Page 1

OPERATING AND MAINTENANCE

INSTRUCTIONS

HIGH POWER TWT AMPLIFIER

Ametek CTS US

Instruments for Industry

903 South Second Street

Ronkonkoma, NY 11779

Phone 631 467-8400

Fax 631 467-8558

Email :

MODEL T188-250

DOCUMENT NUMBER

T188-250MN.V1.0

Page 2

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE

1.0 INTRODUCTION ............................................................................................................................... 3

2.0 GENERAL DESCRIPTION ................................................................................................................ 4

3.0 WARRANTY INFORMATION ........................................................................................................ 10

4.0 GENERAL INFORMATION

4.1 Scope Of This Manual ......................................................................................................... 11

4.2 Operation Overview ............................................................................................................. 11

4.3 General Specifications ......................................................................................................... 12

4.4 Functional Description ......................................................................................................... 12

4.5 Protection Circuits ............................................................................................................... 13

4.6 Status Indicators, Controls and Connectors ......................................................................... 13

4.7 TWT Operating Instructions ................................................................................................ 15

4.8 Data Sheets ................................................................................................................. 18

5.0 PRINCIPLES OF OPERATION

5.1 Proper Usage And Warnings ............................................................................................... 17

5.2 Features ................................................................................................................ 17

6.0 IEEE-488 INTERFACE OPTION

6.1 Introduction.......................................................................................................................... 18

6.2 Remote Initialization ............................................................................................................ 18

6.3 GPIB Address ...................................................................................................................... 18

6.4 IEEE-488 Commands .......................................................................................................... 19

6.5 RS-232 ................................................................................................................. 21

7.0 MAINTENANCE AND SERVICING

7.1 Periodic Maintenance .......................................................................................................... 22

7.2 Servicing The Amplifier ...................................................................................................... 22

7.3 Equipment Return Procedure ............................................................................................... 23

LIST OF FIGURES

FIGURE DESCRIPTION PAGE

1.0 TWTA ILLUSTRATION ................................................................................................................... 3

2.0 SYSTEM BLOCK DIAGRAM............................................................................................................ 6

3.0 REAR PANEL ILLUSTRATION ........................................................................................................ 9

4.0 FRONT DISPLAY PANEL START UP MENU ............................................................................... 11

5.0 GPIB ADDRESS MENU ................................................................................................................. 12

6.0 OPERATE MENU ................................................................................................................. 13

7.0 TURNING ON THE AMPLIFIER .................................................................................................... 14

8.0 OPERATE MODE ................................................................................................................. 15

LIST OF APPENDICES

SECTION APPENDIX DESCRIPTION PAGE

8.0 A DATA SHEETS .................................................................................................... 24

9.0 B DRAWINGS.......................................................................................................... 25

Page

2

Page 3

SECTION 1.0

INTRODUCTION

Congratulations on the purchase of your new Wide Band Amplifier from Instruments For Industry,

Inc. Your new Wide Band Amplifier incorporates the finest advancements in the state of the art

electronics technology available in a compact, portable and versatile package. Your Wide Band

Amplifier's quality, performance and trouble free operation depends on you thoroughly reading

through this manual and familiarizing yourself with its proper operation and usage.

Your Wide Band Amplifier comes with the following accessories, be sure to check your packaging

for the items listed below before disposing of the packaging.

CONTENTS

( For a typical Wide Band Amplifier )

Quantity Description

1 TWT High Power Wide Band Amplifier, P/N T188-250

1 Mating AC Power Line cord

1 Operation and Instruction Manual

1 Data Sheets (Included with the unit)

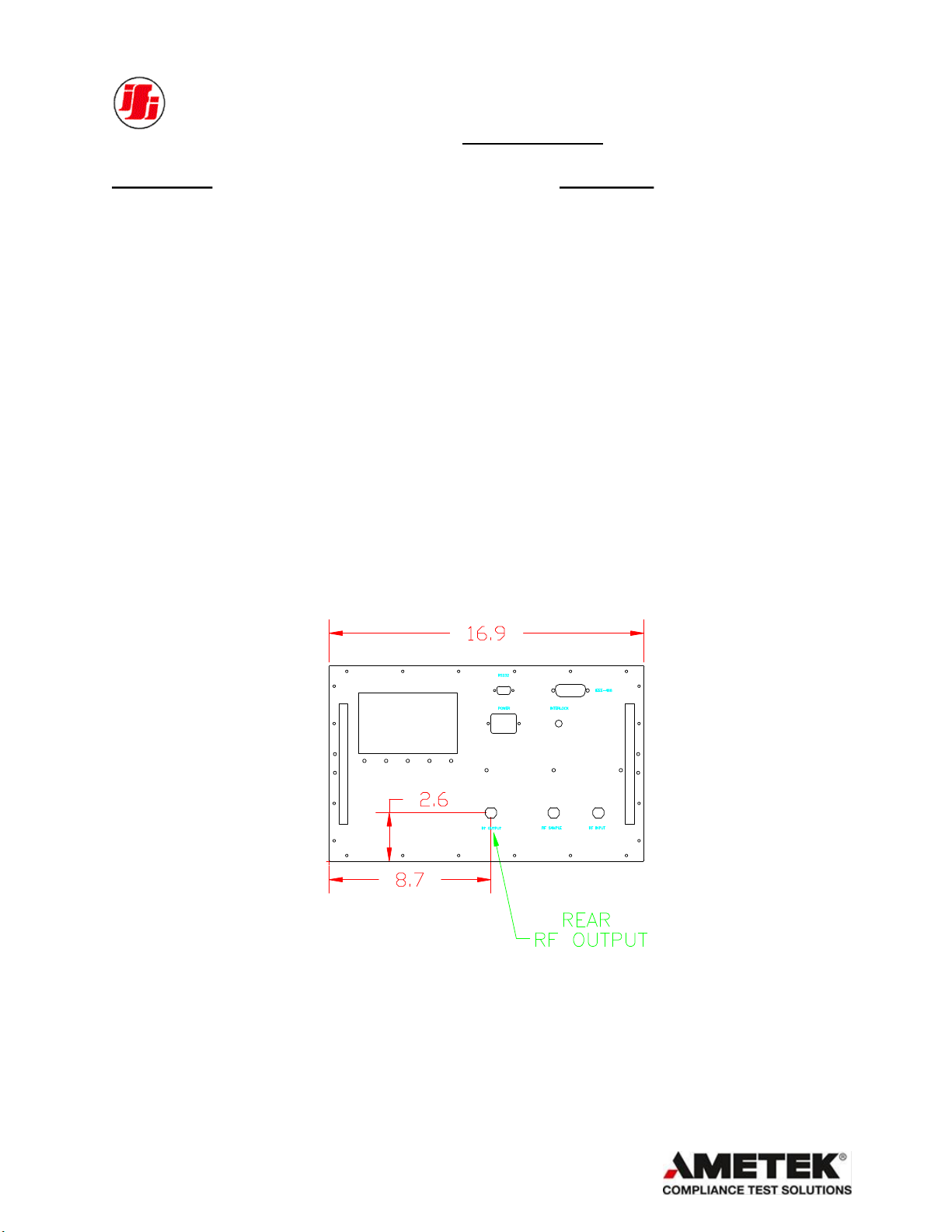

FIGURE 1.0

OUTLINE DRAWING

Page

3

Page 4

SECTION 2.0

GENERAL DESCRIPTION

The Instruments For Industry, Inc. ( IFI ) manufactured TWT Wide Band Amplifier is a Bench Top

or rack mount amplifier providing a nominal output power of at least 250 Watts from 7.0 GHz to

18.0 GHz . The minimum saturated output power midband of the operating frequency range is more

than 250 Watts.

The Amplifier features a Touchscreen Display that displays continuous forward and reflected power

metering. The display also provides the operator with operating status and self diagnostic fault

indications.

The Amplifier incorporates protection circuits that monitor and control so that the amplifier cannot be

damaged by any mismatched load.

The Amplifier has an IEEE-488, RS232 ,USB and Ethernet interface which allows the amplifier to be

remotely controlled through the use of a computer .

To operate the Amplifier, connect a Single phase or three phase power line (50/60 Hz), to the Power

line connector on the rear panel of the unit.

Page

4

Page 5

SECTION 3.0

WARRANTY INFORMATION

Instruments For Industry, Inc. (IFI) warrants each product of its manufacture to be free from any

defect in material and workmanship for a period of three years from shipment to the original

purchaser. All warranty returns, however, must first be authorized by our factory office

representative. Refer to the Service Section for information on how to return items for warranty

repair.

Warranty liability shall be limited to repair or replacement of, or part thereof, which proves to be

defective after inspection by IFI. This warranty shall not apply to any IFI product that has been

disassembled, modified, physically or electrically damaged or any product that has been subjected to

conditions exceeding the applicable specifications or ratings.

IFI shall not be liable for any direct or consequential injury, loss or damage incurred through the use,

or the inability to use, any IFI product.

IFI reserves the right to make design changes to any IFI product without incurring any obligation to

make the same changes to previously purchased units.

This warranty is the full extent of obligation and liability assumed by IFI with respect to any and all

IFI products. IFI neither makes, nor authorizes any person to make, any other guarantee or warranty

concerning IFI Products.

SECTION 4.0

Page

5

Page 6

GENERAL INFORMATION

4.1 SCOPE OF THIS MANUAL

This manual is intended to inform a qualified transmitter operator or technician of the normal

operating and maintenance procedures for the TWT Amplifier. It is not intended to be a course of

instruction for unqualified personnel.

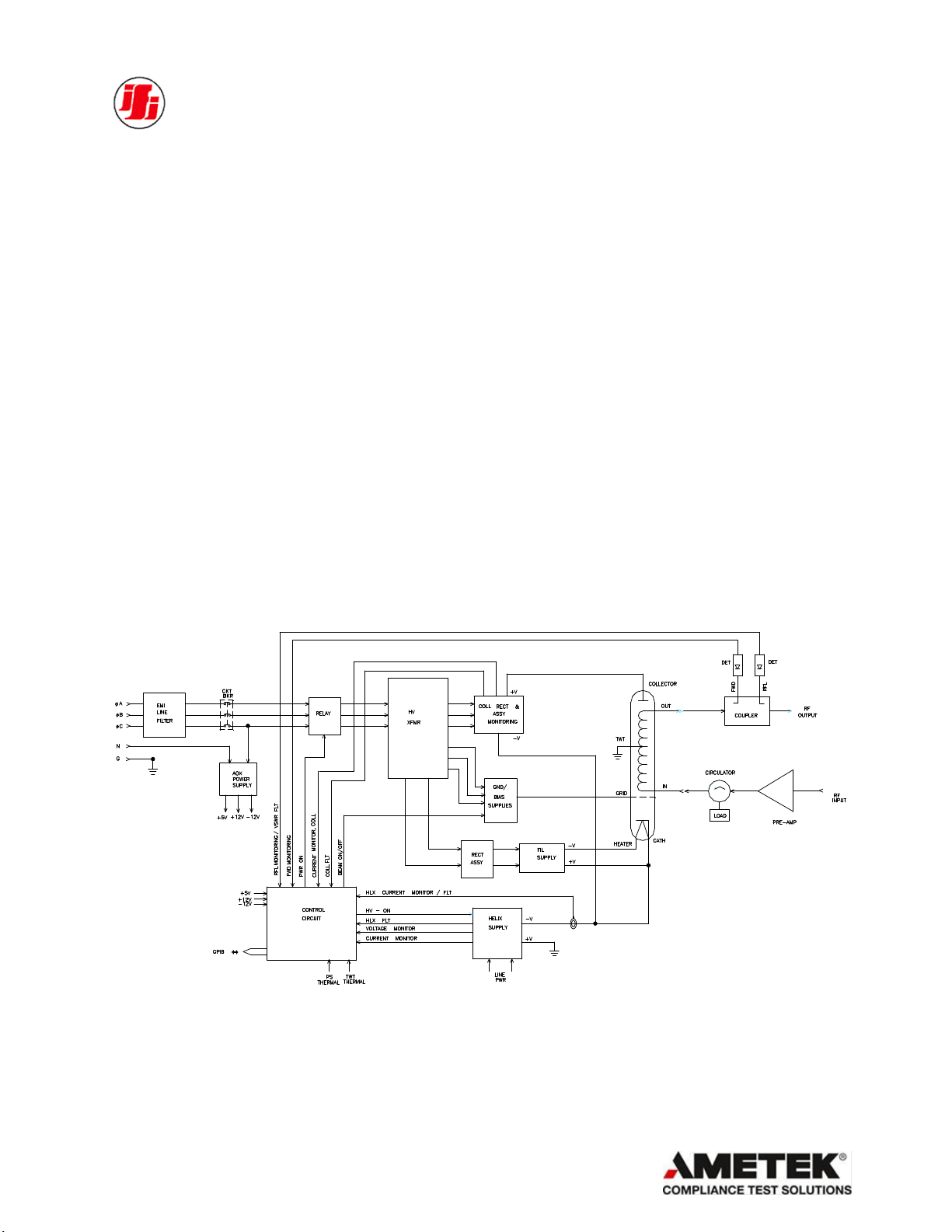

4.2 OPERATION OVERVIEW

The Amplifier is designed to amplify a low level microwave signal and supply a high power CW

output. The Amplifier system function is accomplished primarily through the use of a Traveling

Wave Tube (TWT), control circuitry and power supplies, which can be controlled either locally or

remotely. The major subassemblies are mounted on two separated decks. The upper deck houses the

Collector supply, Filament supply, TWT, control circuitry and all the RF components. The lower

deck houses the Helix supply.

FIGURE 2.0

SYSTEM BLOCK DIAGRAM

4.3 GENERAL SPECIFICATIONS

Page

6

Page 7

The specifications listed below represent the minimum performance characteristics at the

time of delivery.

SPECIFICATIONS

Frequency Response: 7.0 GHz – 18.0 GHz

Power Output: 250 Watts

AC Source: 100-240VAC, 50/60 Hz, Single Phase [refer to label information

provided on the amplifier]

Power Gain: 55 dB

Input Impedance: Nominal 50 Ohms unbalanced

Output Impedance: Nominal 50 Ohms unbalanced

Input Signal Levels: < 0 dBm ( 1.0 mW ) See data sheet for specific input drive levels

Duty Cycle: CW

Spurious: -50dBc

4.4 Functional Description

The required voltages and currents to operate the TWT are provided by the Helix, Collector and

Filament supplies. The Helix supply provides the negative high voltage potential between TWT

Cathode and ground. The Collector supply provides the high voltage potential between the TWT

Cathode and Collector. The Filament supply provides the Heater voltage and floats at high voltage

Cathode potential. In some tubes a Grid element is used to switch the TWT beam ON and OFF.

The primary control circuitry and the service power supplies (+5V, +/- 12V, + 24V) are energized

when the main circuit breaker is turned ON. Upon pressing the AMP ON switch, the Filament and the

Collector supplies are energized and a three minute warm up time is initiated. At the completion of

the three minute time out the Helix supply is enabled and the Amplifier then goes to STBY mode if

no faults were detected. Upon pressing the OPERATE switch the TWT is then turned ON.

Page

7

Page 8

4.5 PROTECTION CIRCUITS

The TWT Amplifier is designed with a variety of protection circuits to provide safeguards for the

amplifier should any adverse electrical conditions occur or if the amplifier accidentally experiences

operator deviation of the design application. Listed below are the safeguards.

4.5.1 Overheat Protection

The TWT, a critical component of this Amplifier, is mounted to a heat sink, which is in turn, air

cooled by high efficiency blower. Should an overheating condition occur, either through component

failure or by a restricted airflow, the Amplifier contains heat sensors that will shut down the system.

As a result, the air inlet and outlet openings should be free of obstructions for proper cooling of the

amplifier. Operation is restored by the Reset button when the amplifier cools to normal temperature

levels.

4.5.2 Power Supply Faults

The Power Supply Fault circuit monitors the Helix and Collector power supplies and produces a fault

indication should any voltage level deviate from normal operating parameters. Each power supply

voltage output is monitored and displayed. Should any power supply voltage deviate from the design

parameters, the Power Supply Fault Indication LED (RED), located on the front panel of the

Amplifier will illuminate and the related fault will be displayed on the LCD display located on the

front panel.

4.5.3 Mismatch Protection

The Amplifier is designed to operate with a tuned 50 Ohm load. Should any mismatching of the 50

Ohm load occur, the Reverse Power, also called Reflective Power, will increase, producing a high

VSWR. The Amplifier microprocessor monitors the Reverse Power levels by utilizing a Dual

Directional Coupler. When the Reflected Power exceeds 25% the Amplifier Output Power The

amplifier will go to STBY and the High VSWR message will be indicated on the LCD display. The

Reverse Power is also displayed on the LCD Display for operator monitoring for any mismatched

load.

4.6 STATUS INDICATORS, CONTROLS AND CONNECTORS

The Amplifier has various controls and status indicators which are identified below and can be

visually located on Figure 1.0, Outline Drawing and Figure 3.0, Rear Panel Illustration. A narrative

description for the function and purpose of each control and status indicator is provided within

paragraphs 4.7.1 and 4.7.2.

Page

8

Page 9

RF AMPLIFIER

Front Panel: Rear Panel:

POWER ON/OFF Ckt Bkr AC PWR, IEC or MS Power Connector

Touchscreen Display USB

RF Input, N Type Female

FWD Sample Port, N Type Female

IEEE-488, Connector

RS232 Remote Control

Ethernet Remote Control

Interlock

RF Output , WRD750

FIGURE 3.0

REAR PANEL ILLUSTRATION

Page

9

Page 10

4.7.1 TOUCHSCREEN SOFT KEYS

INDICATOR FUNCTION

Fault : The FLT RST illuminates Red when either the Helix or the Collector

Power Supplies deviate from the design parameters. The Amplifier will

revert to AMP OFF mode. It also illuminates when either a Thermal or

Airflow condition occurs outside design parameters. Should an

excessive temperature condition occur while monitoring the TWT

temperature of the Heatsink, the Amplifier will revert to AMP OFF

mode. The Touchscreen will indicate which fault had occurred.

TOTAL/OPRT HOUR Elapsed time Indication on the Touchscreen, presents total hours that

the TWT Filament or Beam has been energized.

LOC RMT The LOC / RMT indicates, when illuminated Green, that the amplifier

is in the remote-control mode of operation via any Remote Control.

GPIB (xx) The address selection can be done through the front panel using the

touchscreen display. Holding the GPIB softkey will change the address

BAND 1/BAND 2 (OPT129) This optional feature allows the use of an Harmonic Filter to the limit

the TWT Harmonics. Band 1 is the default through Band and Band 2 is

filtered Band.

ALC ON/OFF (OPTIONAL) The ALC ON/ OFF is for Automatic Leveling Control this Optional

Feature levels the Power Based on the FWD Power Indication. The unit

must Have the Gain Control Feature in order for the ALC to function

4.7.2 CONTROLS

CONTROL FUNCTION

Power ON / OFF Circuit Breaker to turn ON/OFF main prime power to the Amplifier.

OFF/ON The Touchscreen OFF/ON softkey is a momentary switch which, when

pressed to ON position, Filament and Collector supplies are energized

after the Filament time out.

STBY / OPRT When set to OPERATE mode it turns TWT Beam ON, when

set to STBY it turns TWT Beam OFF.

FLT/RST When a Fault occurs the touchscreen button FLT/RST will turn Red.

Pressing this will reset the fault

Page

10

Page 11

4.7 TWT OPERATING INSTRUCTIONS

A) Apply power to the unit using the front panel ON/OFF switch. After 5 secs the splash screen will

display. Once it displays the Boot-up will start .

Figure 4.0, Front Panel Display – Splash Screen

Figure 4.1, Front Panel Display –Boot-Up

Page

11

Page 12

Start-Up Menu

After Boot-up the Start-up Menu will show and the amplifier can be controlled either Remotely or

Manually. Figure 5 is a typical screen customized to the amplifier

Figure 5.0, Front Panel Display – OFF Screen

Page

12

Page 13

Turning ON the Amplifier

FIGURE 7.0 – TURNING ON THE AMPLIFIER (Typical)

1. Press the OFF/ON Softkey .The unit will immediately start the “FILAMENT WARMUP” and

will start the countdown starting with the required time for the applicable TWT incorporated

in the amplifier. In this mode the Filament and Grid (if applicable) supplies will be energized.

2. After the time out, the High Voltage supplies will energize and at that point, if no faults exist,

the STANDBY (STBY/OPRT) mode will be highlighted Yellow.

3. The display will show the Helix and Collector voltages as seen in Figure 8.0.

Page

13

Page 14

FIGURE 8.0 – STANDBY MODE (Typical)

1. Place the unit in OPERATE (OPR) mode. In this mode the TWT will be turned ON.

2. The display will show the Helix and Collector currents as per TWT operating data sheet

FIGURE 9.0 – OPERATE MODE (Typical)

Page

14

Page 15

FAULTS: All Hard Faults will display in the Status Bar and the Actual Fault will be listed in the

Fault Bar. After a Hard Fault to regain control the amplifier the FLT/RST softkey must be

pressed. This will put the amplifier in the OFF Mode and you must restart the amplifier.

Soft Faults such as VSWR Limit or Interlock Open will only show up in the STATUS bar and

turns the amplifier to STANDBY. Once the fault is cleared the amplifier can immediately return

to OPERATE

FIGURE 10.0– FAULT SCREEN

Page

15

Page 16

OPTION 129S (HARMONIC FILTER) : If the amplifier is configured with Harmonic Filters,

the screen will have a Band selection. Band 1 is usually configured as the through Band. This is

done as protection, so the filter is not driven out of Band. Band 2 is the Harmonic Filter Band,

The Band Frequency limits will be displayed on the Front Panel and also recorded on the data

sheet.

FIGURE 11.0A – OPERATE MODE BAND 1

FIGURE 11.0B – OPERATE MODE BAND 2

Page

16

Page 17

4.8 DATA SHEETS

Provided with each Amplifier are specific Test Data Sheets measured from the amplifier using a

calibrated 50 Ohm Pad to assist the operator in maximizing the performance of the Wide Band

Amplifier.

The accuracy of the Metering is ± .5 dB ( nominal ) so to provide the operator with the ability to

maximize the performance of the wide band amplifier.

The Test Data Sheets are located within Appendix A

Page

17

Page 18

SECTION 5.0

PRINCIPLES OF OPERATION

5.1 PROPER USAGE AND WARNINGS

5.1.1 Controlling Power Output

With a nominal 50 ohm resistive load and an input signal appropriate to produce a power output

within the limitations specified above, the amplifier may be placed in operation. To interrupt the

output, simply interrupt the input signal. The amplifier may be run indefinitely at rated output.

Output power is usually measured with a power meter and suitable power Termination.

5.1.2 Input Signal Levels

The Amplifier is designed to operate with less than a 0 dBm (1.0 mW) input signal. It is not

advisable to over drive any amplifier and depend on protection circuits to maintain proper gain

control. IFI makes available with each shipped amplifier specific data and curves so the operator will

know the proper input signal levels to more efficiently operate the amplifier, refer to Paragraph 4.7

herein.

5.2 Features

5.2.1 Preamplifier

The Preamplifier provides the proper drive levels to the TWT to obtain the proper Output Power.

The preamplifier is powered from a low voltage power supply that is independent of the main power

supply.

5.2.2 Power Amplifier

The Power amplifier consists of TWT as the main amplification stage. It is powered by several

power supplies; Filament supply, Helix supply and Collector supply.

Page

18

Page 19

SECTION 6.0

6.1 INTRODUCTION

The Instruments For Industry, Inc. (IFI) Amplifiers can be operated remotely from a computer

having IEEE-488 (GPIB), RS-232, USB or ETHERNET. These interfaces will allow the

amplifier to be remotely controlled by sending commands to the amplifier. Additionally, the

amplifier status and forward and reverse power readings may be read over the remote.

6.2 IEEE-488.2 INTERFACE

The IFI Amplifiers have the IEEE-488.2, General Purpose Interface Bus (GPIB) interface. All

amplifier functions can be controlled by coded messages sent over the interface bus via the

24-pin socket connector on the rear panel of the unit. IEEE-488.2 Standard is implemented,

which defines the protocols and syntax of commands. The GPIB command codes for the IFI

Amplifier series are discussed on subsequent pages and, for ease of identification; the

command codes are identified within the text by bold capital characters. For full information

on the IEEE protocols and syntax, the IEEE-488.2 Standard should be consulted.

6.2.1 GPIB Address

Each amplifier has a unique GPIB address that allows communication to the amplifier on a

multi-bus interface (like GPIB). The GPIB address of the amplifier is set by via the Front

panel using the Control knob at the start up menu. Select an address that is different than the

addresses of any other instruments on the GPIB bus.

6.2.2 Using National Instruments’ GPIB Controllers

In order for the amplifiers to operate correctly with a National Instruments GPIB controller

card, the following must be done: (Items 1-5 are done in the IBCONF program.)

1. Set "Terminate reads on EOS" to yes.

2. Set "Set EOI with EOS on Writes" to yes.

3. Set the EOS byte to 0Ah (an ASCII line feed character).

4. Set "Send EOI at end of writes" to yes.

5. Set "Enable repeat addressing" to yes at the board level.

6. When sending command strings to the amplifier, a carriage return character (0Dh)

followed by a line feed character (0Ah), must always be appended to the command,

IEEE-488.2 INTERFACE

Page

19

Page 20

otherwise the amplifier will wait indefinitely for the CR-LF combination. If

this happens the unit will have to be powered off and back on to reset this

condition. (The interface device will automatically assert the EOI line during the LF if

items 2 - 4, above, are set to yes in the IBCONF program.) As an example, when issuing

the zero attenuation command using the IBIC or WIBIC program, the command string

would look like this: "ZA\r\n". (The \r is National Instruments' notation for the carriage

return, and the \n is the line feed or 'new line' character.) Notice that the commands are

upper case only.

6.3 RS-232 INTERFACE

RS-232, a standard which defines the communication between DTE, data terminal equipment

to DCE, data communication equipment. The IFI Amplifiers have a RS-232, serial interface.

All amplifier functions can be controlled by coded messages sent over the interface bus via the

9-pin D-type socket connector on the rear panel of the unit.

1.3.1 RS-232 Wiring

Connect the serial port of the amplifier to a computer using a null modem cable or a standard

serial cable with a null modem adapter.

Pin #s Signal Name Remote Terminal I/O

2 TXD Output to remote terminal

3 RXD Input from remote terminal

5 Signal GND Signal reference

The RS-232 Serial Communication Settings:

Baud Rate: 9600 Baud.

Data Bits: 8

Parity: None

Stop bits: 1

Flow control: None

6.4 RS-422 / RS-485 INTERFACE

The IFI Amplifiers have the RS-422 and RS-485, serial interfaces. All amplifier functions can

be controlled by coded messages sent over the interface bus via the 9-pin D-type (RS-422) and

RJ-11 (RS-485), connector on the rear panel of the unit.

6.4.1 RS-422/RS-485 Wiring

Connect the RS-422/RS-485 port of the amplifier to a computer cable.

The RS-422/RS-485 Serial Communication Settings:

Page

20

Page 21

Baud Rate: 9600 baud.

Data Bits: 8

Parity: None

Stop bits: 1

Flow control: None

6.5 ETHERNET INTERFACE [when applicable]

The IFI Amplifiers have an Ethernet Interface. All amplifier functions can be controlled by

coded messages sent over the interface bus via RJ-45 connector on the rear panel of the unit.

1.5.1 Description

The Ethernet Interface allows the IFI Amplifiers to communicate with and participate in a

Local Area Network using RJ-45 cable.

The Internet protocol suite (commonly TCP/IP) is the set of communications protocols that

implement the protocol stack on which the Internet and most commercial networks run. It is

named for two of the most important protocols in it: the Transmission Control Protocol (TCP)

and the Internet Protocol (IP), which were also the first two networking protocols defined.

Today's IP networking represents a synthesis of two.

TCP/IP uses four numbers to address a computer. Each computer must have a unique four

numbers address. The numbers are always between 0 and 255. Addresses are normally written

as four numbers separated by a period like this: 192.168.1.50.

The Ethernet interface is a cable bus which runs over copper or fiber. The copper interfaces

use either a coaxial cable or differential twisted pairs. The Ethernet network is defined by

IEEE 802.3 standard. Descriptions for each of the physical lines are provided below.

Ethernet Bus 10/100BaseT Pin-Out

Name Pin Cable Color Pin Name

TX+ 1 White/Orange 1 TX+

TX- 2 Orange 2 TX-

RX+ 3 White/Green 3 RX+

4 Blue 4

5 White/Blue 5

RX- 6 Green 6 RX-

7 White/Brown 7

8 Brown 8

Page

21

Page 22

6.6 REMOTE COMMAND FORMAT

The IFI Amplifiers remote commands are a string of ASCII characters with the following

format:

Command Code End Of String Characters

The Command Code is a three to nine characters command code which the system interprets

to determine the type of action to take. See Remote commands below.

The End of String characters are two ASCII characters, a carriage return character (0D hex)

followed by a line feed character (0A hex) that must follow the command code for all

commands.

NOTES:

1. ALL COMMANDS AND REQUESTS MUST CONSIST ENTIRELY OF UPPER

CASE ALPHANUMERIC CHARACTERS.

2. ALL VALUES DISPLAYED DO NOT SHOW THE ZEROS TO THE LEFT OF THE

NUMBER VALUE.

1.6.1 Remote/Local Control

When the amplifier receives a command over the remote interface, it automatically switches

to REMOTE operation, pressing the LOCAL key on the front panel returns the unit to normal

manual local operation. Optional mode is when the computer host must send a REMOTE

command for the amplifier to go remote. In this option all status commands can be read while

the amplifier is in local mode and they will not revert the amplifier to remote. An additional

LOCAL command is applied to put amp in local mode if it was set for remote operation

Page

22

Page 23

1.6.2 REMOTE COMMANDS

IEEE COMMANDS FOR TWTA

Code TWTA function

OFF AMP OFF

ON

STBY

OPRT

RESET

AMP ON

Standby

Operate

Fault Reset

ATTUxx Increase Attenuation (xx- # of steps) [Response with Gain value, ‘GAIN: XXXXX

%’](optional)

ATTDxx Decrease Attenuation (xx- # of steps) [Response with Gain value, ‘GAIN:

XXXXX %’](optional)

BAND Selects Band of Operation & Returns, ‘XXXXXXXXXXXXXXXX’ [Optional]

REQUEST STATUS

Code AMPLIFIER STATUS

STATUS OFF

FAULT

STANDBY INTERLOCK OPEN

REMOTE OPERATION DISABLED

EXCESS PULS W [ In Pulse unit only ]

EXCESS DTY CYC [ In Pulse unit only ]

ON-WARMUP

OPERATE

FAULT

INTERLOCK OPEN

HIGH VSWR

Returns Detailed Message

THERMAL FAULT

HIGH HELIX CURRENT FAULT

HELIX VOLTAGE FAULT

COLLECTOR CURRENT FAULT

COLLECTOR VOLTAGE FAULT

LOW AIRFLOW FAULT

Page

23

Page 24

POWER AND METERING - STATUS RESPONSES FOR AMP

CODE TWTA FUNCTION

POWERFWD

Returns Forward Power Value in Watts, ‘POWER FWD: XXXXX W’

POWERRFL Returns Reflected Power Value in Watts, ‘POWER RFL: XXXXX W’

HELIXV Returns Helix Volts Value in Volts, ‘HELIXV: XXXXX V’

HELIXI Returns Helix Current Value in milliamps, ‘HELIXI: XXXXX mA’

COLLV Returns Collector Volts Value in Volts, ‘COLLV: XXXXX V’

COLLI Returns Collector Current Value in milliamps, ‘COLLI: XXXXX mA’

FILAMENTV Returns Filament Volts Value in Volts, ‘FILAMENT V: XXXXX V’

[Optional]

GRIDV Returns Grid Volts Value in Volts, ‘GRID V: XXXXX V’ [Optional]

FILAMENTH Returns Filament Hours Value, ‘FIL HRS: XXXXX’

BEAMH Returns Beam Hours Value, ‘BEAM HRS: XXXXX’

PULSEW Returns Pulse Width Value, ‘PULS W: XXXXX.X uS’ [ In Pulse unit only ]

FRQNCY Returns Pulse Frequency Value, ‘REP RATE: XXXXXX Hz’ [ In Pulse

unit only ]

DUTYCYC Returns Duty Cycle Value, ‘DTY CYC: XXXXX %’ [ In Pulse unit only ]

ZEROATT Sets the Amplifier for ZERO Attenuation & Returns, ‘GAIN: 00100 %’

[Optional]

FULLATT Sets the Amplifier for FULL Attenuation & Returns, ‘GAIN: 00000 %’

[Optional]

MODEL

SN

*IDN?

Returns ASCII response comprising of four data fields in the format

Returns Model number of the unit

Returns Serial number of the unit

<Manufacturer>, <Model>, <Serial Number>, <Firmware Version>

*RST

Reset Command, Sets the Amplifier to the factory default power up state

(reboots MPU)

Page

24

Page 25

1.7 REMOTE EXAMPLE CODE

RS-232 USB or Ethernet, Example using Hyper-terminal

1. Connect serial port of amplifier to computer using a null modem cable or a standard serial

cable with a null modem adapter.

2. Use a program such as Hyper-terminal to communicate with the amplifier. (To find Hyper-

terminal go to Start Programs Accessories Communications Hyper Terminal,

and click on Hyper terminal.

To setup Hyper terminal follow the directions below.

When Hyper terminal runs a setup dialog box will open:

For RS-232:

2.1 Enter a name and choose an icon. Click OK.

2.2 In the Connect Using box select your Comm. port (Ex. “Direct to Com1” or

“Com1”) for RS-232 or TCP/IP for Ethernet remote. Click OK.

2.3 In Bits per Second select “9600”.

2.4 In Data Bits select “8”.

2.5 In Parity Select “None”.

2.6 In Stop bits select “1”.

2.7 In Flow control select “None”

2.8 Click OK.

For Ethernet:

2.1 Enter a name and choose an icon. Click OK.

2.2 In the Connect Using box select TCP/IP for Ethernet remote. Click OK.

2.3 Enter an IP Address in Host Address box and 10001 in Port Number box. Click

OK.

3. If you use Hyper-terminal steps 2.1 to 2.8 will set up Com1 to communicate at 9600 baud,

8 bits, and no parity with 1 stop bit and steps 2.1 to 2.3 will set up Ethernet to

communicate at 57600 baud.

4. Turn amplifier line power ON.

5. To place the amplifier in remote operation type in a valid command such as “STATUS”

and then hit the “Enter” key. The amplifier will then go into remote operation and the

status will be displayed on the computer.

Page

25

Page 26

6.8 See the section 1.6.2 REMOTE COMMANDS for the list of usable commands and

responses.

REMOTE EXAMPLES

Command to read the amplifiers status:

ASCII String to amplifier: STATUS(cr)(lf)

Hex equivalent of string: 0x53,0x54,0x41,0x54,0x55,0x53,0x0d,0x0a

Action: None

Response: Responds with the amplifiers current status.

Example of response: STANDBY(cr)(lf)

Hex value of example response: 0x53,0x54,0x41,0x4e,0x44,0x42,0x59,0x0a,0x0d

Command to place unit in operate mode:

ASCII String sent to amplifier: OPRT(cr)(lf)

Hex equivalent of string: 0x4f, 0x50, 0x52, 0x54,0x0d,0x0a

Action: The amplifier will go to Operate mode if the amplifier was previously in Standby mode.

Response: None

Example of response: N/A

Hex value of example: N/A

Command to read the amplifiers forward power:

ASCII String to amplifier: POWERFWD(cr)(lf)

Hex equivalent of string: 0x50,0x4f,0x57,0x45,0x52,0x46,0x57,0x44,0x0d,0x0a

Action: None

Response: Responds with the amplifiers forward power reading.

Example of response : POWER FWD: 09005 W(cr)(lf)

Hex value of example response :

0x50,0x4f,0x57,0x45,0x52,0x20,0x46,0x57,0x44,0x3a,0x20,0x30,0x39,0x30,0x30,0x35,0x2

Page

26

Page 27

Controlling the amplifier with the web-based interface

You can control the amplifier remotely via a web-based interface through a web browser.

IMPORTANT Please note that the amplifier and computer must be on the same local network.

Obtaining the amplifiers IP address

Connect the amplifier to a network by inserting an ethernet cable, and then turn the unit on.

Once you are at the main display, you should note in the top right corner the IP address of the

amplifier.

Page

27

Page 28

Accessing the web-based amplifier interface

Enter the amplifier’s IP address in the address bar of your web browser, using the following format,

and then press [ENTER]

http://[IP Address]:8000

At this point, any action performed via the web interface or the amplifier’s display, will show in each

of the screens.

Changing the amplifiers IP address

Page

28

Page 29

To change the IP address of the amplifier to a static IP, you can access the ethernet configuration

menu of the amplifier from the front display, or remotely.

From the front display:

- Press and hold the [LOC/RMT] button for 8 seconds, and you will be

prompted with the following ethernet configuration menu

Primary Ethernet

IP Address Displays the current IP address of the amplifier

Subnet Mask Displays the current Subnet Mask of the amplifier

Default Gateway By default, this field is left unpopulated*

Static IP Off by default. Enable to set a static IP address

Secondary Ethernet

IP Address Displays the IP address of the secondary ethernet controller

Subnet Mask Displays the Subnet Mask of the secondary ethernet controller

*Default Gateway only needs to be entered for Static IP configuration

Page

29

Page 30

Cross

-

Over

Direct Cross-Over Communication with Ethernet

Should you want to communicate with the amplifier directly, using a desktop or laptop pc, you can

accomplish this by using a cross-over ethernet cable.

It is recommended that you first issue an IP to the amplifier via a routers DHCP server, and then configure

the amplifier with a static IP.

Initial Configuration

The MPU by default is set to obtain an IP address automatically from a local DHCP server (such as a

router).

Both the computer being used to send commands, and the MPU, must be on the same local network.

For testing purposes, the following configurations were used.

Configuration 1 – Network Router

The computer and MPU are plugged into two separate ports of a router (Linksys BEFSR81). A router by

default is set to act as a local DHCP server and should work out of box in this way. The router was

modified to only issue IP addresses within a specific range of 192.168.1.50 through 192.168.1.99.

PC IP = 192.168.1.51

MPU IP = 192.168.1.50

Using HyperTerminal, a remote connection using Ethernet was established to begin testing.

Once connected, the following commands were issued to verify functionality.

- STATUS

- *IDN?

- OPRT

- STBY

Following this, the MPU was then configured with a static IP address using the SETTINGS -> EDIT

commands. The following values were set:

- STATIC IP = Y

- STATIC IP Value = 192.168.1.64

- SAVE SETTINGS = Y

Page

30

Page 31

The MPU was then rebooted with the *RST commanded, and it was verified that the MPU display

showed the correct static IP address.

Using HyperTerminal, a remote connection was established again, and the same commands listed above

were retested.

Following this test, the MPU was reset to receive an IP from the DHCP server. Again, using the SETTINGS

-> EDIT commands. The following values were set:

- STATIC IP = N

- STATIC IP Value = 1.1.1.1

- SAVE SETTINGS = Y

The MPU was then rebooted again and it was verified that the IP had changed to a dynamic IP address.

MPU IP = 192.168.1.50

PC IP = 192.168.1.51

Configuration 2 – Network Router + Network Switch

The PC and MPU were disconnected from the router and hooked up to a network switch (Linksys

SRW224G4) and used in an unmanaged mode (standard switch configuration). A single CAT5E cable was

ran from the router to the switch.

Following turn on of all the equipment, the following IP addresses were issued:

MPU IP = 192.168.1.51

PC IP = 192.168.1.50

A remote connection, via Ethernet, was reestablished with the MPU and the same commands were sent

to verify functionality.

Following this, the MPU was then configured with a static IP address again using the SETTINGS -> EDIT

commands. The following values were set:

- STATIC IP = Y

- STATIC IP Value = 192.168.1.96

- SAVE SETTINGS = Y

The MPU was then rebooted, and the correct static IP value was displayed on the front display of the

MPU.

Using HyperTerminal, a remote connection was established again, and the same commands listed above

were retested.

Once complete, the MPU was reset to accept a DHCP IP address, and once rebooted, the IP address of

the MPU went back to 192.168.1.51

Page

31

Page 32

SECTION 7.0

MAINTENANCE AND SERVICING

7.1 PERIODIC MAINTENANCE

The only periodic maintenance required on the TWT amplifier system is insuring that the cooling

vents are not obstructed in such a manner that the airflow is restricted. Periodic cleaning of the vents

may be required depending on the degree of dust in the atmosphere.

7.2. SERVICING THE AMPLIFIER

Servicing of the amplifier by the operator is not recommended. Most of the internal circuitry requires

special and unique test instruments to trouble shoot, align and calibrate the circuits. Should servicing

be required, refer to Paragraph 7.3.

7.2.1 TROUBLESHOOTING

PROBLEM CAUSE SOLUTION COMMENTS

TOUCHSCREEN display

blank

Amp will not go to Operate

mode

Helix supply fault after

warm-up time

Helix Supply fault when

turning amplifier to OPRT

mode.

Collector supply fault Collector supply faulty Check Collector voltage output

Air Flow fault No sufficient Air-inlet Move any obstructions from air

Thermal fault Over-heating Make sure airflow is adequate

No service voltages Check line power.

Check service voltages,

+12VDC, -12VDC, 5VDC

Door interlock open,

High VSWR

Helix Power supply faulty Check Helix voltage output

HV arcing (Overcurrent

fault).

TWT gassy

Check that door interlock BNC

connector is terminated with

either 50 Ohms or short.

Check RF output termination

connection.

without TWT connected

Disconnect TWT and operate

amplifier. Check for arcing if

fault consist.

Degas TWT by leaving Amp in

STBY mode for few hours.

without TWT connected

inlet sections

and ambient temperature within

the limit.

Connect AC line to

specified Prime power

source.

Refer to S/N tag on unit

When operating any RF

amplifier proper

termination must be

connected to the RF output

connector.

Check on the

TOUCHSCREEN display

for the fault description.

Danger High Voltages

TWTA must be turned ON

at least once a month, so to

eliminate TWT gassing up.

Check on the

TOUCHSCREEN display

for the fault description.

Danger High Voltages

Page

32

Page 33

7.3 EQUIPMENT RETURN PROCEDURE

Should such an event arise that the Amplifier requires repair or calibration, it is recommended that the

reader follow the Equipment Return Procedure so the equipment can be repaired or calibrated and

returned in a efficient and timely manner.

7.3.1 Request a RMA Number

Contact the IFI Service Department either in writing or by calling (631) 467-8400 and request a

Return Material Authorization (RMA) Number. The RMA Number is the method IFI uses to prepare

its' services for returned material in transit and acts as a tracking document for the returned material

through the repair or calibration process. The RMA also documents the customers' specific

instructions or reason related to the return of the material.

7.3.2 Return All Accessories

In the interest of saving time and expediting the repair or calibration process, return all the associated

accessories described in Section 1.0 when returning the equipment for repair or calibration. In many

cases, a faulty accessory could give the illusion that the equipment itself has failed. For this reason it

is important to return the all the accessories with the equipment. It is also IFI's policy to verify

performance of all associated accessories of Section 1.0 before returning the equipment to service.

7.3.3 Packaging The Equipment

When returning equipment to the manufacturer, always wrap each accessory separately and provide

sufficient protective material around each item to prevent damage from handling and shipping

conditions.

7.3.4 Reference The RMA Number

As detailed in Paragraph 7.3.1, always reference the IFI assigned RMA Number on your Packing List

and Purchase Order and also when any inquiries are made.

Page

33

Page 34

APPENDIX A

TEST DATA SHEETS

Page

34

Page 35

APPENDIX B

Drawings Package

900874 INTERCONNECT DIAGRAM

Page

35

Loading...

Loading...