Page0

OPERATING MANUAL

BLAST CHILLER

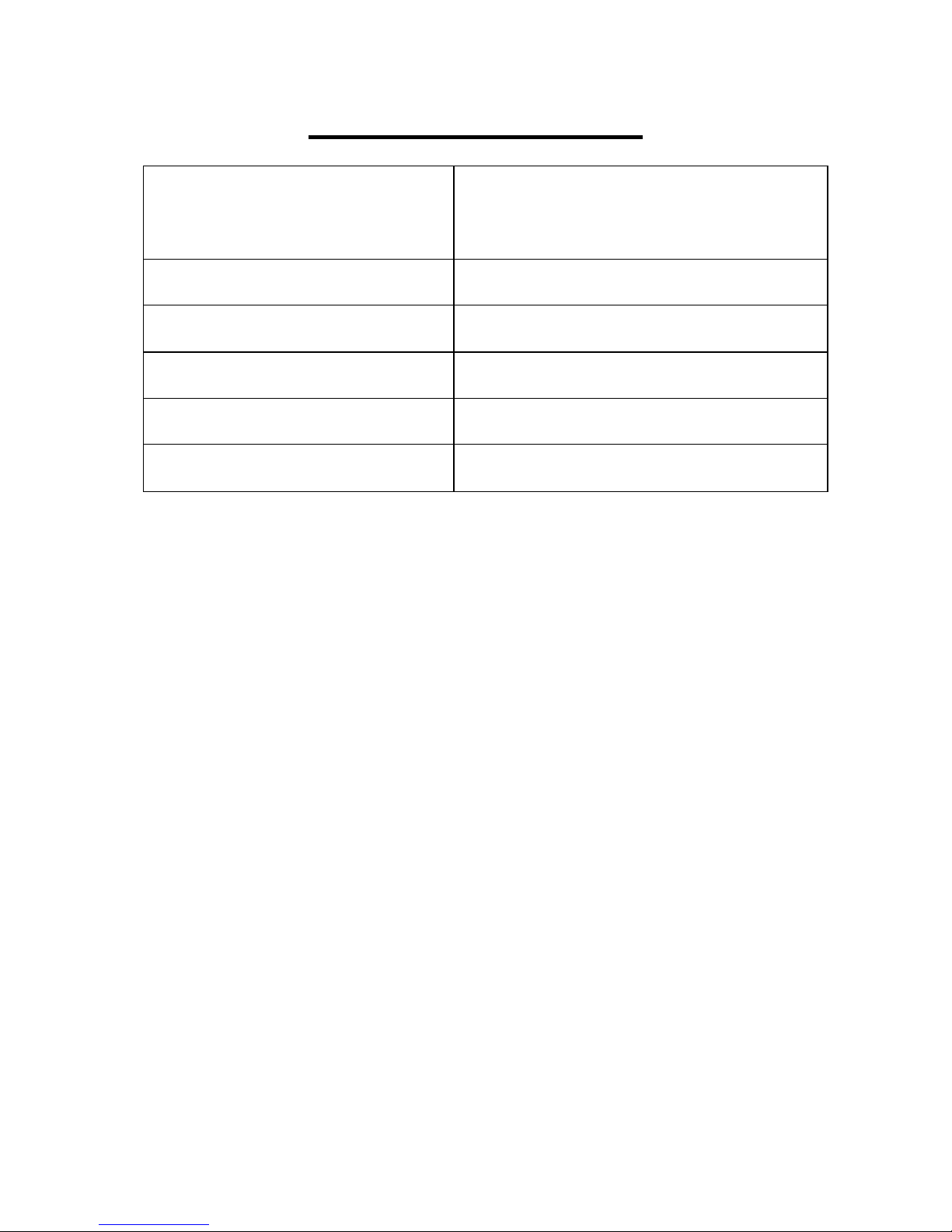

Page1

Device » Article number

Type » Part number

SF 5P » 07900

SF 5 N » 07901

SF 6P » 07902

SF 6 N » 07903

SF 10P » 07904

SF 10 N » 07905

SF 20P » 07906

SF 20 N » 07907

Page2

Table of contents

Table of contents Page 2

Preface Page 3

Information about gas safety Page 4

Installation Page 5

Control panel Page 7

Engagement of the operations Page 9

Cleaning and maintenance Page 10

Guarantee / assurance Page 12

Notes on safety Page 13

Page3

Preface

The present instruction appertains to the documents delivered with the equipment and contains all necessary information for a

correct service and maintenance of the product: protective film do remove (to make of Abb2)and, that the packing material

according to the valid rules of the country, in which the product is used, non-polluting is disposed.

The user should read then through the contained information attentively and keep the instruction in a slightly accessible place

for all users authorized to that.

Our product is certain for the professional use and may from that only served by specialists for his functional purpose and

exclusively graze

For possible damage, that are to be put down to an inappropriate use of the product, onto a transport with

inappropriate means, onto illicit alterations as well as all steps, that were not considered in this instruction , the

manufacturer does not take over any liability.

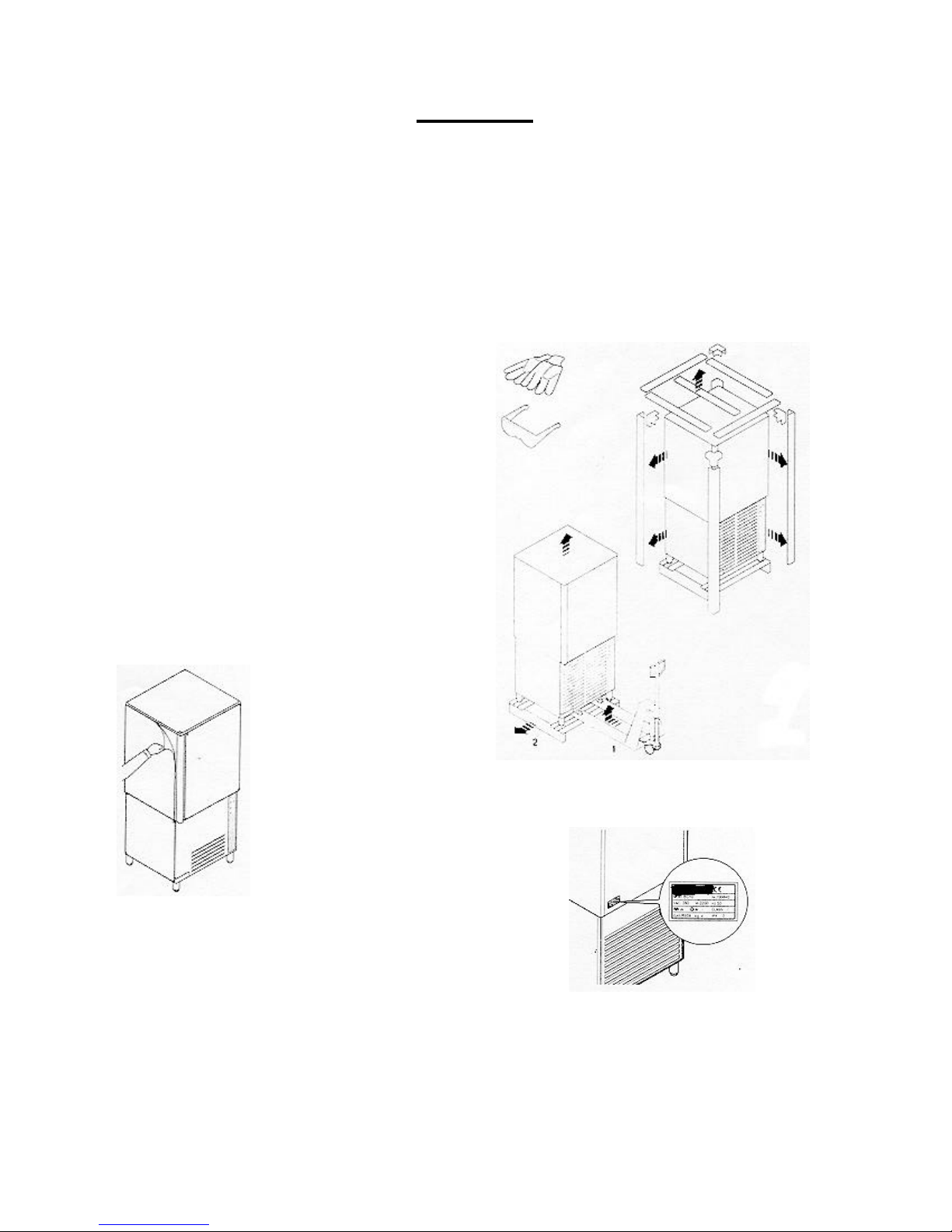

• Transportation Pic1

Any product shift may

only with means of transport calm for that

to occur as a lifting truck or

Manual truck, that half the one

Having to exceed product length.

• Unpacking

To attract protective gloves and wrapping

loosen (Pic1) equipment with the aid of a lifting truck

remove lift foot remove and

setting up at the destination.

• Safety

Before the electric supply of the machine must be

guaranteed, that the dates V, Kw N hertz of the stages as

well as the service with the information. On the number plate

(Pic 3) to agree on the reverse page of the equipment

Pic2

Pic3

Before any cleaning and maintenance jobs

always pulling the power plug of the equipment.

Page4

Information about the gas safety

Danger signalling:

- Suffocation

- A fast liquid vaporization can lead to

frostbite

Immediate help efforts:

- In case of inhalation:

Bring That one injured immediately onto the

fresh air and, if necessary, to add oxygen or to

carry out the mouth-to-mouth resuscitation.

Giving no adrenaline or similar substances.

- In the case of eye contact:

Rinse Eyes with plenty water and carefully at

least 15 minutes long. After that visit a Doctor

for look up.

- With skin contact:

Beats immediately with plenty water wash

and to take off impure lining immediately.

Toxic information:

- Local effect

A narcosis effect can induce a concentration

which is basically above the boundary value.

The inhalation of highly concentrated and

decomposing products can breath need (Water

lung) for the result have.

- Specific effect:

A fast liquid vaporization can lead to

frostbite.

Fire measures:

- Adequate fire extinguishers x-arbitrary

- Special dangers: Increase of pressure

- Special means: Chilling with water.

Measures with accidental gas escape:

- Individual precautions

Bringing the personnel into safety rooms.

Anticipating an adequate aeration and

employing own protection agents.

- Evaporated environmental precautions

- Evaporated cleaning means

Handling:

- In the working spaces a sufficient change of

air and/ or Gas vacuum procedure- to carry

out . Itself is recommended to use only well

ventilated rooms.

Information of ecological kind:

- Okotoxic effect

Pentafluorine ethane (R125): global heating potential of the halo carbides; HGWP;

(R l 1 = 1) = 0.84.

Ozone impoverishment potential;

COP; (R l 1 = 1 ) = 0.

Tetrafluorethane: (R134a): ): global heating potential of the halo carbides;

HGWP; (R11 = 1 ) = 0.28.

Ozone impoverishment potential;

COP; (R 11 = 1) = 0.

Trifluorethane: global heating - potential of

the halo carbides; HGWP;(R11 = 1) =1,1.

Ozone impoverishment potential;

COP; (R11 = 1 ) = 0.

Disposal references:

Recycling the product. If this should not be

possible, the elimination in one furnished for

that and to the reception and neutralization of

gases and other poisonous workmanship

products must authorize plant are carried out.

Page5

Installation

The installation may only be from specialists under

observation of the legal accident protection

definitions of the valid rules of law of the country in

which the device is used l at this has the specialists

the task, to check possible fire prevention rules.

Setting up the machine at the planned place and letting

in this case a sufficient open space (at least 10 cm)

between the device and possible walls or obstacles

which could prevent the correct air circulation (Pic 4)

Pic4

Make that freedom of movement is available

sufficiently for the maintenance operations

The device may not be in rooms with small air

circulation into the full sun with high temperature

levels or into the proximity of heat sources are set up

(Pic 5)

Pic5

Aligning the device with the aid of a spirit level and

through the arrangement of the feet with adjustable

elevation

(Pic 6)

Surrounding temperature must not exceed that

boundary 32°C since the correct operation can not in

addition be guaranteed to the machine

In case of special placements the plumber must take

into account the possibility to equip the product with a

covering.

(Pic 7)

Page6

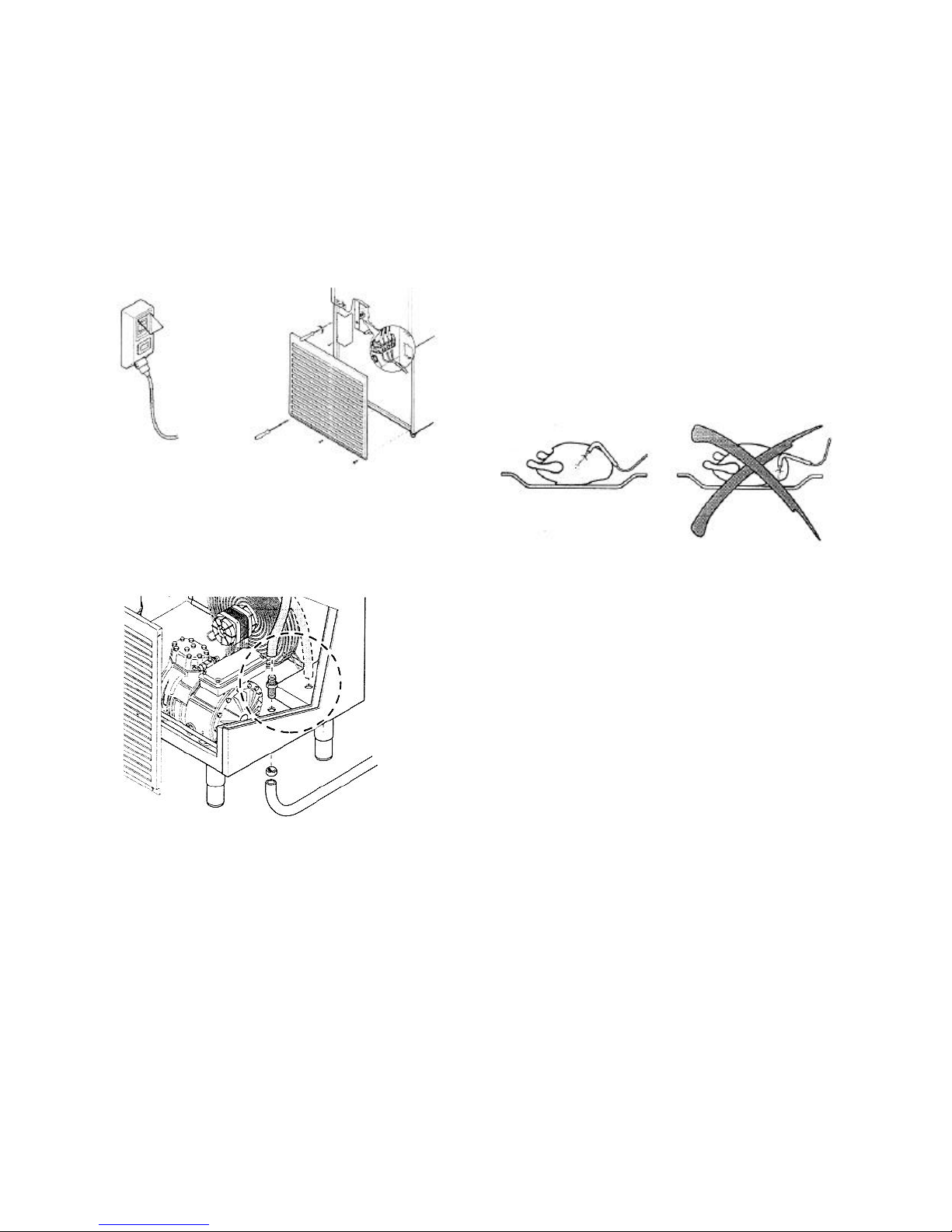

• Electric supply

The equipment must connect onto the mains voltage by

means of one error current - safety switch, under

observation of the valid rules of law

the country's, in which it fits and ( Pic 8) is connected.

The earth wire must be connected onto an earthing

system Pic 8

Drain

The device is supplied with a receptacle to the

absorption of water of condensation. As an alternative

to that the drain can be connected onto the connector in

this connection at the ground

(Pic 9)

Control checks

If during the transportation the equipment was not in

upright situation, at least four hours must pass by until

the machine can be turned on

Before the engagement the following controls carry

out:

Checking the connection to the water pipe during the

operation through the regulation of the pressure valve.

Checking the correct circulation of the water of

condensation. The standard pressure values check The

Electric Supply The Current Consumption check

Checking possible gas escapes through installationconditional questions or punches. A complete cold or

freezing - cycle carry out.

The customer must have received the necessary

information about the correct use of the product. The

installation and setting-up of the equipment may be

carried out only by the specialists that together with the

customer the assurance certificate will sign.

THE manufacturing firm is not liable for possible

thing or person damage, that were caused through

an unproper installation.

• Protection appliances at the device

Door – Micro switch

Safety pressure switch stops the apparatus operation

near doorway

Turns on at over and lower pressure in the cooling

circuit, thermal relay compressor and engine fan turns

on in •case of overload and incorrect operation

• Heart sensor

Must be introduced in the middle (the heart) of the

product, consider, that not spiked the needlepoint lace

the product or osculated the receptacle (Pic 10)

Before every use the cleaning of the probe is to be

recommended to avoid impurities flat receptacles, no

lids or insulating sheets employ since in this way

through the direct contact with the cold air the cool

times are reduced. For a fast cooling receptacles with

3,5 kg are to product as well as to a fat property of 8

cm. or at a fast deepfreeze 5, advisable, cm

Storage

In the cold producer the product is homogeneous and

not concentrated distribute. It is indispensable that the

products of the room temperature to be chilled or to be

chilled deeply remain criticized as little as possibly,

around in this way a greater tenderness of the

Food's achieve.

It recommends, not to introduce foods with a

temperature of under +70C° into the cold producer the .

The freezing-property conducts during the fast cooling

+70°C - +5°C and +70°C, l8°C during the deepfreeze.

After the cooling or deepfreeze the product with a deck

is, a protective foil or to keep under pressure

hermetically.

The chilled products are kept in a refrigerator at +4C,

the deep-frozen products in a deep freezer at -20°C

The cold producer is not a normal refrigerator !

Page7

• Operations

Fig. 11

• Patching panel information

START / STOP press button

Compressor Led

Temperature&timedisplay

display

Cooling press button

Deepfreeze press button

Storage press button

Alarm Led

Time press button

Led exhaust wheels

Pin probe Led

Thawing course Led

Programming Led

ON / OFF press button

Page8

START / STOP

Switch the chosen cycle at switched off machine

COOLING (+70°C - +5°C )

Prepares with plus temperature or anyway 0°C approaches the

machine the cooling in front of. THIS IS TEMPERATURE -WORTH

through a programming parameter variable.

DEEPFREEZE (+70°C - -18°C )

Prepare with minus temperature the machine for the cooling. This IS

TEMPERATURE -WORTH through a programming parameter variable

STORAGE

Prepare the machine for the preserving of the foods.

If neither the cooling press button nor deepfreeze were pressed, the

machine works just the same as a normal refrigerator does, the

storage temperature can be prepared with regard to those ones for

that in the planned value (middle or small temperature) through

fitting keystroke (that in this connection Led lights up). If, however,

the cool course is prepared already through this keystroke only to

light up the Led of the temperature of the cool course preset

concerning that.

Heart sensor

Announce the temperature either in the cell or in the product heart. The lighting

up of the corresponding Led announces the chosen option.

TIME THAWING COURSE LED

Switch off the pin probe. At reached time e nd; that through

the parameter in this connection was prepared, one goes from

to the cooling to the storage/preserving about. The display gives

the still missing time to at the end of the cool course at Through

Keystroke "pin probe" becomes some seconds

take one of the two announced.

ON/OFF

The reversing gear turns on and from. The EWFC 1000 stands

always turnedly also in the eliminated state under tension

COMPRESSOR LED

Announces that the compressor in operation is. A possible flashing

shows the switch on - wait state at.

FAN ROTOR LED

Announces that the exhaust wheels in operation are. A possible

flashing shows the switch on - wait state at.

PIN LED

If at, the pin is turned on: if from, the pin is switched off since the

time circuit function was chosen. A flashing announces, that the pin

is in the wait state, meant a flashing after a certain space of time after

the start of the cooling course that the pin was not introduced in the

product and the control is Time Switched automatically.

THAWING COURSE LED

This system warning light announces, that the thawing course

became turned on.

PROGRAMMING LED

Flash during the programming onto.

ALARM LED

Led combined with alarm repetition exit. Near alarm probe

turned on.

• Functional references

During the device engagement becomes through

keystroke that one

Requested selection of the desired operation . On the display the

information "SEL" appears and that following Led's

light up.

Cooling

Deepfreeze

Storage

Page9

Engagement the following operations through respective keystroke possible:

1. Cooling (+70°C/+3°C) Press button Press button cycle start

2. Deepfreeze (+70°C/-18°C) Press button Press button cycle start

3. Storage (+3°C) Press button Led at Press button cycle start

4. Storage (-18°C) Press button Led at Press button cycle start

5. Cooling (+70°C/+3°C) storage + (+3°C) Press button +Button Press button cycle start

6. Deepfreeze (+70°C/ 18°C) storage + (-18°C) Press button +Button Press button cycle start

Course of events manner

The food into the cell pursue pin probe into the middle of the product

to be chilled insert.

ON/OFF takes about the press button

turning on On the display

the SEL information appears and

the following Led's to light up onto.

Cooling

Deepfreeze

Storage

There are three choices.

Cooling in the product heart

(advisable)

Pressing press button to

cooling

(if after the cooling the foods

) press button are supposed to be lain

down

Pressing storage .

Cycle through START/STOP keystroke

to turn on ON the display appears

the one measured from the probe

Temperature level.

Deepfreeze in the product heart

(advisable)

Pressing press button to deepfreeze

if after the deepfreeze the foods

) storage press button are supposed to be lain down

press.

Cycle through START/STOP keystroke

turn on and on that

Display appears to that of the probe

measured temperature level.

After the cooling and deepfreeze

become in case of turned on storage

the foods with a temperature level

from +3C (after the cooling) or -18 C

(after the deepfreeze) keeps.

In Any Case appears on the display

the respective temperature level of the cell.

Page10

Cooling with Time controller

Cooling press button

then time press button

and START/STOP

press.

On the display appears

the calm cool time.

For the change of the timing

Press button of PROG after that of

ON/OFF

as long as press, to the display

ilA announces. For the change the

Timing and through keystroke

RED. is

about the ON/OFF press button, that

one becomes

During increases and through keystroke

ON/OFF reduced.

That appearing on the display

Time is in the minute - cycle through

START/STOP keystroke

to turn on.

• List of the alarm signals

CP Chamber probe does not function

HP Probe in the heart functions not

EP Evaporator probe does not function

LI Temperature outside the min boundary value

HI Temperature outside the boundary value max

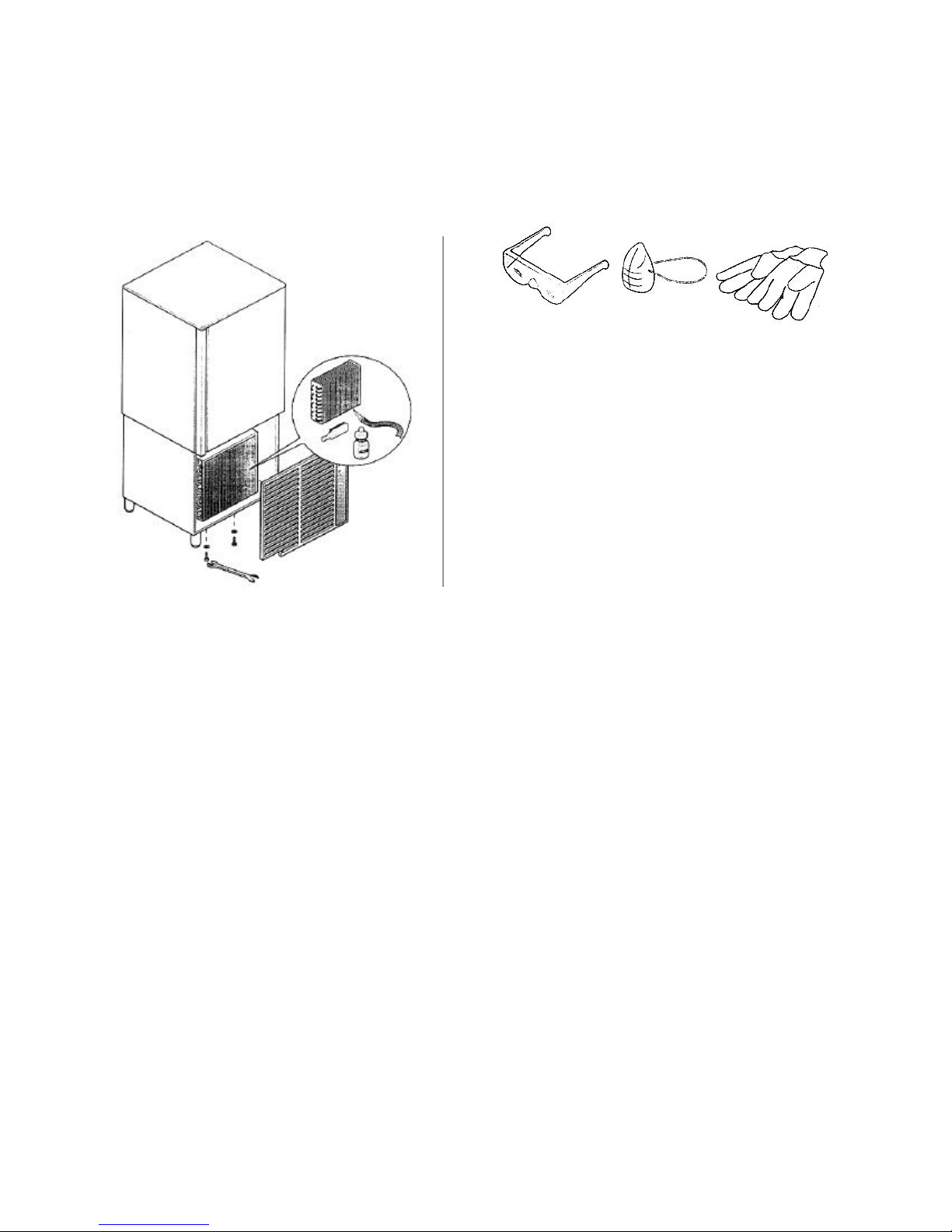

Cleaning and maintenance

After every working day the interior of the cool cell is

carefully to be cleaned, around To guarantee a correct

hygiene and quality of the handled foods.

Only with water and neutral detergent clean (Pic 12)

No abrasives. Dredge or diluent employ.

Out the possibility the water of condensation onto the ground

to let tile (Pic 9), our products also with one are

Receptacle to the water of condensation absorption loads, that regular

must be emptied (fig. 13).

Time controller deepfreeze

Deepfreeze press button then TIME press

button

and START/STOP press. On that

The calm deep-freezing - time appears to display.

For the change of the press button timing

PROG after that of ON/OFF as long as

press,

until the display announces ilC. For the change

the

Timing and through RED keystroke,

ON/OFF is above the press button, becomes

the time extends and through keyst roke

ON/ OFF reduced.

That appearing on the display,

Time is in minutes cycle through

START / STOP keystroke

turning on.

If the pin probe was not introduced in the product heart,

the device automatically runs for a limited time (the at

last entered time). Lighting that one up Led time and

PROBE onto.

For the retention of the serviceability of the machine the

condenser is, to keep that behind the front grill clean. To that

is for the elimination of the dirt on the bracings ( \Pic. 14) to

carry out a monthly cleaning with a metal brush and a

vacuum cleaner no peaked subjects employ.

Page11

For the retention of the serviceability of the machine the condenser

is, to keep that is behind the front rust clean To that is for the

elimination of the dirt on the b racings ( \Pic. 14) to carry out a

monthly cleaning with a metal brush and a vacuum cleaner. Do not

employ any peaked subjects.

During the maintenance and cleaning jobs gloves are to use, some

eyeglasses and a protection mask.

After these work flows are that one before the engagement

Equipment the protectors again attach.

Non standard maintenance

This maintenance may be carried out only by the specialists

that is authorized to jobs and this product typology.

Disposal

The cold producer is equipped wit h refrigerant or with

lubricating oil. From that the disposal in this connection or

elimination of the severe observation of the valid rules of law of

the country are, in which the installation is carried out.,

subordinate.

Page12

Guarantee / assurance

1.1 Company

IME

A-5020 Salzburg/Austria

Telephone (++43) 0662 880070

Facsimile (++43) 0662 8800708

TRADER

MACHINE TYPE

Blast Chiller Type.........

MACHINE-NO.

-------------------------------------------------

YEAR OF MANUFACTURE

-------------------------------------------------

DELIVERY DATE

-------------------------------------------------

a) Our customer obliges, to check the product immediately upon delivery and inform us of obvious lacks

immediately in writing possible. Claims, that emerge later are also to be announced immediately in

writing, this at the latest within the legal warranty time period. If the customer refrains from the immediate

defect-signalling, the product is regarded so as being approved of. The customer has the immediate

occasion to give to us the check of the state of the device on site.

b) The guarantee occurs fundamentally through improvement. Price reduction claims come only then to the

effect, if we have agreed explicitly in writing.

c) We provide guarantee for all devi ces supplied by us - except for used merchandise, for which we do not

take over any guarantee - this within 6 months from actual delivery of the product at the Customers.

Within this period of time we render full material replacement. Freight and wrapping costs and/or way time

and ride costs are charged by us in any case.

d) We only guarantee, that within proper connection to the prescribed tension as well as at perfect voltage

ratios, correct service as well as installed in conformity to regulations, from which Operating manual clear

maintenance, expert installation through a licensed electrician the usually presupposed or explicitly

guaranteed services and functions are filled. We point out explicitly, that the measurements indicated in

our brochures or catalogues, services or functions in the same way as the design, at any time also

without previous announcement can be changed and are un-obligatory from that. We do not render any

guarantee in the case of contacts of unauthorized hand and/or non-compliance of the valid terms of

payment. The guarantee does not refer to glass, fireclay or parts which are subject to natural wear. A

warranty claim is fulfilled only with presentation of the corresponding bill and announcement of the serial

number of the device.

e) The guarantee for the expert market includes only the free substitute of defective parts, at which the

repair parts are sent against settlement to the customers and the customer at accrued liability of the

defective part a corresponding credit is exhibited.

f) For damages or mistakes that do not damage the definition of-appropriate use, no liability is taken over

g) Further claims of our customer are turned away, in particular compensation for direct and/or indirect

damages (Faulty consequential damages), unless, there are intention or coarse negligence.

Page13

Notes on safety

1.) Read the device operating manual exactly before initiation and consider

!

2.) All maintenance and cleaning jobs to be carried out only at switched off

device (Main power switch on „0).

3.) Service of the device only of trained personnel.

4.) Putting main power switches on „0" also in case of stoppages.

5.) All repair jobs (in particular with electric troubles) may be carried out

only by specialists at the machine.

6.) Use only accessories and attachments which are indicated in the

operating manual. The use of other accessories can mean a danger for

you.

7.) This device is exclusively to the chilling and freezing of suitable foods.

Case of fault

power- and/or. gas pipe supply to be interrupted through main power switches (or for

example protection, etc power plug.). Do not start device under no circumstances again if

device or incoming lines show damages or the reason for malfunction is unclear. In this

case the device must not be used before after an inspection through a professional service

again. Hot oil (for example near deep fat fryers) not to temper with water.

Loading...

Loading...