed to the Service Manager, Impact Instrumentation, Inc., 19 Fairfield Place, West Caldwell,

New Jersey 07006, 973/882-1212 or email: service@impactii.com .

Cautionary Note

Prior to servicing this device, be aware of the presence of potentially dangerous operating voltages.

Disconnect power supply and the internal battery prior to performing any service.

Internal components are susceptible to damage from static discharge. All servicing operations MUST be done

in an ESD controlled environment.

Please review all warnings and cautions in this manual, the device’s Operation manual and the RCS

Operation manual prior to servicing the 731 series ventilator.

Helpful Hints

Before attempting to service this instrument, please take a few moments to ensure that the problem is not

accessory-related. Always check the integrity of all tubing and fittings and verify that tubing is not crimped

or cracked.

Always safeguard your personal well being when troubleshooting electronic circuitry. Keep jewelry and

liquids from the vicinity of active circuitry.

Limited Copyright Release

Permission is hereby granted to any United States Military or Governmental agency to reproduce all

materials furnished herein for use in a United States Military or Governmental service training program. No

other individual, company or agency are granted the permission to copy or reproduce any materials

furnished herein without the written permission of Impact®.

906-0731-04 Rev. B Sept. 2012 Page 4 of 68

Page 5

Warranty

Impact Instrumentation, Inc. warrants 731 series devices and their replacement service

part kits to be free from all defects in material and workmanship for a period of one (1)

year from the date of delivery to the final purchaser

During the warranty period, Impact will repair or replace the device or any part which

upon examination is shown to be defective. At its sole discretion, Impact may choose

to supply a new or equivalent replacement product or refund the amount of the

purchase price. To qualify for such repair, replacement, or refund, the defective device

must be returned to Impact or Impact’s authorized service provider within thirty (30)

days from the date that the defect is discovered. This warranty does not apply if the

device has been repaired or modified without the authorization of Impact or if the

damage was caused by incorrect storage, failure to perform recommended

maintenance, use of the product in applications not described in the intended use

statement, negligence or an accident.

Batteries, which by their nature are consumable and subjected to environmental

extremes, will be warranted for a period of ninety (90) days. Accessories, also

consumable in usage, such as connecting hose and breathing circuits, are not

warranted.

DISCLAIMER OF IMPLIED & OTHER WARRANTIES:

THE PRECEDING WARRANTY IS THE EXCLUSIVE WARRANTY AND IMPACT

INTRUMENTATION, INC. MAKES NO OTHER WARRANTY OR

REPRESENTATION OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED,

WITH RESPECT TO MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE OR ANY OTHER MATTER. THE REMEDIES STATED IN THIS

DOCUMENT WILL BE THE EXCLUSIVE REMEDIES AVAILABLE FOR ANY

DEFECTS OR FOR DAMAGES RESULTING FROM ANY CAUSE WHATSOEVER

AND WIHOUT LIMITATION.

IMPACT INSTRUMENTATION, INC. WILL NOT IN ANY EVENT BE LIABLE FOR

CONSEQUENTIAL OR INCEDENTAL DAMAGES OF ANY KIND, WHETHER

FROM DEFECTIVE OR NONCONFORMING PRODUCTS, BREACH OR

REPUDIATION OF ANY TERM OR CONTTION OF THE DOCUMENT,

NEGLIGENCE, OR ANY OTHER REASON

THE WARRANTIES SET FORTH ABOVE ARE IN LIEU OF ALL OTHER

WARRANTIES, EXPRESSED OR IMPLIED, WHICH ARE HEREBY DISCLAIMED

AND EXCLUDED BY SELLER, INCLUDING WITHOUT LIMITATION ANY

WARRANY OF MERCHANTABILITY OF FITNESS FOR A PARTICULAR PURPOSE

OR USE.

Masimo Pulse Oximeter

This device uses Masimo SET® technology to provide continuous pulse oximeter and heart rate monitoring

and is covered under one or more of the following U.S.A. patents: 5,758,644, 5,823,950, 6,011,986,

6,157,850, 6,263,222, 6,501,975 and other applicable patents listed at www.masimo.com/patents.htm.

906-0731-04 Rev. B Sept. 2012 Page 5 of 68

Page 6

WARNING! Electric shock hazard: Do not remove equipment covers except to replace batteries! An

operator may only perform maintenance procedures specifically described in this manual. Refer servicing

to Impact or an authorized Impact Service Center in the repair of this equipment.

WARNING! The device is intended for use by qualified personnel only! The operator should read this

manual, all precautionary information, and specifications before using the device!

WARNING! Possible explosion hazard if used in the presence of flammable anesthetics or other flammable

substances in combination with air, oxygen-enriched environments or nitrous oxide!

WARNING! During operation the device should not be stacked on top of or under other medical equipment

due to the possibility of electromagnetic interference between the device and other equipment. (The

device was subjected to EMC testing in accordance with Military Mil-STD-461F and Commercial IEC 606011-2 and FDA Reviewers Guidance specifications.)

WARNING! Grounding:

Connect the device only to a three-wire, grounded, hospital-grade receptacle! The three-conductor

plug must be inserted into a properly wired three-wire receptacle; if a three-wire receptacle is not

available, a qualified electrician must install one in accordance with the governing electrical code.

Do not under any circumstances remove the grounding conductor from the power plug!

Do not use extension cords or adapters of any type! The power cord and plug must be intact and

undamaged.

If there is any doubt about the integrity of the protective earth conductor arrangement, operate the

oximeter on internal battery power until the AC power supply protective conductor is fully functional!

WARNING! To ensure patient electrical isolation, connect only to other equipment with electronically

isolated circuits!

WARNING! Do not use antistatic or conductive hoses or tubing with this device!

WARNING! Do not connect to an electrical outlet controlled by a wall switch or dimmer!

WARNING! As with all medical equipment, carefully route the ventilator circuit hose and tubing, patient

cabling, and external power cables to reduce the possibility of patient entanglement or strangulation!

WARNING! Do not place the device or external power supply in any position that might cause it to fall on

the patient! Do not lift the device by the power supply cord, ventilator circuit or pulse oximeter patient

cable!

WARNING! Do not use the device, its pulse oximeter or pulse oximetry sensors during magnetic resonance

imaging (MRI) scanning! Induced current could potentially cause burns. The device and/or its pulse

oximeter may affect the MRI image and the MRI unit may affect device operation or the accuracy of the

oximetry measurements.

WARNING! The device must be connected to a grounded AC power supply when connected to AC power.

The device and its integrated pulse oximeter are referred to as an IEC 601/F device in the summary situation

table contained in IEC-601-1-1.

WARNING! USB Interconnection: Do not operate the device on a patient when the USB is connected to any

other device.

NOTE: The USB interconnection does not support automatic record keeping.

WARNING! The Impact supplied ventilator circuit’s labeling provides the resistance and compliance values

for the circuits under normal operating conditions. If added accessories are used (e.g. humidification, filters

etc.), the operator should assure they do not degrade the performance of the device. If non-Impact circuits

are used, the operator should assure these circuits do not affect the performance of the device.

CAUTION! Federal law restricts this device to sale by or on the order of a physician.

CAUTION! Service is to be performed by qualified biomedical equipment technicians only.

WARNINGS AND CAUTIONS REGARDING USE

731Series and Pulse Oximeter

906-0731-04 Rev. B Sept. 2012 Page 6 of 68

Page 7

CAUTION! Internal components are susceptible to damage from static discharge. Do not remove device

covers.

NOTE: This Operation Manual is not meant to supersede any controlling standard operating procedure

regarding the safe use of assisted ventilation.

NOTE: Follow all governing regulations regarding the disposal of any part of this medical device.

NOTE: Follow all governing regulations regarding the handling of materials contaminated by body fluids.

NOTE: Follow all governing regulations regarding shipment of the Li batteries.

WARNING! A pulse oximeter should not be used as an apnea monitor.

WARNING! A pulse oximeter should be considered an early warning device. As a trend towards patient

deoxygenation is indicated, blood samples should be analyzed by a laboratory co-oximeter to completely

understand the patient’s condition.

WARNING! MEASUREMENTS

If the accuracy of any measurement does not seem reasonable, first check the patient’s vital signs by

alternate means and then check the pulse oximeter for proper functioning.

Inaccurate measurements may be caused by:

Incorrect sensor application or use

Significant levels of dysfunctional hemoglobin (e.g., carboxyhemoglobin or methemoglobin)

Intravascular dyes such as indocyanine green or methylene blue

Exposure to excessive illumination, such as surgical lamps (especially ones with a xenon light source),

bilirubin lamps, fluorescent lights, infrared heating lamps, or direct sunlight (exposure to excessive

illumination can be corrected by covering the sensor with a dark or opaque material)

Excessive patient movement

Venous pulsations

Placement of a sensor on an extremity with a blood pressure cuff, arterial catheter, or intravascular

line

The pulse oximeter can be used during defibrillation, but the readings may be inaccurate for a short

time.

WARNING! Interfering Substances: Carboxyhemoglobin may erroneously increase readings. The level of

increase is approximately equal to the amount of carboxyhemoglobin present. Dyes, or any substance

containing dyes, that change usual arterial pigmentation may cause erroneous readings.

WARNING! ALARMS Check alarm limits each time the pulse oximeter is used to ensure that they are

appropriate for the patient being monitored.

WARNING! Loss of pulse signal can occur in any of the following situations:

The sensor is too tight

There is excessive illumination from light sources such as a surgical lamp, a bilirubin lamp, or sunlight

A blood pressure cuff is inflated on the same extremity as the one with a SpO

2

sensor attached

The patient has hypotension, severe vasoconstriction, severe anemia, or hypothermia

There is arterial occlusion proximal to the sensor

The patient is in cardiac arrest or is in shock

Pulse Oximeter Specific Warnings And Cautions

906-0731-04 Rev. B Sept. 2012 Page 7 of 68

Page 8

WARNING! Sensors:

Before use, carefully read the LNCS

®

sensor directions for use.

Use only Masimo oximetry sensors for SpO

2

measurements. Other oxygen transducers (sensors)

may cause improper performance.

Tissue damage can be caused by incorrect application or use of an LNCS

®

sensor, for example by

wrapping the sensor too tightly. Inspect the sensor site as directed in the sensor Directions for Use

to ensure skin integrity and correct positioning and adhesion of the sensor.

Do not damage LNCS

®

sensors. Do not use an LNCS® sensor with exposed optical components. Do

not immerse the sensor in water, solvents, or cleaning solutions (the sensors and connectors are not

waterproof). Do not sterilize by irradiation, steam or ethylene oxide. See the cleaning instructions

in the directions for reusable Masimo LNCS® sensors.

Do not use damaged patient cables. Do not immerse the patient cables in water, solvents or

cleaning solutions (the patient cables are not waterproof). Do not sterilize by irradiation, steam or

ethylene oxide. See the cleaning instructions in the directions for reusable Masimo patient cables.

CAUTION! Possession or purchase of this device does not convey any expressed or implied license to use

the device with unauthorized sensors or cables which would, alone, or in combination with this device fall

within the scope of one or more of the patents relating to this device. Impact cannot assure the proper

functioning of this device if it is used with unauthorized sensors or cables.

906-0731-04 Rev. B Sept. 2012 Page 8 of 68

Page 9

MAINTENANCE

Operational inspection – after every 1,000 hours of use or more

frequently if the ventilator has been used in austere environments,

confirm that that device functions properly by power cycling the

ventilator while it is connected to a ventilator circuit and test lung.

Operate the ventilator at its default settings and exercise the

membrane buttons and the rotary optical encoder to ensure they

operate as intended.

Accessory inspection – replace power supply if there is damaged or

cracked casing, plugs, or cut/frayed or exposed wiring.

Filter inspection – check the foam and disk filter for dust/dirt build up

and/or physical damage. Replace if dirt is visible or filter is damaged.

Battery inspection – check the battery icon to ensure battery is

charging and that the ventilator operates correctly.

Breathing circuit inspection – check on a daily basis the breathing

circuit for damage or wear including but not limited to cracking,

discoloration or disfigurement. If there is any sign of physical

degradation or the unit is indicating breathing circuit problems,

replace with a new breathing circuit.

High Pressure Hoses inspection: Examine hoses for cracking,

discoloration and disfigurement. Wipe the exterior wall with a damp,

soapy cloth. Dry with a lint-free cloth. Examine end connection

fittings for damaged threads and sharp edges. Replace if defective,

DO NOT attempt to repair.

This device should be incorporated into a regular maintenance program to ensure safe and effective

operation. Electro-mechanical and pneumatic components are subject to wear and fatigue over time and

components will deteriorate more quickly when used continuously. To maintain safe operation, it is the

user's responsibility to ensure that periodic inspections and maintenance is performed and that

recommended maintenance is performed by Impact or a certified Impact trained technician.

Routine Inspections

Routine inspections should be performed on this ventilator at regular intervals and prior to its being placed

into service. Routine inspections consist of the following:

Cleaning

1. The ventilator’s outer case should be cleaned with a damp soapy cloth and thoroughly dried with a

lint-free cloth. Make sure that all exposed surfaces are cleaned and dried.

2. For general decontamination/cleaning situations, a 10% bleach solution applied with a damp cloth

is an effective decontaminant that can be used. Since the potential amount of contaminants that

our ventilators might be exposed to is so large, it is difficult to provide an appropriate cleaning

method for each type of exposure. An effective cleaning agent for one type of exposure may not be

effective with another and cleaning and sterilizing practices may vary between institutions. Impact

Instrumentation, Inc. suggests that each facility have in place a procedure for the cleaning and

disinfection of its medical equipment and that these procedures be consulted for further guidance.

906-0731-04 Rev. B Sept. 2012 Page 9 of 68

Page 10

3. Care must be taken to prevent liquids from entering the ventilator. Never submerge the ventilator

WARNING! Never use oil or grease of any kind with O2 or compressed gas equipment.

CAUTION! DO NOT store batteries in a discharged condition.

and avoid using excessive amounts of water that might enter the unit.

4. Never use abrasives or chlorinated hydrocarbon based cleansers when cleaning the ventilator, they

will damage the plastic and interface lens.

Storage Information

For optimal prolonged storage periods, the device should be stored indoors. The environment should be

clean and out of direct sunlight. Storage in non-controlled environments is permissible if batteries are

removed.

For long-term storage, the optimum storage temperature range is -15 C to 21 C (5 F to 71 F). Battery life is

diminished at temperatures above 35 C (95 F). It is recommended that batteries be discharged to 50%

capacity if long term storage above 35 C (95 F) is expected. DO NOT store batteries in a discharged

condition. Short-term, less than 10 days, storage temperatures should range between -15 C to 49 C (5 F

and 120 F) with no degradation to the device.

When batteries are in extended storage, it is recommended that they receive a refresh charge at

recommended intervals when not continuously connected to an external power source:

STORAGE AMBIENT RECHARGE INTERVAL

Below 68 F (20 C) 12-months

68 F to 86 F (20 C to 30 C) 6-months

86 F to 104 F (30 C to 40 C) 3-months

Following periods of extended storage in non-controlled environments, allow the device sufficient time to

stabilize to a temperature within its specified operating range (see section entitled BATTERY CARE AND

RECHARGING).

If the device is subject to 6-months of continuous storage/non-use, or longer, this device should be powered

on to initiate the device’s self test routine. The user should confirm that the batteries are sufficiently

charged before patient-use is attempted.

Post-Contaminated Environment Cleaning

If the ventilator is operated in an environment where it may have been exposed to contamination from a

hazardous materials accident, mass epidemic or weapon of mass destruction, Impact recommends that the

guidelines below be followed.

1. The ventilator’s outer case should be cleaned with a damp soapy cloth and thoroughly dried

with a lint-free cloth. Make sure that all exposed surfaces are cleaned and dried.

2. For general decontamination/cleaning situations, a 10% bleach solution applied with a damp

cloth is an effective decontaminant that can be used. Since the potential amount of

contaminants that our ventilators might be exposed to is so large, it is difficult to provide an

appropriate cleaning method for each type of exposure. An effective cleaning agent for one

type of exposure may not be effective with another and cleaning and sterilizing practices may

vary between institutions. Impact Instrumentation, Inc. suggests that each facility have in place

906-0731-04 Rev. B Sept. 2012 Page 10 of 68

Page 11

a procedure for the cleaning and disinfection of its medical equipment and that these

CAUTION! Do not operate the compressor without a filter in place.

CAUTION! There are no user serviceable parts except the filter components described above.

CAUTION! When used in dusty/dirty environments the foam and disk filters should be checked, and

replaced as needed. This will prevent particle build up on the transducer screen and the need to take the

unit out of service for maintenance by a biomedical technician.

procedures be consulted for further guidance.

3. Care must be taken to prevent liquids from entering the ventilator. Never submerge the

ventilator and avoid using excessive amounts of water that might enter the unit.

4. Never use abrasives or chlorinated hydrocarbon based cleansers when cleaning the ventilator,

they will damage the plastic and interface lens.

5. Always follow the decontamination procedures specified by the local Incident Command Safety

Officer.

6. Equipment should be cleaned and decontaminated as soon as possible after use. Personnel

should always wear the appropriate Personal Protective Equipment while decontaminating

equipment.

7. The ventilator’s outer case should be cleaned with a damp soapy cloth and thoroughly dried

with a lint-free cloth. Make sure that all exposed surfaces are cleaned and dried.

8. For general decontamination/cleaning situations, a 10% bleach solution applied with a damp

cloth is an effective decontaminant that can be used. Since the potential amount of

contaminants that our ventilators might be exposed to is so large, it is difficult to provide an

appropriate cleaning method for each type of exposure. An effective cleaning agent for one

type of exposure may not be effective with another and cleaning and sterilizing practices may

vary between institutions. Impact Instrumentation, Inc. suggests that each facility have in place

a procedure for the cleaning and disinfection of its medical equipment and that these

procedures be consulted for further guidance.

9. Care must be taken to prevent liquids from entering the ventilator. Never submerge the

ventilator and avoid using excessive amounts of water that might enter the unit.

10. Never use abrasives or chlorinated hydrocarbon based cleansers when cleaning the ventilator,

they will damage the plastic and interface lens.

Removable Foam Filter Replacement

Removable Foam Filter: The Removable Foam Filter is located on the right side of the ventilator. It should

be inspected and replaced if needed every 1,000 hours of operation or more frequently if used in dusty

environments. Remove the filter using a pair of tweezers or similar tool. Examine the filter for dirt, lint, or

general wear. Replace if necessary (Part # 465-0028-00). DO NOT attempt to clean this filter.

Fresh Gas/Emergency Air Intake Disk Filter Replacement

Fresh Gas/Emergency Air Intake Disk Filter: The Fresh Gas/Emergency Air Intake Disk Filter (Part #4650027-00) is located behind the Removable Foam Filter. This filter provides a second level of filtration to the

ambient air that is delivered to the patient. This filter must be checked periodically and replaced when

necessary. The device triggers an alarm when the combination of Removable Foam Filter and Fresh

Gas/Emergency Air Intake Disk Filter become dirty. This alarm signifies that the device is still able to deliver

the correct tidal volume but one or more of its filters need replacement. The Fresh Gas/Emergency Air

Intake Disk Filter can be visually inspected after the Removable Foam Filter is removed. If the filter appears

discolored it must be replaced. See Appendix 5 in the Operation Manual: Internal Filter Change/Insertion.

906-0731-04 Rev. B Sept. 2012 Page 11 of 68

Page 12

CAUTION! If filters have been exposed to biological matter dispose of them following Universal Precaution

procedures for your facility.

NOTE: Do not attempt to clean this filter and do not operate internal compressor without filter in place.

CAUTION! Only use the Power Supply provided with the unit. Use of any other power supply could cause

damage or create a fire and/or destroy the battery and unit.

CAUTION! If you witness a battery or the battery compartment starting to balloon, swell up, smoke or feel

excessively hot, turn off the unit, disconnect external power and observe it in a safe place for

approximately 15 minutes and send the unit for service. Never puncture or disassemble the battery packs

or cells.

CAUTION! Never attempt to completely discharge the battery by shorting or some other method and

never ship the battery in a completely discharged state.

CAUTION! During continuous, uninterrupted use (>100 hours) it is recommended that the ventilator be

disconnected from AC power for 30 seconds to allow the battery to run diagnostics while the battery is

discharging.

NOTE: The ventilator continuously monitors the available power sources; occasionally a false low priority

power alarm can be triggered for ~1 second. These false alarms immediately clear themselves.

Battery Capacity, Care and Recharging

While the unit is operating on battery power, users can best determine the relative amount of charge in the

internal battery by looking at the BATTERY Icon/Indicator. The BATTERY icon appears in outline form and is

filled with horizontal rows of lines indicating its current capacity. Each line represents approximately 5% of

battery capacity.

The device uses a rechargeable lithium-ion battery which offers a wide temperature operating range, does

not exhibit "memory" characteristics (reduced capacity) or vent hydrogen gas. The life of this battery

depends, to a great extent, upon the care it receives. Avoid exposing it to direct sunlight or heat sources

and never store the battery at temperatures above 76 °C (170 °F) for more than 2 hours. Following these

simple guidelines will prevent premature charge depletion and reduction of battery life.

If the unit was supplied without the battery installed or battery replacement is required see Appendix 4:

Internal Battery Change/Insertion.

1. Battery charging is controlled by ventilator in the temperature range of 0 C to 45 C (32F to 113 F)

to provide the best life time for the battery

2. The battery has a discharge (operational) temperature range of -25° to 49° C (-13 F to 120 F) (as

validated by Impact Instrumentation).

3. DO NOT store the ventilator with the batteries discharged. Always store with the battery fully

charged.

4. For long-term storage, the optimum storage temperature range is -15 C to 21 C (5 F to 71 F).

Lithium-ion batteries exhibit excellent charge retention characteristics. Prolonged periods of disuse will not

substantially reduce operating capability. If long-term storage/non-use is common, recharge the unit every

six months; this will insure that battery charge is maintained at 80% capacity or better. The 731 series

devices’ battery rapidly recharges to 90% of its capacity in approximately 2 hours. It will take approximately

another 2 hours of trickle-charging to top off the battery to 100% of its capacity. Continuous charging is

permissible with the supplied 12 VDC Power Cable or AC/DC Power Supply.

Operating power will always default to the external power source to preserve the internal battery charge.

This assures that power is available for transport use or emergency back-up. If the EXTERNAL POWER LOW/ FAIL

alarm occurs, the device will automatically revert to its internal batteries for operating power.

The BATTERY Icon/Indicator – indicates (1) the presence of a functional battery, (2) when the battery is

charging and (3) what its current capacity is. The BATTERY icon appears in outline form and is filled with

906-0731-04 Rev. B Sept. 2012 Page 12 of 68

Page 13

horizontal rows of lines indicating its current capacity. When the battery is charging, these horizontal rows

Maintenance Activity

Year after initial purchase of ventilator

1 2 3 4 5 6 7

8

Replace inlet oxygen and compressor foam

and disk filters

* * * * * * *

*

Perform a Periodic Maintenance Check

(PMC)

* * * * * * *

*

Replace the main battery

*

*

Replace the real time clock battery (RTC)

*

*

Inspect and replace if needed any internal

tubing, gaskets, or O-Rings that show signs of

wear

*

*

Inspect internal pneumatic & electro-

mechanical components

*

*

of lines cyclically scroll vertically, one row at a time, from the bottom row to the top. When the battery is

fully charged, the icon is completely filled with lines and scrolling stops. Each line represents approximately

5% of battery capacity. During internal battery operation a horizontal line “disappears” as battery capacity

is reduced by a 5% increment. The BATTERY icon will flash off/on when a BATTERY POWER LOW alarm occurs.

The icon will flash off/on and present with a diagonal line when no battery is connected.

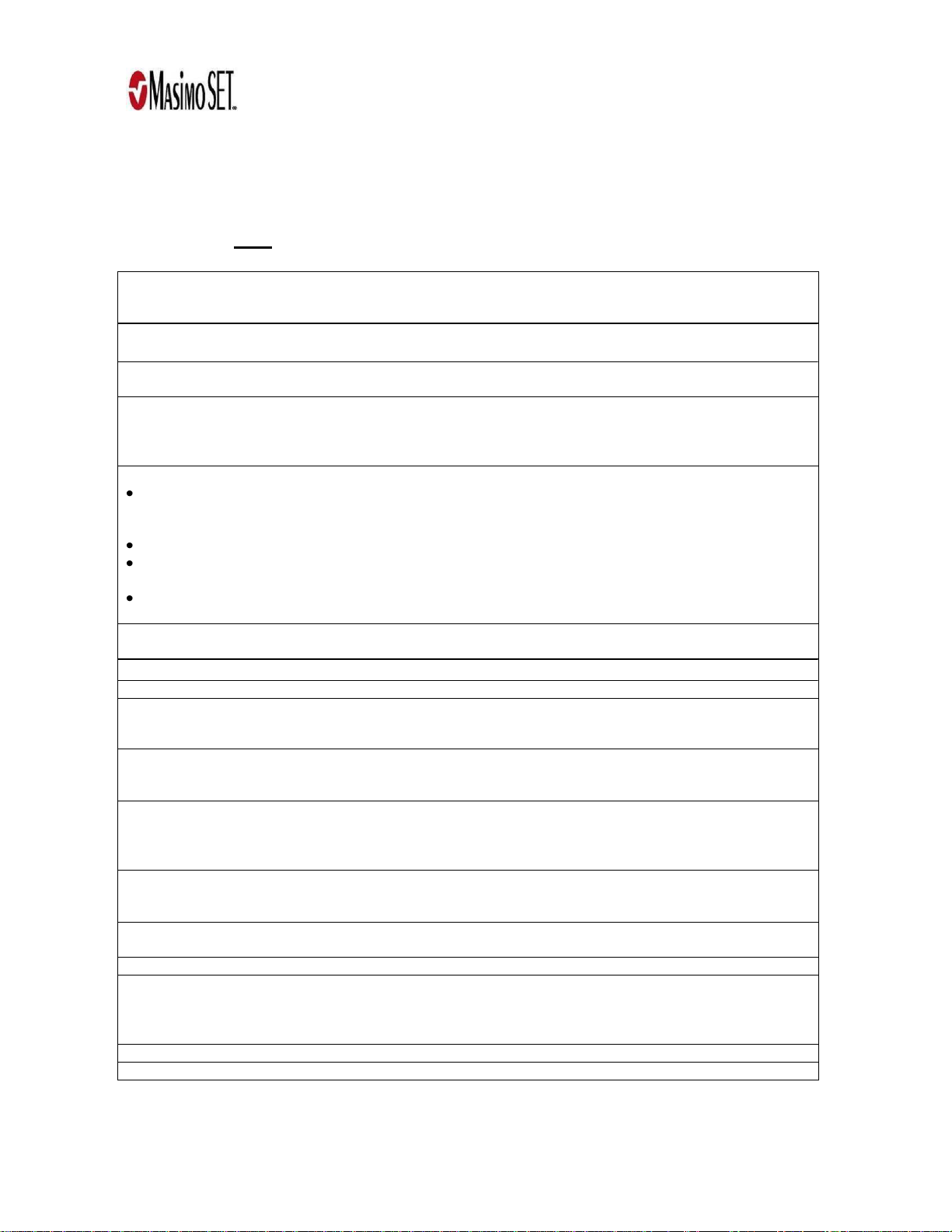

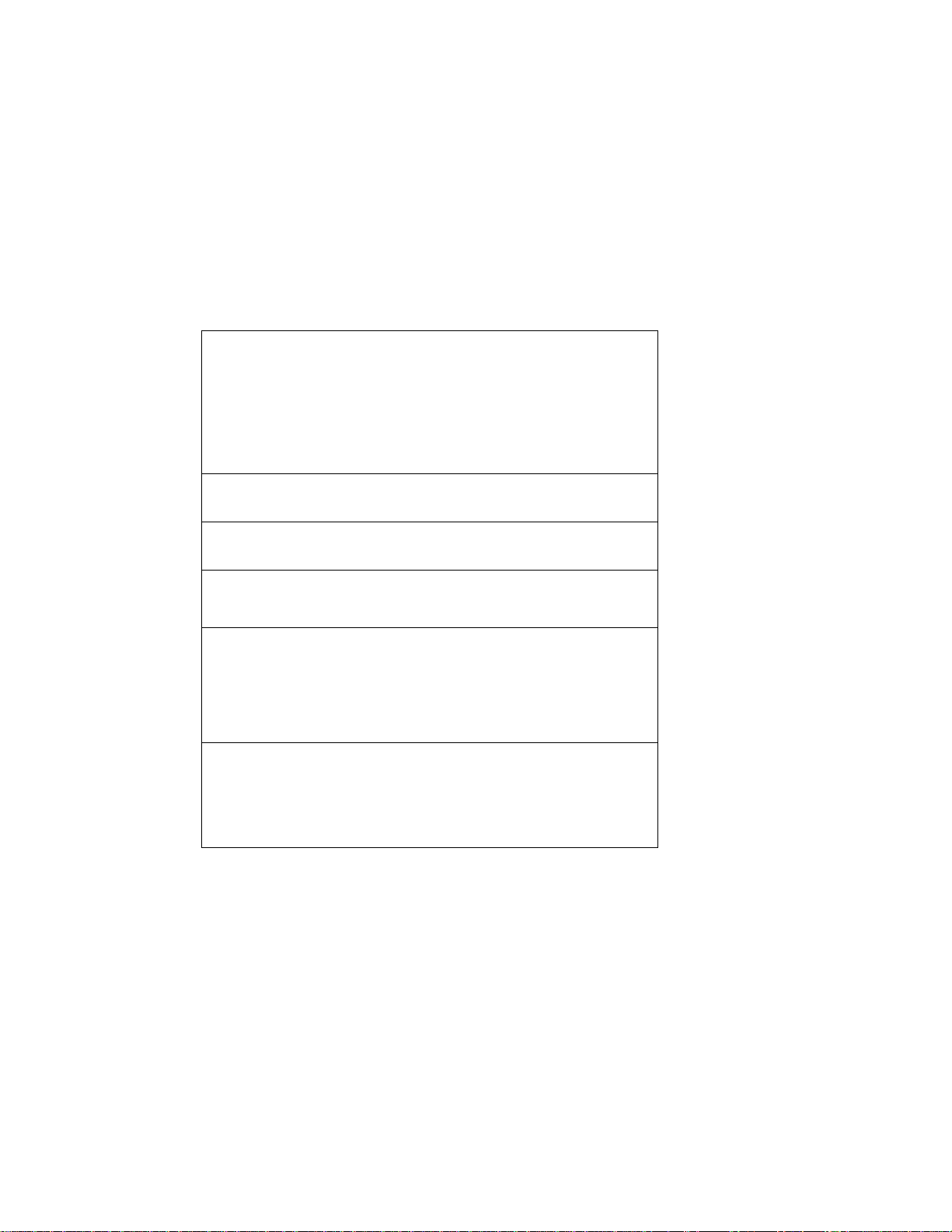

Preventive Maintenance (PM)

Scheduled replacement of filters, batteries, seals and mechanical/pneumatic moving parts will ensure the

device is always operating at peak performance. The table below describes the scheduled interval for

routine parts replacement, calibration and functional testing. Ventilators used in extreme environments

may warrant earlier or more frequent maintenance scheduling.

Table 1 Maintenance Schedule.

Periodic Maintenance Check (PMC)

At start up, the device performs a self check that includes a check for pre-existing alarm conditions.

Following start up, the presence of alarm conditions is checked continuously. When in operation the

ventilator circuit connects to a pressure transducer in the ventilator. Periodically, the transducer

recalibrates itself using the ambient air pressure as a reference. This process maintains a consistent

transducer baseline over a wide temperature and altitude range to assure display, monitoring and triggering

accuracy.

The ventilator also automatically performs an AUTO CAL procedure that affects 3 transducer systems:

Compressor Flow, Oxygen Flow and Airway Pressure. The purpose of AUTO CAL is to compensate for small

temperature related drifts in the transducer offset (zeroing). The AUTO CAL is performed at start up during

the self check and then every 5 minutes thereafter. However, if a temperature change emceeing +/-1.5oC is

sensed, the AUTO CAL time interval is reduced automatically to assure a stable pressure measurement

baseline. This continuous correction for variations in ambient temperature and pressure enable the

ventilator to deliver targeted volumes and pressure over the entire operating altitude and temperature

ranges described in the operations manual.

The automated self check at start up and the AUTO CAL tests confirm that the device is operating within its

specifications when in use. If the start up or AUTO CAL tests fail, the unit will not operate. Because the

automated tests do not confirm that flow and pressure outputs from the device are verified against a

controlled external pressure, flow and temperature measurement device, the PMC procedure should be

done every 12 months or after 1,500 hours of use, or to reset the ‘performance maintenance check’ low

906-0731-04 Rev. B Sept. 2012 Page 13 of 68

Page 14

priority alarm, to document that the ventilator has been maintained and is operating properly. The PMC

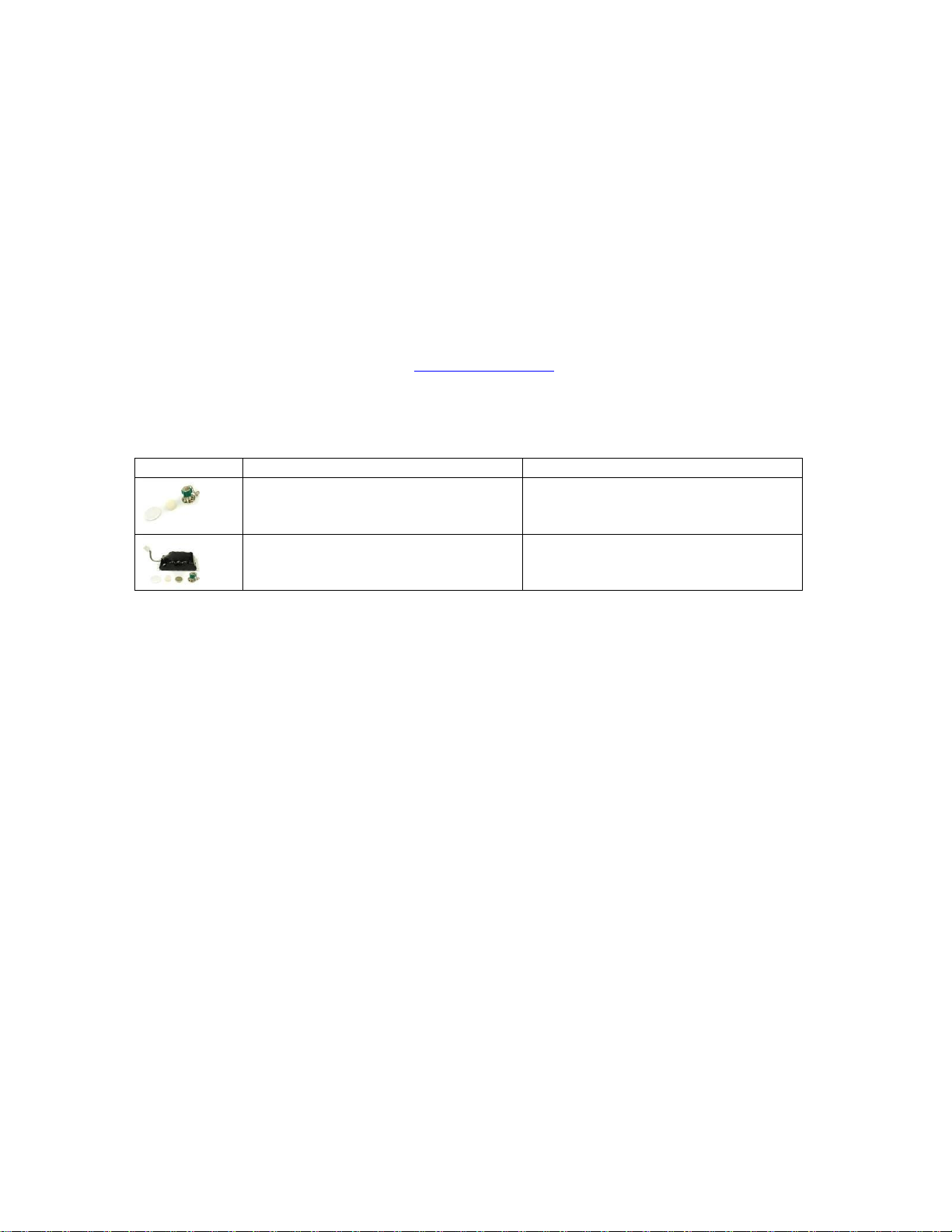

Picture

Description

Kit #

Annual Preventive Maintenance Kit

712-0731-20

4-Year Preventive Maintenance Kit

712-0731-21

should also be performed whenever the operator suspects that the device is not functioning properly or

following mass deployment and before the device is returned to storage. If the device fails the PMC it

should be maintained by a certified Impact service technician in the field or at Impact authorized service

locations. A secure record of PMC results should be maintained for devices not returned to Impact for

maintenance.

Impact’s 731 series service tool the RCS is needed to perform the PMC and reset the ‘performance

maintenance check’ low priority alarm. This tool includes can be purchased from Impact for use by Impact

trained and certified biomedical technicians. Alternatively, 731 series can be sent to an Impact authorized

service center for PMC or other service requirements.

In addition to automating and documenting the PMC process, the RCS is also capable of calibrating the

device and installing and verifying software upgrades and updates to the 731 series of devices.

If you would like to return the ventilator to Impact for service please contact Impact prior to returning this

instrument. (Telephone 973.882.1212, email service@impactii.com). A Returned-Goods-Authorization

number (RGA #) will be issued. The RGA # must appear on both the packing slip and address label. This will

facilitate better tracking of the returned item and result in improved scheduling and handling.

Annual and 4-Year PM Kits are available to trained personnel and service centers.

906-0731-04 Rev. B Sept. 2012 Page 14 of 68

Page 15

Troubleshooting and Repairs

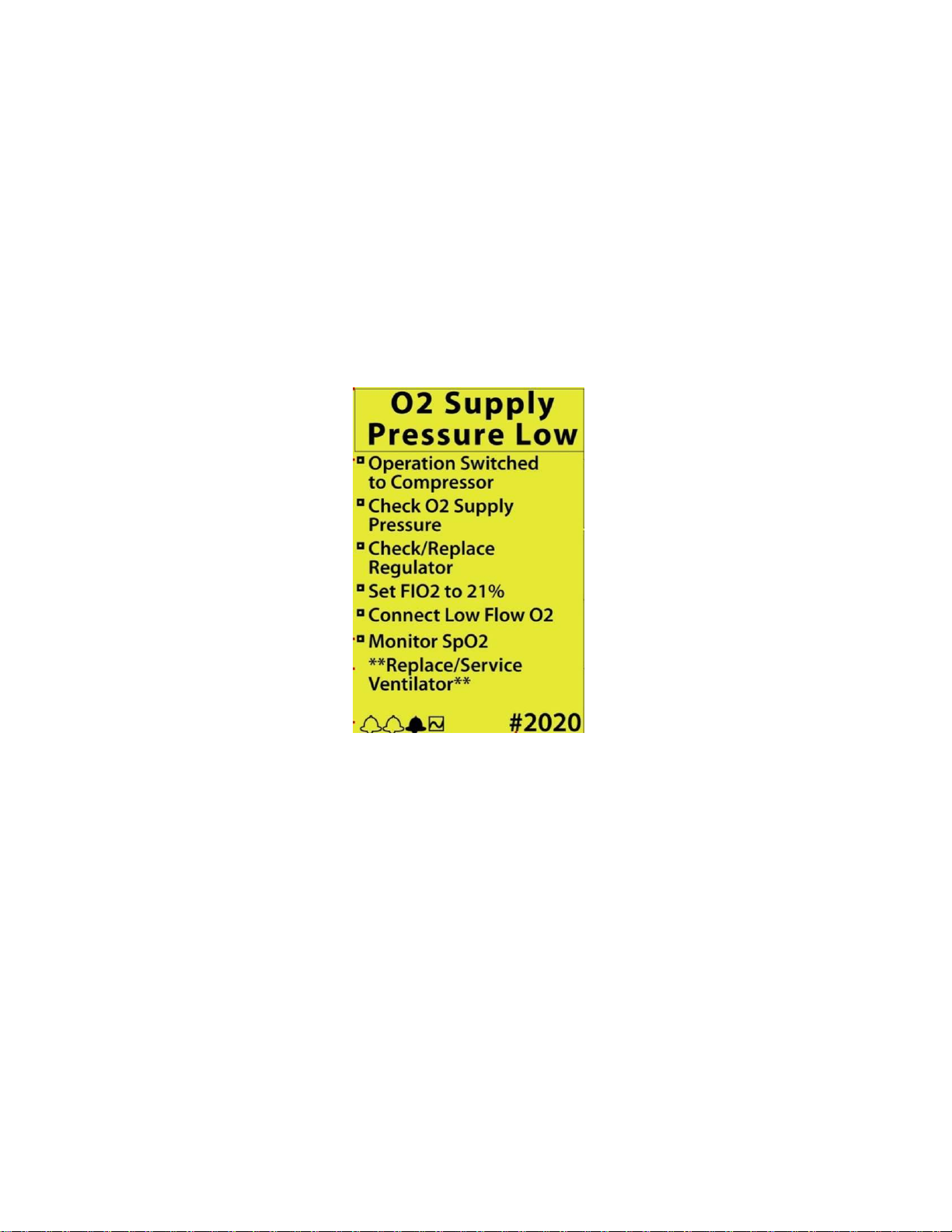

The device uses a comprehensive suite of alarms to alert the operator and guide their actions to resolve the

alarm condition and assure patient safety. At the onset of an alarm, the screen displays the alarm name and

then a series of context-sensitive help messages (see Figure 2 example). These messages serve to guide the

operator by presenting suggestions as to the cause and resolution of a particular alarm. When multiple

alarms occur they are prioritized and displayed based on the risk to the patient. Should the operator not be

able to correct the problem, the ventilator should be taken out of use and sent to an authorized Impact

repair facility.

Trained bio-med technicians are encouraged to use a systematic approach to solving issues with the

ventilator. Use the Alarm Category and Service Code matrices listed in Appendix to resolve the problem or

to identify the suggested replacement service kit. Check on-hand availability or order the kit(s) from Impact,

then follow the detailed instructions listed to replace the kit. Trained repair facilities can contact Impact’s

technical service department via email: service @impactii.com or by telephone toll free: 800-969-0750 or

973-882-1212 for troubleshooting and repair recommendations.

ALARM & PLOT LIST: FIGURE 2

Service Kits

Service kits, which are preassembled and factory tested subassemblies, are available should physical

damage or problems of an unforeseen nature arise. Service kits are available only to qualified trained

biomedical personnel or authorized Impact service centers. Each kit replacement must be followed by a

HiPot test (See section titled HiPot Testing ), then either by a functional test or a calibration and functional

test using the Remote Calibration System (RCS).The following table lists the kits for each 731 series model.

906-0731-04 Rev. B Sept. 2012 Page 15 of 68

Page 16

Service Kit Listing

Description

EMVP

Eagle II

Picture

Kit #

Picture

Kit#

Membrane Panel Kit

712-0731-01

712-EGL2-01

SPM/Vent Assembly Kit

712-0731-02

712-EGL2-02

Battery Compartment Kit

712-0731-03

712-EGL2-03

712-EGL2-13 (MR)

Outer Air Intake Kit

712-0731-04

712-EGL2-04

Bezel Assembly Kit

712-0731-05 (EMVP)

712-AEV1-01 (AEV)

712-EGL2-05

Power Knob Kit

712-0731-06

712-EGL2-06

USB Connector Plate Kit

712-0731-07

712-EGL2-07

Front Case Assembly Kit

712-0731-08 (EMVP)

712-AEV1-02 (AEV)

712-EGL2-08

Battery Case Bottom Cover Kit

712-0731-09

712-EGL2-08

EMV Chassis Kit

712-0731-10

712-EGL2-10

Connector Panel Kit

712-0731-11

712-EGL2-11

Back Case Kit

712-0731-12

712-EGL2-12

PIM Board Kit

702-0731-02

702-0731-02

CPU/UIM & SPO2 Stack Kit

712-0731-14

712-0731-14

USB Connector Kit

712-0731-15

712-0731-15

Gas Output Kit

712-0731-16

712-0731-16

Power Input Kit

712-0731-17

712-0731-17

Oxygen Inlet Fitting Kit

712-0731-18

712-0731-18

Selector Knob Kit

712-0731-19

392-0066-00

906-0731-04 Rev. B Sept. 2012 Page 16 of 68

Page 17

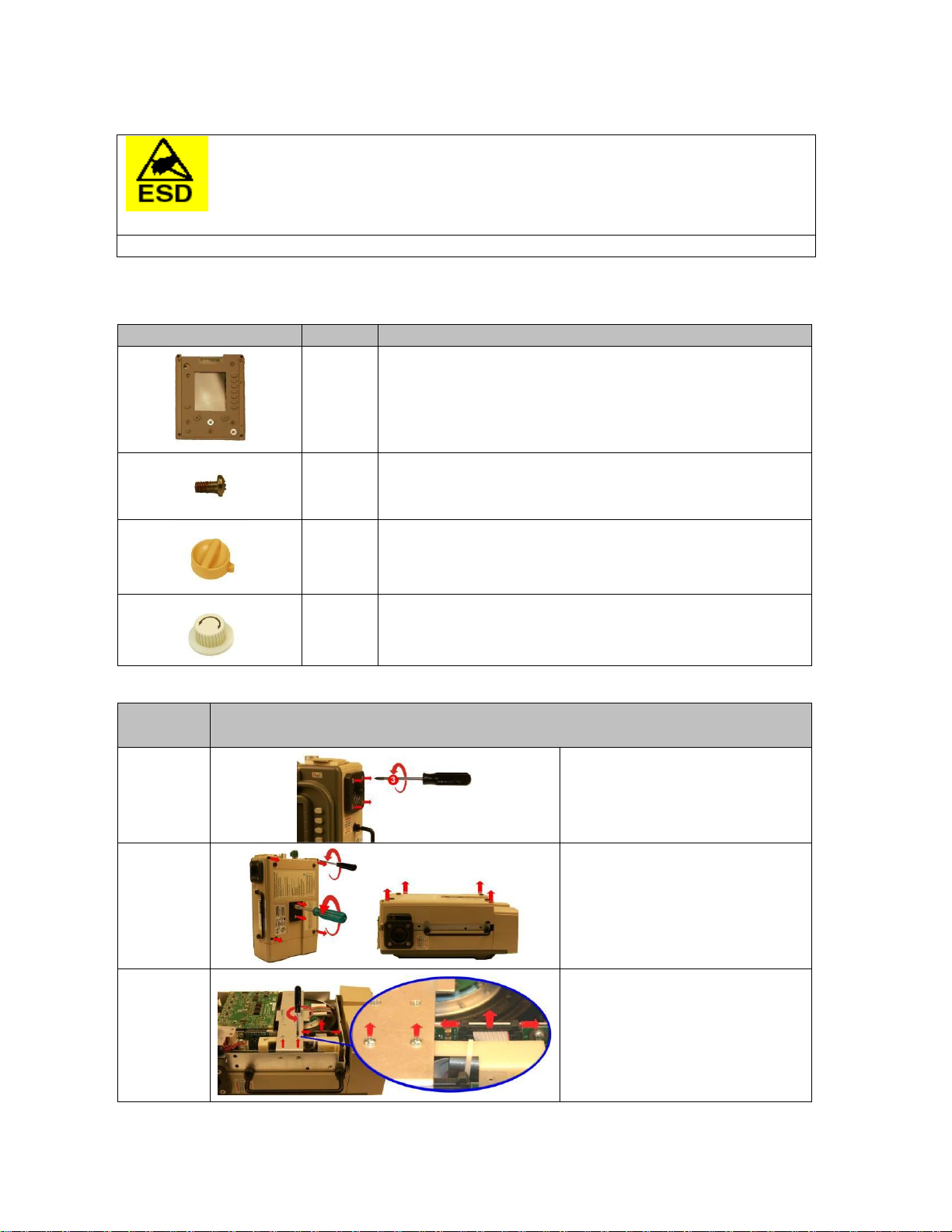

Replacement Instructions

STEP NO.

DIRECTIONS

1

Loosen but do not remove the

(4) 8-32 X 3 screws on the outer air

intake.

2

Loosen and remove the (2) 10-32

Keps nuts and the (4) 6-32 X 2

screws. Remove the back case by

lifting from the ventilator.

3

Remove the (2) 4-40 X ¼ screws on

the Dovetail Mounting Bracket and

disconnect the ribbon cable on the

PIM PCB by simultaneously applying

pressure on the two locking “ears”.

ITEM

QTY

DESCRIPTION

1

Membrane Panel Assembly

7

Screw, Phillips, Pan Head, Zinc Plated, 4-40 X 1/4

1

Power Select Knob with Set screw

1

Selector Knob

CAUTION! Internal components are susceptible to damage from static discharge. All servicing

operations MUST be done in an ESD controlled environment.

CAUTION! Disconnect external power and battery pack prior to performing any service.

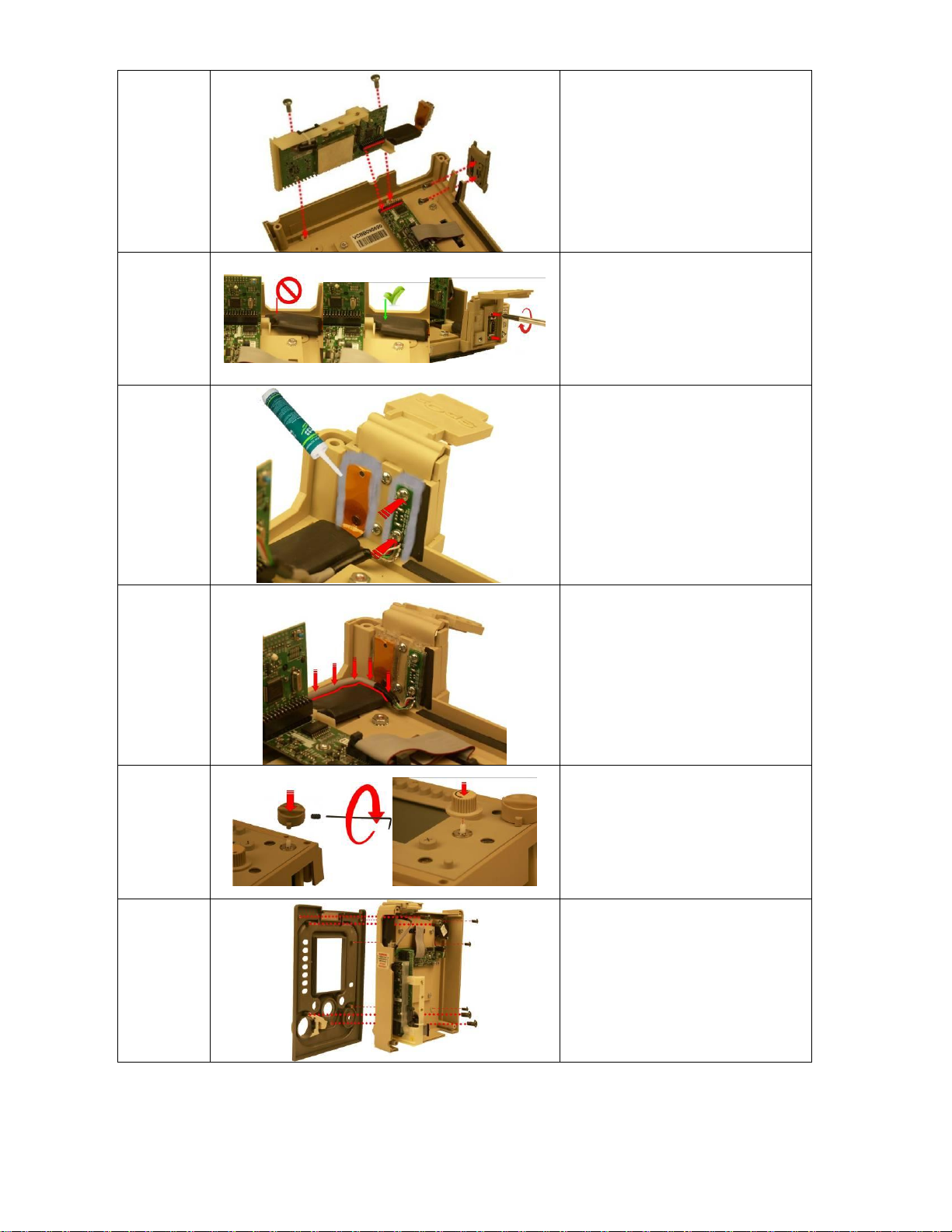

Membrane Panel Kit 712-0731-01 / 712-EGL2-01

Contents:

Instructions:

906-0731-04 Rev. B Sept. 2012 Page 17 of 68

Page 18

4

Flip the ventilator over and remove

the front case assembly by lifting it

straight up away from the ventilator

module.

5

Remove the bezel by loosening and

removing the (7) 4-40 X ¼ screws

that hold the bezel to the front case.

6

Using a sharp knife, carefully cut the

RTV sealant around the USB Printed

Circuit Board and around the SPO2

Connector. Be careful not to cut

either cable.

7

Loosen and remove the two 4-40 X

3/16 screws holding the Mini USB

Cable Assembly to the front case.

Loosen and remove the two M2.5 X

5mm screws holding the SPO2 cable

to the front case.

8

Loosen and remove the two (2)

6-32 X 5/16 screws that hold the

CPU/UIM & SPO2 Stack to the front

case.

9

Lift the CPU/UIM & SPO2 Stack up

from the front case. Handle the

SPO2 cable with extreme care. Do

not pull on the cable.

10

Loosen and remove the two 4-40 X

5/16 screws holding the USB

Connector Plate to the front case.

906-0731-04 Rev. B Sept. 2012 Page 18 of 68

Page 19

11

Tighten the two 4-40 X 5/16 screws

holding the USB Connector Plate to

the replacement front case. Tighten

the two (2) 6-32 X 5/16 screws that

hold the CPU/UIM & SPO2 Stack to

the front case. Make sure that all the

pins on the header mate correctly.

12

Make sure the SPO2 Flex Cable lays

flat against the front case and is

assembled correctly into the UIM

Bracket and SPO2 Isolation Shield.

Insert and tighten the two M2.5 X

5mm screws holding the SPO2 cable

to the front case.

13

Remove any excess RTV sealant from

the SPO2 flex cable and USB PCB.

Tighten the two 4-40 X 3/16 screws

holding the USB PCB to the front

case. Apply RTV sealant to USB PCB

and SPO2 flex cable. Allow to

dry/cure.

14

Dress the USB Connector cable along

the case and over the SPO2 flex

cable.

15

Place the included power knob on

the new membrane panel switch -

align with flat on switch – insert the

included 6-32 X ¼ set screw and

tighten. Push the included selector

knob on the membrane panel switch

- align with flat on switch .

16

Place the front case assembly on to

the bezel and tighten the included

(7) 4-40 X ¼ screws.

906-0731-04 Rev. B Sept. 2012 Page 19 of 68

Page 20

17

Place the front case assembly over

the vent module and tighten the (2)

4-40 X ¼ screws unto the dovetail

mounting bracket. Reconnect the

ribbon cable unto the PIM PCB.

Make sure the two locking “ears”

lock into position.

18

Attach the back case to the vent

module and align cover with handle,

air intake housing and dovetail

mounting studs. Insert and tighten

the included (2) 10-32 Keps nuts and

the (4) 6-32 X 2” screws.

19

Tighten the (4) 8-32 X 3 screws on

the outer air intake.

20

Perform HiPot Testing then perform

Calibration and Functional Test using

the RCS.

906-0731-04 Rev. B Sept. 2012 Page 20 of 68

Page 21

SPM Kit 712-0731-02 / 712-EGL2-02

STEP NO.

DIRECTIONS

1

Loosen but do not remove the

(4) 8-32 X 3 screws on the outer air

intake.

2

Loosen and remove the (2) 10-32

Keps nuts and the (4) 6-32 X 2

screws. Remove the back case by

lifting from the ventilator.

3

Remove the (2) 4-40 X ¼ screws on

the Dovetail Mounting Bracket and

disconnect the ribbon cable on the

PIM PCB by simultaneously applying

pressure on the two locking “ears”.

4

Flip the ventilator over and remove

the front case assembly by lifting it

straight up away from the ventilator

module.

5

Remove the battery compartment

cover by unscrewing the (4) 6-32 X

5/16 screws.

6

Remove the battery by unscrewing

the (4) 6-32 X 2 ¼ screws and

detaching the plug from its locking

latch.

ITEM

QTY

DESCRIPTION

1

SPM/Vent Assembly

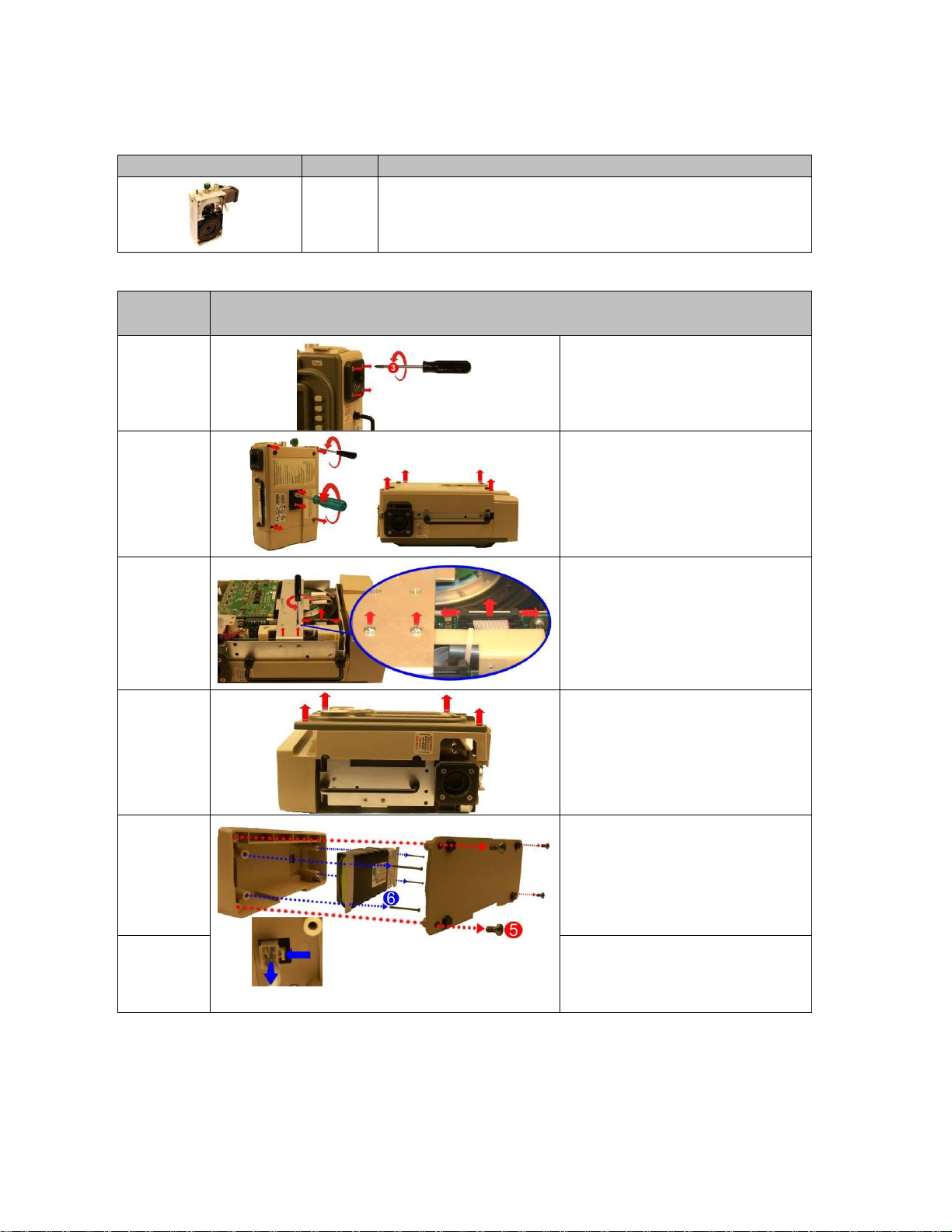

Contents:

Instructions:

906-0731-04 Rev. B Sept. 2012 Page 21 of 68

Page 22

7

Unscrew the (4) 6-32 X 5/16 Phillips

screws to remove the damaged battery

compartment case.

8

Loosen and remove the (2) 4-40 X 1 ¼

Screws and nylon spacers supporting the

Power Input assembly unto the chassis.

9

Loosen and remove the (2) 6-32 X ¼

screws holding the chassis to the dovetail

mounting bracket and remove the SPO2

insulator. Loosen and remove the (2) 8-

32 X ¼ screws holding the chassis to the

vent module.

10

Insert screwdriver through the holes on

the chassis to loosen and remove the (2)

6-32 x 5/16 screws holding the chassis to

the vent module.

11

Lift the damaged chassis from the

ventilator module.

12

Disconnect the Power Input cable from

the PIM PCB by pressing on the locking

latch and pulling the cable straight up

from the connector.

13

Remove the PIM PCB by loosening the (5)

4-40 X 5/16 screws.

906-0731-04 Rev. B Sept. 2012 Page 22 of 68

Page 23

14

Remove the Dovetail stabilizer bracket by

loosening and removing the (2) 6-32 x ¼

and the (2) 4-40 X ¼ screws.

15

Install the dovetail stabilizer bracket onto

the new SPM assembly by tightening the

(2) 6-32 X ¼ and (2) 4-40 X ¼ screws.

16

Secure the PIM Board to the new SPM

with the (5) 4-40 x 5/16 screws.

17

Secure the chassis to the vent module

using the (2) 6-32 X ¼ screws with SPO2

insulator, the (2) 8-32 X ¼ and the (2) 6-

32 x 5/16 screws.

18

Secure the Power Input assembly to the

Chassis using the (2) spacers and (2) 4-40

X 1 ¼ screws. Do not over-tighten the

screws.

906-0731-04 Rev. B Sept. 2012 Page 23 of 68

Page 24

19

Rotate battery compartment to mate

with upper and lower case cutouts and

press firmly into place. Secure with (4) 6-

32 X 5/16 screws provided.

20

Re-assemble the battery by connecting

its cable to the connector (pull on cable

to insure it is locked in place) then

tightening the (4) 6-32 X 2 ¼ screws.

21

Re-assemble the battery compartment

cover by tightening the (4) 6-32 X 5/16

screws.

22

Place the front case assembly over the

vent module and tighten the (2) 4-40 X ¼

screws unto the dovetail mounting

bracket. Reconnect the ribbon cable unto

the PIM PCB. Make sure the two locking

“ears” lock into position.

23

Attach the back case to the vent module

and align cover with handle, air intake

housing and dovetail mounting studs.

Insert and tighten the included (2) 10-32

Keps nuts and the (4) 6-32 X 2” screws.

24

Tighten the (4) 8-32 X 3 screws on the

outer air intake.

25

Perform HiPot Testing then perform

Calibration and Functional Test using the

RCS.

906-0731-04 Rev. B Sept. 2012 Page 24 of 68

Page 25

Battery Compartment Kit 712-0731-03 / 712-EGL2-03

Step No.

Directions

1

Remove the battery

compartment cover by

unscrewing the (4) 6-32 X 5/16

screws.

2

Remove the battery by

unscrewing the (4) 6-32 X 2 ¼

screws and detaching the plug

from its locking latch.

3

Unscrew the (4) 6-32 X 5/16

Phillips screws to remove the

damaged battery compartment

case.

4

Rotate battery compartment to

mate with upper and lower case

cutouts and press firmly into

place. Secure with (4) 6-32 X

5/16 screws provided.

5

Re-assemble the battery by

connecting its cable to the

connector (pull on cable to

insure it is locked in place) then

tightening the (4) 6-32 X 2 ¼

screws.

6

Re-assemble the battery

compartment cover by tightening

the (4) 6-32 X 5/16 screws.

7

Perform HiPot Testing then

perform Functional Test using

the RCS.

ITEM

QTY

DESCRIPTION

1

Battery Compartment Case with Gaskets

4

Screw, Phillips, Pan Head, SS, 6-32 X 5/16

Contents:

Instructions:

906-0731-04 Rev. B Sept. 2012 Page 25 of 68

Page 26

Outer Air Intake Kit 712-0731-04 / 712-EGL2-04

STEP NO.

DIRECTIONS

1

Remove the damaged Outer Air Intake by

unscrewing the (4) 8-32 X 3 screws.

2

The O-Ring is pre-installed into the groove on

40mm Adapter. Verify it is inserted correctly.

3

Place Intake Plate over 40mm Adapter and the 4

8-32 X 3 screws through Intake Plate and 40mm

Adapter.

4

Rotate assembly such that the alignment pin on

the BV Filter Holder mates with the alignment

hole on the 40mm Adapter.

5

Place entire assembly into BV Filter Holder and

tighten the included (4) 8-32 X 3 screws.

6

Perform HiPot Testing then perform Calibration

and Functional Test using the RCS.

ITEM

QTY

DESCRIPTION

1

Plate, Intake

4

Screw, PFH, SS, 8-32 X 3

1

Adapter, 40mm with O-Ring

1

O-Ring, Buna, 2-3/8X2.5X1/16" (Pre-installed into 40mm adapter)

Contents:

Instructions:

906-0731-04 Rev. B Sept. 2012 Page 26 of 68

Page 27

Bezel Assembly Kit 712-0731-05 / 712-EGL2-05 / 712-AEV1-01

STEP NO.

DIRECTIONS

1

Loosen but do not remove the

(4) 8-32 X 3 screws on the outer air intake.

2

Loosen and remove the (2) 10-32 Keps nuts

and the (4) 6-32 X 2 screws. Remove the

back case by lifting from the ventilator.

3

Remove the (2) 4-40 X ¼ screws on the

Dovetail Mounting Bracket and disconnect

the ribbon cable on the PIM PCB by

simultaneously applying pressure on the

two locking “ears”.

4

Flip the ventilator over and remove the

front case assembly by lifting it straight up

away from the ventilator module.

ITEM

QTY

DESCRIPTION

1

Bezel Assembly

7

Screw, Phillips, Pan Head, Zinc Plated, 4-40 X 1/4

1

EMV Label

1

EMVP Label

Contents:

Instructions:

906-0731-04 Rev. B Sept. 2012 Page 27 of 68

Page 28

5

Remove the bezel by loosening and

removing the (7) 4-40 X ¼ screws that hold

the bezel to the front case.

6

Select the correct label for your device,

peel the backing off and affix to the front

bezel.

7

Install the new bezel by tightening the

included (7) 4-40 X ¼ screws.

8

Place the front case assembly over the vent

module and tighten the (2) 4-40 X ¼ screws

unto the dovetail mounting bracket.

Reconnect the ribbon cable unto the PIM

PCB. Make sure the two locking “ears” lock

into position.

9

Attach the back case to the vent module

and align cover with handle, air intake

housing and dovetail mounting studs.

Insert and tighten the included (2) 10-32

Keps nuts and the (4) 6-32 X 2” screws.

10

Tighten the (4) 8-32 X 3 screws on the

outer air intake.

11

Perform HiPot Testing then perform

Functional Test using the RCS.

906-0731-04 Rev. B Sept. 2012 Page 28 of 68

Page 29

Power Knob Kit 712-0731-06 / 712-EGL2-06

STEP NO.

DIRECTIONS

1

Loosen but do not remove the

(4) 8-32 X 3 screws on the outer air intake.

2

Loosen and remove the (2) 10-32 Keps nuts

and the (4) 6-32 X 2 screws. Remove the

back case by lifting from the ventilator.

3

Remove the (2) 4-40 X ¼ screws on the

Dovetail Mounting Bracket and disconnect

the ribbon cable on the PIM PCB by

simultaneously applying pressure on the

two locking “ears”.

4

Flip the ventilator over and remove the

front case assembly by lifting it straight up

away from the ventilator module.

5

Remove the bezel by loosening and

removing the (7) 4-40 X ¼ screws that hold

the bezel to the front case.

ITEM

QTY

DESCRIPTION

1

Power Knob

1

Screw, Socket, Cup Point, Set, 6-32 X 1/4 (installed into knob)

Contents:

Instructions:

906-0731-04 Rev. B Sept. 2012 Page 29 of 68

Page 30

6

On the membrane panel assembly, loosen

the 6-32 X ¼ set screw using a 1/16 Ball Hex

Driver (located in the power knob) and lift

the damaged knob from the membrane

panel.

7

Place the replacement knob on the

membrane panel switch - align with flat on

switch – insert the included 6-32 X ¼ set

screw and tighten.

8

Install the new bezel by tightening the

included (7) 4-40 X ¼ screws.

9

Place the front case assembly over the vent

module and tighten the (2) 4-40 X ¼ screws

unto the dovetail mounting bracket.

Reconnect the ribbon cable unto the PIM

PCB. Make sure the two locking “ears” lock

into position.

10

Attach the back case to the vent module

and align cover with handle, air intake

housing and dovetail mounting studs.

Insert and tighten the included (2) 10-32

Keps nuts and the (4) 6-32 X 2” screws.

11

Tighten the (4) 8-32 X 3 screws on the

outer air intake.

12

Perform HiPot Testing then perform

Calibration and Functional Test using the

RCS.

906-0731-04 Rev. B Sept. 2012 Page 30 of 68

Page 31

USB Connector Plate Kit 712-0731-07 / 712-EGL2-07

STEP NO.

DIRECTIONS

1

Loosen but do not remove the

(4) 8-32 X 3 screws on the outer air

intake.

2

Loosen and remove the (2) 10-32 Keps

nuts and the (4) 6-32 X 2 screws.

Remove the back case by lifting from

the ventilator.

3

Remove the (2) 4-40 X ¼ screws on

the Dovetail Mounting Bracket and

disconnect the ribbon cable on the

PIM PCB by simultaneously applying

pressure on the two locking “ears”.

4

Flip the ventilator over and remove

the front case assembly by lifting it

straight up away from the ventilator

module.

5

Remove the bezel by loosening and

removing the (7) 4-40 X ¼ screws that

hold the bezel to the front case.

ITEM

QTY

DESCRIPTION

1

USB Connector Plate Assembly

2

Screw, Phillips, Pan Head, Zinc Plated, 4-40 X 5/16

Contents:

Instructions:

906-0731-04 Rev. B Sept. 2012 Page 31 of 68

Page 32

6

Using a sharp knife, carefully cut the

RTV sealant around the USB Printed

Circuit Board and around the SPO2

Connector. Be careful not to cut either

cable.

7

Loosen and remove the two 4-40 X

3/16 screws holding the Mini USB

Cable Assembly to the front case.

Loosen and remove the two M2.5 X

5mm screws holding the SPO2 cable

to the front case.

8

Loosen and remove the two (2)

6-32 X 5/16 screws that hold the

CPU/UIM & SPO2 Stack to the front

case.

9

Lift the CPU/UIM & SPO2 Stack up

from the front case. Handle the SPO2

cable with extreme care. Do not pull

on the cable.

10

Loosen and remove the two 4-40 X

5/16 screws holding the damaged USB

Connector Plate to the front case.

11

Insert and tighten the two included 4-

40 X 5/16 screws holding the

replacement USB Connector Plate to

the front case.

12

Tighten the two (2) 6-32 X 5/16 screws

that hold the CPU/UIM & SPO2 Stack

to the front case. Make sure that all

the pins on the header mate correctly.

906-0731-04 Rev. B Sept. 2012 Page 32 of 68

Page 33

13

Make sure the SPO2 Flex Cable lays

flat against the front case and is

assembled correctly into the UIM

Bracket and SPO2 Isolation Shield.

Insert and tighten the two M2.5 X

5mm screws holding the SPO2 cable

to the front case.

14

Remove any excess RTV sealant from

the SPO2 flex cable and USB PCB.

Tighten the two 4-40 X 3/16 screws

holding the USB PCB to the front case.

Apply RTV sealant to USB PCB and

SPO2 flex cable. Allow to dry/cure.

15

Place the included power knob on the

new membrane panel switch - align

with flat on switch – insert the

included 6-32 X ¼ set screw and

tighten. Push the included selector

knob on the membrane panel switch -

align with flat on switch .

16

Place the front case assembly on to

the bezel and tighten the included (7)

4-40 X ¼ screws.

17

Place the front case assembly over the

vent module and tighten the (2) 4-40

X ¼ screws unto the dovetail

mounting bracket. Reconnect the

ribbon cable unto the PIM PCB. Make

sure the two locking “ears” lock into

position.

18

Attach the back case to the vent

module and align cover with handle,

air intake housing and dovetail

mounting studs. Insert and tighten the

included (2) 10-32 Keps nuts and the

(4) 6-32 X 2” screws.

19

Tighten the (4) 8-32 X 3 screws on the

outer air intake.

20

Perform HiPot Testing then perform

Calibration and Functional Test using

the RCS.

906-0731-04 Rev. B Sept. 2012 Page 33 of 68

Page 34

Front Case Assembly Kit 712-0731-08 / 712-EGL2-08 / 712-AEV1-02

STEP NO.

DIRECTIONS

1

Loosen but do not remove the

(4) 8-32 X 3 screws on the outer air

intake.

2

Loosen and remove the (2) 10-32 Keps

nuts and the (4) 6-32 X 2 screws.

Remove the back case by lifting from

the ventilator.

3

Remove the (2) 4-40 X ¼ screws on

the Dovetail Mounting Bracket and

disconnect the ribbon cable on the

PIM PCB by simultaneously applying

pressure on the two locking “ears”.

4

Flip the ventilator over and remove

the damaged front case assembly by

lifting it straight up away from the

ventilator module.

ITEM

QTY

DESCRIPTION

1

Front Case Assembly

2

Screw, Phillips, Pan Head, Zinc Plated, 4-40 X 1/4

1

EMV Label

1

EMVP Label

Contents:

Instructions:

WARNING: Disconnect external power and battery pack prior to performing service.

906-0731-04 Rev. B Sept. 2012 Page 34 of 68

Page 35

5

Place the replacement front case

assembly over the vent module and

tighten the (2) 4-40 X ¼ screws unto

the dovetail mounting bracket.

Reconnect the ribbon cable unto the

PIM PCB. Make sure the two locking

“ears” lock into position.

6

Attach the back case to the vent

module and align cover with handle,

air intake housing and dovetail

mounting studs. Insert and tighten the

included (2) 10-32 Keps nuts and the

(4) 6-32 X 2” screws.

7

Tighten the (4) 8-32 X 3 screws on the

outer air intake.

8

Select the correct label for your

device, peel the backing off and affix

to the front bezel.

9

Update serial numbers using

the RCS:

a. Use the “C:\program

files\impact\EMV\bin\

EmvDLGui.exe” to change

the serial numbers.

b. Use the RCS FD app to re-

flash the firmware.

10

Perform HiPot Testing then perform

Calibration and Functional Test using

the RCS.

906-0731-04 Rev. B Sept. 2012 Page 35 of 68

Page 36

Battery Case Bottom Cover Kit 712-0731-09 / 712-EGL2-09

STEP NO.

DIRECTIONS

1

Remove the damaged cover by unscrewing

the (4) 6-32 X 5/16 screws.

2

Remove backing from Bumper feet and place

one at each corner of Battery case bottom

cover.

3

Rotate cover to align with battery

compartment then insert and tighten the (4)

6-32 X 5/16 screws.

4

Perform HiPot Testing then perform

Functional Test using the RCS.

ITEM

QTY

DESCRIPTION

1

Battery case bottom cover

4

Screw, Phillips, Pan Head, SS, 6-32 X 5/16

4

Bumper, Rubber, Foot, P/S, Round, 1/2" Dia. X 1/8", Blk

Contents:

Instructions:

906-0731-04 Rev. B Sept. 2012 Page 36 of 68

Page 37

EMV Chassis Kit 712-0731-10 / 712-EGL2-10

STEP NO.

DIRECTIONS

1

Loosen but do not remove the

(4) 8-32 X 3 screws on the outer air

intake.

2

Loosen and remove the (2) 10-32 Keps

nuts and the (4) 6-32 X 2 screws.

Remove the back case by lifting from

the ventilator.

3

Remove the (2) 4-40 X ¼ screws on

the Dovetail Mounting Bracket and

disconnect the ribbon cable on the

PIM PCB by simultaneously applying

pressure on the two locking “ears”.

4

Flip the ventilator over and remove

the front case assembly by lifting it

straight up away from the ventilator

module.

ITEM

QTY

DESCRIPTION

1

EMV Chassis Assembly

2

Screw, Phillips, Pan Head, SS, 6-32 X 5/16

2

Screw, Phillips, Flat Head, 8-32 X 1/4, Undercut, ZP

2

Screw, Phillips, Flat Head, 6-32 X 1/4, Undercut

1

SPO2 Insulator

Contents:

Instructions:

906-0731-04 Rev. B Sept. 2012 Page 37 of 68

Page 38

5

Remove the battery compartment cover

by unscrewing the (4) 6-32 X 5/16

screws.

6

Remove the battery by unscrewing the

(4) 6-32 X 2 ¼ screws and detaching the

plug from its locking latch.

7

Unscrew the (4) 6-32 X 5/16 Phillips

screws to remove the damaged battery

compartment case.

8

Loosen and remove the (2) 4-40 X 1 ¼

Screws and nylon spacers supporting the

Power Input assembly unto the chassis.

9

Loosen and remove the (2) 6-32 X ¼

screws holding the chassis to the dovetail

mounting bracket and remove the SPO2

insulator. Loosen and remove the (2) 8-

32 X ¼ screws holding the chassis to the

vent module.

10

Insert screwdriver through the holes on

the chassis to loosen and remove the (2)

6-32 x 5/16 screws holding the chassis to

the vent module.

11

Lift the damaged chassis from the

ventilator module.

906-0731-04 Rev. B Sept. 2012 Page 38 of 68

Page 39

12

Secure the replacement Chassis to the

vent module using the included (2) 6-32 X

¼ screws with SPO2 insulator, the (2) 8-

32 X ¼ and the (2) 6-32 x 5/16 screws.

13

Secure the Power Input assembly to the

Chassis using the (2) spacers and (2) 4-40

X 1 ¼ screws. Do not over-tighten the

screws.

14

Rotate battery compartment to mate

with upper and lower case cutouts and

press firmly into place. Secure with (4) 6-

32 X 5/16 screws provided.

15

Re-assemble the battery by connecting

its cable to the connector (pull on cable

to insure it is locked in place) then

tightening the (4) 6-32 X 2 ¼ screws.

16

Re-assemble the battery compartment

cover by tightening the (4) 6-32 X 5/16

screws.

17

Place the front case assembly over the

vent module and tighten the (2) 4-40 X ¼

screws unto the dovetail mounting

bracket. Reconnect the ribbon cable unto

the PIM PCB. Make sure the two locking

“ears” lock into position.

906-0731-04 Rev. B Sept. 2012 Page 39 of 68

Page 40

18

Attach the back case to the vent module

and align cover with handle, air intake

housing and dovetail mounting studs.

Insert and tighten the included (2) 10-32

Keps nuts and the (4) 6-32 X 2” screws.

19

Tighten the (4) 8-32 X 3 screws on the

outer air intake.

20

Perform HiPot Testing then perform

Calibration and Functional Test using the

RCS.

906-0731-04 Rev. B Sept. 2012 Page 40 of 68

Page 41

Connector Panel Kit 712-0731-11 / 712-EGL2-11

STEP NO.

DIRECTIONS

1

Loosen but do not remove the

(4) 8-32 X 3 screws on the outer air

intake.

2

Loosen and remove the (2) 10-32 Keps

nuts and the (4) 6-32 X 2 screws.

Remove the back case by lifting from

the ventilator.

3

Remove the (2) 4-40 X ¼ screws on

the Dovetail Mounting Bracket and

disconnect the ribbon cable on the

PIM PCB by simultaneously applying

pressure on the two locking “ears”.

4

Flip the ventilator over and remove

the front case assembly by lifting it

straight up away from the ventilator

module.

ITEM

QTY

DESCRIPTION

1

Connector Panel Assembly

3

8-32 X 1/4 Screw

4

6-32 Keps Nut

2

O-Ring ½” OD X 3/8” ID

Contents:

Instructions:

906-0731-04 Rev. B Sept. 2012 Page 41 of 68

Page 42

5

Remove the O2 Inlet fitting by

unscrewing the dust cap then unscrewing

the (3) 8-32 X 7/16 screws.

6

Loosen and remove the (3) 8-32 X ¼

screws. Loosen and remove the Gas

Output fitting using a 1-inch deep-socket

wrench.

7

Disconnect the Power Input cable by

pressing on the locking latch and pulling

the cable straight up from the connector.

8

Loosen and remove the (2) 4-40 X 1 ¼

Screws and nylon spacers supporting the

Power Input assembly unto the chassis.

9

Loosen and remove the (2) 6-32 Keps

nuts using a 5/16 open-end wrench.

10

Using a needle nose pliers, carefully

remove the 3 tubing on the

“Transducer”, “Exhaust Do not Occlude”,

and “Exhalation Valve” fittings.

11

Loosen and remove the (2) 6-32 Keps

nuts using a 5/16 open-end wrench.

906-0731-04 Rev. B Sept. 2012 Page 42 of 68

Page 43

12

Lift the damaged connector panel

assembly out from the SPM.

13

Place the included ½” OD X 3/8” ID O-ring

onto the manifold.

14

Position the replacement Connector

Panel over the SPM and secure with the

(4) included 6-32 Keps nuts.

15

Secure the Power Input assembly to the

Chassis using the (2) spacers and (2) 4-40

X 1 ¼ screws. Do not over-tighten the

screws. Connect the Power Input cable

by inserting into connector. Insure that

locking latch engages.

16

Insert the 3 tubing unto their correct

connectors. “V_BACKUP” to “Exhalation

Valve”, V_ACAL” to “Transducer” and

smallest tubing to “Exhaust do Not

occlude”

17

Secure the connector panel to the vent

module using the (3) included 8-32 X ¼

screws.

18

Insert the included 3/8” ID O-Ring unto

the Oxygen Inlet fitting and the existing

1/2” ID O-ring unto the Gas Output

adapter.

906-0731-04 Rev. B Sept. 2012 Page 43 of 68

Page 44

19

Place Oxygen Inlet Fitting over the

connector panel then insert and tighten

with the (3)8-32 X 7/16 screws.

Place fitting and O-ring unto Gas Output

and tighten with a 1” deep socket

wrench. (Do not cross thread).

20

Place the front case assembly over the

vent module and tighten the (2) 4-40 X ¼

screws unto the dovetail mounting

bracket. Reconnect the ribbon cable unto

the PIM PCB. Make sure the two locking

“ears” lock into position.

21

Attach the back case to the vent module

and align cover with handle, air intake

housing and dovetail mounting studs.

Insert and tighten the included (2) 10-32

Keps nuts and the (4) 6-32 X 2” screws.

22

Tighten the (4) 8-32 X 3 screws on the

outer air intake.

23

Perform HiPot Testing then perform

Calibration and Functional Test using the

RCS.

906-0731-04 Rev. B Sept. 2012 Page 44 of 68

Page 45

Back Case Kit 712-0731-12 / 712-EGL2-12

STEP NO.

DIRECTIONS

1

Loosen but do not remove the

(4) 8-32 X 3 screws on the outer air intake.

2

Loosen and remove the (2) 10-32 Keps nuts

and the (4) 6-32 X 2 screws. Remove the

case by lifting from the ventilator.

3

Place the replacement cover over ventilator

and align cover with handle, air intake

housing and dovetail mounting studs. Insert

and tighten the included (2) 10-32 Keps nuts

and the (4) 6-32 X 2” screws.

4

Tighten the (4) 8-32 X 3 screws on the outer

air intake.

5

Perform HiPot Testing then perform

Functional Test using the RCS.

ITEM

QTY

DESCRIPTION

1

Back Case Assembly

4

Screw, Phillips, Pan Head, SS, Black Oxide, 6-32 X 2

2

Nut, Keps, 10-32

Contents:

Instructions:

906-0731-04 Rev. B Sept. 2012 Page 45 of 68

Page 46