Page 1

FCB VIPER DISPENSER

Installation Instructions

Viper (2-BRL) CO

Viper (3-BRL) CO

2 Ventilation Kit

2 Ventilation Kit

Release Date: July 14, 2009

Publication Number: 899400001INS

Revision Date: September 3, 2010

Revision: C

Visit the IMI Cornelius web site at www.cornelius.com

for all your Literature needs.

Page 2

The products, technical information, and instructions contained in this manual are subject to change without notice.

These instructions are not intended to cover all details or variations of the equipment, nor to provide for every possible contingency in the installation, operation or maintenance of this equipment. This manual assumes that the

person(s) working on the equipment have been trained and are skilled in working with electrical, plumbing, pneumatic, and mechanical equipment. It is assumed that appropriate safety precautions are taken and that all local

safety and construction requirements are being met, in addition to the information contained in this manual.

This Product is warranted only as provided in Cornelius’ Commercial Warrant applicable to this Product and is subject to all of the restrictions and limitations contained in the Commercial Warranty.

Cornelius will not be responsible for any repair, replacement or other service required by or loss or damage resulting from any of the following occurrences, including but not limited to, (1) other than normal and proper use and

normal service conditions with respect to the Product, (2) improper voltage, (3) inadequate wiring, (4) abuse, (5)

accident, (6) alteration, (7) misuse, (8) neglect, (9) unauthorized repair or the failure to utilize suitably qualified and

trained persons to perform service and/or repair of the Product, (10) improper cleaning, (11) failure to follow installation, operating, cleaning or maintenance instructions, (12) use of “non-authorized” parts (i.e., parts that are not

100% compatible with the Product) which use voids the entire warranty, (13) Product parts in contact with water or

the product dispensed which are adversely impacted by changes in liquid scale or chemical composition.

Contact Information:

To inquire about current revisions of this and other documentation or for assistance with any Cornelius product contact:

www.cornelius.com

800-238-3600

Trademarks and Copyrights:

This document contains proprietary information and it may not be reproduced in any way without permission from

Cornelius.

Printed in U.S.A.

Copyright © 2010, All rights reserved, IMI Cornelius Inc.

Page 3

TABLE OF CONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Document Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Read and Follow ALL Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Recognition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Different Types of Alerts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Qualified Service Personnel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Shipping And Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

CO2 (Carbon Dioxide) Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Mounting in or on a Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Tools Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Assembly Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Regulator Assembly Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Plumbing Line Assembly Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Monthly Maintenance Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Page 4

Viper Installation Manual

DOCUMENT OVERVIEW

Introduction

INTRODUCTION

This document is used to install the CO2 ventilation kit for the Viper 2-Barrel and

3-Barrel Units

Viper 2B: 621260142, 621250142 and 621260142IC

Viper 3B: 621360142, 621350142 and 621360142IC

Prior knowledge of Viper Installation and service procedures is required before

attempting this installation process.

Revision Date: July 14, 2009 www.cornelius.com Revision: B

© 2009, IMI Cornelius Inc. - 1 - Publication Number: 899400001INS

Page 5

Viper Installation Manual

SAFETY INSTRUCTIONS

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

Safety Overview • Read and follow ALL SAFETY INSTRUCTIONS in this manual and

any warning/caution labels on the unit (decals, labels or laminated

cards).

• Read and understand ALL applicable OSHA (Occupational Safety

and Health Administration) safety regulations before operating this

unit.

Recognition

Recognize Safety Alerts

!

This is the safety alert symbol. When you see it in this manual or on the unit,

be alert to the potential of personal injury or damage to the unit.

Different Types of Alerts

SAFETY TIPS

!

DANGER:

Indicates an immediate hazardous situation which if not avoided WILL result in

serious injury, death or equipment damage.

!

WARNING:

Indicates a potentially hazardous situation which, if not avoided, COULD result

in serious injury, death, or equipment damage.

!

CAUTION:

Indicates a potentially hazardous situation which, if not avoided, MAY result in

minor or moderate injury or equipment damage.

• Carefully read and follow all safety messages in this manual and

safety signs on the unit.

• Keep safety signs in good condition and replace missing or damaged

items.

• Learn how to operate the unit and how to use the controls properly.

• Do not let anyone operate the unit without proper training. This appliance is not intended for use by very young children or infirm persons

Publication Number: 899400001INS - 2 - © 2009, IMI Cornelius Inc.

Page 6

Viper Installation Manual

without supervision. Young children should be supervised to ensure

that they do not play with the appliance.

• Keep your unit in proper working condition and do not allow unauthorized modifications to the unit.

QUALIFIED SERVICE PERSONNEL

!

WARNING:

Only trained and certified electrical, plumbing and refrigeration technicians

should service this unit. ALL WIRING AND PLUMBING MUST CONFORM TO

NATIONAL AND LOCAL CODES. FAILURE TO COMPLY COULD RESULT IN

SERIOUS INJURY, DEATH OR EQUIPMENT DAMAGE.

SAFETY PRECAUTIONS

This unit has been specifically designed to provide protection against personal

injury. To ensure continued protection observe the following:

!

Disconnect power to the unit before servicing following all lock out/tag out

procedures established by the user. Verify all of the power is off to the unit

before any work is performed.

Failure to disconnect the power could result in serious injury, death or equipment

damage.

!

Always be sure to keep area around the unit clean and free of clutter. Failure to

keep this area clean may result in injury or equipment damage.

SHIPPING AND STORAGE

!

Before shipping, storing, or relocating the unit, the unit must be sanitized and all

sanitizing solution must be drained from the system. A freezing ambient

environment will cause residual sanitizing solution or water remaining inside the

unit to freeze resulting in damage to internal components.

WARNING:

CAUTION:

CAUTION:

CO2 (CARBON DIOXIDE) WARNING

© 2009, IMI Cornelius Inc. - 3 - Publication Number: 899400001INS

Page 7

Viper Installation Manual

!

DANGER:

CO

2 displaces oxygen. Strict attention MUST be observed in the prevention of

CO

2 gas leaks in the entire CO2 and soft drink system. If a CO2 gas leak is

suspected, particularly in a small area, IMMEDIATELY ventilate the

contaminated area before attempting to repair the leak. Personnel exposed to

high concentrations of CO

by loss of consciousness and DEATH.

MOUNTING IN OR ON A COUNTER

!

WARNING:

When installing the unit in or on a counter top, the counter must be able to

support a weight in excess of 450 lbs. to insure adequate support for the unit.

FAILURE TO COMPLY COULD RESULT IN SERIOUS INJURY, DEATH OR

EQUIPMENT DAMAGE.

Note:

Many units incorporate the use of additional equipment such as

icemakers. When any addition equipment is used you must check with the

equipment manufacturer to determine the additional weight the counter

will need to support to ensure a safe installation.

2 gas experience tremors which are followed rapidly

Publication Number: 899400001INS - 4 - © 2009, IMI Cornelius Inc.

Page 8

PARTS LIST

Viper Installation Manual

INSTALLATION

Table 1

Item

2B Rev 3B Rev 2B 3B

1 910705025 A 910705027 A

2 910705026 A 910705026 A

3 77060100 - 77060100 - Barb Tee SS 1/4” Barb (3) No 5 7

4 77040400 - 77040400 - Barb Elbow SS Barb 1/4"x1/4" No 7 8

5 620717794* - 620717794* - Beverage Tubing

6 309854000 - 309854000 - Oetiker Clamps SS

7 77900500 - 77900500 - Y Connector SS

8 770001353 - 770001353 - Check Valve SS 1/4” Barb End No 1 1

Part No.

Description Mat. Spec. Unit

Pressure reg. for

prod. del. (frnt)

Pressure reg. for

expan. tank (side)

Barrier

-

-

PET

tube

W/Mod. brass

body Assem.

W/Mod. brass

body Assem.

0.265" ID,

0.375" OD,

EATON SYNFLEX TASTERITE 4227-0600

Pet Barrier

Tube, NSF51,

MAX Temp. 150

°F , SK3498-001

, 1-11-0806259”

Open 0.413 Close 0.350

1/4” Y Barb w/ 1/

4” Barb Stem

No 1 1

No 1 1

ft 15 26

No 50 55

No 2 2

* Length of Beverage Tubing depends upon the specific store conditions.

TOOLS REQUIRED

ASSEMBLY INSTRUCTIONS

Regulator Assembly Instructions

1. Turn OFF the Power, Water and CO2 supply to the machine.

2. Release the excess CO

Relief Valve. Assemble Modified Regulator P/N 910705025 or

910705027 (Viper 2B or 3B respectively) & 910705026 (common

between 2B & 3B)

3. Assemble bracket to its original position in machine.

4. Assemble all line connections to their original position.

5. Assemble pressure switch on the replaced side regulator (P/N

910705026) using Teflon tape. Be careful not to disturb any of the

electrical connections.

• Adjustable Wrench

• Oetiker Pliers

• Tube Cutters for beverage tubing

2 pressure from the regulators via the Pressure

© 2009, IMI Cornelius Inc. - 5 - Publication Number: 899400001INS

Page 9

Viper Installation Manual

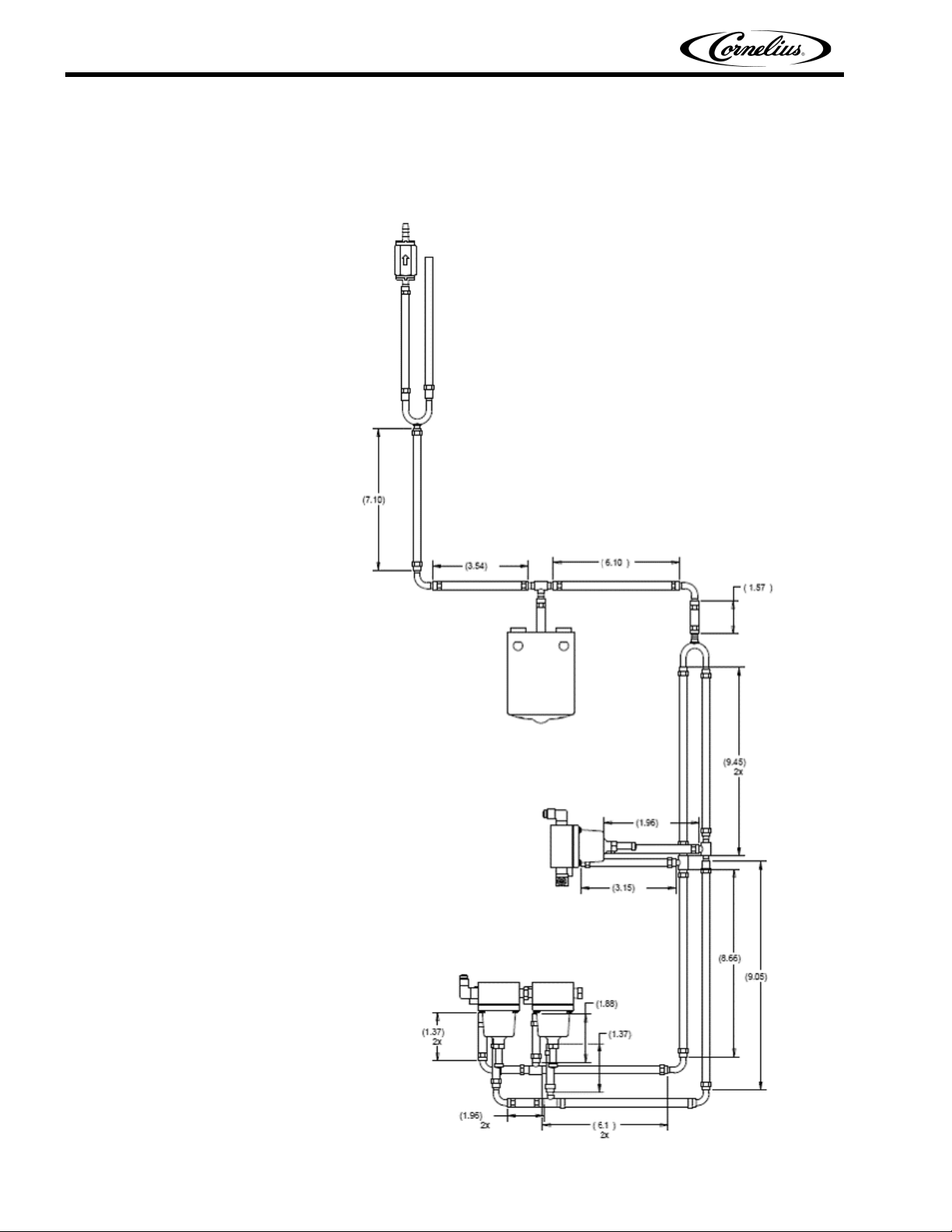

Plumbing Line Assembly Instructions

1. Cut the braided hose tube as shown in the reference diagram (Figure 1

or Figure 2).

Figure 1. Approximate Cut Lengths for Tubes, Viper 2 Barrel

Publication Number: 899400001INS - 6 - © 2009, IMI Cornelius Inc.

Page 10

Viper Installation Manual

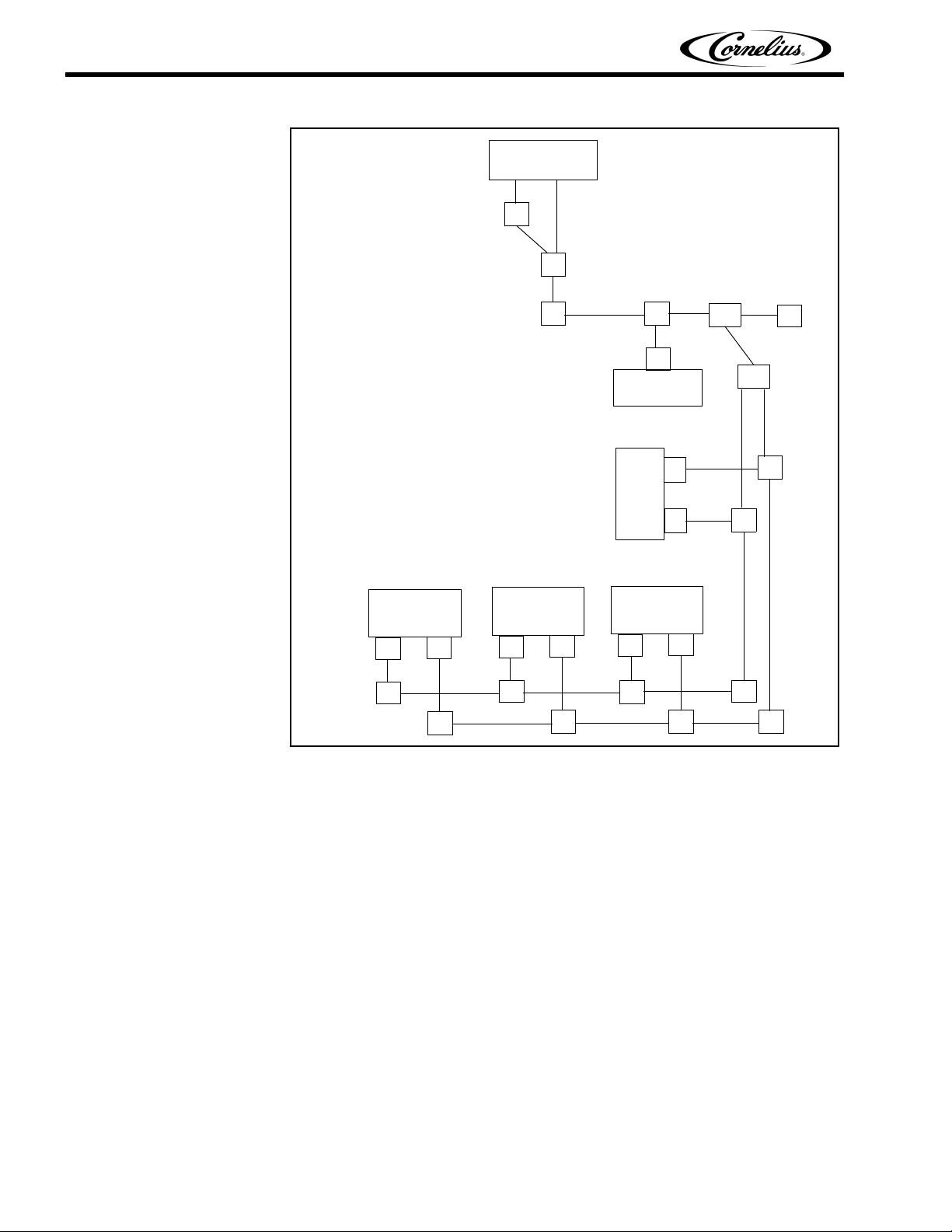

Figure 2. Approximate Cut Lengths for Tubes, Viper 3 Barrel

2. Connect Braided Tubes to Adapter Barbs with Oetiker Clamps and

route the tubes as shown in Figure 3 and Figure 4 for 2-Barrel units

and Figure 5 and Figure 6 for 3-Barrel units, so that the exhaust tube

runs to a naturally ventilated area.

© 2009, IMI Cornelius Inc. - 7 - Publication Number: 899400001INS

Page 11

Viper Installation Manual

Escape to

Atmosphere

C

Y

L T

L

FloJet

A2: Base Ventilation Barb (910705015)

A3: Cone Ventilation Barb (910705016)

T: SS Elbow Connector

L: SS Elbow Connector

Y: 1/4” Y Barb w/1/4” Barb Stem

C: Check Valve

_: Fluid Lines 1/4” Braided Hose Tube)

CO2

Regulator-1

A3

A2

L

L

Figure 3. Representative Plumbing Line Diagram, Viper 2 Barrel

Pump

CO2

Regulator

CO2

Regulator-2

A3

A2

T

T L

A2

A3

L

Y

T

T

L

Publication Number: 899400001INS - 8 - © 2009, IMI Cornelius Inc.

Page 12

Viper Installation Manual

Check Valve

Tube length at this

section depends on

store connections

Y-Connector

FlowJet Pump

Remove filter from the

FlowJet pump and

connect to barb as shown

Regulator Product

Delivery

Regulator Expansion

Tank

Barb, Tee

Barb, Elbow

Figure 4. Representative 3D Plumbing Line Diagram, Viper 2 Barrel

© 2009, IMI Cornelius Inc. - 9 - Publication Number: 899400001INS

Page 13

Viper Installation Manual

Escape to

Atmosphere

C

Y

L T

L

FloJet

A2: Base Ventilation Barb (910705015)

A3: Cone Ventilation Barb (910705016)

T: SS Elbow Connector

L: SS Elbow Connector

Y: 1/4” Y Barb w/1/4” Barb Stem

C: Check Valve

_: Fluid Lines 1/4” Beverage Tube)

CO2

Regulator-1

A3

A2

L

L

Figure 5. Representative Plumbing Line Diagram, Viper 3 Barrel

CO2

Regulator-2

A3

A2

T

T

Pump

CO2

Regulator

CO2

Regulator-3

A3

A2

T

T L

A2

A3

Y

L

L

T

T

L

Publication Number: 899400001INS - 10 - © 2009, IMI Cornelius Inc.

Page 14

Viper Installation Manual

Check Valve

Tube length at this

section depends on

store connections

Y-Connector

FlowJet Pump

Remove filter from the

FlowJet pump and

connect to barb as shown

Regulator Product

Delivery

Regulator Expansion

Tank

Barb, Tee

Figure 6. Representative 3D Plumbing Line Diagram, Viper 3 Barrel

MONTHLY MAINTENANCE SERVICE

The following procedure should be performed on a monthly basis to insure

proper maintenance of the Viper equipment.

• Check all joints for any leakage.

WARNING:Perform the following steps before any service is

attempted.

1. Shut OFF power, water & CO

2. Release system pressure before installation/service.

3. Connect all the braided tubes up to the full length of the adapter barb.

DISCLAIMER

WARNING: Installation of the on-site vent tubing (by others) from IMI

Cornelius equipment to a safe discharge termination or point Failure to comply with the Australian CO

5032-2005: Installation and use of inert gases for beverage

dispensing) in addition to the governing national-state-local

codes may result in serious personal injury or loss of human life.

Barb, Elbow

2 supply before installation/service.

2 Code/Mandate (AS

© 2009, IMI Cornelius Inc. - 11 - Publication Number: 899400001INS

Page 15

Viper Installation Manual

Publication Number: 899400001INS - 12 - © 2009, IMI Cornelius Inc.

Page 16

Page 17

IMI Cornelius Inc.

www.cornelius.com

Loading...

Loading...