Immergas DIM 2 ZONE ErP, DIM 3 ZONE ErP, DIM H-2LT ERP, DIM A-2BT ErP, DIM H-LT ERP Instructions And Warnings

...Page 1

Instructions and warnings

*1.039170ENG*

IE

ERP

MULTI-SYSTEM

DISTRIBUTION

MANIFOLD

DIM 2 ZONE ERP

DIM 3 ZONE ERP

DIM H-LT ERP (1 high-

temperature area 1 low-

temperature zone)

DIM H-2LT ERP (1 high-

temperature area 2 low-

temperature zones)

Page 2

Page 3

Dear Customer,

Our compliments for having chosen a top-quality Immergas product, able to assure well-being and safety for a long period of time. As an Immergas customer,

you can also count on a qualied Aer-Sales Service, prepared and updated to guarantee the constant eciency of your products. Read the following pages

carefully: you will be able to draw useful suggestions regarding the correct use of the appliance. By respecting these suggestions, you will no doubt be satised

with your Immergas product.

For assistance and scheduled maintenance, contact Authorised Immergas Aer-Sales centres: they have original spare parts and are specically trained directly

by the manufacturer.

General recommendations

All Immergas products are protected with suitable transport packaging.

e material must be stored in dry environments protected from bad weather.

e instruction book is an integral and essential part of the product and must also be given to the new user in the case of transfer or succession of ownership.

It must be stored with care and consulted carefully, as all of the warnings provide important safety indications for installation, use and maintenance stages.

is instructions manual provides technical information for installing Immergas appliances. As for the other issues related to the installation of appliances

(e.g. safety in the workplace, environmental protection, injury prevention), it is necessary to comply with the provisions of the regulations in force and the

principles of good practice.

In compliance with the legislation in force, the systems must be designed by qualied professionals, within the dimensional limits established by the Law.

Installation and maintenance must be performed in compliance with the regulations in force, according to the manufacturer's instructions and by professionally

qualied sta, intending sta with specic technical skills in the plant sector, as envisioned by the Law.

Improper installation or assembly of the Immergas appliance and/or components, accessories, kit and devices can cause unexpected problems for people, animals

and objects. Read the instructions provided with the product carefully to ensure proper installation.

Maintenance must be carried out by skilled technical sta. e Authorised Aer-Sales Service represents a guarantee in terms of qualications and professionalism.

e appliance must only be destined for the use for which it has been expressly declared. Any other use will be considered improper and therefore potentially

dangerous.

If errors occur during installation, operation and maintenance, due to non-compliance with technical laws in force, standards or instructions contained in

this book (or however supplied by the manufacturer), the manufacturer is excluded from any contractual and extra-contractual liability for any damages and

the appliance warranty is invalidated.

For further information regarding legislative and statutory provisions relative to the installation of gas heat generators, consult the Immergas site at the

following web address: www.immergas.com

CE DECLARATION OF CONFORMITY

(according to ISO/IEC 17050-1)

e company IMMERGAS S.p.A., with registered oce in via Cisa Ligure 95 42041 Brescello (RE), whose design, manufacturing and aer-sales assistance

processes comply with the requirements of standard UNI EN ISO 9001:2008,

e multi-system hydraulic manifolds DIM 2 ZONE ERP, DIM 3 ZONE ERP, DIM H-2LT ERP, DIM H-2LT ERP comply with the following European

Directives and Delegated European regulations:

“Eco-design” Directive 2009/125/EC, “Energy labelling” Directive 2010/30/EC, EU Regulation 811/2013, EU Regulation 813/2013, “Electromagnetic

Compatibility” Directive 2004/108/EC, “Eciency” Directive 92/42/EC and “Low-Voltage” Directive 2006/95/EC.

Immergas S.p.A. declines all liability due to printing or transcription errors, reserving the right to make any modications to its technical and commercial

documents without prior notice.

DECLARES that:

Mauro Guareschi

Research & Development Director

Signature:

Page 4

INDEX

USER pageINSTALLER page MAINTENANCE TECHNICIAN page

1 Installing the device ....................................5

1.1 Description of the device. .......................... 5

1.2 Installation recommendations. ................. 5

1.3 Main dimensions. ......................................6

1.4 Hydraulic connection. ................................7

1.5 Electrical connection. ................................7

1.6 Installation layouts......................................8

1.7 Commissioning the device. .....................10

1.8 Circulation pump......................................10

1.9 Sizing the systems. ....................................10

1.10 Kits available on request. .........................10

1.11 Main components. ....................................12

2 Use and maintenance instructions .........14

2.1 General warnings. ..................................... 14

2.2 Warnings for the user. ..............................14

2.3 Cleaning the case. ..................................... 14

3 Checks and maintenance .........................15

3.1 Wiring diagram DIM 2 zone ErP. ........... 16

3.2 Wiring diagram DIM 3 zone ErP. ........... 17

3.3 DIM H-LT ErP Wiring diagram. ............18

3.4 DIM H-2LT ErP Wiring diagram. ..........19

3.5 DIM connection to boiler via IMG BUS. 20

3.6 DIM connection to boiler via zone

signal state..................................................21

3.7 DIM connections to ON/OFF room

thermostats. ...............................................22

3.8 DIM connections to ON/OFF room

thermostats and C.A.R.V2 /

SUPER C.A.R. remote controls. ..............24

3.9 DIM connections to ON/OFF room

thermostats and C.A.R.V2 or C.A.R

Universal remote control. ........................24

3.10 Connection between 2 DIM with

hydraulics in parallel. ...............................25

3.11 DIM connection to another DIM

or to Hercules zone kit with

hydraulics in series. ..................................27

3.12 Description of main functions. ...............28

3.13 Zone management P.C.B. ......................... 28

3.14 External temperature probe (Optional). 29

3.15 Troubleshooting. .......................................29

3.16 Technical data. ..........................................30

Page 5

INSTALLING

1

THE DEVICE

1.1 DESCRIPTION OF THE DEVICE.

e “DIM” code (Disgiuntore Idrico Multi-impianti) identies a series of kits that Immergas

proposes for the management of mixed zone

central heating systems with large water capacities. In particular, they are kits that can only

be coupled with some boiler models in the

Immergas range, including an open manifold

(distribution manifold) and are available in four

dierent congurations:

• DIM 2 zones ErP, to be used to manage systems

divided into 2 zones;

• DIM 3 zones ErP, to be used to manage systems

divided into 3 zones;

• DIM H-LT ErP, for the management of mixed

systems with dierentiated temperature (e.g. a

zone with radiators and one with radiant oor

panels);

• DIM H-2LT ErP, for the management of mixed

systems with dierentiated temperature (e.g. a

zone with radiators and two with radiant oor

panels);

IMPORTANT: the boiler models set up for coupling

with the manifolds are Immergas boilers with P.C.B.

designed for the management of zone systems.

ese kits are characterised by the possibility

to be recessed into the wall, therefore they have

no clearance.

Each zone served by the manifold is managed

by a room chrono-thermostat connected to the

DIM. Whenever envisioned by the boiler, it is

possible to use an Immergas Remote control to

control one of the system zones (successively

called main zone).

1.2 INSTALLATION

RECOMMENDATIONS.

e place of installation of the appliance and

relative Immergas accessories must have suitable

features (technical and structural), such as to allow for (always in safe, ecient and comfortable

conditions):

- installation (according to the provisions of the

technical legislation and technical regulations);

- maintenance operations (including scheduled,

periodic, routine and special maintenance);

- removal (outdoors in the place for loading and

transporting the appliances and components)

as well as their eventual replacement with

appliances and/or equivalent components.

Only professionally qualified companies are

authorised to install the Immergas Multi-System Distribution Manifold. Installation must be

carried out according to regulation standards,

current legislation and in compliance with local

technical regulations and the required technical

procedures. Before installing the device, ensure

that it is delivered in perfect condition; if in

doubt, contact the supplier immediately. Packing

materials (staples, nails, plastic bags, polystyrene

foam, etc.) constitute a hazard and must be

kept out of the reach of children. In the event

of malfunctions, faults or incorrect operation,

turn the device o immediately and contact an

authorised company (e.g. the Authorised Technical Assistance Centre, which has specically

trained sta and original spare parts). Do not

attempt to modify or repair the appliance alone.

Failure to comply with the above implies personal

responsibility and invalidates the warranty.

1-1

3

2

Recess installation.

Perform the masonry work, creating an opening

in the wall suitable to contain the device (See par.

"Main dimensions").

Insert the distribution manifold (1) into its seat,

remembering to open the four support ns (2)

before insertion (Fig. 1-1).

Protect the side edges and the front cover during

recess preparation for the device.

IMPORTANT: the hydraulic and electrical connections must be made within the device unit;

you must therefore position the frame rst and

then perform the connections.

Attention: the recessed frame is not a supporting

structure and cannot replace the piece of wall

removed. It is therefore necessary to check the

correct positioning inside the wall.

Wall-hanging installation.

Fasten the frame to the wall using four expansion

plugs, suitable for the type of wall and weight

of the device (not supplied) and using the four

drilled holes (see Fig. 1-2 pos. X).

Use the fairlead and the sheath-holder (3)

supplied to limit the inltration of water inside

the frame.

INSTALLERUSER

2

1

MAINTENANCE TECHNICIAN

5

Page 6

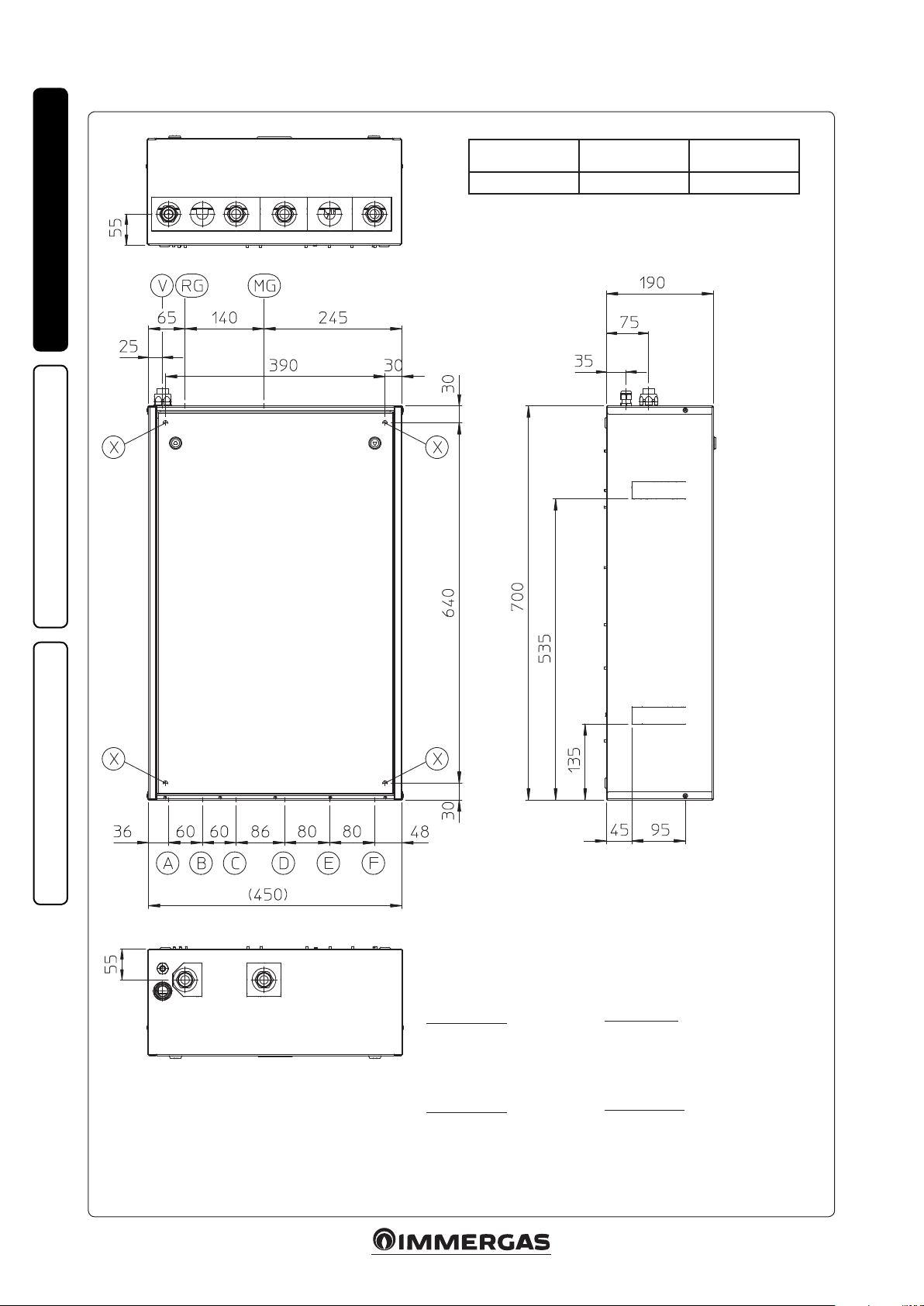

1.3 MAIN DIMENSIONS.

1-2

INSTALLERUSER

Height

(mm)

700 450 190

Width (mm) Depth (mm)

MAINTENANCE TECHNICIAN

Key:

RG - Generator return (G 3/4”)

MG - Generator ow (G 3/4”)

V - Electrical connection

X - Holes for DIM wall-mounted

fastening

DIM 2 Zone ErP

A - Zone return 1 (G 3/4”)

C - Zone return 2 (G 3/4”)

D - Zone ow 2 (G 3/4”)

F - Zone ow 1 (G 3/4”)

DIM 3 Zone ErP

A - Zone return 1 (G 3/4”)

B - Zone return 3 (G 3/4”)

C - Zone return 2 (G 3/4”)

D - Zone ow 2 (G 3/4”)

E - Zone ow 3 (G 3/4”)

F - Zone ow 1 (G 3/4”)

6

DIM H-LT ErP

A - High return temperature (G 3/4”)

B - Low return temperature (G 1”)

E - Low ow temperature (G 1”)

F - High ow temperature (G 3/4”)

DIM H-2LT ErP

A - High return temperature (G 3/4”)

B - Zone 1 low return temperature (G 1”)

C - Zone 2 low return temperature (G 1”)

D - Zone 1 low ow temperature (G 1”)

E - Zone 2 low ow temperature (G 1”)

F - High ow temperature (G 3/4”)

Page 7

1.4 HYDRAULIC CONNECTION.

Attention: before making the appliance connec-

tions, clean the heating system thoroughly (pipes,

radiators, etc.) with special pickling or de-scaling

products to remove any deposits that could

compromise the correct operation of the device.

A chemical treatment of the thermal system water is required, in compliance with the technical

standards in force, in order to protect the system

and the appliance from deposits (e.g., lime scale),

slurry or other hazardous deposits.

e hydraulic connections must be made in a

rational manner using the values as per Fig. 1-2.

IMPORTANT: remove all the protection caps

from the system ow and return pipes before

making the hydraulic connections.

e connections can be made directly using the

female couplings on the distribution manifold

or by inserting system cut-o cocks (optional).

ese cocks are particularly useful for maintenance as they allow you to drain the distribution

manifold separately without having to empty the

entire system.

N.B.: Immergas does not supply the G1” cocks to

be installed in the low-temperature zone.

Check that the expansion vessel in the boiler

allows for the increase in volume of the water

resulting from its central heating without opening the safety valve. If this is not the case, an

expansion vessel with appropriately dimensioned

capacity must be installed on the system.

e DIM is set up for the insertion of the automatic “jolly” vent valve to be mounted on the

manifold. is is recommended for better air

venting inside the system.

If two DIM devices are installed in parallel, two

manual valves must be tted in order to ensure

the correct balance of the hydraulic circuit.

1.5 ELECTRICAL CONNECTION.

e appliance has an IPX5D protection degree;

electrical safety of the appliance is achieved only

when it is connected properly to an ecient

earthing system, as specied by current safety

standards.

Attention: Immergas S.p.A. declines any responsibility for damage or physical injury caused by

failure to connect the boiler to an ecient earth

system or failure to comply with the reference

standards.

Moreover, ensure that the electrical installation

corresponds to the maximum absorbed power

specications as shown on the recessed unit data

plate. e distribution manifold is supplied complete with an “X” type power cable without plug.

e power supply cable must be connected to a

230V ±10% / 50Hz mains supply respecting L-N

polarity and earth connection; this network

must also have a multi-pole circuit breaker with

class III over-voltage category.

To protect from possible dispersions of DC voltage, it is necessary to provide a type A dierential

safety device.

When replacing the power supply cable, contact a

qualied company (e.g. the Immergas Authorised

Aer-Sales Technical Assistance Service).

For the main power supply to the appliance,

never use adapters, multiple sockets or extension leads.

Important: it is mandatory to prepare two electrical connection lines in order to separate the

power supply of each distribution manifold from

all other low-voltage connections, according to

the standards in force regarding electrical systems. ese lines must arrive inside the recessed

frame via relevant sheaths or ducts, passing

through the fairlead and the sheath-holder supplied and located on the upper side of the device.

• Connecting the boiler P.C.B. is connection

(low-voltage) ensures the dialogue between

the boiler and the DIM. Make the connections

as indicated in chapter 3, according to your

appliance model.

N.B.: the electrical connection between the

electronic boards must be made using cables

with a minimum section of 0.50 mm2 and a

maximum section of 2.5 mm2; the length of

these connections must not exceed 15 metres.

• Room thermostat connection On - O. e

room thermostats to be connected to the DIM

must have a potential free contact. e On-O

room thermostats relative to the zones must be

connected as indicated in Fig. 3-8 or 3-9.

• Immergas remote control connection.

Connect the remote controls as indicated in

gures 3-11, 3-12 and as specied in the boiler

instruction manual.

• External probe connection (optional). e

external probe controls the ow temperature of

the system and varies the operation mode and

controlled zones depending on its connection

(see par. 3.14).

- e external probe must be connected to

the boiler by connecting the manifold and

the boiler via IMG BUS. (fig. 3-5). The

temperature read by the external probe is

sent to the manifold via bus. e manifold

will then adjust the ow temperature of the

various zones, according to the settings of the

trimmer and area management probe.

- e external probe must be connected to

the manifold by connecting the manifold

and boiler via signal state. is way, it will

be possible to adjust the ow temperature of

the mixed zones. In these conditions, another

probe must be connected to the boiler if it is

necessary to correlate the direct zone ow

with the external temperature (see Fig. 3-6).

INSTALLERUSER

MAINTENANCE TECHNICIAN

7

Page 8

1.6 INSTALLATION LAYOUTS.

If you are using a Comando Amico Remoto V2

(C.A.R.V2) or Super C.A.R. zone control remote

control, it must be connected directly to the

boiler (see instructions in boiler manual). e

chrono-thermostat will control the pre-dened

zone on the manifold as the main zone.

e C.A.R.V2 or Super C.A.R. remote control

must be set with on-o operation (see the relative

instruction manual).

In this case, the T.A. electric connections of the

zone, dened as the main zone of the manifold,

must be le free.

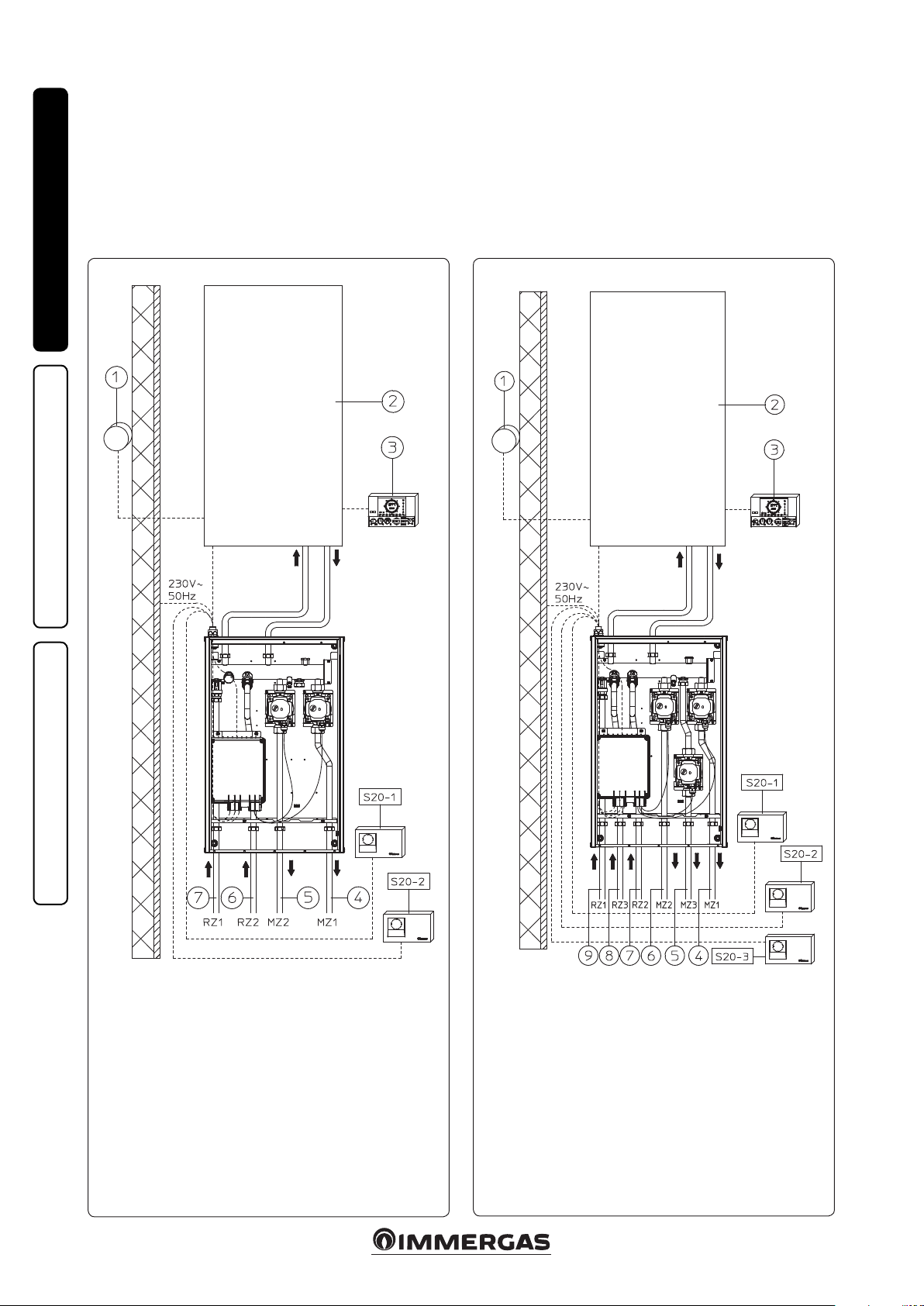

Installation layout of 2 homogeneous zones. Installation layout with 3 zones in High Temperature or 3 zones in Low

INSTALLERUSER

1-3

Temperature.

1-4

MAINTENANCE TECHNICIAN

Key:

S20-1 - Room thermostat zone 1

S20-2 - Room thermostat zone 2

1 - External probe (optional)

2 - Boiler

3 - Comando Amico RemotoV2 or Super C.A.R. remote control

(optional)

4 - Flow to zone 1 system

5 - Flow to zone 2 system

6 - Return from zone 2 system

7 - Return from zone 1 system

Factory settings dene zone 1 as the main zone.

(See g. 3-1 for electrical connection and zone board setting)

Key:

S20-1 - Room thermostat zone 1

S20-2 - Room thermostat zone 2

S20-3 - Room thermostat zone 3

1 - External probe (optional)

2 - Boiler

3 - Comando Amico RemotoV2 or Super C.A.R. remote control

(optional)

4 - Flow to zone 1 system

5 - Flow to zone 3 system

6 - Flow to zone 2 system

7 - Return from zone 2 system

8 - Return from zone 3 system

9 - Return from zone 1 system

Factory settings dene zone 1 as the main zone.

(See g. 3-2 for electrical connection and zone board setting)

8

Page 9

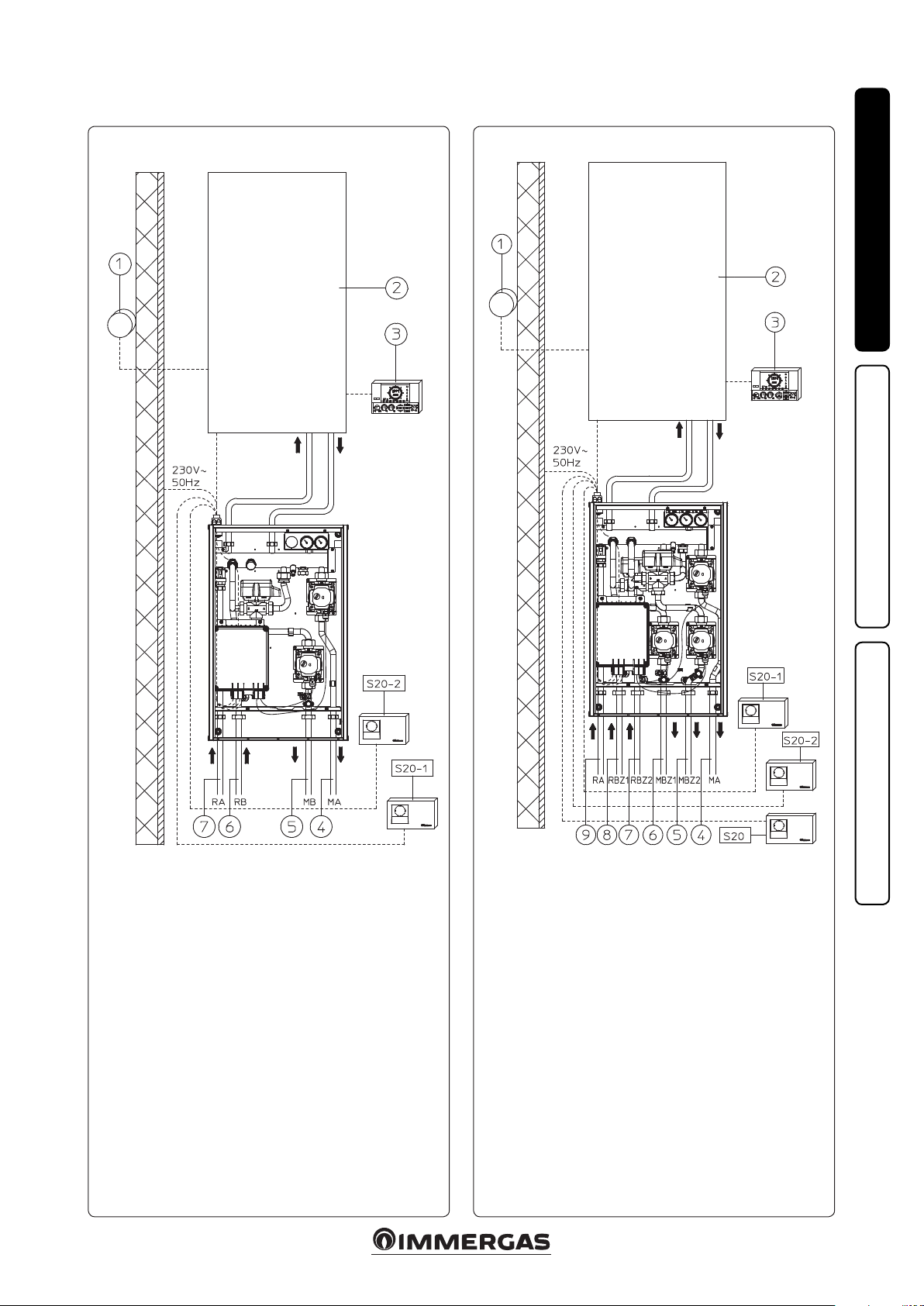

DIM A-BT installation layout (1 zone in H. T. and 1 zone in L. T.).

DIM H-2LT installation layout (1 zone in H. T. and 2 zone in L. T.).

1-5 1-6

INSTALLERUSER

Key:

S20-1 - Zone 1 room thermostat (high temperature)

S20-2 - Zone 2 room thermostat (low temperature)

1 - External probe (optional)

2 - Boiler

3 - Comando Amico RemotoV2 remote control (optional)

4 - High-temperature system ow

5 - Low-temperature system ow

6 - Return from Low-Temperature system

7 - High-temperature system return

Factory settings dene zone 2 as the main zone.

(See g. 3-3 for electrical connection and zone board setting)

Key:

S20 - High-temperature zone room thermostat

S20-1 - Low-temperature zone 1 room thermostat

S20-2 - Low-temperature zone 2 room thermostat

1 - External probe (optional)

2 - Boiler

3 - Comando Amico RemotoV2 remote control (optional)

4 - High-temperature system ow

5 - Zone 2 Low-Temperature system ow

6 - Zone 1 Low-Temperature system ow

7 - Zone 2 Low-Temperature system return

8 - Zone 1 Low-Temperature system return

9 - High-temperature system return

Factory settings dene zone 2 as the main zone.

(See g. 3-4 for electrical connection and zone board setting)

9

MAINTENANCE TECHNICIAN

Page 10

1.7 COMMISSIONING THE DEVICE.

System lling. Once the device is connected, ll

the system via the boiler lling valve.

Filling is performed at low speed to ensure the

release of air bubbles in the water via the boiler

and central heating system vents and the distribution manifold (if any).

Close radiator vent valves when only water

escapes from them.

Close the lling cock when the boiler pressure

gauge indicates approx. 1.2 bar.

IMPORTANT: during these operations, start

INSTALLERUSER

the circulation pumps by acting on the main

switch positioned on the boiler control panel

aer having activated the T.A. devices relating

to the various zones.

(Only for DIM H-LT and H-2LT).

Act manually on the 3-way mixing vale using the

relevant lever on the electric actuator, keeping the

same opening in order to de-aerate the system

and, if necessary, control the correct operating

pressure.

Once these operations are complete, make sure

that the lever on the electric actuator is free from

the manual lock position.

1.8 CIRCULATION PUMP.

e pump is ideal for the requirements of each

central heating system in a domestic and residential environment. In fact, the pump is equipped

with electronic control that allows you to set

advanced functions.

Adjustments. Turn the selector and position it on

the desired curve to adjust the circulator pump.

Program LED

P 1 lower (ΔP-V)

P 2 upper (ΔP-V)

C 3 lower (ΔP-C) - H=3 m

C 4 upper (ΔP-C) - H=4 m

Min. - Max. blue

MAINTENANCE TECHNICIAN

green

orange

- Program P (1 lower 2 upper ) (P-V) - Pro-

portional curve (green LED). This allows

the pressure level (head) to be proportionally

reduced as the system heat demand decreases

(ow rate reduction). anks to this function,

the electric power consumption of the circulator pump is reduced further: the energy

(power) used by the pump decreases according to the pressure level and ow rate. With

this setting, the pump guarantees optimal

performance in most heating systems, thereby

being particularly suitable in single-pipe and

two-pipe installations. Any noise originating

from the water ow in the pipes, valves and

radiators is eliminated by reducing the head.

Optimal conditions for thermal comfort and

acoustic well-being.

- Programs C (3 lower 4 upper ) (P-C) Constant curve (orange LED). e circulator

pump maintains the pressure level (head)

constant as the system heat demand decreases

(ow rate reduction). With these settings, the

circulator pump is suitable for all oor systems

where all the circuits must be balanced for the

same drop in head.

- MIN. - MAX. program (blue LED). e pump

is distinguished by adjustable operating curves

by positioning the selector in any point between

the Min. and Max. positions, thereby satisfying

any installation requirement (from a simple

single-pipe to more modern and sophisticated

systems) and always guaranteeing optimum

performance. e precise working point can be

selected in the entire eld of use by gradually

adjusting the speed.

Real-time diagnostics: a lit LED (in various

colours) provides information regarding the

pump operating status, see g. 1-7

Possible pump release. The pump block is

indicated by a xed red LED switching on. Turn

the selector up to the MAX. position, disconnect

and reconnect the power to restart the automatic

release process. e pump will then activate the

procedure, which will last for a maximum of

15 minutes and the LED will ash upon each

restart. It then turns blue for a few seconds and

goes back to red if the attempt to restart is not

successful. Once the process is complete, position

the selector back on the desired curve and if the

problem has not been resolved, perform the

manual release procedure as described below.

- Disconnect the power to the boiler (the LED

switches o).

- Close the system ow and return and allow the

pump to cool down.

- Empty the system circuit via the relative cock.

- Remove the motor and clean the impeller.

- Once unblocked, remount the motor.

- Fill the primary circuit; restore boiler power

and set the desired curve.

Attention: a scalding hazard is present due to

high uid temperatures and pressures. Scalding

hazard as a result of contact.

1.9 SIZING THE SYSTEMS.

e ow temperatures to the various system

zones may be reduced with respect to the boiler

outlet temperatures, according to the mixture

of the ow and return uids inside the DIM. In

the event that the DIM is used to feed Low-Temperature zones, check that the design parameters

allow you to achieve a maximum surface temperature of the radiant oor in compliance with

standard UNI EN 1264.

1.10 KITS AVAILABLE ON REQUEST.

• System cut-o cock kit (on request). e manifold is designed for the installation of system

interception cocks, to be placed on the ow

and return pipes of the connection assembly.

is kit is particularly useful for maintenance

as it allows the DIM to be drained separately

without having to empty the entire system.

• External probe kit.

• Safety thermostat kit.

• By pass kit for H-LT and H-2LT. versions.

e above-mentioned kits are supplied complete

with instructions for assembly and use.

Circulating pump

LED

LED steady on

Flashing white LED Noises during cir-

LED steady on Flow rate too high Reduce rotation speed

LED o

Red LED

Description Diagnostics Remedy

Pump

noisy

culation of the heat

transfer uid

e circulator does

not work

Insucient system pressure, circulating pump

in cavitation

Presence of foreign matter in the impeller Remove the motor and clean the impeller

Presence of air in the system Vent the system

Power outage

Faulty circulating pump Replace the circulating pump

Rotor seized Remove the motor and clean the impeller

Insucient power supply voltage Check boiler power supply voltage

Restore correct thermal circuit pressure

Ensure the boiler is correctly powered, ensure

the circulator is correctly powered

10

1-7

Page 11

Head available to the direct zone system xed speed.

High-temperature zone

1-8

A

Head (kPa)Head (kPa)

Low-temperature zone

A

MAX

Flow rate (l/h)

MAX

Flow rate (l/h)

MIN

MIN

Key:

A = Available head

B

B = Power absorbed by the circulator

pump (dotted area)

INSTALLERUSER

Circulator pump absorbed power (W)Circulator pump absorbed power (W)

B

Head available to the direct zone system proportional or constant speed.

High-temperature zone

C

D

Head (kPa)Head (kPa)

I

Flow rate (l/h)

Low-temperature zone

C

D

E

I

G

H

E

L

F

G

H

L

F

Key:

C = Head available to the system with circula-

tor pump selector in position C4 (standard

setting)

D = Head available to the system with circula-

tor pump selector in position C3

E = Head available to the system with circula-

tor pump selector in position P2

F = Head available to the system with circula-

tor pump selector in position P1

G = Circulator pump power with selector in

position C4 (standard setting)

H = Circulator pump power with selector in

Circulator pump absorbed power (W)Circulator pump absorbed power (W)

position C3

I = Circulator pump power with selector in

position P2

L = Circulator pump power with selector in

position P1

1-9

MAINTENANCE TECHNICIAN

Flow rate (l/h)

11

Page 12

1.11 MAIN COMPONENTS.

INSTALLERUSER

DIM 2 Zone

1-10

Key:

1 - Hydraulic manifold

2 - Drain tting

3 - Zone 1 pump

4 - Electrical connection box

5 - Zone 1 ''Europa'' one-way valve

6 - Zone 2 pump

7 - Zone 2 ''Europa'' one-way valve

MAINTENANCE TECHNICIAN

DIM 3 Zone

1-11

Key:

1 - Hydraulic manifold

2 - Drain tting

3 - Zone 1 pump

4 - Electrical connection box

5 - Zone 1 ''Europa'' one-way valve

6 - Zone 2 pump

7 - Zone 3 pump

8 - Zone 3 ''Europa'' one-way valve

9 - Zone 2 ''Europa'' one-way valve

12

Page 13

DIM A-BT

1-12

INSTALLERUSER

Key:

1 - Flow temperature thermometers

2 - Hydraulic manifold

3 - Drain tting

4 - Zone 1 pump

5 - Zone 2 ow probe

6 - Zone 2 safety thermostat

7 - Electrical connection box

8 - Zone 2 3-way mixing valve

9 - Zone 2 mixing valve motor

10 - Zone 2 pump

11 - Zone 1 "Europa" one-way valve

DIM 1 zone H-2LT

Key:

1 - Flow temperature thermometers

2 - Hydraulic manifold

3 - Drain tting

4 - High-temperature zone pump

5 - Zone 2 low-temperature safety thermo-

stat

6 - Zone 2 low-temperature ow probe

7 - Electrical connection box

8 - Low-temperature zone 1 3-way mixing

valve

9 - Low-temperature zone 1 mixing valve

motor

10 - Low-temperature zone 2 3-way mixing

valve

11 - Low-temperature zone 1 safety thermo-

stat

12 - Low-temperature zone 1 ow probe

13 - Low-temperature zone 1 circulator

14 - High-temperature zone "Europa" one-

way valve

15 - Low-temperature zone 2 mixing valve

motor

16 - Low-temperature zone 2 circulator

1-13

MAINTENANCE TECHNICIAN

13

Page 14

USE AND MAINTENANCE

2

INSTRUCTIONS

2.1 GENERAL WARNINGS.

If the device must be deactivated temporarily,

act directly on the main switch to power o the

system and work safely

• Attention: using any components that use

electrical power requires the observation of

some fundamental rules:

- do not touch the device with wet or moist parts

INSTALLERUSER

of the body; do not touch when barefoot.

- if the device is wall-mounted: do not pull the

electric cables, do not leave the device exposed

to the elements (rain, sun, etc.);

- the device power cable must not be replaced by

the user;

- in the event of damage to the cable, switch the

device o and exclusively contact professionally

qualied sta for replacement;

- if the device is not going to be used for a certain

period, disconnect the main power switch.

2.2 WARNINGS FOR THE USER.

is device does not require any regulation or

control by the user; the opening of the device front

lid is therefore prohibited.

e only operation that the user must perform is

that of periodically checking the water pressure of

the system in the boiler. e boiler pressure gauge

should read a value of between 1 and 1.2 bar.

If the pressure is below 1 bar (with the circuit cool),

restore normal pressure via the lling v alve located

in the boiler (see boiler instruction book).

N.B.: close the valve aer the operation.

If pressure values reach around 3 bar, the boiler

safety valve may be activated.

In this case, remove water from a radiator air

vent valve until a pressure of 1 bar is achieved,

or ask for assistance from professionally qualied

personnel.

In the event of frequent pressure drops, contact

qualied sta for assistance to eliminate any

system leakage.

At the end of its service life, the appliance must

not be disposed of like normal household waste

nor abandoned in the environment, but must

be removed by a professionally authorised

company. Contact the manufacturer for disposal

instructions.

MAINTENANCE TECHNICIAN

2.3 CLEANING THE CASE.

Use damp cloths and neutral detergent to clean

the manifold casing. Never use abrasive or powder detergents.

14

Page 15

CHECKS AND

3

MAINTENANCE

- Check connection to a 230V-50Hz power

mains via an omni-polar disconnector (magnetothermal circuit breaker), correct L-N polarity

and the earthing connection;

- check that the magnetothermal circuit breaker

is working properly;

- make sure the central heating system is lled

with water and that the pressure gauge indicates

a pressure of 1-1.2 bar;

- make sure that the air valve cap (if present)

is open and that the system is appropriately

de-aerated;

- check the activation of the main switch located

upstream of the appliance;

- check the sealing eciency of water circuits;

- check the correlation between the electric and

hydraulic connections;

- (only for DIM H-LT or H-2LT) with request

for heat in the mixed zones, check the correct

opening and closure of the mixing valve,

opening the latter to check the system safety

thermostat intervention (the boiler ow temperature must be set over 60 °C).

Even if just one single safety check provides a

negative result, do not commission the system.

INSTALLERUSER

15

MAINTENANCE TECHNICIAN

Page 16

3.1 WIRING DIAGRAM DIM 2 ZONE ERP.

Power supply

230 Vac 50 Hz

Y./G.

Brown

Grey Blue

Black

INSTALLERUSER

3-1

Blue

Blue

MAINTENANCE TECHNICIAN

Blue

Brown

Y./G.

ZONES

CONTROL UNIT

Black

Red

CONNECTION

TO DIM SAFETY

THERMOSTAT

Key:

B4 - External probe (optional)

M10-1 - Zone 1 pump

M10-2 - Zone 2 pump

R12 - Zone 2 low-temperature ow

regulation trimmer

R13 - Zone 3 low-temperature ow

regulation trimmer

S25 - Board setting selector

S26 - Board setting selector

S27 - Board setting selector

T2 - Zone control unit low-voltage

feeder

Brown

CONNECTIONS TO ON/

OFF ROOM THERMOSTATS

SWITCH

Brown

OFF ON

BUS IMG CONNECTION

ZONES SIGNAL STATE

INLET FROM BOILER OR

OTHER DIM

CENTRAL HEATING REQUEST

OUTLET TO BOILER

OR OTHER DIM

CENTRAL HEATING REQUEST INLET

FROM OTHER DIM

ZONES SIGNAL STATE OUTLET

FOR OTHER DIM

By connecting the zone control Room ermostats, it is necessary to

eliminate the jumpers in the zones control unit

on terminal board X9.

TO BOILER

Connecting the DIM safety thermostat, it is necessary to

eliminate the jumper on X7.

ZONE CONTROL UNIT SETTINGS

N°

OFF ON

1 Homogeneous zone control Mixed zone control

2 N° 1 mixed zone (Z2) N° 2 mixed zones (Z2 and Z3)

3 MASTER board SLAVE board

4 Main zone = zone 1 Main zone = zone 2

5 Super C.A.R.: main zone ow control Super C.A.R.: system ow control

6

Mixed zones max. temperature =

50°C

Mixed zones max. temperature = 75°C

7 Normal functioning Multi-zone recognition state

8 Not used Not used

Mixed zones minimum temperature

9

= 25°C

Mixed zones minimum temperature

= 35°C

N.B.: the default settings are highlighted in bold.

On connecting the zone control Room ermostats, it is necessary to eliminate the jumpers present in the zone control unit on terminal board X9.

On connecting the DIM safety thermostat, it is necessary to eliminate the jumper on X7.

e zone control C.A.R.V2 or Super C.A.R. remote

control must be connected directly to the boiler

and it will control Zone 1, which is pre-set as the

main zone on the manifold set as the Master (see

are used, the chrono-thermostat must be set with

on-o operation (see instructions in the relative

booklet). The H.T. electric connections controlled by the chrono-thermostat must be free.

table above). In the event that two or more zones

16

Page 17

3.2 WIRING DIAGRAM DIM 3 ZONE ERP.

Power supply

230 Vac

50 Hz

Blue

Brown

Grey

Black

Blue

3-2

Blue

Blue

INSTALLERUSER

Blue

Brown

Y./G.

ZONES

CONTROL UNIT

Black

Red

CONNECTION

TO DIM SAFETY

THERMOSTAT

Key:

B4 - External probe (optional)

M10-1 - Zone 1 pump

M10-2 - Zone 2 pump

M10-2 - Zone 3 circulator

R12 - Zone 2 low-temperature ow

regulation trimmer

R13 - Zone 3 low-temperature ow

regulation trimmer

S25 - Board setting selector

S26 - Board setting selector

S27 - Board setting selector

T2 - Zone control unit low-voltage

feeder

Brown

CONNECTIONS TO ON/

OFF ROOM THERMOSTATS

SWITCH

Brown

Brown

OFF ON

BUS IMG CONNECTION

ZONES SIGNAL STATE

INLET FROM BOILER OR

OTHER DIM

CENTRAL HEATING REQUEST

OUTLET TO BOILER

OR OTHER DIM

CENTRAL HEATING REQUEST INLET

FROM OTHER DIM

ZONES SIGNAL STATE OUTLET

FOR OTHER DIM

By connecting the zone control Room ermostats, it is necessary to

eliminate the jumpers in the zones control unit

on terminal board X9.

TO BOILER

Connecting the DIM safety thermostat, it is necessary to

eliminate the jumper on X7.

ZONE CONTROL UNIT SETTINGS

N°

OFF ON

1 Homogeneous zone control Mixed zone control

2 N° 1 mixed zone (Z2) N° 2 mixed zones (Z2 and Z3)

3 MASTER board SLAVE board

4 Main zone = zone 1 Main zone = zone 2

5 Super C.A.R.: main zone ow control Super C.A.R.: system ow control

6

Mixed zones max. temperature =

50°C

Mixed zones max. temperature = 75°C

7 Normal functioning Multi-zone recognition state

8 Not used Not used

Mixed zones minimum temperature

9

= 25°C

Mixed zones minimum temperature

= 35°C

MAINTENANCE TECHNICIAN

N.B.: the default settings are highlighted in bold.

On connecting the zone control Room ermostats, it is necessary to eliminate the jumpers present in the zone control unit on terminal board X9.

On connecting the DIM safety thermostat, it is necessary to eliminate the jumper on X7.

e zone control C.A.R.V2 or Super C.A.R. remote

control must be connected directly to the boiler

and it will control Zone 1, which is pre-set as the

main zone on the manifold set as the Master (see

are used, the chrono-thermostat must be set with

on-o operation (see instructions in the relative

booklet). The H.T. electric connections controlled by the chrono-thermostat must be free.

table above). In the event that two or more zones

17

Page 18

3.3 DIM HLT ERP WIRING DIAGRAM.

Power supply

230 Vac

50 Hz

Blue

Brown

Grey

Black

INSTALLERUSER

Y./G.

Blue

Brown

Red

Black

Red

Blue

ZONES

CONTROL UNIT

Red

Red

CONNECTION

TO DIM SAFETY

THERMOSTAT

Blue

Brown

CONNECTIONS TO ON/

OFF ROOM THERMOSTATS

3-3

Black

Red

Orange

Brown

OFF ON

BUS IMG CONNECTION

ZONES SIGNAL STATE

INLET FROM BOILER OR

OTHER DIM

CENTRAL HEATING REQUEST

OUTLET TO BOILER

OR OTHER DIM

CENTRAL HEATING REQUEST INLET

FROM OTHER DIM

ZONES SIGNAL STATE OUTLET

FOR OTHER DIM

By connecting the zone control Room ermostats, it is necessary

to eliminate the jumpers in the zones control unit

TO BOILER

Connecting the DIM safety thermostat, it is necessary to

on terminal board X9.

eliminate the jumper on X7.

Key:

B4 - External probe (optional)

B3-2 - Zone 2 low-temperature ow

probe

E7-2 - Zone 2 low-temperature safety

thermostat

M10-1 - Zone 1 pump

M10-2 - Zone 2 pump

M31-2 - Mixing valve zone 2

R12 - Zone 2 low-temperature ow

MAINTENANCE TECHNICIAN

R13 - Zone 3 low-temperature ow

regulation trimmer

regulation trimmer

S25 - Board setting selector

S26 - Board setting selector

S27 - Board setting selector

T2 - Zone control unit low-voltage

feeder

On connecting the zone control Room ermostats, it is necessary to eliminate the jumpers present in the zones control unit on terminal board X9.

On connecting the DIM safety thermostat, it is necessary to eliminate the jumper on X7.

e zone control C.A.R.V2 or Super C.A.R. remote

control must be connected directly to the boiler

and it will control Zone 2, which is pre-set as the

main zone on the manifold set as the Master (see

table above). In the event that two or more zones

ZONE CONTROL UNIT SETTINGS

N°

SWITCH

OFF ON

1 Homogeneous zone control Mixed zone control

2 N° 1 mixed zone (Z2) N° 2 mixed zones (Z2 and Z3)

3 MASTER board SLAVE board

4 Main zone = zone 1 Main zone = zone 2

5 Super C.A.R.: main zone ow control Super C.A.R.: system ow control

6

Mixed zones max. temperature =

50°C

Mixed zones max. temperature = 75°C

7 Normal functioning Multi-zone recognition state

8 Not used Not used

Mixed zones minimum temperature

9

= 25°C

Mixed zones minimum temperature

= 35°C

N.B.: the default settings are highlighted in bold.

are used, the chrono-thermostat must be set with

on-o operation (see instructions in the relative

booklet). The H.T. electric connections controlled by the chrono-thermostat must be free.

18

Page 19

3.4 DIM H2LT ERP WIRING DIAGRAM.

Power supply

230 Vac

50 Hz

Blue

Brown

Grey

Black

Blue

3-4

Blue

Blue

Black

Black

INSTALLERUSER

Y./G.

Blue

Brown

ZONES

CONTROL UNIT

Red

Red

Red

Black

Black

Black

Black

Red

Black

CONNECTION

TO DIM SAFETY

THERMOSTAT

Key:

B4 - External probe (optional)

B3-2 - Zone 2 low-temperature ow

probe

B3-3 - Zone 3 low-temperature ow

probe

E7-2 - Zone 2 low-temperature safety

thermostat

E7-3 - Zone 3 low-temperature safety

thermostat

M10-1 - Zone 1 pump

M10-2 - Zone 2 pump

M10-2 - Zone 3 circulator

M31-2 - Mixing valve zone 2

M31-3 - Zone 3 mixing valve

R12 - Zone 2 low-temperature ow

regulation trimmer

R13 - Zone 3 low-temperature ow

regulation trimmer

S25 - Board setting selector

S26 - Board setting selector

S27 - Board setting selector

T2 - Zone control unit low-voltage

feeder

Brown

Orange

Brown

Brown

CONNECTIONS TO ON/

OFF ROOM

THERMOSTATS

Red

Red

Orange

OFF ON

ZONES SIGNAL STATE

INLET FROM BOILER OR

OTHER DIM

ZONE CONTROL UNIT SETTINGS

N°

SWITCH

OFF ON

1 Homogeneous zone control Mixed zone control

2 N° 1 mixed zone (Z2) N° 2 mixed zones (Z2 and Z3)

3 MASTER board SLAVE board

4 Main zone = zone 1 Main zone = zone 2

5 Super C.A.R.: main zone ow control Super C.A.R.: system ow control

6

Mixed zones max. temperature =

50°C

7 Normal functioning Multi-zone recognition state

8 Not used Not used

Mixed zones minimum temperature

9

= 25°C

N.B.: the default settings are highlighted in bold.

CENTRAL HEATING REQUEST

OUTLET TO BOILER

OR OTHER DIM

CENTRAL HEATING REQUEST INLET

FROM OTHER DIM

ZONES SIGNAL STATE OUTLET

By connecting the zone control Room ermostats, it is necessary

to eliminate the jumpers in the zones control unit

BUS IMG CONNECTION

TO BOILER

Connecting the DIM safety thermostat, it is necessary to

FOR OTHER DIM

on terminal board X9.

eliminate the jumper on X7.

MAINTENANCE TECHNICIAN

Mixed zones max. temperature = 75°C

Mixed zones minimum temperature

= 35°C

On connecting the zone control Room ermostats, it is necessary to eliminate the jumpers present in the zones control unit on terminal board X9.

On connecting the DIM safety thermostat, it is necessary to eliminate the jumper on X7.

e zone control C.A.R.V2 or Super C.A.R. remote

control must be connected directly to the boiler

and it will control Zone 2, which is pre-set as

the main zone on the manifold. e H.T. electric

connections controlled by the chrono-thermostat

N.B.: in systems that require a high-temperature

mixed zone (by setting switch 6), it is necessary

to remove the relative safety thermostat at 55 °C

in the controlled zone and carry out a jumper on

the free terminals. Perform this operation with

the utmost care and only when it is necessary.

must be free.

19

Page 20

3.5 DIM CONNECTION TO BOILER VIA IMG BUS.

ONLY FOR BOILERS SET UP FOR DIGITAL COMMUNICATION WITH ZONE CONTROL UNIT.

ZONES CONTROL UNIT DIM V2

INSTALLERUSER

Eliminate the jumper on terminal board X15 of the

integrated P.C.B.

SUPERIOR KW INTEGRATED P.C.B.

3-5

MAINTENANCE TECHNICIAN

Blue

Brown

Y./G.

Power supply

230 Vac

External probe

50 Hz

(optional)

N.B.: In this mode, the remote control cannot be connected to terminals 44 and 41 of the integrated P.C.B.

On boiler models set up for digital communication with the zone control unit, the BUS dialogue can be activated with a wide exchange of

interactions between boiler and DIM, the main ones being:

e DIM will receive the following from the boiler:

- Digital zone state signal;

- Temperatures regulated on display for the Low-Temperature zones (where possible);

- External temperature probe connected to boiler.

e boiler will receive the following from the DIM:

- Zone central heating request;

- Boiler ow temperature correlated to the zones request;

- Error codes of the faults present on the zone control unit.

20

Page 21

3.6 DIM CONNECTION TO BOILER VIA

ZONE SIGNAL STATE.

N.B.: in this connection mode, when the boiler

must be disconnected from the supply voltage,

it is also necessary to power o the manifold.

IMMERGAS MODELS WITH ZONE SIGNAL STATE OUTLET

Terminal 21 allows you to activate the analogue dialogue with a strict exchange of information

between boiler and DIM:

- e DIM receives the zone signal state from the boiler;

- e boiler receives the central heating operation request from the DIM.

- e DIM must be connected to its own external probe (if necessary);

- e DIM low-temperature zone ow temperature must be regulated by its trimmer.

Eliminate the jumper on terminal board X15 of

the integrated P.C.B.

ZONES CONTROL UNIT DIM V2

External probe

(optional)

INTEGRATED P.C.B.

External probe

(optional)

Blue

Brown

Power supply

230 Vac

50 Hz

3-6

INSTALLERUSER

Y./G.

CONNECTION TO GENERAL BOILERS

ZONES CONTROL UNIT DIM V2

3-7

Boiler ignition request:

to terminals 15 and 16 of zones control unit

the potential free contact of the boiler ignition control relay

(230 Vac, 0.5 A max).

e contact is closed with active request.

If the DIM is connected to the boiler without the zone signal state or the IMG BUS dialogue, the

zone pumps are controlled only by the respective room thermostats. In this case, the pumps cannot

be controlled from the boiler, activating them for example for post-circulations or deactivating

them by selecting the “summer” function on the boiler.

e DIM must be connected to its own external probe (if necessary).

e DIM Low-Temperature zone ow temperature must be regulated by its trimmer.

MAINTENANCE TECHNICIAN

External probe

(optional)

21

Page 22

3.7 DIM CONNECTIONS TO ON/OFF ROOM THERMOSTATS.

WIRING DIAGRAM FOR DIM CONNECTION TO ON-OFF ROOM THERMOSTATS.

INSTALLERUSER

Key:

S20-1 - Room thermostat zone 1

S20-2 - Room thermostat zone 2

S20-3 - Room thermostat zone 3

Note: All components represented in this diagram are optional.

3-8

ZONES CONTROL

UNIT DIM V2

AREA CONTROL ROOM

THERMOSTATS

All zones on the DIM can be controlled by the relative room thermostat.

On connecting the room thermostats, it is necessary to eliminate the jumpers present on the X9 terminal board of the zones control unit.

WIRING DIAGRAM FOR DIM CONNECTION TO ON-OFF ROOM THERMOSTATS WITH SHARED ZONES.

ZONES

CONTROL

UNIT DIM V2

AREA PORTION CONTROL ROOM THERMOSTATS

MAINTENANCE TECHNICIAN

AREA CONTROL ROOM

THERMOSTATS

ZONE SHUTTER VALVES WITH MICRO LIMIT SWITCH

Key:

M30-1.1 - Portion valve 1 of zone

M30-1.2 - Portion valve 2 of zone

M30-1.3 - Portion valve 3 of zone

S20-2 - Room thermostat zone 2

S20-3 - Room thermostat zone 3

S20-1.1 - Portion 1 room thermostat of zone

S20-1.2 - Portion 2 room thermostat of zone

S20-1.3 - Portion 3 room thermostat of zone

S30.1 - Portion valve 1 of zone end run micro switch

S30.2 - Portion valve 2 of zone end run micro switch

S30.3 - Portion valve 3 of zone end run micro switch

Note: All components represented in this diagram are

optional.

All zones on the DIM can be controlled by the relative room thermostat, prior to the

elimination of the jumpers on terminal block X9.

e room thermostat contacts can be replaced by those of the end run micro-switches

belonging to other zone valves inserted into the hydraulic circuit downstream from

the zone pumps.

In the case of a single zone (controlled by a unique pump), it is divided into several

portions (controlled by various zone valves); the wiring diagram shown above must

be followed.

3-9

Zone valve supply

voltage

22

Page 23

Example of hydraulic diagram for dividing zone 1 DIM into three portions.

External probe

BOILER

1st DIM V2 3 ZONES

Zones

control unit

DIM V2

(optional)

3-10

INSTALLERUSER

Zone 2 Zone 3

Key

M30-1.1 - Portion valve 1 of zone 1

M30-1.2 - Portion valve 2 of zone 1

M30-1.3 - Portion valve 3 of zone 1

S20-2 - Room thermostat zone 2

S20-3 - Room thermostat zone 3

S20-1.1 - Portion 1 room thermostat of zone 1

S20-1.2 - Portion 2 room thermostat of zone 1

S20-1.3 - Portion 3 room thermostat of zone 1

Portion 1 of

zone 1

Portion 2 of

zone 1

Portion 3 of

zone 1

MAINTENANCE TECHNICIAN

23

Page 24

3.8 DIM CONNECTIONS TO ON/OFF ROOM THERMOSTATS AND C.A.R.V2 / SUPER C.A.R.. REMOTE CONTROLS.

Key:

S20-1 - Zone 1 room thermostat (optional)

S20-3 - Zone 3 room thermostat (optional)

Super C.A.R. Super Comando Amico Remoto remote control

(optional)

Eliminate the jumper on terminal board X15 of

the integrated P.C.B.

INTEGRATED P.C.B.

External

probe

(optional)

is diagram represents an example of the connection of the

Super C.A.R. remote control. It

is possible to connect the Super

C.A.R., (or C.A.R.

control to terminals 42 and 43 and

on all boiler boards suitable for

communicating with their remote

controls (see boiler instruction

INSTALLERUSER

book).

On connecting the zone control

room thermostats or the Super

CAR remote control, it is necessary to eliminate the jumpers

present in the zone control unit

on terminal board X9 and on the

integrated P.C.B. on clamp X15.

Any Super C.A.R. remote control

must be connected to the control

panel on terminals 42 and 43,

respecting polarity.

e Super C.A.R. remote control

can control the zone set as the

main zone on the relative control

unit.

With the Super C.A.R. remote

control connected to the ends

of the terminals corresponding

to the Room ermostat of the

main zone, NOTHING else must

be connected (no thermostat nor

jumper).

V2

)

remote

ZONES CONTROL

UNIT DIM V2

AREA CONTROL ROOM

THERMOSTATS

Super CAR

(Optional)

Blue

Brown

Power supply

230 Vac

50 Hz

3-11

Y./G.

3.9 DIM CONNECTIONS TO ON/OFF ROOM THERMOSTATS AND C.A.R.V2 OR C.A.R UNIVERSAL REMOTE CONTROL.

V2

(or C.A.R. Universal) remote control to terminals 41 and 44 on all boiler

Power supply

230 Vac

External probe

(optional)

Yellow/green

MAINTENANCE TECHNICIAN

3-12

ZONES CONTROL

AREA CONTROL ROOM

THERMOSTATS

UNIT DIM V2

E

xample of C.A.R.

boards suitable for interacting with these remote options (see the instruction manual of the boiler).

On connecting the zone control room thermostats or the CAR V2remote control, it is necessary

to eliminate the jumpers in the zone control unit on terminal board X9, on the integrated P.C.B.

on clamp X15 and respect the polarity.

e C.A.R.V2 remote control can control the zone set as the main zone on the relative control unit.

With C.A.R.V2 remote control connected to the ends of the terminals corresponding to the Room

ermostat of the main zone, NOTHING else must be connected (no thermostat nor jumper).

CAR v2

(Optional)

50 Hz

Brown

Blue

Key:

S20-1 - Zone 1 room thermostat (optional)

S20-3 - Zone 3 room thermostat (optional)

C.A.R.V2 - Comando Amico Remoto remote control V2 (optional)

MAIOR EOLO INTEGRATED P.C.B.

24

Page 25

3.10 CONNECTION BETWEEN 2 DIM WITH HYDRAULICS IN PARALLEL.

DIM TO BOILER BUS CONNECTION WIRING DIAGRAM.

If the rst DIM is connected to the boiler via IMG

BUS and a second one is to be connected in parallel,

connect the central heating request of the second

DIM to the rst one using input X11.

e rst DIM will be connected to the boiler via

IMG BUS and it will detect the value of the external

probe from the boiler.

e LT zone ow temperature of the rst DIM

will be set on Superior kW boilers connected via

IMG BUS, or on DIM zone control unit trimmers

when the same is connected to boilers dierent to

Superior kW.

e second DIM receives only the zone signal state

from the rst DIM and it must be connected to

an external probe (if required); the relative ow

temperature of LT zones of the second DIM must

be adjusted on its trimmers.

ZONES CONTROL

UNIT 1st DIM V2

ZONES CONTROL

UNIT 2nd DIM V2

3-13

INSTALLERUSER

BUS IMG connection to boiler

DIM TO BOILER STATE SIGNAL CONNECTION WIRING DIAGRAM.

Boiler ignition request

If the rst DIM is connected to the boiler via zone signal state and a second one is to be connected hydraulically in parallel, connect the central heating request

of the second DIM to the rst one using input X5.

e rst DIM must be connected to one of its external

probes (if required) and the LT zone ow temperature

must be adjusted on its trimmers.

e second DIM receives only the zone signal state

from the rst DIM and it must be connected to an

external probe (if required); the relative ow temperature of LT zones of the second DIM must be adjusted

on its trimmers.

ZONES CONTROL

UNIT 1st DIM V2

External

probe

(optional)

3-14

ZONES CONTROL

UNIT 2nd° DIM V2

MAINTENANCE TECHNICIAN

External

probe

(optional)

Zones signal state from boiler

External

probe

(optional)

25

Page 26

Example of hydraulic diagram for parallel connection of 2 DIM.

3-15

INSTALLERUSER

BOILER

External probe

(optional)

MAINTENANCE TECHNICIAN

1st DIM V2 3 ZONES

Zones

control unit

DIM V2

Zone 2 1st DIM Zone 2 2nd DIMZone 31st DIM Zone 3 2nd DIMZone 1 1st DIM Zone 1 2nd DIM

Key:

S20-1.1 - Zone 1 room thermostat 1st DIM

S20-1.2 - Zone 2 room thermostat 1st DIM

S20-1.3 - Zone 3 room thermostat 1st DIM

S20-2.1 - Zone 1 room thermostat 2nd DIM

S20-2.2 - Zone 2 room thermostat 2nd DIM

S20-2.3 - Zone 3 room thermostat 2nd DIM

External probe

(optional)

2nd DIM V2 3 ZONES

Zones

control unit

DIM V2

26

Page 27

3.11 DIM CONNECTION TO ANOTHER DIM OR TO HERCULES ZONE KIT WITH HYDRAULICS IN SERIES.

3-16

With two DIM connected to each other in series,

connect the central heating request of the second

DIM to the HT input of the rst one on the zone in

which it has been connected.

In the example, it is supposed that the second DIM is

connected on the output of zone 2 of the rst DIM.

ZONES CONTROL

UNIT 2nd DIM V2

All considerations shown in this layout are valid

also if a DIM is connected to a Hercules kW boiler

with zone kit.

e rst DIM will be connected to the boiler via zone

signal state or IMG BUS (where permitted) and it

ZONES CONTROL UNIT 1st DIM V2

or kW Hercules kit zones control unit

can receive the value of the external probe from the

boiler only if the IMG BUS interaction is available.

e LT zone ow temperature of the rst DIM will

be set on Superior kW boilers connected via IMG

BUS, or on DIM zone control unit trimmers when

the same is connected to boilers dierent to Superior

kW or does not use the IMG BUS communication.

e second DIM receives only the zone signal state

from the rst DIM and it must be connected to an

external probe (if required); the relative ow temperature of LT zones of the second DIM must be

adjusted on its trimmers.

INSTALLERUSER

Example of hydraulic diagram for connection in series of 2 DIM.

3-17

External probe

BOILER

(optional)

1st DIM V2 3 ZONES 1st DIM v2 A-2BT

External probe

(optional)

Zones

control unit

DIM V2

External probe

(optional)

Zones

control unit

DIM V2

Key:

S20-1.1 - Zone 1 room thermostat 1st DIM

S20-1.3 - Zone 3 room thermostat 1st DIM

S20-2.1 - Zone 1 room thermostat 2nd DIM

S20-2.2 - Zone 2 room thermostat 2nd DIM

S20-2.3 - Zone 3 room thermostat 2nd DIM

MAINTENANCE TECHNICIAN

27

Zone 2 2nd DIMZone 3 1st DIM Zone 3 2nd DIMZone 1 1st DIM Zone 1 2nd DIM

Page 28

3.12 DESCRIPTION OF MAIN

FUNCTIONS.

ree-way valves/anti-block pumps.

The device is supplied with a function that

makes the pumps start (according to the model

installed) at least 1 once every 24 hours in order

to reduce the risk of pump blocking due to prolonged inactivity. In the case of the H-LT and

H-2LT versions, the same function also acts on

the mixing valve in order to prevent and avoid

the risk of blocking due to prolonged inactivity.

INSTALLERUSER

Post-circulation.

System post-circulation can be performed, controlled by the boiler, in the system zone selected

as the main zone (see installation layout).

Summer DHW/functioning priority.

In the case of DHW or boiler functioning priority in Summer mode, all active pumps are

deactivated and any mixing valves are closed

(only for L-HT and H-2LT versions). Normal

functioning of the DIM re-starts at the end of

the DHW phase, taking the boiler switch to the

Winter position.

Mixing valve initialisation.

(Only for DIM H-LT and H-2LT).

Every time that the the appliance is powered,

initialisation of the mixing valves is carried

out, closing them for three minutes. is way,

synchronisation is performed between the P.C.B.

and the mixing valve. e transfer of heat energy

to the Low-Temperature zone can only take place

at the end of this initialisation phase.

Anti-freeze.

(Only for DIM H-LT and H-2LT).

e P.C.B. is supplied with a function that protects the Low-temperature system if the system

water drops below 5°C.

3.13 ZONE MANAGEMENT P.C.B.

e zone control unit can be congured using

the selector switches on the unit (14 Fig. 3-18),

via which you can choose between the following

options:

n° OFF ON

Homogeneous

1

zone control

N° 1 mixed zone

S25

2

(Z2)

3 Master board Slave board

Main zone =

4

zone 1

Super CAR: main

5

zone ow control

S26

Mixed zones max.

6

temperature =

50°C

Normal func-

7

tioning

8 Not used Not used

S27

Mixed zones min-

9

imum temperature = 25°C

- S26 (5) can only be modified if the Super

C.A.R. remote control can be coupled with the

Superior kW range boilers.

- S26 (6) in the event of the setting with max.

ow temperature of 75°C, the relative safety

thermostat must be replaced with one suitable

for supporting this temperature.

Warnings. Various LEDs are present on the

board to display the functioning status and to

indicate any anomalies.

e LEDs from 1 to 7 (13 Fig. 3-18) identify the

activation of the relative relay:

- LED H1 zone 1 activation (high temperature)

- LED H2 zone 2 activation (low temperature)

- LED H3 zone 3 activation (optional)

- LED H4 mixer opening zone 2 L.T.

Mixed zone

control

N° 2 mixed zones

(Z2 and Z3)

Main zone =

zone 2

Super CAR: system ow control

Mixed zones max.

temperature =

75°C

Multi-zone recognition state

Mixed zones minimum temperature = 35°C

- LED H5 mixer opening zone 2 L.T.

- LED H6 mixer opening zone 3 (optional)

- LED H7 mixer closing zone 3 (optional)

e LED H11 signals that the zone management

board is powered.

LEDs 8 and 9 indicate the functioning status of

the board:

Warning H8 H9 H10

CH request presence ON OFF OFF

Disabling of active

zones

Zone 2 safety ther-

mostat intervention

Zone 2 L.T. probe

fault

Zone 3 safety ther-

mostat intervention

Zone 3 L.T. probe

fault

Bus IMG anomaly OFF ON A ON A

IMG communication

present

Intervention of

safety thermostat

B.T. DIM

Key:

ON = ON

OFF = OFF

ON L = Slow ashing (0.6 s on, 0.6 s o)

ON V = Fast ashing (0.3 s on, 0.3 s o)

ON F = Flash ashing (0.2 s on, 1 s o)

ON A = Alternate ashing

ON L OFF OFF

OFF ON OFF

OFF ON L OFF

OFF OFF ON

OFF OFF ON L

OFF OFF ON F

OFF ON V OFF

Zone management P.C.B.

MAINTENANCE TECHNICIAN

3-18

Key:

13 - Relay functioning signal LED (H1 ÷ H7)

14 - Zone management board functioning mode selectors

15 - Zone 3 low ow temperature regulation trimmer.

16 - Zone 2 low ow temperature regulation trimmer.

17 - Board functioning status signal LED

18 - Board functioning status signal LED

19 - Board functioning status signal LED

20 - Board power supply signal LED

28

Page 29

3.14 EXTERNAL TEMPERATURE PROBE

OPTIONAL.

e manifold is designed for the application of

the external probe (Fig. 3-19), which is available

as an optional kit. e probe can be connected

directly to the manifold P.C.B. or to the boiler

electrical system and allows the max. system

ow temperature to be automatically decreased

when the external temperature increases, in

order to adjust the heat supplied to the system

according to the change in external temperature. e external probe always operates when

connected, regardless of the presence or type of

room chrono-thermostat used, and can work in

combination with Immergas timer thermostats.

e external probe must be electrically connected

as indicated in the Fig. 3-5, 3-6, 3-11, 3-12, 3-13,

3-14 or 3-16.

• Control of the High-Temperature zone. e

correlation between ow temperature to the

system and external temperature is determined

by the parameters set on the boiler. See boiler

instructions manual.

• Control of the Low-Temperature zone. e

correlation between ow temperature to the

system and external temperature is determined

by the position of the trimmer (15 or 16 Fig.

3-18) on the zone board according to the curve

represented in the diagram (Fig. 3-20).

3-19

45

31

• No external temperature probe. To set the ow

temperature of the low-temperature zones, it

is necessary to act using a screwdriver on the

trimmer (R12 or R13) present on the zone

control unit following the table provided below

(15 or 16 Fig. 3-18).

Trimmer

position

R12 or R13

Trimmer

position

R12 or R13

Low-temperature

zone ow

(25 ÷ 50 °C)

1 25 °C 25 °C

2 30°C 37.5 °C

3 35°C 50 °C

4 40°C 62.5 °C

5 50 °C 75°C

Low-temperature

zone ow

(35 ÷ 50 °C)

1 35°C 35°C

2 39 °C 45°C

3 43 °C 55 °C

4 47 °C 65°C

5 50 °C 75°C

High-temperature

zone ow

(25 ÷ 75 °C)

High-temperature

zone ow

(35 ÷ 75 °C)

58

Note: using an IMG BUS connection to the

Superior kW boiler, the low-temperature zones

are regulated on the boiler display.

Note: when the external probe is connected, the

OFFSET action can be regulated (with Superior

kW boilers only).

3.15 TROUBLESHOOTING.

- Presence of air in the system. Check the opening of the boiler vents, the central heating

system and the DIM, act on the 3-way mixing

valve, keeping it open for de-aeration (only for

H-LT and H-2LT version). Make sure the system pressure and expansion vessel factory-set

pressure values are within the set limits; the

factory-set value for the expansion vessel must

be 1.0 bar, and system pressure between 1 and

1.2 bar.

- Low-temperature safety thermostat intervention. It can depend on the blocked pump, the

blocked mixing valve or an anomaly on the

P.C.B. Check the correct operation of the components indicated above, making sure that the

anomalies signalled by ashing of the LEDS H9

or H10 (according to the cases) on the P.C.B.

disappear.

- Low-temperature ow regulation NTC probe

anomaly. Replace the component and/or check

its correct operation, making sure that the

anomaly signalled via switch-on of the LEDS

H9 or H10 (according to the cases) on the

P.C.B. disappears.

- Low-temperature zone flow temperature

insucient or too low. It can depend on an

incorrect regulation of the trimmer (R12 or

R13) present on the P.C.B. from the blocked

or broken mixing valve (only for H-LT and

H-2LT version), or on the temperature set on

the lower boiler with respect to that requested

in the low-temperature circuit (only for boilers connected without IMG BUS). Check the

correct regulation of the trimmer, check the

correct operation of the mixing valve (only for

H-LT and H-2LT versions). Make the boiler

function with a ow temperature over that set

for the low-temperature zone (only for boilers

connected without IMG BUS).

- e table below identies the errors displayed

on the boiler, when the manifolds are connected with the IMG BUS:

INSTALLERUSER

Correction law of the ow temperature depending on the external temperature and user

Low-temperature zone

adjustments of the central heating temperature.

POSITION OF THE TRIMMER

ZONE P.C.B.

In brackets, temperature value with 25°/50° range

FT = Low-temperature zone Flow Temperature

ET = External temperature.

29

3-20

Code Description

Zone 2 Low-Temperature probe

32

anomaly

Zone 3 Low-Temperature probe

33

anomaly

Low-temperature zone 2 safety ther-

34

mostat intervention

Low-temperature zone 3 safety ther-

35

mostat intervention

36 IMG BUS communication loss

DIM safety thermostat intervention

46

(optional)

MAINTENANCE TECHNICIAN

Page 30

3.16 TECHNICAL DATA.

DIM 2 zone

ErP

Maximum nominal pressure bar 3 3 3 3

Maximum operating pressure °C 90 90 90 90

Low-temperature circuit minimum set-point regulation temper-

ature

Low-temperature circuit maximum set-point regulation temper-

ature

Low-temperature safety thermostat intervention °C -- -- 55 55

INSTALLERUSER

Water content in device l 1.3 1.7 1.5 1.9

Total head available in direct zone with 1000 l/h ow rate (max.) kPa (m c.a.) 31.40 (3.20) 31.40 (3.20) 31.40 (3.20) 29.20 (2.98)

Total head available in mixed zone (mixing valve open) with 1000

l/h ow rate (max.)

Empty device weight kg 17.3 19.8 19.7 23.2

Full device weight kg 18.6 21.5 21.2 25.1

Electrical connection V/Hz 230/50 230/50 230/50 230/50

Maximum input A 0.62 0.95 0.62 0.95

Installed electric power W 100 135 100 135

Power in stand-by W 1.2 1.2 1.2 1.2

EEI value - ≤ 0.23 - Part. 2 ≤ 0.23 - Part. 2 ≤ 0.23 - Part. 2 ≤ 0.23 - Part. 2

Electric plant protection - IPX5D IPX5D IPX5D IPX5D

Maximum distance between boiler - DIM m 15 15 15 15

°C -- -- 25 or 35 25 or 35

°C -- -- 50 or 75 50 or 75

kPa (m c.a.) -- -- 30.30 (3.10) 30.30 (3.10)

DIM 3 zone

ErP

DIM H-LT

ErP

DIM H-2LT

ErP

MAINTENANCE TECHNICIAN

30

Page 31

Page 32

Follow us

Immergas Italia

immergas.com

Immergas S.p.A.

42041 Brescello (RE) - Italy

Tel. 0522.689011

Fax 0522.680617

Certied company ISO 9001

is instruction booklet is made of ecological paper Cod. 1.039170ENG - rev. ST.002145/000 - 09/15 - Inglese per IRLANDA (IE)

Loading...

Loading...