Page 1

Installation

Manual

IMPORTANT:

It is the responsibility of the Service Person

to ensure that the water supply to the

dispensing equipment is provided with

protection against backflow by an air gap as

defined in ANSI/ASME A112. 1.2-1979; or an

approved vacuum breaker or other such

method as proved effective by test.

VA 13

CARBONATOR

Water pipe connections and fixtures directly

connected to a potable water supply shall be

sized, installed, and maintained according to

Federal, State, and Local codes.

When installing in an area regulated by the

City of Los Angeles Plumbing and/or

Mechanical Codes, a City of Los Angeles

approved reduced pressure principle

backflow preventer shall be installed on each

potable water supply to each carbonator.

Manual Part No. 318511001

EIMI Cornelius Inc.; 1982-2001

Control Code D

April 1,1982

Revised: November 30, 2001

Page 2

TABLE OF CONTENTS

SAFETY INFORMATION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RECOGNIZE SAFETY INFORMATION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNDERSTAND SIGNAL WORDS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FOLLOW SAFETY INSTRUCTIONS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CO2 (CARBON DIOXIDE) WARNING 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SHIPPING, STORING, OR RELOCATING UNIT 1. . . . . . . . . . . . . . . . . . . . . . .

GENERAL INFORMATION 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TO THE USER OF THIS MANUAL 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLAIMS INSTRUCTIONS 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARRANTY REFERENCE INFORMATION 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DESIGN DATA 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT DESCRIPTION 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

THEORY OF OPERATION 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNPACKING AND INSPECTION 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IDENTIFICATION OF LOOSE–SHIPPED PARTS 7. . . . . . . . . . . . . . . . . . . . . . . . . .

SELECTING LOCATION 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLING THE UNIT 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLACING UNIT IN OPERATING LOCATION 7. . . . . . . . . . . . . . . . . . . . . . . . . .

CONNECTING PLAIN WATER INLET SUPPLY LINE TO UNIT 8. . . . . . . . . .

CONNECTING CO2 INLET SUPPLY LINE 9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONNECTING CARBONATED WATER OUTLET LINE 9. . . . . . . . . . . . . . . .

PERMANENT ELECTRICAL POWER CONNECTION TO DOMESTIC UNIT IF

REQUIRED BY LOCAL CODES 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PREPARATION FOR OPERATION 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTING CARBONATOR CO2 REGULATOR AND TURN PLAIN

WATER INLET LINE ON 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT OPERATION 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

WATER PUMP MOTOR WILL NOT OPERATE. 15. . . . . . . . . . . . . . . . . . . . . . . . . . . .

WATER PUMP MOTOR WILL NOT SHUT OFF. 15. . . . . . . . . . . . . . . . . . . . . . . . . . .

ERRATIC CYCLING OF CARBONATOR. 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WATER PUMP MOTOR OPERATES BUT WATER PUMP DOES NOT PUMP

WATER. 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WATER PUMP CAPACITY TOO LOW. 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARRANTY 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LIST OF FIGURES

FIGURE 1. VA 13 CARBONATOR 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 2. CARBONATOR CONNECTIONS 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 3. CARBONATOR ASSEMBLY COMPONENTS 10. . . . . . . . . . . . . . . . . . .

FIGURE 4. WIRING DIAGRAM (MODEL NO. 416411000,1621, and 496411000) 13

i

318511001

Page 3

TABLE OF CONTENTS (cont’d)

LIST OF FIGURES CONT’D)

FIGURE 5. WIRING DIAGRAM (MODEL NO. 496411020) 13. . . . . . . . . . . . . . . . . . .

FIGURE 6. WIRING DIAGRAM (MODEL NO. 496411040) 14. . . . . . . . . . . . . . . . . . .

LIST OF TABLES

TABLE 1. DESIGN DATA 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TABLE 2. LOOSE-SHIPPED PARTS 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

318511001

ii

Page 4

SAFETY INFORMATION

Recognize Safety Information

This is the safety-alert symbol. When you see this

symbol on our machine or in this manual, be alert to

the possibility of personal injury.

Follow recommended precautions and safe operating

practices.

Understand Signal Words

A signal word - DANGER, WARNING, OR CAUTION

is used with the safety-alert symbol. DANGER identifies the most serious hazards.

DANGER

Safety signs with signal word DANGER or WARNING

are typically near specific hazards.

General precautions are listed on CAUTION safety

signs. CAUTION also calls attention to safety messages in this manual.

WARNING

CAUTION

Follow Safety Instructions

Carefully read all safety messages in this manual and on your machine safety signs. Keep safety signs in

good condition. Replace missing or damaged safety signs. Learn how to operate the machine and how to

use the controls properly. Do not let anyone operate the machine without instructions. Keep your machine in

proper working condition. Unauthorized modifications to the machine may impair function and/or safety and

affect the machine life.

CO2 (Carbon Dioxide) Warning

CO2 Displaces Oxygen. Strict Attention must be observed in the prevention of CO2 (carbon dioxide)

gas leaks in the entire CO2 and soft drink system. If a CO2 gas leak is suspected, particularly in a

small area, immediately ventilate the contaminated area before attempting to repair the leak. Personnel exposed to high concentration of CO2 gas will experience tremors which are followed rapidly by

loss of consciousness and suffocation.

Shipping, Storing, Or Relocating Unit

CAUTION: All water must be purged from the Unit if exposed to freezing temperature. A freezing ambient temperature will cause residual water remaining inside the Unit to freeze resulting in damage to

internal components of the Unit.

1 318511001

Page 5

THIS PAGE LEFT BLANK INTENTIONALLY

318511001

2

Page 6

GENERAL INFORMATION

TO THE USER OF THIS MANUAL

This Manual is a guide for servicing and maintaining this equipment. Refer to Table Of Contents for page location of detailed information pertaining to questions that may arise. A Service Manual (P/N 318511005) for this

equipment is available upon request.

This Unit must be serviced by a qualified Service Person. This Unit contains no User serviceable parts.

CLAIMS INSTRUCTIONS

Claims: In the event of shortage, notify the carrier as well as IMI Cornelius immediately. In the event of dam-

age, notify the carrier. IMI Cornelius is not responsible for damage occurring in transit, but will gladly

render assistance necessary to pursue your claim. Merchandise must be inspected for concealed damage within 15 days of receipt.

WARRANTY REFERENCE INFORMATION

Warranty Registration Date

(to be filled out by customer)

Unit Part Number:

Serial Number:

Install Date:

Local Authorized

Service Center:

DESIGN DATA

Table 1. Design Data

Model Numbers

115 VAC Unit (Liquid dual check valve) 416411000

115 VAC Unit (With vented dual check valve) 1621

230 VAC Unit (Liquid dual check valve) 496411000

230 VAC Unit (Liquid dual check valve) 496411020

230 VAC Unit (Liquid dual check valve) 496411040

3 318511001

Page 7

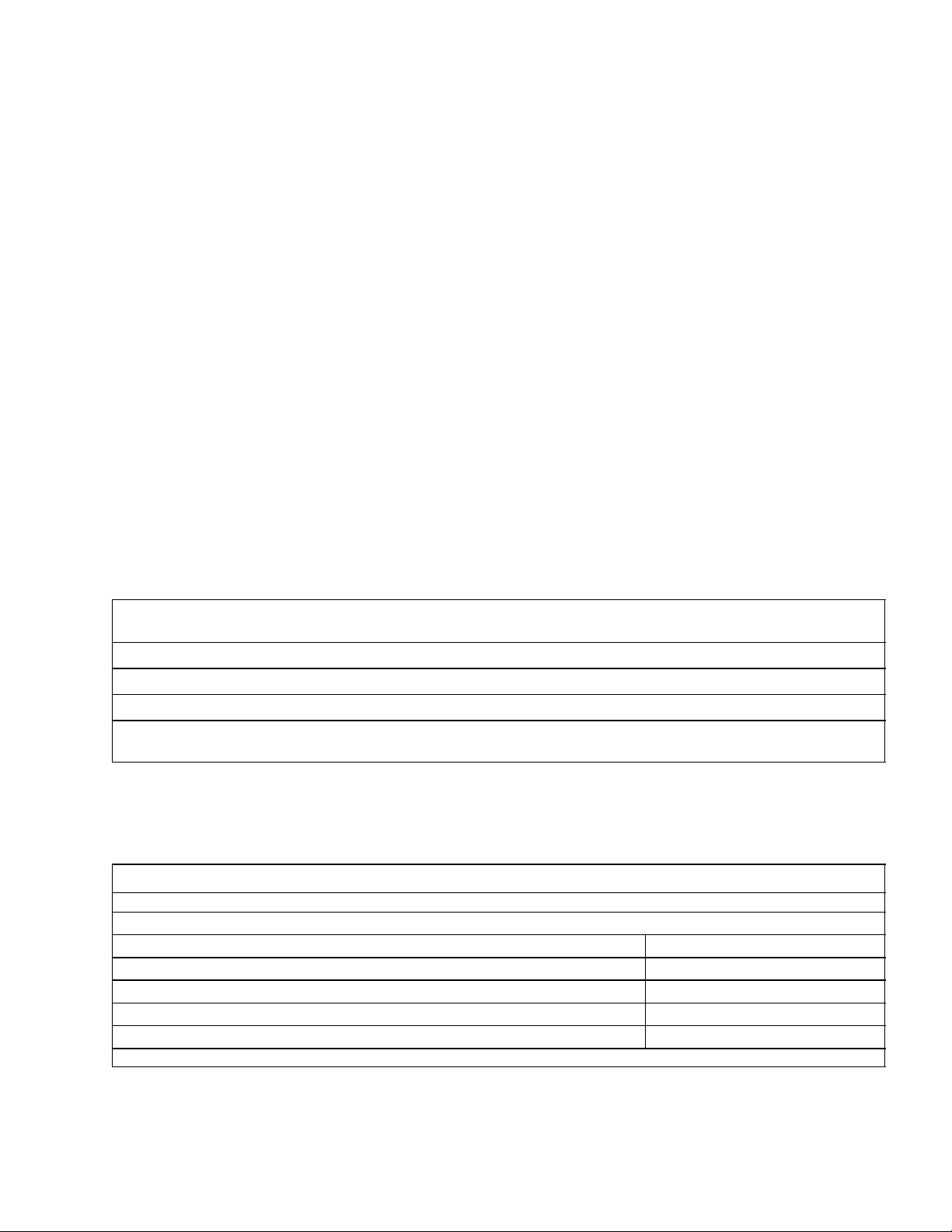

Table 1. Design Data (cont’d)

Overall Dimensions:

Width 6-3/8 inches

Height 15 inches

Depth 14 inches

Weight:

Dry 28-3/4 pounds

Shipping 30-1/4 pounds

Ambient Operating Temperature 40° F to 100° F

Maximum Operating CO

Pressure 125 PSI

2

Electrical Requirements:

Operating Voltage and Current Draw See Unit Nameplate

FIGURE 1. VA 13 CARBONATOR

UNIT DESCRIPTION

The carbonator is a compact Unit that may be installed in a remote location from where its carbonated water

outlet is to be connected to a post-mix dispenser or a system. The purpose of the Unit is to mix plain water and

carbon dioxide (CO2) gas which results in and provides carbonated water for a post-mix dispenser or a system.

The Unit consists basically of a water pump, motor, and a carbonated water tank. The water pump has a liquid

dual check valve (Unit Model No. 416411000, 496411000, 496411020, and 496411040) or a Vented Dual Check

Valve (Unit Model No. 1621) on its outlet to prevent carbonated water from back flowing into the city water system. The Vented Dual Check Valve vents water and possibly CO2 gas out of a vent port on failure of the primary

check valves. Should such venting occur, the primary check valve should be replaced. The Unit CO2 inlet has a

single check valve to prevent carbonated water back flow into the CO2 regulator.

318511001

4

Page 8

THEORY OF OPERATION

A CO2 cylinder delivers carbon dioxide (CO2) gas through an adjustable CO2 regulator to the carbonated water

tank. At the same time, plain water is pumped into the carbonated water tank by the water pump and is carbonated by CO

tank forces the tank and balance control mechanism down to activate the level control switches. Activating the

level control switches disrupts electrical power to and stops the water pump motor. As carbonated water is dispensed from the tank, the tank becomes lighter allowing the tank and balance control mechanism to rise which

again activates the level control switches. Activating the level control switches restores electrical power to the

water pump motor allowing the carbonated water tank to be replenished.

gas also entering the tank. Carbonated water enters the tank until the weight of the water in the

2

5 318511001

Page 9

THIS PAGE LEFT BLANK INTENTIONALLY

318511001

6

Page 10

INSTALLATION

UNPACKING AND INSPECTION

NOTE: This Unit was thoroughly inspected before leaving the factory and the carrier has accepted and

signed for it. Any damage or irregularities should be noted at the time of delivery and immediately reported to the delivering carrier. Request a written inspection report from the Claims Inspector to substantiate any necessary claim. File the claim with the delivering carrier, not IMI Cornelius Inc.

1. After unit has been uncrated, remove shipping tape and other packing material. Check for obvious damage

and follow procedure in preceding NOTE if damage is evident.

2. Unpack LOOSE–SHIPPED PARTS. Make sure items are present and in good condition.

Table 2. Loose-Shipped Parts

Item

No.

1 178025100 Tapered Gasket, White 2

2 311304000 Tapered Gasket, Black 1

Part No. Name Qty.

IDENTIFICATION OF LOOSE–SHIPPED PARTS

1. TAPERED GASKETS, WHITE (item 1) are used to seal connections when connecting lines to fittings labeled CO2 INLET and CARB WATER OUTLET on the Unit.

2. TAPERED GASKET, BLACK (item 2) is used to seal connection when connecting plain water inlet supply

line to the Unit.

SELECTING LOCATION

Locate unit so following requirements are satisfied.

1. Locate the Unit in a cool area close to a properly grounded electrical outlet with proper electrical requirements fused at 15-amps (slow-blow). No other electrical appliance should be connected to this circuit. For

accessibility, the electrical outlet must not be located behind the Unit. ALL WIRING MUST CONFORM TO

NATIONAL AND ELECTRICAL CODES.

2. Locate the Unit close to a plain water source line with requirements as outlined in CAUTION note under

CONNECTING PLAIN WATER INLET LINE TO UNIT. Plain water inlet line from plain water source line to

the Unit should be 3/8-inch I.D. (minimum) food-grade plastic.

3. Locate the Unit close to a permanent drain if installing Unit (P/N 1621) which is equipped with a vented

Dual-Check Valve which must have it’s vent tube routed to a permanent drain.

INSTALLING THE UNIT

PLACING UNIT IN OPERATING LOCATION

7 318511001

Page 11

CAUTION: This Unit must not be installed in an unsheltered outdoor location where it will

be exposed to the elements.

IMPORTANT: Before putting carbonator into operation, carbonator cover must be removed and packing

block must be removed from below the water pump motor.

1. Place carbonator in operating location meeting requirements of SELECTING LOCATION. MAKE SURE

CARBONATOR IS SITTING IN LEVEL POSITION FOR PROPER OPERATION.

2. Remove two screws securing the cover assembly on the Unit, then remove the cover.

3. Remove packing block from below the water pump motor.

4. Install cover assembly on the Unit and secure with two screws.

5. Unit Model No. 1621.

IMPORTANT: A vented dual-check valve assembly is installed in this carbonator between the water

pump outlet and the water inlet to the carbonator tank as shown in Figure 3. The vented dual-check

valve assembly vents carbonated water, and possibly CO2 gas out of a vent port upon failure of the

primary check valves. Should such venting occur, the vented dual-check valve assembly must be

replaced.

CAUTION: Route free end of the vented dual–check valve vent tube to a permanent drain to

avoid serious water damage in the event of a check valve failure.

Route free end of the vented dual-check valve vent tube, protruding out the end of the carbonator cabinet, to a

permanent drain. TO AVOID POSSIBLE BACK-SUCTION FROM THE PERMANENT DRAIN, LOCATE THE

END OF THE VENTED DUAL-CHECK VALVE VENT TUBE ABOVE THE DRAIN OR AS REQUIRED BY THE

LOCAL PLUMBING CODE.

CONNECTING PLAIN WATER INLET SUPPLY LINE TO UNIT

CAUTION: Check minimum flow rate and maximum pressure of the plain water inlet supply

line. MINIMUM FLOW RATE MUST BE AT LEAST 100-GALLONS PER HOUR. If flow rate is

less than 100-gallons per hour, starving of the carbonator water pump will occur. Starving

will allow the carbonator water pump to overheat causing the safety thermostat on the water pump

outlet to disrupt electrical power to and stop the water pump motor. Overheating could occur if the

plain water inlet supply line flow rate drops below 100-gallons per hour. WATER PRESSURE MUST

BE 10-PSI LESS THAN THE CO2 PRESSURE. (Example: operating CO2 pressure is 80-psi,

maximum water pressure can be no more than 70-psi, etc.). Water over pressure (higher than

operating pressure) can cause carbonator flooding, malfunction, and leakage through the

carbonator tank relief valve. If water is exceeding maximum pressure specifications, a Water

Pressure Regulator Kit (P/N 310150000) or equivalent must be installed in the plain water inlet

supply line. If fitting connector is not available, tap into the plain water supply line with a 3/8-flare

saddle valve (P/N 315664000) or equivalent.

NOTE: IMI Cornelius Inc. recommends that a water shutoff valve and water filter be installed in the

plain water inlet supply line (see Figure 2) . A Cornelius Water Filter (P/N 313860000) and Quick Disconnect Set (P/N 313867000) are recommended.

1. Make sure food grade flexible plastic 3/8-inch I.D. (minimum) plain water inlet line provides adequate water

flow rate and pressure as outlined in CAUTION note.

318511001

8

Page 12

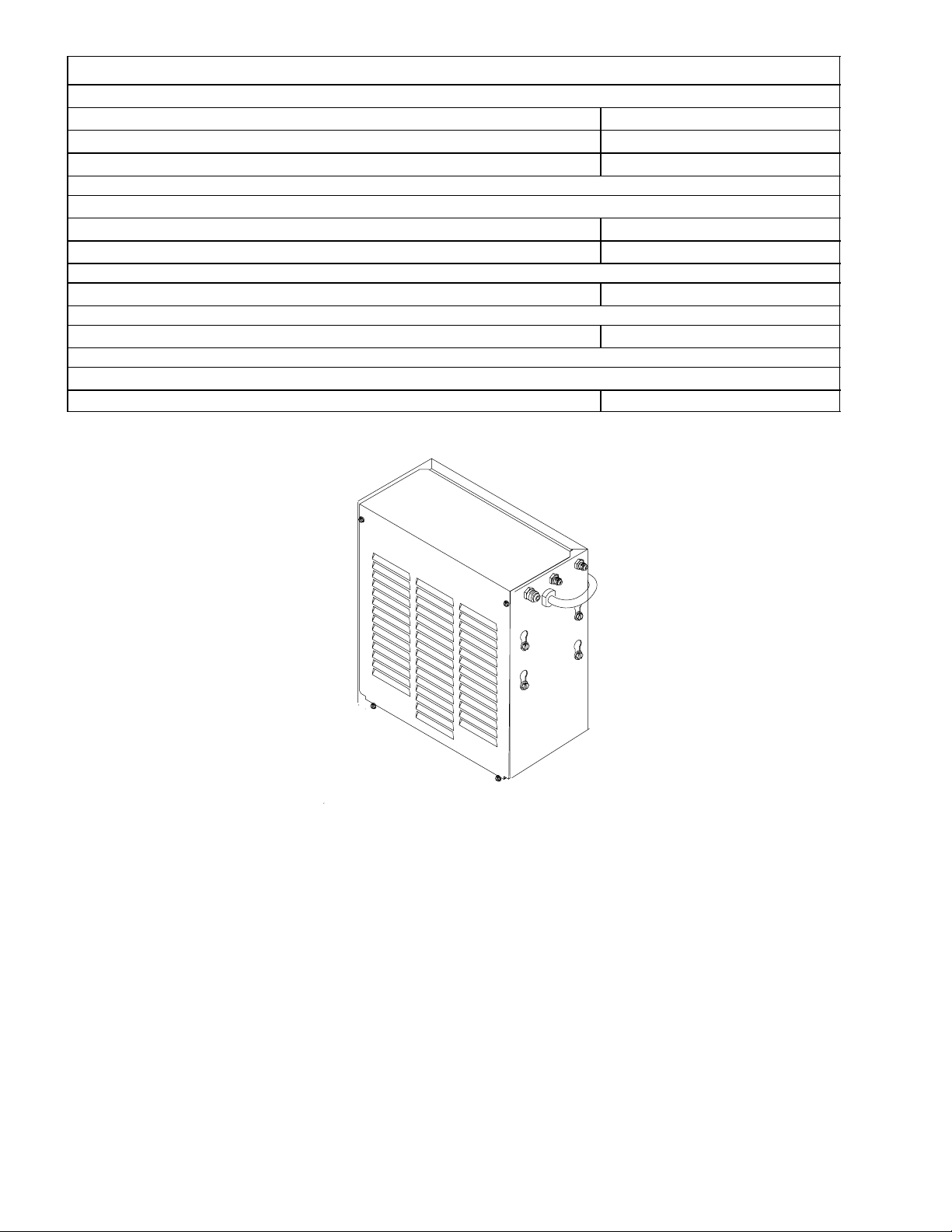

PLAIN WATER INLET

CARB (CARBONATED)

WATER

POWER CORD

CO2 INLET

FIGURE 2. CARBONATOR CONNECTIONS

Before connecting plain water inlet line to the Unit, open the water line for a period of time to flush out any

metal shavings resulting from connecting the water line to the fitting connector or saddle valve.

2. Remove shipping cap from the 3/8-inch flare (5/8-18) male fitting on the Unit labeled “WATER

INLET”.

3. Install TAPERED GASKET (item 2) in the plain water inlet line swivel nut, then connect the water line to the

3/8-flare male fitting labeled “WATER INLET” on the Unit.

CONNECTING CO2 INLET SUPPLY LINE (see Figure 2)

1. Remove shipping cap from the 1/4–inch flare (7/16-20) male fitting on the Unit stamped “CO2 INLET”.

2. Connect CO2 inlet supply line from the CO2 regulator to the 1/4-inch flare (7/16-20) male fitting on the Unit

labeled “CO2 INLET”. Seal connection with TAPERED GASKET, WHITE (item 1).

CONNECTING CARBONATED WATER OUTLET LINE (see Figure 1)

WARNING: Under no circumstances should copper tubing, copper fittings, or brass fittings be used

to connect the Unit carb (carbonated) water outlet to the post-mix dispenser or system. CO2 gas

contact with copper tubing, copper fittings, or brass fittings will cause a health hazard.

1. Remove shipping cap from the 1/4-inch flare (7/16-20) male fitting stamped “CARB WATER” on the Unit.

2. Extend length of food grade flexible plastic tubing from the Unit carbonated water outlet to the carbonated

water inlet of the post-mix dispenser or system, then connect to dispenser or system.

3. Connect food grade flexible plastic tubing to 1/4-inch flare (7/16-20) male fitting labeled “CARB WATER” on

the Unit. Seal connection with TAPERED GASKET, WHITE (item 1).

PERMANENT ELECTRICAL POWER CONNECTION TO DOMESTIC UNIT IF

REQUIRED BY LOCAL CODES

(see applicable Figure 3, 4, or 5)

1. Remove two screws securing the cabinet cover, then remove cover.

9 318511001

Page 13

2. Loosen two screws securing the motor wiring compartment cover, then remove the cover.

3. Disconnect ground electrical wire from under the ground terminal connection screw located inside the motor wiring compartment.

4. Disconnect the black and white power cord wires inside the motor wiring compartment.

5. Remove power cord and strain relief from the Unit.

COVER

WATER PUMP MOTOR

(ELECTRICAL CONNECTIONS)

CARBONATED

WATER TANK

RELIEF

VALV E

RETAINING SCREWS (2)

WATER PUMP

SAFETY THERMOSTAT

FIGURE 3. CARBONATOR ASSEMBLY COMPONENTS

LIQUID DUAL CHECK

VALV E

OR

VENTED DUAL–CHECK

VALV E

WARNING: The Unit must be electrically grounded to avoid possible fatal electrical shock

or serious injury to the operator. The Unit power cord is equipped with a three-prong plug.

If a three-hole (grounded) electrical outlet is not available, use an approved method to

ground the Unit.

318511001

10

Page 14

6. Connect 115 VAC, 60 Hz or 220–240 VAC, 50 Hz electrical power from the disconnect switch (not furnished) fused at 15-amps (slow-blow) to the Unit with No. 16 AWG wire in suitable conduit or BX sheath.

Install power source green or green/yellow wire under the ground terminal lug located inside control box as

shown. Connect black or brown power cord wire with wire nut and white or blue wire under nut on motor

terminal. All WIRING MUST CONFORM TO NATIONAL AND LOCAL ELECTRICAL CODES.

7. Install motor wiring compartment cover and secure the two cover screws.

8. Install cabinet cover and secure with two screws.

PREPARATION FOR OPERATION

ADJUSTING CARBONATOR CO2 REGULATOR AND TURN PLAIN WATER INLET LINE

ON

CAUTION: Before connecting the CO2 regulator assembly to the CO2 cylinder, turn the

regulator adjusting screw to the left (counterclockwise) until all tension is relieved from the

adjusting screw spring.

1. Open (counterclockwise) CO2 cylinder valve slightly to allow the lines to slowly fill with CO2 gas, then open

the valve fully to back-seat the valve. (Back-seating the valve prevents leakage around the valve shaft).

2. Adjust the carbonator CO2 regulator to a nominal 80-psi.

3. Open one of the Post-Mix Dispenser dispensing valves to exhaust trapped air inside the carbonator tank.

CAUTION: Never operate the carbonator with the plain water inlet line shutoff valve closed.

‘‘Dry running” the water pump will burn out the pump. A pump damaged in this manner is

not covered by warranty.

4. Open the plain water inlet line shutoff valve.

UNIT OPERATION

NOTE: The carbonator tank liquid levels (pump cut-in and cut-out) were adjusted at the factory and

should require no further adjustment. If carbonator tank relief valve opens before the water pump motor cycles off, adjust carbonator tank liquid levels as instructed in Service Manual (P/N 318511004).

WARNING: The Unit must be electrically grounded to avoid possible fatal electrical shock

or serious injury to the operator. The Unit power cord is equipped with a three-prong plug.

If a three-hole (grounded) electrical outlet is not available, use an approved method to

ground the Unit.

1. Connect electrical power to the Unit. Water pump will start and fill the carbonated water tank with carbonated water. Water pump will stop when tank is full.

WARNING: CO2 Displaces Oxygen. Strict Attention must be observed in the prevention of

CO2 (carbon dioxide) gas leaks in the entire CO2 and soft drink system. If a CO2 gas leak is

suspected, particularly in a small area, immediately ventilate the contaminated area before

attempting to repair the leak. Personnel exposed to high concentration of CO2 gas will experience

tremors which are followed rapidly by loss of consciousness and suffocation.

11 318511001

Page 15

WARNING: Disconnect electrical power to the carbonator to prevent personal injury before

attempting any internal maintenance. Only qualified personnel should service internal

components or electrical wiring.

2. Check for CO2, carbonated water, and plain water leaks and if evident, tighten any loose connections.

CAUTION: To prevent a fire hazard, no object should be placed or stored on top of the Unit.

318511001

12

Page 16

SAFETY THERMOSTAT

LEVEL CONTROL

SWITCH (2)

WATER PUMP

POWER CORD

FIGURE 4. WIRING DIAGRAM (MODEL NO. 416411000, 1621, AND 496411000)

WATER PUMP

LEVEL CONTROL

SWITCH (2)

POWER CORD

FIGURE 5. WIRING DIAGRAM (MODEL NO. 496411020)

13 318511001

Page 17

LEVEL CONTROL

SWITCH (2)

WATER PUMP

POWER CORD

FIGURE 6. WIRING DIAGRAM (MODEL NO. 496411040)

318511001

14

Page 18

TROUBLESHOOTING

WARNING: Disconnect electrical power to the carbonator to prevent personal injury before

attempting any internal maintenance. Only qualified personnel should service the internal

components or the electrical wiring.

If repairs to the carbonated water or the plain water systems must be made, disconnect electrical

power to the Unit, then shut off CO2 and plain water sources. Dispense from dispensing valve until

carbonator tank CO2 pressure has been relieved.

Trouble Probable Cause Remedy

WATER PUMP MOTOR WILL

NOT OPERATE.

A. Power cord unplugged or

circuit breaker open in panel

box.

B. Inoperative water pump motor. B. Replace water pump motor as

C. Dirty balance mechanism. C. Clean balance mechanism.

D. Loose connections and/or

open electrical circuit.

E. Overheated motor cut off by

thermal overload protector.

F. Inoperative level control

switches.

G. Binding or damaged balance

mechanism.

H. Water pump binding (new or

replacement pumps only).

I. Water pump damaged. I. Replace water pump as

A. Plug in power cord or reset circuit

breaker.

instructed.

D. Tighten connections and/or repair

open circuit. Check line voltage.

E. Check for proper line voltage.

Check for restricted pump

discharge.

F. Replace level control switches as

instructed.

G. Repair or replace balance

mechanism.

H. Remove water pump from motor,

rotate pump or motor shaft 180

degrees, then recouple pump to

motor.

instructed.

WATER PUMP MOTOR WILL

NOT SHUT OFF.

J. Safety thermostat inoperative

(Models 416411000 and

1621).

K. Water pressure low or

pressure switch inoperative

(Model 496411020 only)

A. Foreign object restricting tank

movement.

B. Dirty balance mechanism. B. Clean balance mechanism.

C. Leak in carbonated water line. C. Tighten or replace line.

D. Inoperative level control

switches.

E. Binding or damaged balance

mechanism.

15 318511001

J. Replace safety thermostat as

instructed.

K. Restore water pressure or

replace pressure switch.

A. Remove foreign object.

D. Replace level control switches as

instructed.

E. Repair or replace balance

mechanism.

Page 19

Trouble RemedyProbable Cause

ERRATIC CYCLING OF

CARBONATOR.

WATER PUMP MOTOR

OPERATES BUT WATER

PUMP DOES NOT PUMP

WATER.

WATER PUMP CAPACITY

TOO LOW.

A. Balance mechanism spring

obstructed or ‘‘cocked’’.

A. Remove obstruction. Make sure

spring is perpendicular to spring

release and is not twisted.

B. Dirty balance mechanism. B. Clean balance mechanism.

A. Water pump inlet water

strainer screen dirty.

A. Clean or replace water strainer

screen as instructed.

B. Kinked water supply line. B. Straighten water supply line.

C. Restriction between water

C. Remove restriction.

pump outlet and carbonator

tank inlet.

D. Foreign object in water pump

bypass.

D. Clean. (Note: Count number of

turns bypass screw makes when

removing and install same

number of turns.)

E. Water pump worn out. E. Replace water pump as

instructed.

A. Water pump inlet water

strainer screen dirty.

A. Clean or replace water strainer

screen as instructed.

B. Water supply capacity too low. B. Inlet water supply must be at a

minimum of 100-gallons per hour

with a maximum water pressure

of 70-psi.

C. Water filter clogged. C. Replace water filter.

D. Inoperative water pump. D. Replace water pump as

instructed.

318511001

16

Page 20

WARRANTY

IMI Cornelius Inc. warrants that all equipment and parts are free from defects in material and workmanship under normal use and service. For a copy of the warranty applicable to your Cornelius, Remcor or Wilshire product, in your country, please write, fax or telephone the IMI Cornelius office nearest you. Please provide the

equipment model number, serial number and the date of purchase.

IMI Cornelius Offices

AUSTRALIA D P. O. 210, D RIVERWOOD, D NSW 2210, AUSTRALIA D (61) 2 533 3122 D FAX (61) 2 534 2166

AUSTRIA D AM LANGEN FELDE 32 D A-1222 D VIENNA, AUSTRIA D (43) 1 233 520 D FAX (43) 1-2335-2930

BELGIUM D BOSKAPELLEI 122 D B-2930 BRAASCHAAT, BELGIUM D (32) 3 664 0552 D FAX (32) 3 665 2307

BRAZIL D RUA ITAOCARA 97 D TOMAS COELHO D RIO DE JANEIRO, BRAZIL D (55) 21 591 7150 D FAX (55) 21 593 1829

ENGLAND D TYTHING ROAD ALCESTER D WARWICKSHIRE, B49 6 EU, ENGLAND D (44) 789 763 101 D FAX (44) 789 763 644

FRANCE D 71 ROUTE DE ST. DENIS D F-95170 DEUIL LA BARRE D PAR IS, FRANCE D (33) 1 34 28 6200 D FAX (33) 1 34 28 6201

GERMANY D CARL LEVERKUS STRASSE 15 D D-4018 LANGENFELD, GERMANY D (49) 2173 7930 D FAX (49) 2173 77 438

GREECE D 488 MESSOGION AVENUE D AGIA PAR AS KEV I D 153 42 D ATHENS, GREECE D (30) 1 600 1073 D FAX (30) 1 601 2491

HONG KONG D 1104 TAIKOTSUI CENTRE D 11-15 KOK CHEUNG ST D TAIKOKTSUE, HONG KONG D (852) 789 9882 D FAX (852) 391 6222

ITALY D VIA PELLIZZARI 11 D 1-20059 D VIMARCATE, ITALY D (39) 39 608 0817 D FAX (39) 39 608 0814

NEW ZEALAND D 20 LANSFORD CRES. D P. O. BOX 19-044 AVONDALE D AUCKLAND 7, NEW ZEALAND D (64) 9 8200 357 D FAX (64) 9 8200 361

SINGAPORE D 16 TUAS STREET D SINGAPORE 2263 D (65) 862 5542 D FAX (65) 862 5604

SPAIN D POLIGONO INDUSTRAIL D RIERA DEL FONOLLAR D E-08830 SANT BOI DE LLOBREGAT D BARCELONA, SPAIN D (34) 3 640 2839 D FAX (34) 3 654 3379

USA D ONE CORNELIUS PLACE D ANOKA, MINNESOTA D (763) 421-6120 D FAX (763) 422-3255

LD004

4/21/98

17 318511001

Page 21

Page 22

IMI CORNELIUS INC.

CORPORATE HEADQUARTERS:

One Cornelius Place

Anoka, Minnesota 55303-6234

(763) 421-6120

(800) 238-3600

Loading...

Loading...