Page 1

INSTALLATIONINSTRUCTIONS

FREESTANDINGELECTRICRANGEWITHDOUBLEOVENS

INSTRUCTIONSD'INSTALLATIONPOURCUISINIERE

e=

ELECTRIQUEAUTOPORTANTEAVEC FOURSDOUBLES

TableofContents Tabledesmafi@res

RANGE SAFETY ............................................................................. 1

INSTALLATION REQUIREMENTS ................................................ 2

Tools and Parts............................................................................ 2

Location Requirements ................................................................ 2

Electrical Requirements - U.S.A. Only ......................................... 4

Electrical Requirements - Canada Only ...................................... 5

INSTALLATION INSTRUCTIONS .................................................. 5

Unpack Range ............................................................................. 5

Adjust Leveling Legs.................................................................... 5

InstallAnti-Tip Bracket ................................................................. 6

Electrical Connection - U.S.A. Only ............................................. 7

Verify Anti-Tip Bracket Is Installed and Engaged ...................... 12

Level Range ............................................................................... 12

Complete Installation ................................................................. 13

Moving the Range ...................................................................... 13

SI_CURITI_ DE LA CUISINII_RE ................................................. 14

EXIGENCES D'INSTALLATION ................................................. 15

Outils et pieces ........................................................................ 15

Exigences d'emplacement ...................................................... 15

Specifications electriques ........................................................ 17

INSTRUCTIONS D'INSTALLATION .......................................... 17

Deballage de lacuisiniere ........................................................ 17

Reglage des pieds de nivellement ........................................... 17

Installation de la bride antibasculement .................................. 18

Verifier que la bride antibasculement est

bien installee et engagee ......................................................... 18

Reglage de I'aplomb de la cuisiniere ....................................... 19

Achever I'installation ................................................................ 20

Deplacement de la cuisiniere ................................................... 20

RANGESAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

iMPORTANT:

Save for local electrical inspector's use.

iMPORTANT :

A conserver pour consultation par I'inspecteur local des installations 61ectriques.

W10722848A

Page 2

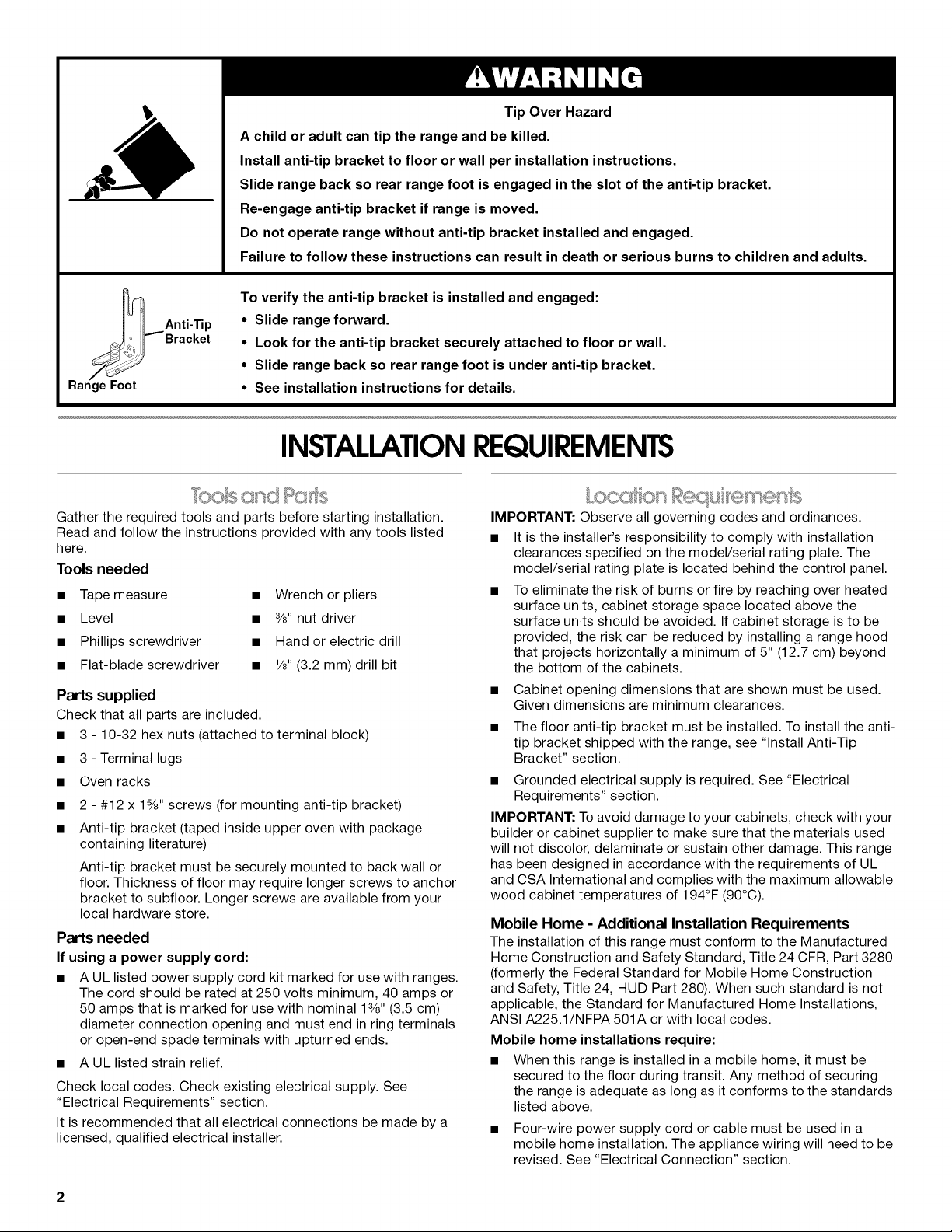

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation instructions.

Slide range back so rear range foot is engaged in the slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed and engaged.

Failure to follow these instructions can result in death or serious burns to children and adults.

To verify the anti-tip bracket is installed and engaged:

h Anti-Tip

Ra_ '''Bracket

• Slide range forward.

• Look for the anti-tip bracket securely attached to floor or wall.

• Slide range back so rear range foot is under anti-tip bracket.

• See installation instructions for details.

INSTALLATIONREQUIREMENTS

s Grid

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Tools needed

• Tape measure • Wrench or pliers

• Level • 3/8"nut driver

• Phillips screwdriver • Hand or electric drill

• Flat-blade screwdriver • 1/8"(3.2 mm) drill bit

Parts supplied

Check that all parts are included.

3 - 10-32 hex nuts (attached to terminal block)

3 - Terminal lugs

Oven racks

2 - #12 x 1%" screws (for mounting anti-tip bracket)

Anti-tip bracket (taped inside upper oven with package

containing literature)

Anti-tip bracket must be securely mounted to back wall or

floor. Thickness of floor may require longer screws to anchor

bracket to subfloor. Longer screws are available from your

local hardware store.

Parts needed

If using a power supply cord:

• A UL listed power supply cord kit marked for use with ranges.

The cord should be rated at 250 volts minimum, 40 amps or

50 amps that is marked for use with nominal 13/8"(3.5 cm)

diameter connection opening and must end in ring terminals

or open-end spade terminals with upturned ends.

• A UL listed strain relief.

Check local codes. Check existing electrical supply. See

"Electrical Requirements" section.

It is recommended that all electrical connections be made by a

licensed, qualified electrical installer.

Tip Over Hazard

IMPORTANT: Observe all governing codes and ordinances.

• It is the installer's responsibility to comply with installation

clearances specified on the model/serial rating plate. The

model/serial rating plate is located behind the control panel.

• To eliminate the risk of burns or fire by reaching over heated

surface units, cabinet storage space located above the

surface units should be avoided. If cabinet storage is to be

provided, the risk can be reduced by installing a range hood

that projects horizontally a minimum of 5" (12.7 cm) beyond

the bottom of the cabinets.

Cabinet opening dimensions that are shown must be used.

Given dimensions are minimum clearances.

The floor anti-tip bracket must be installed. To install the anti-

tip bracket shipped with the range, see "Install Anti-Tip

Bracket" section.

• Grounded electrical supply is required. See "Electrical

Requirements" section.

IMPORTANT: To avoid damage to your cabinets, check with your

builder or cabinet supplier to make sure that the materials used

will not discolor, delaminate or sustain other damage. This range

has been designed in accordance with the requirements of UL

and CSA International and complies with the maximum allowable

wood cabinet temperatures of 194°F (90°C).

Mobile Home - Additional installation Requirements

The installation of this range must conform to the Manufactured

Home Construction and Safety Standard, Title 24 CFR, Part 3280

(formerly the Federal Standard for Mobile Home Construction

and Safety, Title 24, HUD Part 280). When such standard is not

applicable, the Standard for Manufactured Home Installations,

ANSI A225.1/NFPA 501A or with local codes.

Mobile home installations require:

• When this range is installed in a mobile home, it must be

secured to the floor during transit. Any method of securing

the range is adequate as long as it conforms to the standards

listed above.

• Four-wire power supply cord or cable must be used in a

mobile home installation. The appliance wiring will need to be

revised. See "Electrical Connection" section.

2

Page 3

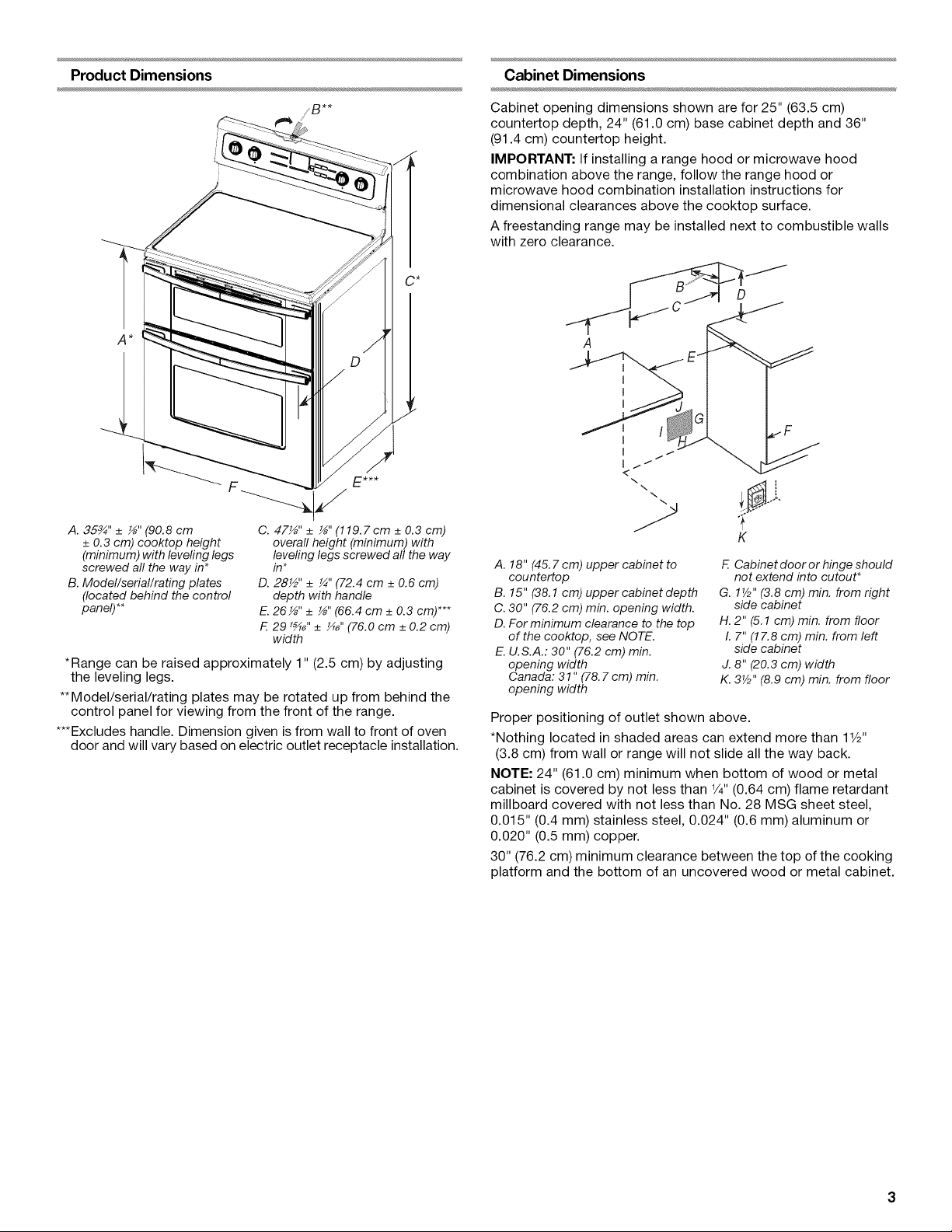

Product Dimensions

Cabinet Dimensions

Cabinet opening dimensions shown are for 25" (63.5 cm)

countertop depth, 24" (61.0 cm) base cabinet depth and 36"

(91.4 cm) countertop height.

IMPORTANT: If installing a range hood or microwave hood

combination above the range, follow the range hood or

microwave hood combination installation instructions for

dimensional clearances above the cooktop surface.

A freestanding range may be installed next to combustible walls

with zero clearance.

A

E***

A. 353/4"+__" (90.8 cm

+ 0.3 cm) cooktop height

(minimum)with leveringlegs

screwed aftthe way in*

B. Model/serial/rating plates

(locatedbehind the control

panel)**

F-._.

C. 471/8"+ _" (119.7cm + 0.3 cm)

overallheight (minimum)with

leveringlegsscrewed all the way

in*

D.28½" +_¼"(72.4cm +_0.6 cm)

depth with handle

E. 26_" + _" (66.4 cm + 0.3 cm)***

F. 29 1_,, + _,, (76.0 cm + 0.2 cm)

width

*Range can be raised approximately 1" (2.5 cm) by adjusting

the leveling legs.

**Model/serial/rating plates may be rotated up from behind the

control panel for viewing from the front of the range.

***Excludes handle. Dimension given is from wall to front of oven

door and will vary based on electric outlet receptacle installation.

A. 18" (45. 7 cm) upper cabinet to

countertop

B. 15" (38.1 cm) upper cabinet depth

C. 30" (76.2 cm) min. opening width.

D. For minimum clearance to the top

of the cooktop, see NOTE.

E. U.S.A.: 30" (76.2 cm) min.

opening width

Canada: 31" (78. 7 cm) min.

opening width

F. Cabinet door or hinge should

not extend into cutout*

G. 1_/2''(3.8 cm) min. from right

side cabinet

H. 2" (5.1 cm) min. from floor

I. 7" (17.8 cm) min. from left

side cabinet

J. 8" (20.3 cm) width

K. 3V2"(8.9 cm) min. from floor

Proper positioning of outlet shown above.

*Nothing located in shaded areas can extend more than 11/2"

(3.8 cm) from wall or range will not slide all the way back.

NOTE: 24" (61.0 cm) minimum when bottom of wood or metal

cabinet is covered by not less than 1/4"(0.64 cm) flame retardant

millboard covered with not less than No. 28 MSG sheet steel,

0.015" (0.4 mm) stainless steel, 0.024" (0.6 mm) aluminum or

0.020" (0.5 mm) copper.

30" (76.2 cm) minimum clearance between the top of the cooking

platform and the bottom of an uncovered wood or metal cabinet.

Page 4

...._,,_,_,q>,._,......_,........_,_,o,_,__,,,_,_,_@2_%_' y

Ifcodespermitandaseparategroundwireisused,itis

recommendedthataqualifiedelectricalinstallerdeterminethat

thegroundpathandwiregaugeareinaccordancewithlocal

codes.

Donotuseanextensioncord.

Besurethattheelectricalconnectionandwiresizeareadequate

andinconformancewiththeNationalElectricalCode,ANSI/

NFPA70-latesteditionandalllocalcodesandordinances.

Acopyoftheabovecodestandardscanbeobtainedfrom:

NationalFireProtectionAssociation

1BatterymarchPark

Quincy,MA02169-7471

WARNING:Improperconnectionoftheequipment-grounding

conductorcanresultinariskofelectricshock.Checkwitha

qualifiedelectricianorservicetechnicianifyouareindoubtasto

whethertheapplianceisproperlygrounded.Donotmodifythe

powersupplycordplug.Ifitwillnotfittheoutlet,haveaproper

outletinstalledbyaqualifiedelectrician.

Electrical Connection

To properly install your range, you must determine the type of

electrical connection you will be using and follow the instructions

provided for it here.

• Range must be connected to the proper electrical voltage

and frequency as specified on the model/serial rating plate.

The model/serial rating plate is located behind the control

panel. Refer to the figures in "Product Dimensions" in the

"Location Requirements" section.

• This range is manufactured with the neutral terminal

connected to the cabinet. Use a 3-wire, UL listed, 40- or 50-

amp power supply cord (pigtail) (see the following Range

Rating chart). If local codes do not permit ground through the

neutral, use a 4-wire power supply cord rated at 250 volts,

40- or 50-amps and investigated for use with ranges.

Range Rating* Specified Rating of

Power Supply Cord Kit

and Circuit Protection

120/240 Volts 120/208 Volts Amps

8.8- 16.5 KW 7.8- 12.5 KW 40 or 50"*

16.6 - 22.5 KW 12.6 - 18.5 KW 50

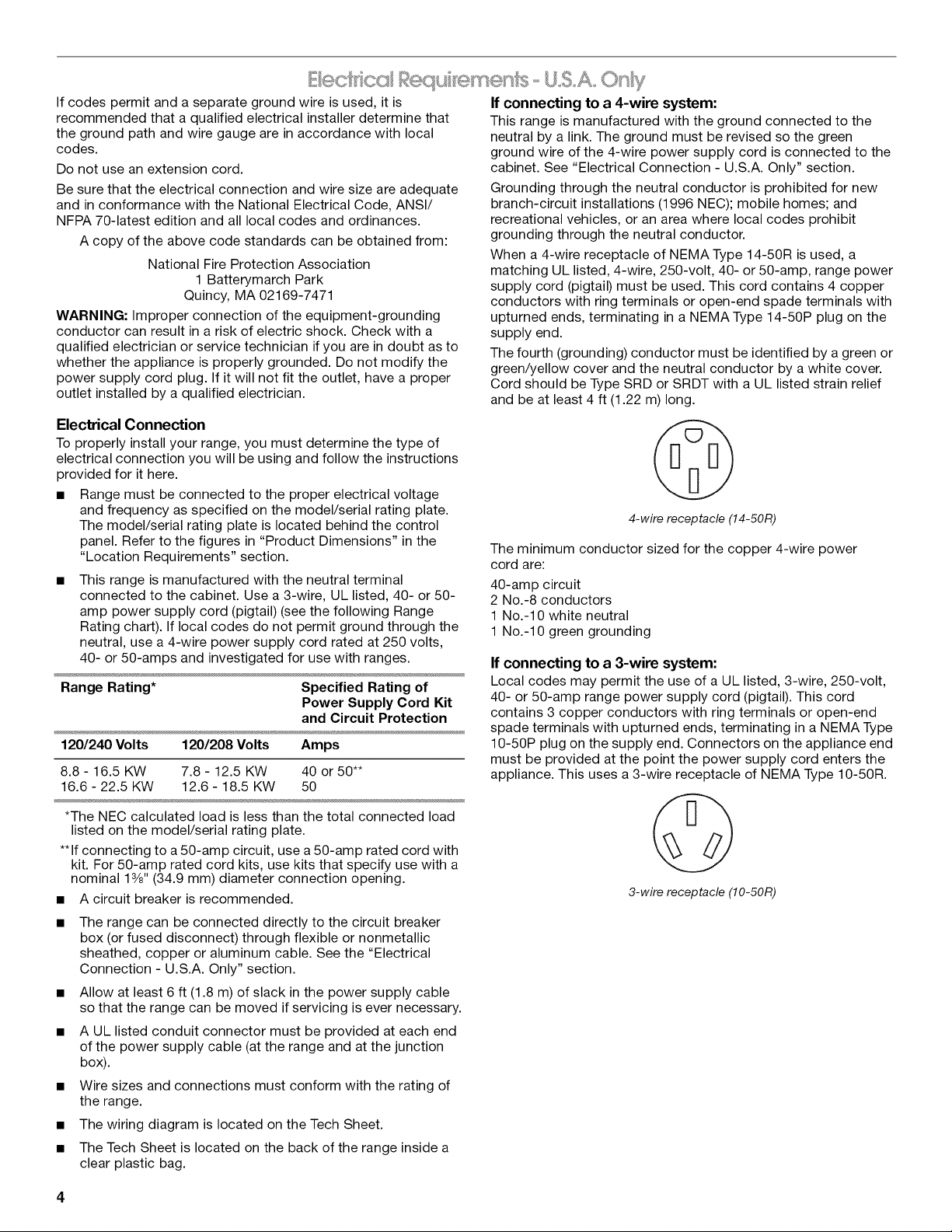

If connecting to a 4-wire system:

This range is manufactured with the ground connected to the

neutral by a link. The ground must be revised so the green

ground wire of the 4-wire power supply cord is connected to the

cabinet. See "Electrical Connection - U.S.A. Only" section.

Grounding through the neutral conductor is prohibited for new

branch-circuit installations (1996 NEC); mobile homes; and

recreational vehicles, or an area where local codes prohibit

grounding through the neutral conductor.

When a 4-wire receptacle of NEMA Type 14-50R is used, a

matching UL listed, 4-wire, 250-volt, 40- or 50-amp, range power

supply cord (pigtail) must be used. This cord contains 4 copper

conductors with ring terminals or open-end spade terminals with

upturned ends, terminating in a NEMA Type 14-50P plug on the

supply end.

The fourth (grounding) conductor must be identified by a green or

green/yellow cover and the neutral conductor by a white cover.

Cord should be Type SRD or SRDT with a UL listed strain relief

and be at least 4 ft (1.22 m) long.

@

4-wire receptacle (14-50R)

The minimum conductor sized for the copper 4-wire power

cord are:

40-amp circuit

2 No.-8 conductors

1 No.-10 white neutral

1 No.-10 green grounding

If connecting to a 3-wire system:

Local codes may permit the use of a UL listed, 3-wire, 250-volt,

40- or 50-amp range power supply cord (pigtail). This cord

contains 3 copper conductors with ring terminals or open-end

spade terminals with upturned ends, terminating in a NEMA Type

10-50P plug on the supply end. Connectors on the appliance end

must be provided at the point the power supply cord enters the

appliance. This uses a 3-wire receptacle of NEMA Type 10-50R.

*The NEC calculated load is less than the total connected load

listed on the model/serial rating plate.

**If connecting to a 50-amp circuit, use a 50-amp rated cord with

kit. For 50-amp rated cord kits, use kits that specify use with a

nominal 13/8"(34.9 mm) diameter connection opening.

• A circuit breaker is recommended.

• The range can be connected directly to the circuit breaker

box (or fused disconnect) through flexible or nonmetallic

sheathed, copper or aluminum cable. See the "Electrical

Connection - U.S.A. Only" section.

• Allow at least 6 ft (1.8 m) of slack in the power supply cable

so that the range can be moved if servicing is ever necessary.

• A UL listed conduit connector must be provided at each end

of the power supply cable (at the range and at the junction

box).

• Wire sizes and connections must conform with the rating of

the range.

• The wiring diagram is located on the Tech Sheet.

• The Tech Sheet is located on the back of the range inside a

clear plastic bag.

3-wire receptacle (10-50R)

Page 5

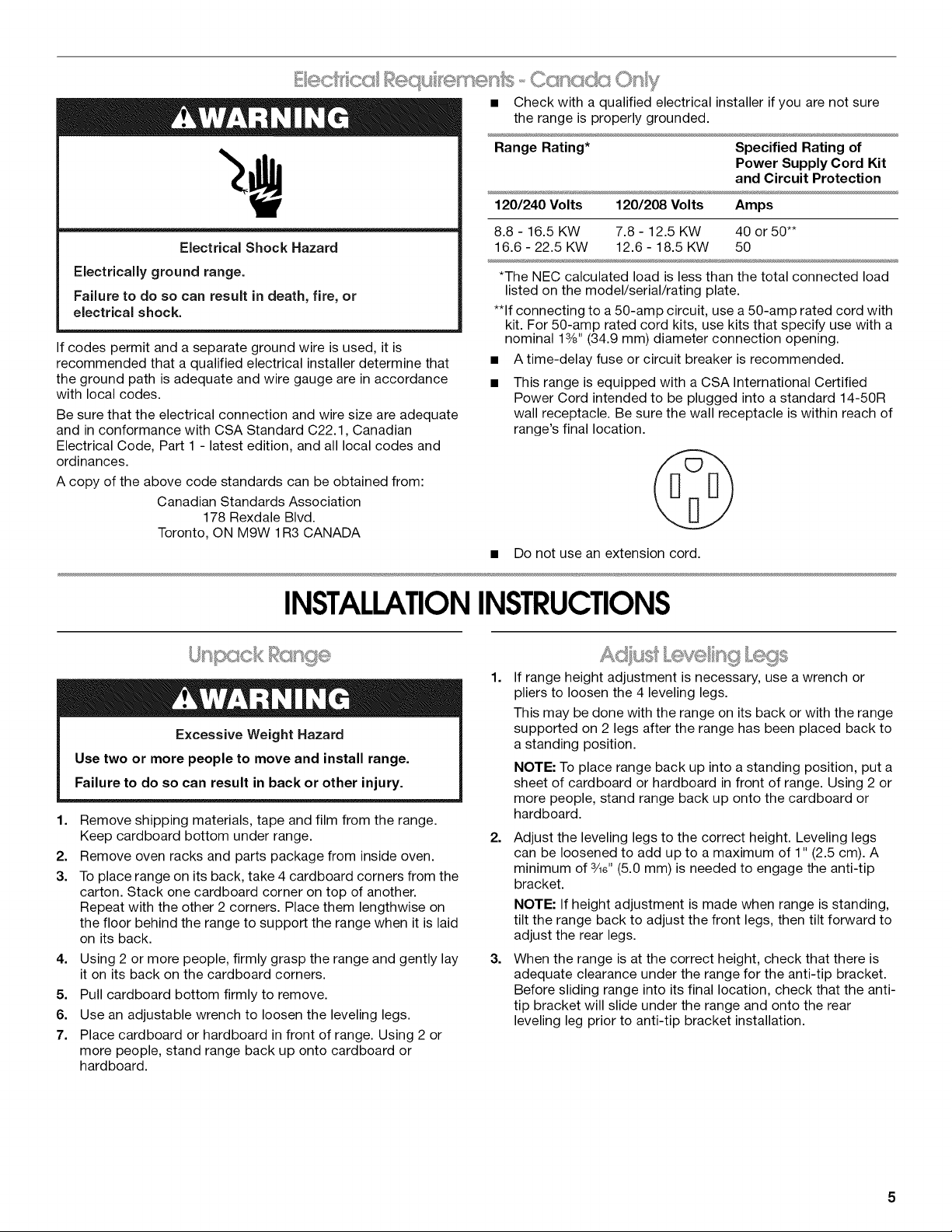

Electrical Shock Hazard

Electrically ground range.

Failure to do so can result in death, fire, or

electrical shock.

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrical installer determine that

the ground path is adequate and wire gauge are in accordance

with local codes.

Be sure that the electrical connection and wire size are adequate

and in conformance with CSA Standard C22.1, Canadian

Electrical Code, Part 1 - latest edition, and all local codes and

ordinances.

A copy of the above code standards can be obtained from:

Canadian Standards Association

178 Rexdale Blvd.

Toronto, ON M9W 1R3 CANADA

• Check with a qualified electrical installer if you are not sure

the range is properly grounded.

Range Rating* Specified Rating of

Power Supply Cord Kit

and Circuit Protection

120/240 Volts 120/208 Volts Amps

8.8 - 16.5 KW 7.8- 12.5 KW 40 or 50"*

16.6 - 22.5 KW 12.6 - 18.5 KW 50

*The NEC calculated load is less than the total connected load

listed on the model/serial/rating plate.

**If connecting to a 50-amp circuit, use a50-amp rated cord with

kit. For 50-amp rated cord kits, use kits that specify use with a

nominal 13/8"(34.9 mm) diameter connection opening.

• A time-delay fuse or circuit breaker is recommended.

• This range is equipped with a CSA International Certified

Power Cord intended to be plugged into a standard 14-50R

wall receptacle. Be sure the wall receptacle is within reach of

range's final location.

• Do not use an extension cord.

INSTALLATIONINSTRUCTIONS

' .... * Bsn,ge

Excessive Weight Hazard

Use two or more people to move and install range.

Failure to do so can result in back or other injury.

1. Remove shipping materials, tape and film from the range.

Keep cardboard bottom under range.

2. Remove oven racks and parts package from inside oven.

3. To place range on its back, take 4 cardboard corners from the

carton. Stack one cardboard corner on top of another.

Repeat with the other 2 corners. Place them lengthwise on

the floor behind the range to support the range when it is laid

on its back.

4. Using 2 or more people, firmly grasp the range and gently lay

it on its back on the cardboard corners.

5. Pull cardboard bottom firmly to remove.

6. Use an adjustable wrench to loosen the leveling legs.

7. Place cardboard or hardboard in front of range. Using 2 or

more people, stand range back up onto cardboard or

hardboard.

Ad@ t1 I%<

1,

If range height adjustment is necessary, use a wrench or

pliers to loosen the 4 leveling legs.

This may be done with the range on its back or with the range

supported on 2 legs after the range has been placed back to

a standing position.

NOTE: To place range back up into a standing position, put a

sheet of cardboard or hardboard in front of range. Using 2 or

more people, stand range back up onto the cardboard or

hardboard.

2. Adjust the leveling legs to the correct height. Leveling legs

can be loosened to add up to a maximum of 1" (2.5 cm). A

minimum of 3/16"(5,0 mm) is needed to engage the anti-tip

bracket.

NOTE: If height adjustment is made when range is standing,

tilt the range back to adjust the front legs, then tilt forward to

adjust the rear legs.

3. When the range is at the correct height, check that there is

adequate clearance under the range for the anti-tip bracket.

Before sliding range into its final location, check that the anti-

tip bracket will slide under the range and onto the rear

leveling leg prior to anti-tip bracket installation.

Page 6

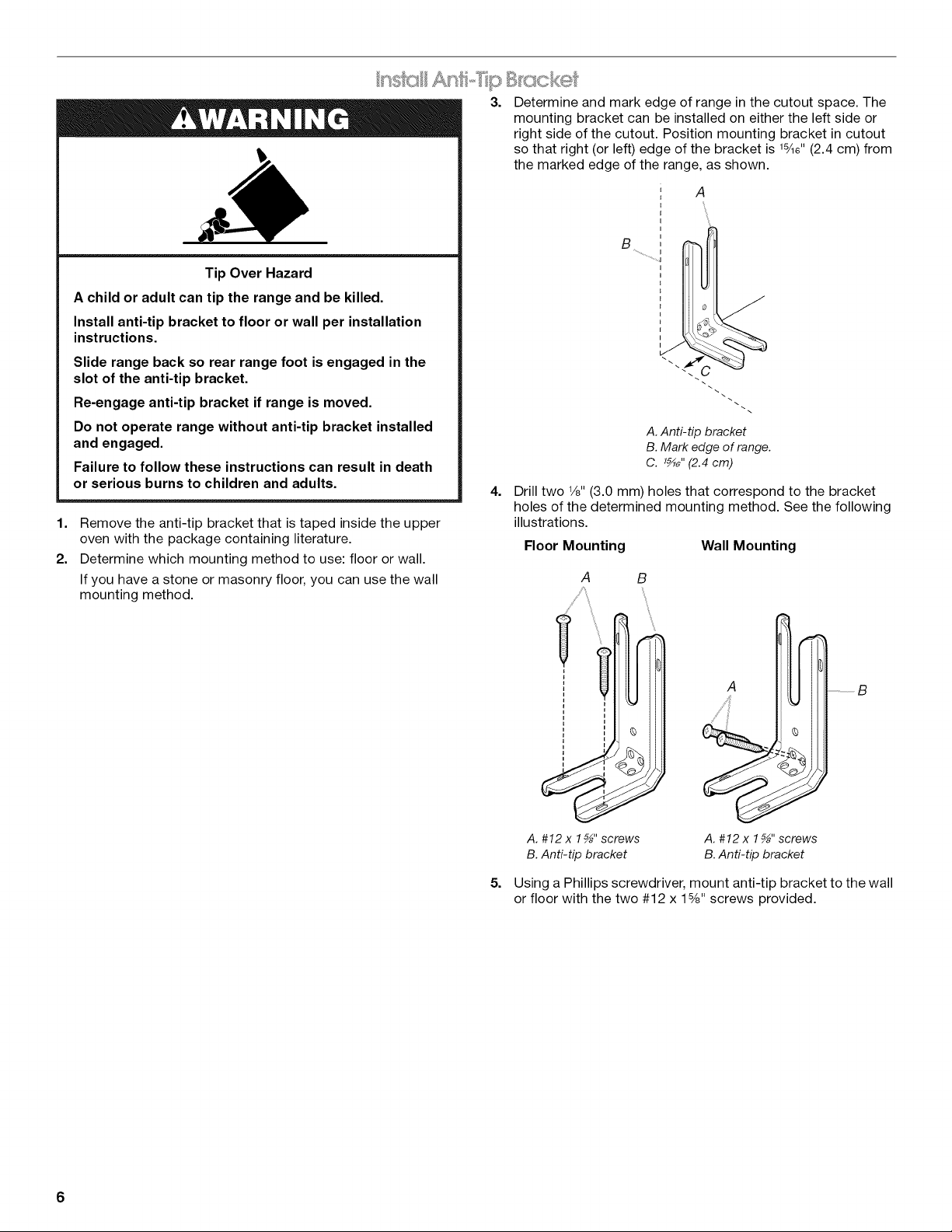

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation

instructions.

Slide range back so rear range foot is engaged in the

slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed

and engaged.

Failure to follow these instructions can result in death

or serious burns to children and adults.

1. Remove the anti-tip bracket that is taped inside the upper

oven with the package containing literature.

2. Determine which mounting method to use: floor or wall.

If you have a stone or masonry floor, you can use the wall

mounting method.

3. Determineandmarkedgeofrangeinthecutoutspace.The

mountingbracketcanbeinstalledoneithertheleftsideor

rightsideofthecutout.Positionmountingbracketincutout

sothatright(orleft)edgeofthebracketis1%e"(2.4cm)from

themarkededgeoftherange,asshown.

A

5S

x

A. Anti-tip bracket

B. Mark edge of range.

C. 1_,, (2.4 cm)

4=

Drill two 1/8"(3.0 mm) holes that correspond to the bracket

holes of the determined mounting method. See the following

illustrations.

Floor Mounting Wall Mounting

A B

B

A. #12 x 1 5_,,screws

B. Anti-tip bracket

5. Using a Phillips screwdriver, mount anti-tip bracket to the wall

or floor with the two #12 x 1%" screws provided.

A. #12 x 1 5_,,screws

B. Anti-tip bracket

6

Page 7

Power Supply Cord

Direct Wire

Electrical Shock Hazard

Disconnect power before servicing.

Use a new 40 amp power supply cord.

Plug into a grounded outlet.

Failure to follow these instructions can result in death,

fire, or electrical shock.

1=

Disconnect power.

2.

Use Phillips screwdriver to remove the terminal block cover

screw located on the back of the range. Pull cover down and

toward you to remove cover.

3.

Remove plastic tag holding three 10-32 hex nuts from the

middle post of the terminal block.

Electrical Shock Hazard

Disconnect power before servicing.

Use 8 gauge copper or 6 gauge aluminum wire.

Electrically ground range.

Failure to follow these instructions can result in death,

fire, or electrical shock.

Style 1: Power supply cord strain relief

• Assemble a UL listed strain relief in the opening.

J:

ii

ir

x/

4. Add strain relief.

. i"]........

A. UL listed strain refief

Feed the power supply cord through the strain relief in the

cord/conduit plate on bottom of range. Allow enough

slack to easily attach the wiring to the terminal block.

• Tighten strain relief screw against the power supply cord.

Page 8

Style 2: Direct wire strain relief

• Use Phillips screwdriver to remove screws and slide

cord/conduit plate down and out.

• Position cord/conduit plate as shown in the following

illustration.

• Replace cord/conduit plate and insert screws.

Feed the flexible conduit through the strain relief, allowing

enough slack to easily attach wiring to the terminal block.

Tighten strain relief screw against the flexible conduit.

5. Replace back panel and screws on rear of range.

6. Complete installation following instructions for your type of

electrical connection:

4-wire (recommended)

3-wire (if 4-wire is not available)

Electrical Connection Options

If your home has: And you will be Go to Section:

connecting to:

4-wire receptacle

(NEMA type 14-50R)

A UL listed,

250-volt

minimum,

40-amp, range

power supply

cord

4-wire connection:

Power supply cord

• Assemble a UL listed conduit connector in the opening.

i ............ " ............

t

4-wire direct

(12.7 cm)

3-wire receptacle

(NEMA type 10-50R)

3-wire direct

1 it

(7.6 crn)

A fused

disconnect or

circuit breaker

box

A UL listed,

250-volt

minimum,

40-amp, range

power supply

cord

A fused 3-wire connection:

disconnect or Direct wire

circuit breaker

box

4-wire connection:

Direct wire

3-wire connection:

Power supply cord

A. Removable retaining nut

B. Strain relief

8

Page 9

4-wire connection: Power Supply Cord

Use this method for:

• New branch-circuit installations (1996 NEC)

• Mobile homes

• Recreational vehicles

• In an area where local codes prohibit grounding through the

neutral

1. Part of metal ground strap must be cut out and removed.

5. Use 3/8"nut driver to connect the neutral (white) wire to the

center terminal block post with one of the 10-32 hex nuts.

A

F

B

C

A

B

C

A. Metal ground strap

B. Discard

C. Ground-link screw

2. Use Phillips screwdriver to remove the ground-link screw

from the back of the range. Save the ground-link screw and

the end of the ground link under the screw.

3. Feed the power supply cord through the strain relief in the

cord/conduit plate on bottom of range. Allow enough slack to

easily attach the wiring to the terminal block.

i i i !J

i ................................

I

/'

D

A. 10-32 hex nut

B. Ground-link screw

C. Line 1 (black)

D. Green ground wire

E.Neutral (center) wire

F. Line 2 (red)

6. Connect line 1 (black) and line 2 (red) wires to the outer

terminal block posts with 10-32 hex nuts.

7. Securely tighten hex nuts.

NOTE: For power supply cord replacement, only use a power

cord rated at 250 volts minimum, 40 amps or 50 amps that is

marked for use with nominal 13/8"(3.5 cm) diameter

connection opening, with ring terminals and marked for use

with ranges.

8. Replace terminal block access cover.

3-wire connection: Power Supply Cord

Use this method only if local codes permit connecting chassis

ground conductor to neutral wire of power supply cord.

1. Feed the power supply cord through the strain relief in the

cord/conduit plate on bottom of range. Allow enough slack to

easily attach the wiring to the terminal block.

i!- /o,,

D

A. Terminal block

B. Ground-link screw

4=

Use Phillips screwdriver to connect the green ground wire

C. Cord/conduit plate

D. Power supply cord wires

from the power supply cord to the range with the ground-link

screw. The ground wire must be attached first.

C

D

A. Terminal block C. Cord/conduit plate

B. Ground-link screw D. Power supply cord wires

Page 10

2,

Use 3/8"nut driver to connect the neutral (white) wire to the

center terminal block post with one of the 10-32 hex nuts.

4-wire Connection: Direct Wire

......J

A

B

C

A. 10-32 hex nut

B. Line 1 (black)

C. Ground-link screw

D. Neutral (white) wire

E.Line 2 (red)

3. Connect line 1 (black) and line 2 (red) wires to the outer

terminal block posts with 10-32 hex nuts.

4. Securely tighten hex nuts.

NOTE: For power supply cord replacement, only use a power

cord rated at 250 volts minimum, 40 amps or 50 amps that is

marked for use with nominal 13/8"(3.5 cm) diameter

connection opening, with ring terminals and marked for use

with ranges.

5. Replace terminal block access cover.

Direct Wire Installation: Copper or Aluminum Wire

E

Use this method for:

• New branch-circuit installations (1996 NEC)

• Mobile homes

• Recreational vehicles

• In an area where local codes prohibit grounding through the

neutral

1. Part of metal ground strap must be cut out and removed.

A

B

C

A.Metal ground strap

B.Discard

C.Ground-link screw

2. Use Phillips screwdriver to remove the ground-link screw

from the back of the range. Save the ground-link screw and

the end of the ground link under the screw.

3. Pull the conduit through the strain relief on cord/conduit plate

on bottom of range. Allow enough slack to easily attach

wiring to the terminal block.

This range may be connected directly to the fuse disconnect or

circuit breaker box. Depending on your electrical supply, make

the required 3-wire or 4-wire connection.

1. Strip outer covering back 3" (7.6 cm) to expose wires. Strip

the insulation back 1" (2.5 cm) from the end of each wire.

1 it

(7.6 cm)

2. Allow enough slack in the wire to easily attach the wiring

terminal block.

3. Complete electrical connection according to your type of

electrical supply (4-wire or 3-wire connection).

IL.................i

G

A. Terminal block

B. Ground-link screw

C. Cord/conduit plate

D. Line 2 (red) wire

C

D

F

E. Neutral (white) wire

F. Line 1 (black) wire

G. Bare (green) ground wire

10

Page 11

4=

Attach terminal lugs to line 1 (black), neutral (white), and line 2

(red) wires. Loosen (do not remove) the setscrew on the front

of the terminal lug and insert exposed wire end through

bottom of terminal lugs. Securely tighten setscrew to

XX Ibs-in. torque. See Bare Wire Torque Specifications chart.

! !

! !

| !

C

A. Terminal lug D. Neutral (white) wire

B. Setscrew E. Line 2 (red) wire

C. Line 1 (black) wire

Bare Wire Torque Specifications

Attaching terminal lugs to the terminal block - 20 Ibs-in. (2.3 N-m)

Wire Awg Torque

8 gauge copper 25 Ibs-in. (2.8 N-m)

6 gauge aluminum 35 Ibs-in. (4.0 N-m)

5. Use Phillips screwdriver to connect the bare (green) ground

wire to the range with the ground-link screw. The ground wire

must be attached first and must not contact any other

terminal.

6. Use 3/8"nut driver to connect the neutral (white) wire to the

center terminal block post with one of the 10-32 hex nuts.

3-wire connection: Direct Wire

Use this method only if local codes permit connecting ground

conductor to neutral supply wire.

1. Pull the conduit through the hole and conduit plate on bottom

of range. Allow enough slack to easily attach the wiring to the

terminal block.

! //

C

F

A. Terminal block

B. Ground-link screw

C. Cord/conduit plate

2=

Attach terminal lugs to line 1 (black), bare (green) ground, and

D. Line 2 (red) wire

E. Bare (green) ground wire

F. Line 1 (black) wire

line 2 (red) wires. Loosen (do not remove) the setscrew on the

front of the terminal lug and insert exposed wire end through

bottom of terminal lugs. Securely tighten setscrew to

XX Ibs-in. torque. See Bare Wire Torque Specifications chart.

A

A

L

F

D

E

C

A. 10-32 hex nut

B. Line 1 (black)

C. Bare (green) ground wire

D. Ground-link screw

E. Neutral (white) wire

F. Line 2 (red)

G. Terminal lug

7. Connect line 1 (black) and line 2 (red) wires to the outer

terminal block posts with 10-32 hex nuts.

8. Securely tighten hex nuts.

9. Replace terminal block access cover.

C D

A. Terminal lug

B. Setscrew

C. Line 1 (black) wire

D. Bare (green) ground wire

E. Line 2 (red) wire

11

Page 12

Bare Wire Torque Specifications

Attaching terminal lugs to the terminal block - 20 Ibs-in. (2.3 N-m)

Wire Awg Torque

8 gauge copper 25 Ibs-in. (2.8 N-m)

6 gauge aluminum 35 Ibs-in. (4.0 N-m)

3. Use 3/8"nut driver to connect the bare (green) ground wire to

the center terminal block post with one of the 10-32 hex nuts.

"L

F

A

E

B

D

C

A. 10-32 hex nut

B. Line 1 (black)

C. Ground-link screw

D. Bare (green) ground wire

E.Line 2 (red)

F. Terminal lug

4. Connect line 1 (black) and line 2 (red) wires to the outer

terminal block posts with 10-32 hex nuts.

5. Securely tighten hex nuts.

6. Replace terminal block access cover.

3. If the rear of the range lifts more than 1/2"(1.3 cm) off the floor

without resistance, stop tilting the range and lower it gently

back to the floor. The range foot is not engaged in the anti-tip

bracket.

IMPORTANT: If there is a snapping or popping sound when lifting

the range, the range may not be fully engaged in the bracket.

Check to see if there are obstructions keeping the range from

sliding to the wall or keeping the range foot from sliding into the

bracket. Verify that the bracket is held securely in place by the

mounting screws.

4. Slide the range forward, and verify that the anti-tip bracket is

securely attached to the floor or wall.

5. Slide range back so the rear range foot is inserted into the

slot of the anti-tip bracket.

IMPORTANT: If the back of the range is more than 2" (5.1 cm)

from the mounting wall, the rear range foot may not engage the

bracket. Slide the range forward and determine if there is an

obstruction between the range and the mounting wall. If you

need assistance or service, refer to the "Assistance or Service"

section of the Use and Care Guide, or the cover or "Warranty"

section of the User Instructions, for contact information.

6. Repeat steps 1 and 2 to ensure that the range foot is

engaged in the anti-tip bracket.

If the rear of the range lifts more than 1/2"(1.3 cm) off the floor

without resistance, the anti-tip bracket may not be installed

correctly. Do not operate the range without anti-tip bracket

installed and engaged. Please reference the "Assistance or

Service" section of the Use and Care Guide, or the cover or

"Warranty" section of the User Instructions, to contact

service.

1,

Place the outside of your foot against the bottom front of the

oven door to keep the range from moving, and grasp the

lower right or left side of the control panel as shown.

NOTE: If your countertop is mounted with a backsplash, it

may be necessary to grasp the range higher than is shown in

the illustration.

1,

Place a rack in oven.

2.

Place level on rack and check levelness of range, first side to

side; then front to back.

3. If range is not level, pull range forward until rear leveling leg is

removed from the anti-tip bracket.

4. Use a wrench or pliers to adjust leveling legs up or down until

the range is level. Push range back into position.

5. Check that rear leveling leg is engaged in the anti-tip bracket.

NOTE: Range must be level for satisfactory baking

performance.

2. Slowly attempt to tilt the range forward.

If you encounter immediate resistance, the range foot is

engaged in the anti-tip bracket.

12

Page 13

If removing the range is necessary for cleaning or maintenance:

I. Check that all parts are now installed. If there is an extra part,

go back through the steps to see which step was skipped.

2. Check that you have all of your tools.

3. Dispose of/recycle all packaging materials.

4. Check that the range is level. See the "Level Range" section.

5. Use a mild solution of liquid household cleaner and warm

water to remove waxy residue caused by shipping material.

Dry thoroughly with a soft cloth. For more information, read

the "Range Care" section of the Use and Care Guide.

6. Read the range Use and Care Guide.

7. Plug power cord into appropriate outlet. Slide range into its

final location. Check that the flexible conduit or power supply

cord are not bent.

8. Turn power on. Turn on surface elements and oven. See the

Use and Care Guide for specific instruction on range

operation.

If range does not operate, check the following:

• Household fuse is intact and tight; or circuit breaker has not

tripped.

• Range is plugged into a grounded outlet.

• Electrical supply is connected.

• See the "Troubleshooting" section in the Use and Care Guide.

When the range has been on for 5 minutes, check for heat. If

range is cold, turn off the range and contact a qualified

technician.

For power supply cord-connected ranges:

1. Slide range forward.

2. Unplug the power supply cord.

3. Complete cleaning or maintenance.

4. Plug power supply cord into a grounded outlet.

5. Slide range back so rear range foot is under anti-tip bracket.

6. Refer to the "Verify Anti-Tip Bracket Is Installed and

Engaged" section to verify engagement.

7. Check that range is level.

For direct-wired ranges:

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation

instructions.

Slide range back so rear range foot is engaged in the

slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed

and engaged.

Failure to follow these instructions can result in death

or serious burns to children and adults.

When moving range, slide range onto cardboard or hardboard to

avoid damaging the floor covering.

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

1. Disconnect power.

2. Slide range forward.

3. Complete cleaning or maintenance.

4. Slide range back so rear range foot is under anti-tip bracket.

5. Refer to the "Verify Anti-Tip Bracket Is Installed and

Engaged" section to verify engagement.

6. Check that range is level.

7. Reconnect power.

13

Page 14

SECURITEDELACUISINIERE

Votre securite et celle des autres est tres importante.

Nous donnons de nombreux messages de s_curit_ importants dans ce manuel et sur votre appareil m_nager. Assurez-vous de

toujours lire tousles messages de s_curit_ et de vous y conformer.

Ce symbole d'alerte de s_curit_ vous signale les dangers potentiels de d_c_s et de blessures graves & vous

et & d'autres.

Voici le symbole d'alerte de s_curit&

Tous les messages de s_curit_ suivront le symbole d'alerte de s_curit_ et le mot "DANGER" ou

"AVERTISSEMENT". Ces mots signifient •

Risque possible de d_cbs ou de blessure grave si vous ne

suivez pas imm_diatement les instructions.

Risque possible de d_cbs ou de blessure grave si vous

ne suivez pas les instructions.

Tousles messages de s_curit_ vous diront quel est le danger potentiel et vous disent comment r_duire le risque de blessure et

ce qui peut se produire en cas de non-respect des instructions.

I antibasculement

Bride

Pied de la cuisiniere

Risque de basculement

Un enfant ou une personne adulte peut faire basculer la cuisini_re, ce qui peut causer un

d_cbs.

Fixer la bride antibasculement au plancher ou au mur, conform_ment aux instructions

d'installation.

Faire glisser de nouveau la cuisinibre de fa_on a ce que le pied arribre de la cuisinibre se

trouve dans la fente de la bride antibasculement.

R_engager la bride antibasculement si la cuisinibre a _t_ d_plac_e.

Ne pas faire fonctionner la cuisinibre si la bride antibasculement n'est pas install_e et engag_e.

Le non-respect de ces instructions peut causer un d_cbs ou des brl)lures graves aux enfants et

aux adultes.

Pour v_rifier que la bride antibasculement est bien install_e et engag_e :

• Faire glisser la cuisini_re vers I'avant.

• V_rifier que la bride antibasculement est bien fix_e au plancher ou au mur.

• Faire de nouveau glisser la cuisini_re vers I'arri_re de sorte que le pied de la cuisini_re

se trouve sous la bride antibasculement.

• Voir les instructions d'installation pour plus de d_tails.

14

Page 15

EXIGENCESD'INSTALLATION

Rassembler les outils et composants necessaires avant

d'entreprendre I'installation. Lire et observer les instructions

fournies avec chacun des outils de la liste ci-dessous.

Outils n_cessaires

• Metre-ruban • Cle ou pince

• Niveau • Tourne-ecrou 3/8"

• Tournevis Phillips • Perceuse manuelle ou

• Tournevis a lame plate electrique

• Foret de 1/8"(3,2 mm)

Pi_ces fournies

Verifier que toutes les pieces sont presentes.

• 3 ecrous hexagonaux de 10-32 (joints au bloc de

raccordement)

3 attaches de bornes

Grilles du four

2 vis n°12 x 1%" (pour le montage de la bride

antibasculement)

• Bride anti-basculement (fixee par ruban adhesif a I'interieur

du four superieur avec le sachet de documentation)

La bride antibasculement doit etre bien fixee a la cloison

arriere ou au plancher. Uepaisseur du plancher peut

necessiter des vis plus Iongues pour I'ancrage de la bride

dans le sous-plancher. Des vis plus Iongues sont disponibles

aupres de votre quincaillerie locale.

Pi_ces n_cessaires

En cas d'utilisation d'un c&ble d'alimentation _lectrique :

• Cordon d'alimentation (homologation UL) con£;u pour

I'utilisation avec une cuisiniere. Le cordon doit comporter les

caracteristiques suivantes : service 250 volts minimum, 40 A

ou 50 A, compatible avec une ouverture de diametre nominal

13/8"(3,5 cm) pour le raccordement, et avec cosses rondes ou

en fourche a pointes relevees a I'extremite de chaque

conducteur.

• Un serre-c&ble (homologation UL).

Consulter les codes Iocaux. Verifier I'alimentation electrique

existante. Voir la section "Specifications electriques".

II est recommande de faire realiser tousles raccordements

electriques par un electricien qualifie agree.

IMPORTANT : Observer les dispositions de tous les codes et

reglements en vigueur.

• C'est i_I'installateur qu'incombe la responsabilite de

respecter les distances de separation exigees, specifiees sur

la plaque signaletique de I'appareil. La plaque signaletique se

trouve derriere le tableau de commande.

• Afin de supprimer le risque de brOlures ou d'incendie lie au

fait de se pencher au-dessus des plaques de cuisson

chaudes, les placards de rangement au-dessus des plaques

doivent etre evites. Si des placards de rangement sont

envisages, le risque peut etre reduit par I'installation d'une

hotte de cuisine depassant le bas des placards d'au moins 5"

(12,7 cm) horizontalement.

• Respecter les dimensions indiquees pour les ouvertures

decouper dans les placards. Ces dimensions constituent les

valeurs minimales des degagements.

• La bride antibasculement de plancher doit etre installee. Pour

I'installation de la bride antibasculement fournie avec la

cuisiniere, voir la section "Installation de la bride

antibasculement".

• Une source d'electricite avec liaison & la terre est necessaire.

Voir la section "Specifications electriques".

IMPORTANT : Afin d'eviter d'endommager les placards,

consulter le constructeur de la maison ou le fabricant des

placards pour determiner si les materiaux utilises peuvent subir

un changement de couleur, une destratification ou d'autres

dommages. Cette cuisiniere a ete con(_ue conformement aux

exigences des normes UL et CSA International et respecte les

temperatures maximales permises de 194°F (90°C) pour les

placards en bois.

R_sidence mobile - Specifications additionnelles

respecter Iors de I'installation

L'installation de cette cuisiniere doit etre conforme aux

dispositions de la norme Manufactured Home Construction and

Safety Standard, Title 24 CFR, Part 3280 (anciennement Federal

Standard for Mobile Home Construction and Safety, Title 24,

HUD Part 280). Lorsque cette norme n'est pas applicable,

I'installation doit satisfaire aux criteres de la norme Standard for

Manufactured Home Installations, ANSI A225.1/NFPA 501A ou

aux dispositions des codes Iocaux.

Autres crit_res a respecter pour une installation en r_sidence

mobile :

• Dans le cas de I'installation de cette cuisiniere dans une

residence mobile, la cuisiniere doit etre fixee au plancher

durant tout deplacement du vehicule. Toute methode de

fixation de la cuisiniere est adequate dans la mesure oQelle

satisfait aux criteres des normes mentionnees ci-dessus.

Pour une installation en residence mobile, un c&ble ou cordon

d'alimentation a quatre fils doit etre utilis& Le c&blage de

I'appareil devra etre revise. Voir la section "Raccordement

electrique".

15

Page 16

Dimensions du produit Dimensions du placard

Les dimensions de I'espace d'installation entre les placards sont

valides pour I'installation entre des placards de 24" (61,0 cm) de

profondeur avec plan de travail de 25" (63,5 cm) de profondeur et

36" (91,4 cm) de hauteur.

IMPORTANT • En cas d'installation d'une hotte ou d'un

ensemble hotte/micro-ondes au-dessus de la cuisiniere, suivre

les instructions fournies avec la hotte ou I'ensemble hotte/micro-

ondes concernant les dimensions de degagement a respecter

au-dessus de la surface de la table de cuisson.

Une cuisiniere autoportante peut etre installee sans aucun

degagement &proximite de parois combustibles.

A

A. Hauteur minimale de la table

de cuisson avec pieds de

nivellement completement

relev4s : 35_" +__" (90,8 cm

+_0,3 cm)*

B. Plaques signal4tiques (situ4es

derriere le tableau de

commande)**

C. Hauteur minimale de la table de

cuisson avec pieds de

nivellement completement

relev4s : 471/8"+__" (119, 7 cm +_

0,3 cm)**

D. Profondeur avec poign4e : 28½"

+_¼" (72,4 cm +_0,6 cm)

E. 26 _" +__" (66,4 cm +_0,3 cm)***

F. Largeur de 29 15_,,+_¼_,,(76 cm

+_0,2 cm)

*La cuisiniere peut etre surelevee d'environ 1" (2,5 cm) en

ajustant les pieds de nivellement.

**11est possible de faire pivoter les plaques signaletiques vers le

haut a partir de I'arriere du tableau de commande afin qu'elles

soient visibles depuis I'avant de la cuisiniere.

***Poignee non comprise. La dimension fournie correspond & la

distance du mur & I'avant de la porte du four et varie en

fonction de I'installation de la prise electrique murale.

A. 18" (45,7 cm) entre le placard

sup4rieur et le plan de travail

B. Profondeur des placards

sup4rieurs : 15" (38,1 cm)

C. Largeur de I'ouverture 30"

(76,2 cm) min.

D. Pour la distance fibre

minimale vers la partie

sup4rieure de la table de

cuisson, voir la REMARQUE.

E. U.S.A. : Largeur de

I'ouverture 30" (76,2 cm) min.

Canada : Largeur de

I'ouverture 31" (78,7 cm) min.

E La porte ou charniere du

placard ne doit pas d4passer

I'int4rieur de Ibuverture *

G. 1V2"(3,8 cm) min. depuis le

placard de droite

H. 2" (5,1 cm) min. depuis le

plancher

I. 7" (17,8 cm) min. depuis le

placard de gauche

J. 8" (20,3 cm) de largeur

K. 3Y2" (8,9 cm) min. depuis le

plancher

Position correcte de la prise illustree ci-dessus.

*Aucun element situe dans les zones grisees ne dolt depasser de

plus de 11/="(3,8 cm) depuis le mur, sans quoi la cuisiniere ne

glissera pas jusqu'au fond.

REMARQUE • Distance de separation minimale de 24" (61 cm)

Iorsque le fond d'un placard de bois ou de metal est protege par

une planche ignifugee d'au moins 1/4"(0,64 cm) recouverte d'une

feuille metallique d'epaisseur egale ou superieure & : acier calibre

28 MSG, acier inoxydable 0,015" (0,4 mm), aluminium 0,024"

(0,6 mm), ou cuivre 0,020" (0,5 mm).

Distance de separation de 30" (76,2 cm) ou plus entre le dessus

de la table de cuisson et le fond d'un placard de bois ou de metal

non protege.

16

Page 17

Risque de choc _lectrique

Relier la cuisini_re & la terre.

Le non-respect de cette instruction peut causer

un d_c_s, un incendie ou un choc _lectrique.

Si les codes en vigueur le permettent et qu'un conducteur

distinct de liaison a la terre est utilise, on recommande qu'un

electricien qualifie verifie que la liaison a la terre et la taille du

conducteur de liaison a la terre sont adequates et conformes aux

prescriptions des codes Iocaux.

Verifier que le raccordement &la source d'electricit6 et le calibre

des conducteurs sont conformes aux prescriptions de la plus

recente edition des normes CSA C22.1, partie 1 - Code canadien

de I'electricit6, et de tout code ou reglement local en vigueur.

On peut obtenir un exemplaire des normes ci-dessus aupres de :

Canadian Standards Association

178 Rexdale Blvd.

Toronto, ON M9W 1R3 CANADA

• En cas de doute quant a la qualite de la liaison &laterre de la

cuisiniere, consulter un electricien qualifie.

Specifications _lectriques Intensit_ nominale

pour la cuisini_re* sp_cifi_e du cordon

d'alimentation et de la

protection du circuit

120/240 volts 120/208 volts Amperes

8,8 - 16,5 KW 7,8 - 12,5 KW 40 ou 50**

16,6-22,5KW 12,6-18,5KW 50

*La charge NEC calculee est inferieure a la charge totale

connectee indiquee sur la plaque signaletique.

**En cas de raccordement a un circuit de 50 A, utiliser un cordon

de 50 A nominaux avec son ensemble. Pour les cordons de

50 A nominaux, utiliser des ensembles qui specifient une

utilisation avec une ouverture pour le raccordement d'un

diametre nominal de 1%" (34,9 mm).

• On recommande I'emploi de fusibles temporises ou

disjoncteurs.

• Cette cuisiniere est dotee d'un cordon d'alimentation

(homologation CSA International) destine a _tre branche sur

une prise de courant murale standard 14-50R. Veiller ace

que la prise de courant murale soit placee a portee de la

position de service finale de la cuisiniere.

• Ne pas utiliser de cable de rallonge.

INSTRUCTIONSD'INSTALLATION

Risque du poids excessif

Utiliser deux ou plus de personnes pour d_placer et

installer la cuisini&re.

Le non=respect de cette instruction peut causer

une blessure au dos ou d'autre blessure.

1. Oter les materiaux d'emballage, le ruban adhesif et le film de

la cuisiniere. Laisser la base de carton sous la cuisiniere.

2. Retirer les grilles de four et le sachet de pieces de I'interieur

du four.

3. Pour placer la cuisiniere sur sa partie posterieure, sortir les

4 coins de protection du carton d'emballage. Empiler I'un des

coins sur un autre. Rep6ter avec les 2 autres coins. Les

disposer sur le plancher dans le sens de la Iongueur derriere

la cuisiniere en guise de support Iorsque la cuisiniere est

placee sur sa partie posterieure.

4. A I'aide de deux personnes ou plus, saisir fermement la

cuisiniere et la poser delicatement sur sa partie posterieure,

sur les coins de protection.

5. Tirer fermement sur la partie inferieure du carton pour le retirer.

6. Utiliser une cle a molette pour desserrer les pieds de

nivellement.

7. Placer le carton ou lepanneau de fibres dur devant la cuisiniere.

/_,I'aide de deux personnes ou plus, relever la cuisiniere et la

placer sur le carton ou sur le panneau de fibres dur.

1=

Si un ajustement de la hauteur de la cuisiniere est necessaire,

utiliser une cle ou une pince pour desserrer les 4 pieds de

nivellement.

Ceci dolt _tre effectue alors que la cuisiniere repose sur sa

partie posterieure ou qu'elle est soutenue par 2 pieds apres

avoir ete replacee en position verticale.

REMARQUE : Pour replacer la cuisiniere en position

verticale, placer un carton ou un panneau de fibres dur

devant la cuisiniere./_, I'aide de deux personnes ou plus,

relever la cuisiniere et la placer sur le carton ou le panneau de

fibres dur.

2. Ajuster les pieds de nivellement a la hauteur necessaire. Les

pieds de nivellement peuvent _tre desserres pour ajouter une

hauteur maximale de 1" (2,5 cm). Un minimum de %e"

(5,0 mm) est necessaire pour engager la bride

antibasculement.

REMARQUE : Si un ajustement de la hauteur est effectu_

alors que la cuisiniere est debout, incliner la cuisiniere vers

I'arriere pour ajuster les pieds avant, puis incliner la cuisiniere

vers I'avant pour ajuster les pieds arriere.

3. Lorsque la cuisiniere est a la hauteur souhaitee, verifier qu'il y

a un espace suffisant sous la cuisiniere pour Ioger la bride

antibasculement. Avant de faire glisser la cuisiniere a son

emplacement final, verifier qu'il sera possible de faire glisser

la bride antibasculement sous la cuisiniere et sur le pied de

nivellement arriere avant I'installation de la bride

antibasculement.

17

Page 18

c£ton de (s bd® Gnf b(:]sct i etn®n,t

Risque de basculement

Un enfant ou une personne adulte peut faire basculer la

cuisiniere, ce qui peut causer un d_ces.

Fixer la bride antibasculement au plancher ou au mur,

conform_ment aux instructions d'installation.

Faire glisser de nouveau la cuisiniere de fa£on a ce que

le pied arriere de la cuisiniere se trouve dans la fente

de la bride antibasculement.

R_engager la bride antibasculement si la cuisiniere a

_t_ d_plac_e.

Ne pas faire fonctionner la cuisiniere si la bride

antibasculement n'est pas install_e et engag_e.

Le non-respect de ces instructions peut causer un

d_ces ou des br_lures graves aux enfants et aux

adultes.

1. Retirer la bride antibasculement fixee dans le four superieur

par du ruban adhesif avec le sachet de documentation.

2. Determiner la methode de montage a utiliser : au plancher ou

au mur.

Pour un plancher en pierre ou en briquetage, on peut utiliser

la methode de montage au mur.

3. Determiner et marquer I'emplacement du bord de la

cuisiniere dans I'espace & decouper. On peut installer la bride

de montage du c6te gauche ou droit du decoupage.

Positionner la bride de montage dans la zone decoup6e de

fa(;on & ce que le bord droit (ou gauche) de la bride se trouve

&_%e"(2,4 cm) de I'emplacement du bord de la cuisiniere, tel

qu'illustr&

A

4.

Percer deux trous de V8"(3,0 mm) qui correspondent aux

trous de la bride selon la methode de montage determin6e.

Voir ci-dessous.

Montage au plancher Montage au tour

A B

B

A. Vis n°12 x 1_" A. Vis n°12 x 1 _"

B. Bride antibasculement B. Bride antibasculement

5.

A I'aide d'un tournevis Phillips, monter la bride

antibasculement sur lemur ou sur le plancher avec les deux

vis n° 12 x 1%" fournies.

...........bale G itxxsct e setq

1. Placer I'exterieur du pied contre la partie inferieure avant de

la porte du four et saisir le c6te inferieur droit ou gauche du

tableau de commande tel qu'indiqu&

REMARQUE • Si le plan de travail comporte un dosseret, il

faudra peut-_tre saisir la cuisiniere plus haut que ce

qu'indique I'illustration.

18

B

A. Bride antibasculement

B. Marquage de I'emplacement du

bord de la cuisiniere

C. 1_,, (2,4 cm)

2.

Tenter d'incliner la cuisiniere vers I'avant avec precaution.

Si vous rencontrez une resistance immediate, cela signifie

que le pied de la cuisiniere est engage dans la bride

antibasculement.

Page 19

3. Si I'arriere de la cuisiniere se souleve de plus de 1/2"(1,3 cm)

du plancher sans opposer de resistance, cesser d'incliner la

cuisiniere et la reposer doucement sur le plancher. Le pied de

la cuisiniere n'est pas engage dans la bride antibasculement.

IMPORTANT • Si I'on entend un claquement ou un bruit

d'eclatement Iorsqu'on souleve la cuisiniere, cela signifie peut-

_tre que la cuisiniere n'est pas bien engagee dans la bride.

Verifier qu'aucune obstruction n'emp_che la cuisiniere de glisser

vers lemur ou le pied de la cuisiniere de glisser dans la bride.

Verifier que la bride est fermement maintenue en place par les vis

de montage.

4. Glisser la cuisiniere vers I'avant et verifier que la bride

antibasculement est bien fixee au plancher ou au mur.

5. Faire glisser de nouveau la cuisiniere de fa_;on & ce que le

pied arriere de la cuisiniere se trouve dans la fente de la bride

antibasculement.

IMPORTANT : Si I'arriere de la cuisiniere se trouve a plus de

2' (5,1 cm) du mur de montage, cela signifie que le pied arriere

de la cuisiniere n'est peut-_tre pas engage dans la bride. Glisser

la cuisiniere vers I'avant et determiner si un objet fait obstruction

entre la cuisiniere et la paroi de montage. Pour assistance ou

depannage, consulter la section "Assistance ou Service" du

guide d'utilisation et d'entretien, la couverture ou la section

"Garantie" des instructions d'utilisation pour obtenir les

coordonnees des personnes & contacter.

6. Rep6ter les etapes 1 et 2 pour s'assurer que le pied de la

cuisiniere est bien engage dans la bride antibasculement.

Si I'arriere de la cuisiniere se souleve de plus de 1/2'(1,3 cm)

du plancher sans opposer de resistance, cela peut signifier

que la bride antibasculement n'est pas correctement

installee. Ne pas faire fonctionner la cuisiniere si la bride

antibasculement n'est pas installee et engagee. Consulter la

section "Assistance ou Service" du guide d'utilisation et

d'entretien, la couverture ou la section "Garantie" des

instructions d'utilisation pour pouvoir contacter un service de

depannage.

1.

Placer une grille dans le four.

2.

Placer un niveau sur la grille et contr61er I'aplomb de la

cuisiniere, d'abord transversalement, puis dans le sens avant/

arriere.

3. Si la cuisiniere n'est pas d'aplomb, la tirer de nouveau pour

que le pied de nivellement arriere se degage de la bride

antibasculement.

4. Utiliser une cle pour regler les pieds de nivellement vers le

haut ou vers le bas jusqu'& ce que la cuisiniere soit d'aplomb.

Repousser la cuisiniere pour la remettre en place.

5. Verifier que le pied de nivellement arriere est engage dans la

bride antibasculement.

REMAROUE • La cuisiniere doit _tre d'aplomb pour que les

resultats de cuisson au four soient satisfaisants.

19

Page 20

_h_;_ ¸_'_,, _ _ _

1. Verifier que toutes les pieces sont maintenant installees. S'il

reste une piece, passer en revue les differentes etapes pour

decouvrir laquelle aurait et6 oubliee.

2. Verifier la presence de tous les outils.

3. 121iminer/recycler tousles materiaux d'emballage.

4. Verifier que la cuisiniere est d'aplomb. Voir "Reglage de

I'aplomb de la cuisiniere".

5. Utiliser une solution d'eau tiede et de nettoyant menager

doux pour eliminer tout residu de cire laiss6 par les materiaux

d'emballage. Secher parfaitement avec un linge doux. Pour

plus d'informations, lire la section "Entretien de la cuisiniere"

dans le Guide d'utilisation et d'entretien.

6. Lire le Guide d'utilisation et d'entretien de la cuisiniere.

7. Brancher le cordon electrique dans la prise de courant

appropriee. Faire glisser la cuisiniere & son emplacement

final. Verifier que le c&ble flexible ou le cordon electrique ne

sont pas d6formes.

8. Mettre I'appareil sous tension. Mettre en marche les el6ments

de surface et le four. Pour des instructions specifiques

concernant I'utilisation de la cuisiniere, consulter le Guide

d'utilisation et d'entretien.

Si la cuisini_re ne fonctionne pas, contr61er ce qui suit :

• Les fusibles du domicile sont intacts et serres; le disjoncteur

n'est pas declench&

• La cuisiniere est branchee sur une prise reliee & la terre.

• La prise de courant est correctement alimentee.

• Consulter la section "Depannage" dans le Guide d'utilisation

et d'entretien.

Apr_s 5 minutes de fonctionnement de la cuisiniere, verifier la

chaleur. Si la cuisiniere est froide, I'eteindre et contacter un

technicien qualifi&

Risque de basculement

Un enfant ou une personne adulte peut faire basculer la

cuisiniere, ce qui peut causer un d_ces.

Fixer la bride antibasculement au plancher ou au mur,

conform_ment aux instructions d'installation.

Faire glisser de nouveau la cuisiniere de fa£on a ce que

le pied arriere de la cuisiniere se trouve dans la fente

de la bride antibasculement.

R_engager la bride antibasculement si la cuisiniere a

_t_ d_plac_e.

Ne pas faire fonctionner la cuisiniere si la bride

antibasculement n'est pas install_e et engag_e.

Le non-respect de ces instructions peut causer un

d_ces ou des br_lures graves aux enfants et aux

adultes.

Lorsqu'on deplace la cuisiniere, la faire glisser sur une planche

de carton ou en materiau dur pour eviter d'endommager le

rev_tement du sol.

Si le deplacement de la cuisiniere est necessaire pour le

nettoyage ou I'entretien :

1.

Faire glisser la cuisiniere vers I'avant.

2.

Debrancher le cordon d'alimentation electrique.

3.

Effectuer le nettoyage ou I'entretien.

4.

Brancher le cordon electrique dans une prise de courant

reliee a la terre.

5=

Faire glisser de nouveau la cuisiniere de fa£_on& ce que le

pied arriere de la cuisiniere se trouve sous la bride

antibasculement.

W10722848A

© 2014.

All rights reserved. Used under license in Canada

Tous droits reserves. Utilise sous licence au Canada.

6. Pour verifier que la bride est bien engagee, consulter la

section "Verifier que la bride anti-basculement est bien

installee et engagee".

7. Verifier que la cuisiniere est d'aplomb.

Printed in U.S.A.

Imprime aux E.-U.

7/14

Loading...

Loading...