Page 1

Owner / Operator Manual

IMPORTANT:

TO THE INSTALLER.

It is the responsibility of

the Installer to ensure that

the water supply to the

dispensing equipment is

provided with protection

against backflow by an air

gap as defined in

ANSI/ASME A112.1.2-1979;

or an approved vacuum

breaker or other such

method as proved effective

by test.

Water pipe connections

and fixtures directly

connected to a potable

water supply shall be

sized, installed, and

maintained according to

Federal, State, and Local

Codes.

THIS DOCUMENT CONTAINS IMPORTANT INFORMATION

This Manual must be read and understood before installing or

operating this equipment

Release Date: October 28, 2005

Revision Date: December 22, 2005

Publication Number: 630460146OPR

Revision: A

www.cornelius.com

IMI Cornelius Inc.

Page 2

Page 3

Page 4

Page 5

Page 6

Page 7

TABLE OF CONTENTS

Model and Serial Location 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Xtreme Ice Machine 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial Number Explanation 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Freight Damage Claims Procedure 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Specifications 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Microban 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Instructions 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Location of Equipment 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Baffle Installation 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Set-Up 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dispenser Installation 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Plumbing Connections 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Check Points 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Start Up Sequence 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preventative Maintenance Sequence 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unit Selection 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Normal Operations 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Start Up Sequence (Primary) 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Secondary Start Up 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dump Cycle 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Water Fill Cycle 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pre Chill Cycle (300’s, 500’s, 600’s, 800’s, 1000’s, and 1200’s) 10. . . . . . . . . . .

pre chill cycle (1400’s and 1800’s) 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Freeze Cycle 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Harvest Cycle 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dump Cycle 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fan Control 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting Bridge Thickness 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Total Ice Capacity 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ice Production Check 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LED Indicators 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flashing Code for Self Diagnostics (300’s, 500’s, 600’s, 800’s, 1000’s,

and 1200’s) 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

flashing code for self diagnostics (1400’s and 1800’s) 13. . . . . . . . . . . . . . . . . . .

Harvest Button 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Harvest 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unit Check 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clean Button 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clean Cycle 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 8

Maintenance 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Ice Machine Inspection 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the Exterior 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the Condenser 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air–Cooled Condenser 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Water-Cooled Condenser (and regulating valve) 16. . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the Interior 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning Procedure if there is Ice on the Evaporator Plate. 16. . . . . . . . . . . . . . .

Cleaning the Water System and Evaporator 16. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sanitizing the Water System and the Evaporator 17. . . . . . . . . . . . . . . . . . . . . . . .

Before Calling for Service 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warranty 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 9

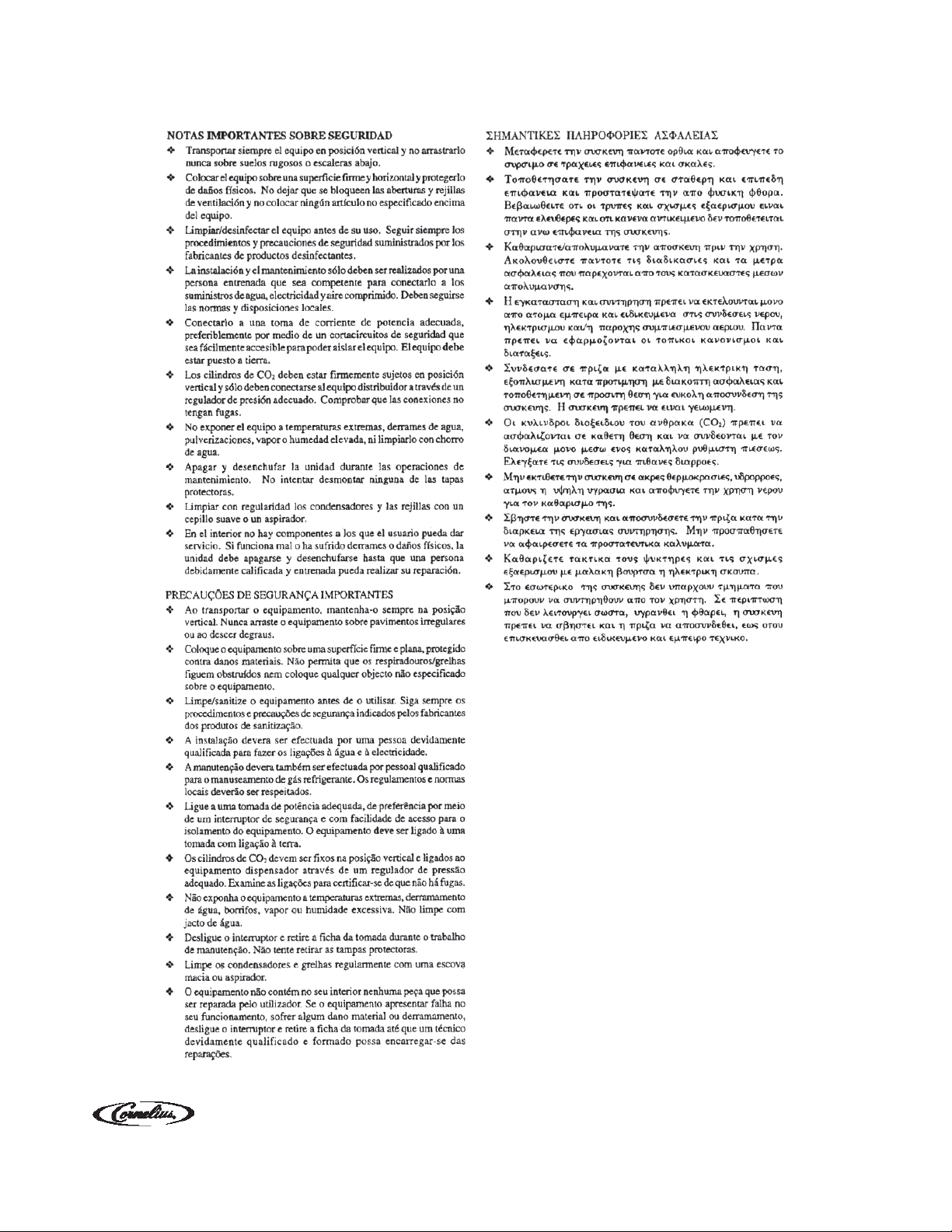

MODEL AND SERIAL LOCATION

XTREME ICE MACHINE

Condenser Discharge Air

Deflector (as required)*

Bin Adapter (as required)*

Model/Serial

Number Location

*Bin adapters and condenser discharge air deflector may be equipped depending on your location or the size of

the storage bin.

Record the model number and the serial number of your ice equipment. These numbers are required when requesting information from your local dealer/distributor/service company.

Model Number – Date Installed –

Serial Number – Purchased From -

SERIAL NUMBER EXPLANATION

63 A 01 01 BC 101

Sequential Number

Product Code (PC) – Ice Maker

Week of Manufacture – First week of the year

Year of Manufacture – 2001

Control Code (Revision Level)

Manufacturing Location – Mason City

December 22, 2005

1

630460146OPR

Page 10

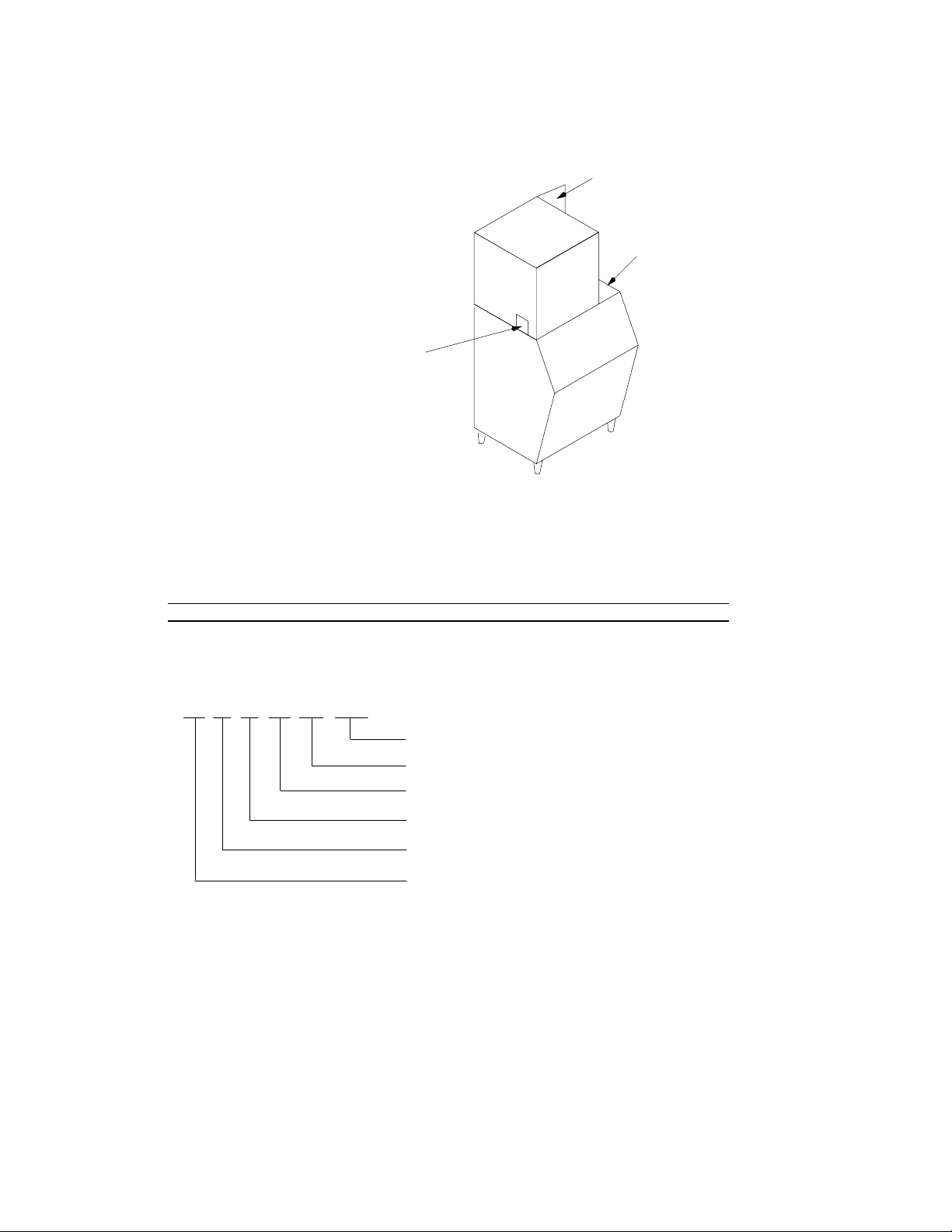

SPECIFICATIONS

The following table contains equipment specification information for the Ice Machines.

Model

UNIT

Volts

Phase

Hertz

No. Wires

MIN. CIRCUIT

Amps

MAX. FUSE

SIZE

Amps

REFRIGERANT

Type

Weight (oz)

Weight (g)

COMPRESSOR

LRA

RLA

CONDENSER

FAN MOTOR

Amps

Watts

WATER PUMP

Amps

Watts

Model

UNIT

Volts

Phase

Hertz

No. Wires

MIN. CIRCUIT

Amps

MAX. FUSE

SIZE

Amps

REFRIGERANT

Type

Weight (oz)

Weight (g)

COMPRESSOR

LRA

RLA

CONDENSER

FAN MOTOR

Amps

Watts

WATER PUMP

Amps

Watts

XAC

322/330

R404a

19

539

1.7

50

XWC

830

R404a

33

936

NA

NA

XWC

322/330

R404a

15

426

58.8

9.2

NA

NA

XRC

830

R404a

170

4,820

60

8.9

NANA1.2 (2)

XAC

522/530

115

1

60

2+Ground

XWC

522/530

XRC

522/530

XAC

630

XWC

630

230

1

60

2+Ground

20 15 20

20 15 20

R404a

25

709

1.7

50

R404a

23

652

68

11.9

NA

NA

R404a

135

3,827

NA

NA

R404a

40

1,134

1.1

75

R404a

35

992

40.6

6.9

NA

NA

0.7

20

XAC

1030

XWC

1030

XRC

1030

XAC

1230

XWC

1230

230

1

60

2+Ground

20

20

R404a

42

1,191

60 (2)

R404a

33

936

90

12

NA

NA

R404a

R404a

170

4,820

1,191

13.5

NANA1.2 (2)

60 (2)NANA

49

96

R404a

45

1,276

84

12.2

0.7

20

XRC

630

R404a

170

4,820

NA

NA

XRC

1230

R404a

210

5,954

NA

NA

XAC

830

R404a

42

1,191

60

8.9

1.1

75

XWC

1230

E50

2+Ground

R404a

45

1,276

76

13.0

NA

NA

XAC

1444

E50

220

1

50

30

30

R404a

67

1,900

96

21.5

0.6

1/15hp

630460146OPR

2

December 22, 2005

Page 11

XAC

20

20

322

E50

R404a

19

539

1.75

50

XRC

1844

3PH

R404a

NA

NA

XAC 330

E50

10 15

10 15

R404a

19

539

26.3

3.9

1.75

50

XWC

522/530

E60

230

1

60

2+Ground

34

6.8

NA

NA

XAC 522

E50

220

1

50

2+Ground

R404a

25

709

1.75

50

XWC

522

E50

220

1

50

2+Ground

R404a

23

652

31

5.6

NA

NA

XAC 530

E50

R404a

25

709

31

5.6

1.75

50

XAC

522/530

E60

230

1

60

2+Ground

R404a

26

737

34

6.8

1.2

60

Model

UNIT

Volts

Phase

Hertz

No. Wires

MIN. CIRCUIT

Amps

MAX. FUSE

SIZE

Amps

REFRIGERANT

Type

Weight (oz)

Weight (g)

COMPRESSOR

LRA

RLA

CONDENSER

FAN MOTOR

Amps

Watts

WATER PUMP

Amps

Watts

Model

UNIT

Volts

Phase

Hertz

No. Wires

MIN. CIRCUIT

Amps

MAX. FUSE

SIZE

Amps

REFRIGERANT

Type

Weight (oz)

Weight (g)

COMPRESSOR

LRA

RLA

CONDENSER

FAN MOTOR

Amps

Watts

WATER PUMP

Amps

Watts

XAC

1444

R404a

67

1900

0.6

1/15

HP

XAC

630

E50

15 20

15 20 20 15 15

R404a

40

1134

34

5.5

1.1

75

XWC

1444

30

30

R404a

36

1021

108

17

NA

NA

XAC

830

E50

R404a

42

1191

54

8.1

1.1751.2(2)

XRC

1444

R404a

7088

XAC

1030

E50

220

1

50

2+Ground

R404a

1191

11.3

60(2)

230

1

60

2+Ground

R404a R404a R404a

250

NA

NA

1/3HPNANA

R404a

42

83

1.2(2)

XAC

1844

2.7

XAC

1230

E50

49

1389

76

13

60(2)

XWC

1844

30

40

179

28

XAC

1844

3PH

R404a R404a

2.7

1/3HPNANA

XRC

1844

NA

NA

0.7

XWC

1844

3PH

230

3

60

3+Ground

20 15 15

135

17

0.7

NA= Not applicable

Important: All product supply voltage specifications are –5%/+10% for proper component

operation.

December 22, 2005

3

630460146OPR

Page 12

GENERAL

FREIGHT DAMAGE CLAIMS PROCEDURE

The deliverer of your equipment (freight company, distributor or dealer) is responsible for loss or damage of your

shipment. All claims must be filed with the deliverer of your equipment. Please follow the steps below to determine if your shipment is satisfactory or if a claim must be filed:

1. Check the number of products delivered against the number of products listed on the delivery receipt.

Should the totals not match, have the driver note all errors on both copies and both you and the driver sign

and date said notation.

2. Inspect all cartons for visible damage. Open and inspect as required before the driver leaves and have him

or her note any damage on the receipts. All damaged claims must be inspected within 15 days of delivery.

Notify your carrier immediately if concealed damage is found after delivery.

3. Should concealed damage be found when product is unpacked, retain the packing material and the product

and request an inspection from the deliverer.

4. All claims for loss or damage should be filed at once. Delays in filing will reduce the chance of achieving a

satisfactory resolution to the claim.

TECHNICAL SPECIFICATIONS

S Cube Size: 5/8”W X 7/8”H X 7/8”D

S Ambient Temperature: 50_F/10_C – 100_F/38_C

S Water Temperature: 50_F/10_C – 90_F/32_C

S Water Pressure: 20–80 psi

S Maximum Fuse Size: See Nameplate

S Circuit Amp: See Nameplate

S Refrigerant Type: R–404a

S Refrigerant Charge: See Nameplate

Microban

IMI Cornelius Ice Maker Product includes Microbanr Built–In Product Protection to inhibit the

growth of odor and stain causing bacteria, mold, and mildew. This will improve the units performance between cleaning, but should not exclude the standard cleaning process. Please

refer to the Maintenance section of this manual for proper cleaning procedures. Microban is

a registered trademark of the Microban Products company, Huntersville NC 28078.

630460146OPR

4

December 22, 2005

Page 13

INSTALLATION INSTRUCTIONS

Installation and start-up of the equipment should be performed by the distributor or the dealer’s professional

staff.

LOCATION OF EQUIPMENT

For maximum performance the location should be away from heat sources such as ovens, direct sunlight, hot

air discharge, etc.

To reduce cost of maintenance and loss of efficiency, avoid placing air-cooled equipment in areas where grease,

flour and other airborne contaminants are present. Allow a minimum of 6I (15.24 cm) clearance at the rear and

right side for proper air circulation. Restricted air circulation will affect the efficiency and required maintenance of

the product.

IMPORTANT: Never operate your equipment in room temperature below 50_F (10_) or above 100_F

(38_C). Should the location of your product ever be exposed to freezing temperatures, it must be shut

down and winterized.

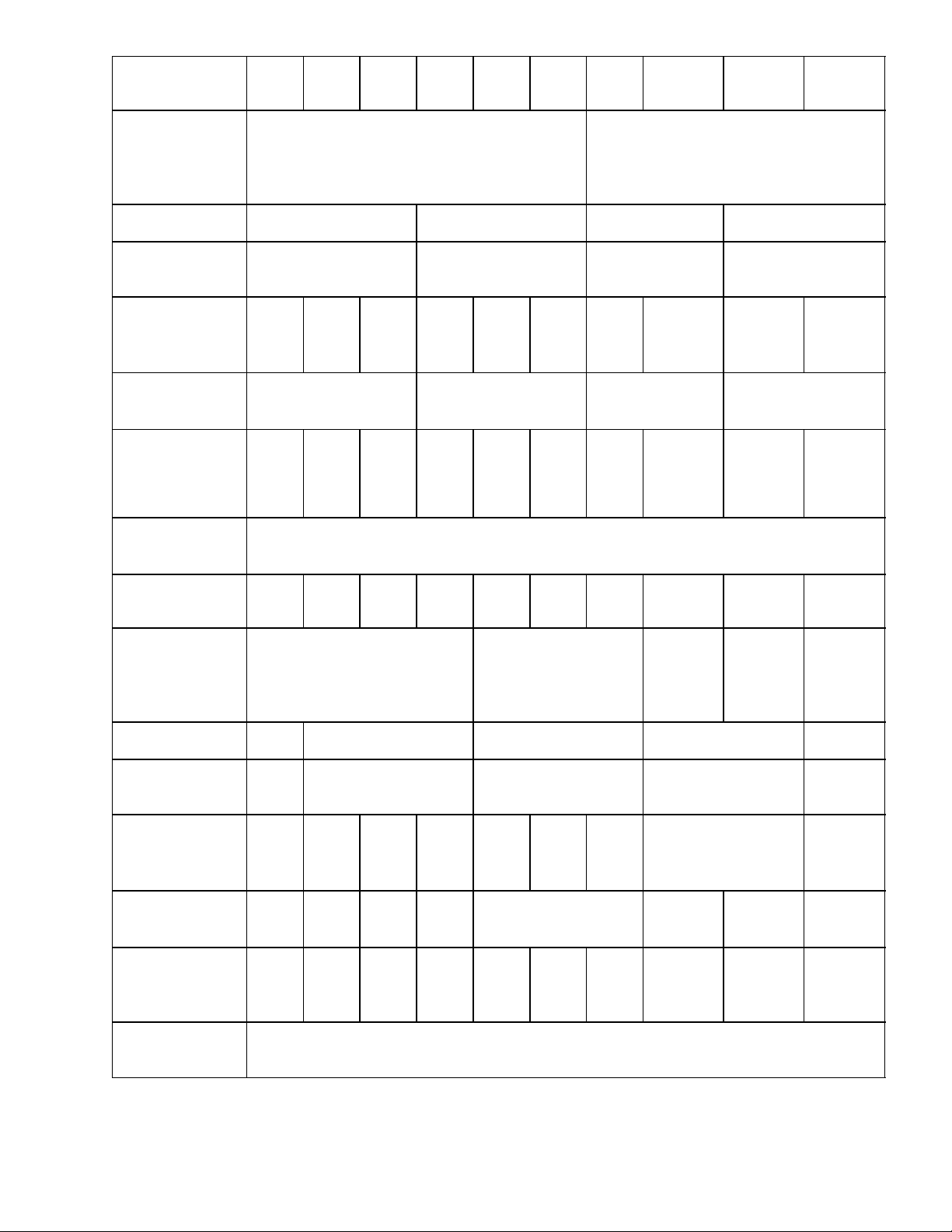

Baffle Installation

NOTE: The baffle is only used on the 1030, 1230, 1444, and 1844.

The baffle must be used when the right hand side of the icemaker is installed in a corner. This will prevent discharge air from recirculating to the condenser.

1. Loosen three screws, as shown in Fig. 1.

2. Install baffle, as shown in Fig. 1. with paper towards the front of the unit.

3. Tighten the three screws.

December 22, 2005

FIG. 1

5

630460146OPR

Page 14

EQUIPMENT SET-UP

The following steps refer to the set-up of the ice bin and the cuber:

1. Remove the bin from its carton, place it on its back and install the legs into the bottom of the bin. Bins must

be installed on legs or sealed to the floor with RTV-732 sealant.

2. Set the bin up on its legs. Place the bin in its final location and level it with the adjustable feet in the legs.

NOTE: It is critical that the unit be level to ensure adequate ice production.

3. Unpack the cuber from its carton, and set in place on the bin and adjust as required. Leave all panels on

the cuber until it is set in place on the dispenser or bin.

4. Remove all internal packing from the cuber. Remove tape from evaporator curtain.

THREAD LEVELING

LEG INTO BASE

FIG. 2

FIG. 3

NOTE: Bin adapter and condenser air baffles may be required in certain installations.

630460146OPR

6

December 22, 2005

Page 15

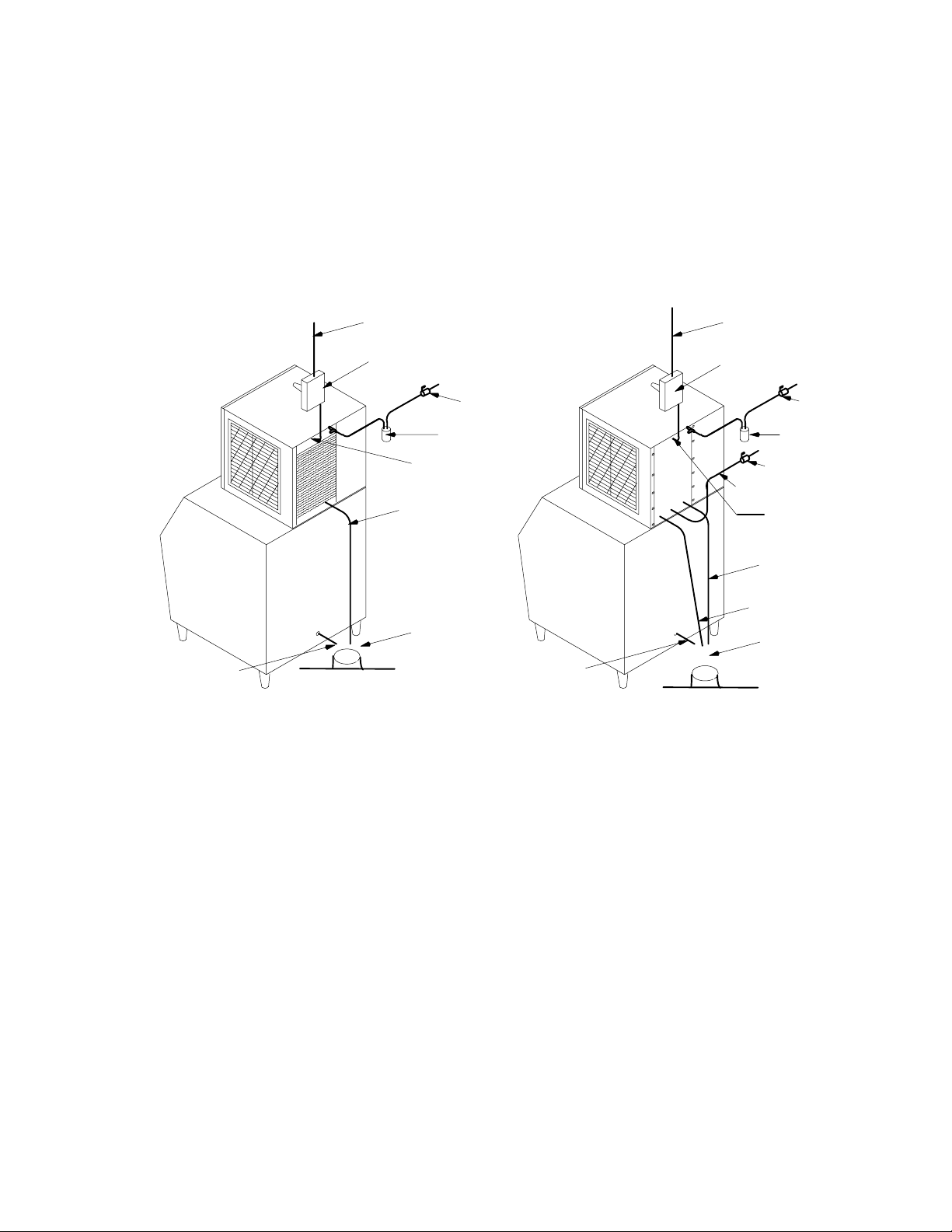

DISPENSER INSTALLATION

1. The proper cuber/dispenser installation package should be ordered. This package will include gasket material, and hold-down bracket, and bin stat.

2. RTV applications (See Fig. 2 above). If the ice bin is full, new ice will not be able to drop. Instead it blocks

the evaporator curtain open and no additional ice is made. This new ice may start to melt and the resulting

liquid can leak out of the joint between the ice maker and bin. To prevent this problem, seal the joint with

food grade silicon sealant.

3. Install bin thermostat (Part Number 631500074).

Electrical Service Line

Manual Disconnect

Switch

Shut-Off Valve

Water Filter

STRAIN RELIEF

MUST BE USED

Dump

Valve

Drain

Tube

*Air Gap 4”

“minimum”

FIG. 4 FIG. 5

Bin Drain

Floor Drain

Tube

AIR-COOLED MODELS

* An air gap of at least twice the diameter of the water supply inlet plus a minimum of 1” (25 mm) must

exist between the floor drain and drain tube.

Bin Drain

Tube

WATER-COOLED MODELS

Electrical Service Line

Manual Disconnect Switch

Shut-Off Valve

Water Filter

Shut-Off Valve

Condenser Water Inlet

Strain Relief

must be used

Dump Valve

Drain Tube

Condenser Water

Drain Tube

*Air Gap 4”

“minimum”

Floor Drain

Note: Leave all panels on the cuber until it is in place on the bin.

PLUMBING CONNECTIONS

1. All plumbing lines and connections must conform to local and

national plumbing codes.

2. Line shut-off valves must be located in supply water lines for cuber and condenser if product is watercooled. Water supply to water-cooled condenser must include a stand-pipe to prevent “water

hammer”.

3. Should your local water supply quality require the installation of a water filter system, consult your local distributor or dealer for proper size required.

4. Water supply pressure must not be lower than 20 PSI (1.37 BAR), nor should it exceed 80 PSI (5.516

BAR).

NOTE: Water filters larger then 5 microns do not give proper protection. Water pressures above 80

PSI (5.516 BAR) will destroy the filter.

DRAIN LINES: Bin and cuber drain lines must never be connected together and must be vented.

NOTE: Always flush inlet water lines 1–2 minutes before connecting to Ice Maker.

December 22, 2005

7

630460146OPR

Page 16

ELECTRICAL

1. All wiring and connections must conform to national and local electrical codes.

2. Wire size and circuit protection must conform to specifications and cuber must be on a separate electrical

circuit.

3. Strain relief connectors must be used at the junctions box of the control box and the cuber.

4. Cuber must be grounded by the control box ground screw or other method for intentional safety grounding

that meets code requirements.

5. A manual disconnect in a convenient location to the cuber must be installed.

NOTE: See Remote Install Instructions in the Xtreme Service and Training Manual (TP00952).

NOTE: All HP-62 (R404A) ice machines have a voltage range of –5%, +10% from the serial plate rating.

INSTALLATION CHECK POINTS

1.

2. Does electrical and plumbing meet code requirements?

3. If water-cooled, are inlet and drain connections to condenser correct to prevent “water hammer”?

4.

5. Is there 6I clearance on all sides and top for proper air circulation?

6.

7.

NOTE: A 6” top clearance will improve service accessibility.

Has bin and cuber been leveled and sanitized?

Are drain lines separate and vented?

Does the water curtain move freely, and does the inlet solenoid valve shut off incoming water to the

water pan?

Has the unit been properly sealed to the bin or dispenser?

START UP SEQUENCE

1.

2.

3. The unit will go through a 45 second hot gas defrost to remove any ice on the evaporator.

NOTE: If there is a very large slab of ice on the evaporator you will need to push the manual harvest

button to remove it.

4. If the water pan is empty, the unit will go through a fill cycle.

5.

Check all connections.

Turn on the main power switch, the red LED will flash (6) times then be on steady for (4) seconds.

There will be approximately a (45) second evaporator pre chill, then the water pump will start, and the

freeze cycle begins.

PREVENTATIVE MAINTENANCE SEQUENCE

The installation is not complete until you are sure the owner–operator understands the cuber operation and his

or her responsibility of preventative maintenance.

Does the owner–operator know:

1.

2. How to start and/or shut down the product, clean and sanitize it?

3.

4.

5.

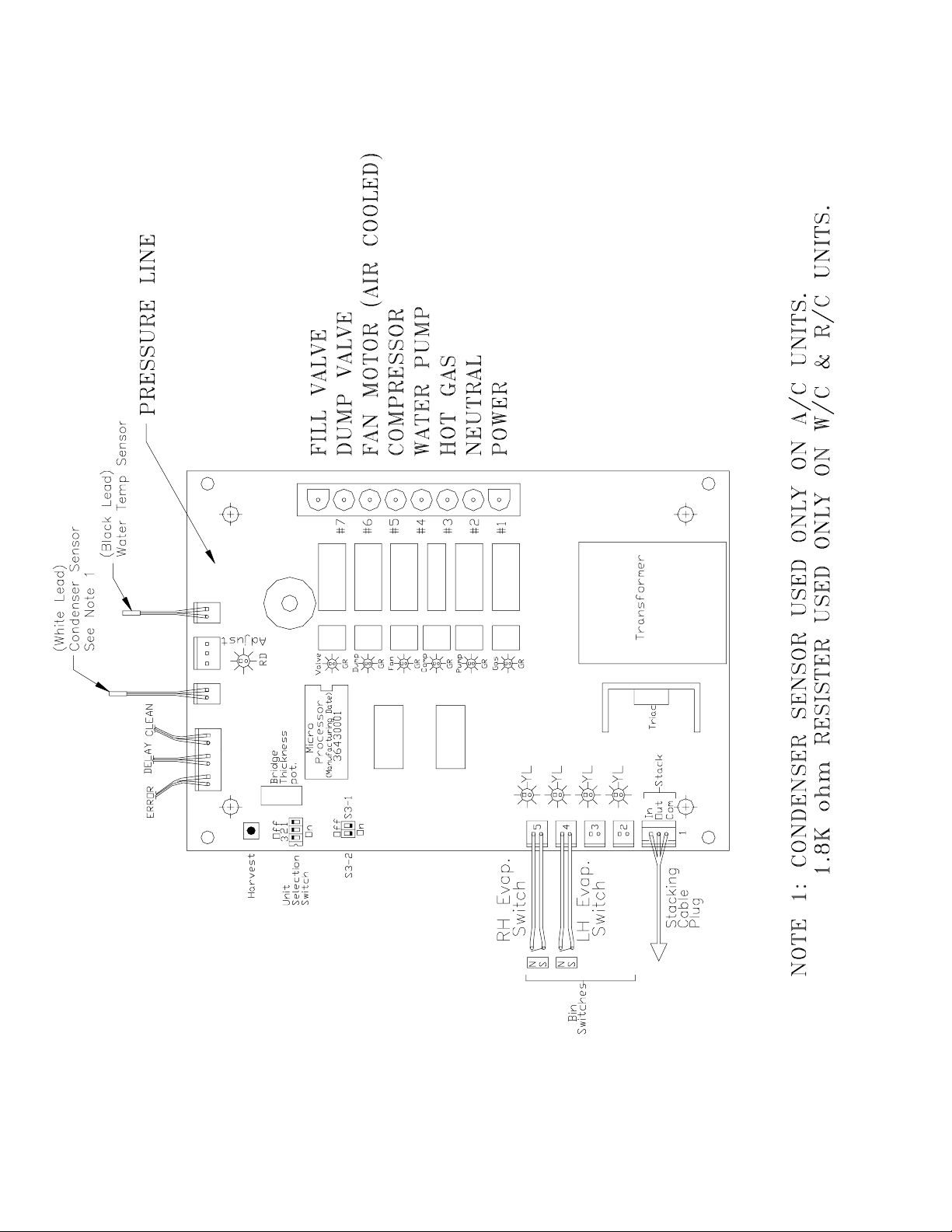

NOTE: CONDENSER SENSOR USED ONLY ON A/C UNITS. 1.8K ohm RESISTER USED ONLY ON W/C

& R/C UNITS.

630460146OPR

Location of electrical disconnect switch and water shut–off valves?

Bin full operation and reset operation of high pressure cutout (water–cooled and remote products

only)?

How to clean the condenser and fan blade?

Whom to call for product information and/or service?

8

December 22, 2005

Page 17

OPERATION

UNIT SELECTION

1. The unit selection dip switches tell the microprocessor the correct water level difference for harvest and the

number of proximity switch circuits to monitor.

2. The unit selection dip switches are a series of 3 switches that can be placed in either the ON or OFF position.

3. The following list shows the dip switch settings for each model:

NOTE: The unit selection switches are preset at the factory to the correct model. Use the chart below if

the control is replaced.

Model

Switch 1 Switch 2 Switch 3 Proximity Switch Circuits

500 ON OFF OFF 1

300 OFF OFF OFF 1

600/800/1000 OFF ON OFF 1

1200 ON ON OFF 2

1400/1800 OFF OFF ON 2

NORMAL OPERATIONS

1. Start up sequence.

2. Secondary start up.

3. Dump cycle.

4. Water fill cycle.

5. Pre chill cycle.

6. Freeze cycle.

7. Harvest cycle.

8. Continue with the dump cycle.

9. Fan cycle runs continuously after the secondary start up (88–100_F).

10. The safety features are monitored during the proper cycle.

PRESSURE

LINE

December 22, 2005

FIG. 6

PRESSURE TRANSDUCER

START LEVEL (A)

WATER PAN

DEFROST LEVEL (B)

DUMP LEVEL (C)

1. During fill, water level rises to (A).

2. During Ice Product cycle, water level lowers

to (B). Defrost cycle initiated.

3. During Defrost cycle, water level lowers to (C).

4. When Proximity Switch(es) close, fill valve

opens and water level rises to (A).

9

630460146OPR

Page 18

START UP SEQUENCE (PRIMARY)

1. Check all connections.

2. Turn on the main power switch, the red LED will flash (6) times, then be on steady for (4) seconds.

3. The unit will go through a 45 second hot gas defrost to remove any ice that might be on the evaporator.

NOTE: If there is a very large slab of ice on the evaporator you will need to push the manual harvest

button to remove it.

4. If the water pan is empty, the unit will go through a fill cycle.

5. There will be approximately a (45) second evaporator pre chill, then the water pump will start, and the

freeze cycle begins.

SECONDARY START UP

1. Compressor starts after ERROR LED extinguishes, and the green COMP LED turns on.

2. Compressor runs continuously after secondary start up sequence.

3. Hot gas valve opens for a 45 second period.

4. Green GAS LED is on when the hot gas valve opens.

5. After 45 seconds, the hot gas valve de–energizes.

NOTE: If there is a very large slab of ice on the evaporator you will need to push the manual harvest

button to remove it.

DUMP CYCLE

1. Dump valve opens.

2. Green DUMP LED is on when the dump valve energizes.

3. If the water level is not at the high level the fill valve opens.

4. The green FILL LED is on when the fill valve energizes.

5. If the water level is below the minimum level the water pump remains off.

6. Once the water is a above the minimum level the water pump turns on.

7. The green PUMP LED is on when the water pump is on.

8. After a 15 second flush cycle the fill valve de–energizes.

9. The water pump turns on to drop the water level to the minimum level.

WATER FILL CYCLE

1. The fill valve opens.

2. The green FILL LED is on when the fill valve energizes.

3. Once the water level reaches the maximum level the fill valve de–energizes.

NOTE: During the initial filling of the water pan, air is captured inside the pressure sensor pick up.

When the pressure inside, the pressure sensor pick up rises to a predetermined value, the pressure

transducer shuts off the water fill valve and starts the pre chill cycle then the freeze cycle.

PRE CHILL CYCLE (300’S, 500’s, 600’s, 800’s, 1000’s, and 1200’s)

1. The water pump turns on 45 seconds into the cycle.

2. After another 45 seconds, the fill valve turns on.

3. Once the water level reaches the maximum level the fill valve de–energizes.

PRE CHILL CYCLE (1400’s and 1800’s)

1. After the water fill cycle is complete, the water pump turns on.

2. When the water temperature reaches 40 degrees F, the pump turns off.

3. After one minute, the pump comes back on.

4. After another ten seconds, the fill valve opens.

5. Once the water level reaches the maximum level, the fill valve closes.

630460146OPR

10

December 22, 2005

Page 19

FREEZE CYCLE

1. Ten seconds after the fill valve turns off, the microprocessor records the water level.

2. Using the recorded high water level, the calibration level and the ice thickness level, the microprocessor

calculates a harvest level.

3. The microprocessor monitors the water level until it reaches the harvest level.

As ice builds on the evaporator the water level in the water pan drops. This is called batch harvesting.

HARVEST CYCLE

1. The hot gas solenoid opens.

2. The microprocessor monitors the proximity switches waiting for the circuit to open.

3. Once all of the proximity switch circuits have opened, the hot gas solenoid closes.

4. The microprocessor monitors the proximity switches to close.

5. Once all the proximity switch circuits close, the harvest cycle terminates.

NOTE: When the pressure inside, the pressure sensor pick up lowers to a predetermined value, the

pressure transducer starts the harvest cycle.

DUMP CYCLE

1. The dump cycle can be changed by moving the setting on the dump cycle dip switches.

2. If both switches are off, the machine dumps water after each cycle. This is the factory set point.

3. If switch 1 is on an switch 2 is off, the machine dumps after every third harvest.

4. If switch 1 is off an switch 2 is on, the machine dumps after every seventh harvest.

5. Once the water reaches the minimum level, the dump valve de–energizes and the pump turns off.

FAN CONTROL

1. Fan control operates when the hot gas solenoid is closed.

2. The fan turns off when the condenser temperature is below 88_F.

3. The fan turns on when the condenser temperature is above 100_F.

ADJUSTING BRIDGE THICKNESS

For optimum ice production and maximum cube separation, the ice connecting the individual cubes should be a

minimum of 1/8I (.32cm) thick.

FIG. 7

BRIDGE 1/8I (0.32 cm)

Should a different thickness of the bridge be desired, it will be required to adjust the ice thickness “POT”, located on the circuit board, as follows:

1. Thinner Bridge – turn the ice thickness “pot” adjustment screw C.W. one full turn. Allow two cycles before

determining if additional adjustments are required.

2. Thicker Bridge – turn the ice thickness “pot” adjusting screw C.C.W. one full turn. Allow two cycles before

determining if additional adjustments are required.

NOTE: Never judge the thickness of the ice from the first batch of the ice produced – the first cycle is

a balance cycle. Always wait for the second cycle before making any adjustments.

TOTAL ICE CAPACITY

Ice capacity of any ice maker is affected by many operating conditions, such as water and air temperature and

location factors. Please review the capacity tables in this manual for average 24-hour capacity under various

conditions.

NOTE: All printed capacity ratings are 10% except 50 HZ units. These products have 12% increase

in cycle time and capacity decrease of approximately 17%.

December 22, 2005

11

630460146OPR

Page 20

ICE PRODUCTION CHECK

If air cooled, take air temperature at the intake of the condenser, 2I from the condenser fins, and Incoming water temperature at the outlet of the “fill” valve.*

Cycle time (CT) = freeze time plus harvest time, in minutes and seconds. 1440 divided by CT = number of

cycles per 24 hours.

Measure weight of ice from one cycle in pounds and fractions of a pound.

EXAMPLE: Weight/cycle x cycles/day = total production/24 hrs. Compare to the production tables.

* If water cooled, be certain water regulator valve is set to maintain 260 - 271 PSI head pressure, or set condenser outlet temperature to 108_F – 111_F

LED INDICATORS

The LEDs are board circuit indicators. If the LED in the functional board circuit is complete, check component.

Example: Contactor does not energize and LED is “ON”, board circuit is OK. Check contactor, coil, leads, &

connections.

Yellow:

S Evaporator switch(s) (proximity)

Green:

S Water dump valve

S Compressor contactor

S Water Pump

S Hot Gas Valve

S Condenser Fan (cycles on & off with fan)

S Fill Valve

Red:

S Error (located on the electrical box front).

S Delay (located on the electrical box front).

S Ice thickness Adjustment.

Refer to flash codes for control and system diagnostics. Add the flash codes before status indicators.

FLASHING CODE FOR SELF DIAGNOSTICS (300’s, 500’s, 600’s, 800’s,

1000’s, and 1200’s)

Delay LED Error LED

1 High Condenser Temperature Warning 1 High Condenser Temp. Shutdown

4 Low Condenser Temperature Delay 2 Failed Freeze Time Out Shutdown

5 Water Inlet Warning 3 Failed Harvest Shutdown

5 Failed Water System Shutdown

6 End of Clean Cycle Shutdown

8 Open Condenser Thermistor Shutdown

630460146OPR

12

December 22, 2005

Page 21

FLASHING CODE FOR SELF DIAGNOSTICS (1400’s and 1800’s)

Delay LED Error LED

1 High Condenser Temperature Warning 1 High Condenser Temp. Shutdown

4 Low Condenser Temperature Delay 2 Failed Freeze Time Out Shutdown

5 Water Inlet Warning 3 Failed Harvest Shutdown

4 Failed Water Temperature Shutdown

5 Failed Water System Shutdown

6 End of Clean Cycle Shutdown

7 Open Water Thermistor Shutdown

8 Open Condenser Thermistor Shutdown

Status Indicator

Green LED Condenser Fan

Yellow LED Left Water Curtain

Green LED Hot Gas Valve

Green LED Water Pump

Yellow LED Right Water Curtain

Green LED Compressor Contactor

Red LED Error

Green LED Dump Valve

Green LED Fill Valve

Yellow LED Delay

Red LED Ice Thickness Adjustment

Curtain Open

Yellow LED off Right evaporator curtain open.

Yellow LED off Left evaporator curtain open.

Pre-Chill Mode

Condenser Fan

Compressor Green LED (on) Compressor contactor activeĆcompressor running.

Right Curtain Yellow LED (on) Right evaporator curtain closed.

Left Curtain Yellow LED (on) Left evaporator curtain closed (only if unit has two evaporators).

Fill Valve Green LED (on) Fill valve open.

Dump Valve Green LED (on) Dump valve open.

Green LED (on or off) Condenser fan cycles on and off depending upon condenser temperature.

Ice-Making Mode

Green LED (on or off) Condenser fan cycles on and off depending upon condenser temperature.

Green LED (on) Water pump active.

Green LED (on) Compressor contactor active - compressor running.

Yellow LED (on) Right evaporator curtain closed.

Yellow LED (on) Left evaporator curtain closed (only if unit has two evaporators).

Harvest Mode

Hot Gas

Compressor Green LED (on) Compressor contactor activeĆcompressor running.

Green LED (on) Hot gas valve open.

Yellow LED (on) Right evaporator curtain closed. When the ice falls and the curtain opens, the LED

will turn off.

Yellow LED (on) Same as above if there is a second (left) evaporator.

December 22, 2005

13

630460146OPR

Page 22

HARVEST BUTTON

Manual Harvest

1. At any time after secondary start up, the machine can be put into the harvest cycle by depressing the harvest button.

2. Pressing the harvest button will tell the microprocessor to skip directly to the harvest cycle.

3. Once the harvest cycle completes, the machine continues with normal operations.

Unit Check

1. Like manual harvest, any time after secondary start up the micro processor monitors the harvest button.

2. If the harvest button is depressed and held for 5 seconds, the unit goes into a check mode.

3. All outputs are initially turned off.

4. Then the microprocessor powers each output individually for one second.

5. This continues for 10 minutes or until the power is cycled.

CLEAN BUTTON

Clean Button

FIG. 9

CLEAN CYCLE

1. The clean cycle can only be initiated during the 45 second hot gas cycle in Secondary Start Up.

2. The clean cycle starts when the CLEAN button is pressed.

3. The hot gas valve opens.

4. The microprocessor monitors the proximity switch circuits, waiting for all circuits to open.

5. Once all circuits have opened, the hot gas valve closes.

6. If all of the proximity switch circuits do not open in 4 minutes, the hot gas valve closes.

7. The fill valve opens.

8. Once the water level reaches the maximum water level, the fill valve closes.

9. The water pump turns on.

10. After 10 minutes the dump valve opens.

11. Once the water reaches the minimum level, the water pump turns off and the dump valve closes.

12. The fill valve opens.

13. Once the water reaches the maximum water level, the fill valve closes.

14. The water pump turns on, and the dump valve opens.

15. Once the water reaches the minimum water level, the water pump turns off and the dump valve closes.

16. The fill valve opens.

17. Once the water reaches the maximum water level, the fill valve closes.

18. The water pump turns on, and the dump valve opens.

19. Once the water reaches the minimum water level, the water pump turns off and the dump valve closes.

20. All outputs turn off.

21. The ERROR LED flashes 6 times at 4 second intervals.

22. The machine will not run until the power is cycled off and back on.

630460146OPR

14

December 22, 2005

Page 23

MAINTENANCE

SEMI-ANNUAL MAINTENANCE

1. GENERAL ICE MACHINE INSPECTION

2. CLEANING THE EXTERIOR

3. CLEANING THE CONDENSER –

AIR-COOLED

WATER-COOLED

4. INTERIOR CLEANING –

CLEANING PROCEDURES

SANITIZING PROCEDURES

GENERAL ICE MACHINE INSPECTION

S Check all water fittings and tubes for leaks. Also, make sure the refrigeration tubing is not rubbing or vibrat-

ing against other tubing panels, etc.

S Do not stack anything (boxes, etc.) on or around the ice machine.

S Do not cover the ice machine while it is operating. There must be adequate air flow through and around the

ice machine to ensure long component life and adequate ice production.

CLEANING THE EXTERIOR

1. Clean the area around the ice machine as often as necessary to maintain cleanliness and efficient operation.

2. Sponge dust and dirt off the outside of the ice machine with mild soap and water. Wipe dry with a soft clean

cloth.

WARNING: Stainless steel panels should be cleaned with mild soap or a commercial

stainless steel cleaner. Do not use cleaners containing bleaching agents: they usually

contain chlorine which stains stainless steel. Heavy stains should be removed with

stainless steel wool. Never use plain steel wool or abrasive pads because they will scratch

the panel and cause rusting.

CLEANING THE CONDENSER

CAUTION: Condenser fins are sharp. Use care

when cleaning them.

Disconnect electric power to the ice machine at the electric service switch box before cleaning condenser!

Air–Cooled Condenser

A dirty condenser restricts airflow which results in excessively high operating temperatures. High operating temperatures reduce ice production and shorten component life. Clean the condenser at least every six months.

CAUTION: Condenser fins are sharp. Use care

when cleaning them.

December 22, 2005

15

630460146OPR

Page 24

1. Clean the outside of the condenser with a soft brush or vacuum with a brush attachment. Brush or wash

condenser from top to bottom, not from side to side. Be careful not to bend the fins. Shine a flashlight

through the condenser to check for dirt between the fins.

2. If further cleaning is required, blow compressed air through the condenser from the inside. Take care not to

bend the fan blades. Shine a flashlight through the condenser to check that all the dirt is removed.

Any bent condenser fins must be straightened with a fin comb. Contact

your local service agent to do this service.

Water-Cooled Condenser (and regulating valve)

The water-cooled condenser and water regulating valve may require cleaning due to scale build-up.

Low ice production, high water consumption, and high operating temperatures and pressures all may be symptoms of restrictions in the condenser water circuit.

The cleaning procedures require special pumps and cleaning solutions and, therefore, should be performed by

qualified maintenance or service personnel.

CLEANING THE INTERIOR

Approved ice machine cleaners by brand names:

S Calgon Nickel Safe (green color only)

NOTE: Failure to use approved products will void the warranty.

CAUTION: Ice machine cleaners are acidic-based chemicals. Before beginning any

cleaning of the cuber, the ice in the storage bin or dispenser must be removed.

WARNING: When using any chemical, rubber gloves and eye protection should be worn.

WARNING: Do not remove the small clear tube from the fitting located in the water pan.

Doing so will result in erratic behavior of the ice machine.

Cleaning Procedure if there is Ice on the Evaporator Plate.

1. Turn the power switch on.

2. Press the clean button to start a 4 minute defrost cycle (button is located on the front of the control panel).

3. After harvest cycle, add ice machine cleaner and follow cleaning procedure.

Use ice machine cleaner on a coarse-surface cloth material (such as terry cloth) and wipe down the inside wall

of the evaporator area, the water pan, the water curtain and the plastic water deflector. If the water distributor

tube has heavy scale build-up, remove and soak it in full-strength nickel safe ice machine cleaner (or exchange

the tube and clean the scaled tube at a later date). *See figures and #6 and #7.

Cleaning the Water System and Evaporator

1. Turn the power switch to “OFF”.

2. Remove all ice from the storage bin.

3. Remove the water curtain(s), pour 1/2 oz. of ice machine cleaner down the top of the evaporator. The

cleaner will drain into the water pan.

4. Remove the water distributor tube (refer to fig. 10), disassemble water distributor tube (refer to fig. 11), and

clean with the brush and “Calgon Nickel Safe” ice machine cleaner.

630460146OPR

16

December 22, 2005

Page 25

FIG. 10

INNER WATER DISTRIBUTOR

”O” RING

SCALE 1:2

FIG. 11

WATER DIST. ASSEMBLY

”O” RING

INNER WATER DISTRIBUTOR BARB

5. Return the water curtain(s) to their proper operating positions.

6. Add 5 oz. for the 300’s, 8 oz. for the 500’s, 600’s, and 800’s, 12 oz. for the Dual Evaporator, and 16 oz. for

the Quad of “Calgon Nickel Safe” ice machine cleaner directly into the water pan (green only).

7. Turn the power switch to “ON” , allow the compressor to start, and depress the clean button two times on

the front of the electrical box.

8. The unit will run through a fifteen (15) minute cleaning cycle. This includes 3 rinse cycles.

9. Once the cleaning cycle finishes, the error LED will flash 6 times.

10. When the clean cycle is complete, turn the power switch to “OFF” for five (5) seconds, then to “ON”. The

unit will return to normal operating mode. Discard the first batch of ice produced.

NOTE: Please Take Note of the Following:

S Ice machines should only be cleaned when needed, not by a timed schedule of every 60 days, etc.

S Should your ice machine require cleaning more than twice a year, consult your distributor or dealer about

proper water treatment.

Sanitizing the Water System and the Evaporator

NOTE: To be performed only after cleaning the ice machine:

1. Turn the power switch to “OFF”.

2. Add 1/4 ounce (7.08 g) sodium hypochlorite solution (common liquid laundry bleach) to the water pan. You

may also use a commercial sanitizer such as Calgon Ice Machine Sanitizer following the directions on the

product label.

3. Turn the Cuber power switch “ON” allowing the compressor to start. Depress the clean button two times on

the control board. The unit will run through a 15 minute sanitizing cycle.

4. Once the sanitizing cycle is complete, the error LED will flash 6 times. Turn the power switch to “OFF” for

5 seconds and then turn to “ON”. Discard the first batch of ice produced.

5. To sanitize the bin and other surface areas, use 1 ounce of liquid bleach per gallon of water and wipe all

areas with the solution. Or use a commercial sanitizer.

6. Cleaning and sanitizing are now complete. Cuber may be returned to normal service.

December 22, 2005

17

630460146OPR

Page 26

630460146OPR

18

December 22, 2005

Page 27

BEFORE CALLING FOR SERVICE

If a problem arises during the operation of your ice machine, follow the checklist below before calling for service.

CHECKLIST

Problem

ICE MACHINE DOES NOT

OPERATE

ICE MACHINE STOPS AND

CAN BE RESTARTED BY

TURNING POWER SWITCH

OFF THEN BACK ON AGAIN

ICE MACHINE DOES NOT

RELEASE ICE OR IS SLOW

TO HARVEST

POOR QUALITY ICE. (ICE

SOFT OR NOT CLEAR)

Probable Cause Remedy

A. No electrical power to ice

machine.

B. Tripped high pressure cutout. B. Reset high pressure cut-out.

C. ON switch set improperly. C. Set switch at ON.

D. Water curtain stuck open. D. Water curtain must swing freely.

A. Safety limit feature stopping

ice machine.

A. Ice machine evaporator dirty. A. Clean the evaporator, the water

B. Ice machine not level. B. Level ice machine.

C. Air–cooled models: low

ambient.

D. Water regulating valve leaking

during harvest mode

(water–cooled ice machines).

A. Quality of incoming water. A. Contact qualified service

B. Water filtration element needs

to be changed.

C. Ice machine dirty. C. Clean and sanitize ice machine,

D. Water dump valve not working. D. Disassemble and clean the water

E. Water softener working

improperly (if installed).

A. Replace fuse, reset circuit

breaker, turn on main switch.

A. Refer to safety limit feature.

system and sanitize ice machine.

C. Minimum ambient is 50_F .

D. Refer to water–cooled condenser.

company to test quality of water

and make appropriate filter

recommendations.

B. Replace filter.

pages 5 & 6.

dump valve.

E. Repair water softener.

SAFETY LIMIT FEATURE

In addition to standard safety controls such as the high pressure cut-out, your ice machine features built-in safety limits that stop the ice machine if conditions exist that may result in a major component failure.

Before calling for service, restart the ice machine using the following procedures:

1. Turn power switch off and then back to “ON” position. If the safety limit feature has stopped the ice machine,

it will restart after a short delay. Proceed to Step 2, but if the ice machine does not restart, refer to “Ice Machine Does Not Operate” in the problem checklist.

2. Let the ice machine operate to determine if the condition recurs...

a. If the ice machine stops again, the condition recurred; call for service.

b. If the ice machine continues to run, the condition corrected itself; let the machine run.

December 22, 2005

19

630460146OPR

Page 28

WARRANTY

IMI Cornelius Inc. warrants that all equipment and parts are free from defects in material and workmanship under normal use and service. For a copy of the warranty applicable to your Cornelius product, in your country, please write, fax or telephone the IMI Cornelius office nearest you

(www.cornelius.com). Please provide the equipment model number, serial number and the date of

purchase.

630460146OPR

20

December 22, 2005

Page 29

IMI CORNELIUS INC.

WWW.CORNELIUS.COM

Loading...

Loading...