Page 1

Veerrssiioonn

V

Setup and Assembly Manual

R11

R

This device is compliant.

Page 2

File: BE3-R1-SetupAndAssembly-H.doc

Page 3

Introduction

Dear Customer,

We congratulate you on the acquisition of this innovative product from Image Access.

We at Image Access are proud of the work we do; it is the result of our extremely high

standards of production and stringent quality control.

With the Bookeye® 3, Image Access offers an efficient Planetary Scanner which covers a

wide scope of applications due to its versatility. Its integrated web based user interface

makes all functions available in structured menus.

For this reason, we ask you to read all manuals of the Bookeye® 3 attentively before

starting to work with it. By doing so, you will avoid risks to the user, operation errors and

you can control all functions from the beginning.

In addition please consider the following points:

• Damages to your unit may have occurred during shipping. Please check for

damages immediately after delivery of the unit. Inform your supplier if damage has

occurred.

• Read and ensure that you understand the safety notes. They were developed for

your protection and safety as well as to protect the unit.

• Regular maintenance conserves the high quality and safety of the Bookeye® 3

during the entire service life.

If you have any further questions, please feel free to contact your local dealer or

Image Access directly. Our staff will be happy to help you.

We wish you success and complete satisfaction with your daily work with the

Bookeye® 3.

Regards

Your Image Access Team

Setup and Assembly Manual Page 3

Page 4

About this Manual

Setup and Assembly Manual

This Setup and Assembly Manual has been written for users and technical staff with

some basic mechanical as well as software skills. Many resellers will offer on-site

installation, therefore, some parts of the manual might be of minor interest to the reader.

Nevertheless, Section B and Section C must be carefully read to guarantee maximum

performance and quality of the product.

The access level at which these setup and adjustment processes are performed is called

“Poweruser”. This “Poweruser” level is password protected from access by the normal

operator.

All manuals can be downloaded from our customer service portal at

http://service.imageaccess.de

manuals.

This manual is divided into four sections, A to D.

Section A describes the hardware of the device. It includes unpacking and

mechanical installation. These instructions must be followed carefully to

ensure proper functionality, best possible quality, and performance of the

device. This device is a precise optical instrument and should be handled

accordingly.

. Be sure to always check for the latest versions of these

Section B describes the software setup. It includes the optical adjustments necessary

after the setup. The section also describes the option installation

procedure.

Section C describes troubleshooting procedures and test scan generation.

Section D shows all technical data and necessary declarations.

Printed in Germany. All rights reserved.

Reproduction in whole or in part in any form or medium without express written permission of Image

Access is prohibited.

Scan2Net® is a registered trademark of Image Access. All other designated brands herein are trademarks of Image Access.

All other trademarks are the property of their respective owners.

Image Access reserves the right to change the described products, the specifications or documents at

every time without prior notice. For the most recent version, always check our web site

www.imageaccess.de

© 2008 – 2009 by Image Access GmbH, Wuppertal, Germany.

or the customer service portal at http://service.imageaccess.de

Page 4 Setup and Assembly Manual

Page 5

A

Version History

Version Published in Content/Changes/Supplements

A November 2005 Preliminary version.

Description of the device elements.

Description of assembling steps.

B January 2006 Preliminary version.

Some changes at the body element base. Order of assembling steps

for the camera neck and camera head has been changed.

C February 2006 Preliminary version.

Chapter added: Scan2Net Firmware Adjustment Procedure.

D February 2006 Preliminary version.

Additional information in chapter Final Mechanical Adjustments.

New: Recovery Function

E April 2006 First Final Edition.

General formatting and several technical changes.

F August 2006

G November 2006 Second Edition: Additional information concerning measurement of

H January 2009

Second Edition: Chapter A.1.2 added.

Chassis A and B introduced. Chapter B2 changed.

dditional information concerning adjustment of the lamps, see

chapter A.2.4.1 to A.2.4.4.

Auto Focus, chapter B.2.2. to B.2.2.2. Differentiation between

Chassis A and Chassis B.

New chassis version.

List of assembling material revised.

Additional information in chapter B.2 Mandatory Optical Adjustments

Renew of some screenshots of the user interface because of new

firmware version.

NOTE:

This equipment has been tested and found to comply with the limits for a class A digital device, pursuant to

Part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and radiate radio frequency energy and, if not installed and used in accordance with the operation

manual, may cause harmful interference to radio communications.

Operation of these equipment in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at his own expense.

Setup and Assembly Manual Page 5

Page 6

Table of Contents

A Hardware Setup--------------------------------------------------------------12

A.1 Content on Delivery ................................................................................. 12

A.1.1 Tools and Assembling Material 15

A.1.2 Device Location 16

A.1.2.1 Environment 16

A.1.2.2 Ambient Light 16

A.1.2.3 Scanner Table 17

A.1.2.4 Power outlet 17

A.2 Assembling the Components ................................................................... 18

A.2.1 Assembling the Camera Head to the Neck 18

A.2.2 Assembling Lamps and Camera to the Body Element 21

A.2.3 Assembling the Glass Plate 28

A.2.4 Setting the Initial Lamp Position 33

A.2.4.1 Performing the mechanical adjustment of the lamps 34

A.2.4.2 Saving the lamp positions 37

A.2.4.3 Leaving the initialization mode without saving 37

A.2.4.4 Lamp position control mode 38

Page 6 Setup and Assembly Manual

Page 7

Table of Contents, part 2

B Software Setup--------------------------------------------------------------- 39

B.1 Setup Network IP Address........................................................................39

B.2 Mandatory Optical Adjustments ................................................................42

B.2.1 Scan Start 45

B.2.2 Auto Focus 47

B.2.2.1 Auto Focus Measurement with Glass Plate Opened 48

B.2.2.2 Auto Focus Measurement with Glass Plate Closed 50

B.2.3 Scan Center 52

B.2.4 White Balance 53

B.2.4.1 Some Basic Information 53

B.2.4.2 White Balance with Glass Plate opened 55

B.2.4.3 White Balance with Glass Plate closed 57

B.2.5 Laser Check 58

B.3 Options and Settings ................................................................................60

B.3.1 Time Server 60

B.3.2 Sound Control 61

B.3.3 Firmware Update 62

B.3.4 Install Options 63

B.3.5 Install ICC Profiles 64

Setup and Assembly Manual Page 7

Page 8

Table of Contents, part 3

C Tests and Troubleshooting ---------------------------------------------- 65

C.1 Network Performance Test ...................................................................... 65

C.2 Scan Test Targets.................................................................................... 67

C.2.1 Scan CSTT Test Target 67

C.2.2 Scan IT8 Test Target 68

C.3 Recovery Function................................................................................... 69

C.3.1 Important Notes before recovering to Factory Defaults 69

C.3.2 How to Recover to Factory Defaults 69

C.4 Troubleshooting Matrix ............................................................................ 71

C.5 Error Codes ............................................................................................. 73

D Technical Data---------------------------------------------------------------- 76

D.1 Scanner Specifications ............................................................................ 76

D.2 Ambient Conditions.................................................................................. 76

D.3 Electrical Specifications ........................................................................... 77

D.4 Dimensions and Weight ........................................................................... 78

Page 8 Setup and Assembly Manual

Page 9

Table of Pictures

Picture 1: Transport box ....................................................................................................12

Picture 2: Cardboard separator with lamps and neck........................................................13

Picture 3: Reference folder removed .................................................................................13

Picture 4: Scanner main body and camera head box........................................................14

Picture 5: Camera head in cardboard box ......................................................................... 14

Picture 6: Attaching camera neck to camera head ............................................................18

Picture 7: Check the alignment … .....................................................................................19

Picture 8: ... at both sides ..................................................................................................19

Picture 9: Fastening at position A......................................................................................19

Picture 10: Fastening at position B....................................................................................19

Picture 11: Camera neck assembled at camera head.......................................................20

Picture 12: Placing the cover on the neck .........................................................................20

Picture 13: Cover in final position ......................................................................................20

Picture 14: Fastening the screws.......................................................................................20

Picture 15: Two persons(!) lift the device out of the transport box.....................................21

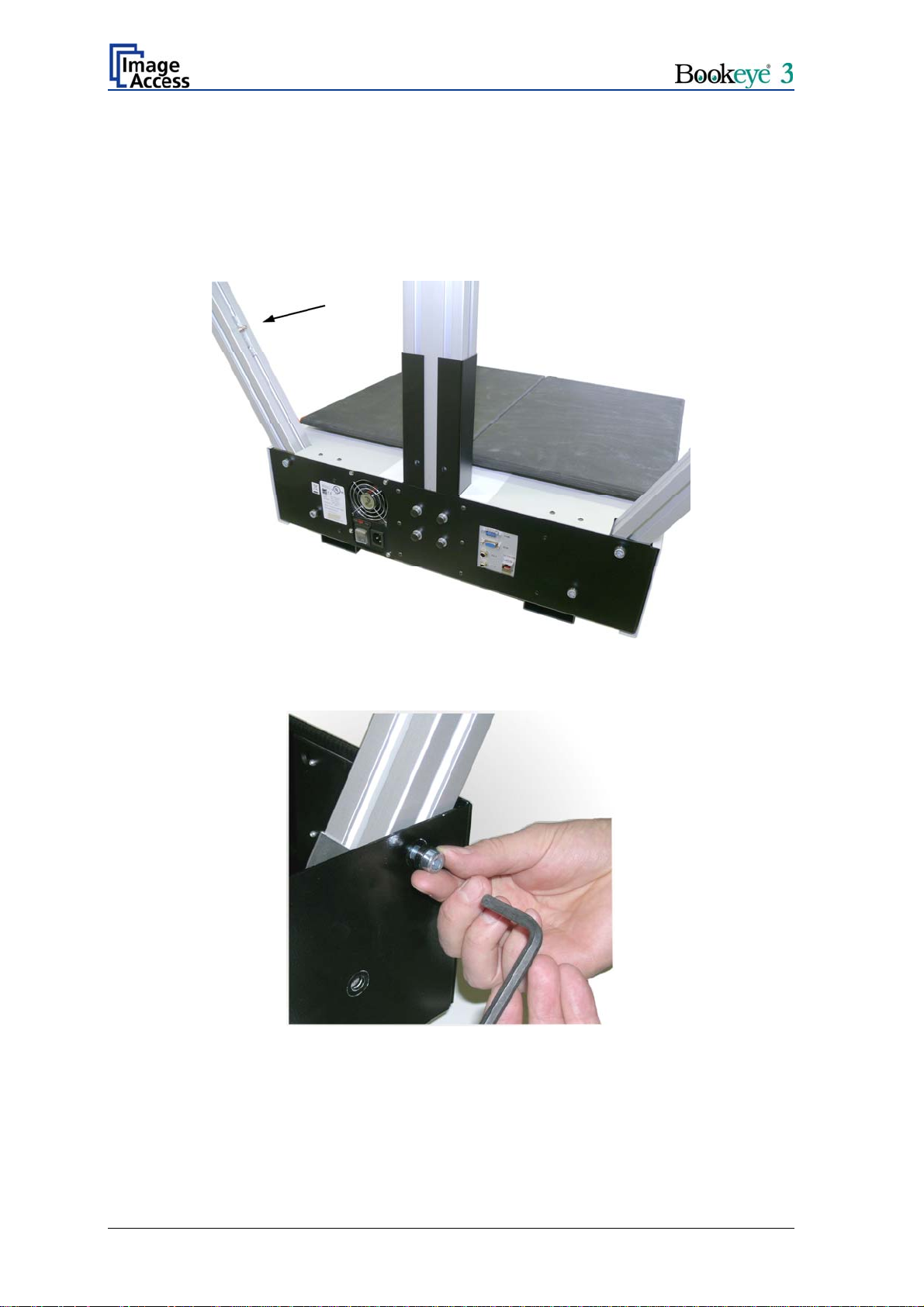

Picture 16: Removing the transport screws .......................................................................22

Picture 17: Removing the countersunk socket screw ........................................................22

Picture 18: Remove marked screws ..................................................................................23

Picture 19: Body element cover opened............................................................................23

Picture 20: Position of gas spring fixture at right lamp.......................................................24

Picture 21: Fixing the lamp ................................................................................................24

Picture 22: Camera neck assembly ................................................................................... 25

Picture 23: Front side.........................................................................................................25

Picture 24: Back side.........................................................................................................25

Picture 25: Connector board with camera neck cables .....................................................26

Picture 26: Connector of flat ribbon cable..........................................................................26

Picture 27: Cable loop .......................................................................................................26

Picture 28: Keyboard cable while moving the body cover .................................................27

Picture 29: Body cover at edge of power supply ...............................................................27

Picture 30: Book cradle controller......................................................................................28

Picture 31: Bearing in the center of the glass plate ...........................................................28

Picture 32: T-slot nut in corresponding position.................................................................29

Picture 33: Hinge mounted at right lamp ...........................................................................29

Picture 34: Position of locking springs ...............................................................................30

Picture 35: Removing the locking spring ...........................................................................30

Picture 36: Gas spring mounted to glass plate..................................................................31

Picture 37: Locking spring inserted....................................................................................31

Picture 38: Locking spring locked ......................................................................................31

Picture 39: Gas spring completely mounted ......................................................................32

Picture 40: Press the keys simultaneously ........................................................................34

Setup and Assembly Manual Page 9

Page 10

Table of Pictures, part 2

Picture 41: Lamps in start position .................................................................................... 35

Picture 42: Up/down key on right side of keyboard ........................................................... 35

Picture 43: Light beam on right side of the book cradle .................................................... 36

Picture 44: Light beam adjusted........................................................................................ 37

Picture 45: Start screen..................................................................................................... 39

Picture 46: Login level screen ........................................................................................... 40

Picture 47: Poweruser Main Menu screen ........................................................................ 40

Picture 48: Network configuration screen.......................................................................... 41

Picture 49: Scan2Net Start screen .................................................................................... 43

Picture 50: Buttons for login levels .................................................................................... 43

Picture 51: Poweruser Main Menu screen ........................................................................ 44

Picture 52: Adjustment & Support screen ......................................................................... 44

Picture 53: Scan Start adjust screen ................................................................................. 45

Picture 54: Scan Start results............................................................................................ 46

Picture 55: Available glass plate positions ........................................................................ 47

Picture 56: Auto Focus measurement with open glass plate ............................................ 48

Picture 57: Auto Focus results .......................................................................................... 49

Picture 58: Information about book cradles position ......................................................... 50

Picture 59: Auto focus measurement screen .................................................................... 51

Picture 60: Scan Center screen ........................................................................................ 52

Picture 61: Brightness Correction Factor screen............................................................... 54

Picture 62: R G B controls................................................................................................. 54

Picture 63: Glass plate positions for white balance........................................................... 55

Picture 64: White Balance screen, glass plate opened ..................................................... 56

Picture 65: White Balance screen, glass plate closed....................................................... 57

Picture 66: Laser Check screen ........................................................................................ 58

Picture 67: Laser check result ........................................................................................... 59

Picture 68: Adjust Time & Date screen ............................................................................. 60

Picture 69: S2N Sound System screen ............................................................................. 61

Picture 70: Link Sounds to Events screen......................................................................... 61

Picture 71: Update Scanner firmware screen.................................................................... 62

Picture 72: Install Option screen .......................................................................................63

Picture 73: ICC Profile screen ........................................................................................... 64

Picture 74: Perform Speed Test screen ............................................................................ 65

Picture 75: Network Analyzer Parameters screen............................................................. 66

Picture 76: Network Analyzer Result screen ..................................................................... 66

Picture 77: Scan Test Target screen................................................................................. 67

Picture 78: CSTT Test Target screen................................................................................ 67

Picture 79: Scan Test Target screen................................................................................. 68

Picture 80: IT8 Test Target screen.................................................................................... 68

Picture 81: Connectors on rear panel................................................................................ 69

Page 10 Setup and Assembly Manual

Page 11

Setup and Assembly Manual Page 11

Page 12

A Hardware Setup

A.1 Content on Delivery

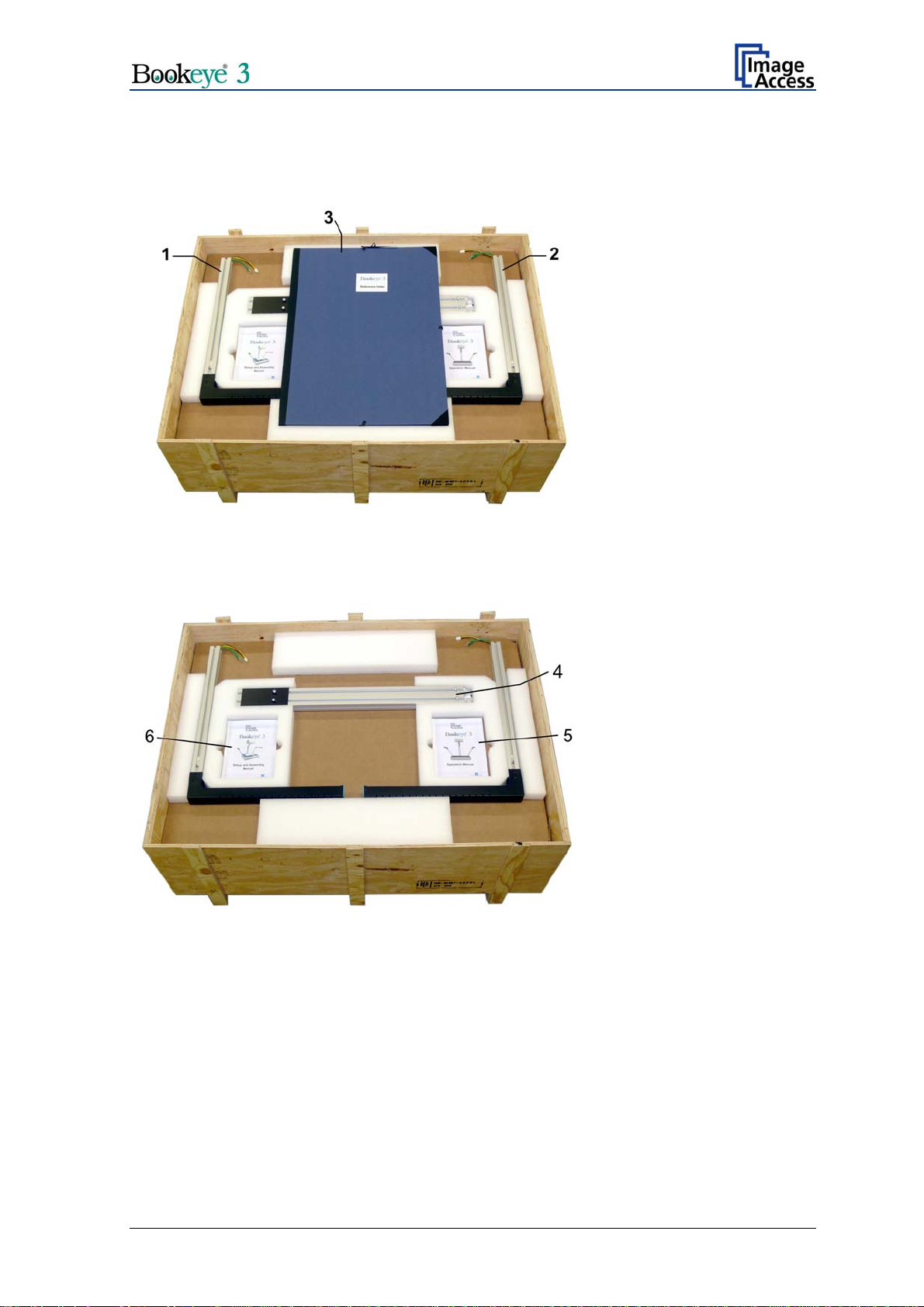

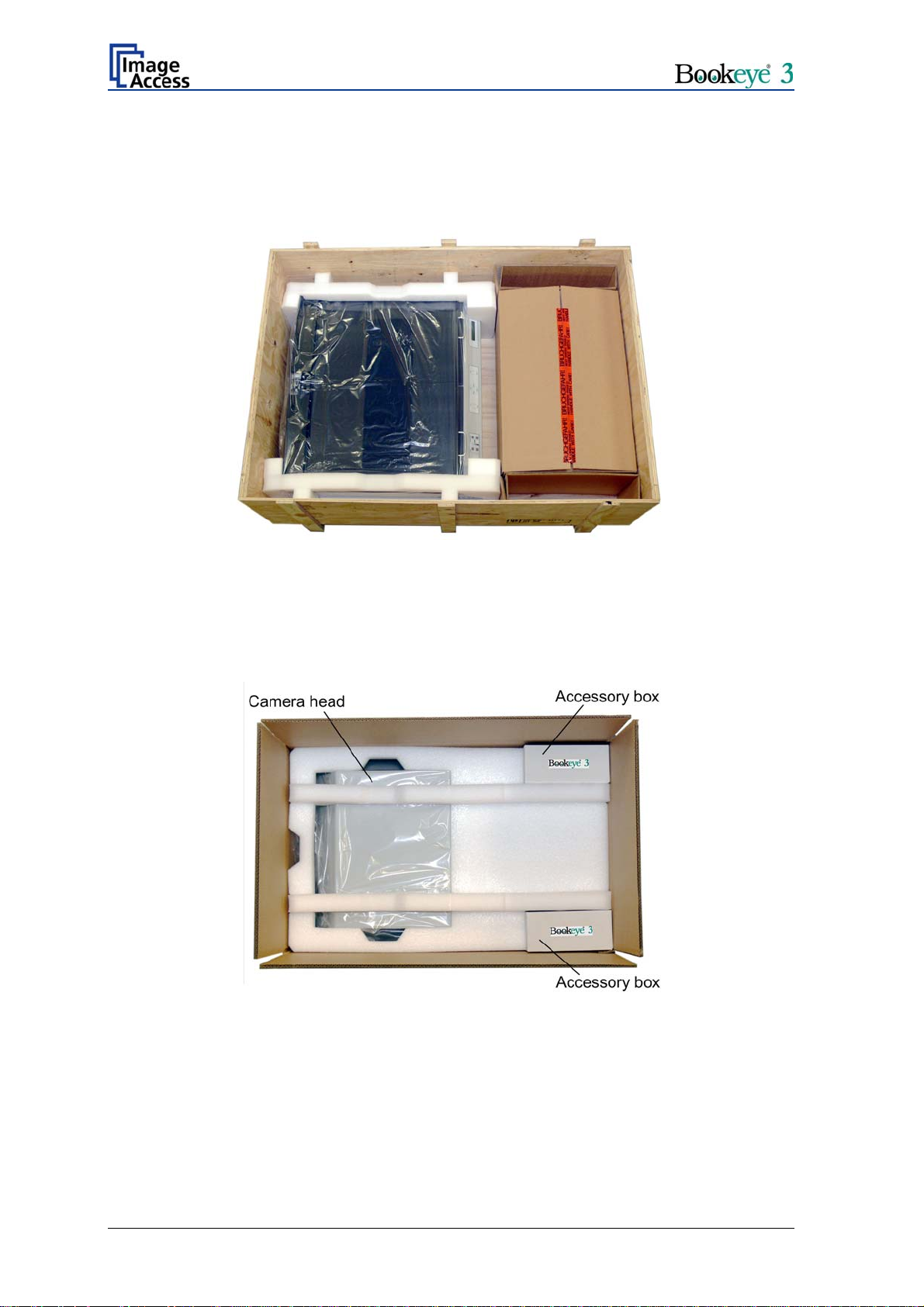

The Bookeye® 3 scanner is delivered in a wooden transport box.

Picture 1: Transport box

The transport box contains all components of the scanner. These are

• the two lamps,

• the camera neck,

• the glass plate,

• a cardboard box containing the camera head and the integrated short part of the

camera neck,

• the accessory boxes and

• the reference folder with some test targets.

Please note: Keep the wooden transport box and the cardboard box for future use!

For warranty returns, the scanner must be sent back in the original

transport box to avoid transport damages.

The crates and the inserts have been designed and tested to withstand all impacts, in

accordance with the internationally recognized test procedure ISTA-1B for packages over

150lbs or 68kg. Details can be found at http://www.ista.org/Testing/Tests.htm

This requires that the packaging instructions are followed precisely. One common mistake

made is that additional parts are put in the side pockets formed between the crate and the

PE- inserts. This space must be free of obstacles in any case; because in the case of an

impact, the inserts will compress to 40% of their original size and the free space will be

used up completely.

.

Page 12 Setup and Assembly Manual

Page 13

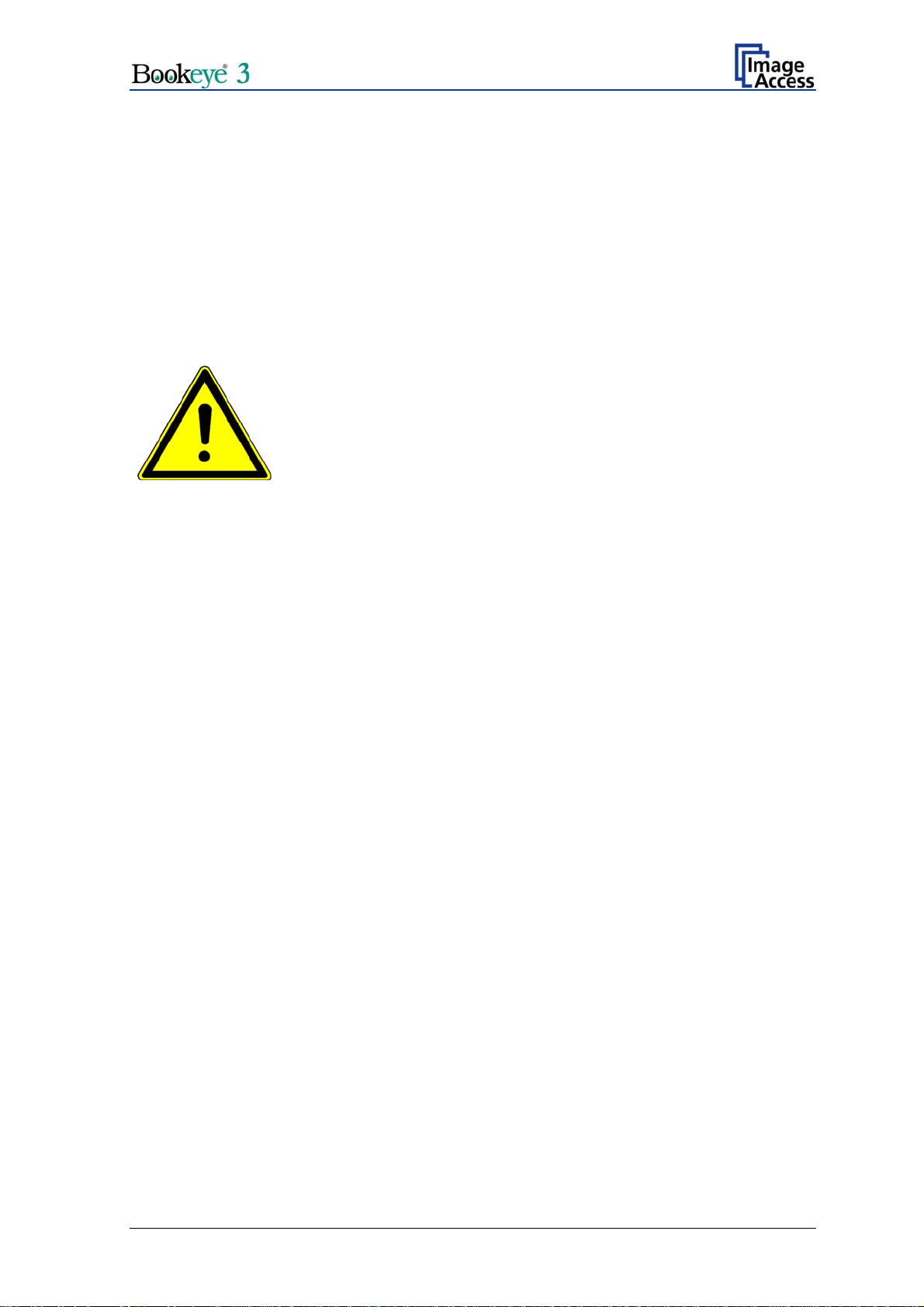

On the cardboard separator are placed two lamps, the reference folder, the camera neck

below the reference folder, and two manuals. All parts are held in position by foam rubber

elements.

Lamps: (1) and (2)

Reference folder: (3)

Picture 2: Cardboard separator with lamps and neck

Picture 3: Reference folder removed

Camera neck: (4)

Manuals: (5) and (6)

Setup and Assembly Manual Page 13

Page 14

Remove the cardboard separator. Now the scanner’s main body and the cardboard box

with the camera head are visible.

The main body is wrapped into a protection foil and is hold with two foam rubber elements

in its position.

Picture 4: Scanner main body and camera head box

Two book cradle plates are attached to the scanner’s main body.

Take the cardboard box out of the transport box. The cardboard box contains the camera

head and the short part of the camera neck. The short part of the camera neck is attached

to the camera head.

Picture 5: Camera head in cardboard box

In addition to the camera head, the transport box also contains two accessory boxes.

Page 14 Setup and Assembly Manual

Page 15

A.1.1 Tools and Assembling Material

The accessory boxes contain the assembly materials and some tools.

Tools:

1x Allen wrench with ball shaped head, size 6 mm

1x Allen wrench, size 4 mm

1x Allen wrench, size 3 mm

1x Allen wrench, size 2.5 mm

Assembling material:

6x Allen screws, M4x10. Used to fix the cover of the scanner to the scanner’s body.

8x Allen screws, M8x12, with plastic washers. Used to fix the lamps (4x) to the scanner

housing, to fix the hinges to the lamps (2x), and to fix the green cover (2x).

2x Allen screws, M8x14; with metal washers. Used to fix camera head and camera neck.

10x Allen set screws, M8x8. Used to fix the camera neck at the scanner’s body (8x) and to

fix the neck to the camera head (2x).

4x Lens head Allen screws, M4x10. Used to fix the cover of the scanner to the scanner’s

body.

2x Hinges

2x Gas springs for the glass plate

A Recovery key

A network cable, a cross-over cable, and a power cable.

Micro fiber cleaning cloth for the book cradle and other surfaces.

Please note: Keep the transport boxes for future use! For warranty returns, the scanner

must be sent back in the original transport box to avoid transport

damages.

In the camera neck, four T-slot nuts are inserted.

Two T-slot nuts are used as counterparts to the screws which fix the camera head to the

camera neck. The two T-slot nuts on the rear side are used as counterparts to the screws

which fix the cover between camera head and neck.

Setup and Assembly Manual Page 15

Page 16

A.1.2 Device Location

A.1.2.1 Environment

Choose a location that complies with the limits of temperature and humidity. Refer to

chapter D.2 for detailed environmental specification.

A.1.2.2 Ambient Light

The location should have a controlled ambient light situation. Light scenarios to avoid are

direct sunlight, spot light from light beams, light sources that cause sharp shadows on the

scanning bed, high levels of ambient light and varying light conditions.

The Bookeye® 3 scanner is an open system with a built-in high quality light source. Open

system means, that the ambient light is added to the light seen by the camera.

The recommended location for the Bookeye® 3 scanner:

• Is not exposed to daylight.

• Is evenly illuminated from the ceiling with fluorescent lamps with electronic

ballasts. The light intensity measured on the book cradles should be 300 lux or

less.

• The light should not cause any shadows; therefore the variation of the intensity

across the scan area should be kept below 20%.

If the fluorescent lamps are powered by non electronic ballasts, they will produce a flicker

twice the frequency of the main power supply (100Hz or 120Hz). If the intensity of this

light becomes too high, vertical stripes of even distances of approx. 8-12 pixels will be

visible on the scan.

Direct sunlight will vary over the day and will result in overexposed images. Sunlight also

can produce sharp shadows.

Light beams from spot lights will also produce sharp shadows. They emit (in most cases)

a high level of infrared light. Infrared light is not visible to the human eye but not the

camera. The light source of the Bookeye® 3 scanner itself has no infrared content at all.

The advantage is that the scanner does not have an image quality degrading infrared

filter. Too much infrared content will result in overexposure.

The Bookeye® 3 scanner has an integrated “White Balance” function. This function will

compensate the ambient light influences. Therefore it is recommended to perform the

“White Balance” function when the ambient light scenario has been changed.

Page 16 Setup and Assembly Manual

Page 17

A.1.2.3 Scanner Table

Place the device on a flat and solid base, preferable a solid table.

Please note: The load bearing capacity of the table must correspond to the device

weight. The table should be build to hold at least three times the weight of

the unit.

Also it should not shake or move to avoid image distortions. If the table is too weak it can

be attached to a solid wall to stabilize it.

A.1.2.4 Power outlet

Ensure that the power outlet is always accessible when the scanner

is placed at its working position.

This will help to separate the device from the power outlet in case of an emergency.

Setup and Assembly Manual Page 17

Page 18

A.2 Assembling the Components

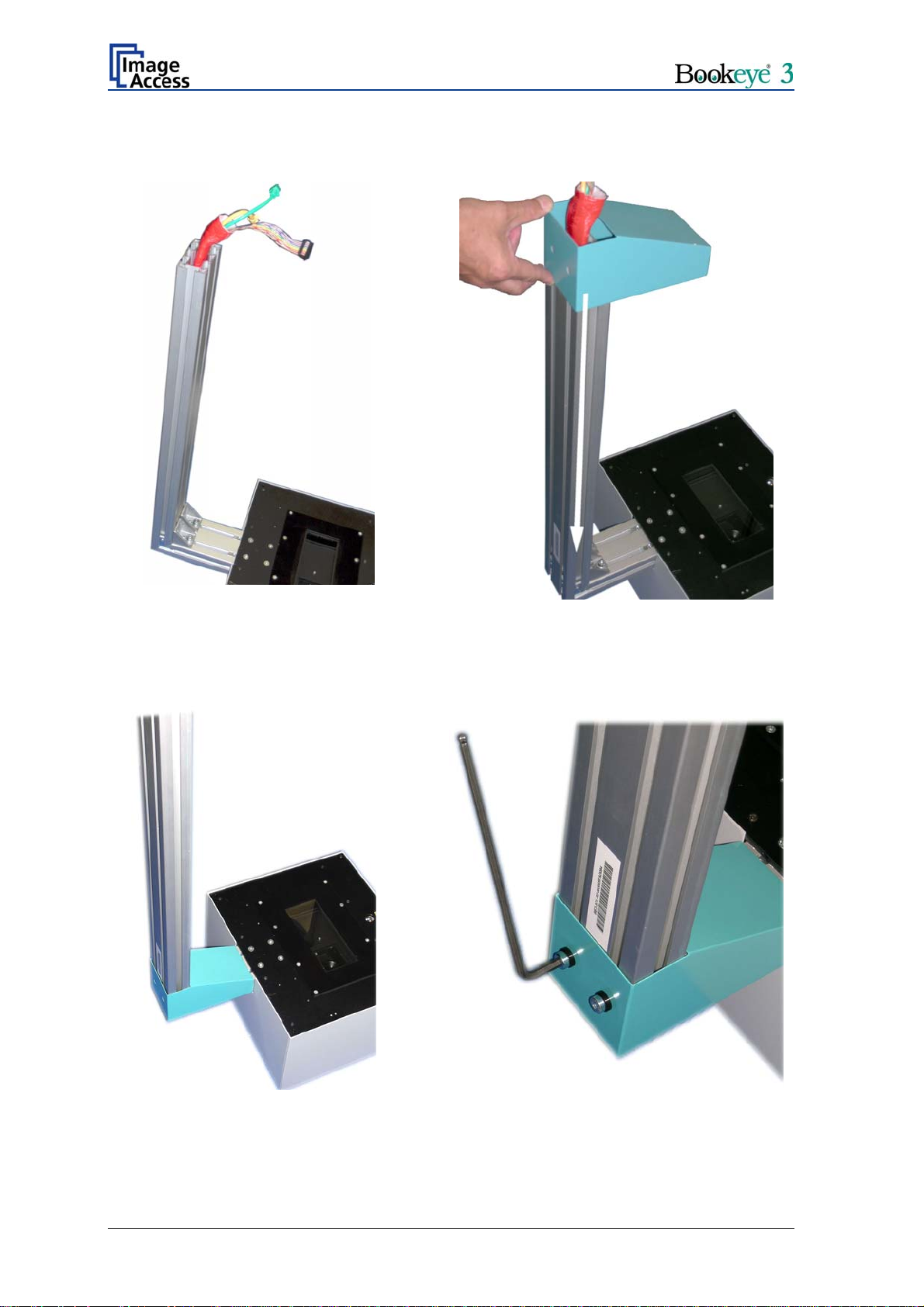

A.2.1 Assembling the Camera Head to the Neck

Take the camera head out of its transport box and place it on a suitable table.

Note: For the following steps, the camera head must be placed with the top side down

on the table.

The cables coming out of the camera head must be inserted into the neck and must be

guided through it.

One end of the neck and the end of the camera head element are cut at a corresponding

angle.

Insert the cables at this end of the neck and push them forward carefully. The cables are

protected by a flexible foam material tube.

Picture 6: Attaching camera neck to camera head

When the cables have been pushed through the upper side of the neck, position the neck

over the fastening angles.

Page 18 Setup and Assembly Manual

Page 19

Place the T-slot nuts in the neck corresponding to the fastening brackets before fastening.

Before fastening the screws, check the alignment of the two neck elements to each other.

There must not be a gap between the two neck elements.

Picture 7: Check the alignment …

Picture 8: ... at both sides

To ensure a proper angle alignment between the short neck and the long neck it is

necessary to fasten the screws in the given order.

At first fasten the two Allen set screws M8x8 in the fastening angle at position A.

Then continue with the two Allen screws M8x14, using a metal washer at each screw, in

the fastening brackets (B).

Picture 9: Fastening at position A Picture 10: Fastening at position B

Setup and Assembly Manual Page 19

Page 20

Picture 11 shows both components fully assembled. Finally, place the green cover on the

neck as shown below in the following pictures.

Î

Picture 11: Camera neck assembled

at camera head

Fasten the cover with two Allen screws M8x12. Use plastic washers with the screws.

Picture 12: Placing the cover on the neck

Î

Picture 13: Cover in final position

Page 20 Setup and Assembly Manual

Picture 14: Fastening the screws

Page 21

A.2.2 Assembling Lamps and Camera to the Body Element

Take the body element out of the transport box.

Note: Because of the device weight, lifting the body element out of the transport box

must be done by two persons.

Picture 15: Two persons(!) lift the device out of the transport box

Place it on a suitable stable surface. The bearing capacity of the table must exceed the

total weight of the scanner.

Before continuing with the next steps, remove the foam rubber elements and the

protection foil.

Setup and Assembly Manual Page 21

Page 22

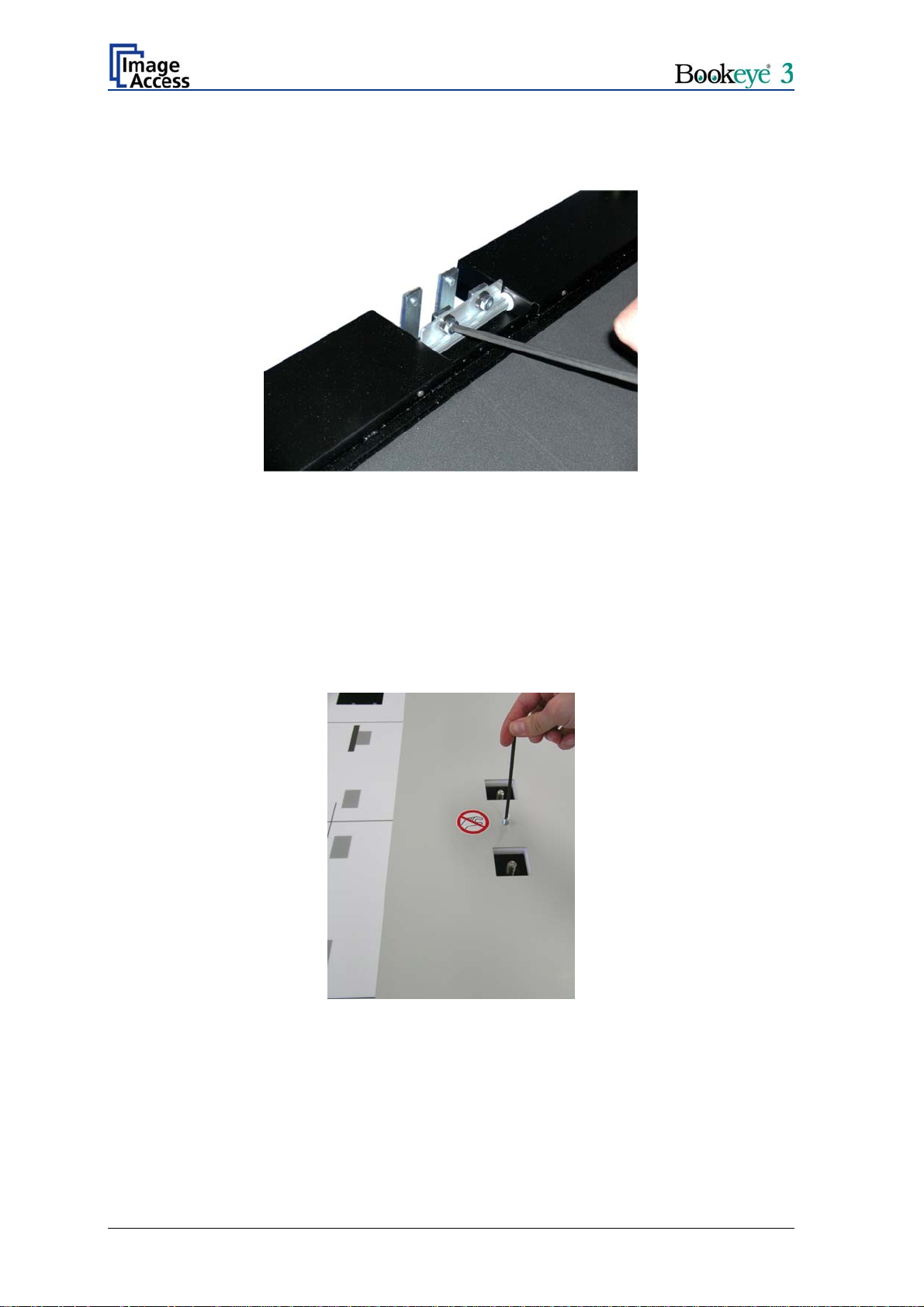

The glass plate is fixed to the scanner with two Allen screws M8x12 for transporting.

Remove the Allen screws and keep them for later use.

Picture 16: Removing the transport screws

Lift the glass plate off and store it temporarily in a place where it cannot be broken.

Storing it in the transport box is recommended.

Insert eight Allen set screws M8x8 into the fastening elements where the transport Allen

screws were removed.

Pull the book cradle plates out of the body element.

Remove the countersunk socket screws between the book cradle drives. Use the 4 mm

Allen wrench.

Picture 17: Removing the countersunk socket screw

Page 22 Setup and Assembly Manual

Page 23

Picture 18: Remove marked screws

Remove the four screws at the back of the housing between the openings for the lamps

and the neck opening.

CAUTION!

Danger of injury!

Never put your fingers in the driving element openings.

Slide the body element cover approximately 300 mm (≈ 12 inch) to the front side. This will

make the lamp holder brackets and the mounting brackets for the camera neck

accessible.

Picture 19: Body element cover opened

Setup and Assembly Manual Page 23

Page 24

Insert the lamps into the lamp holder brackets in the body element. The lamps have preinstalled fixtures for the gas spring. The fixtures must be positioned at the inside near to

the camera neck. Picture 20 shows the position of the fixture in the right lamp.

Note: The definition of “right side” and “left side” always refers to the normal operating

position, i.e. from the front side of the scanner.

Picture 20: Position of gas spring fixture at right lamp

Fix each lamp with two Allen screws M8x12. Use a plastic washer with each screw.

Picture 21: Fixing the lamp

Connect the two lamp cables to the corresponding connector in the body element.

Page 24 Setup and Assembly Manual

Page 25

Before inserting the camera neck into the body element, slide the black cover over the

neck. The open side of the cover must be placed to the back of the camera neck. Picture

20 shows the correct position of the cover on the camera neck.

The position of the T-slot nuts in the camera neck front side should match with the

boreholes in the front of the black cover. They will be used later to hold the glass plate

bearing.

Picture 22: Camera neck assembly

Note: It is recommended to perform the next steps with two persons. One person holds

and positions the camera neck while the second person handles the cables.

Slide the complete camera neck over the mounting brackets in the body element. Press

the flexible tube a little at the outside. Picture 22 shows how to place the flexible tube with

the cables between the mounting brackets.

Fasten the camera neck at the front and back with the Allen set screw M8x8.

Picture 23: Front side Picture 24: Back side

Setup and Assembly Manual Page 25

Page 26

Connect the camera neck cables to the sockets at the connector board which is found

directly in opposite to the fastening elements of the camera neck. The connectors are

marked with colored labels. Always connect cables with matching colors.

Picture 25: Connector board with camera neck cables

The connector for the flat ribbon cable has no colored label, but is easily identified by its

characteristic form.

Picture 26: Connector of flat ribbon cable

Check all connectors and cables for secure

connection. It is recommended to position the cables

in a loop as shown in the picture on the left.

Picture 27: Cable loop

Page 26 Setup and Assembly Manual

Page 27

Slide the body element cover slowly back on the body element.

Important: While moving the body cover back on the body element, watch the

keyboard cable (item (1) in the picture below). Picture 28 shows how to

hold the keyboard cable.

Picture 28: Keyboard cable while moving the body cover

Pull the keyboard cable carefully in arrow direction until the edge of the body cover

reaches the edge of the power supply. Then release the cable and slide the body cover in

its final position.

Picture 29: Body cover at edge of power supply

Insert the screws in the following order:

1. The two countersunk socket screws between the driving elements of the book cradles.

2. The four lens head screws at the back of the housing, between the lamps and the

camera neck.

3. The six Allen screws at the bottom.

First, fasten the screws loosely. Check the position of the body element cover again and

tighten all screws securely.

Setup and Assembly Manual Page 27

Page 28

A.2.3 Assembling the Glass Plate

Insert the book cradle plates into the driving elements and place the foam rubber mats on

the plates.

Connect the scanner to the mains power and switch it on with the main power switch. The

main power switch is found on the rear side of the scanner, next to the power connector.

The green START LED on the keyboard lights up. This signalizes that the scanner is in

stand-by mode.

Press the green START button to start the scanner. When the start sequence is finished

after approximately 30 seconds, the display shows: READY TO SCAN

The book cradle plates are controlled by the eight buttons in the middle of the keyboard

field.

Picture 30: Book cradle controller

Press and hold the upper button with the double arrow to move both book cradle plates

upwards simultaneously. At the upper end position, the book cradle motors stop

automatically.

Place the glass plate on the book cradle plates. The position of the bearing in the middle

of the glass plate must match with the boreholes in the black cover. Insert two Allen

screws, M8x12, into the bearing and fix it to the camera neck.

Picture 31: Bearing in the center of the glass plate

Page 28 Setup and Assembly Manual

Page 29

Place the T-slot nuts in each lamp at a position corresponding to the position of the axes

at the right and left side of the glass plate.

Picture 32: T-slot nut in corresponding position

Slide a hinge on each axis.

Fix each hinge to the lamp with an Allen screw M8x12.

Picture 33: Hinge mounted at right lamp

Setup and Assembly Manual Page 29

Page 30

Each gas spring has on its ends special locking springs inserted.

Important: The locking springs always must be removed before placing or removing

the gas springs at the glass plate or on the pin at the lamps.

Picture 34: Position of locking springs

Picture 34 shows the position of the locking springs at the lamp and at the glass plate.

When the scanner is delivered, the gas springs are already mounted to the lamps. They

only must be mounted to the glass plate.

To mount the gas springs to the glass plate, remove only the locking spring at the glass

plate side of the gas spring.

At first turn the locking spring (1.) over the ball head of the gas spring. It needs a little

force to move the spring over the ball head.

Then pull it out of the boreholes (2.).

Picture 35: Removing the locking spring

Page 30 Setup and Assembly Manual

Page 31

Open the glass plate completely, hold it in this position and click the gas spring onto the

pin of the glass plate.

Picture 36: Gas spring mounted to glass plate

Repeat the procedure with the second gas spring.

Finally insert the locking springs at both gas springs.

Picture 37: Locking spring inserted

Picture 38: Locking spring locked

Setup and Assembly Manual Page 31

Page 32

Picture 39: Gas spring completely mounted

The opening angle of the glass plate can be modified by moving the fixtures in the lamps.

Note: Modifying the opening angle of the glass plate should only be done with the help of

a second person!

Open the glass plate completely. One person must hold the glass plate in this position

while the second person opens the Allen set screw in the fixture slightly.

The opening angle can now be modified. When the glass plate opening angle is set to the

desired position, the Allen set screws must be fastened securely.

Page 32 Setup and Assembly Manual

Page 33

A.2.4 Setting the Initial Lamp Position

The lamp position must be initialized after assembling the Bookeye® 3 scanner. The

reason for this procedure is as follows:

The scanners lamps turn under software control and project a vertical beam of light onto

the scanning surface. Both lamps and the CCD have to move perfectly synchronized to

achieve the highest brightness level during the whole sweep.

The scanner’s CCD motor and the lamp motors form an electronic gear that performs very

complex movements under software control while scanning books and other objects that

are not completely flat. This only works if the initial position after a power up cycle is in a

known state.

Each lamp has a home position switch that acts as a reference. When a lamp is

assembled into the scanner, the light beam position relative to the home position switch is

unknown. To make known all positions of the above described electronic gear, the

following initialization has to be executed.

All positions in the electronic gear are adjusted via software later but the initial adjustment

must be made manually.

The initialization of the lamps is done in two steps.

• The first steps is the mechanical adjustment. For the mechanical adjustment the

keys for book cradle control will be used.

• The second step is the electronic adjustment. The electronic adjustment will be

controlled by the device firmware and runs fully automatically.

During the mechanical adjustment of the lamps the keyboard display shows some

information.

Start the Bookeye® 3 scanner. After some internal tests have been performed, the display

will show the message READY TO SCAN.

Setup and Assembly Manual Page 33

Page 34

A.2.4.1 Performing the mechanical adjustment of the lamps

The keys for the book cradle control are located in the center of the keyboard, see figure

below.

Figure 1: Book cradle control keys

To initialize the lamps, the scanner must be switched to the lamp initializing mode.

Press and hold the two keys in the middle of the book cradle control field and

simultaneously press the green START button (Picture 40).

Picture 40: Press the keys simultaneously

The lamps light up and move to their start positions.

The display shows

Adjust the light beams

Read spec for more info!

The scanner plays the sound “Attention please!” to indicate that it is in the initialization

mode.

Note: If no key is pressed for approx. 20 seconds the scanner ends the initialization

mode automatically. The sound “OK” will be played and the display shows

Saving new positions

Page 34 Setup and Assembly Manual

Page 35

If the lamps are in their start positions, the maximum light level must be present at the left

edge and the right edge of the book cradle respectively.

Picture 41: Lamps in start position

The position of the left lamp is changed by pressing the left up/down key of the keyboard.

The position of the right lamp is adjusted accordingly with the right up/down key of the

keyboard.

Picture 42: Up/down key on right side of keyboard

Press the keys to move the light beam on the book cradle. The upper key moves the light

beam to inside of the book cradle, the lower key moves the light beam to the outside.

Setup and Assembly Manual Page 35

Page 36

At the top of the lamp arm, the light beam is also visible. It is helpful to check the light

beam at both positions to finally leave it in the correct position.

Picture 43: Light beam on right side of the book cradle

Press the down key to move the light beam to the

outside.

Press the up key to move the light beam to the inside.

The above pictures show the right lamp. Corresponding steps must be performed for the

left lamp.

Page 36 Setup and Assembly Manual

Page 37

The two screw head caps at the upper end of the lamp arm help to set the light beam to

the best position.

Picture 44: Light beam adjusted

A.2.4.2 Saving the lamp positions

Press the green START button to save both lamp positions.

The sound “OK” will be played and the display shows

Saving new positions

The lamp positions will also be saved automatically when the time out period has passed

without any activity.

A.2.4.3 Leaving the initialization mode without saving

Press the red STOP button to leave the initialization mode. The lamp positions will not be

saved.

Setup and Assembly Manual Page 37

Page 38

A.2.4.4 Lamp position control mode

The position of the lamps and their maximum travel distance can easily be checked

through the values shown in the keyboard display in this control mode.

The scanner must be in the “lamp initialization mode”. To switch the scanner to the “lamp

initialization mode”, use the key combination as described in chapter A.2.4.1.

+

+

Press the left or right up key together with the cradles up key

or

press the left or right down key together with the cradles down key

The display will change to the “lamp position control mode”.

The display shows two values for each lamp:

SW: <value>

Shows the current rotation angle of the lamp, measured from the position of the reference

switch. The position that activated the reference switch is defined as the zero point for the

lamp movements.

ABS: <value>

Shows the angle the lamp has moved after pressing the button combination. It is assumed

that the lamps have been manually adjusted to be optically straight as described in

chapter A.2.4.1

With the key combination described above, the lamps will move at a higher speed than

with the up key or down key only.

In this mode, the lamps can be moved to their maximum positions for testing purposes.

The function of the home position switch and its position can also be tested in this mode.

NOTE: If the lamp is moved beyond its normal maximum position, the scanner plays the

warning sound: “Attention”

This lamp position can not be saved for safety reasons.

This mode ends automatically after a short time-out period or directly after pressing the

STOP button on the scanner keyboard.

The lamps must be able to freely move within an angle of +/- 45° before they touch their

corresponding mechanical end position. The minimum requirement is that they move 45°

in the direction of the scanning bed; a limitation in the other direction can be tolerated. If

that limitation exists on one lamp, they can also be swapped to continue working with the

scanner.

The reference switch position is also of importance. The switch should be activated shortly

before the lamp is blocked. A distance of an angle of 2 – 4° is ideal, higher values are no

concern, lower values must be corrected. The correction is done by bending the sheet

metal piece that activates the switch.

Page 38 Setup and Assembly Manual

Page 39

B Software Setup

B.1 Setup Network IP Address

After shipment or after a reset to factory defaults, the scanner will have the

default IP address 192.168.1.50.

This IP address is most likely not a valid address in your local network, therefore the

address has to be changed.

To perform this, a connection to the scanner must be established. First, note all network

settings in your local PC. Then change the settings in your local PC to IP address

192.168.1.1 and subnet mask to 255.255.255.0.

Enter the IP of the scanner into your browser. The start screen of the scanner opens.

Picture 45: Start screen

In the start screen go to Setup Device .

Setup and Assembly Manual Page 39

Page 40

Choose the login level Poweruser using the default password "Poweruser".

Picture 46: Login level screen

In the Base Settings section click at Network Configuration .

Picture 47: Poweruser Main Menu screen

Page 40 Setup and Assembly Manual

Page 41

Now change the IP address, subnet mask and gateway to a valid address or select DHCP

to obtain an IP address automatically.

Picture 48: Network configuration screen

If the IP address has been changed, the device has to be powered down and up again.

Change the settings of your local PC back to the previous network settings. Enter the new

IP address of the scanner and go to the “Poweruser” main menu again.

Setup and Assembly Manual Page 41

Page 42

B.2 Mandatory Optical Adjustments

Whenever the device is setup for the first time, moved to a different location, cleaned or

serviced and after a software update; some adjustments have to be performed to

guarantee maximum quality and accuracy.

Access to these functions is only possible through the login level “Poweruser”, default

password “Poweruser”. The person having access to this level can change the password

and thereby limit access to normal operators.

The following functions use special test targets that were supplied with the scanner. Do

not try to perform any of these adjustments without the proper test targets.

The Bookeye

— White Reference Target 110x670

— Line Reference Sheet LRS-200

Please ensure that adjustments are made following the sequence below.

1. Perform the Scan Start function. This will synchronize the CCD main drive motor

®

3 scanner is delivered with the following test targets:

with the lamp motors so that the CCD is centered along the horizontal axis and the

lamp beams follow as precisely as possible.

2. Execute the Auto Focus function to establish a basic reference for the focus

motor. This function should also be invoked any time the scanner seems to be out

of focus.

3. The next step is the White Balance function. This calibrates the scanner’s CCD

and optics relative to the lamp light and the remaining ambient light. This function

should be invoked if the brightness seems to have shifted, the ambient light

situation has changed significantly or the images have horizontal stripes on them.

4. The next step is the Laser Check function. This function checks all properties of

the laser line and will return overall skew and position of the laser line.

Page 42 Setup and Assembly Manual

Page 43

All adjustments described in chapter B.2 and its subchapters start from the main screen of

the login level ”Poweruser”.

Start your browser software. Enter the IP address of the scanner in your browser to open

the start menu.

Picture 49: Scan2Net Start screen

In the start screen go to Setup Device .

Choose the login level Poweruser using the default password "Poweruser".

Picture 50: Buttons for login levels

The next screen shows the main menu screen.

Setup and Assembly Manual Page 43

Page 44

Locate the section Adjustments & Support and go to Adjustments .

Picture 51: Poweruser Main Menu screen

Start in section Focus & Scan Area Adjustments. Select the appropriate menu items as

described in the following paragraphs.

Picture 52: Adjustment & Support screen

Page 44 Setup and Assembly Manual

Page 45

B.2.1 Scan Start

This function adjusts the position of the CCD camera and the lamps relative to each other.

The electronic gear mentioned previously is fine-tuned with this routine. The first test

performed is the maximum turn of the lamps. The lamps will hit against their mechanical

end position, which will produce an audible sound. This is necessary to check whether the

lamps can be turned in and out far enough.

Then the scanner scans the test target, finds the white to black change in the middle of

the test target and takes this position as the optical middle. It is very important to move the

test target against the neck and center it as precisely as possible. Any deviation of the test

target in the horizontal direction from the ideal position will be present in all scans

afterwards.

After the optical middle is established, the scanner moves its CCD camera to the newly

found middle position. Both lamps are moved backward and forward to find the maximum

brightness of the beam. When the position is found it is stored. This will override the

previous manual setting. The manual setting was necessary to have at least some

synchronized lights during the first step when the scanner tries to locate the optical

middle.

To perform the function follow the steps 1) and 2) as described on the screen.

Picture 53: Scan Start adjust screen

Press the Next Step button.

Setup and Assembly Manual Page 45

Page 46

After a short time, the scanner will return some measured values. The detailed values are

only of interest for trained service technicians. As long as the results are all shown in

green text, the device is properly calibrated.

An error is always shown in red text and usually comes with an explanatory remark.

Picture 54: Scan Start results

1. Click the button New Values in the section Controls to repeat the measurement.

Or

2. Click the button Back to Adj. Menu in the section Menu controls to return to the

adjustments menu (see Picture 52).

Page 46 Setup and Assembly Manual

Page 47

B.2.2 Auto Focus

This function automatically locates the lens position for the highest level of sharpness and

best image quality.

First, select the current glass plate position.

This value measured with the selected glass plate position is the reference for all focus

adjustments used later during e.g. book fold correction, folder mode scanning or fixed

focus scanning.

Picture 55: Available glass plate positions

Press the Next Step button below the picture corresponding to the selected glass plate

position.

Setup and Assembly Manual Page 47

Page 48

B.2.2.1 Auto Focus Measurement with Glass Plate Opened

Perform the measurement as follows:

3. Open the scanner’s book cradle completely, as shown on the screen.

Note: The position of the book cradles is verified. If the book cradles are not in the

lowest (home) position, a Retry button and a message are displayed on the

screen instead of the Next Step button .

4. Press the Next Step button. The measurement starts.

Picture 56: Auto Focus measurement with open glass plate

After the Autofocus function has completed, the results will be displayed. Values displayed

in green indicate valid results. Any error will be shown in red text, followed by some

explanatory remarks.

Note: It is normal that the measurement will return different values each time the

measurement is repeated. The lens motor has a very high resolution and the

best focal point has to be found in the already large focal range, therefore a

variation of 50 – 100 in values is normal.

Page 48 Setup and Assembly Manual

Page 49

Picture 57: Auto Focus results

5. Click the button New Values in the section Controls to repeat the measurement.

Or

6. Click the button Back to Adj. Menu in the section Menu controls to return to the

adjustments menu (see Picture 52).

Setup and Assembly Manual Page 49

Page 50

B.2.2.2 Auto Focus Measurement with Glass Plate Closed

Perform the measurement as follows:

7. Close the book cradles.

8. Place the Line Reference Sheet S2N LRS-200 on the scanner’s book cradle as

shown on the screen and align it as described.

9. Move the book cradles to the upper position. Close the glass plate.

Note: The position of the book cradles is verified. If the book cradles are not in the

upper position a Retry button instead of the Next Step button and a

message is displayed on the screen.

Picture 58: Information about book cradles position

After moving the book cradles to the upper position press the Retry button.

Page 50 Setup and Assembly Manual

Page 51

When the book cradles are in the upper position the screen shows the following:

Picture 59: Auto focus measurement screen

10. Press the Next Step button The measurement starts.

After the Autofocus function has completed, the results will be displayed. Values displayed

in green indicate valid results. Any error will be shown in red text, followed by some

explanatory remarks.

Note: It is normal that the measurement will return different values each time the

measurement is repeated. The lens motor has a very high resolution and the

best focal point has to be found in the already large focal range, therefore a

variation of 50 – 100 in values is normal.

11. Click the button New Values in the section Controls to repeat the measurement.

Or

12. Click the button Back to Adj. Menu in the section Menu controls to return to the

adjustments menu (see Picture 52).

Setup and Assembly Manual Page 51

Page 52

B.2.3 Scan Center

This function is fully manual.

The optical middle in the driving (horizontal) direction has already been corrected by

adjusting the distance between the home position of the camera and the optical middle

position.

In contrast, the vertical middle cannot be adjusted but is found at a certain pixel position

on the CCD. If an individual scanner head is slightly tilted towards the front of the scanner,

the camera’s middle position also moves in the same direction and the scanner “sees”

more area at the keyboard side of the scanning bed.

Since all scanners have some spare pixels that are not used, the middle can be adjusted

by defining a certain number of pixels at the lower edge of the scanning bed which the

scanner should ignore.

The input field only takes positive values, the unit is pixels.

Perform the function as follows:

13. Press the Scan Center button in the Adjustments & Support screen (Picture 52).

Type in the offset value in pixels.

Picture 60: Scan Center screen

14. Press the Adjust value button to permanently store the value.

15. Click the button Back to Adjustment Menu to return to the adjustments menu.

Page 52 Setup and Assembly Manual

Page 53

B.2.4 White Balance

B.2.4.1 Some Basic Information

The white balance function is the most important function for consistent image quality.

This is especially important in the type of open scanning environment present in planetary

scanners.

Although all scanners have a function similar to the white balance, the light situation inside

a flatbed scanner is much more controlled than with the Bookeye® family of scanners. A

normal flatbed scanner has to be calibrated once in a while, maybe every couple of

weeks. This is necessary to compensate for light degradation, accumulation of dust, loss

of sensitivity of the CCD and other long term effects.

By contrast Bookeye® scanners have to be calibrated more than once a day if the

ambient light situation changes significantly.

To be able to fully understand the results of a white balance, the following

information is helpful:

The scanner has built in light sources of known and stable quality consisting of the most

state-of-the-art white LEDs but generally receives some significant ambient light from the

ceilings or windows of unknown intensity, color temperature and usually with some

amount of flicker.

During the white balance measurement, all internal and external light sources are

combined and illuminate the target. The intended target for this function is the

White Reference Target 225x670, which has a very even, non-glossy and extremely

white surface.

In the first step, the overall sensitivity of the scanner is adjusted in such a way that the

brightest area results in an almost saturated output signal. This assures that the largest

density range possible is used. After this adjustment is done, the uneven light distribution

on the CCD caused by the imbalance of the lamps, the ambient light introduced, the

imperfections of the lens and other factors; has to be compensated for. This measurement

results in a correction function that has higher correction factors at the upper and lower

edges of the scan bed and almost no correction in the vicinity of the brightest area.

If the above is understood, it is understandable that the quality of the test target is of

utmost importance to the result of the white balance. The test target is a reflective one and

reflects the light in a diffuse way. If the test target has dirt, wrinkles or anything on it visible

to the human eye, the CCD will also see this and will overcompensate in these areas.

Although the internal software has been programmed to eliminate these imperfections to a

certain degree, it still leads to unreliable results if the target is not good enough.

If the target is good enough and ambient light level is not too high, the scanner will

calibrate successfully. Calibration means that the “white” of the test target in the given

illumination situation produces a “white” output in the digital domain. Consequently, all

scans of white paper that has different properties than the test target results in brightness

and possibly color shifts. Because the inexperienced user may become irritated if the

“white” paper turns out to be lightly grayish and somewhat uneven; many competitors

clamp the brighter pixels to fully white. This looks better but introduces artifacts, therefore

this is only optional with a Bookeye®.

Setup and Assembly Manual Page 53

Page 54

There are three ways to change the result of the white balance.

The first way is to use the Brightness Correction button in the white balance menu. This

button changes the gains settings up to ± 2dB, while positive values make the scans look

brighter.

Picture 61: Brightness Correction Factor screen

The second way of changing the results is invoked if the individual R G B controls in the

scanner application are used. They allow changing the color temperature of the original

reference scan.

Picture 62: R G B controls

The third way is the easiest and most straightforward method. Change the target. If

scanning newspaper is the goal, the white balance could be performed on a blank section

of a newspaper page. This will turn all other scanned pages to white in the digital domain.

Page 54 Setup and Assembly Manual

Page 55

B.2.4.2 White Balance with Glass Plate opened

Start in the Adjustments & Support screen (Picture 52).

Perform the measurement as follows:

1. Find the section White Balance Adjustments and click the button White Balance .

Picture 63: Glass plate positions for white balance

Press the Next Step button below the picture corresponding to the selected glass plate

position.

2. Close the book cradles completely and move them to the lowest position.

Note: The position of the book cradles is verified. If the book cradles are not in the

lowest (home) position, a Retry button and a message are displayed on the

screen instead of the Next Step button.

After moving the book cradles to the lowest position press the Retry button.

Setup and Assembly Manual Page 55

Page 56

3. Place the White Reference Target 225x670 at the marked position.

Picture 64: White Balance screen, glass plate opened

4. Press the Next Step button. The measurement starts.

After the Autofocus function has completed, the results will be displayed. Values displayed

in green indicate valid results. Any error will be shown in red text, followed by some

explanatory remarks.

5. Click the button Back to Adjustment Menu to return to the adjustments menu.

Page 56 Setup and Assembly Manual

Page 57

B.2.4.3 White Balance with Glass Plate closed

Start in the Adjustments & Support screen (Picture 52).

Perform the measurement as follows:

1. Find the section White Balance Adjustments and click the button White Balance .

Press the Next Step button below the picture corresponding to the selected glass plate

position. Picture 63 shows the available positions of the glass plate.

2. Close the book cradles completely and move them to the upper position.

Note: The position of the book cradles is verified. If the book cradles are not in the

upper position a Retry button and a message are displayed on the screen

instead of the Next Step button.

After moving the book cradles to the upper position, press the Retry button.

3. Place the White Reference Target 225x670 at the marked position.

Picture 65: White Balance screen, glass plate closed

4. Press the Next Step button.

After the Autofocus function has completed, the results will be displayed. Values displayed

in green indicate valid results. Any error will be shown in red text, followed by some

explanatory remarks.

5. Click the button Back to Adjustment Menu to return to the adjustments menu.

Setup and Assembly Manual Page 57

Page 58

B.2.5 Laser Check

This function checks the integrity and position of the laser line. The function will return

skew and relative position to its ideal values and is used to track potential misalignment.

Start in the Adjustments & Support screen (Picture 52).

Perform the measurement as follows:

1. Find the section Focus & Scan Area Adjustments. Press the Laser Check button.

Note: The position of the book cradles is verified. If the book cradles are not in the

lowest (home) position a Retry button instead of the Next Step button and

a message is displayed on the screen.

After moving the book cradles to the lower position press the Retry button.

2. Place the White Reference Target 225x670 at the marked position.

Picture 66: Laser Check screen

3. Press the Next Step button. The measurement starts.

Page 58 Setup and Assembly Manual

Page 59

4. After the function has finished, the results will be displayed. As long as the displayed

text is green, the result is ok. Any error will be shown in red followed by some

explanatory remarks.

Picture 67: Laser check result

5. Click the button New Values in the section Controls to repeat the measurement.

Or

6. Click the button Back to Adj. Menu in the section Menu controls to return to the

adjustments menu (see Picture 52).

At this point, all mandatory setup functions have been completed. Click the

Scan2Net logo on top of the screen and go to Launch Scan Application to start

scanning.

Setup and Assembly Manual Page 59

Page 60

B.3 Options and Settings

The following options and software settings are optional and are not necessary for the

basic operation of the device. Some of them provide more convenience for the operator

while others are software options that can enhance image quality or perform other

optional functions.

B.3.1 Time Server

Locate the section Base Settings in the Poweruser screen.

Click the button Adjust Time & Date to set various parameters.

Picture 68: Adjust Time & Date screen

Select time format, time zone, daylight saving and time server IP address. Manually set

time or let the system set it at every power up.

Note: The default image name contains current time and date, therefore

synchronizing the internal clock is recommended

Page 60 Setup and Assembly Manual

Page 61

B.3.2 Sound Control

Locate the section Base Settings in the Poweruser screen and go to Sound System .

The volume can be adjusted and other sound files can be uploaded.

Picture 69: S2N Sound System screen

A sound file can be assigned to various action items. The assigned sound will be played

every time the condition occurs. The default setting can be overwritten by selecting the

appropriate WAV file and then moving it over by pressing the Å button.

Picture 70: Link Sounds to Events screen

Setup and Assembly Manual Page 61

Page 62

B.3.3 Firmware Update

Locate the section Updates & Uploads and go to Update Scanner Firmware .

Select the “Post update behavior” of the scanner from the list.

Picture 71: Update Scanner firmware screen

Browse and select the previously downloaded firmware update file.

The appropriate firmware can be downloaded from the Image Access Customer Service

Portal at http://service.imageaccess.de

.

Page 62 Setup and Assembly Manual

Page 63

B.3.4 Install Options

Locate the section Updates & Uploads and go to Install Options .

All option keys displayed in green are valid and installed. A new key must be entered

completely without blanks or spaces followed by the Apply button. If the key text does

not turn green, the key is invalid or does not belong to this specific scanner or option.

Note: Option keys are valid only for one option on a specific scanner denoted by its

serial number.

If a key is accidentally deleted it can always be obtained again at the Image

Access Customer Service Portal http://service.imageaccess.de

cost.

without extra

Picture 72: Install Option screen

Setup and Assembly Manual Page 63

Page 64

B.3.5 Install ICC Profiles

Locate the section Updates & Uploads and go to ICC Profiles .

Picture 73: ICC Profile screen

Select either Printer Profiles or Scanner Profile .

In the next screen, browse for a new ICC profile and select it. It will replace the previous

file.

Page 64 Setup and Assembly Manual

Page 65

C Tests and Troubleshooting

C.1 Network Performance Test

It is sometimes desirable to check network performance if the scanner seems to be

operating slowly. The scanner itself has a gigabit network interface and can transfer data

at a sustained rate of almost 100Mbytes per second. This is far more than most standard

PCs can handle and comes very close to the maximum bandwidth of the gigabit network.

If the scanner runs in a 100Mbit networks it is already slowed down significantly,

particularly if the file sizes are large. Sometimes the network’s response times are poor

because routers and/or switches with slow performance are used, or the topology of the

network is not optimal.

This analyzer checks the response time between the scanner and any arbitrary IP

address in the network. In most cases, the IP address would be the one from the PC

operating the scanner, but FTP links can also be checked via this function.

Perform the test as follows:

Locate the section Adjustments & Support and go to Network Analyzer .

Go to Perform Speed Test .

Picture 74: Perform Speed Test screen

Setup and Assembly Manual Page 65

Page 66

Type in a valid IP address in the same network and subnet.

Picture 75: Network Analyzer Parameters screen

Check the results in the following screen. Single digit millisecond response times are

good, the example shown is from a well structured gigabit network.

Picture 76: Network Analyzer Result screen

Page 66 Setup and Assembly Manual

Page 67

C.2 Scan Test Targets

The scanner has a function for scanning specific test targets. If one of the test targets is

scanned, all image parameters are set to a known state to enable a remote system to

analyze the quality of the scanner. One or more CSTT test targets are included in the

initial scanner shipment. They are used to troubleshoot various types of image quality

problems. Any time Image Access support is contacted, you will be asked to provide a

test scan of the CSTT target.

Image Access is the first vendor that has established a portal with an Image Quality

Server online 24 hours at 7 days a week. The Image Quality Server can be reached at

http://service.imageaccess.de

black points, geometric distortions, resolution and many more parameters and displays

them in an easy to understand form. A time stamped certificate can be printed out to

document the scanner’s quality level at any given time.

C.2.1 Scan CSTT Test Target

Locate the section Adjustments & Support, go to Scan Test Targets and click the

button Scan CSTT Test Target .

. The server automatically analyzes color tracking, white and

Picture 77: Scan Test Target screen

Place the CSTT test targets on the scanner as displayed.

Picture 78: CSTT Test Target screen

Press the Next Step button and follow the instructions.

Setup and Assembly Manual Page 67

Page 68

C.2.2 Scan IT8 Test Target

The test scan of a standard IT8 test target is used to generate an ICC profile for the

specific scanner. The scan can be provided to the Image Access Customer Service Portal

at http://service.imageaccess.de

can then be uploaded into the scanner.

Locate the section Adjustments & Support, go to Scan Test Targets and click the

button Scan IT8 Test Target .

and the system will generate an ICC profile. This profile

Picture 79: Scan Test Target screen

Place the IT8 test targets on the scanner as displayed.

Picture 80: IT8 Test Target screen

Press the Next Step button and follow the instructions.

Page 68 Setup and Assembly Manual

Page 69

C.3 Recovery Function

The recovery function resets all parameters of the device to factory defaults after a fatal

system breakdown.

The recovery key is necessary to invoke the recovery procedure. The key is delivered with

every device. It is marked with the label Recovery.

Important: The recovery function resets the IP address to the factory default value of

192.168.1.50. If the scanner had a different IP address, it will be necessary

to use the cross over cable and change the network settings on the local

computer.

C.3.1 Important Notes before recovering to Factory Defaults

Write down the values for IP address, subnet mask and gateway of the device before

starting the recovery sequence.

The recovering to factory defaults described in the following should only be executed after

a fatal system breakdown!

After recovering to factory default, all firmware updates have to be executed! Make sure

an update file is available on the local computer.

After recovering to the factory defaults, all adjustment procedures described in the

previous sections have to be executed again!

C.3.2 How to Recover to Factory Defaults

1. Power down the device.

2. Plug the recovery key into the serial port at the rear panel of the device.

Picture 81: Connectors on rear panel

3. Power the device up via the start button.

Setup and Assembly Manual Page 69

Page 70

4. When the recovery key is found in the serial port, the recovery sequence is

automatically executed. All viable system data will be restored and necessary repair

steps will be taken without the need of any user interaction.

Important: Do not switch off the device at any time during the recovery procedure!

Note: The recovery sequence can last up to four minutes. While the recovery

sequence is running, no message will be displayed.

5. When the recovery sequence has finished the device will power down automatically.

6. Unplug the recovery key after the device has powered down.

7. Power up the device and launch the scan application in your browser.

The IP address of the device will have the factory default value: 192.168.1.50

8. Change the network parameters to the values which were used before running the

recovery sequence.

Select Setup Device Î Poweruser . Locate the section Base Settings and click

the button Network . Enter the values for IP address, subnet mask, and default

gateway.

Click the Apply button. Confirm the following message by clicking the OK button.

In the next screen click the Reboot button.

Reconnect to the device using the new IP address.

9. Select Setup Device Î Poweruser . Locate the section Updates & Uploads and

click the button Update Firmware . Perform a firmware update.

10. After the firmware update all software adjustments for the device must be performed.

Select Setup Device Î Poweruser . Locate the section Adjustments & Support

and click the button Adjustments . Perform the adjustments by clicking the

appropriate buttons.

Page 70 Setup and Assembly Manual

Page 71

C.4 Troubleshooting Matrix

Problem Possible cause Action

Green start button does not

light up.

Start button does not power

up the device.

Stop button does not power

down the device.

Image is darker than

expected.

Image is brighter than

expected.

Image is darker on one side

than on the other side.

No power Check main outlet, power cord, power-

on switch on the back of the device.

Connector failure, software

glitch …

Internal software hangs,

application hangs …

The target used for white

balance is much brighter

than the scanning target.

The target is much brighter

than the target used for

white balance.

The electronics gear is out

of sync.

Switch power off for at least 10

seconds. Retry after green start button

lights up again.

End all applications and retry. If

problem persists, press the start

button for at least 10 seconds. Power

up again.

Go to the White Balance function

and modify the Brightness Correction

setting.

Go to the White Balance function

and modify the Brightness Correction

setting.

Exercise the Scan Start procedure.

Image shows a color shift

towards red (tint)

Image shows a color shift

towards blue (tint)

Image shows a color shift

towards red (tint)

Image shows areas that are

overexposed and too bright.

The target used for white

balance is more blue than

the scanning target.

The target used for white

balance is more red than

the scanning target.

The scanner receives

significant amounts of

infrared light (sun or spot

lights) not visible to the

human eye.

The scanner receives too

much ambient light from a

point source like sunlight,

spotlight etc.

Go to the RGB adjustments and lower

the gain on red.

Go to the RGB adjustments and lower

the gain on blue.

Change position, close blinds, dim

down or shut off any bright spot lights.

Change position, close blinds, dim

down or shut off any bright spot lights.

Setup and Assembly Manual Page 71

Page 72

Problem Possible cause Action

Image has unevenly spaced

vertical stripes or streaks.

Image has evenly spaced

vertical stripes or streaks.

Image has horizontal stripes

or streaks.

Scanning two A4 (letter)