Page 1

20000004637

IKA® RW 47 digital

Operating instructions EN

Reg.-No. 4343-01

Page 2

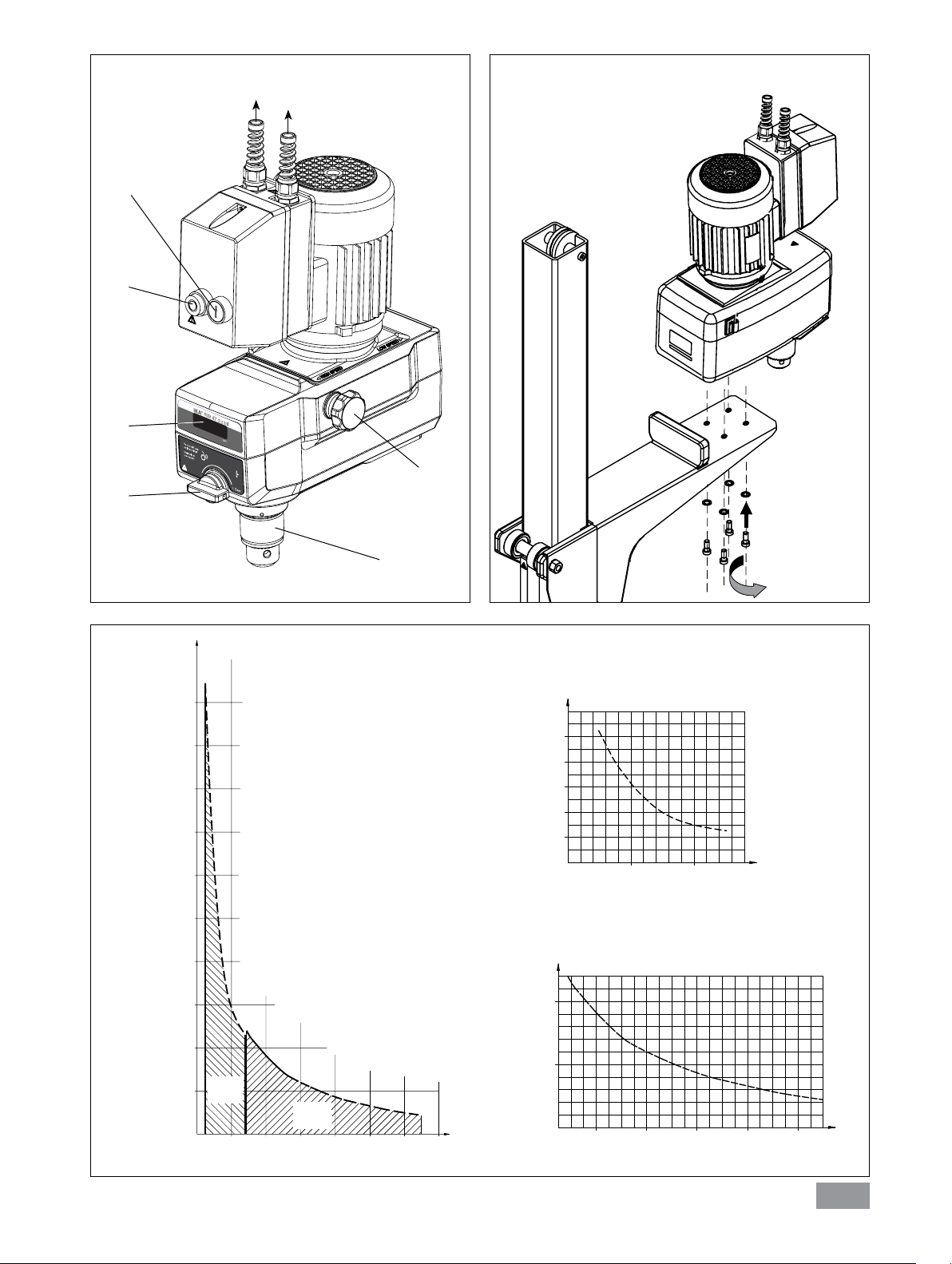

Drehmoment der Abtriebswelle

Grenzkurve Getriebestufe II

Anschluss-Sicherheitsendschalter

connection-limit switch

A

B

D

Rotating

direction!

E

Anschluss-Netz

connection-power supply

C

Fig. 1

M

[Nm]

55

50

40

35

30

25

Drehmoment der Abtriebswelle

Torque at output shaft

20

15

F

Fig. 3

M

[Nm]

Drehmoment der Abtriebswelle

M

[Nm]

Grenzkurve Getriebestufe I

Limit curve gear level I

50

4040

30

20

10

Torque at output shaft

Drehzahl der Abtriebswelle

Torque at output shaft

Limit curve gear stage II

10

200100 n [rpm]

Fig. 2

10

Arbeitsbereich

Getriebestufe I

5

workspace

Gear Level I

0 200 400 600 800 1000 1200 1400

Arbeitsbereich

Getriebestufe II

workspace

Gear Level II

Drehzahl der Abtriebswelle

Output shaft speed

n [rpm]

5

Torque at output shaft

400 600 800 1000 1200

Drehzahl der Abtriebswelle

Torque at output shaft

n [rpm]

2

Page 3

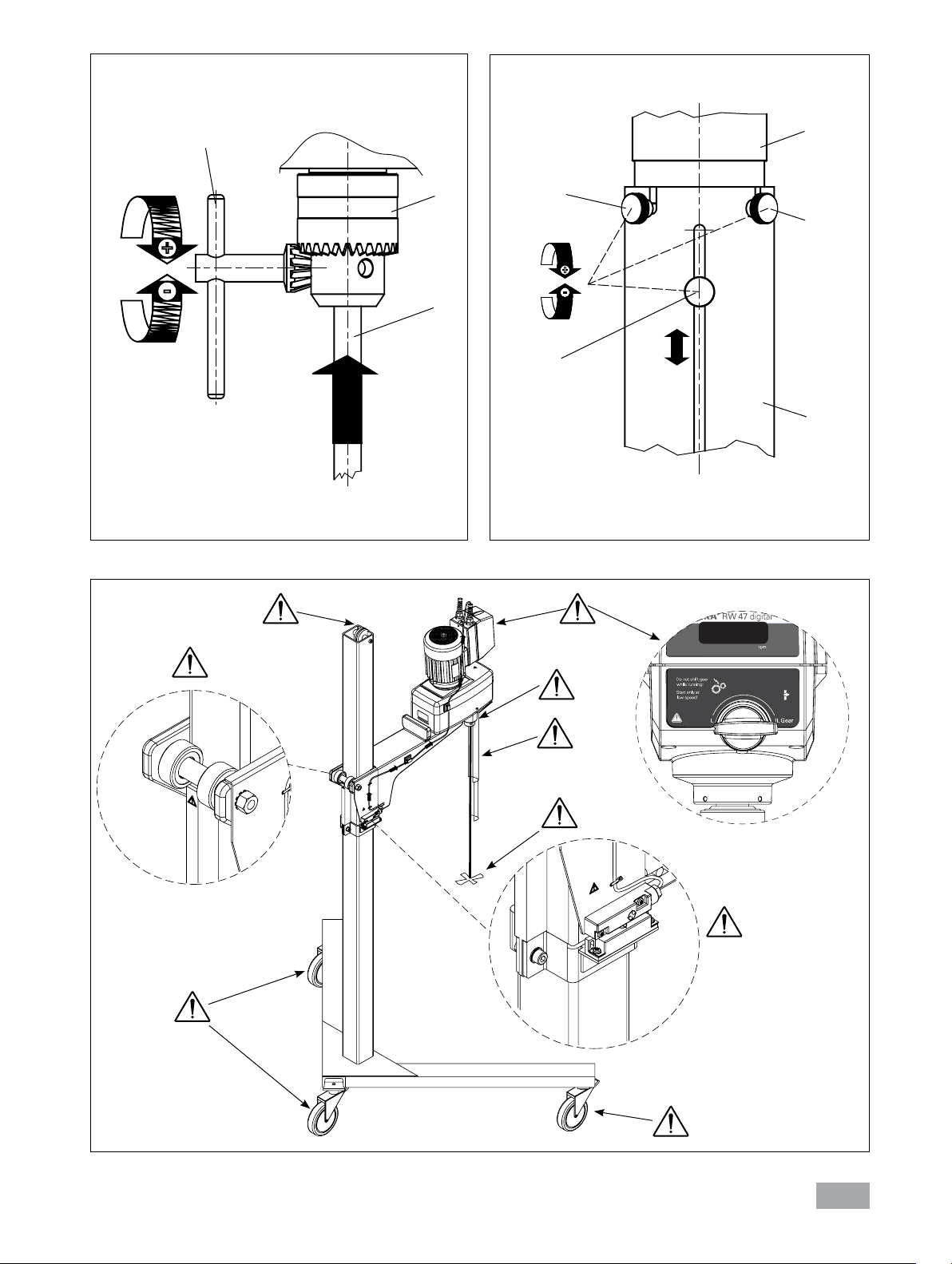

Rotating

direction!

G

M

Fig. 4

H

J

J

I

L

K

Fig. 5

Fig. 8

3

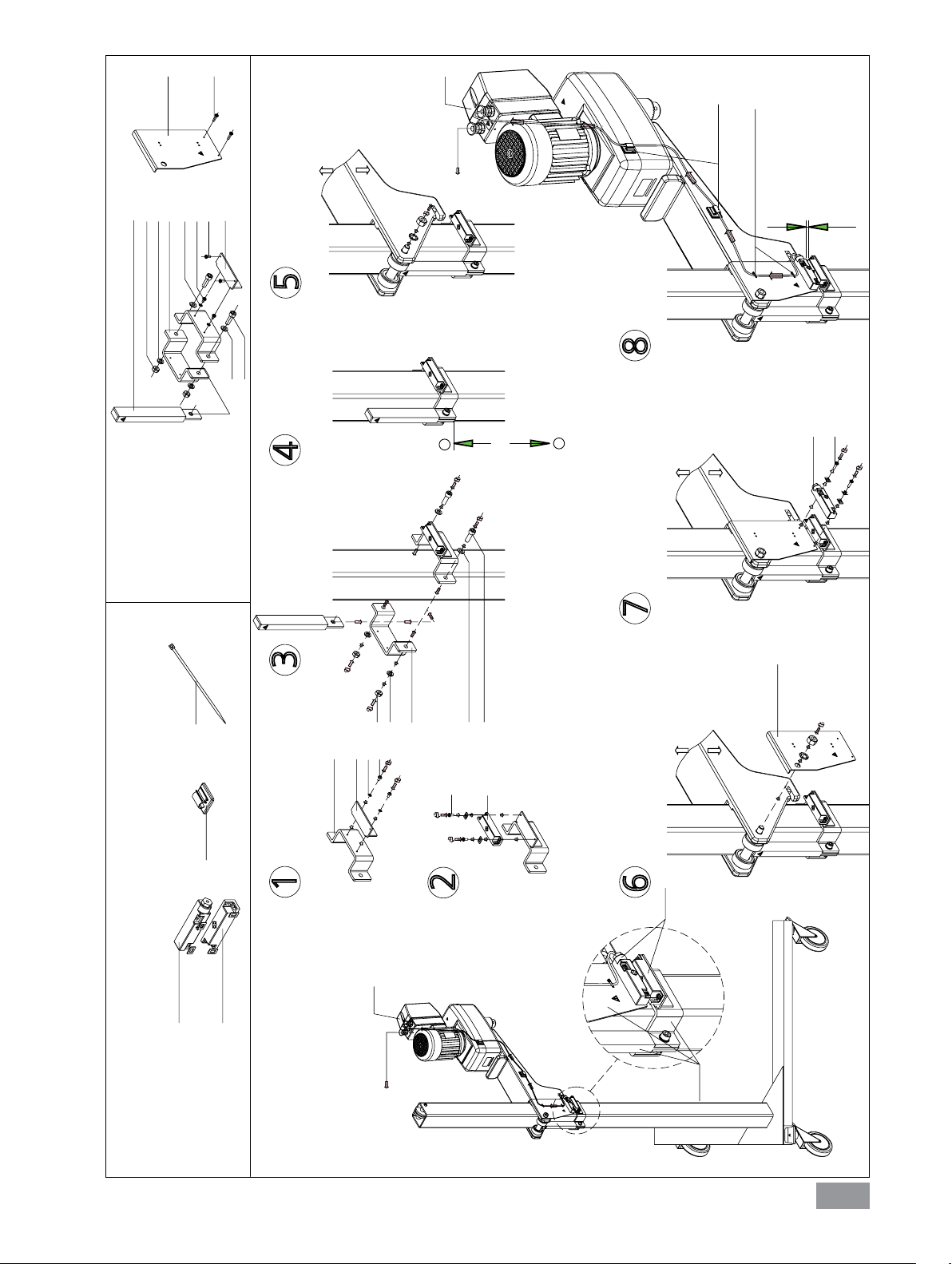

Page 4

3 (2x)

12(1x)

SI 400

1975

1973

(3x)

230/400V

50/60 Hz

5 (2x)

8 (2x)

9 (2x)

11(1x)

SI 472

(1x)

6 (2x)

1 (2x)

2 (2x)

10

5

8

7 (2x)

4 (2x)

3

2*

4

3

+

ΔL

–

12

2*(1x)

SI 400

1973 (2x)

(2x)

1975

2

2

2

4

1*

6 7

SI 400

SI 472

5

8

9

1

9

6

10

1

1*(1x)

SI 400

(3x)

230/400V

50/60 Hz

Fig. 6

4

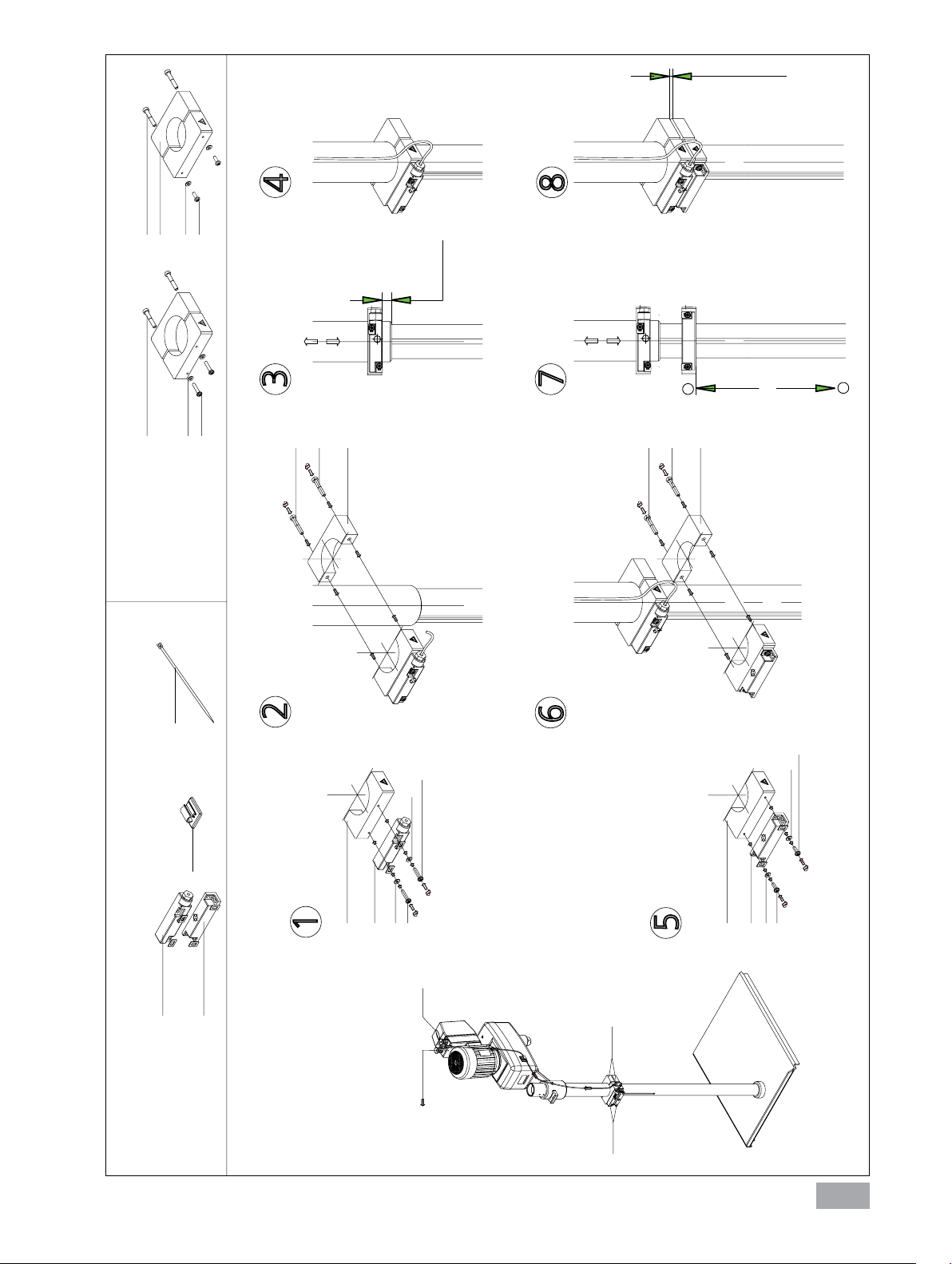

Page 5

4

(2x)

4 (1x)

2 2 (4x)

7

3

MIN 5 mm

MAX 8 mm

8

5 (1x)

SI 474

(2x)

1973

3

3 (4x)

1 (2x)

5

2 2

2

1

3

6 7

+

2

2

4

ΔL

7

3

–

2*(1x)

SI 400

1975 (2x)

5

1

1*(1x)

1

2*

3

(3x)

SI 400

230/400 V

50/60 Hz

SI 474

SI 400

5

4

3

7

1*

Fig. 7

5

Page 6

Source language: German

EN

Contents

Page

EC-Declaration of conformity 6

Explication of warning symbols 6

Safety instructions 7

Correct use 9

Unpacking 9

Useful information 9

Drive 9

Motor circuit breaker 10

Gear speed change 10

Output shaft 10

Speed display 10

Commissioning 10

Securing 11

Switching on the instrument 11

Maintenance and cleaning 12

Error codes 13

Warranty 13

Accessories 13

Permitted IKA® stirrer tools 13

Technical data 14

Wiring diagram 15, 16

EC-Declaration of conformity

We declare under our sole responsibility that this product corresponds to the regulations 2006/42/EC and 2004/108/ EC and

conforms with the standards or standardized documents: EN 61010-1, -2-051; EN 12 100-1, -2;

60204-1.

EN 61326-1 and EN

Explication of warning symbols

General hazard

DANGER

WARNING

CAUTION

This symbol identifies information that is of vital importance for safeguarding your health

and safety. Disregarding this information can lead to health impairment and injuries.

This symbol identifies information that is of importance for the technically correct functioning

of the system. Disregarding this information can result in damage to the instrument or to system

components.

This symbol indicates information which is important for ensuring that the operations of the

instrument

information can result in inaccurate results.

are performed eciently and for using the instrument. Failure to observe this

6

Page 7

Safety instructions

•

Read the operating instructions in full before

starting up and follow the safety instructions.

• Keep the operating instructions in a place where

it can be accessed by everyone.

• Ensure that only trained staff work with the instrument.

•

Follow the safety instructions, guidelines, occupational health and safety and accident prevention regulations.

• Because the options for combining products,

tools, stirring vessel, experiment and medium

are nearly endless, user safety cannot be ensured simply with design requirements on the

part of the product. For this reason, it may

become necessary for users to take other precautionary safety measures. For example, glass

devices or other stirring vessels that are sensitive

to mechanical stress can be damaged or shattered by an imbalance, increasing the speed too

quickly or too little distance between the stirring

element and the stirring vessel. Users can suffer

serious injury from glass breakage or from the

freely rotating stirring element.

• Uncontrolled reactions can be triggered by mixing the heated material insuciently or by the

energy generated by selecting a speed that is

too high. In case of these and other increased

operational hazards, users must take additional

appropriate safety precautions (e.g. shatter protection). In any case, when using critical or hazardous materials in your processes, IKA® recommends to use additional appropriate measures

to ensure safety in the experiment. For example,

users can implement measures that inhibit fire

or explosions or comprehensive monitoring

equipment. Furthermore, users must make sure

that the OFF switch of the IKA® product can be

accessed immediately, directly and without risk

at any time, and above all, in case of fault.

DANGER

• Only process media that will not react dangerously to the extra energy produced through

processing. This also applies to any extra energy

produced in other ways, e.g. through light irradiation.

If installation or positioning

cannot ensure this access

at all times, an additional

EMERGENCY STOP switch

that can be easily accessed

must be installed in the work

area.

•

Do not operate the instrument in explosive atmospheres, with hazardous substances or under

water.

•

Process pathogenic materials only in closed ves-

sels under a suitable fume hood. Please contact

IKA® application support if you have any ques-

tion.

•

The instrument is not suitable for manual operation.

•

The high torque developed by the RW 47 digital

requires particular care in the choice of stand, cross

sleeve and anti-rotation element for the agitating

vessel.

• Set up the stand in a spacious area on an even,

stable, clean, non-slip, dry and fireproof surface.

• You must ensure that the stirring element is securely clamped in the chuck!

•

Use stirring shaft protective equipment and a

safety cutout for height adjustable stands!

• The agitated vessels used for stirring have to be

secured. Consider on a good stability of the entire structure.

DANGER

•

Protect the instrument and accessories from

bumping and impacting.

• Check the instrument and accessories before-

hand for damage each time when you use

them. Do not use damaged components.

•

Safe operation is only guaranteed with the acces-

sories described in the ”Accessories” section.

• Always switch the main switch in the OFF position or disconnect the power before changing

stirring element and fitting allowed accessories.

• The instrument can only be disconnected from

the mains supply by pulling out the mains plug

or the connector plug.

• The socket for the mains cord must be easily

accessible.

•

Socket must be earthed (protective ground

contact).

•

The voltage stated on the type plate must cor-

respond to the mains voltage.

• Please observe the permitted speed for the stirring element. Never set higher speed.

• Make certain that the unit is set at the lowest

speed before commissioning; otherwise, the

unit will begin running at the speed set in last

operation. Gradually increase the speed.

• Pay attention when setting the speed to any

imbalance of the stirrer tools and possible

spraying of the medium to be stirred.

Please pay attention to

the dangerous parts of the

equipment in Fig. 8.

7

Page 8

DANGER

DANGER

DANGER

DANGER

DANGER

•

There may be electrostatic activity between the

medium and the output shaft which could cause

a direct danger.

• After an interruption in the power supply or a

mechanical interruption during a stirring process, the unit does not restart automatically.

• It is important to note that the surfaces of the

motor (cooling fins) and certain parts of the

bearing may get very hot during operation.

• Never cover the ventilation slots or cooling ns

on the motor as these are needed for cooling

the drive system.

• Avoid knocking and impacting on the lower end

of the shaft and the chuck gear teeth. Even minor, invisible damage can lead to imbalance and

uneven shaft action.

• Ensure that the stand does not start to move.

Never operate the instrument with the stirrer tools

rotating freely. Ensure that

parts of the body, hair, jewelry or items of clothing

cannot be trapped by the

rotating parts.

Wear your personal protective equipment in accordance with the hazard category of the medium to be

processed; otherwise there

is a risk of:

- splashing of liquids

- projectile parts

-

body parts, hair, clothing

and jewelry getting caught.

Beware of the risk of

- flammable materials

-

glass breakage as a result of

mechanical shaking power.

Reduce the speed if:

- the medium splashes out

of the vessel because the

speed is too high

- the instrument is not running smoothly

- the instrument begins to

move around because of

dynamic forces

- malfunction.

Do not touch rotating

parts during operation!

•

Imbalance of the output shaft, the chuck and

in particular the stirring tools can lead to uncontrolled resonant vibrational behavior of the

instrument and the whole assembly. Glass devices and stirrer containers can be damaged

or shattered by this. It can cause injury to the

operator, also can damage the rotating stirring

tool. In this case exchange the stirring tool for

one without imbalance or remedy the cause of

the imbalance.

it to the dealer or the manufacturer along with

a description of the fault.

• If the instrument is operated too long in overload or if the ambient temperature is too high,

the instrument switches off permanently.

• The machine must only be opened by trained

specialists, even during repair. The instrument

must be unplugged from the power supply before opening. Live parts inside the instrument

may still be live for some time after unplugging

from the power supply.

WARNING

WARNING

DANGER

• Before commissioning, the correct direction of

rotation of the motor must always be ensured

(test run without stirring tool: motor rotation as

indicated of the arrow on the front foil, clockwise rotation, looking down on motor). The

wrong direction of rotation can lead to the stirring tool coming off the shaft.

• If the unit is operated in different locations with

a 5-pin plug, the direction of rotation must be

checked before each commissioning, with no

stirring tool fitted.

If there is still imbalance, return

Covering or parts that are

capable of being removed

from the unit without accessory equipment have

to be reattached to the

unit for safe operation in

order to prevent, for example, the ingress of fluids, foreign matter, etc..

The unit must be switched

off (motor standstill) before changing to another

gear speed, otherwise the

toothed gears in the reduction stage will be damaged.

The equipment must be

wired by a qualified technician, otherwise there is a risk

of electric shock!

8

Page 9

Correct use

• Use

For mixing/stirring liquids with low to high viscosity by using various stirring tools.

Intended use: Stand device (Chuck downward).

• Range of use (indoor use only)

- Laboratories - Technical colleges

- Pharmacies - Small-scale production

Unpacking

• Unpacking

- Please unpack the device carefully

-

In the case of any damage a detailed report must

be sent immediately (post, rail or forwarder).

This equipment is suitable for use in all areas except:

- Residential areas

-

Areas that are connected directly to low-voltage

supply network that also supplies residential areas.

The safety of the user cannot be guaranteed:

- If the instrument is operated with accessories

that are not supplied or recommended by the

manufacturer

- If the instrument is operated improperly contrary

to the manufacturer’s specifications

- If the instrument or the printed circuit board are

modified by third parties.

• Delivery scope

- an RW 47 digital overhead stirrer

- an operating instructions

- four hexagonal socket screws

- a hexagon socket offset screw key

- a chuck key

- a warranty card

.

Useful information

You can set speed from 57 to 1300 rpm with the

50 Hz (mains frequency) and speed from 69 to

1560 rpm with the 60 Hz (mains frequency). The

unit may heats up during use. The ample cooling

surfaces on the motor serve to distribute and radiate the heat as evenly as possible.

You can also use large mixing vessels together

IKA® stands without any problem.

with

Drive

The motor can be infinitely adjusted via a friction

wheel drive unit but is operated in one position

only. The power output, rotational speed and

torque of the motor are regarded as constant and

are optimized for this operating position. After

the friction wheel drive the motor power output

is transmitted to the output shaft of the stirrer via

either the first or second stage of the subsequent

manually adjustable toothed gear train.

The unit comes without a connection cable because the user’s installation means that it is not

possible to issue a standard length cable due to

the different sizes of premises. Experts can determine the pin assignment from the wiring plan.

The output shaft is not designed as a hollow shaft

and allows inserting the stirring element until it

stops. It is important to ensure that the stirrer

shank is securely clamped in the chuck.

Neglecting all losses, the power at the output shaft

during power transmission (conversion) is always as

great as the power output of the motor. The gear

train merely provides rpm and torque conversion,

which can be described in purely theoretical terms

by the characteristic curve plotted in Fig. 2.

Friction wheel wear is kept low by a helical clutch

matched to the gear train. The down-pressure required at the friction wheel is adjusted by the helical

clutch according to the moment acting on the stirrer

shaft. A low torque results in a low down-pressure;

a high torque results in a high down pressure.

9

Page 10

Motor circuit breaker

The ball race three-phase motor is maintenancefree. Its attached switching unit features a special

safety device for operation in the case of overcurrent and under-voltage (under-voltage release)

to permanently disconnect the motor and avoid

thermal damage. The instrument can only be

started up again by activating the ON switch (A,

see Fig. 1), when power permitted for the motor

is supplied.

You can nd the basic connection and rating for

the motor on its rating plate.

Gear speed change

You can select one between two gear positions (I

and II) using the toggle button (E, see Fig. 1) on

the front of the instrument. You can only switch

to a different cog wheel gear level when the instrument is switched off (motor stopped).

Output shaft

The safety switch SI 400 can also be connected

to the motor switching unit. When used in combination with an

switch on the instrument only at a defined height

in the stand’s working range.

If the stirring unit is operated in such a way that

the instrument’s OFF switch (B, see Fig. 1) is not

accessible, you must add another EMERGENCY

STOP switch to the work area so that it can be

easily reached.

Otherwise this may cause damage to the gear

cogs. The arrow on the front foil indicates the direction of the chuck.

WARNING

IKA® stand, this allows the user to

Only change the gear position at standstill!

The clamping chuck and output shaft permit clamping IKA® recommend stirrer tools (see “Permitted

IKA® Stirrer tools“ section).

Speed display

The rotation speed is adjusted by means of the

rotary knob (C, see Fig. 1) on the side of the overhead stirrer.

Commissioning

The overhead stirrer RW 47 digital must be secured to a stable stand (e.g. R 474 or R 472) with

four screws and wired according to the wiring diagram for proper use. The stirring vessel must al-

ways be well secured for safety reasons. You must

also ensure that the mounting equipment (e.g.

floor stand, telescope stand) is set up in such a

way that it is not liable to topple and does not start

to move during the stirring procedure. Accessories

must be assembled and wired according to the assembly instructions (Fig. 3 to Fig. 7).

The output shaft is not de

DANGER

The rotation speed is displayed directly in revolutions

per minute (rpm) on the display (D,

If the stirring unit is operated in such a way that the

instrument’s OFF switch (B, see Fig. 1) is not accessible, you must add an another EMERGENCY

STOP switch to the work area so that it can be

easily reached.

signed as a hollow shaft.

Please see section “Safety

instructions“!

see Fig. 1

).

10

Page 11

If above conditions are

met, the instrument is

ready for operation after

plugging in the mains plug.

Securing

Points of particular danger (such as crushing, rotating parts, clamping screws for stand legs and rollers etc.) are marked in Fig. 8 with an exclamation

mark. Please pay particular attention to these danger

points during operation!

Securing the overhead stirrer to the stand

Diagram (see Fig. 3)

Place RW 47 digital overhead stirrer on the arm of

the stand. Fasten the overhead stirrer to the stand

from below with hexagonal socket screws supplied.

The help of an assistant is needed for screwing on

the overhead stirrer. The cable clips included in the

delivery package are required for fixing the power

cable of the unit (see Fig. 6 and Fig. 7).

Check that the stirrer is held in position firmly prior to

each use and also at regular intervals. The position of

the stirrer must only be adjusted when the equipment

is stationary and the power supply is disconnected.

Securing the stirring element using the chuck

Diagram (see Fig. 4)

Slide the stirring element (I) into the chuck (H).

Tighten the chuck firmly using the chuck key (G).

The stirring tool must only be changed when the

equipment is stationary and the power supply is

disconnected.

Securing the stirring shaft protector

Diagram (see Fig. 5)

You must use stirring shaft protector (K), e.g. R 301,

when working to prevent injury. Use the bolts (J) to

attach the plastic half-shell pieces to the stirrer (M),

as shown in Fig. 5. The screw (L) can be used to

adjust the length of the stirring shaft protector.

Check that the stirring shaft protector is held in position securely prior to each use and also at regular

intervals. The position of the stirring shaft protector

must only be adjusted when the equipment is stationary and the power supply is disconnected.

Securing the safety switch to R 472 floor stand

Diagram (see Fig. 6)

There is a danger of trapping between the

safety limit switch, switch contacts and the

end stop!

Secure the safety switch SI 400 safety switch to

the support rod of R 472 floor stand via fixing device SI 472. For this, follow the assembly instructions for “Safety switch” in the Fig. 6.

Securing the safety switch to R 474 telescopic stand

Diagram (see Fig. 7)

There is a danger of trapping between the

safety limit switch, switch contacts and the

end stop!

Mount the safety switch SI 400 safety switch to

the support rod of R 474 telescopic stand via fixing device SI 474. For this, follow the assembly

instructions for “Safety switch” in the Fig. 7.

Switching on the instrument

Check whether the voltage given on the type plate

corresponds to the available mains voltage.

The socket used must be

earthed (fitted with earth

contact).

If these conditions have been met

ready to operate when the mains plug is plugged in.

If these conditions are not met, safe operation is not

guaranteed and the machine could be damaged.

When working with safety switch SI 400, the instrument only starts up once it has been set to the

designated working height and the switch contact

activates the safety switch.

, the machine is

11

Page 12

During commissioning of the machine the output

shaft starts to run at the speed setting in last operation. Therefore check the setting of the control

knob (speed). Also ensure that the speed set is

suitable for the test medium selected. If you are unsure, set the motor slide to the lowest speed (front

motor slide stop) using the rotary control knob (C)

on the side and the gear to the lowest level.

Maintenance and cleaning

The instrument will start up when you press the

ON switch (A) on the motor.

If the unit has not been used for some time, a

knocking noise will be heard when switching on,

which is due to the preload on the friction lining

of the friction wheel drive. This has no detrimental

effect on the function of the unit, and the knocking

noise will disappear after a short running-in period.

The equipment is maintenance-free. It is only

subject to the natural wear and tear of components and their statistical failure rate.

Cleaning

DANGER

Use only cleaning agents which have been approved by

Dirt Cleaning agent

Dye isopropyl alcohol

Construction

material

Cosmetics

Foodstuff

Fuel

For materials which are not listed, please request

information from

Wear protective gloves during cleaning the devices.

Electrical devices may not be placed in the cleansing

agent for the purpose of cleaning.

Do not allow moisture to get into the equipment

when cleaning.

IKA® to clean the instruments.

For cleaning unplug the

equipment!

water containing tenside/

isopropyl alcohol

water containing tenside/

isopropyl alcohol

water containing tenside

water containing tenside

IKA® application support.

When cleaning the unit, take particular care not to

bring substances containing oil or grease into contact with the running surfaces of the cone pulley and

the friction wheel. This would substantially reduce

the frictional coecient resulting from the pairing

of the friction wheel and cone pulley materials, and

would impair power transmission in the unit.

Spare parts order

When ordering spare parts, please give:

- machine type

- manufacturing number, see type plate

- item and designation of the spare part see

www.ika.com, spare parts diagram and spare

parts list

- software version.

Repair

Please send in equipment for repair only

after it has been cleaned and is free from

any materials which may constitute a health

hazard.

For repair, please request the “Decontamination

Certificate” form IKA® or use the download

printout of it from IKA® website: www.ika.com.

If you require servicing, return the equipment in its

original packaging. Storage packaging is not sucient. Please also use suitable transport packaging.

Before using another than the recommended

method for cleaning or decontamination, the user

must ascertain with

not destroy the instrument.

IKA® that this method does

12

Page 13

Error codes

The fault is shown by an error code on the display (D) as following if the error occurs, e.g. Er 4.

Proceed as follows in such cases:

F Switch the device switch (B) off.

F Remove the stirrer tool and remove the instrument from the assembly.

F Reduce the speed and switch on (instrument switch (A)) the device without the stirrer tool.

Error code Cause Effect Solution

Er 8

If the actions described fails to resolve the fault or another error code is displayed then take one of the

following steps:

- Contact the service department

- Send the instrument for repair, including a short description of the fault.

Speed sensor fault or overload

motor off Switch off the instrument

Warranty

In accordance with

warranty period is 24 months. For claims under

the warranty please contact your local dealer. You

may also send the machine direct to our factory,

enclosing the delivery invoice and giving reasons

for the claim. You will be liable for freight costs.

IKA® warranty conditions, the

Accessories

R 472 Floor stand

R 474 Telescopic stand

R 301 Stirring shaft protection

R 301.1 Support holder

Permitted IKA® stirrer tools

R 1345 Propeller stirrer

R 2302 Propeller stirrer

R 1385 Propeller stirrer

R 1388 Propeller stirrer

R 1302 Dissolver stirrer

Max. Speed rpm

≤

800

≤

600

≤

800

≤

400

≤

1000

The warranty does not cover worn out parts, nor

does it apply to faults resulting from improper use,

insucient care or maintenance not carried out in

accordance with the instructions in this operating

manual.

SI 400 Safety switch

SI 472 Fixing device

SI 474 Fixing device

Max. Speed rpm

R 1355

R 1376

R 2311

R 1333

Centrifugal stirrer ≤ 800

Paddle stirrer ≤ 800

Paddle stirrer ≤ 600

Anchor stirrer ≤ 800

13

Page 14

Technical data

Speed range

Speed adjustment Stepless

Speed display

Speed setting accuracy

Deviation of speed measurement

Max. torque stirrer shaft Ncm

Maximum stirring quantity (water) ltr 200

Max. viscosity mPas 100000

Permitted on-time % 100

Nominal voltage VAC 3 x 400 Y 3 x 230 ∆ 3 x 400 Y 3 x 230 ∆

Frequence Hz 50 50 60 60

Motor speed rpm 2880 2850 3425 3425

Motor input power W 554 548 489 490

Motor output power W 370 370 370 370

Maximum output at stirrer shaft W 300 300 300 300

Protection type to DIN EN 60529 IP 54

Protection class I (protective earth)

Exess voltage category II

Contamination level 2

Protection at overloaded Yes / overcurrent and undervoltage switch on the

Fuse (adjustable) A 1 1,75 0,86 1,5

Perm. ambient temperature °C + 5 to + 40

Perm. ambient humidity (rel.) % 80

Drive

Clamping chuck – clamping range mm

Housing

Dimension (W x D x H) mm 145 x 465 x 358

Weight (with clamping chuck) kg 16

Operation at a terrestrial altitude m max. 2000 above sea level

(50Hz stage I)

(50Hz stage II)

(60Hz stage I)

(60Hz stage II)

rpm 57 – 275

275 – 1300

69 – 330

330 – 1560

Didplsy (LED)

rpm

rpm

± 1

± 10

4642 (with 57 rpm)

3000 (with 100 rpm)

285 (with 1000 rpm )

three-phase motor

Rib cooled three-phase motor with friction wheel

drive and subsequent 2-stage toothed gear train

3

–

16

Coated aluminium casting and thermoplastic plastic

Sbuject to technical changes!

14

Page 15

Verdrahtungsplan / wiring diagram:

3x 230V / 50/60Hz

H

LRD 06

LRD 06

LRD 06

LRD 06

LRD 06

Nicht im Lieferumfang /

Not included in delivery

Sicherheitsschalter/

Safety switch

BU

BN

Nicht im Lieferumfang/

Not included in delivery

Netzkabel/

Mains cabel

L1 L2 L3

GNYE

TEST

0

H

TEST

0

H

TEST

0

TEST

0

A

I

0

A

Einstellung (Strom [A]) des Relais/

Overload (current [A]) adjustment

I

I

Gerätevariante/

device variant

RW47 digital

3x230V / 50Hz

RW47 digital

3x230V / 60Hz

Auslösesimulation/

Trip test

S09

S10

9596

I

Position Rückstellung Hand (H) - Auto (A)/

manuel (H) - auto RESET

IKA-Lieferzustand : Auto (A)

IKA-delivery status : Auto (A)

I

click

R E S E T

S T O P

Funktion Stop/

Stop function

95

96

Stromwert(einstellen)/

current (adjust)

1.75A

1.5A

A1

A2

RD

RD

1 L1

Schütz /

Contactor

14 NO

2 T1

LRD 06

0

A

98 NO

97 NO

4 T2

2 T1

Motorschutz-Relais/

Motor protection relay

WH

L1

L2

U1

U2

RD

3 L2

5 L3

21 NC

22 NC

4 T2 6 T3

R E S E T

I

S T O P

96 NC

95 NC

6 T3

BN

L3

V2 W2

YE BK

RD

A113 NO

RD

RD

A2

RD

RD

f

GY

W1V1

GNYE

Motor / motor

(Dreieckschaltung)

(delta-connection)

GNYE

BU

Power PCB

BU

BU

Hall Sensor PCB

RD

WH

BK

GND

WH

+5v

RD

LED Display PCB

RD

Wire Twisted

WH

RD

WH

BK

Litzenkennzeichnung nach IEC 60757/

Stranded conductor colour coding to IEC 60757

15

Page 16

Verdrahtungsplan / wiring diagram:

3x 400V / 50/60Hz

H

LRD 06

LRD 06

LRD 06

LRD 06

LRD 06

Nicht im Lieferumfang /

Not included in delivery

Sicherheitsschalter/

Safety switch

BU

BN

Nicht im Lieferumfang/

Not included in delivery

Netzkabel/

Mains cabel

L1 L2 L3 N

GNYE

TEST

0

H

TEST

0

H

TEST

0

TEST

0

A

I

0

A

Einstellung (Strom [A]) des Relais/

Overload (current [A]) adjustment

I

I

Gerätevariante/

device Variant

RW47 digital

3x400V / 50Hz

RW47 digital

3x400V / 60Hz

Auslösesimulation/

Trip test

S00

S03

S01

Stromwert(einstellen)/

current (adjust)

9596

I

Position Rückstellung Hand (H) - Auto (A)/

manuel (H) - auto RESET

IKA-Lieferzustand : Auto (A)

IKA-delivery status : Auto (A)

I

click

R E S E T

S T O P

Funktion Stop/

Stop function

95

96

1.00A

1.00A

0.86A

BU

RD

1 L1

5 L3

LRD 06

97 NO

14 NO

2 T1

2 T1

WH

L1

U1

3 L2

21 NC

13 NO A1

A2

22 NC

6 T3

4 T2

R E S E T

I

0

A

S T O P

96 NC

98 NO

95 NC

6 T3

4 T2

GY

BN

L2 L3

V1

W1

RD

RD

f

d

Schütz /

Contactor

Motorschutz-Relais/

Motor protection relay

A1

A2

GNYE

Motor / motor

Sternschaltung/

YEV2BK

W2

star-connection

U2

RD

RD

BU

BU

GNYE

RD

RD

Power PCB

BU

BU

Hall Sensor PCB

RD

WH

BK

WH

GND

+5v

RD

RD

WH

LED Display PCB

WH

BK

RD

Wire Twisted

Litzenkennzeichnung nach IEC 60757/

Stranded conductor colour coding to IEC 60757

Klemmleiste/

Connector block

16

Page 17

®

IKA

- Werke GmbH & Co.KG

Janke & Kunkel-Str. 10

D-79219 Staufen

Tel. +49 7633 831-0

Fax +49 7633 831-98

sales@ika.de

www.ika.com

Loading...

Loading...