Page 1

Instruction booklet and

*1.041956ENG*

warning

IE

HYDRO FS

Page 2

We would first of all like to thank you for having chosen one of our products.

We are sure you will be happy with it because it represents the state of the art in the technology of

home air conditioning.

By following the suggestions contained in this manual, the product you have purchased will operate

without problems, giving you optimum room temperatures with minimum energy costs.

Symbols

The pictograms in the next chapter provide the necessary

information for correct, safe use of the appliance in a rapid,

unmistakable way.

Safety pictograms

Warning

The operation described may cause physical harm if not

carried out in accordance with safety regulations.

Dangerous electrical current

Make personnel aware that the operation described may

lead to electrical shocks if not carried out in accordance

with safety regulations.

High temperature danger

Of safety regulations, the risk of burns caused by contact

with components with high temperatures.

Prohibition

Refers to prohibited actions.

2

Page 3

Summary

1. General ...................................................... 5

1.1 General warnings ............................................ 5

2. Modulating temperature controller kit .. 6

2.1 Assembly, set-up and connection .................... 6

2.2 Assembly ........................................................ 6

2.3 Set-up of auxiliary dip-switch functions B and C 7

2.4 CP presence contact input connection............. 7

2.5 Air temperature probe assembly ....................... 8

2.6 Connections ................................................... 9

3. 4-speed temperature controller kit ..... 10

3.1 Assembly and connections ............................ 10

3.2 Assembly ...................................................... 10

3.3 Air temperature probe assembly ..................... 11

3.4 Connections ................................................. 11

3.5 Water probe kit management ......................... 11

4. Universal card kit for commercial

temperature controller ......................... 12

4.1 Assembly and connections ............................ 12

4.2 Assembly ...................................................... 12

4.3 Connection diagram with 3-speed thermostat 13

4.4 Connections with 3-speed thermostats .......... 13

4.5 LED signals ................................................... 14

4.6 Water probe management with 3-speed

thermostat .................................................... 14

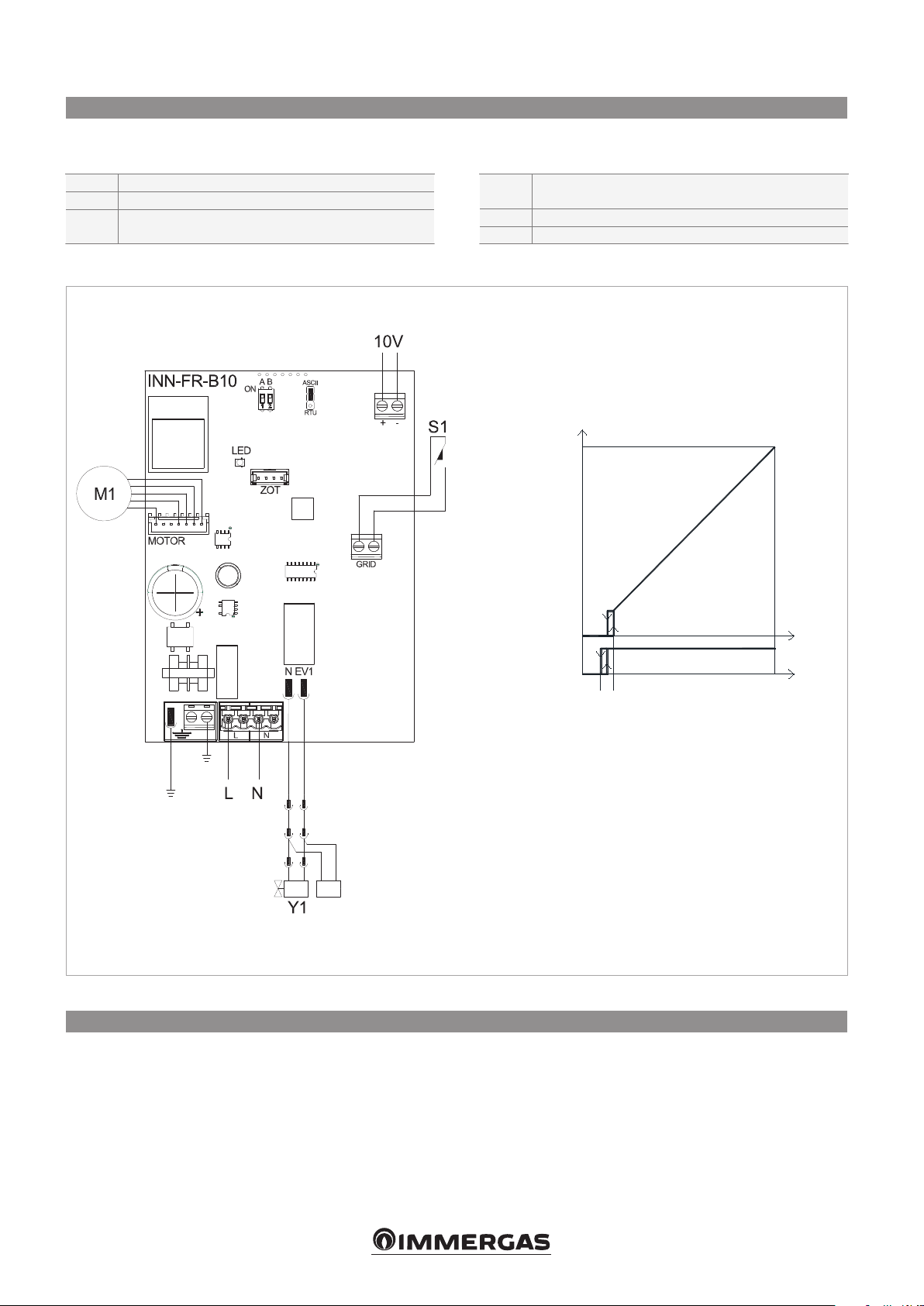

5. 0-10 V demand board kit ....................... 15

5.1 Assembly and connections ............................ 15

5.2 Assembly ...................................................... 15

5.3 LED signals ................................................... 15

5.4 Connection diagram with 0-10V DC

thermostats / signals ..................................... 16

5.5 Connections with 0-10V thermostats.............. 16

6. Feet kit .................................................... 17

6.1 Assembly ...................................................... 17

7. 2-way/3-way valve unit kit ..................... 18

7.1 List of hydraulic accessories .......................... 18

7.2 Pipeline diameter ........................................... 18

7.3 Access to inner parts ..................................... 18

7.4 Mounting the thermostatic head ..................... 19

7.5 Lockshield adjustment ................................... 19

7.6 Way valve with thermo-electric head kit .......... 21

7.7 Way valve with thermo-electric head deviator

valve kit ......................................................... 22

7.8 Connections ................................................. 24

7.9 2-way valve unit kit ........................................ 25

7.10 3-way valve unit kit ........................................ 26

8. Cooler-convector, heating, cooling

and deumidification ............................... 27

8.1 Fundamental safety rules ............................... 27

8.2 Description ................................................... 27

8.3 Identification .................................................. 28

8.4 Charts of Water flow - Pressure drop .............. 29

8.5 Dimensions ................................................... 30

8.6 Product delivery ............................................ 31

8.7 Handling and transportation ........................... 31

8.8 Access to inner parts ..................................... 31

8.9 Installation ..................................................... 32

8.10 Minimum installation distances ....................... 32

8.11 Vertically mounted ......................................... 33

8.12 Hydraulic connections ................................... 34

8.13 Condensation discharge ................................ 35

8.14 Electrical connections .................................... 36

8.15 Filling the system ........................................... 36

8.16 Evacuation of air when filling system ............... 37

8.17 First commissioning ....................................... 37

9. Modulating temperature controller kit . 38

9.1

SMART TOUCH electronic control panel..............38

9.2

Display ................................................................. 38

9.3 Key function .................................................. 38

9.4 General On Switch ........................................ 39

9.5 Activation ...................................................... 39

9.6 Heating/cooling operation modes setting ........ 39

9.7 Stand By ......................................................... 39

9.8 Temperature selection ................................... 40

9.9 Automatic operation ..................................... 40

9.10 Silent operation ............................................ 40

9.11 Night-time operation ..................................... 40

9.12 Operation at maximum ventilation speed ....... 40

9.13 Key lock ........................................................ 41

9.14 Reduce brightness to minimum ...................... 41

9.15 Deactivation .................................................. 41

9.16 Room temperature probe regulation offset ...... 41

9.17 Switching off for long periods ......................... 41

9.18 Error signals .................................................. 42

10. 4-speed temperature controller kit ..... 43

10.1

LCD electronic control panel ...............................43

10.2 LED indications ............................................. 43

10.3 Key function .................................................. 43

10.4 General On Switch ........................................ 43

10.5 Activation ...................................................... 44

10.6 Heating/cooling operation modes setting ........ 44

10.7 Stand By ......................................................... 44

10.8 Temperature selection ................................... 44

10.9 Ventilation speed regulation ............................ 44

10.10 Key lock .......................................................... 45

10.11 Reduce brightness to minimum ...................... 45

10.12 Deactivation .................................................. 45

10.13 Switching off for long periods ......................... 45

10.14 Error signals .................................................. 45

11. Maintenance ........................................... 46

11.1 Cleaning the outside ...................................... 46

11.2 Cleaning air suction filter ................................ 46

11.3 Energy saving tips ......................................... 47

3

Page 4

12. Troubleshooting ..................................... 48

12.1 Table of anomalies and remedies ................... 48

4

Page 5

1. GENERAL

1.1 General warnings

- This instruction is an integral part of the booklet of

the appliance on which the kit is installed. Please consult

this booklet for general warnings and fundamental safety

rules.

- This manual is designed only for the qualified

and authorised installation technician, who must be

sufficiently trained and in possession of all psychophysical requirements as per the law.

- All operations must be carried out with care and

according to best practices, and in compliance with

workplace safety regulations.

- After unpacking, check that the contents are intact

and that all parts are included. If not, contact the agent

who sold the appliance to you.

- It is forbidden to modify the safety or adjustment

devices without authorisation from and indications of the

manufacturer.

- It is forbidden to dispose of, or leave in the reach of

children, the packaging materials which could become

a source of danger.

- Repairs or maintenance must be performed by the

Technical Assistance Service or by qualified personnel

in accordance with this manual. Do not modify or tamper

with the appliance as this could create dangerous

situations and the manufacturer will not be liable for any

damage caused.

5

Page 6

2. MODULATING TEMPERATURE CONTROLLER KIT

2.1 Assembly, set-up and connection

The controllers have two independent clean contacts for

controlling a refrigerator unit, a boiler and a presence input.

The 2 tube versions have a 230V output to power the

summer and winter solenoid valve.

The 10 kΩ water temperature probe positioned in the

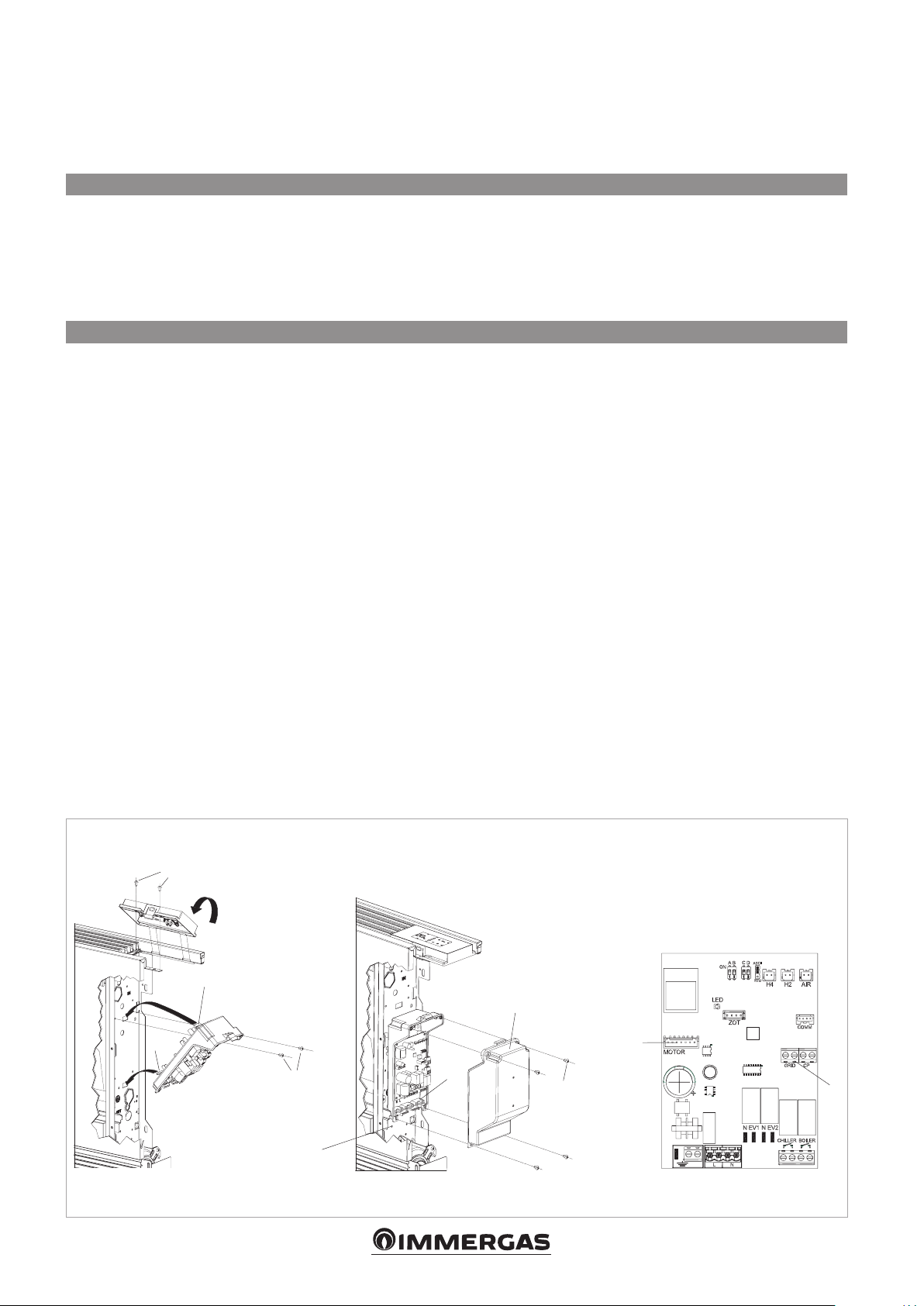

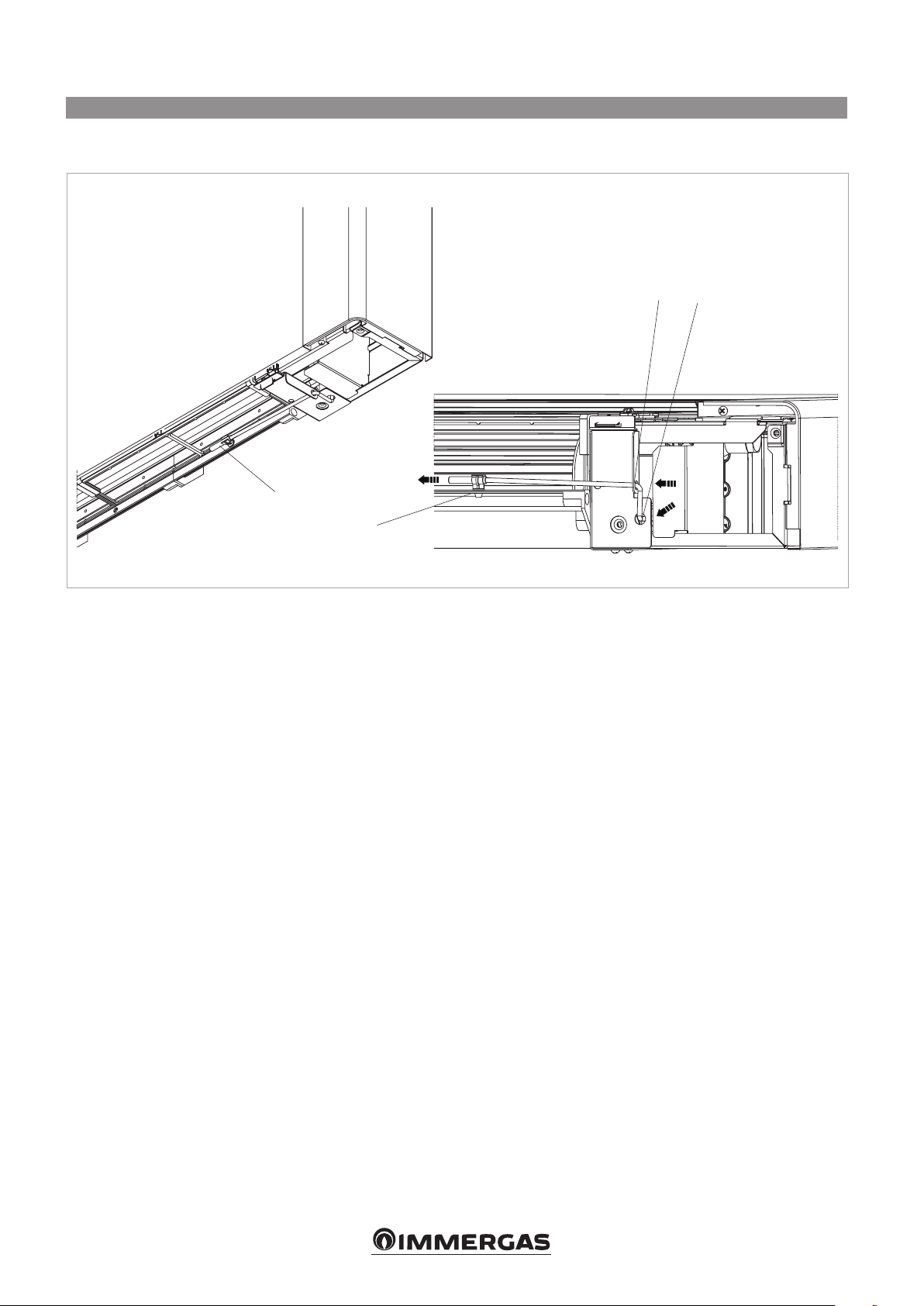

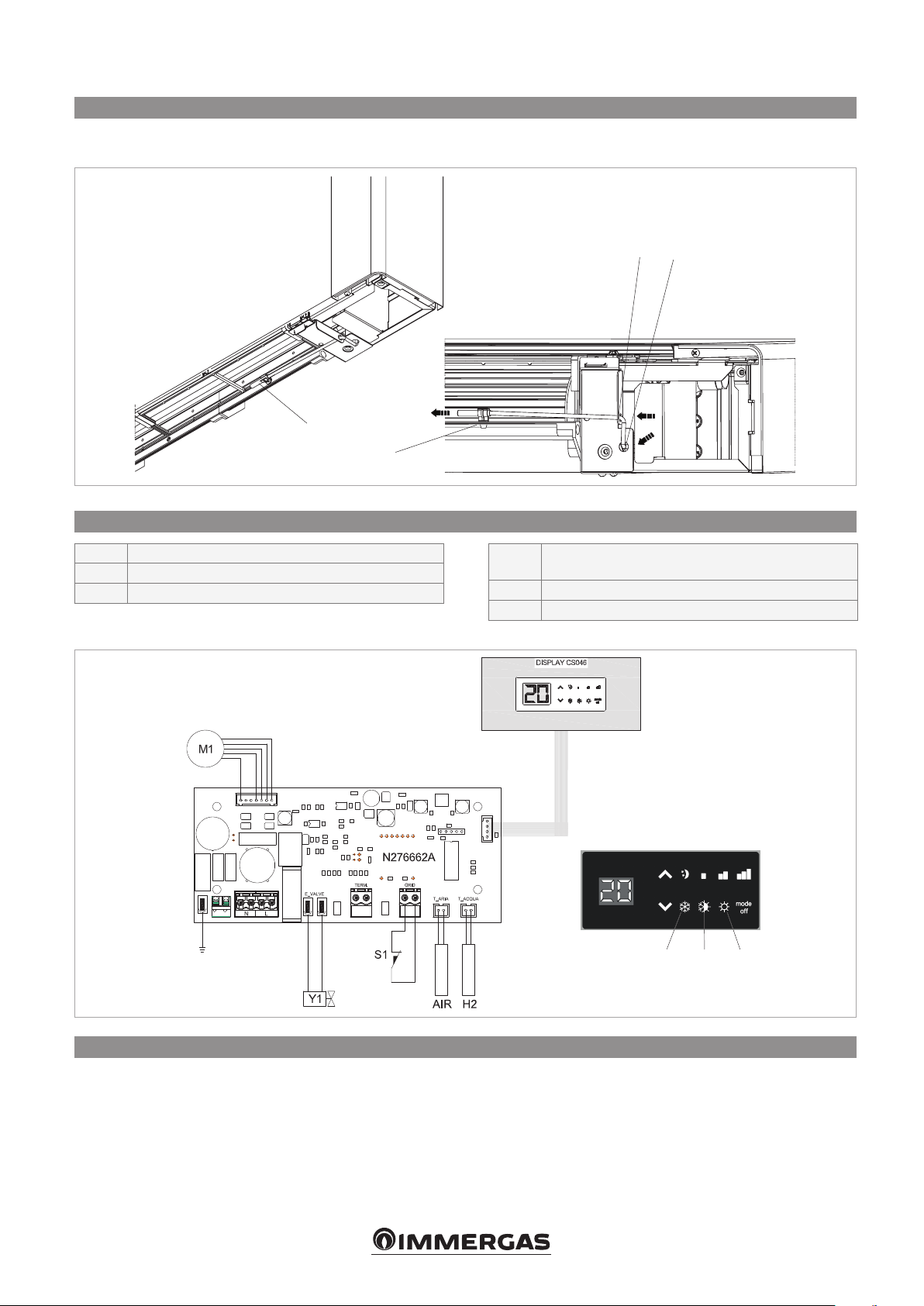

2.2 Assembly

Slide the control panel into its housing in the upper part

of the device and fix it with the two fixing screws (ref. A).

To install the connection box:

- open the box (ref. B);

- lock the lower tooth into its hole (ref. C) on the side of

the device;

- hook the upper part of the box to the side (ref. D);

- fix it with the two fixing screws (ref. E);

- connect the grounding cable to the fan coil body (ref. M)

using the fixing screws (the minimum force that must be

applied for tightening screws must be around 2N);

- connect the fast connector of the MOTOR to the other

on the board (ref. I) *;

- on the two GRID block terminals (ref. L) there is a bridge

which must not be removed.

- For other versions, remove the bridge and connect the

two terminals originating on the grill safety microswitch*;

compartment on the battery regulations the minimum level

when heating (30°C) and the maximum level when cooling

(20°C).

The board also has a function when there is no water

probe, in such cases the fan stop thresholds are ignored.

- connect the water probe to the H2 connector on the

device.

The water temperature probe controls the temperature

inside the batteries and determines when the fan starts

according to pre-set parameters (minimum operation

in winder and maximum in summer).** Check that

they are correctly inserted into the compartment on

the battery.

- Connect the electrics, tidy cables and fix them with

the three clevises supplied (ref. G);

- close the box with the 4 screws (ref. H);

- refit the vanity plate on the side of the unit;

- tighten the upper screws on the control panel;

- place the screw head covers in their housing on the

control panel;

* For versions with hydraulic connections on the right,

refer to the relevant paragraph

** The regulation also works without a water probe

connected

A

D

B

C

E

G

H

I

L

M

6

Page 7

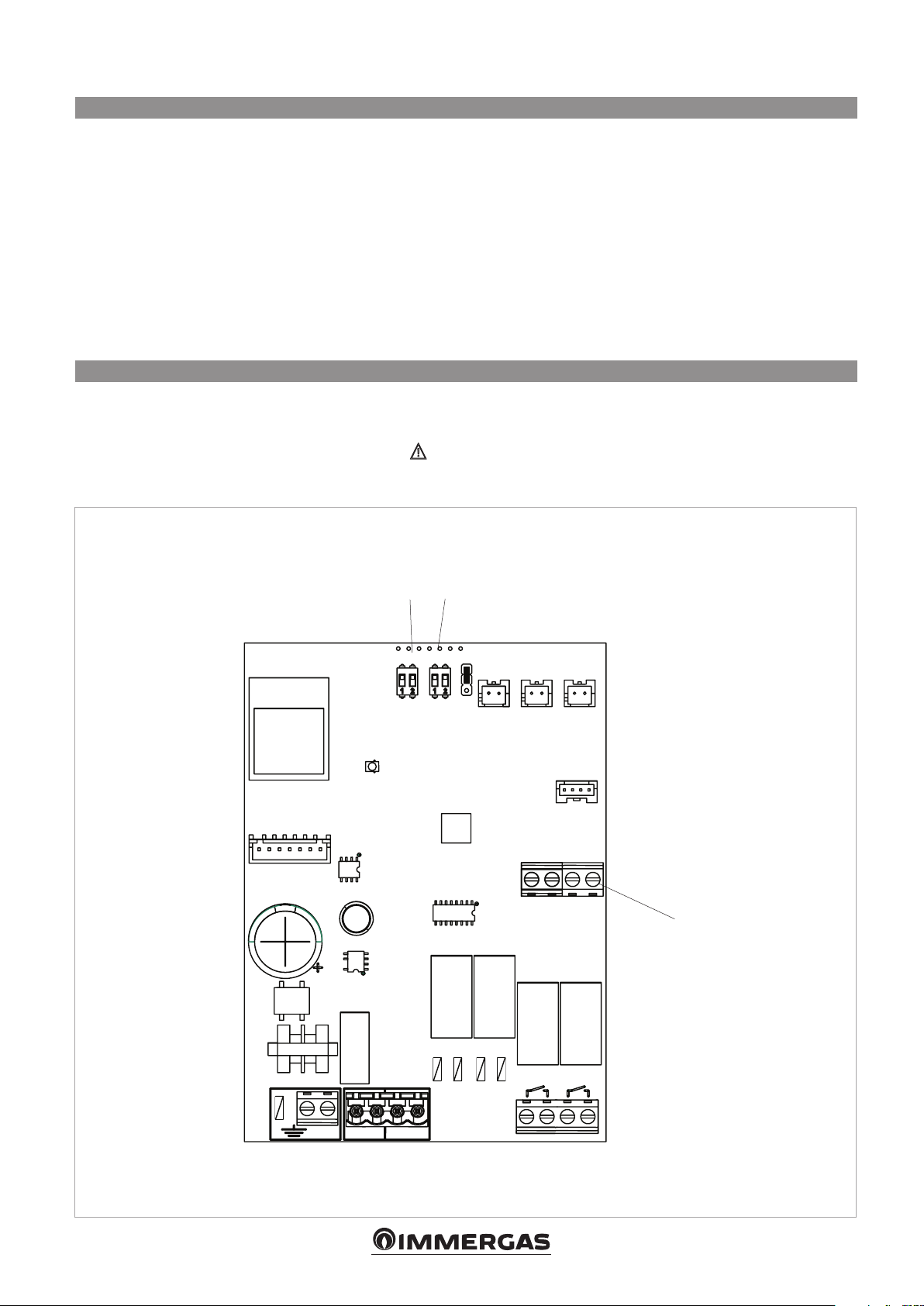

2.3 Set-up of auxiliary dip-switch functions B and C

There are two dip switches on the controller circuit board

for configuring unit operation as per requirements.

- The night-time heating operation logic is modified by

using dip switch C:

- in the ON position, the fan is always off, and heats the

room using radiation and natural convection, as with

traditional radiators; in the off position it operates as a

normal fan.

- By positioning dip switch B to ON, when cooling, the

fan operates at the minimum speed even after having

2.4 CP presence contact input connection

On closing the contact connected to the CP input (ref. A)

the panel is placed in stand-by mode.

If the contact is open the unit is active, if the contact is

closed it is deactivated when a key is pressed the

symbol flashes.

reached the set point, to allow for more uniform

operation of the temperature probe and to avoid

layering in the air. With the cursor in the OFF position,

the functions are cycled (4 minutes ON, 10 minutes

OFF).

The input cannot be connected in parallel to that of other

electronic boards (use separate contacts).

MOTOR

LED

ON

C

B

C

BA

D

ASCII

RTU

H4 H2 AIR

COMM

GRIDGRIDCP

A

N EV1 N EV2

LN

CHILLER BOILER

7

Page 8

2.5 Air temperature probe assembly

- To position the temperature probe (ref. A):

- pass the probe through the hole on the shoulder (ref. B)

A

D

- insert the probe into the lower hole (ref. C)

- fix the probe on the relevant hook (ref. D)

C

B

8

Page 9

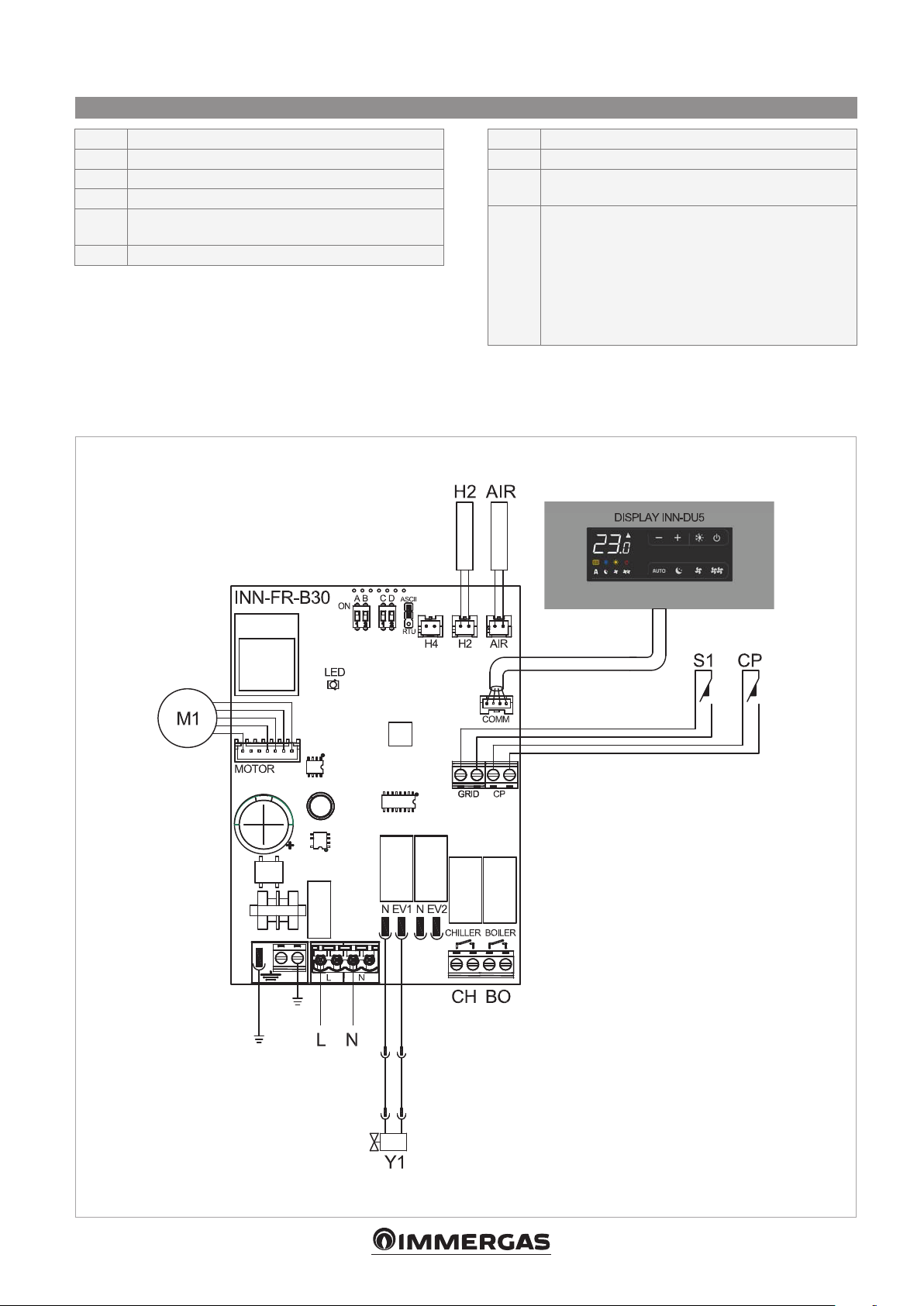

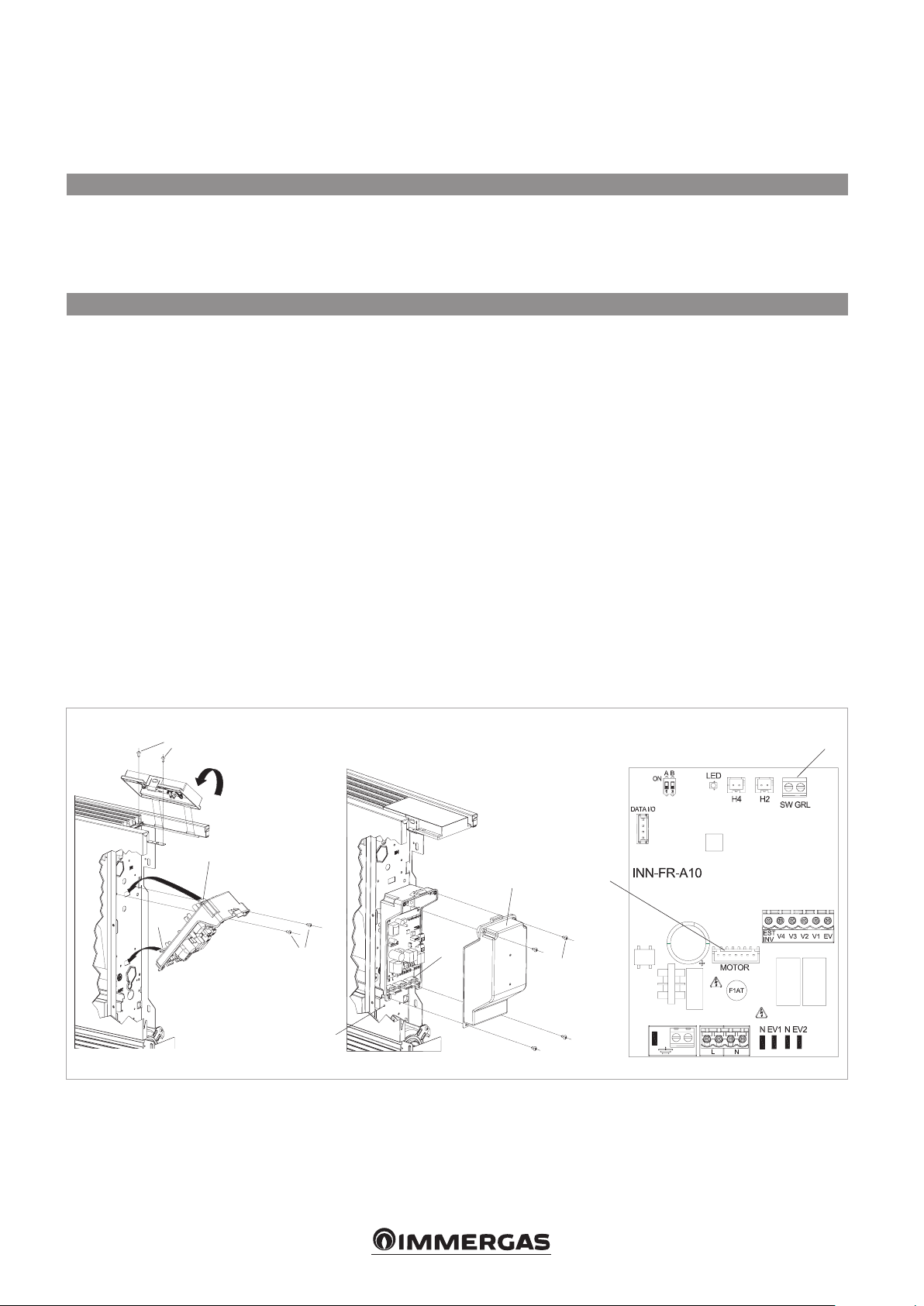

2.6 Connections

H2* water temperature probe 10 kΩ

AIR air temperature probe 10 kΩ

M1 DC inverter fan motor

S1 grill safety micro-switch

Y1

L-N

water solenoid valve (230V/ 50Hz 1A output

voltage)

electrical power supply 230V/50Hz

BO boiler consent output (free contact max 1A)

CH chiller consent output (free contact max 1A)

CP

* If after switching the power on the board detects

presence input sensor (if closed, the fan coil unit

is placed in standby)

the probe, start-up occurs in normal conditions

with the minimum water temperature when

heating (30°C) and maximum when cooling

(20°C).

The board also has a function when there is no

probe, in such cases the fan stop minimum and

maximum thresholds are ignored.

9

Page 10

3. 4-SPEED TEMPERATURE CONTROLLER KIT

3.1 Assembly and connections

The on-board controller with speed selector and ON/OFF

key, room thermostat adjustable from 5 to 40°C, winter

summer selector and minimum winter temperature function

3.2 Assembly

Slide the control panel into its housing in the upper part

of the device and fix it with the two fixing screws (ref. A).

To install the board:

- connect the grounding cable to the unit structure (ref.

M) using the fixing screws (the minimum force that

must be applied for tightening screws must be around

2N);

- connect the fast connector of the MOTOR to the other

on the board (ref. I) *;

N.B.: should the board not be fitted in the factory, the

fan motor must be rotated 180° due to the length of

the standard fan coil cable.

- on the two GRID block terminals (ref. L) there is a

bridge which must not be removed.

- For other versions, remove the bridge and connect the

two terminals originating on the grill safety microswitch;

N.B.: should the two brown terminals on the unit be

too short, replace them with those included in the kit

packaging.

- connect the water probe connector H2 (ref. F) on the

(30°C) and maximum summer temperature (20°C) is suitable

for fitting on board the unit and has a 230V - 1A output for

controlling a solenoid valve.

unit.

The water temperature probe controls the temperature

inside the batteries and determines when the fan

starts according to pre-set parameters (minimum

operation in winter and maximum in summer). Check

that they are correctly inserted into the compartment

on the battery.

- make the electrical connections, tidy the cabling;

- refit the vanity plate on the side of the unit;

- tighten the upper screws on the control panel;

- place the screw head covers in their housing on the

control panel;

- * For versions with hydraulic connections on the

right, refer to the relevant paragraph.

A

M

10

L

F

Page 11

3.3 Air temperature probe assembly

- To position the temperature probe (ref. A):

- pass the probe through the hole on the shoulder (ref. B)

A

D

3.4 Connections

H2 water temperature probe 10 kΩ

M1 DC inverter fan motor

S1 grill safety micro-switch

- insert the probe into the lower hole (ref. C)

- fix the probe on the relevant hook (ref. D)

C

B

Y1

L-N 230V/50Hz electrical power supply

AIR air temperature probe 10 kΩ

water solenoid valve (230V/ 50Hz 1A output

voltage)

3.5 Water probe kit management

If the board detects the water temperature detecting probe

on the device positioned in the relevant compartment of

the battery, it starts in normal conditions. If the probe is not

connected, its absence is indicated by the blue and red

LEDs flashing together, and operation stops.

To confirm operation without the probe, press and hold the

summer/winter button for 5 seconds (ref. A).

This condition is saved by the board for future start-ups.

C A D

In any case, as and when the probe is connected, the unit

returns to normal operation with temperature thresholds.

If the unit operates with the probe connected and the water

temperature is not suitable for active functioning (over 20°C

when cooling, under 30°C when heating) the fan will stop

and the anomaly will be indicated by the corresponding LED

flashing (cooling: blue C or heating: red D).

11

Page 12

4. UNIVERSAL CARD KIT FOR COMMERCIAL TEMPERATURE

CONTROLLER

4.1 Assembly and connections

Assembled on-board the unit, this card allows the regulation

of the motor with fixed speeds; it can be combined with

control panels with thermostat and with all control panels

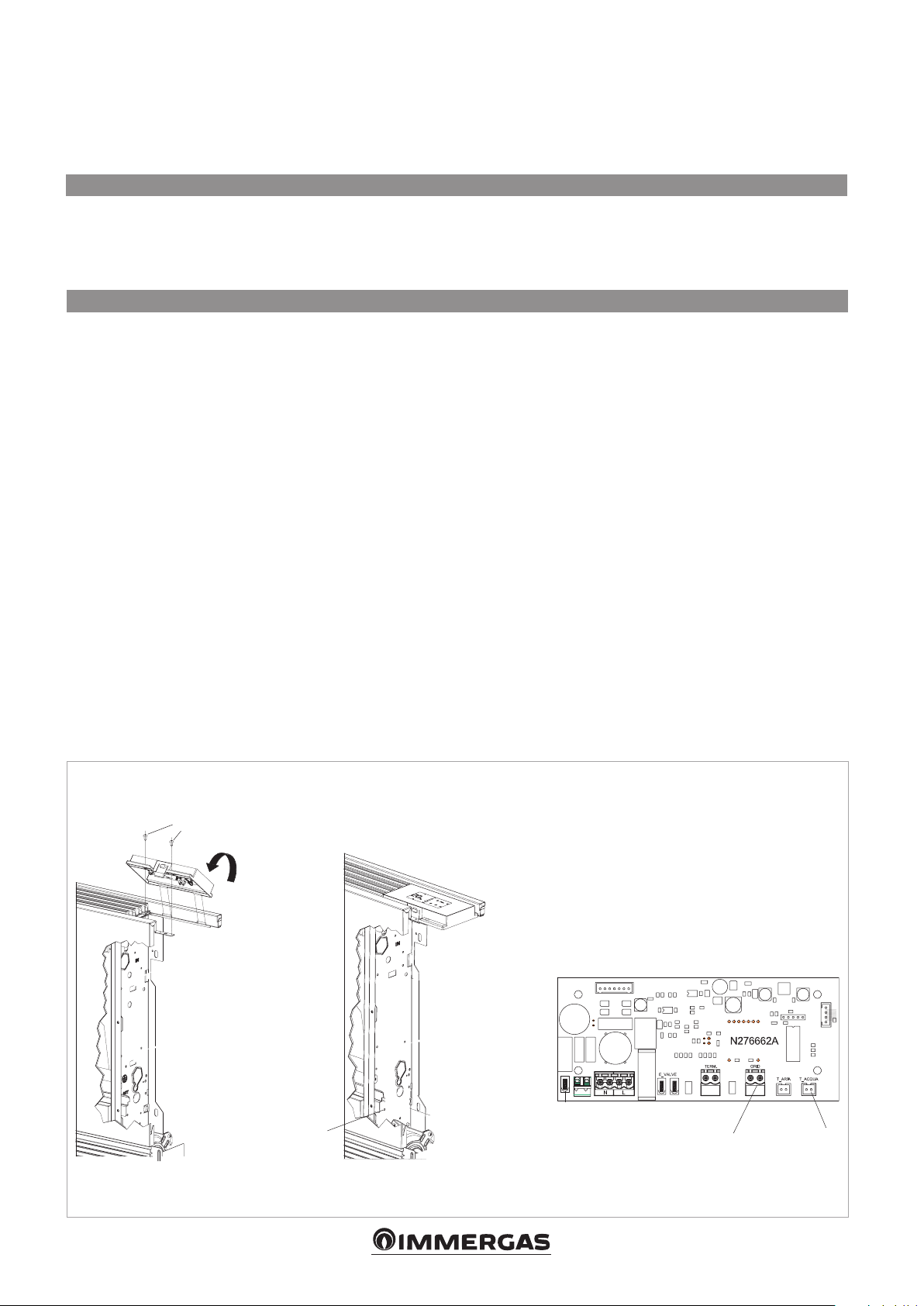

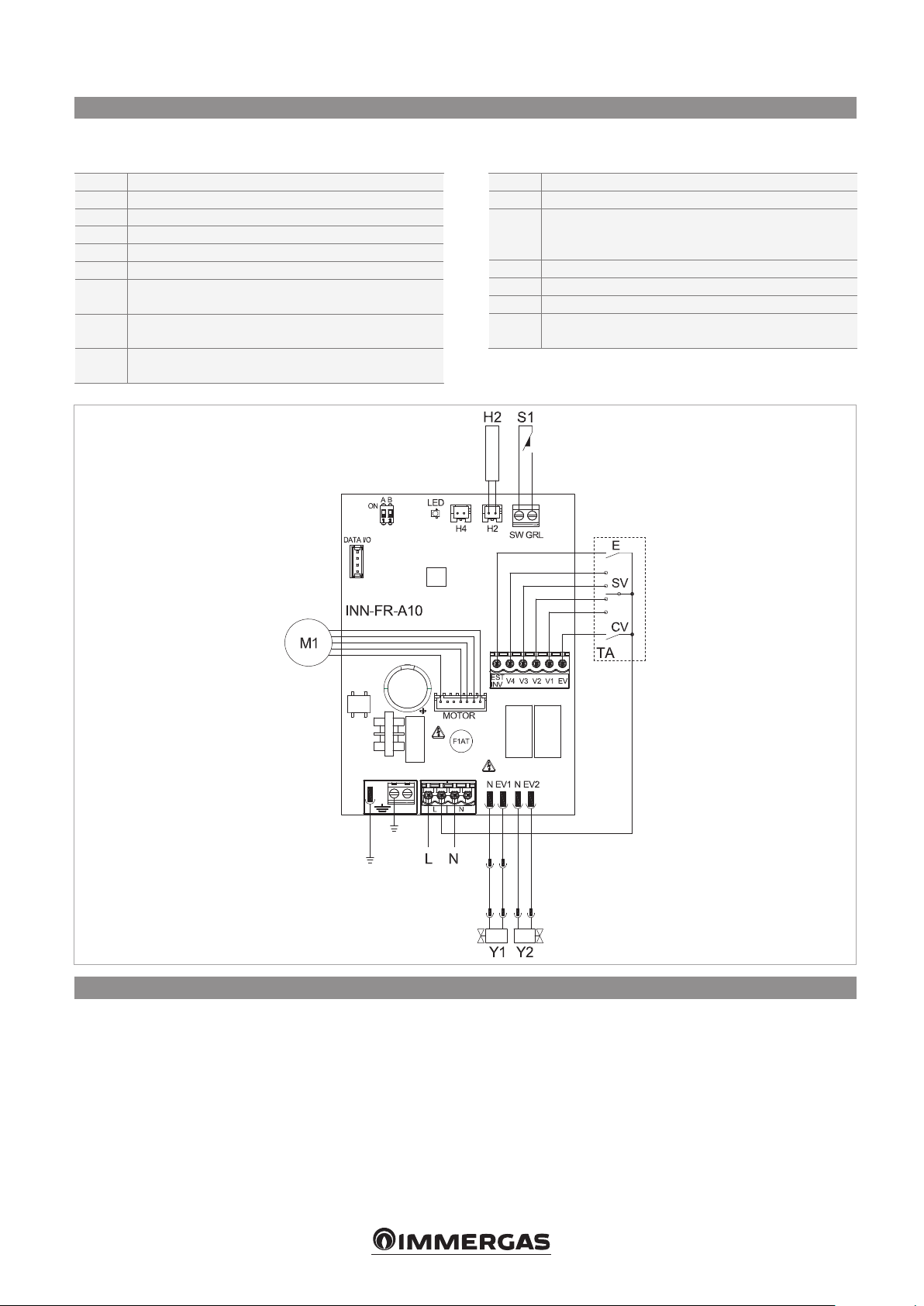

4.2 Assembly

Slide the blanking panel into its housing in the upper part of

the device and fix it with the two fixing screws (ref. A).

To install the connection box:

- open the box (ref. B);

- lock the lower tooth into its hole (ref. C) on the side of

the device;

- hook the upper part of the box to the side (ref. D);

- fix it with the two fixing screws (ref. E);

- connect the grounding cable to the unit body (ref. M)

using the fixing screws (the minimum force that must be

applied for tightening screws must be around 2N);

- on the two SW GRL block terminals (ref. L) there is a

bridge which must not be removed.

available in the market.

It has a 230 V output to pilot the summer and winter solenoid

valve.

- For other versions, remove the bridge and connect the

two terminals originating on the grill safety microswitch*;

- connect the fast connector of the MOTOR to the other

on the board (ref. I);

- Connect the electrics, tidy cables and fix them with

the three clevises supplied

- close the box with the 4 screws

- refit the vanity plate on the side of the unit;

- tighten the upper screws on the blanking panel;

- place the screw head covers in their housing on the

blanking panel;

* For versions with hydraulic connections on the right,

refer to the relevant paragraph.

(ref. G)

;

(ref. H)

;

A

L

D

B

I

C

E

G

H

M

12

Page 13

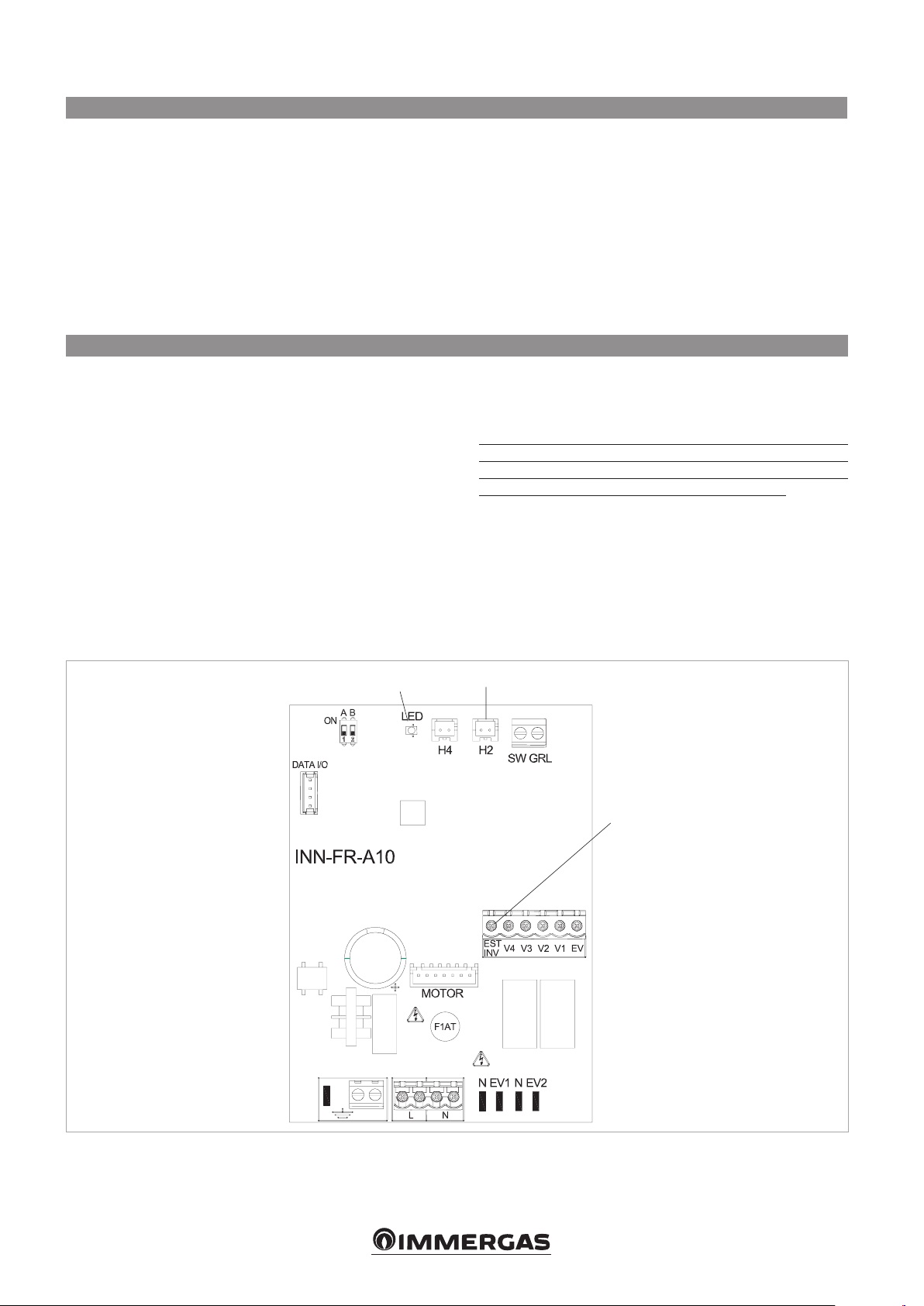

4.3 Connection diagram with 3-speed thermostat

Make the electrical connections to a thermostat fit for use

according to the diagram.

L-N electrical supply 230V-50Hz

EV solenoid valve permission input

V1 maximum fan speed

V2 medium fan speed

V3 minimum fan speed

V4 supersilent speed

E

Y2

Y1

heating selection input, cooling

See paragraph on Water Probe Management

output for mobile suction panel servo (power

output 230V/ 50Hz 1A)

water solenoid valve (230 V/ 50 Hz 1A output

voltage)

M1 DC inverter fan motor

S1 safety micro-switch for grill

3-speed room thermostat (to be purchased,

TA

CV thermostat permission

SV speed selector

H2* water temperature probe (10 kΩ)

*

installation and connection to be made by

installer)

positioned in the on-board battery.

See paragraph on Water Probe Management

4.4 Connections with 3-speed thermostats

The CV input is the board ON/OFF which when open puts

the board in stand-by. It must be bridged to the L terminal

on the 230V power supply to activate solenoid valve Y1.

The 4 speed inputs V1, V2, V3 and V4, when bridged

to the L terminal on the 230V power supply, activate the

fan if the S1 input to which the grill safety microswitch is

connected is closed. The sequence is: maximum speed

(1400 rpm on terminal V1), medium speed (1100 rpm on

terminal V2), minimum speed (680 rpm on terminal V3)

and supersilent speed (400 rpm on terminal V4).

Connect the three thermostat speeds to 3 out of the 4

available inputs as per the characteristics and use of the

room: connect, for example, medium speed V2, minimum

V3 and supersilent V4 for residential applications, when

greater silence is required, whereas V1, V2 and V3 can be

connected for commercial applications where the thermal

yield is more important.

If multiple inputs are simultaneously closed, the motor will

run at a number of revs equal to that of the connection

with the highest speed.

Multiple cards can be connected in parallel to a single

thermostat, also using different speeds.

13

Page 14

4.5 LED signals

The LED (ref. A) is off if the CV input is not closed (stand-by

condition).

It turns on when the CV contact is closed and indicates

normal operation.

• Flashes frequently if the grille microswitch S1 is activated

due to the filter cleaning operation

• 1 flash + pause indicates a fan stoppage alarm due to

unsuitable water (with H2 water probe connected).

• 2 flashes + pause due to a motor alarm (e.g. blockage

caused by foreign objects, faulty rotation sensor).

4.6 Water probe management with 3-speed thermostat

If the board is used with electromechanical thermostats, or with

other commercial controllers with water probe, the on-board

probe H2 should not be connected and the fan is controlled by

the remote control.

If on the other hand the controller is not set up for managing the

water probe, this function can be performed by the board, by

connecting the 10 kΩ probe on the battery to the H2 connector

on the board (ref. B).

In this case the board carries out the minimum temperature

function for heating operations and maximum temperature

function for cooling. Therefore, if the water temperature is not

suitable for active operation (above 20°C when cooling, under

30°C when heating) the fan is stopped and the anomaly is

signalled by a single flash + pause of the LED (ref. A).

• 3 flashes + pause indicates a disconnected or faulty

water probe alarm.

The discrimination between heating/cooling is actuated via the

Summer-Winter (ref. C) input of the board: leaving it open the

board activates heating, closed activates cooling.

If after having connected the probe it is disconnected or

measures incorrect values (e.g. installation of 2 kΩ probe in the

place of the 10 kΩ probe) the anomaly is signalled by 3 flashes

+ pause of the LED (ref. A) and operation is stopped.

To confirm operation without a probe, turn the power to the

board off and then on again.

This condition is saved by the board for future start-ups.

In any case, as and when the probe is connected, the unit

returns to normal operation with temperature thresholds.

A

B

C

14

Page 15

5. 0-10 V DEMAND BOARD KIT

5.1 Assembly and connections

When fitted on board the machine it allows for managing the

motor, with modulated speed; motor regulation can be made

using an analogue 0-10V DC input with 25 kΩ impedance.

5.2 Assembly

Slide the blanking panel into its housing in the upper part of

the device and fix it with the two fixing screws (ref. A).

To install the connection box:

- open the box (ref. B);

- lock the lower tooth into its hole (ref. C) on the side of

the device;

- hook the upper part of the box to the side (ref. D);

- fix it with the two fixing screws (ref. E);

- connect the grounding cable to the unit structure using

the fixing screws (the minimum force that must be

applied for tightening screws must be around 2N);

- on the two GRID block terminals (ref. I) there is a bridge

which must not be removed.

A

For board control outputs these impedance values must be

considered, especially when controlling more than one unit

in parallel.

It has a 230 V output to pilot the solenoid valve.

- For other versions, remove the bridge and connect the

two terminals originating on the grill safety microswitch;*

- connect the fast connector of the MOTOR to the other

on the board (ref. H);

- Connect the electrics, tidy cables and fix them with

the three clevises supplied

- close the box with the 4 screws

- refit the vanity plate on the side of the unit;

- tighten the upper screws on the blanking panel;

- place the screw head covers in their housing on the

blanking panel;

* For versions with hydraulic connections on the right,

refer to the relevant paragraph.

(ref. F)

;

(ref. G)

;

D

C

E

5.3 LED signals

The LED (ref. L) is off is the input signal is less than 0.9V.

It turns on with values greater than 1V and indicates normal

operation.

• Flashes frequently if the grille microswitch S1 is activated

due to the filter cleaning operation

L

H

I

B

F

G

• 2 flashes + pause due to a motor alarm (e.g. blockage

caused by foreign objects, faulty rotation sensor).

15

Page 16

Y2

)

5.4 Connection diagram with 0-10V DC thermostats / signals

Make the electrical connections to a thermostat fit for use

according to the diagram

L-N Electrical power supply 230V-50 Hz

10V Appliance piloting input 0÷10 V

Y1

water solenoid valve (230V/ 50Hz 1A output

voltage)

Input impedance 25 kΩ

Y2

M1

S1 safety micro-switch for grill

output for mobile suction panel servo (power

output 230 V/ 50Hz 1A)

DC inverter fan motor

OUTPUT FEATURES

MAX rpm

M1

MIN rpm

5.5 Connections with 0-10V thermostats

The 10V input, if the S1 input which the grill safety micro

switch is connected to is closed, activates solenoid valve Y1

and regulations fan revolutions.

The speed "ramp" provides for linear regulation from the

minimum value (400 rpm) to the maximum value (1,400 rpm)

ON

Y1

OFF

0

1

1,1

0,9

for voltage values ≥ 1.1V÷10 V DC.

The motor is off when values are lower than 1V DC.

The Y1 solenoid valve is activated for power values > 1V

DC and switches off then the power drops below 0.9V

DC.

10

10 V

INPUT

(V DC

16

Page 17

6. FEET KIT

6.1 Assembly

This instruction is an integral part of the booklet of the

appliance on which the kit is installed. Please consult this

booklet for general warnings and fundamental safety rules.

These accessories cover the hydraulic pipes coming

up through the floor. They should be fitted on Hydro FS

appliances anchored to the back wall.

They have a sleek design and are also easy to remove for

maintenance or cleaning.

A threaded supports B supports cover

These Feet should not be used to anchor the terminal to

the ground.

- Rest the back of the appliance on a horizontal surface;

- screw the four threaded supports provided to the

structure;

- stand the appliance up again and fasten it to the wall;

- fit the two covers to the supports.

A

A

B

B

17

Page 18

7. 2-WAY/3-WAY VALVE UNIT KIT

To avoid penalising the performance of the system the

water inlet and outlet must be as indicated in the various

figures.

For a rapid and correct assembly of the components

follow carefully the sequences described in the various

sections.

This instruction is an integral part of the booklet of the

appliance on which the kit is installed. Please consult this

booklet for general warnings and fundamental safety rules.

7.1 List of hydraulic accessories

- 2-way valve unit with thermo-electric head kit. - 3-way deviator valve unit with thermo-electric head

deviator valve kit.

7.2 Pipeline diameter

The minimum internal diameter that must be respected for

the pipelines of the hydraulic connections varies according

U.M. 200 400 600 800 1000

support covers mm 12 14 16 18 20

to the model:

7.3 Access to inner parts

- Lift it up the side panels.

- Move orizzontally to remove.

A Left panel

B Right panel

18

Page 19

7.4 Mounting the thermostatic head

Tighten the plastic disc to the valve body. Attach the head

to the valve body.

To facilitate the system mounting, filling and venting

operations, even without electric power, the thermostatic

head is supplied with a tool that keep it open.

A plastic tool

B valve body

C

B

Remove the tool from the thermostatic head before

starting the system.

C thermostatic head

A

7.5 Lockshield adjustment

The lockshields supplied with the hydraulic kits provide

an adjustment that balances the system load losses. To

ensure a correct adjustment and balancing of the circuit,

follow the procedure indicated below:

- With a screwdriver, loosen and remove the slotted

grub screw inside the hexagonal head.

- Close the adjustment screw using a 5 mm Allen key

(A)

- Re-tighten the slotted grub screw then mark the

reference point for the adjustment with an “x” (B).

- Align the screwdriver with the “x”, then open with

a number of turns (C) according to diagram Äp-Q

shown on page 22.

The number of turns refers to the micrometric screw

Then fully open the screw (D). Now the pre-adjustment

has been set and will not change if there are repeated

openings or closings with the Allen key.

19

Page 20

Load losses based on the adjustment of the lockshield

present in all kits.

20

Page 21

mbar

1000

900

800

600

700

400

200

100

80

60

40

20

10

8

6

4

2

500

300

90

70

50

30

P

9

7

5

3

1

20

40

60

80

30

50

70

90

100

200

400

600

800

1000

300

500

700

900

3000

2000

qm = kg/h

0.1

0.2

0.3

0.5

0.7

0.9

0.4

0.6

0.8

1

2

4

3

5

7

9

6

8

10

30

20

40

60

80

100

50

70

90

kPa

KV

s

4000

KVS = 3,60

7.6 Way valve with thermo-electric head kit

Consists of an automatic valve with thermo-electric head

and a lockshield, fitted with micrometric adjustment,

capable of balancing the system load losses.

load losses in completely open position of 2-way valve

present in kits.

The kit contains the insulation to be mounted on the valve

and on the lockshield.

21

Page 22

7.7 Way valve with thermo-electric head deviator valve kit

Consists of a 3-way deviator valve with thermo-electric

head and a lockshield, fitted with micrometric adjustment,

capable of balancing the system load losses).

Diagram of load losses of deviator valve, present in kit, in

completely open position.

The kit contains the insulation to be mounted on the valve

and on the lockshield.

22

Page 23

Diagram of load losses of deviator valve, present in kit, in

completely closed position.

23

Page 24

A

7.8 Connections

The choice and sizing of the hydraulic lines must be made

by an expert who must operate according to the rules of

good technique and the laws in force.

To make the connections:

- position the hydraulic lines

- tighten the connections using the “spanner and

counter spanner” method

- check for any leaks of liquid

- coat the connections with insulating material

A Eurokonus adapter

B Spanner and counter spanner

The hydraulic lines and joints must be thermally insulated.

Avoid partially insulating the pipes.

Do not over-tighten to avoid damaging the insulation.

Use hemp and green paste to seal the threaded

connections; the use of Teflon is advised when there is

anti-freeze in the hydraulic circuit.

C Coat the connections with insulating material

B

C

24

Page 25

7.9 2-way valve unit kit

Consists of an automatic valve with thermo-electric head

and a lockshield, fitted with micrometric adjustment,

capable of balancing the system load losses.

- Remove the side panel as indicated in paragraph Side

opening.

- Assemble the components as indicated in figure

- Apply the supplied insulation.

1 thermo-electric head (n.1)

2 lockshield (n.1)

3 2-way valve (n.1)

The kit contains the insulation to be mounted on the valve

and on the lockshield.

When the hydraulic components have been mounted,

connect the thermo-electric head connectors with the

wiring connectors on the machine.

X thermo-electric head connectors

Y wiring connectors

1

3

2

X

Y

25

Page 26

7.10 3-way valve unit kit

Consists of an automatic 3-way diverter valve with thermo-electric

head and a lockshield, fitted with micrometric adjustment, capable

of balancing the system load losses. The kit contains the insulation

to be mounted on the valve and on the lockshield.

- Remove the side panel as indicated in paragraph Side

opening.

Floor mounted version

1 thermo-electric head (n.1)

2 lockshield (n.1)

3 3-way valve (n.1)

4 outlet union (n.1)

- Assemble the components as indicated in figure

- Apply the supplied insulation.

When the hydraulic components have been mounted,

connect the thermo-electric head connectors with the

wiring connectors on the machine.

5 1/2” flexible tube 230 (n.1)

X thermo-electric head connectors

Y wiring connectors

1

3

5

4

2

X

Y

26

Page 27

8. COOLER-CONVECTOR, HEATING, COOLING AND DEUMIDIFICATION

8.1 Fundamental safety rules

Do not allow children or unassisted disabled people to use

the unit.

Do not open the access covers and carry out technical or

cleaning activities before disconnecting the unit from the power

grid by positioning the system’s main switch in the “off” position.

It is forbidden to modify the safety or regulation devices without

the authorisation and directions of the manufacturer.

Do not stand, sit and/or place objects on the unit.

Do not pull, detach or twist the electrical wires coming out of

the unit, even when the unit is disconnected from the power grid.

8.2 Description

Do not spray or throw water directly on the unit.

Do not dispose of, abandon or leave the potentially hazardous

packaging materials within the reach of children.

It is strictly forbidden to touch any moving parts, interfere with

them or introduce pointed objects through the grids.

Do not touch the unit while barefoot and/or partially wet.

The device is a terminal facility that contains in a single

device the best solution for the heating, cooling and

dehumidification. Allows you to achieve energy efficiency

very high for the possibility of being coupled with

generators of heat at low temperature such as: heat

pumps, condensing boilers integrated systems withsolar

collectors. Thanks to a sophisticated temperature

controller, the device, providing excellent thermal comfort

in every season. Heats and cools very rapidly and once it

reaches the desired temperature, keeps it very precisely

in utter silence. In heating mode, the device develops

an effective natural convective effect (similar to that of a

radiator) which greatly reduces the need to activate the

ventilation. Its harmonious design and exceptionally low

depth of only 15 cm make it integrated into any type of

environment for all furnishing needs.

The unit combined with different control panels on board

have the factory settings with parameters for maximum

speed to 1700 rpm. To modify these parameters follow

the procedures contained in instructions supplied with the

control panel.

27

Page 28

8.3 Identification

Technical Tag

The technical tag shows all technical and performance

data of the unit. Should the tag get lost, please ask for a

duplicate tag from the Technical Service.

Any tampering with, the removal or the lack of the

Technical Tag or of any other element whose absence

prevents certain identification of the product makes it

more difficult to install and maintain the product.

Main components:

A

B

D

E

F

H

I

L

M

N

P

Structure

Heat exchanger

Fan unit

Electric motor controlled by INVERTER

Supply air grille reversible

Drain pan

Back structural

Front cover

Removable side panels

Air filter

R version micro-fan

28

Page 29

8.4 Charts of Water flow - Pressure drop

Pressure drop [hPa]

Pressure drop [hPa]

Water ow [l/h] Water ow [l/h]

29

Page 30

8.5 Dimensions

Size 23 45 64 76 94

Dimensions

A mm 140

B mm 80

C mm 20

D mm 20

E mm 400

Dimensions: Tivano - Tivano R

L mm 723

Net weight

Kg 17

923 1123

20 23

1323 1523

26 29

30

Page 31

8.6 Product delivery

Preliminary instructions

We suggest to take the equipment out of its packaging

only when it has been placed in position at the

installation point.

Carefully remove any adhesive strips positioned on the

unit.

Scope of supply

Also supplied:

8.7 Handling and transportation

The unit must be handled by skilled technicians,

appropriately equipped and with the appropriate tools

to manage the unit’s weight in compliance with the

accident prevention regulations.

8.8 Access to inner parts

- Lift it up the side panels.

- Move orizzontally to remove.

Do not dispose of, abandon or leave the potentially

hazardous packaging materials within the reach of

children.

A Left panel

B Right panel

31

Page 32

8.9 Installation

Preliminary instructions

The place of installation must be determined by the

system’s designer or by an expert in the field and must

take into account the technical requirements and the

current standards and legislation.

Before starting installation, decide the placement of the

unit taking into account the minimum required distances.

Detailed information on the unit (measurements,

dimensions, fastenings, required distances, etc.) are

shown in the “Technical Data” chapter.

The unit is designed for vertical installation on the floor.

In order to guarantee the correct operation of the

equipment, the units must be installed so that the air outlet

and inlet shall remain unobstructed.

In case of concealed installation a detachable section

cut into the suspended ceiling is required in order to

access the unit.

8.10 Minimum installation distances

Figure indicates the minimum mounting distances

between the wall-mounted cooler-convector and furniture

present in the room.

The unit must be mounted so as to guarantee the

circulation of the processed air throughout the whole

environment.

Check that:

- The support wall can support the weight of the unit.

- The wall section does not include bearing elements,

pipes or electric lines.

We suggest to avoid:

- Sunbeams and nearness to heat sources.

- Damp environments and locations where the unit

might come into contact with water.

- Environment containing oil vapours

- Environment contaminated by high frequencies

The following descriptions of the various phases of

assembly and the related drawings refer to a version of

the machine with connections on the left.

32

Page 33

8.11 Vertically mounted

When mounting on the floor with support feet, refer to

the individual instructions leaflets supplied and the relative

manual for the mounting of the feet.

- Using the paper template, trace the position of the

two fixing brackets on the wall.

- Use a suitable drill to make the holes with and insert

the toggle bolts (2 for each bracket); fix the two

brackets. Do not over-tighten the screws so that the

brackets can be adjusted with a spirit level.

A Toggle bolts B Brackets

- Fully tighten the four screws to block the two brackets.

- Check the stability by manually moving the brackets

to the right and to the left, up and down.

- Mount the unit, checking that it fits correctly onto the

brackets and checking that it is stable.

33

Page 34

8.12 Hydraulic connections

Size 23 45 64 76 94

Pipes

Diameter mm 12 14 16 18 20

The choice and sizing of the hydraulic lines must be made

by an expert who must operate according to the rules of

good technique and the laws in force.

To make the connections:

- Position the hydraulic lines

- Tighten the connections using the “spanner and

counter spanner” method

- Check for any leaks of liquid

- Coat the connections with insulating material.

Accompanying this unit there are two adapters to transform

A

Eurokonus adapter

the 3/4” Eurokonus connections in 3/4” BSP. In this case

use hemp and green paste or similar to seal the threaded

connections; the use of Teflon is advised when there is

anti-freeze in the hydraulic circuit.

The hydraulic lines and joints must be thermally

insulated.

Avoid partially insulating the pipes.

Do not over-tighten to avoid damaging the insulation.

34

Page 35

8.13 Condensation discharge

The condensation discharge network must be suitably

sized and the pipeline positioned so that it keeps a

constant inclination, never less than 1%.

In the vertical installation, the discharge pipe (16 mm

diameter) is connected directly to the discharge tray,

positioned at the bottom of the side shoulder underneath

the hydraulic fixtures.

- If possible, make the condensation liquid flow directly

in a gutter or a “rainwaters” discharge.

- When discharging directly into the main drains, it is

advisable to make a siphon to prevent bad smells

returning up the pipe towards the room. The curve

of the siphon must be lower than the condensation

collection bowl.

- If the condensation needs to be discharged into a

container, it must be open to the atmosphere and

the tube must not be immerged in water to avoid

problems of adhesiveness and counter-pressure that

would interfere with the normal outflow.

- If there is a height difference that could interfere with

the outflow of the condensation, a pump must be

mounted:

- In a vertical installation mount the pump under the

lateral drainage tray;

A

B

Discharge fitting

Pipe for the flow of liquid

Such pumps are commonly found in commerce.

However, on completion of the installation it is advisable

to check the correct outflow of the condensation liquid by

slowly pouring about ½ l of water into the collection tray in

about 5-10 minutes.

Mounting the condensation discharge pipe in the

vertical version

Connect to the condensation collection tray discharge

union a pipe for the outflow of the liquid blocking it

adequately. Check that the drip-collector extension is

present and correctly installed.

Make sure that the machine is installed perfectly level

or with a slight inclination towards the condensation

discharge;

Insulate carefully the inflow and outflow pipes up to

the machine union to prevent any drops of condensation

outside the same collection bowl;

Insulate the bowl condensation discharge pipe along

all of its length.

C

Extension drip

35

Page 36

8.14 Electrical connections

Preliminary instructions

Detailed information on the unit (measurements,

dimensions, fastenings, required distances, etc.) are

shown in the “Technical Data” chapter.

The manufacturer waives all liability for damages

caused by lack of grounding or departure from the

electrical diagrams.

Check that:

- The characteristics of the power supply network shall

be appropriate for the unit’s power requirements,

taking into account also other equipment which might

be operated in parallel.

- Electrical voltage shall be equal to the nominal value

+/- 10%, with a maximum phase unbalance of 3%.

Mandatory items:

- The use of an omnipolar magnetothermic switch,

lockable line disconnector, compliant with CEI-EN

8.15 Filling the system

When starting up the system, make sure that the hydraulic

unit lockshield is open. If there is no electric power and the

thermo-valve has already been powered use the special

cap to press the valve stopper to open it.

standards (contacts open by at least 3 mm), with

adequate disconnection power and differential

protection in compliance with the electrical data table

below, installed next to the unit.

- Ground the unit thoroughly.

Do not use gas and water pipes to ground the unit.

Connection

Make electrical connections according to the

requirements set out in sections General Warnings and

Foundamental Safety Rules by reference to the patterns

present in the installation and accessories manuals.

Before doing any work, make sure the power is

switched off.

36

Page 37

8.16 Evacuation of air when filling system

- Open all the system interception devices (manual or

automatic);

- Start the filling by slowly opening the system water

filling tap;

- For the installed in a vertical position, take a screwdriver

and act on the highest breather of the battery.

8.17 First commissioning

Preliminary instructions

Check that:

- All safety conditions have been fulfilled

- All connections have been made correctly

- The hydraulic test of the circuit and condensate

discharge has been done successfully.

- Grounding has been done correctly.

- All connections have been fastened well.

A Venting of the battery

- When water starts coming out of the breather valves

of the appliance, close them and continue filling until

reaching the nominal value for the system.

Check the hydraulic seal of the gaskets.

It is advisable to repeat these operations after the

appliance has been running for a few hours and periodically

check the pressure of the system.

Start

- Position the unit’s main switch in the “on” position.

- Turn the unit on with the control.

- Check performance in the various modes.

Please consult the instructions for information on how

to use the control.

37

Page 38

A

B

9. MODULATING TEMPERATURE CONTROLLER KIT

9.1

SMART TOUCH electronic control panel

These controls make room temperature adjustment (with

offset settable from the keyboard) completely autonomous

through the AUTO, SILENT, NIGHT and MAX programmes

by means of a probe located in the lower part of the device,

ensuring anti-freeze safety even when set to stand-by.

The control panel has a memory, so settings will not be

lost if the appliance is switched off or in the power supply

is cut.

9.2

Display

After 20 seconds from the last action the panel

brightness will be reduced for improved night-time

comfort, and the room temperature will appear on the

display. Press any key to restore maximum brightness.

The 10 kΩ water temperature probe positioned in the

device battery regulations the minimum level when heating

(30°C) and the maximum level when cooling (20°C).

A Display

B Keys

Any statuses and alarms are also shown on the display by

using 8 specific symbols:

Automatic operation

Silent operation

Maximum ventilation speed

Night-time operation

Heating on

9.3 Key function

The various functions are set using 8 backlit keys:

Temp + is for increasing the set temperature

Temp - is for decreasing the set temperature

Heating / Cooling: for changing the operation

mode between heating and cooling

Sets the regulation ventilation speed between

a minimum and maximum value to an entirely

automatic mode

Cooling on

Supervision on Flashing with presence switch CP

closed.

Alarm indicator (solid light)

Panel off indicator

Resistance active indicator

Night-time operation: limits ventilation speed

to a contained level and the set temperature

is adjusted automatically.

Maximum speed operation: Allows for the

maximum ventilation speed to be set

ON/Stand-By: for activating the device or for

putting it in stand-by.

Silent: limits ventilation speed to a more

contained value

38

Page 39

9.4 General On Switch

In order to manage the device via the control panel, this

must be connected to the mains electricity.

If a general switch is installed on the power line, this must

also be switched on.

- Turn the device on by activating the general

switch.

9.5 Activation

- To activate the device

Key Operation Display

Press the ON Stand-by key

Select one of the 4 operating modes by pressing the relative key.

9.6 Heating/cooling operation modes setting

Key Operation Display

Keep the Heating / Cooling key pressed for approx. 2 seconds to change the mode

between heating and cooling, which is indicated by the 2 symbols that appear if

heating or cooling is active.

When heating, the symbol displays when the set point is higher than ambient

temperature, both are off when the set point is lower.

When cooling, the symbol displays when the set point is lower than ambient

temperature, both are off when the set point is higher.

From off to on

One of the two symbols flashing means that the water

temperature (hot or cold) is not sufficient, and stops

the fan until the temperature reaches a level suitable for

reaching the required temperature.

If after switching the power on the board detects the

H2 probe, start-up occurs in normal conditions with the

minimum and maximum thresholds.

The board also has a function when there is no H2 probe,

in such cases the fan stop thresholds are ignored.

9.7 Stand By

Key Operation Display

Press and hold the ON Stand-By key for approx. 2 seconds. No illuminated signals

on the display at all means that the system is in stand-by (no operation).

When the control is in this operating mode, anti freezing is

in any case guaranteed. If the ambient temperature drops

below 5°C, the solenoid valves on the hot water output

and the boilers are opened.

Off

39

Page 40

9.8 Temperature selection

Key Operation Display

Set the required room temperature using the two increase/decrease keys to set the

temperature value on the 3-digit display.

20.5

The adjustment range is from 16 to 28°C in intervals of

0.5°C, but out-of-range values are also accepted, from

5°C to 40°C (unless in auto mode).

Only set these values for brief periods, and then set a

intermediate value.

The controller is very precise - set it to the required value

and wait for the controller to regulate itself according to the

actual room temperature detected.

9.9 Automatic operation

Key Operation Display

Press and hold the AUTO key. The function being activated is indicated by the

relevant symbol appearing on the display.

Ventilation speed adjustment is carried out automatically

between the minimum and maximum values, according to

the distance of the actual room temperature from the set

point, according to a PI-type algorithm.

9.10 Silent operation

Key Operation Display

Press and hold the Silent key. The function being activated is indicated by the

relevant symbol appearing on the display.

Ventilation speed is limited to a contained maximum value.

9.11 Night-time operation

Key Operation Display

Press and hold the Night-time operation key. The function being activated is

indicated by the relevant symbol appearing on the display.

By selecting this mode, ventilation speed is limited to a

very contained level and the set temperature is adjusted

automatically, as follows:

- decreases by 1°C after one hour and by another

degree after two hours in heating mode;

- increases by 1°C after one hour and by another

degree after two hours in cooling mode;

9.12 Operation at maximum ventilation speed

Key Operation Display

Press and hold the Max Operation key. The function being activated is indicated by

the relevant symbol appearing on the display.

In this operation mode, the maximum possible power level

is activated whether heating or cooling.

Once the desired room temperature is reached, we

recommend selecting one of the other 3 operation modes

for increased comfort and sound levels.

40

Page 41

9.13 Key lock

Key Operation Display

By pressing both the + and - keys for 3 seconds, all keys are locked locally, and

this is indicated by "bL" appearing on the display.

All actions are disabled to the user and whenever any key is pressed, "bL" will

appear. To unlock the keys, repeat the sequence.

9.14 Reduce brightness to minimum

bL

After 20 seconds from the last action, the panel brightness

will be reduced for improved night-time comfort, and the

room temperature will appear on the display.

Key Operation Display

With the display off, press and hold the + key for 5 seconds until "01" is displayed.

Use the - key to change the value to 00 and wait 20 seconds to check the setting

has been accepted.

If this brightness is still disturbing, the display can be

switched off completely.

9.15 Deactivation

Key Operation Display

Press and hold the ON Stand-By key for approx. 2 seconds. No illuminated signals

on the display at all means that the system is in stand-by (no operation).

The controller also ensures anti freezing when in stand-by.

Off

9.16 Room temperature probe regulation offset

As the detection probe is towards the bottom of the

device, the temperature detected may at times differ from

the actual room temperature.

By using this function, the value displayed can be adjusted

in a range from -9/+12 K in intervals of 0.1°C.

Use this adjustment with care, and only after having

actually detected a discrepancy compared with the actual

room temperature using a reliable device!

00

Key Operation Display

With the display off, press and hold the - key for 5 seconds to access the menu

which allows adjustment (using the + and - keys) of the AIR probe offset displayed,

from -9 to +12 K in 0.1 K intervals.

After 20 seconds from the last action, the panel switches off and the setting is

stored.

9.17 Switching off for long periods

When switching off for a season or for holidays, proceed

as follows:

- Deactivate the device

- Turn the general unit switch to off.

- The antifreeze function is not active.

41

00.0

Page 42

9.18 Error signals

Error Display

Faulty room temperature (AIR) probe

Problem with fan motor (e.g. blockage caused by foreign objects, faulty rotation sensor).

Water temperature probe fault for 2-tube versions (H2).

In this case, ensure that the probe installed is 10 kΩ.

Engaging of grill microswitch S1 due to filter cleaning operation

E1

E2

E3

Gr

42

Page 43

A

B

10. 4-SPEED TEMPERATURE CONTROLLER KIT

10.1

LCD electronic control panel

The controller makes the regulation of room temperature

entirely automatic using the set point setting which can be

adjusted between 5°C and 40°C, to one of the 4 speeds

and the summer/winter setting.

As it is connected to the water temperature probe, in

the battery it has the function of detecting the minimum

temperature in winter (30°C) and maximum temperature

in summer (20°C).

The control panel has a memory, so settings will not be lost

if the appliance is switched off or in the power supply is cut.

10.2 LED indications

After 20 seconds from the last action, the panel

brightness will be reduced for improved night-time comfort,

and the room temperature will appear on the display. Press

any key to restore maximum brightness.

A Display

B

Keys and

LEDs

The 6 LEDs display the operational states:

Green symbol minimum speed

Green symbol medimum speed

Green symbol maximum speed

10.3 Key function

The various functions are set using 4 keys:

Temp + is for increasing the set temperature

Temp - is for increasing the set temperature

10.4 General On Switch

In order to manage the fan coil via the control panel, this

must be connected to the mains electricity.

If a general switch is installed on the power line, this must

Green symbol Super silent function

Red symbol heating

Blue symbol cooling

Heating / Cooling: for changing the operation

mode between heating and cooling (2 seconds)

For activating the device, for selecting one of the

4 speeds or for placing in stand-by (2 seconds).

also be switched on.

- Turn the device on by activating the general switch.

43

Page 44

10.5 Activation

To activate the device

Key Operation Display

Press the mode/off key Off → On

Select one of the 4 operating speeds by pressing the relative mode/off key. When

heating, the symbol displays when the set point is higher than ambient temperature,

both are off when the set point is lower. When cooling, the symbol displays when

the set point is lower than ambient temperature, both are off when the set point is

higher.

10.6 Heating/cooling operation modes setting

Key Operation Display

Keep the Heating / Cooling key pressed for approx. 2 seconds to change the mode

between heating and cooling, which is indicated by the 2 symbols that appear if

heating or cooling is active.

One of the two symbols flashing means that the water

temperature (hot or cold) is not sufficient, and stops

the fan until the temperature reaches a level suitable for

reaching the required temperature.

10.7 Stand By

Key Operation Display

Press and hold the mode/off key for approx. 2 seconds. No illuminated signals on

the display at all means that the system is in stand-by (no operation).

10.8 Temperature selection

Key Operation Display

Set the required room temperature using the two increase/decrease keys to set the

temperature value on the 2-digit display.

The adjustment range is from 15 to 30°C in intervals of

1°C, but out-of-range values are also accepted, from 5°C

(Lo) to 40°C (Hi).

Only set these values for brief periods, and then set a

intermediate value.

The controller is very precise - set it to the required value

and wait for the controller to regulate itself according to the

actual room temperature detected.

10.9 Ventilation speed regulation

Key Operation Display

Each time the mode/off button is pressed the fan speed moves between supersilent,

minimum, medium and maximum.

The function being activated is indicated by the relevant symbol appearing on the

display.

On → Off

The super silent setting activates powerful dehumidifying

when cooling and only radiation (with the fan off, and

solenoid valve activated) when heating.

By setting the highest speed, the maximum possible

power level is activated immediately whether heating or

cooling.

Once the desired room temperature is reached, we

recommend selecting one of the other 3 operation modes

for increased comfort and sound levels.

44

Page 45

10.10 Key lock

Key Operation Display

When the increase and decrease keys are pressed simultaneously for 5 seconds,

all keys are locally locked; this is indicated by bL appearing on the display.

All actions are disabled to the user and whenever any key is pressed, "bL" will

appear.

To unlock the keys, repeat the sequence.

10.11 Reduce brightness to minimum

After 20 seconds from the last action, the panel brightness

will be reduced for improved night-time comfort, and the

room temperature will appear on the display.

If this brightness is still deemed to be disturbing, the display

can be switched off completely by pressing the Heating/

Cooling key for 20 seconds until the display shows .

To return to normal minimum brightness, press the

Heating/Cooling button for 20 seconds until the display

shows .

10.12 Deactivation

Key Operation Display

Press and hold the mode/off key for approx. 2 seconds. No illuminated signals on

the display at all means that the system is in stand-by (no operation).

10.13 Switching off for long periods

When switching off for a season or for holidays, proceed

as follows:

- Deactivate the device

- Turn the general unit switch to off.

10.14 Error signals

Off → On

Error Led Display

Faulty room temperature (AIR) probe 6 LEDs flashing (alarm with automatic

reset).

Water temperature probe (H2) positioned in the main battery fault 2 LEDs

flashing (possible manual reset)*.

Problem with fan motor (e.g. blockage caused by foreign objects, faulty

rotation sensor). 4 LEDs flashing simultaneously (alarm with automatic reset).

Water demand (hot or cold) insufficient (above 20°C when cooling, below

30°C when heating).

The LED of the selected function flashes and the fan is stopped until the

water temperature reaches a suitable level to satisfy the demand.

Grill protection micro switch tripped due to accidental opening of the grill or

when filter cleaning is operating.

* If the board detects the water temperature probe on the

device, it starts in normal conditions. If the probe is not

connected, operation can be confirmed without the probe

by pressing the Heating/Cooling key for 5 seconds.

45

E1

E1

E1

o

Gr

Page 46

11. MAINTENANCE

Periodic maintenance is essential to keep the fan coil

always efficient, safe and reliable over time. It must be

11.1 Cleaning the outside

Before every cleaning and maintenance intervention,

disconnect the appliance from the mains by switching

off the master switch.

Wait until the parts have cooled down to avoid the risk

of burns.

11.2 Cleaning air suction filter

After a period of continuous operation and in consideration

of the concentration of impurities in the air, or when he

intends to restart the plant after a period of inactivity,

proceed as described. The periodicity is twice yearly in

normally clean environment.

done at least once a year by a qualified service engineer

Service.

Do not use abrasive sponges or abrasive or corrosive

detergents to avoid damaging the painted surfaces.

When necessary, clean the outer surfaces of the cooler-

convector with a soft cloth damp cloth.

Extraction of filter cells

- Extract the filter, pulling it horizontally outwards.

A Filter

B Lower edge

C

Filter housing

46

Page 47

Cleaning filtering seats

- Suck up the powder with a vacuum cleaner

- Wash the filter with running water without using

detergents or solvents, and leave to dry.

- Remount the filter on the cooler-convector, taking

care to insert the lower flap into its seat.

It is forbidden to use the unit without the net filters.

After finishing the cleaning of the filter, check that the

panel is mounted correctly.

A Filter

B Lower edge

C

Filter housing

11.3 Energy saving tips

- Always keep the filters clean;

- When far possible, keep the doors and windows

closed in the room being conditioned;

- Limit where possible the effect of direct sun rays in the

rooms being conditioned (use curtains, shutters etc.)

47

Page 48

12. TROUBLESHOOTING

In case of water leaks or anomalous functioning

immediately cut off the power supply and close the water

taps.

Should one of the following anomalies occur, contact

Technical Service Assitant or an authorised qualified

person, but do not intervene personally.

12.1 Table of anomalies and remedies

Out of warranty repairs and maintenance can be performed

by Technical Service Assitant or by qualified personnel.

EFFECT CAUSE REMEDY

A delayed activation of

the ventilation respect to

the new temperature or

function settings.

The appliance does not

activate the ventilation.

The ventilation does not

activate even if there is

hot or cold water in the

hydraulic circuit.

The appliance leaks water

during the heating function.

There are formations of

dew on the front panel.

There are drops of water on

the air outlet grill.

The appliance leaks water

only during the cooling

function.

The appliance makes a

strange noise.

The circuit valve needs some time to

open and as a result the hot or cold

water takes time to circulate in the

appliance.

No hot or cold water in the system.

The hydraulic valve remains closed

The fan motor is blocked or burnt out.

The micro-switch that stops the

ventilation when the filter grill is opened

does not close correctly.

The electrical connections are not

correct.

Leaks in the hydraulic connections of

the system.

Leaks in the valve unit. Check the state of the gaskets.

Thermal insulation unstuck.

In situations of high humidity (>60%)

condensation could form, especially at

the minimum ventilation speeds.

The condensation bowl is blocked. Slowly pour a bottle of water in the low part of the

The condensation discharge does not

need an inclination for correct drainage.

The connection pipes and the valve unit

are not insulated well.

The fan touches the structure.

The fan is unbalanced.

Check the clogging of filters and clean

them if necessary.

- The ventilation does not activate even if there is hot or

cold water in the hydraulic circuit.

- The appliance leaks water during the heating function.

- The appliance leaks water only during the cooling

function.

- The appliance makes an excessive noise.

- There are formations of dew on the front panel.

Wait for 2 or 3 minutes to open the circuit valve.

Check that the water boiler or cooler are

functioning correctly.

Dismount the valve body and check if the water

circulation is restored.

Check the working efficiency of the valve by

powering it separately with 230V. If it activates

the problem could be the electronic control.

Check the windings of the motor and thefree

rotation of the fan.

Check that by closing the grill the micro-switch

contact is activated.

Check the electrical connections.

Check the leak and fully tighten the connections.

Check the correct positioning of the thermoacoustic

insulation paying attention to that in the front above

the finned battery.

As soon as the humidity starts falling the

phenomenon disappears. In any case the presence

of a few drops of water in the appliance does not

indicate a malfunction.

battery to check the drainage; if necessary, clean

the bowl and/or increase the inclination of the

drainage pipe.

Check the insulation of the pipes.

Check the clogging of filters and clean them if

necessary.

The unbalancing causes excessive vibrations of the

machine; replace the fan.

Clean the filters.

48

Page 49

495051

Page 50

Page 51

Page 52

immergas.com

Immergas S.p.A.

42041 Brescello (RE) - Italy

Tel. 0522.689011

Fax 0522.680617

Certied company ISO 9001

is instruction booklet is made of ecological paper Cod. 1041956ENG - rev. ST003596/000 - 04/18 - Inglese per IRLANDA (IE)

Loading...

Loading...