INSTALLATION MANUAL

Liquid Base Beverage Dispenser

IMI CORNELIUS INC.

Telephone (800) 238–3600

www.cornelius.com

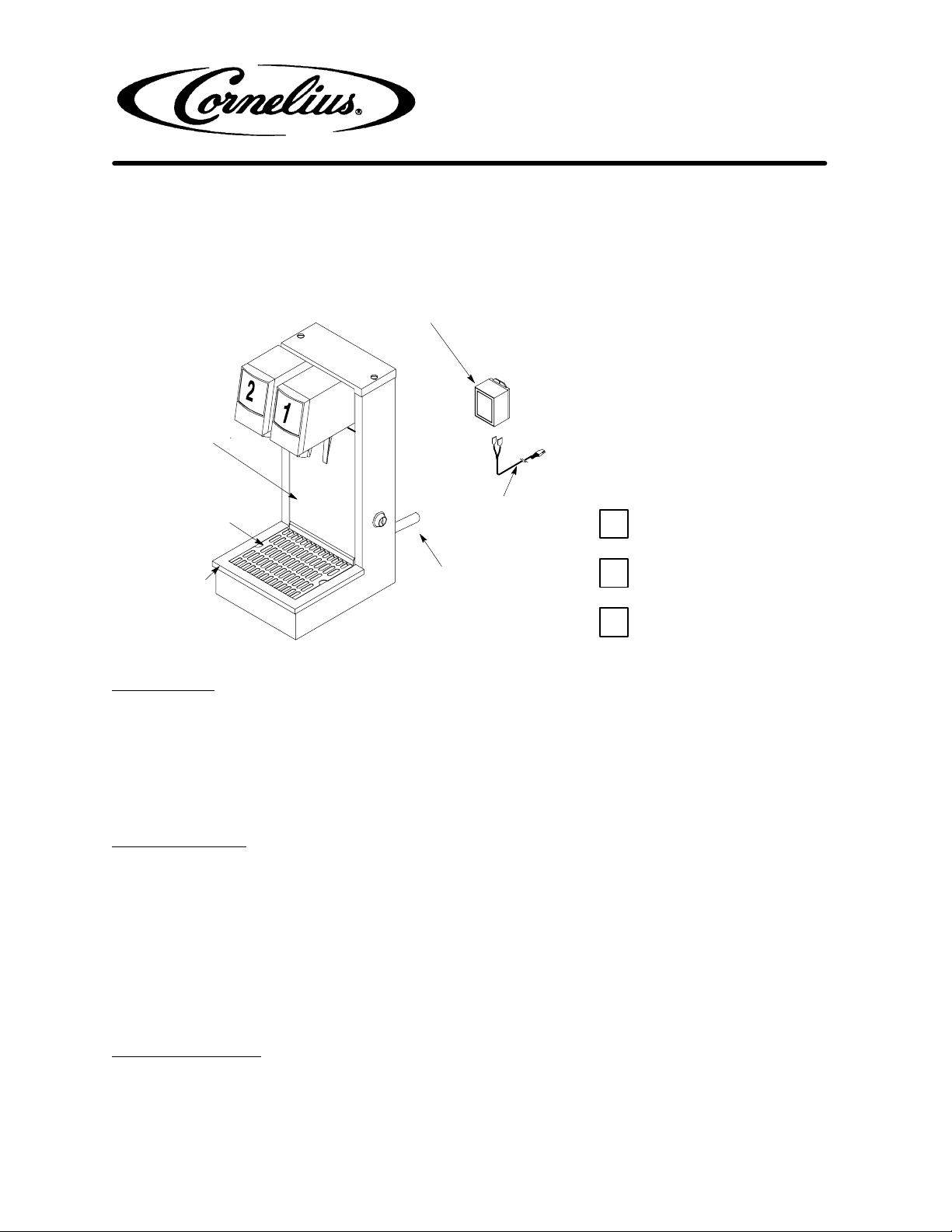

24 VOLT

TRANSFORMER

Design data

Overall Dimensions:

Width 7 1/2”

Height 17 1/2”

Depth 9 1/8”

Weight: 9 lbs

FRONT

ACCESS PANEL

Electrical Requirements:(if applicable)

15 Amp Circuit, 115v 60hz

.52 Amp Unit Current Draw

24v 60hz, Dispensing valves

Installation Check List :

Counter Top with access to route

concentrate supply lines.

Cold Water Supply, With Shutoff

REST

DRIP

TRAY

CUP

(24 Volts) cord to

dispensing valves

SUPPLY INLET

15 Amp,115v60hz Outlet, Within 5’

(if applicable)

RECEIVING

Each Unit is completely tested under operating conditions and thoroughly inspected before shipment. At time of

shipment, the carrier accepts the Unit and any claim for damage in transit must be made with the carrier. Upon

receiving Unit from the delivering carrier, carefully inspect the carton for visible indication of damage. Any damage or irregularities should be noted at time of delivery (or not later than 15 days from date of delivery) and immediately reported to the delivering carrier. Request a written inspection report from the Claims Inspector to

substantiate claim. File claim with the delivering carrier, not with IMI Cornelius Inc.

INSTALLATION

Place Unit in selected location to install unit.

Use mounting template (See page No. 3), to drill mounting holes for installing unit to counter top.

Manufacturer requires the use of all 6 bolt locations on the template to fasten to countertop.

Liberally apply a sealant, such as Dow Corning RTV 731 or equivalent, to the unit flange bottom surface,per

(NSF) requirements, the unit must be sealed to the counter top.

Make connections as follows:

Plain Water Source Connections:

TO THE INSTALLER

It is the responsibility of the installer to ensure that the water supply to the dispensing equipment is

provided with protection against backflow by an air gap as defined in ANSI/ASME A112. 1.2-1979; or an

approved vacuum breaker or other such method as proved effective by test.

Water pipe connections and fixtures directly connected to a potable water supply shall be sized,

installed, and maintained according to Federal, State, and Local laws.

IMI Cornelius Inc; 2004

Revision A

300387005INS

November 1, 2004

1. Flush plain water source thoroughly before connecting to Unit.

2. Connect plain water source to water inlet tube labeled ‘‘WATER’’.

Concentrate Line Connection:

1. Connect concentrate source lines to inlet lines from dispenser, labeled ‘‘1 or 2 etc.’’. DO NOT CONNECT

SOURCE LINES TO CONCENTRATE AT THIS TIME.

Transformer Connections: (for electric valve units)

1. Connect Unit cord two-pin connector to the mating connector on the transformer output (24V) cord.

Steps of final installation:

1. Plug transformer into electrical outlet with proper electrical requirements.

2. Open shutoff valve in plain water source line.

3. Inspect connections for leaks.

4. Place a waste container under each nozzle and operate valve(s) to remove air from the plain water line.

5. Connect concentrate supply to concentrate system.

6. Open cylinder shutoff valve to apply the calculated pressure (approx. 40 PSI) to the concentrate system.

7. Operate each dispensing valve to remove air from the lines.

8. Check all lines for leaks.

9. Adjust Dispensing Valves for Water-To-Concentrate “Ratio” of dispensed drinks as instructed on ”BRIXING

VALVES” instructions.

NOTE: Concentrate system must be sanitized before Unit is put into operation. Refer to

Owner/Operator Manual for procedure.

10. Apply flavor decals to valve covers.

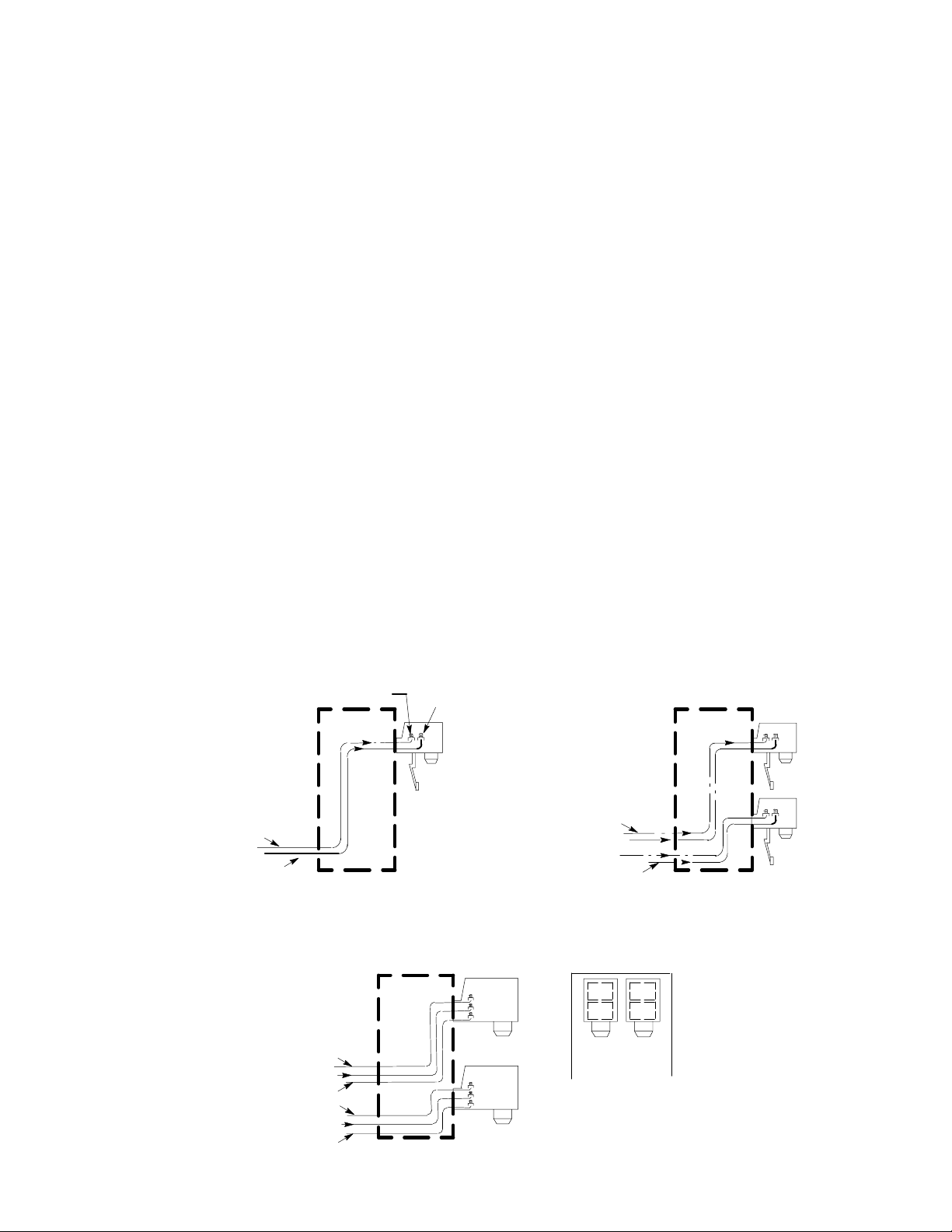

ADJUSTABLE WATER

FLOW REGULATOR

ADJUSTABLE CONCENTRATE

FLOW REGULATOR

1

2

”WATER” IN

CONCENTRATE NO. ”1” IN

ONE SINGLE-FLAVOR

DISPENSING VALVE

”WATER” IN

CONCENTRATE NO. ”1” IN

”WATER” IN

CONCENTRATE NO. ”2” IN

TWO SINGLE-FLAVOR

DISPENSING VALVES

CONCENTRATE NO. ”1” IN

CONCENTRATE NO. ”2” IN

CONCENTRATE NO. ”3” IN

CONCENTRATE NO. ”4” IN

300387005INS

”WATER” IN

”WATER” IN

1

2

3

4

FLOW DIAGRAMS

2

1

3

2

4

TWO TWO-FLAVOR

DISPENSING VALVES

OUTSIDE BASE OF LBBD

2”X4-1/2”

CUT–OUT FOR THRU COUNTERTOP

INLET LINE HOOKUP

5/16” HOLE (6)

LBBD MOUNTING TEMPLATE

WITH BASE DIM. OF 7–1/4” X 9”

300387005INS

FRONT OF UNIT

3

Loading...

Loading...