Page 1

20000023248

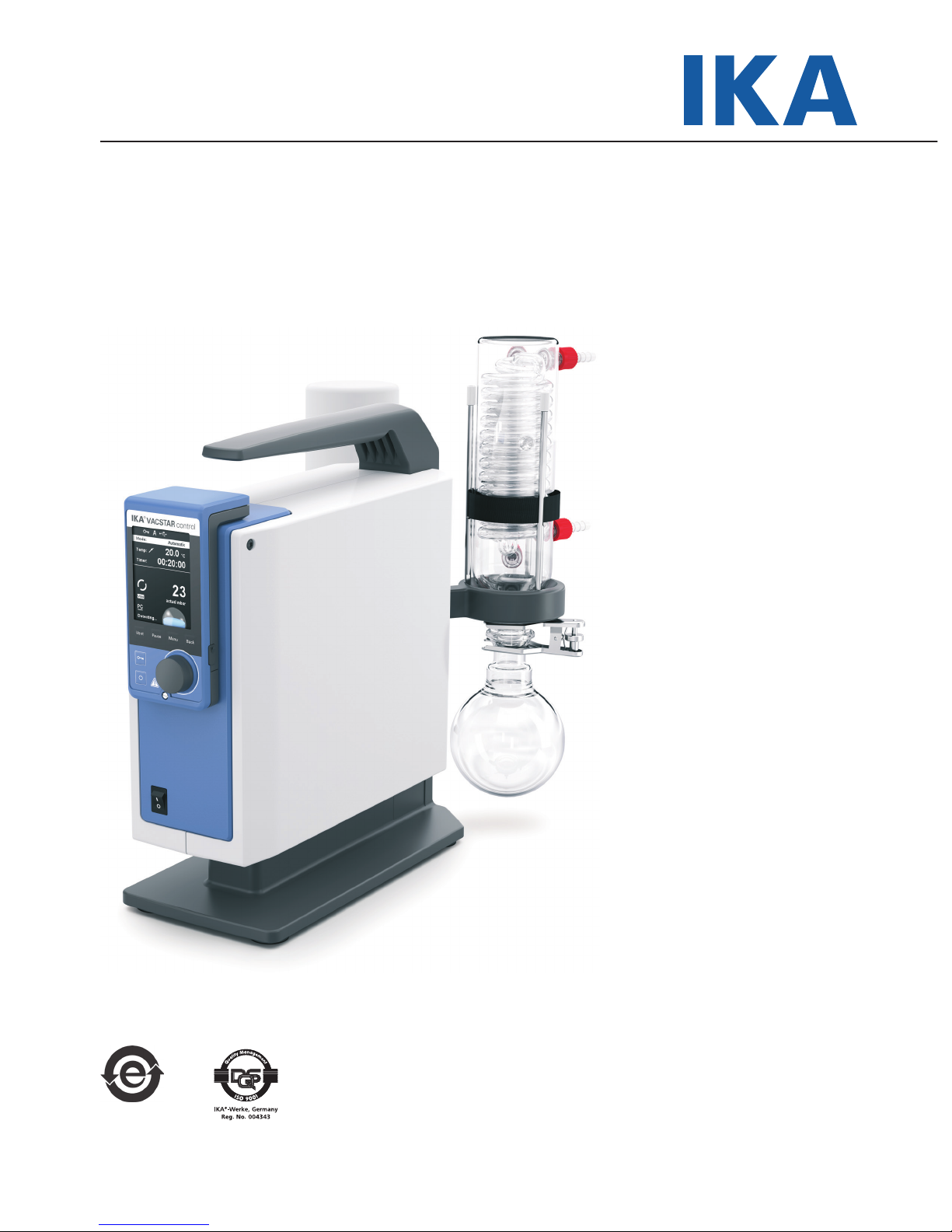

IKA Vacstar control

IKA Vacstar control_102018

Operating instructions EN

Page 2

2

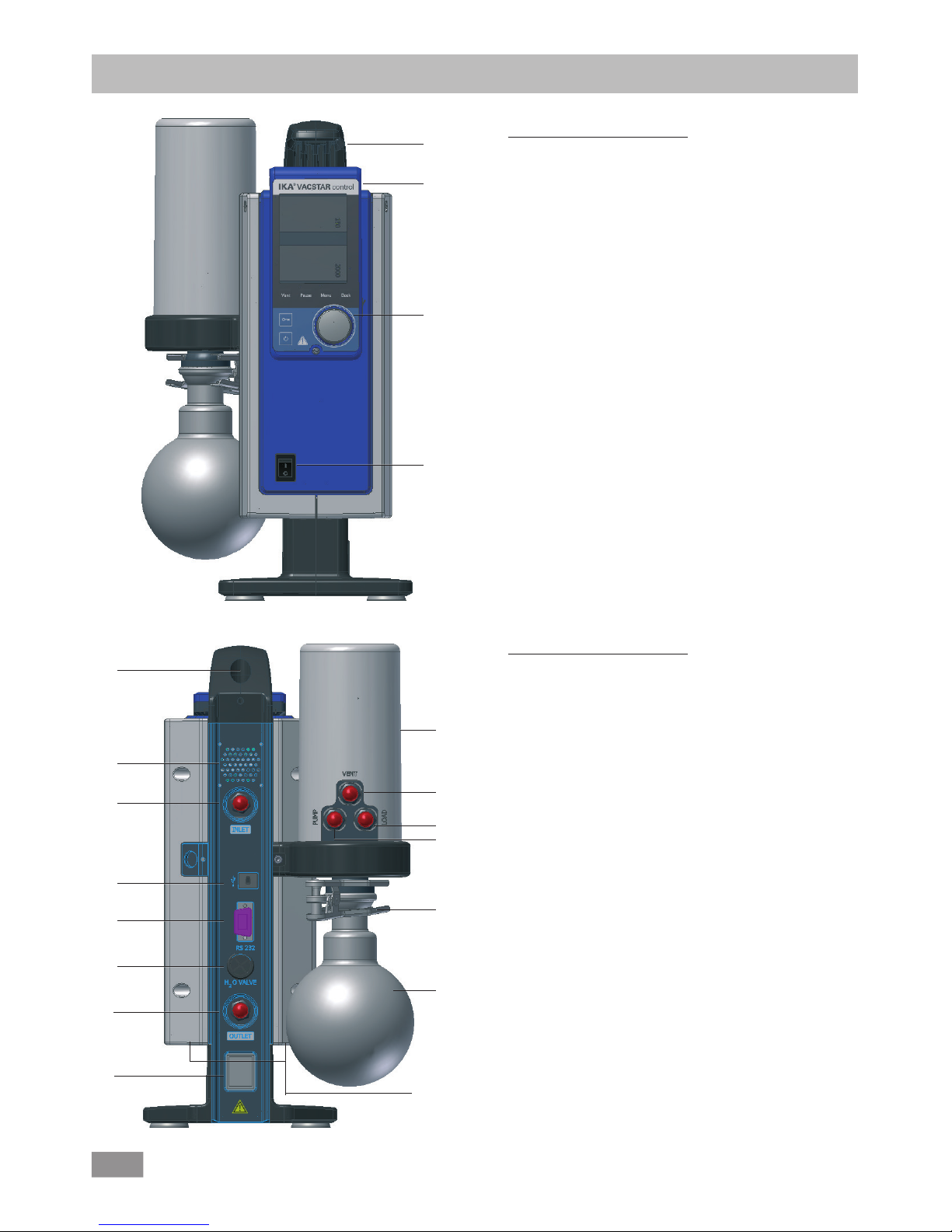

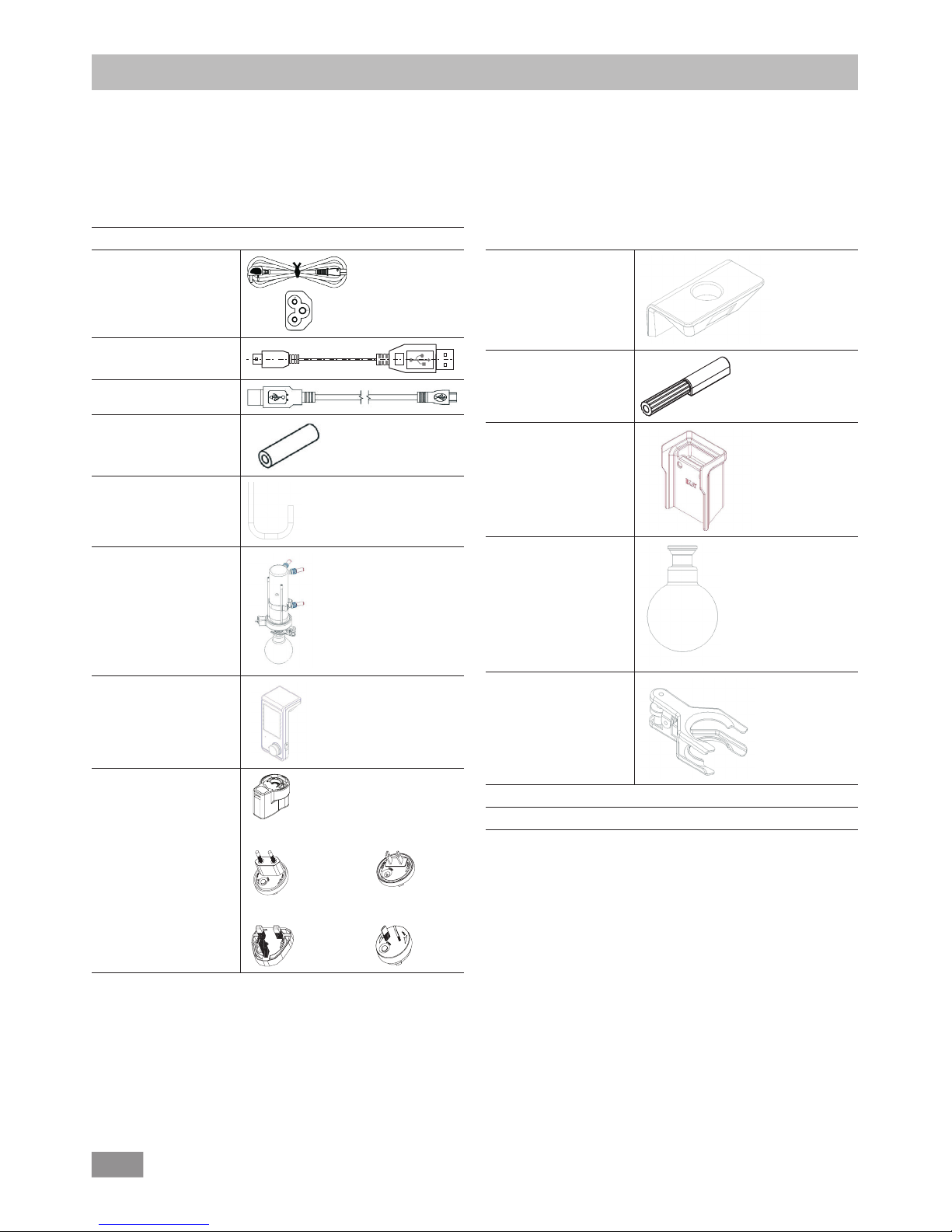

Device setup

Fig. 2

5

6

7

8

9

10

11

16

13

Pos. Description

1 Handle

2 WiCo (see chapter "Operator panel and display")

3 Rotating/pressing knob

4 Main switch (on/off)

Fig. 1

Pos. Description

5 Handle securing screw

6 Fan/Ventilation slit

7 Hose connection for suction line d= 8 mm (INLET)

8 USB interface

9 RS 232 interface

10 Water Valve Connection

11 Hose connection for pressure line d= 8 mm (OUTLET)

12 Mains cable connection

13 Pressure Device

14 Hose connection for ventilation line d= 8mm

15 Hose connection for load line d= 8mm

16 Hose connection for suction line d= 8 mm (INLET)

17 Clamp

18 Receiving flask

1

2

3

4

14

12

15

17

18

6

Page 3

3

Source language: German

Page

Device setup................................................................................................................................................................................ 2

EU Declaration of conformity ..................................................................................................................................................... 3

Explanation of warning symbols ................................................................................................................................................. 3

Warranty ................................................................................................................................................................................... 3

Safety instructions ...................................................................................................................................................................... 4

Unpacking ................................................................................................................................................................................. 6

Intended use ................................................................................................................................................................................ 7

Useful information ..................................................................................................................................................................... 7

Assembly and setting up............................................................................................................................................................... 9

Wireless controller (WiCo) .......................................................................................................................................................... 11

Operator panel and display ....................................................................................................................................................... 11

Commissioning .......................................................................................................................................................................... 12

Interfaces and outputs ............................................................................................................................................................... 20

Maintenance and cleaning ......................................................................................................................................................... 21

Error codes ................................................................................................................................................................................ 22

Accessories ................................................................................................................................................................................ 22

Product contact parts ................................................................................................................................................................. 22

Technical data ............................................................................................................................................................................ 23

Contents

We declare under our sole responsibility that this product corresponds to the directives 2006/42/EC, 2014/35/EU, 2014/30/EU and

2011/65/EU and conforms with the following standards or normative documents: EN 61010-1, EN 61326-1, EN 60529 and EN ISO 12100.

A copy of the complete EU Declaration of Conformity can be requested at sales@ika.com.

Bluetooth

®

module:

Directive: 2014/53/EU Standards: EN 60950-1, EN 300328, EN 301489-1, EN 301489-17

EU Declaration of conformity

Explanation of warning symbols

According to IKA‘s Terms and Conditions of sale and delivery, this

product is covered by a warranty for a period of 24 months. Please

contact your dealer for any warranty claims. If you wish, you can

send the device

directly to

our factory. Please provide

the sales

invoice and state the reasons for your guarantee claim. In this

case, you are responsible for shipping and handling costs.

Warranty

The warranty does not cover wearing parts, or defects that are the

result of improper use, insucient care and maintenance or failure

to follow the instructions in this operating manual.

EN

DANGER

WARNING

NOTE

CAUTION

Indicates an (extremely) hazardous situation, which, if not avoided, will result in death, serious injury.

Indicates a potentially hazardous situation, which, if not avoided, can result in death, serious injury.

Indicates a potentially hazardous situation, which, if not avoided, can result in injury.

Indicates practices which, if not avoided, can result in equipment damage.

Page 4

4

Safety instructions

General information

DANGER

Always wear personal protective

equipment in accordance with the

hazard class of the media being

worked with - otherwise there are

dangers due to spraying liquids, and

release of toxic or flammable gases.

NOTE

Please read the instruction manual

in full before use and follow the

safety instructions.

• Keep the

instruction

manual in a

place where

it can be

accessed easily.

• Ensure that only trained staff use the device.

• Follow the safety instructions, guidelines, occupational health

and safety and accident prevention regulations.

• The device and all parts of the device must not be used on

people or animals.

• Do not expose human or human body parts to vacuum.

For protection of the equipment

WARNING

Ensure that the substances used

with the device are compatible

with the materials of the device

parts that come into contact with

the product; see the chapter “Product contact parts”.

Work with the device

DANGER

You can

prevent

the

release

of

solvent vapours

into the atmosphere

using a

the downstream emis-

sion condenser VSE1.

WARNING

Inhaling or coming into contact

with media

such as poisonous

liquids, gases, spray mists,

vapours,

dusts or biological materials can

endanger the health of the user.

Ensure that all connections are

well sealed and free of leaks if you

are working with such media.

• The vacuum pump IKA Vacstar control must only be operated

under the conditions described in the chapter “Technical data”.

• Prevent release of the materials. Take measures to protect

staff and the environment.

• Pay attention to possible interactions or chemical or physical

reactions when working with media at reduced pressure and

increased temperature.

• There can be electrostatic processes between the medium

and the device which can lead to direct danger.

• Some medium may be released due to the residual leakage

rate of the device.

• Before commissioning check that all the housing parts are

present and fastened to the device.

• Do not lift the pump if the handle is loose and the handle

securing screw (Fig. 2, 5) is loose or missing!

• Only switch ON the pump if the pump is standing vertically.

• Connect the hose connections (INLET-OUTLET) and interfaces

in

accordance

with the

labelling

on the

device

and the

operating instructions.

• Ensure that the temperature of the evacuated medium is below its ignition temperature. The pumping process (compression) increases the temperature of the medium additionally.

• Ensure that vapours containing solvent cannot be sucked into

the pump.

• Prevent occurence of explosive mixtures; if appropriate connect inert gas for ventilation and/or thinning.

• Do not use the pump to create pressure.

• Observe the permitted pressure at the inlet and outlet side;

see the chapter “Technical data”.

• The gas flow must only be regulated/throttled in the suction-side line.

• When using the emission condenser VSE1 ensure that the

coolant is flowing freely.

CAUTION

The specified settings

on the

rating

plate must coincide with the actual

mains supply.

• The device is only disconnected from the mains supply when

the power or device plug is removed.

• The socket for the power cord set must be easy to access.

Device setup

DANGER

Do not use the device in explosive

atmospheres, it is not EX-protected.

In order to avoid injury to persons

and damage to property, observe

the relevant protective and accident prevention measures when

processing hazardous substances.

• Set up the device in accordance with the chapter “Setting up”

and connect the connection lines and interfaces as described.

• Set up the device control in a spacious area on an even, stable, clean, non-slip, dry and fireproof surface.

• Never work with a faulty or incorrectly connected device.

• Connect the vacuum pump to an exhaust line. Ensure that

the exhaust line cannot be kinked! The maximum permitted

length for the exhaust line is 2 metres.

• Prevent occurence of explosive mixtures; if appropriate connect inert gas for ventilation and/or thinning.

Page 5

5

Accessories

• Safe

operation

can only be

ensured

when working with

accessories as described in the “Accessories” section.

• Carefully observe the operating instructions for additional devices (e.g. rotary evaporators), with which the vacuum pump

IKA Vacstar control is operated.

• The pressure at the gas inlet and outlet must not exceed

1100 mbar.

WiCo

DANGER

Please note the following safety instructions for the battery pack RB 1

(rechargeable battery).

CAUTION

If during operation the battery pack

RB 1 (rechargeable battery) becomes

fully discharged, the device will contin

ue to run or is shut down depending

on the value settings for exceeding the

time. If the device is set so that it con

tinues to run when the battery of the

Wireless Controller (WiCo) is fully dis

charged, the only means of switching

the station off are the "safe STOP" and

the off switch!

• Keep the battery pack out of reach of children at all times.

• Store the battery pack in a cool, dry place.

• Never throw the battery pack into a fire. Keep it away from di

-

rect sunlight and temperatures above 60 °C. High temperatures

will damage the battery pack and render it unusable. Tempera

-

tures above 100 °C may cause it to explode.

• Never throw the battery pack into water or expose it to moisture. Water may lead to a short-circuit, causing the battery

pack to explode.

Disposal instructions

• When disposing of the IKA battery pack, please tape over the

contacts with adhesive tape to prevent short-circuiting due to

moisture or contact with metal components. Short-circuiting

may result in an explosion.

• Elastic hoes may be deformed under vacuum.

• Only use flexible hose lines.

• Observe your

emergency

measures for power failure and

ensure that the device is put in a safe mode (see the chapter:

Commissioning, Operating mode).

• Only use IKA approved accessories!

• Use only original IKA spare parts!

• Do not deform or crush the battery pack or damage it in any

other way. This can cause battery fluid to leak and/or the battery pack to explode.

• When not in use, keep battery packs away from paperclips,

coins, keys, nails, screws or other small metal objects which

could cause the contacts to be bridged. Short-circuiting may

result in an explosion.

• Explosion of a battery pack may release battery fluid and cause

a fire.

• The lithium polymer battery pack must only be used and charged

in IKA products designed for use with this battery pack.

• When the battery pack is inserted it should slide in easily and

without resistance. Do not force it.

• If the battery pack is removed for an extended period of time,

store it in a sealed plastic bag to prevent short-circuiting due to

moisture or contact with metal components.

• The operating temperature range of the battery pack is from

0 °C to +45 °C. Note that the battery pack capacity will be

reduced at temperatures below 20 °C.

• Only the rechargeable battery types recommended in the tech

nical data may be used in the device!Do not charge batteries

that have leaked or that are discolored, deformed or damaged

in any other way.

End users are obliged by law to return all used disposable and

rechargeable batteries. Throwing them into the house-hold

waste is prohibited! Disposable/rechargeable batteries contaiing harmful substances are marked with this symbol to indicate

that they may not be disposed of as household waste.

• The device, accessories, packaging and batteries must be di

posed of in accordance with local and national regulations.

• Covers or parts that can be removed from the device without

tools must later be refitted to ensure safe operation, unless

anything else is connected at this point. This will prevent the

infiltration of foreign objects, liquids and other contaminants.

• Unwanted

liquids that have

entered

can be

removed

by

extracting air during no-load operation.

• Avoid knocks or impact to the device.

• The device must only be opened by trained, skilled personnel

(who have been authorised to do so).

• The device must not be modified without authorisation from IKA.

• To ensure sufficient cooling for the vacuum pump IKA

Vacstar

control, the ventilation slits on the housing must not be covered.

• Only use original

replacement

parts for

maintenance

to

ensure that the device works reliably.

• Watch out for water

condensation

inside and outside the

device. Warm up the device first, if it has been brought in

from a cold environment.

• Never fasten the vaccum pump over a heating bath.

• Ensure that no solids and/or liquids can enter the diaphragm

of the vacuum pump IKA Vacstar control through the suction

line of the pump. This damages the diaphragm and other internal parts of the pump. This reduces flowrate and the final

pressure can no longer be achieved. Deposits may be produced in the interior, reducing service life and causing leaks.

Page 6

6

Unpacking

Unpacking

• Unpack the device carefully.

• Any damage should be notified immediately to the shipping

agent (post oce, railway network or transport company).

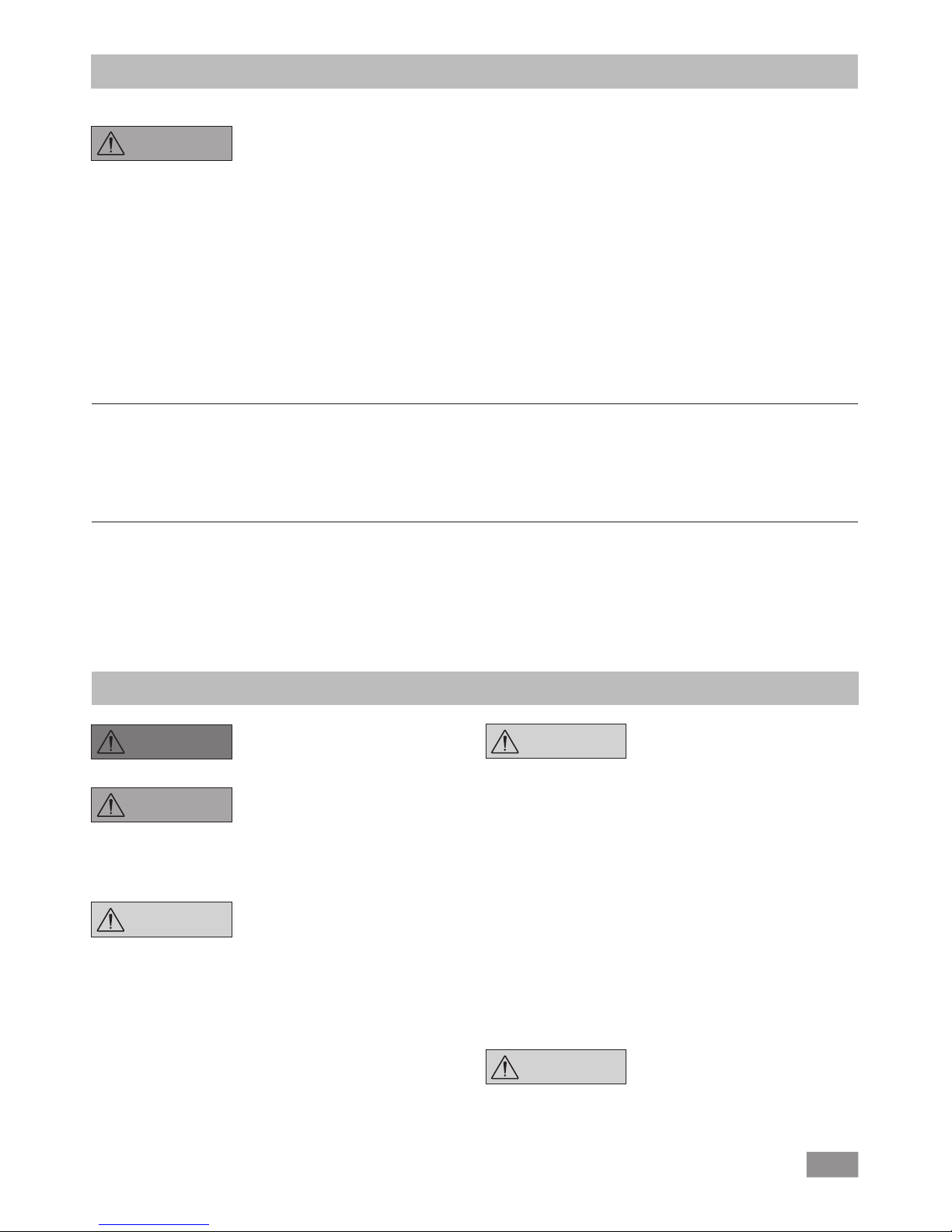

Scope of delivery

Diaphragm vacuum pump

IKA Vacstar

control

Power cord set

USB A - USB B cable

A

USB A - USB micro B

Vacuum hose 1 m

Vacuum Hose 0.3 m

(connection Vacstar to

Vacuum Safety VSE 1)

Vacuum Safety VSE 1

Wireless Controller

(WiCo)

OS 1.0 power supply unit

(for WiCo):

Adapter

UK

Adapter

USA, China

Adapter

Australia

Adapter

Europe, Switzerland

Cover

Screw driver

(screw driver to screw

WiCo on station)

Bracket

Flask

Spherical clamp

User guide

Warranty card

Page 7

7

Use

WARNING

The device must not be used for:

- evacuating biological habitats,

-

evacuating explosive, corrosive

or similar gases,

- throughput/use of liquids

The device is not suitable for:

- pumping up objects

- pumping liquids

- use in potentially explosive

atmospheres

- underwater

- underground

Set up

the IKA Vacstar control in a spacious area on an even, stable, clean,

non-slip, dry and fireproof surface.

Intended use

Useful information

DANGER

You can

prevent

the

release of

solvent vapours

into

the

atmosphere

using

a VSE 1.

WARNING

If the pump (station) generates vibration, the Wireless Controller

must be bolted to the pump using

the screw (p. 11), or positioned remotely from the stirrer (station)

whilst it is running.

CAUTION

Special care must be taken when

working with gas mixtures that include condensable gases (e.g. solvents). If diaphragm pumps are

used with such gases they condense

in the pump’s air flow. This leads to

a build-up of pressure in the vacuum chamber, which in turn influences the effectiveness and service life

of the diaphragms and valves.

CAUTION

If liquid or condensate enters the

vacuum chambers, the specified

minimum working pressure is no

longer achieved.

To

protect

the inner valves and

diaphragms against liquid, use an

upstream condensate separator,

such as a Woulff bottle.

It is generally recommended that

you run the pump with no load at

the end of the

process

(no-load

operation, approx. 3 up to max. 5

minutes) to dispel any residues in

the pump.

If applicable, vent the recipient.

To do this, remove the suction line

during manual operation.

NOTE

Observe the operating instructions

of the relevant devices.

Area of use (indoor use only)

- Laboratories - Schools

- Pharmacies - Universities

The device is suitable for use in all areas (EMC class A and B).

The laboratory diaphragm vacuum pump IKA

Vacstar

Control used

together with other laboratory devices to create and maintain vacuum. Vacuum controller and vacuum sensor is part of the device.

Along with the accessories recommended by IKA, the vacuum

pump IKA Vacstar control is suitable for controlled evacuation to a

specified final pressure e.g. for operating an IKA rotary evaporator.

It can also be used for classical separation, filtration or drying in

the laboratory.

With the integrated vacuum controller, the IKA Vacstar control can

operate automatically, for boiling point detection, scheduled pressure-time curves or programs from the solvent library.

Intended use: Tabletop device

Wireless remote control

Before using the wireless link between the Wireless Controller

(WiCo) and the laboratory device, first check whether your region

is included in the radio communications approval for the device.

If it is not, WiCo must remain on the station.

The safety of the user cannot be ensured:

• if modifications are made to the device or parts of the device

by third parties!

• if the device is operated in contravention of the safety instructions!

Page 8

8

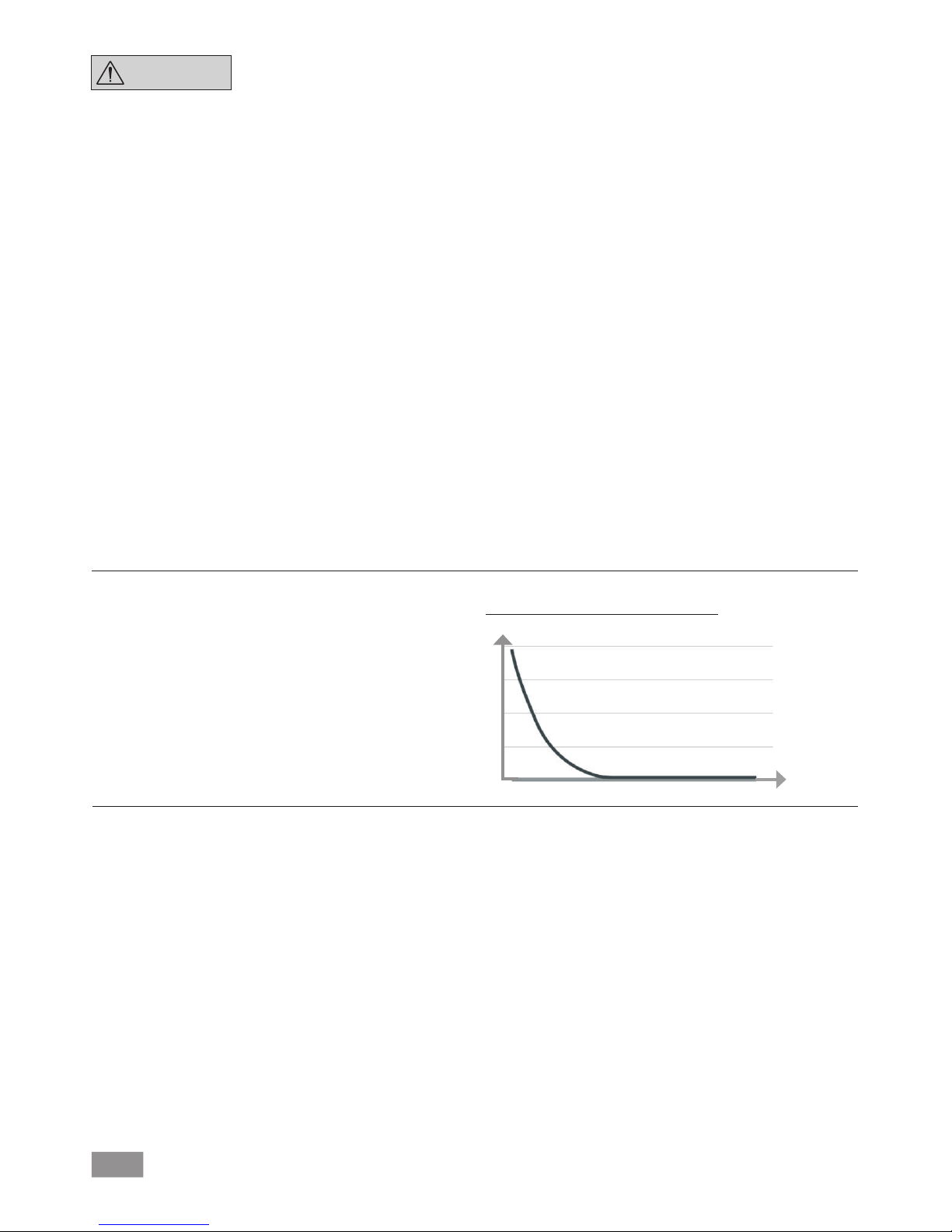

Analogue speed control

With this control, the speed of the pump, and therefore its suction power, is reduced the closer the measured pressure reaches

the target value. Once the target value is reached, the pump only

operates according to the leakage rate of the system. This enables

quiet functioning, precise vacuum control and a long service life

for the moving pump parts. Exact automatic boiling point recognition is possible with this type of control, meaning that the system

reaches and keeps the solvent at its boiling point in automatic

mode.

t

mbar

must be used, for example. Diaphragm vacuum pumps are often

used as pumps for the preliminary stage in these contexts.

Compressing and releasing the pressure on air creates a noise. The

pump is quieter the less air is transported. This means that there is less

operating noise during normal operation if the pressure is reduced.

The IKA

Vacstar

control is controlled via a Wireless Controller

(WiCo). If the WiCo is attached to the station, data exchange between the pump (station) and WiCo is performed via the contacts

(page 11, (A/Q)) "Home" symbol appears on the display of the

WiCo. If the WiCo is neither bolted to the station the data exchange between the pump and WiCo is performed via Bluetooth®.

In this case the Bluetooth® symbol is displayed. Depending on the

structure of the building, the WiCo can be operated at a distance

of up to 150 m from the station, using the Bluetooth® connection.

The WiCo can be attached to the pump (station), or can be installed in a safe place easily accessible by the user while the pump

is running. If the WiCo is attached to the station, the rechargeable

battery is automatically recharged via the contacts (page 11, (A/Q))

The rechargeable battery can also be charged via the USB port of

the WiCo.

In automatic operation with controlled speed the pump reduces its

speed when it reaches the target value. If the leakage rate in the

entire system is low enough, the speed may even be set to “zero”.

Schematic view of speed vacuum control

NOTE

Generally speaking, the smaller the

volume to be evacuated, the lower

the speed should be. The final pressure is not controlled.

Diaphragm vacuum pumps are oscillating displacement pumps.

The diaphragms expand the volume of the vacuum chamber to

produce an underpressure, which sucks air into the chamber. The

air is then pressed out of the vacuum chamber by subsequent

compression. Changes between the inlet and outlet are controlled

by diaphragm valves.

The physical unit for pressure is 1 Pascal [Pa].

However people often still use the unit millibar [mbar] colloquially.

1 mbar = 100 Pa

1 bar = 10

5

Pa

1 Pa = 10

-5

bar

1 Pa = 0.01 mbar

A distinction is made between different ranges in vacuum tech-

nology.

Rough vacuum: 10

5

to 10² Pa (1000 to 1 mbar)

Fine vacuum: 10² to 10

-1

Pa (1 to 10-3 mbar)

High vacuum: 10-1 to 10-5 Pa (10-3 to 10

-7

mbar)

Ultra high vacuum < 10-5 Pa (< 10

-7

mbar)

The periodic movements of the diaphragms create a vacuum at

the pump inlet. Diaphragm vacuum pumps work with a rough

vacuum of up to 10

2

Pa. Lower pressures cannot be achieved with

these pumps.

To create fine, high and ultra high vacuums, oil-sealed vacuum

pumps, screw pumps, diffusion pumps or turbomolecular pumps

Charging the RB 1 battery pack (rechargeable battery)

The battery pack of the Wireless Controller can be charged by any

of the following means:

• on the Vacstar station

• via a USB cable at the PC or station

• via an OS 1.0 power supply unit.

Page 9

9

Assembly and setting up

NOTE

Ensure that you follow the general

rule, that the recipient (load/vacuum container/glass condenser)

should always be connected to the

suction line at its highest point.

This reduces the risk of liquids entering the vacuum pump.

Liquid in the pump chambers makes

the pump properties worse.

Connect the hose connections (INLET/OUTLET) and interfaces in accordance with the labelling on the

pump and the operating instructions.

The connections are barbed hose connectors. Ensure that the hoses have hose clips if applicable.

Lay the hoses in such a way that no condensate can flow into the

pump.

Ensure that the air can enter the ventilation slit (Fig. 2, 6) unhindered.

Install a condensate separator (e.g. a VSW 1 in the suction line

before the intake spigot of the pump to protect against water

coming in.

If solvent vapours are sucked in, the emission condenser after the

pump helps to condense it, and prevents it being released into the

atmosphere.

Fig. 4

Fig. 5

Fig. 3

Water in

Water out

Page 10

10

conjunction with other devices with

labworldsoft® laboratory

device software. For further information see the chapter “

Interfaces

and outputs”.

Fig. 2, 10: Water valve connection

Connect the

optional

water

throttle

valve

(VSW1)

to the

dia-

phragm vacuum pump.

The water

flow

to the

emission

condensor is controlled using the water valve. The valve is opened as

soon as the pump is switched on.

Fig. 2, 11: Hose connection for suction line d= 8 mm OUTLET

Connect the suction line to this connection.

Link this connection to the recipient (rotary evaporator condenser,

laboratory reacor etc.) with a vacuum hose.

Fig. 2, 12: Power cord set connection

Check that the voltage information on the rating plate matches

your mains supply. Connect the power cord set to supply electricity.

Connection of interfaces

Fig. 2, 11: Hose connection d= 8 mm OUTLET

Link this connection to the emission condenser with a vacuum

hose, or fit a sound absorber to the end.

NOTE

Put the end of the hose in the fume

hood!

Check there is a free outlet on the

pressurised side!

Do not use a throttle on the pressurised side and do not close the

outlet! Connect the exhaust line to

this connection.

Fig. 2, 8: USB interface

Connect the vacuum pump IKA

Vacstar

control to a PC with a USB

A - USB B cable. Any device software updates can be loaded using

the IKA FUT software tool.

Fig. 2, 9: RS 232 interface

You can connect the IKA

Vacstar

control vacuum pump to a PC

using an RS 232 interface cable. The pump can be operated in

OUT

IN

cooling IN

cooling OUT

2

115/230 VAC

115/230 VAC

vacuum:

signal / power:

1

cooling

1 Recipient (load, e.g. rotary evaporator, reactor)

2 Vacuum separator (e.g. Woulff bottle)

Configuration

NOTE

Observe the operating instructions

for the devices.

When the target value is reached, the speed of the pump is

automatically reduced to a minimum of “0 rpm”. If the target

value has been reached, the pump sucks according to the leakage

rate of the vacuum system. Automatic boiling point detection is

possible.

Page 11

11

Wireless controller (WiCo)

Operator panel and display

Pos. Name

A PCB Contact Station PCB contact for WiCo

B Bluetooth

®

LED

Communication light

C PCB light Communication light

D Bluetooth

®

Recall key

WiCo connection

E Safe Stop Stop any function when WiCo is

unavailable

F Screw point WiCo to station securing position

G Displays Display the values and settings

H "Menu" key Press it once: main menu is displayed

Press it a second time: back to the

working screen

I "Back" key Return to the previous menu level

J USB interface Charging WiCo and connection to

computer

K Rotating/

pressing knob

Navigation, selecting and changing the

settings in the menu

L

Securing

screw

Secure the Wico to the station

M On/Off key Switching the Wireless Controller on and

off

N Lock key Key disable and rotary/push knob disable

O "Vent" key To vent the load if necessary during the

vacuum process

P "Pause" key Temporarily stop the function of the

device for required period.

Note: can resume the function by

pressing the button again

Q PCB Contact WiCo contact PCB to station

Changing the RB 1 battery pack in the WiCo

DANGER

Please comply with the relevant

safety instructions in the "Safety

instructions" section for the RB 1

battery pack!

Securing the WiCo to the stirrer

Attach the Wireless Controller (WiCo) to the charging contact provided on the station, and bolt it to the Vacstar station with the

screw.

Vacstar control Station

B

A

F

E

D

C

WiCo

N

M

L

K

J

I

H

G

O

Q

P

Page 12

12

NOTE

Observe the operating instructions

for the devices.

Check if the voltage specified on the type plate matches the available mains voltage. If these conditions are met, the device is ready

for operation when it is plugged in to the mains.

The socket used must be earthed

(grounded contact).

Otherwise safe operation is not guaranteed or the device may be

damaged.

Observe the ambient conditions indicated under “Technical data”.

Commissioning

Switching on

After switching off via the main switch (Fig. 1, (4)), the device type,

device designation, user-defined device name and the firmware

version are shown in the display.

Firmware Update Tool

After the start screen, the information start screen for the Firmware Update Tool appears. You can use the tool to update the software of your IKA device to the latest version. Firmware updates

contain new functions or optimisations of previous functions. You

can download the Firmware Update Tool at www.ika.de/fut.

Working screen (factory settings)

The following working screen appears automatically in the display.

Explanation of symbols on the working screen

Lock key:

This symbol means that the function of the key and of the rotary

knob for controlling the vacuum controller are disabled. The symbol no longer appears if the functions are enabled once again by

pressing the lock key a second time (min. 1 sec.).

Bluetooth®:

This symbol means the station and the WiCo are communicating

via Bluetooth

®

. The symbol no longer appears if no Bluetooth

®

communication is being performed.

B Operating mode:

The operating mode currently selected (A, B, C, D).

USB:

The vacuum controller is communicating via a USB cable. The symbol no longer appears if no USB cable is being used for communicating with the station.

Timer:

Appears when the timer display is active in the display.

PC:

The vacuum controller is connected to a computer and the device

is being controlled from the computer.

Page 13

13

PR:

The device is being controlled from the selected program.

Running mode:

The vacuum pump is running in a measurement

Vent:

The venting is enabled.

Vacuum:

The current pressure is less than the existing atmospheric pressure.

Detection:

This symbol is displayed during the automatic boiling point search,

the system pressure is reduced further.

Navigation menu and menu structure:

Navigation menu:

Press "Menu" key (H).

Select the menu by turning the rotating/pressing knob (K) to the right or left to select the desired menu

or sub-menu, which can then be selected by pressing the rotating/pressing knob (K).

Press or turn the rotating/pressing knob (K) again to select the desired menu option and edit the values

or settings, or activate/deactivate a function.

Turn the rotating/pressing knob to "OK" and press the "Back" (I) or "Menu" key (H) to end the procedure

and return to the previous menu or working screen.

Note: The menu option activated is highlighted blue in the display. Menus which are grayed out are inactive.

Navigation menu: Press the “Menu“ key (H) and turn the rotary/push knob (K)

Press the "Back" key (I) or the "Menu" key (H)

Note: If you press the “Menu“ key (H), the system skips directly back to the working screen.

If you press the “Back“ key (I), the system skips back to the previous display.

Back Back Back

Menu

Menu

Boiling:

This symbol indicates that a boiling point has been found automatically, the system pressure is kept constant.

Home:

The Wireless Controller is connected to the station and is communicating with the station via the charging contacts. The symbol no

longer appears if the WiCo is removed from the station.

Battery pack (rechargeable battery):

The charging status of the RB 1 battery pack within the WiCo. The

charging symbol appears if the WiCo

• is connected to a PC via a USB cable

• is connected to the power supply unit OS 1.0 via a USB cable

• is connected to the station via the charger contacts.

K

I

H

Page 14

14

Menu structure:

Factory settings

Menu

Pump

Limits

Cleaning

Deutsch

...

Display Timer

B

C

Operating Mode A

Display

Timer

Timer functions

Programs Program 01

....

Settings Languages English

Units

Temperature ºC

ºF

Safety

Modes

Automatic

Manual

Pump %

Program

Start after

Duration

Pump speed

Clean now

Actions after stop

Open water valve

Open vacuum valve

Cleaning

Maximum

Minimum

Manual

Maximum

Minimum

Pump %

Solvent library

Acetonitril

N-Amylalkohol

....

Time

Beep after stop

Activate

D

Program 10

Select

Edit

Delete

Edit/Insert/Delete

Last measurement

Select

Edit

Delete

Edit/Insert/Delete

Service Valves

Venting valve

Close/Open

Water valve

Close/Open

mbarPressure

torr

mmHg

hPa

Factory update info

Communication

Brightness

Pressure max.

Operating mode

Logic version

Volume

Pressure min.

Pump % max.

Pump % min.

Key tone

Device name

Firmware Update Info

Display version

Activated

Deactivated

20 %

05:00 [mm:ss]

Add solvente (No.1 ~ 5)

Pump

Display

Black/White

Background

Standard Mode

Battery Mode

Sound

Factory setting

Menu values

Programs

All

Bluetooth

®

Remote control

Paring

Information

Deactivated

Deactivated

-

06:00 [mm:ss]

00:00:01 [hh:mm:ss]

2 mbar

1100 mbar

100 %

0 %

-

-

-

-

Activated

Activated

Deactivated

Deactivated

Deactivated

Deactivated

Deactivated

Deactivated

Deactivated

Activated

Deactivated

Open

00:30

-

-

-

-

-

-

-

-

Deactivated

Open

Activated

Deactivated

Deactivated

Activated

Deactivated

Deactivated

Deactivated

-

Activated

B

Vacstar control

100 %

Black

80 %

Activated

10 %

Activated

-

-

-

Activated

Activated

Activated

-

-

-

1100 mbar

2 mbar

100 %

0 %

Safe pressure

Safe pump rate

Time

Password

1100 mbar

000

20 %

Page 15

15

Menu details

Pump

1. Press the "Menu" key (N).

2. Select the menu "Pump" and confirm the input.

3. Select the following settings:

- Modes

- Cleaning

- Limits

- Solvent library

- Actions after stop

Modes

Automatic:

In the “Modes” menu, you can enable automatic boiling point recognition by selecting the “Automatic” menu item. No other parameters

must be set. The boiling point is detected automatically. For rotary

evaporators with heating bath, it must be ensured that the tempering

medium and solvents have a constant temperature (e.g. 60 °C).

Manual

In the “Manual” menu item, the target value can be specified (e.g.

in "mbar”). The system is evacuated until the target value.

Pump %

By selecting the “Pump %” menu item, the pump can be operated

continuously

with a running performance of between 100 % and 1 %.

Program

Under the “Program” menu, 10 user-defined pressure-time profiles

can be created. The last measurement which is in manual mode can

be saved as a program. The target value and the running performance can only be entered within the set limits (see menu item “Limits”) switching to the working screen and pressing the rotary/push

knob starts the process. Pressing the knob again stops the process.

Cleaning

NOTE

The “Cleaning” menu item increases

the service life of the pump, since

solvent residues do not remain inside the pump.

The cleaning of the pump ensures that solvent residues are removed in the pump after the measurement. For this purpose, the

pump should run at a low speed rate while the system is venting.

The air flowing through the pump ensures that the solvent residues are discharged from the pump. If the cleaning option is

selected, the cleaning process will start after the measurement has

finished (see “Actions after stop”).

You can also clean the pump without using the corresponding menu

item. To do this, remove the hoses and operate the pump at the end

of a working cycle (test, test series, end of the day ...) at idling speed.

Start after…

Start a cleaning process after a measurement was running for at

least a interval. The default time is 5 minutes. This means that a

measurement must be run for at least 5 minutes, so that cleaning

is performed at the end of the measurement.

Duration

Specifies how long the cleaning process should be performed.

Pump speed

Determines at what power (in %) the pump is operated during

cleaning. If the power is set too high this can lead to a pressure drop

in the system.

Clean now

If you want to perform a cleaning, you can select it with this setting.

Page 16

16

Timer

1. Press the "Menu" key (N).

2. Select the menu "Timer" and confirm the input.

3. Select the following settings:

- Timer functions

- Display

Timer functions

NOTE

Timer function is disabled in auto

and program mode

You can stop the evacuation procedure before expiry of the set time.

In this case the countdown of the

timer is interrupted.

In the ”Timer” menu you can specify that the timer is displayed

on the display/working screen. A tick () shows that the option

is activated. This setting specify the actual time for the evacuation

procedure.

A default time can also be set for the timer. This setting start evacuation for a standard time. The device can emit a signal (beep)

after the set target time has elapsed.

Operating mode

1. Press the "Menu" key (N).

2. Select the menu "Operating mode" and confirm the input.

3. Select the following settings.

Operating mode A

In this operating mode, the set target value is not saved when the

current run comes to an end or the device is switched off.

Limits

In this menu, limits for the target value can be set.

Solvent Library

In the “solvent library”, the most common solvents are assigned a

function to determine the steam temperature at the set pressure

and vice versa. This provides assistance when setting these parameters in manual mode, for example, evaporation processes with

a rotary evaporator.

Actions after stop

Here you can define actions that should be performed when a test

has ended.

Page 17

17

Display

1. Press the "Menu" key (N).

2. Select the menu "Display" and confirm the input.

3. Select the following settings:

- Timer

In the “Display“ menu you can specify what information will be

displayed on the main screen.

Programs

1. Press the "Menu" key (N).

2. Select the menu "Programs" and confirm the input.

Select

To select a program, use the rotary/push knob and press “Select”.

Only a program which has the right parameters can be selected.

When a program has been successfully selected, this is indicated by a tick mark (). The vacuum controller is then in program

mode. In the main screen, the program view can then be selected

by turning the knob to the right. Turning the knob to the left returns to the main screen.

Start

To start a selected program, the push knob must be pressed in the

main screen.

Edit

Edit the selected program parameters. Start to edit the selected

program parameters by pressing on menu option "Edit" with rotary/push knob. You can edit, delete or insert one selected program

segment in the program.

Delete

Deletes the selected program. If a selected program is deleted by

pressing on menu option "Delete" with rotary/push knob, all the

program parameters will be emptied. The tick () disappears.

Details for editing the program

In this program, you can define up to 10 segments. The selected

segment is highlighted. Then, you can edit, delete or insert a segment in this program. The program is save automatically.

Edit

If the background of a selected value is yellow, you can change the

setting of the pressure value or the time value.

Delete

When a highlighted segment is deleted, the subsequent segments

move upward, closing the gap created by the deleted segment.

Operating mode B

In this operating mode, the set target value is saved when the

current run comes to an end or the device is switched off, and the

value can be changed.

Operating mode C

In this operating mode, the set target value is saved when the

current run comes to an end or the device is switched off and the

value cannot be changed.

Operating mode D

In this operating mode, the set pressure value will be set with a

short display and is saved when the current run ends or the device

is switched off.

Page 18

18

When a program is being edited, following screen appears. Sample for editing the program

Safety

1. Press the "Menu" key (N).

2. Select the menu "Safety" and confirm the input.

In the “Password“ menu, you can protect the WiCo settings using

a password. (factory setting: 000)

Time Out

In the “Time Out“ menu, you can set a time limit. This time limit

applies if there is a communication failure between the IKA Vacstar

and the WiCo or the communication range is exceeded. The IKA

Vacstar will continue to run at the set speed until the set time

has expired. After that the IKA Vacstar will continue to run at the

set safety pressure (manual mode) or safety pump rate( Pump %

mode) (see the "Safety" menu).

Edit pressure

Edit time

Example of saving the last measurement

Page 19

19

Service

1. Press the "Menu" key (N).

2. Select the menu "Service" and confirm the input.

In the “Service” menu, the valves and the pump can be operated

individually and also checked to ensure that they are operating

correctly.

Settings

1. Press the "Menu" key (N).

2. Select the menu "Settings" and confirm the input.

Languages

The “Languages“ option allows you to select the desired language

by turning and pressing the rotary/pressing knob (B). A tick ()

indicates the language that is set for the system.

Units

The “Units” option allows you to select the desired unit for displaying the pressure by turning and pressing the rotary/push knob. For

the pressure, the choice is “mbar”, “hPa”, “mmHg” or “Torr”. A

tick () indicates the unit that is set for the system.

Display

The ”Display“ option allows you to change the background color

and brightness of the working screen.

Sound

The ”Sound” option allows you to activate/deactivate the keypress sound and to set the volume.

Factory settings

You can choose this function if you want to reset the system parameters. There are three options to choose: "menu values", "programs" and "all". Select the option which is going to be reset.

Communication

The “Device name” option allows you to input a device name.

The device name appears on the opening screen when the device

is switched on. This can be useful when using multiple devices

with different set- tings. This also facilitates the identification of

each device when communicating with a PC via USB, RS232 and

Bluetooth

®

, for example.

Note: The coupling "Pairing" can only be performed if the wireless

controller is mounted on the station (see chapter "Device setup"

Fig. 1).

Information

The ”Information” option offers you an overview of the most important system settings of the IKA Vacstar Control.

NOTE

The initial setting for the time limit

is 30 seconds. You can set a value of

up to 60 minutes for this time limit.

Safe speed

In the "Safety" menu, you can specify a pressure or pump rate that is

appropriate and safe for the suction task. The safety pressure or safety pump rate applies if there is a communication failure between the

IKA Vacstar and the WiCo or the communication range is exceeded.

NOTE

The initial setting of the safety

pressure is 1100 mbar and or safety

pump rate is 20 %. it is implemented after expiry of the time limit

(see "Time out").

Page 20

20

Interfaces and outputs

NOTE

Please comply with the system requirements together with the operating instructions and help section included with the software.

The device can be operated in “Remote” mode via an RS232 or

USB interface using the laboratory software labworldsoft

®

. The RS

232 interface (M) at the back of the device is fitted with a 9-pole

SUB-D jack which can be connected to a PC. The pins are assigned

serial signals.

USB Interface

The Universal Serial Bus (USB) is a serial bus system which allows

the device to be connected to the PC. Devices that support USB

can be connected to each other whilst they are running (hot plugging) and provide automatic recognition of the connected devices

and their properties.

Use the USB interface in conjunction with labworldsoft® for operation in “Remote” mode and for updating the firmware using the

“Firmware update tool”.

Installation

Before the device is connected with the PC using the USB data

cable, the USB driver must be installed.

The USB driver can be downloaded from the website.

Serial interface RS 232 (V 24)

Configuration:

• The functions of the interface circuit between the dev ice

and the automation system are a selection from the signals

specified in the EIA standard RS232 as per DIN 66020 Part 1.

• Standard RS 232, corresponding to DIN 66259 Part 1 is valid

for the electric characteristics of the interface circuits and assignment of signal states.

• Transmission process: Asynchronous character transmission

in start-stop operation.

• Transmission type: Full duplex.

• Character format: Character composition according to data

format in DIN 66022 for start-stop operation. 1 start bit, 7

character bits, 1 parity bit (even), 1 stop bit.

• Transmission speed: 9600 Bits/s.

• Data flow control: none

• Access method: Data transmission from the device to the

computer only occurs after a request from the computer.

Command syntax and format

The following points should be noted for the instruction set:

• Commands are generally sent from the computer (master) to

the device (slave).

• The device only responds to requests from the computer.

Even error messages are not send spontaneously from the

device to the computer (automation system).

• The commands are transmitted in captial letters.

• Commands and parameters, as well as consecutive parame-

ters, must be separated by at least one space (code: hex 0x20

).

• Each individual command (including parameters and data)

and all responses are completed with CRLF (code: hex 0x20

hex 0x0d hex 0x0A) and can have a maximum length of 50

characters.

• The dot is used for decimal separators in a floating-point val-

ue (code: hex 0x2E).

The details given above generally comply with the recommendations of NAMUR (NAMUR recommendations for the design of

electrical plug-in connectors for analogue and digital signals in

laboratory MSR devices. Rev. 1.1).

The NAMUR commands and the additional IKA specific commands

are only used as low-level commands for communication between the

device and the PC. With an appropriate terminal or communication

program, these commands can be transmitted directly to the device.

NAMUR commands Function

Command

Firmware

Version

Description

IN_PARA1 0.0.020 Return the actual values

OUT_PARA1 0.0.020 Set the set values for the pump

control

OUT_PARA2 0.0.020 Set the set values for Bluetooth

connection

OUT_STATUS 0.0.020 Send the actual device status

IN_STATUS 0.0.020 Reads the status of a device

IN_VERSION 0.0.020 Read the version of the firmware

IN_DATE 0.0.020 Read the release date of the display/

logic firmware

IN_NAME 0.0.020 Read the name of the device

IN_DEVICE 0.0.020 Read the device type.

IN_ADDRESS 0.0.020 Read mac address of Wico.

IN_PARING 0.0.020 Read paired mac address of station.

OUT_ADDRESS 0.0.020 Write new paired mac addresses of

both station and Wico.

IN_SP_66 0.0.020 Reads the set pressure value

OUT_SP_66 0.0.020 Sets set point pressure value

IN_PV_66 0.0.020 Reads the actual pressure value

IN_MODE_66 0.0.020 Reads the evacuating mode

OUT_

MODE_66

0.0.020 Sets the evacuating mode

IN_ERROR 0.0.020 Reads error state

OUT_ERROR 0.0.020 Test Error. Sends out error code

IN_BT_NAME 0.0.020 Reads Bluetooth Device Name

IN_CUSTOM_

DEVICE_NAME

0.0.020 Reads custom device name

OUT_CUSTOM_DEVICE_

NAME

0.0.020 Sets custom device name

IN_WD1@ 0.0.020 Reads communication watchdog

time

OUT_WD1@ 0.0.020 Sets communication watchdog time

OUT_WD2@ 0.0.020 Set PC communication watchdog

time 2

OUT_SP_41 n

(0 -100 %)

0.0.020 Set the PC safety pump rate

OUT_SP_42 0.0.020 Set the PC safety pressure

RESET 0.0.020 Switch to normal operating mode

START_66 0.0.020 Starts the measurement

STOP_66 0.0.020 Stops the measurement

ENTER_IAP 0.0.020 Starts IAP mode

CALIB_66 0.0.020 It is used to calibrate vacuum.

IN_CALIB_66 0.0.020 It is used to read vacuum calibration

values

OUT_CALIB_66 0.0.020 It is used to calibrate vacuum.

Page 21

21

Accessories: PC 1.1 cable (device to PC)

Required for connecting the 9-pin socket to a PC.

Fig. 10

USB A - USB B cable

Required for connecting the USB interface (L) to a PC.

USB B

USB A

A

Fig. 11

Maintenance and cleaning

The device is maintenance-free. However it is subject to natural

wear and tear on parts and their statistical failure rate.

Unplug from the mains before cleaning.

Only clean the IKA device using these IKA approved cleaning

agents:

Dirt Cleaning agent

Dyes Isopropyl alcohol

Building materials Water containing detergent, isopropanol

Cosmetics Water containing detergent, isopropanol

Food Water containing detergent

Fuels Water containing detergent

Other materials Please ask IKA

• Wear protective gloves when cleaning the devices.

• Do not place electrical appliances into the cleaning agents for

cleaning purposes.

• Ensure no liquid enters the device during cleaning.

• Please consult with IKA before using any cleaning or decontamination methods not specifically recommended.

Ordering spare parts

When ordering spare parts, please make sure to indicate the fol-

lowing:

• Device type

• Device manufacturing number; see rating plate

• Reference number and description of spare part; see spare

part diagram and list at www.ika.de.

Repairs

Please only send devices in for repair that have been

cleaned and are free of materials which might present

health hazards.

For this, use the “certificate of compliance” form which you

can obtain from IKA or can download a version for printing from

the IKA website www.ika.de

If your appliance requires repair, return it in its original packaging.

Storage packaging is not sucient. also use appropriate transport

packaging.

1

2 RxD

3 TxD

4

5 GND

6

7 RTS

8 CTS

9

1

RxD 2

TxD 3

4

GND 5

6

RTS 7

CTS 8

9

PC

1

2

3

4

5

6

7

8

9

9

8

7

6

5

4

3

2

1

“Watchdog” functions; monitoring of the serial data flow

If, once this function has been activated (see NAMUR commands),

there is no retransmission of the command from the computer

within the set time (“watchdog time”), the Evacuation function is

switched off in accordance with the set “watchdog” mode or is

returned to previously set target values. The data transmission may

be interrupted by, for example, a crash in the operating system,

a power failure in the PC or an issue with the connection cable

between the computer and the device.

“Watchdog” mode 1

If event WD1 should occur, the evacuation function is switched

off and WD1 Watchdog Error is displayed. Set watchdog time to

m (20- 1,500) seconds, with watchdog time echo. This command

launches the watchdog function and must be transmitted within

the set watchdog time.

“Watchdog” mode 2

If there is an interruption in data communications (longer than the

set watchdog time), the speed target value is changed to the set

WD safety speed limit. The warning PC 2 is displayed. The WD2

event can be reset with OUT_WD2@0 - this also stops the watchdog function.

Set watchdog time to m (20- 1,500) seconds, with watchdog time

echo. This command launches the watchdog function and must

be transmitted within the set watchdog time.

Page 22

22

Error codes

If an error occurs, this is shown in an error on the display (B), e.g. Error 4.

Proceed as follows:

• Switch the device off on the device switch,

• Take corrective measure,

• Switch device back on.

Error code Description Detection Reason Action

Error 3 Device temperature

error

The temperature of

device has exceeded the

limit.

The temperature is too high. Stop the device for a while and restart

again. If the problem occurs again and

again, please call service department.

Error 4 Motor overload Motor overload The motor is blocked be-

cause of overload.

Stop the device for a while and restart

again. If the problem occurs again and

again, please call service department.

Error 8 Speed sensor fault. Device can’t detect the

pump speed.

The sensor occurs some

unknown errors that device

can’t read the speed value.

Call service department.

Error 9 Storage Error Read or write internal

flash error.

Read or write internal flash

error.

Call service department.

In the event that the fault cannot be eliminated using the measures described or another error code is displayed:

• Please contact the Service Department,

• Send the device and a brief description of the fault.

Accessories

• Vacuum hose IKA VH.SI.8

• PC 1.1 cable (RS 232)

• Woulff bottle/water valve set VSW1

For further accessories see www.ika.de

Product contact parts

Name Material

Connection spigot PPS

Connection piece PPS

Distributor PPS

Head piece PPS

Diaphragm valve/O-ring FFPM

Diaphragm NBR/PTFE

Clamp PPS

Connection piece PTFE

Pressure sensor AL203

Page 23

23

Technical data

Base unit Value

Pump rate max. [m³/h] 1.32

Pump rate max. [l/min] 22

Final pressure without gas ballast [mbar] 2

Suction levels [-] 4

Cylinder [-] 4

Connection diameter suction side [mm] 8

Connection diameter pressure side [mm] 8

Input pressure min. [mbar] 2

Input pressure max. [mbar] 1030

Boiling point detection [-] yes

Solvent library [-] yes

Analog speed vacuum control [-] yes

Speed control [-] Turning knob

Display [-] TFT

Pressure unit / scale [-] mbar, hPa, mmHg, Torr

Vacuum sensor [-] yes

Vacuum sensor type [-] ceramic Al2O3

Pressure max. for pressure sensor [bar] 1.2

Measurement range (absolute) min. [mbar] 1

Measurement range (absolute) max. [mbar] 1030

Resolution pressure [mbar] 1

Measurement uncertainty [mbar] 1

Venting valve [-] yes

Condensate trap [-] yes

Emission condenser [-] yes

Timer [-] yes

Noise at low. pressure [dB(A)] 54

Material in contact with medium [-] Al2O3, PTFE, FPM, PPS

Housing material [-] Alu-cast coating

Mode automatic [-] yes

Mode manual [-] yes

Mode pump % [-] yes

Mode program [-] yes

Width [mm] 270

Depth [mm] 500

Height [mm] 435

Weight [kg] 14

Permissible ambient temperature min. [°C] 5

Protection class II

Overvoltage category !

Degree of contamination 1

Use above max. MSL m 2000

Firmware update yes

Page 24

24

Base unit Value

Permissible ambient temperature max. [°C] 40

Permissible relative humidity [%] 80

Protection class according to DIN EN 60529 [-] IP 20

USB interface [-] yes

RS 232 interface [-] yes

Voltage [V] 100 - 240

Frequency [Hz] 50/60

Power input [W] 140

Power input standby [W] 1.5

Average values.

Subject to technical changes!

Page 25

25

Page 26

IKA - Werke GmbH & Co.KG

Janke & Kunkel-Str. 10

D-79219 Staufen

Tel. +49 7633 831-0

Fax +49 7633 831-98

sales@ika.de

www.ika.com

Loading...

Loading...