Page 1

20000017582

IKA Vacstar digital_112017

IKA Vacstar digital

Operating instructions EN 5

Source language: German

Mode d’emploi FR 19

Instrucciones de manejo ES 33

Instruções de serviço PT 47

Page 2

Device setup

A

Pos. Description

EN

A Handle

B Display

C Rotating/pressing knob

B

D Main switch (on/off)

Pos. Désignation

FR

A Poignée

B Achage

C

C Bouton rotatif/poussoir

D Interrupteur principal (marche/arrêt)

Pos. Denominación

ES

A Asa

B Pantalla

D

C Mando giratorio/pulsador

D Interruptor principal (on/off)

Item Designação

PT

A Alça

B Tela

C Botão giratório/de pressão

D Interruptor principal (liga/desliga)

Fig. 1

2

Page 3

E

F

G

H

I

J

K

L

Pos. Description

E Handle securing screw

F Vacuum controller VC 10 stand hole

G Stand securing screw

H Fan / ventilation slit

I Hose connection for suction line d= 8 mm (INLET)

J Accessory fastening (emission condenser)

K Connection for vacuum controller VC 10 (Mini DIN)

L USB interface

M RS 232 interface

N Water valve connection

O Hose connection for pressure line d= 8 mm (OUTLET)

P Power supply cable connection

EN

M

N

O

H

P

Fig. 1

Pos. Denominación

E Tornillo de fijación del mango

F Orificio de soporte del controlador de vacío VC 10

G Tornillo de fijación del soporte

H Ventilador/Ranura de ventilación

I Conexión de manguera para el conducto de aspiración

d= 8 mm (INLET)

J Fijación de accesorios (condensador de emisiones)

K

Conexión para el controlador de vacío VC 10 (mini DIN)

L Interfaz USB

M Interfaz RS-232

N Conexión para la válvula de agua

O Conexión de manguera para el conducto de presión

d=8mm (OUTLET)

P Conexión para el cable de alimentación

Pos. Désignation

E Vis de sécurité de la poignée

F Alésage de statif contrôleur de vide VC 10

G Vis de sécurité du statif

H Ventilateur/Fente de ventilation

I Raccord de flexible de la conduite d’aspiration

d= 8 mm (INLET)

J Fixation d’accessoire (condenseur d’émissions)

K Prise contrôleur de vide VC 10 (mini DIN)

L Port USB

M Port RS 232

N Prise vanne d’eau

O Raccord de flexible de la conduite de refoulement

d= 8 mm (OUTLET)

P Prise pour le câble réseau

ES

Item Designação

E Parafuso de trava da alça

F Controlador de vácuo VC 10 furo do suporte

G Parafuso de trava do suporte

H Ventilador/furos de ventilação

I Conexão para linha de sucção d= 8 mm (INLET)

J Fixação acessórios (condensador de emissão)

K Conexão para controlador de vácuo VC 10 (Mini DIN)

L Interface USB

M Interface RS 232

N Conexão para válvula de água

O Conexão para linha de descarga d= 8 mm (OUTLET)

P Conexão para cabo de rede

FR

PT

Page 4

Page 5

Source language: German

Contents

Device setup .............................................................................................................................................................................. 2/3

Declaration of conformity .......................................................................................................................................................... 5

Warning symbols ....................................................................................................................................................................... 5

Warranty ................................................................................................................................................................................... 5

Safety instructions ...................................................................................................................................................................... 6

Unpacking ................................................................................................................................................................................. 7

Correct use ................................................................................................................................................................................ 8

Useful information ..................................................................................................................................................................... 8

Setting up .................................................................................................................................................................................. 9

Commissioning .......................................................................................................................................................................... 12

Interfaces and outputs ............................................................................................................................................................... 13

Maintenance and cleaning ......................................................................................................................................................... 14

Error codes ................................................................................................................................................................................ 15

Accessories ................................................................................................................................................................................ 15

Product contact parts ................................................................................................................................................................. 15

Technical data ............................................................................................................................................................................ 16

EN

Page

Declaration of conformity

We declare under our sole responsibility that the product to which this declaration relates is in conformity with directives 2014/35/EU,

2006/42/EC, 2014/30/EU an

EN 61326-

1 and EN ISO 12100.

d 2011/65/EU and conforms with the following standards or normative documents:

EN 61010-1, EN

60529

Warning symbols

DANGER

WARNING

CAUTION

NOTE

Indicates an (extremely) hazardous situation, which, if not avoided, will result in death, serious injury.

Indicates a potentially hazardous situation, which, if not avoided, can result in death, serious injury.

Indicates a potentially hazardous situation, which, if not avoided, can result in injury.

Indicates practices which, if not avoided, can result in equipment damage.

Warranty

,

According to IKA‘s Terms and Conditions of sale and delivery, this

product is covered by a warranty for a period of 24 months. Please

contact your dealer for any warranty claims. If you wish, you can

send the device directly to our

invoice and state the reasons for your guarantee claim. In this

case, you are responsible for shipping and handling costs.

factory

. Please

provide

the sales

The warranty does not cover wearing parts, nor defects that are

the result of improper use, insucient care and maintenance or

failure to follow the instructions in this operating manual.

5

Page 6

Safety instructions

For your protection

NOTE

• Keep the instruction

accessed easily.

• Ensure that only trained staff use the device.

• Be sure to comply with all safety instructions, directives and

all matters of health, safety and accident prevention in the

workplace.

• The device and all parts of the device must not be used on

people or animals.

Device configuration

DANGER

• Set up the device in accordance with the chapter “Setting up”

and connect the connection lines and interfaces as described.

• Set up the device on a stable, even, non-flammable surface.

Accessories

• Safe

• Carefully observe the operating instructions for additional

• The pressure at the gas inlet and outlet must not exceed

operation

accessories as described in the “Accessories” section.

devices (e.g. rotary evaporators, vacuum controllers), with

which the vacuum pump IKA Vacstar digital is operated.

1100 mbar.

Please read the instruction manual

in full before use and follow the

safety instructions.

manual in a place where

The

vacuum

digital is not designed to be set up

in

potentially explosive atmospheres.

can only be

pump IKA Vacstar

ensured

when

working

it

can be

with

DANGER

• Do not expose human or animal body parts to vacuum.

• Do not work with the device underwater or underground.

• Never work with a faulty or incorrectly connected device.

• Set up the vacuum pumps in appropriate and

extractor hoods, or set up an exhaust gas line to them. Ensure

that the exhaust gas line cannot be kinked! The maximum

permitted exhaust gas line length is 2 metres.

• Occurence of explosive mixtures; if appropriate

gas for ventilation and/or thinning.

• Elastic elements may be pressed together under vacuum.

• Only use flexible hose lines.

• Observe your

ensure that the device is put in a safe state (see the chapter:

Commissioning, Operating mode).

Always wear personal protective

equipment in accordance with the

hazard class of the media being

worked with - otherwise there are

dangers due to spraying liquids,

and release of toxic or flammable

gases.

emergency

measures for power failure and

functioning

connect

inert

Work with the device

DANGER

WARNING

• The vacuum pump IKA Vacstar digital must only be operated

under the conditions described in the chapter “Technical data”.

• Prevent release of the materials listed above. Take measures

to protect staff and the environment.

• Pay attention to possible interactions or chemical or physical

You can prevent the release of solvent vapours into the atmosphere

using a downstream emission condenser.

The vacuum pump is not suitable

for use with

materials that

an air

Do not operate the pump while it is

open. Otherwise there is a danger

of severe injuries as a hand may be

pulled into the moving parts.

Inhaling or coming into contact

with media

liquids, gases, spray

dusts or biological materials can

endanger the health of the user.

Ensure that all connections are

well sealed and free of leaks if you

are working with such media.

self-igniting materials

are

flammable without

supply

, or

explosive

such as

materials.

poisonous

mists,

vapours,

reactions when working with media at reduced pressure and

increased temperature.

• There can be electrostatic processes between the medium

and the device which can lead to direct danger.

• Some medium may be released due to the residual leakage

,

rate of the device.

• Before commissioning check that all the housing parts are

present and fastened to the device.

• Do not lift the pump if the handle is loose and the handle

securing screw (E) is loose or missing!

• Only switch the pump on if the pump is standing vertically.

• Connect the hose connections (INLET-OUTLET) and interfaces

in accordance with

operating instructions.

• Ensure

• Ensure that vapours containing solvent can be sucked into

• Do not use the pump to create pressure.

• Observe the permitted pressure at the inlet and outlet side;

• The

• Use a solenoid valve or a check valve in the suction line if

• When using an emission condenser ensure that the coolant

that the

its ignition

increases the temperature of the medium additionally.

the pump.

see the chapter “Technical data”.

suction-side line.

there are several load units.

is flowing freely.

temperature.

gas

flow must only be regulated/throttled in the

the

temperature

The pumping process

labelling on

of the evacuated

the device and the

medium is below

(compression)

6

Page 7

Protection of the device

WARNING

CAUTION

• The device is only disconnected from the power supply when

the power or device plug is removed.

• The socket for the power supply cable must be easy to access.

• Covers or parts that can be removed from the device without

tools must later be refitted to ensure safe operation, unless

anything else is connected at this point. This will prevent the

infiltration of foreign objects, liquids and other contaminants.

• Unwanted liquids

extracting air during no-load operation.

• Avoid knocks or impact to the device.

Ensure that the substances used

with the device are compatible

with the materials of the device

parts that come into contact with

the

product; see

“

Product

The

rating plate must coincide with the

actual power supply.

that

contact parts”.

specified settings on the

have entered

the

chapter

can be removed by

Unpacking

Unpacking

• Unpack the device carefully.

• Any damage should be notified immediately to the shipping

agent (post oce, railway network or transport company).

• The device must only be opened by trained, skilled personnel

(who have been authorised to do so).

• The device must not be modified without authorisation from

IKA.

• To ensure sufficient cooling for

digital, the ventilation slits on the housing must not

Vacstar

be covered.

• Only use original

ensure that the device works reliably.

• Watch out for

device. Warm up the device first, if it has been brought in

from a cold environment.

• Never fasten the vaccum pump over a heating bath.

• Ensure that no solids and/or liquids can enter the diaphragm

of the vacuum pump IKA Vacstar digital through the suction

line of the pump. This damages the diaphragm and other

internal parts of the pump. This reduces delivery capacity and

the final pressure can no longer be achieved. Deposits may

be produced in the interior, reducing service life and causing

leaks.

replacement

water condensation

the vacuum pump IKA

parts for

maintenance

inside and outside the

to

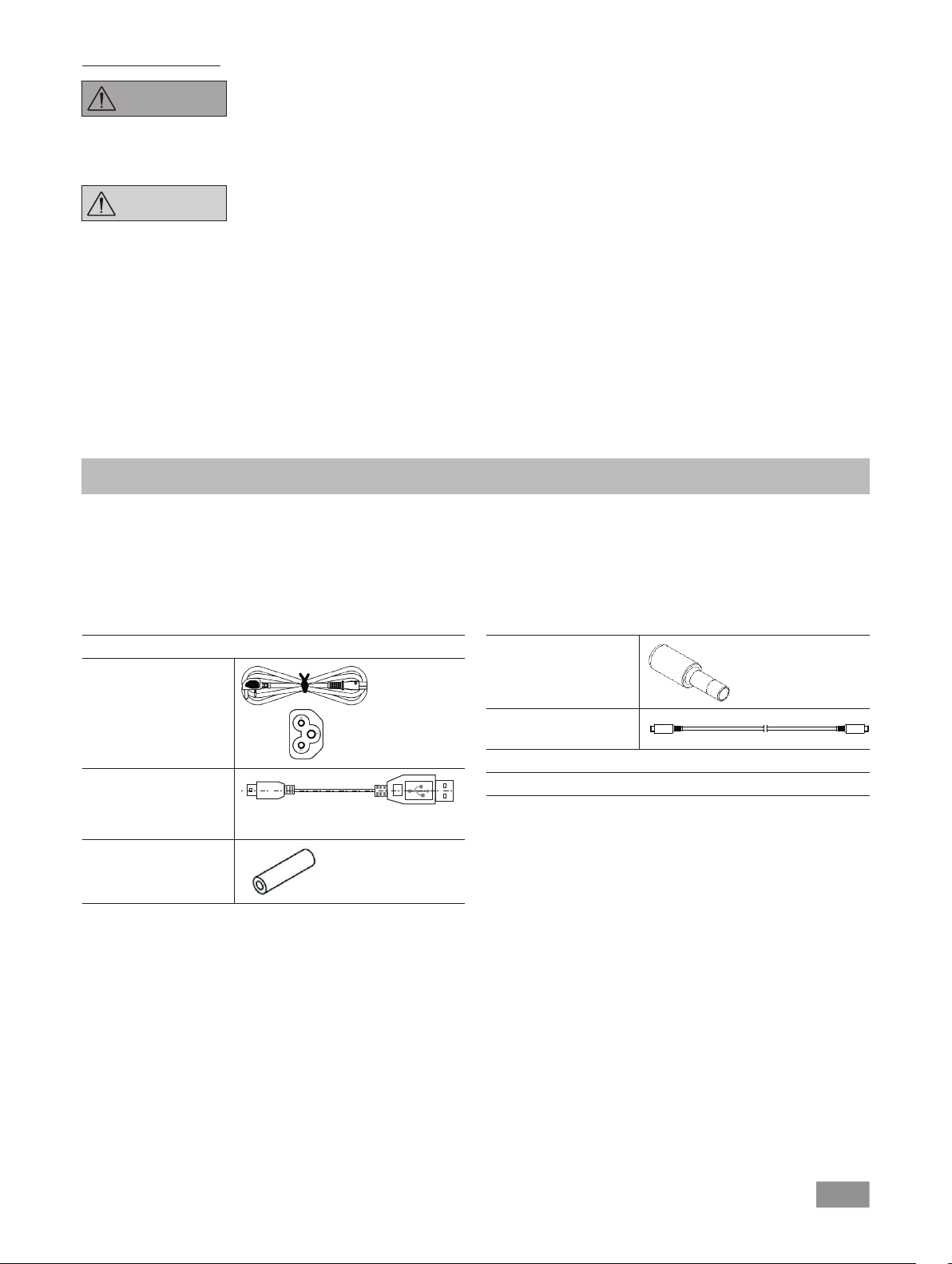

Scope of delivery

Diaphragm vacuum pump

Power supply cable

Laptop Euro

Power supply cable

Laptop GB

Power supply cable

Laptop CH

USB A - USB B cable

Vacuum hose 1m

IKA Vacstar digital

Silencer

Connecting cable MVP

10.100

Operating instructions

A

Warranty card

7

Page 8

Correct use

Use

WARNING

The laboratory diaphragm vacuum pump

together with other laboratory devices to create a vacuum.

For specific vacuum control, an additional vacuum controller IKA

VC 10 or IKA rotary evaporator RV 10 auto is required.

Area of use (only indoors)

The device is suitable for use in

The safety of the user cannot be ensured:

• if the device is used in conjunctions with accessories not

made or recommended by the manufacturer!

The device must not be used for:

- evacuating biological habitats,

-

evacuating explosive, corrosive

or similar gases,

- throughput/use of liquids

The device is not suitable for:

- pumping up objects

- pumping liquids

- use in potentially explosive

atmospheres

- underwater

- underground

residential

IKA Vacstar digital is

areas and all other areas.

used

Standalone operation

The vacuum pump can be operated without a controller.

The delivery

speaking, the smaller the volume to be evacuated, the lower the

speed should be. The final pressure is not controlled.

Operation with accessories

Along with the accessories recommended by IKA, the vacuum

pump

specified final pressure e.g. for operating an IKA

It can also be used for classical separation, filtration or drying in

the laboratory.

With an appropriate vacuum controller

evaporator (e.g. RV 10 auto), the

automatically, for automatic boiling point detection, scheduled

pressure-time

Intended use: Tabletop device

• if modifications are made to the device or parts of the device

• if the device is

capacity

IKA Vacstar digital

by third parties!

instructions!

can be set using the adjustable speed.

is suitable for controlled evacuation to a

(e.g. VC 10)

Vacstar digital

curves or programs from the solvent library, for example.

operated in contravention of the safety

rotary evaporator.

can be operated

Generally

or with a rotary

DANGER

CAUTION

Useful information

You can

solvent vapours into

using

condenser.

Special care must be taken when

working with gas

include condensable gases (e.g.

solvents). If diaphragm pumps are

used with

in the pump’s air flow. This leads

to a build-up of pressure in the

vacuum chamber,

influences the effectiveness and

service life of the diaphragms and

valves.

If liquid or condensate enters the

vacuum chambers, the specified

minimum working pressure is no

longer achieved.

To

diaphragms against liquid, use an

upstream condensate separator,

such as a Woulff bottle.

prevent the release

the atmosphere

a downstream emission

mixtures

such

gases they

which in turn

protect

the inner valves and

of

that

condense

CAUTION

NOTE

Diaphragm vacuum pumps are oscillating displacement pumps.

The diaphragms expand the volume of the vacuum chamber to

produce an underpressure, which sucks air into the chamber. The

air is then pressed out of the vacuum chamber by subsequent

compression. Changes between the inlet and outlet are controlled

by diaphragm valves.

The physical unit for pressure is 1 Pascal [Pa].

However people often still use the unit millibar [mbar] colloquially.

1 mbar = 100 Pa

1 bar = 10

1 Pa = 10

1 Pa = 0.01 mbar

5

Pa

-5

bar

It is generally recommended that

you run the pump with no load at

the end of the

operation, approx. 3 up to max. 5

minutes) to dispel any residues in

the pump.

If applicable, vent the recipient.

To do this, remove the suction line

during manual operation.

Observe the operating instructions

of the relevant devices.

process (no-load

8

Page 9

A distinction

is made

between different ranges

in vacuum

technology.

Rough vacuum: 10

Fine vacuum: 10² to 10

High vacuum: 10

Ultra high vacuum < 10

5

to 10² Pa (1000 to 1 mbar)

-1

-1

Pa (1 to 10-3 mbar)

to 10-5 Pa (10-3 to 10

-5

Pa (< 10

-7

mbar)

-7

mbar)

The periodic movements of the diaphragms create a vacuum at

the pump inlet. Diaphragm vacuum pumps work with a rough

vacuum of up to 10

2

Pa. Lower pressures cannot be achieved with

these pumps.

To create fine, high and ultra high vacuums, oil-sealed vacuum

pumps, screw pumps, diffusion pumps or turbomolecular pumps

must be used, for example. Diaphragm vacuum pumps are often

used as pumps for the preliminary stage in these contexts.

Compressing and releasing the pressure on air creates a noise. The

pump is quieter the less air is transported. This means that there

is less operating noise during normal operation if the pressure is

reduced.

A fitted exhaust hose with a sound absorber can also be used to

reduce noise.

In automatic operation with controlled speed the pump reduces

its speed when it reaches the target value. If the leakage rate in the

entire system is low enough, the speed may even be set to “zero”.

When combined with the vacuum controller VC 10 or the

rotary

evaporator with integrated vacuum controller RV 10 auto,

the

pump can

also

be used for

“two-position control” (valve-controlled)

or “analogue speed control” of the vacuum.

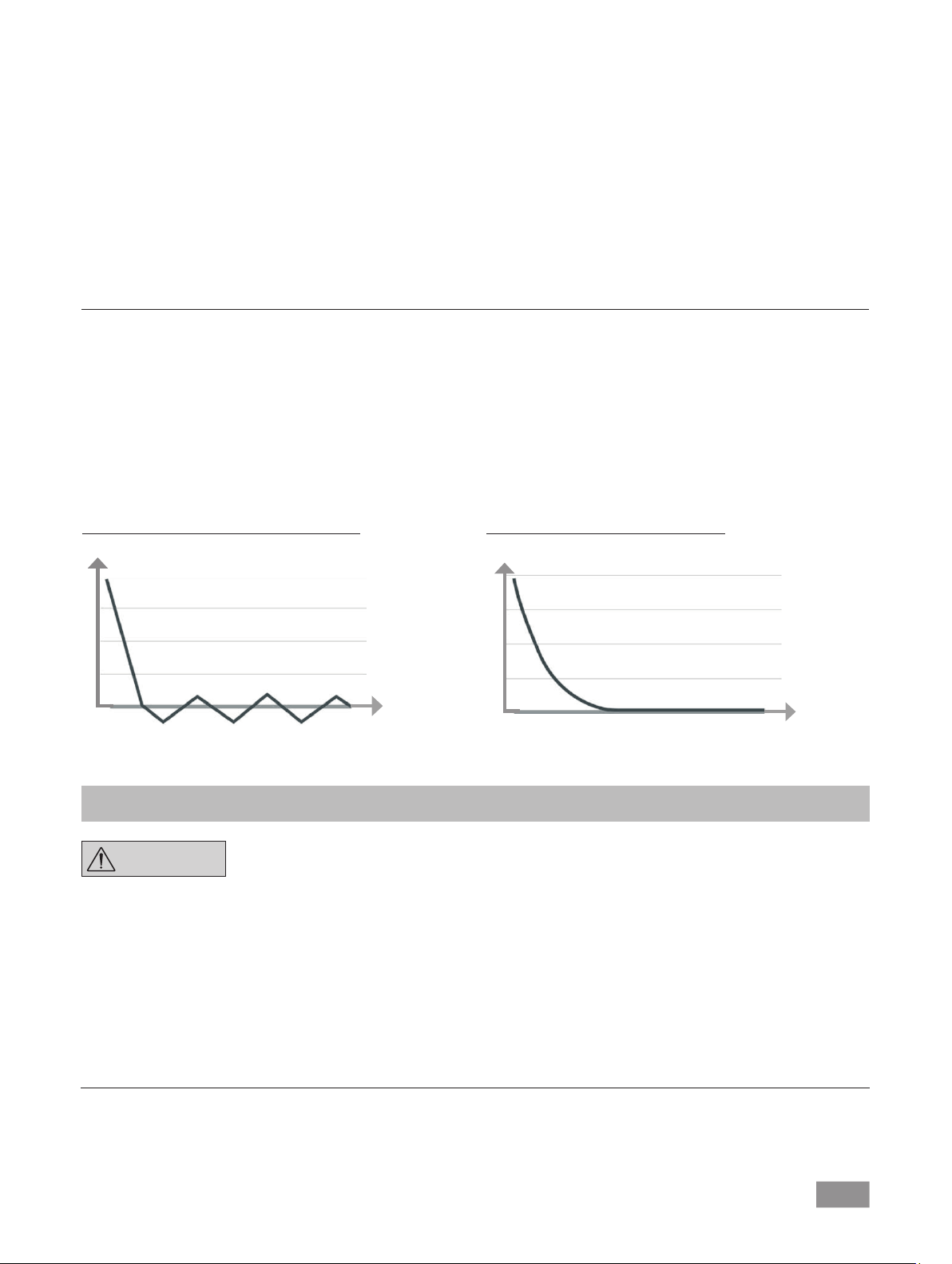

Two-position control

When the target value is reached, the suction line is interrupted.

Due to the small delay between the times when the pressure value

is detected, when comparison is made with the target value, when

a vacuum valve is switched off and when the suction line of the

vacuum-producing system are switched off, it is easy to go below

the set target value. If the pressure in the system goes up again

due to a natural leakage rate, the suction line valve opens.

Schematic view of two-position vacuum control

mbar

t

Setting up

Analogue speed control

With this control, the speed of the pump,

and therefore its

suction

power, is reduced the closer the measured pressure reaches the

target value. Once the target value is reached,

the pump only

operates according to the leakage rate of the system. This enables

quiet functioning, precise vacuum control and a long service life

for the

moving pump parts

. Exact

automatic boiling

point

recognition

is

possible with this type of control, meaning that the system reaches

and keeps the solvent at its boiling point in automatic mode.

Schematic view of speed vacuum control

mbar

t

NOTE

Ensure that you follow the general

rule

, that

the

recipient

(load/vacuum

container/glass condenser) should

always

be connected to

line at its

highest

point.

the suction

This reduces

the risk of liquids entering the vacuum

pump.

Liquid in the pump chambers

makes the pump properties worse.

Connect the hose

connections

(INLET/OUTLET) and interfaces in

accordance with

pump and the

the labelling on the

operating instructions.

The connections are barbed hose connectors

. Ensure that the

hoses have hose clips if applicable.

Lay the hoses in such a way that no condensate can flow into the

pump.

Ensure that the air can enter the ventilation slit (H) unhindered.

Install a condensate separator (e.g. a Woulff bottle) in the suction

line before the intake spigot of the pump to protect against water

coming in.

If solvent vapours are sucked in, an emission condenser (accessory)

after the pump helps to condense it, and prevents it being released

into the atmosphere.

9

Page 10

Connection of interfaces

NOTE

O: Hose connection d= 8 mm OUTLET

Link this connection to the emission condenser with a vacuum

hose, or fit a sound absorber to the end.

NOTE

K: Connection for vacuum controller VC 10 (Mini DIN)

You can connect the vacuum pump and the vacuum controller

VC 10 or the

connection cable

vacuum control.

The vacuum controller detects the pump and switches to

speed-vacuum control mode. Two-position control is deactivated.

rotary evaporator RV10 auto

MVP 10.100

Observe the relevant connections

(see Fig. 1).

Put the end of the hose in the

extractor hood!

Check there is a free outlet on the

pressurised side!

Do not use a throttle on the

pressurised side

the outlet! Connect the exhaust

line to this connection.

for

precise speed-controlled

and do not close

with the analogue

L: USB interface

Connect the vacuum pump IKA Vacstar digital to a PC with a USB

A - USB B cable. Any device software updates can be loaded using

the IKA FUT software tool.

M: RS 232 interface

You can connect the IKA Vacstar digital vacuum pump to a PC

using an RS 232 interface cable. The pump can be operated in

conjunction with other devices with

device software.

and outputs”.

N: Water valve connection

Connect the optional water

diaphragm vacuum pump.

condensor is controlled using the water valve. The valve is opened

as soon as the pump is switched on.

I: Hose connection for suction line d= 8 mm INLET

Connect the suction line to this connection.

Link this connection to the recipient (rotary evaporator condenser,

laboratory reacor etc.) with a vacuum hose.

P: Power supply cable connection

Check that the voltage information on the rating plate matches

your mains supply. Connect

electricity.

For

further

information

labworldsoft® laboratory

see the chapter “Interfaces

throttle

valve RV 10.5001

The water

the

power supply

flow to the emission

cable

to the

to supply

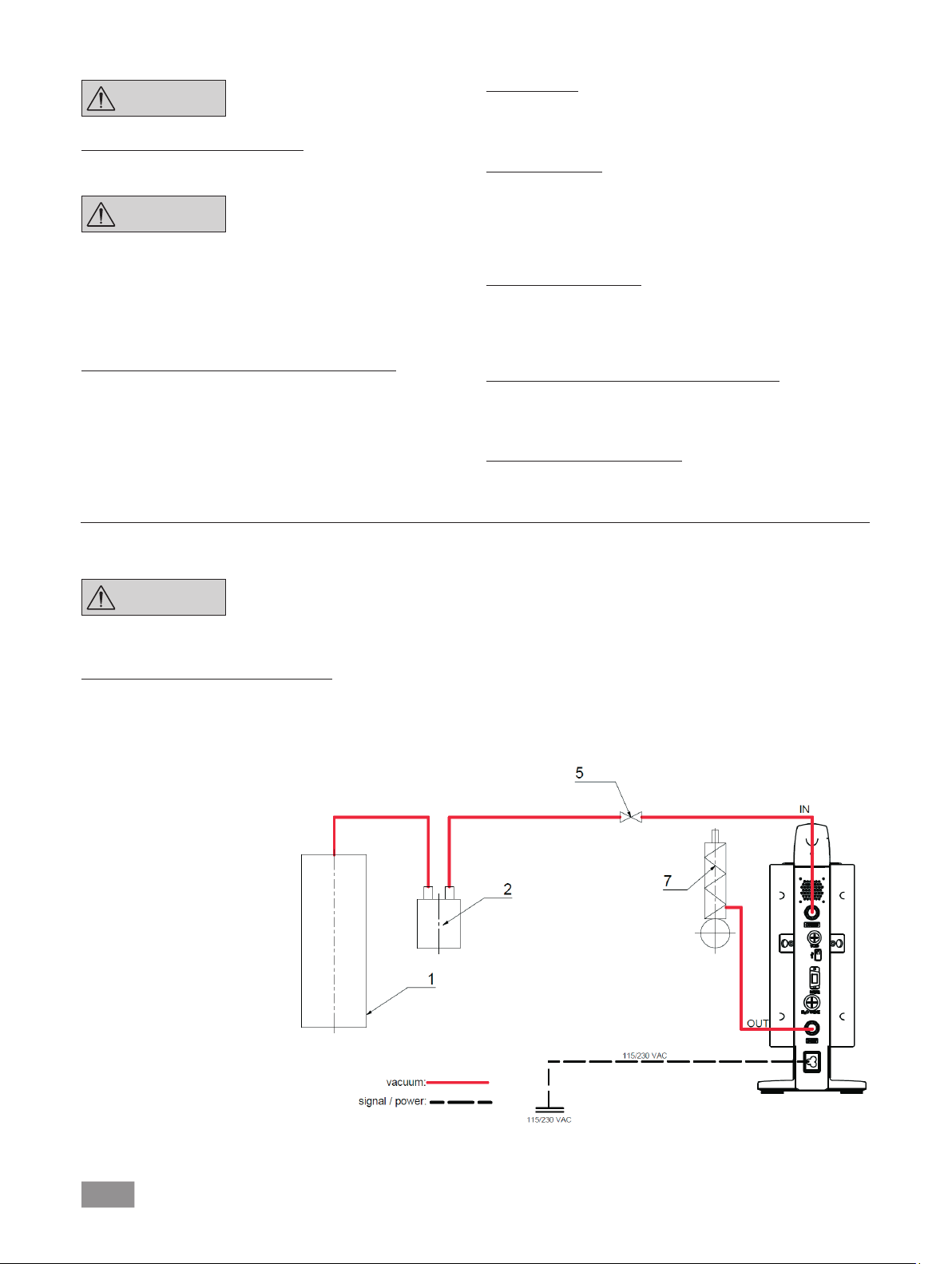

Configuration

NOTE

Two-position control:

IKA Vacstar digital in standalone operation

Vacuum created without a controller through simple suction, no

vacuum target value control possible.

The pump speed can be changed by manually setting the speed

using the rotating/pressing knob (C) of the vaccum pump.Manual

1 Recipient (load, e.g. rotary

evaporator, reactor)

2 Vacuum separator (e.g. Woulff

bottle)

5 Vacuum valve/ball valve

7 Emission condenser

Observe the operating instructions

for the devices.

activation of the vacuum valve or ball valve.

Rough vacuum control is possible, for example, with the vacuum

control valves VCV 1 and VCV 2, by mixing in air from outside.

10

Page 11

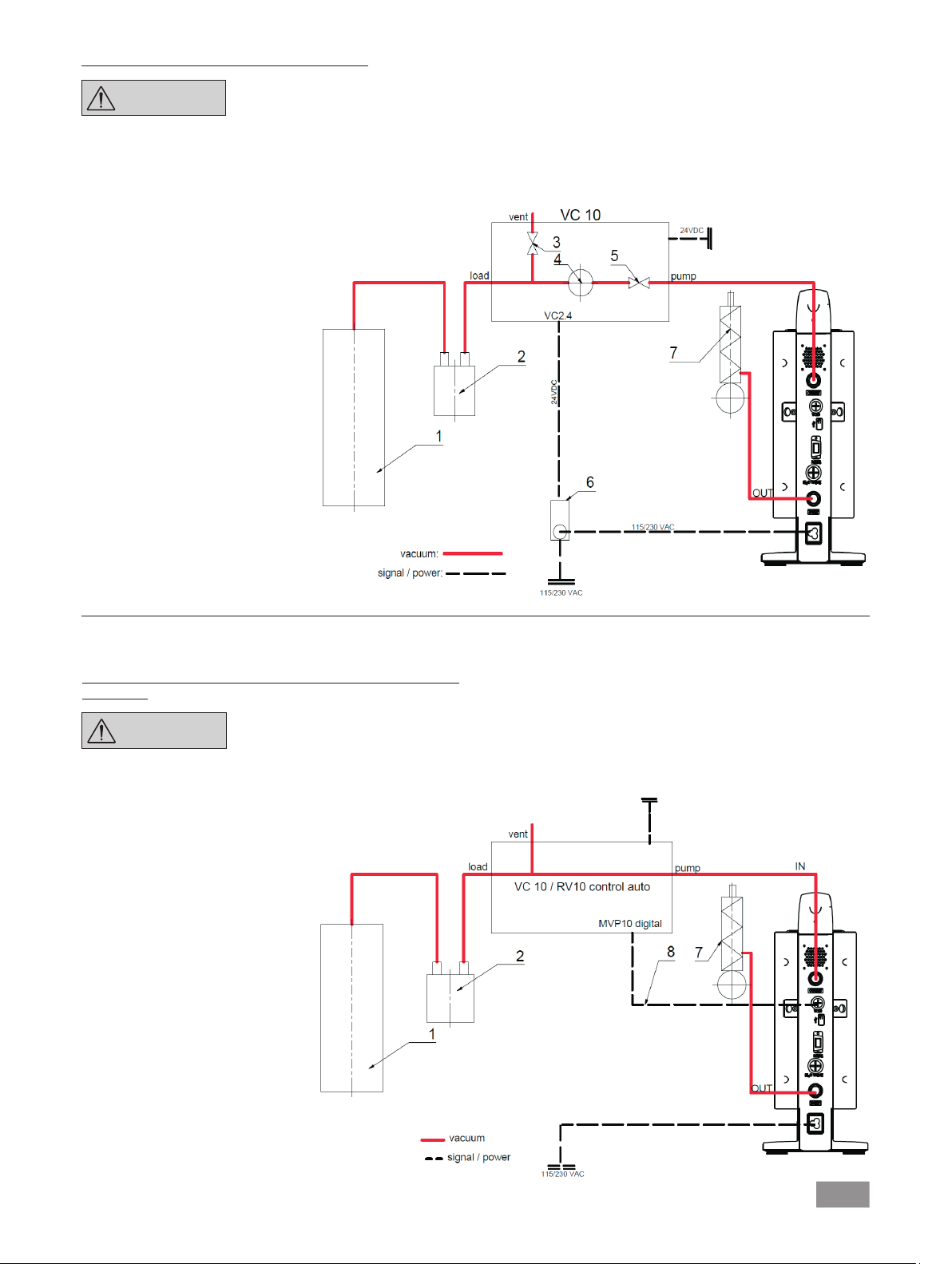

IKA Vacstar digital with vacuum controller VC 10

NOTE

When the target value is reached, the suction line is closed by the

vacuum valve integrated in the VC 10. The pump speed can be

changed by manually setting the speed.

1 Recipient (load, e.g. rotary

evaporator, reactor)

2 Vacuum separator (e.g. Woulff

bottle)

3 Vent valve

4 Pressure sensor

5 Vacuum valve/ball valve

6 Pump cut-out unit VC 2.4

7 Emission condenser

Cannot

water valve RV 10.5001 in conjunction

with VC 2.4.

Refer to the operating instructions

for the vacuum controller VC 10!

be operated with optional

When using the optional pump cut-out unit

VC 2.4 (ref. 6) the pump is switched off when the target value is

reached (operating mode B).

This

device configuration

cut-out unit VC 2.4. The pump runs on. For good control, the

pump should be operated at a low speed.

is also

possible without

the pump

Speed regulation

IKA Vacstar digital with vacuum controller VC 10 or rotary

RV 10 auto

NOTE

Automatc setting of the operating mode “Speed regulation” as

soon as the

connects the pump

1 Recipient (load, e.g. rotary

evaporator, reactor)

2 Vacuum separator (e.g.

Woulff bottle)

7 Emission condenser

8 Analogue connecting cable

MVP 10.100

analogue connecting cable

Observe the operating instructions

for the devices.

MVP 10.100 (ref. 8)

with the vacuum controller or rotary evaporator.

evaporator

When the target value is reached, the pump speed is

matically

value is reached, the pump applies

rate of the vacuum system. Automatic boiling point recognition

is possible.

reduced to a minimum of “0 rpm”. Once the target

suction according to the

24 VDC

115/230 V

auto-

leakage

11

Page 12

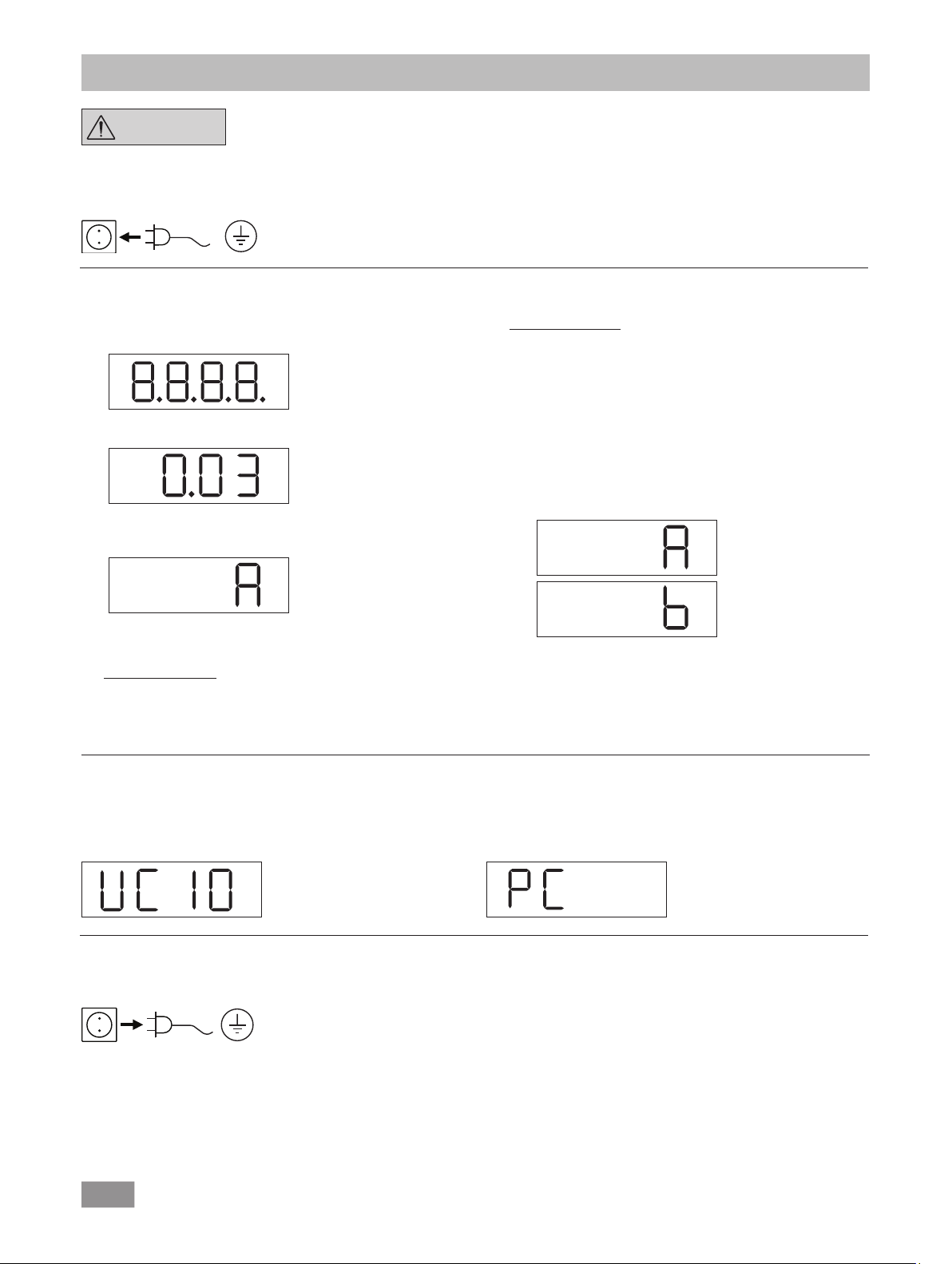

Commissioning

NOTE

Check if the voltage specified on the type plate matches the available mains voltage. If these conditions are met, the device is ready

for operation when it is plugged in to the mains.

Switching on

1. Switch on the device using the main switch (D). All display

sements are shown to enable a visual check.

2. Software version number display (e.g. vers. 1.00).

3. Operating mode display (A; B). (Factory setting: Operating

mode A)

Observe the operating instructions

for the devices.

The socket used must be earthed

(grounded contact).

Otherwise safe operation is not guaranteed or the device may be

damaged.

Observe the ambient conditions indicated under “Technical data”.

Operating mode B:

In this operating mode, the set target value is saved when the

current run comes to an end or the device is switched off, and

the value can be changed.

Operating mode B is required particularly in combination with

the pump cut-out unit VC 2.4.

Automatic restart after mains power is cut off.

Changing operating mode:

1. Press the rotating/pressing knob (C) and switch on the

device at the main switch (D) at the same time to change

between the two operating modes.

The operating mode can be changed when you switch on the

device.

Operating mode A:

In this operating mode, the set target value is not saved when

the current run comes to an end or the device is switched off.

No automatic restart after mains power is cut off.

Switching on with several interfaces

If the pump is operated via the analogue connecting cable MVP

10.100 with the vacuum controller VC 10 or the rotary evaporator

RV 10 auto, “VC 10” is shown on the display.

Switching off

Switch off the device using the main switch (D).

Unplug the appliance from the

mains socket to disconnect it from

the mains.

In standalone operation or two-position operation in combination

with the vacuum controller VC 10 the target speed can be set by

turning the rotating/pressing knob (C). Push to start the pump and

push again to stop it. A flashing light on the display (B) indicates

when the device is running.

If the vacuum controller is connected to a PC, “PC” is shown on

the display (B).

12

Page 13

Interfaces and outputs

NOTE

The device can be operated in “Remote” mode via an RS232 or

USB interface using the laboratory software labworldsoft

232 interface (M) at the back of the device is fitted with a 9-pole

SUB-D jack which can be connected to a PC. The pins are assigned

serial signals.

USB Interface

The Universal Serial Bus (USB) is a serial bus system which allows

the device to be connected to the PC. Devices that support USB

can be connected to each other whilst

plugging) and provide automatic

devices and their properties.

Use the

USB interface

operation in “Remote” mode and for updating the firmware using

the “Firmware update tool”.

Installation

Before the device is connected with the PC using the USB data

cable, the USB driver must be installed.

The USB driver can be downloaded from the website:

Serial interface RS 232 (V 24)

Configuration:

• The functions of the interface circuit between the device and

the automation system

in the EIA standard RS232 as per DIN 66020 Part 1.

• Standard RS 232, corresponding to DIN 66259 Part 1 is valid

for the electric characteristics of the

assignment of signal states.

• Transmission process: Asynchronous character transmission

in start-stop operation.

• Transmission type: Full duplex.

• Character format: Character composition according to data

format in DIN 66022 for start-stop operation. 1 start bit, 7

character bits, 1 parity bit (even), 1 stop bit.

• Transmission speed: 9600 Bits/s.

• Data flow control: none

• Access method: Data transmission from the device to the

computer only occurs after a request from the computer.

Command syntax and format

The following points should be noted for the instruction set:

• Commands are generally sent from the computer (master) to

the device (slave).

• The device only responds to requests from the computer.

Even error messages are not send spontaneously from the

device to the computer (automation system).

• The commands are transmitted in captial letters.

• Commands

must be separated by at least one space (code: hex 0x20).

• Each individual command (including parameters and data)

and all responses are completed with CRLF (code: hex 0x20

hex 0x0d hex 0x0A) and can have a maximum length of 50

characters.

• The dot is used for decimal separators in a floating-point val-

ue (code: hex 0x2E).

and

Please comply with

requirements together with the

operating instructions and help

section

included with

they are running

recognition of the

in conjunction with

are a selection from the signals specified

interface

parameters,

as well as consecutive parameters,

the system

the software.

®

. The RS

connected

labworldsoft®

circuits and

(hot

for

The

details

given

of NAMUR (NAMUR recommendations for the design of electrical

plug-in connectors for analogue and digital signals in laboratory

MSR devices. Rev. 1.1).

The NAMUR commands and the additional IKA-specific

commands are only used as low-level

between the device and the PC. With an appropriate terminal or

communication program, these commands can

directly to the device.

NAMUR commands Function

IN_NAME Read device name

IN_PV_4 Read current speed value

IN_SP_4 Read rated speed value

OUT_SP_4 Adjust the rated speed value

START_4 Start evacuation

STOP_4 Stop evacuation

RESET Switch to normal operating mode

OUT_NAME Set device name

OUT_SP_42@n Setting WD safety limit speed with

OUT_WD1@m Watchdog mode 1

OUT_WD2@m Watchdog mode 2

“Watchdog” functions; monitoring of the serial data flow

If, once this function has been activated (see NAMUR commands),

there is no retransmission of the command from the computer

within the set time (“watchdog time”), the Evacuation function is

switched off in accordance with the set “watchdog” mode or is

returned to previously set target values. The data transmission may

be interrupted by, for example, a crash in the operating system,

a power failure in the PC or an issue with the connection cable

between the computer and the device.

“Watchdog” mode 1

If event WD1 should occur, the evacuation function is switched

off and ER2 is displayed. Set watchdog time to m (20- 1,500)

seconds, with watchdog time echo. This command launches the

watchdog function

time.

“Watchdog” mode 2

If there is an interruption in data communications (longer than the

set watchdog time), the speed target value is changed to the set

WD safety speed limit. The warning PC 2 is displayed. The WD2

event can be reset with

function.

Set watchdog time to m (20 - 1,500) seconds, with watchdog

time echo. This command launches the watchdog function and

must be transmitted within the set watchdog time.

above generally comply

set value echo

and must be transmitted within the

OUT_WD2@0 -

with the

recommendations

commands for communication

be transmitted

set watchdog

this also stops

the watchdog

13

Page 14

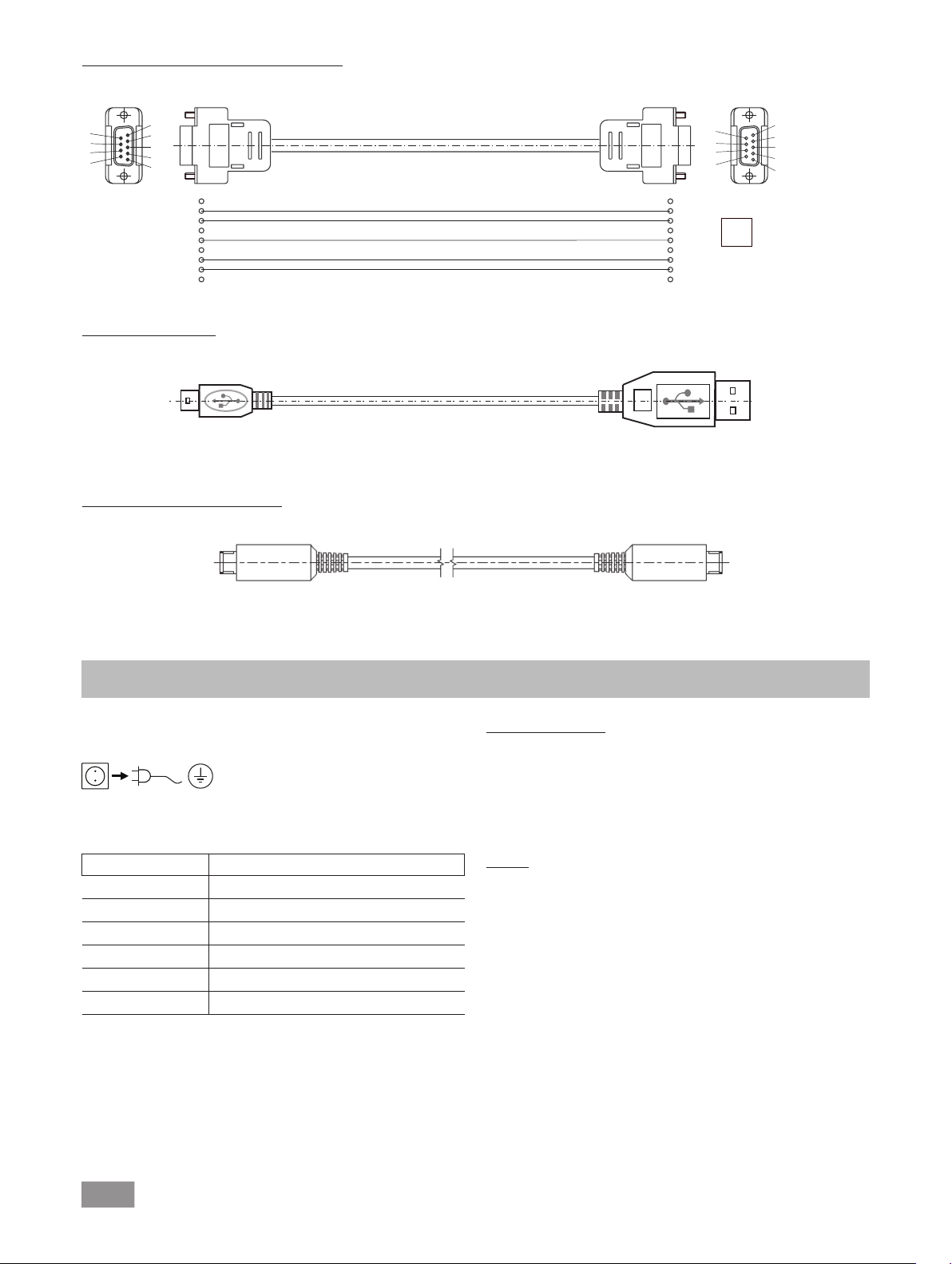

Accessories: PC 1.1 cable (device to PC)

9

9

Required for connecting the 9-pin socket to a PC.

6

7

8

9

1

2

3

4

5

RxD 2

TxD 3

GND 5

RTS 7

CTS 8

1

4

6

USB A - USB B cable

Required for connecting the USB interface (L) to a PC.

USB B

Connecting cable MVP 10.100

Required for connecting VC 10 and RV 10 auto with the diaphragm vacuum pump

A

IKA Vacstar digital

9

8

7

6

1

2 RxD

3 TxD

4

PC

5 GND

6

7 RTS

8 CTS

(speed operation).

5

4

3

2

1

USB A

Fig. 10

Fig. 11

Fig. 12

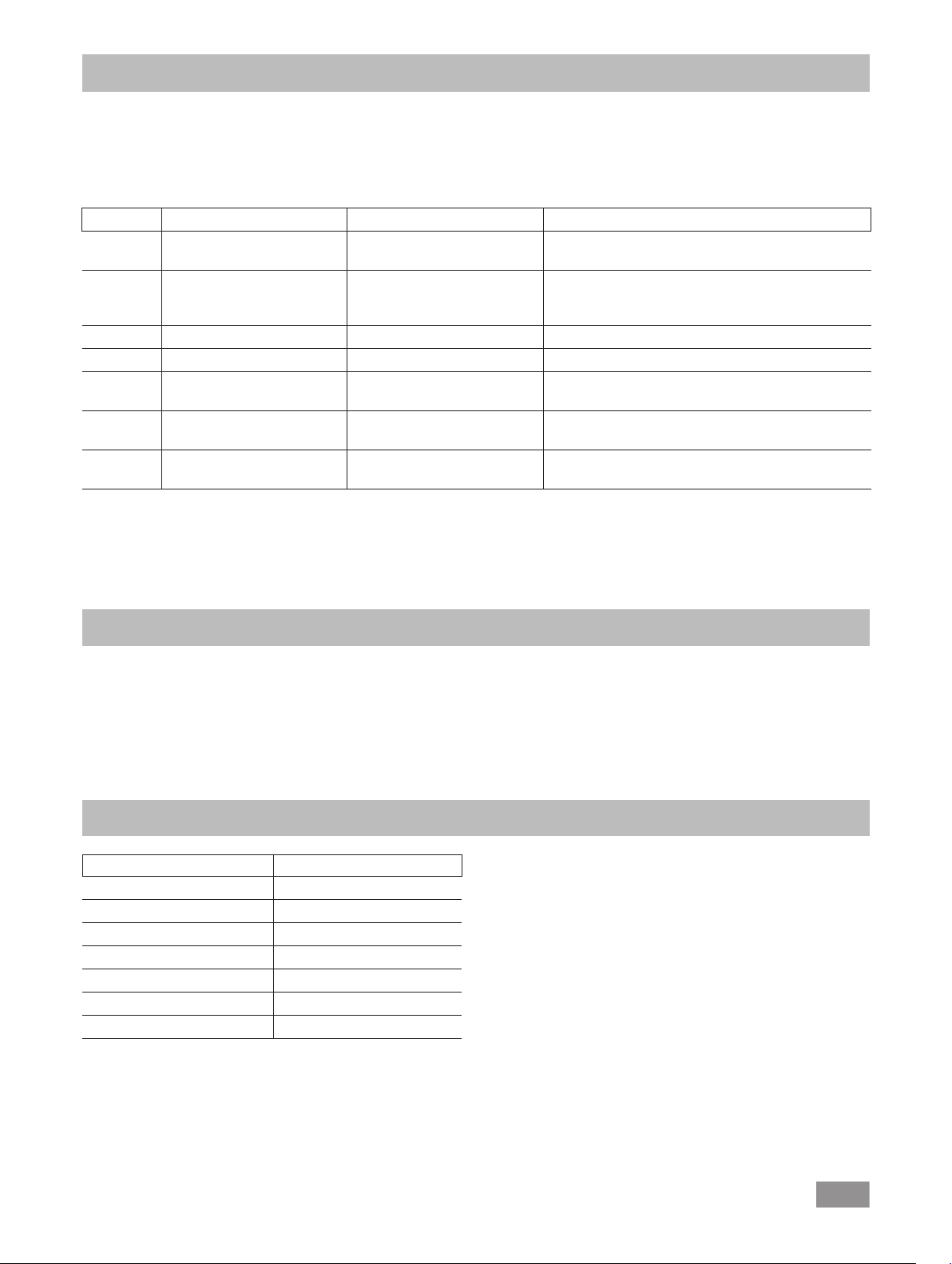

Maintenance and cleaning

The device is maintenance-free. However it is subject to natural

wear and tear on parts and their statistical failure rate.

Unplug from the mains before cleaning.

Only clean the IKA device using these IKA-approved cleaning

agents:

Dirt Cleaning agent

Dyes Isopropyl alcohol

Building materials Water containing detergent, isopropanol

Cosmetics Water containing detergent, isopropanol

Food Water containing detergent

Fuels Water containing detergent

Other materials Please ask IKA

• Wear protective gloves when cleaning the devices.

• Do not place electrical appliances into the cleaning agents for

cleaning purposes.

• Ensure no liquid enters the device during cleaning.

• Please consult with IKA before using any cleaning

decontamination methods not specifically recommended.

or

Ordering spare parts

When ordering spare parts,

please make sure

to indicate the

following:

• Device type

• Device manufacturing number; see rating plate

• Reference number and description of spare part; see spare

part diagram and list at www.ika.de.

Repairs

Please only send devices in for repair that have been

cleaned and are free of materials which might present

health hazards.

For this, use the “certificate of compliance” form which you

can obtain from IKA or can download a version for printing from

the IKA website www.ika.de

If your appliance requires repair, return it in its original packaging.

Storage packaging is not sucient. also use appropriate transport

packaging.

14

Page 15

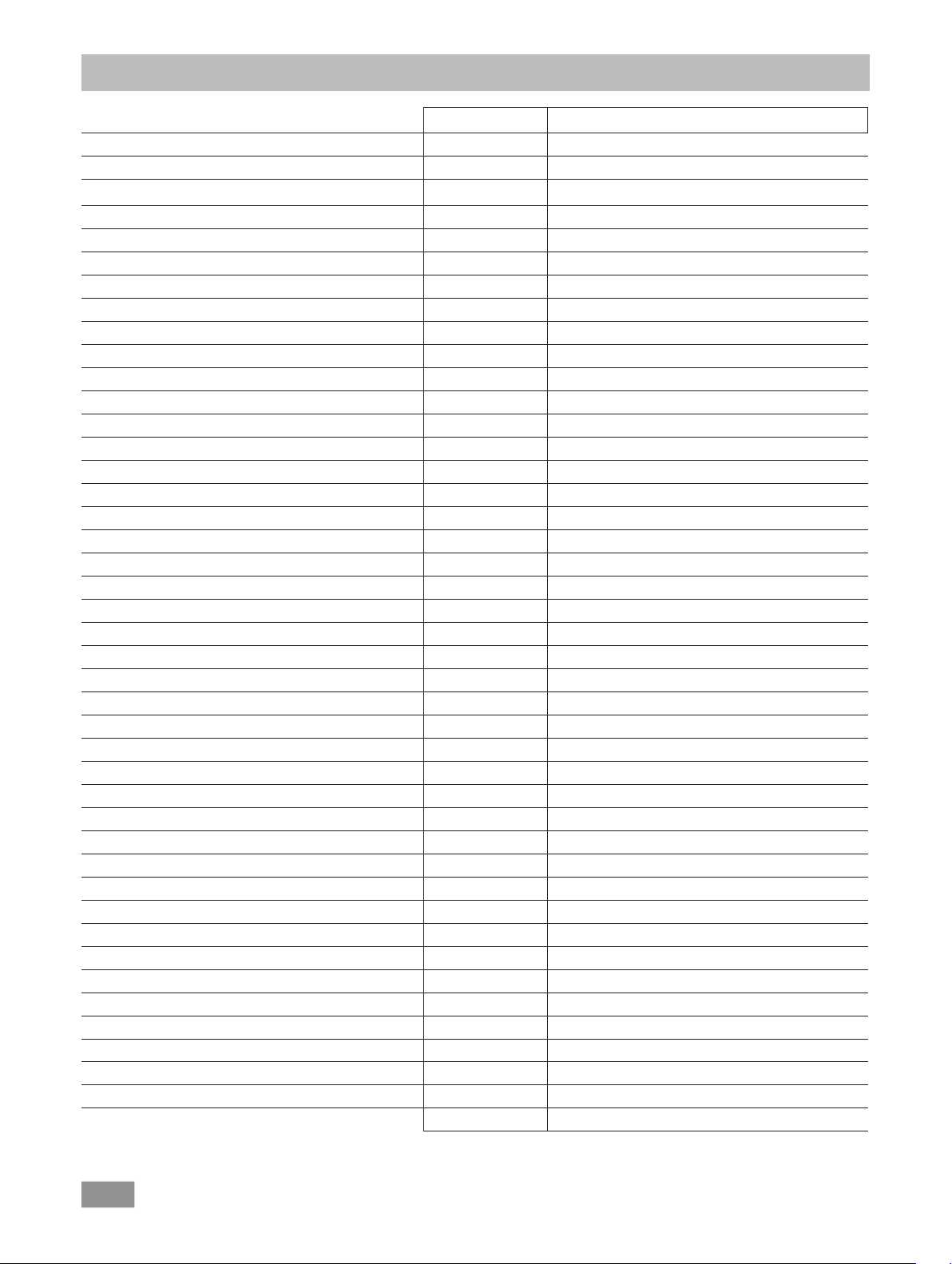

Error codes

If an error occurs, this is shown in an error on the display (B), e.g. Error 4.

Proceed as follows:

• Switch the device off on the device switch,

• Take corrective measure,

• Switch device back on.

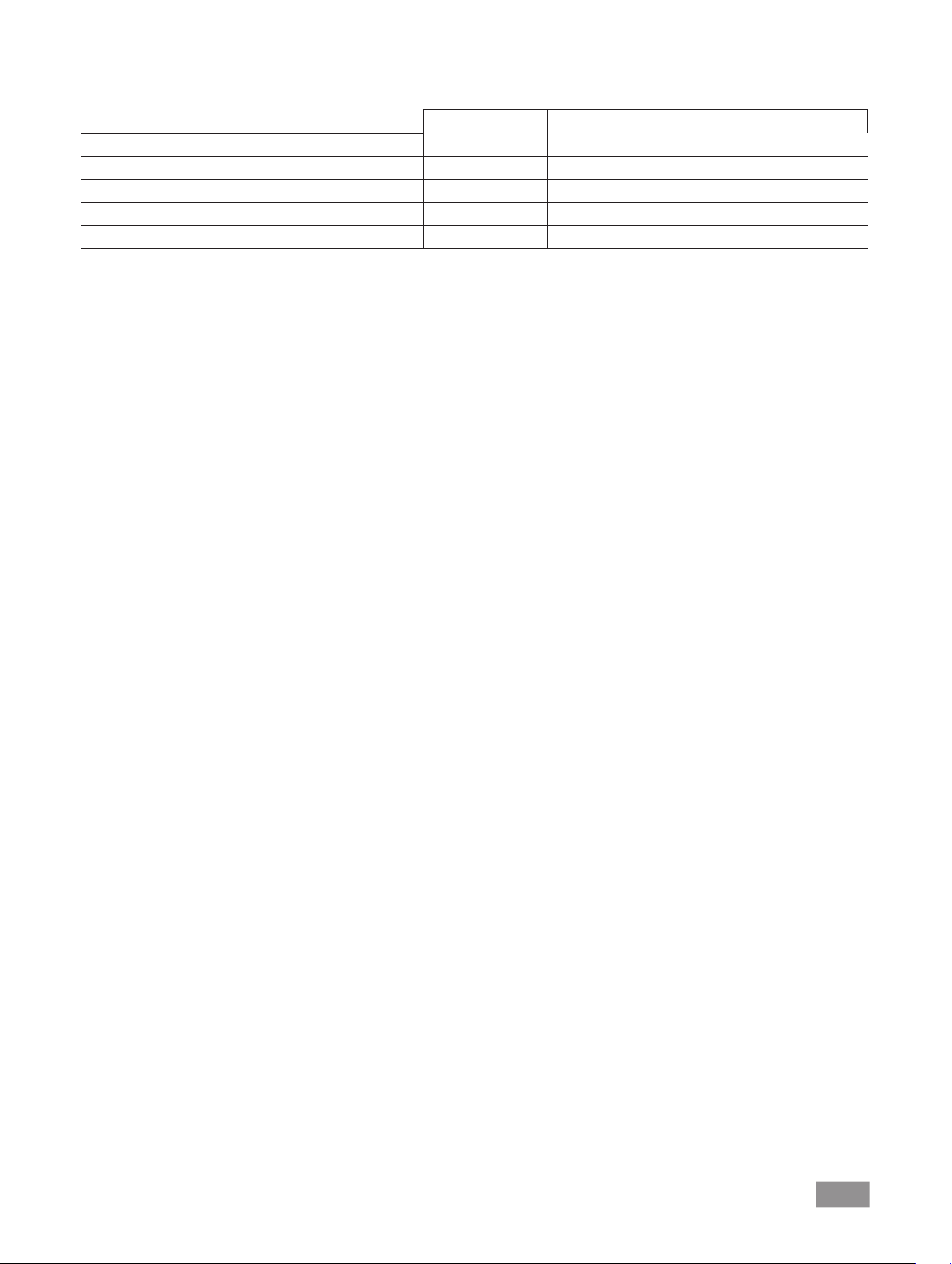

Error Cause Reason Solution

Error 3 Overheat The pump does not run Switch off the pump, disconnect it from the mains, let

Error 4 Motor blocked/overload The pump does not run Switch off the pump, disconnect it from the mains

Error 8 Hall sensor defective The pump does not run Service

Error 9 BLP self-test/EEPROM error The pump does not run Service

No display Pump diaphragm defective Minimum pressure and suction

rate are not achieved

No display Diaphragm valve defective Minimum pressure and suction

rate are not achieved

No display Liquid in the pump chambers Minimum pressure and suction

rate are not achieved

In the event that the fault cannot be eliminated using the measures described or another error code is displayed:

• Please contact the Service Department,

• Send the device and a brief description of the fault.

it cool down.

Let the pump cool down.

Ventilate the vacuum system to normal pressure.

Service

Request a maintenance kit

Service

Request a maintenance kit

Let the pump run dry (no-load operation)

• Vacuum controller IKA VC 10

• Vacuum control valve IKA

• Check valve IKA VC 10.300

• Vacuum hose IKA VH.SI.8

• PC 1.1 cable (RS 232)

Name Material

Connection spigot PPS

Connection piece PPS

Distributor PPS

Head piece PPS

Diaphragm valve FFPM

Diaphragm NBR/PTFE

Clamp PPS

VCV 1 and VCV 2

Accessories

• Maintenance kit

• Vacuum safety emission condenser VSE 1

• Woulff bottle/water valve set VSW1

For further accessories see www.ika.de

Product contact parts

15

Page 16

Technical data

Base unit Value

Delivery capacity max. m³/h 1.32

Delivery capacity max. L/min 22

Final pressure mbar 2

Suction steps 4

Cylinder 4

Connection diameter suction side mm 8

Connection diameter pressure side mm 8

Gas ballast valve no

Inlet pressure min. mbar 2

Inlet pressure max. mbar 1030

Boiling point recognition no

Solvent library no

Two-position control yes

Analogue speed-vacuum control yes

Speed setting option rotating/pressing knob

Speed min. rpm 285

Speed max. rpm 1200

Display LED

Vacuum sensor no

Vent valve no

Condensate separator no

Emission condenser no

Volume at minimum pressure dB(A) 54

Product contact material PTFE, FFPM, PPS, NBR

Housing material Cast alu, coated

Appropriate for clean room no

Explosion-proof no

Width mm 150

Depth mm 370

Height mm 375

Weight kg 11.5

Permitted ambient temperature min. °C 5

Permitted ambient temperature max. °C 40

Permitted relative humidity % 80

Protection class according to DIN EN 60529 IP 20

RS 232 interface yes

USB interface yes

Analogue output no

Voltage V 100-240

Frequency Hz 50/60

Power consumption W 130

Standby power consumption W 1.5

DC VDC 24

16

Page 17

Base unit Value

Protection class II

Overvoltage category I

Degree of contamination 1

Use above max. sea level m 2000

Firmware update yes

Subject to technical changes

17

Page 18

18

Page 19

Traduction

Table des matières

Structure de l’appareil ............................................................................................................................................................... 2/3

Déclaration de conformité ......................................................................................................................................................... 19

Explication des symboles ........................................................................................................................................................... 19

Garantie .................................................................................................................................................................................... 19

Consignes de sécurité ............................................................................................................................................................... 20

Déballage ................................................................................................................................................................................. 21

Utilisation conforme .................................................................................................................................................................. 22

Informations utiles .................................................................................................................................................................... 22

Installation ................................................................................................................................................................................ 23

Mise en service ......................................................................................................................................................................... 24

Interfaces et sorties ................................................................................................................................................................... 27

Entretien et nettoyage............................................................................................................................................................... 28

Messages d’erreurs ................................................................................................................................................................... 29

Accessoires ............................................................................................................................................................................... 29

Pièces en contact avec le produit .............................................................................................................................................. 29

Caractéristiques techniques ....................................................................................................................................................... 30

FR

Page

Déclaration de conformité

Nous déclarons, sous notre seule responsabilité, que ce produit est conforme aux dispositions des directives 2014/35/UE, 2006/42/CE,

2014/30/UE e

t 2011/65/UE ainsi qu’aux normes et documents normatifs suivants:

EN 61010-1, EN

60529

, EN 61326-

1 et EN ISO 12100.

Explication des symboles

DANGER

AVERTISSEMENT

PRUDENCE

REMARQUE

Situation (extrêmement) dangereuse dans laquelle le non-respect des consignes de sécurité peut causer la

mort ou des blessures graves.

Situation dangereuse dans laquelle le non-respect des consignes de sécurité peut causer la mort ou des

blessures graves.

Situation dangereuse dans laquelle le non-respect des prescriptions de sécurité peut causer des blessures

graves.

Indique par exemple les actions qui peuvent conduire à des dommages m

atéri

els.

Garantie

Conformément aux conditions de vente et de livraison d’IKA, la

garantie s’étend sur une période de 24 mois. En cas de demande

de garantie, s’adresser au distributeur. Il est également possible

d’expédier l’appareil accompagné de la facture et de la raison de

la réclamation directement à notre usine. Les frais de port sont à

la charge du client.

La garantie ne s’étend pas aux pièces d’usure et n’est pas valable

pour les erreurs causées par une manipulation non conforme, un

entretien et une maintenance insusants ou le non-respect des

instructions du présent mode d’emploi.

19

Page 20

Consignes de sécurité

Pour votre sécurité

REMARQUE

• Conservez

à tous.

• Veillez à

l’appareil.

• Respectez les consignes de sécurité, les directives, ainsi que

les mesures de prévention des accidents.

• L’appareil et ses

personnes ou les animaux.

Structure de l’appareil

le

mode d’emploi

ce que seul un

DANGER

• Mettez l’appareil en place conformément au chapitre «Installation», et raccordez les câbles et les interfaces comme décrit.

• Placez l’appareil sur une surface stable, plane et non inflammable.

• Ne travaillez jamais

fectueux.

Lisez entièrement le mode

avant la mise en service et

les consignes de sécurité.

de manière à ce qu’il soit accessible

personnel formé travaille avec

pièces ne doivent pas être utilisés sur les

La pompe à vide IKA Vacstar digital

n’est pas conçue pour être installée

dans les zones à atmosphère explosive.

avec un appareil mal raccordé ou dé-

d’emploi

respectez

DANGER

• Ne soumettez pas au vide des parties du corps de personnes

ou d’animaux.

• N’utilisez pas l’appareil sous l’eau ou sous terre.

• Placez la pompe à vide dans une hotte de laboratoire adaptée

et fonctionnelle ou raccordez-la à une conduite d’évacuation

de la fumée. Veillez à ne pas couder la conduite d’évacuation! La longueur de la conduite d’évacuation ne doit pas

dépasser 2m!

• Évitez la formation de mélanges explosibles, raccordez éventuellement un gaz inerte pour la ventilation et/ou pour la dilution.

Portez votre équipement de protection

personnelle en fonction de la

classe de

en raison du danger présenté par

les projections de liquides et les

dégagements de gaz toxiques ou

inflammables!

danger du milieu à traiter,

Accessoires

• La sécurité du travail n’est garantie qu’en utilisant les

accessoires décrits au chapitre «Accessoires».

• Respectez attentivement

additionnels (p. ex. évaporateur rotatif, contrôleur de vide)

avec lesquels la pompe à vide

• La pression à l’entrée

1100mbar.

Utilisation de l’appareil

et à la sortie du gaz ne doit pas dépasser

DANGER

AVERTISSEMENT

le mode d’emploi des appareils

IKA Vacstar digital

La sortie de vapeurs de solvants

dans l’atmosphère peut être évitée

avec un condenseur d’évacuation

placé en aval.

La pompe à vide n’est pas conçue

pour une utilisation avec les

substances auto-inflammables,

les

substances inflammables

en l’absence d’apport d’air ou les

substances explosives.

Ne faites jamais fonctionner la

pompe quand elle

Sinon, il y a un risque de blessures

graves en cas d’insertion de la

main dans des pièces rotatives!

L’inhalation ou le contact avec des

milieux tels que les liquides

toxiques

pulvérisation, les vapeurs, les

poussières ou les substances

biologiques peut être dangereux

pour la santé de l’utilisateur.

Assurez-vous

tous les raccords lors de

de ces milieux.

, les gaz, les brouillards de

de l’étanchéité de

fonctionne.

est ouverte.

l’utilisation

• Les éléments élastiques peuvent être comprimés sous l’effet

du vide.

• Ut

ilisez exclusivement des conduites flexibles.

• En cas de panne électrique, suivez vos mesures d’urgence et

assurez-vous de placer l’installation dans un état sûr (voir le

chapitre Mise en service

• La pompe à vide IKA Vacstar digital doit être exploitée exclusivement dans les conditions décrites au chapitre «Caractéristiques techniques».

• Empêcher le dégagement des substances susmentionnées.

Prenez des mesures de protection pour le personnel et l’environnement.

• Tenez compte des éventuelles interactions ou réactions

chimiques ou physiques, lors de la manipulation de milieux

sous pression réduite et température accrue.

• Des processus électrostatiques peuvent se produire entre le

milieu et l’appareil et engendrer un danger.

• En raison du taux de fuite résiduel de l’appareil, un relargage

du milieu peut se produire.

• Avant la mise en service, vérifier que toutes les pièces du carter sont présentes et fixées sur l’appareil.

• Ne soulevez pas la pompe si la poignée est desserrée et si la

vis de sécurité de la poignée (E) est dévissée ou manquante!

• Activez la pompe uniquement si la pompe est à la verticale.

• Reliez les raccords de flexibles (INLET-OUTLET) et les interfaces conformément aux inscriptions sur l’appareil et aux indications du mode d’emploi.

• Assurez-vous que la température du milieu évacué se trouve

sous la température d’inflammation. Le processus de pompage (compactage) fait encore monter la température du

milieu.

, Mode de fonctionnement).

20

Page 21

• Attention, des vapeurs contenant des solvants peuvent être

aspirées dans la pompe!

• N’utilisez pas la pompe pour générer de la pression!

• Respectez la pression autorisée côté entrée et côté sortie, voir

le chapitre «Caractéristiques techniques».

• Une régulation/un rétrécissement du flux de gaz n’est autori-

Pour protéger l’appareil

AVERTISSEMENT

PRUDENCE

• Pour débrancher l’appareil du secteur, tirez sur la fiche secteur de l’appareil.

• La prise de courant utilisée pour le câble secteur doit être

facile d’accès.

• Les caches et les pièces qui peuvent être retirés de l’appareil

sans outillage, doivent être remontés sur l’appareil pour garantir la sécurité, dès lors qu’aucun autre raccordement n’a

lieu à cet endroit. Ceci permet d’éviter l’infiltration de liquides

ou la pénétration de corps étrangers.

• Les liquides aspirés par inadvertance peuvent être évacués en

aspirant de l’air.

Assurez-vous de la compatibilité

des substances utilisées avec l’appareil avec les matériaux des

pièces de l’appareil en contact

avec le produit, voir le chapitre «

Pièces en contact avec le produit ».

L’indication de la tension sur la

plaque signalétique doit coïncider

avec la tension du secteur.

sé(e) que dans la conduite côté aspiration!

• Utilisez plusieurs électrovannes ou clapets antiretour dans la

conduite d’aspiration en cas d’utilisation de plusieurs dispositifs de charge.

• En cas d’utilisation d’un condenseur d’émissions, veillez à

l’écoulement libre du liquide de refroidissement!

• Évitez les coups et les chocs sur l’appareil.

• Seul le personnel qualifié (autorisé) est habilité à ouvrir l’appareil

• L’appareil ne doit pas être modifié sans l’autorisation d'IKA.

• Pour permettre un refroidissement suffisant de la pompe à

vide IKA Vacstar digital, les fentes d’aération du carter ne

doivent pas être couvertes.

• Pour la remise en état, utilisez exclusivement des pièces détachées d’origine, afin de garantir la fiabilité de l’appareil.

• Tenir compte de la condensation de l’eau à l’intérieur et à

l’extérieur de l’appareil. Réchauffer d’abord l’appareil s’il

vient d’un environnement froid.

• Ne raccordez jamais la pompe à vide à un bain de thermostatisation.

• Veillez à ce qu’aucun corps solide et/ou liquide ne pénètre

dans la membrane de la pompe à vide IKA Vacstar digital via

la conduite d’aspiration. Cela endommagerait la membrane

et d’autres pièces internes à la pompe. Le débit s’en trouverait réduit et la pression finale ne serait plus atteinte. Desdépôts peuvent apparaître à l’intérieur de l’appareil, ce qui en

réduit la durée de vie et provoque des fuites!

Déballage

Déballage

• Déballez l’appareil avec précaution.

• En cas de dommages, établissez immédiatement un constat

correspondant (poste, chemin de fer ou transporteur).

Contenu de la livraison

Pompe à vide à membrane

Câble secteur d’ordina-

teur portable

Câble USB A - USB B

Flexible de vide 1m

IKA Vacstar digital

A

Silencieux

Câble de connexion

MVP 10.100

Mode d’emploi

Carte de garantie

21

Page 22

Utilisation conforme

Utilisation

AVERTISSEMENT

La pompe à vide à membrane de laboratoire

à générer du vide

laboratoire.

Pour la régulation définie du vide, un régulateur de vide

IKA VC 10

Domaine d’utilisation (uniquement en intérieur)

L’appareil peut être utilisé dans toutes les zones résidentielles et

tous les autres secteurs.

L’utilisateur n’est plus protégé:

• si l’appareil est utilisé avec des accessoires non fournis ou non

ou un évaporateur rotatif IKA RV 10 auto est nécessaire.

recommandés par le fabricant!

Ne pas utiliser l’appareil pour:

- L’évacuation d’espaces vitaux

biologiques,

-

L’évacuation de volume de gaz

explosifs, corrosifs ou autres,

- Le passage/l’utilisation

L’appareil n’est pas adapté pour:

- le pompage d’objets

- le pompage de liquides

- les zones à atmosphère explosive

- sous l’eau

- en extérieur

IKA Vacstar digital sert

en combinaison avec d’autres appareils

de liquides!

supplémentaire

de

Fonctionnement individuel

La pompe à vide peut fonctionner sans contrôleur.

La vitesse de rotation réglable permet d’ajuster le débit.

manière générale, plus le volume à évacuer est petit, plus la vitesse

de rotation doit être faible. La pression finale n’est pas régulée.

Fonctionnement avec des accessoires

En combinaison avec les accessoires recommandés par IKA, la

pompe à vide

sur une pression finale définie, p. ex. pour le fonctionnement d’un

évaporateur rotatif IKA.

En outre, elle sert aux opérations

filtration ou de séchage en laboratoire.

Avec un contrôleur de vide adapté

évaporateur rotatif

fonctionner

automatique du point d’ébullition, des courbes pression-temps

ou des programmes provenant de la bibliothèque des solvants

peuvent être exécutés.

Utilisation prévue: Appareil de table

• si des modifications ont été apportées par un tiers à l’appareil

ou à des pièces de l’appareil!

• si l’appareil est utilisé sans respecter les

IKA Vacstar digital

(p. ex. RV 10 auto) la Vacstar digital

de manière automatisée, ainsi une détection

est adaptée à l’évacuation régulée

classiques de séparation, de

(p. ex. VC 10) ou avec un

consignes

de sécurité!

De

peut

DANGER

PRUDENCE

Informations utiles

La sortie de vapeurs de solvants

dans l’atmosphère peut être évitée

avec un condenseur d’évacuation

placé en aval.

Une prudence particulière s’impose lors des travaux avec des mélanges gazeux qui contiennent des

gaz condensables (p. ex. vapeur

d’eau ou solvants). L’utilisation des

pompes à membrane avec de tels

gaz entraîne leur condensation

dans le flux d’air de la pompe. Ceci

génère une pression dans la

chambre de vide qui réduit la performance et la durée de vie des

membranes et soupapes.

Si du liquide ou du condensat pénètre dans les chambres de vide, la

pression de service minimale indiquée n’est plus atteinte.

Pour protéger les soupapes intérieures et les membranes du liquide, utilisez un séparateur de

condensat placé en amont (par

exemple: flacon de Woulfe).

PRUDENCE

REMARQUE

Les pompes à vide à membrane sont des pompes d’évacuation

oscillantes. Les membranes génèrent par expansion du volume

dans la chambre de vide une dépression qui a pour effet l’arrivée

d’air dans la chambre. La compression qui suit chasse l’air de la

chambre de vide. La commutation entre l’entrée et la sortie est

commandée via des soupapes à membrane.

L’unité physique de la pression est 1 Pascal [Pa].

On utilise aussi couramment l’unité millibar [mbar].

1 mbar = 100 Pa

1 bar = 10

1 Pa = 10

1 Pa = 0,01 mbar

5

-5

Pa

bar

De manière générale, il est recommandé de laisser tourner la pompe

à vide à la fin d’un processus

(marche à vide pendant 3 à 5minutes maxi) afin d’évacuer les

éventuels résidus présents dans la

pompe.

Pour ce faire, ventilez le récipient

si besoin.

En mode manuel, retirez la conduite

d’aspiration.

Tenez compte des instructions

d’utilisation des appareils concernés.

22

Page 23

Dans la technique de vide, on distingue différents secteurs.

5

Vide grossier: 10

Vide fin: 10² à 10

Vide poussé: 10

Ultravide < 10

à 10² Pa (1000 à 1 mbar)

-1

Pa ( 1 à 10-3 mbar)

-1

à 10-5 Pa (10-3 à 10

-5

Pa ( < 10

-7

-7

mbar)

mbar)

Les mouvements périodiques de la membrane génèrent un vide à

l’entrée de la pompe. Les pompes à vide à membrane fonctionnent

en vide grossier jusqu’à 10

2

Pa. Ces pompes ne permettent pas

d’obtenir des pressions plus faibles.

Pour générer du vide fin, du vide poussé et de l’ultravide, il faut

utiliser des pompes à vide étanches à l’huile, des pompes à vis, des

pompes à diffusion ou des pompes turbomoléculaires. Les pompes

à vide à membrane servent souvent ici de pompes d’entrée.

La compression et la détente de l’air génèrent un bruit. La pompe

est d’autant plus silencieuse que la quantité d’air transporté est

faible. Ceci a pour conséquence que le bruit de fonctionnement

en mode normal baisse parallèlement à la pression.

Un flexible d’évacuation à silencieux sert également à la réduction

du bruit.

En mode automatique à vitesse de rotation régulée, la pompe réduit sa vitesse de rotation quand elle atteint la valeur théorique.

Si le taux de fuite du système est faible, la vitesse de rotation est

même régulée sur «zéro».

En cas de combinaison avec le contrôleur de vide VC 10 ou l’évaporateur rotatif à contrôleur de vide intégré RV 10 auto, la pompe

peut aussi bien servir à la «régulation à deux points» (commande

par soupape) qu’à la «régulation analogique de la vitesse de rotation» du vide.

Régulation à deux points

Une fois la valeur de consigne atteinte, la conduite d’aspiration est

fermée. En raison du délai minimal entre

pression et la comparaison avec la valeur

la détection de la

valeur de

théorique pour commuter

une vanne de vide ainsi que la puissance d’aspiration du système

générant le vide, la valeur théorique définie n’est pas tout à fait

atteinte.

taux de fuite naturel,

Si la pression augmente encore dans le système

la vanne ouvre

la conduite d’aspiration.

en raison du

Illustration schématique d’une régulation du vide à deux points

mbar

t

Régulation analogique de la vitesse de rotation

Avec cette régulation, la vitesse de rotation de la pompe, et donc

la puissance d’aspiration, est réduite à mesure que la valeur de

pression

mesurée s’approche

de la valeur théorique.

Une fois la valeur

de consigne atteinte, la pompe ne tourne plus qu’en fonction du

taux de fuite du système. Cette régulation se caractérise par un

fonctionnement silencieux, la précision de la régulation du vide

et une grande longévité des pièces mobiles de la pompe. Ce type

de régulation permet la détection automatique précise du point

d’ébullition, ce qui signifie que le système cherche et maintient en

mode automatique le point d’ébullition du solvant.

Illustration schématique d’une régulation du vide asservie au régime

mbar

t

REMARQUE

Installation

Tenez compte de la consigne générale de toujours relier le récipient

(charge/récipient à vide/refroidisseur de verre) à la conduite d’aspiration en son point le plus haut.

Vous réduisez ainsi le risque d’infiltration de liquide dans la pompe à

vide.

La présence de liquide dans les

chambres de la pompe impacte négativement les caractéristiques de

la pompe.

Reliez les raccords de flexibles

(INLET-OUTLET) et les interfaces

conformément aux inscriptions

sur la pompe et aux indications du

mode d’emploi.

Les raccords sont de type olive de flexible. Si besoin, fixez les

flexibles avec des colliers.

Installez les flexibles de manière à empêcher l’infiltration de

condensat dans la pompe.

Veiller à garantir l’entrée libre de l’air dans les fentes d’aération (H).

Installez dans la conduite d’aspiration un dispositif de séparation

du condensat (p. ex. flacon de Woulfe) devant le raccord d’aspiration de la pompe, pour éviter l’infiltration de liquide.

En cas d’aspiration de vapeurs de solvants, un condenseur d’émissions, installé en aval de la pompe (accessoire), contribue à les

condenser et empêche leur relargage dans l’atmosphère.

23

Page 24

Raccordement des interfaces

REMARQUE

O: Raccord de flexible d= 8 mm OUTLET

Utilisez ce raccord pour relier un flexible de vide au condenseur

d’émissions ou installer un silencieux à l’extrémité du flexible.

REMARQUE

K: Prise contrôleur de vide VC 10 (mini DIN)

Vous pouvez relier la pompe à vide et le contrôleur de vide VC 10

ou l’évaporateur rotatif RV 10 auto avec le câble de connexion

analogique MVP 10.100 pour obtenir une régulation précise du

vide asservie au régime.

Le contrôleur de vide détecte la pompe et commute sur le mode

de régulation du vide asservie au régime. La régulation analogique

à deux points est désactivée.

Tenez compte des raccords concernés (voir Fig. 1).

Installez l’extrémité du flexible

dans la hotte de laboratoire!

Veillez à une évacuation libre côté

pression!

Côté pression, n’utilisez pas

d’étrangleur et ne refermez pas l’évacuation ! Reliez la conduite d’évacua

tion de la fumée à ce raccord.

L: Port USB

Reliez la pompe à vide IKA Vacstar digital à un PC avec le câble

USB A - USB B. L’outil logiciel IKA FUT permet de charger d’éventuelles mises à jour du logiciel de l’appareil.

M: Port RS 232

Vous pouvez relier la pompe à vide IKA Vacstar digital à un PC,

via un câble d’interface RS 232. La pompe peut fonctionner avec

le logiciel d’appareils de laboratoire labworldsoft

avec d’autres appareils. Vous trouverez d’autres informations au

chapitre «Interfaces et sorties».

N : Prise vanne d’eau

Reliez la vanne d’étranglement d’eau optionnelle RV 10.5001 à la

pompe à vide à membrane. La vanne d’eau permet de piloter le

débit de l’eau vers le condenseur à émissions. La vanne s’ouvre dès

que la pompe est activée.

I: Raccord de flexible de la conduite d’aspiration d= 8 mm INLET

Reliez la conduite d’aspiration à ce raccord.

Utilisez ce raccord pour relier un flexible de vide au récipient

(refroidisseur d’évaporateur rotatif, raccord de laboratoire, etc.).

P: Prise pour le câble réseau

Comparez l’indication de tension sur la plaque de puissance à la

tension réseau disponible. Raccordez le câble réseau à l’alimentation en tension.

®

en combinaison

Configuration

REMARQUE

Régulation à deux points:

IKA Vacstar digital en mode individuel

Génération de vide sans contrôleur par simple aspiration, aucune

régulation possible de la valeur théorique de vide.

Il est possible de modifier manuellement la vitesse de la pompe

avec le bouton

1 Récipient (charge, p. ex. éva-

porateur rotatif, réacteur)

2 Séparateur de vide (p. ex.

flacon de Woulfe)

5 Vanne de vide/robinet à bois-

seau sphérique

7 Condenseur d’émissions

rotatif/

Respectez les modes d’emploi des

appareils.

poussoir

(C)

de la pompe à vide.

Actionnement

sphérique.

Une régulation grossière du vide est, p. ex., possible avec les

vannes de régulation VCV 1 et VCV 2 en ajoutant de l’air.

manuel de la vanne de vide ou du robinet à boisseau

24

Page 25

IKA Vacstar digital avec contrôleur de vide VC 10

REMARQUE

Une fois la valeur théorique atteinte, la conduite d’aspiration est

fermée via la vanne de vide intégrée dans le VC 10. Il est possible

de modifier manuellement la vitesse de la pompe.

1 Récipient (charge, p. ex. éva-

porateur rotatif, réacteur)

2 Séparateur de vide (p. ex.

flacon de Woulfe)

3 Vanne de ventilation

4 Capteur de pression

5 Vanne de vide/robinet à bois-

seau sphérique

6 Coupure de la pompe VC 2.4

7 Condenseur d’émissions

Fonctionnement impossible avec la

vanne d’eau optionnelle RV 10.5001

en combinaison avec le VC 2.4.

Respectez le mode d’emploi du

contrôleur de vide VC 10!

En cas d’utilisation de la coupure de pompe optionnelle VC 2.4

(rep. 6), la pompe se coupe une fois la valeur théorique atteinte

(mode de fonctionnement B).

Cette configuration de l’appareil est aussi possible sans le dispositif

de coupure de la pompe IKA VC 2.4. La pompe tourne. Pour une

bonne régulation, la pompe doit tourner à une vitesse réduite.

Régulation de régime

IKA Vacstar digital

rotatif TV 10 auto

REMARQUE

Réglage automatique du mode «Régulation du régime», dès lors

que le câble de connexion analogique MVP 10.100 (rep. 8) relie la

pompe au contrôleur de vide ou à l’évaporateur rotatif.

1 Récipient (charge, p. ex. éva-

porateur rotatif, réacteur)

2 Séparateur de vide (p. ex.

flacon de Woulfe)

7 Condenseur d’émissions

8 Câble de connexion analo-

gique MVP 10.100

avec contrôleur de vide VC 10 ou évaporateur

Respectez les modes d’emploi des

appareils.

Une fois la valeur théorique atteinte, le régime de la pompe est

réduit automatiquement à «0tr/min». Si la valeur théorique est

atteinte, la pompe tourne en fonction du taux de fuite du système.

La détection automatique du point d’ébullition est possible.

24 VCC

115/230 V

25

Page 26

Mise en service

REMARQUE

Vérifiez si la tension indiquée sur la plaque

tension du réseau disponible correspondent. Si ces conditions sont

remplies, l’appareil est prêt à fonctionner une fois le bloc secteur

branché.

Mise en marche

1. Allumez l’appareil au moyen de l’interrupteur principal (D).

Tous les segments d’achage apparaissent pour le contrôle

visuel.

2. Achage de la version du logiciel (exemple Vers. 1.00).

3. Achage du mode de fonctionnement défini (A; B).

(Réglage d’usinemode A)

Respectez les modes d’emploi des

appareils.

signalétique et la

La prise utilisée doit être mise à la

terre (contact à conducteur de

protection).

Sinon, le fonctionnement sûr n’est pas garanti ou l’appareil risque

de subir des dommages.

Veuillez tenir compte des conditions ambiantes stipulées dans les

«Caractéristiques techniques».

Mode de fonctionnement B:

Dans ce mode de fonctionnement, la valeur théorique définie

est mémorisée à la fin du processus en cours ou à la coupure

de l’appareil, la valeur peut être modifiée.

Le mode de fonctionnement B est nécessaire en particulier en

combinaison avec la coupure de pompe VC 2.4.

Redémarrage automatique après coupure de courant.

Modification du mode de fonctionnement:

1. En appuyant simultanément sur le bouton

(C) et en allumant l’appareil avec l’interrupteur principal

(D),

vous pouvez choisir l’un des deux modes de

fonctionnement.

rotatif/poussoir

Le mode de fonctionnement peut être modifié à la mise en

marche.

Mode de fonctionnement A:

Dans ce mode de fonctionnement, la valeur théorique définie

n’est pas mémorisée à la fin du processus en cours ou à la

coupure de l’appareil.

Pas de redémarrage automatique après la coupure de courant.

Mise en marche avec plusieurs interfaces

de

Si la pompe est reliée au contrôleur

rotatif RV 10

indique «VC 10»

Arrêt

Éteignez l’appareil au moyen de l’interrupteur principal (D).

avec le câble de connexion MVP 10.100, l’achage (B)

.

vide VC 10 ou à

Tirez

sur la

fiche secteur pour

débrancher l’appareil!

l’évaporateur

En fonctionnement individuel ou à deux points, en combinaison

avec le contrôleur de vide VC 10, il est possible de régler la vitesse

de consigne en tournant le bouton rotatif/poussoir (C). Appuyer

pour démarrer la pompe et appuyer à nouveau pour l’arrêter. Le

mode de régulation (appareil en marche) est indiqué par un point

clignotant à l’achage (B).

Si le contrôleur de vide est relié à un PC, l’écran ache (B) «PC».

26

Page 27

Ports et sorties

REMARQUE

L’appareil peut fonctionner en mode «Remote» par les interfaces

RS 232 ou USB avec le logiciel de laboratoire labworldsoft

port RS 232 (M) au dos de l’appareil, doté d’une prise SUB-D à

9 pôles, peut être relié à un PC. Les broches sont affectées de

signaux en série.

Port USB

L’USB (Universal Serial Bus)

permettant de relier l’appareil au PC. Les appareils dotés d’un port

USB peuvent être reliés entre eux au cours du fonctionnement

(hot-plugging)

être détectés automatiquement.

Le port USB sert en combinaison avec

fonctionnement en mode «Remote»

à l’aide de «l’outil de mise à jour de micrologiel».

Installation

Avant de relier l’appareil au PC avec un câble de données USB,

installer le pilote USB.

Le pilote USB peut être téléchargé à la page web suivante:

Port série RS232 (V 24)

Configuration :

• La fonction

système d’automatisation est une

spécifiés dans la norme EIA RS 232, conformément à la partie

1 de la norme DIN 66020.

• Les caractéristiques électriques des circuits

l’affectation des états des signaux sont régies par la norme

RS 232, conformément à la partie 1 de la norme DIN 66259.

• Procédure de transmission

caractères en mode start/stop.

• Type de transmission: Duplex intégral.

• Formats de caractères: Caractères conformes au format de

données stipulé dans la norme DIN 66022 pour le mode

Start-Stop. 1 bit de démarrage ; bits 7 caractères ; 1 bit de

parité (pair = Even); 1 bit d’arrêt.

• Vitesse de transmission: 9600 bits/s.

• Commande du flux de données: aucune

• Procédure d’accès: Un transfert de données de l’appareil vers

l’ordinateur n’est exécuté que sur requête de l’ordinateur.

Syntaxe de commande et format

Tenir compte des points suivants concernant le jeu d’instructions:

• Les commandes sont en général envoyées de l’ordinateur

(maître) à l’appareil (esclave).

• L’appareil n’émet que sur demande de l’ordinateur.

les messages d’erreur ne sont pas spontanément transmis par

l’appareil à l’ordinateur (système d’automatisation).

• Les commandes sont transmises en majuscules.

• Les commandes, paramètres et les suites de paramètres sont

séparés par au moins un espace (code hex 0x20).

• Chaque commande (y compris les paramètres et les données)

et chaque réponse se termine par CRLF (code: hex 0x20 hex

0x0d hex 0x0A) et a une longueur maximale de 50 caractères.

• Le séparateur décimal d’un nombre en virgule flottante est le

point (code : hex 0x2E).

et les

des câbles d’interface entre l’appareil et le

Respectez

requise, le mode d’emploi et les

aides du logiciel.

appareils

la configuration

est un

reliés, ainsi que

système de bus en série

leurs

labworldsoft® pour le

et la mise à jour du micrologiciel

sélection des signaux

: Transmission asynchrone de

minimale

caractéristiques,

d’interface et

Également,

®

. Le

Les explications précédentes sont globalement

recommandations du cercle de travail NAMUR (recommandations

NAMUR relatives à l’exécution de connexions électriques pour le

transfert de signaux analogiques et numériques à des appareils de

laboratoire individuels MSR. Rév. 1.1).

Les commandes NAMUR et les commandes

spécifiques à IKA servent uniquement de commandes de bas

niveau pour la communication entre l’appareil et le PC. Avec un

terminal ou un programme de communication

i

nstructions peuvent directement être transmises à l’appareil.

Commandes NAMUR

IN_NAME Lire le nom de l’appareil

IN_PV_4 Lire la vitesse actuelle

IN_SP_4 Lire la vitesse nominale

OUT_SP_4 Régler la vitesse nominale

START_4 Démarrer l’évacuation

STOP_4 Arrêter l’évacuation

RESET Commuter sur le mode normal

OUT_NAME Définir le nom de l’appareil

OUT_SP_42@n Réglage de la vitesse de sécurité du WD

OUT_WD1@m Mode Watchdog 1

OUT_WD2@m Mode Watchdog 2

Fonction «Watchdog», surveillance du flux de données

sériel

Si, après activation de cette fonction (voir les commandes Namur),

dans la période de surveillance définie («délai du watchdog»), la