Page 1

O

O

p

p

err

e

attii

a

o

o

n

n

M

M

a

a

n

u

n

This device is compliant.

all

u

a

This device is compliant.

Page 2

File: WT25_OperationManual_G2.doc

Page 3

2008 – 2010 by Image Access GmbH, Wuppertal, Germany.

Printed in Germany. All rights reserved.

Reproduction in whole or in part in any form or medium without express written permission of

Image Access is prohibited. Scan2Net® is a registered trademark of Image Access. Other

designated brands herein are trademarks of Image Access.

All other trademarks are the property of their respective owners.

Image Access reserves the right to change the described products, the specifications or

documents at any time without prior notice. For the most recent version, always check our web

site www.imageaccess.de

Manual Page 3

or the customer service portal at http://service.imageaccess.de

Page 4

Introduction

Dear Customer,

We congratulate you on the acquisition of this innovative product from Image Access.

We at Image Access are proud of the work we do; it is the result of our extremely high

standards of production and stringent quality control.

With this scanner, Image Access offers an efficient scanner which covers a wide scope

of applications due to its versatility. Its integrated web based user interface makes all

functions available in structured menus.

This operation manual is designed to lead you through all situations which will arise

when using the scanner.

For this reason, we ask you to read the manual attentively before starting to work with

the scanner. By doing so, you will avoid operation errors and you can control all

functions from the beginning.

In addition please consider the following points:

Damages to your unit may have occurred during shipping. Please check for

damages immediately after delivery of the unit. Inform your supplier if damage

has occurred.

Read and ensure that you understand the safety notes. They were developed

for your protection and safety as well as to protect the unit.

Regular maintenance conserves the high quality and safety of your scanner

during the entire service life.

If you have any further questions, please feel free to contact your local dealer or

Image Access, Inc. directly. Our staff will be happy to help you.

For your daily work with your new scanner, we wish you success and complete

satisfaction.

Regards

Your Image Access Team

Page 4 Manual

Page 5

About this Manual

Operation Manual

The Operation Manual gives all information about the normal operation and behavior

of the device. It is written for people who only operate the device and do not perform

setup and adjustment procedures. All device elements and software functions are

described in detail, although some of them might never be used. This manual does not

cover any application software. Refer to the appropriate application software manual to

learn about the application software.

Setup and Assembly Manual

The Setup and Assembly Manual is written for technical staff with some basic

mechanical as well as software skills. Many resellers will offer on-site installation;

therefore, large parts or all of the setup and assembly manual might not be of interest

to the reader. The access level at which the setup and adjustment processes are

performed is called “Power user”. This “Power user” level is password protected from

access by the normal operator.

All manuals can be downloaded from our customer service portal at

http://service.imageaccess.de

manuals.

This manual is divided into four sections, A to D.

Section A describes the hardware of the device. It includes unpacking and

mechanical installation. These instructions must be followed carefully to

ensure proper functionality, best possible quality and performance of the

device. This device is a precise optical instrument and should be

handled accordingly.

Section B describes the software setup. It includes the optical adjustments

necessary after the setup. The section also describes the installation

procedure for software options.

Section C describes troubleshooting procedures and test scan generation.

Section D shows all technical data and declarations.

. Be sure to always check for the latest versions of these

Manual Page 5

Page 6

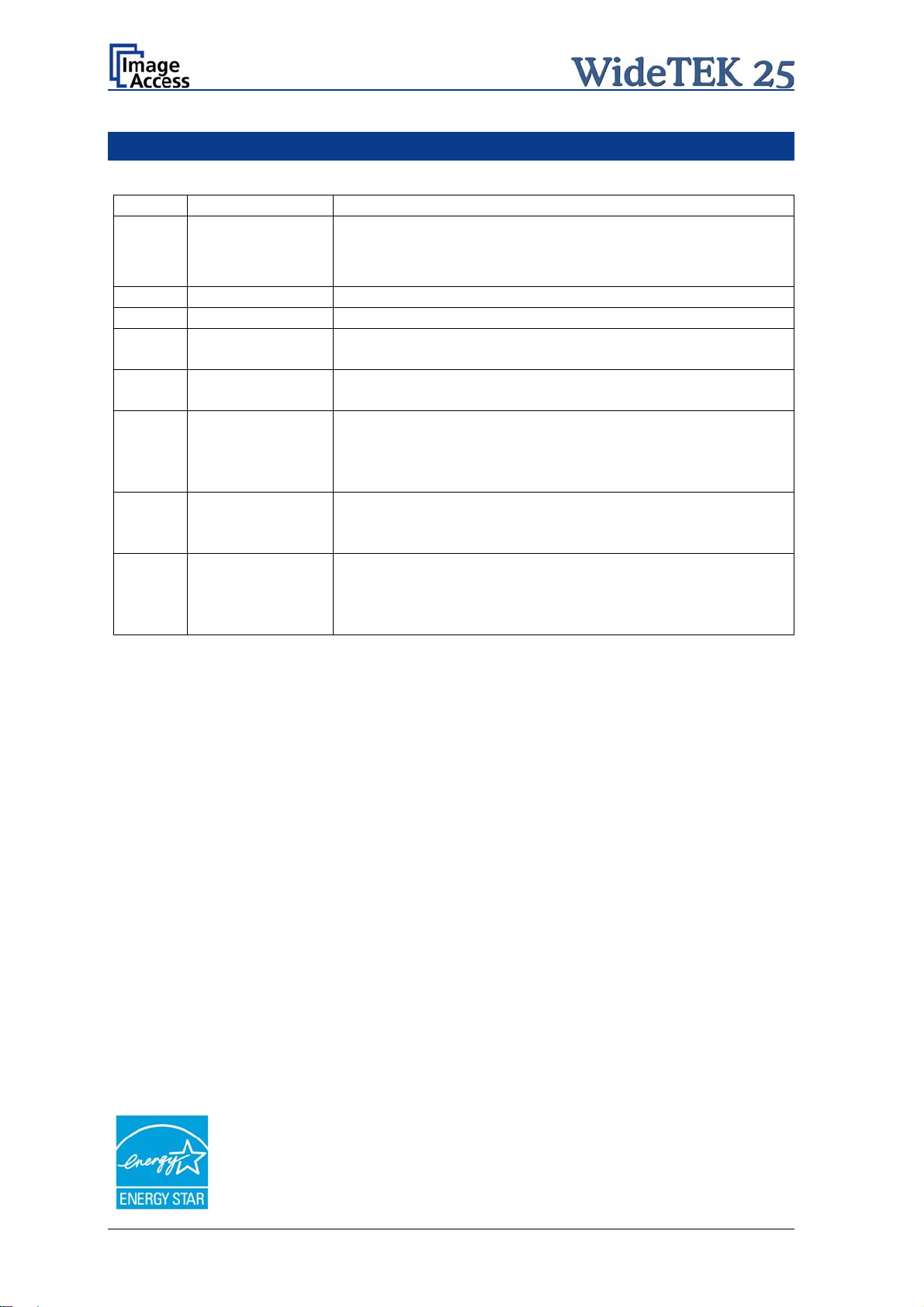

Version History

Version Published in Content/Changes/Supplements

A April 2008 Preliminary release version.

Because of the preliminary status of this manual some variations

in the screenshots of the S2N user interface are possible.

B May 2008 Preliminary version for S2N software version 5.

C June 2008

D October 2008 Hardware improvements: Two transportation locks at the back.

E December 2008 Additional information concerning the menu “Format” in the S2N

F March 2009

G September 2009 Chapter B.2.3.2 added. Description of “Despeckle” function.

G2 February 2010 Additional information about certifications.

First release.

Some minor modifications in the wording of the describing texts.

user interface.

Firmware V 5.20.

New functions in the S2N user interface / the touch panel.

New: Adaptive Stitching 2D, “Image Control 2” menu in the touch

panel.

Some minor modifications in the wording of the describing texts.

Order of chapters A.5 to A.8 have been changed.

Chapter D.3 Electr. Spec.: New value for stand-by consumption,

anothe

r power supply is used.

As an ENERGY STAR® Partner, Image Access has determined that this

product meets the ENERGY STAR® guidelines for energy efficiency.

Page 6 Manual

Page 7

Table of Content

Introduction--------------------------------------------------------------------------4

About this Manual -----------------------------------------------------------------5

Version History ---------------------------------------------------------------------6

A Hardware ----------------------------------------------------------------------- 14

A.1 Safety Notes ........................................................................................................14

A.1.1 Marking of Safety Notes 14

A.2 Certification..........................................................................................................14

A.3 General Notice.....................................................................................................14

A.4 Safety Precautions...............................................................................................15

A.5 Device Location ...................................................................................................16

A.6 Maintenance and Repair......................................................................................17

A.6.1 Cleaning 17

A.6.1.1 Surfaces 17

A.6.1.2 Glass plate 17

A.7 Content on Delivery .............................................................................................18

A.8 Transportation Locks ...........................................................................................19

A.8.1 Removing the transportation locks 19

A.8.2 Inserting the transportation locks 20

A.9 Connecting to the Power Source.........................................................................21

A.9.1 Connectors on the Back 22

A.10 Powering up the WideTEK 25..............................................................................23

A.11 WideTEK 25 Touch Panel ...................................................................................23

A.11.1 Starting the WideTEK 25 from Stand-By Mode 23

A.11.2 Turning-off the WideTEK 25 by the Touch Panel 24

A.11.3 The Help Function 24

A.11.4 Navigating through the Screens 25

A.11.5 How to Enter or Change Values 25

Manual Page 7

Page 8

Table of Content, part 2

A.11.6 Self Test Mode 26

A.11.6.1 IP Address 27

A.11.6.2 White Balance 28

A.11.6.3 Lamp On / Off 28

A.11.6.4 Exit Selftest 28

A.11.6.5 Touch Adjust 29

A.11.6.6 Touch Test 29

A.11.6.7 Stitch Test 30

A.11.6.8 EMV Test 30

A.11.6.9 Shutdown Scanner 30

A.11.7 Start Menu Screen 31

A.11.8 Output Control Screen 32

A.11.8.1 FTP Server 32

A.11.8.2 Email Address 34

A.11.8.3 Windows Network 35

A.11.8.4 Viewer Control 36

A.11.8.5 Sound Control 37

A.11.9 Image Control Screen 38

A.11.9.1 Image Control 1 38

A.11.9.2 Image Control 2 40

A.11.9.3 Image Control 3 41

A.11.10 Format Control Screen 42

A.11.10.1 Format Control 1 42

A.11.10.2 Format Control 2 43

A.11.11 File Control Screen 44

A.11.11.1 JPEG 44

A.11.11.2 TIFF 45

A.11.11.3 PNM 45

A.11.11.4 PDF 46

A.11.12 Transport Control Screen 47

A.11.12.1 Start button 47

A.11.12.2 Bidir. scan 47

A.11.13 Job 48

A.11.13.1 Creating a Job 48

A.11.13.2 Selecting a Job 50

A.11.13.3 Deleting a Job 50

A.11.14 Software Option: Scan2VGA 51

Page 8 Manual

Page 9

Table of Content, part 3

Software ------------------------------------------------------------------------ 52

B

B.1 Start Screen.........................................................................................................52

B.2 The Main Screen .................................................................................................53

B.2.1 The Options Screen 55

B.2.2 The Properties Screen 57

B.2.3 The Camera Screen 61

B.2.3.1 Threshold Dynamic / Threshold Fixed 63

B.2.3.2 Despeckle 63

B.2.4 The Settings Screen 64

B.2.5 The Format Screen 66

B.3 Output Options.....................................................................................................68

B.3.1 Output Option Save 68

B.3.2 Output Option Show 69

B.3.3 Output Option Print 70

B.3.4 Output Option Copy 71

B.3.4.1 Remote Printer 71

B.3.4.2 Printing Enhancement 73

B.3.5 Output Option FTP Upload 74

B.3.5.1 FTP Server 74

B.3.6 Output Option Mail 76

B.3.6.1 Mail Server 76

B.3.7 Output Option Network 78

B.3.7.1 SMB Configuration 79

B.3.8 Output Option USB 80

B.3.8.1 USB Storage Device 81

B.4 Information...........................................................................................................82

B.5 The Setup Screen................................................................................................83

B.5.1 Login Screen 83

B.5.2 Access Level User 84

B.5.2.1 Device Info Screen 85

B.5.2.2 Operation Info Screen 86

B.5.2.3 User Settings Screen 87

Manual Page 9

Page 10

Table of Content, part 4

Tests and Troubleshooting ---------------------------------------------- 92

C

C.1 Troubleshooting Matrix........................................................................................ 92

C.2 Error Codes......................................................................................................... 93

C.3 Warnings.............................................................................................................95

C.4 Information .......................................................................................................... 95

D Technical Data---------------------------------------------------------------- 96

D.1 Scanner Specifications........................................................................................ 96

D.2 Ambient Conditions.............................................................................................96

D.3 Electrical Specifications.......................................................................................97

D.4 Dimensions and Weight ...................................................................................... 97

D.5 CE Declaration of Conformity.............................................................................. 98

D.6 FCC Declaration of Conformity ........................................................................... 99

Page 10 Manual

Page 11

Table of Pictures

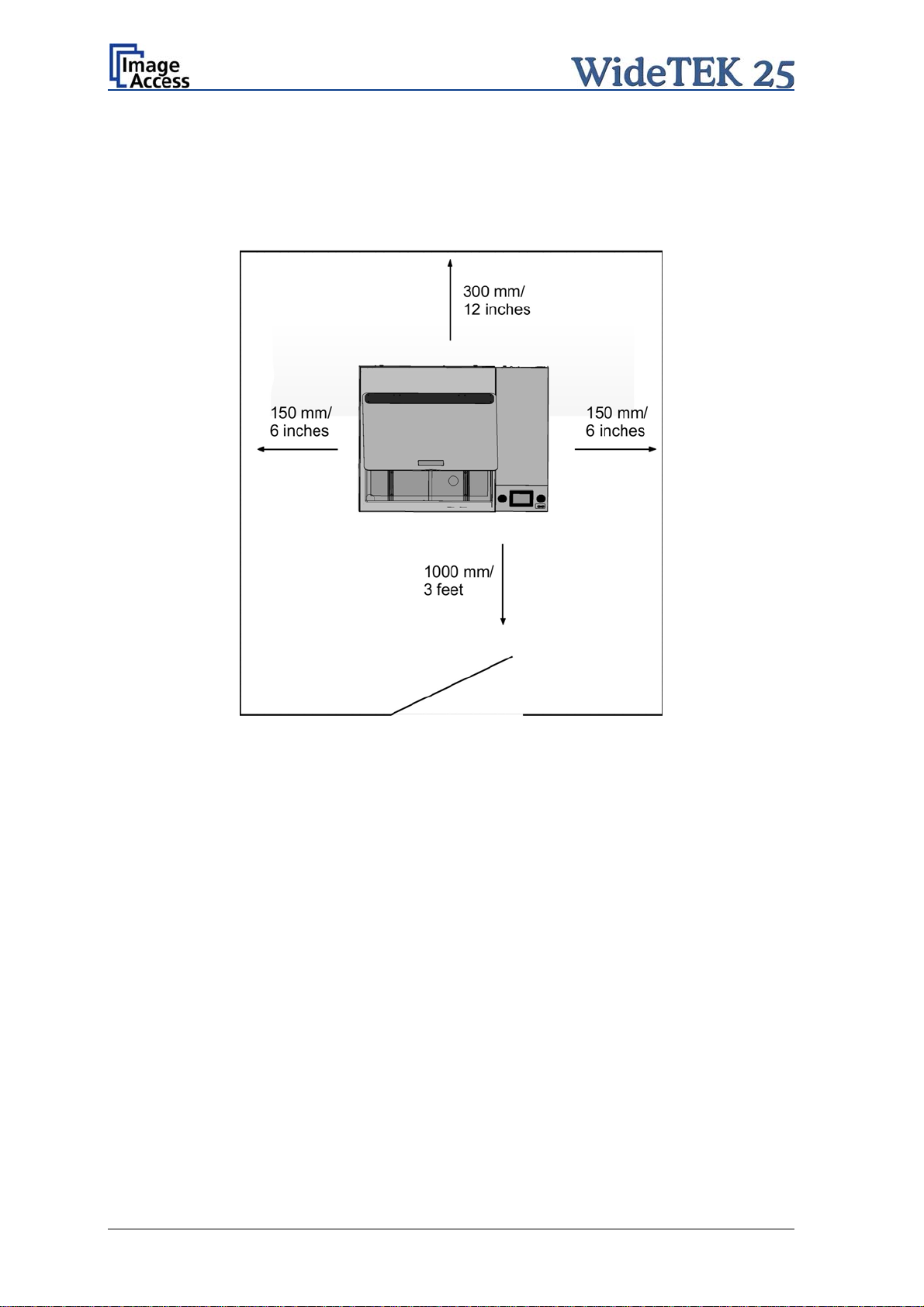

Picture 1: Minimum distances............................................................................................16

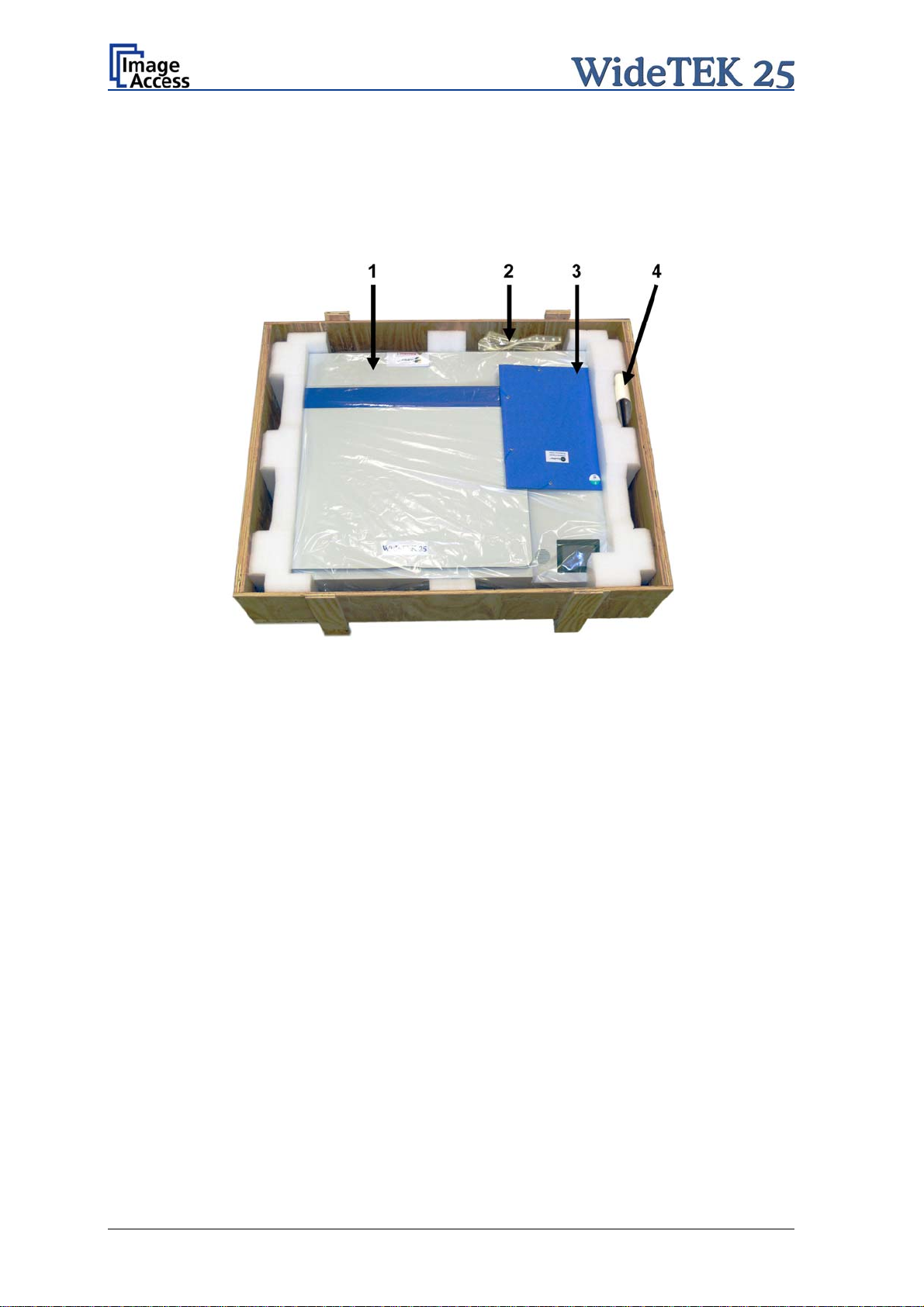

Picture 2: Scanner WideTEK 25 in transport box..............................................................18

Picture 3: Position of transportation locks..........................................................................19

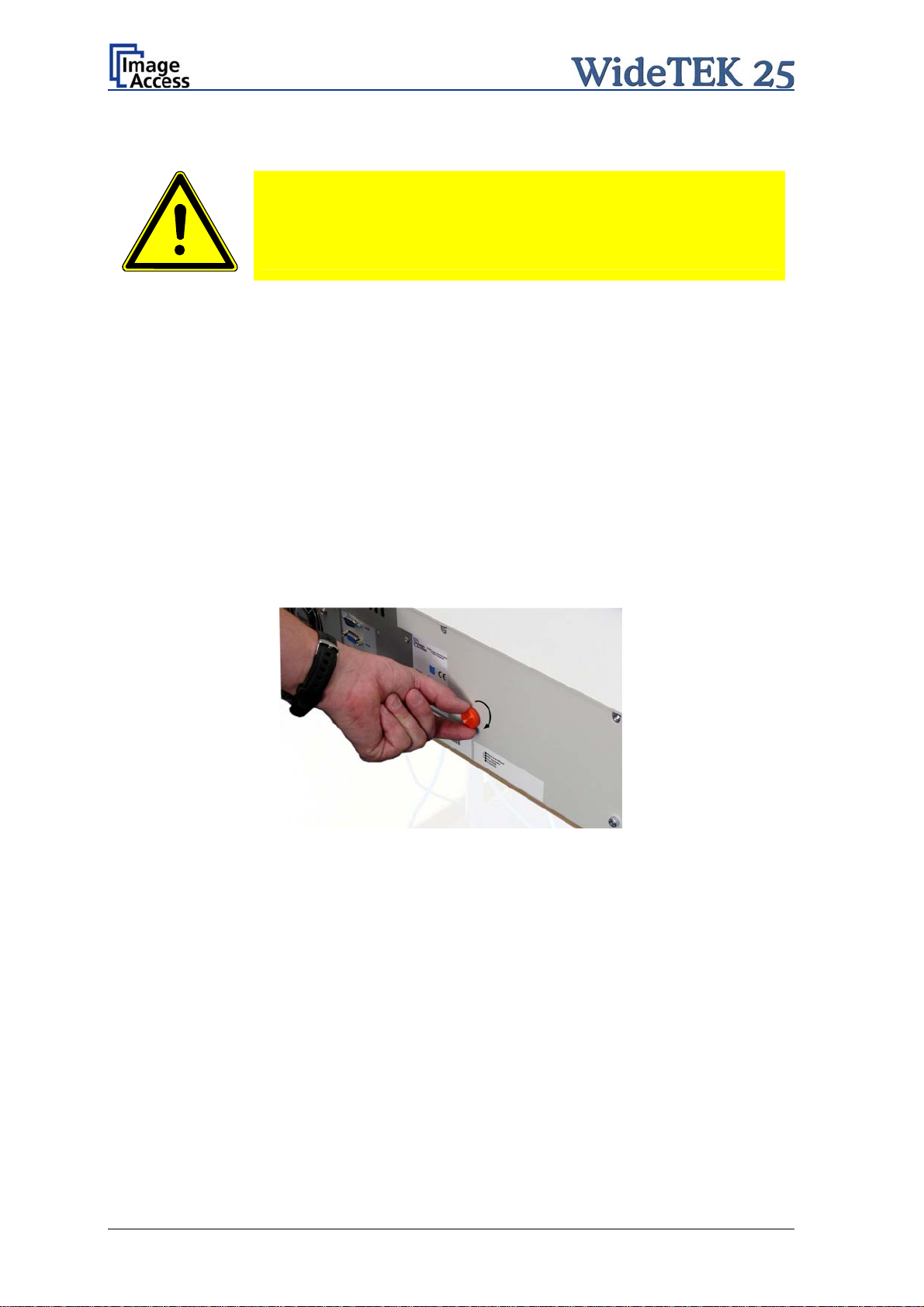

Picture 4: Removing the transportation lock......................................................................19

Picture 5: Inserting the transportation lock ........................................................................20

Picture 6: Back of WideTEK 25 .........................................................................................22

Picture 7: Connectors on the WideTEK 25........................................................................22

Picture 8: Start menu screen.............................................................................................23

Picture 9: Touch panel while shut down in progress .........................................................24

Picture 10: Keyboard with capital letters............................................................................25

Picture 11: Keyboard with lower case letters.....................................................................25

Picture 12: Self Test 1 .......................................................................................................26

Picture 13: Self Test 2 .......................................................................................................26

Picture 14: Network setup..................................................................................................27

Picture 15: Numeric key pad..............................................................................................27

Picture 16: Confirm changes .............................................................................................27

Picture 17: Place the control sheet....................................................................................28

Picture 18: Results of White Balance Test ........................................................................28

Picture 19: Testing the touch panel...................................................................................29

Picture 20: Stitch Test screen............................................................................................30

Picture 21: Start menu screen...........................................................................................31

Picture 22: Output controls................................................................................................32

Picture 23: Ftp Server 1.....................................................................................................32

Picture 24: Ftp Server 2.....................................................................................................33

Picture 25: E-mail address parameters .............................................................................34

Picture 26: Network parameters........................................................................................ 35

Picture 27: Input a Network Address.................................................................................35

Picture 28: Viewer Control.................................................................................................36

Picture 29: System events and sound files........................................................................37

Picture 30: Image Control 1...............................................................................................38

Manual Page 11

Page 12

Table of Pictures, part 2

Picture 31: Image Control 2...............................................................................................40

Picture 32: Image Control 3...............................................................................................41

Picture 33: Format Control 1.............................................................................................42

Picture 34: Format Control 2.............................................................................................43

Picture 35: File Control......................................................................................................44

Picture 36: Transport Control............................................................................................47

Picture 37: List of available jobs........................................................................................48

Picture 38: Keyboard of input screen................................................................................48

Picture 39: Creating a job..................................................................................................49

Picture 40: Entering the password .................................................................................... 49

Picture 41: Number of password elements .......................................................................49

Picture 42: Scan2VGA ...................................................................................................... 51

Picture 43: Start screen.....................................................................................................52

Picture 44: Main screen.....................................................................................................53

Picture 45: Shutdown confirmation....................................................................................54

Picture 46: Options screen.............................................................................................55

Picture 47: Properties screen......................................................................................... 57

Picture 48: 8bit Color.........................................................................................................58

Picture 49: User Defined Format.......................................................................................59

Picture 50: Additional Margin/Auto Density slider ............................................................. 60

Picture 51: Set deskew angle............................................................................................60

Picture 52: Camera screen ............................................................................................61

Picture 53: Exposure control slider....................................................................................62

Picture 54: Threshold method selector..............................................................................63

Picture 55: Despeckle function.......................................................................................... 63

Picture 56: Settings screen............................................................................................64

Picture 57: Available skins ................................................................................................ 65

Picture 58: Scan status window ........................................................................................ 65

Picture 59: Format screen.............................................................................................. 66

Picture 60: Rectangle dragged with mouse.......................................................................67

Page 12 Manual

Page 13

Table of Pictures, part 3

Picture 61: "Zoom in" result...............................................................................................67

Picture 62: Output Option Show........................................................................................69

Picture 63: Output Options in Scan Window......................................................................69

Picture 64: Output Option Print..........................................................................................70

Picture 65: Available List of Printers for Option Print.........................................................70

Picture 66: Output Option Copy.........................................................................................71

Picture 67: Output Option FTP Upload..............................................................................74

Picture 68: Output Option Mail...........................................................................................76

Picture 69: Output Option Network....................................................................................78

Picture 70: Output Option: USB.........................................................................................80

Picture 71: USB stick in USB connector............................................................................80

Picture 72: Information.......................................................................................................82

Picture 73: Login screen....................................................................................................83

Picture 74: User screen.....................................................................................................84

Picture 75: Device Info screen...........................................................................................85

Picture 76: Operation Info screen......................................................................................86

Picture 77: Available user settings..................................................................................... 87

Picture 78: User Settings screen.......................................................................................88

Picture 79: Volume level....................................................................................................89

Picture 80: Foot pedal settings..........................................................................................90

Picture 81: Splitting start page...........................................................................................91

Manual Page 13

Page 14

A Hardware

A.1 Safety Notes

Read and ensure that you understand the safety notes.

They are designed for your protection and for your safety.

Follow all safety notes to avoid damage to the device.

A.1.1 Marking of Safety Notes

All safety notes are marked with a yellow triangle warning sign.

Next to the warning sign, you’ll find a description of the danger.

Safety Note!

Example text.

A.2 Certification

The WideTEK 25 scanner fulfills all requirements of the following safety standards:

IEC 60950-1, International Safety Standard for Information Technology Equipment

UL 60950-1, Safety for Information Technology Equipment (US standard)

CAN/CSA C22.2 No.60950-1, Safety for Information Technology Equipment

(Standard for Canada)

EN 60950-1, Safety for Information Technology Equipment (European standard)

A.3 General Notice

This manual describes the functions of a complete equipped WideTEK 25 scanner. If your

device is not equipped with all features, deviations are possible.

Page 14 Manual

Page 15

A.4 Safety Precautions

Warning: Please read all the safety precautions before you operate the scanner. Serious

injury can occur to you or to others if you do not know how to use it safely.

To prevent fire or shock hazard, do not expose this device to rain

or any type of moisture.

Follow all safety precautions to avoid personal injury or damage to the device.

1. Place the scanner in a clean, well-ventilated room. Do not operate the scanner in an

area with poor ventilation.

2. Openings in the scanner’s housing in the front or at the back are provided for air

circulation. Do not cover or block the openings.

3. Do not place the scanner near a heat or cold emitting source such as a space heater,

furnace, or air conditioning unit.

4. Do not place the scanner near any devices or electrical boxes emitting high voltage.

5. Always place the scanner on a stable surface.

6. Do not lean on the scanner.

7. Do not place cups containing liquids or other such objects on top of the scanner or on

the scanner table. If liquid spills into the scanner it can cause damage. If this occurs,

turn the scanner off, unplug the power cord from the wall receptacle and contact the

Image Access Technical Support.

8. Do not put any objects into any scanner housing openings unless specifically

instructed to do so by Image Access Technical Support.

9. Do not disassemble the scanner. If there is a need to disassemble the scanner,

please contact the Image Access Technical Support.

10. Do not use the scanner if it has been physically damaged. If this occurs, turn the

scanner off, unplug the power cord from the wall receptacle and contact the

Image Access Technical Support.

11. The scanner should be used only with the power cord that is supplied with the

scanner. If you are unsure, please contact the Image Access Technical Support.

12. Image Access recommends plugging the scanner into an appropriately-rated power

conditioner.

13. Always turn the power off and unplug the power cord from the wall receptacle before

cleaning the scanner.

14. When cleaning, only use Image Access approved cleaners. Do not use any type of

solutions, abrasives, or acids such as acetone, benzene, kerosene, mineral spirits,

ammonia, or nitric acid. Do not use any cleaners that contain these chemicals.

15. Use a dry or damp lint free cloth for cleaning the scanner.

16. Do not spray any liquids directly onto the scanner. Spray cleaning fluids directly onto

the cleaning cloth and use the cloth to clean the scanner.

Manual Page 15

Page 16

A.5 Device Location

Please allow a minimum of 150 mm (6 inch) from any side walls and 300 mm (12 inch)

from a back wall. Leave one meter (3 feet) minimum distance from any door or entrance

way. Use the illustration below as a guide.

Picture 1: Minimum distances

Do not operate the scanner in an area that has poor air circulation and/or that is nonventilated.

Place the WideTEK 25 on a flat and solid base. The load bearing capacity of the base

must correspond to the device weight.

Placing the WideTEK 25 on the optional floor stand is recommended for the best

ergonomic position while using the scanner.

Choose a location that complies with the limits of temperature and humidity. Refer to the

technical specification.

Note: Before using the WideTEK 25 scanner in the new environment allow at least one

hour for temperature adaptation.

Temperature adaptation means:

A fast change from cold to warm environmental conditions can build up

condensation inside the housing. This will result in unfavorable scanned images

and could cause permanent damages to the unit.

Page 16 Manual

Page 17

A.6 Maintenance and Repair

Note: There are not any parts or components of the WideTEK 25 scanner which can

be repaired by the user.

All repairs and service works should be done by a trained technician only.

A.6.1 Cleaning

Important: Ensure that no liquids will penetrate into the device housing.

A.6.1.1 Surfaces

Use a soft, dampened cloth to clean the housing of the scanner. Recommended is a micro

fiber cloth.

A.6.1.2 Glass plate

Important: Do not use any cleanser with solvents to clean the glass plate!

The glass plate of the WideTEK 25 has a special non-reflective surface coating.

Clean the glass plate with an appropriate glass cleaner and use a soft cloth.

Recommended is a micro fiber cloth.

After cleaning dry the glass plate with a soft cloth.

Manual Page 17

Page 18

A.7 Content on Delivery

The scanner is delivered in a wooden transport box. The transport box also contains two

plastic bags, a folder with reference targets, and the manuals.

Picture 2 shows the transport box including all material which comes with the scanner.

Picture 2: Scanner WideTEK 25 in transport box

1: Scanner WideTEK 25.

2: Plastic bag with “Recovery Key” and cable set. The cable set consist of:

Network cable. Connects the scanner to the network. All network parameters such as

IP address, subnet mask and gateway must be set via the touch panel prior to the

first use.

Crossover cable. Connects the scanner directly to a computer via the network card.

Power cable. Connects the scanner to the wall outlet

3: Reference folder. It contains:

4x Color Scanner Test Target CSTT-1

4x Line Reference Sheet LRS-200

4: Plastic bag with 3x White Reference Targets WT36-Z-02-A.

Please note: Keep the wooden transport box for future use! In case of guarantee the

scanner must be sent back in the original transport box to avoid transport

damages.

Page 18 Manual

Page 19

A.8 Transportation Locks

A.8.1 Removing the transportation locks

Attention

The transportation locks have to be removed before initial start-up

of the device!

The transportation locks are located at the back of the scanner. A label marks each

transportation locks.

Picture 3: Position of transportation locks

Turn the transportation lock counterclockwise to remove it.

Picture 4: Removing the transportation lock

Important: Keep the transport lock for future use!

The transportation locks must be inserted before every transport. This will prevent the

sensitive components inside the camera box unit against damages.

Manual Page 19

Page 20

A.8.2 Inserting the transportation locks

Attention

Before transporting insert the transportation locks to prevent the

camera box unit against damages!

Before inserting the transportation locks the camera box unit must be moved into transport

position.

The transport position of the camera box unit is at the back side of the scanner – seen

from the operator’s position.

When the power down sequence ends normally, the camera box unit moves to its

transport position. If the camera box unit is in any other position after switching off, restart

the device as described in chapter A.11.1.

Afterwards turn it off as described in chapter A.11.2. The power down sequence moves

the camera

and switches the device to stand-by mode.

box unit to the transport position, finalizes all internal processes in the scanner

Switch off the WideTEK 25 at the main power switch (see Picture 7).

Picture 5: Inserting the transportation lock

Insert carefully the transportation locks which come with the scanner.

Hand-tighten by turning it clockwise. Using more force could result in damage of the

camera box unit.

Page 20 Manual

Page 21

A.9 Connecting to the Power Source

Before connecting the scanner to the electrical outlet check the following items:

Ensure the electrical outlet is in perfect condition and that it is

properly grounded.

Ensure that the electrical outlet is equipped with a fuse with the

proper capacity.

The electrical outlet must be near this device and must be easily

accessible.

Inspect the power cable and ensure that it is undamaged.

Use only the power cable delivered with the scanner.

Turn the device off before plugging or unplugging any cable.

All connectors are positioned at the right side of the back of the housing, seen from the

operator’s position (i.e. from the front of the scanner).

Manual Page 21

Page 22

A.9.1 Connectors on the Back

Picture 6: Back of WideTEK 25

Picture 7: Connectors on the WideTEK 25

1: Power connector and main power switch

2: Serial connector

3: VGA conne ctor

4: Two foot pedal connectors

5: Network cable connector

Page 22 Manual

Page 23

A.10 Powering up the WideTEK 25

The main power switch is found above the power connector. Picture 7 shows the position

of the power connector and main power switch.

After connecting the scanner to the electrical outlet, switch the main power switch to

position I. When the main power switch is in position I, the scanner is in stand-by mode.

NOTE:

While using

only be switched on and off by the touch panel!

the WideTEK 25 in work conditions, it should

A.11 WideTEK 25 Touch Panel

The WideTEK 25 parameters can be set and modified with the integrated touch panel. It

shows an easy-to-use menu and helps the user to control all scanner parameters with the

touch of a finger.

When the WideTEK 25 is powered up using the main power switch, the touch panel is

illuminated in a dimmed mode and shows the stand-by screen. The stand-by screen

shows the Image Access logo and the blinking message Touch screen to power up.

A.11.1 Starting the WideTEK 25 from Stand-By Mode

When the WideTEK 25 is in stand-by mode, it can be started by tapping the touch panel

on any arbitrary position. The touch panel lights up and a rotating hourglass indicates that

the start sequence is running.

When the start-up sequence is finished, the touch panel shows the start menu screen.

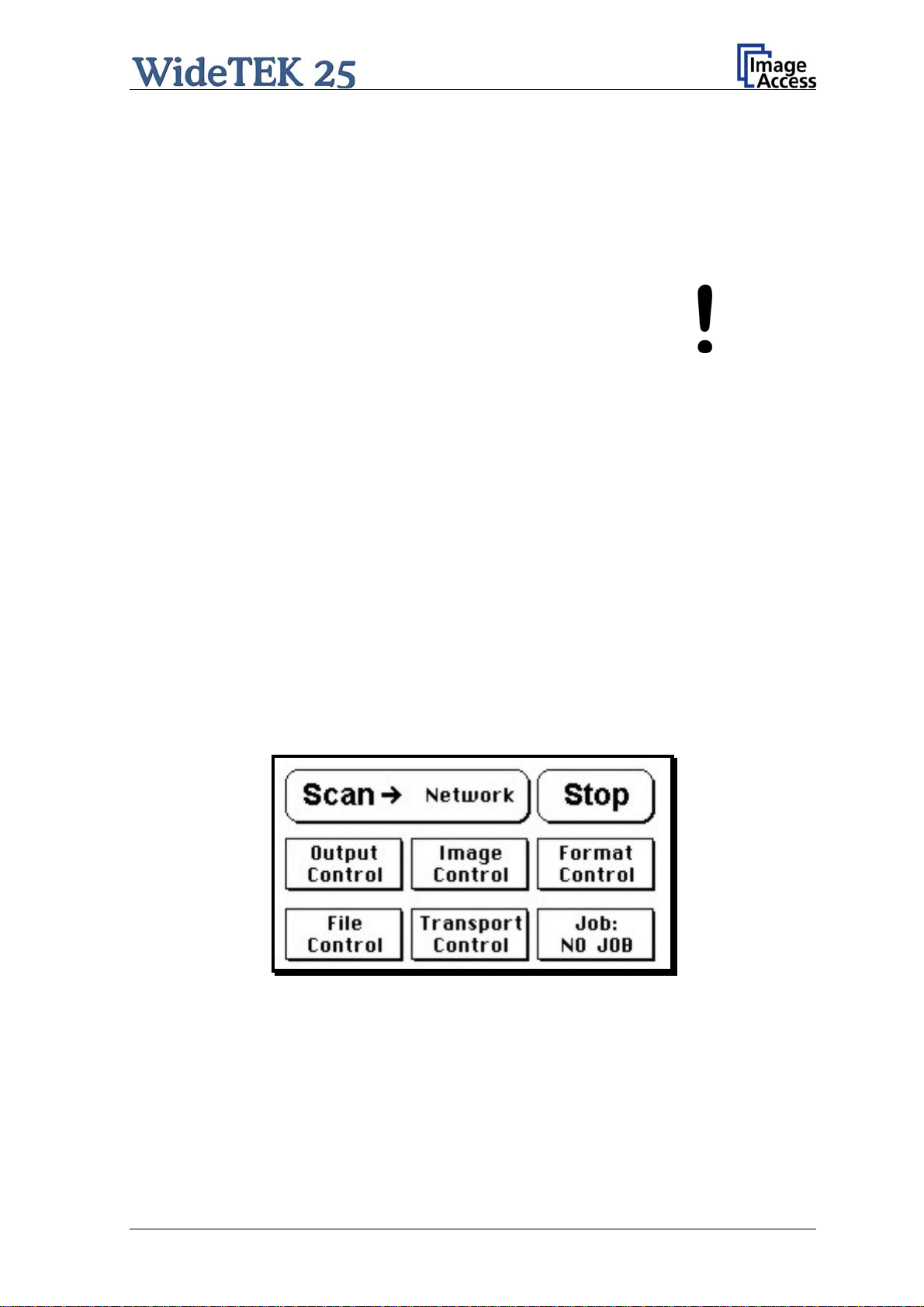

Picture 8: Start menu screen

Manual Page 23

Page 24

A.11.2 Turning-off the WideTEK 25 by the Touch Panel

ays turn off the WideTEK 25 scanner with the Stop button on

NOTE:

Alw

the touch panel!

The main power switch should only

is in stand-by mode and before it is disconnected from the electrical

outlet.

To turn off t

While the Stop button is held, a counter in the button shows the remaining time until the

WideTEK 25 is powered down. “Going to sleep in x seconds”

At the end of the power down sequence, the display will be dimmed.

he WideTEK 25, press and hold the Stop button on the touch panel.

Picture 9: Touch panel while shut down in progress

be used when the WideTEK 25

A.11.3 The Help Function

To support the user when working with the WideTEK 25, a help function is integrated into

the touch panel menus. A Question Mark (?) symbol in the lower right corner of the

screen activates the help function.

After touching the question mark, all controls in the screen start blinking. To see the

corresponding help text, the appropriate control must be touched. To return to the

respective screen, the screen must be touched again on any arbitrary place.

Page 24 Manual

Page 25

A.11.4 Navigating through the Screens

Some of the screens show on the bottom line the buttons

Returns to the former screen. Somet

Switches to

the next logical screen, e.g. from Format Control 1 to

imes only the symbol < is displayed.

Format Control 2. Sometimes only the symbol > is displayed.

Resets all values in the

respective screen to default value.

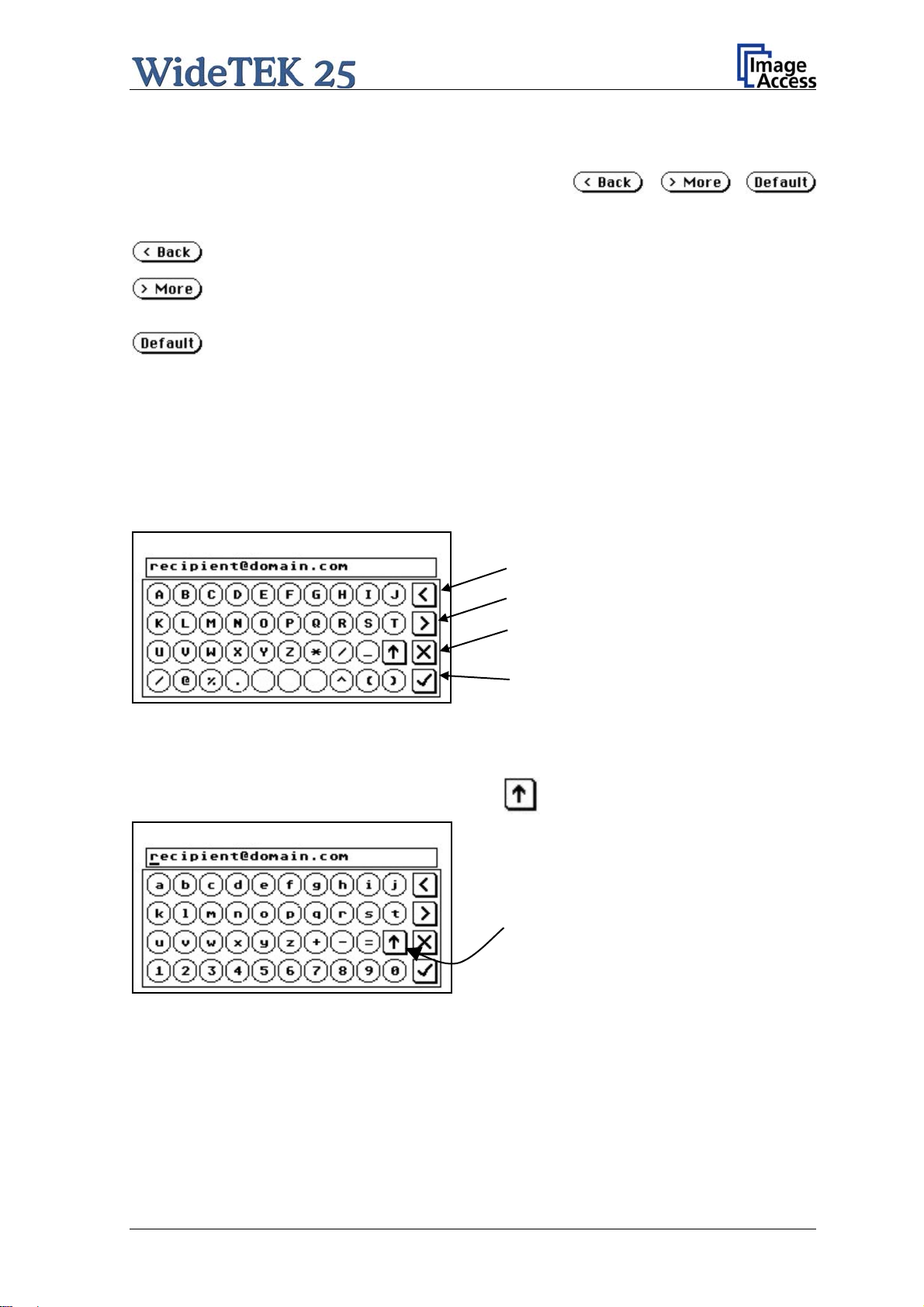

A.11.5 How to Enter or Change Values

To enter new values or change existing values, the corresponding field or line in the

screen must be touched. If a parameter requires an alphanumeric value, the touch panel

display changes and shows a keyboard with which text and numeric values can be

entered.

Moves cursor to the left.

ht.

he cursor

Picture 10: Keyboard with capital letters

Moves cursor to the rig

Erases the character at t

position.

Checkmark symbol returns to previous

screen.

The keyboard enables the user to enter capital letters, lower case letters, special

characters as well as numbers.

The content of the keys is switched with this key:

Toggles between capital letters and

special symbols (e.g. backslash or @)

and lower case letters and numbers.

Picture 11: Keyboard with lower case letters

Manual Page 25

Page 26

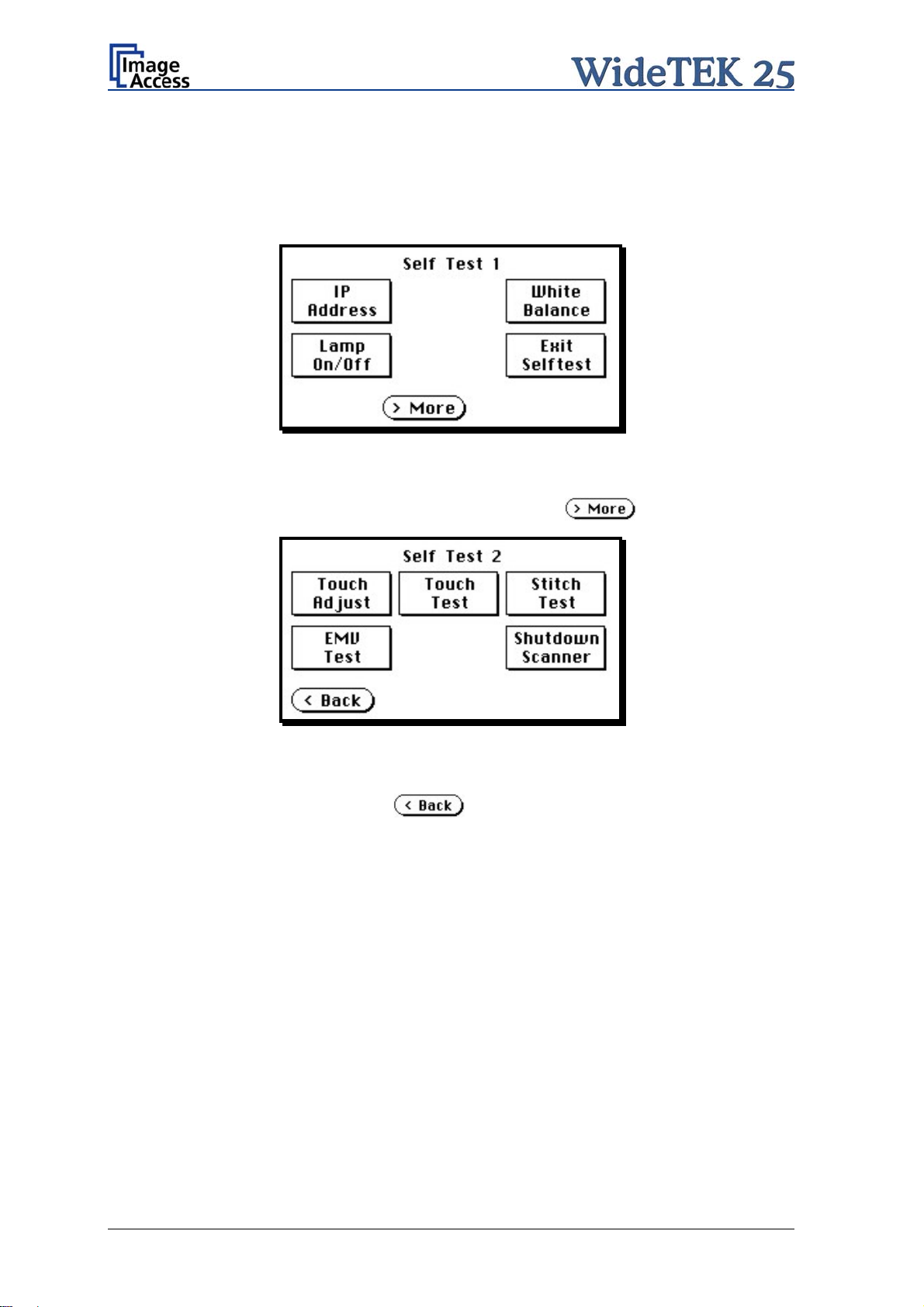

A.11.6 Self Test Mode

While the start sequence is running, the WideTEK 25 can be switched to Self Test mode.

Tapping on the touch panel at least three times starts the setup mode. After the start

sequence is finished, the touch panel shows the Self Test 1 screen.

Picture 12: Self Test 1

To move forward to the Self Test 2 screen touch the button

Picture 13: Self Test 2

To return to the former screen touch

.

.

Page 26 Manual

Page 27

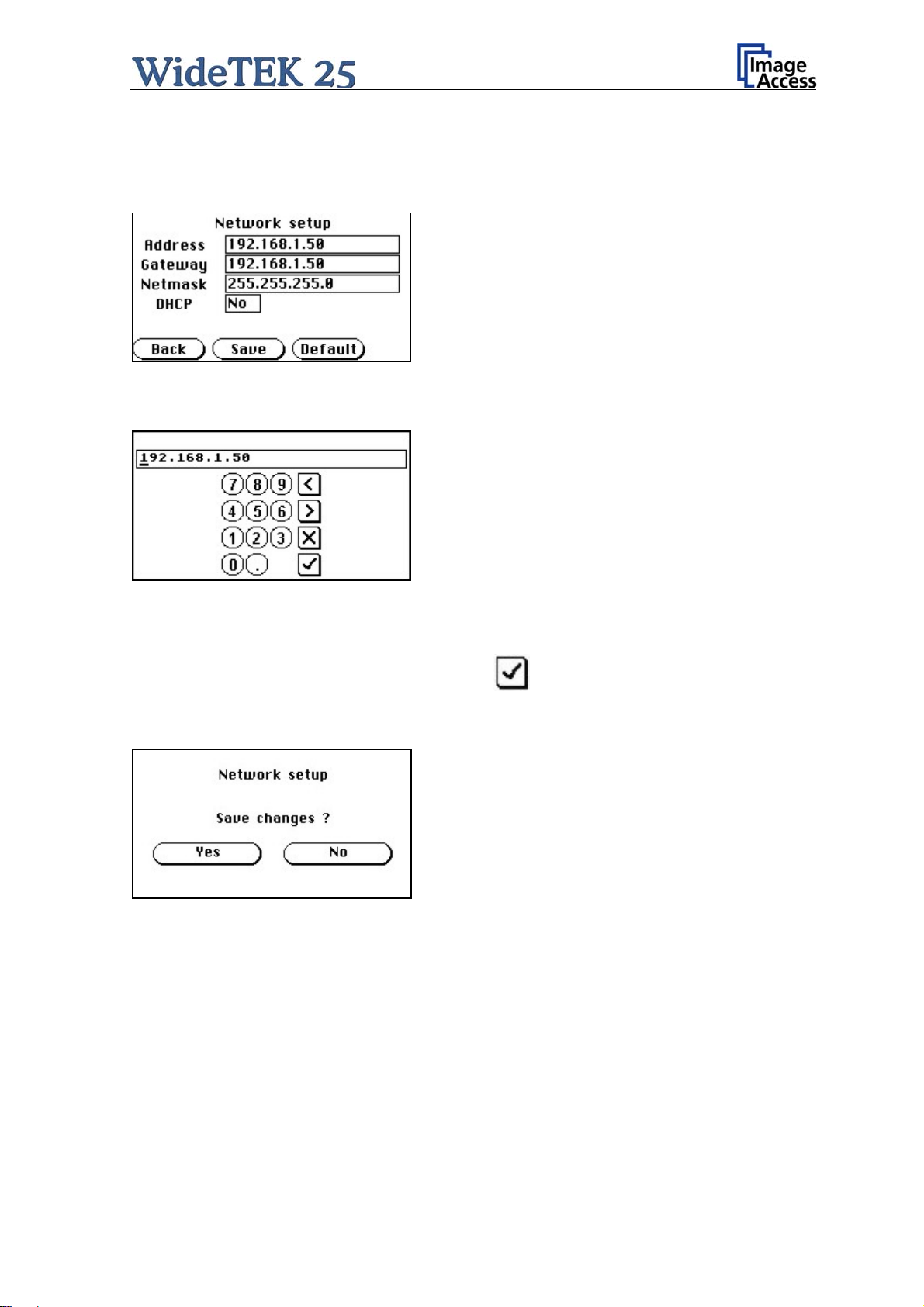

A.11.6.1 IP Address

Touch the control field IP Address. The touch panel changes to the Network setup

screen.

Picture 14: Network setup

Touch on the line to be changed, e.g. the Address line. The touch panel shows:

Picture 15: Numeric key pad

Enter the new values. The < and > keys move the cursor, the X key deletes the number at

the cursor position.

To finalize

the input tap on the checkmark key.

If entries have been changed, a screen opens where the changes must be confirmed.

Yes confirms the changes, No discards the changes.

Picture 16: Confirm changes

After the changes have been saved, the setup screen is displayed again.

Manual Page 27

Page 28

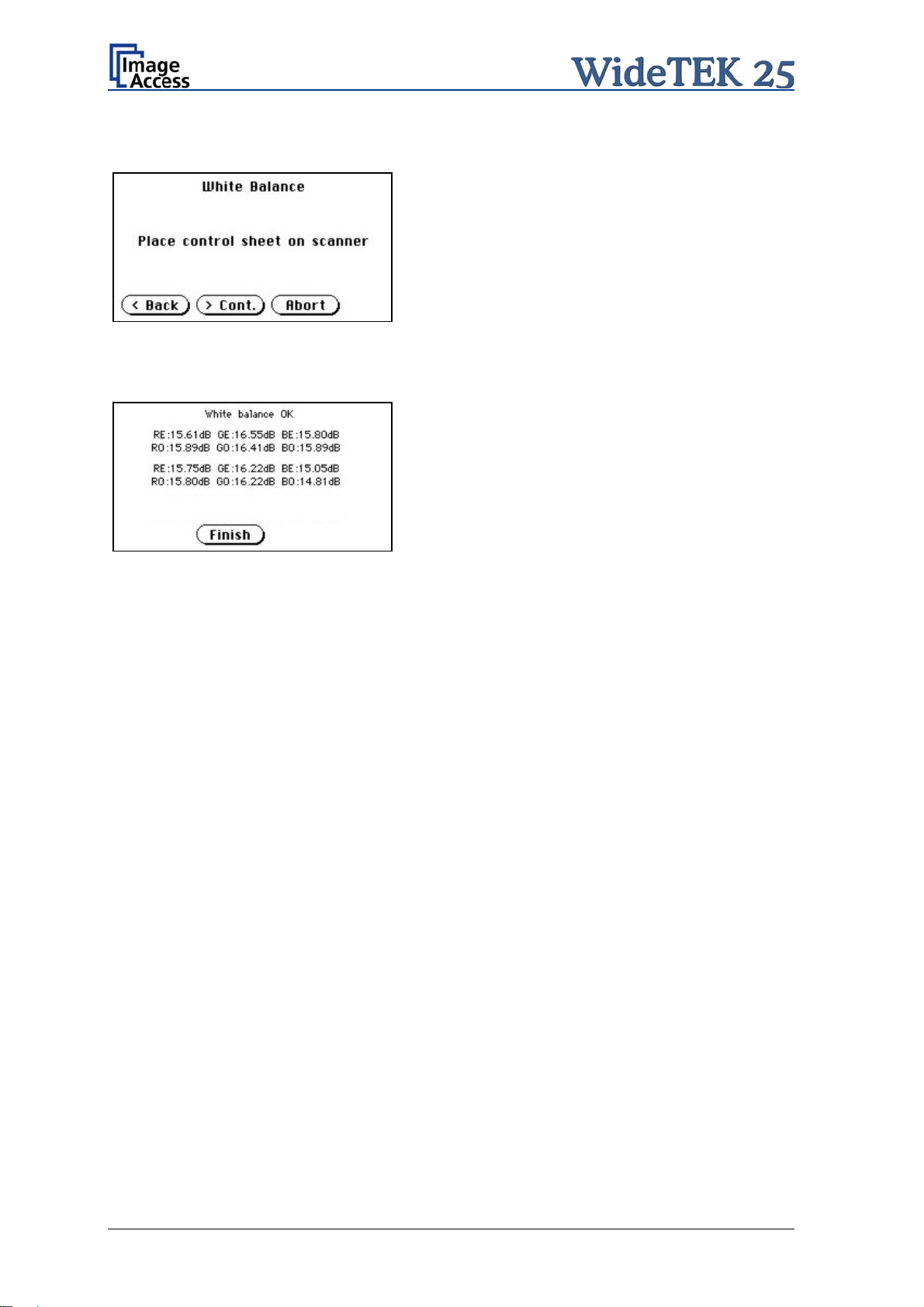

A.11.6.2 White Balance

Picture 17: Place the control sheet

Picture 18: Results of White Balance

Test

Touch the White Balance button t

o start the

white balance measurement sequence. Place the

white reference sheet on the upper edge of the

glass plate. The white reference sheet must

cover the complete width of the glass plate. Then

touch the Cont. button.

The measurement lasts a short time.

The Abort button returns to the previous screen

if the white balance measurement should not be

executed.

After the white balance has been finished, the

result is displayed

Touch the Finish button to return to the

Self Test 1 screen.

A.11.6.3 Lamp On / Off

Touch the Lamp On / Off button to switch the lamps on. As long as the button is touched,

the lamps will shine.

A.11.6.4 Exit Selftest

Touching Exit Selftest finalizes the setup mode, switches to the operation mode and

shows the start menu.

Page 28 Manual

Page 29

A.11.6.5 Touch Adjust

This function defines the dimension of the writing area of the touch panel. The first step

after selecting this function must be done very quickly to activate the adjustment

procedure.

Note: It is recommended to read first, then act. It is recommended to use for the

following adjustment steps an appropriate pen, e.g. as used with a PDA.

Touch the Touch Adjust button, then press and hold the touch panel. The first message

on the screen can be ignored.

After a short moment a blinking dot appears at the upper left corner of the touch panel and

the instruction Touch this blinking dot is displayed. Touch the blinking dot with the tip of

a suitable pen.

In the next step the instruction changes to the lower right corner. Repeat touching the

blinking dot in the lower right corner. After this, the touch panel returns to the Self Test 2

screen and the setup procedure is finished.

It is recommended to check the adjustment with the Touch Test function.

A.11.6.6 Touch Test

Touch Test is used to check the correct function of the touch panel.

Picture 19: Testing the touch panel

After selecting this function the display changes to a blank area.

By using an appropriate pen, e.g. as used with a PDA, write some symbols or lines on the

touch panel. While writing, check the correlation between the pen’s position and the

position of the signs that have been written.

If the difference is to large, repeat the adjustment as described in chapter A.11.6.5.

To return to the prior scr

een, touch the button

Manual Page 29

Page 30

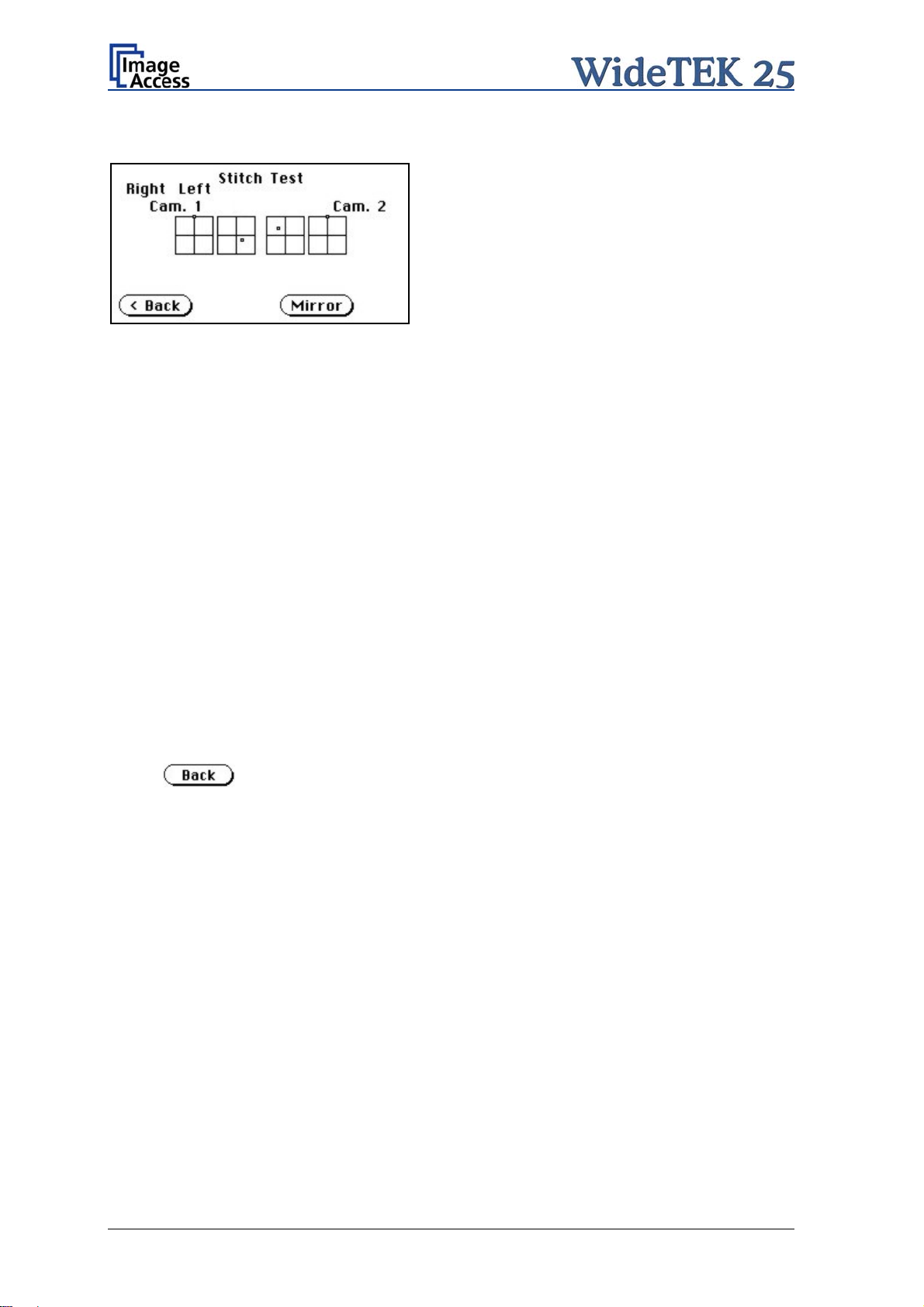

A.11.6.7 Stitch Test

Picture 20: Stitch Test screen

Press the Stitch Test button to start the stitch test. This starts a program in which you can

see an automatically updated view of the stitching indicators for each camera. The

measurement will be executed continuously, once every second.

The cameras left and right are identified as the left and right cameras when looking at the

scanner from the operator’s view (i.e. from the front of the scanner). Each camera has a

set of two stitching coordinate boxes. A stitching coordinate box consists of four

quadrants.

Picture 20 shows a typical situation of the stitching indicator

s. That means, that all camera

settings are within the specified tolerances.

Ideally, the stitching indicators (the small dots inside the four-quadrant boxes) should be

positioned close to the center of the crosshairs.

If a stitching adjustment is necessary, it must be done by a trained technician.

A.11.6.8 EMV Test

This function is used for Electromagnetic Compatibility (EMC) tests.

After inserting a test document into the scanner, the scan sequence is repeated until the

button is pressed.

A.11.6.9 Shutdown Scanner

Switches the WideTEK 25 scanner off.

Page 30 Manual

Page 31

A.11.7 Start Menu Screen

Picture 21: Start menu screen

When all initial tests are finished, the display shows the start menu screen.

At the top of the start menu, the main controls to start a scan sequence and to stop the

current action are displayed.

The scanned image can be directed to different targets.

The selected target is named between the Scan and the Stop button. Picture 21 shows

as selected

target the network in which the scanner is integrated.

The controls in the middle line and in the lower line of the menu are used to configure the

parameters in detail.

Manual Page 31

Page 32

A.11.8 Output Control Sc reen

Picture 22: Output controls

A.11.8.1 FTP Server

The “Ftp Server” button on the Output Control menu enables the user to enter all

necessary information for data transfer to a dedicated FTP server. The parameters are

entered in two screens named Ftp Server 1 and Ftp Server 2.

A.11.8.1.1 Ftp Server 1

This screen

contains the server IP address and the port, the user name and the password

for the server access. Additionally a path to an existing directory on the FTP server where

the files should be stored can be entered.

Returns to the previous screen.

Changes to the Ftp Server 2 screen.

Picture 23: Ftp Server 1

Note:

The IP address 127.0.0.1 (as shown in the above picture) does not represent a

real existing FTP server. This IP address is typically used in networks to make the

own system, the so-called “localhost”, available for TCP/IP applications.

Page 32 Manual

Page 33

A.11.8.1.2 Ftp Server 2

This screen contains all data for the connection with a FTP server.

Stores all parameters.

Erases all changes.

Picture 24

: Ftp Server 2

Use prox

y Select Yes to use a proxy server for the connection.

Auth. Defines the type of authentication at the FTP server. By tapping on the

field the methods will be switched.

Anonymous: An anonymous connection will be used. The data in the fields

User and Password from the FTP Server 1 mask will be

ignored.

Login/Password: To save the images on the FTP server a login name and a

password must be entered.

Ask the administrator of your FTP server for the necessary information to get access to

the designated FTP server.

Manual Page 33

Page 34

A.11.8.2 Email Address

This menu item enables the user to send the scanned image to any arbitrary e-mail

address.

Picture 25: E-mail address parameters

To store all entries of this menu touch the button .

A.11.8.2.1 Input an E-Mail Address

Tap on the line of the e

Picture 10 and Picture 11. Enter the desired e-mail address. The @ symbol is found on

the keyboard in the capital letter layout in the bottom line.

-mail address. The screen changes to input mode as shown in

To delete a character place the cursor below the character and tap on the X key.

When the complete e-mail address is entered, tap on the checkmark key to return to the

previous screen.

To store the values touch the button

To return to the former menu, touch the button

If entries ha

ve been changed, a screen opens where the changes must be confirmed.

.

Yes confirms the changes, No discards the changes.

Page 34 Manual

Page 35

A.11.8.3 Windows Network

Allows the user to

define the network path where the image should be stored,

the define the authentication method,

define the user name,

define the password,

define the filename

Picture 26: Network parameters

To store all entries of this menu touch the button .

A.11.8.3.1 Input a Network Address

Picture 27: Input a Network Address

Tap on the line of the network path name. The touch panel screen changes and displays

the keyboard layout.

The slash symbol / is found on the keyboard in the capital letter layout in the bottom line.

To delete a character place the cursor below the character and tap on the X key.

When the complete network address is entered, tap on the checkmark key to return to the

previous screen.

To store the values touch

.

To return to the former menu, touch the button .

If entries ha

ve been changed, a screen opens where the changes must be confirmed.

Yes confirms the changes, No discards the changes.

Manual Page 35

Page 36

A.11.8.4 Viewer Control

An external monitor can be connected to the WideTEK 25 to show the scanned image

directly.

Touching the Viewer Control button starts the Zoom/Move Control mode. When this

mode is active, the displayed image on the screen can be moved and the zoom factor can

be changed.

Navigation

keys

Picture 28: Viewer Control

Increases the zoom factor.

Decreases the zoom factor.

Zooms the image to its genuine dimension (100%) without scaling.

Returns to the prior menu.

If the image dimension overlaps the monitor dimension, the navigation keys can be used

to scroll the displayed area on the monitor.

Page 36 Manual

Page 37

A.11.8.5 Sound Control

The menu item Sound Control allows the user to link sounds to system events.

Picture 29: System events and sound files

To select a system event, touch the scroll bar in the left window or the up/down arrows.

The currently selected sound file associated with this system event will be displayed in the

right window.

To select a different sound file from the list, touch the up/down arrows or the scroll bar in

the right window until the sound file to be used is marked in reverse color.

To modify the sound volume, move the scroll bar between the loudspeaker symbols up- or

downwards.

Returns to the prior menu.

Links the system event and the marked sound.

Plays the sound which is marked in reverse color.

Manual Page 37

Page 38

A.11.9 Image Control Screen

The parameters are set in two screens named Image Control 1 and Image Control 2.

A.11.9.1 Image Control 1

Picture 30: Image Control 1

In general:

Tap the + or – to change the values in steps of one.

Tap the + or – and hold for at least five steps, then the value changes in steps of five.

A.11.9.1.1 Brightness

The brightness control

defines the resulting brightness of the image. A lower value results

in darker images, a higher value results in brighter images.

Values close to 0% or 100% may result in unwanted artifacts.

A.11.9.1.2 Contrast

The contrast control def

ines the contrast of the image. A lower value results in an image

that is smoother, a higher value shows more details and the image will become crisper.

Values close to 0% or 100% may result in unwanted artifacts.

A.11.9.1.3 Gamma

The gamma control defines the gamma

correction used by the scanner camera. A value

of 1,6 is a good approximation. The range of values are from 0 (no gamma) to 2,5

(maximum gamma).

A higher gamma value shows more details in darker areas and compresses bright areas.

Page 38 Manual

Page 39

A.11.9.1.4 Sharpness

An automatic sharpening algorithm is applied to the image before any other operation is

performed.

The value zero disables the function. Very high values may produce artifacts, depending

on the document characteristics.

A.11.9.1.5 Resolution

This parameter defines the scanner’s resolutio

n. This button offers three ways to set the

desired value:

Tap the + or – to change the resolution in steps of one DPI.

Tap the + or – and hold for at least five steps, then the value changes in steps of five

DPI.

Tap the numeric value in the middle of the button. This will step through the list of

available resolutions.

A.11.9.1.6 Color mode

The color mode parameter defines t

he color mode if scanning in color or the algorithm

used for binarization in binary mode.

24b color 24 bit color mode

8b color 8 bit color mode

Grayscale 8 bit grayscale mode

Binary 1 bit black/white mode

Photo 1 bit black/white mode with dithering. Dithering means that finest details in

the image are optimized by rastering.

This control also influences the compression method that is offered in the File Control

screen.

Chapter A.11.4 gives information about the buttons

.

Chapter A.11.3 gives information concerning the help function, which is activated by the

Question Mark symbol.

Manual Page 39

Page 40

A.11.9.2 Image Control 2

Picture 31: Image Control 2

Note: Depending on the selected color mode, some buttons may not be displayed.

A.11.9.2.1 Threshold (only in Binary mode)

Defines the

Available modes are Fixed and Auto.

contrast control mode.

Fixed: The contrast is fixed to defined value.

Auto: The contrast of the image set dynamically, depending on the values found in

the image. This can be used to improve delicate details in the image.

A.11.9.2.2 Despeckle (only in Binary mode)

Remo

ves isolated pixel in the images.

Available modes are 4x4p and Off.

A.11.9.2.3 Invert (only in Binary and Photo mo

de)

Inverts the displayed image.

A.11.9.2.4 Stitching

Defines the

stitching method which is used to merge the image data to one image.

Fixed: Merges the image data at a specified offset area.

Adapt.2D: Merges the image data dynamically.

A.11.9.2.5 ICC Profile

ICC profiles add color co

rrection values to each scanned image.

Page 40 Manual

Page 41

A.11.9.3 Image Control 3

Picture 32: Image Control 3

Note: Only in the color modes 24b color, 8b color, and Grayscale.

A.11.9.3.1 Exposure

Defines the

Available are Black Cut, Auto and Fixed.

exposure correction mode.

Black cut All color values in the image which are below the threshold for black are

displayed as black.

Auto Activates the threshold for black and the automatic brightness control.

Automatic brightness control means the brightness range of the image is

expanded to the maximum range of the scanner. This converts the darkest

areas of the image to solid black and the brightest areas to solid white.

Fixed Switches off the exposure correction mode.

A.11.9.3.2 Exp. Black

Defines the

value for the threshold for black.

Chapter A.11.4 gives information about the buttons

.

Chapter A.11.3 gives information concerning the help function, which is activated by the

Question Mark symbol.

Manual Page 41

Page 42

A.11.10 Format Control Screen

The parameters are set in two screens; Format Control 1 and Format Control 2. By

using the Back and More buttons, you can switch between the Format Control screens.

A.11.10.1 Format Control 1

Picture 33: Format Control 1

A.11.10.1.1 Format

This control specifies the format of the document. In most cases the setting Auto should

be selected.

The format list includes the well known DIN A formats as well as US ANSI formats, e.g.

Letter or US C. Some formats are specified with an additional L(andscape) or P(ortrait).

A.11.10.1.2 Doc shape

Defines the

documents structure. Flat is currently the only available setting.

A.11.10.1.3 Start page

This define

s the start page if Splitting is activated.

A.11.10.1.4 Rotation

The value

set here defines the rotation of the image in a clockwise direction after

scanning.

A.11.10.1.5 Mirror

This control

activates the horizontal mirroring of the image.

It can be useful if scanning a transparency or a blueprint from the back side.

A.11.10.1.6 Splitting

The followin

g options are valid:

Left: The image is taken from the left side of the specified area.

Right: The image is taken from the right side.

Auto: Divides the specified scan area symmetrically into two sides and sends the

images consecutively. The second image will be sent without scanning the

document again.

The start is defined in Start Page (see chapter A.11.10.1.3).

Page 42 Manual

Page 43

A.11.10.2 Format Control 2

Picture 34: Format Control 2

A.11.10.2.1 Auto margin

The Auto margin control detects the edges of a document and cuts it out of the scanned

image.

If the value (in pixels) is negative, the resulting image will be smaller than the document.

This is helpful to remove unwanted borders from the image.

If the value is positive some of the background will remain in the scanned image.

A.11.10.2.2 Auto density

The Auto density function detect

s the edges of a document only if they are surrounded

by a dark background.

This control specifies the density level used to decide whether a pixel belongs to the

background or not. A value of 40 is the proper setting in most cases.

Note: When scanning very dark documents, it could be necessary to vary this value to

detect the correct document dimension with the format setting Auto (see chapter

A.11.10.1).

A.11.10.2.3 Auto skew

The image of the scanne

d area will be deskewed before it is displayed.

Auto skew enables the deskew function and defines the maximum angle of the document

to be deskewed.

Chapter A.11.4 gives information about the buttons

.

Chapter A.11.3 gives information concerning the help function, which is activated by the

Question Mark symbol.

Manual Page 43

Page 44

A.11.11 File Control Screen

Picture 35: File Control

The control File format specifies the file format of the image file. Depending on the

selected file format all other controls in this screen vary. The list of formats includes

JPEG, TIFF, PNM, and PDF (if the option is installed).

A.11.11.1 JPEG

When selecting the file format JPEG the functions of the controls are:

JPEG quality: Defines the compression. The JPEG quality level is defined with this

control. A higher percentage gives better quality but the file size will

increase. A lower factor will show some artifacts in the image but the

file size will be reduced.

Prev. quality: The JPEG quality level used for the preview is selected here. A higher

percentage gives better quality but the file size will increase. A lower

factor will show some artifacts but the file size will be reduced.

Prev. scale: This control defines the preview scale factor. Higher values result in

smaller previews; lower factors will produce larger previews but take

more time to send and display.

Page 44 Manual

Page 45

A.11.11.2 TIFF

When selecting the file format TIFF the functions of the controls are:

Note: Depending on the selected color mode in Image Control the available

compression methods vary.

TIFF compr.

None: Available with all color modes.

JPEG: Available with “24b color” and “Grayscale”. Additionally the controls

“JPEG quality” and “Prev. quality” will be displayed.

CCITT G4: Available with “Photo” and “Binary”.

Prev. scale: This control defines the preview scale factor used. Higher values result

in smaller previews; lower factors will produce larger previews but take

more time to send and display.

A.11.11.3 PNM

When selecting the file format PNM only the preview scale can be selected.

Manual Page 45

Page 46

A.11.11.4 PDF

When selecting the file format PDF the functions of the controls are:

JPEG quality: Defines the compression rate. The JPEG quality level is defined with

this control. A higher percentage gives better quality but the file size

will increase. A lower factor will show some artifacts in the image but

the file size will be reduced.

Prev. quality: The JPEG quality level used for the preview is selected here. A higher

percentage gives better quality but the data size will increase. A lower

factor will show some artifacts but the data size will be reduced.

Prev. scale: This control defines the preview scale factor. Higher values result in

smaller previews; lower factors will produce larger previews but take

more time to send and display.

PDF compr: “None” disables the data compression. The controls “JPEG quality”

and “Prev. quality” will not be displayed.

“JPEG” enables the data compression. The controls as shown above

will be displayed.

Chapter A.11.4 gives information about the buttons

.

Chapter A.11.3 gives information concerning the help function, which is activated by the

Question Mark symbol.

Page 46 Manual

Page 47

A.11.12 Transport Control Screen

Picture 36: Transport Control

A.11.12.1 Start button

The Start button defines the start method of the scanner.

Direct: The scan starts when the scanner receives the start command from the

application.

Wait: The scan will only start if the start button is pressed. The start button can also be

a foot pedal.

A.11.12.2 Bidir. scan

The Bidir. scan button defines the scan direction of the scanner.

On: The scanner scans in both directions (bidirectional). This increases the

document throughput while scanning documents of similar dimensions.

Off: The scanner always starts scanning from its zero position. This setting is

recommended if the dimension of the documents vary.

Manual Page 47

Page 48

A.11.13 Job

Picture 37: List of available jobs

The control Job allows the user to create and store specific settings of the scanner. This

is useful if the scanner is operated by several users with different settings for document

size, resolution or other parameters.

A.11.13.1 Creating a Job

Creating a “job” is done in a few steps.

First, the job settings have to be specified; i.e. definition of document size, resolution, file

format etc. When all settings have been specified, tapping on Job in the

Start Menu Screen opens the screen displayed in the picture above.

Tapping in the line Job name will o

screen with the keyboard. Here the job name can

be entered. The new job name must be

confirmed with the checkmark button.

Picture 38: Keyboard of input screen

Refer to chapter A.11.5 for get more information how to handle the keyboard.

pen the input

Page 48 Manual

Page 49

Picture 39: Creating a job

Picture 40: Entering the password

Tap on Create to save the job.

Tap on with password to save the job in

combination with a password.

Tap on Cancel to cancel procedure.

If a password should be used, tapping on the

button with password opens a screen as shown

in the picture on the left.

Tapping in the empty field opens the screen with the alphanumeric keyboard (Picture 38).

Enter the password.

Tap on the checkmark button in the alphanumeric keyboard to confirm the password and

to return to the former screen.

The screen now shows the number of elements

of the password.

Tapping on Ok returns to the list of available jobs

(Picture 37).

The job is n

Picture 41: Number of password elements

ow active.

If no password for the job is necessary, tapping on Create opens a screen where the

operator is asked to confirm the new job name. This is easily done with the Yes button.

Manual Page 49

Page 50

A.11.13.2 Selecting a Job

New job names are added to the list of available jobs.

Jobs can b

e selected from the list of available

jobs by tapping on the selection arrow or directly

on the job name.

Tapping the Select button activates the job.

Selecting a password protected job opens a

screen where the operator must enter the

password. Tapping in the empty field opens the

alphanumeric keyboard and the password can be

entered.

Tapping on the checkmark button finalizes the

input sequence.

After the password is entered, the screen shows the Select job screen (see above) again.

Tapping on the Ok button finally selects the job and returns to the Start Menu Screen.

A.11.13.3 Deleting a Job

Select the job to be deleted from the list of available jobs.

Tap on the Delete button.

In the next screen, ta

delete the job.

If the job is password protected, the password

must be entered first. After selecting the job to be

deleted, a screen opens where the password is

entered.

Tap on the empty field. The screen with the

alphanumeric keyboard opens. Enter the

password and tap on the checkmark button to

finalize the input sequence.

In the next screen tap on Ok.

p on the Yes button to

The screen

returns to the Start Menu Screen.

Page 50 Manual

Page 51

A.11.14 Software Option: Scan2VGA

An external monitor can be connected to the WideTEK 25 to show, edit and save the

actual scanned image on the fly.

When the scan sequence has been finished the menu in the touch panel changes.

By tapping at the respective buttons the menus

can be sele

cted.

Picture 42: Scan2VGA

With touchin

Scan settings which made

changed here again and the results are shown

directly at the external monitor.

The edited image can be saved by touching the

Save button. Available targets are:

Network

USB

Printer

FTP

Email

g the Exit button the mode will be left.

before can be

Manual Page 51

Page 52

B Software

Essentially, the scanner is a web server and comes with its own HTML-based user

interface. To access a Scan2Net scanner, any standard web browser can be utilized.

B.1 Start Screen

Start your browser.

Enter the IP address of the scanner. The default IP address of the scanner: 192.168.1.50

The start screen of the integrated user interface will be displayed.

Picture 43: Start screen

Launch Scan Application switches to the main screen. Detailed information will be found

starting in chapter B.2.

Setup Device switches to the setup menu. Detailed information will be found starting in

chapter B.5.

Information gives a short summary of the device parameters. Information will be found

in chapter B.4.

Page 52 Manual

Page 53

B.2 The Main Screen

After launching the scan application, the main screen of the integrated user interface will

open. The main screen is structured in three parts. Switching between the sections is

done with a mouse click.

Picture 44: Main screen

1: The menu bar of the large frame on the upper right part has five menu items:

Options

Properties

Camera

Settings

Format

Click at a menu item to select and set parameters of the scanner.

Manual Page 53

Page 54

2: The eight control buttons in the lower part of the screen control the output modes.

As default the output mode Show is selected. After clicking onto the button Preview or

onto the button Scan Now a window opens and shows the image.

When selecting Save the scanned image will not be displayed. Instead of the second

window a box opens where the desired directory can be set.

Selecting Print will display the scanned image in a second window and direct the

scanned image to locally available printers.

Selecting Copy prints directly to a previously installed network printer.

Selecting FTP Upload scans directly to a FTP server.

Selecting Mail sends the scanned image directly to a previously defined e-mail

address.

Selecting Network uploads the scanned image directly to a previously defined

workstation in the network.

Selecting USB the scanned image is stored on an USB stick. A USB stick can be

connected to the scanner at the connector at the front side.

3: The frame on the left side shows the buttons for preview scan (Preview) and main

scan (Scan Now).

Pressing this button switches the scanner off.

If the red button is pressed, the following window will appear.

Picture 45: Shutdown confirmation

Click on the button Shutdown and the scanner switches off.

Page 54 Manual

Page 55

B.2.1 The Options Screen

Picture 46: Options screen

The Document Mode allows the user to select between different types of documents.

Currently the only mode is Flat Mode. In this mode the scanner works with a fixed focus

setting, regardless of the actual shape of the document.

The Preview Scale selector will be used for previews. If set to Auto, the function will

perform a best fit before the image is displayed on the screen.

The Preview JPEG Quality (%) determines the compromise between quality and

compression rate. A higher quality factor produces larger files. The default setting of 40 is

a good compromise for most documents.

The Bidirectional Scan allows two settings:

Bidirectional Scan: Yes: The camera scans the selected scan area size and stops at

the position where the scan area ends. The next scan

sequence starts from this position in opposite direction.

Bidirectional Scan: No: The camera scans the selected scan area size and returns to

its initial start position. While the camera returns to the start

position the document can be changed.

Manual Page 55

Page 56

Image Rotation

The image can be rotate

d before it is displayed.

The rotation can be any degree of out of 90°, 180°, 270° or none. The

angle is defined in the clockwise direction.

Click on the selection arrow and select the rotation angle from the list.

The Embedded ICC switch is either Yes or No.

The Embedded Meta Data switch is either Yes or No.

Clicking the Option link opens a window, where the

embedded metadata can be entered.

The Mirror function can be set to None or Horizontal or Vertical.

Page 56 Manual

Page 57

B.2.2 The Properties Screen

Picture 47: Properties screen

The Color Mode allows the user to select various color modes. 24bit Color, 8bit Color,

Grayscale, Binary and Photo are available color modes.

The available color modes are displayed in the picture on

the left.

To select a color mode first click on the selection arrow, then

select a mode from the list.

Manual Page 57

Page 58

The File Format defines the file format that is used to store a scanned document.

Note: There are some interdependencies between Color Mode and File Format.

That means, it is not possible to combine all color modes with all file formats.

For example, an image scanned in “24bit Color” can not be stored in TIFF file

format with TIGG G4 compression.

Depending upon the selected file format, the control beside it can vary:

Example:

Color Mode 8bit Color, File Format TIFF

TIFF Compression is d

isplayed

additionally.

Picture 48: 8bit Color

The Stitching selector

defines the method for the merging of the data of the cameras.

Fixed Select this setting when scanning documents with a plain surface

without crinkles or when a short scan time is important.

Adaptive 2D Default setting.

Select this setting when scanning documents with uneven structured

surface, e.g. multiple folded paper. The image data will be merged

dynamically. The time until the image is displayed will increase a little.

Page 58 Manual

Page 59

The Splitting Image function allows the operator to split the image of the scanned

document.

Off: No page splitting.

Auto: The first image is taken from the side which is defined in

the setup menu as start page. Click on Preview or Scan

now again to get the other half.

Left: The image is taken from the left half of the specified area.

Right: The image is taken from the right half of the specified

area.

The Format list offers various standard paper formats.

If Auto is selected, th

e scanner scans the complete document and then crops the

document to its real size. This function is highly advanced and works with default values

most of the time.

If User is selected the User defined format control opens. It allows to

set the values for Height and Width of the area to be scanned. It also

allows to define the position of the area to be scanned. The position is set

by the values for X Offset and Y Offset.

Note: The point of origin for X Offset and Y Offset is defined in the

upper left corner of the document area. Only positive values are allowed.

Picture 49: User Defined Format

Manual Page 59

Page 60

An Additional Margin [mil] can be added to or taken away from the image.

Picture 50: Additional Margin/Auto Density slider

The margin is defined in mil (1/1000 inch). The desired value can be entered as a

numeric value or by clicking on the slider and moving it to the desired value. If a numeric

value us entered, confirm the input with the ENTER key or the TAB key on the PC

keyboard.

The Auto Density (Binary) parameter defines the scanner’s sensitivity for the automatic

format detection. Default value: 40

When scanning dark documents, the value should be reduced in small steps until the

desired result is achieved.

In general: The higher the numeric value, the more contrast there must be between

background and scanned document.

The Use Deskew control activates the automatic deskew function.

If Yes is selected, a slid

er is displayed which

allows to set the maximum corrected angle.

Picture 51: Set deskew angle

The desired

value can be entered as a numeric value or by clicking on the slider and

moving it to the desired value.

If a numeric value us entered, confirm the input with the ENTER key or the TAB key on

the PC keyboard.

Page 60 Manual

Page 61

B.2.3 The Camera Screen

Picture 52: Camera screen

The Resolution field allows the operator to set the desired resolution in two ways.

Selecting the resolution: Click the selection arrow beside the right field. Select the

desired value from the list.

Entering the resolution: Enter any value between 150 dpi and 1200 dpi into the left

field. Confirm the input with the ENTER key or the TAB key on

the PC keyboard.

If the entered resolution differs from the values offered in the

list, user defined is displayed in the right field.

The Brightness [%] slider defines the brightness of the resulting image. Lower brightness

values make the image darker.

The Contrast [%] slider defines the contrast of the resulting image. Higher contrast

values show more details. If scanning in binary modes (i.e. Line Art or Photo), the

behavior of the contrast slider changes.

The Image Sharpness slider invokes an advanced algorithm which sharpens the image

according to the local content of a given area.

Manual Page 61

Page 62

The Exposure function sets the threshold value for the black cut function or for the auto

exposure function.

Note: The Exposure function is not displayed in the color modes Binary and Photo.

Picture 53: Exposure control slider

When Black Cut or Auto are selected, an additional slider is displayed.

No

Black Cut

Value range from

0 (zero) to 100.

Auto

Value range from

0 (zero) to 100.

Function disabled.

Sets the thr

eshold for black. All pixel values found in the image below

the selected value are set to black.

Result: The image contrast is improved.

Sets the thr

eshold for black and activates the automatic exposure

control.

These function searches the image for the highest and the lowest pixel

value. The highest pixel value is defined as “white”. Is the lowest pixel

value higher than the threshold it is defined as “black”. Otherwise all

values below the threshold are defined as “black”.

Result: Automatic contrast control and the image contrast is improved.

The Gamma slider does the gamma correction directly inside the camera electronics.

Three typical settings are available through the check boxes directly below the slider.

The Color Gain drop down list changes the gain on a specific channel. This function is

used to eliminate any color shift or tints from the background.

Page 62 Manual

Page 63

B.2.3.1 Threshold Dynamic / Threshold Fixed

Picture 54: Threshold method selector

In the color mode Binary an additional button allows to select between Dynamic and

Fixed threshold.

Dynamic The contrast level in the image varies depending on the content of the

document. This can help to improve fine details in the image.

Note: In the Dynamic mode modify the setting of the contrast slider

carefully because if set to the extremes, unexpected image artifacts

can occur.

Fixed The contrast level is fixed to a specific value.

B.2.3.2 Despeckle

Picture 55: Despeckle function

The Despeckle function is only available in color mode Binary.

This function removes isolated speckles in the image. Its use is recommended if old

documents on crumpled paper or vellum should be scanned.

Manual Page 63

Page 64

B.2.4 The Settings Screen

Picture 56: Settings screen

Language Selector Sets the language of the user interface. Available languages are

English (english), German (deutsch), French (francais), Polish

(polski), and Russian (Cyrillic script).

Note: After selecting the language the user interface changes immediately

to the selected language.

If Russian is selected, all text is displayed in Cyrillic script.

Page 64 Manual

Page 65

Skin Selector

The Skin Selector allows the operator to choose

between different surfaces (skins) for the user interface.

The picture on the left shows the currently available

surfaces. More skins can be designed and integrated by

the user.

Picture 57: Available skins

Tool Tips If activated the user will be informed with short texts about the available

functions in each screen. With the drop down list, the delay time can be

defined. Selecting No Tool Tips switches this function off.

Show Status Window If set to is set to Yes a small window opens where some scan

status information is displayed.

Picture 58: Scan status window

Use IES Opens an additional window where the Image Enhancement System is

displayed in demo mode. The IES allows to modify specific scan

parameters.

Manual Page 65

Page 66

B.2.5 The Format Screen