Page 1

VIPER 2 FLAVOR, VIPER 3 FLAVOR &

VIPER 4 FLAVOR

Service Manual

Release Date: October 28, 2008

Publication Number: 621260373SER

Revision Date: August 6, 2010

Revision: E

Visit the IMI Cornelius web site at www.cornelius.com

for all your Literature needs.

Page 2

The products, technical information, and instructions contained in this manual are subject to change without notice.

These instructions are not intended to cover all details or variations of the equipment, nor to provide for every possible contingency in the installation, operation or maintenance of this equipment. This manual assumes that the person(s) working on the equipment have been trained and are skilled in working with electrical, plumbing, pneumatic,

and mechanical equipment. It is assumed that appropriate safety precautions are taken and that all local safety and

construction requirements are being met, in addition to the information contained in this manual.

This Product is warranted only as provided in Cornelius’ Commercial Warrant applicable to this Product and is subject to all of the restrictions and limitations contained in the Commercial Warranty.

Cornelius will not be responsible for any repair, replacement or other service required by or loss or damage resulting

from any of the following occurrences, including but not limited to, (1) other than normal and proper use and normal

service conditions with respect to the Product, (2) improper voltage, (3) inadequate wiring, (4) abuse, (5) accident,

(6) alteration, (7) misuse, (8) neglect, (9) unauthorized repair or the failure to utilize suitably qualified and trained

persons to perform service and/or repair of the Product, (10) improper cleaning, (11) failure to follow installation,

operating, cleaning or maintenance instructions, (12) use of “non-authorized” parts (i.e., parts that are not 100%

compatible with the Product) which use voids the entire warranty, (13) Product parts in contact with water or the

product dispensed which are adversely impacted by changes in liquid scale or chemical composition.

Contact Information:

To inquire about current revisions of this and other documentation or for assistance with any Cornelius product contact:

www.cornelius.com

800-238-3600

Trademarks and Copyrights:

This document contains proprietary information and it may not be reproduced in any way without permission from

Cornelius.

Printed in U.S.A.

Copyright © 2010, All rights reserved, IMI Cornelius Inc.

Page 3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Manual Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Read and Follow ALL Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Recognition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Different Types of Alerts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Qualified Service Personnel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Shipping And Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

CO2 (Carbon Dioxide) Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Mounting in or on a Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Cart Information and Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Dispensed Product Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Overrun, as Applied to Carbonated Beverages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Overrun Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Overrun is a Variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Specific Product Ingredients Affect Overrun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

BRIX Affects Overrun. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Low Dispensing Volume Affects Overrun. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Carbonation Level in Liquid Product Affects Overrun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Freezing Affects Overrun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

CO2 System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Water System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Syrup System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Control Panel Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Control Panel Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Control Panel Menu Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

System Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Unit Data Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Error Status Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Error Log Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Page 4

Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Clock Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Events Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Setting Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Setting the Sleep and Wakeup Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Viscosity Setup Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Options Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Maintenance Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Barrel Maintenance Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Manual Diagnostic Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Totals Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

BRIX Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Motor Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

System Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Pressure Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Maintaining Product Quality. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Dispensed Product Throughput . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Programmed Defrost Scheduling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Sleep Mode Recommendations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Viscosity Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Starting the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Preventative Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Monthly Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Cleaning Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Semi-Annual Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Inspecting and Replacing Scraper Blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Cleaning the Syrup Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Servicing Motorman Dispensing Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Sanitizing the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Emptying a Barrel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Sanitizing the Barrel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Flushing the System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Cleaning the Water Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Component Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Barrel Motor Seal Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Page 5

Removing the Existing Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Installing a New Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Motor Seal Leak Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Barrel Motor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Motor Run Capacitor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Water Pump Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

CO2 Shutoff Solenoid Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Syrup and Water Shutoff Solenoid Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

CO2 Regulator Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Condenser Fan Motor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Compressor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Hot Gas Solenoid Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Liquid Line Solenoid Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Syrup Pressure Switch Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Water Pressure Switch Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Display Board Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Control Board Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Backward/Forward Compatibility with Older Software Versions . . . . . . . . . . . . . . . . . . . . . . . . 71

Motor Board Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Troubleshooting the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Troubleshooting Product Not Cold. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Page 6

Page 7

Viper Service Manual

MANUAL OVERVIEW

INTRODUCTION

The organization of this manual allows the user to scan quickly to the subject of

interest along the left side of a page and to read the detail about the subject or

procedure on the right side of the page. The manual provides the detail needed

for newcomers to the industry while allowing experienced technicians to skip

over the details and move quickly through the material.

This manual is designed as a guide to the technician in maintaining and

servicing the Viper system. The Viper system is simple in design and has built-in

features and diagnostic controls to help the service technician quickly and

accurately service the machine.

The unit consists of multiple freeze barrels that each contain an internal beater

driven by a rear mounted electric motor, a refrigeration system, timer-controlled,

automatic hot gas defrost system and interconnecting tubing and controls

required to dispense the product.

Some of the system features and functions are listed below:

• Simple User Interface LCD Display

• Real Time Clock

• Incoming Line Voltage Sensing

• Pressure Sensing of Incoming Water, Syrup and CO

• System Error Handling

• Error Log

• Viscosity Control

2

© 2008-2009, IMI Cornelius Inc. - 1 - Publication Number: 621260373SER

Page 8

Viper Service Manual

SAFETY INSTRUCTIONS

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

Safety Overview • Read and follow ALL SAFETY INSTRUCTIONS in this manual and

any warning/caution labels on the unit (decals, labels or laminated

cards).

• Read and understand ALL applicable OSHA (Occupational Safety

and Health Administration) safety regulations before operating this

unit.

Recognition

Recognize Safety Alerts

!

Different Types of Alerts

This is the safety alert symbol. When you see it in this manual or on the unit, be

alert to the potential of personal injury or damage to the unit.

!

DANGER:

Indicates an immediate hazardous situation which if not avoided WILL result in

serious injury, death or equipment damage.

!

WARNING:

Indicates a potentially hazardous situation which, if not avoided, COULD result in

serious injury, death, or equipment damage.

!

CAUTION:

Indicates a potentially hazardous situation which, if not avoided, MAY result in

minor or moderate injury or equipment damage.

SAFETY TIPS

• Carefully read and follow all safety messages in this manual and

safety signs on the unit.

Publication Number: 621260373SER - 2 - © 2008-2009, IMI Cornelius Inc.

Page 9

Viper Service Manual

• Keep safety signs in good condition and replace missing or

damaged items.

• Learn how to operate the unit and how to use the controls properly.

• Do not let anyone operate the unit without proper training. This

appliance is not intended for use by very young children or infirm

persons without supervision. Young children should be supervised to

ensure that they do not play with the appliance.

• Keep your unit in proper working condition and do not allow

unauthorized modifications to the unit.

QUALIFIED SERVICE PERSONNEL

!

WARNING:

Only trained and certified electrical, plumbing and refrigeration technicians should

service this unit. ALL WIRING AND PLUMBING MUST CONFORM TO

NATIONAL AND LOCAL CODES. FAILURE TO COMPLY COULD RESULT IN

SERIOUS INJURY, DEATH OR EQUIPMENT DAMAGE.

SAFETY PRECAUTIONS

This unit has been specifically designed to provide protection against personal

injury. To ensure continued protection observe the following:

!

WARNING:

Disconnect power to the unit before servicing following all lock out/tag out

procedures established by the user. Verify all of the power is off to the unit before

any work is performed.

Failure to disconnect the power could result in serious injury, death or equipment

damage.

!

CAUTION:

Always be sure to keep area around the unit clean and free of clutter. Failure to

keep this area clean may result in injury or equipment damage.

© 2008-2009, IMI Cornelius Inc. - 3 - Publication Number: 621260373SER

Page 10

Viper Service Manual

SHIPPING AND STORAGE

!

CAUTION:

Before shipping, storing, or relocating the unit, the unit must be sanitized and all

sanitizing solution must be drained from the system. A freezing ambient

environment will cause residual sanitizing solution or water remaining inside the

unit to freeze resulting in damage to internal components.

CO2 (CARBON DIOXIDE) WARNING

!

DANGER:

CO2 displaces oxygen. Strict attendtion MUST be observed in the prevention of

CO2 gas leaks in the entire CO2 and soft drink system. If a CO2 gas leak is

suspected, particularly in a small area, IMMEDIATELY ventilate the contaminated

area before attempting to repair the leak. Personnel exposed to high

concentrations of CO

of consciousness and DEATH.

2 gas experience tremors which are followed rapidly by loss

MOUNTING IN OR ON A COUNTER

!

WARNING:

When installing the unit in or on a counter top, the counter must be able to support

a weight in excess of 450 lbs.

TO COMPLY COULD RESULT IN SERIOUS INJURY, DEATH OR EQUIPMENT

DAMAGE.

Note:

Many units incorporate the use of additional equipment such as

icemakers. When any addition equipment is used you must check with the

equipment manufacturer to determine the additional weight the counter

will need to support to ensure a safe installation.

CART INFORMATION AND MOUNTING

These carts are also designed with movable wheels that act as outriggers to

provice stability to the unit when it is being moved.

to insure adequate support for the unit. FAILURE

Publication Number: 621260373SER - 4 - © 2008-2009, IMI Cornelius Inc.

Page 11

Viper Service Manual

!

WARNING:

The above listed mounting bolts must be installed and the wheels extended and

locked in the outboard position prior to moving the unit.

Failure to comply could result in serious injury, death or equipment

damage.

DISPENSED PRODUCT CONDITIONS

Overrun, as Applied to Carbonated Beverages

Overrun Definition

Overrun is defined as product expansion that takes place in the frozen

carbonated drink. It is caused primarily by CO2 gas breakout and secondarily by

freezing.

Overrun is a Variable

Specific Product Ingredients Affect Overrun

BRIX Affects Overrun

The percentage or degree of overrun depends on a number of factors. The

specific syrup, BRIX, low dispensing volume, carbonation level in the liquid

product and freezing of the product. These items all affect overrun. After these

factors hav been considered, desired viscosity (product consistency) adjustment

may be made on the unit. The viscosity adjustment adjusts product texture from

very wet to light.

Each syrup has its own specific formulation of makeup. Fruit flavors contain

citric acids that colas do not. Colas also differ in ingredients from one brand to

another. Each product formulation has its own peculiarities regarding the way

the product absorbs carbonation and the way it releases carbonation.

Sugar in carbonated drinks is like anti-freeze in water. The higher the BRIX, the

greater the resistance of the product to freezing. Conversly, in products with

lower BRIX, freezing takes place at higher termperatures than for high-BRIX

products. Thus, BRIX affects overrun because the amount of sugar in a drink

has a direct bearing on the product’s freezing characteristics.

© 2008-2009, IMI Cornelius Inc. - 5 - Publication Number: 621260373SER

Page 12

Viper Service Manual

Low Dispensing Volume Affects Overrun

When a unit sits idle fo a period of time with no drinks being dispensed, CO2 gas

in the system takes a “set”. When the first few drinks are drawn off after an idle

period, CO2 gas has less tendancy to break out as the drink is dispensed. The

result is that these first drinks hav less overrun than drinks dispensed during

peak-use periods.

Carbonation Level in Liquid Product Affects Overrun

Freezing Affects Overrun

The higher the specific carbonation level in a given product, the greater the

potential for carbonation breakout in frozen carbonated form of that drink. For

example, drinks with 3.0 volume of carbonation have more gass breakout in

frozen carbonated form and more overrun than drinks that contain 2.0 volumes

of CO

2 gas.

Freezing causes approximately a 5-7 percent expansion in dispensed frozen

carbonated drinks. The degree of freezing is limited because the finished drink is

intended to be sipped through a straw. This is not possible if the product is too

“solid”.

Publication Number: 621260373SER - 6 - © 2008-2009, IMI Cornelius Inc.

Page 13

INTRODUCTION

Viper Service Manual

SYSTEM OVERVIEW

The Viper unit consists of the following systems and hardware:

Multiple freeze barrels, each containing an internal scraper bar driven by an AC

motor.

A refrigeration system and an intelligent, hot gas defrost system.

The components are enclosed in a powder-coated steel frame to prevent corrosion. It is covered with ventilated cladding panels and a lighted merchandiser.

The cladding is easily removable to facilitate installation, service and maintenance.

Each barrel has a transparent faceplate, with an integral relief valve and a

removable, self-closing dispensing valve mounted on the front. A removable drip

tray, with cup rest is located directly below the dispensing valves.

A programmable control system with a control panel that controls operational

and diagnostic functions and settings is located behind the merchandiser.

© 2008-2010, IMI Cornelius Inc. - 7 - Publication Number: 621260373SER

Page 14

Viper Service Manual

THEORY OF OPERATION

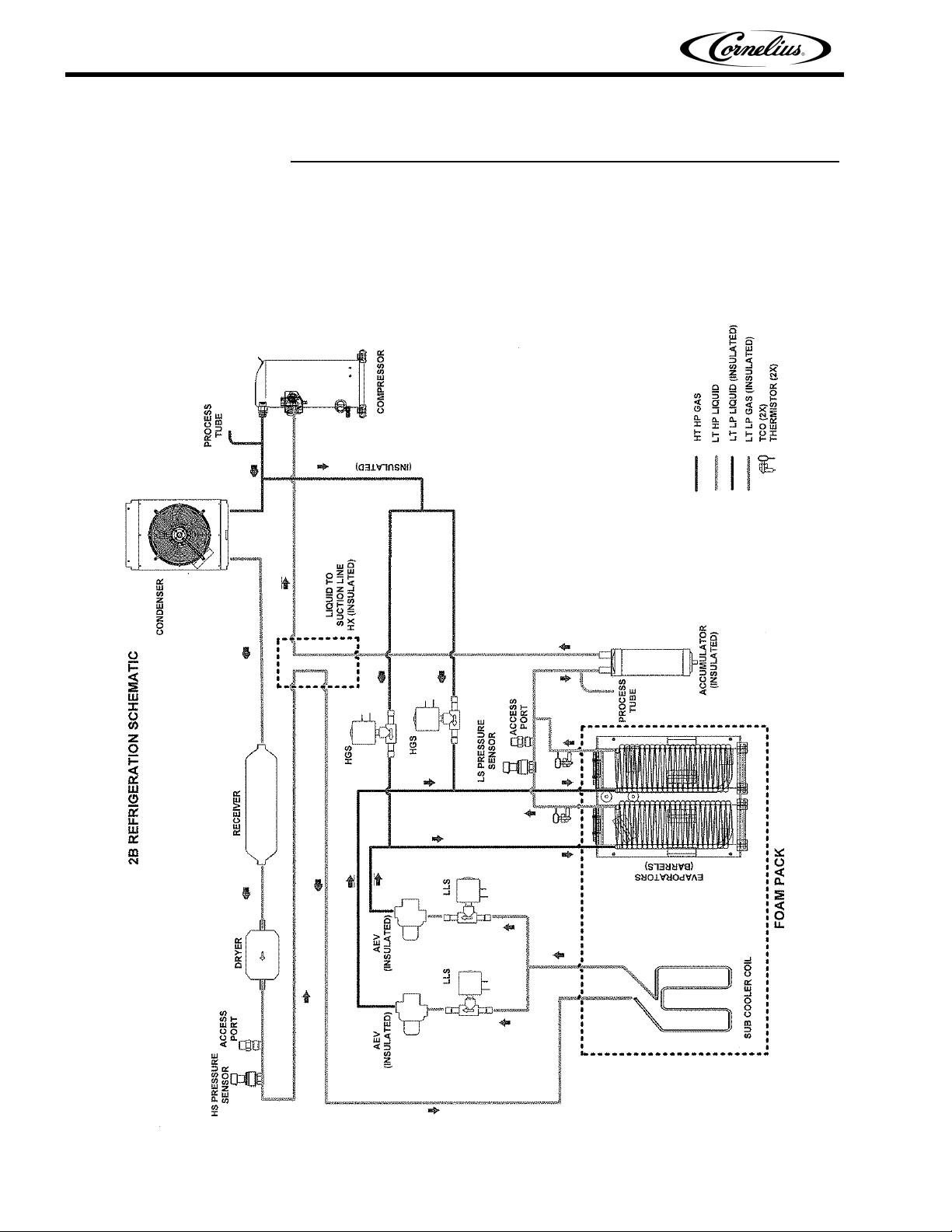

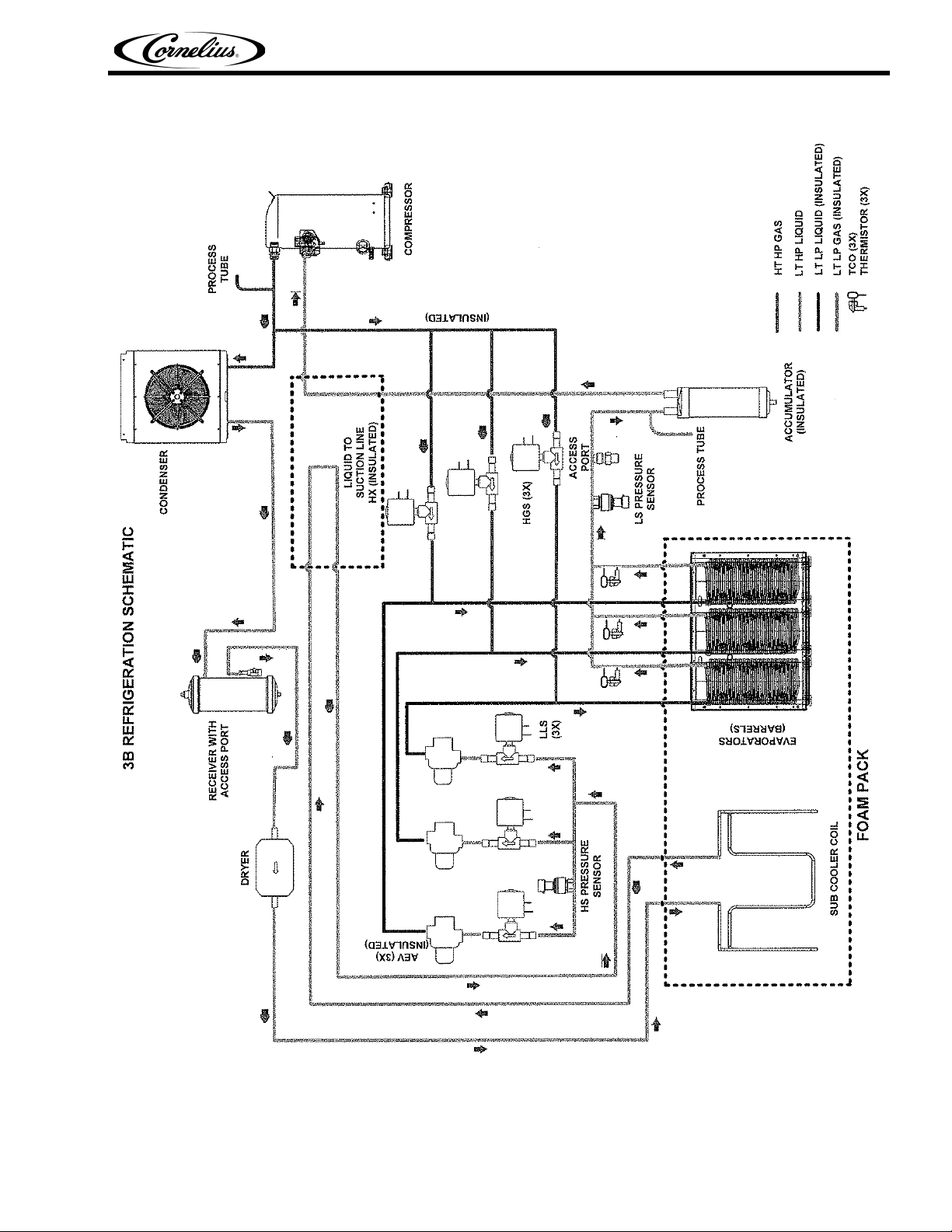

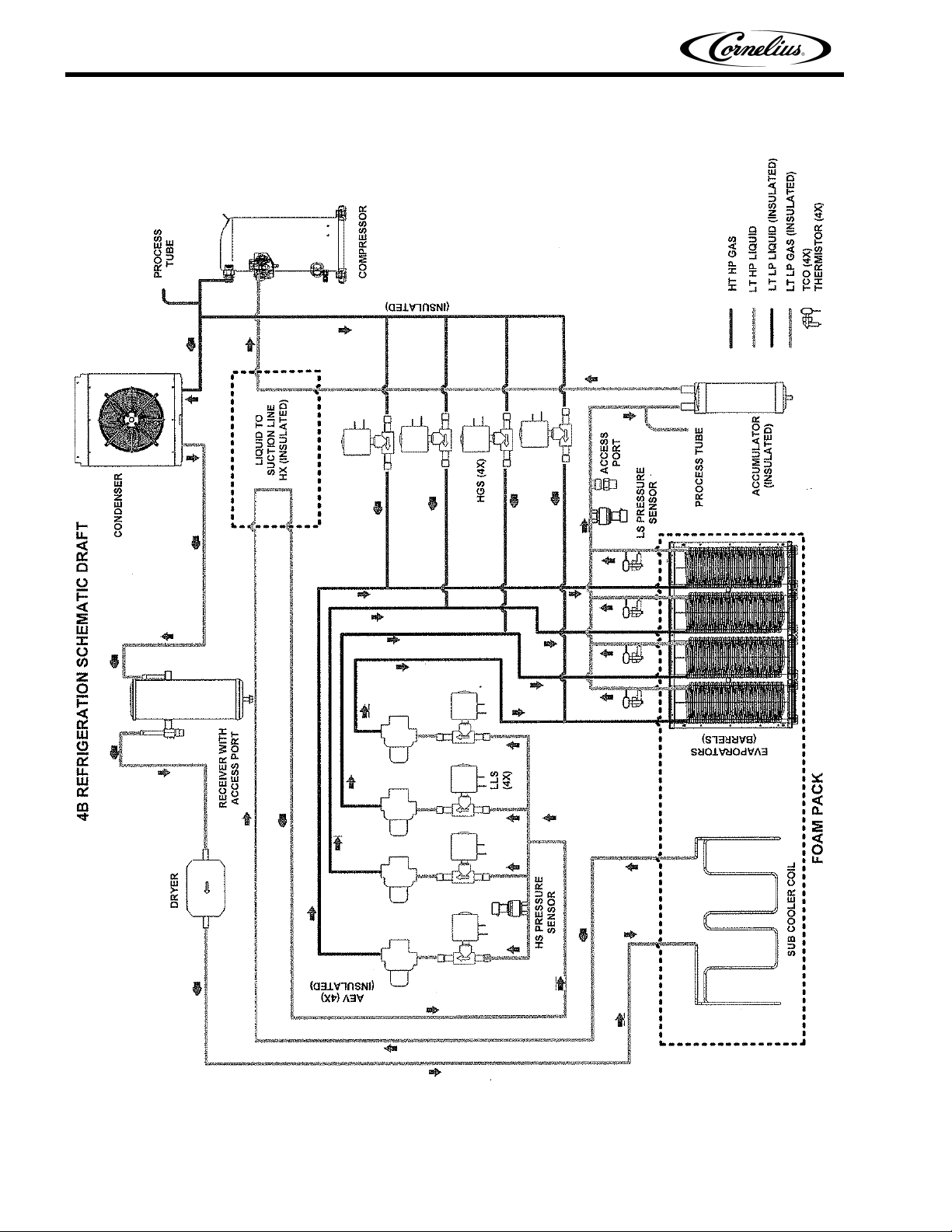

The refrigeration system schematic is shown in Figure 1. It provides the basic

configuration for the Viper refrigeration system.

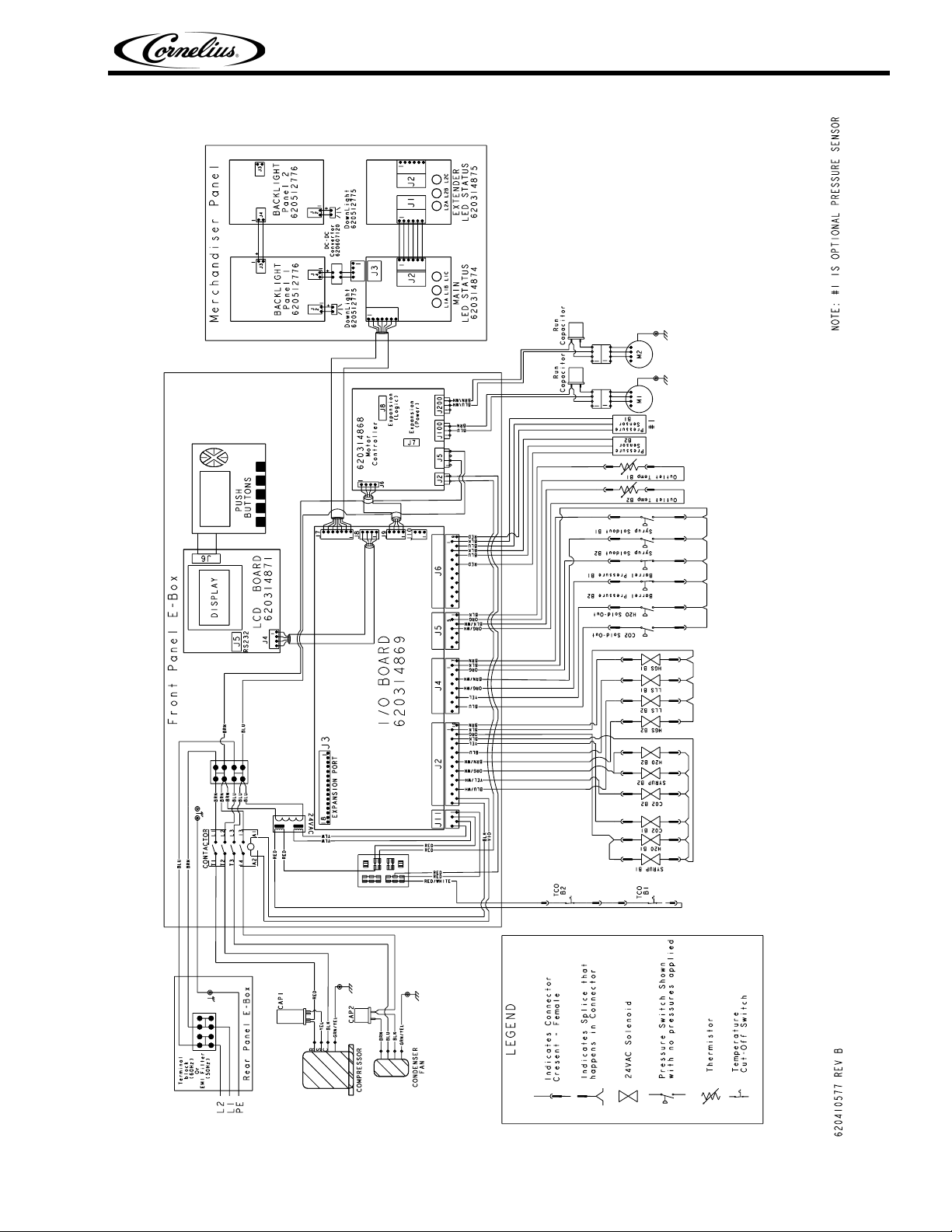

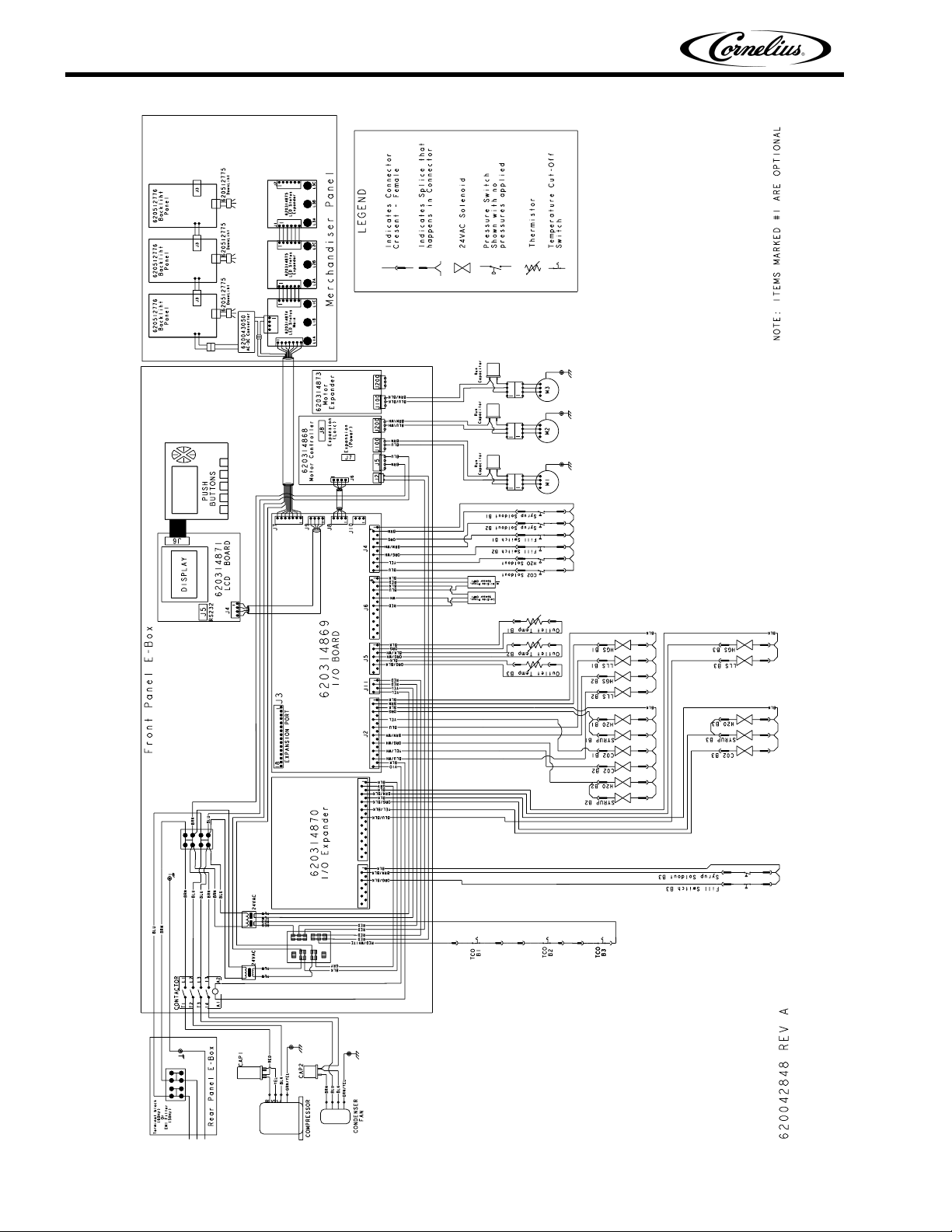

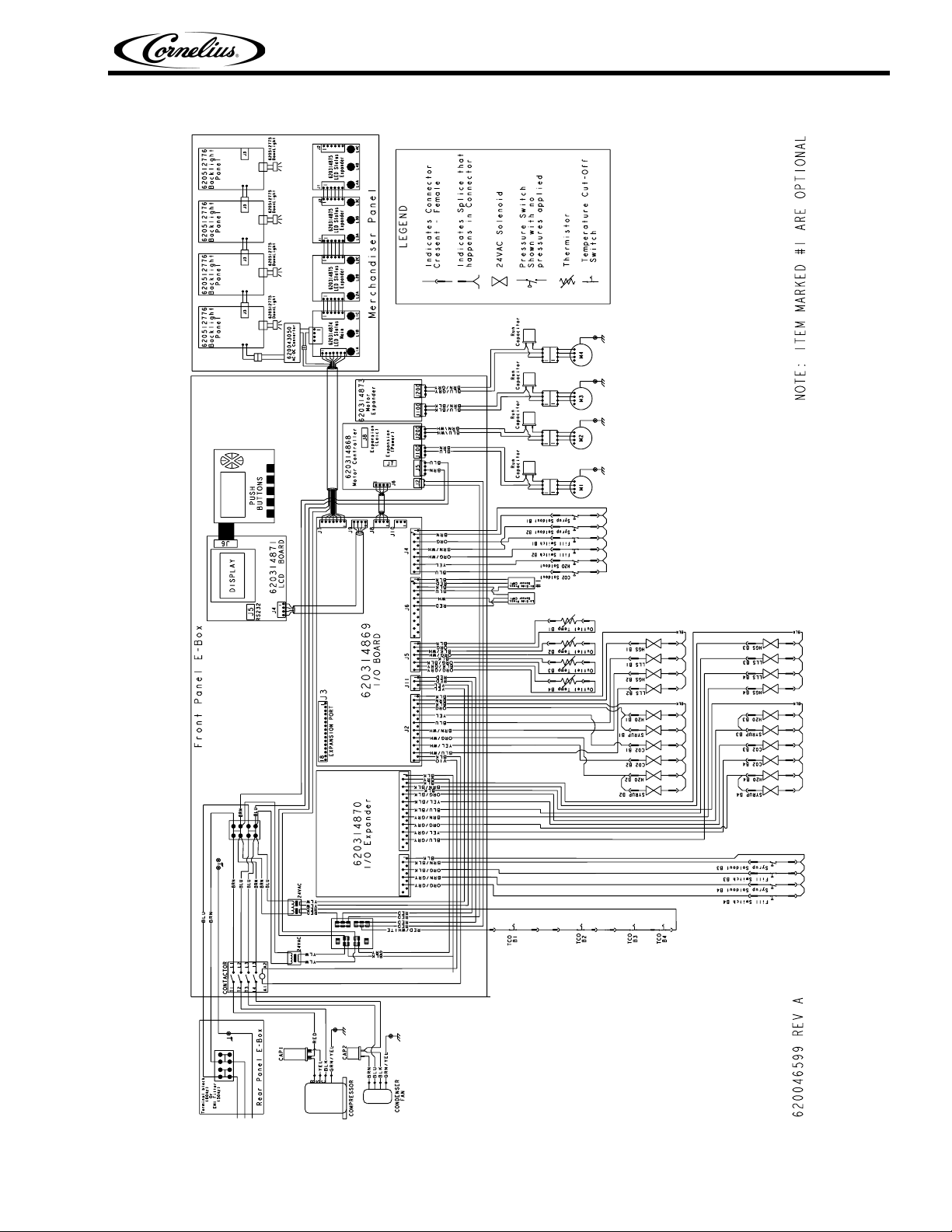

The wiring diagram of the 2-Barrel Viper unit is shown in Figure 4, the wiring diagram of the 3-Barrel Viper unit is shown in Figure 5 and the wiring diagram of the

4-Barrel Viper unit is shown in Figure 6. These diagrams show the details of the

electrical connections in the unit.

Figure 1. Viper System 2-Barrel Refrigeration Schematic

Publication Number: 621260373SER - 8 - © 2008-2010, IMI Cornelius Inc.

Page 15

Viper Service Manual

Figure 2. Viper System 3-Barrel Refrigeration Schematic

© 2008-2010, IMI Cornelius Inc. - 9 - Publication Number: 621260373SER

Page 16

Viper Service Manual

Figure 3. Viper System 4-Barrel Refrigeration Schematic

Publication Number: 621260373SER - 10 - © 2008-2010, IMI Cornelius Inc.

Page 17

Viper Service Manual

J3

J4

BACKLIGHT

1

+

1

J3

PUSH

BUTTONS

BACKLIGHT

Merchandiser Panel

J6

DISPLAY

Front Panel E-Box

BRN

BRN

T1 L1

T2 L2

BLU

BRN

CONTACTOR

BRN

BRN

BLU

T3 L3

LCD BOARD

J5

RS232

BLU

BLU

BLU

1314

A1A2

620314871

1

J4

RED

Panel 2

620512776

Panel 1

620512776

RED

J

J

J

24VAC

1

+

2

DC-DC

Convertor

1

+

4

1

+

2

J7

J3

1

18

YLW

YLW

DownLight

620512775

620607120

1

1

DownLight

620512775

Motor

620314868

1

1

J8

EXPANSION PORT

1

J2J1

1

1

J3

J2

J8

(Logic)

Expansion

(Power)

Expansion

J7

Controller

J6

1

1

J9

J10

I/O BOARD

620314869

1

RED

RED

RED/WHITE

L2CL2A L2B

EXTENDER

620314875

LED STATUS

L1CL1A L1B

MAIN

620314874

LED STATUS

Run

Capacitor

M2

1

1

Run

Capacitor

M1

1

1

B1

Sensor

Pressure

#1

B2

Sensor

Pressure

J200

J100

BRN\ WH

BLU\ WH

1

BRN

BLU

1

J5

Syrup Soldout B1

Syrup Soldout B2

Barrel Pressure B1

Barrel Pressure B2

H2O Sold-Out

CO2 Sold-Out

B1

TCO

Outlet Temp B1

Outlet Temp B2

HGS B1

LLS B1

LLS B2

HGS B2

H20 B2

SYRUP B2

C02 B2

C02 B1

H20 B1

SYRUP B1

11

J2

RED

9

BLK

1

BLU

BLK

BLU

RED

BLK

1

ORG

5

BLK/WH

ORG/WH

BRN

7

BLK

ORG

1

BRN/WH

ORG/WH

YEL

BLU

BRN

10

BLK

1

ORG

BLK

YEL

BLU

BRN/WH

ORG/WH

J2J11 J4 J5 J6

YEL/WH

BLU/WH

1

VIO

BLK

RED

RED

B2

TCO

NOTE: #1 IS OPTIONAL PRESSURE SENSOR

RED

block

Terminal

(60Hz)

Or

(50Hz)

EMI Filter

CAP1

Rear Panel E-Box

CAP2

BLK

YEL

GRN/YEL

SRC

BRN

COMPRESSOR

BLK

BLU

GRN/YEL

FAN

CONDENSER

LEGEND

Indicates Splice that

happens in Connector

Indicates Connector

Cresent - Female

Pressure Switch Shown

with no pressures applied

24VAC Solenoid

Temperature

Thermistor

Cut-Off Switch

L2L1PE

620410577 REV B

Figure 4. Viper 2-Barrel Wiring Diagram

© 2008-2010, IMI Cornelius Inc. - 11 - Publication Number: 621260373SER

Page 18

Viper Service Manual

J2

1

620314875

LED Status

1

J1

1

620314875

LED Status

1

1

1

620314874

LED Status

1

J7

J3

1

EXPANSION PORT

18

Expander

Expander

Main

1

620314868

J9

L3CL3A L3B

L2CL2A L2B

L1CL1A L1B

Motor

620314873

J8

Expansion

Motor Controller

1

J8

620314869

J3

DownLiht

Panel

Backliht

620512776

Panel

Backliht

620512776

Panel

Backliht

620512776

620512775

J3

DownLiht

620512775

J3

DownLiht

620512775

PUSH

BUTTONS

J6

LCD BOARD

DISPLAY

620314871

1

J4

J5

RS232

Front Panel E-Box

BLU

BRN

620043050

AC-DC Converter

LEGEND

Indicates Splice that

Indicates Connector

Cresent - Female

Merchandiser Panel

J200

BRN/BLK

BLU/BLK

J100

Expander

(Loic)

(Power)

Expansion

J7

1

J6

1

J10

I/O BOARD

BRN\ WH

BLU\ WH

J200

BRN

BLU

J100

BLU

BRN

J5

J2

1

1

BRN

7

ORG

BRN/WH

J4

ORG/WH

YEL

BLU

BLK

1

RED

9

BLK

BLU

WH

RED

J6

BLK

1

ORG

BLK/WH

ORG/WH

BLK

J5

ORG/BLK

RED

1

RED

YEL

YEL

J11

BLK

1

BRN

BLK

ORG

YEL

BLU

BRN/WH

J2

ORG/WH

YEL/WH

BLU/WH

BLK

VIO

BLK

11

GRY

BLK

BRN/BLK

BLK

ORG/BLK

YEL/BLK

BLU/BLK

Pressure Switch

happens in Connector

Shown with no

24VAC Solenoid

Run

Capacitor

Run

Capacitor

Run

Capacitor

Sensor CMP1

Hi-Side Press.

Sensor CMP1

Lo-Side Press.

Thermistor

pressures applied

M3

1

1

M2

1

1

M1

1

1

Syrup Soldout B1

Syrup Soldout B2

Fill Switch B1

Fill Switch B2

H2O Soldout

CO2 Soldout

#1

Temperature Cut-Off

Switch

Outlet Temp B1

Outlet Temp B2

Outlet Temp B3

HGS B1

LLS B1

HGS B2

LLS B2

H20 B1

SYRUP B1

C02 B1

C02 B2

H20 B2

SYRUP B2

NOTE: ITEMS MARKED #1 ARE OPTIONAL

BLK

BLK

BLK

HGS B3

LLS B3

BLK

H20 B3

SYRUP B3

C02 B3

BLK

BRN

BLU

Or

(60Hz)

(50Hz)

EMI Filter

Terminal block

BRN

T1 L1

CONTACTOR

T2 L2

BRN

BRN

BLU

BLU

BLU

1314

A2A1

T3 L3

Rear Panel E-Box

GRN/YEL

RED

RED

RED

RED

FAN

CONDENSER

RED/WHITE

BRN/BLK

ORG/BLK

B1

TCO

B2

TCO

B3

B3

TCO

TCO

620314870

I/O Expander

24VAC

YLW

YLW

RED

RED

24VAC

YLW

YLW

RED

CAP1

BLK

YEL

GRN/YEL

SRC

GRY

BLK

CAP2

BLK

BRN

BLU

COMPRESSOR

Syrup Soldout B3

Fill Switch B3

620042848 REV A

Figure 5. Viper 3-Barrel Wiring Diagram

Publication Number: 621260373SER - 12 - © 2008-2010, IMI Cornelius Inc.

Page 19

Viper Service Manual

J3

620512775

DownLight

Panel

620512776

Backlight

J3

620512775

DownLight

Panel

620512776

Backlight

J3

620512775

DownLight

Panel

620512776

Backlight

J3

620512775

DownLight

Panel

620512776

Backlight

PUSH

BUTTONS

J6

DISPLAY

Front Panel E-Box

BRN

BLU

BRN

T1 L1

CONTACTOR

LCD BOARD

620314871

1

J4

J5

RS232

BLU

BRN

BLU

BLU

BRN

BLU

BRN

1314

A2A1

T2 L2

T3 L3

620043050

AC-DC Converter

24VAC

24VAC

J2

J1

J2

J1

1

1

J7

1

18

YLW

YLW

RED

RED

YLW

YLW

1

Expander

620314875

LED Status

1

1

Expander

620314875

LED Status

1

1

Expander

620314875

LED Status

1

1

Main

620314874

LED Status

1

J3

EXPANSION PORT

L4CL4A L4B

L3CL3A L3B

LEGEND

L2CL2A L2B

Merchandiser Panel

L1CL1A L1B

Motor

Expander

620314873

J8

(Loic)

(Power)

Expansion

Expansion

J7

620314868

1

Motor Controller

J6

1

1

J8

J10

I/O BOARD

620314869

620314870

I/O Expander

GRY

BLK

1

7

J4

9

J6

J5

J11

J2

11

RED

RED

RED

RED

J9

Indicates Splice that

happens in Connector

Indicates Connector

Cresent - Female

BRN/GRY

BLU/GRY

J200

BRN/BLK

BLU/BLK

J100

BRN\ WH

BLU\ WH

J200

BRN

BLU

J100

BLU

BRN

J5

J2

1

BRN

ORG

BRN/WH

ORG/WH

YEL

BLU

BLK

1

RED

BLK

BLU

WH

RED

BLK

1

ORG

BLK/WH

ORG/WH

BLK

ORG/BLK

BLK/GRY

ORG/GRY

RED

1

RED

YEL

YEL

BLK

1

BRN

BLK

ORG

YEL

BLU

BRN/WH

ORG/WH

YEL/WH

BLU/WH

BLK

VIO

BLK

GRY

BLK

BRN/BLK

BLK

ORG/BLK

YEL/BLK

BLU/BLK

BRN/GRY

ORG/GRY

YEL/GRY

BLU/GRY

BLK

BRN/BLK

ORG/BLK

BRN/GRY

ORG/GRY

RED/WHITE

24VAC Solenoid

Pressure Switch

Shown with no

pressures applied

Run

Capacitor

1

Run

Capacitor

1

Run

Capacitor

1

Run

Capacitor

1

Sensor CMP1

Hi-Side Press.

#1

Sensor CMP1

Lo-Side Press.

B1

TCO

Temperature Cut-Off

Thermistor

M4

1

M3

1

M2

1

M1

1

Syrup Soldout B1

Syrup Soldout B2

Fill Switch B1

Fill Switch B2

H2O Soldout

CO2 Soldout

Outlet Temp B1

Outlet Temp B2

Outlet Temp B3

Outlet Temp B4

B2

TCO

Switch

HGS B1

LLS B1

HGS B2

LLS B2

H20 B1

SYRUP B1

C02 B1

C02 B2

H20 B2

SYRUP B2

TCOB3TCO

NOTE: ITEM MARKED #1 ARE OPTIONAL

BLK

BLK

B4

HGS B3

LLS B3

LLS B4

HGS B4

H20 B3

SYRUP B3

C02 B3

C02 B4

H20 B4

SYRUP B4

Syrup Soldout B3

Fill Switch B3

Syrup Soldout B4

Fill Switch B4

BLK

BLK

RED

CAP2

BLK

YEL

GRN/YEL

SRC

COMPRESSOR

GRN/YEL

BLK

BRN

BLU

FAN

CONDENSER

620046599 REV A

Or

(60Hz)

(50Hz)

EMI Filter

Terminal block

CAP1

Rear Panel E-Box

Figure 6. Viper 4-Barrel Wiring Diagram

© 2008-2010, IMI Cornelius Inc. - 13 - Publication Number: 621260373SER

Page 20

Viper Service Manual

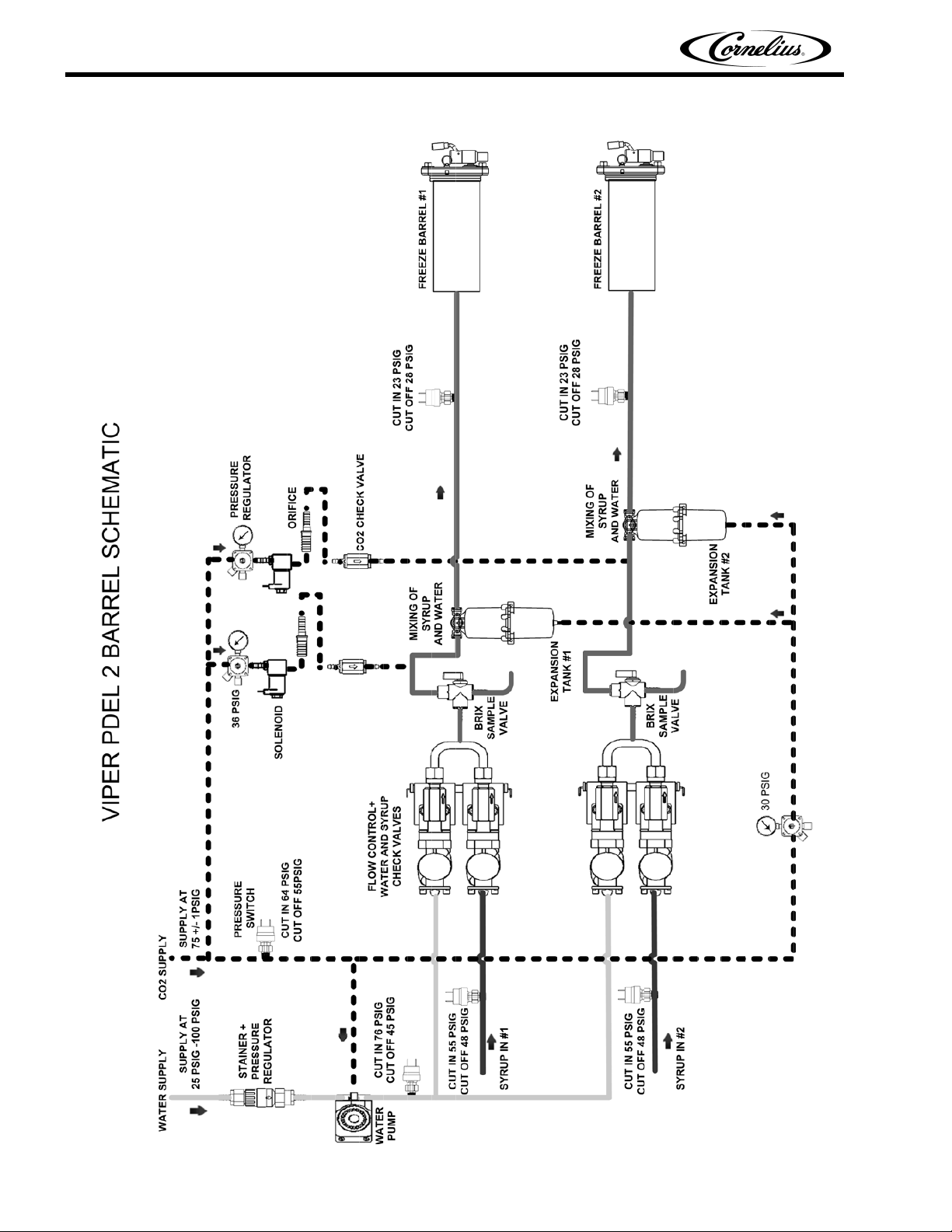

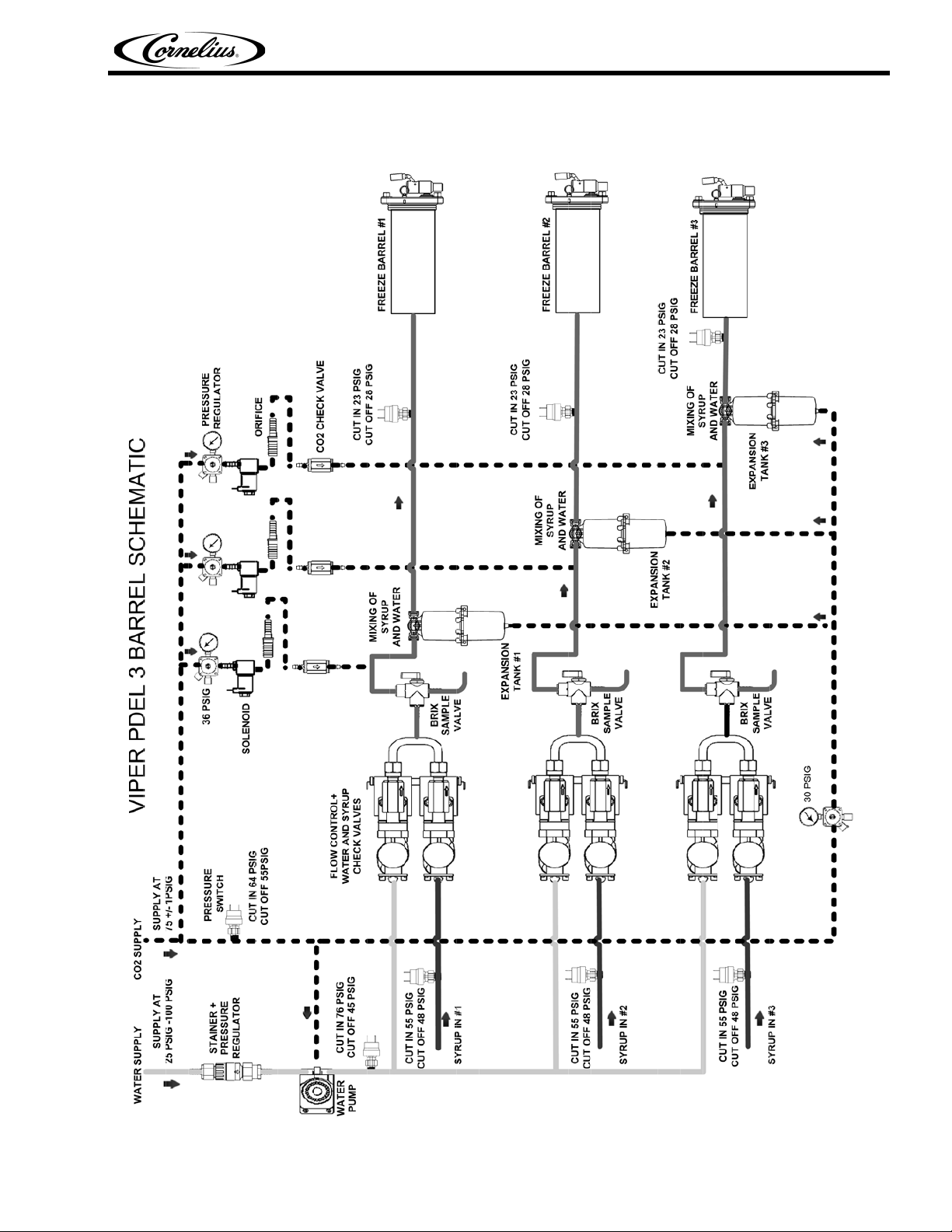

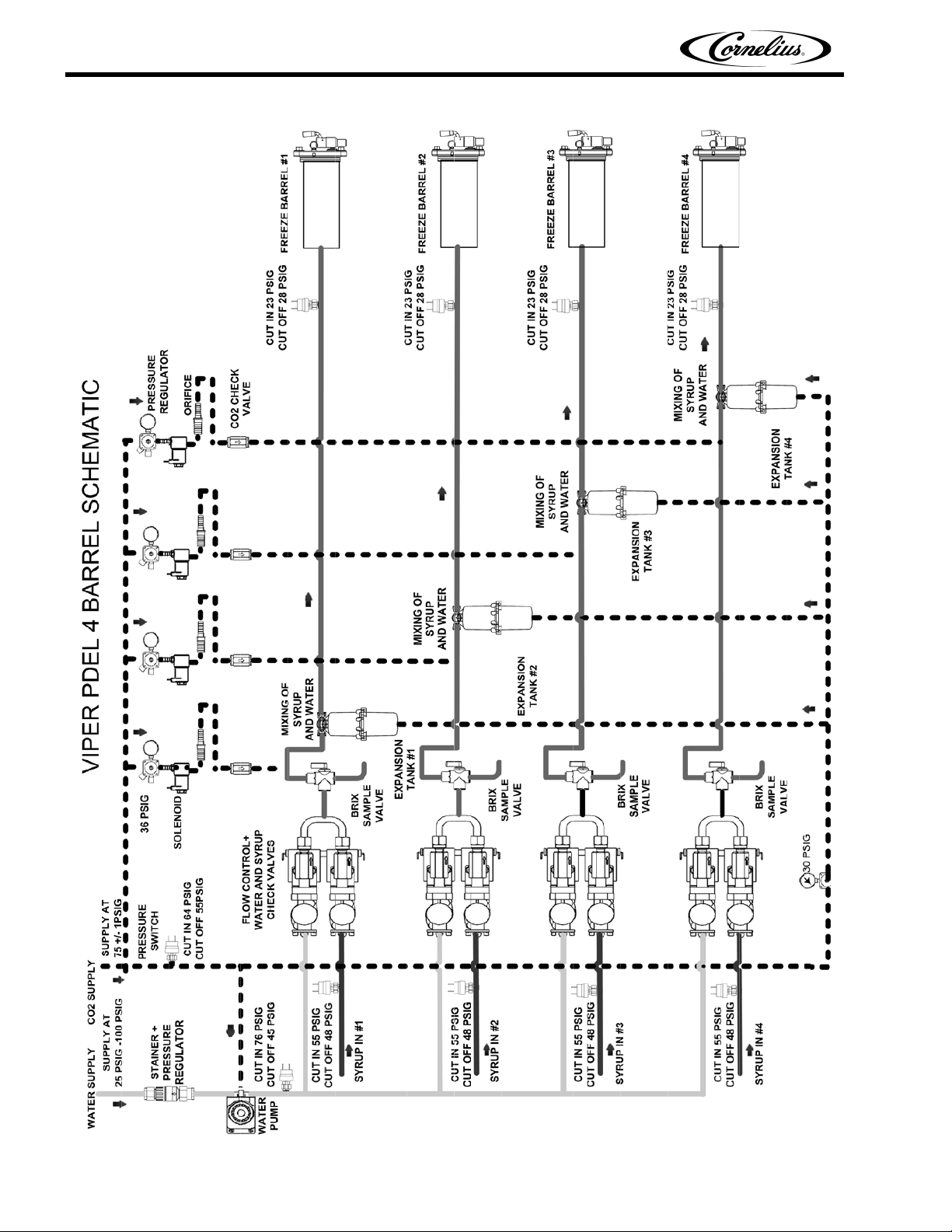

An overall schematic of the three delivery systems contained in the unit are

shown in Figure 9, Figure 10 and Figure 11. The CO2 system is on top, the water

system is in the middle and the syrup system is at the bottom of the diagram.

The CO2 system interacts with both the water and syrup systems. It provides

pressure and carbonation for the syrup/water product mix.

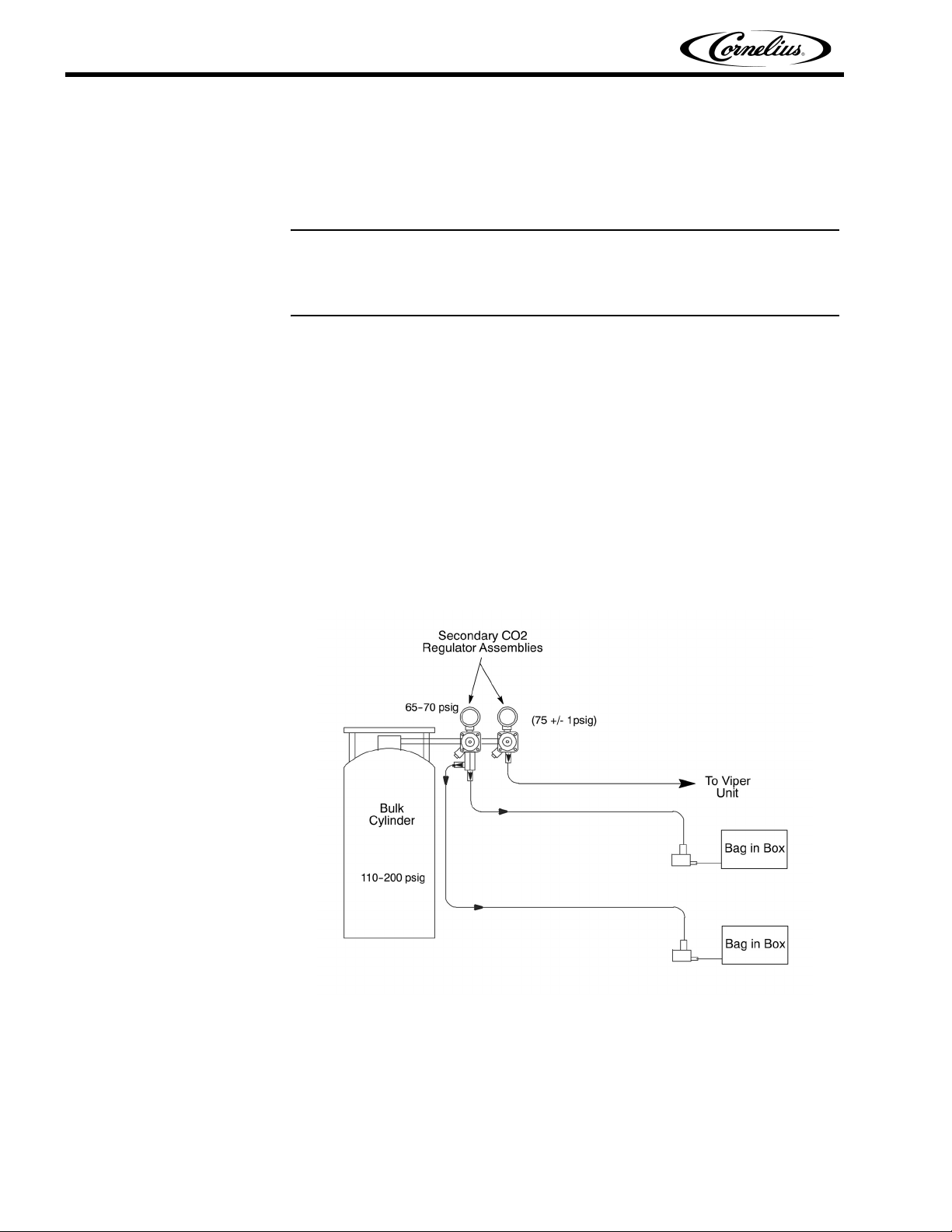

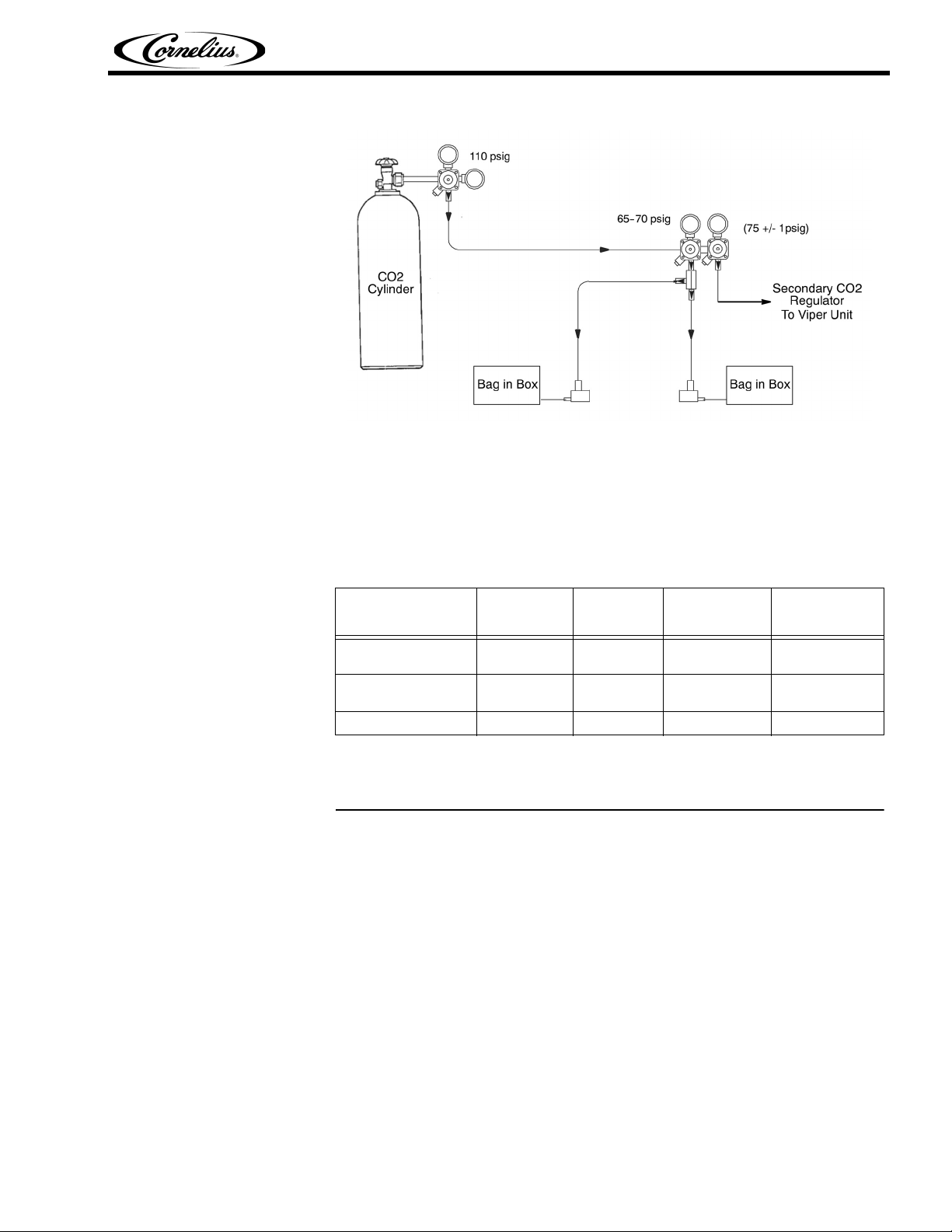

CO2 System

A CO2 tank or bulk CO2 supply delivers carbon dioxide gas (CO2) to an adjustable secondary CO2 regulator assembly that is attached to the tank as shown in

Figure 7 and Figure 8. The CO2 system also supplies CO2 to the water boost

pump, the expansion tank regulator and the secondary CO2 tank regulators.

CO2 enters the expansion tank regulator and is reduced to approximately 30

psig to feed holding pressure on the expansion tank. This provides a force to

work against the barrel pressure when the product freezes and expands.

CO2 also enters the secondary regulators. These regulators are used to adjust

barrel overrun/expansion for various products. The pressure settings for various

types of syrup are shown in Table 1. Overrun CO2 pressure is applied to the CO2

control solenoids through preset orifices and on to the in-line check valves.

From the in-line check valve, the CO

Figure 7. Typical Bulk Cylinder CO2 Connection

2 flows into the product line.

Publication Number: 621260373SER - 14 - © 2008-2010, IMI Cornelius Inc.

Page 21

Viper Service Manual

Figure 8. Typical Tank CO2 Connection

Table 1 provides guidelines for machine settings based on general syrup type.

Several factors, including syrup formulation, level of citric acids, etc, will impact

settings. These settings are to provide initial adjustments to achieve product

overruns in the 80-120% range.

Table 1

Syrup Type

FCB Syrup w/

Foaming Agent

FCB Syrup w/o

Foaming Agent

FUB FUB 7 N/A 30

NOTE: For citric syrups, adjust the CO

Syrup

Type Set

FCB 4 34-36 PSIG 30

FCB 4 32-36 PSIG 30

Viscosity Pressure Expansion

2 pressures down by 2-4 PSIG from

the above to compensate for the lower CO2 adsorption.

© 2008-2010, IMI Cornelius Inc. - 15 - Publication Number: 621260373SER

Page 22

Viper Service Manual

Figure 9. 2-Barrel System Schematic

Publication Number: 621260373SER - 16 - © 2008-2010, IMI Cornelius Inc.

Page 23

Viper Service Manual

Figure 10. 3-Barrel System Schematic

© 2008-2010, IMI Cornelius Inc. - 17 - Publication Number: 621260373SER

Page 24

Viper Service Manual

Figure 11. 4-Barrel System Schematic

Publication Number: 621260373SER - 18 - © 2008-2010, IMI Cornelius Inc.

Page 25

Water System

Syrup System

Viper Service Manual

Incoming water flows to a water pressure regulator that is preset to 30 psig. It

flows through the water booster pump, to the regulator and through a sold-out

switch.

Once through the boost pump, the water supply is split to each barrel and is fed

to the water flow controls. From the flow rate control, the water passes through a

single ball check valve and mixes with the syrup in a wye fitting for injection into

the freeze barrel.

Syrup enters the unit through a sold-out switch. It enters a similar flow control to

the water system, passes through a single-ball check valve and into the wye fitting where it meets the water for injection into the freeze barrel.

CONTROL PANEL

Introduction

The Viper unit uses a microprocessor based control system that monitors and

controls all of the major systems and components of the machine. Temperatures

and pressures are monitored, along with pumps, valves and the refrigeration

system. They are managed by the control system to provide a consistently high

quality product with optimal efficiency.

The control system is set up by the service provider to perform the tasks necessary to keep the Viper unit operating correctly. In addition to controlling the unit,

the control system keeps track of the diagnostic information used when adjusting and/or repairing the machine.

The control system needs to be accessed in the following situations:

• Installing the Viper

• Modifying Operating Characteristics

• Checking Performance

• Servicing/Repairing the Machine

• Checking for Error Messages

The control system is accessed using the control panel located behind the

lighted merchandiser. The control panel contains an LCD display and buttons

shown in Figure 12.

There are 2 levels of access to the control panel: The first level can be accessed

by the operator for normal operation and the second level is used by qualified

© 2008-2010, IMI Cornelius Inc. - 19 - Publication Number: 621260373SER

Page 26

Viper Service Manual

service technicians for installation and service functions. The service functions

can be secured (locked out) so that an operator does not have access to them.

The control panel has a structured organization of menus. The outline of this

structure is shown in Figure 13. The Maintenance sub-menu is not visible when

the security feature is on.

The first menu that is displayed after the unit is powered up and stabilized is the

BARREL STATUS or HOME menu, shown in Figure 12. This menu is displayed

when the unit is running in normal operation.

Control Panel Display

The control panel display has two main areas. The first area is the menu display

area. This area presents information about the status and settings of the

machine. It also displays menus of actions that are taken to modify the functioning of the machine.

Control Panel Buttons

Menu

BARREL

STATUS

#1 FREEZE 87

#2 FREEZE 68

Display

Area

12:51P

MAR 04

MENU ON OFF DFRST SPIN

Menu Buttons

Figure 12. Control System Display

The second area are the buttons and arrows located across the bottom and on

the right side of the control panel. There are up to five buttons and four directional arrows that may be used on a screen to activate and control various the

functions of the system. Each button that is active for a given menu has a label

directly above it. The label describes what that button controls. For example,

from the Barrel Status menu, pressing button 1 (labeled MENU) displays the

Select menu with more options — pressing button 3 (labeled OFF) turns off the

highlighted barrel.

On each menu below the Select menu, there is a button (labeled BACK) to save

any settings and return to the previous menu. There is another button (GO) to

advance to the highlighted menu.

Publication Number: 621260373SER - 20 - © 2008-2010, IMI Cornelius Inc.

Page 27

Viper Service Manual

Initialization

Main

Sub-Menus

Screens

Unit Data

Barrel

Status

(Home Screen)

Setup

Sub-Menus

Clock Setup

Event Setup

Maintenance

Sub-Menus

Barrel Maint.

Manual Diag

Error Status

Error Log

Barrel Data

Unit Data

Software Ver.

Figure 13. Software Structure

Option Setup

Viscosity Setup

Totals

Brix Setup

Motor Setup

System Setup

© 2008-2010, IMI Cornelius Inc. - 21 - Publication Number: 621260373SER

Page 28

Viper Service Manual

CONTROL PANEL MENU DESCRIPTIONS

The following section describes the information displayed on each control panel

menu and the interactions and settings that are controlled by that menu.

System Menus

The system menu structure allows the user to control the unit through the control

panel. Operational settings, optional parameters, troubleshooting and error

information are controlled through this menu system.

The Barrel Status menu, shown in Figure 14, is the home screen for the unit.

During normal operation, this screen is displayed on the control panel.

BARREL

STATUS

12:51P

MAR 04

MENU ON OFF DFRST SPIN

#1 FREEZE 87

#2 FREEZE 68

Figure 14. Main Screen

Table 2

Button Description

MENU Displays the Main menu

ON Turns on the highlighted barrel

OFF Turns off the highlighted barrel

DFRST Initiates a manual defrost on the highlighted barrel. Manual defrost is lim-

SPIN Turns off refrigeration, if on and mixes the product in the barrel.

ited to a four minute cycle.

Main Menu

To access the menus for the system from the Barrel Status menu, press the

MENU button. This displays the Select menu, shown in Figure 15. The Setup

and Maintenance menus are accessed through the buttons shown at the bottom

of the display.

NOTE: If security is turned on, the MAINT button is not displayed.

Publication Number: 621260373SER - 22 - © 2008-2010, IMI Cornelius Inc.

Page 29

Viper Service Manual

SELECT

12:51P

MAR 04

BACK MAIN SETUP MAINT GO

UNIT DATA

ERROR STATUS

ERROR LOG

Figure 15. Select Screen

When the Select menu is displayed, the Unit Data is highlighted. To access the

Unit Data menu, press the GO button. Refer to Table 3, the Select menu, for

button functions.

Table 3

Button Description

BACK Returns the display to the Barrel Status menu

MAIN Highlighted to indicate current menu

SETUP Opens the Setup menu

MAINT Displays and opens Maintenance menu,

GO Opens the highlighted selection on the current menu

if security is off or accessed

Unit Data Menu

The Unit Data screen, shown in Figure 16, provides information about the

individual barrels in the system. When DATA is highlighted and the GO button is

pressed on the Select menu, the display shows the first barrel in the system and

some of its parameters. To view the next barrel, press the Down arrow on the

right side of the display. Continue pressing the Down arrow to view the data on

all barrels in the system. Refer to Table 4 for button functions.

UNIT

DATA

12:51P

MAR 04

BACK BRL UNIT VER

#1 FREEZE

OUTLET TEMP 33

VISCOSITY: 9

REFRIGERATION: ON

AV OZ/HR/3 HR: 80

DEFROST TIMER: 2:50:23

o

F

Figure 16. Unit Data Screen

Table 4

Button Description

BACK Returns the display to the Select menu

BRL Displays the data for a single barrel, including Outlet Temperature, Vis-

cosity, if Refrigeration is On or Off, Average Ounces of product dispensed

per hour for the last three hours and Defrost Lock Time until next defrost

© 2008-2010, IMI Cornelius Inc. - 23 - Publication Number: 621260373SER

Page 30

Viper Service Manual

Button Description

UNIT Displays the real time input voltage and frequency being supplied to the

VER Displays the version number of the UI, I/O, Motor and Status boards

Error Status Menu

The Error Status menu, shown in Figure 17, displays any current errors contained in the Error Messages List.

There are three types of errors that can be generated by the system. These

error types and a description of their meaning are listed in Table 5.

Error Type Description

System A System error displays the same information across all barrels in the unit.

Barrel A Barrel error is limited to a specific barrel

Limp A Limp error is an error that doesn’t prevent the unit from operating, but limits

Table 4

unit and the low, high or both refrigeration pressures for the unit, depending on the settings of the compressor sensors in the Unit Data screen, as

shown in Figure 36.

installed in the unit

Table 5

functionality.

The possible messages from the control system and a description of the errors

are shown in Table 6. The button functions are described in Table 7.

ERROR

STATUS

12:51P

MAR 04

BACK

#1 MOTOR PWR

COMP HIGH

Figure 17. Error Status Screen

Table 6

Displayed

Message

HOT GAS Off System Occurs when the barrel outlet temperature exceeds

HOT BARREL Off System Occurs when the barrel outlet temperature exceeds

MTR CTL FAIL System The motor controller reported a fault, triacs are

TCO OPEN System TCO (Temperature Cut Off) has occurred on the

Action Type Description

115 oF for more than one minute and the compressor is on.

115 oF for more than one minute and the compressor is off.

shorted and there is a loss of motor on/off functionality.

refrigeration oulet of a barrel or the 24VAC power

has failed.

Publication Number: 621260373SER - 24 - © 2008-2010, IMI Cornelius Inc.

Page 31

Viper Service Manual

Table 6

Displayed

Message

COMM ERR IO System A communications error occurred between the IO

COMM ERR

MTR

BARREL

REFRG

MTR CAL ERR Barrel Occurs if a calibration initiated from the Motor

CMP HI-PRESS System This error is generated if the low side pressure is

BRL TEMP OUT Barrel Indicates thermistor reading is at min. or max. value

MOTOR STALL Barrel Motor stalled. A two minute defrost and two retries

METER FAIL Barrel Metering chip is nonresponsive.

BRL RECOVER Barrel Barrel viscosity is too high. Motor cannot rotate.

COM ERR STAT Limp Communications error, the system continues to run.

HIGH VOLTAGE System The unit is experiencing voltage greater than

LOW VOLTAGE System The unit is experiencing voltage less than 200VAC.

NO MOTOR Barrel The motor is reporting no current draw when acti-

FILL ERROR Barrel Barrel has not filled properly within 2 min.

H2O OUT System Water pressure is too low for proper operation. This

CO2 OUT System CO2 pressure is below required operating pressure.

SYRUP OUT Barrel Syrup pressure is below required operating pres-

CLOCK System The real time system clock is not functioning.

MTR CTL

EEPROM

Action Type Description

board and the UI board.

System UI board cannot communitcate with the motor

board.

Barrel Compressor has been on for more than 45 minutes

and the viscosity of the barrel is not satisfied with

no draws.

Setup menu fails. This indicates that the power

draw of the motor is outside the allowable calibration range.

greater than 55 psi for greater than 30 sec. Only

checked when barrels are in freeze mode and compressor is running more than two minutes.

for 30 sec. without changing.

are allowed, then the message is displayed,

Automatic two minute defrost to thaw barrel.

260VAC. System is enabled when line voltage

drops below 260VAC for two minutes.

System is enabled when line voltage rises above

200VAC for two minutes.

vated. Motor is unplugged or thermal cutoff has

tripped.

error occurs when the H2O sensor reports no or low

water pressure for more than one second. Error is

cleared 10 sec. after restoral.

This error occurs when the CO2 sensor reports no

or low CO2 pressure for more than one second.

Error is cleared 10 sec. after restoral.

sure. This error occurs when the syrup sensor

reports no or low syrup pressure for more than one

second. Error is cleared 10 sec. after restoral.

System Motor control EEPROM is bad or missing.

Table 7

Button Description

BACK Returns the display to the Select menu

RESET Allows the user to reset the highlighted error (This button only appears on

© 2008-2010, IMI Cornelius Inc. - 25 - Publication Number: 621260373SER

certain manually resettable errors.)

Page 32

Viper Service Manual

Error Log Menu

The Error Log screen displays information about any errors generated by the

unit, as shown in Figure 18. If no errors have been detected, the right side of the

display is blank. To view more than one error, press the Up or Down arrows on

the right side of the display to scroll through the error log. Button functions are

described in Table 8.

Setup Menu

ERROR

LOG

12:51P

MAR 04

BACK

ERROR NUMBER 2

#3 COMM FAIL

OCCUR: 2:44 PM

3/04/08

CLEAR: 2:52 PM

3/04/08

Figure 18. Error Log Screen

Table 8

Button Description

BACK Returns the display to the Select menu

The Setup menu provides the means to change various settings to local

preferences, such as time, date and temperature formats. It also allows the user

to adjust the unit for the type of syrup being served in each barrel.

To access the Setup menu from the Barrel Status menu, press the MENU

button. This displays the Select menu, shown in Figure 15. Press the SETUP

button to display the Setup menu, shown in Figure 19. To set up the unit options,

use the Up and Down arrows on the right side of the control panel to highlight

the choices on the display. When the desired option is highlighted, press the GO

button to access that menu.

SELECT

12:51P

MAR 04

BACK MAIN SETUP MAINT GO

BACK MAIN SETUP MAINT GO

Publication Number: 621260373SER - 26 - © 2008-2010, IMI Cornelius Inc.

CLOCK SETUP

EVENTS SETUP

VISC SETUP

OPTION SETUP

Figure 19. Setup Screen

Page 33

Clock Setup Menu

Viper Service Manual

Table 9

Button Description

BACK Returns the display to the Select menu

MAIN Opens the Main menu

SETUP Highlighted to indicate that the Setup menu is displayed

MAINT Displays button and opens Maintenance menu, if security is off or

accessed

GO Opens the highlighted selection on the current menu

Select the CLOCK SETUP menu from the Select menu, shown in Figure 19.

This displays the Clock Setup menu, shown in Figure 20. Button functions are

described in Table 10.

Setting the Clock

CLOCK

SETUP

12:51P

MAR 04

BACK CLOCK DST - +

TIME: 11:00 AM

DATE: 01/01/00

Figure 20. Clock Setup Screen

Table 10

Button Description

BACK Returns the display to the Select menu

CLOCK Highlighted to indicate that the Clock menu is displayed

DST Opens the Daylight Savings Time menu

- Decrements the highlighted field

+ Increments the highlighted field

Select the CLOCK SETUP menu from the Select menu, shown in Figure 19.

This displays the Clock Setup menu, shown in Figure 20. To set the time,

perform the procedure in Table 11.

Table 11

Step Action Procedure

Set clock time Use up and down arrows on the right side of the con-

1

Select hour field Use the left and right arrows to select hour field

2

© 2008-2010, IMI Cornelius Inc. - 27 - Publication Number: 621260373SER

trol panel to highlight TIME display on screen.

Page 34

Viper Service Manual

Step Action Procedure

3

4

5

6

7

To set the date, perform the procedure in Table 12 and refer to Figure 20.

Step Action Procedure

1

2

3

4

5

6

7

Table 11

Set correct hour Use the + or - buttons at the bottom of the display to

set the proper hour.

Select minute field Use the left and right arrows to select minute field.

Set correct minute Use the + or - buttons at the bottom of the display to

set the proper minute.

Select AM/PM field If the 12 hour clock option is selected, use the left and

right arrows to select the AM/PM field.

Set AM/PM Use the + button at the bottom of the display to set the

AM/PM setting.

Table 12

Set date Use up and down arrows on the right side of the con-

trol panel to highlight DATE display on screen.

Select month field Use the left and right arrows to select month field

Set correct month Use the + or - buttons at the bottom of the display to

set the correct month.

Select day field Use the left and right arrows to select day field.

Set correct day Use the + or - buttons at the bottom of the display to

set the correct day.

Select year field Use the left and right arrows to select year field.

Set correct year Use the + or - buttons at the bottom of the display to

set the correct year.

Setting Daylight Savings Time

Once the date and time are set properly, daylight savings time settings can be

done. The Daylight Savings Time menu is shown in Figure 21. If daylight

savings time is off, press the + button to activate it. The button functions are

described in Table 13. To set daylight savings time, perform the procedure in

Table 14.

NOTE: Default daylight savings settings are for the U.S.

CLOCK

SETUP

12:51P

MAR 04

BACK CLOCK DST - +

Figure 21. Daylight Savings Setup Screen

DST: ON

SPRING MONTH: MAR

SPRING WEEK: 1

FALL MONTH: OCT

FALL WEEK: L

Publication Number: 621260373SER - 28 - © 2008-2010, IMI Cornelius Inc.

Page 35

Viper Service Manual

Table 13

Button Description

BACK Returns the display to the Select menu

CLOCK Opens the Clock menu

DST Highlighted to indicate DST menu

- Decrements the highlighted field by one increment

+ Increments the highlighted field by one increment

Table 14

Step Action Procedure

Set daylight savings time Press DST button at the bottom of display to open day-

1

Select DST Use the up and down arrows to select DST.

2

Set DST on Use the + button to turn on daylight savings time.

3

Select SPRING MONTH Use up and down arrows to select SPRING MONTH.

4

Set SPRING MONTH Use the + or - buttons at the bottom of the display to set

5

Select SPRING WEEK Use up and down arrows to select SPRING WEEK.

6

Set SPRING WEEK Use the + or - buttons at the bottom of the display to set

7

Select FALL MONTH Use the up and down arrows to select FALL MONTH.

8

Set FALL MONTH Use the + or - buttons at the bottom of the display to

9

10

11

Select FALL WEEK Use up and down arrows to select FALL WEEK.

Set FALL WEEK Use the + or - buttons at the bottom of the display to set

light savings time display, shown in Figure 21.

the correct month.

the correct week. The choices are 1, 2, 3 or L.

set the correct month.

the correct week. The choices are 1, 2, 3 or L.

Events Setup Menu

When the daylight savings settings are complete, press the BACK button to

save the settings and return to the Select menu, shown in Figure 19.

The Events Setup menu, shown in Figure 22, allows the user to set sleep

periods for the unit and to lock out the defrost cycle during peak busy times.

Sleep periods and defrost lockouts may be programmed for any day of the week

or for all days of the week, depending on business requirements. Button

functions are described in

EVENT

SETUP

12:51P

MAR 04

BACK CLEAR - +

Table 15.

DAY SUN

SLEEP 10:00 PM

WAKEUP 08:00 AM

DEFROST LOCK 1: 05:15 PM

DEFROST LOCK 2: 09:30 AM

DEFROST LOCK 3: ------------

Figure 22. Event Setup Screen

© 2008-2010, IMI Cornelius Inc. - 29 - Publication Number: 621260373SER

Page 36

Viper Service Manual

Button Description

BACK Returns the display to the Select menu and saves current settings

CLEAR Clears the highlighted field on the menu

- Decrements the highlighted field

+ Increments the highlighted field

When the sleep and wakeup settings and the defrost lockout settings are

complete, press the BACK button to save the settings and return to the Select

menu, shown in Figure 19.

Setting Events

Events setup allows the user to set sleep periods for the unit and to lock out the

defrost cycle during peak busy times. Sleep periods and defrost lockouts may be

programmed for individual days of the week or for all days of the week,

depending on location requirements.

Table 15

Setting the Sleep and Wakeup Times

Sleep and wakeup times are set on the Event Setup menu shown in Figure 22.

To set the sleep and wakeup times, perform the procedure in Table 16.

When the unit goes into a sleep period, the barrel automatically defrosts for four

minutes. Also, if a barrel is off when the sleep cycle starts, the barrel continues

to be in the off state when the sleep cycle ends. If a barrel is running when the

sleep cycle starts, the barrel starts back up when the sleep cycle ends.

Wakeup should be scheduled for approximately one hour before product is

required.

NOTE: Setting the sleep time after midnight requires you to set it

during the next day. (i.e. Saturday night at 1am must be set as 1am

on Sunday, etc.) If this type of setting is required, you cannot set

another sleep cycle during that following day, i.e. Sunday.

Table 16

Step Action Procedure

1

2

3

4

5

6

Set sleep and wakeup

times

Select DAY The DAY field is highlighted.

Set DAY Use the + or - buttons at the bottom of the display

Select SLEEP Use the up and down arrows to highlight SLEEP.

Set hour field Use the left and right arrows to select the hour

Set minute field Use the left and right arrows to select the minute

Open the Events Setup menu, shown in Figure 22

by pressing the GO button.

to set the desired day or all days.

field and press the + or - buttons to change the

hour.

field and press the + or - buttons to change the

minutes (15 min. increments)

Publication Number: 621260373SER - 30 - © 2008-2010, IMI Cornelius Inc.

Page 37

Viper Service Manual

Setting Defrost Lockout

Table 16

Step Action Procedure

7

8

9

Select AM/PM field If the 12 hour clock option is selected, use the left

and right arrows to select the AM/PM field. Then

press the + or - buttons to change between AM

and PM.

Select DAY for Wakeup Repeat Steps 2 and 3 as needed.

Select WAKEUP Use the up and down arrows to highlight

WAKEUP and repeat Steps 5 through 7 to set the

WAKEUP times.

When the sleep and wakeup settings are complete, press the BACK button to

save the settings and return to the Select menu, shown in Figure 19.

From the Barrel Status menu, shown in Figure 14, press the MENU button and

then press the SETUP button to display the Setup menu. Use the up and down

arrows on the right of the control to highlight the Events Setup menu, then press

GO to enter the menu (Figure 22).

The lockout can also be set day by day or for all days with up to three lockout

periods of three hours each per day. These lockout periods may be overlapped

to provide from three to nine hours of defrost lockout, if desired. When the

periods are overlapped, it is recommended that the defrost lockouts for

sequential lockout periods be overlapped by 15 minutes. The defrost lockout

affects all barrels in the unit. To set the defrost lockouts, perform the procedure

in Table 17.

Table 17

Step Action Procedure

1

2

3

4

5

6

7

8

9

10

11

12

Set defrost lockout Open Events Setup menu, shown in Figure 22

Select DAY The DAY field is highlighted.

Set DAY Use the + and - buttons at the bottom of the display

Select DEFROST LOCK 1Use the up and down arrows to highlight

Set hour field Use left and right arrows to select hour field

Set minute field Use left and right arrows to select minute field

Select AM/PM field If the 12 hour clock option is selected, use the left

Select DEFROST LOCK

2

Select DEFROST LOCK 3Repeat Steps 2 through 10 for the DEFROST

to set the desired day or all days.

DEFROST LOCK 1.

Use the + and - buttons at the bottom of the display

to set the desired hour.

Use the + and - buttons at the bottom of the display

to set the desired minute (in 15 min. increments).

and right arrows to select the AM/PM field.

Use the + button at the bottom of the display to set

the AM/PM field.

Repeat Steps 2 through 10 for the DEFROST

LOCK 2 time, if desired.

LOCK 3 time, if desired.

When the defrost lockout settings are complete, press the BACK button to save

the settings and return to the Select menu, shown in Figure 19.

© 2008-2010, IMI Cornelius Inc. - 31 - Publication Number: 621260373SER

Page 38

Viper Service Manual

Viscosity Setup Menu

The viscosity maintained in the freeze barrels depends on the type of product

being served. Some products are served best at a higher viscosity, while others

require a lower viscosity for best quality. The Viscosity menu, shown in Figure

23, allows the user to adjust the viscosity in each barrel to the optimum setting

for each type of syrup.

VISC

SETUP

12:51P

MAR 04

BACK ALL - +

#1 VISC RANGE 6 48-110

#2 VISC RANGE 6 48-110

Figure 23. Viscosity Setup Screen

Refer to the Installation manual for the recommended settings based on syrup

type.

Table 18

Step Action Procedure

Set viscosity range From the Setup screen (Figure 19), open the Viscos-

1

Select barrel Use the Up and Down arrows to highlight the desired

2

Select range field Use Left and Right arrows to select range field

3

Set range Use the + or - buttons at the bottom of the display to

4.

Select barrel Repeat Steps 2 through 4 for all barrels.

5

ity Setup screen, shown in Figure 23.

barrel.

set the desired range.

To set all barrels in the system to the same viscosity setting, perform Steps 1

through 4 in Table 18, and then press the ALL button at the bottom of the display

while highlighting the viscosity setting you desire for all the barrels. When the

viscosity settings are complete, press the BACK button to save the settings and

return to the Select menu, shown in Figure 19.

Options Setup Menu

The Option Setup menu allows the user to set the various options available in

the system. These options are listed in Table 19. The Option Setup menu is

shown in Figure 24.

The functions of the display buttons change, depending on the highlighted

selection on the Option Setup screen. Refer to Table 19 for a listing of the button

functions for the various field selections.

Publication Number: 621260373SER - 32 - © 2008-2010, IMI Cornelius Inc.

Page 39

Viper Service Manual

OPTION

SETUP

12:51P

MAR 04

BACK oF oC

TEMP FORMAT

DATE FORMAT USA

TIME FORMAT 12 HR

POS LIGHTING ALWAYS

#1 SYRUP TYPE: FCB

#2 SYRUP TYPE: FCB

Figure 24. Option Setup Screen

o

F

Table 19

Option Button 2 Button 3 Button 4 Button 5

Temp F or m at

Date Format USA EURO

Time Format 12 HR 24 HR

POS Lighting OFF ALWAYS SLEEP

#1 SYRUP TYPE FCB FCB-L FUB FUB-L

#X SYRUP TYPE FCB FCB-L FUB FUB-L

°F °C

When all the options are set to the desired settings for the unit, press the BACK

button to store these settings and return to the Select menu, shown in Figure 19.

Setting the Temperature Format

Setting the Date Format

Setting the Time Format

The temperature format displayed by the unit may be set to either Centigrade or

Farenheit. Press the °F button to display readings in Farenheit and press the °C

button to display readings in Centigrade.

The date format can be displayed in either United States or European format. To

display U.S. date format, press the USA button. This displays the date in mm/dd/

yy format. Press the EURO button to display the date in dd/mm/yy format.

Time format can be displayed in either 12 or 24 hour format. To display the clock

settings in 12 hour format (1:08 P), press the 12 HR button. To display settings

in 24 hour format (23:05), press the 24 HR button.

Setting the POS Lighting

POS Lighting is controlled by the POS LIGHTING field on the Option Setup

menu (Figure 24). To turn off the merchandiser lighting, press the OFF button

© 2008-2010, IMI Cornelius Inc. - 33 - Publication Number: 621260373SER

Page 40

Viper Service Manual

while the POS LIGHTING field is highlighted. To turn on the merchandiser

lighting permanently, press the ALWAYS button. To turn the merchandiser

lighting on and off with the Sleep settings, press the SLEEP button.

Setting the Type of Syrup

Syrup type for each barrel may be selected by highlighting the desired barrel

and pressing the appropriate button, FCB, FCB-L, FUB or FUB-L. FCB is for

Frozen Carbonated Beverage, FCB-L is for Frozen Carbonated Beverages Light (diet), FUB is for Frozen Uncarbonated Beverages and FUB-L is for Frozen Uncarbonated Beverages - Light (diet). Each of these settings provides the

proper viscosity and temperature settings for the type of syrup being used.

Maintenance Menu

Barrel Maintenance Menu

The Maintenance menu, shown in Figure 25, is only available to service personnel or other authorized users, if security is enabled.

The Maintenance menu is used for barrel maintenance, diagnostics, BRIX setup

and system information. It allows the technician access to the unit during periodic maintenance or troubleshooting problems. It sometimes overrides the normal inputs from the system in order to perform this task.

SELECT

12:51P

MAR 04

BACK MAIN SETUP MAINT GO

BARREL MAINT

MANUAL DIAG

TOTALS

BRIX SETUP

MOTOR SETUP

SYSTEM

Figure 25. Select Screen

The Barrel Maintenance menu, shown in Figure 26, allows the service technician to clean, rinse and sanitize the system on a barrel by barrel basis. The barrel must be OFF in order to perform the barrel maintenance functions. As a

warning to the technician, the “Do Not Drink” status indicators are illuminated on

the barrels when entering the Barrel Maintenance menu.

The procedure for purging a barrel is shown in Table 20. The procedure for filling

a barrel is shown in Table 21. The procedure for running the scraper blade only

on a barrel is shown in Table 22 and the procedure for waking up a barrel is

shown in Table 24.

Publication Number: 621260373SER - 34 - © 2008-2010, IMI Cornelius Inc.

Page 41

Viper Service Manual

Purging a Barrel

BARREL

MAINT

12:51P

MAR 04

BACK PURGE FILL SPIN

#1 PURGE

#2 OFF

Figure 26. Barrel Maintenance Screen

Table 20

Step Action Procedure

1 Purge a barrel From the Select menu (Figure 25), open the Barrel

2 Select the barrel Use the Up and Down arrows to highlight the desired

3 Select Purge function Press the PURGE button at the bottom of the display

4 Empty the barrel Place a container under the barrel dispensing valve,

5 Complete the procedure When the barrel is completely empty, close the dis-

Maintenance menu, shown in Figure 26.

barrel

to select purge for the highlighted barrel

open the dispensing valve and dispense all the product from the barrel. As the product level lowers in the

barrel, partially close the valve to avoid spurting.

pensing valve and press the STOP button at the bottom of the display to turn off the purge. Press the

BACK button to return to the Select menu.

NOTE: When the PURGE button is pressed, it changes to a STOP

button.

Filling a Barrel

Table 21

Step Action Procedure

Fill a barrel From the Select menu (Figure 25), open the Barrel

1

Select the barrel Use the Up and Down arrows to highlight the desired barrel

2

Select Fill function Press the FILL button at the bottom of the display to fill

3

Finish filling the barrel When the fill completes, intermittently open and close

4

Complete the procedure Press the STOP button at the bottom of the display to

5

NOTE: When FILL button is pressed, it changes to a STOP button.

© 2008-2010, IMI Cornelius Inc. - 35 - Publication Number: 621260373SER

Maintenance menu, shown in Figure 26.

the highlighted barrel

the relief valve to bleed CO2 from the barrel.

stop the fill. Press the BACK button to return to the

Select menu.

Page 42

Viper Service Manual

Run the Barrel Motor

Step Action Procedure

1

2

3

4

Rinsing a Barrel

When rinsing a barrel, the Barrel Maintenance menu cannot be used. The procedure must be done manually, as described in Table 23.

Table 22

Run a barrel From the Setup menu (Figure 25), open the Barrel

Maintenance menu, shown in Figure 26.

Select the barrel Use the Up and Down arrows to highlight the desired

barrel

Select Run function Press the SPIN button at the bottom of the display to

start the motor in the highlighted barrel

Stop the procedure Press the STOP button at the bottom of the display to

stop the motor. Press the BACK button to return to the

Select menu.

NOTE: When RUN button is pressed, it changes to a STOP button.

Manual Diagnostic Menu

Table 23

Step Action Procedure

Empty a barrel If the barrel has liquid in it, use the Purge procedure in

1

Rinse a barrel Go to the Barrel Status menu (Figure 12).

2

Select the barrel Use the Up and Down arrows to highlight the desired

3

Turn off the barrel Press the OFF button at the bottom of the display to turn

4

Override Water Solenoid Press the manual bypass on the water solenoid and fill

5

Run the barrel motor Use the procedure in Table 22 to rinse the barrel.

6

Complete the procedure Repeat the Purge procedure in Table 20 to empty the

7

Table 20 to empty the barrel.

barrel

off the barrel.