Ikea IH3402YS0 Owner’s Manual

|KEA ®

30" (76.2 CM) RANGE HOOD

I ,_ i_¸ _,_I_ _

For questions about features, operation/performance, parts,accessories or service, call: 1-866-664-2449.

In Canada,for assistance, installation and service, call: 1-866-664-2449.

CAMPANA PARACOCINA DE30"(76,2 CM)

Si tiene preguntas respecto alas caracteristicas, funcJonamJento,rendimJento,partes, accesorJoso servicio t@cnico,Ilameal: 1-866-664-2449.

HOTTED'ASPIRATIONDE30"(76,2 CM)

Au Canada, pour assistance, installation ou service, composez le 1-866-664-2449

Table of Contents//ndice/Table des matieres .................................................................. 2

For warranty concerns, do not take the appliance back to the store. Please contact us in U.S.A. or Canada at 1-866-664-2449.

This product features a Limited Warranty - See the "Warranty" section for complete details. IKEA®appliances carry a 5-year

warranty (excludes LAGAN family - see warranty for coverage details).

NOTE: Proof of Purchase is required to obtain warranty service.

Si tiene dudas acerca de la garantia, no devuelva el aparato a la tienda. P6ngase en contacto con nosotros en los EE.UU. o en Canada

al 1-866-664-2449.

Este producto tiene una garantia limitada - Consulte la secci6n "Garantia" para obtener todos los detalles. Los aparatos IKEA®tienen

una garantia de 5 aSos (excluyendo los de la familia LAGAN - consulte la garantia para ver los detalles acerca de la cobertura).

NOTA: Se requiere la prueba de compra para obtener servicio bajo la garantia.

Pour toute question concernant I'application de la garantie, ne pas rapporter I'appareil au magasin. Veuillez nous contacter aux €:.-U.

ou au Canada au 1-866-664-2449.

Ce produit est couvert par une garantie limitee - Voir la section "Garantie" pour des details complets. Les appareils IKEA®sont couverts

par une garantie de 5 ans (hormis les appareils de la serie LAGAN - voir la garantie pour des details concernant les modalites de

garantie).

REMARQUE : Une preuve d'achat est obligatoire pour obtenir I'application de la garantie.

iMPORTANT: READ AND SAVE THESE INSTRUCTIONS.

FOR RESiDENTiAL USE ONLY.

JMPORTANTE: LEAY GUARDE ESTAS JNSTRUCCJONES.

SOLO PARA USO RESIDENClAL

iMPORTANT : URE ET CONSERVER CES iNSTRUCTiONS.

POUR UTJUSATJON RESJDENTJELLE UNJQUEMENT.

LI3Z8B/W10404066E

TABLEOF CONTENTS

RANGE HOOD SAFETY ................................................................. 3

INSTALLATION REQUIREMENTS ................................................ 5

Tools and Parts ............................................................................ 5

Location Requirements ................................................................ 5

Venting Requirements .................................................................. 6

Electrical Requirements ............................................................... 7

INSTALLATION INSTRUCTIONS .................................................. 8

Prepare Location .......................................................................... 8

Install Range Hood ..................................................................... 10

Make Electrical Connection ....................................................... 12

Complete Installation ................................................................. 12

[NDICE

SEGURIDAD DE LA CAMPANA PARA COCINA ....................... 18

REQUlSITOS DE INSTALACION ................................................. 20

Herramientas y piezas ................................................................ 20

Requisitos de ubicacion ............................................................. 20

Requisitos de ventilacion ........................................................... 21

Requisitos electricos .................................................................. 22

INSTRUCCIONES DE INSTALACION ......................................... 23

Preparacion de la ubicacion ...................................................... 23

Instalacion de la campana para cocina ..................................... 25

Conexion del suministro electrico .............................................. 27

Complete la instalacion .............................................................. 28

RANGE USE .................................................................................. 12

Range Hood Controls ................................................................. 12

RANGE HOOD CARE ................................................................... 13

Cleaning ...................................................................................... 13

WIRING DIAGRAM ....................................................................... 14

ASSISTANCE OR SERVICE ......................................................... 15

In the U.S.A ................................................................................ 15

In Canada ................................................................................... 15

Accessories ................................................................................ 15

WARRANTY .................................................................................. 16

USO DE LA CAMPANA PARA COCINA ..................................... 28

Controles de la campana para cocina ....................................... 28

CUlDADO DE LA CAMPANA PARA COCINA ............................ 29

Limpieza ..................................................................................... 29

DIAGRAMA DE CABLEADO ........................................................ 30

AYUDA O SERVICIO TI_CNICO ................................................... 31

En los EE.UU.............................................................................. 31

Accesorios .................................................................................. 31

GARANTiA ..................................................................................... 32

TABLEDESMATIERES

SI_CURITI_ DE LA Ho'n'E DE CUlSINIi=RE ............................... 34

EXIGENCES D'INSTALLATION ................................................... 36

Outils et pieces ........................................................................... 36

Exigences d'emplacement ......................................................... 36

Exigences concernant I'evacuation ........................................... 37

Specifications electriques .......................................................... 38

INSTRUCTIONS D'INSTALLATION ............................................ 39

Preparation de I'emplacement ................................................... 39

Installation de la hotte ................................................................ 41

Raccordement electrique ........................................................... 43

Achever I'installation .................................................................. 44

UTILISATION DE LA HOTTE ....................................................... 44

Commandes de la hotte de cuisiniere ....................................... 44

ENTRETIEN DE LA Ho'n'E .......................................................... 45

Nettoyage ................................................................................... 45

SCHI_MA DE C.&,BLAGE............................................................... 46

ASSISTANCE OU SERVICE ......................................................... 47

Au Canada .................................................................................. 47

Accessoires ................................................................................ 47

GARANTIE ..................................................................................... 47

2

RANGE HOOD SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

State of California Proposition 65 Warnings:

WARNING: This product contains one or more chemicals known to the State of California to cause cancer.

WARNING: This product contains one or more chemicals known to the State of California to cause birth defects or other

reproductive harm.

iMPORTANT SAFETY iNSTRUCTiONS

WARNING: TO REDUCE THE RISK OF FIRE, ELECTRIC

SHOCK, OR INJURY TO PERSONS, OBSERVE THE

FOLLOWING:

m Use this unit only in the manner intended by the

manufacturer. If you have questions, contact the

manufacturer.

m Before servicing or cleaning the unit, switch power off at

service panel and lock the service disconnecting means to

prevent power from being switched on accidentally. When

the service disconnecting means cannot be locked,

securely fasten a prominent warning device, such as a tag,

to the service panel.

m Installation work and electrical wiring must be done by

qualified person(s) in accordance with all applicable codes

and standards, including fire-rated construction.

m Do not operate any fan with a damaged cord or plug.

Discard fan or return to an authorized service facility for

examination and/or repair.

m Sufficient air is needed for proper combustion and

exhausting of gases through the flue (chimney) of fuel

burning equipment to prevent backdrafting. Follow the

heating equipment manufacturer's guideline and safety

standards such as those published by the National Fire

Protection Association (NFPA), the American Society for

Heating, Refrigeration and Air Conditioning Engineers

(ASHRAE), and the local code authorities.

m When cutting or drilling into wall or ceiling; do not damage

electrical wiring and other utilities.

m Ducted fans must always be vented outdoors.

CAUTION: For general ventilating use only. Do not use

to exhaust hazardous or explosive materials and vapors.

CAUTION: To reduce risk of fire and to properly exhaust

air, be sure to duct air outside - do not vent exhaust air into

spaces within walls or ceilings, attics or into crawl spaces,

or garages.

WARNING: TO REDUCE THE RISK OF FIRE, USE ONLY

METAL DUCTWORK.

WARNING: TO REDUCE THE RISK OF A RANGE TOP

GREASE FIRE:

m Never leave surface units unattended at high settings.

Boilovers cause smoking and greasy spillovers that may

ignite. Heat oils slowly on low or medium settings.

m Always turn hood ON when cooking at high heat or when

flambeing food (i.e. Crepes Suzette, Cherries Jubilee,

Peppercorn Beef Flamb6).

m Clean ventilating fans frequently. Grease should not be

allowed to accumulate on fan or filter.

m Use proper pan size. Always use cookware appropriate for

the size of the surface element.

WARNING: TO REDUCE THE RISK OF INJURY TO

PERSONS IN THE EVENT OF A RANGE TOP GREASE

FIRE, OBSERVE THE FOLLOWING: a

m SMOTHER FLAMES with a close fitting lid, cookie sheet, or

metal tray, then turn off the burner. BE CAREFUL TO

PREVENT BURNS. Ifthe flames do not go out

immediately, EVACUATE AND CALL THE FIRE

DEPARTMENT.

m NEVER PICK UP A FLAMING PAN - you may be burned.

m DO NOT USE WATER, including wet dishcloths or towels -

a violent steam explosion will result.

m Use an extinguisher ONLY if:

- You know you have a class ABC extinguisher, and you

already know how to operate it.

- The fire is small and contained in the area where it

started.

- The fire department is being called.

- You can fight the fire with your back to an exit.

aBased on "Kitchen Fire Safety Tips" published by NFPA.

m WARNING: To reduce the risk of fire or electrical shock,

do not use this fan with any solid-state speed control

device.

READ AND SAVE THESE INSTRUCTIONS

INSTALLATIONREQUIREMENTS

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Tools needed

• Drill

• 1V4" (3.0 cm) drill bit

• 1/8"(3.0 mm) drill bit for pilot holes

• Pencil

• Wire stripper or utility knife

• Tape measure or ruler

• Caulking gun and weatherproof caulking compound

• Flat-blade screwdriver

• Phillips screwdriver

• Saber or keyhole saw

• Metal snips

• Compass or 8" (20.3 cm) circle template

Parts supplied

Remove parts from package. Check that all parts are included.

• 2 - 3.5 x 9.5 mm screws

• 31/4"x 10" (8.3 x 25.4 cm) rectangular vent damper

• 7" (17.8 cm) round vent mounting plate

• T-10 Torx®tadapter

• 4- 4.5 x 13 mm mounting screws

Parts needed

• 1 - 75W max, 120V incandescent light bulb

• Wall or roof cap with damper to match vent system

• 3 - UL listed wire connectors

• Vent clamps/duct tape as required

For cabinets with recessed bottoms:

• Two 2" (5.1 cm) wide filler strips. Length and thickness

determined by recess dimensions.

• Four flat head wood screws or machine screws with washers

and nuts (to attach filler strips).

For 7" (17.8 cm) round vented installations:

• 7" (17.8 cm) round metal vent system

For 31/4'' x 10" (8.3 x 25.4 cm) rectangular vented installations:

• 31/4"X 10" (8.3 X 25.4 cm) rectangular metal vent system

For non-vented (recirculation) installations:

• Charcoal filter kit. For information on ordering, see the

"Accessories" section.

IMPORTANT: Observe all governing codes and ordinances.

• It is the installer's responsibility to comply with installation

clearances specified on the model/serial rating plate. The

model/serial rating plate is located inside the range hood on

the left wall.

• Range hood location should be away from strong draft areas,

such as windows, doors and strong heating vents.

• Cabinet opening dimensions that are shown must be used.

Given dimensions provide minimum clearance. Consult the

cooktop/range manufacturer installation instructions before

making any cutouts.

• Grounded electrical outlet is required. See "Electrical

Requirements" section.

• All openings in ceiling and wall where range hood will be

installed must be sealed.

These range hoods are factory set for vented installations.

Models that are capable of being installed as non-vented

(recirculating) require charcoal filters. See the "Accessories"

section to order charcoal filter kit.

For Mobile Home Installations

The installation of this range hood must conform to the

Manufactured Home Construction Safety Standards, Title 24

CFR, Part 328 (formerly the Federal Standard for Mobile Home

Construction and Safety, title 24, HUD, Part 280) or when such

standard is not applicable, the standard for Manufactured Home

Installation 1982 (Manufactured Home Sites, Communities and

Setups) ANSI A225.1/NFPA 501A, or latest edition, or with local

codes.

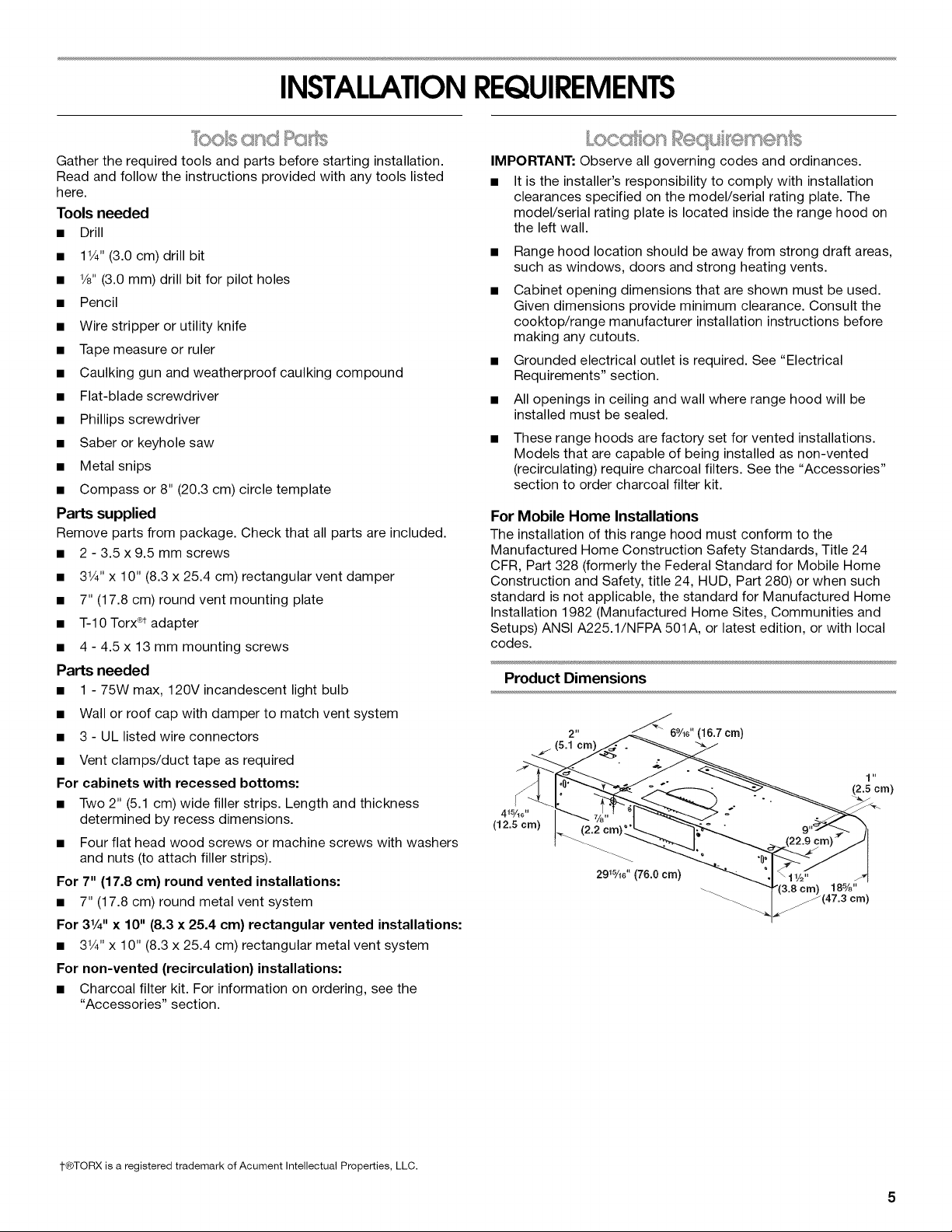

Product Dimensions

415/16"

(12.5crn)

291%d' (76.0 cm)

1-®TORX is a registered trademark of Acument Intellectual Properties, LLC.

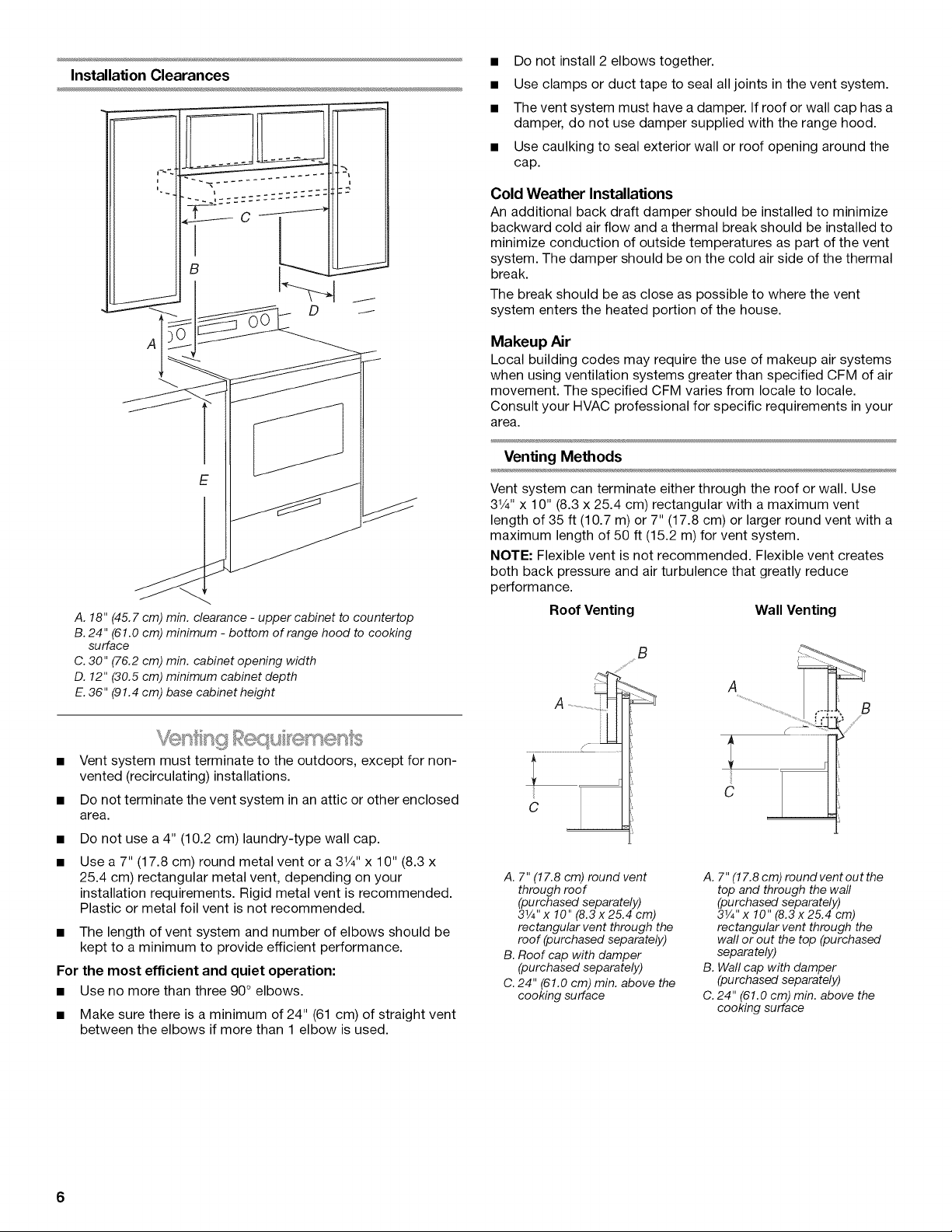

Installation Clearances

E

A. 18" (45. 7 cm) min. clearance - upper cabinet to countertop

B. 24" (61.0 cm) minimum - bottom of range hood to cooking

surface

C. 30" (76.2 cm) min. cabinet opening width

D. 12" (30.5 cm) minimum cabinet depth

E.36" (91.4 cm) base cabinet height

• Do not install 2 elbows together.

• Use clamps or duct tape to seal all joints in the vent system.

• The vent system must have a damper. If roof or wall cap has a

damper, do not use damper supplied with the range hood.

• Use caulking to seal exterior wall or roof opening around the

cap.

Cold Weather Installations

An additional back draft damper should be installed to minimize

backward cold air flow and athermal break should be installed to

minimize conduction of outside temperatures as part of the vent

system. The damper should be on the cold air side of the thermal

break.

The break should be as close as possible to where the vent

system enters the heated portion of the house.

Makeup Air

Local building codes may require the use of makeup air systems

when using ventilation systems greater than specified CFM of air

movement. The specified CFM varies from locale to locale.

Consult your HVAC professional for specific requirements in your

area.

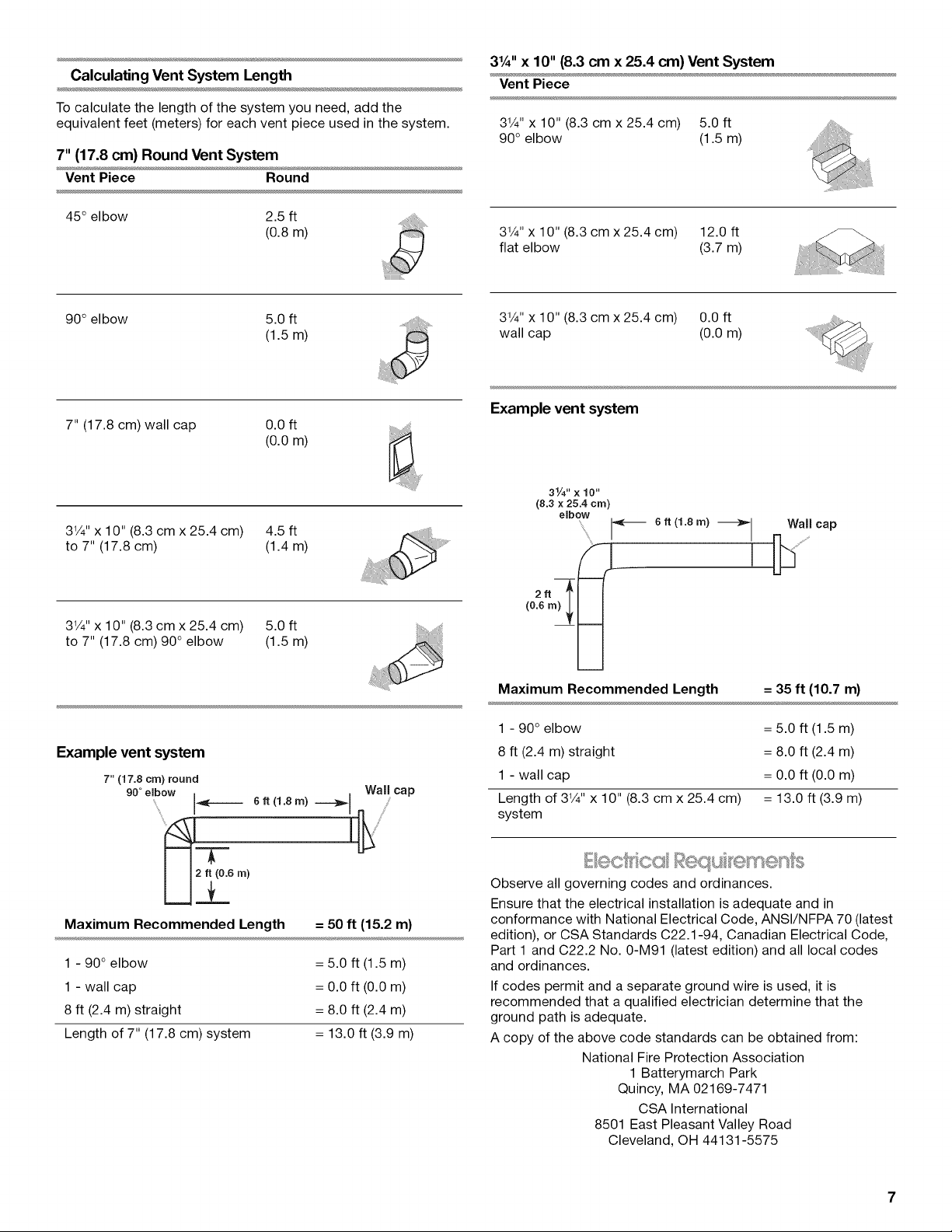

Venting Methods

Vent system can terminate either through the roof or wall. Use

31/4'' x 10" (8.3 x 25.4 cm) rectangular with a maximum vent

length of 35 ft (10.7 m) or 7" (17.8 cm) or larger round vent with a

maximum length of 50 ft (15.2 m) for vent system.

NOTE: Flexible vent is not recommended. Flexible vent creates

both back pressure and air turbulence that greatly reduce

performance.

Roof Venting Wall Venting

B

B

• Vent system must terminate to the outdoors, except for non-

vented (recirculating) installations.

• Do not terminate the vent system in an attic or other enclosed

area.

Do not use a 4" (10.2 cm) laundry-type wall cap.

Use a 7" (17.8 cm) round metal vent or a 31/4"x 10" (8.3 x

25.4 cm) rectangular metal vent, depending on your

installation requirements. Rigid metal vent is recommended.

Plastic or metal foil vent is not recommended.

• The length of vent system and number of elbows should be

kept to a minimum to provide efficient performance.

For the most efficient and quiet operation:

• Use no more than three 90° elbows.

• Make sure there is a minimum of 24" (61 cm) of straight vent

between the elbows if more than 1 elbow is used.

f -

f

I

C

A. 7" (17.8 cm) round vent

through roof

(purchased separately)

3W' x 10" (8.3 x 25.4 cm)

rectangular vent through the

roof (purchased separately)

B. Roof cap with damper

(purchased separately)

C. 24" (61.0 cm) min. above the

cooking surface

C

A. 7" (17.8 cm) round vent out the

top and through the wall

(purchased separately)

31/4'' x 10" (8.3 x 25.4 cm)

rectangular vent through the

wall or out the top (purchased

separately)

B. Waft cap with damper

(purchased separately)

C. 24" (61.0 cm) min. above the

cooking surface

6

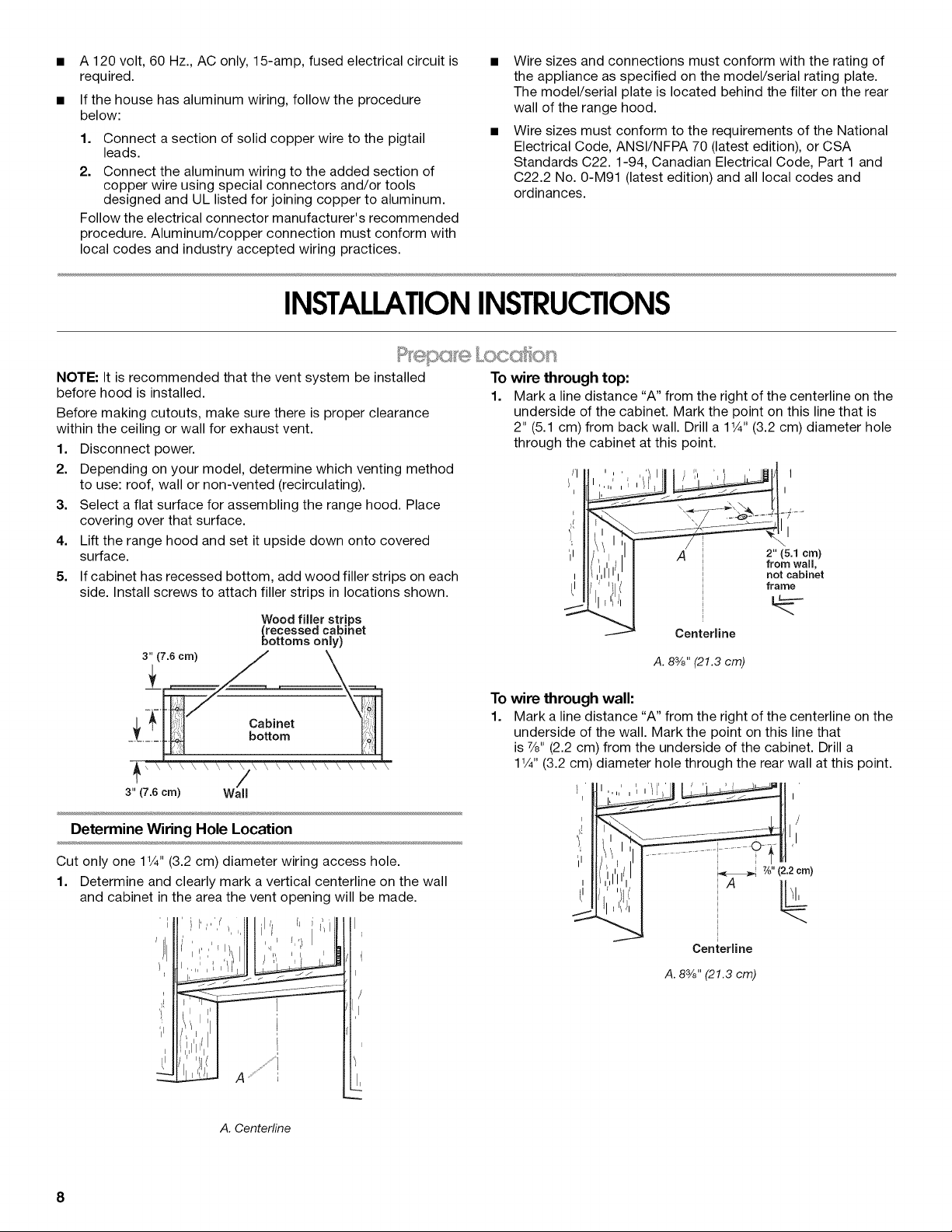

Calculating Vent System Length

To calculate the length of the system you need, add the

equivalent feet (meters) for each vent piece used in the system.

7" (17.8 cm) Round Vent System

Vent Piece Round

45° elbow 2.5 ft

(0.8m)

31A''x 10" (8.3 cm x 25.4 cm) Vent System

VentPiece

31/4"x 10" (8.3 cm x 25.4 cm) 5.0 ft

90° elbow (1.5 m)

31/4"x 10" (8.3 cm x 25.4 cm) 12.0 ft

flat elbow (3.7 m)

90° elbow 5.0 ft

(1.5m)

7" (17.8 cm) wall cap 0.0 ft

(0.0m)

31/4"x 10" (8.3 cm x 25.4 cm) 4.5 ft

to 7" (17.8 cm) (1.4 m)

31/4''x 10" (8.3 cm x 25.4 cm) 5.0 ft

to 7" (17.8 cm) 90 ° elbow (1.5 m)

Example vent system

7" (17.8 cm) round

90 ° elbow cap

I-_---- 6. (I8 m) -----_1

Wall

31/4"x 10" (8.3 cm x 25.4 cm) 0.0 ft

wall cap (0.0 m)

Example vent system

31/4,,x 10 ,,

(8.3 x 25.4 cm)

embow

6 ft (1.8 m)

Maximum Recommended Length

1 - 90° elbow

8 ft (2.4 m) straight

1 - wall cap

,f

Length of 31/4'' x 10" (8.3 cm x 25.4 cm)

system

Wall cap

= 35 ft (10.7 m)

= 5.0 ft (1.5 m)

= 8.0 ft (2.4 m)

= 0.0 ft (0.0 m)

= 13.0 ft (3.9 m)

Maximum Recommended Length = 50 ft (15.2 m)

1 - 90 ° elbow

1 - wall cap

8 ft (2.4 m) straight

Length of 7" (17.8 cm) system

= 5.0 ft (1.5 m)

= 0.0 ft (0.0 m)

= 8.0 ft (2.4 m)

= 13.0 ft (3.9 m)

Observe all governing codes and ordinances.

Ensure that the electrical installation is adequate and in

conformance with National Electrical Code, ANSl/NFPA 70 (latest

edition), or CSA Standards C22.1-94, Canadian Electrical Code,

Part 1 and C22.2 No. 0-M91 (latest edition) and all local codes

and ordinances.

If codes permit and aseparate ground wire is used, it is

recommended that a qualified electrician determine that the

ground path is adequate.

A copy of the above code standards can be obtained from:

National Fire Protection Association

1 Batterymarch Park

Quincy, MA 02169-7471

CSA International

8501 East Pleasant Valley Road

Cleveland, OH 44131-5575

• A 120 volt, 60 Hz., AC only, 15-amp, fused electrical circuit is

required.

• If the house has aluminum wiring, follow the procedure

below:

1. Connect a section of solid copper wire to the pigtail

leads.

2. Connect the aluminum wiring to the added section of

copper wire using special connectors and/or tools

designed and UL listed for joining copper to aluminum.

Follow the electrical connector manufacturer's recommended

procedure. Aluminum/copper connection must conform with

local codes and industry accepted wiring practices.

INSTALLATIONINSTRUCTIONS

• Wire sizes and connections must conform with the rating of

the appliance as specified on the model/serial rating plate.

The model/serial plate is located behind the filter on the rear

wall of the range hood.

• Wire sizes must conform to the requirements of the National

Electrical Code, ANSI/NFPA 70 (latest edition), or CSA

Standards C22.1-94, Canadian Electrical Code, Part 1 and

C22.2 No. 0-M91 (latest edition) and all local codes and

ordinances.

NOTE: It is recommended that the vent system be installed

before hood is installed.

Before making cutouts, make sure there is proper clearance

within the ceiling or wall for exhaust vent.

1. Disconnect power.

2. Depending on your model, determine which venting method

to use: roof, wall or non-vented (recirculating).

3. Select a flat surface for assembling the range hood. Place

covering over that surface.

4. Lift the range hood and set it upside down onto covered

surface.

5. If cabinet has recessed bottom, add wood filler strips on each

side. Install screws to attach filler strips in locations shown.

Wood filler strips

(recessed cabinet

bottomsonly)

?o°m,/ \

3" (7.6 cm) Wall

To wire through top:

1. Mark a line distance "A" from the right of the centerline on the

underside of the cabinet. Mark the point on this line that is

2" (5.1 cm) from back wall. Drill a 1W' (3.2 cm) diameter hole

through the cabinet at this point.

2" (5.1 cm)

from waH_

not cabinet

frame

Centerline

A. 83/8'' (21.3 cm)

To wire through wall:

1. Mark a line distance "A" from the right of the centerline on the

underside of the wall. Mark the point on this line that

is 7/8"(2.2 cm) from the underside of the cabinet. Drill a

11/4"(3.2 cm) diameter hole through the rear wall at this point.

Determine Wiring Hole Location

Cut only one 11/4"(3.2 cm) diameter wiring access hole.

1. Determine and clearly mark a vertical centerline on the wall

and cabinet in the area the vent opening will be made.

,i,_,,,,'/_,,, iI,} (_ ;r_l

I

I,

A. Centerline

8

Centerline

A. 8_"_l.3cm)

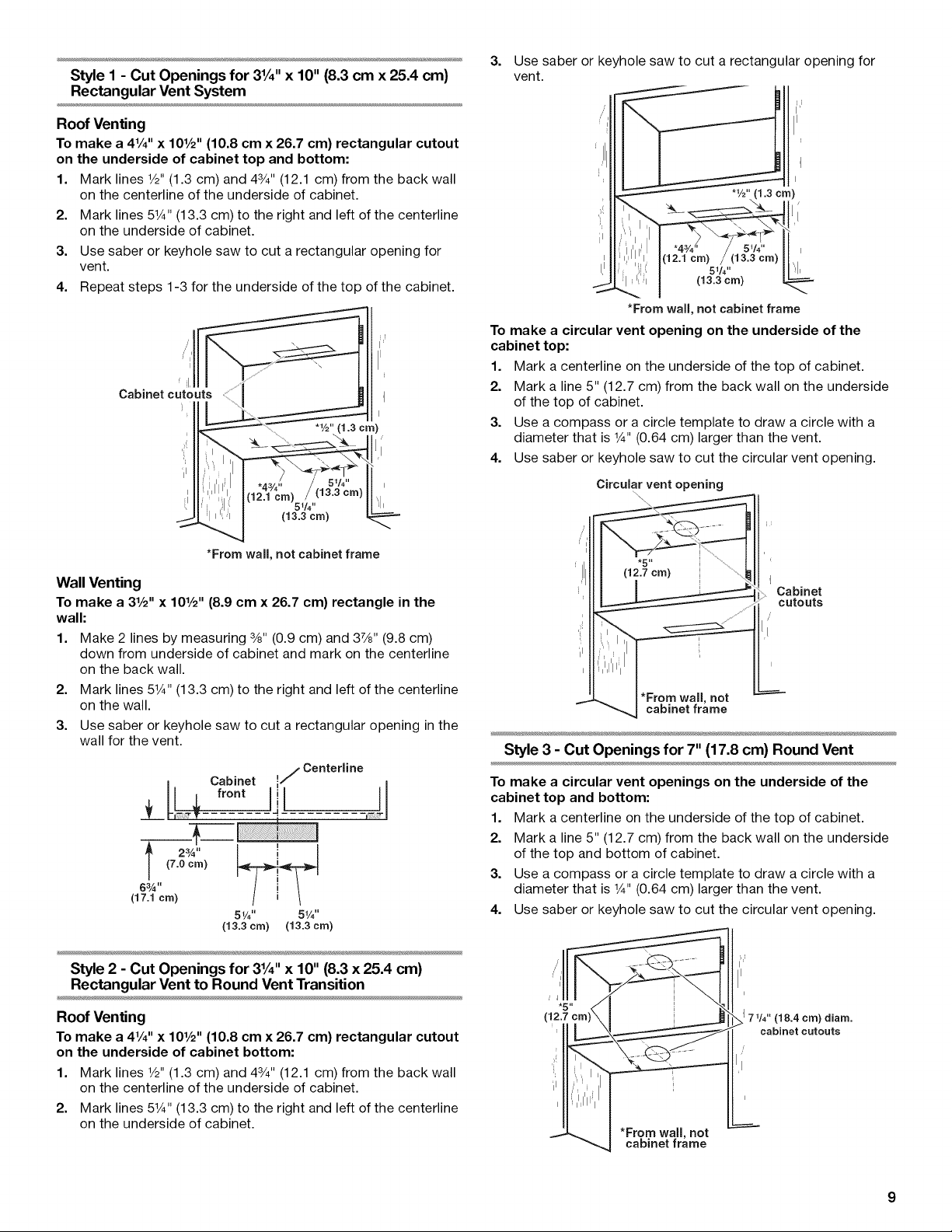

StyleI - CutOpeningsfor3%"x10"(8.3cmx25.4cm)

RectangularVentSystem

Roof Venting

To make a 41/4'' x 101/2'' (10.8 cm x 26.7 cm) rectangular cutout

on the underside of cabinet top and bottom:

1. Mark lines 1/2"(1.3 cm) and 43/4'' (12.1 cm) from the back wall

on the centerline of the underside of cabinet.

2. Mark lines 51¼''(13.3 cm) to the right and left of the centerline

on the underside of cabinet.

3. Use saber or keyhole saw to cut a rectangular opening for

vent.

4. Repeat steps 1-3 for the underside of the top of the cabinet.

Cabinet cutouts

I

I

"1/2" (1.3 cm)

li

(12.1 cm)54_4,,'

"43/4"

(13.3 cm)

3.

Use saber or keyhole saw to cut a rectangular opening for

vent.

//

/ iI

i i

*W' (1.3cm)

*From wall, not cabinet frame

To make a circular vent opening on the underside of the

cabinet top:

1. Mark a centerline on the underside of the top of cabinet.

2. Mark a line 5" (12.7 cm) from the back wall on the underside

of the top of cabinet.

3. Use a compass or a circle template to draw a circle with a

diameter that is 1¼,,(0.64 cm) larger than the vent.

4. Use saber or keyhole saw to cut the circular vent opening.

Circular vent opening

*From wall, not cabinet frame

Wall Venting

To make a 31/2'' x 101/2'' (8.9 cm x 26.7 cm) rectangle in the

wall:

1. Make 2 lines by measuring 3/8"(0.9 cm) and 37/8'' (9.8 cm)

down from underside of cabinet and mark on the centerline

on the back wall.

2. Mark lines 51¼''(13.3 cm) to the right and left of the centerline

on the wall.

3. Use saber or keyhole saw to cut a rectangular opening in the

wall for the vent.

I Cabinet I/

/ Centerline

front i !

(7.0 cm)

t

63A,,

23A"

(17.1 cm)

54/4'' 54/4''

(13.3 cm) (13.3 cm)

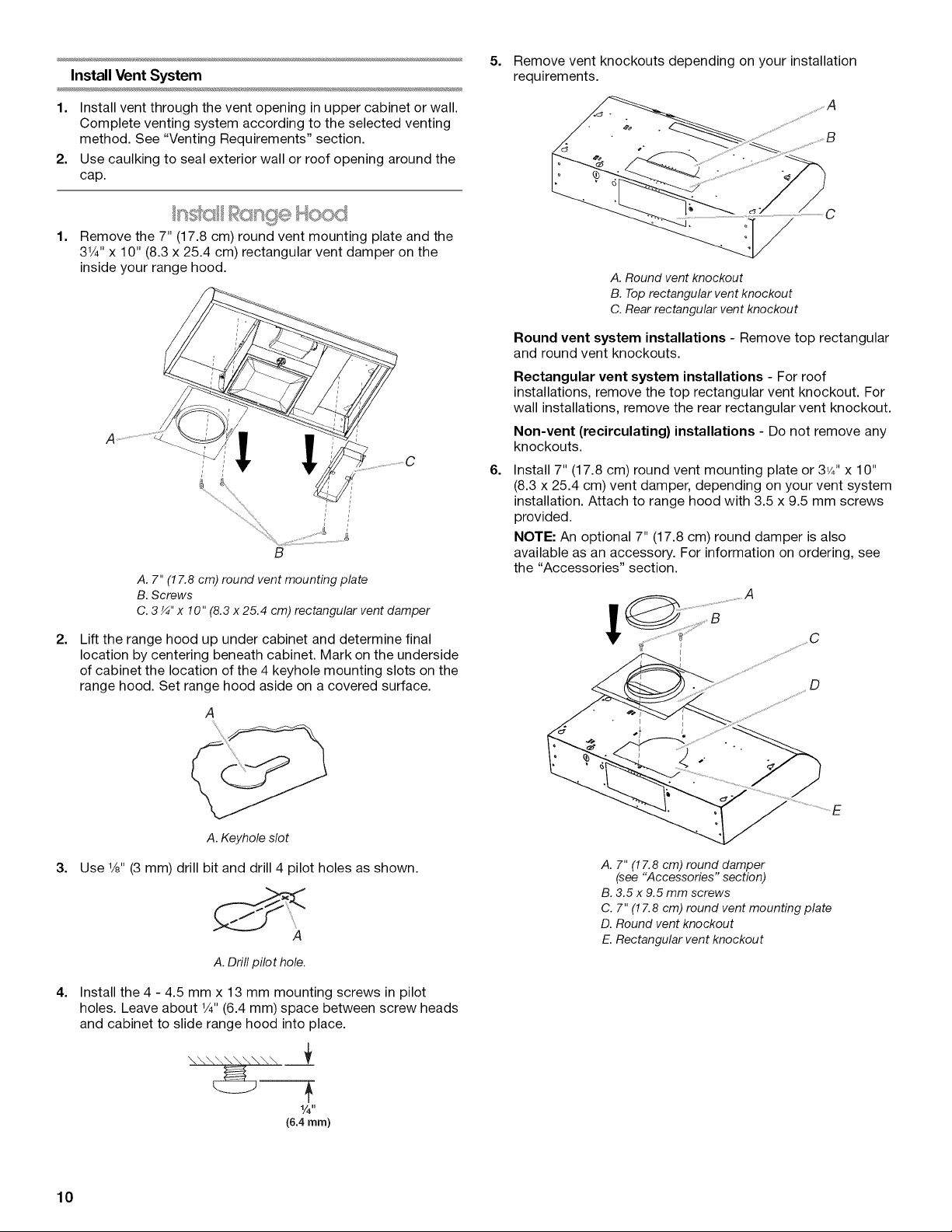

Style 2 - Cut Openings for 31/4'' x 10" (8.3 x 25.4 cm)

Rectangular Vent to Round Vent Transition

Cabinet

cutouts

_J caDmel: flame

Style 3 - Cut Openings for 7" (17.8 cm) Round Vent

To make a circular vent openings on the underside of the

cabinet top and bottom:

1. Mark a centerline on the underside of the top of cabinet.

2. Mark a line 5" (12.7 cm) from the back wall on the underside

of the top and bottom of cabinet.

3. Use a compass or a circle template to draw a circle with a

diameter that is 1¼,,(0.64 cm) larger than the vent.

4. Use saber or keyhole saw to cut the circular vent opening.

Roof Venting

To make a 41/4'' x 101/2'' (10.8 cm x 26.7 cm) rectangular cutout

on the underside of cabinet bottom:

1. Mark lines 1/2"(1.3 cm) and 43/4"(12.1 cm) from the back wall

on the centerline of the underside of cabinet.

2. Mark lines 51¼''(13.3 cm) to the right and left of the centerline

on the underside of cabinet.

*From wall, not

cabinet frame

17V4" (18.4 cm) diam.

cabinet cutouts

/

I

Install Vent System

1. Install vent through the vent opening in upper cabinet or wall.

Complete venting system according to the selected venting

method. See "Venting Requirements" section.

2. Use caulking to seal exterior wall or roof opening around the

cap.

1.

Remove the 7" (17.8 cm) round vent mounting plate and the

3%" x 10" (8.3 x 25.4 cm) rectangular vent damper on the

inside your range hood.

B

A. 7" (17.8 cm) round vent mounting plate

B. Screws

C. 3 ¼" x 10" (8.3 x 25.4 cm) rectangular vent damper

2.

Lift the range hood up under cabinet and determine final

location by centering beneath cabinet. Mark on the underside

of cabinet the location of the 4 keyhole mounting slots on the

range hood. Set range hood aside on a covered surface.

A

5. Remove vent knockouts depending on your installation

requirements.

C

A. Round vent knockout

B. Top rectangular vent knockout

C. Rear rectangular vent knockout

Round vent system installations - Remove top rectangular

and round vent knockouts.

Rectangular vent system installations - For roof

installations, remove the top rectangular vent knockout. For

wall installations, remove the rear rectangular vent knockout.

Non-vent (recirculating) installations - Do not remove any

knockouts.

6.

Install 7" (17.8 cm) round vent mounting plate or 3,/4"x 10"

(8.3 x 25.4 cm) vent damper, depending on your vent system

installation. Attach to range hood with 3.5 x 9.5 mm screws

provided.

NOTE: An optional 7" (17.8 cm) round damper is also

available as an accessory. For information on ordering, see

the "Accessories" section.

..........A

!

D

A. Keyhole slot

3.

Use 1/8"(3 mm) drill bit and drill 4 pilot holes as shown.

A

A. Drift pilot hole.

4.

Install the 4 - 4.5 mm x 13 mm mounting screws in pilot

holes. Leave about 1/4"(6.4 mm) space between screw heads

and cabinet to slide range hood into place.

\\\\\\\\\\ i_

1/4"

(6.4 rnrn)

10

E

A. 7" (17.8 cm) round damper

(see "Accessories" section)

B. 3.5 x 9.5 mm screws

C. 7" (17.8 cm) round vent mounting plate

D. Round vent knockout

E. Rectangular vent knockout

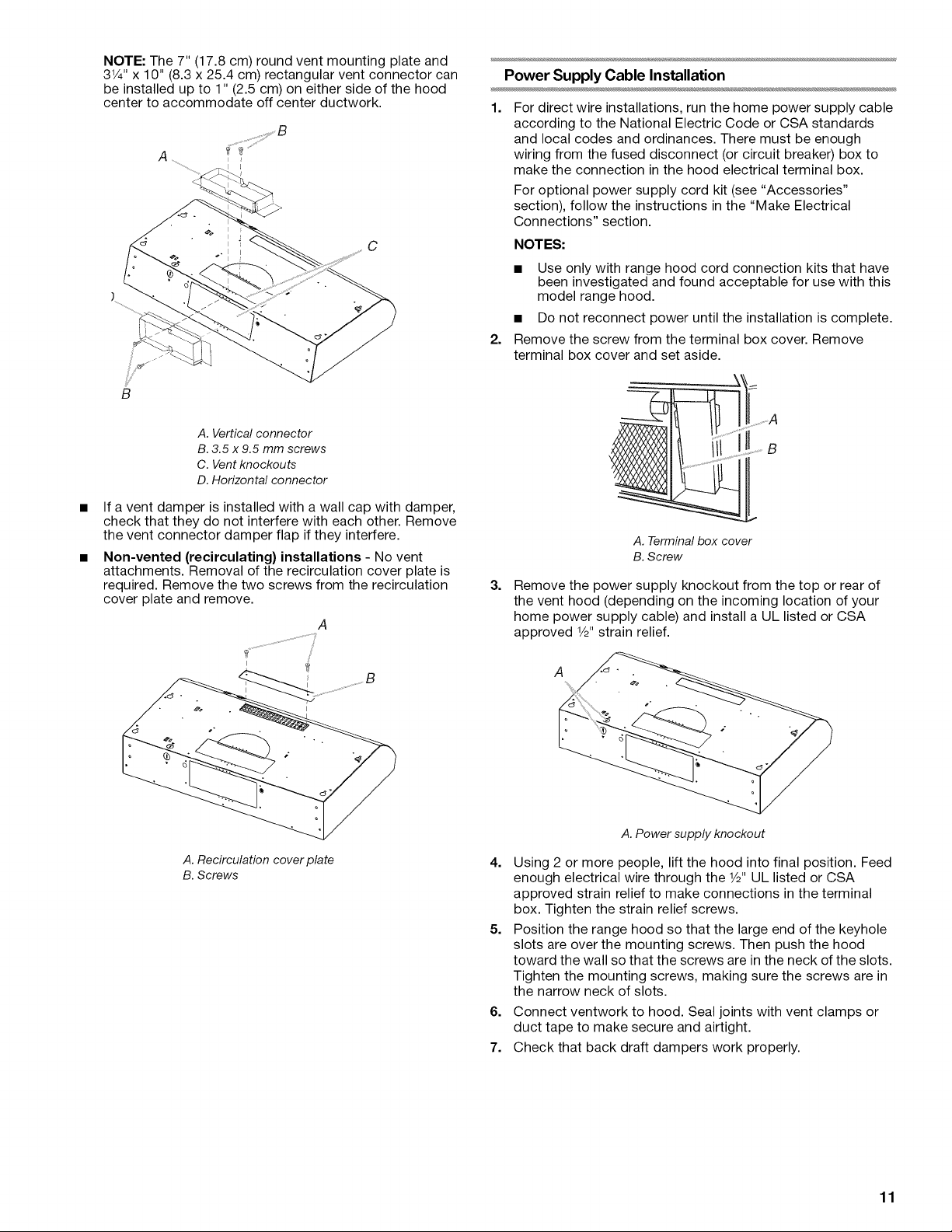

NOTE: The 7" (17.8 cm) round vent mounting plate and

31/4'' x 10" (8.3 x 25.4 cm) rectangular vent connector can

be installed up to 1" (2.5 cm) on either side of the hood

center to accommodate off center ductwork.

A .....

C

B

A. Vertical connector

B. 3.5 x 9.5 mm screws

C. Vent knockouts

D. Horizontal connector

If a vent damper is installed with a wall cap with damper,

check that they do not interfere with each other. Remove

the vent connector damper flap if they interfere.

Non-vented (recirculating) installations - No vent

attachments. Removal of the recirculation cover plate is

required. Remove the two screws from the recirculation

cover plate and remove.

A

Power Supply Cable Installation

1. For direct wire installations, run the home power supply cable

according to the National Electric Code or CSA standards

and local codes and ordinances. There must be enough

wiring from the fused disconnect (or circuit breaker) box to

make the connection in the hood electrical terminal box.

For optional power supply cord kit (see "Accessories"

section), follow the instructions in the "Make Electrical

Connections" section.

NOTES:

• Use only with range hood cord connection kits that have

been investigated and found acceptable for use with this

model range hood.

• Do not reconnect power until the installation is complete.

2=

Remove the screw from the terminal box cover. Remove

terminal box cover and set aside.

LA

A. Terminal box cover

B. Screw

3=

Remove the power supply knockout from the top or rear of

the vent hood (depending on the incoming location of your

home power supply cable) and install a UL listed or CSA

approved 1/2'strain relief.

A. Recirculation cover plate

B. Screws

A

A. Power supply knockout

4. Using 2 or more people, lift the hood into final position. Feed

enough electrical wire through the 1/2"UL listed or CSA

approved strain relief to make connections in the terminal

box. Tighten the strain relief screws.

5. Position the range hood so that the large end of the keyhole

slots are over the mounting screws. Then push the hood

toward the wall so that the screws are in the neck of the slots.

Tighten the mounting screws, making sure the screws are in

the narrow neck of slots.

6. Connect ventwork to hood. Seal joints with vent clamps or

duct tape to make secure and airtight.

7. Check that back draft dampers work properly.

11

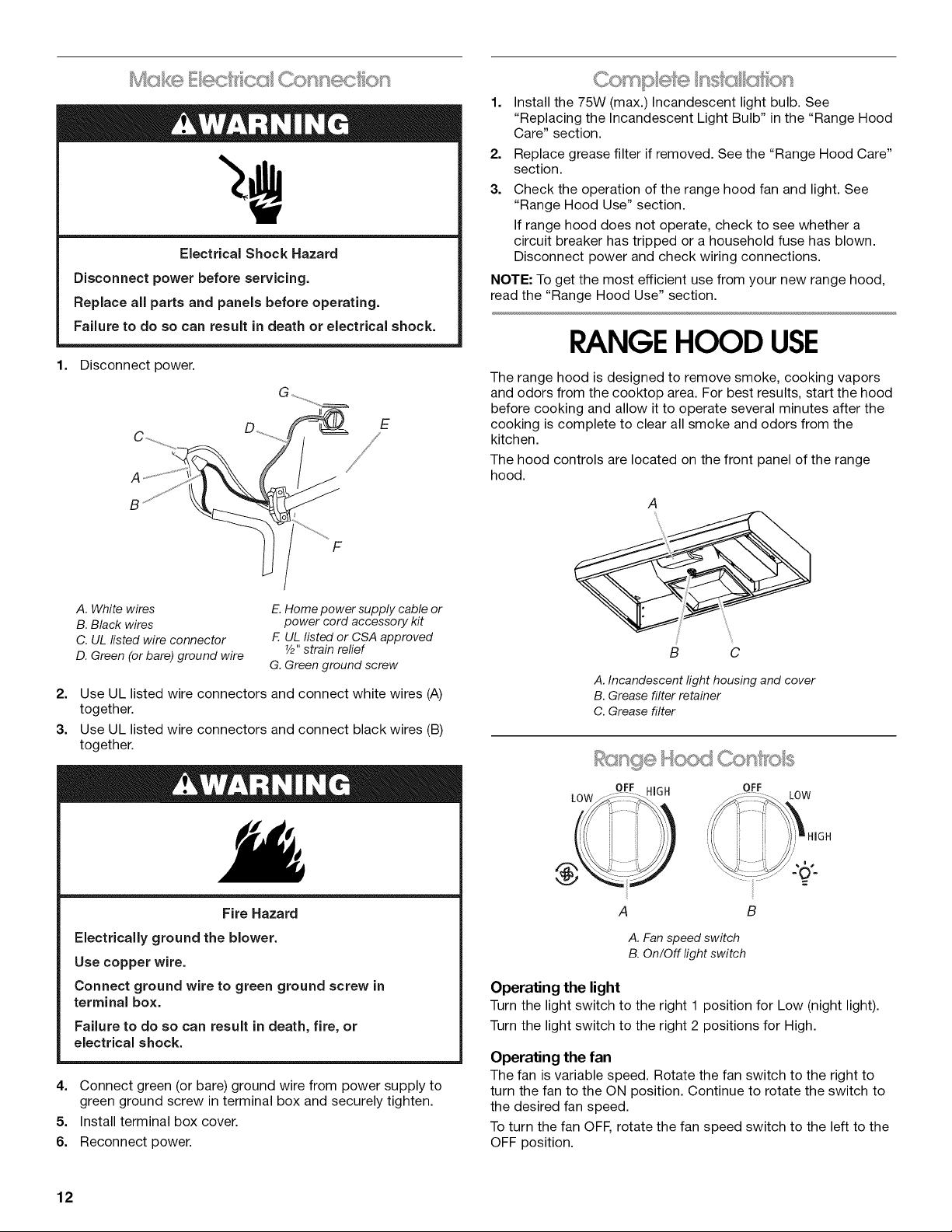

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

1. Disconnect power.

E

F

1. Install the 75W (max.) Incandescent light bulb. See

"Replacing the Incandescent Light Bulb" in the "Range Hood

Care" section.

2. Replace grease filter if removed. See the "Range Hood Care"

section.

3. Check the operation of the range hood fan and light. See

"Range Hood Use" section.

If range hood does not operate, check to see whether a

circuit breaker has tripped or a household fuse has blown.

Disconnect power and check wiring connections.

NOTE: To get the most efficient use from your new range hood,

read the "Range Hood Use" section.

RANGEHOOD USE

The range hood is designed to remove smoke, cooking vapors

and odors from the cooktop area. For best results, start the hood

before cooking and allow it to operate several minutes after the

cooking is complete to clear all smoke and odors from the

kitchen.

The hood controls are located on the front panel of the range

hood.

A

iiiiiiii

A. White wires

B. Black wires

C. UL listed wire connector

D. Green (or bare) ground wire

E. Home power supply cable or

power cord accessory kit

F. UL listed or CSA approved

Y2"strain refief

G. Green ground screw

2. Use UL listed wire connectors and connect white wires (A)

together.

3. Use UL listed wire connectors and connect black wires (B)

together.

Fire Hazard

Electrically ground the blower.

Use copper wire.

Connect ground wire to green ground screw in

terminal box.

Failure to do so can result in death, fire, or

electrical shock.

4. Connect green (or bare) ground wire from power supply to

green ground screw in terminal box and securely tighten.

5. Install terminal box cover.

6. Reconnect power.

B C

A. Incandescent fight housing and cover

B. Grease filter retainer

C. Grease filter

OFF

LO_ -OF-F_ HHIGH

A B

A. Fan speed switch

B. On/Off light switch

LOW

Operating the light

Turn the light switch to the right 1 position for Low (night light).

Turn the light switch to the right 2 positions for High.

Operating the fan

The fan is variable speed. Rotate the fan switch to the right to

turn the fan to the ON position. Continue to rotate the switch to

the desired fan speed.

To turn the fan OFF, rotate the fan speed switch to the left to the

OFF position.

12

RANGEHOOD CARE

IMPORTANT: Clean the hood and grease filters frequently

according to the following instructions. Replace grease filter

before operating hood.

Exterior Surfaces:

IMPORTANT: Do not use soap-filled scouring pads, abrasive

cleaners, Cooktop Polishing Creme, steel wool, gritty washcloths

or paper towels.

To avoid damage to the stainless steel, do not use cleaners that

contain chlorine.

Cleaning Method:

• Rub in direction of grain to avoid scratching or damaging the

surface.

For stainless steal models, Stainless Steel Cleaner and Polish

Part Number 31462A (not included): See "Assistance or

Service" section to order.

• Liquid detergent or all-purpose cleaner:

Rinse with clean water and dry with soft, lint-free cloth.

• Glass cleaner to remove fingerprints.

Metal Grease Filter

For vented installations:

1. Remove screw from the grease filter retainer.

2. Turn the grease filter retainer to release filter.

For non-vented (recirculating) installations:

The charcoal filter is not washable. It should last up to 6 months

with normal use.

1. Replace metal grease filter with a charcoal filter. For

information on ordering, see the "Accessories" section.

To replace filter:

1. Remove screw from the grease filter retainer.

2. Turn the grease filter retainer to release filter.

3. Reinstall the filter by placing the back edge in the channel at

rear of hood. Push filter into place, turn the filter retainer to

secure filter to range hood.

4. Replace screw in the grease filter retainer.

Replacing the Incandescent Light Bulb

Turn off the range hood and allow the light bulb to cool.

1. Disconnect power.

2. Squeeze the plastic lens cover and remove it from the hood.

B

A

A. Filter retainer

3. Wash metal filters as needed in dishwasher or hot detergent

solution.

4. Reinstall the filter by placing the back edge in the channel at

rear of hood. Push filter into place, turn the filter retainer to

secure filter to range hood.

5. Replace screw in the grease filter retainer.

A. Light bulb socket

B. Lens cover

3. Screw light bulb into socket.

4. Replace lens cover by squeezing cover and inserting tabs

into slots.

5. Reconnect power.

If new light does not operate, make sure the lamp is inserted

correctly before calling service.

13

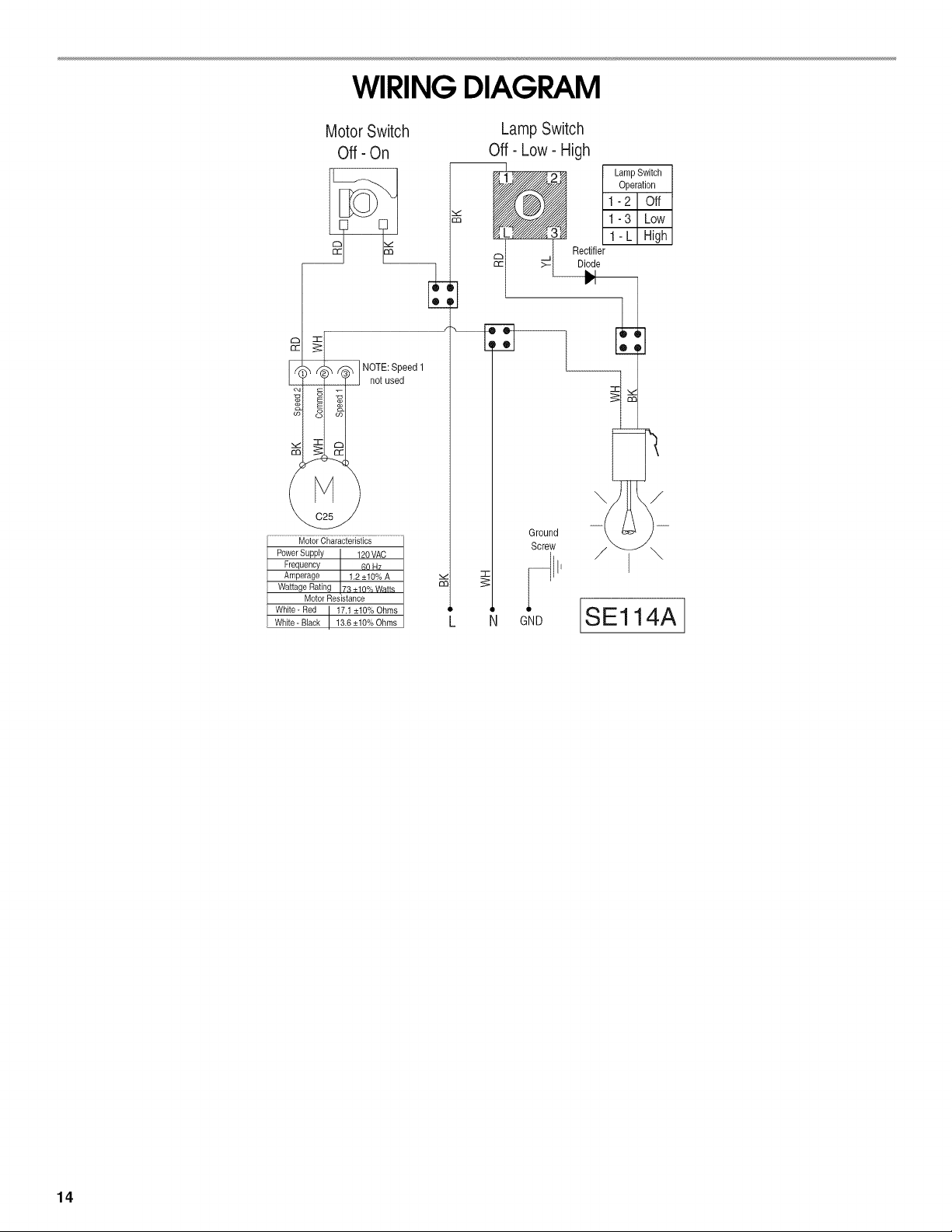

WIRING DIAGRAM

Motor Switch

Off- On

rr _

I_ ='[ _T I notused

Motor Characteristics

PowerSupply 120VAC

Frequency 60 Hz

Amperage 1.2 _+10%A

Wattage Rating 73 +10% Watts

Motor Resistance

White- Red 17.1 +_10%Ohms

White-Black 13.6_+10%Ohms

NOTE: Speed 1

Lamp Switch

Off- Low- High

Rectifier

Diode

Lamp Switch

Operation

1-2 Off

1-3 Low

1-L High

14

ASSISTANCEORSERVICE

Before calling for assistance or service, please check to see

whether a circuit breaker has tripped or a household fuse has

blown. It may save you the cost of a service call. If you still need

help, follow the instructions below.

When calling, please know the purchase date and the complete

model and serial number of your appliance. This information will

help us to better respond to your request.

If you need replacement parts

If you need to order replacement parts, we recommend that you

use only factory specified parts. Factory specified parts will fit

right and work right because they are made with the same

precision used to build every new IKEA® appliance.

To locate factory specified parts in your area, call us or your

nearest designated service center.

Call the Whirlpool Customer eXperience Center

toll free: 1-866-664-2449,

Our consultants provide assistance with:

• Features and specifications on our full line of appliances.

• Installation information.

• Use and maintenance procedures.

• Accessory and repair parts sales.

• Specialized customer assistance (Spanish speaking, hearing

impaired, limited vision, etc.).

• Referrals to local dealers, repair parts distributors, and

service companies. Whirlpool designated service technicians

are trained to fulfill the product warranty and provide after-

warranty service, anywhere in the United States.

To locate the Whirlpool designated service company in your

area, you can also look in your telephone directory Yellow

Pages.

For further assistance

If you need further assistance, you can write to Whirlpool

Corporation with any questions or concerns at:

IKEA Brand Home Appliances

Customer eXperience Center

553 Benson Road

Benton Harbor, MI 49022-2692

Please include a daytime phone number in your correspondence.

Call the Whirlpool Canada LP Customer eXperience Centre toll

free: 1-866-664-2449.

Our consultants provide assistance with:

• Features and specifications on our full line of appliances.

• Use and maintenance procedures.

• Accessory and repair parts sales.

• Referrals to local dealers, repair parts distributors, and

service companies. Whirlpool Canada LP designated service

technicians are trained to fulfill the product warranty and

provide after-warranty service, anywhere in Canada.

For further assistance

If you need further assistance, you can write to Whirlpool

Canada LP with any questions or concerns at:

Customer eXperience Centre

Whirlpool Canada LP

200 - 6750 Century Ave.

Mississauga, Ontario L5N 0B7

Please include a daytime phone number inyour correspondence.

Stainless Steel Cleaner and Polish

Order Part Number 31462A

Charcoal Filter Kit

Order Part Number W10355450

Power Cord Kit

Order Part Number W10355452

7" (17.8 cm) Round Damper

Order Part Number W10355451

15

Loading...

Loading...