Page 1

INSTRUCTION

OPERATION

SUCTION

AND

MODEL

MANUAL

&

SERVICE

PRESSURE

SURGICAL

317M

APPARATUS,

NSN

CONTRACT

IMPACT

6515-01-174-1477

NO.

SP0200-94-C-8511

INSTRUMENTATION,

INC.

REV

A

(02/94)

Page 2

TABLE

OF

CONTENTS

LIST

OF

ILLUSTRATIONS

SHIPPING

ACCESSORIES

LIMITED

CALIBRATION

UNPACKING

LOCATION

WARNINGS

ASSEMBLY,

ASSEMBLY

INTERCONNECTIONS

Hydrophobic

INITIAL

SECTION

CONTENTS

LIST

COPYRIGHT

NOTICE

USE

OF

REGARDING

INTERCONNECTIONS

Filter,

ADJUSTMENTS

I.

OPERATION

SUBJECT

RELEASE

USE

-

Suction

Module,

Collection

Jar

System

AND

INITIAL

Overflow

Shutoff

PAGE

ADJUSTMENTS

Valve,

INTRODUCTION

OPERATION

DESCRIPTION

OPERATING

SUCTIONING

PRESSURE

VACUUM

COLLECTION

OPERATOR

ROUTINE

CLEANING

Component

Exterior

Control

Collection

Overflow

Hydrophobic/Bacterial

MAINTENANCE

OF

CONTROLS

POWER

REGULATOR

JAR

SYSTEM

PERFORMANCE

CARE

Case

Module

AND

Removal

Canisters

Shutoff

Valve

SELECTION

Filter

AND

INDICATORS

&

STOPPING

CHECKS

MAINTENANCE,

1-1

1-1

21

Page 3

TABLE

OF

CONTENTS

(cont’d)

IN

CASE

OF

OPERATOR

OPERATOR

STORAGE INFORMATION

LIMITED

SPECIFICATIONS

SECTION

INTRODUCTION

CAUTIONARY

HELPFUL

DISASSEMBLY/REASSEMBLY

CALIBRATION

CIRCUIT

WARRANTY

II.

HINTS

DESCRIPTIONS

SUBJECT

DIFFICULTY

CORRECTIBLE

PROBLEMS

SERVICE

NOTE

PROCEDURE

PROBLEMS

REQUIRING

PAGE

3-1

SERVICE

41

41

4-1

5-1

51

5-1

6-1

7-1

8-1

PREVENTATIVE

TROUBLESHOOTING

TECHNICAL

BILLS

OF

MATERIAL

ELECTRICAL

IMPACT

MAINTENANCE

GUIDE

DOCUMENTATION

SCHEMATIC

INSTRUMENTATION,

INSPECTIONS

INC.,

27

Fairfield

dic

Place,

West

9-1

10-1

11-1

Caldwell,

NJ

07006

Page 4

LIST

OF

FIGURE

1.

2

3.

4.

2

6.

7

8.

9.

ILLUSTRATIONS

#

Model

317M

Main

Features

Interconnection

Filter/Collection

Interconnection

Interconnection

Controls,

Panel

Composite

Frame

Side

Cover

Inner

Assembly

Pump

Diagram - Suction

Jar

Diagram - Three

Diagram - Four

Circuit

Illustration

Assembly

Assembly

System

Breakers

Depicting

DESCRIPTION

Module/Overflow

Suction

Suction

and

Major

Bottle

Bottle

Indicators

Sub-Assemblies

Shutoff

Configuration

Configuration

Valve/Hydrophobic

PAGE

iv

vii

viii

ix

11

111

11-2

11-3

11-4

10.

14.

12:

13.

14.

15.

Collection

Vacuum

Chassis

Control

Outer

Functional

Canister

Gauge/Regulator

Assembly

Module

Assembly

Case

Block

Assembly

Overflow

&

Diagram

Pressure

&

Shutoff

Manifold

Assemblies

Valve

Assemblies

11-5

11-6

11-7

11-8

11-9

11-10

-这

-

Page 5

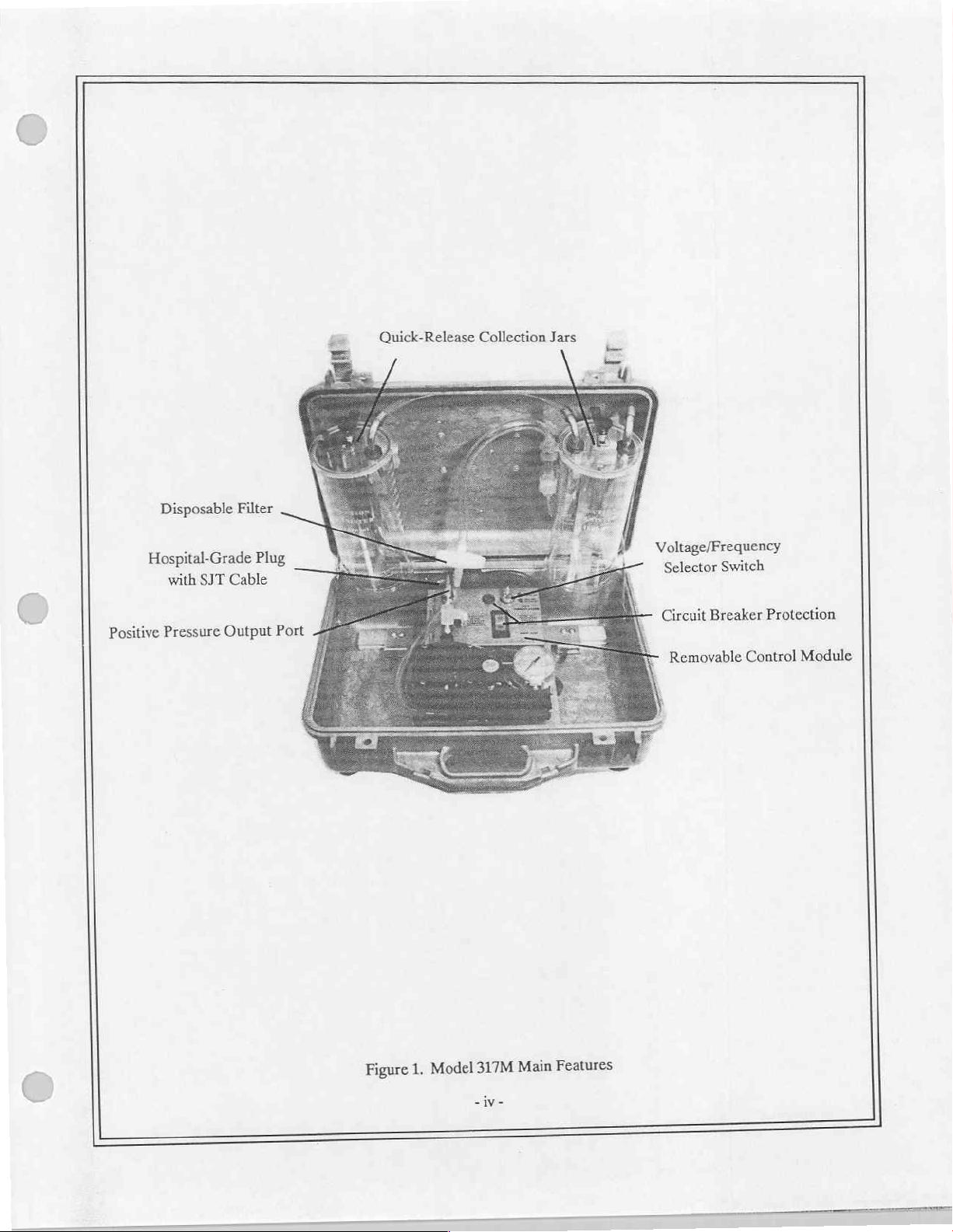

Hospital-Grade

He

Positive

Disposable

with

SJT

Cable

Pressure

Output

Filter

Plug

Port

s

Quick-Release

Collection

Jars

Voltage/Frequency

elector

ircuit

EMEA

Removable

ker

Breaker

Sel

Switcl

P

Control

ŞA

i

Module

Figure

1,

Model

317M

iv-

Main

Features

Page 6

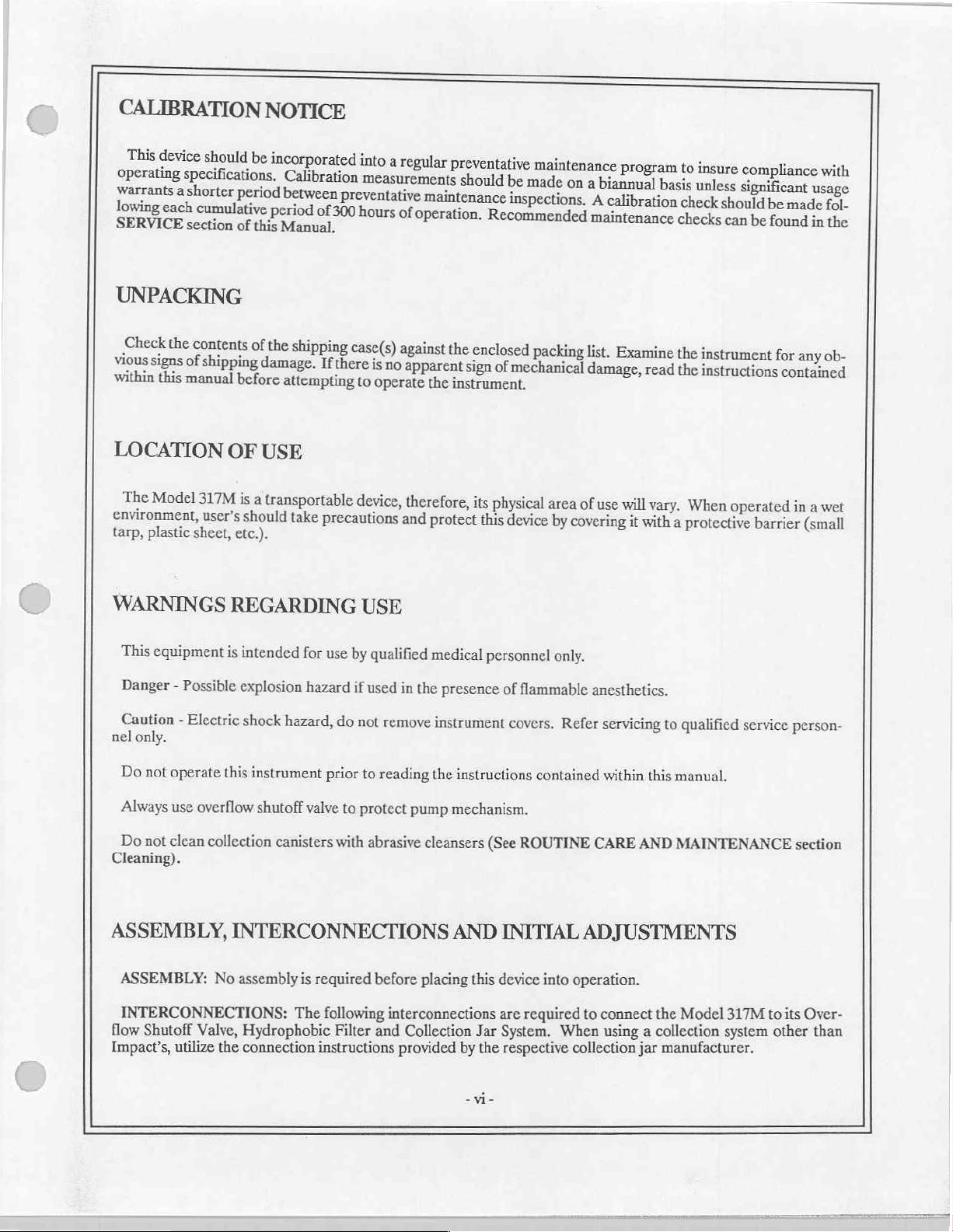

SHIPPING

Each

Model

lea.

Apparatus

Lea.

Control

2

ca.

Reusable

1

ca.

Assembly,

1

ea.

Hose,

1

ea.

Hose,

2ea.

Suction

2

ea.

Instruction

lea.

Filter,

CONTENTS

317M

is

shipped

Outer

Module

Collection

Overflow

Clear,

Clear,

Hose,

Manual,

Disposable,

with

the

following

Container

Canister

Shutoff

PVC,

6”

PVC,

Sterile,

Long

12"

Long

Clear

Operation

Hydrophobic/Bacterial

System

Valve

&

Service

contents:

ACCESSORIES

The

Accessories

number.

description

Accessories

and

Send

written

Telephonic

Part

Number

465-0005-00

540-0067-00

540-0068-00

703-0317-02

704-0317-02

820-0018-00

906-0317-01

quantity

orders:

LIST

List

contains

may

required.

purchase

201/882-1212

common

be

ordered

orders

to:

Impact

Р.О.

27

West

Description

Filter,

Disposable,

Hose,

Clear,

Hose,

Clear,

Assembly,

Assembly,

Tubing,

Instruction

Collection

Overflow

Suction,

Manual,

items,

required

direct

from

Instrumentation,

Вох

508

Fairfield

PVC,

PVC,

Place

Caldwell,

Hydrophobic

6"

Long

12"

Long

Canister

Shutoff

Sterile,

9/32"

Operation & Service

from

Impact.

New

Jersey

Valve

1D.

time

When

Inc.

X

6º

to

time.

ordering,

07006

Each

please

item

include

is

preceeded

the

by

part

its

part

number,

LIMITED

Permission

tract

for

COPYRIGHT

is

hereby

use

in a military

granted

service

RELEASE

to

the

training

Department

program

of

Defense

and other

to

reproduce

technical

training

all

material

programs.

furnished

under

this

con-

Page 7

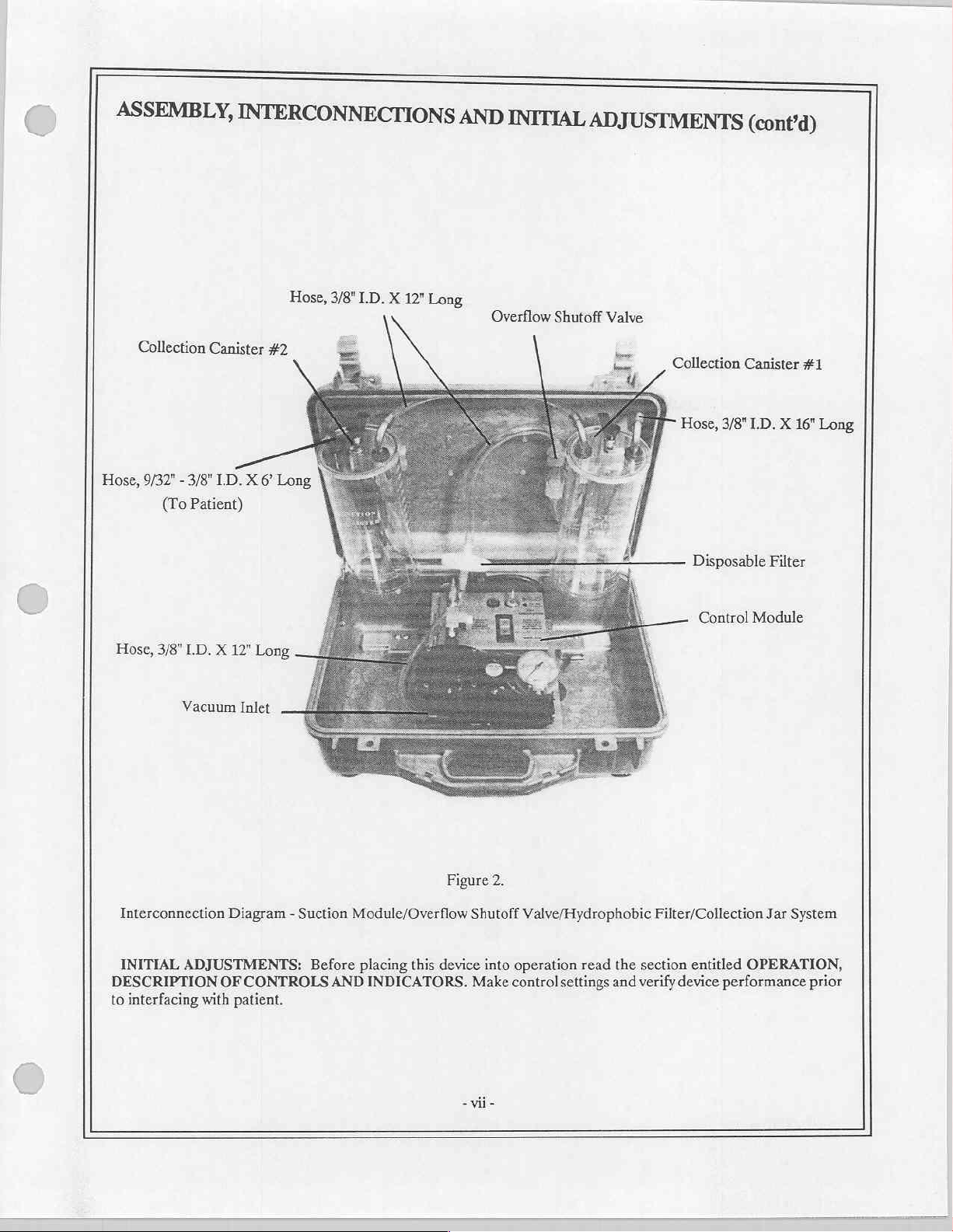

CALIBRATION

This

device

operating

warrants

lowing

SERVICE

UNPACKING

Check

vious

within

specifications.

a

each

the

signs

this

should

shorter

καν

of

manual

period

cumulative

contents

shipping

before

NOTICE

be

incorporated

Calibration

between

period

μας

ο

of

ο.

of

the

shipping

damage.

If

attempting

into

a

regular

measurements

preventative

300

hours

of

o;

case(s) against

there

is

no

apparent

to

operate

preventative

should

maintenance

eration.

pi

the

Recommended

the

enclosed

sign

of

instrument.

maintenance

be

made

on

inspections.

packing

mechanical

a

A

maint:

list.

damage,

program

biannual

calibration

basis

'enance

ce

Examine

read

to

insure

compliance

unless

check

check

checks

the

the

significant

should

can

instrument

instructions

be

be

found

for

contained

usage

made

i

in

any

with

fol-

the

ob-

LOCATION

The

Model

317M

environment,

sheet,

plastic

tarp,

WARNINGS

This

equipment

Danger

Caution

nel

Do

Always

Do

Cleaning).

only.

not

not

-

Possible

-

Electric

operate

overflow

use

clean

OF

USE

is

a

transportable

user’s

should

etc.).

REGARDING

is

intended

explosion

shock

this

instrument

shutoff

collection

take

precautions

for

use

hazard

hazard,

canisters

do

prior

valve

with

device,

USE

by

qualified

if

used

not

to

reading

protect

to

abrasive

therefore,

and

protect

medical

in

the

remove

instrument

the

pump

cleansers

its

physical

this

device

personnel

presence

instructions

mechanism,

of

covers.

(See

area

of

by

covering

only.

flammable

Refer

contained

ROUTINE

use

will

vary.

it

with

a

anesthetics.

servicing

within

CARE

to

this

manual.

AND

MAINTENANCE

When

operated

protective

qualified

service

in

barrier

person-

section

a

wet

(small

ASSEMBLY,

ASSEMBLY:

INTERCONNECTIONS:

flow

Shutoff

Impact’s,

utilize

INTERCONNECTIONS

No assembly

Valve,

Hydrophobic

the

connection

is

required

The

following

instructions

Filter

AND

before

placing

interconnections

and

Collection

provided

this

by

Jar

the

INITIAL

device

into

are

required

System.

respective

When

ADJUSTMENTS

operation.

to

connect

using a collection

collection

the

jar

manufacturer.

Model

317M

system

to

its

other

Over-

than

Page 8

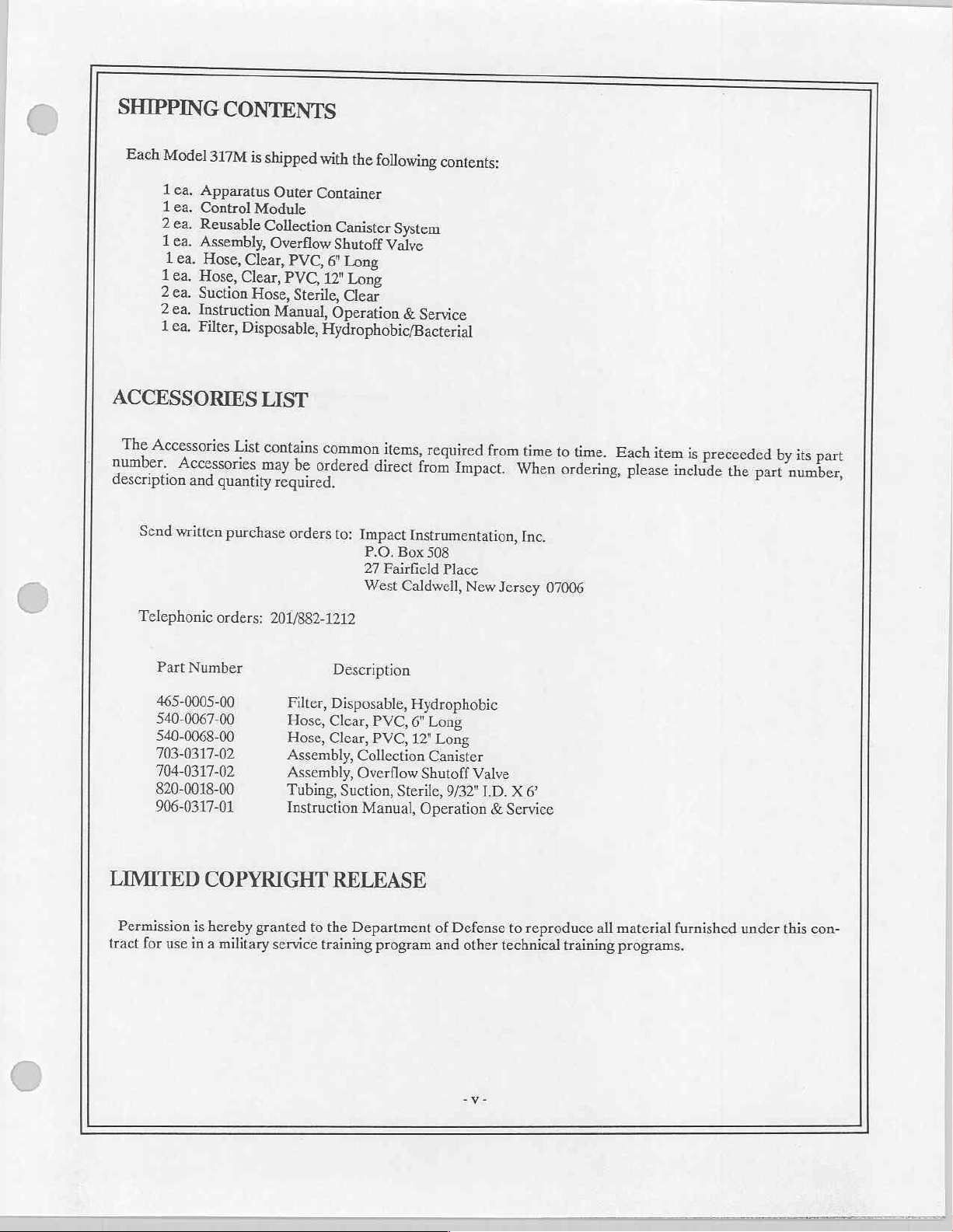

ASSEMBLY,

INTERCONNECTIONS

Hose,

3/8"

I.D. X 12"

Long

AND

Overflow

INITIAL

Shutoff

ADJUSTMENTS

Valve

(cont'd)

Collection

Hose,

Hose,

Canister

9/32" - 3/8"

(To

Patient)

3/8"

LD. X 12"

Vacuum

LD. X 6

Long

Inlet

#2

Long

=

ie

Interconnection

INITIAL

DESCRIPTION

to

interfacing

Diagram - Suction

ADJUSTMENTS:

OF

CONTROLS

with

patient.

Module/Overflow

Before

placing

AND

INDICATORS.

this

device

Figure

Shutoff

into

Make

-vii-

2.

Valve/Hydrophobic

operation

control

read

settings

Filter/Collection

the

and

verify

section

entitled

device

Jar

System

OPERATION,

performance

prior

Page 9

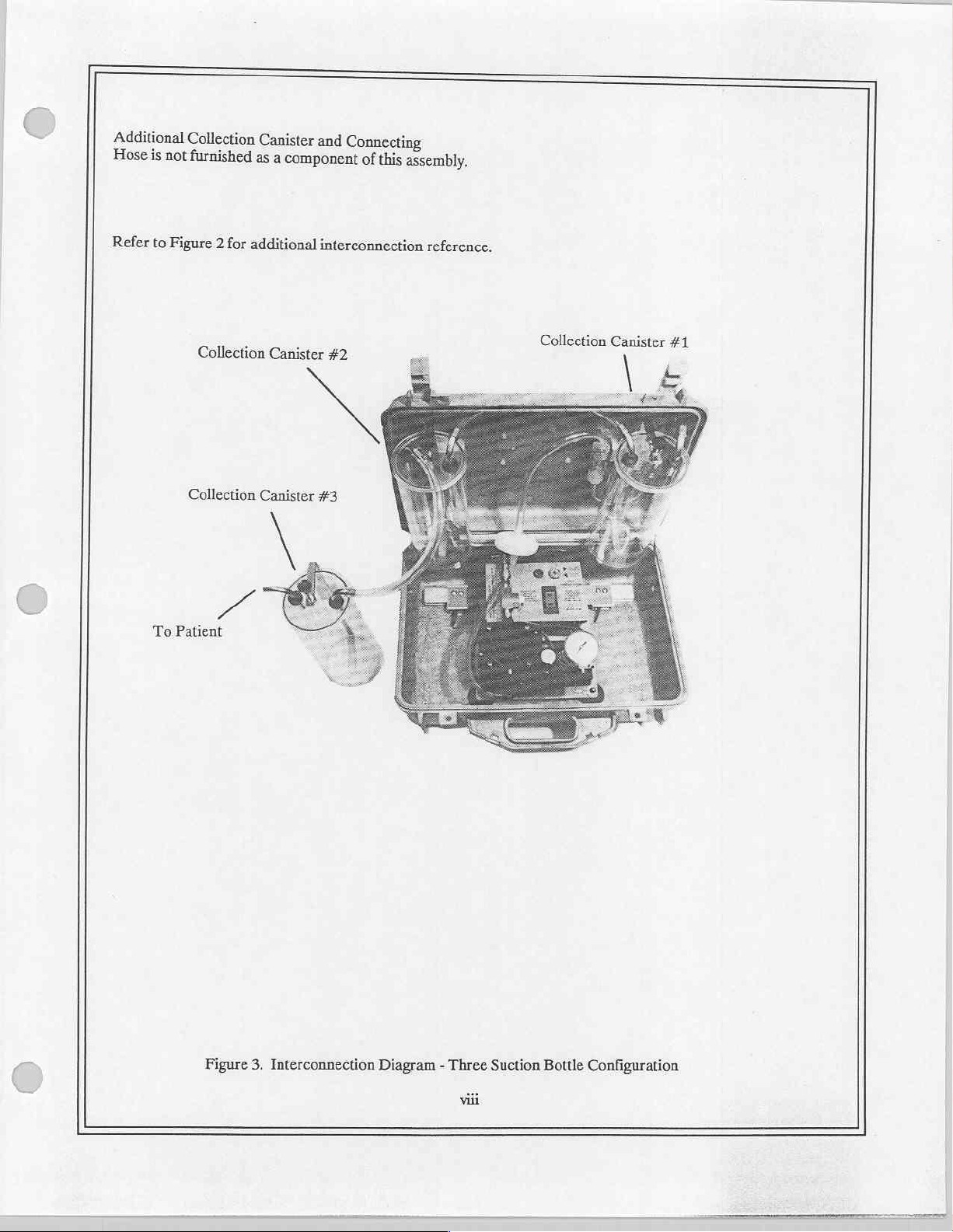

Additional

Hose

is

not

Refer

to

Figure

Collection

furnished

Collection

Collection

2

for

additional

Canister

as

Canister

and

a

component

interconnection

Canister

#3

Connecting

of

this

assembly.

reference.

#2

Collection

Canister

#1

To

Patient

Figure

3.

Interconnection

Diagram - Three

Suction

Bottle

Configuration

Page 10

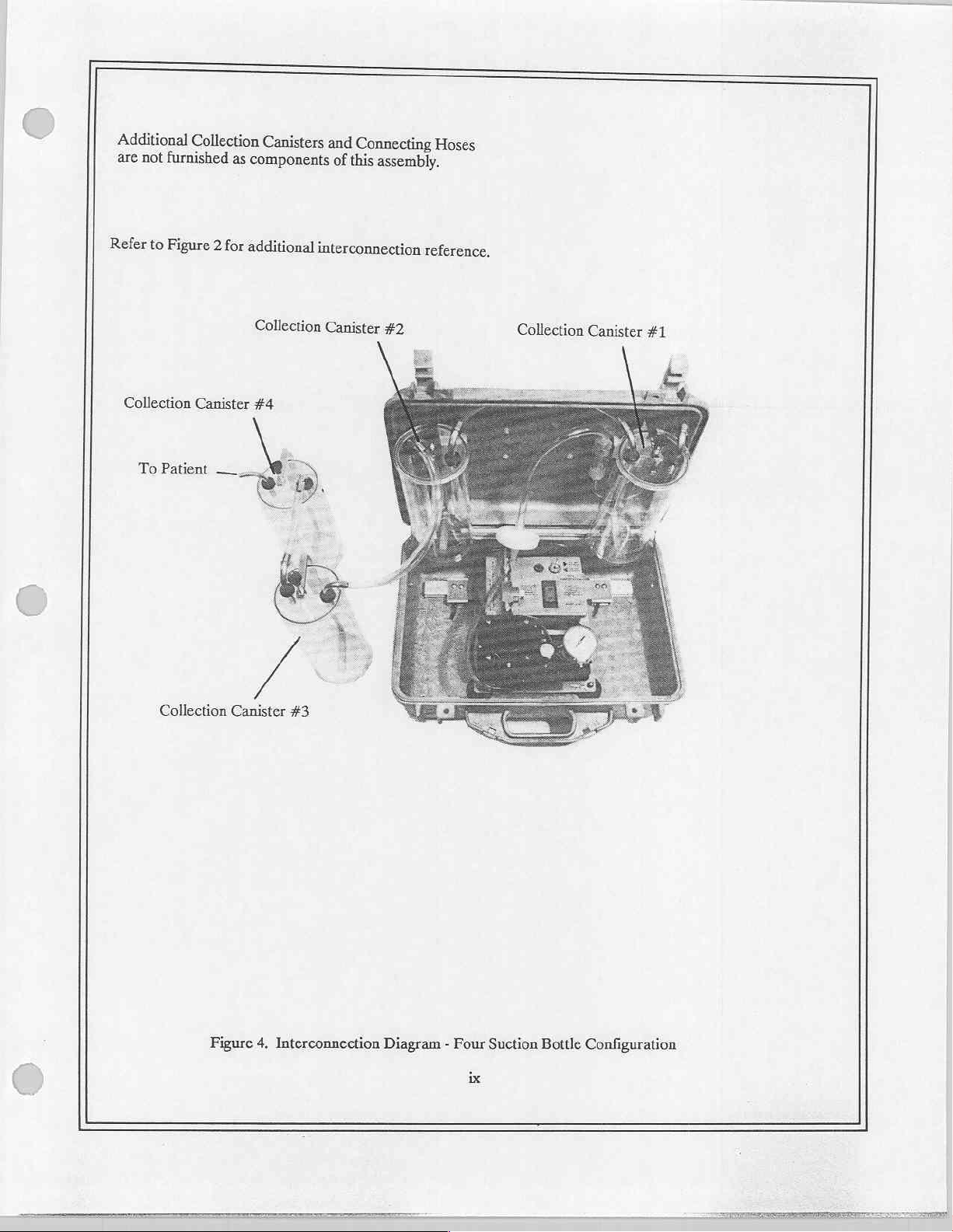

Additional

are

not

furnished

Refer

to

Figure

Collection

Collection

2

Canister

Canisters

as

components

for

additional

Collection

#4

and

Connecting

of

this

interconnection

Canister

Hoses

assembly.

reference,

#2

Collection

Canister

#1

Collection

Canister

Figure

#3

4,

Interconnection

Diagram - Four

ix

Suction

Bottle

Configuration

Page 11

SECTION L OPERATION

INTRODUCTION

The

Impact

Operating

The

Model

cuits, a dual-scale

lection

device

trol

module

ment.

This

suctioning.

OPERATION

Model

voltages

317M

canister

is

housed

and

is

device

Read

317M

and

frequencies

consists

vacuum

system;

intended

overflow

within.a

collection

instructions

the

is a self-contained,

for

115/230

of a control

gauge

structural

canisters

use

for

module

with

adjustable

shutoff

valve;

ABS

enclosure

are

rail

non-explosive

in

contained

mounted

within

general-purpose, Suction/Pressure

VAC,

50/60

HZ

are

"key

switch"

containing:

regulator,

hydrophobic/bacterial

atmospheres:

this

vacuum/pressure

and

featuring

with

latch-locks

quick

manual

pressure

for

before

port

filter

release

surgical

attempting

guides

apparatus

selectable

pump,

with

and

attachment

and

integral

to

procedures;

designed

for

control

overload

facilitate

to

and

protection; a dual

tubing.

carrying

oral,

operate

for

world-wide

power

The

handle.

removal

this

and

and

nasal

instrument.

field

use.

usage.

supply

cir-

col-

complete

The

con-

deploy-

tracheal

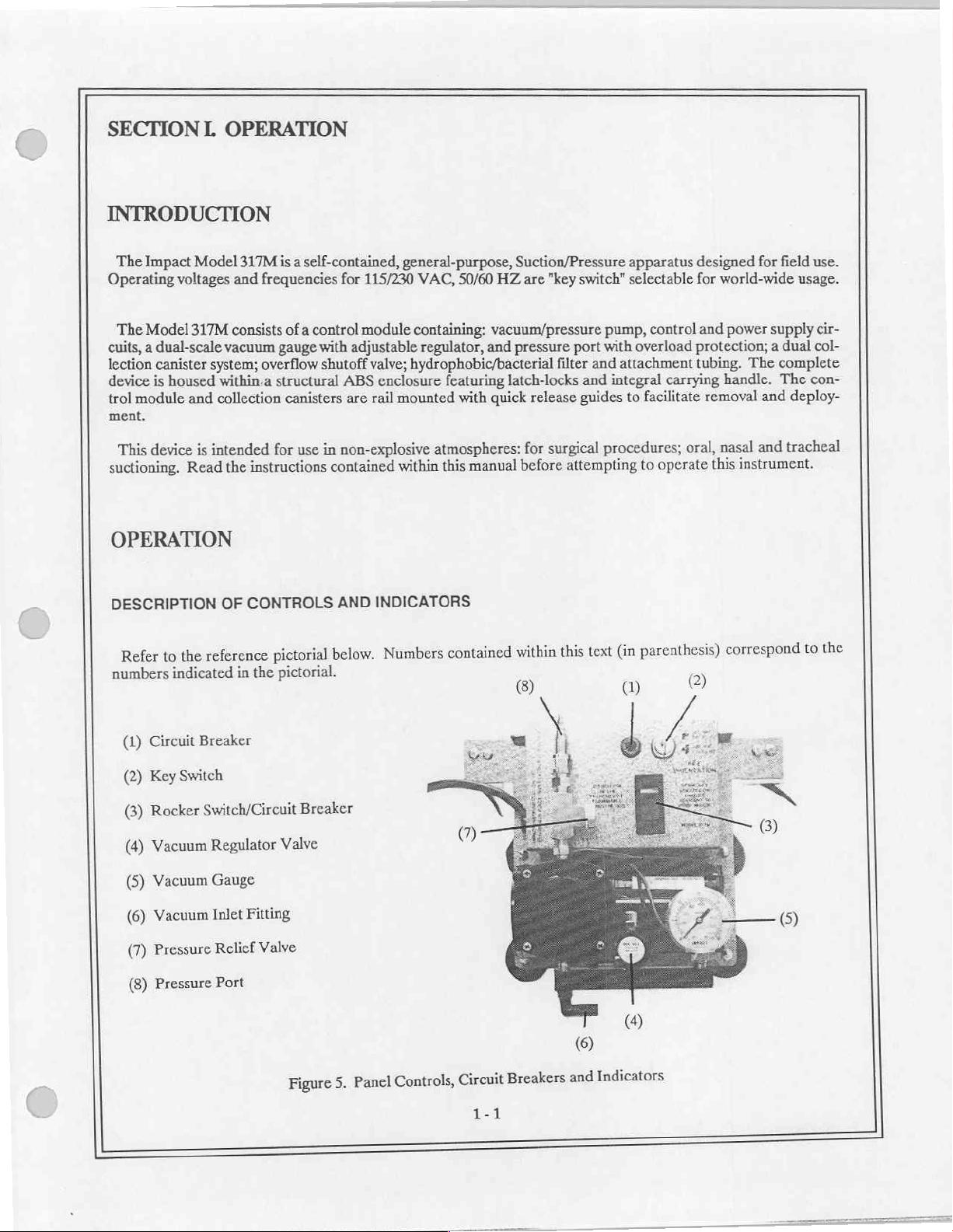

DESCRIPTION

the

to

Refer

numbers

(1)

(2)

(3)

(4)

Circuit

Key

Rocker

Vacuum

(5)

Vacuum

Vacuum

(6)

(7)

Pressure

(8)

Pressure

indicated

Switch

CONTROLS

OF

reference

Breaker

Switch/Circuit

Regulator

Gauge

Inlet

Relief

Port

pictorial

in

the

Fitting

Valve

pictorial.

Valve

AND

below.

Breaker

INDICATORS

Numbers

contained

within

(8)

this

text

parenthesis)

(in

0)

©

correspond

to

the

5.

Figure

Panel

Controls,

Circuit

1-1

Breakers

and

Indicators

Page 12

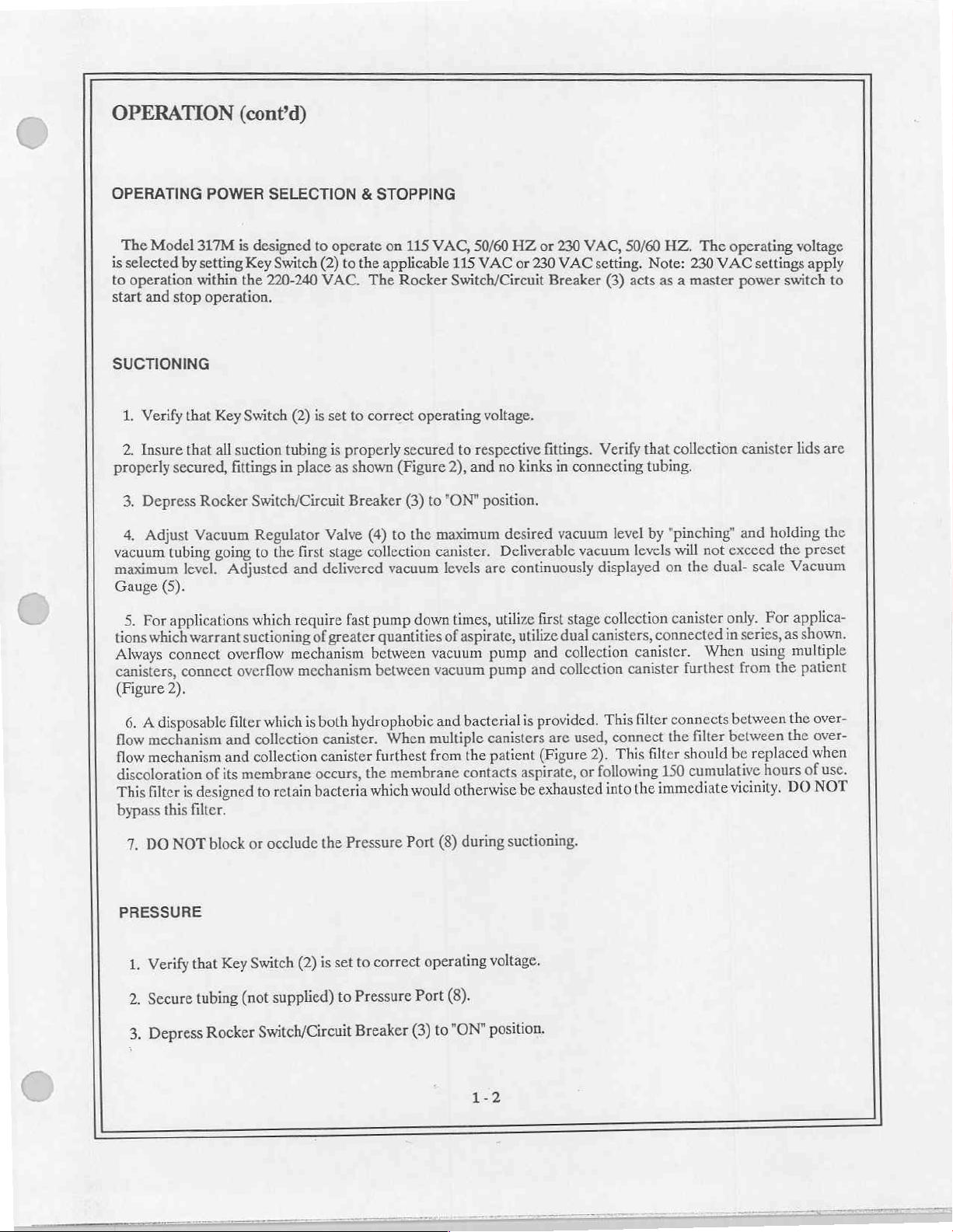

OPERATION

OPERATING

_

The

Model

is

selected

to

operation

start

and

SUCTIONING

1.

Verify

2.

Insure

properly

3.

Depress

4,

Adjust

vacuum

maximum

Gauge

POWER

317M

by

setting

within

stop

operation.

that

that

secured,

Rocker

Vacuum

tubing

level.

(5).

(cont’d)

SELECTION & STOPPING

is

designed

Key

Switch

the

220-240

Key

Switch

all

suction

fittings

going

Adjusted

in

Switch/Circuit

Regulator

to

the

to

(2)

VAC.

(2)

is

tubing

place

Valve

first

delivered

and

operate

to

the

The

set

to

correct

is

properly

as

shown

Breaker

(4)

stage

collection

on

115

VAC,

applicable

Rocker

secured

(Figure

(3)

to

vacuum

115

Switch/Circuit

operating

to

2),

to

"ON"

the

maximum

canister.

levels

50/60

HZ

VAC

or

230

voltage.

respective

and

no

kinks

position.

desired

Deliverable

continuously

are

or

230

VAC,

VAC

setting.

Breaker

fittings.

Verify

in

connecting

vacuum

vacuum

displayed

50/60

(3)

acts

level

HZ. The

Note:

as a master

that

collection

tubing.

by

"pinching"

levels

will

on

230

not

the

operating

VAC

settings

power

canister

and

exceed

scale

dual-

voltage

apply

switch

lids

holding

the

preset

Vacuum

to

are

the

applications

For

5.

warrant

which

tions

disposable

A

6.

mechanism

mechanism

filter

this

DO

7.

Verify

1.

Secure

2.

Depress

3.

connect

connect

2).

of

designed

is

filter.

block

NOT

that

tubing

Rocker

Always

canisters,

(Figure

flow

flow

discoloration

This

bypass

PRESSURE

require

which

suctioning

overflow

overflow

filter

and

and

membrane

its

Key

(not

mechanism

mechanism

which

collection

collection

retain

to

occlude

or

Switch

(2)

supplied)

Switch/Circuit

fast

greater

of

hydrophobic

both

is

canister.

canister

occurs,

bacteria

Pressure

the

set

is

to

down

pump

quantities

between

between

When

furthest

membrane

the

would

which

Port

correct

to

Pressure

Breaker

Port

(3)

times,

aspirate,

of

vacuum

vacuum

bacterial

and

multiple

from

(8)

operating

to

canisters

the

contacts

otherwise

during

(8).

position.

"ON"

first

utilize

utilize

and

pump

and

pump

provided.

is

are

patient

voltage.

(Figure

aspirate,

exhausted

be

suctioning.

collection

stage

canisters,

dual

collection

collection

used,

or

canister

This

connect

This

2).

following

into

canister

connected

canister.

furthest

connects

filter

filter

the

should

filter

cumulative

150

immediate

the

only.

series,

in

When

from

between

between

be

vicinity.

applica-

For

shown.

as

multiple

using

patient

the

the

the

replaced

of

hours

DO

over-

over-

when

use.

NOT

1-2

Page 13

OPERATION

PRESSURE

4.

DO

nect

the

sure

related

5. A Pressure

NOT

block

VACUUM

The

selected

vacuum.

holding

vacuum

play

during

(cont'd)

NOT

block

overflow

applications.

or

REGULATOR

Vacuum

by

rotating

Vacuum

the

vacuum

levels

operation

(cont'd)

or

occlude

mechanism,

Relief

Valve

occlude

Regulator

will

this

the

Vacuum

regulator

tubing

not

exceed

on

Vacuum

filter,

(7)

limits

valve.

Valve

(4)

Regulator

adjustments

going

to

this

preset

the

dual-scale

Inlet

Fitting

suction hose(s)

maximum

works

in

Valve

should

the

first

maximum.

Vacuum

(6), or

and

deliverable

conjunction

(4):

be

made

stage

collection

Gauge

suction

collection

pressure

with

clockwise

to

the

canister

Adjusted

(5).

lines.

canister(s)

to

the

Vacuum

to

increase

maximum

(canister

and

delivered

It

is

recommended

when

11

pounds

Gauge

vacuum;

desired

closest

vacuum

that

the

utilizing

per

(5).

counterclockwise

vacuum

this

square

Vacuum

level

to

"patient").

levels

will

device

inch

by

"pinching"

continuously

user

discon-

for

pres-

(PSI).

levels

to

Deliverable

DO

may

decrease

and

be

dis-

COLLECTION

ALWAYS

which

canisters,

Collection

agents

tants

OPERATOR

Before

performance.

1.

use

permanently

may

hydrophobic

canisters

chlorinated

or

please

note

Bushings:

placing

operating

Verify

JAR

SYSTEM

overflow

the

damage

filter,

may

hydrocarbons.

the

following

Collection

Hose

PERFORMANCE

Canister

Fittings:

device

this

power

shutoff

be

valve

vacuum

the

overflow

repeatedly

material

and

CHECKS

operation,

into

selections

provided

pump.

shutoff

sterilized

determine

To

content:

Covers:

the

115

at

unit

this

with

Vacuum

control

and

valve

ethylene

using

compatibility

Polycarbonate

Stainless

Neoprene

operator

230

or

Stecl

Rubber

can

VAC.

protect

to

is

tubing

module

dioxide

with

perform

suction

the

provided

Vacuum

commercially

various

for

Inlet

DO

gas.

operational

mechanism

interconnection

Fitting

use

NOT

available

checks

from

of

(6).

abrasive

cleanser/disinfec-

insure

to

overflows

collection

cleansing

proper

2.

Verify

continuous

operation.

1-3

Page 14

OPERATION

OPERATOR

3.

Test

4.

Insure

PERFORMANCE

the

vacuum

that

(cont'd)

regulator

all

hoses and

CHECKS

for

correct

fittings

are

(cont'd)

operation

properly

at

various

connected.

vacuum

settings.

Page 15

ROUTINE

CLEANING

NOTE:

disinfectant.

canister

to

avoid

II.

fectant, a mild

The

ment.

(1)

fully

module

Arail edge

to-guide

locked

Routine

With

and

shortly

risk

of

SERVICE,

©

Component

control

The

cam-locking

to

module

control

the

right.

or

canisters

view

interface

into

the

CARE

bacterial

DISASSEMBLY/ASSEMBLY).

spray

guide.

rail’s

AND

decontaminations

the

device operating,

thereafter

growth.

disinfectant

Removal

and

module

Each

To

lock,

can

discloses a concave

is

made

rectangular

MAINTENANCE

into

the

In

the

or

ethylene

collection

is

secured

guide contains a locking

slide

the

lever

slide

along

their

when

(1)

track.

which

vacuum

event

canisters

with

and

the

do

not

involve

simply

spray a small

inlet

of

of

an

aspirate

All

pump

oxide

gas.

may

be

two

(2)

cam-locking

to

the

left.

rails

for

repositioning

rectangular

convex

track

the

removal

amount

the

pump

head.

overflow,

head

components

removed

lever.

When

track. A guide

is

from

guides,

To

release

the

guide

or

"tipped"

into

removal.

of

aspirate

of

disinfectant

This

remove

their

edge

may

respective

each

collection

tension

lever

is

view

the

convex

the

can

be

effected

directly

should

be

performed

pump

head

assembly

be

sterilized

rails

for

canister

(unlock

in

its

discloses a convex

the

unlocked

track,

and

guide),

using a spray

into

the

collection

after

each

(SECTION

using a liquid

cleaning

is

position,

(2)

or

secured

slide

the

track.

the

guide

use

disin-

deploy-

with

one

the

lever

control

The

rail-

lever

is

©

Exterior

Periodically

trol

module,

facilitate

©

Control

UNPLUG

cloth

damp

Collection

Collection

Impact’s

cleansing

cleanser/disinfectants,

Case

or

when

collection

cleaning.

Module

POWER

suffice

will

Canisters

canister

reusable

agents

collection

or

Collection

Hose

Fittings:

Bushings:

applicable,

canisters,

CORD

systems

before

most

in

chlorinated

please

Canister

clean

overflow

cleaning

Disinfectant

cases.

should

be

canisters

hydrocarbons.

note

the

and

Covers:

the

exterior

shutoff

cleaned

may

following

valve,

control

or

repeatedly

be

material

Polycarbonate

Stainless

Neoprene

case

using a mild,

hydrophobic/bacterial

module.

spraying

disposed

To

DO

recommended

is

in

of

sterilized

determine

content:

Steel

Rubber

non-

NOT

accordance

using

compatibility

abrasive

filter

liguids

allow

regular

at

with

ethylene

cleanser.

and

to

their

gas.

oxide

with

Remove

any

stored

accessories

control

enter

intervals.

respective

commercially

instructions.

NOT

DO

the

module.

abrasive

use

available

con-

to

A

2-1

Page 16

ROUTINE

©

Collection

1.

Thoroughly

Collection

plunger

shown

The

tion.

reassembling.

knob

2.

Tubing

3.

Insure

4.

Orient

in

®

Overflow

overflow

Disinfectant

©

Hydrophobic/Bacterial

CARE

Canisters

clean

canisters

up

with

is

considered

that

all

collection

2.

Figure

Shutoff

shutoff

AND

(cont'd)

collection

are

held

one

hand

disposable

covers

and

canisters

Valve

valve

may

solutions

should

MAINTENANCE,

canister(s),

in

place

and

pull

and

parts

are

as

shown

be

disassembled

be

Filter

and

by

a

spring

the

canister

should

securely

in

Figure

diluted

according

fittings

be

fastened

and

after

loaded

forward

discarded

2

following

cleaned

to

CLEANING

each

use.

plunger.

with

following

after

cleaning,

using

their

To

the

other.

cleaning.

warm

respective

(cont’d)

quickly

each

soapy

remove

use.

Route

connecting

water

instructions.

either

or

a

canister,

tubing

mild

disinfectant

Dry

thoroughly

and

pull

the

filter

as

solu-

before

DO

NOT

attempt

replaced

hours

DO

port

As

come

MAINTENANCE

Routine

service.

1.

2.

siderably

3.

aspirate

4.

whenever

of

use,

NOT

bypass

allowed

or

filters

become

evident.

maintenance

Routine

Cleaning

Filter

checks - replace

or

following

Overflow

or

following

Operational

to

clean

it

becomes

whichever

this

filter.

accumulate

to

occluded

Filter

replacement

maintenance

checks - as

150

shutoff

valve - clean

150

checks - as

the

discolored

comes

first.

Its

intended

in

with

should

be

should

described

when

hours

hours

of

described

disposable

or

use

head.

pump

the

particulate

will

restore

performed

consist

above.

discolored,

of

cumulative

in

warm,

cumulative

in

OPERATOR

hydrophobic/bacterial

contacts

is

to

matter

device

on

of

contact

use,

soapy

use.

aspirate,

retain

during

performance

this

apparatus

the

following:

with

water

Dry

thoroughly

PERFORMANCE

bacteria

repeated

aspirate

or

with a mild

filter.

airflow

which

to

at

regular

occurs, airflow

before

This

item

is

impeded,

would

be

usages,

its

a

reduction

original

disinfectant

airflow

intervals

reassembling.

CHECKS.

is

disposable

or

following

exhausted

in

device

levels.

and

prior

performance

solution

and

150

through

airflow

to

being

diminishes

when

contacted

should

cumulative

the

pressure

will

be-

placed

into

con-

with

be

5.

Tubing

checks - replace

crimped,

cracked

or

worn

tubing

2-2

as

required.

Page 17

IN

CASE

OF

DIFFICULTY

Authorization

nor

does

Impact

servicing.

Impact

schematics.

mended

Customer

OPERATOR

Common

integrity

cessory

To

vacuum

vacuum

OPERATOR

will,

upon

Such

that

staff

Service

CORRECTIBLE

problems may

of

all

tube

item

or

isolate a problem,

jar

from

from

the

PROBLEMS

to

service

Instrumentation,

departments

members

Department.

the

#2

overflow

this

instrument

request,

connections,

Suction

jar

to

provide

are

attend a factory

PROBLEMS

be

quickly

Module

check

for

vacuum

#1,

shutoff

REQUIRING

tubing,

by

Inc.

assume

competent

encouraged

rectified

fittings,

by

testing

vacuum

valve

from

to

at

jar

the

SERVICE

other

than

any

responsibility

biomedical

to

contact

training

by

the

users.

and

for

vacuum

inlet

to

#1

Vacuum

course.

Should

control

of

the

Inlet

factory-trained

engineering

the

factory

Details

the

settings.

at

various

each

item,

vacuum

filter,

Fitting

and

and/or

liability

for

may

Model

One

locations.

tracing

from

(6).

assistance

be

317M

can

certified

departments

backwards

the

personnel

resulting

when

obtained

fail

to

operate

quickly

to

filter

by

isolate

the

will

from

such

with

service

needed

through

and

contacting

properly,

problems

the

overflow

not

be

given,

unauthorized

data

and

it

is

recom-

the

Impact

verify

the

to

an

ac-

system,

shutoff

i.e.

valve,

tests

the

If

contact

sary,

have

Please

request.

described

your

Model

the

Model

The

above

nearest

and

317M

not

do

Impact

Serial

Serial

operating

resolve

representative

Numbers

Number

an

ready

located

is

or

and

problem,

Impact

the

any

the

on

other

outer

service

Customer

pertinent

case

is

data

identification

required.

Service

Department

wish

you

label.

Should

include

to

(201)

your

in

be

882-1212.

servicing

neces-

service

Page 18

STORAGE

For

prolonged

and

out

of

should

be

The

Model

or

parts

Following

stabilize

LIMITED

Impact

for a period

of

manufacturing

is

tampered

SPECIFICATIONS

INFORMATION

storage

direct

sunlight.

low.

317M

may

replacements.

periods

to a temperature

Instrumentation,

of

of

WARRANTY

one

(1)

origin.

with,

misused

periods,

Storage

be

stored

extended

within

Inc.

warrants

year.

Accessories,

This

warranty

or

serviced

the

Model

temperatures

for

lengthy periods

storage

its

in

non-controlled

specified

this

which

is

neither

by

unauthorized

317M

should

should

of

time,

operating

instrument

by their

range

assignable

personnel.

be

stored

indoors.

range

between

without

environments,

(see

SPECIFICATIONS,

to

be

free

from

nature

are

consumable,

nor

transferable,

The

5'F

and

requiring

allow

the

all

defects

nor

environment

104F

(-15‘C

periodic

will

maintenance

Model

below).

in

materials and

be

warranted

does

it

to

317M

apply

should

sufficient

if

be

clean,

40‘C),

humidity

inspections

time

workmanship

only

for

defects

this

instrument

to

Vacuum:

Airflow:

Temperature

Controls:

Collection

Power:

Case:

Size:

Cube:

Weight:

Warranty:

SPECIFICATIONS

Capacity:

Operating

CONTAINED

Range:

550

mm/Hg

(22

31

Liters

Per

-29'C

to

60'C

Power

Switch - OFF/ON

Vacuum

1600cc x 2

Nominal

Structural

47cm

12

9.8

One

HEREIN

W

cu.

kg

(1)

ft.

(25

Adjust

115/230

x

ycar,

REPRESENT

inches/mercury)

Minute

(-20'F

ABS

18cm

lbs.)

(LPM)

to

VAC,

integeral

with

39cm

x

H

limited

140'F)

HZ

50/60

(18.5"

D

TYPICAL

carrying

x7"

W

DEVICE

handle

Hx

D)

15.5"

PERFORMANCE

Page 19

SECTION

II.

SERVICE

INTRODUCTION

The

information

personnel

iz

therefrom.

Impact

however,

in

travel,

The

lated

field

Should

Number

Number

trained

en

Instrumentation

travel

meal

Impact

matter.

Place,

factory

ready

is

contained

in

resulting

and

and

time

service

Allservice

West

Caldwell,

servicing

and

any

located

on

the

care

from

unauthorized

will

meal

costs

costs

facility

requests

become

other

the

outer

herein

is

and

servicing

provide

resulting

charged

encourages

may

New

Jersey 07006,

necessary,

pertinent

case

identification

intended

of this

servicing

service

to

be

training

therefrom

the

user

dialogue

addressed

201/882-1212.

or

data

you

only

for

use

product.

nor

will

at

shall

be

at

prevailing

from

user

to

the

technical

wish

assistance

to

include

label.

by

factory-trained,

The

manufacturer

it

be

held

liable

the

manufacturing

borne

by

the

rates.

service

Service

personnel

Manager,

is

required,

in

your

and

does

for

site

user.

Training

Impact

please

service

certified

not

any

injuries

at

no

towards

Instrumentation,

request.

personnel

authorize

or

schooling

at

the

rectifying

have

the

The

or

damages

charge

user’s

site

any

Model

Model

or

military

assume

incurred

to

will

service

Inc.,

27

317M

317M

any

users;

result

re-

Fair-

Serial

Serial

CAUTIONARY

Prior

to

servicing

HELPFUL

Before

not

Check

Insure

hydrophobic/bacterial

ment

from

attempting

accessory

the

that

the

to

Refer

the

of

Always

safeguard

the

vicinity

related,

integrity

all

circuitry.

NOTE

this

device,

HINTS

repair/calibrate

to

all

of

collection

filter

schematic

Always

your

of

active

insure

and

tubing

canisters

is

not

dirty

assembly

and

insure

personal

circuitry.

well

that

Key

instrument,

this

fittings.

properly

seal

or

clogged.

pictorials

integrity

the

when

being

Switch

(2)

is

please

tubing

that

Verify

that

and

trouble

when

ground

circuit

of

troubleshooting

set

for

the

take

is

overflow

shooting.

appropriate

moments

few

a

crimped

not

mechanisms

Isolate

correct

the

and

electronic

operating

insure

to

cracked

or

not

do

problem

the

mains

AC

circuitry.

Keep

voltage.

that

to

due

stick.

a

to

voltage.

jewelry

problem

the

fatigue.

Verify

that

functional

liquids

and

is

the

seg-

Page 20

DISASSEMBLY/REASSEMBLY

REQUIRED

Screwdriver,

Screwdriver,

3/8"

socket

3/8"

open

end

Pliers,

needle

Open

end

wrench,

Bench

vise

PUMP

screws

secured

down. The

head

pump

head

slotted

ment.

HEAD

Four

(4)

in

Once

the

with

Flapper

screw

head.

is

sometimes

screw which

Reinsert

10-32 X 1/2

order

pump

valves

which

TOOLS

slotted,

phillips

with

drive

wrench

nosed

with

smooth

to

access

head

four

(4)

are

flapper

valves

is

Removing

compressed

secures

and

medium

head,

handle

adjustable,

slotted

is

8-32 X 3/8

located

secured

these

tighten

size

medium

10"

jaws

cap

the

pump

removed,

phillips

inside

are

each

to a metal

screws

and

the

facing

the

slotted

size

head

screws

head

for

the

pump

flat

the

pump

held

in

disk.

should

prevents

flapper

screw

secure

cleaning

diaphragm

head

screws

head

and

place

by a small

Four

(4)

release

the

disk

valve.

which

the

the

pump

head

or

servicing

is

"clamps"

can

8-32 X 7/16 phillips

disk,

assembly

Set the

will

quickly

(see

Figure

accessible

be

rectangular

however, a gasket

flapper and

the

seen

from

"back

for

diaphragm

once

coming

out"

to

the

pump

9).

cleaning

the

head

flat

washer

flat

located

free.

its

rectangular

the

housing.

or

replacement.

in

place.

is

removed

and

head

screws

Should

disk

assembly.

Remove

and

6-32 X 3/16

fasten

between

this

washer

the

occur,

A metal

turned

slotted

this

disk

aside

these

upside

disk

to

and

pump

remove

for

the

four

disk,

bind

the

the

mo-

The

underside

sembled

To

sure

screw.

NOTE:

sure

head

CAUTION:

Pump

vacuum

by

reassemble,

that

the

Orient

Refer

ports.

in

place

head

and

of

the

removing

valves

Tightly

using

Test

components

pressure

its

align

lay

cach

washer

to

Figure 9 for

secure

the

for

disk

assembly

respective

the

fiber

flush on

vacuum

port

with

the

disk

four

(4)

must

functions

the

be

gasket

disk

the

proper

with

10-32 X 1/2

the

at

assembled

exposes a fiber

6-32 X 3/16

within

surface.

stamped

orientation

its

vacuum

and

the

four

slotted

and

negate

will

slotted

pump

Each

word

(4)

port

gasket

bind

head.

valve

"UP"

visible.

of

the

assembled

8-32 X 3/8

cap

head

reassembly

after

oriented

as

intended

and

second

head

screw

and

Secure a flapper

is

held

to

the

disk

Set

the

disk

phillips

shown

flat

screws.

prior

in

operation.

device

head

Figure

flapper

assembled

to

to

valve.

rectangular

valve

to

each

with a rectangular

disk

avoid

reversing

screws.

returning

9.

Mount

this

Deviation

This

valve

washer.

side

of

washer

within

the

vacuum

the

device

result

will

can

be

the

disk

making

and

slotted

the

pump

and

assembled

patient

for

reversal

in

disas-

head.

pres-

pump

use.

of

Page 21

DISASSEMBLY/REASSEMBLY

VACUUM

Disassembly

of

these

which

To

This

Place

disconnect

ly

disassembled

To

head

respective

CONTROL

GAUGE/REGULATOR

of

the

two

assemblies

are

secured under

disassemble,

will

prevent

the

reassemble,

in

the

pump

each

vise,

port.

MODULE

remove

damage

head

manifold

using

insure

using

Do

vacuum

contain

high

the

to

in

the

at

the

adjustable

that

minimal

not

reverse

(INNER

AND

gauge/regulator

tapered

torque

pump

chromed

vise

and

the

point

all

fittings

holding

port

CASE)

(cont'd)

PRESSURE

and

pressure

pipe

threads.

pressures

head

and/or

secure

where

wrench

are

force.

connections.

to

as

described

smooth

with

it

enters

and

vise

correctly

Refer

MANIFOLDS

manifolds

Caution

achieve

minimal

an

earlier. A vise,

surfaces.

holding

the

pump

(see

Figure

aligned

to

Figure

are

must

be

airtight

and

force.

head.

Each

11).

tightened

11

and

seal.

periodically

exercised

with

Using

manifold

insure

to

protective

an

on

each

that

each

required.

prevent

(smooth)

adjustable

component

manifold.

manifold

Most

components

breakage

jaws

is

open

end

may

be

Secure

is

secured

of

fittings

required.

wrench,

individual-

the

pump

to

its

The

Control

Pump

Assembly,

The

control

is

rail

Remove

The

remove

pump.

(unlock

in

edge

into

ASSEMBLY

Pump

bind

with

Set

tension

lever

A

to-guide

locked

PUMP

slotted

To

sembly

Module

To

module

the

its

unlocked

view

discloses a concave

interface

the

is

the

rail’s

Control

Assembly

screws,

head

entire

the

hand,

one

Pump

the

Assembly

access

any

is

secured

guide),

slide

position,

when

made

rectangular

Module

(see

Pump

remove

Assembly

Assembly

Figure

electrically

and

Assembly;

each

consists

of

with

the

the

(1)

track.

down,

of a Chassis

these

assemblies,

two

lever

control

and

convex

the

mechanically

is

9)

position

the

of

then

Assembly,

the

(2)

cam-locking

the

to

fully

module

rectangular

(Inner

connected

three

separate

can

track

Case)

via

Inner

the

mounting

Side

Frame

Control

guides.

right.

slide

track. A guide edge

"tipped"

is

as

mounted

an

automotive

the

Module

Each

lock,

To

along

into

the

to

on

which

in

directed

insulated

Case

screws

guide

slide

its

rail

the

the

Chassis

two-conductor

of

one

connector

Assembly,

must

be

removed

contains a locking

lever

the

for

repositioning

view

discloses a convex

convex

preceding

its

go

track,

Assembly

sides.

through

halves.

section.

automotive-grade

While

the

Inner

the

to

and

with

grasping

Chassis

Cover

from

the

lever.

left.

or

remoyal.

the

(2)

three

underside

Assembly

Outer

To

the

When

track.

guide

8-32

(3)

connector.

Pump

the

and

Case.

release

guide

The

rail-

lever

3/8

X

As-

the

into

is

Page 22

DISASSEMBLY/REASSEMBLY

PUMP

Service

tween

INNER

Pump

ASSEMBLY

NOTE:

To

To

The

lips

electrically

The

brown

Itis

acceptable

personnel

reassemble,

metal

surfaces

COVER

remove

pan

the

Assemblies

Inner

Cover

head

connected

Cover

Inner

from

wires

(cont'd)

should

reverse

and

ASSEMBLY

Inner

as

described

Assembly

screws.

Assembly

CB1;

to

separate

determine

the

above

are

neatly

Cover

Assembly

is

Remove

to

the

rest

can

the

and

the

which

procedure.

"dressed"

earlier

secured

these

of

the

electrically

be

"faston"

(cont'd)

automotive

method

out

(Figure

within

to

screws

circuitry

8),

this

the

Chassis and

to

disconnected

connected

connector

is

more

Insure

that

of

the

way.

it

is

necessary

section.

disengage

and

black

halves

prior

convenient.

the

automotive

to

remove

Side

the

by

white

Frame

Inner

Assemblies

Cover.

removing

wires

to

removing

connector

the

Control

The

"faston"

the

T1

from

the

wires

Module

with

four

Inner

Cover

connected

(refer

three

mounting

are

not

(Inner

(4)

4-40 X 5/16

Assembly

Electrical

to

"pinched"

Case)

white

black,

Schematic).

screws.

be-

and

phil-

remains

and

reassemble; connect

To

wires

and

secure

SIDE

FRAME

remove

To

Cover

The

screws.

separated

be

and

tor

Removal

reassemble;

To

the

to

the

Assemblies

Frame

Side

Remove

to

red

the

of this

Chassis

Assembly

each

with

the

four

ASSEMBLY

Assembly,

Frame

Side

as

described

Assembly

screws

these

electrically

blue

and

Assembly

connect

disconnect

wires

provides

each

and

to

wire

(4)

phillips

earlier

(Figure

7)

disengage

to

from

to

wire

secure

the

with

respective

its

pan

necessary

is

it

within

secured

is

the

assembly.

this

(refer

fan

service

access

respective

its

the

head

this

to

Side

four

location,

screws.

remove

to

section.

Chassis

the

Frame

Disconnect

Electrical

to

transformer

to

in-line

phillips

(4)

carefully

Control

the

Assembly

red

the

T1,

head

Four

the

carefully

screws.

Assembly.

Schematic).

connection,

pan

close

Module

four

by

(4)

and

bridge

Inner

the

(Inner

(4)

in-line

wires

black

rectifier

attach

Cover

Case),

X

4-40

"faston"

from

D1-4

the

avoid

to

Pump

phillips

5/16

connections

pump

the

and

Frame

Side

pinching

Inner

and

head

pan

must

connec-

capacitor

C1.

Assembly

Page 23

CALIBRATION

EQUIPMENT

1,

Vacuum

to

dampen

2.

Pressure

oscillations).

3.

Flow

PROCEDURES

NOTE:

1.

Vacuum

exposed,

a)

Connect

REQUIRED

Gauge,

needle

Gauge,

Meter

(Rotameter),

All

calibration

Tests:

even

slightly,

device

PROCEDURE

0

-

30"

Hg

(0

-

760

oscillations).

0

-

30

PSI,

+/-3%

0

-

40

tests

may

be

All

vacuum

to

to a live

tests

atmosphere.

A.C.

power

mmHg),

accuracy

LPM,

+/-3%

performed

must

be

The

pressure

source.

+/-

3%

or

better.

accuracy

with

device

performed

port,

accuracy

(A

liquid

or

better,

mounted

in

the

absence

however,

or

better.

filled

minimum

within

of

must

(A

gauge

its

air

flow.

remain

liquid

filled

is

preferrable

inlet

fitting

outer

case.

Insure

unblocked.

gauge

bore

that

to

dampen

1/4",

no

vacuum

is

preferrable

needle

port

is

b)

Insure

©)

Insure

proceeding

before

d)

Close

e)

Turn

f)

Connect

g)

The

reading.

mmHg.

titled

h)

at

between

IMPORTANT

cluded

far

tive

Allow

CALIBRATION

Verify

preset

vacuum

vacuum

in

excess

circuit

that

all

that

all

vacuum

power

vacuum

device

will

for

Allow

for

similar

maximum

NOTICE:

inlet

of

pump

breaker

tubing,

tubing

further

regulator

on.

vacuum

readings

vacuum

gauges

will

fittings

is

free

with

gauge

to

now

commence

stabilization

gauge

PROBLEMS.

between

levels

which

The

at

the

time

motor

capability.

trip

to

and

collection

from

kinks

calibration

valve

by

turning

patient

prevent

inlet

"pumping

gauge

of

tolerances

the

of

100,

can

be

additive.

vacuum

of

the

power

The

any

canisters

and

fatigue

verifications.

its

knob

fully

fitting

of

the

down"

and

final

in

vacuum

300

must

on

sequence

motor

and

reading.

mmHg

be

will

damage

reading

device

and

gauge

electrical

are

properly

cracks.

verify

gauge

"stall",

Replace

clockwise.

leftmost

drawing

that

If

and

to

verify

connected

can

result

temporarily

from

connected

all

collection

a

vacuum

reading

reading

device

the

test

gauge

linearity.

after

power

in a startup

draw

occurring.

and

tubing

exhibiting

canister.

as

evidenced

fact

in

is

below

is

vacuum

gauge.

Allow

is

applied

motor

excessive

tightly

to

equal

standards

Repeat

for

torque

current,

secured.

these

characteristics

by

the

vacuum

greater

or

see

this

tolerance

to

the

device.

requirement

and

gauge

500

than

section

procedure

differences

the

en-

An

oc-

that

is

protec-

Page 24

CALIBRATION

VACUUM

2,

posed,

side

a)

b)

c)

d)

tubing.

e)

f)

If

pressure

3.

Air

phere.

TESTS

Pressure

even

slightly,

circuit.

the

of

Connect

that

Insure

Connect

Insure

Turn

Verify

that

Insure

power

a

measurement

flow

DO

NOT

Test:

device

pressure

that

minimum

test:

PROCEDURES

(cont’d)

All

pressure

to

atmosphere.

live

a

to

fittings

all

gauge

pressure

tubing

on.

pressure

is

Air

flow

occlude

tests

must

Do

power

A.C.

secured.

tightly

are

to

pressure

gauge

connecting

is

rated

for

use

reading

below

10

PSI

measurements

any

ports

on

be

not

source.

port.

under

of 10

see

must

the

pressure

(cont'd)

made

in

the

block

or

occlude

tubing

section

is

pressure.

PSI.

Allow

entitled

be

taken

circuit

free

absence

the

from

fatigue

for

pressure

CALIBRATION

with

the

or

air

flow

of

air

flow.

pressure

or

gauge

vacuum

and

measuring

Insure

relief

valve

signs

of

tolerance

PROBLEMS.

pressure

instrument.

that

no

pressure

or

any

ports

cracking.

when

taking

circuits

on

the

Replace

final

exposed

port

is

ex-

vacuum

defective

reading,

to

atmos-

a)

Connect

b)

Remove

secured.

©)

Insure

that

tics.

d)

Connect

e)

Turn

power

f)

Verify a minimum

ing

is

below

30

IMPORTANT

diameter

imum.

restricting

of

at

Bends

effect

device

to a live

disposable

all

tubing

flow

meter

on.

free

LPM

see

NOTE:

least

1/4” so

in

tubing,

upon

and

flow.

A.C.

filter

from

is

free

to

the

patient

air

flow

section

All

connecting

as

not

the use

power

source.

circuit,

from

kinks

or

port

on

of

30

LPM.

entitled

to

CALIBRATION

tubing

unnecessarily

of

connection

Insure

fatigue

the

leftmost

Allow

and

fittings

restrict

elbows

that

all

tubing,

cracking.

collection

for

flow

meter

PROBLEMS.

used

flow.

Connecting

to

the

fittings

Replace

tolerance

with

the

flow

meter

and

any

tubing

canister.

when

measuring

tubing

should

collection

exhibiting

taking

final

flow

meter

lengths

also

should

be

avoided

canisters

these

must

are

characteris-

reading,

have

be

kept

as

each

tightly

If

read-

an

inner

to a min-

has

a

Page 25

CALIBRATION

CALIBRATION

1.

Vacuum

and

collection

vacuum

LY/REASSEMBLY

the

tings.

measurement

SEMBLY/REASSEMBLY

sure

collection

ly

regulating

If

these

steps

diaphragm

2.

Pressure

Replace

If

these

If

the

above

that

3.

Air

flow

mounted.

the

PROBLEMS

tests:

canister

valve

do

not

is

not

test:

defective

steps

do

test.

steps

diaphragm

test:

If

canisters.

Insure

PROCEDURES

If

insufficient

components.

is

closed

result

in

desired

instructions.

cracked

If

an

not

If

the

fail

an

Replace

that

or

worn.

insufficient

tubing

which

result

in

desired

pressure

to

result

in

instructions.

is

not

crimped

insufficient

defective

the

vacuum

vacuum

Replace

(turned

vacuum

Verify

that

Replace

pressure

is

crimped

pressure

reading

proper

Verify

or

air

flow

tubing

regulating

(cont’d)

readings

fully

exceeds

pressure

worn.

reading

are

all

defective

clockwise).

readings,

all

flapper

the

reading

or

readings,

10

that

Replace

is

which

valve

made,

tubing

Verify

remove

valves

are

pump

head

is

made,

cracked.

partially

PSI,

this

readings,

all

made,

is

is

remove

flapper

the

insure

crimped

closed

insure

the

which

that

the

pump

properly

gasket

insure

the

Verify

that

occlude

valve

requires

the

valves

are

pump

head

the

proper

or

cracked.

(turned

proper

is

crimped

the

pump

head

sealing

if

torn

or

proper

the

pump

the

replacement.

pump

properly

gasket

connection

Verify

fully

clockwise).

connection

or

cracked.

head

is

securely

as

described

and

tightly

cracked.

connection

head

pressure

head

as

described

sealing

if

torn

or

that

the

of

all

in

the

secured.

of

all

is

securely

relief

valve

and

tightly

cracked.

of

all

tubing,

pump

tubing,

Insure

mounted.

DISASSEMB-

tubing

head

fittings

that

Insure

and

mounted.

during

in

the

DISAS-

secured.

fittings

is

secure-

the

that

fit-

the

In-

and

If

these

steps

do

not

SEMBLY/REASSEMBLY

sure

that

the

diaphragm

result

in

the

instructions.

is

not

crimped

desired

Verify

or

worn.

air

flow

reading,

all

that

Replace

remove

flapper

the

pump

are

valves

head

the

pump

properly

gasket

head

sealing

if

torn

as

described

and

or

cracked.

in

the

secured.

tightly

DISAS-

In-

Page 26

CIRCUIT

P1,

CB1,

S1

115

or

230

VAC.

output.

incoming

DC

purpose

the

overloads.

cases,

device

CB1

AC

D1-4

and

C1

signal

suitable

is

to

vacuum/pressure

Waveforms

considerable

performance

DESCRIPTIONS

and

T1

represent a voltage

TI

is a dual-primary,

is a two-pole,

line,

represent a full-wave

for

maintain a continuous

and

voltage

leeway

multi-voltage

powering

pump

over a broad

the

motor.

measurements

has

been

range

(Refer

selection

power

circuit

bridge

pump

and

air

flow,

Circuit

have

given

as to

of

conditions.

breaker

to

the

circuit. SI

transformer

breaker/switch

rectifier

and

fan

motors.

during

operation,

CB2

***NOTE***

been

noted

what

constitutes

attached

rated

filter

M1

protects

at

various

schematic

is a Key

for

50/60

which

protects

capacitor

represents

within

the

rectifier

locations

an

acceptable

Switch

the

which

Hz

operation

the

for

converting

the

miniature

electronics

and

on

voltage

drawing).

allows

selection

with a nominal

"hot"

and

"neutral"

the

12

cooling

enclosure.

motor

circuits

the

schematic

value

in

of

sides

VAC

to a filtered

fan's

motor.

M2

represents

against

drawing.

order

to

maintain

nominal

12

VAC

of

the

Its

current

In

most

Page 27

PREVENTATIVE

Preventative

mance.

Preventative

If

monthly

If

monthly

VISUAL

1.

Inspection

be

replaced

2.

Check

3.

Check

4.

Check

PERFORMANCE

maintenance

These

inspections

maintenance

usage

usage

CHECKS:

of

as

necessary.

the

vacuum

the

disposable

collection

tubing,

MAINTENANCE

inspections

should

inspections

is

less

than

is

greater

canisters

CHECKS:

than

Visual

fittings

gauge

Hydrophobic

consist

50

hours - PMI

100

hours - PMI

checks

should

and

collection

for a "zero

for

chips

Performance

should

of

both

(PMI)

bimonthly.

include,

area"

Filter

or

cracks

checks

INSPECTIONS

be

incorporated

visual

and

performance

should

canisters

reading

for

be

made

monthly.

but not be

for

cracks,

when

discoloration.

in

bottle,

for

should

on a routine

as

follows:

limited

crimps,

the

device

Replace

worn

or

include,

but

basis

checks,

to:

leakage

is

turned

if

discolored.

loose

fitting

not

be

to

insure

and

cleaning

and

general

off.

lids.

limited

proper

Replace

to:

device

when

wear.

as

perfor-

warranted.

They

should

required.

1.

Check

Check

2.

OPERATION

3.

Check

4.

Check

CLEANING:

portion

of

tactile

feel

and

various

the

cam-locking

this

operating

portion

Overflow

Refer

manual.

of

to

guides

operation

modes

this

manual).

Shutoff

for

ROUTINE

the

of

switches

(refer

Valve.

Insure

attachment

CARE

and

the

to

that

the

and

detachment

MAINTENANCE

AND

controls.

OPERATOR

ball

float

PERFORMANCE

does

not stick

operation.

"CLEANING"

and

CHECKS

is

debris

section

free.

the

in

section

OPERATION

in

the

Page 28

TROUBLESHOOTING

SYMPTOM:

Check

Disconnect

SYMPTOM:

Verify

voltages

ly

secured.

SYMPTOM:

Check

for

correct

clockwise.

SYMPTOM:

Check

for

active

M2

proper

at