Page 1

20000015716

STARVISC 200-2.5 control_062018

IKA STARVISC 200-2.5 control

Page 2

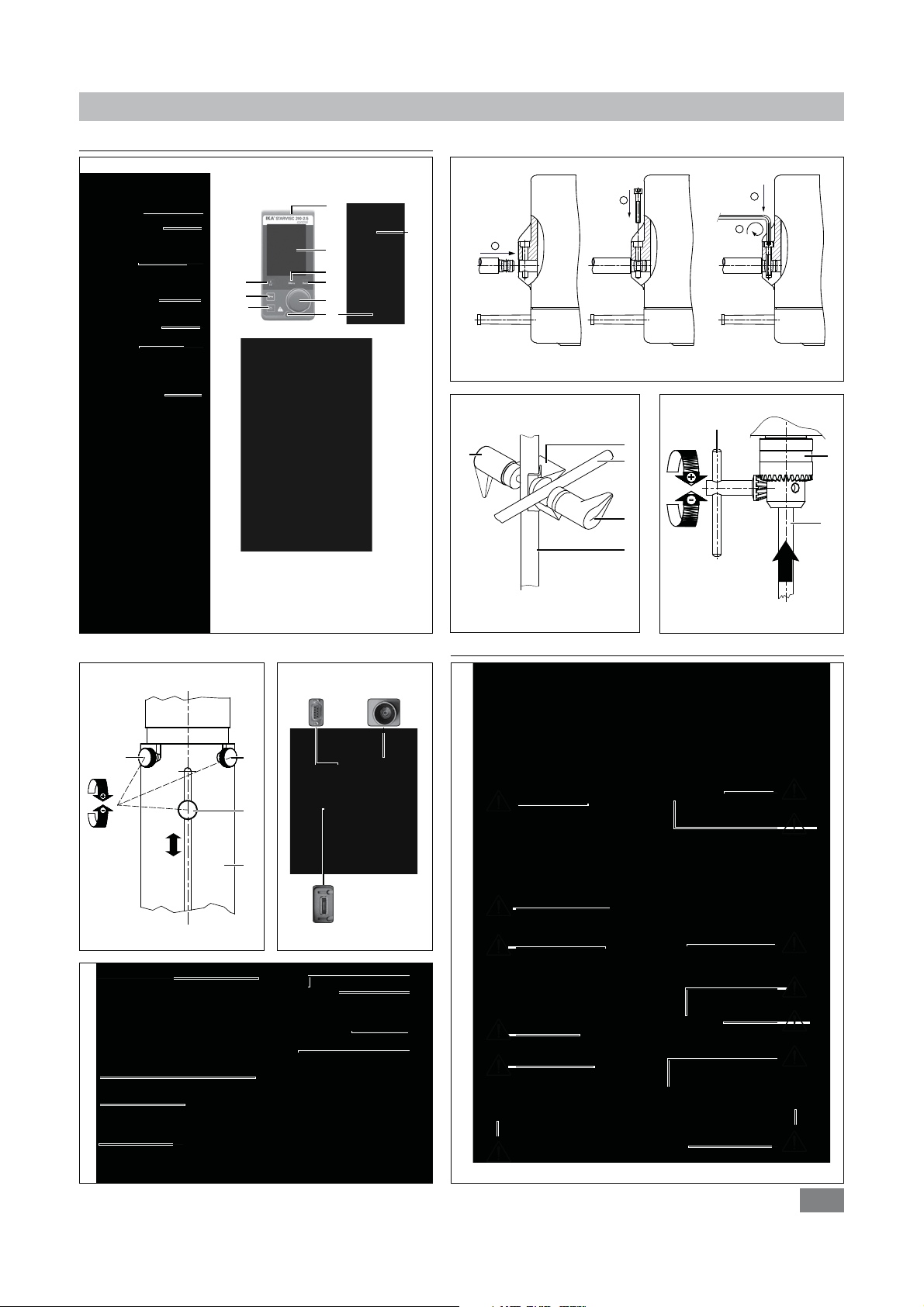

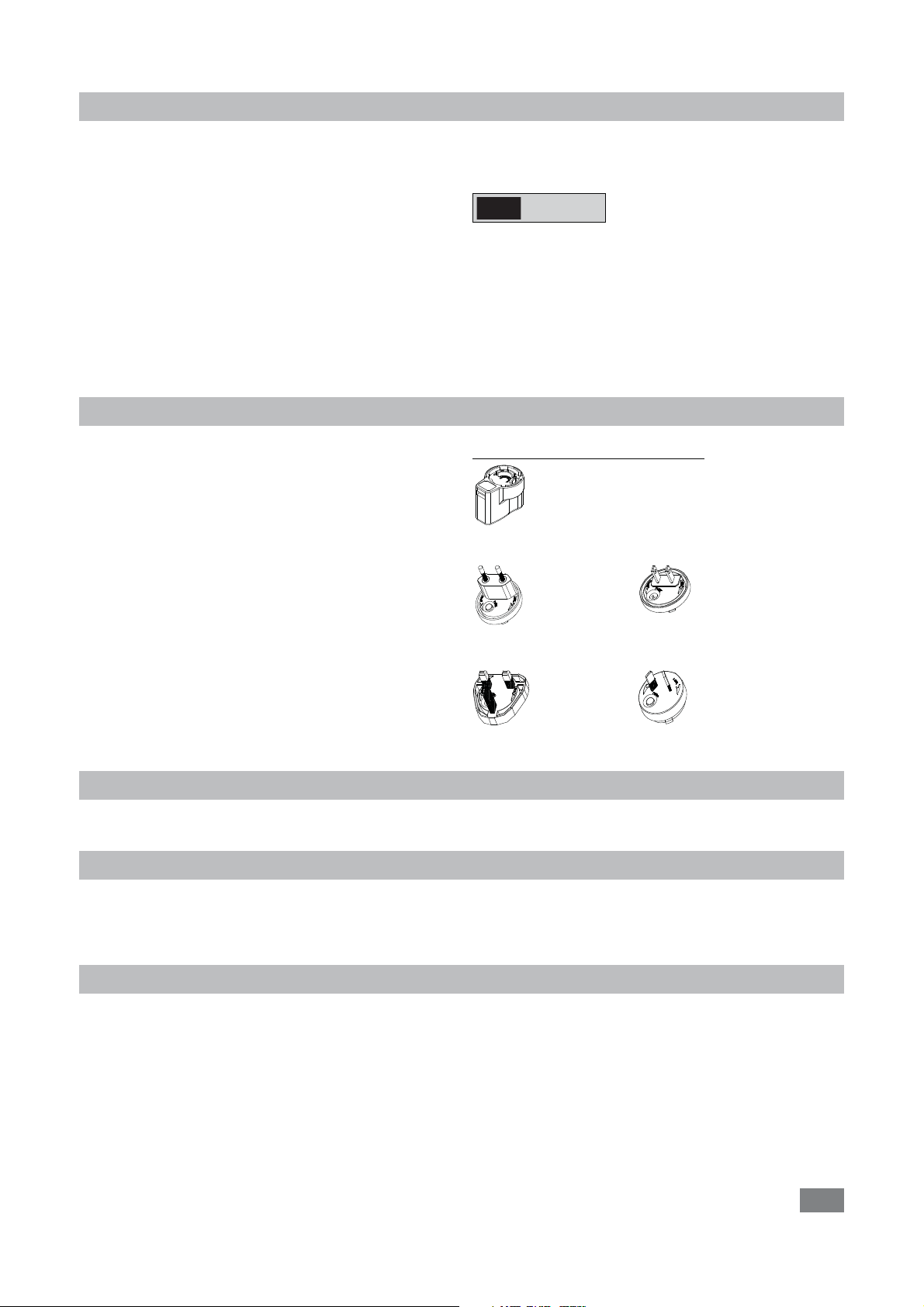

Device setup

Device setup / Dangerous parts

STARVISC 200-2.5 control

station

G

H

A

Wireless Controller

(WiCo)

E

F

K

L

M

I

J

D

Q

C

N

O

B

P

1

2

3

4

Fig. 2

K

Fig. 3

H

J

G

I

L

M

Fig. 4

G

Fig. 1

Dangerous parts

RS 232

T

U

U

S

Q

Fig. 5 Fig. 6

G

X

W

Temp. Sensor

USB

H

Z

G

I

V

Fig. 7

Fig. 8

2

Page 3

Source language: German

EN

Contents

Page Page

Device setup / Dangerous parts 2

Declaration of Conformity 3

Note for USA (FCC) 3

Note for Canada (IC) 3

Explication of warning symbols 4

Safety instructions 4

Correct use 6

Unpacking 6

Drive 6

Motor protection 6

Speed – normal operation 6

Speed – overload operation 7

Output shaft 7

Speed display 7

Commissioning 7

Securing 7

Switching on the device 9

Useful information 9

WiCo 10

Interfaces and outputs 20

Maintenance and cleaning 22

Error codes 22

Warranty 22

Accessories 23

Permitted IKA stirrer tools 23

Technical data 24

EU Declaration of Conformity

We declare under our sole responsibility that this product corresponds to the regulations 2014/35/EU, 2006/42/EC, 2014/30/EU and

2011/65/EU and conforms with the standards or standardized documents EN 61010-1, EN 61010-2-051, EN 61326-1, EN 60529 and

EN ISO 12100.

Bluetooth

Directive: 2014/53/EU Standards: EN 60950-1, EN 300328, EN 301489-1, EN 301489-17

A copy of the complete EU Declaration of Conformity can be requested at sales@ika.com.

®

module:

Note for USA (FCC)

This equipment complies with Part 15 of the FCC rules. Any changes or modifications not expressly approved by the Manufacturer could

void your authority to operate the equipment. This device complies with Part 15 of the FCC rules subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept all interference received, including interference that may cause undesired operation.

NOTE:

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial

environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause

harmful interference in which case the user will be required to correct the interference at his own expense.

Note for Canada (IC)

This device complies with Industry Canada license-exempt RSS standard(s). Operation is subject to the following two conditions:

(1) This device may not cause interference

(2) This device must accept any interference, including interference that may cause undesired operation of the device.

This device complies with Health Canada’s Safety Code 6 / IC RSS-210. The installer of this device should ensure that RF radiation is not

emitted in excess of the Health Canada’s requirement.

3

Page 4

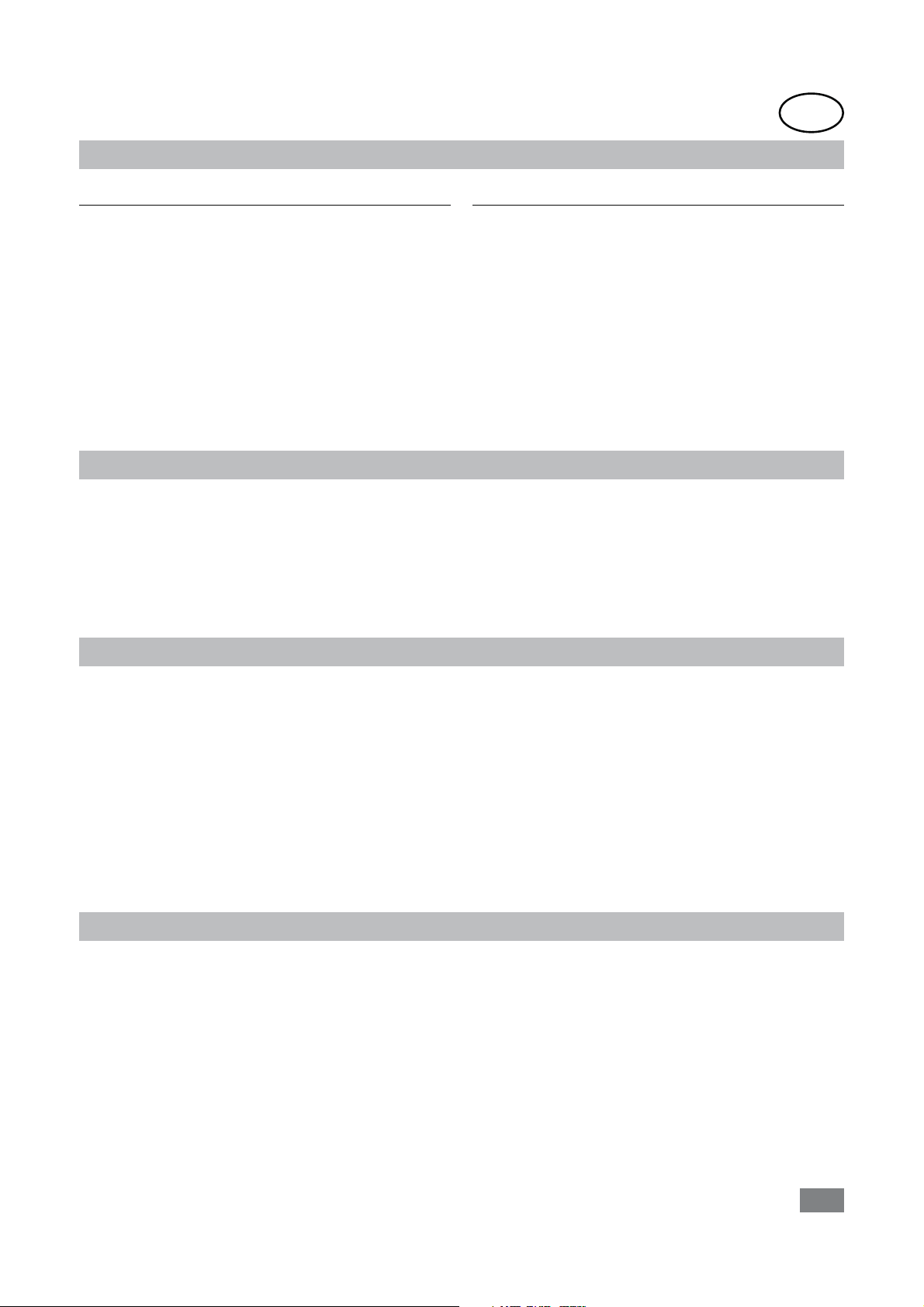

Explication of warning symbols

DANGER

WARNING

CAUTION

Indicates an (extremly) hazardous situation, which, if not avoided, will result in death, serious injury.

Indicates a hazardous situation, which, if not avoided, can result in death, serious injury.

Indicates a potentially hazardous situation, which, if not avoided, can result in injury.

Indicates practices which, if not avoided, can result in equipment damage.

NOTICE

NOTICE

Pay attention to the magnetic field affection.

Safety instructions

•

Read the operating instructions in full before starting up

and follow the safety instructions.

• Keep the operating instructions in a place where it can be accessed by everyone.

• Ensure that only trained staff work with the device.

•

Follow the safety instructions, guidelines, occupational health

and safety and accident prevention regulations.

• Because the options for combining products, tools, stirring vessel, experiment and medium are nearly endless, user safety cannot be ensured simply with design requirements on the part of

the product. For this reason, it may become necessary for users

to take other precautionary safety measures. For example, glass

device or other stirring vessels that are sensitive to mechanical

stress can be damaged or shattered by an imbalance, increasing

the speed too quickly or too little distance between the stirring

element and the stirring vessel. Users can suffer serious injury

from glass breakage or from the freely rotating stirring element.

• Uncontrolled reactions can be triggered by mixing the heated

material insuciently or by the energy generated by selecting a

speed that is too high. In case of these and other increased operational hazards, users must take additional appropriate safety

precautions (e.g. shatter protection). In any case, when using

critical or hazardous materials in your processes, IKA recommends to use additional appropriate measures to ensure safety

in the experiment. For example, users can implement measures

that inhibit fire or explosions or comprehensive monitoring

equipment. Furthermore, users must make sure that the OFF

switch of the IKA product can be accessed immediately, directly

and without risk at any time.

CAUTION

that can be easily accessed must be installed in the work area.

• Only process media that will not react dangerously to the extra

energy produced through processing. This also applies to any extra energy produced in other ways, e.g. through light irradiation.

•

Do not use the device in hazardous areas, it is not EX-proof. In the

case of substances which can form an ignitable mixture, appropriate protective measures, such as working under a fume hood,

must be taken. In order to avoid injury to persons and damage

to property, please observe the relevant protective and accident

prevention measures when processing hazardous substances.

• Process pathogenic materials only in closed vessels under a suitable fume hood. Please contact IKA application support if you

have any question.

If mains switch cannot ensure this access at all

times, an additional EMERGENCY STOP switch

• The device is not suitable for hand-held operation.

• The high torque developed by the device requires particular care

in the choice of stand, cross sleeve and anti-rotation element for

the agitating vessel.

• Set up the stand in a spacious area on an even, stable, clean,

non-slip, dry and fireproof surface.

• You must ensure that the stirring element is securely clamped in

the chuck!

WARNING

• Use stirring shaft protective equipment!

• The agitated vessels used for stirring have to be secured. Consider on a good stability of the entire structure.

WARNING

•

Protect the device and accessories from bumping and impacting.

•

Check the device and accessories beforehand for damage each

time when you use them. Do not use damaged components.

• Safe operation is only guaranteed with the accessories described

in the ”Accessories” section.

• When changing tools device has to be switched off of separated

from mains, because someone else is able to switch on device

via WiCo.

• The device can only be disconnected from the mains supply by

pulling out the mains plug or the connector plug.

• The socket for the mains cord must be easily accessible.

• Socket must be earthed (protective ground contact).

• The voltage stated on the type plate must correspond to the mains

voltage.

•

Please observe the permitted speed for the stirring element. Never

set higher speed.

• Make certain that the unit is set at the lowest speed before commissioning; otherwise, the unit will begin running at the speed

set in last operation. Gradually increase the speed.

•

Pay attention when setting the speed to any imbalance of the stirrer tools and possible spraying of the medium to be stirred.

WARNING

hair, jewelry or items of clothing cannot be trapped by the rotating

parts.

Remove the chuck key from the chuck before turning on the device.

Please pay attention to the dangerous parts

of the equipment in Fig. 8.

Never operate the device with the stirrer tools

rotating freely. Ensure that parts of the body,

4

Page 5

WARNING

medium to be processed, there is a risk of:

- splashing of liquids

- projectile parts

- body parts, hair, clothing and jewelry getting caught.

NOTICE

- flammable materials

-

glass breakage as a result of mechanical shaking power.

NOTICE

- the medium splashes out of the vessel because the speed is too

high

- the device is not running smoothly

- the device begins to move around because of dynamic forces

- an error occurs.

WARNING

• There may be electrostatic activity between the medium and the

output shaft which could cause a direct danger.

• After an interruption in the power supply or a mechanical interruption during a stirring process, the unit does not restart automatically.

•

It is important to note that the surfaces of the motor (cooling

fins) and certain parts of the bearing may get very hot during

operation.

• Never cover the ventilation slots or cooling fins on the motor or

on the device.

• Avoid knocking and impacting on the lower end of the shaft and

the chuck gear teeth. Even minor, invisible damage can lead to

imbalance and uneven shaft action.

• Ensure that the stand does not start to move.

•

Imbalance of the output shaft, the chuck and in particular the stirring tools can lead to uncontrolled resonant vibrational behavior

of the device and the whole assembly. Glass apparatus and stirrer

containers can be damaged or shattered by this. It can cause injury

to the operator, also can damage the rotating stirring tool. In this

case exchange the stirring tool for one without imbalance or rem

edy the cause of the imbalance.

it to the dealer or the manufacturer along with a description of

the fault.

• If the device is operated too long in overload or if the ambient

temperature is too high, the device switches off permanently.

• The device must only be opened by trained specialists, even dur

ing repair. The device must be unplugged from the power supply

before opening. Live parts inside the device may still be live for

some time after unplugging from the power supply.

NOTICE

equipment have to be reattached to the unit for safe operation

in order to prevent, for example, the ingress of fluids, foreign

matter, etc..

NOTICE

depending on the value settings for exceeding the time and safety

speed. If the device is set so that it continues to run when the bat

tery of the WiCo is fully discharged, the only means of switching

the station off are the "safe STOP" and the off switch!

Wear your personal protective equipment in

accordance with the hazard category of the

Beware of the risk of:

Reduce the speed if:

Do not touch rotating parts during operation!

-

If there is still imbalance, return

-

Covering or parts that are capable of being

removed from the unit without accessory

If during operation the battery pack RB 1 (rechargeable battery) becomes fully discharged,

the device will continue to run or is shut down

-

NOTICE

• Keep the battery pack out of reach of children at all times.

• Store the battery pack in a cool, dry place.

• Never throw the battery pack into a fire. Keep it away from direct sunlight and temperatures above 60 °C. High temperatures

will damage the battery pack and render it unusable. Temperatures above 100 °C may cause it to explode.

• Never throw the battery pack into water or expose it to moisture. Water may lead to a short-circuit, causing the battery pack

to explode.

•

Do not deform or crush the battery pack or damage it in any

other way. This can cause battery fluid to leak and/or the battery pack to explode.

• When not in use, keep battery packs away from paperclips,

coins, keys, nails, screws or other small metal objects which

could cause the contacts to be bridged. Short-circuiting may

result in an explosion.

• Explosion of a battery pack may release battery fluid and cause

a fire.

• The lithium polymer battery pack must only be used and charged

in IKA products designed for use with this battery pack.

• When the battery pack is inserted it should slide in easily and

without resistance. Do not force it.

• If the battery pack is removed for an extended period of time,

store it in a sealed plastic bag to prevent short-circuiting due to

moisture or contact with metal components.

• The operating temperature range of the battery pack is from

0 °C to +45 °C. Note that the battery pack capacity will be reduced at temperatures below 20 °C.

•

Only the rechargeable battery types recommended in the technical data may be used in the device!

Do not charge batteries that have leaked or that are discolored, deformed or damaged in any other way.

Disposal instructions:

• When disposing of the IKA battery pack, please tape over the

contacts with adhesive tape to prevent short-circuiting due to

moisture or contact with metal components. Short-circuiting may

result in an explosion.

• Do not throw used battery packs into your household waste. Dis-

pose of them properly in accordance with statutory regulations.

End users are obliged by law to return all used disposable

and rechargeable batteries. Throwing them into the house-

hold waste is prohibited. Disposable/rechargeable batteries

containing harmful substances are marked with this symbol to

indicate that they may not be disposed of as household waste.

• You can return used disposable and rechargeable batteries free

of charge to your local authority collection site or to any battery

retailer. In doing so you will be complying with statutory regulations and helping to protect the environment.

• Batteries must be disposed of in accordance with local and national regulations.

Please note the following safety instructions for the battery pack RB 1 (rechargeable battery):

5

Page 6

Correct use

• Use:

For mixing/stirring liquids with low and high viscosities by various stirring tools.

Intended use: Stand device (chuck points down).

• Range of use (indoor use only):

- Laboratories -

- Pharmacies - Universities

ireless remote control:

• W

Before using the wireless link between the WiCo and the laboratory device, first check whether your region is included in the

radio communications approval for the device. If it is not, remote

control can also be performed using a USB cable.

Schools

Unpacking

The device is suitable for use in all areas (EMC class A and B).

NOTICE

The safety of the user cannot be guaranteed:

- if the device is operated with accessories that are not supplied or

recommended by the manufacturer.

- if the device is operated improperly or contrary to the manufacture’s specifications.

-

if the device or the printed circuit board are modified by third parties.

Note: close to the magnetic material

may affect the accuracy of the torque

measuring.

• Unpacking:

- Unpack the device carefully.

- Any damage should be notified immediately to the shiping

agent (post, rail or logistic company).

• Delivery scope:

- STARVISC 200-2.5 control station with a WiCo

- Extension arm

- Hexagonal socket screw

- Hexagon socket offset screw key

- Chuck key

- Protective cover

- Pt 1000 temperature sensor

- OS 1.0 power supply unit

- USB 2.0 cable (micro A – micro B)

- USB 2.0 cable (A – micro B)

- User guide

- Warranty card

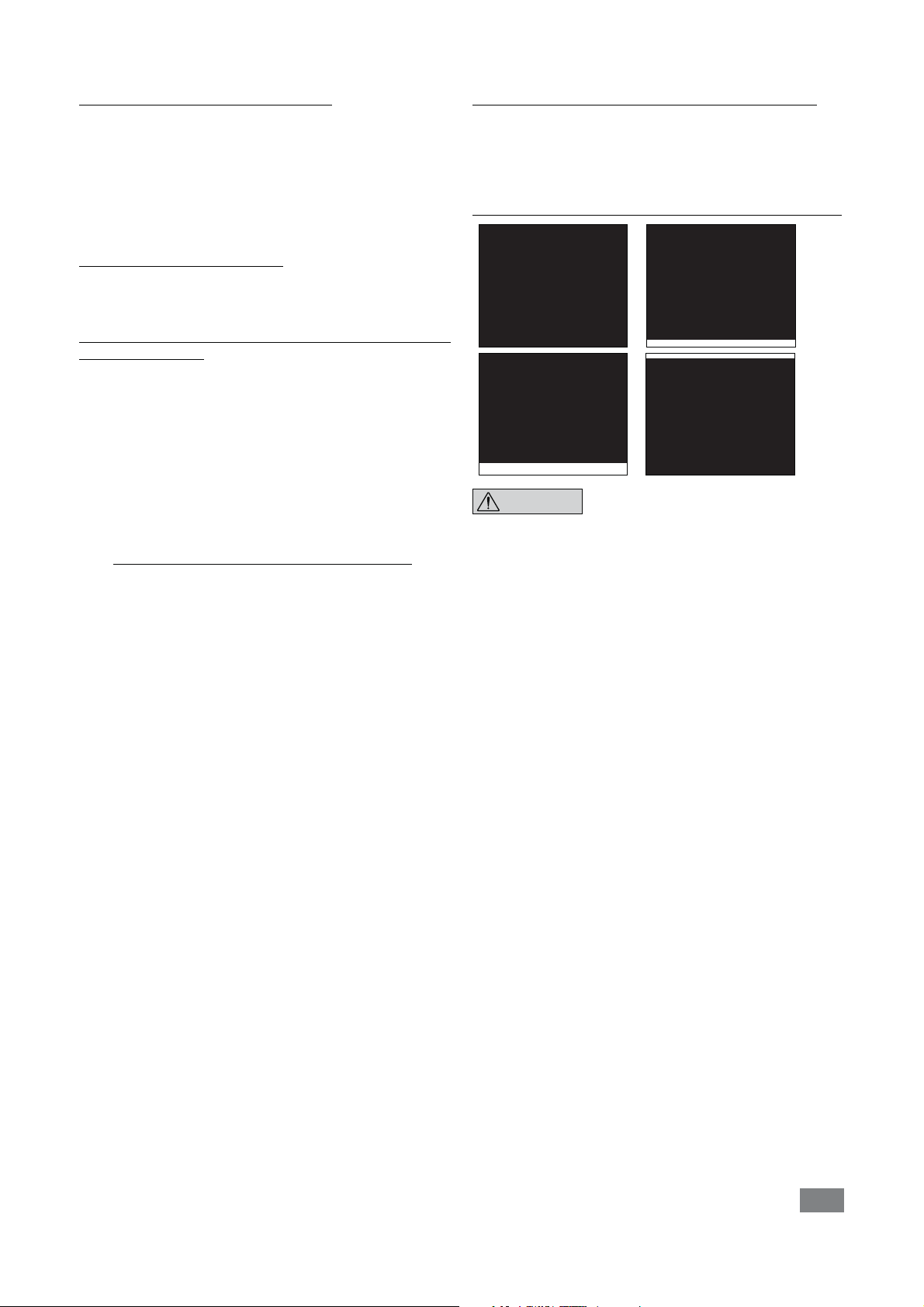

OS 1.0 power supply unit (for WiCo):

Adapter

Europe, Switzerland

Adapter

England

Adapter

USA, China

Adapter

Australia

Drive

The rotary knob (B, see Fig. 1) of the WiCo allows the speed of the stirrer to be adjusted over the entire speed range.

Motor protection

The stirring device is suitable for continuous operation. The motor

current is limited electronically. The device has an anti-stall and

anti-overload system.

Speed – normal operation

Speed - regulated (no variation in speed):

The speed is monitored and regulated by processor controlled.

The target speed is constantly compared with the actual rotation speed value of the output shaft and variations corrected. This

guarantees a constant speed even if the viscosity of the substance

being stirred changes.

If a fault occurs, a safety circuit immediately switches off the motor permanently through a relay in the power board. A fault occurs

if the safe functioning of the device is compromised.

Fluctuations in mains voltage within the permitted tolerance range

have no effect on the quality of regulation and constancy of speed.

The speed is set using the front knob (B, see Fig. 1). During normal

operations the speed value on the display (C, see Fig. 1) corresponds

to the speed of the output shaft in revolutions per minute (rpm).

6

Page 7

Speed – overload operation

In order to overcome peaks in the load such as arise when a solid

or viscous medium is added, the stirrer can be run for a brief period at twice its rated power. When running in the overload range

(for instance if the viscosity has increased at a particular stage of

the process) the speed will be reduced to a degree sucient to

keep the torque on the stirrer shaft within the rated torque of the

device.

The speed is continually adjusted whilst the stirrer is running to

correspond to the operating conditions and so that it matches the

set speed as closely as possible.

Output shaft

The clamping chuck and output shaft permit clamping IKA recommend stirrer tools (see section “Permitted IKA stirrer tools“).

For safety reason, the stirrer cover must be pushed back into the

opening of the housing so that it is properly closed. This is the only

way to ensure that working with the unit is safe and that media

cannot enter the device.

Speed display

Overload status 1:

The device is already running within the overload range, whereby

the actual speed does not match the set speed. This condition is

maintained as long as neither the motor current nor the temperature exceeds their permissible limit value.

This is indicated by the torque value flashing in the display.

Once the load reduces to a value within the normal range again,

the torque value ceases to flash.

Overload status 2:

If the device is subjected to a fluctuating load which causes the

torque to be more than double the normal torque, the actual

speed of the stirrer shaft is quickly reduced to zero.

Message in the display: Error 4 (see “Error codes” section).

NOTICE

Please see section “Safety instructions“!

The speed is set using the rotary knob (B, see Fig.1) on the front

of the WiCo.

Commissioning

Assemble the overhead stirrer and all necessary accessories on a

stable, even, non-slip surface. The overhead stirrer must be secured

to a stable stand (e.g. R 2722 or R 2723) with a cross-sleeve (e.g.

R 270). The stirring vessel must always be securely fixed for safety

reasons. You must also ensure that the mounting device (stand) is

set up in such a way that it is not liable to topple and does not start

to move during the stirring procedure.

Securing

Securing the extension arm to the overhead stirrer

Diagram (see Fig. 2)

Ensure that the extension arm is fitted securely.

Vibration may cause the screw to become loose. It is therefore

necessary for safe use to occasionally check that the extension

arm is attached securely. Tighten the hexagonal socket screw as

required.

Securing the overhead stirrer to the stand

Diagram (see Fig. 3)

First secure the cross sleeve (H) to the stand (I). Then secure the

extension arm (J) of the overhead stirrer in the open side of the

cross sleeve which is facing upwards. Once you have set the position required for the stirring procedure, firmly tighten the two

clamping bolts (G).

Check that the stirrer is held in position firmly prior to each use and

also at regular intervals. The position of the stirrer must only be

adjusted when the equipment is stationary and the power supply

is disconnected.

The speed is displayed directly in revolutions per minute (rpm) in

the display (C, see Fig.1) of the WiCo.

Accessories must be assembled according to the

bly instructions (Fig. 2 to

Securing the stirring element using the chuck

Diagram (see Fig. 4)

Slide the stirring element (M) into the chuck (L). Tighten the chuck

firmly using the chuck key (K).

The stirring element must only be changed when the equipment is

stationary and the power supply is disconnected.

Securing the stirring shaft protector

Diagram (see Fig. 5)

Use a stirring shaft protector (Q), e.g. R 301, to provide protection

against injury when working with the device.

Use the bolts (U) to attach the plastic half-shell pieces to the stirrer (T), as shown in Fig. 5. The screw (S) can be used to adjust the

length of the stirring shaft protector.

Check that the stirring shaft protector is held in position securely

prior to each use and also at regular intervals. The position of the

stirring shaft protector must only be adjusted when the equipment

is stationary and the power supply is disconnected.

Fig. 7).

If above conditions are met, the device is

ready for operation after plugging in the

mains plug.

following assem-

7

Page 8

Securing the mixing vessel to the stand

Diagram (see Fig. 7)

First fix the cross sleeve (H) to the stand (I).

Then attach the bracket (Z) of the strap clamp in the open side of

the cross sleeve which is facing upwards according to the position

of stirrer and the mixing vessel, firmly tighten the two clamping

bolts (G).

Clamp the mixing vessel (V) with the flexible clamping band (W) and

secure the flexible band (W) by means of the clamping lever (X).

Securing the WiCo to the stirrer

Diagram (see Fig. 1)

Attach the WiCo to the charging contact provided on the station,

and bolt it to the station with the screw (P).

Connection of the temperature sensor, USB and RS232

cables to the stirrer

Diagram (see Fig. 6)

The USB, RS 232 or temperature sensor cable should be plugged

into the appropriate port after the covers have been removed as

shown in Fig. 6.

Once the device has been connected to the PC using the USB data

cable, it will then transmit information to the Windows operating

system to tell it which device drivers are required. Windows will

then either:

- Load the driver

- Install the driver automatically, if it is not already installed

- Prompt you to perform a manual installation

Open http://www.ika.com/ika/lws/download/usb-driver.zip.

Charging the RB 1 battery pack (rechargeable battery)

The battery pack of the WiCo can be charged by any of the following means:

- on the station

- via a USB cable at the PC or station

- via an OS 1.0 power supply unit.

Replacing the RB 1 battery pack in the Wireless Controller

NOTICE

Please comply with the relevant safety

instructions in the "Safety instructions"

section for the RB 1 battery pack!

8

Page 9

Switching on the device

Check whether the voltage given on the type plate corresponds to

the available mains voltage.

The socket used must be earthed (fitted

with earth contact).

If these conditions have been met, the machine is ready for operation when the mains plug is plugged in.

If these conditions are not met, safe operation is not guaranteed

and the machine could be damaged.

Before the first time to use the stirrer, fasten the WiCo to the station with the screw (P, see Fig. 1), so that the rechargeable battery

(RB1 battery pack) in the WiCo can be charged.

After the device has been switched on at the mains switch (A, see

Fig. 1) the device name and software version appear in the display

(C, see Fig. 1) of the WiCo (D, see Fig. 1). After a few seconds a

signal sounds, the last setting of speed is displayed (mode B).

Once

the working screen is displayed, the stirrer is ready for operation.

If the WiCo is switched on and is not attached to the stirrer (the station), the green LED bar (G, see Fig. 1) and the green Bluetooth

®

LED

(F, see Fig. 1) on the stirrer (station) will light up. Make sure that the

speed selected is appropriate for the trial run. If in doubt, use the

rotary knob (B, see Fig. 1) to select the slowest speed. To start or stop

the stirrer function, press the rotary knob (B).

The control elements of the WiCo can be disabled by pressing

the button (L

, see Fig. 1

) about 2 seconds, so that no inadvertent

changes are made while the device is running (the lock symbol

appears in the display).

Presse the button (L) about 2 seconds enables the control elements again (lock cymbol

disappears from the display).

NOTICE

In emergency the stirrer (station) can be

switched off by pressing the “safe STOP“

button (I, see Fig.1) on the front of the stirrer. In this case the LED

bar (G, see Fig.1) changes color from green to red, and flashes.

A message appears on the display, advising that the stirrer (station)

has been forcibly switched off. To restart the stirrer, switch the main

sswitch (A, see Fig. 1) of the stirrer (station) OFF and ON.

If the Bluetooth® function of the WiCo is active, you can use the

Bluetooth

®

search button (H

, see Fig. 1

) to search for the WiCo. A

beep signal will be audible even if the WiCo is switched off.

• Speed setting:

You can use the rotary knob (B, see Fig. 1) to pre-set the required

speed before you start the device. If you then press the rotary

knob(B) the device starts at the speed you set. When a change

is made to the speed, the rated speed is shown in the display (C,

see Fig. 1). When the device is stopped, the button (K, see Fig.

1) can be used to switch between the two speed ranges (I and

II). When in standby mode, the display (C) shows the set speed.

The stirrer has two different speed ranges:

Range I: low speed, high torque.

Range II: high speed, low torque.

• Correct procedure for changing the speed range:

- Switch the device off at the rotary knob (B, see Fig. 1).

- Switch the speed range with button (K, see Fig. 1).

- Change the speed with the rotary knob (B).

- Switch the device on at the rotary knob (B).

- The speed can be varied at any time in operation.

- The speed appears in the display (C, see Fig. 1).

Useful information

The stirrer is controlled via a WiCo. If the WiCo is attached to the

station, data exchange between the stirrer (station) and WiCo

is performed via the contacts (E, Q, see Fig. 1). "Home" symbol

appears on the display of the WiCo. If the WiCo is connected

to the stirrer (station) via a USB (Universal Serial Bus) cable, the

symbol appears. If the WiCo is neither bolted to the station

nor connected to the stirrer (station) via a USB cable, the data

exchange between the stirrer and WiCo is performed via Blue-

®

tooth

. In this case the Bluetooth® symbol is displayed.

Depending on the structure of the building, the WiCo can be operated at a distance of up to 150 m from the station, using the

Bluetooth

®

connection.

The WiCo can be attached to the stirrer (station), or can be installed in a safe place easily accessible by you while the stirrer is

running.

If the WiCo is attached to the station, the rechargeable battery

is automatically recharged via the contacts (Q, see Fig. 1). The rechargeable battery can also be charged via the USB port of the

WiCo (see “Charging the RB 1 battery pack (rechargeable battery)“

in the “Securing“ section).

NOTICE

If the stirrer (station) generates vibration, the

WiCo must be bolted to the stirrer using the

screw (P, see Fig. 1), or positioned remotely from the stirrer (station) whilst it is running.

9

Page 10

Control elements of the WiCo:

Item Designation

M On/Off button: Switching the WiCo on and off

L Lock button: Disable buttons and rotary / push knobs

N Menu button: Press it once: main menu is displayed

Press it a second time: back to the working screen

N

K

L

M

B Rotary/push knob: Navigation, selecting and changing the settings in the menu

O

O Back button: Return to the previous menu level / reset the torque

K Gear button: Change the gear in different speed / torque ranges

B

Note: Can be activated only when the station is in stand-by mode.

WiCo

Working screen at the time of delivery:

Torque:

Reset Torque

Timer:

,

B

0.0 Ncm

J

00:00:00

The start screen appears for a few seconds after

the WiCo is switched on. The device name and

Back

the software version are displayed. After this, the

following working screen appears automatically

0

in the display.

actual rpm

Note: The wireless symbol appears only when

set rpm

the stirrer (station) is switched on.

Explanation of symbols on the working screen:

Torque:

Temp.:

Timer:

00:00

PC

controlled

B

100

45.0

99:00:00

,

LIMIT 2000

The symbols displayed change depending on the

Ncm

status and settings of the WiCo. The screen be-

ºC

low shows the most significant symbols on the

working screen.

300

actual rpm

rated rpm

Bluetooth®:

This symbol means the station and the WiCo are communicating

via Bluetooth

The symbol no longer appears if no Bluetooth

®

.

®

communication is

being performed.

Lock:

This symbol means that the function of the buttons and of the

rotary knob for controlling the WiCo are locked.

The symbol no longer appears if the functions are unlocked once

again by pressing the lock button a second time.

B Operating mode:

This symbol indicates the operating mode currently selected (A,

B, C).

USB:

This symbol means the station is communicating via a USB cable.

The symbol no longer appears if no USB cable is being used for

communicating with the station.

Home:

This symbol means that the WiCo is connected to the station and

is communicating with the station via the charging contacts.

The symbol no longer appears if the WiCo is removed from the

station.

Battery pack (rechargeable battery):

This symbol indicates the charging status of the RB 1 battery pack

within the WiCo.

The charging symbol appears if the WiCo

- is connected to a PC via a USB cable

- is connected to a station via a USB cable

- is connected to the power supply unit OS 1.0 via a USB cable

- is connected to the station via the charger contacts.

Gear ratio (speed range):

The stirrer has two different speed ranges:

Range I: low speed/high torque.

Range II: high speed/low torque.

LIMIT Speed limit:

This symbol indicates upper speed limit set for the stirrer. The setting

of the device in delivery status is the maximum permissible speed

of the stirrer.

Temperature sensor:

This symbol appears when the temperature display is active in the

display.

PC

controlled PC control symbol:

This symbol means that either the station or the WiCo is connected to a computer and the stirrer is being controlled from the

computer.

PR

controlled

Program control:

This symbol means the device is controlled by user defined program.

Continuous mode:

This symbol indicates that the stirrer is in continuous mode and

indicates the direction of rotation of the stirrer.

00:00

Intermittent mode:

This symbol indicates that the stirrer is in intermittent mode.

10

Page 11

Navigation menu and menu structure:

Menu navigation:

) Press the "Menu" button (N).

) Select the menu by turning the rotary/push knob (B) to the right or left to select the desired menu or

sub-menu, which can then be selected by pressing the rotary/push knob.

) Press or turn the rotary/push knob (B) again to select the desired menu option and edit the values or

settings, or activate/deactivate a function.

)

Turn the rotary/push knob (B) to "OK" and press the "Back" button (O) or "Menu" button (N) to end the

procedure and return to the previous menu or working screen.

N

Note: The menu option activated is highlighted yellow in the display.

O

Navigation menu: ¼ Press the “Menu“ button (N) and turn the rotary/push knob (B)

» Press the "Back" button (O) or the "Menu" button (N)

B

Navigation control

elements in the menu

B

00:00:00

,

0 Ncm

J

actual rpm

Torque:

Reset Torque

Timer:

Note: If you press the “Menu“ button (N), the system skips directly back to the working screen.

If you press the “Back“ button (O), the system skips back to the previous display.

set rpm

Menu

Back

0

Menu

Tempe

0

Back

Stirring

Back

Menu

Stirring

Speed Limit

Torque Limit

Torque Display

Intermittent Mode

Torque Calibration

Back

h Stirring

Speed Limit

Speed Limit

2000

OK

rpm

11

Page 12

Menu structure:

Stirring

Viscosity

Temperature

Timer Set

Menu

Operating Mode A

Display Torque

Programs

Safety

Settings Languages

Speed Limit

Torque Limit

Torque Display

Intermittent Mode

Run/Stop

Torque Calibration

Density

Stirrer

Display

Auto Zeroing

Maximum Speed

Probe Temperature

Display

Display

B

C

Temperature

Timer

Viscosity

Program 1

Program 2

...

Time Out

Safe Speed

assword

P

English

Deutsch

Units Temperature ºC

Display

...

Background

Brightness

Firmware Update Info

Sound

Factory Settings

Communication

Volume

Key Tone

Device Name

Remote Control

Bluetooth

Information

Stirring

Safety

Software

Firmware Update Info

Run TimeInterval

Stop Time

ºF

Black

White

Standard Mode

Battery Mode

WiCo

Other

Max Speed

Max Torque

Interval Run

Interval Stop

Time Out

Safe Speed

Version

Station Version

Operating Mode

Factory settings

2000 rpm

200 Ncm

activated

00:00 [mm:ss]

00:00 [mm:ss]

-

1.000 g/cm

3

R 1345 HV

-

-

-

-

00:00:00 [hh:mm:ss]

activated

activated

-

activated

activated

-

yes

-

-

00:30 [mm:ss]

100 rpm

000

activated

-

activated

activated

60 %

20%

activated

100 %

-

IKA Starvisc

activated

activated

yes

yes

yes

yes

yes

yes

yes

yes

yes

yes

12

Page 13

Menu (details):

Stirring:

Speed Limit:

The ”Speed Limit” menu allows the user to set the desired maximum upper speed limit for the stirrer. The initial setting is the maximum permissible speed of the stirrer. If the user changes this setting, the WiCo saves the new value for future stirring tasks.

If the “Speed Limit” has been changed, then the speed can be

adjusted only within the new range.

Torque Limit:

The ”Torque Limit” menu allows the user to set the desired maximum deliverable torque limit. The initial setting is the maximum

permissible torque of the device.

If the user changes this setting, the WiCo saves the new value for

future stirring tasks.

If the “Torque Limit“ has been changed, the stirrer can deliver an

operating torque only up to the value specified as the maximum

torque limit.

Note: The torque limit can be overload for about 10 seconds. This

is necessary to cater for stirring tasks which require metering and

feeding additives.

Intermittent Mode:

Torque Display:

The ”Torque Display” menu allows the user to specify that the

torque is shown in the display. A tick shows that the option is

activated.

Note: Pressing the "Back" button while the device is running resets the torque to 0 Ncm. The Δ symbol then appears in the display in front of the torque value.

Symbol rotation

direction

Chuck rotation

direction

Speed

Time

Graph

Factory setting: continuous mode

CW

∞ / CW...

Speed

Function “Run / Stop“ is activated:

Time

CW

Run-Stop-Run / CW ...

Fig. 9

Torque Calibration:

This menu allows the torque to be calibrated. All torque resulting from bearing friction is excluded from the torque calculation. This is

performed with no stirrer element attached. A duration of 30 sec. and speed of 50 rpm are set automatically.

Note: Calibration can be performed only when a USB cable is being used. For this, remove the WiCo from the station (see "Interfaces

and outputs" section, figure “Connection capability: WiCo to the EUROSTAR station“).

The run time and stop time can be set separately.

13

Page 14

Viscosity:

Density:

In order to measure the kinematic viscosity of a certain medium, the

user need to input the density of the medium. Changing the density

by rotating knob (B).

Stirrer:

Before measuring the kinematic viscosity, select a proper stirrer tool.

Meanwhile, set the correct stirrer tool accordingly in the menu option by rotating knob (B).

Definition of the viscosity range:

mpa·s

VLV (Very Low Viscosity) 1 ... 100 Aqueeous media

LV (Low Viscosity) 100 ... 1000 Light oil

MV (Medium Viscosity) 1000 ... 10000 Heavy oil

HV (High Viscosity) 10000 ... 100000 Pastes, creams

Measuring condition:

Propeller stirrer: R 1345

Suitable for measuring viscosity range

(mpa

·s

):

HV: 10000 up to 100000

R 1345

Optimum speed (rpm) and permissible

speed range in viscosity range:

HV: 200 (50 ... 300)

Measuring error max.: ± 13%.

Sample volume: 1000 ml

Necessary beaker: HF 2000 DIN 12331

2000 ml, high shape.

240 mm

20 mm

1000 ml

120 mm

Measuring condition:

Dissolver stirrer: R 1302

Suitable for measuring viscosity

range (mpa

HV: 10000 up to 100000

·s

):

R 1302

Optimum speed (rpm) and permissible speed range in viscosity

range:

HV: 200 (50 ... 400)

Measuring error max.: ± 12%.

Sample volume: 1500 ml

Necessary beaker: HF 3000

210 mm

1500 ml

DIN 12332 3000 ml, low shape.

10 mm

Measuring condition:

Paddle stirrer: R 1375

Suitable for measuring viscosity range (mpa

·s

):

HV: 10000 up to 100000

Optimum speed (rpm) and permissible speed

range in viscosity range:

HV: 100 (50 ... 250)

R 1375

Measuring error max.: ± 16%.

Sample volume: 600 ml

600 ml

Necessary beaker: HF 800

DIN 12331 800 ml, high shape.

170 mm

10 mm

86 mm

Measuring condition:

Anchor stirrer: R 1330

Suitable for measuring viscosity range (mpa

·s

):

HV: 10000 up to 100000

Optimum speed (rpm) and permissible speed

range in viscosity range:

R 1330

HV: 300 (100 ... 400)

Measuring error max.: ± 5%.

Sample volume: 200 ml

Necessary beaker: HF 250

200 ml

112 mm

DIN 12331 250 ml, high shape.

5 mm

62 mm

Measuring condition:

Anchor stirrer: R 1331

Suitable for measuring viscosity range

(mpa

·s

):

R 1331

HV: 10000 up to 100000

Optimum speed (rpm) and permissible

speed range in viscosity range:

HV: 300 (50 ... 300)

Measuring error max.: ± 4%.

Sample volume: 1700 ml

1700 ml

Necessary beaker: HF 2000

DIN 12331 2000 ml, high shape.

240 mm

10 mm

120 mm

Display:

When you need to show the viscosity on the screen, you need active the “Display“ under “Viscosity“ menu option and meanwhile

deactivate one of “Torque”, “Temperature” or “Timer” display.

150 mm

14

Page 15

Auto Zeroing:

For compensation mechanical friction and grease viscosity, you must auto-zero the device before you measure the viscosity:

Before auto-zeroing, empty the vessel according to the reminding of the WiCo firstly.

Set the maximum speed higher a little than the select speed in the following viscosity measuring.

For example: when you use R 1345 HV and the optimum speed (200 rpm) to measure a medium viscosity, the maximum speed should

be set as about 210 to 250 rpm.

The zeroing processing will take about 150 seconds.

Viscosity measuring:

In order to achieve optimum measurement result, the device should run idle (without stirrer tool) more than 30 minutes at the speed 2000

rpm. Then, perform auto zeroing as above instructions.

After auto zeroing, you can start to measure the medium viscosity as following:

) Input the density for the test medium.

) Select the stirrer tool as required.

) Active the viscosity display.

) Back to working screen and set speed for measuring.

) Start to run the device.

Ö Read the viscosity value when the figure get steady.

Note: The formulas for calculating the viscosity have been put together for the respective viscosity range with the vessels listed and the

stirring elements appertaining thereto, based upon the physical laws and taking into account the smallest error square out of more than

20 measuring values (with Newtonian calibration oils at 22 ºC).

Measuring error calculating formula:

B - A

A

A – Standard oil viscosity

= X %

B – Measured viscosity

Example for viscosity measuring:

When you measure a medium in following status:

Kinematic viscosity range: 10000 mpa·s to 100000 mpa·s

Medium density: 0.980 g/cm

3

Stirrer tool: R 1302

1. Warm up the device:

Remove the stirrer tool from the device and switch the device to range II (high speed range). Run the device with speed 2000 rpm

more than 30 minutes.

2. Perform auto Zeroing to the device:

Stop the device and enter the menu option "Auto Zeroing" under "Viscosity".

Press on "OK" in "Empty the vessel" screen.

Set the maximum speed (e.g.:210 rpm) to the auto zeroing. The maximum speed should be higher a little than the speed that will be

used for viscosity measuring in next step.

Press on "OK" to start the auto zeroing. This process will take about 150 seconds.

Menü

Viskosität

Viskosität

Dichte

R

ührer

Display

Automat. Nullabgleich

> Viskosität

Automat. Nullabgleich

Gefäß leeren!g

> Viskosität

Automat. Nullabgleich

Max. Drehzahl:

50 rpm

> Viskosität

Automat. Nullabgleich

Max. Drehzahl:

210 rpm

> Viskosität

Automat. Nullabgleich

Max. Drehzahl:

210 rpm

> Viskosität

Automat. Nullabgleich

Bitte warten...

OK

OK

OK

OK

15

Page 16

3. Set the medium density:

Set the medium density by rotating the knob.

Press on "OK" to confirm the setting.

Viskosität

Dichte

Rührer

Display

Automat. Nullabgleich

> Viskosität

Dichte

1.000 g/cm

3

> Viskosität

Dichte

0.980 g/cm

> Viskosität

Dichte

3

0.980 g/cm

3

OK

OK

OK

4. Select the stirrer tool:

Select the proper the stirrer tool: R 1302 HV.

Press on "OK" to confirm the setting.

Viskosität

Dichte

Rührer

Display

Automat. Nullabgleich

> Viskosität

Rührer

R 1345 HV

OK

> Viskosität

Rührer

R 1302 HV

OK

> Viskosität

Rührer

R 1302 HV

OK

5. Activate the viscosity display:

Viskosität

Dichte

Rührer

Display

Automat. Nullabgleich

Viskosität

Dichte

Rührer

Display

Automat. Nullabgleich

Note: after backing to the working screen, if the viscosity is not shown, please enter menu "Display" and deactivate one of

"Torque", "Temperature" or "Timer".

Then, activated the viscosity display.

6. Secure proper vessel and stirrer tool:

Switch off the device and secure stirrer tool R 1302 to the stirrer. Then, secure the

3000 ml low shape beaker (DIN 12332) to the assembly.

See section "Securing".

7. Fill 1500 ml the medium to the vessel.

8. Set the speed range and test speed:

Switch on the device. Set the device to speed range I (high torque) and set the speed to 200 rpm.

9. Start measuring and read the viscosity value:

Start the measuring by pressing the knob and the device starts to run with the set speed. Read the viscosity value when the figure get

steady.

Temperature:

In the ”Temperature” menu the user can specify that the temperature sensor is displayed on the display/working screen. A tick

shows that the option is activated. The precondition for this is that

a temperature sensor is connected to the EUROSTAR station. If

no temperature sensor is connected, or an error is present or the

temperature rises above 350 °C, three dashes are shown as the

temperature value.

Note:

Please comply with the temperature measurement range of

the external temperature sensor specified in the "Technical data"

section. The temperature display can be in either °C or °F (see the

Timer:

In the ”Timer” menu the user can specify that the timer is displayed on the display/working screen. A tick shows that the option

is activated. This setting allows the user to specify the actual time

for the stirring procedure.

A default time can also be set for the timer. This setting allows the

user to start the stirring task for a standard time. The device stops

automatically after expiry of the set time, and the set time used for

the stirring procedure appears in the display.

Note: The user can stop the stirring function before expiry of the

set time. In this case the countdown of the timer is interrupted.

”Settings“ menu).

16

Page 17

Operating Mode:

Operating Mode A:

In this operating mode, the set speed is not saved when the current

run comes to an end or the device is switched off.

Operating Mode B:

In this operating mode, the set speed is saved when the current

run comes to an end or the device is switched off, and the value

can be changed.

Operating mode C:

In this operating mode, the set speed is saved when the current

run comes to an end or the device is switched off, and the value

cannot be changed.

Display:

In the “Display“ menu the user can specify what information will be

displayed on the main screen.

Note: If the ”Torque”option is activated, by pressing the ”Back“

button the user can reset the current torque to 0 Ncm as a reference value. At the same time the Δ appears in front of the Ncm unit.

Programs:

Under menu "Programs", 5 user-defined speed (rpm)-time profiles

can be created. In addition, the user could define the intermittent

mode is activated or not in the programs.

If the intermittent mode is activated, the run time/stop time value

from "Intermittent Mode" setting will be taken.

Note: If user need to activate the intermittent mode in one segment

of a program, he should set the "Run time/Stop time" in menu option "Interval", meanwhile activate the "Run/Stop" function in menu

option "Intermittent Mode" (see section "Stirring").

Once a programs has been selected, the following options are available.

Start: Start the selected program upon request.

When the selected program is started by pressing on menu option

"Start" with

the program control. Press "OK" with

rotary/push knob, screen reminds the user to confirm

rotary/push knob to start the

program control.

Edit: Edit the selected program parameters.

Start to edit the selected program parameters by pressing on menu

option "Edit" with rotary/push knob. The user can edit, delete or

insert one selected program segment in the program.

When user edits the program time for at least one segment, tick (

√

)

for respective program will appear.

Delete: Deletes the selected program.

If a selected program is deleted by pressing on menu option "Delete"

with rotary/push knob, all the program parameters will be emptied.

The tick (

√

) disappears.

Details for editing the program:

When a program is being edited, following screen appears.

PROGRAM 1

Seg

rpm Time

No

1

2

3

4

5

Edit Delete Insert

.

0 00:00 No

hh:mm

In this program, user can define up to 5 seg-

Interm.

ments. The selected segment is highlighted.

Mode

Then, the user can edit, delete or insert a

segment in this program.

When the "Back" button is pressed after ed

iting, the program is save automatically.

-

Edit:

When the highlighted "edit" symbol appear on the right top of

the screen, the user could change the speed (rpm), time value or

intermittent mode setting.

Note: The speed (rpm) value can be changed during the speed

limit range of the device. The time can be set from 1 minute to

10 hours.

Delete:

When delete a highlighted segment, the settings will be emptied. The

section jump to next segment.

Insert:

With the insert option, a new segment will be insert below the

selected segment. The default settings for the new segment are as

following:

rpm: 0

Time (hh:mm): 00:01

Intermittent Mode: No

View the program in graph:

After a program is being edited, press the "Back" button to save the settings. Press the "Back" button again, the screen back to follow screen.

Programs

Program 1

Program 2

am 3

Progr

Program 4

Program 5

Start Edit Delete

If no button or knob is pressed or turned for 5 seconds, pictorially

respective program will be shown.

PROGRAM 1 Detail

500

250

rpm

Press the rotary/push knob on option "Detail", the detailed settings

of every segment can be seen.

PROGRAM 1 Detail

500

Seg No.: 1

rpm: 100

250

Time (hh:mm:ss): 00:10:00

Interm. Mode: Yes

rpm

Turn the rotary/push knob, the details screen of every segment can

be switched.

PROGRAM 1 Detail

500

Seg No.: 2

rpm: 200

250

Time (hh:mm:ss): 00:10:00

Interm. Mode: No

rpm

17

Page 18

Example for editing the program:

Programs

Program 1

Program 2

ogram 3

Pr

Program 4

Program 5

Start Edit Delete

Program 1

Program 2

Program 3

Program 4

Program 5

Start

Programs

Edit Delete

Start

Programs

Pr

ogram 1

Program 2

Program 3

Program 4

Program 5

PROGRAM 1

Seg

rpm Time

hh:mm

0 00:00 No

Interm.

Mode

No.

1

2

3

4

Delete

Edit

5

Edit Delete Insert

PROGRAM 1

Seg

rpm Time

No.

hh:mm

0 00:00

1

2

3

4

5

Edit Delete Insert

Interm.

Mode

No

PROGRAM 1

Seg

rpm Time

No.

hh:mm

0 00:00 No

1

2

3

4

5

Edit Delete Insert

PROGRAM 1

Seg

rpm Time

No.

hh:mm

150 00:00

1

2

3

4

5

Edit Delete Insert

PROGRAM 1

Seg

rpm Time

No.

hh:mm

100 00:10

1

2

3

4

5

Edit Delete Insert

Interm.

Mode

Interm.

Mode

No

Interm.

Mode

No

rpm Time

hh:mm

0 00:00 No

rpm Time

hh:mm

150 00:00

rpm Time

hh:mm

150 00:10

edit

edit

edit

PROGRAM 1

Seg

No.

1

2

3

4

5

Edit Delete Insert

PROGRAM 1

Seg

No.

1

2

3

4

5

Edit Delete Insert

PROGRAM 1

Seg

No.

1

2

3

4

5

Edit Delete Insert

Interm.

Mode

Interm.

Mode

No

Interm.

Mode

No

rpm Time

hh:mm

100 00:00

rpm Time

hh:mm

150 00:10

rpm Time

hh:mm

150 00:10

edit

edit

edit

PROGRAM 1

Seg

No.

1

2

3

4

5

Edit Delete Insert

PROGRAM 1

Seg

No.

1

2

3

4

5

Edit Delete Insert

PROGRAM 1

Seg

No.

1

2

3

4

5

Edit Delete Insert

Interm.

Mode

No

Interm.

Mode

No

Interm.

Mode

Yes

PROGRAM 1

Seg

rpm Time

No.

hh:mm

100 00:00

1

2

3

4

5

Edit Delete Insert

PROGRAM 1

Seg

rpm Time

No.

hh:mm

150 00:10

1

2

3

4

5

Edit Delete Insert

PROGRAM 1

Seg

rpm Time

No.

hh:mm

150 00:10

1

2

3

4

5

Edit Delete Insert

Interm.

Mode

No

Interm.

Mode

No

Interm.

Mode

Yes

Edit speed (rpm)

Edit time (hh:mm)

Edit intermittent mode (Yes/No)

PROGRAM 1

Seg

rpm Time

No.

1

2

3

4

5

Edit Delete Insert

hh:mm

100 00:10

Interm.

Mode

Yes

Programs

Program 1

Program 2

Pr

ogram 3

Program 4

Program 5

Start Edit Delete

1000

5 s

500

rpm

PROGRAM 1

Seg

rpm Time

No.

hh:mm

150000:10

1

00:00

2

3

4

5

Edit Delete Insert

PROGRAM 1 Detail

Interm.

Mode

Yes

No

Back

Back

1000

rpm

PROGRAM 1 Detail

Seg No.: 1

rpm: 150

500

Time (hh:mm:ss): 00:10:00

Interm. Mode: Yes

PROGRAM 1

Seg

rpm Time

No.

hh:mm

150

00:10

1

150

00:10

2

500

00:20

3

800

00:10

4

1000

00:30

5

Edit Delete Insert

PROGRAM 1 Detail

1000

Seg No.: 2

rpm: 150

500

Time (hh:mm:00): 00:10:00

Interm. Mode: No

rpm

Interm.

Mode

Yes

No

No

No

Yes

Program diagram

Note: When intermittent mode is active, dashed line is used to represent

the speed (rpm).

18

Page 19

Safety:

Time Out:

In the “Time Out“ menu, you can set a time limit. This time limit

applies if there is a communication failure between the station

and the WiCo or the communication range is exceeded. The station

will continue to run at the set speed until the set time has expired.

After that the stirrer (station) will continue to run at the set safe

speed (see the "Safe speed" menu).

Note: The initial setting for the time limit is 30 seconds. You can

set a value of up to 60 minutes for this time limit.

NOTICE

speed, or the set speed if that is less than the safe speed.

Safe Speed:

In the “Safe Speed“ menu, you can specify a speed that is appropriate and safe for the stirring task. The safe speed applies if there is a

communication failure between the station and the WiCo or the

communication range is exceeded.

Note: The initial setting of the safe speed is 100 rpm is implemented after expiry of the time limit (see "Time out").

Password:

In the “Password“ menu, you can protect the WiCo settings using a

password (factory setting: 000).

If the intermittent mode is activated, the station

immediately switches to run at the set safe

Settings:

Languages:

The “Languages“ option allows you to select the desired language by turning and pressing the rotary/push knob (B). A tick

indicates the language that is set for the system.

Units:

The ”Units“ option allows you to select the desired unit for displaying the temperature. The choice is between ”°C” or ”°F” and

is made by turning and pressing the rotary/push knob (B). A tick

indicates the unit that is set for the system.

Display:

The ”Display“ option allows you to change the background color

and brightness of the working screen.

Sound:

The ”Sound” option allows you to activate/deactivate the keypress sound and to set the volume.

Factory Settings:

Select the ”Factory Settings” option by turning and pressing the

rotary/push knob. The system requests confirmation to recreate

the factory settings. Pressing the ”OK” button resets all the sys

tem settings to the original standard values set at dispatch from

the factory (see "Menu structure").

Communication:

The ”Device name” menu option allows you to edit the device name. This can relatively identify the paired station.

The ”Remote Control" menu option allows you to select

WiCo or other device as the remote control device.

The ”Bluetooth

tivate the ”Bluetooth

®

” menu option allows you to activate/deac-

®

” function. A tick (√) shows that the

option is activated.

Information:

The ”Information” option offers you an overview of the most important system settings of the stirrer.

-

19

Page 20

Interfaces and outputs

The device can be operated in “Remote” mode via an RS 232 or

USB interface using the laboratory software labworldsoft

®

.

The RS 232 interface at the back of the device is fitted with a

9-pole SUB-D port which can be connected to a PC. The pins are

assigned serial signals.

The USB port at the rear of the stirrer is used for the connection

between the PC and the WiCo. The WiCo also has a USB port,

located on its right side. It can also be used to connect to a PC for

“remote control“.

Note: Please comply with the system requirements together with the

operating instructions and help section included with the software.

USB interface:

The Universal Serial Bus (USB) is a serial bus for connecting the

device to the PC. Equipped with USB devices can be connected to

a PC during operation (hot plugging). Connected devices and their

properties are automatically recognized. Use the USB interface in

conjunction with labworldsoft

®

for operation in “Remote” mode

and also to update the firmware.

Installation:

First, download the latest driver for IKA devices with USB interface

from:

http://www.ika.com/ika/lws/download/usb-driver.zip.

Install the driver by running the setup file. Then connect the IKA

device through the USB data cable to the PC. The data communication is via a virtual COM port. Configuration, command syntax

and commands of the virtual COM ports are as described in RS

232 interface.

Serial interface RS 232:

Configuration

- The functions of the interface connections between the stirrer ma-

chine and the automation system are chosen from the signals specified in EIA standard RS 232 in accordance with DIN 66 020 Part 1.

- For the electrical characteristics of the interface and the alloca-

tion of signal status, standard RS 232 applies in accordance with

DIN 66 259 Part 1.

- Transmission procedure: asynchronous character transmission in

start-stop mode.

- Type of transmission: full duplex.

- Character format: character representation in accordance with

data format in DIN 66 022 for start-stop mode. 1 start bit; 7

character bits; 1 parity bit (even); 1 stop bit.

- Transmission speed: 9600 bit/s.

- Data flow control: none

- Access procedure: data transfer from the stirrer machine to the

computer takes place only at the computer’s request.

Command syntax and format:

The following applies to the command set:

- Commands are generally sent from the computer (Master) to the

stirrer machine (Slave).

- The stirrer machine sends only at the computer’s request. Even

fault indications cannot be sent spontaneously from the stirrer

machine to the computer (automation system).

- Commands are transmitted in capital letters.

- Commands and parameters including successive parameters are

separated by at least one space (Code: hex 0x20).

- Each individual command (incl. parameters and data) and each response are terminated with Blank CR LF (Code: hex 0x20 hex 0x0d

hex 0x20 hex 0x0A) and have a maximum length of 80 characters.

- The decimal separator in a number is a dot (Code: hex 0x2E).

The above details correspond as far as possible to the recommendations of the NAMUR working party (NAMUR recommendations

for the design of electrical plug connections for analogue and

digital signal transmission on individual items of laboratory control

equipment, rev. 1.1).

The NAMUR commands and the additional specific IKA commands serve only as low level commands for communication

between the stirrer machine and the PC. With a suitable terminal

or communications programme these commands can be transmitted directly to the stirrer equipment. The IKA software package,

labworldsoft

®

, provides a convenient tool for controlling stirring

equipment and collecting data under MS Windows, and includes

graphical entry features, for motor speed ramps for example.

The following table summarises the (NAMUR) commands understood by the IKA control equipment.

Commands Function

IN_NAME

IN_PV_3

IN_PV_4

IN_PV_5

IN_SP_4

IN_SP_5

IN_SP_6

IN_SP_8

OUT_SP_4 xxx

OUT_SP_5 xxx

OUT_SP_6 xxx

OUT_SP_8 xxx

START_4

STOP_4

RESET

OUT_MODE_n (n= 1 or 2)

IN_MODE

Read device name

Read PT1000 value

Read current speed value

Read current torque value

Read rated speed value

Read the torque limit value

Read the speed limit value

Read the safety speed value

Adjust the rated speed value xxx

Adjust the torque limit value xxx

Adjust the speed limit value xxx

Adjust the safety speed value xxx

Start the motor

Stop the motor

Switch to normal operating mode

Change the speed range

Read the speed range

PC 1.1 Cable (Station to PC):

Required for connecting the 9-pin socket to a PC.

6

7

8

9

1

2

3

4

5

1

RxD 2

TxD 3

4

GND 5

6

RTS 7

CTS 8

9

1

2 RxD

3 TxD

4

5 GND

6

7 RTS

8 CTS

9

9

8

7

6

5

4

3

2

1

PC

20

Page 21

Connection capability: WiCo to the station:

micro B

USB 2.0 cable micro A – micro B

micro A

Connection capability: station to the computer:

PC 1.1 cable

or

USB 2.0 cable

USB A – micro B

micro B

USB 2.0 cable

USB A – micro B

micro B

USB A

USB A

USB micro B

9-pin RS 232 9-pin RS 232

A

USB micro B

A

USB micro B

9-pin RS 232 9-pin RS 232

USB micro A

USB A

USB A

PC 1.1 cable

or

USB 2.0 cable

USB A – micro B

micro B USB A

A

USB micro B USB A

21

Page 22

Maintenance and cleaning

The device is maintenance-free. It is only subject to the natural

wear and tear of components and their statistical failure rate.

Cleaning:

For cleaning disconnect the main plug!

Use only cleaning agents which have been approved by IKA to

clean IKA devices.

Dirt Cleaning agent

Dyes isopropyl alcohol

Construction materials

Cosmetics

Foodstuffs

Fuels

For materials which are not listed, please request information from

IKA application support.

Wear protective gloves during cleaning the devices.

Electrical devices may not be placed in the cleansing agent for the

purpose of cleaning.

Do not allow moisture to get into the device when cleaning.

Before using another than the recommended method for cleaning or decontamination, you must ascertain with IKA that this

water containing tenside/isopropyl alcohol

water containing tenside/

water containing tenside

water containing tenside

isopropyl alcohol

method does not destroy the device.

Spare parts order:

When ordering spare parts, please give:

- machine type

- manufacturing number, see type plate

-

item and designation of the spare part see

spare parts diagram and spare parts list

- Software version.

Repair:

Please send in device for repair only after it has been

cleaned and is free from any materials which may constitute a health hazard.

For this, you should request the “Decontamination Certificate”

from IKA, or use the download printout of it from the IKA website www.ika.com.

If you require servicing, return the device in its original packaging. Storage packaging is not sucient. Please also use suitable

transport packaging.

www.ika.com,

Error codes

The fault is shown by an error message in the display (C) as following if the error occurs, e.g. Error 4.

Proceed as follows in such cases:

)

Switch the device switch (A) off.

)

Remove the stirrer tool and remove the device from the assembly.

)

Reduce the speed and switch on (device switch (A)) the device without the stirrer tool.

Error Cause Effect Solution

Error 2 Motor current sensor fault motor off - Switch off the device

Error 3 Temperature inside device is too high motor off - Switch off the device and allow it to cool down

Error 4 Motor blockage or overload motor off - Switch off the device

- Decrease the load on the motor and restart again

Error 8 Speed sensor fault or overload motor off - Switch off the device

Error 21 Safety relay fault motor off - Switch off the device

If the actions described fails to resolve the fault or another error code is displayed then take one of the following steps:

- Contact the service department

- Send the device for repair, including a short description of the fault.

Warranty

In accordance with IKA warranty conditions, the warranty period

is 24 months. For claims under the warranty please contact your

local dealer. You may also send the machine direct to our factory,

enclosing the delivery invoice and giving reasons for the claim. You

will be liable for freight costs.

The warranty does not cover worn out parts, nor does it apply

to faults resulting from improper use, insucient care or maintenance not carried out in accordance with the instructions in this

operating manual.

22

Page 23

Accessories

R 2722 H-stand

R 2723 Telescopic stand

R 270 Cross sleeve

R 271 Cross sleeve

RH 5 Strap clamp

R 301 Stirrer shaft protection

R 301.1 Support holder

PC 1.1 Cable

See more accessories on www.ika.com.

Permitted IKA stirrer tools

max. speed

(rpm)

R 1302 Dissolver stirrer n 1000

R 1342 Propeller stirrer 2000

R 1345 Propeller stirrer n 800

R 1381 Propeller stirrer 2000

R 1382 Propeller stirrer 2000

R 1385 Propeller stirrer 800

R 1388 Propeller stirrer 400

R 1389 Propeller stirrer, PTFE 800

R 1311 Turbine stirrer 2000

R 1312 Turbine stirrer 2000

R 1313 Turbine stirrer 800

H 70 Extension cable

H 62.51 Stainless steel sensor

H 66.51 Stainless steel sensor, glass-coated

RB 1 Battery pack

OS 1.0 Power supply

USB 2.0 cable (micro A – micro B)

USB 2.0 cable (A – micro B)

Protective cover

max. speed

(rpm)

R 1375 Paddle stirrer n 800

R 1376 Paddle stirrer 800

R 1330 Anchor stirrer n 1000

R 1331 Anchor stirrer n 1000

R 1333 Anchor stirrer 800

n Note: the stirrer tool can be used for viscosity measuring.

23

Page 24

Technical data

station

Speed range I (high torque)

Speed range II (high speed)

Speed adjustment Stepless

Speed display TFT / WiCo

Speed setting accuracy rpm ± 1

Deviation – speed measurement

Max. torque at stirrer shaft: Speed range I

Speed range II

Torque measurement yes

Torque I max.

Torque II max.

Torque display yes

Deviation of torque measurement (in range: 0... 250 Ncm) Ncm ± 2.5

Max. stirring quantity (water) ltr 100

Viscosity measurement yes

Viscosity display yes

Max. viscosity mPa·s 100000

Intermittent operation yes

Port for external temperature sensor yes

Temperature display yes

Timer function yes

Permitted on time % 100

Operating voltage VA

Frequency Hz 50 / 60

Max. input power W 130

Max. output power at stirring shaft W 84

IP code according to EN 60529 IP 40

Protection class I

Excess voltage category II

Contamination level 2

Protection at overload yes / motor current limitation

Ambient temperature °C + 5 ... + 40

Ambient humidity (rel.) % 80

Drive Brushless motor

Clamping chuck – clamping range mm 0.5 – 10

Hollow shaft internal diameter mm 10.3

Extension arm (Ø x L) mm 16 x 220

Housing

Dimensions (W x D x H), without extension arm, with WiCo mm 91 x 231 x 395

Weight (with extension arm and clamping chuck) kg 5.9

Operation at a terrestrial altitude m max. 2000

Interface USB, RS 232

Temperature measurement resolution K 0.1

Measurement range, temperature °C - 10 ... + 350

Limiting deviation, temperature sensor Pt 1000 DIN EN 60751 class A

Measurement accuracy, temperature K ± 0.5 + tolerance PT 1000 (DIN EN 60751 class A)

rpm 0 / 6 ... 400

0 / 30 ... 2000

Speed < 300 rpm: ± 3 rpm

Speed > 300 rpm: ± 1%

Ncm 200

40

Ncm 200 (Max. overload: 400 Ncm in 20 min.)

40 (Max. overload: 80 Ncm in 20 min.)

C 230 ± 10 %

115 ± 10 %

100 ± 10 %

Coated aluminium casting and thermoplastic plastic

K ≤ ± (0.15 + 0.002 x ITI)

24

Page 25

WiCo

Permitted on time % 100

Max. communication distance (dependent on the building)

Dimensions (W x D x H) mm 71 x 74 x 151

Weight kg 0.28

Ambient temperature

Ambient humidity (relative) % 80

IP code according to EN 60529 IP 40

Interface USB

Battery pack

Voltage V 3.7

Charging capacity mAh 2000

Charging time h 4.5

Working time h 15

Battery type Lithium-polymer

Subject to technical changes!

m 150

°C

+ 5 ... + 40

25

Loading...

Loading...