Page 1

REMOTE COOLING UNIT

UC-40 and UCC-40

Installation and Service Manual

Release Date: September 28, 2004

Publication Number: 710160089

Revision Date: N/A

Revision: N/A

Visit the IMI Cornelius web site at www.cornelius.com for all your Literature needs.

Page 2

INSTALLATION AND SERVICE MANUAL

The products, technical information, and instructions contained in this manual are subject

to change without notice. These instructions are not intended to cover all details or variations of the equipment, nor to provide for every possible contingency in the installation,

operation or maintenance of this equipment. This manual assumes that the person(s)

working on the equipment have been trained and are skilled in working with electrical,

plumbing, pneumatic, and mechanical equipment. It is assumed that appropriate safety

precautions are taken and that all local safety and construction requirements are being

met, in addition to the information contained in this manual.

To inquire about current revisions of this and other documentation or for assistance with

any Cornelius product contact:

www.cornelius.com

800-238-3600

Trademarks and copyrights:

Aurora, Cornelius, Decade, Hydro Boost, Sitco, Spirit, UF-1, Vanguard, Venture, Olympus, and Vista are registered trademarks of IMI Cornelius Inc.

Optifill trademark is pending.

This document contains proprietary information and it may not be

reproduced in any way without permission from Cornelius.

Printed in U.S.A.

Copyright © 2004, All Rights Reserved, IMI Cornelius, Inc.

Page 3

Installation and Service Manual

IMPORTANT INFORMATION AND SAFETY NOTES. PLEASE READ BEFORE

INSTALLING DISPENSER.

• Always transport equipment in an upright position and never drag over rough floors or down steps.

• A trained person, who is qualified to make connections to water, electrical and/or compressed gas

supplies must only carry out installation and maintenance. Local by-laws/regulations must be

followed.

• Switch off and unplug electrical power to unit during maintenance operations. Do not attempt to

remove any protective covers.

• Locate equipment on a firm, level surface and protect from physical damage. Mounting surface must

be able to support 500 lbs. (227kg) weight. Never allow air vents/louvers to become blocked and do

not place any non-specified items on top. Regularly clean condensers and louvers with a soft brush or

vacuum.

• This dispenser is for indoor use only. Do not expose equipment to extremes of temperature, water

spillage, spray, steam, or high humidity or clean with water jet into dispenser components because

this could cause damage to electrical components and shock to personnel. Do not place or store

objects on top of unit.

• This dispenser must be connected to correctly rated electrical power outlet, preferably protected by a

safety cutout and is easily accessible for isolation of the equipment. The equipment must be earth

grounded.

• Use and ELCB (earth leakage circuit breaker)/GFCI (ground fault interrupt) for electrical power

protection.

• Use an HVAC circuit breaker to the power outlet circuit supplying the dispenser.

• Each module or accessory requires a 120 VAC 15 Amp 60 HZ grounded outlet. If 230 VAC 50/

60 HZ, use a minimum of 10 Amp outlet for each module or accessory.

• Ambient temperature must not exceed 90oF (32.3oC) on units with merchandisers.

WATER SYSTEM

• Insufficient water supply to carbonator will cause pump damage.

WARNING: If the installation is idle and exposed to freezing temperatures, disconnect water

supply lines and blow out all water from pump, carbonator tank, and dispensing system.

WARNING: UNDETECTED CO2 LEAKS MAY CAUSE HARM OR DEATH DUE TO ASPHYXIATION.

CO2 tank must be located next to a solid wall and chained to the wall. CO2 cylinders must be

secured in a vertical position and only connected to dispensing equipment via a suitable

pressure regulator. Check connections for leaks.

WARNING: DO NOT lift dispenser modules by valve housing assemblies. Lifting by the valve

housing assemblies will cause damage to the housing.

WARNING: System must be sanitized in accordance with the procedures found in this manual

under the cleaning and maintenance section.

WARNING: Before attempting to remove the refrigeration deck, disconnect all electrical power.

Melt the ice bank and thoroughly drain the water bath. See additional notes in Water Bath

Cleaning Section in the manual.

© 2004, IMI Cornelius Inc. - 1 - Publication Number: 710160089

Page 4

Installation and Service Manual

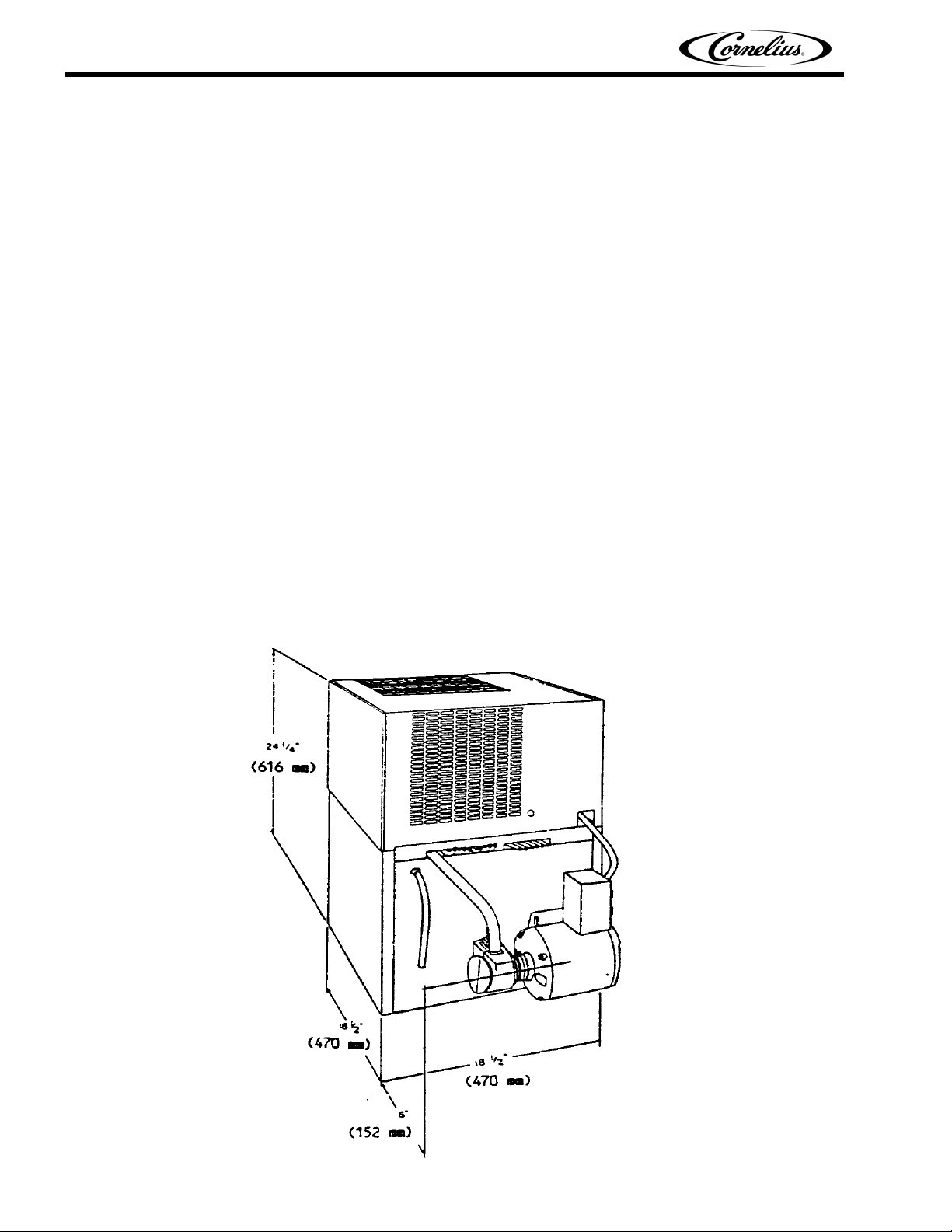

DIMENSIONS

See Illustration Below

SHIPPING WEIGHT

135 lbs. (61.4 kg)

OPERATING WEIGHT

241 lbs. (109.5 kg)

ELECTRICAL RATING

115 VAC/60HZ/14.6 AMPS; 220VAC/50-60HZ/7.3 AMPS

Transformer: (Built In) 24VAC Secondary

REFRIGERATION

1/3 HP (Lift Out Type)

SPECIFICATIONS

Condenser: Air Cooled

Refrigerant: R134a

APPROVAL

U.L., C.S.A., N.S.F.

Publication Number: 710160089 - 2 - © 2004, IMI Cornelius Inc.

Page 5

MECHANICAL SERVICE REQUIREMENTS

LOCATION

The dispenser will tolerate a surface +/- 1/2o or +/- 1/8” per foot or +/- 10.4mm per meter maximum slope

without affecting refrigeration capacity or cause water spillage from water bath.

Do not install dispenser next to any heat producing equipment such as furnaces, ovens, deep-fat fryers.

Never store items on top of dispenser which will restrict the air flow through the air-cooled condenser coil.

Clearance: The space above the dispenser must have a minimum of 16 inches (406mm). Of clearance

to allow for the removal of the top cover and refrigeration chassis and to provide adequate ventilation.

There should be at least 1 inch (25.4mm) of clearance on each side and to the rear of the dispenser for

servicing and ventilation.

ELECTRICAL

The electrical power supply should conform with that printed on dispenser name plate.

All other electrical connections are to comply with local codes.

A wiring diagram can be found in Section 7.0 of this instruction manual.

A separate electrical circuit with a minimum rating equal to the electrical ratings shown on the dispenser

nameplate (amperage and voltage) is recommended for satisfactory operation.

Installation and Service Manual

WATER SUPPLY & DRAINAGE

A water supply having a 1/2” O.D. (12.7mm) copper water tube, minimum is required with a minimum 20

PSIG (1.4 bar) line pressure.

A shut-off valve within three feet (1 meter) of the unit is recommended.

A suitable water filter is recommended to ensure top quality drinks.

A water pressure regulator or reducing valve should be installed in line to the main water supply and set

at 30 to 40 psi (2.1 to 2.8 bar). By limiting the incoming water pressure, a 15 psi (1.05 bar) pressure

differential (water pressure versus higher carbonator CO2 gas pressure) will ensure that flooding of the

carbonator tank does not occur.

Teflon pipe tape should be used (as required) on any fittings used in the water system.

Any contaminants such as dirt, cutting oil, pipe dope left in the system may affect the quality of the

finished drink. Therefore, flush water lines prior to start up.

CARBON DIOXIDE (CO2) GAS SUPPLY TO CARBONATOR

For the product tank supply line use a CO2 regulator capable of 0 psig to 100 psig (6.8 bar) normal

working pressure. Recommended setting 75 psi (5.17 bar).

A minimum CO2 gas supply pressure 15 psi (1.05 bar) greater than the incoming water pressure will

ensure that flooding of the carbonator tank will not occur.

© 2004, IMI Cornelius Inc. - 3 - Publication Number: 710160089

Page 6

Installation and Service Manual

SYRUP COMPONENTS

Syrup containers, sold as an accessory, are stainless steel with a capacity of five gallons (18.9 liters).

They are equipped with a CO2 gas quick disconnect fitting and syrup quick disconnect fitting.

The dispenser’s syrup outlets are 1/4” (6.4mm) barb fittings, and are located at the front wall, mid-height,

of the dispenser.

Each syrup inlet in labeled with the valve number that it services.

If the “syrup in” lines need replacement or extension, a .265 I.D. (6.7 mm I.D.) polytube is recommended.

Avoid using soft or easily collapsible tubing on the “syrup in” lines.

Only stainless steel or plastic, barb or compression type fittings should be used on any syrup or soda

water connections.

Optional bag-in-box system is also suitable for use with this beverage cooler.

Publication Number: 710160089 - 4 - © 2004, IMI Cornelius Inc.

Page 7

Installation and Service Manual

INSTALLATION AND START UP PROCEDURE

1. Remove dispenser and related parts from the corrugated shipping carton.

2. Locate dispenser at point of operation.

3. Connect the building’s electrical supply to the dispenser’s main power box (see wiring diagram).

4. It is recommended that the unit’s drain be permanently plumbed to the building drain and conform

to all plumbing codes and regulations.

5. Remove the dispenser’s top cover by removing two screws found on the top surface of cover.

6. Remove the filler cap found on the refrigeration platform. Pour clean cool water through the filler

hole until water is seen flowing from the overflow tube which is connected to the building’s plumbing

system. Replace filler cap and top cover.

7. Now start the refrigeration system by plugging the system’s main power cord into the outlet

provided in the cabinet’s main electrical box.

8. It is normal to see a small amount of water being displaced from the water bath through the

overflow tube as the ice bank is built.

9. A generalized fluid/gas diagram is provided at the end of this manual.

10. Position the CO2 gas tank in a secure location. Assemble high pressure regulator to CO2 gas

cylinder and run jumper line to low pressure regulator.

11. Position the syrup tanks or bag-in-box components in the desired location. Attach the CO2 gas

lines leading from the low pressure regulator to these tanks, or B.I.B. manifold.

12. Connect syrup lines from tanks or bag-in-box system to the appropriate inlets at the front of the unit.

The syrup outlet lines from the cooling unit to the dispensing tower(s) are now connected using

(normally .265” I.D.) insulated polytubing conduit.

13. The low pressure gas regulator which controls the flow of syrup to each dispensing valve is

normally set at 25 psig to 35 psig (1.75 to 2.45 bar) or as required for proper operation of the valve.

For diet type syrup, the tank pressures should be set at from 3 to 8 psi (.21 to .56 bar) or as

recommended by the syrup supplier. Additional pressure may be necessary depending on the

distance from the syrup tank to the unit.

14. Mount the water filter assembly (if used) and water regulator in a convenient location.

15. Connect water inlet line to water regulator, set at 30 to 40 psig (2.1 to 2.8 bar), to water filter, and

then to the 3/8” (9.5mm) barbed water inlet of the UCC-40.

16. Connect a (.265” I.D.) (6.7mm I.D.) CO2 gas line from the high pressure CO2 regulator to the 1/4”

(6.4mm) barbed “CO2 Supply Connection” fitting at the UCC-40. This fitting supplies CO2 gas to

the built-in carbonator tank. The normal setting range of the high pressure CO2 gas regulator is 55

to 80 psi (3.85 to 5.6 bar), but may be set as high as 100 psi (7 bar).

17. The soda water outlet fitting of the UCC-40 (a pump with tag) is connected to the dispensing

tower(s) using the 3/8” I.D. (9.5mm I.D.) line of an insulated polytubing conduit.

18. The recirculating (return) soda water from the dispensing tower(s) is connected to the 3/8” (9.5mm)

barb fitting (tag) of the UCC-40 using a 3/8” I.D. (9.5mm) line of an insulated polytubing conduit.

19. After all connections to water, CO2 gas, electrical power and syrup containers are made, check for

leaks.

20. Be sure syrup tanks or BIB boxes contain syrup.

21. Turn on water. Open the pressure relief valve on the carbonator tank by lifting the wire ring, and

hold it open until water flows from the relief valve. Close the relief valve and turn on the CO2 gas

and electrical power in that order. DO NOT operate carbonator pump with water supply shut off.

22. To fill all lines with carbonated water, cycle the carbonator several times by operating the

dispensing valves. If valves do not operate check that the valve switch it “ON”.

23. The recirculating soda water “pump/motor” is controlled by the rocker switch at the unit’s electrical

box identified as “RECIRC. PUMP SWITCH”. This switch is now turned “ON”.

24. The dispensing valves should be adjusted in accordance to the instructions of the dispensing tower

or valve manufacturer.

© 2004, IMI Cornelius Inc. - 5 - Publication Number: 710160089

Page 8

Installation and Service Manual

ICE BANK CONTROL REPLACEMENT

1. Disconnect power to dispenser.

2. Remove cap from drain tube and position the drain tube in the drain pan and drain the water bath.

3. Refill water bath with warm water at a temperature of 120oF (49oC). Let stand for ten (10) minutes

to melt ice bank. If ice remains, repeat Steps 2 and 3 until all ice is melted. Failure to melt all ice

may cause the dispenser to freeze-up after the new ice bank control is installed.

4. Remove two screws from dispenser top and remove top.

5. Remove old ice bank control.

6. Install new ice bank control by pushing probe down into the 3/4” tube until it stops on the bottom of

the tube. Secure probe with tape.

7. Fill water bath with fresh water. Replace dispenser top and secure with two screws.

8. Connect dispenser to power source and turn ON.

Publication Number: 710160089 - 6 - © 2004, IMI Cornelius Inc.

Page 9

CLEANING AND MAINTENANCE

NOTE: The dispenser must be cleaned and sanitized after installation and, thereafter, as required

by state and local health departments, or every three months minimum.

Continuous maintenance of this unit is a basic requirement for proper operation and sanitation, including

all support equipment utilized in the daily operation of this equipment.

1. On a daily basis, clean the external cabinet (splash areas) with mild soap and warm water. Wash

the cup rest and drip pan in cleaning solution and rinse with warm tap water. DO NOT use strong

bleach or detergents or they may discolor and corrode the cabinet materials. DO NOT use steel

wool or other abrasive scouring pads.

2. DO NOT use excessively hot water which may cause damage to plastic components.

3. The water bath should be cleaned two to four times annually, depending upon local water

conditions and in accordance with state and local health departments.

4. Cleaning of the refrigeration components should be performed by a qualified service person.

Disconnect power before removing the dispenser top. The dispenser top grilles should be cleaned

periodically to maintain efficient refrigeration. Condenser fins should be combed, if needed, to

maintain adequate circulation. Clogged condensers can lead to premature compressor failure.

SANITIZING, CLEANING, & MAINTENANCE

Installation and Service Manual

This section details the following:

A. Sanitizing of System

B. Daily Cleaning

C. Ice Water Bath Maintenance

It will be necessary to periodically check and correct the water level of the water bath.

The frequency of filling will depend on the environment within which the dispenser is operating and

consequently, the degree of evaporation of water.

Noisy operation and/or reduced cooling capacity can be caused by insufficient water in the water bath.

The condenser coil will require periodical cleaning to ensure correct air flow and cooling at the

condenser. The frequency of cleaning will depend on the environment within which the dispenser

operates.

All refrigeration components have been factory lubricated for life-time service and will require no further

lubrication.

CLEANING AND SANITIZING PROCEDURE

Water Circuits: Cleaning and sanitizing is not required for potable water circuits. Potable water lines

should remain connected and operational during the cleaning and sanitizing procedures for syrup

circuits.

NOTE: Carbonated Water Lines must remain connected and operational during cleaning and

sanitizing of the syrup circuits. Sanitizing of the valve without the carbonated water side

operational, may leave bacteria in the nozzle, diffuser, and syrup tube.

CLEANING EQUIPMENT AND SUPPLIES

• Recommended cleaner: A.C. Fergusson Company #3391 or any caustic-base (low sudsing, non-

perfumed, easily rinsed) detergent solution which provides a minimum 2% sodium hydroxide. The

solution should be prepared in accordance with the manufacturer’s instructions. Solution should be

room temperature.

• Recommended sanitizer: A.C. Fergusson Company SuperChlor (1 ounce in 5 gallons of water) or

any sanitizer which provides a minimum of 200 parts per million of available chlorine. Solution should

be room temperature.

© 2004, IMI Cornelius Inc. - 7 - Publication Number: 710160089

Page 10

Installation and Service Manual

• Three five (5) gallon figals (syrup tanks) and fittings, cleaned and sanitized (one for water; one for

cleaner; one for sanitizer)

• Containers for cleaner and sanitizer solutions

• Clean, nonabrasive cloths

• Bucket

• Small brush

• Extra nozzles

• Extra jumpers

CLEANING PROCEDURES

1. Disconnect each syrup container from its product line. Fill a figal with clean water, pressurize to 40

to 60 psig and connect the pressurized figal to the syrup product line. Remove syrup from the lines

by activating the dispensing valve. Continuously activate the dispensing valve until all syrup has

been purged from the product lines and valves as noted by the flow of clean water from the valves.

All product lines should be sequentially purged of syrup using this procedure.

2. Clean all lines and fittings with cleaning solution and rinse with clean, room temperature water to

remove all traces of residual product.

3. Clean each valve product line as follows: Fill a figal with dissolved cleaning solution, pressurize to

40 to 60 psig and connect the pressurized figal to the syrup product line. Activate the dispensing

valve continuously for one (1) minute to remove all air bubbles. Pressurize the lines by pulsing the

valves, 15 seconds ON, OFF, then immediately ON again for fifteen (15) cycles, then allow the

valve to remain flowing for three (3) minutes. Repeat pulsing and flowing the valves again until all

cleaning solution has been used.

WARNING: DO NOT allow cleaning and sanitizing solutions to remain in syrup systems longer

than is necessary to complete these procedures. Exceeding contact time will result in damage to

valve components.

4. Wait three (3) minutes and then flush the cleaning solution from the lines with clean water by

connecting a pressurized figal with clean water. Pressurized and flush the valves by pulsing the

valve for (15) cycles and then flushing three (3) minutes as described in the previous paragraph.

Continue pulsing and flushing until testing with phenolphthalein shows the rinse water is free of

residual detergent.

5. Sanitize each valve product line as follows: Be sure all connections are cleaned and sanitized

before connecting to each product line. Fill a figal with dissolved sanitizing solution, pressurize to

40 to 60 psig and connect the pressurized figal to the syrup product line. Activate the dispensing

valve continuously for one (1) minute to remove all air bubbles. Allow the sanitizing solution to flow

through each valve while activating the valves for fifteen (15) cycles, then leave valves OFF and

allow to stand pressurized for thirty (30) minutes. Activate the valves for fifteen (15) cycles, then

flush remaining sanitizer continuously through the valves.

6. Remove the nozzles and the diffuser assemblies from the valves, disengage diffuser assembly

components and clean with cleaning solution. Agitate the assemblies to assure assemblies are

clean. Place them in a container of sanitizing solution for fifteen (15) minutes. Wearing sanitary

gloves, remove the nozzles and diffuser assemblies from the sanitizing solution, drain dry, then

reassemble them to the valves.

7. Reconnect the syrup containers to their respective circuits and ready the unit for operation.

8. Draw drinks to refill lines and flush the sanitizing solution from the dispenser. Taste the beverage to

verify that there is no off-taste (chlorine).

WATER BATH CLEANING

It is recommended that the water bath be cleaned two to four times annually, depending upon local

conditions and/or required by state and local health departments. The water bath should be clean to

obtain maximum cooling efficiency.

Publication Number: 710160089 - 8 - © 2004, IMI Cornelius Inc.

Page 11

Installation and Service Manual

WARNING: Melt ice bank completely, disconnect electrical power and the wiring harness quick

disconnect on the refrigeration deck before draining the water bath and attempting to remove the

refrigeration deck from the water bath or permanent damage to the deck or coil basket may

result.

The water bath compartment is well insulated and it may take five or six hours for the ice to melt.

Refilling with warm water may help to melt the ice more rapidly.

1. Remove plug from the drain tube (located under the drip tray) and position the tube to drain into the

drain pan.

2. After the ice has melted, remove the deck.

3. Thoroughly clean around all the coils and between all crevasses with a brush and cleaning solution

to remove all algae and foreign matter. Dry the water bath.

4. Clean the condenser with a vacuum cleaner or a soft bristle brush.

5. Clean compressor, agitator motor and fan assembly with a cloth, wiping off accumulated dust.

6. Place the refrigeration deck into its original position.

7. Replace drain tube plug and fill the water bath with clean cold water.

8. Reconnect the wire harness on the refrigeration deck.

9. Place cabinet top back onto the unit in its original position and secure.

10. Clean and sanitize product lines and valves per number 4 above before placing dispenser into

service.

© 2004, IMI Cornelius Inc. - 9 - Publication Number: 710160089

Page 12

Installation and Service Manual

LIQUID LEVEL CONTROL WITH TIMER

PURPOSE OF L.L.C. WITH TIMER

The liquid level control with timer is designed to protect the pump of a carbonation system against

running dry and consequent pump damage.

OPERATION

Designed to operate as a normal liquid level control under normal conditions. The timer circuit monitors

the running time of the pump motor. If the pump motor runs continuously for the specified time period,

the timer circuit will discontinue the operation of the pump motor until the reset switch is manually reset.

NOTE: The built-in carbonator normal refill time for the UCC-40 is 3 to 5 seconds (15 fl oz. [444

ml] normal refill volume).

Usually, when the water flow to the pump is interrupted for any extended period, the residual water

present in the pump warms up and will eventually evaporate, but as it warms up it continues to lubricate

the wear points of the pump. Experience has shown that a seven minute interruption in water flow is not

significantly detrimental to the future operation of the pump.

WARNING: The L.L.C. with timer will give no protection against the initial startup of a new

carbonator pump with no water being present at the pump. A new pump which has never

pumped water is considered dry and will suffer damage in a matter of 2 to 3 minutes.

FEATURES

220v/50z and 115v/60z models are available.

3-minute and 7-minute models are available.

Designed to control and protect a 1/2hp maximum pump motor.

Reset

A. Challenger and Enterprise carbonator.

• Separate manual reset switch (#35-0181) ensures that the cause of the problem has been

corrected before continued use of the pump motor. This feature has been provided in these

carbonators since January 1, 1995.

• Carbonators built before January 1, 1995 can be fitted with the time style liquid level control and

can be manually reset be disconnecting the power supply cord from the electrical supply and then

reconnecting same.

B. Overcounter Dispensers with built-in Carbonators (models CTC-20, CTC-40)

• These models have a rocker switch which controls the power supply to the liquid level control

(carbonation system). This switch is accessible through the top surface of the top cover of the

CTC-40, and located on the top left corner of the front valve mounting plate of the model CTC-20.

The timer can be reset by turning this rocker switch “off” and then “on” again.

Publication Number: 710160089 - 10 - © 2004, IMI Cornelius Inc.

Page 13

WIRING DIAGRAM

Installation and Service Manual

60439011 230V/50HZ

60439010 115V/60HZ

60439013 230V/50Z

60439012 115V/60Z

© 2004, IMI Cornelius Inc. - 11 - Publication Number: 710160089

Page 14

Installation and Service Manual

FLUIDS/GAS DIAGRAM

Publication Number: 710160089 - 12 - © 2004, IMI Cornelius Inc.

Page 15

WIRING DIAGRAM

UCC-40 WIRING DIAGRAM

Installation and Service Manual

© 2004, IMI Cornelius Inc. - 13 - Publication Number: 710160089

Page 16

Installation and Service Manual

UCC-40 PARTS EXPLODED DIAGRAM

Publication Number: 710160089 - 14 - © 2004, IMI Cornelius Inc.

Page 17

Installation and Service Manual

UCC-40 PARTS LIST

Item New Part No Description Old Part No. Torrington Part

1 26-0064 Cabinet Ass’y 119-178-007

2 26-0146 Coil Ass’y - Freon 119-184-001

3 55-0339 Control - Temperature 155-969-000 186074001

4 23-0218 Plate - Compressor (1/3 hp) 119-066-004

5 35-0128 Power Cord (115v) 119-360-000

35-0124 Power Cord (220v) 115-558-000

6 55-0087 Condenser 101-434-000

7 23-0510 Shroud - Fan 115-194-000

8 35-0015 Blade - Fan 105-240-000

9 35-0094 Motor - Fan (115v) 119-646-000

35-0097 Motor - Fan (220v) 119-805-220

10 23-0302 Handle 119-118-000

11 23-0040 Bracket - Agitator Motor 115-659-000

(2 Required)

12 40-0411 Washer 106-141-000

13 35-0078 Motor - Agitator 115v 119-447-009

35-0079 Motor - Agitator 220v 119-447-229

14 23-0107 Bracket - Fan Motor 103-024-000

15 55-0031 Bushing 103-067-000

16a 26-0360 Compressor Ass’y 1/3hp 115v

35-0148 Relay 1/3 hp 115v 101-049-000

35-0104 Overload 1/3hp 115v 101-050-000

16b 26-0366 Compressor Ass’y

1/3hp 220v/50hz

35-0151 Relay 1/3hp 220v/50hz 119-803-001

35-0106 Overload 1/3hp 220v/50hz 119-803-002

16c 26-0362 Compressor Ass’y

1/3hp 220v/60hz

35-0152 Relay 1/3hp 220v/60hz 119-803-261

35-0107 Overload 1/3hp 220v/60 hz 119-803-262

17 23-0419 Lid Gray 119-165-007

18 26-0061 Bulb Holder 112-544-675

(Temperature Control)

23-0064 Bracket - Bulb Holder 119-791-097

19 26-0058 Blade - Agitator 115-790-001

20 40-0252 Pin - Cotter S.S. 106-140-000

21 40-0262 Plug - Cap 113-035-000 31699012

22 23-0130 Bracket - Line 119-185-707

23 55-0033 Bushing 119-426-875 34065

24 23-0208 Basket - Product Coil 119-192-001

25 65-0085 Tube - Vinyl 104-299-000

26 40-0019 Clamp 108-111-000 48114005

27 65-0047 Tube - Insulation 3/8 I.D. 104-249-000

28 40-0081 Connector S.S. 3/8 MPT x 3/8B 115-576-000 77081400

29 40-0243 Fitting - Compression 119-688-002

3/8 Tube x 3/8 MPT

30 55-0275 Pump S.S. 50 GPH 107-776-000

31 55-0215 Cover Insulation (Left) 115-396-000

32 55-0214 Cover Insulation (Right) 115-395-000

33 40-0249 Nut - Pack 3/8 119-689-000

34 40-0297 Screw 110-861-902 718400297

35 35-0035 Clamp V c/w Bolt 100-361-000 20543

36 35-0115 Pin - Hitch 101-046-002

37 35-0072 Motor 1/3hp 115v 115-442-000 60030058

35-0075 Motor 1/3hp 220v 50/60hz 115-442-220 71860673

38 40-0208 O Ring 103-123-000 31525012

39 26-0136 Coil Assembly CO2 Water 119-993-728

40 23-0231 Cover - Electrical Box 119-446-001

41 23-0819 Wrapper Electrical Box 115v 119-465-006

23-0783 Wrapper Electrical Box 220v 119-465-001

42 35-0062 Control - Liquid Level 115v 110-863-000

35-0065 Control - Liquid Level 220v 50/60hz 110-863-220 60439010

43 40-0288 Screw 103-462-000

No.

© 2004, IMI Cornelius Inc. - 15 - Publication Number: 710160089

Page 18

Installation and Service Manual

44 23-0230 Cover - Electrical Box (115 v only) 119-070-002

45 55-0035 Bushing 119-446-000

46 35-0137 Receptacle Single Outlet (115v only) 119-425-000

47 40-0038 Fitting - Compression 3/8B x 3/8 Tube 119-688-000 60285002

48 26-0888 CO2 Water Return 119-993-729

49 35-0182 Switch - Rocker 115-650-000

50 23-0185 Box Electrical (115v only) 119-070-006

51 40-0424 Washer - Cup 119-435-001

52 40-0282 Screw 119-435-001

53 40-0407 Washer 103-296-000

54 35-0055 Grommet 101-162-001 60065064

55 35-0158 Sleeve 119-622-000

56 23-0303 Heat Sink 105-139-000

57 40-0284 Screw 102-649-000

58 40-0294 Screw 108-120-000

59 40-0241 Fitting Compression 1/4 Tube x 3/8 B 119-334-000

60 40-0240 Fitting Compression 119-078-000 77030402

61 40-0204 O Ring 103-074-000

62 40-0244 Nut - Pack 1/4 105-313-000

63 26-0345 Coil Pre-Chill 119-865-002

64 35-0035 Clamp V c/w Bolt 100-361-000 20543

65 40-0046 Connector Brass 3/8MPT x 3/8 F 115-109-375

66 40-0418 Washer 3/8 Flare 115-354-000 48033002

67 40-0175 Nut - Swivel 3/8F 110-918-000 77030100

68 40-0153 Nipple - Swivel 1/4B 110-919-000

69 26-0431 Filter Assembly 110-934-000

70 55-0276 Pump - Brass 125 GPH 110-872-000

71 26-0421 Electrode Assembly 19” 119-915-019

72 40-0116 Elbow S.S. 1/4B X 1/4 Swivel Nut 112-708-000 77040100

73 40-0016 Clamp 105-039-000 48114003

74 65-0003 Tube - Braid 115-115-000 174478000

75 40-0409 Washer 1/4 Flare 104-053-000 30359

76 26-0038 Back Check Single 113-139-000 65259001

77 40-0065 Connector S.S. 1/4B X 1/4B 100-826-000 77040200

78 40-0412 Washer 110-861-004

79 40-0120 Elbow S.S. 3/8B X 1/4 Swivel Nut 115-512-000 77040900

80 40-0418 Washer 3/8 Flare 115-534-000 4803002

81 23-0070 Bracket - Mounting Carb Tank 119-891-006

82 40-0422 Washer - Lock S.S. 119-903-000 40734001

83 40-0188 Nut S.S. 1/4 119-464-001

84 55-0073 Carb Tank Ass’y 119-862-007

85 40-0216 O Ring 113-180-000

86 26-0685 Valve - Pressure Relief 110-948-000 71860230

87 55-0040 Insert - Water Inlet .087 110-862-087

88 26-0037 Back Check - Double Valve 110-947-000

89 55-0198 Body - Filter Brass 3/8 NPT 110-924-00

90 55-0197 Screen - Filter 103-948-000

91 40-0206 O Ring 103-113-000

92 40-0130 Fitting Inlet Brass 3/8 F 110-924-000

93 40-0208 O Ring 103-123-000 31525012

94 55-0013 Spring - Back Check 115-050-000

95 55-0012 Ball - S.S. Back Check 115-049-000 64560

96 55-0011 Seat Fitting - Back Check 115-048-000

97 40-0207 O Ring 103-122-000 31525003

98 55-0010 Body - Single Back Check 1/4 Flare 115-046-000

99 55-0016 Body - Double Back Check 115-449-000

Publication Number: 710160089 - 16 - © 2004, IMI Cornelius Inc.

Page 19

IMI Cornelius Inc.

www.cornelius.com

Loading...

Loading...