Page 1

QUEST ELITE 2000

Service Manual

Release Date: May 10, 2010

Publication Number: 620048922SER

Revision Date: December 18, 2010

Revision: 5

Visit the IMI Cornelius web site at www.cornelius.com

for all your Literature needs.

Page 2

The products, technical information, and instructions contained in this manual are subject to change without notice.

These instructions are not intended to cover all details or variations of the equipment, nor to provide for every possible contingency in the installation, operation or maintenance of this equipment. This manual assumes that the person(s) working on the equipment have been trained and are skilled in working with electrical, plumbing, pneumatic,

and mechanical equipment. It is assumed that appropriate safety precautions are taken and that all local safety and

construction requirements are being met, in addition to the information contained in this manual.

This Product is warranted only as provided in Cornelius’ Commercial Warrant applicable to this Product and is subject to all of the restrictions and limitations contained in the Commercial Warranty.

Cornelius will not be responsible for any repair, replacement or other service required by or loss or damage resulting

from any of the following occurrences, including but not limited to, (1) other than normal and proper use and normal

service conditions with respect to the Product, (2) improper voltage, (3) inadequate wiring, (4) abuse, (5) accident,

(6) alteration, (7) misuse, (8) neglect, (9) unauthorized repair or the failure to utilize suitably qualified and trained persons to perform service and/or repair of the Product, (10) improper cleaning, (11) failure to follow installation, operating, cleaning or maintenance instructions, (12) use of “non-authorized” parts (i.e., parts that are not 100%

compatible with the Product) which use voids the entire warranty, (13) Product parts in contact with water or the

product dispensed which are adversely impacted by changes in liquid scale or chemical composition.

Contact Information:

To inquire about current revisions of this and other documentation or for assistance with any Cornelius product contact:

www.cornelius.com

800-238-3600

Trademarks and Copyrights:

This document contains proprietary information and it may not be reproduced in any way without permission from

Cornelius.

Printed in U.S.A.

Page 3

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Read and Follow ALL Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Recognition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Different Types of Alerts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Qualified Service Personnel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Shipping And Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Mounting in or on a Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Unit Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Nameplate Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Concentrate Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Recommended Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Water Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Water Supply Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Ice Bank/Pull Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Plumbing Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Concentrate Handling and Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Loading Concentrate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Changing Concentrate Containers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

BRIXING Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Checking/Adjusting the BRIX Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Planned Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Daily . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Flush System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Clean Splash Zones & Dispense Nozzles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Weekly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Sanitize the Juice Dispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Sanitize Pump System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Prepare Dispenser for Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Semi Annually . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Clean Water Inlet Strainer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Clean Chassis Interior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Page 4

Check and Top-Off Water Ice Bath . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Annually . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Replace Pump Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Removing Pump Platform(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Replacing the Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Troubleshooting Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Assembly Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

IMI Cornelius Standard Service Call Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Page 5

Quest Elite 2000 Service Manual

!

DANGER:

!

WARNING:

CAUTION:

!

!

SAFETY INSTRUCTIONS

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

Safety Overview • Read and follow ALL SAFETY INSTRUCTIONS in this manual and any

warning/caution labels on the unit (decals, labels or laminated cards).

• Read and understand ALL applicable OSHA (Occupational Safety and

Health Administration) safety regulations before operating this unit.

Recognition

Recognize Safety Alerts

This is the safety alert symbol. When you see it in this manual or on the unit,

be alert to the potential of personal injury or damage to the unit.

Different Types of Alerts

SAFETY TIPS

Indicates an immediate hazardous situation which if not avoided WILL result in

serious injury, death or equipment damage.

Indicates a potentially hazardous situation which, if not avoided, COULD result

in serious injury, death, or equipment damage.

Indicates a potentially hazardous situation which, if not avoided, MAY result in

minor or moderate injury or equipment damage.

• Carefully read and follow all safety messages in this manual and safety

signs on the unit.

• Keep safety signs in good condition and replace missing or damaged items.

• Learn how to operate the unit and how to use the controls properly.

Do not let anyone operate the unit without proper training. This appliance is

•

not intended for use by very young children or infirm persons without supervision. Young children should be supervised to ensure that they do not play

with the appliance.

© 2010, IMI Cornelius Inc. - 1 - Publication Number: 620048922SER

Page 6

Quest Elite 2000 Service Manual

!

WARNING:

!

WARNING:

!

WARNING:

CAUTION:

!

CAUTION:

!

• Keep your unit in proper working condition and do not allow unauthorized

modifications to the unit.

QUALIFIED SERVICE PERSONNEL

Only trained and certified electrical, plumbing and refrigeration technicians

should service this unit. ALL WIRING AND PLUMBING MUST CONFORM TO

NATIONAL AND LOCAL CODES. FAILURE TO COMPLY COULD RESULT IN

SERIOUS INJURY, DEATH OR EQUIPMENT DAMAGE.

SAFETY PRECAUTIONS

This unit has been specifically designed to provide protection against personal

injury. To ensure continued protection observe the following:

Disconnect power to the unit before servicing following all lock out/tag out

procedures established by the user. Verify all of the power is off to the unit before

any work is performed.

Failure to disconnect the power could result in serious injury, death or equipment

damage.

To avoid a hazard due to instability of the appliance, it must be fixed in

accordance with the instructions.

Always be sure to keep area around the unit clean and free of clutter. Failure to

keep this area clean may result in injury or equipment damage.

SHIPPING AND STORAGE

Before shipping, storing, or relocating the unit, the unit must be sanitized and all

sanitizing solution must be drained from the system. A freezing ambient

environment will cause residual sanitizing solution or water remaining inside the

unit to freeze resulting in damage to internal components.

Publication Number: 620048922SER - 2 - © 2010, IMI Cornelius Inc.

Page 7

Quest Elite 2000 Service Manual

!

WARNING:

MOUNTING IN OR ON A COUNTER

When installing the unit in or on a counter top, the counter must be able to

support a weight in excess of 140 lbs. (63.5 kg.) to insure adequate support for

the unit. FAILURE TO COMPLY COULD RESULT IN SERIOUS INJURY, DEATH

OR EQUIPMENT DAMAGE.

© 2010, IMI Cornelius Inc. - 3 - Publication Number: 620048922SER

Page 8

Quest Elite 2000 Service Manual

UNIT SPECIFICATIONS

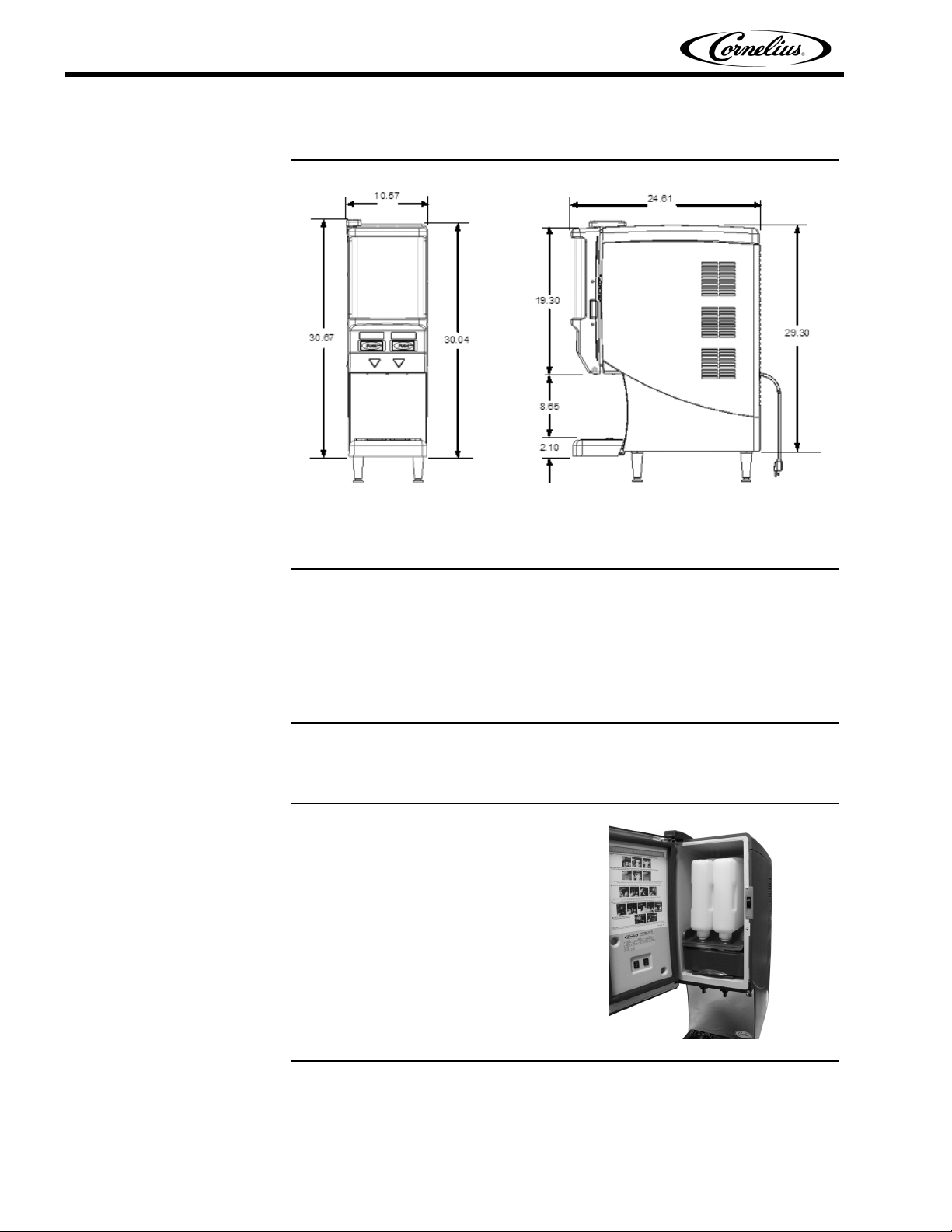

Figure 1. Unit Dimensions

Nameplate Data

Concentrate Storage

Model QUEST ELITE 2000, 115 VAC, 4.5 amps, 1 phase 60 hertz, 6.00 oz. (170g)

R-134a refrigerant. Test press: High side 400 psi (2757.9 kilopascals), (27.6 bar).

Low side 88 psi (606.7 kilopascals), (6.1 bar).

Model QUEST ELITE 2000, 230 VAC, 2.25 amps, 1 phase 50 hertz, 6.00 oz.

(170g) R-134a refrigerant. Test press: High side 400 psi (2757.9 kilopascals), (27.6

bar). Low side 88 psi (606.7 kilopascals), (6.1 bar).

Two 0.8 gallon (3.0 liter) disposable bottles.

Publication Number: 620048922SER - 4 - © 2010, IMI Cornelius Inc.

Page 9

Quest Elite 2000 Service Manual

CAUTION:

!

Recommended Clearance

Electrical Connection

12” (30.48 cm) on top and 4” (10.16 cm) required in back for air circulation and 2”

at the sides of the unit.

6 ft. long (1.83 m) power cord with 3-prong plug attached to dispenser. Export

models are shipped with a European plug. The plug is accessible after installation.

ONLY trained and certified electrical technicians should replace the power cord or

the unit should be returned to an Authorized Service Center for power cord

replacement.” The replacement cord must meet all requirements of the original

equipment manufacturer.

Failure to comply could result in serious injury, death or damage to the

equipment.

Power Supply

Water Connection

15 amps at 120 volts dedicated power supply.

20 amps at 230 volts dedicated power supply.

3/8 in. (0.95 cm) SAE male flare fitting on dispenser.

The new hose sets supplied with the appliance are to be used and that old hose

sets should not be reused.

© 2010, IMI Cornelius Inc. - 5 - Publication Number: 620048922SER

Page 10

Quest Elite 2000 Service Manual

Water Supply Requirements

60 psi (413.7 kilopascals) (4.1 bar) maximum static pressure. 30 psi (206.8

kilopascals) (2.1 bar) minimum dynamic pressure; i.e., flowing pressure measured

at dispenser water inlet with 3.0 (88.7 ml) per second water flow. Optimum

recommended pressure 50 psi (344.7 kilopascals) (3 .5 bar) dynamic pressure.

Ice Bank/Pull Down

Weight 7-8 lbs. (3.2 - 3.6 kg.). Pull Down: 3 hours at 75°F (24°C)

Publication Number: 620048922SER - 6 - © 2010, IMI Cornelius Inc.

Page 11

Quest Elite 2000 Service Manual

!

WARNING:

Water

Connection

This appliance is intended to be used in household and similar applications such

as the following:

• Staff kitchen areas in shops, offices and other working environments.

• Farm houses and by clients in hotels, motels and other residential type envi-

• Bed and breakfast type environments

• Catering and similar non-retail applications

PLUMBING REQUIREMENTS

This dispenser must be connected to a COLD WATER system with operating

pressure between 20 and 100 psi (138 and 690 kPa). This water source must be

capable of producing a minimum flow rate of 3 fluid ounces (88.7 milliliters) per

second. A shut off valve should be installed in the line before the dispenser. Install

a regulator in the line when pressure is greater than 100 psi (690 kPa) to reduce it

to 50 psi (345 kPa). The regulator is also necessary if the water source has

pressure fluxuations. The main water inlet is a 3/8" (9.52 mm) MFL connection.

APPLICATIONS

ronments

This equipment must be installed to comply with the International Plumbing

Code of the International Code Council and the Food Code Manual of the Food

and Drug Administration (FDA). For models installed outside the U.S.A., you

must comply with the applicable PlumbingISanitation Code for your area.

Failure to comply could result in serious injury, death or damage to the equipment.

© 2010, IMI Cornelius Inc. - 7 - Publication Number: 620048922SER

Page 12

Quest Elite 2000 Service Manual

!

WARNING:

CONCENTRATE HANDLING AND LOADING

It is recommended that the concentrate be thawed in a refrigerated 35°F to 40°F

(1.6°C to 4.4°C) compartment for a minimum of 48 hours prior to loading it into the

Quest Juice Dispenser.

Concentrate must be completely thawed and within the temperature range of

35°F to 40°F (1.6°C to 4.4°C) prior to loading. Failing to supply concentrate

inside the recommended temperature range, especially below 35°F (1.6°C),

causes an out of BRIX drink (refer to the BRIXing Procedure section for details).

LOADING CONCENTRATE

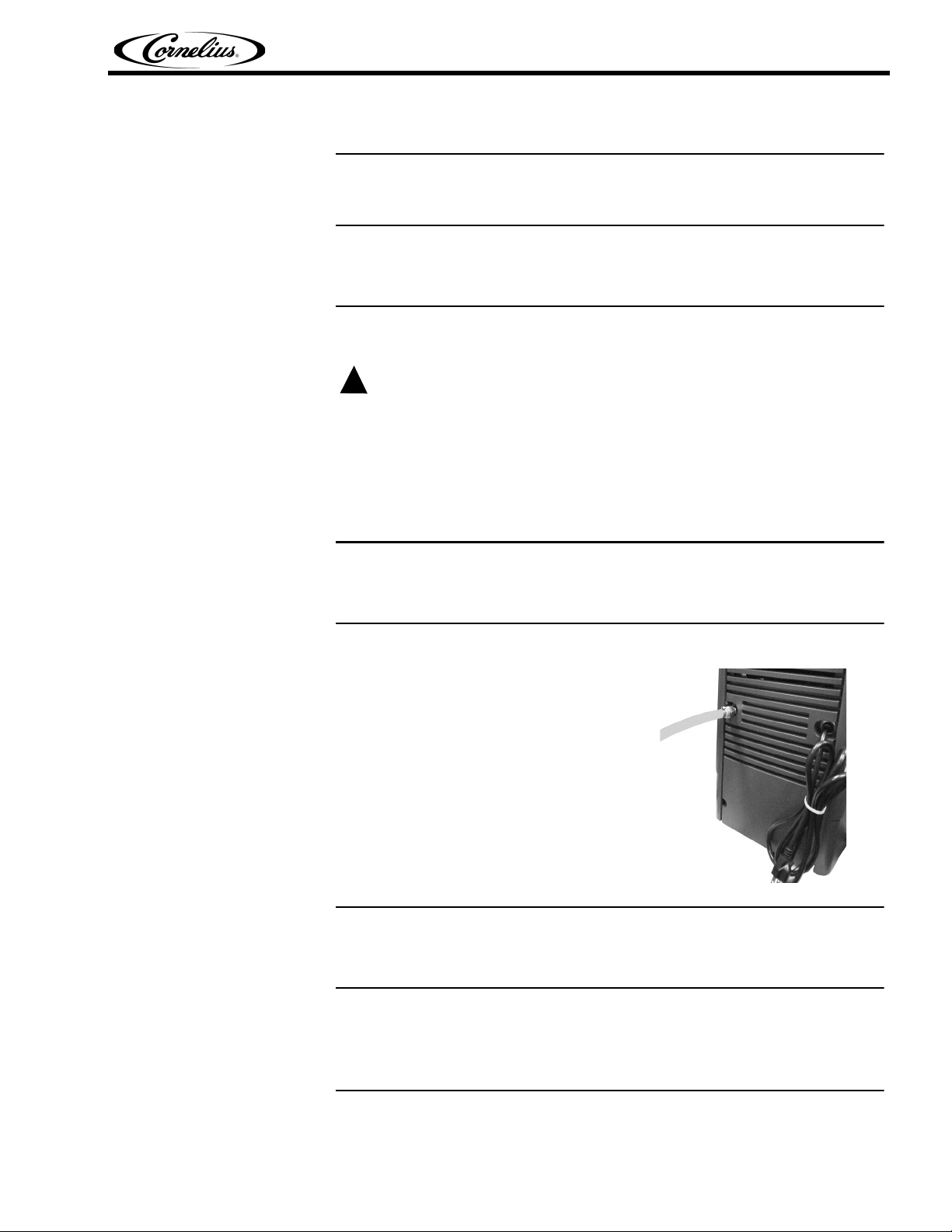

The Quest Juice Dispenser is designed to use either disposable juice concentrate

containers or the optional Cornelius generic refillable container (sold separately).

Figure 2. Refillable Concentrate Container

1. Thoroughly shake concentrate container prior to use.

2. Place concentrate containers on the dispensing platform shelf inside the

refrigerated cabinet.

3. Engage the concentrate container by pressing it downward into the bottle

adapter opening on the dispensing platform.

NOTE: Be sure to lubricate the o-ring seal on the container nozzle.

This ensures a good seal and allows the pumps to draw

concentrate from the containers more easily. Failure to create

a good seal at this connection may result in weak drinks and/or

seepage of concentrate.

4. Prime each pump by closing the cabinet door and press each dispense

button until concentrate flows from the dispense nozzles.

CHANGING CONCENTRATE CONTAINERS

1. Open the cabinet door and move the valve handle from the

Flush

position, see Figure 3.

Dispense

to

Publication Number: 620048922SER - 8 - © 2010, IMI Cornelius Inc.

Page 13

Quest Elite 2000 Service Manual

Dispense/Flush

Levers

Figure 3. Dispense/Flush Lever Location

2. Close the door. Depress and hold the dispense button (Figure 4) until clear

water flows from the dispense nozzle.

Figure 4. Dispense Buttons

3. Open the cabinet door and return the handle to the

Dispense

position.

4. Depress and hold the dispense button for 1-2 seconds. This relieves water

pressure from the concentrate pump system.

5. Load the concentrate container (see Figure 5 and Loading Concentrate

Section, Page 8).

Figure 5. Loading a Concentrate Container

© 2010, IMI Cornelius Inc. - 9 - Publication Number: 620048922SER

Page 14

Quest Elite 2000 Service Manual

BRIXING PROCEDURE

NOTE: If concentrate is not properly thawed, it will adversely affect

the amount of concentrate dispensed. Thawed product should

be between 35°F/1.6°C to 40°F/4.4°C.

SUPPLIES

• 1 - Small 12 oz. cup (354.8 ml)

• 1 - Large 21 oz. cup (621.1 ml)

• 1 - Straw

• Paper Towels

• 1 - Thermometer

• 1 - Refractometer

• 1 - Flat Bladed Screwdriver

NOTE: The refractometer shown is P/N 511004000, and is available

through your local Cornelius Distributor.

CHECKING/ADJUSTING THE BRIX SETTING

The following instructions are for use with a refractometer.

1. Dispense approximately 8 oz. (237 ml) of drink and discard. Now draw a

second 8 oz. (237 ml) drink.

2. Check drink temperature with a accurate thermometer (target is 35 to 45°F,

or 1.6 to 7.2°C). Discard this drink after checking temperature.

NOTE: If drink temperature is not within the target range, refer to the

basic troubleshooting section.

3. Dispense a 12 oz (354.8 ml) drink sample into a clean, dry cup. Thoroughly

stir the sample using a straw.

4. Using the straw, transfer a small sample of the finished drink to the

refractometer lens (refer to operating instructions supplied with your

refractometer). Check the BRIX reading against the BRIX chart shown in

Tab l e 1 .

NOTE: The BRIX chart shown in Table 1 is generic and intended for

reference use only. Contact your frozen concentrate supplier for

specific BRX readings.

Flavor Ratio BRIX

Orange Juice 4-1 11.8

Grapefruit Juice 5+1 10.6

Cranberry Cocktail 4+1 13.5

Apple Juice 5+1 12.0

Table 1.

Publication Number: 620048922SER - 10 - © 2010, IMI Cornelius Inc.

Page 15

Quest Elite 2000 Service Manual

Dispense/Flush Lever

Water Flow

Controls

Table 1.

Flavor Ratio BRIX

Grape 5+1 13.0

Lemonade 5+1 10.5

Tropical Punch 5+1 11.8

Sweetened Ice Tea 7+1 6.0

Pineapple Juice 4+1 12.8

Prune Juice 2+1 16.0

5. To change the BRIX setting, simply readjust the water flow rate. Located on

each of the valve assemblies inside the refrigerated compartment are the

adjusting screws for the water flow rate (one per valve).

If the BRIX reading is too high or low, rotate the appropriate water flow control

according to Figure 6. Repeat steps 1-5 until the proper BRIX setting is achieved.

Figure 6. BRIX Adjustment

IMPORTANT: When making changes to the water flow control, do not

rotate more than 1/4 turn per adjustment. Additionally,

prior to taking your next BRIX reading, momentarily

press the corresponding dispense button several times

prior to drawing a sample. This clears any remnants

from the dispense nozzle AND helps move the flow

control to its new setting.

© 2010, IMI Cornelius Inc. - 11 - Publication Number: 620048922SER

Page 16

Quest Elite 2000 Service Manual

Dispense/Flush

Levers

Mixing

Chambers

PLANNED MAINTENANCE SCHEDULE

DAILY

Flush System

1. Move all of the Dispense/Flush levers (located on the platform assembly in

the refrigerated cabinet) to the

drip tray below each dispense nozzle (Figure 7).

Flush

position. Place an empty cup on the

Clean Splash Zones & Dispense Nozzles

Figure 7. Platform Assembly with Dispense/Flush Levers

2. Close the door and depress each dispense button for 2-3 seconds or until

clear water flows from each dispense nozzle.

Figure 8. Dispense Buttons

3. Return the Dispense/Flush levers to the

4. Press each Dispense button for 1 to 2 seconds to release the water

pressure present in the concentrate pump system.

1. On a daily basis, clean the external cabinet and splash areas using a clean

damp cloth. Remove and wash the cup rest and drip tray using mild dish

soap.

Dispense

position.

Publication Number: 620048922SER - 12 - © 2010, IMI Cornelius Inc.

Page 17

!

WARNING:

WEEKLY

Quest Elite 2000 Service Manual

2. Remove the dispense nozzles and static mixers by rotating each 90° and

pulling down. Remove the mixing chambers by pulling straight forward.

Wash using mild dish soap.

IMPORTANT: DO NOT wash nozzles, static mixers, or mixing

chambers in a dish washer. This will distort the plastic

and damage the o-rings. Additionally, do not soak them

in sanitizing solution longer than 2 minutes.

Flush once a day for better quality drinks.

Do not leave the unit in FLUSH mode. Leaving the unit in flush mode may result

in damage.

Check concentrate to water brix ratio (refer to the Checking/Adjusting the BRIX

Setting Section, Page 10).

Sanitize the Juice Dispenser

1. Rinse the unit with hot water.

2. Prepare two 2 oz. (59 ml) packets of Stera-Sheen Green Label sanitizing

3. Remove the juice concentrate containers and place them in separate

4. Flush the system by following the instructions in Flush System on page 12.

5. Fill a clean empty concentrate container with one quart of extremely hot tap

6. Remove the mixing chambers, nozzles, and static mixers. Rinse in hot water

7. Place the mixing chambers, nozzles, and static mixers in a separate

solution (or similar brand) by dissolving each packet in 1 gallon (3.8L) of

potable water to insure 200 ppm of available chlorine.

IMPORTANT: Use potable water at 80°F-100°F (26.7°C-37.8°C). Water

above this range breaks down the chlorine count and

minimizes sanitation.

refrigerated compartment.

water, approximately 140°F (60°C) and place the container into the unit.

Dispense all of the hot water into a large container. Repeat for all the

remaining dispense valves.

to remove excess pulp and concentrate.

container of sanitizing solution and agitate vigorously. Allow the parts to

soak for two minutes, then rinse thoroughly with fresh tap water.

8. Reinstall the static mixer, nozzles, and mixing chambers.

Sanitize Pump System

1. Fill a clean concentrate container with 2 quarts (1.9L) of fresh sanitizing

solution.

© 2010, IMI Cornelius Inc. - 13 - Publication Number: 620048922SER

Page 18

Quest Elite 2000 Service Manual

CAUTION:

!

Dispense/Flush

Levers

Mixing

Chambers

2. Place Dispense/Flush levers (located on the platform assembly in the

refrigerated cabinet) to the

3. Press and hold the dispense button for 90 seconds then release. Allow

sanitizing solution to remain in the lines for 5 minutes.

Dispense

Figure 9. Dispense/Flush Levers

position.and close the door.

Prepare Dispenser for Use

SEMI ANNUALLY

Figure 10. Dispense Buttons

4. After 5 minutes, dispense the remaining sanitizing solution.

1. Replace sanitizing solution container with a concentrate container and close

the door.

2. Press and hold the dispense button until juice appears from the nozzle. Next

dispense and discard at least two 8 oz. (236.6ML) cups of juice in order to

prime the system and prepare it for operation.

The following procedures require removal of the dispenser side panel(s).

Disconnect the power cord (See Figure 11.) from the receptacle prior to

proceeding.

Publication Number: 620048922SER - 14 - © 2010, IMI Cornelius Inc.

Page 19

Quest Elite 2000 Service Manual

Clean Water Inlet Strainer

Figure 11. Pull AC Plug from Wall Outlet

1. Remove the right side panel from the dispenser.

2. Turn off the water supply to the dispenser.

3. Remove the access port from the “Y” shaped water inlet solenoid located on

the right side of the dispenser. (See Figure 12)

4. Clean and reinstall the stainless steel water strainer.

Clean Chassis Interior

1. Clean the condenser cooling fins.

2. Clean the air inlet grilles located on the rear and top panels of the dispenser.

3. Clean the interior base.

4. Wipe the fan blades clean.

5. Reinstall the right side panel, turn on the water supply, and plug the

dispenser into the power receptacle.

Check and Top-Off Water Ice Bath

1. Remove the drip tray and lower splash panel.

Figure 12. Right Side of Dispenser

© 2010, IMI Cornelius Inc. - 15 - Publication Number: 620048922SER

Page 20

Quest Elite 2000 Service Manual

Drip Tray

Lower Splash Panel

Cup Rest

If the Ice bath level is below the

Filling the Ice Bath procedure in the Installation manual (P/N 620048922INS).

ANNUALLY

Replace Pump Tubing

Figure 13. Drip Tray and Cup Rest

Full

indicator, top it off with water. Refer to the

Removing Pump

Platform(s)

A replacement pump tubing kit, part#45098, is available. The kit consists of one

pre-cut length of pump tubing, two white plastic hose clamps, and instructions.

1. Remove the concentrate containers from the dispenser and place them in a

refrigerator.

2. Remove the cabinet shelf that the concentrate containers sit on.

3. Flush the system prior to removing the pump platform (refer to the Daily

Section, Page 12). Remove the dispense nozzles and static mixers.

4. Unplug the water line quick disconnect by pressing the gray button (See

Figure 14).

Publication Number: 620048922SER - 16 - © 2010, IMI Cornelius Inc.

Page 21

Quest Elite 2000 Service Manual

Front & Rear

Pump Halves

Pump Motor

Water Manifold

Water Solenoid

Locking Latch

Bottle Adapter

Juice Inlet

Water Inlet

Quick Connector

Pump Body Screws

BRIX Adjustment Screw

Concentrate

Delivery Tubes

1

2

3

4

Figure 14. Interior Details

5. Slide the locking latch forward. Lift the platform slightly and pull forward to

gain access to the electrical connector (see Figure 14).

6. Unplug the electrical connector by squeezing the locking tabs on either side and

pulling out the connector. Lift and remove the pump platform (see Figure 14).

Replacing the Tubing When the pump platform has been removed, replace the tubing by performing the

following procedure.

1. Remove the two white plastic hose clamps from the pump tube connections

(See Figure 14) and remove the concentrate delivery tubes from the hose

ends.

2. Loosen and remove the four screws from the pump body (See Figure 15).

Figure 15. Pump Body Screws

© 2010, IMI Cornelius Inc. - 17 - Publication Number: 620048922SER

Page 22

Quest Elite 2000 Service Manual

Pump Tubing

Roller

Assembly

3. Remove ONLY the rear pump body half to reveal the pump tubing and

rollers (See Figure 16).

4. Remove the old pump tubing from the pump body. If the roller assembly

comes out with the tubing, place it back into the pump housing.

to align the roller assembly shaft keyway to the motor shaft so that the

two interlock.

5. Firmly press the new tubing into the pump body around the roller assembly,

making sure to keep the protruding ends even with each other.

6. Once the tubing is in place, hold the tubing with one hand, capture the lower

part of the tubing with the outer housing, then proceed to capture the shaft

of the roller assembly and push the rear pump housing into place. Make

sure to capture the tubing within the body and not pinch it between the

halves. Do not use any tool other than your finger tips to manipulate the

tubing into the housing or you may damage the tubing.

Make sure

Figure 16. Pump Assembly

7. While holding the pump halves together with your hand, reinsert the four

thumb screws (See Figure 15) and tighten using a cr i ss-cross pattern as

shown. The thumb screws should be tightened about 1/4 turn beyond snug.

8. Insert the two concentrate delivery tubes into the pump tubing ends and

secure them using the new hose clamps supplied in the kit. Be sure to use

pliers to squeeze and tighten the hose clamps.

Publication Number: 620048922SER - 18 - © 2010, IMI Cornelius Inc.

Page 23

Quest Elite 2000 Service Manual

TROUBLESHOOTING GUIDE

The following tables contain trouble-shooting information intended to aid an

experienced service person in diagnosing operational problems that may occur. For

further assistance, contact the IMI Cornelius Technical Services department at 1888-248-5568 (763) 421-6120 outside the United States) between the hours of

7:30A.M. and 5:00P.M. Central Standard Time. You must have the model and serial

number (Located on the right side of the dispenser) when calling.

Ta bl e 2

Symptom Probable Cause Remedy

Unit totally inoperative

No Cooling

A. No power to dispenser due to tripped

circuit breaker.

B. Loose or broken power supply connection inside dispenser.

A. Line voltage not within nameplate

specification causing compressor overload to trip.

B. No water in water ice bath or water

level extremely low, exposing ice bank

sensing probe.

C. Defective Ice Bank Control or sensing

probe.

D. Cabinet fan inoperative resulting in

warm concentrate (water continues to

cool).

E. Compressor short cycles on overload.

F. Compressor starts but hums & trips

overload.

G. Defective compressor overload or start

capacitor.

H. Compressor starts but does not switch

off of start winding.

I. Refrigerant leak.

A. Reset circuit breaker. Confirm that

breaker is correct size & no other equipment is operating on the same circuit. Also

confirm that supply voltage is +/-10% of

nameplate specification.

B. Repair connection.

A. Contact an electrician.

B. Fill ice bath to proper water level.

C. Replace.

D. Replace.

E. Excessively high discharge pressure due

to restricted condenser or inoperative condenser fan motor.

F. Seized or shorted compressor,

replace.

G. Test & replace.

H. Relay or compressor is defective. Test

& replace faulty item.

I. Repair leak, evacuate & recharge system.

© 2010, IMI Cornelius Inc. - 19 - Publication Number: 620048922SER

Page 24

Quest Elite 2000 Service Manual

Symptom Probable Cause Remedy

Ta bl e 2

No water dispensed,

concentrate only

No water & no concentrate, refrigeration

is working.

No concentrate dispensed, water only.

A. No water in dispenser.

B. Water supply line inside refrigerated

cabinet disconnected from pump platform.

C. Water solenoid located on pump platform

clogged or defective.

D. Main water solenoid/strainer located at

the rear of dispenser is clogged, binding or

defective.

E. Water supply pressure is greater than 80

psi (5.5 bar) forcing BRIX flow control closed.

F. Freeze-up of water coil in ice bath.

A. Black service switch located on the

rear of the cabinet door in OFF position.

B. White door switch open

C. 6.25 amp fuse inside front electrical

box blown.

D. No output from transformer.

E. Defective voltage regulator board

(VRB) located inside front electrical box.

F. Defective dispense push button or portion control board.

A. Concentrate container not fully

engaged into receptacle on pump platform.

B. Dispense/Flush lever in FLUSH position

C. Concentrate too cold, not properly

thawed.

A. Restore water.

B. Reconnect

C. Disassemble & clean solenoid.

Replace if necessary.

D. Remove & clean strainer. Confirm

24VDC is present at solenoid during dispense. Confirm solenoid coil is not open.

Disassemble & clean solenoid.

E. Add external regulator & lower pressure to 50 psi (3.5 bar).

F. Unplug dispenser & allow 2-4 hrs. to

thaw. Check operation of agitator motor & ice

bank control.

Refrigeration system may be low on charge

resulting in a deformed ice bank & freeze-up

of water coil in ice bath.

A. Turn on switch.

B. Door switch must be closed in order to

dispense. Check switch operation &

replace if necessary.

C. Replace with 6.25, 250VAC slow blow

fuse & test.

D. Confirm transformer output of 24VAC

+/-2. Replace transformer if necessary.

E. Measure across the VDC output of the

board. There should be 28VDC present

when the dispense button is pressed.

Replace VRB if necessary.

F. Test & replace if necessary.

A. Refer to Concentrate Loading section

of this manual.

B. Move lever to DISPENSE position

C. Concentrate should be 35 to 40°F (1.7

to 4.5°C) prior to loading.

D. Replace pump motor.

D. Defective pump motor.

A. Ambient air around dispenser is too

warm.

B. Excessive demand on dispenser.

Warm drinks

Water continuously

drips from nozzle in

OFF mode.

Publication Number: 620048922SER - 20 - © 2010, IMI Cornelius Inc.

C. Dirty condenser coil.

D. Inoperative condenser fan.

E. Defective Ice Bank Control.

F. Loss of refrigerant charge due to leak

in system.

A. Main water solenoid at base of unit or

water solenoid on pump platform not shutting off completely.

A. Relocate dispenser.

B. Add water pre-cooler or second dispenser

C. Clean condenser coil.

D. Replace condenser fan motor.

E. Test & replace if necessary.

F. Repair leak and recharge system.

A. Clean solenoid(s), replace parts as

necessary (refer to Planned Maintenance

section).

Page 25

Quest Elite 2000 Service Manual

Ta bl e 2

Symptom Probable Cause Remedy

Concentrate warm,

water cold.

BRIX problem

Pump inoperative

Machine continues to

dispense after dispense button is

released or dispenses without operator input.

A. Cabinet fan inoperable.

B. Agitator motor/pump inoperable or

restricted.

C. Loss of refrigerant charge due to leak

in system.

A. Water supply pressure too low, less

than 20 psi (1.4 bar) flowing water pressure.

B. Water flow control binding or spring is

defective.

C. Improperly thawed concentrate. BRIX

changes as concentrate temperature

changes (concentrate becomes thinner as

temperature rises)

A. Pump motor defective.

B. No power to transformer or no 24VAC

output from transformer.

C. Defective voltage regulator board

(VRB) located inside front electrical box.

D. Defective dispense control board

(Push button or portion control).

A. Push button or portion control pad

stuck in ON position.

B. Relay on voltage regulator board

(VRB) stuck on.

A. Check/replace fan.

B. Check/replace agitator motor.

C. Repair leak & recharge system.

A. Correct water supply problem to

ensure a constant 50 psi (3.5 bar) flowing

to dispenser.

B. Clean and/or replace parts as necessary.

C. Concentrate should be 35 to 40°F (1.7

to 4.5°C) prior to loading.

A. 28VDC should be present at pump

motor during dispense. If voltage is present & motor does not start, replace motor.

B. Confirm transformer has line voltage

present on primary side. If no 24VAC output

from secondary, replace transformer.

C. Confirm board produces 28VDC present

when dispense button is pressed (refer to

Electrical Box Wiring Diagram for VDC output location). Replace VRB if necessary.

D. Test & replace if necessary.

A. Disconnect wire harness from rear of portion control and close the door. If unit does not

dispense on its own, dispense control board

is bad (stuck on).

B. Disconnect 4-wire harness from lower

right comer of VRB. If unit continues to dispense on its own VRB is defective (relay

stuck on).

© 2010, IMI Cornelius Inc. - 21 - Publication Number: 620048922SER

Page 26

Quest Elite 2000 Service Manual

ASSEMBLY DRAWINGS

Figure 17. System Wiring Diagram Quest Elite 2

Publication Number: 620048922SER - 22 - © 2010, IMI Cornelius Inc.

Page 27

Quest Elite 2000 Service Manual

Figure 18. Main Electrical Box Wiring Diagram Quest Elite 2

© 2010, IMI Cornelius Inc. - 23 - Publication Number: 620048922SER

Page 28

Quest Elite 2000 Service Manual

IMI CORNELIUS STANDARD SERVICE CALL GUIDE

The table below will be used by IMI Cornelius Inc. as a STANDARD service call

guide to determine fair and reasonable labor charges for warranty repairs.

Charges in excess of these rates will be subject to review and/or adjustments.

The labor warranty referenced in the Certificate of Warranty in this manual applies

to the replacement of the defective part. IMI Cornelius Inc. will not accept labor

warranty claims for water leaks applicable to the installation, clogged drains,

adjustments of any kid including regulators, pumps, thermostats, ratio, or brix

settings, stratification issues, preventative maintenance, sanitizing, etc. IMI

Cornelius Inc. will consider only actual service time on the equipment. Charges for

mileage, holiday pay, night charges, and overtime will not be considered. All labor

claim that are fare, reasonable, and within the terms of the warranty and allotted

repair times will be paid in U.S. Dollars.

Any questions regarding the warranty procedures can be directed to our Technical

Services group at 1-800-238-3600 (763-421-6120 outside the United States).

*Recovery and pump down require at least two hours depending on contamination

and is not included in the allotted repair time shown above.

Publication Number: 620048922SER - 24 - © 2010, IMI Cornelius Inc.

Page 29

Page 30

IMI Cornelius Inc.

www.cornelius.com

Loading...

Loading...