Page 1

INSTALLATIONINSTRUCTIONS

30" (76.2 CM) GAS BUILT-INCOOKTOP

INSTRUCTIONS D'INSTALLATION .

DE LATABLEDE CUISSON A GAZ ENCASTREEDE

30" (76,2 CM)

Table of Contents/Table des mati_res

COOKTOP SAFETY ..................................................................................... 1

INSTALLATION REQUIREMENTS ............................................................. 2

Tools and Parts ......................................................................................... 2

Location Requirements ............................................................................. 3

Electrical Requirements ............................................................................ 4

Gas Supply Requirements ........................................................................ 4

INSTALLATION INSTRUCTIONS ............................................................... 5

Prepare Cooktop ...................................................................................... 5

Install Cooktop .......................................................................................... 5

Make Gas Connection .............................................................................. 6

Complete Installation ................................................................................ 7

WIRING DIAGRAM ...................................................................................... 8

SI_CURITI_ DE LA TABLE DE CUISSON ................................................... 9

EXIGENCES D'INSTALLATION ................................................................ 10

Outillage et pieces .................................................................................. 10

Exigences d 'emplacement ..................................................................... 10

Sp6cifications 61ectriques ....................................................................... 11

Specifications de I'alimentation en gaz .................................................. 12

INSTRUCTIONS D'INSTALLATION ......................................................... 13

Pr6paration de la table de cuisson ......................................................... 13

Installation de la table de cuisson .......................................................... 13

Raccordement au gaz ............................................................................ 14

Achever I'installation ............................................................................... 15

SCHleMAS DE CABLAGE ......................................................................... 16

COOKTOP SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

iMPORTANT:

installer: Leave installation instructions with the homeowner.

Homeowner: Keep installation instructions for future reference.

iMPORTANT :

Jnstallateur : Remettre les instructions d'installation au propri6taire.

Propri6taire : Conserver les instructions d'installation pour r6f6rence ult6rieure.

501910200427

Page 2

WARNING: If the information in this manual is not followed exactly, a fire or explosion

may result causing property damage, personal injury or death.

- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

- WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch.

• Do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the fire department.

- Installation and service must be performed by a qualified installer, service agency or

the gas supplier,

WARNING: Gas leaks cannot always be detected by smell.

Gas suppliers recommend that you use a gas detector approved by UL or CSA.

For more information, contact your gas supplier.

If a gas leak is detected, follow the "What to do if you smell gas" instructions.

In the State of Massachusetts, the following installation instructions apply:

• Installations and repairs must be performed by a qualified or licensed contractor, plumber, or gasfitter qualified or licensed by

the State of Massachusetts.

• If using a ball valve, it shall be a T-handle type.

• A flexible gas connector, when used, must not exceed 3 feet.

INSTALLATIONREQUIREMENTS

t'OOSc_...........

Gatherthe required tools and parts before starting installation.

Tools needed

• Tape measure • Phillips screwdriver

• Flat-blade screwdriver • Marker or pencil

• 15/le"combination wrench • Pipe-joint compound

• Pipe wrench

• Pliers • Noncorrosive leak-detection

• Level

resistant to LP gas

solution

Parts supplied

• Gas pressure regulator

• Burner grates (3)

• Burner caps (4)

• Clamping brackets (4)

• 1" (2.5 cm) clamping screws (4)

• Foam strip

Parts needed

Check local codes and consult gas supplier. Check existing gas

supply and electrical supply. See "Electrical Requirements" and

"Gas Supply Requirements" sections.

2

Page 3

IMPORTANT: Observe all governing codes and ordinances. Do

not obstruct flow of combustion and ventilation air.

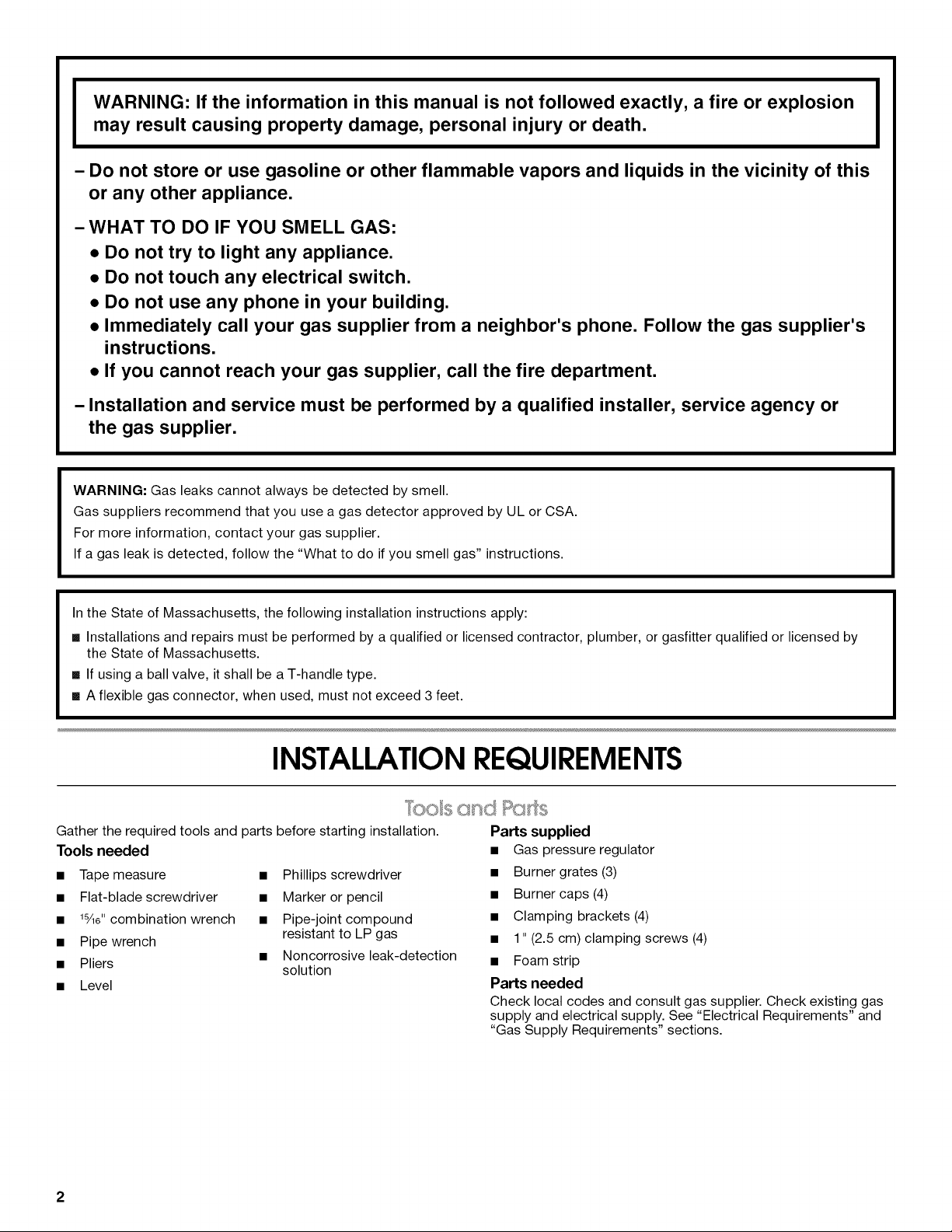

It is the installer's responsibility to comply with installation

clearances specified on the model/serial rating plate. The

model/serial rating plate is located on the underside of the

cooktop burner box.

f ........................................................................................

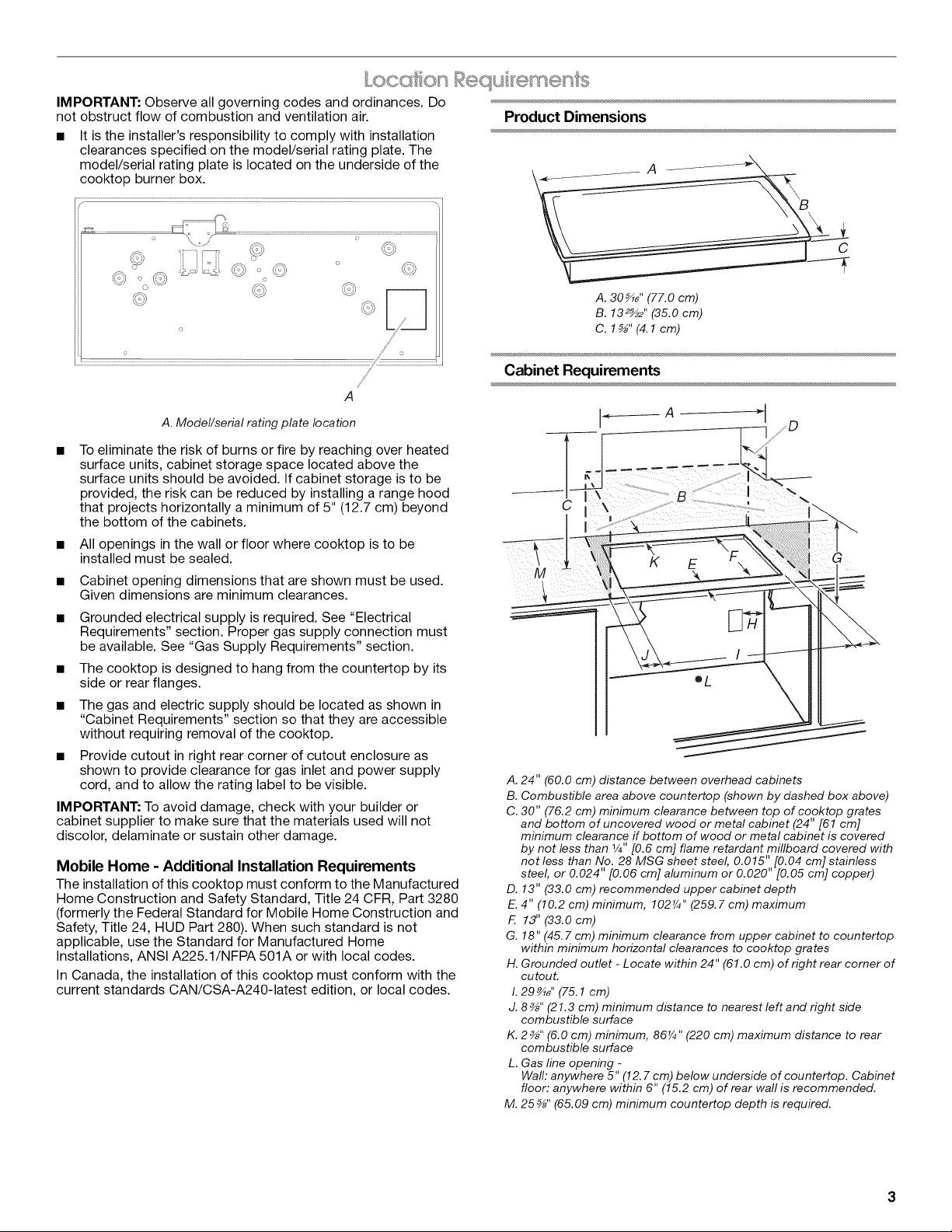

Product Dimensions

A

o

o

o ,,,/_

/

/

A

A. Model/serial rating plate location

To eliminate the risk of burns or fire by reaching over heated

surface units, cabinet storage space located above the

surface units should be avoided. If cabinet storage is to be

provided, the risk can be reduced by installing a range hood

that projects horizontally a minimum of 5" (12.7 cm) beyond

the bottom of the cabinets.

All openings in the wall or floor where cooktop is to be

installed must be sealed.

Cabinet opening dimensions that are shown must be used.

Given dimensions are minimum clearances.

Grounded electrical supply is required. See "Electrical

Requirements" section. Proper gas supply connection must

be available. See "Gas Supply Requirements" section.

The cooktop is designed to hang from the countertop by its

side or rear flanges.

The gas and electric supply should be located as shown in

"Cabinet Requirements" section so that they are accessible

without requiring removal of the cooktop.

Provide cutout in right rear corner of cutout enclosure as

shown to provide clearance for gas inlet and power supply

cord, and to allow the rating label to be visible.

IMPORTANT: To avoid damage, check with your builder or

cabinet supplier to make sure that the materials used will not

discolor, delaminate or sustain other damage.

Mobile Home - Additional Installation Requirements

The installation of this cooktop must conform to the Manufactured

Home Construction and Safety Standard, Title 24 CFR, Part 3280

(formerly the Federal Standard for Mobile Home Construction and

Safety, Title 24, HUD Part 280). When such standard is not

applicable, use the Standard for Manufactured Home

Installations, ANSI A225.1/NFPA 501A or with local codes.

In Canada, the installation of this cooktop must conform with the

current standards CAN/CSA-A240-1atest edition, or local codes.

C

A. 30_" (77.0 cm)

B. 132_2 '' (35.0 cm)

C. 1_" (4.1cm)

Cabinet Requirements

C

G

M

A. 24" (60.0 cm) distance between overhead cabinets

B. Combustible area above countertop (shown by dashed box above)

C. 30" (76.2 cm) minimum clearance between top of cooktop grates

and bottom of uncovered wood or metal cabinet (24" [61 cm]

minimum clearance if bottom of wood or metal cabinet is covered

by not less than 1/4"[0.6 cm] flame retardant millboard covered with

not less than No. 28 MSG sheet steel, 0.015" [0.04 cm] stainless

steel, or 0.024" [0.06 cm] aluminum or 0.020" [0.05 cm] copper)

D. 13" (33.0 cm) recommended upper cabinet depth

E.4" (10.2 cm) minimum, 102¼" (259.7 cm) maximum

F. 13" (33.0 cm)

G. 18" (45.7 cm) minimum clearance from upper cabinet to countertop

within minimum horizontal clearances to cooktop grates

H. Grounded outlet - Locate within 24" (61.0 cm) of right rear corner of

cutout.

I.29 _" (75.1 cm)

J. 8_" (21.3 cm) minimum distance to nearest left and right side

combustible surface

K. 2_" (6.0 cm) minimum, 86¼" (220 cm) maximum distance to rear

combustible surface

L. Gas line opening -

Waft: anywhere 5" (12. 7 cm) below underside of countertop. Cabinet

floor: anywhere within 6" (15.2 cm) of rear wall is recommended.

M. 25 _" (65.09 cm) minimum countertop depth is required.

Page 4

NOTES: After making the countertop cutout, some installations

may require notching down the base cabinet side walls to clear

the burner box. Toavoid this modification, use a base cabinet with

sidewalls wider than the cutout.

If cabinet has a drawer, a 4" (10.2 cm) depth clearance from the

countertop to the top of the drawer (or other obstruction) in base

cabinet is required. The drawer depth may need to be shortened

to avoid interfering with the regulator.

IMPORTANT: If installing a range hood or microwave hood

combination above the range, follow the range hood or

microwave hood combination installation instructions for

dimensional clearances above the cooktop surface.

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

IMPORTANT: The cooktop must be electrically grounded in

accordance with local codes and ordinances, or in the absence of

local codes, with the National Electrical Code, ANSI/NFPA 70 or

Canadian Electrical Code, CSA C22.1.

This cooktop is equipped with an electronic ignition system that

will not operate if plugged into an outlet that is not properly

polarized.

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrical installer determine that

the ground path is adequate.

A copy of the above code standards can be obtained from:

National Fire Protection Association

One Batterymarch Park

Quincy, MA 02269

CSA International

8501 East Pleasant Valley Road

Cleveland, Ohio 44131-5575

• A 120 volt, 60 Hz, AC only, 15-amp, fused electrical circuit is

required. A time-delay fuse or circuit breaker is also

recommended. It is recommended that a separate circuit

serving only this cooktop be provided.

• Electronic ignition systems operate within wide voltage limits,

but proper grounding and polarity are necessary. Check that

the outlet provides 120-volt power and is correctly grounded.

• The wiring diagrams are provided with this cooktop. See

"Wiring Diagram" section.

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

if connected to LP, have a qualified person make sure

gas pressure does not exceed 14" (36 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

Observe all governing codes and ordinances.

IMPORTANT: This installation must conform with all local codes

and ordinances. In the absence of local codes, installation must

conform with American National Standard, National Fuel Gas

Code ANSI Z223.1 - latest edition or CAN/CGA B149 - latest

edition.

IMPORTANT: Leak testing of the range must be conducted

according to the manufacturer's instructions.

Type of Gas

Natural Gas:

This cooktop is design-certified by CSA International for use with

Natural gas or, after proper conversion, for use with LP gas.

• This cooktop is factory set for use with Natural gas. To convert

to LP gas, see the Gas Conversion instructions provided inthe

literature package. The model/serial rating plate located on

the right/center underside of the burner box has information

on the types of gas that can be used. If the types of gas listed

do not include the type of gas available, check with the local

gas supplier.

LP Gas conversion:

Conversion must be done by a qualified service technician.

No attempt shall be made to convert the appliance from the gas

specified on the model/serial rating plate for use with a different

gas without consulting the serving gas supplier. See the Gas

Conversion instructions provided in the package containing

literature.

Gas Supply Line

Provide a gas supply line of 3/4"(1.9 cm) rigid pipe to the

cooktop location. A smaller size pipe on longer runs may

result in insufficient gas supply. Pipe-joint compounds that

resist the action of LP gas must be used. Do not use

TEFLON ®ttape. With LP gas, piping or tubing size can be

1/2"minimum. Usually, LP gas suppliers determine the size and

materials used in the system.

Page 5

Flexible metal appliance connector:

• If local codes permit, use a 1/2"or 3/4"I.D. flexible stainless

steel tubing gas connector, designed by CSA to connect

the cooktop to the rigid gas supply line.

• A 3/8"male pipe thread is needed for connection to the

female pipe threads of the inlet to the appliance pressure

regulator.

• Do not kink or damage the flexible metal tubing when

moving the cooktop.

Rigid pipe connection:

The rigid pipe connection requires a combination of pipe

fittings to obtain an in-line connection to the cooktop. The

rigid pipe must be level with the cooktop connection. All

strains must be removed from the supply and fuel lines so

cooktop will be level and in line.

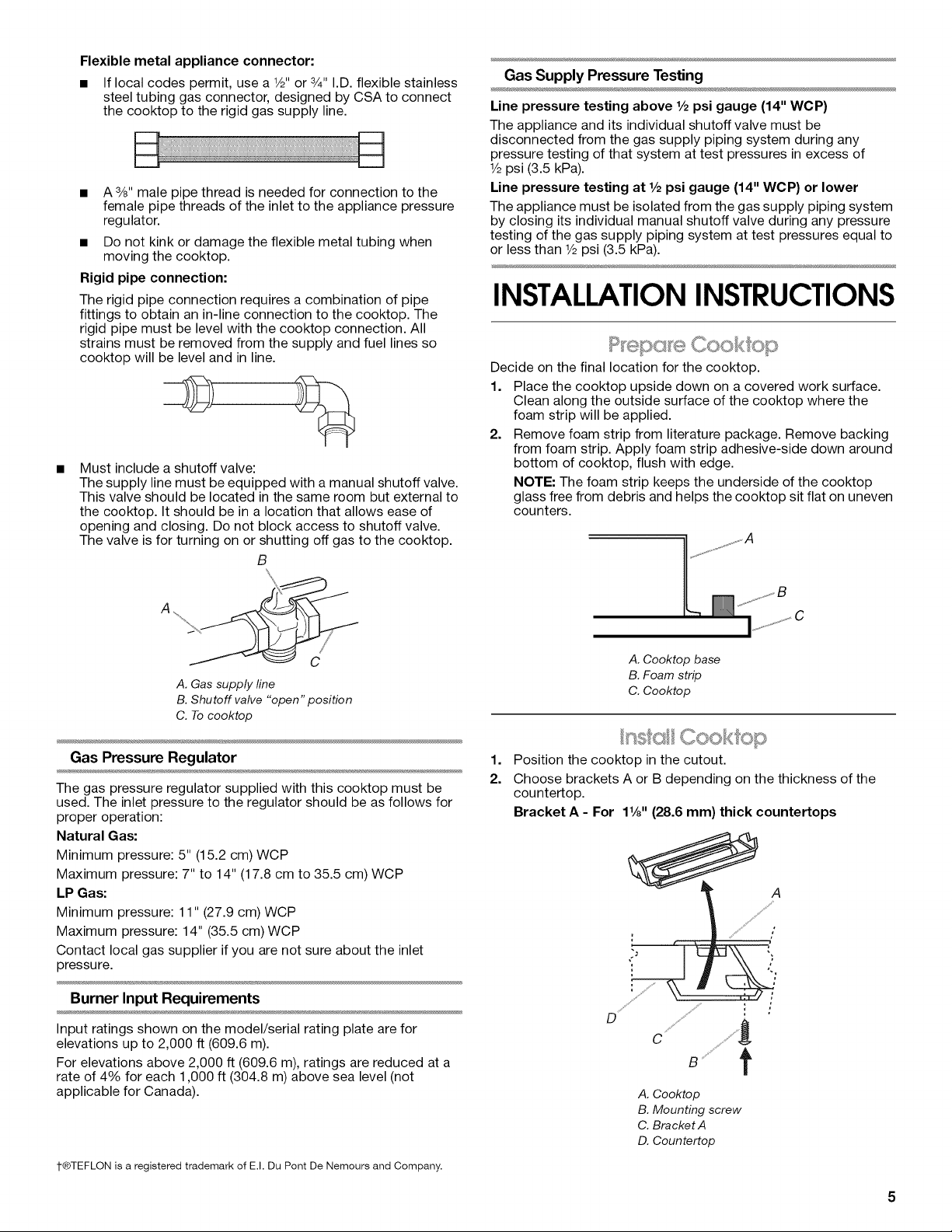

Must include a shutoff valve:

The supply line must be equipped with a manual shutoff valve.

This valve should be located in the same room but external to

the cooktop. It should be in a location that allows ease of

opening and closing. Do not block access to shutoff valve.

The valve is for turning on or shutting off gas to the cooktop.

B

Gas Supply Pressure Testing

Line pressure testing above 1/2psi gauge (14" WCP)

The appliance and its individual shutoff valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of

1/2psi (3.5 kPa).

Line pressure testing at 1/2psi gauge (14" WOP) or lower

The appliance must be isolated from the gas supply piping system

by closing its individual manual shutoff valve during any pressure

testing of the gas supply piping system at test pressures equal to

or less than 1/2psi (3.5 kPa).

INSTALLATIONINSTRUCTIONS

,....,,.,,......,,..,,,_JO0/{ O©

Decide on the final location for the cooktop.

1. Place the cooktop upside down on a covered work surface.

Glean along the outside surface of the cooktop where the

foam strip will be applied.

2. Remove foam strip from literature package. Remove backing

from foam strip. Apply foam strip adhesive-side down around

bottom of cooktop, flush with edge.

NOTE: The foam strip keeps the underside of the cooktop

glass free from debris and helps the cooktop sit flat on uneven

counters.

"%" 7

A. Gas supply line

B. Shutoff valve "open" position

C. To cooktop

Gas Pressure Regulator

The gas pressure regulator supplied with this cooktop must be

used. The inlet pressure to the regulator should be as follows for

proper operation:

Natural Gas:

Minimum pressure: 5" (15.2 cm) WCP

Maximum pressure: 7" to 14" (17.8 cm to 35.5 cm) WCP

LP Gas:

Minimum pressure: 11" (27.9 cm) WCP

Maximum pressure: 14" (35.5 cm) WCP

Contact local gas supplier if you are not sure about the inlet

pressure.

Burner Input Requirements

Input ratings shown on the model/serial rating plate are for

elevations up to 2,000 ft (609.6 m).

For elevations above 2,000 ff (609.6 m), ratings are reduced at a

rate of 4% for each 1,000 ft (304.8 m) above sea level (not

applicable for Canada).

1-®TEFLON is a registered trademark of E.I. Du Pont De Nemours and Company.

A. Cooktop base

B. Foam strip

C. Cooktop

nsI s Coo < o

1.

Position the cooktop in the cutout.

2.

Choose brackets A or B depending on the thickness of the

countertop.

Bracket A - For 1%" (28.6 ram) thick countertops

D / .......

C ....//'/_

t

A. Cooktop

B. Mounting screw

C. Bracket A

D. Countertop

Page 6

Bracket B - For 11/2'' (38.0 mm) thick countertops

_A

D iS _ii#,!Y_ .... _///,

g '/id_

A. Cooktop

B. Mounting screw

C. Bracket B

D. Countertop

3.

Secure the cooktop. Attach mounting brackets at the hole

locations (A)using the screws supplied.

View of underside of cooktop

A A

Explosion Hazard

Use a new CSA International approved gas supply line.

install a shut=off valve.

Securely tighten all gas connections.

if connected to LP, have a qualified person make sure

gas pressure does not exceed 14" (36 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

To Assemble Pressure Regulator:

1. Using 2 or more people, stand the cooktop on its side or back.

2. Connect the flexible stainless steel connector to the pressure

regulator using a _/2"male pipe thread adapter and nipple.

A combination of pipe fittings must be used to connect the

cooktop to the existing gas line. Shown following is a typical

connection. Your connection may be different, according to

the supply line type, size and location.

A

B

3. Install the pressure regulator with the arrow pointing up

toward the bottom of the cooktop base and in a position

A. Mounting hole locations

B. Front of cooktop

where you can reach the regulator cap.

A

A. Access cap

B. Rear of cooktop

C. Gas pressure regulator

D. Up arrow. Regulator must be installed with

arrow pointing up to cooktop bottom.

IMPORTANT: All connections must be wrench-tightened. Do

not make connections to the gas regulator too tight. Making

the connections too tight may crack the regulator and cause a

gas leak. Do not allow the regulator to turn on the pipe when

tightening fittings.

Use only pipe-joint compound made for use with Natural and LP

gas.

Do not use TEFLON ®tape. You will need to determine the fittings

required depending on your installation.

6

Page 7

Typical flexible connection

1. Apply pipe-joint compound made for use with LP gas to the

smaller thread ends of the flexible connector adapters (see G

in the following illustration).

2. Attach 1 adapter and nipple to the gas pressure regulator and

the other adapter and nipple to the gas shutoff valve. Tighten

both adapters and nipples.

3. Use a 1%e"combination wrench and pliers to attach the

flexible connector to the adapters. Check that connector is

not kinked.

A. %" nipple

B. %" adapter

C. Flexible connector

D. Y2"nipple

E. Gas pressure regulator

F 7/2"adapter

G. Use pipe-joint compound.

H. Manual gas shutoff valve

Complete Connection

1. Open the manual shutoff valve in the gas supply line. The

valve is open when the handle is parallel to the gas pipe.

A. Closed valve

B. Open valve

2.

Test all connections by brushing on an approved noncorrosive

leak-detection solution. Bubbles will show a leak. Correct any

leak found.

3.

Remove surface burner caps and grates from parts package.

Align notches in burner caps with pins in burner base. Burner

caps should be level when properly positioned. If burner caps

are not properly positioned, surface burners will not light.

Place burner grates over burners and caps.

B C

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

4. Plug into a grounded 3 prong outlet.

Electronic Ignition System

Initial lighting and gas flame adjustments

Surface burners use electronic igniters in place of standing pilots.

When the cooktop control knob is turned to the "LITE" position,

the system creates a spark to light the burner. This sparking

continues, as long as the control knob is pushed in.

Check Operation of Surface Burners

1. Push in and turn the surface burners control knobs to the

"LITE" position.

The surface burner flame should light within 10 seconds. The

first time a surface burner is lit it may take longer than

10 seconds to light because of air in the gas line.

2. Check the flame on "HI" for a blue color. It should be clean

and soft in character. No yellow tip, blowing or lifting of flame

should occur. Occasional orange flashes are normal and

reflect different elements in the air or gas.

3. Repeat at "LO" position.

4. After verifying the proper burner operation, turn the control

knobs to "OFR"

If burners do not light properly:

• Turn surface burner control knob to the "OFF" position.

Check that the power supply cord is plugged in and the circuit

breaker has not tripped or the fuse blown.

Check that the gas shutoff valves are set to the "open"

position.

Check that burner caps are properly positioned on burner

bases.

Recheck operation of surface burners. If a burner does not light at

this point, turn control knobs to "Off" and contact your dealer or

authorized service company for assistance.

A. Igniter electrode

B. Burner cap

C. Burner base

Page 8

Adjust Flame Height

The surface burner "low" flame should be a steady blue flame

approximately 1¼.(0.64 cm) high.

A

A. Low flame

B.High flame

If the "low" flame needs to be adjusted:

The flame can be adjusted using the adjustment screws

underneath the control knob.

1. Set the burner flame to "LO."

2. Remove the control knob.

3. Tighten screw to reduce flame height. Loosen screw to

increase flame height.

4. Replace the control knob.

5. Test the flame by turning the control from "LO" to "HI,"

checking the flame at each setting.

A.Adjustment screw

WIRING DIAGRAM

The power cord on this cooktop is equipped with a 3 prong (grounding) plug which mates with standard 3 prong (grounding) wall

receptacles.

Caution: Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and

dangerous operation. Verify proper operation after servicing.

120 VAC 60Hz

Plug

Line Neutral

1/4"Wide Blade sA6"WideBlade

Ground

RoundBlade

1 Phase

15 or 20 Amp

W

G or G/Y

BK

: Power Supply

Valve

Spark Module

Switches

BK

/

BK

/__

J__

G

(1)PLCS

SwitchesOnValves

Electriccircuit closed when

knobis rotated550to 950

counterclockwisefromOff

BR

(3) PLCS

YOR ___

igniter

E,ectrodes ___ _

8

Page 9

SECURITEDELA TABLEDECUlSSON

Votre securite et celle des autres est tres importante.

Nous donnons de nombreux messages de s_curit_ importants dans ce manuel et sur votre appareil m_nager. Assurez-vous de

toujours lire tousles messages de s_curit_ et de vous y conformer.

Ce symbole d'alerte de s_curit_ vous signale les dangers potentiels de d_c_s et de blessures graves &vous

et & d'autres.

Voici le symbole d'alerte de s_curit&

Tousles messages de s_curit_ suivront le symbole d'alerte de s_curit_ et le mot "DANGER" ou

"AVERTISSEMENT". Ces mots signifient •

Risque possible de d_cbs ou de blessure grave si vous ne

suivez pas imm_diatement les instructions.

Risque possible de d_cbs ou de blessure grave si vous

ne suivez pas les instructions.

Tousles messages de s_curit_ vous diront quel est le danger potentiel et vous disent comment r_duire le risque de blessure et

ce qui peut se produire en cas de non-respect des instructions.

AVERTISSEMENT •Si les renseignements dans ce manuel ne sont pas exactement

observes, un incendie ou une explosion peut survenir, causant des dommages au

produit, des blessures ou un deces.

- Ne pas entreposer ni utiliser de I'essence ou d'autres vapeurs ou liquides inflammables

proximite de cet appareil ou de tout autre appareil electromenager.

-QUE FAIRE DANS LE CAS D'UNE ODEUR DE GAZ :

• Ne pas tenter d'allumer un appareil.

• Ne pas toucher a un commutateur electrique.

• Ne pas utiliser le telephone se trouvant sur les lieux.

• Appeler immediatement le fournisseur de gaz a partir du telephone d'un voisin. Suivre

ses instructions.

• .&.defaut de joindre votre fournisseur de gaz, appeler les pompiers.

- L'installation et I'entretien doivent _tre effectues par un installateur qualifie, une agence

de service ou le fournisseur de gaz.

AVERTISSEMENT : L'odorat ne permet pas toujours la detection d'une fuite de gaz.

Les distributeurs de gaz recommandent I'emploi d'un detecteur de gaz (homologation UL ou CSA).

Pour d'autre information, contacter le fournisseur de gaz local.

En cas de detection d'une fuite de gaz, executer les instructions "Que faire dans le cas d'une odeur de gaz".

Dans 1'12tatdu Massachusetts, les instructions d'installation suivantes sont applicables :

[] Les travaux d'installation et r_paration doivent 6tre executes par un plombier ou tuyauteur qualifi_ ou licenci_, ou par le

personnel qualifi_ d'une entreprise licenci_e par 1'12tatdu Massachusetts.

[] Si une vanne & boisseau sph_rique est utilis_e, elle doit comporter une manette "T".

[] Si un conduit de raccordement flexible est utilis_, sa Iongueur ne doit pas d_passer 3 pi.

Page 10

EXIGENCESD'INSTALLATION

Rassembler les outils et pi@ces n@cessaires avant de commencer

I'installation.

Outillage n_cessaire

• M_tre-ruban • Tournevis Phillips

• Tournevis a lame plate • Marqueur ou crayon

• Cle mixte de _5/le" • Compose d'etanch6it6 des

• Cle a tube

• Pince

• Niveau detection des fuites

Pi_ces fournies

• Detendeur

• Grilles de brQleur (3)

• Chapeaux de brQleur (4)

• Brides de fixation (4)

• Vis de fixation de 1" (2,5 cm) (4)

• Bande de mousse

Pi_ces n_cessaires

Verifier les codes Iocaux et consulter le fournisseur de gaz.

Verifier I'alimentation en gaz et I'alimentation electrique

existantes. Voir les sections "Specifications electriques" et

"Specifications de I'alimentation en gaz".

IMPORTANT : Observer les dispositions de tousles codes et

r_glements en vigueur. Ne pas obstruer le flux de combustion et la

ventilation.

C'est & I'installateur qu'incombe la responsabilite de respecter

les distances de separation specifi6es sur la plaque

signaletique de I'appareil. La plaque signaletique des numeros

de modele et de serie est situ6e sur la face inferieure de la

boite de brQleur de la table de cuisson.

/ ...........................................................................................

raccords filetes - resistant

au propane

• Solution non corrosive de

Respecter les dimensions indiqu6es pour la cavite

d'installation entre les placards. Ces dimensions tiennent

compte des valeurs minimales des degagements de

separation.

Une source d'electricit6 avec liaison & la terre est necessaire.

Voir la section "Specifications electriques". Une source de gaz

adequate doit _tre disponible. Voir la section "Specifications

de I'alimentation en gaz".

De par sa conception, la table de cuisson est suspendue sur

le plan de travail, par les rebords des c6tes ou de I'arriere.

Veiller & placer les sources de gaz et d'electricit6 selon les

indications de la section "Dimensions du placard", pour

qu'elles soient accessibles sans depose de la table de

cuisson.

Prevoir une ouverture dans I'angle arriere droit de I'enceinte

(voir I'illustration) pour le passage de la canalisation de gaz et

du c&ble d'alimentation electrique et pour que I'etiquette

signaletique soit visible.

IMPORTANT : Pour eviter tout dommage, consulter le

constructeur de la maison ou le fabricant des placards pour

determiner si les materiaux utilises peuvent subir un changement

de couleur, une destratification ou d'autres dommages.

R_sidence mobile - Sp6cifications additionnelles

respecter Iors de I'installation

L'installation de cette table de cuisson doit _tre conforme aux

dispositions de la norme Manufactured Home Construction and

Safety Standard, Title 24 CFR, Part 3280 (anciennement Federal

Standard for Mobile Home Construction and Safety, Title 24, HUD

Part 280). Lorsque cette norme n'est pas applicable, I'installation

doit satisfaire aux criteres de la norme Standard for Manufactured

Home Installations, ANSI A225.1/NFPA 501A ou aux dispositions

des codes Iocaux.

Au Canada, I'installation de cette table de cuisson doit satisfaire

aux stipulations de la version la plus recente de la norme CAN/

CSA-A240, ou des codes Iocaux en vigueur.

Dimensions du produit

¸ o

©°o ©

: __

A

A. Emplacement de la plaque signal_tique

Afin de supprimer le risque de brQlures ou d'incendie en se

penchant au-dessus des unites de surface chauffees, le

rangement en armoire doit _tre evit& Si le rangement en

armoire est envisage, le risque peut _tre reduit par

I'installation d'une hotte de cuisine operant horizontalement

sur un minimum de 5" (12,7 cm) au-del& du bas des armoires.

Toutes les ouvertures dans lemur ou le plancher de

I'emplacement d'installation de la table de cuisson doivent

_tre scellees.

10

A. 30_" (77,0 cm)

B. 132_ '' (35,0 cm)

C. 1_" (4,1 cm)

Page 11

Dimensions du placard

C

A. Distance de s_paration de 24" (60,0 cm) entre les placards muraux

B. Zone de matiere combustible au-dessus du plan de travail (espace

d_limit_ par des lignes pointill_es ci-dessus)

C. Distance de s_paration de 30" (76,2 cm) ou plus entre les grilles de

la table de cuisson et le fond d'un placard m_taflique ou de bois

non prot_g_ (distance de s_paration de 24" [61,0 cm] ou plus si le

fond du placard de m#tal ou de bois est prot_g# par une plaque de

¼" (0,6 cm) ou plus de mat_riau r_sistant aux flammes recouvert

d'une feuifle m_tallique d'_paisseur #gale ou sup_rieure _ calibre 28

pour I'acier, 0,015" [0,04 cm] pour I'acier inoxydable, ou 0,024"

[0,06 cm] pour I'aluminium ou 0,020" [0,05 cm] pour le cuivre)

D. Profondeur recommand_e des placards muraux 13" (33,0 cm)

E. 4" (10,2 cm) minimum, 102¼" (259, 7 cm) maximum)

F. 13" (33 cm)

G. Distance de s_paration de 18" (45, 7 cm) ou plus entre placards

muraux et plan de travail avec distance minimale de s_paration

horizontale pour les grifles de la table de cuisson

H. Prise de courant reli_e _ la terre - La situer _ moins de 24" (61,0 cm)

de I'angle arriere droit de I'ouverture d_coup_e.

I. 29 _" (75,1 cm)

J. Distance de s_paration de 8_" (21,3 cm) ou plus par rapport _ la

plus proche surface de mat_riau combustible _ gauche ou _ droite

K. Distance de s_paration de 86¼" (220 cm) maximum et de 2_"

(6 cm) minimum par rapport _ une surface de mat_riau combustible

I'arriere

L. Ouverture pour canafisation de gaz - mur : n'importe oh,

5" (12, 7 cm) au-dessous de la face inf_rieure du plan de travail.

Plancher du placard : n'importe oh, _ moins de 6" (15,2 cm) du mur

arriere (recommandation.)

M. Un plan de travail de profondeur de 25_" (65,09 cm) ou plus est

n_cessaire.

REMARQUES : Apr_s le decoupage de I'ouverture dans le plan

de travail, dans certaines configurations d'installation il sera

necessaire d'entailler les parois laterales du placard inferieur pour

le passage de la boite des brQleurs. Pour eviter cette modification,

utiliser un placard inferieur dont la largeur des parois laterales est

superieure a celle de I'ouverture decoupee.

Si le placard comporte un tiroir, on devra menager une distance

de separation de 4" (10,2 cm) entre le plan de travail et le sommet

du tiroir (ou autre obstruction) dans le placard inferieur. II pourra

etre necessaire de reduire la profondeur du tiroir pour eviter une

interference avec le detendeur.

IMPORTANT: En cas d'installation d'une hotte ou d'un ensemble

hotte/micro-ondes au-dessus de la cuisiniere, suivre les

instructions fournies avec la hotte concernant les dimensions de

degagement & respecter au-dessus de la surface de la table de

cuisson.

Risque de choc _lectrique

Brancher sur une prise a 3 alv_oles reli_e a la terre.

hie pas enlever la broche de liaison a la terre.

hie pas utiliser un adaptateur.

hie pas utiliser un c&ble de rallonge.

Le non=respect de ces instructions peut causer

un d_cbs, un incendie ou un choc _lectrique.

IMPORTANT : La table de cuisson doit etre correctement reliee

la terre en conformite avec les codes et reglements Iocaux en

vigueur, ou en I'absence de tels codes, avec le National Electrical

Code, ANSI/NFPA 70 ou le Code canadien des installations

electriques, CSA C22.1.

Cette table de cuisson est dotee d'un systeme d'allumage

electronique qui ne fonctionnera pas en cas de branchement dans

une prise qui n'est pas correctement polarisee.

Si les codes le permettent et si on utilise un conducteur distinct

de liaison & la terre, il est recommande qu'un electricien qualifie

verifie la qualite de la liaison & la terre.

Pour obtenir un exemplaire de la norme des codes ci-dessus,

contacter :

National Fire Protection Association

One Batterymarch Park

Quincy, MA 02269

CSA International

8501 East Pleasant Valley Road

Cleveland, OH 44131-5575

L'appareil doit etre alimente par un circuit de 120 V, CA

seulement, 60 Hz, 15 amperes, protege par fusible. On

recommande egalement d'utiliser un fusible ou un disjoncteur

temporis& II est recommande de raccorder la table de

cuisson sur un circuit distinct exclusif & cet appareil.

Les systemes d'allumage electronique fonctionnent avec des

limites de tension etendues, mais une liaison &la terre

correcte et une polarite appropriee sont necessaires. Verifier

que la prise fournit une alimentation de 120 V et qu'elle est

correctement reliee a la terre.

• Les schemas de c&blage sont fournis avec cette table de

cuisson. Voir la section "Schemas de c&blage".

11

Page 12

Risque d'explosion

Utiliser une canalisation neuve d'arriv_e de gaz

approuv_e par la CSA international.

Installer un robinet d'arr_t.

Bien setter chaque organe de connexion de la

canalisation de gaz.

En cas de connexion au gaz propane, demander a une

personne qualifi_e de s'assurer que la pression de gaz

ne d_passe pas 36 cm (14 po) de la colonne d'eau.

Par personne qualifi_e, on comprend :

le personnel autoris_ de chauffage,

le personnel autoris_ d'une compagnie de gaz, et

le personnel d'entretien autoris&

Le non=respect de ces instructions peut causer

un d_c_s, une explosion ou un incendie.

Observer les dispositions de tous les codes et r_glements en

vigueur.

IMPORTANT • L'installation doit satisfaire aux criteres de tousles

codes et r_glements Iocaux. En I'absence de code local,

I'installation doit satisfaire aux prescriptions de la plus recente

edition du code national en vigueur : National Fuel Gas Code

ANSI Z223.1 ou CAN/CGA B149.

IMPORTANT : Les tests de fuite de la table de cuisson doivent

_tre effectu6s selon les instructions du fabricant.

Canalisation de gaz

Installer une canalisation de gaz rigide de 34,,(1,9 cm) jusqu'&

I'emplacement d'installation de la table de cuisson. L'emploi

d'une canalisation de plus petit diam_tre ou plus Iongue peut

causer une deficience du debit d'alimentation. On doit utiliser

un compose d'etancheite des tuyauteries resistant a I'action

du gaz propane. Ne pas utiliser de ruban TEFLON% Pour

I'alimentation au propane, le diam_tre des canalisations doit

_tre de _/_"ou plus. Usuellement, le fournisseur de gaz

propane determine les materiaux & utiliser et le diam_tre

appropri&

Raccord m_tallique flexible :

Si les codes Iocaux le permettent, utiliser un connecteur

gaz flexible en acier inoxydable de _/_"ou %" de diam_tre

interne, con£supar CSA pour raccorder la table de cuisson

la canalisation rigide d'alimentation en gaz.

• Un raccord avec filetage m&le de 3/8"est necessaire pour

la connexion sur le raccord & filetage femelle & I'entree du

detendeur de la table de cuisson.

• Ne pas deformer/ecraser/endommager le tube metallique

flexible Iors d'un deplacement de la table de cuisson.

Raccordement par un ensemble rigide :

On doit utiliser une combinaison de raccords pour realiser un

raccordement rigide entre la table de cuisson et la

canalisation de gaz. Le tuyau rigide doit se trouver au m_me

niveau que le raccord de connexion de la table de cuisson. On

doit veiller & ne soumettre les sections de canalisation

d'alimentation &aucun effort de traction ou flexion pour que la

table de cuisson soit d'aplomb et correctement alignee.

Type de gaz

Gaz naturel :

La conception de cette table de cuisson a et6 homologuee par

CSA International pour I'alimentation au gaz naturel, ou pour

I'alimentation au propane apr_s conversion adequate.

• Cette table de cuisson a et6 configuree a I'usine pour

I'alimentation au gaz naturel. Pour effectuer la conversion

pour une alimentation au propane, voir les instructions de

conversion de gaz fournies dans le sachet de documentation.

La plaque signaletique des numeros de modele et de serie

situee sur la face inferieure (adroite/au centre) de la boite de

brQleur indique les types de gaz utilisables. Si le type de gaz

disponible n'est pas mentionne sur la plaque signaletique,

consulter le fournisseur local.

Conversion pour I'alimentation au propane :

L'op_ration de conversion dolt _tre ex_cut_e par un

technicien de r_paration qualifi&

Ne pas entreprendre de convertir la table de cuisson pour

I'utilisation d'un gaz different de celui indiqu_ sur la plaque

signaletique sans d'abord consulter le fournisseur de gaz. Voir les

instructions de conversion de gaz fournies dans le sachet de

documentation.

Robinet d'arr_t necessaire :

La canalisation d'alimentation doit comporter un robinet

d'arr_t manuel. Le robinet d'arr_t manuel doit _tre separe de

la table de cuisson, mais doit se trouver dans la m_me piece.

La canalisation doit se trouver en un endroit facilement

accessible pour les manceuvres d'ouverture/fermeture. Ne

pas entraver I'acces au robinet d'arr_t manuel. Le robinet

d'arr_t manuel est prevu pour ouvrir ou fermer I'alimentation

en gaz de la table de cuisson.

B

A. Canalisation de gaz

B. Robinet d'arr_t manuel - position d'ouverture

C. Vers table de cuisson

1-®TEFLON est une marque d_pos&e de E.I. Du Pont De Nemours et Compagnie

12

Page 13

D_tendeur

Le detendeur fourni avec cette table de cuisson doit _tre utilis& La

pression d'alimentation du detendeur doit _tre comme suit pour un

fonctionnement correct •

Gaz naturel :

Pression minimum • 5" (15,2 cm) (colonne d'eau)

Pression maximum •7" a 14" (17,8 cm & 35,5 cm) (colonne d'eau)

Gaz propane :

Pression minimum • 11" (27,9 cm) (colonne d'eau)

Pression maximum • 14" (35,5 cm) (colonne d'eau)

En cas d'incertitude quant & la pression d'alimentation & etablir,

contacter le fournisseur de gaz local.

Caract_ristiques d'alimentation du br_leur

Les debits thermiques indiques sur la plaque signaletique

correspondent & une altitude d'utilisation inferieure

2000 pi (609,6 m).

Lorsque I'appareil est utilise & une altitude superieure &

2000 pi (609,6 m), on doit reduire le debit thermique indique

de 4 % pour chaque tranche de 1000 pi (304,8 m) au-dessus

du niveau de lamer (non applicable au Canada).

Test de pressurisation de la canalisation de gaz

Pressurisation a une pression sup_rieure a 1/2Ib/po 2

(14" - colonne d'eau)

Lors de tout test de pressurisation de ce systeme a une pression

superieure &1/2Ib/po 2(3,5 kPa), on doit deconnecter la table de

cuisson et son robinet d'arr_t individuel de la canalisation de gaz.

Pressurisation a une pression de 1/2Ib/po 2

(14" - colonne d'eau) ou moins

Lors de tout test de pressurisation de la canalisation de gaz & une

pression egale ou inferieure & 1/2Ib/po2(3,5 kPa), on doit isoler la

table de cuisson de la canalisation de gaz par fermeture de son

robinet d'arr_t manuel individuel.

1=

Placer la table de cuisson dans I'ouverture.

2.

Choisir les supports A ou Ben fonction de I'epaisseur du plan

de travail.

Support A - Pour plans de travail de 1%" (28,6 mm)

d'_paisseur

D ............. ................ [ ':

C

t

A. Tablede cuisson

B. Visde montage

C.Bride A

D. Plan de travail

Support B - Pour plans de travail de 1W' (38,0 mm)

d'_paisseur

INSTRUCTIONS

D'INSTALLATION

Determiner I'emplacement final de la table de cuisson.

1. Placer la table de cuisson & I'envers sur une surface de travail

couverte. Nettoyer le long de la surface exterieure de la table

de cuisson &I'endroit oQ la bande de mousse doit _tre

appliquee.

2. Enlever la bande de mousse du sachet de documentation.

Retirer I'endos de la bande de mousse. Appliquer le c6te

adhesif de la bande de mousse autour du fond de la table de

cuisson, en affleurement avec le rebord.

REMARQUE : La bande de mousse protege la face inferieure

du verre de la table de cuisson des debris et I'aide & reposer &

plat sur des plans de travail irreguliers.

Ih@.......................

A. Base de la table de cuisson

B.Bande de mousse

C. Tablede cuisson

D" ""

A. Tablede cuisson

B. Visde montage

C.Support B

D.Plan de travail

3=

Immobiliser la table de cuisson. Fixer les supports de

montage a I'emplacement des trous (A) des brQleurs a I'aide

des vis fournies.

Vue de la face inf_rieure de la table de cuisson

A A

o

A B A

A. Emplacements des trous de montage

B. Avant de la table de cuisson

13

Page 14

Risque d'e×plosion

Utiiiser une canalisation neuve d'arriv_e de gaz

approuv_e par la CSA International.

installer un robinet d'arr_t.

Bien serrer chaque organe de conne×Jon de la

canalisation de gaz.

En cas de connexion au gaz propane, demander a une

personne qualifi_e de s'assurer que la pression de gaz

ne d_passe pas 36 cm (14 po) de la colonne d'eau.

Par personne qualJfi_e, on comprend :

le personnel autoris_ de chauffage,

le personnel autoris_ d'une compagnie de gaz, et

le personnel d'entretien autoris&

Le non=respect de ces instructions peut causer

un d_c_s, une explosion ou un incendie.

Assemblage du d_tendeur :

1. Placer la table de cuisson en appui sur le c6te ou la face

arriere; avec I'aide de deux personnes ou plus.

2. Connecter le raccord flexible d'acier inoxydable au detendeur

- utiliser un raccord droit et un raccord d'adaptation

comportant un filetage male de 1/2"(NPT).

On doit utiliser une combinaison de raccords de tuyauterie

pour raccorder la table de cuisson & I'alimentation en gaz

existante. On voit ci-dessous une illustration d'un

raccordement typique. Le raccordement peut varier, selon le

type, la dimension et I'emplacement du conduit

d'alimentation.

3. Orienter la fleche du detendeur vers le haut, vers le fond de la

base de la table de cuisson et orienter le detendeur de telle

maniere que le chapeau du detendeur soit accessible.

.............................................g

IMPORTANT : Tous lesraccords doivent @trebien serres

I'aide d'une cl& Ne pas serrerexcessivement lesconnexions

au detendeur. Un serrageexcessif pourrait provoquer une

fissuration du detendeur et une fuite de gaz. Lorsdu serrage

d'un raccord, emp@cherle detendeur de tourner sur letuyau.

Utiliser uniquement un compose d'etancheite des tuyauteries

congu pour I'utilisation avec le gaz naturel ou le propane.

Ne pas utiliser de ruban TEFLON ®.IIsera necessaire de choisir les

raccords a utiliser en fonction de la configuration d'installation.

Raccordement typique par raccord flexible

1. Appliquer sur le filetage le plus petit des raccords de

connexion (voir G sur I'illustration qui suit) un compose

d'etancheite des tuyauteries compatible avec le propane.

2. Connecter un raccord d'adaptation et un raccord droit sur le

detendeur, et un raccord d'adaptation et un raccord droit sur

le robinet d'arr_t. Serrer les connexions.

3=

Utiliser une cle mixte de _sAd'et une pince pour fixer le raccord

flexible sur les raccords d'adaptation. Veiller a ne pas

deformer/ecraser le raccord flexible.

A. Raccord droit de _"

B. Raccord d'adaptation de _"

C. Raccord flexible

D. Raccord droit de Y2"

Completer le raccordement

1. Ouvrir le robinet d'arr_t manuel sur la canalisation de gaz. Le

robinet est ouvert Iorsque la manette est parallele a la

canalisation.

A. Robinet ferm_

B. Robinet ouvert

2=

Verifier tousles raccordements en les badigeonnant d'une

solution de detection des fuites non corrosive approuvee.

L'apparition de bulles indique une fuite. Reparer toute fuite

eventuelle.

E. D_tendeur

F. Raccord d'adaptation de Y2"

G. Appliquer un compos_

d '_tanch_it&

H. Robinet d'arr#t manuel

14

A

'%% •................................C

'%'_.... ====" D

A. Chapeau de I'ouverture d'acces

B. Arriere de la table de cuisson

C. D_tendeur

D. Fleche vers le haut. Le d_tendeur doit _tre

install_ avec la fleche pointant vers le haut

(vers le fond de la table de cuisson).

Page 15

3,

Oter les chapeaux de brQleur de surface et les grilles du

sachet de pieces. Aligner les encoches des chapeaux de

brQleur avec les broches dans la base de chaque brQleur. Un

chapeau de brQleur correctement place dolt _tre horizontal. Si

le chapeau de brQleur n'est pas correctement place, le brQleur

ne peut s'allumer. Placer les grilles de brQleur sur les brQleurs

et les chapeaux.

B

A. Electrode d'allumage

B. Chapeau de brOleur

C. Base du brOleur

C B C

A

Risque de choc _lectrique

Brancher sur une prise a 3 alv_oles reli_e a Jaterre.

Ne pas enlever la broche de liaison a la terre.

Ne pas utiliser un adaptateur.

Ne pas utiliser un c&ble de rallonge.

Le non=respect de ces instructions peut causer

un d_c_s, un incendie ou un choc _lectrique.

4. Brancher sur une prise a 3 alveoles reliee a la terre.

Acheve * nstc:sc£on

Syst_me d'allumage _lectronique

Allumage initial et r_glage des flammes

A la place de flammes de veille, les brQleurs de surface sont dotes

d'allumeurs 61ectroniques. Lorsqu'on place le bouton de

commande d'un brQleur de la table de cuisson & la position "LITE"

(allumage), lesysteme genere des etincelles pour I'allumage du

brQleur. La generation d'etincelles se poursuit aussi Iongtemps

que le bouton de commande est laisse enfonc&

Contr61e du fonctionnement des br_leurs de surface

1. Enfoncer et tourner les boutons de commande des brQleurs

de surface & la position "LITE".

Le gaz dolt s'enflammer sur le brQleur de surface en moins de

10 secondes. Lors de I'allumage initial du brQleur de surface,

le delai d'allumage peut _tre superieur & 10 secondes du fait

de la presence d'air dans la canalisation de gaz.

2. Verifier que la flamme est bleue &la position "HI" (elevee). Elle

dolt _tre nette et douce. On ne dolt pas observer de pointe

jaune, ni d'effet de soufflage ou de separation entre les

flammes et le brQleur. II est normal d'observer parfois des

eclairs orange; ceci est dQ & differents elements dans I'air ou

le gaz.

3. Repeter & la position "LO" (basse).

4. Apres avoir verifie le bon fonctionnement du brQleur, tourner le

bouton de commande & "OFF" (arr_t).

Si le brQleur ne s'allume pas correctement :

• Ramener le bouton de commande du brQleur de surface a la

position "OFF".

• Verifier que le cordon d'alimentation est branche et

correctement alimente (fusible grille? disjoncteur ouvert?)

• Verifier que chaque robinet d'arr_t est ouvert.

• Verifier que le chapeau de brQleur est correctement place sur

la base du brQleur.

S'assurer & nouveau du bon fonctionnement des brQleurs. Si & ce

stade un brQleur ne s'allume pas, tourner les boutons de

commande & "Off" (arr_t) et contacter le revendeur ou un

depanneur agree.

V_rification de la taille des flammes

Pour le reglage au debit thermique minimum, on dolt observer des

flammes stables bleues d'environ 1¼.(0,64 cm).

A Lrd Lrd Lrd Lrd Lrd Lrd

Z

B

Lrd Lrd Lrd Lrd Lrd Lrd

A. D_bit thermique minimum

B. D_bit thermique maximum

15

Page 16

S'il est n_cessaire de r_gler la taille des flammes pour le d_bit

thermique minimum :

La taille des flammes peut _tre regl6e a I'aide des vis de reglage

situ6es sous le bouton de commande.

/

\

\ /

A. Vis de r_glage

1=

Regler la flamme du brQleur a "LO" (basse).

2.

Oter le bouton de commande.

3.

Serrer la vis pour reduire la hauteur de la flamme. Desserrer la

vis pour augmenter la hauteur de la flamme.

4=

Reinstaller le bouton de commande.

5.

Tester le fonctionnement du brQleur •faire passer le bouton de

commande de la position "LO" (basse) & la position "HI"

(elev6e) et observer les flammes pour chaque reglage.

SCHI MA DECh,BLAGE

Le cordon d'alimentation de cette table de cuisson est equip6 d'une fiche de liaison & la terre & 3 broches, qui convient aux prises

murales de liaison &la terre standard &3 broches.

MISE EN GARDE : Lors de route intervention sur les circuits, _tiqueter chaque conducteur avant de le d_connecter.

Une erreur lots du rebranchernent pourrait susciter une situation dangereuse ou un fonctionnernent incorrect.

V@ifierle bon fonctionnernent de I'appareil apres I'intervention.

Fiche

Phase

_Te Neutre

brochede¼"

rrberOChede 5/16"

,, brocheronde

BL

VEou VE/JA |

Commutateurs

des electrovannes

N I

sur les electrovannes JAOU

Lecircuit electriqueseferme lots d'une (3) endroit

rotationdu bouton de 55° &95° dans le sens

Commutateurs __<h

antihoraire(a partir de la position d'arr_t)

MAR

l_lectrodes

d'allumage

120 VCA 60Hz

1 Phase

15 0u 20 A

, J_

= N L

B

Alirnentation

generateur d'etincelles

/

VE

(1)endroit

J

501910200427

© 2008.

All rights reserved.

Tous droits reserves.

6/O8

Printed in Italy

Imprime en Italie

Loading...

Loading...