Page 1

CAUTION - Only trained and certified electrical, plumbing and refrigeration technicians should

service this unit. ALL WIRING AND PLUMBING MUST CONFORM TO NATIONAL AND LOCAL

CODES.

REQUIREMENTS

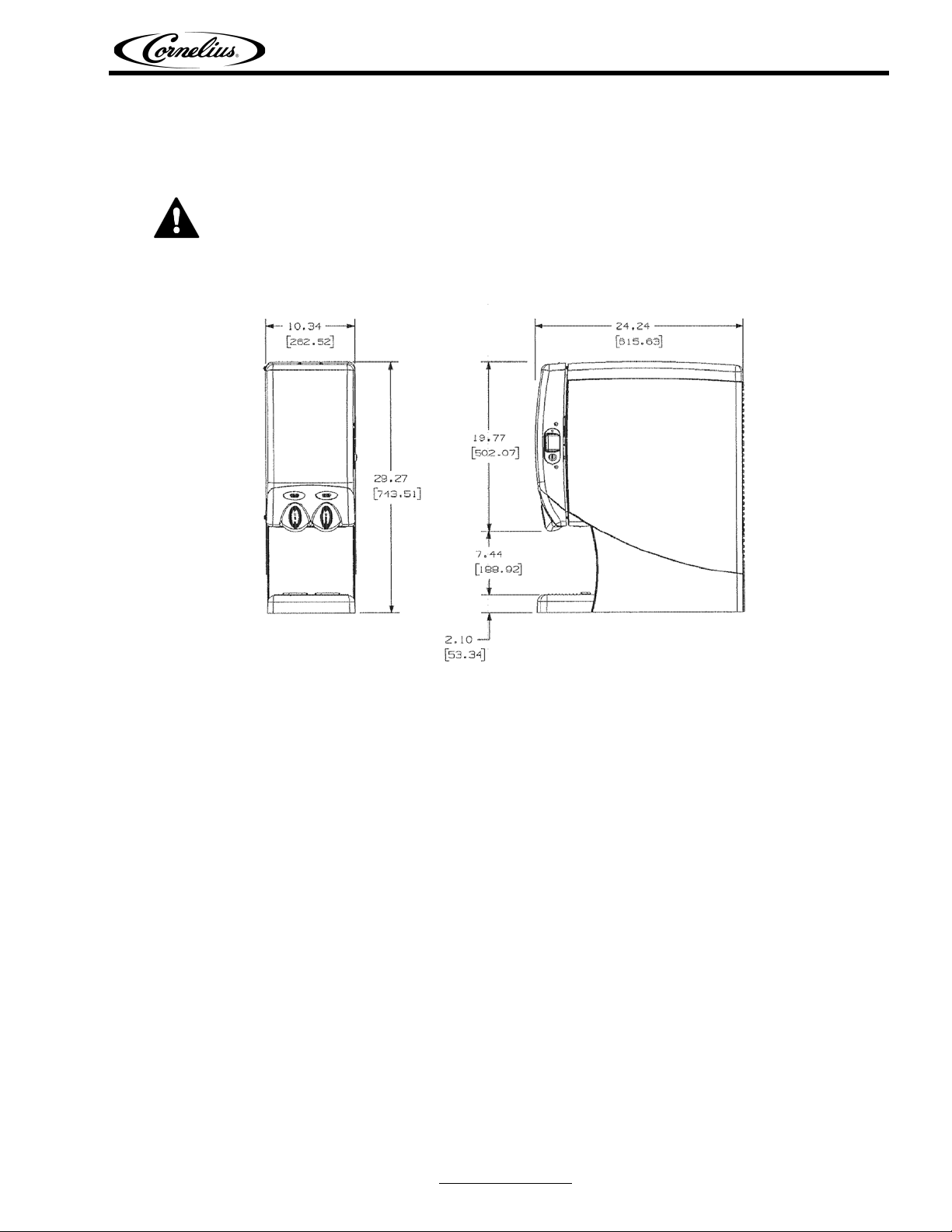

Quest 2000 Installation Manual

INSTALLATION MANUAL

Quest 2000

Nameplate Data: Model QST 2000, 115 VAC, 4.5 amps, 1 phase 60 hertz, 6.25 oz. (177g) R-134a

refrigerant. Test press: High side 400 psi (27.6 bar). Low side 100 psi (6.9 bar).

Model QST 2000, 230 VAC, 2.25 amps, 1 phase 50 hertz, 6.25 oz. (177g) R-134a

refrigerant. Test press: High side 400 psi (27.6 bar). Low side 100 psi (6.9 bar).

Concentrate Storage: Two 0.8 gallon (3.0 liter) disposable bottles.

Clearance Recommended: 12” (30.48 cm) on top and 4” (10.16 cm) required in back for air circulation.

Electrical Connection: 6 ft. long (1.83 m) power cord with 3-prong plug attached to dispenser. Export

models have line cord less plug.

Power Supply: 15 amps at 120 volts dedicated power supply.

20 amps at 230 volts dedicated power supply.

Water Connection: 3/8 in. (0.95 cm) SAE male flare fitting on dispenser.

Water Supply Requirements: 80 psi (5.5 bar) maximum static pressure. 20 psi (1.4 bar) minimum

dynamic pressure; i.e., flowing pressure measured at dispenser water inlet with 3.0

ounces (88.7 ml) per second water flow.

Ice Bank/Pull Down: Weight 7-8 lbs. (4.1-4.5 kg.). Pull Down: 3 hours at 75°F (24°C)

Release Date: August 17, 2006 www.cornelius.com Revision: C

© 2004-2006, IMI Cornelius Inc. - 1 - Publication Number: 720529901INS

Page 2

Quest 2000 Installation Manual

RECEIVING

Each unit is completely tested and inspected before shipment. At time of shipment, the carrier accepts

the unit and any claim for damage must be made with the carrier.

Upon receiving from the carrier, please inspect the carton for visible damage. If damage exists, have the

carrier make a note on the bill of lading and file a claim with the carrier.

UNPACKING

• Remove staples securing carton to pallet.

• Lift carton up and off of unit.

• Remove inserts and shipping bag.

• Open upper cabinet door and remove installation kit.

• Remove bolts securing unit to pallet.

• Lift unit off of pallet.

NOTE: Do not lay the unit on sides or on the back. This may cause vital oils to drain from the

compressor resulting in damage during start-up and consequently voiding the warranty.

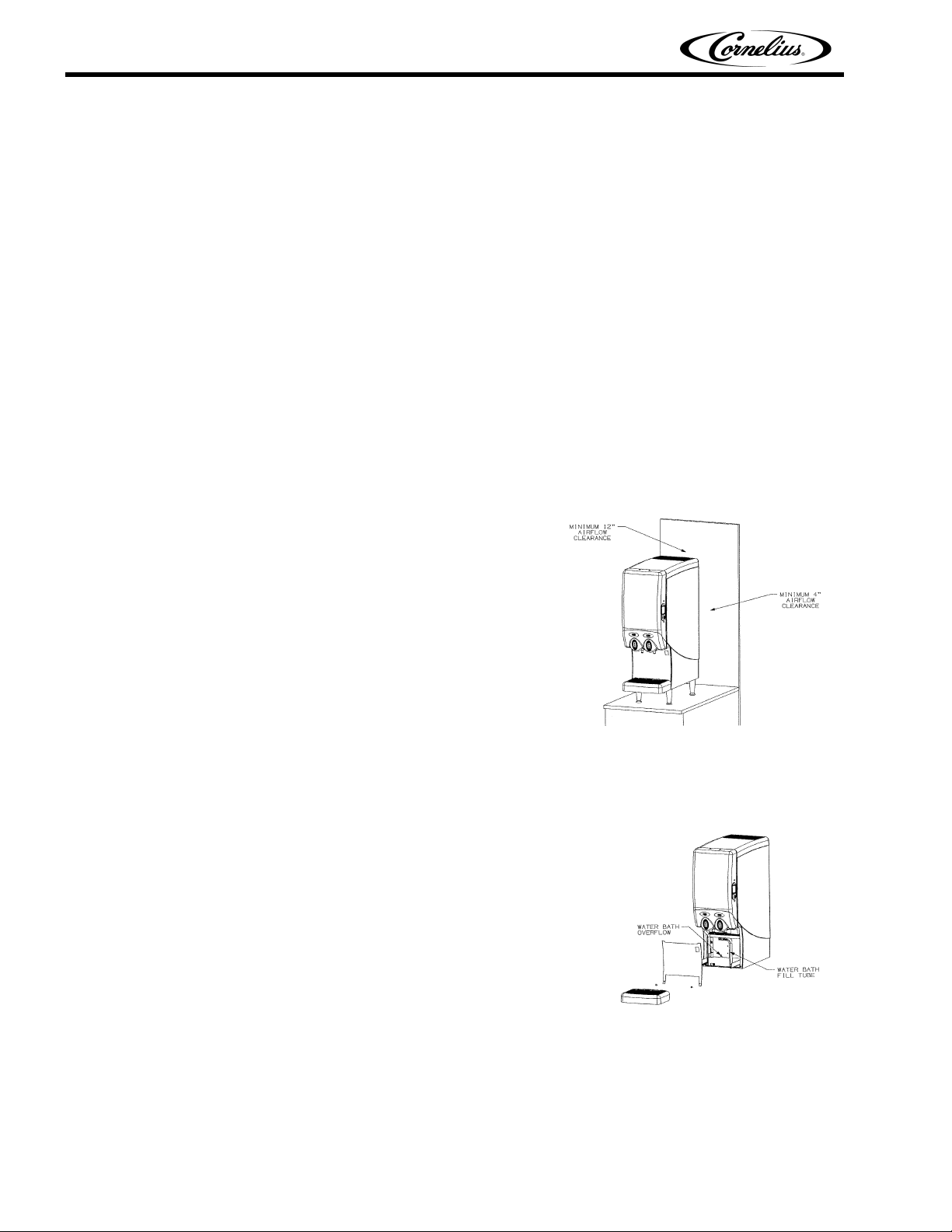

COUNTER LOCATION

Select a location in a well ventilated area, close to a

grounded electrical outlet. If possible do not place the unit

close to hot and/or steaming machines.

The minimum airflow clearance is: 4” (10.16 cm) in back

and 12” (30.48 cm) on top and open to the front.

IMPORTANT: Condenser air is drawn in from the bottom of the rear panel and discharged out the top of the

rear panel. Failure to maintain clearance space will

reduce capacity of the unit and cause premature compressor failure.

Typically the dispenser is placed directly on the counter and

a food grade silicone sealant applied around the base. However, supplied with the dispenser is a counter top sealing gasket. This eliminates the need for sealant and

is much easier to use.

FILLING THE ICE BATH

The ice bath holds approximately 2gallons (7.6 liters) of water. The fill

tube is located behind the front splash plate and capped with a 3/8”

(0.95 cm) male flare connector. Prior to attaching the water supply

line to the dispenser, use it to fill the ice bath by attaching it to the

connector on the fill tube

Slowly open the water shut off valve and fill the ice bath until water

trickles from the overflow. This is the quickest and easiest way to fill

the ice bath.

Once the ice bath is full, store the fill tube in the vertically recessed

holder. The fill tube can now be used as a “sight glass” to monitor the water level in the ice bath.

Publication Number: 720529901INS - 2 - © 2004-2006, IMI Cornelius Inc.

Page 3

CONNECTING WATER SUPPLY

The QST series Juice Dispenser is designed to dispense juice at a high flow rate. It is very important that

the incoming water line be dedicated for use by the dispenser only and does not have other machines

connected which could cause a water surge, (i.e., a dishwasher, coffee maker, etc.).

IMPORTANT: The water supply should be consistent with proper water quality standards (neutral

pH of 7.0 to 8.0), and should not be connected to a water softener. It is the installers responsibility

to ensure that all water connections to the dispenser are sized, installed with adequate backflow

protection, and maintained to comply with Federal, State, and Local Laws.

1. Secure the 3/8” (0.95 cm) swivel nut on the flexible supply tubing to the water inlet

located at the rear of the dispenser. Make sure that the flared gasket is used (tubing and flared gasket are included with the installation kit).

2. When securing flare nut, use a backup wrench on the male side of the inlet fitting

(unit side) to prevent twisting of the copper tube inside the unit and/or possible damage to the water

strainer/solenoid. A water shut off outside the unit is recommended.

ELECTRICAL

A minimum of 15 amps electrical service is needed for 120VAC

power supply.

A minimum of 20 amps electrical service is needed for 230VAC

power supply.

Quest 2000 Installation Manual

PRIMING/FLUSHING WATER SYSTEM

To properly prime the unit with water and remove air pockets in

the system, open the cabinet door and make sure that all the

valve levers are in the “Dispense” position.

Close the door and press the dispense button for a

few seconds. Repeat until a steady flow of water is observed flowing from all dispense valves.

NOTE: Water splashing may occur during this purge cycle.

PROGRAMMING THE PORTION CONTROL

If your dispenser has optional portion controls, they have been pre-programmed from the factory to pour

7, 12, and 16 ounce drinks. The “extra large” (pitcher icon) size has also been pre-programmed to pour

16 ounces. To change the pour sizes, please follow the instructions below:

1. Simultaneously, press and hold “small” and “extra large” push button switches on the Portion Control Module until the “Refill” light starts blinking. Release the switches. The blinking

Refill light indicates the programming mode is active.

2. Place the cup under the dispense nozzle and push the selected size button (small,

medium, large, or extra large). Hold the button in until the cup fills to the desired portion,

then release the button. Repeat the above procedure for the remaining sizes.

3. After programming all the drink sizes, press and release the “cancel/pour” switch to

return the Portion Control to the operational mode. The blinking REFILL light will go out.

If at a future date it is decided to change the portion size of the drinks, the individual sizes can

be adjusted by the above procedure. It is not necessary to reprogram every size. Additionally the portion

control has full memory retention in case of a power failure.

CANCEL/POUR BUTTON

To pour a drink without using a pre-programmed portion control size, simply push and hold the

Cancel/Pour button. Release when the glass is full.

© 2004-2006, IMI Cornelius Inc. - 3 - Publication Number: 720529901INS

Loading...

Loading...