Page 1

S

S

ett

e

u

u

p

p

a

a

M

M

n

n

d

d

a

a

n

n

A

A

u

u

s

s

s

s

all

a

e

m

e

m

This device is compliant.

bll

b

This device is compliant.

y

y

Page 2

File: WT25_SetupAndAssembly_D5.doc

Page 3

Introduction

Dear Customer,

We congratulate you on the acquisition of this innovative product from Image Access.

We at Image Access are proud of the work we do; it is the result of our extremely high

standards of production and stringent quality control.

With this scanner, Image Access offers an efficient scanner which covers a wide scope

of applications due to its versatility. Its integrated web based user interface makes all

functions available in structured menus.

This manual is designed to lead the user through all necessary assembly and setup

steps after the WideTEK 25 has been delivered.

For this reason, we ask you to read the this manual attentively before starting to work

with the scanner. By doing so, you will avoid errors from the beginning and you will be

able to control all functions from easily.

Please also consider the following points:

Damages to your unit may have occurred during shipping. Please check for

damages immediately after delivery of the unit. Inform your supplier if damage

has occurred.

Read and ensure that you understand the safety notes. They were developed

for your protection and safety as well as to protect the unit.

Regular maintenance conserves the high quality and safety of your

WideTEK 25 scanner during the entire service life.

If you have any further questions, please feel free to contact your local dealer or

Image Access directly. Our staff will be happy to help you.

For your daily work with your new scanner, we wish you success and complete

satisfaction.

Regards

Your Image Access Team

Setup and Assembly Manual Page 3

Page 4

About this Manual

Setup and Assembly Manual

The Setup and Assembly Manual is written for technical staff with some basic

mechanical as well as software skills. Many resellers will offer on-site installation;

therefore, large parts or all of the setup and assembly manual might not be of interest

to the reader. The access level at which the setup and adjustment processes are

performed is called “Power user”. This “Power user” level is password protected from

access by the normal operator.

All information about the normal operation and behavior of this device is found in the

Operation Manual.

All available manuals for this device can be downloaded from our customer service

portal at http://service.imageaccess.de

of these manuals.

This manual is divided into four sections, A to D.

. Be sure to always check for the latest versions

Section A describes the hardware of the device. It includes unpacking and

mechanical installation. These instructions must be followed carefully to

ensure proper functionality, best possible quality and performance of the

device. This device is a precise optical instrument and should be

handled accordingly.

Section B describes the software setup. It includes the optical adjustments

necessary after the setup. The section also describes the installation

procedure for software options.

Section C describes troubleshooting procedures and test scan generation.

Section D shows all technical data and declarations.

2008 – 2010 by Image Access GmbH, Wuppertal, Germany.

Printed in Germany. All rights reserved.

Reproduction in whole or in part in any form or medium without express written permission of

Image Access is prohibited. Scan2Net® is a registered trademark of Image Access. Other

designated brands herein are trademarks of Image Access.

All other trademarks are the property of their respective owners.

Image Access reserves the right to change the described products, the specifications or

documents at any time without prior notice. For the most recent version, always check our web

site www.imageaccess.de

Page 4 Setup and Assembly Manual

or the customer service portal at http://service.imageaccess.de/

Page 5

A

Version History

Version Published in Content/Changes/Supplements

A June 2008 First release.

B July 2008 New order in chapter C.

dditional information concerning removing/assembling the device

cover.

C December 2008 Additional transportation lock at the back. New order in chapter A.

D February 2009 New: Chapter C.2.1. Description of the assembling of the new

hinges.

D3 October 2009 Error codes table reworked, table of warnings and information

additionally inserted.

D5 February 2010 Chapters renumbered. Chapter D.3 Electr. Spec. New value for

stand-by consumption, another power supply is used.

As an ENERGY STAR® Partner, Image Access has determined that this product

meets the ENERGY STAR® guidelines for energy efficiency.

Setup and Assembly Manual Page 5

Page 6

Table of Content

Introduction--------------------------------------------------------------------------3

About this Manual -----------------------------------------------------------------4

Version History ---------------------------------------------------------------------5

A Hardware Setup -------------------------------------------------------------- 11

A.1 Safety Notes........................................................................................................ 11

A.1.1 Marking of Safety Notes 11

A.2 Certification ......................................................................................................... 11

A.3 General Notice .................................................................................................... 11

A.4 Safety Precautions.............................................................................................. 12

A.5 Content on Delivery............................................................................................. 13

A.6 The Transportation Locks.................................................................................... 14

A.6.1 Removing the Transportation Lo cks 14

A.6.2 Inserting the Transportation Locks 15

A.7 Device Location...................................................................................................16

A.8 Maintenance........................................................................................................17

A.8.1 Touchscreen 17

A.8.2 Surfaces 17

A.8.3 Glass plate 17

A.9 Repair..................................................................................................................17

A.10 Connectors on the Back...................................................................................... 18

A.10.1 Connecting to the Network 19

A.10.2 Connecting to the Power Source 19

A.10.3 Powering up the WideTEK 25 20

A.11 WideTEK 25 Touch Panel................................................................................... 20

A.11.1 Starting the WideTEK 25 from Stand-By Mode 20

A.11.2 Turning-off the WideTEK 25 by the Touch Panel 21

A.12 Network IP Address............................................................................................. 22

A.12.1 Adapting the IP address with the Touch Panel 22

A.13 Optical Adjustment.............................................................................................. 24

A.13.1 White Balance 24

A.13.1.1 Helpful information about the white balance adj ustment 24

A.13.1.2 Performing the White Balance Adjustment 25

Page 6 Setup and Assembly Manual

Page 7

Table of Content, part 2

Software Setup --------------------------------------------------------------- 27

B

B.1 Start Screen of the Scan2Net User Interface ......................................................27

B.2 Setup Menu .........................................................................................................28

B.2.1 Selecting the Login Level 28

B.3 Poweruser Login Level........................................................................................29

B.3.1 Setting the Network Parameters 30

B.3.2 Adjust Time & Date 31

B.3.3 Sound Control 32

B.3.3.1 Set Volume 33

B.3.3.2 Wave Files 34

B.3.3.3 Link Events 35

B.3.4 Firmware Update 36

B.3.5 Install ICC Profiles 38

B.3.6 Install Option 40

C Maintenance, Tests and Troubleshooting--------------------------- 41

C.1 Separating Device Cover from Device Body .......................................................41

C.2 Assembling the Device Cover to the Device Body ..............................................45

C.2.1 Assembling the Glass Plate Cover 46

C.3 Cleaning the WideTEK 25 Scanner.....................................................................47

C.3.1 Cleaning the Outside of the Glass Plate 47

C.3.2 Cleaning the Inside of the Glass Plate 47

C.4 Scan Test Targets...............................................................................................48

C.4.1 Scan CSTT Test Target 48

C.4.2 Scan IT8 Test Target 49

C.5 Network Analyzer.................................................................................................50

C.6 Recovery Function...............................................................................................52

C.6.1 Important Notes Before Recovering to Factory Defaults 52

C.6.2 How to Recover to Factory Defaults 53

C.7 Troubleshooting Matrix........................................................................................55

C.8 Error Codes and Warnings..................................................................................56

C.8.1 Error Codes 56

C.8.2 Warnings 58

C.8.3 Information 58

Setup and Assembly Manual Page 7

Page 8

Table of Content, part 3

Technical Data---------------------------------------------------------------- 59

D

D.1 Scanner Specifications........................................................................................ 59

D.2 Ambient Conditions............................................................................................. 59

D.3 Electrical Specifications....................................................................................... 60

D.4 Dimensions and Weight...................................................................................... 60

D.5 CE Declaration of Conformity.............................................................................. 61

D.6 FCC Declaration of Conformity ........................................................................... 62

D.7 Mandatory Optical Adjustments ......................Fehler! Textmarke nicht definiert.

D.7.1 White Balance Fehler! Textmarke nicht definiert.

D.7.2 Brightness Correction Fehler! Textmarke nicht definiert.

D.8 Options and Settings.......................................Fehler! Textmarke nicht definiert.

Page 8 Setup and Assembly Manual

Page 9

Table of Pictures

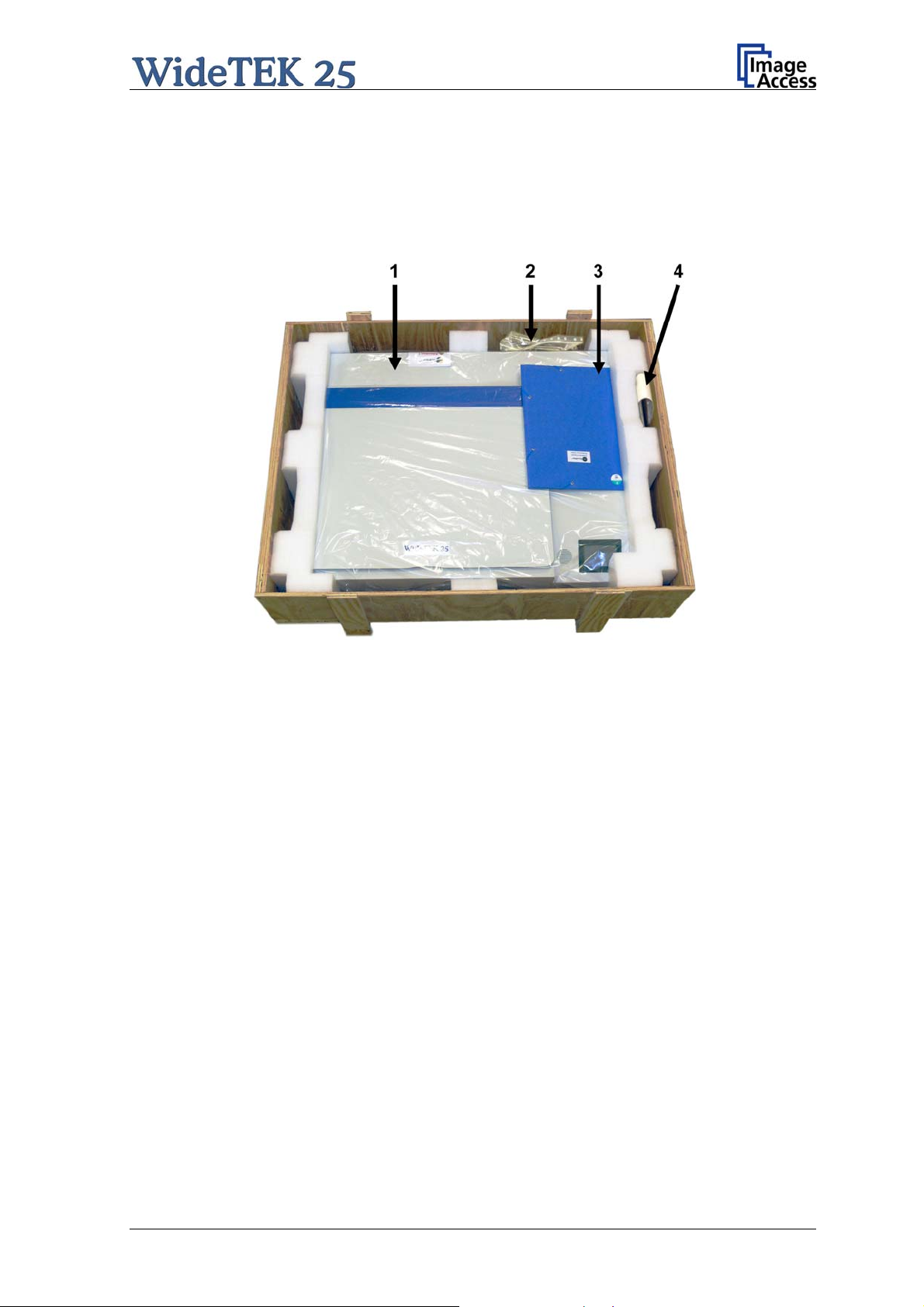

Picture 1: Scanner WideTEK 25 in transport box..............................................................13

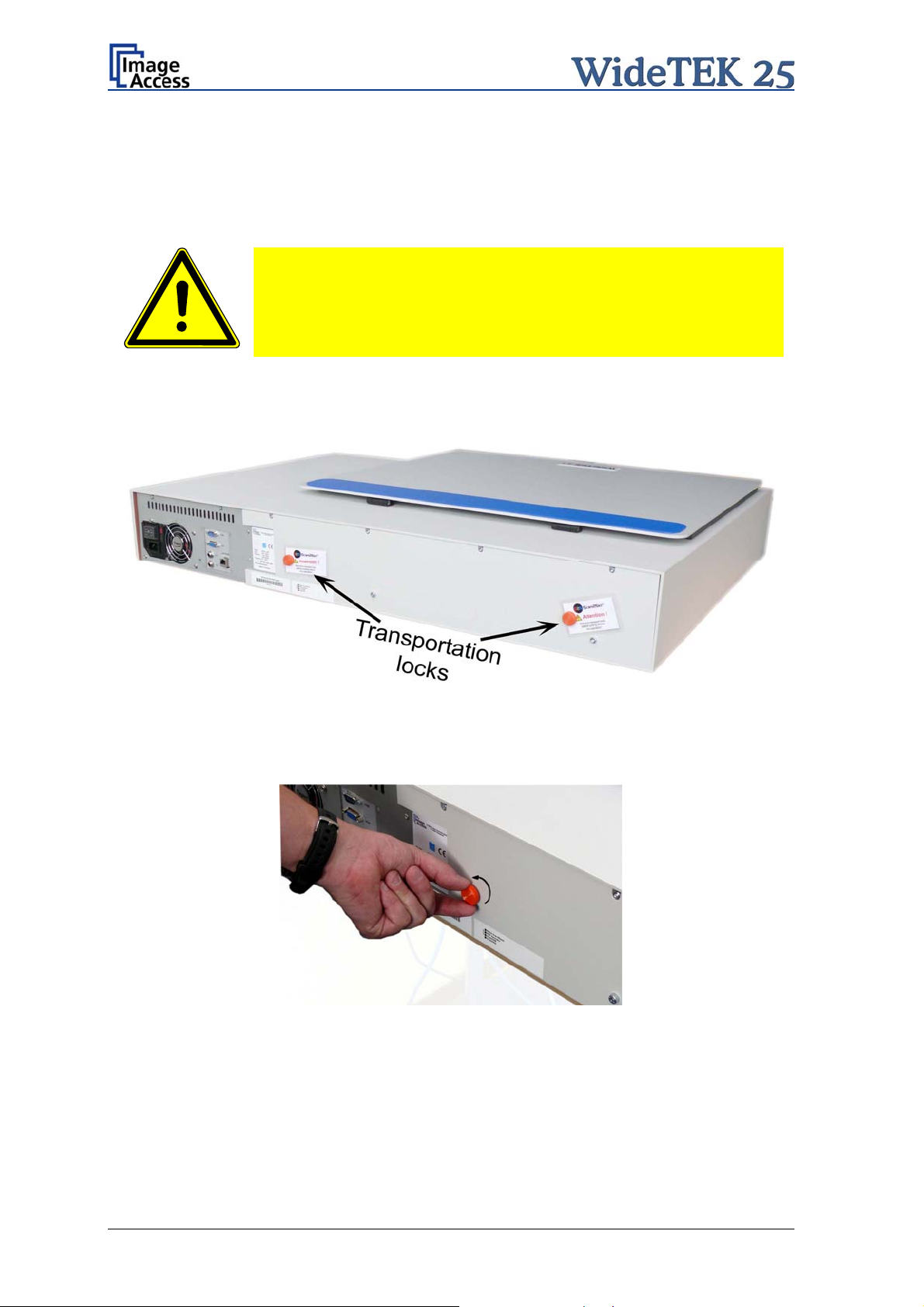

Picture 2: Position of transportation locks..........................................................................14

Picture 3: Removing the transportation lock......................................................................14

Picture 4: Inserting the transportation lock ........................................................................15

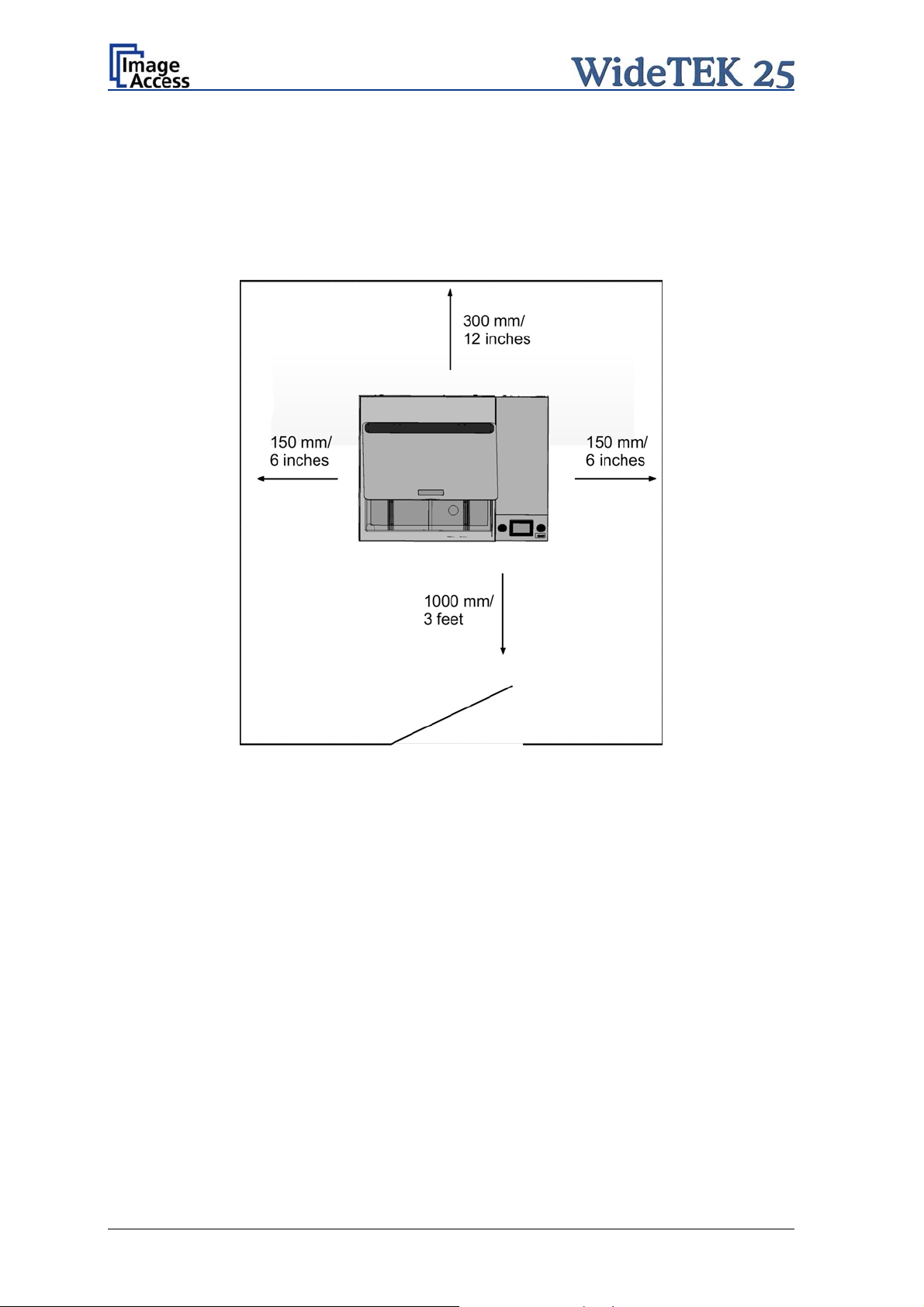

Picture 5: Minimum distances............................................................................................16

Picture 6: Back of WideTEK 25 .........................................................................................18

Picture 7: Connectors on the WideTEK 25........................................................................18

Picture 8: Start menu screen.............................................................................................20

Picture 9: Touch panel while shut down in progress .........................................................21

Picture 10: Menu Self Test 1 .............................................................................................22

Picture 11: Network parameters........................................................................................ 23

Picture 12: Numerical keyboard.........................................................................................23

Picture 13: Confirm changes .............................................................................................23

Picture 14: White Balance screen......................................................................................25

Picture 15: Test target placed on scanner.........................................................................25

Picture 16: Progress indicator............................................................................................26

Picture 17: White balance result........................................................................................26

Picture 18: Start screen.....................................................................................................27

Picture 19: Login level screen............................................................................................28

Picture 20: Poweruser main menu.....................................................................................29

Picture 21: Network parameters of the scanner ................................................................30

Picture 24: Selecting Brightness Correction Value.......Fehler! Textmarke nicht definiert.

Picture 25: Adjust Time and Date Screen..........................................................................31

Picture 26: Sound System screen .....................................................................................32

Picture 27: Link Sounds to Events screen.........................................................................35

Picture 28: Firmware Update.............................................................................................36

Picture 29: Summary of successful firmware update.........................................................37

Picture 30: Install Option screen........................................................................................40

Picture 31: Select ICC Profile............................................................................................38

Picture 32: Upload ICC Profile...........................................................................................39

Picture 33: Arrows point on the hinges to be removed......................................................41

Picture 34: Hexagon head screws to be removed.............................................................41

Setup and Assembly Manual Page 9

Page 10

Table of Pictures, part 2

Picture 35: Lift and pull the device cover...........................................................................42

Picture 36: Arrows mark three of six alignment pins.........................................................42

Picture 37: Lifting the device cover in arrow direction.......................................................43

Picture 38:Separating device cover from device body......................................................43

Picture 39: Disconnecting audio cable..............................................................................44

Picture 40: Disconnecting the signal cable........................................................................44

Picture 41: Lifting the device cover ................................................................................... 45

Picture 42: Device cover in end position...........................................................................45

Picture 43: Setting the damping force of the hinge ........................................................... 46

Picture 44: Position of CSTT test target on the glass plate...............................................48

Picture 45: Position of IT8 test target on the glass plate...................................................49

Picture 46: Network Analyzer screen................................................................................50

Picture 47: IP address for testing......................................................................................51

Picture 48: Network Analyzer test result ........................................................................... 51

Picture 49: Recovery Key..................................................................................................52

Picture 50: Connectors on the WideTEK 25......................................................................53

Page 10 Setup and Assembly Manual

Page 11

A Hardware Setup

A.1 Safety Notes

Read and ensure that you understand the safety notes.

They are designed for your protection and for your safety.

Follow all safety notes to avoid damage to the device.

A.1.1 Marking of Safety Notes

All safety notes are marked with a yellow triangle warning sign.

Next to the warning sign, you’ll find a description of the danger.

Safety Note!

A.2 Certification

The WideTEK 25 scanner fulfills all requirements of the following standards:

IEC 60950, International Safety Standard for Information Technology Equipment

and

UL 60950, Safety of Information Technology Equipment (US and Canadian standard).

A.3 General Notice

This manual describes the functions of a complete equipped WideTEK 25 scanner. If your

device is not equipped with all features, deviations are possible.

Setup and Assembly Manual Page 11

Page 12

A.4 Safety Precautions

Warning: Please read all the safety precautions before you operate the scanner.

Serious injury can occur to you or to others if you do not know how to use it

safely. Please follow the safety precautions in this manual exactly.

To prevent fire or shock hazard, do not expose this device to rain

or any type of moisture.

Follow all safety precautions to avoid personal injury or damage to the device.

1. Place the scanner in a clean, well-ventilated room. Do not operate the scanner in an

area with poor ventilation.

2. Openings in the scanner’s housing in the front or at the back are provided for air

circulation. Do not cover or block the openings.

3. Do not place the scanner near a heat or cold emitting source such as a space heater,

furnace, or air conditioning unit.

4. Do not place the scanner near any devices or electrical boxes emitting high voltage.

5. Always place the scanner on a stable surface.

6. Do not lean on the scanner.

7. Do not place cups containing liquids or other such objects on top of the scanner or on

the scanner table. If liquid spills into the scanner it can cause damage. If this occurs,

turn the scanner off, unplug the power cord from the wall receptacle and contact the

Image Access Technical Support.

8. Do not put any objects into any scanner housing openings unless specifically

instructed to do so by Image Access Technical Support.

9. Do not disassemble the scanner. If there is a need to disassemble the scanner, please

contact the Image Access Technical Support.

10. Do not use the scanner if it has been physically damaged. If this occurs, turn the

scanner off, unplug the power cord from the wall receptacle and contact the

Image Access Technical Support.

11. The scanner should be used only with the power cord that is supplied with the

scanner. If you are unsure, please contact the Image Access Technical Support.

12. Image Access recommends plugging the scanner into an appropriately-rated power

conditioner.

13. Always turn the power off and unplug the power cord from the wall receptacle before

cleaning the scanner.

14. When cleaning, only use Image Access approved cleaners. Do not use any type of

solutions, abrasives, or acids such as acetone, benzene, kerosene, mineral spirits,

ammonia, or nitric acid. Do not use any cleaners that contain these chemicals.

15. Use a dry or damp lint free cloth for cleaning the scanner.

16. Do not spray any liquids directly onto the scanner. Spray cleaning fluids directly onto

the cleaning cloth and use the cloth to clean the scanner.

Page 12 Setup and Assembly Manual

Page 13

A.5 Content on Delivery

The scanner is delivered in a wooden transport box. The transport box also contains two

plastic bags, a folder with reference targets, and the manuals.

Picture 1 shows the transport box including all material which comes with the scanner.

Picture 1: Scanner WideTEK 25 in transport box

1: Scanner WideTEK 25.

2: Plastic bag with “Recovery Key” and cable set. The cable set consist of:

Network cable. Connects the scanner to the network. All network parameters such as

IP address, subnet mask and gateway must be set via the touchscreen prior to the

first use.

Crossover cable. Connects the scanner directly to a computer via the network card.

Power cable. Connects the scanner to the wall outlet

3: Reference folder. It contains:

4x Color Scanner Test Target CSTT-1

4x Line Reference Sheet LRS-200

4: Plastic bag with 3x White Reference Targets WT36-Z-02-A.

Please note: Keep the wooden transport box for future use! In case of guarantee the

scanner must be sent back in the original transport box to avoid transport

damages.

Setup and Assembly Manual Page 13

Page 14

A.6 The Transportation Locks

A.6.1 Removing the Transportation Locks

Attention

The transportation locks have to be removed before initial start-up

of the device!

The transportation locks are located at the back of the scanner. A label marks each

transportation lock.

Picture 2: Position of transportation locks

Turn the transportation locks counterclockwise to remove them.

Picture 3: Removing the transportation lock

Important: Keep the transportation locks for future use!

The transportation locks must be inserted before every transport. This will prevent the

sensitive components inside the camera box unit against damages.

Page 14 Setup and Assembly Manual

Page 15

A.6.2 Inserting the Transportation Locks

Attention

Before transporting insert the transportation locks to prevent the

camera box unit against damages!

Before inserting the transportation locks the camera box unit must be moved into transport

position.

The transport position of the camera box unit is at the back side of the scanner – seen

from the operator’s position.

When the power down sequence ends normally, the camera box unit moves to its

transport position. If the camera box unit is in any other position after switching off, restart

the device as described in chapter A.11.1.

Afterwards turn it off as described in chapter A.11.2. The power down sequence moves

the camera

and switches the device to stand-by mode.

box unit to the transport position, finalizes all internal processes in the scanner

Switch off the WideTEK 25 at the main power switch (see Picture 7).

Picture 4: Inserting the transportation lock

Insert carefully the transportation locks which come with the scanner.

Hand-tighten by turning it clockwise. Using more force could result in damage of the

camera box unit.

Setup and Assembly Manual Page 15

Page 16

A.7 Device Location

Please allow a minimum of 150 mm (6 inches) from any side walls and 300 mm (12

inches) from a back wall. Leave one meter (3 feet) minimum distance from any door or

entrance way. Use the illustration below as a guide.

Picture 5: Minimum distances

Do not operate the scanner in an area that has poor air circulation and/or that is nonventilated.

Place the WideTEK 25 on a flat and solid base. The load bearing capacity of the base

must correspond to the device weight.

Placing the WideTEK 25 on the optional floor stand is recommended for the best

ergonomic position while using the scanner.

Choose a location that complies with the limits of temperature and humidity. Refer to the

technical specification.

Note: Before using the WideTEK 25 scanner in the new environment allow at least one

hour for temperature adaptation.

Temperature adaptation means:

A fast change from cold to warm environmental conditions can build up

condensation inside the housing. This will result in unfavorable scanned images

and could cause permanent damages to the unit.

Page 16 Setup and Assembly Manual

Page 17

A.8 Maintenance

Important: While cleaning the scanner, ensure that no liquids will penetrate into the

device housing.

A.8.1 Touchscreen

The touchscreen can be cleaned with a dry micro fiber cloth. Before cleaning the

touchscreen the WideTEK 25 must be switched off (see chapter A.11.2) and the main

power switch (see Picture 7, item 1) must be set to position 0.

A.8.2 Surfaces

Use a soft, dampened cloth to clean the housing of the scanner. Recommended is a micro

fiber cloth.

A.8.3 Glass plate

Important: Do not use any cleanser with solvents to clean the glass plate!

The glass plate of the WideTEK 25 has a special non-reflective surface coating.

Clean the glass plate with an appropriate glass cleaner and use a soft cloth.

Recommended is a micro fiber cloth.

After cleaning dry the glass plate with a soft cloth.

A.9 Repair

Note: There are not any parts of the WideTEK 25 scanner which can be repaired by

the user.

All repairs should be done only by a trained technician.

Setup and Assembly Manual Page 17

Page 18

A.10 Connectors on the Back

All connectors are positioned at the right side of the back of the housing, seen from the

operator’s view (i.e. from the front of the scanner).

Picture 6: Back of WideTEK 25

Picture 7: Connectors on the WideTEK 25

1. Power connector and main power switch

2. Serial connector

3. VGA connector

4. Two foot pedal connectors

5. Network cable connector

Page 18 Setup and Assembly Manual

Page 19

A.10.1 Connecting to the Network

Insert the network cable (delivered with the scanner) into the network cable connector

(Picture 7, #5). Connect the other side of the cable to a plug-in of an existing network.

Alternatively the scanner can be connected dir

ectly to a computer with network card by

using the crossover cable. In this case ensure that the network addresses used by the

computer and the scanner allow direct connection.

A.10.2 Connecting to the Power Source

Before connecting the scanner to the electrical outlet check the following items:

Ensure the electrical outlet is in perfect condition and that it is

properly grounded.

Ensure that the electrical outlet is equipped with a fuse with the

proper capacity.

The electrical outlet must be near this device and must be easily

accessible.

Inspect the power cable and ensure that it is undamaged.

Use only the power cable delivered with the scanner.

Turn the device off before plugging or unplugging any cable.

Setup and Assembly Manual Page 19

Page 20

A.10.3 Powering up the WideTEK 25

The main power switch is found above the power connector. Picture 7 shows the position

of the power connector and main power switch.

Connect the power cable with the electrical outlet and switch the main power switch to

position I. When the main power switch is in position I, the scanner is in stand-by mode.

NOTE:

While using the WideTEK 25 in work conditions, it should

only be switched on and off by the touch panel!

A.11 WideTEK 25 Touch Panel

The WideTEK 25 parameters can be set and modified with the integrated touch panel. It

shows an easy-to-use menu and helps the user to control all scanner parameters with the

touch of a finger.

When the WideTEK 25 is powered up using the main power switch, the touch panel is

illuminated in a dimmed mode and shows the stand-by screen. The stand-by screen

shows the Image Access logo and the blinking message Touch screen to power up.

A.11.1 Starting the WideTEK 25 from Stand-By Mode

When the WideTEK 25 is in stand-by mode, it can be started by tapping the touch panel

on any arbitrary position. The touch panel lights up and a rotating hourglass indicates that

the start sequence is running.

When the start-up sequence is finished, the touch panel shows the start menu screen.

Picture 8: Start menu screen

Page 20 Setup and Assembly Manual

Page 21

A.11.2 Turning-off the WideTEK 25 by the Touch Panel

NOTE:

Always turn off the WideTEK 25 scanner with the Stop button on

the touch panel!

The main power switch should only be used before the scanner is

disconnected from the electrical outlet.

To turn off the WideTEK 25, press and hold the Stop button on the touch panel.

While the Stop button is held, a counter in the button shows the remaining time until the

WideTEK 25 is powered down.

Picture 9: Touch panel while shut down in progress

At the end of the power down sequence, the display will be dimmed.

Setup and Assembly Manual Page 21

Page 22

A.12 Network IP Address

Controlling the WideTEK 25 scanner is based on the Scan2Net technology.

That means, access to the scanner and to the integrated Scan2Net interface will occur by

using a network connection. Every browser software can be used to work with the

scanner.

The default network IP address of the scanner is 192.168.1.50

This IP address is also valid after using the function “Reset to Factory Defaults”.

To adapt the scanner to an existing network, the IP address and other network

parameters can be modified by using the touch panel as well as the Scan2Net interface.

The following chapter will describe how the IP address can be modified with the touch

panel. Another chapter, following later, will describe how to modify the IP address by

using the Scan2Net interface.

A.12.1 Adapting the IP address with the Touch Pa nel

When the WideTEK 25 is in stand-by mode, it can be started by tapping the touch panel

on any arbitrary position. The touch panel lights up and a rotating hourglass indicates that

the start sequence is running.

While the start sequence is running, tap on the touch panel at least three times

successively.

At the end of the start sequence the touch panel shows the menu Self Test 1.

Picture 10: Menu Self Test 1

By tapping the fields you can change to the submenus.

Page 22 Setup and Assembly Manual

Page 23

Tap on the field IP Address. The menu in the touch panel changes and shows the

Network setup mask.

Picture 11: Network parameters

Tap on the line to be changed, e.g. the Address line. The touch panel will show the

following:

Picture 12: Numerical keyboard

Enter the values with the displayed numerical key board. The keys < and > will move the

cursor, the key X deletes the character at the current cursor position.

After entering the IP address, tap on

the checkmark symbol finally.

The touch panel display then will change and shows the network parameters.

To save the modified values tap on the field Save.

The display changes again. Tap on Yes to confirm saving of the new values.

Picture 13: Confirm changes

After saving the changes the display returns to the Self Test 1 menu (Picture 10).

Setup and Assembly Manual Page 23

Page 24

A.13 Optical Adjustment

Whenever the device is setup for the first time, moved to a different location, cleaned or

serviced and/or after a software update; some adjustments have to be performed to

guarantee maximum quality and accuracy.

A.13.1 White Balance

The white balance function is the most important function for consistent image quality.

To ensure optimal performance, the WideTEK 25 should be calibrated in regular intervals

to compensate for light degradation, variations in the paper quality of the documents to be

scanned, and other long term effects;

A.13.1.1 Helpful information about the white balance adjustment

The scanner has built-in light sources of known and stable quality consisting of state-ofthe-art white LEDs.

In the first step, the overall sensitivity of the scanner is adjusted in such a way that the

brightest area results in an almost saturated output signal. This assures that the largest

density range possible is used. After this adjustment is done, the uneven light distribution

on the CCD caused by the imbalance of the lamps, the ambient light introduced, the

imperfections of the lens and other factors has to be compensated for.

This measurement results in a correction function which levels the brightness over the

complete scan width.

The quality of the test target is of utmost importance to the result of the white balance.

The test target is on reflective paper which diffuses the light. If the test target has dirt,

wrinkles or anything visible to the human eye on it, the CCD will also see this and will

overcompensate in these areas. Although the internal software has been programmed to

eliminate these imperfections to a certain degree, it still leads to unreliable results if the

target is not of the defined quality.

If the target is of defined quality, the scanner will calibrate successfully. Calibration means

that the “white” of the test target in the given illumination situation produces a “white”

output in the digital domain. Consequently, all scans of white paper having different

properties than the test target results in brightness and possibly color shifts.

Periodically performing the white balance adjustment is recommended to ensure

consistent best scan results.

Page 24 Setup and Assembly Manual

Page 25

A.13.1.2 Performing the White Balance Adjustment

Start the scanner as described in chapter A.11.1.

While the start sequence is running, tap on the touch panel at least three times

successively.

At the end of the start sequence the touch panel shows the menu Self Test 1 (Picture 10).

Tap on the field White Balance to activate the adjustment process.

< Back Returns to the former screen.

> Cont. Starts the measurement.

Abort Stops the measurement and the

display returns to the former

Picture 14: White Balance screen

screen.

Place the white balance test

target WT36-Z-02-A on the

upper margin of the glass

plate.

The test target must cover

the complete width of the

glass plate.

Now tap on > Cont.

Picture 15: Test target placed on scanner

Setup and Assembly Manual Page 25

Page 26

While the white balance adjustment is

running, the touch panel shows a

progress indicator.

Picture 16: Progress indicator

At the end of the measurement the

result will be displayed in the touch

panel.

Tap on the field Finish to return to

the menu Self Test 1.

Picture 17: White balance result

Page 26 Setup and Assembly Manual

Page 27

B Software Setup

Essentially, the scanner is a web server and comes with its own HTML-based user

interface. To access a Scan2Net scanner, any standard web browser can be utilized.

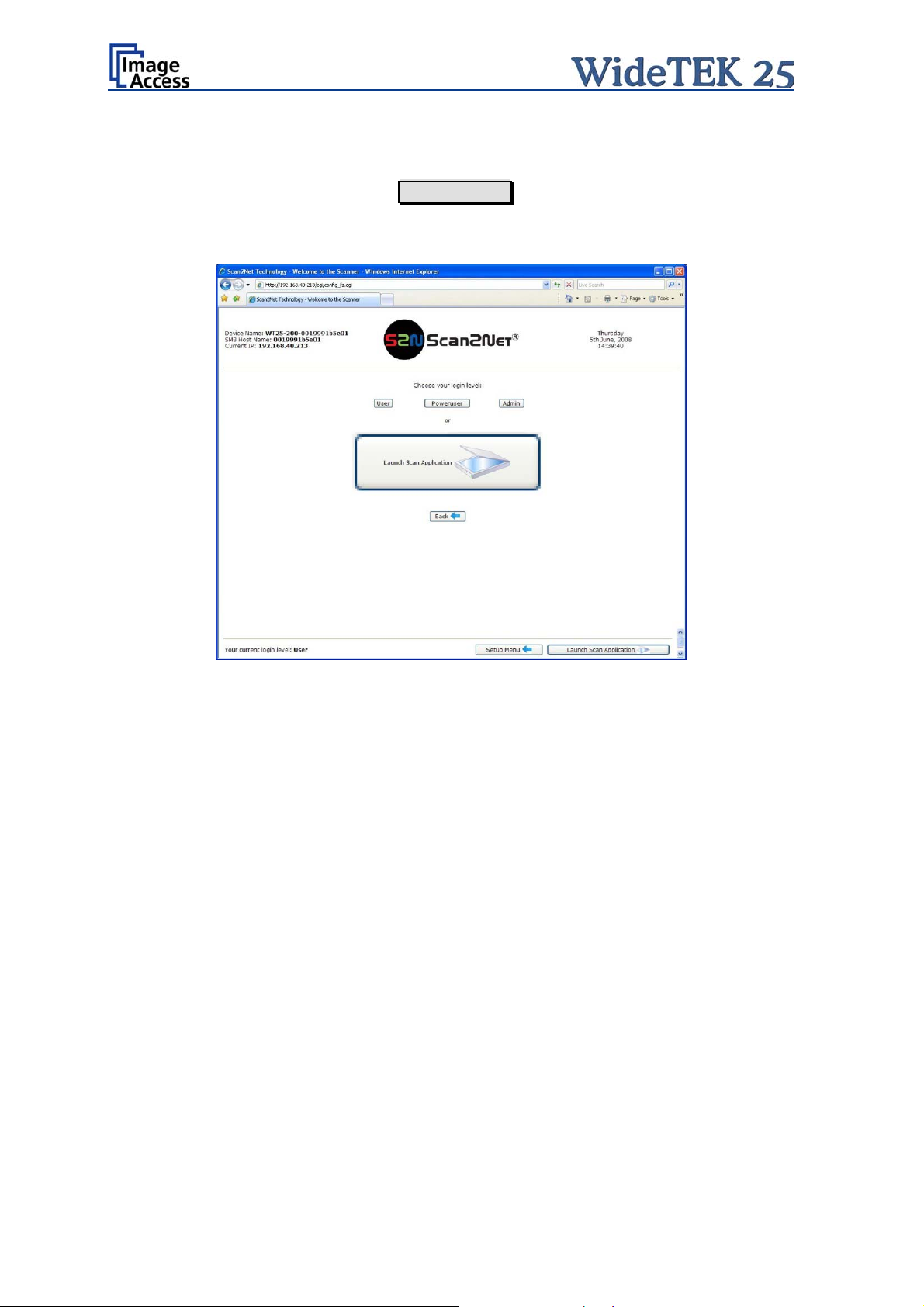

B.1 Start Screen of the Scan2Net User Interface

Start your browser.

Enter the IP address of the scanner. The default IP address of the scanner: 192.168.1.50

The start screen of the integrated user interface will be displayed.

Picture 18: Start screen

The start screen shows three symbols, which lead to the main categories of the Scan2Net

user interface.

Launch Scan Application changes to the main screen of the scanner interface.

Setup Device changes to the setup menu. Start ing with the following chapter, the basics

of the scanner configuration will be described.

Information shows a list of basic information about the scanner, e.g. serial number, the

firmware version, the IP address and many more.

Setup and Assembly Manual Page 27

Page 28

B.2 Setup Menu

Click in the start screen on the button Setup Device .

The next screen shows three buttons to select the login level. The access to the levels

Poweruser and Admin are password protected.

Picture 19: Login level screen

B.2.1 Selecting the Login Level

User This level allows the user to get some status information of the

WideTEK 25 scanner. This are e.g. the firmware version, the remaining

lamp operating time, system information, and many more. Furthermore it

allows to set a few basic parameters.

Poweruser Password protected level. Allows to set an extended range of system

parameters and to execute some adjustments.

Admin Password protected. Allows to set a wide range of system parameters and

to configure the scanner in detail.

Access to the Admin level is limited for trained technicians.

Page 28 Setup and Assembly Manual

Page 29

B.3 Poweruser Login Level

For the following setup steps choose the login level Poweruser .

Default user name and default password for this login level are "Poweruser".

Note: Please consider that both the user name and the password are case-sensitive and

that the first letter of both the user name and password are upper case.

Picture 20: Poweruser main menu

The person having access to this level can change the password and thereby limit access

to normal operators.

The main menu screen for the Poweruser level opens. The main menu is separated in

several sections.

The subsequently described settings broaden the functionality of the scanner or activate

additional functions.

Setup and Assembly Manual Page 29

Page 30

Please notice: The description of the User Settings can be found in the operation

manual, chapter The SetupScreen.

B.3.1 Setting the Network Parameters

Find the section Base Settings and click on the Network Configuration button.

Picture 21: Network parameters of the scanner

Now change the IP address, subnet mask and gateway to a valid address in your network

or select DHCP to obtain an IP address automatically.

After modifying the network parameters click on the Apply button to transfer the new

settings to the scanner. The scanner is now accessible with its new IP address.

Note: Depending on the used browser, it is necessary to delete the cache of the

browser before the scanner is accessible.

Enter the new IP address of the scanner and again open the Poweruser main menu as

previously described.

Page 30 Setup and Assembly Manual

Page 31

B.3.2 Adjust Time & Date

In the Poweruser main menu screen (Picture 20) locate the section Base Settings. Click

on the button Adjust Time & Date .

Picture 22: Adjust Time and Date Screen

Select the time format.

Enter in section NTP Server all parameters for the communication with a NTP server.

Select the time zone and the daylight saving function.

Manually set the time and the date.

Click the button Manually to refresh all above modified data.

Click the button via NTP to connect to the above defined NTP server.

Note: By default, the name of a scanned image contains the scan time and date,

therefore synchronizing the internal clock can be of some value.

Setup and Assembly Manual Page 31

Page 32

B.3.3 Sound Control

Locate the section Base Settings in the Poweruser main menu screen and click the

Sound System button.

Picture 23: Sound System screen

This menu allows to

set the volume,

upload additional sound files to the scanner,

link events to sound files.

Page 32 Setup and Assembly Manual

Page 33

B.3.3.1 Set Volume

Click on the button Set Volume .

Picture 24: Volume level displayed

To set the volume level, click on the desired percentage value in the list left beside the

graphic symbol.

The symbol color changes depending on the selected value.

Up to 30% Up to 60% 70% or higher

Back to Sound Menu returns to the former menu.

Back to Main Menu returns to Poweruser main menu (Picture 20).

Setup and Assembly Manual Page 33

Page 34

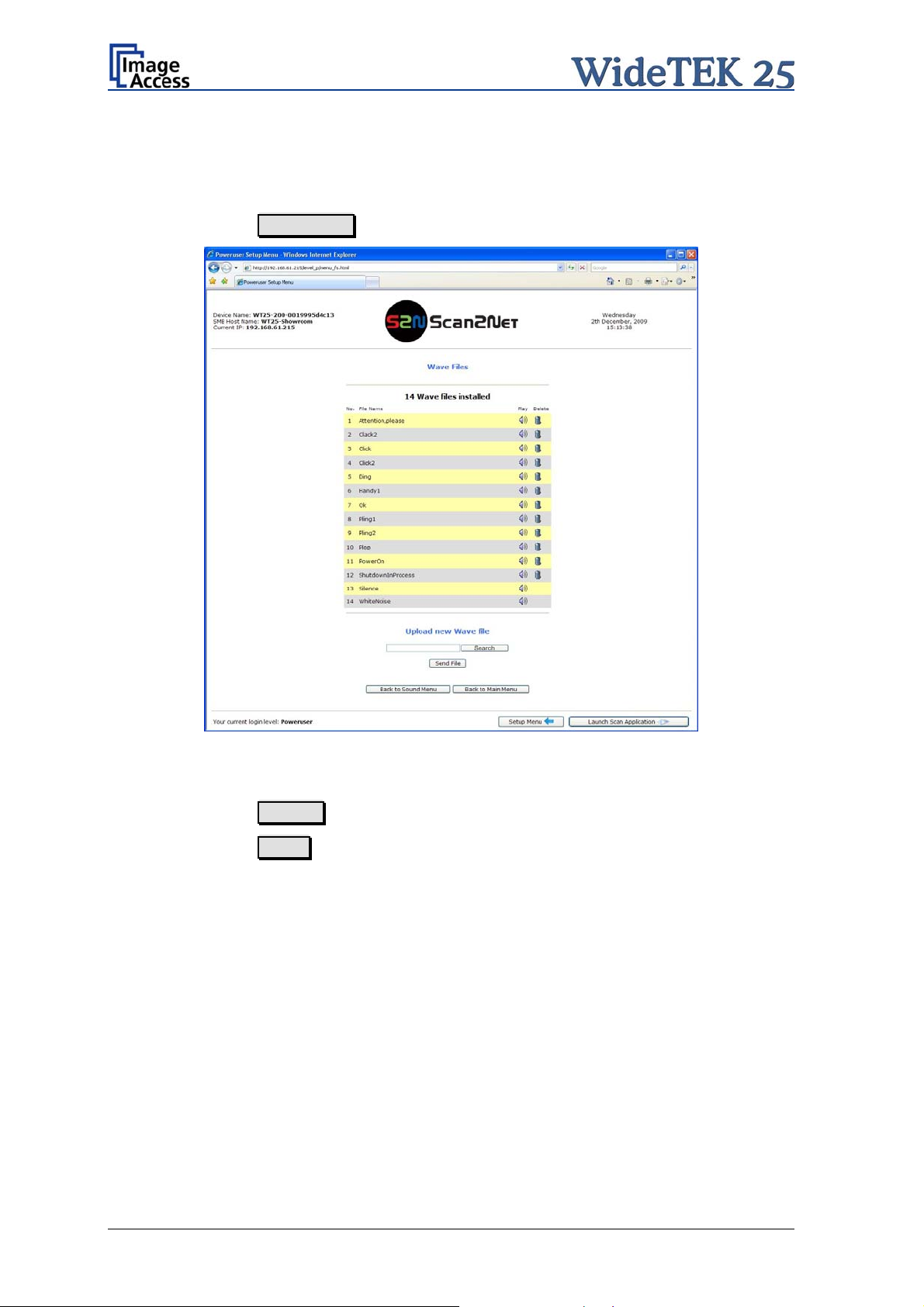

B.3.3.2 Wave Files

Additionally sound files can be uploaded to the already installed sound files. The data

format of the sound files is WAV.

Click on the button Wave Files .

Picture 25: List of sound files

The list of the installed sound files will be displayed.

Click on the button Search to search for the desired WAV sound files.

Click on the button Send to upload the files to the scanner.

Page 34 Setup and Assembly Manual

Page 35

B.3.3.3 Link Events

A sound can be assigned to various action items. This will be played every time the

condition occurs. The default setting can be overwritten.

Click on the button Link Events

Picture 26: Link Sounds to Events screen

The list shows the event and the sound name which is linked to it.

The sound that should replace the current sound can be selected in the next row. Click on

the selection arrow to open the list of available sounds.

The selected sound will be linked to the event by clicking the symbol.

Click on the button Apply to transfer the changes to the scanner.

Back to Sound Menu returns to the former menu.

Back to Main Menu returns to Poweruser main menu (Picture 20).

Setup and Assembly Manual Page 35

Page 36

B.3.4 Firmware Update

The Image Access Customer Service Portal at http://service.imageaccess.de offers

downloads of firmware updates for every Scan2Net scanner. As a registered user, login

with your personal login name and password.

Select Actions S2N Device Updates to download the current firmware version. Enter the

serial number of your scanner and the version number of the firmware installed on the

scanner.

Download the current firmware version to your local PC.

Start the scanner. Select Setup Device and go to the login level Poweruser .

In the main menu screen, locate the section Updates & Uploads and click the

Update Scanner Firmware button.

Browse your local PC and select the previously downloaded firmware update file.

Picture 27: Firmware Update

After the firmware update is complete the scanner must be rebooted to activate the new

firmware.

Select “Reboot” in the line Post update behavior to reboot automatically after the

updating the firmware.

Page 36 Setup and Assembly Manual

Page 37

Click the button Send File to update the scanner’s firmware.

Important: Do not switch off the scanner while executing the firmware update!

The update sequence can last a few minutes. When the update is running, no messages

will be displayed on the screen.

After the firmware is successfully updated, the screen displays a summary.

Picture 28: Summary of successful firmware update

The scanner reboots now with factory default settings.

Setup and Assembly Manual Page 37

Page 38

B.3.5 Install ICC Profiles

Find the section Updates & Uploads in the Poweruser main menu screen and go to

ICC Profiles .

Select either Scanner Profile or Printer Profiles .

Picture 29: Select ICC Profile

The ICC profiles data will be integrated into the image files. ICC profiles match the color

space between scanner and imaging software or the color space between scanner and

printer.

By using ICC profiles scanned images can be reproduced with correct adapted colors.

Page 38 Setup and Assembly Manual

Page 39

Browse for a new ICC profile and select it. It will replace the previous file.

Picture 30: Upload ICC Profile

Setup and Assembly Manual Page 39

Page 40

B.3.6 Install Option

In the main menu screen, locate the section Updates and Uploads and go to

Install Options . All option keys that are displayed in green are valid and installed. A new

key must be entered completely without blanks or spaces followed by the Apply button.

If it does not turn green, the key is invalid or does not belong to this specific scanner or

option.

Picture 31: Install Option screen

Note: Option keys are valid only for one option on a specific scanner denoted by its

serial number.

If a key is accidentally deleted it can always be obtained again at the Image

Access Customer Service portal http://service.imageaccess.de

without

additional costs.

Page 40 Setup and Assembly Manual

Page 41

C Maintenance, Tests and Troubleshooting

C.1 Separating Device Cover from Device Body

Disconnect the power cable before doing any maintenance to the

device.

At first remove the glass plate cover. Two hinges hold the glass plate cover at the device

cover.

Each hinge has three screws which hold it at the device cover. Use a Phillips screwdriver

to remove the two screws on the left and right position. Use an Allen head screw driver,

size 2.5 mm, to remove the screw in the middle position of each hinge.

Note: Use the countersunk Allen head screw only at the middle position of the hinges!

Picture 32: Arrows point on the hinges to be removed

In the next step remove six hexagon head screws at the back side of the device body.

Picture 33: Hexagon head screws to be removed

Setup and Assembly Manual Page 41

Page 42

After the six screws have been removed the device cover must be lifted and pulled a little

at the front side as shown in the picture below.

Picture 34: Lift and pull the device cover

The device cover has six alignment pins on its front side. For easy orientation the position

of the alignment pins are marked in the above picture by the six white crosses.

They are visible when looking from above through the glass plate.

Picture 35: Arrows mark three of six alignment pins

While pulling at the device cover, look through the glass plate and stop pulling when the

alignment pins are out of their boreholes.

Page 42 Setup and Assembly Manual

Page 43

Hold the device cover at the left and right side and lift it up in the arrow direction as shown

in the pictures below.

Picture 36: Lifting the device cover in arrow direction

Picture 37:Separating device cover from device body

Because of the limited cable length it is recommended to place the device cover on the

front part of the device body. A second person should hold the device cover for the

following steps.

Setup and Assembly Manual Page 43

Page 44

Disconnect the audio cable …

Picture 38: Disconnecting audio cable

… and the signal cable.

Picture 39: Disconnecting the signal cable

After both cables are disconnected place the device cover with the glass plate down onto

a flat and stable base.

Page 44 Setup and Assembly Manual

Page 45

C.2 Assembling the Device Cover to the Device Body

The device cover is assembled to the device body in reverse order as described in the

previous chapter C.1.

First connect the audio cable (Picture 38) and the signal cable (Picture 39) to the touch

panel board.

At next slide the device cover onto the device body. Stop shortly before the device cover

comes to the back edge of the device body.

Lift the device body at its back side a little …

Picture 40: Lifting the device cover

…and then slide it carefully into its end position.

Picture 41: Device cover in end position

Watch the alignment pins on the front side. They should slide only a little into their

boreholes.

Setup and Assembly Manual Page 45

Page 46

C.2.1 Assembling the Glass Plate Cover

The glass plate cover has two adjustable hinges. These hinges avoid an undamped

moving of the glass plate cover.

The middle screw allows to set the damping force of the hinge.

Position the hinges of the glass plate cover over the threaded holes. Assemble each hinge

by using two Phillips head screws in the left and right borehole.

Fasten the screws by hand. Do not use an electric tool!

At next insert the countersunk Allen head screws in the middle borehole. Use an Allen

head screw driver, size 2.5 mm, to fasten the screws.

Picture 42: Setting the damping force of the hinge

Fasten the Allen head screws with normal manual strength. Move the glass plate cover

slowly up and down while fastening the Allen head screws.

Intention of this is, that the glass plate cover should move easily, but damped.

Page 46 Setup and Assembly Manual

Page 47

C.3 Cleaning the WideTEK 25 Scanner

Although the WideTEK 25 scanner is constructed with the focus on a minimum of cleaning

requirement, it is needful to clean some parts after a period of using.

C.3.1 Cleaning the Outside of the Glass Plate

It is recommended to clean the outside of the glass plate periodically to ensure constant

good scan results.

To clean the glass plate, lift up the glass cover. Use the microfiber cloth which is delivered

with the WideTEK 25 scanner or a fluff-free cloth.

Note: Because of the coating of the glass plate always use only a few drops of a

mild cleaning fluid with the microfiber cloth.

Moisten the microfiber cloth, then apply a few drops of a mild cleaning fluid and clean the

glass plate without pressing the cloth on it .

Use a soft cotton cloth to dry the glass plate after cleaning.

C.3.2 Cleaning the Inside of the Glass Plate

The inside of the glass plate should be cleaned in larger time periods.

To clean the inside it is necessary to remove the device cover from the device body. See

chapter C.1 for a detailed description of the necessary steps.

To clean th

scanner or a fluff-free cloth.

Note: Because of the coating of the glass plate always use only a few drops of a

Moisten the microfiber cloth, then apply a few drops of a mild cleaning fluid and clean the

glass plate without pressing the cloth on it .

Use a soft cotton cloth to dry the glass plate after cleaning.

e glass plate use the microfiber cloth which is delivered with the WideTEK 25

mild cleaning fluid with the microfiber cloth.

Setup and Assembly Manual Page 47

Page 48

C.4 Scan Test Targets

With the help of this function, the user can scan either a CSTT target or an IT8 target. The

targets are used to analyze specific features of the scanner’s camera and internal

parameters.

Some CSTT test target are delivered with the scanner.

In the Poweruser main menu screen find the section Adjustments & Support. Select

here Scan Test Targets . Another screen opens.

Select here either Scan CSTT Test Target or Scan IT8 Test Target .

C.4.1 Scan CSTT Test Target

When Scan CSTT Test Target is selected, the next screen shows how to position the

target on the document table.

Note: Place the CSTT test target with the printed side on the glass plate.

The picture on the screen shows the target with the printed side up. This is only to help

identifying the test target.

Picture 43: Position of CSTT test target on the glass plate

The test targets will be scanned and the image will be saved to a directory which is

defined by the user. The saved image can be used for support purposes.

Page 48 Setup and Assembly Manual

Page 49

C.4.2 Scan IT8 Test Target

When Scan IT8 Test Target is selected, the next screen shows how to position the

target on the document table.

Note: Place the IT8 test target with the printed side on the glass plate.

The picture on the screen shows the target with the printed side up. This is only to help

identifying the test target.

Picture 44: Position of IT8 test target on the glass plate

The test target will be scanned and the image will be saved to a directory which is defined

by the user. The saved image can be used for support purposes.

Setup and Assembly Manual Page 49

Page 50

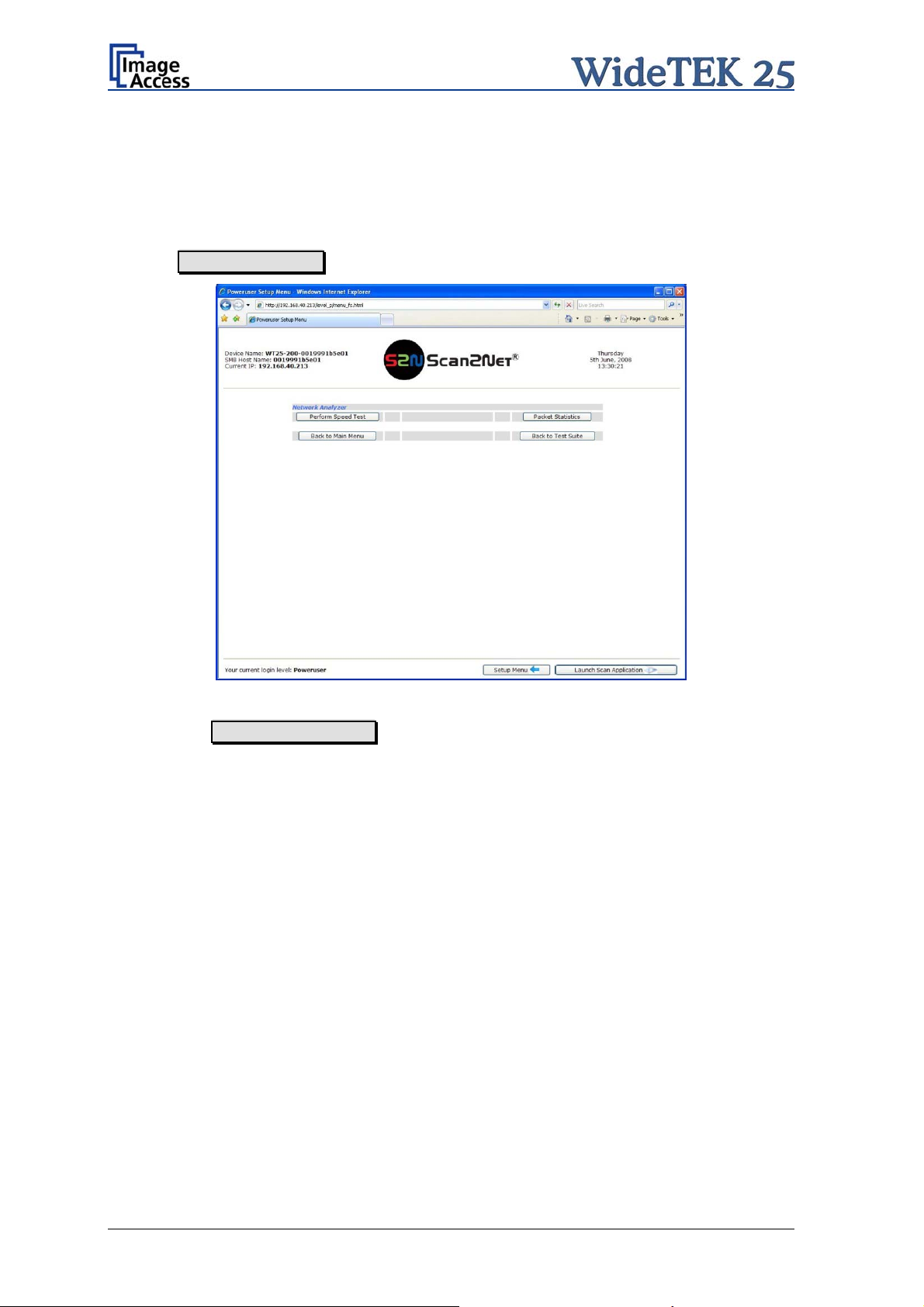

C.5 Network Analyzer

This function provides information about the data transfer speed of the network where the

Scan2Net scanner is installed.

Locate the section Adjustments & Support in the Poweruser main menu screen and

click the Network Analyzer button.

Picture 45: Network Analyzer screen

Click on the Perform Speed Test button and enter the IP address of the device which

should be the target for the test. Also enter the number of packets that should be sent for

testing.

Page 50 Setup and Assembly Manual

Page 51

Click the Perform Test button to start the test.

Picture 46: IP address for testing

The test results will be displayed in a diagram.

Picture 47: Network Analyzer test result

Setup and Assembly Manual Page 51

Page 52

C.6 Recovery Function

The recovery function helps to set all device parameters to factory defaults after a fatal

system breakdown.

The recovery key is necessary to invoke the recovery procedure.

A recovery key is delivered with every device,

it is marked

Picture 48: Recovery Key

Important: The recovery function resets the IP address to the factory default value of

192.168.1.50. It may be necessary to use the crossover cable and change

the network settings on the local computer.

with the label Recovery.

C.6.1 Important Notes Before Recovering to Factory Defaults

The steps described in the following should only be executed after a fatal system

breakdown!

Write down the values for the IP address, subnet mask and gateway of the device before

starting the recovery sequence.

After recovering to the factory default values, a firmware update has to be executed!

Make sure an update file is available on the local computer.

After recovering to the factory defaults, all adjustment procedures described in the

previous sections have to be executed again!

Page 52 Setup and Assembly Manual

Page 53

C.6.2 How to Recover to Factory Defaults

1. Power the device down with the stop button.

1. Power connector

and main power

switch

2. Serial

connector

3. VGA connector

4. Two foot pedal

connectors

5. Network cable

connector

Picture 49: Connectors on the WideTEK 25

2. Plug the recovery key into the serial connector (detail 2 in the above picture) at the

connectors panel.

3. Power the device up via the start button.

The device will start and, after it has found the recovery key to be present in the serial

port, it will automatically execute the recovery sequence. All viable system data will be

restored and necessary repair steps will be taken without the need of any user interaction.

Note: The recovery sequence can last some minutes. While the recovery sequence

is running, no message will be displayed.

4. When the recovery sequence has finished, the device will power down automatically.

Important: Do not switch off the device at any time during the recovery procedure!

5. Unplug the recovery key after the device has powered down.

6. Power up the device and launch the scan application in your browser.

The IP address of the device will have the factory default value: 192.168.1.50

Setup and Assembly Manual Page 53

Page 54

7. Change the network parameters to the values which were used before running the

recovery sequence.

Select Setup Device Poweruser . Locate the section S2N Base Settings and

click the button Network . Enter the values for IP address, subnet mask, and default

gateway.

Click the Apply button. Confirm the following message by clicking the OK button.

In the next screen, click the Reboot button.

Reconnect to the device using the new IP address.

8. Select Setup Device Poweruser . Locate the section Updates & Uploads and

click the button Update Firmware . Perform a firmware update.

9. After the firmware update, all software adjustments for the device must be performed.

Select Setup Device Poweruser . Locate the section Adjustments & Support

and click the button Adjustments . Perform the adjustments by clicking the

appropriate buttons.

Page 54 Setup and Assembly Manual

Page 55

C.7 Troubleshooting Matrix

Fields with a light blue background need the power user access level. All other fields are

available to all users.

Problem Possible cause Action

The touch screen does not

show the stand-by message.

Touching the touch screen

does not power up the

device.

Touching the STOP button

on the touch screen does

not power down the device.

Image is darker than

expected.

Image is brighter than

expected.

Image has horizontal stripes

or streaks.

No power Check main outlet, power cord, power-

on switch on the left side of the device.

Connector failure, software

glitch …

Internal software hangs,

application hangs …

The target used for white

balance is much brighter

than the scanning target.

The document is much

brighter than the target

used for white balance.

Improper white balance.

Switch power off for at least 10

seconds. Retry after touch screen is

illuminated again.

End all applications and retry. If

problem persists, touch the STOP

button for at least 10 seconds. Power

up again.

Go to the Adjustments function and

modify the Brightness Correction

setting.

Go to the Adjustments function and

modify the Brightness Correction

setting.

Exercise the White Balance

procedure.

Image shows a color shift

towards red (tint)

Image shows a color shift

towards blue (tint)

Image shows a color shift

towards red (tint)

The target used for white

balance is more blue than

the scanning target.

The target used for white

balance is more red than

the scanning target.

The scanner receives

significant amounts of

infrared light (sun or spot

lights) not visible to the

human eye.

Go to the RGB adjustments and lower

the gain on red.

Go to the RGB adjustments and lower

the gain on blue.

Change position, close blinds, dim or

shut off any bright spotlights.

Setup and Assembly Manual Page 55

Page 56

C.8 Error Codes and Warnings

The scanner does report error conditions on the display and through the API. Some errors

are only sent to the API.

A green problem description signals that operation of the scanner is still possible although

the error will have an influence on the behavior or quality of the scanner.

A problem description in red marks an errors which will stop the scanner and inhibits

further scanning.

C.8.1 Error Codes

Error # Error message shown in

the display

1 Scanner in use. An attempt to access the scanner

2 Invalid session ID. An attempt to access the scanner

4 Invalid password The stop button was pressed during

5 E05 S2N BOARD S2N board failure The S2N board is either not found or

7 USER BREAK Stop button pressed. The stop button was pressed during

8 User timeout The function ended because of a

9 Warming up The device is still warming up and

10 Invalid setting value. T he value sent to the device is

11 Setting does not exist. The settings does not exist.

12 Invalid user docsize. The size of the user format is invalid.

14 Invalid resolution or color

20 E20 MOTOR 1 (O)

SCAN DRIVE

21 Error 21 Motor 1:

Transport locked

Error message sent to

application

mode.

Motor 1 (Scan

switch permanently open.

Motor 1 / PCI 1 (Box driv

Transport locked

drive): End

Problem description

was made from a different

application.

with an invalid session ID was made.

the operation.

found defective. Make sure board is

sitting correctly on the motherboard.

the operation.

time out

cannot be used.

invalid.

Either the resolution or the color

mode is invalid.

The home position switch is

permanently open. The mechanics of

the corresponding motor could be

blocked or the switch/cable is

defective.

e):

Page 56 Setup and Assembly Manual

Page 57

Error codes, part 2

Error # Error message shown in

the display

30 File format not supported. The specified file format is not

31 Preview not possible The application specified an invalid

32 Invalid color conversion The application changed the color

33 No image available The application attempted to get an

55 E55 WRONG S2N HW

CCD PORTS

56 E56 WRONG S2N HW

REVISION NOT OK

56 Error 56: S2N Board: wrong

revision

60 Error 60: General camera

error

61 Error 61:

Camera 1 failed

62 Error 62:

Camera 2 failed

Error message sent to

application

rong S2N board detected

W

(not enough CCD ports)

rong S2N Board detected

W

(Revision not OK)

Wrong S2N Board detected

(Revision not OK)

General camera error.

Camera 1

Camera 2 failed.

failed Initializing of camera 1 failed. Check

Problem description

supported or it is invalid in

combination with the color mode.

preview scale. Not all scale factors

are allowed with all image sizes.

depth between scanning and image

transfer and a conversion between

these modes is not possible.

Example: scan in binary, then

changed color mode to truecolor.

image from the scanner and there

was no scan since the device was

turned on.

The S2N board found is not the right

one for this device. Error can occur

after a repair/exchange. Exchange

with correct board.

The S2N board found is not the right

one for this device. Error can occur

after a repair/exchange. Exchange

with correct board.

The S2N board found is not the right

one for this device. Error can occur

after a repair/exchange. Exchange

with correct board.

General error on the CCD camera

board. Check power, cables and

S2N-PCI board.

power, cables and S2N-PCI board.

Initializing of camera 2 failed. Check

power, cables and S2N-PCI board.

65 Error 65:

Camera 1 data bus error

66 Error 66:

Camera 2 data bus error

69 Error 69:

ADC error camera 1

Camera 1 data bus error. Test data transfer to camera failed.

Check cables / connectors to camera

1 and S2N-PCI board.

Camera

Camera 1 adc error. Test data transfer through analog

2 data bus error. Test data transfer to camera failed.

Check cables / connectors to camera

2 and S2N-PCI board.

digital converter failed. Check cables

/ connectors to camera 1.

Setup and Assembly Manual Page 57

Page 58

Error codes, part 3

Error # Error message shown in

the display

Error message sent to

application

Problem description

70 Error 70:

ADC error camera 2

75 General keyboard error General keyboard error. Check

80 E80 BAD LAMP CONFIG Bad lamp config

81 E81 BAD DEVICE CONFIG Bad device configuration

99 Internal error. The firmware has detected an

Camera 2 adc error.

Test data transfer through analog

digital converter failed. Check cables

/ connectors to camera 2.

keyboard and cables.

internal error of unknown cause.

C.8.2 Warnings

Warning # Warning shown in the

display

144 Light level is low

145 Camera adjustment required Camera adjustment required

160 W160 NO WHITE BALANCE

DATA

Warning sent to

Problem description

application

No white balance data No white balance data was found.

The light level is found to be low

during the white balance function.

Perform white balance.

C.8.3 Information

Info. # Information shown in the

display

200 CREATING

RECOVERY PART..

Information sent to

Description

application

Creating Recovery Partition While creating the recovery partition,

the scanner can not be accessed.

Page 58 Setup and Assembly Manual

Page 59

D Technical Data

D.1 Scanner Specifications

Optical System

Maximum Document Size 25 x 17,7 inch / 635 x 420 mm

Optical Resolution 1200 x 600 dpi

Sensor Type:

Two tricolor CCDs, e

proof

ncapsulated and dust-

Sensor Resolution: 45.600 pixels (2x 22.800)

Scan Modes:

Illumination:

Light Source: Two lamps with white LEDs

Warm-up Time: None

Temperature Dependence: None

UV / IR Emission None

Lifetime 50.000 hours scanning time

12bit grayscale (internal

36bit color (internal resolution)

1bit Black/W

8bit Grayscale

24bit Color,

hite

8bit indexed

resolution)

D.2 Ambient Conditions

Operating Temperature +5 to +40° Celsius

Storage Temperature 0 to +60 °Celsius

Relative Humidity 20 to 80% (non-condensing)

Noise Level 48 - 53 dB(A) (Operating)

33 dB(A) (Stand-by)

Setup and Assembly Manual Page 59

Page 60

D.3 Electrical Specifications

This device is Energy Star compliant.

Voltage 100–240V AC

Frequency 50/60 Hz

Power Consumption

Stand-by 0.1 W

Start Procedure 90 W

Ready to scan, lamps off 70 W

Scanning 105 W

D.4 Dimensions and Weight

Scanner outer dimensions 160 x 1026 x 782 mm (H x W x D)

6,3 x 40,3 x 30,8 inch

Weight of Scanner 41 kg

Weight of Transport Box 35 kg

Dimensions of fully packed Transport Box

Total shipping weight 76 kg

400 x 1200 x 960 mm (H x W x D)

15,75 x 47,25 x 37,8 inch

Page 60 Setup and Assembly Manual

Page 61

D.5 CE Declaration of Conformity

The undersigned, representing the manufacturer:

Image Access GmbH

Hatzfelder Strasse 161 – 163

42281 Wuppertal, German

herewith declares that the

Product: WideTEK 25 Scanner

Model Designation: WT25 –XXX

(XXX represents the device version number and configuration details)

Serial number: All

is in conformity with the following European standards and IEC directives:

EMC Directive 2004/108/EEC as per:

EN 55022:1998 + A1: 2000 + A2:2003

EN 61000-3-2:2000 + A2:2005

y

EN 61000-3-3:1995 + A1:2001

EN 55024:1998 + A1:2001 + A2:2003

FCC 47 CFR Ch.1 Part 15

Safety:

Low Voltage Directive (Safety) 2006/95/EEC as per

IEC 60950-1:2001

EN 60950-1:2001

UL 60950-1

CSA C22.2 No 60950-1-03

Wuppertal, 02.06.2008

Thomas Ingendoh , President and CEO

Setup and Assembly Manual Page 61

Page 62

D.6 FCC Declaration of Conformity

Responsible party:

Image Access GmbH

Hatzfelderstrasse 161 – 163

42281 Wuppertal, Germany

Product: WideTEK 25

Model Designation: WT25 –XXX

(XXX represents the device version number and configuration details)

For unique identification of the product configuration, ple ase submit the 12-digit serial number found on the

product to the manufacturer.

This device complies with Part 15, Class B of the FCC Rules. Operation of this

product is subject to the following two conditions: (1) This device may not cause

harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

Page 62 Setup and Assembly Manual

Page 63

For your notes

Setup and Assembly Manual Page 63

Loading...

Loading...