Page 1

20000017329a

T25 easy clean digital/control_072018

IKA T25 easy clean digital

IKA T25 easy clean control

Operating instructions EN

Page 2

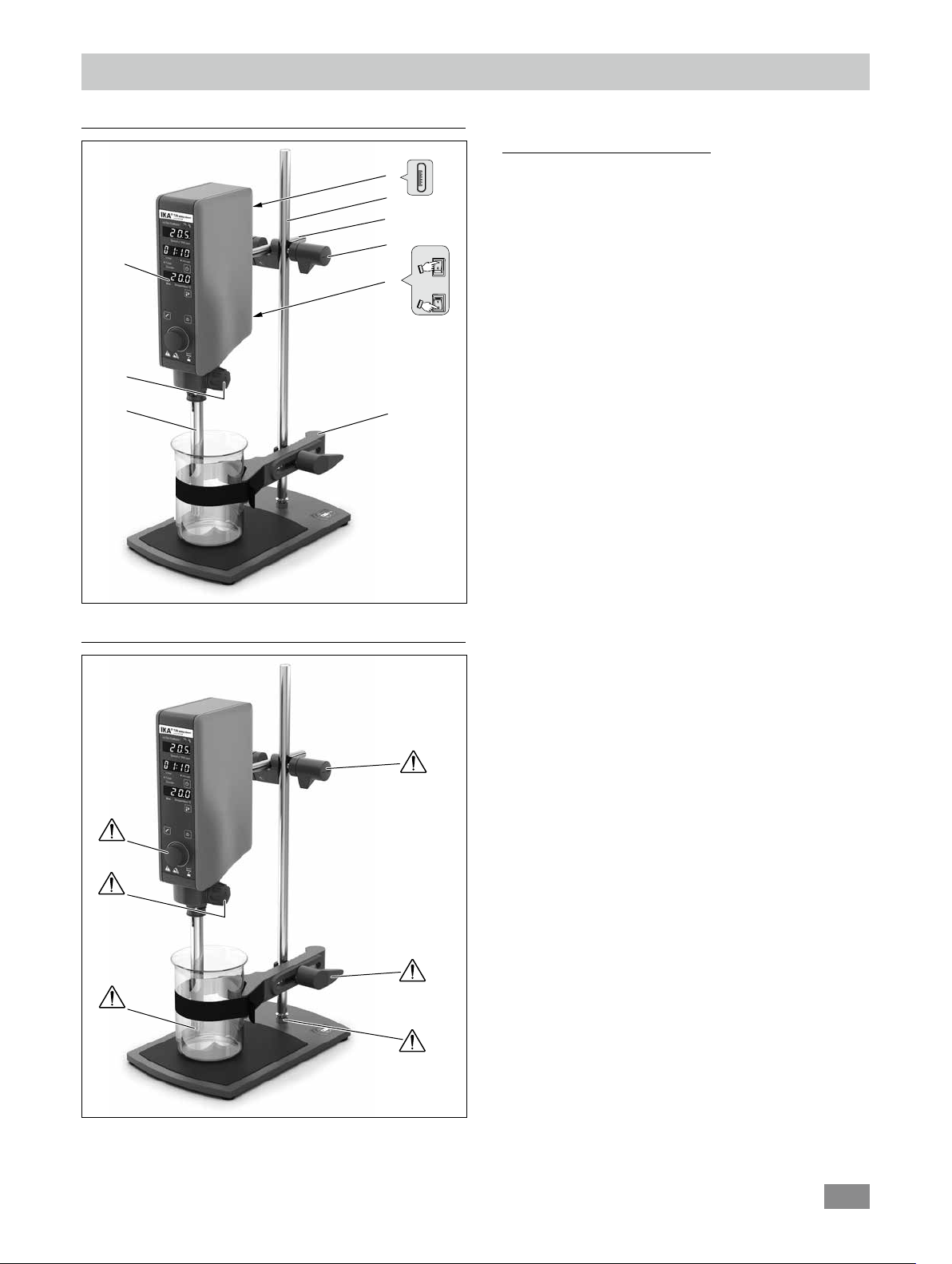

Device setup

On

Off

1

2

Device setup/Dangerous parts

Item Designation

4

5

6

7

8

1 Operator panel and display

2 Turning knob

3 Dispersion tool

4 USB port

5 Stand

6 Extension arm

7 Cross sleeve

8 Power switch

9 Strap clamp

3

Fig. 1

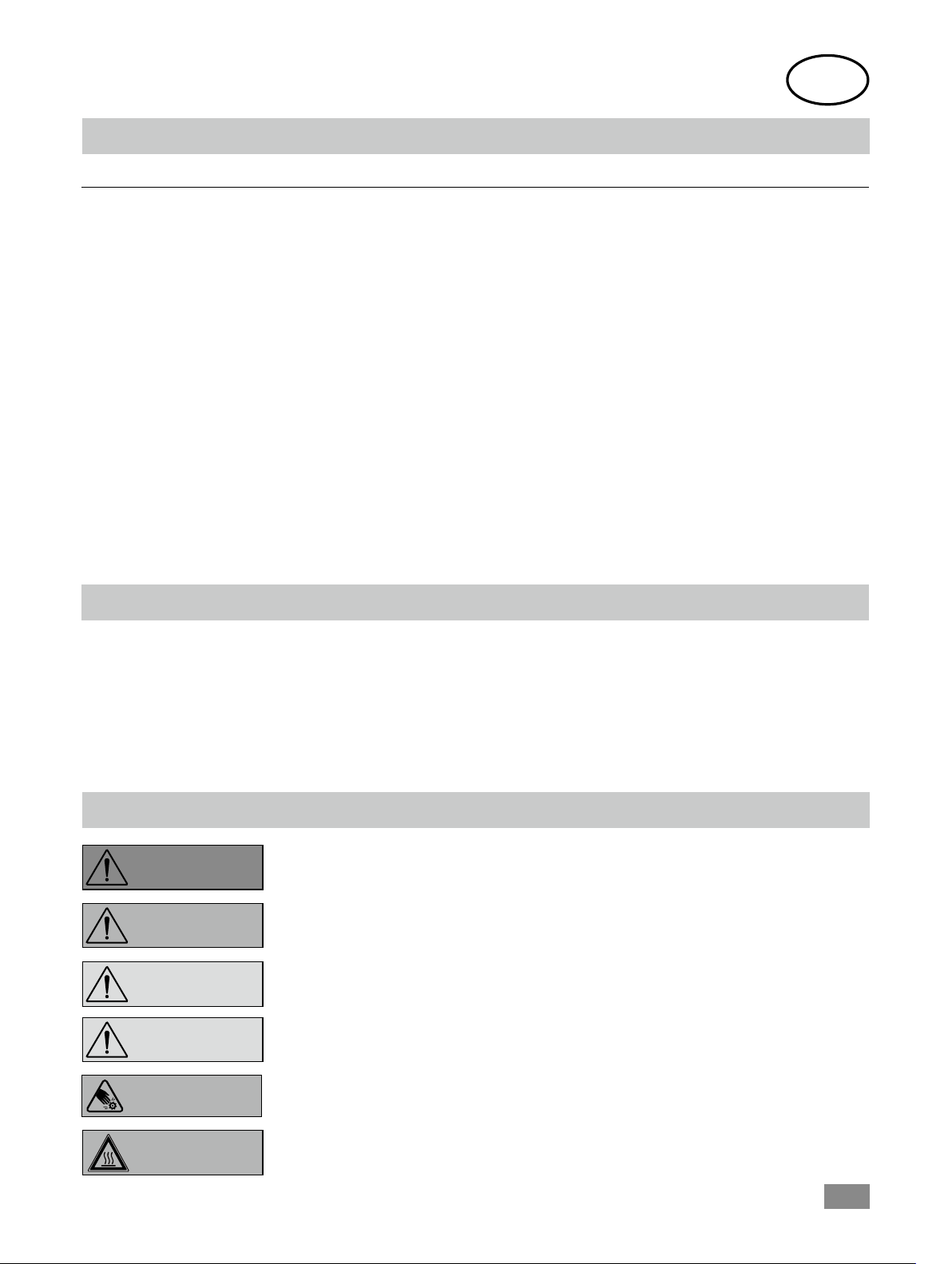

Dangerous parts

9

Fig. 2

2

Page 3

Source language: German

EN

Contents

Page

Device setup/Dangerous parts 2

Declaration of conformity 3

Explication of warning symbols 3

Safety instructions 4

Intended use 5

Unpacking 6

Useful information 6

Drive 6

Securing 7

Operator panel and display 8

Commissioning and operating 10

Interfaces and outputs 12

Accessories 13

Permitted dispersion tools 13

Warning message 14

Error codes 14

Maintenance and cleaning 15

Technical data 16

Warranty 16

EU Declaration of conformity

We declare under our sole responsibility that this product corresponds to the directives 2014/35/EU, 2006/42/EC, 2014/30/

EU and 2011/65/EU and conforms with the following standards or normative documents: EN 61010-1, EN 6010-2-051,

EN 61326-1, EN 60529 and EN ISO 12100.

Bluetooth® module (for T25 easy clean control):

Directive: 2014/53/EU Standards: EN 60950-1, EN 300328, EN 301489-1, EN 301489-17

A copy of the complete EU Declaration of Conformity can be requested at sales@ika.com.

Explication of warning symbols

indicates a hazardous situation which, if not avoided, will result in death or serious injury.

DANGER

indicates a hazardous situation which, if not avoided, could result in death or serious injury.

WARNING

used with the safety alert symbol, indicates a hazardous situation, which, if not avoided,

CAUTION

could result in minor or moderate injury.

is used to address practices not related to personal injury.

NOTICE

WARNING

WARNING

Indicates crushing risk to fingers/hand.

Indicates hazards arising from a hot surface.

3

Page 4

Safety instructions

General information:

• Read the operating instructions in full before starting up and follow the safety instructions.

• Keep the operating instructions in a place where they can

be accessed by everyone.

• Ensure that only trained staff work with the device.

• Follow the safety instructions, guidelines, occupational

health and safety and accident prevention regulations.

DANGER

Beware of the risk of:

- flammable materials

- glass breakage

- sharp edges on the dispersing tool.

CAUTION

processed. There is a risk from:

- splashing and evaporation of liquids

- body parts, hair, clothing and jewellery getting caught.

• The device must only be used in a technically perfect condition.

• Do not cover the ventilation slots on the drive in order to

ensure adequate cooling of the drive.

• The voltage stated on the type plate must correspond to

the power voltage.

• Abrasion of the dispersion equipment or the rotating accessories can get into the medium you are working on.

Please pay attention to the dangerous parts of the equipment in Fig. 2.

Wear your personal protective

equipment in accordance with the

hazard category of the media to be

• Before switching on the dispersing device make sure that

the dispersion tool shaft is immersed in the medium. Observe the operating instructions of the dispersion tools.

• The distance between the dispersion tool and the vessel

bottom should not be less than 10 mm.

• Use the dispersion tool always inside the dispersing vessel.

• Do not use the device without a dispersion tool.

Working with the device:

DANGER

With substances capable of forming an explosive mixture,

appropriate safety measures must be applied, e.g. working under a fume hood.

To avoid body injury and property damage, observe the

relevant safety and accident prevention measures when

processing hazardous materials.

Only process media that will not react dangerously to the

extra energy produced through processing. This also applies to any extra energy produced in other ways, e.g.

through light irradiation.

The device is not suitable for hand-held operation.

Switch off the device at the power switch (item 8) or pull

out the mains plug when changing or handling the dispersing tool.

WARNING

Do not use the device in explosive

atmospheres, it is not EX-protected.

Do not touch rotating parts during

operation!

Device setup:

DANGER

If access to the power switch cannot be ensured, an additional emergency stop switch that can be easily accessed

must be installed in the work area.

WARNING

NOTICE

• Ensure that the dispersion tool is securely properly into

the drive unit.

• All screw connections must be properly tightened.

• Check that the turning knobs are secure and tighten if

necessary.

• Glass vessels must always be secured with a clamp to prevent them spinning.

The power switch of the IKA device

must be accessed immediately, directly and without risk at any time.

Make sure that the unit is stably

mounted. The vessel used for dispersing must be secured.

Set up the stand in a spacious area

on an even, stable, clean, non-slip,

dry and fireproof surface.

WARNING

If a dispersion tool is not inserted into the drive flange as

far as the mark it can become extremely hot in operation

and thus suffer damage.

CAUTION

speed and increase it gradually.

Reduce the speed if the medium splashes out of the vessel

because the speed is too high.

If the interaction between the medium and dispersing

element or working with dispersing tools with a stator

diameter ≥18 mm and a speed of more than 20000 rpm,

makes a loud noise, be sure to wear your personal protective equipment.

The dispersing tool and the coupling flange can become hot during

the operation.

Be aware that the unit starts with the

set speed, which is shown on the display. If uncertain start with the lowest

4

Page 5

NOTICE

eration. This will prevent the infiltration of foreign objects,

liquids and other contaminants.

Never run dispersion tools dry, as the gasket and bearings will be destroyed if the tools are not cooled by the

medium.

• In the event of unbalance or unusual noises, switch off

the device immediately. Replace the dispersion tool. If

there is no difference after the change of the dispersion

tool, return it to the dealer or the manufacturer along

with a description of the fault.

• Ensure that the stand does not start to move.

• Meter powder cannot be placed too close to the flange.

Powder can be blown away by air turbulences of the drive.

• There may be electrostatic discharges between the medium and the dispersing device shaft which could pose a

direct danger.

Covers or parts that can be removed

from the device without tools must

later be refitted to ensure safe op-

Power supply / Switching off the device:

• The device can only be disconnected from the power supply by pulling out the power plug or the connector plug.

• Always disconnect the plug before fitting accessories or

cleaning.

• The socket for the power cord must be easily accessible.

• The device does not start up again automatically following a cut in the power supply.

• The device must only be opened by trained specialists,

even during repair. The device must be unplugged from

the power supply before opening. Live parts inside the

device may still be live for some time after unplugging

from the power supply.

Accessories:

• Protect the device and accessories from bumps and impacts.

• Check the device and accessories beforehand for damage

each time you use them. Do not use damaged components.

• Only dispersion tool approved by IKA may be used.

• Safe operation is only guaranteed with the accessories described in the ”Accessories” chapter.

Disposal of the device:

• The device must be disposed of in accordance with national

regulations

Intended use

Use:

When used in combination with one of our recommended

dispersion tools, the drive unit is a high-speed dispersing

and emulsifying unit capable of handling free-flowing and

liquid media in batches.

Production of:

Emulsions

Dispersions

Wet crushing

Intended use: on stand (dispersion tool points down)

Range of use (indoor use only):

- Laboratories - Schools

- Pharmacies - Universities

The device is suitable for use in all areas (EMC class A and B).

The safety of the user cannot be guaranteed:

- If the device is operated with accessories that are not sup-

plied or recommended by the manufacturer

- If the device is operated improperly or contrary to the

manufacturer’s specifications

- If the device or the printed circuit board are modified by

third parties.

5

Page 6

Unpacking

R

O

T

O

R

S

T

A

T

O

R

Unpacking:

- Unpack the device carefully.

- Any damage should be notified immediately to the shipping

agent (post oce, railway network or logistics company).

Useful information

Dispersion is the dissolution and diffusion of a solid, liquid

or gaseous phase in a liquid that is not consolute with that

phase.

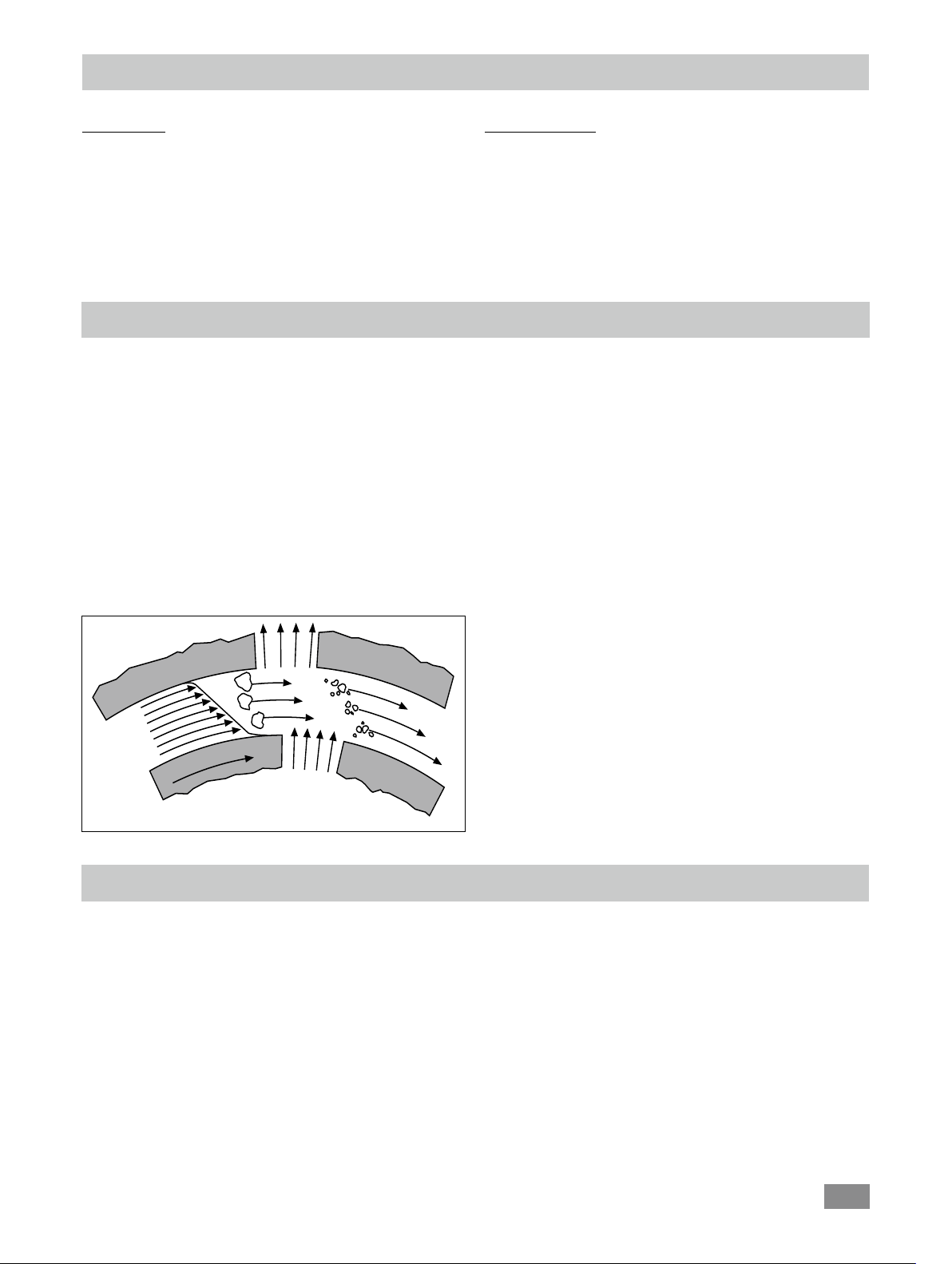

The rotor/stator principle:

Due to the high rotation speed of the rotor, the medium

to be processed is automatically drawn axially into the dispersion head and then forced radially through the slots in

the rotor/stator arrangement. The high accelerations acting

on the material produce extremely strong shear and thrust

forces. In addition, high turbulence occurs in the shear gap

between rotor and stator, which provides optimum mixing

of the suspension.

Delivery scope:

- IKA T 25 easy clean digital or IKA T 25 easy clean control

- Extension arm

- Hexagon socket screw

- Screwdriver DIN 911

- USB 2.0 cabel (A – micro B)

- User guide

- Warranty card.

The dispersion effectiveness is heavily dependent on the

product of the shear gradient and the time the particles

spend in the shear zone. The optimum range for the circumferential velocity of the rotor/stator arrangement is

6–24 m/s.

A processing time of a few minutes is usually sucient to

produce the desired fineness. Long processing times bring

only insignificant improvements in the obtainable fineness;

the energy expended serves merely to increase the temperature of the medium.

Fig. 3

The drive unit opens up a wide range of possibilities for dispersion technology in the conventional laboratory with a

respective performance output of approximately 400 watts

at 25000 rpm.

Drive

The speed is set by using the operating knob. The motor

speed can be read from the LED display. For example, a value of 13.6 corresponds to 13600 rpm.

6

Page 7

Securing

Securing the extension arm to the disperser:

Disperser

Hexagon socket

offset screw key

Hexagonal socket

screw

Extension arm

Fig. 4

Ensure that the extension arm is fitted securely.

Vibration may cause the screw to become loose. It is therefore necessary for safe use to regularly check that the extension arm is attached securely. Tighten the hexangular bolt

as required.

Securing the disperser to the stand:

Cross sleeve

Screw bolt

Extension

arm

Securing the dispersion tool:

Drive unit

!

0 mm

Turning knob

!

Dispersion tool

Fig. 6

Open the turning knob so that the thread does not protrude

into the hole.

Insert the dispersion tool from the bottom into the drive

unit as far as the stop. The shaft tube will audibly click into

place when a small amount of force is applied.

The dispersion tool is fitted correctly when the marking on

the dispersing element is aligned with the bottom edge of

the drive unit.

Now secure the dispersion tool by screwing the turning

knob tightly.

Securing the dispersing vessel to the stand:

Stand

Fig. 5

Check that the disperser is held in position firmly prior to

each use and also at regular intervals. The position of the

disperser must only be adjusted when the equipment is stationary and the power supply is disconnected.

Stand

Strap clamp

Clamping bolt

Clamping

band

Vessel

Fig. 7

7

Page 8

T25 easy clean digital:

Operator panel and display

Item Designation

A "Speed" display: Display the "Speed" value (x 1000 rpm).

B "Timer/Counter" display:

Q

A

B

C

D

E

C "h:min" indicator:

P

D "Timer" indicator:

E "Counter" indicator:

K "Start/Stop" knob:

O

Start/stop dispersing function.

N

L

M

L

On/off button: Switch on/off the device.

M "Timer" button:

N "min:sec" indicator:

O "Timer" setting indicator: Indicate the "Timer" can be set

P "Speed" setting indicator: Indicate the speed can be set

When the device is controlled by Labworldsoft and

Q USB indicator:

Indicate the "Timer" or "Counter" is in hour/minute

Indicate the "Counter" function is activated.

Switch between the setting of speed and timer.

Function

Indicate the "Timer/Counter" value.

[h:min] mode.

Indicate the "Timer" function is activated.

Set the speed.

Set the timer when "Timer" setting is activated.

Indicate the "Timer" or "Counter" is in minute/second

[min:sec] mode.

.

.

tries to change the speed of the device, the display

show PC

Indicates the device is connected to a PC with USB port.

( )

.

Fig. 8

K

8

Page 9

T25 easy clean control:

A

B

C

D

E

F

G

H

I

J

Fig. 9

easy clean

Item Designation Function

R

Q

P

A "Speed" display: Display the "Speed" value (x 1000 rpm).

B "Timer/Counter" display: Indicate the "Timer/Counter" value.

Indicate the remaining time to maintenance.

When device is controlled by a WiCo, the dis-

play show rC ( ) .

O

N

M

C "h:min" indicator: Indicate the "Timer" or "Counter" is in hour/

minute [h:min] mode.

D "Timer" indicator: Indicate the "Timer" function is activated.

E "Counter" indicator:

F "Temperature" display:

Indicate the "Counter" function is activated.

Display the actual temperature value/set max.

temperature value of the medium with the

S 25 EC-T... tool.

If a tool other than the S 25 EC-T... is used,

the display show ---.

G "Max. Temperature" indicator: Indicate the "Max. Temperature" of the dis-

L

persing medium that can be set.

H "Max. Temperature" button: Display the max. temperature setting in run-

ning status.

K

Active the setting function on "Max. Temper-

ature" of the dispersing medium.

I

S 25 EC-T...

dispersion tool indicator: Indicate the S 25 EC-T... dispersion tool is in-

serted.

J

S 25 EC-T...

dispersion tool button: Display the remaining time to maintenance

of

S 25 EC-T...

tool

.

Activate the reset of the maintenance time.

K "Start/Stop" knob: Set the speed value by rotating the knob.

Set the timer value by rotating the knob when

"Timer" setting is activated.

Start/stop the running of the device by press-

ing the knob.

L On/off button: Switch on/off the device.

M "Timer" button: Activate the "Timer" setting.

N "min:sec" indicator: Indicate the "Timer" or "Counter" is in minute/

second [min:sec] mode.

O "Timer" setting indicator: Indicate the "Timer" can be set by rotating the

knob.

P "Speed" setting indicator: Indicate the speed can be set by rotating the

knob.

When the device is controlled by Labworld-

soft and tries to change the speed of the device, the display show PC ( ).

Q USB indicator: Indicates the device is connected to a PC with

the USB port.

R Bluetooth indicator: Indicates the device is communicating with a

WiCo or a PC via the bluetooth.

9

Page 10

Commissioning and operating

Refer to the operating instructions for the filling level of the

medium and the immersion depth into the dispersion tool

used.

If a dispersion tool is not inserted into the drive flange as far

as the mark it can become extremely hot in operation and

thus suffer damage.

So as to avoid unintentional ingress of air into the medium

due to excessively turbulent rotation, the whole unit can be

placed a little off center in the dispersing vessel.

Switching on:

After switching on the power switch (8) of the device, all LED segments light up during self test.

Then, "Timer" display (B) shows the software version.

After that, the device enters standby status and "Speed" setting indicator (P) keeps lighting.

Setting speed:

Activate the device by pressing on/off button (L).

After a beep, the "Speed" setting indicator (P) lights up.

Change the speed setting by rotating the "Start/Stop" knob (K).

The speed value shows on the display (A), e.g.: means the speed is 3200 (3.2 x 1000) rpm.

Start the device by pressing the "Start/Stop" knob (K).

Check whether the voltage given on the type plate corresponds to the available power voltage.

The socket used must be earthed (fitted

with earth contact).

If these conditions have been met, the machine is ready to

operate when the power plug is plugged in.

If these conditions are not met, safe operation is not guaranteed and the machine could be damaged.

Note: After starting, actual speed value flashes until reach the set value.

Setting timer:

Activate the timer setting by pressing timer button (M).

Timer setting indicator (O) lights up.

Change the timer setting by rotating the "Start/Stop" knob (K).

When the timer is set to over 00:00, the timer function is activated and timer indicator (D)

lights up.

The "min: sec" indicator (N) and "h:min" indicator (C) show the unit of the timer value.

Start the device by pressing the "Start/Stop" knob (K).

When the time reach 00:00, the device stops running and the display (A) and (B) show last

settings.

Note: While running, the timer setting can be checked by pressing the timer button (K).

Activating the counter function:

Set the timer to 00:00 [min:sec] by rotating

The counter function is activated and counter indicator (E) lights up.

Start the device by pressing

the

"Start/Stop" knob (K).

the

"Start/Stop" knob (K).

10

Page 11

For T25 easy clean control with

Setting the "Max. Temperature":

Activate the setting function of maximum temperature of the dispersing medium by pressing

"Max. Temperature" setting indicator (G) lights up.

Change the setting by rotating the "Start/Stop" knob (K).

Start the device by pressing the "Start/Stop" knob (K).

Note: When the dispersing medium reaches the set temperature, the device stops and a warning

message is shown on display (A) and (B): hot tool (see section "Warning message").

While running, the "Max. Temperature" setting can be checked by pressing the "Max. Temperature" button (H).

Checking the tool maintenance time:

To

Display (B) shows the tool maintenance time about 2 seconds.

The "min: sec" indicator (N) or "h:min" indicator (C) show the unit of the time value.

Display (B) switches to show the timer value.

Note: The tool maintenance time can be checked in either stop or running status.

When the tool maintenance time is less than 30 minutes, the

cator (I) changes from green to red color.

When the tool maintenance time reaches 0, the value (00:00:00) flashes and meanwhile the

indicator LED (I) is red and flashes.

S 25 EC-T...

"Max. Temperature" button (H).

check the tool maintenance time of

tool button (J).

S 25 EC-T...

dispersion tool only:

S 25 EC-T...

dispersion tool indicator (I) flashes twice.

by pressing

S 25 EC-T...

S 25 EC-T...

dispersion tool indi-

dispersion

Resetting the tool maintenance time:

The default maintenance time of

maintenance (e.g. replacing the bearing) to the dispersion tool when the service time elapse.

When the tool maintenance time reach 0, the device will not stop, but we recommend a maintenance of the tool as soon

as possible. After the maintenance in a IKA service workshop the maintenance time will be reset from the service team. In

all other cases it is possible to reset the maintenance time with the device. Description see below.

* Note: The maintenance time of S 25 EC-T… dispersion tool can be set between 4 to 40 hours according to the request

of your application by rotating the "Start/Stop" knob immediately after resetting the tool maintenance time. The new

value has to confirm by pressing the "Start/Stop" knob. This new value will be the resetting value when the tool will reset

the next time.

S 25 EC-T...

Activate the setting function on the tool maintenance time of

by pressing

Display (B) switches to tool maintenance time.

The

S 25 EC-T...

Press the "Start/Stop" knob (K) to reset the tool maintenance time.

dispersion tool is 20* hours. We recommend to check and carry out necessary

S 25 EC-T...

dispersion tool indicator (I) flashes.

dispersion tool button (J) 3 seconds.

S 25 EC-T...

dispersion tool

11

Page 12

Interfaces and outputs

Remote control:

The device can be connected to a PC using a USB cable and

be operated in “Remote” mode via USB port using labworld-

soft® laboratory software.

The device software can also be updated with a PC via the

USB port.

Note: Please observe the system requirements together

with the operating instructions and help section included

with the software.

USB interface:

The Universal Serial Bus (USB) is a serial bus for connecting

the device to the PC. Equipped with USB devices can be

connected to a PC during operation (hot plugging). Connected devices and their properties are automatically recognized. The USB port can also be used to update firmware.

USB device drivers:

First, download the latest driver for IKA devices with USB

port from:

http://www.ika.com/ika/lws/download/usb-driver.zip.

Install the driver by running the setup file. Then connect the

IKA device through the USB data cable to the PC.

The data communication is via a virtual COM port.

Device software update:

For device software update, visit IKA website www.ika.

com and enter the "Service" menu. Download and run the

Firmware Update Tool.

Find and click the Firmware Update Tool in your PC after

installation. Register your E-mail and password.

Connect the device to your PC via the USB cable. Then, you

can update the device software according to instructions of

the Firmware Update Tool.

Command syntax and format:

The following applies to the command set:

- Commands are generally sent from the computer (Master)

to the device (Slave).

- The device sends only at the computer’s request. Even

fault indications cannot be sent spontaneously from the

device to the computer (automation system).

- Commands are transmitted in capital letters.

- Commands and parameters including successive parameters are separated by at least one space (Code: hex 0x20).

- Each individual command (incl. parameters and data) and

each response are terminated with Blank CR LF (Code: hex

0x0d hex 0x0A) and have a maximum length of 80 characters.

- The decimal separator in a number is a dot (Code: hex

0x2E).

The above details correspond as far as possible to the recommendations of the NAMUR working party (NAMUR recommendations for the design of electrical plug connections for analogue and digital signal transmission on individual items of

laboratory control equipment, rev. 1.1).

The NAMUR commands and the additional specific IKA commands commissioning serve only as low level commands for

communication between the tube driver and the PC. With a suitable terminal or communications program these com-

®

mands can be transmitted directly to the tube driver. The IKA software package, Labworldsoft

, provides a convenient tool

for controlling tube driver and collecting data under MS Windows, and includes graphical entry features, for motor speed

ramps for example.

Commands Function

IN_NAME Read device name.

RESET Switch to normal operation mode

IN_PV_4 Read current speed value

IN_SP_4 Read rated value

OUT_SP_4 X

Adjust the rated speed value

(X = 3000 ... 25000)

START_4

Start the motor

STOP_4 Stop the motor

IN_SOFTWARE Read software ID and version

12

Page 13

Accessories

R 1825 Plate stand

R 1826 Plate stand

R 1827 Plate stand

R 182 Cross sleeve

RH 3 Strap clamp

See more accessories on www.ika.com.

Permitted dispersion tools

Dispersion tools series S 25...

Abbreviations:

S 25: consistent with all dispersing units T 25...

N: PTFE bearing

KV:

D: Without seal

KD: Ball bearing with PTFE bearing with seal

T: Temperature

C: Ceramic bearing

KS: Synthetic material

ST: Saw tooth

EC: easy clean

Ball bearing with axial face seal (suitable for vacuum up to 1 mbar, 6 bar excess pressure)

BC 1000 Beaker cap

Silentstream

T 25 easy clean control WiCo (for T25 easy clean control

only)

S 25 EC - C - 18G - ST Stainless steel

S 25 EC - T - C - 18G - ST Stainless steel

(S 25 EC only suitable for T25 easy clean digital or

T25 easy clean control. Full functionality of the S 25 EC-T

... only with the T25 easy clean control

Note below dispersing status and cleaning status!

).

8G, 10G, 18G, 14G, 25G, 25F:

Stator / shaft tube diameter

G: Coarse

F: Fine

Speed range: up to 25000 rpm

Designation Shaft material

S 25 N - 8G Stainless steel

S 25 N - 10 G Stainless steel

S 25 N - 18 G Stainless steel

S 25 N - 25 G Stainless steel

S 25 N - 25 F Stainless steel

S 25 N - 8G - ST Stainless steel

S 25 N - 10 G - ST Stainless steel

S 25 N - 18 G - ST Stainless steel

S 25 N - 25 G - ST Stainless steel

S 25 KV - 18 G Stainless steel

S 25 KV - 25 G Stainless steel

S 25 KV - 25 F Stainless steel

S 25 D - 10 G - KS Synthetic material

S 25 D - 14 G - KS Synthetic material

S25 KD - 18 G Stainless steel

S25 KD - 25 G Stainless steel

S25 KD - 25 F Stainless steel

S25 KD - 18 G - ST Stainless steel

S25 KD - 25 G - ST Stainless steel

Dispersing status Cleaning status

For applications and further information, please see the operating instructions of the dispersion tools.

Only use the dispersion tools listed and observe the

operating instructions of the dispersion tool.

13

Page 14

Warning message

Any malfunction during operation may be identified by an warning message on the display.

Proceed as follows in such cases:

Warning code Cause Effect Solution

The dispersion tool is not secured

no

properly.

tool

motor off - Secure the dispersion tool properly.

- Restart the device by pressing the "Start/Stop" knob (F).

The medium temperature exceeds

hot

the maximum temperature setting.

(only for S 25 EC-T...).

tool

motor off - Switch off the device using on/off button (L).

- Switch on the device again using on/off button (L).

- Let the medium and dispersion tool cool down or set

higher maximum temperature.

-

Restart the device by pressing the "Start/Stop" knob (K).

Error codes

Any malfunction during operation may be identified by an error message on the display.

Proceed as follows in such cases:

Switch off device using the power switch

Carry out corrective measures

Restart the device.

Error code Cause Effect Solution

E 3 Inside temperature is too high motor off

E 4 Motor can’t run normal (can’t start

or not reach the target speed)

E 25

E 86

E 47

E 48

Internal hardware failure motor off - Send the

Overload motor off - Switch off the

motor off - Switch off the

- Switch off the device and let it cool down.

- Restart the

- Check the structure for possible blockage

- Decrease the speed setting or the load

device

device

.

device.

for repair.

device

If the actions described fails to resolve the fault or another error code is displayed then take one of the following steps:

- Contact the service department

- Send the device for repair, including a short description of the fault.

14

Page 15

Maintenance and cleaning

The device is maintenance-free. It is only subject to the natural wear and tear of components and their statistical failure

rate.

Cleaning:

For cleaning disconnect the main plug!

Use only cleaning agents which have been approved by IKA

to clean IKA devices.

Dirt Cleaning agent

Dye isopropyl alcohol

Construction material water containing tenside/isopropyl alcohol

Cosmetics

Foodstuff

Fuel

water containing tenside/isopropyl alcohol

water containing tenside

water containing tenside

For materials which are not listed, please request information from IKA application support.

Wear protective gloves during cleaning the device.

Electrical device may not be placed in the cleansing agent

for the purpose of cleaning.

Do not allow moisture to get into the device when cleaning.

Before using another than the recommended method for

cleaning or decontamination, the user must ascertain with

IKA that this method does not destroy the device.

Spare parts order:

When ordering spare parts, please give:

- machine type

- manufacturing number, see type plate

- item and designation of the spare part see www.ika.com

- software version.

Repair:

Please send in device for repair only after it has been

cleaned and is free from any materials which may

constitute a health hazard.

For repair, please request the “Decontamination Certificate” form IKA or use the download printout of it from

IKA website: www.ika.com.

If you require servicing, return the device in its original packaging. Storage packaging is not sucient. Please also use

suitable transport packaging.

15

Page 16

Technical data

T25 easy clean digital T25 easy clean control

Operating voltage VAC 220 ... 240 ± 10 %

100 ... 120 ± 10 %

Frequence Hz 50 / 60

Motor rating input W 500

Motor rating output W 400

Volume range (H

Maximum viscosity

Speed range rpm 3000 ... 25000

Speed deviation ± 2% of current speed

Speed display LED

Speed adjustment stepless

Noise without dispersion tool dB (A) ≤ 70

Extension arm (Ø x L) mm 13 x 160

Temperature display no LED

Temperature display resolution °C - 0.1

Timer function yes

Timer display LED

Permit on time % 100

Dimension (W x D x H) mm 89 x 161 x 270

Weight kg 3.0

Permissible ambient temperature °C + 5...+ 40

Permissible relative humidity % 80

IP code according to EN 60529 IP 30

Interface USB USB, bluetooth

Operation at a terrestrial altitude m maximum 2000

O) l 0.001 ... 2

2

mPa•s

5000

Subject to technical changes!

Warranty

In accordance with IKA warranty conditions, the warranty

period is 24 months. For claims under the warranty please

contact your local dealer. You may also send the machine

direct to our factory, enclosing the delivery invoice and giving reasons for the claim. You will be liable for freight costs.

The warranty does not cover worn out parts, nor does it

apply to faults resulting from improper use, insucient care

or maintenance not carried out in accordance with the instructions in this operating manual.

16

Page 17

IKA-Werke GmbH & Co.KG

Janke & Kunkel-Str. 10

D-79219 Staufen

Tel. +49 7633 831-0

Fax +49 7633 831-98

sales@ika.de

www.ika.com

Loading...

Loading...