Page 1

OPERATING AND MAINTENANCE

INSTRUCTIONS

WIDE BAND SOLID STATE AMPLIFIER

Prepared by:

MODEL S251-250

DOCUMENT NUMBER

S251-250MNL V1.0

Instruments for Industry

903 South Second Street

Ronkonkoma, NY 11779

Phone: 631 467-8400

Fax: 631 467-8558

Email: info@ifi.com

Page 2

2

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE

1.0 INTRODUCTION...........................................................................................4

2.0 GENERAL DESCRIPTION ...........................................................................5

2.1 AC Connection and Set-Up ................................................................5

3.0 WARRANTY INFORMATION .....................................................................6

4.0 GENERAL INFORMATION

4.1 Scope Of This Manual ........................................................................7

4.2 General Specifications ........................................................................7

4.3 Protection Circuits ..............................................................................8

4.4 Status Indicators, Controls and Connectors ......................................10

4.5 Operating Instructions .......................................................................13

4.6 Data Sheets ........................................................................................17

5.0 PRINCIPALS OF OPERATION

5.1 Proper Usage And Warnings .............................................................18

5.2 Features Of The Amplifier ...............................................................19

5.3 Level Control Board ..........................................................................20

5.4 Optional Features ..............................................................................20

6.0 AUTOMATIC LEVELING CONTROL (ALC )

6.1 ALC Features .................................................................................... 21

6.2 Leveling Using The "INT' Mode ....................................................... 22

` 6.3 Leveling Using The 'EXT' Mode ...................................................... 23

7.0 IEEE-488 INTERFACE OPTION

7.1 Introduction ....................................................................................... 26

7.2 Remote Initialization ......................................................................... 26

7.3 GPIB Address ................................................................................... 27

7.4 Status Commands ............................................................................. 28

7.5 RS-232 Instructions .......................................................................... 30

8.0 MAINTENANCE AND SERVICING

8.1 Periodic Maintenance ........................................................................ 31

8.2 Servicing The Amplifier ................................................................... 31

8.3 Equipment Return Procedure ............................................................ 32

Page

Page 3

3

LIST OF FIGURES

FIGURE DESCRIPTION PAGE

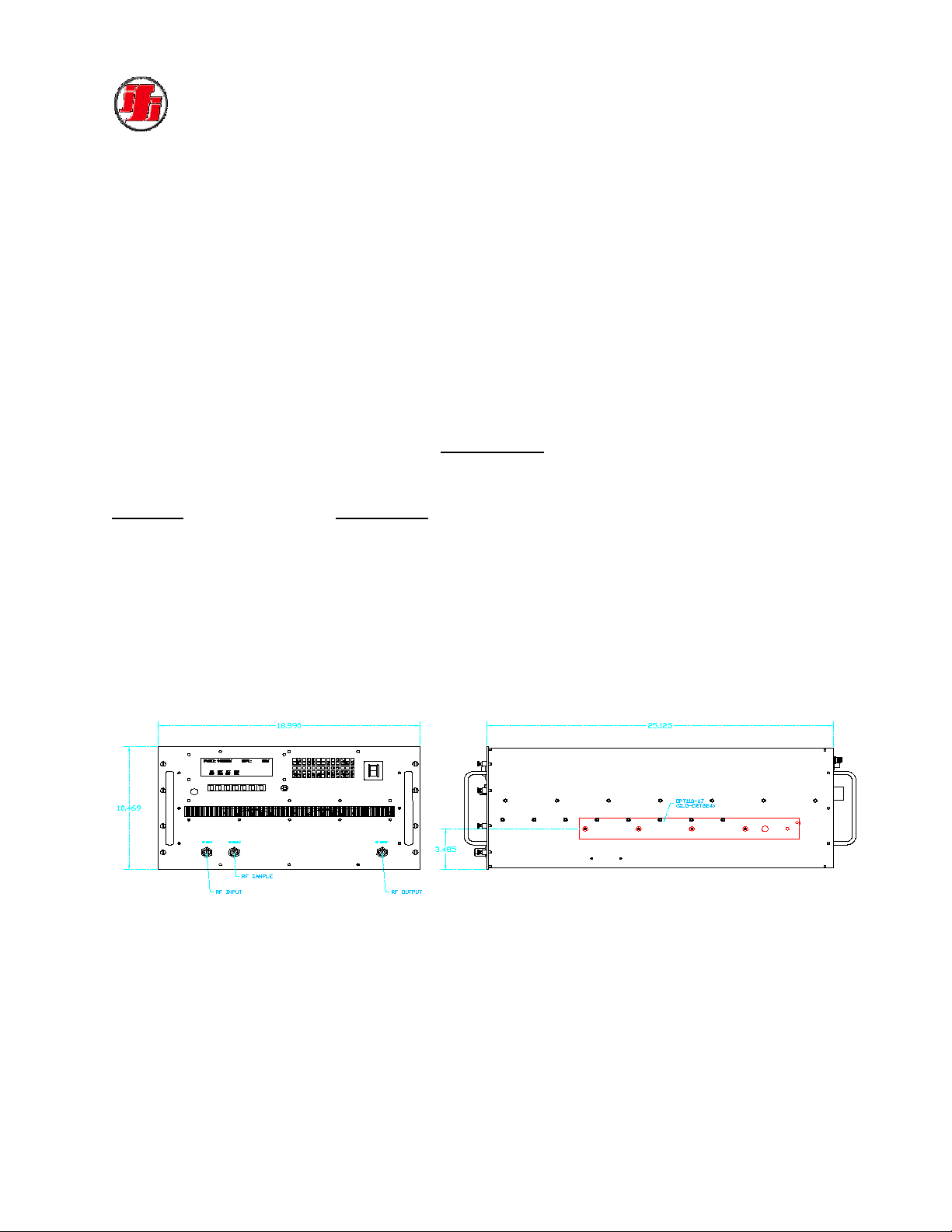

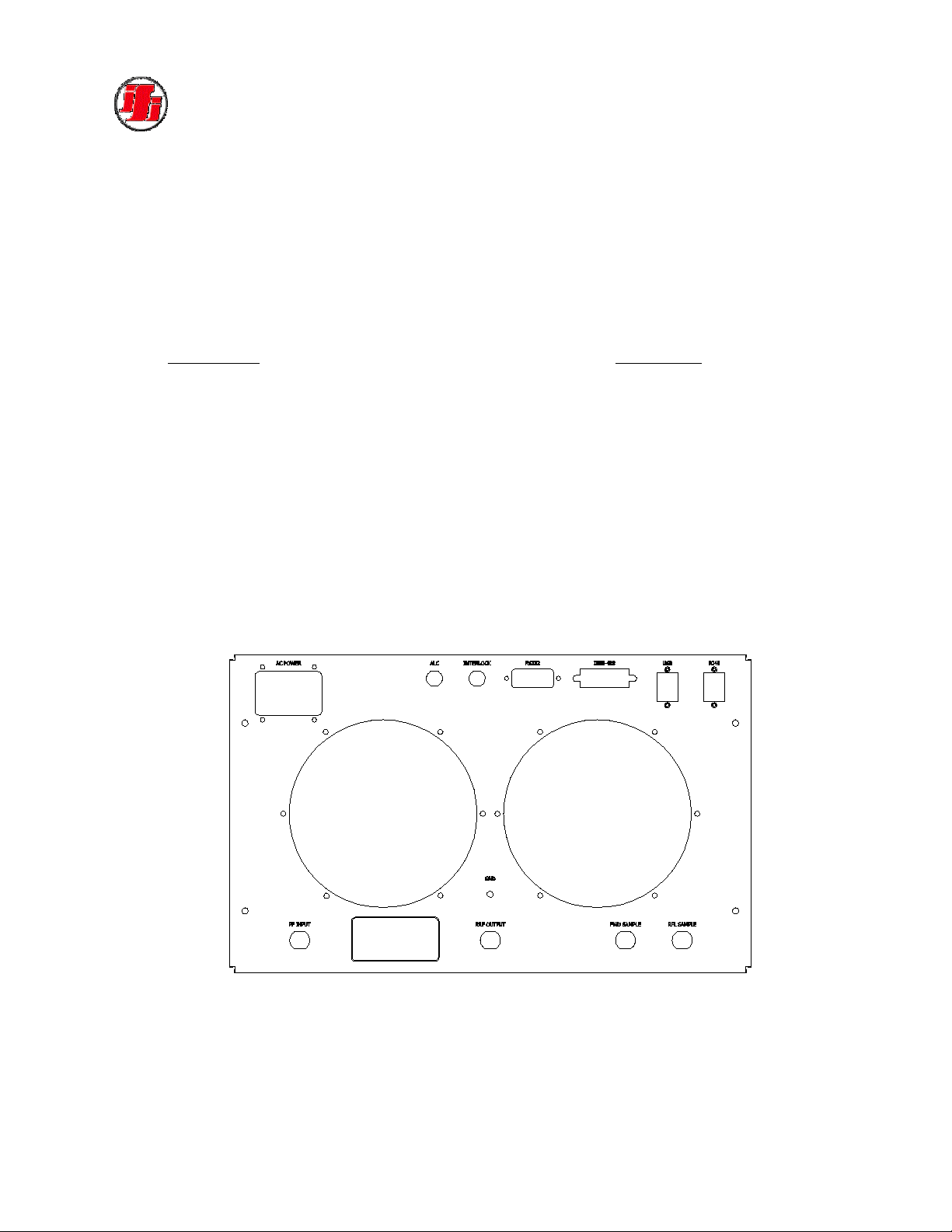

1.0 S251-250 ILLUSTRATION ........................................................................... 4

2.0 S251-250 REAR PANEL ILLUSTRATION ................................................ 10

3.0 FRONT PANEL DISPLAY START-UP MENU ......................................... 13

4.0 GPIB ADDRESS MENU.............................................................................. 14

5.0 MAIN MENU STATUS DISPLAY ............................................................. 15

6.0 TURNING ON THE AMPLIFIER ............................................................... 16

7.0 S251-250 SCHEMATIC DIAGRAM ........................................................... 19

LIST OF APPENDICES

SECTION APPENDIX DESCRIPTION PAGE

9.0 A AMPLIFIER DATA SHEETS .......................................................... 33

10.0 B DRAWINGS PACKAGE ................................................................. 34

Page

Page 4

4

SECTION 1.0

INTRODUCTION

Congratulations on the purchase of your new Wide Band Amplifier from Instruments For Industry,

Inc. Your new Wide Band Amplifier incorporates the finest advancements in state of the art solidstate electronics technology available in a compact, portable and versatile package. Your Wide Band

Amplifier's quality, performance and trouble free operation depends on you thoroughly reading

through this manual and familiarizing yourself with its proper operation and usage.

Your Wide Band Amplifier comes with the following accessories, be sure to check your packaging

for the items listed below before disposing of the packaging.

CONTENTS

(For a typical Wide Band Amplifier )

Quantity Description

1 High Power Wide Band Amplifier, Model S251-250

1 AC power line cord

1 Operation and Instruction Manual, Doc. No. S251-250

1 Amplifier Data Sheets (Included with Unit)

FIGURE 1.0

S251-250 ILLUSTRATION

Page

Page 5

5

SECTION 2.0

GENERAL DESCRIPTION

The Instruments for Industry, Inc. (IFI) manufactured S251-250 Wide Band Amplifier is a Bench Top

or rack mount amplifier providing 250 Watts of RF power from 800 MHz to 2500 MHz

instantaneously.

The Amplifier features a Color Touchscreen that displays continuous forward and reflected power in

three-digit metering. The display also scrolls to provide the operator with operating status and selfdiagnostic fault indications.

The Amplifier is unconditionally stable and incorporates protection circuits that monitor and control

the VSWR input and outputs so the amplifier cannot be damaged by any mismatched load.

The Amplifier may be equipped with an IEEE-488 BUS & RS232 interfaces, which allows the

amplifier to be remotely controlled through the use of as computer.

To operate the Amplifier, connect the single phase power line cord to the IEC connector on the rear

panel.

Page

Page 6

6

SECTION 3.0

WARRANTY INFORMATION

Instruments For Industry, Inc. (IFI) warrants each product of its manufacture to be free from any

defect in material and workmanship for a period of three years from shipment to the original

purchaser. All warranty returns, however, must first be authorized by our factory office

representative. Refer to the Service Section for information on how to return items for warranty

repair.

Warranty liability shall be limited to repair or replacement of, or part thereof, which proves to be

defective after inspection by IFI. This warranty shall not apply to any IFI product that has been

disassembled, modified, physically or electrically damaged or any product that has been subjected to

conditions exceeding the applicable specifications or ratings.

IFI shall not be liable for any direct or consequential injury, loss or damage incurred through the use,

or the inability to use, any IFI product.

IFI reserves the right to make design changes to any IFI product without incurring any obligation to

make the same changes to previously purchased units.

This warranty is the full extent of obligation and liability assumed by IFI with respect to any and all

IFI products. IFI neither makes, nor authorizes any person to make, any other guarantee or warranty

concerning IFI Products.

Page

Page 7

7

SECTION 4.0

GENERAL INFORMATION

4.1 SCOPE OF THIS MANUAL

This manual is intended to inform a qualified transmitter operator or technician of the normal

operating and maintenance procedures for the S251-250. It is not intended to be a course of

instruction for unqualified personnel.

4.2 GENERAL SPECIFICATIONS

The specifications listed below represent the minimum performance characteristics at the time of

delivery.

SPECIFICATIONS

Frequency Response: 800 - 2500 MHz

Power Output: Minimum 250 Watts

AC Source: 220VAC, 50/60, Single Phase

Power Gain: 54 dB

Input Impedance: Nominal 50 Ohms unbalanced

Output Impedance: Nominal 50 Ohms unbalanced

Input Signal Levels: < 0 dBm ( 1.0 mW ) See data sheet for specific input drive levels

Duty Cycle: CW

Spurious: -50dBc

Page

Page 8

8

4.3 PROTECTION CIRCUITS

The S251-250 is designed with a variety of protection circuits to provide safeguards for the amplifier

should any adverse electrical conditions occur or if the amplifier accidentally experiences operator

deviation of the design application. Listed below are the safeguards built into the S251-250.

4.3.1 Over Heat Protection

The S251-250 critical components are mounted to heat sinks, which are, in turn, air cooled by four

fans. Should an over heating condition occur, either through component failure or by a restricted

airflow, the S251-250 contains heat sensors that will shut down the system. As a result, the air inlet

and outlet openings should be free of obstructions for proper cooling of the amplifier. Operation is

restored after Fault Reset when the amplifier cools to normal temperature levels.

4.3.2 Input Protection

The S251-250 is designed to operate with less than a 0 dBm (1.0 mW) input signal however, to

prevent overdriving the amplifier, the Input Protection circuit will activate if the input signal exceeds

3 dBm (2.0 mW) and will automatically compensate for the increased input signal by reducing the

gain of the preamplifier. Even though the amplifier has an Input Protection Circuit, overdriving the

amplifier is not recommended; refer to paragraph 5.1.2 for more details.

4.3.3 Output Protection

The S251-250 incorporates a microprocessor controlled Output Protection Circuit which monitors the

Forward Power Meter indication and limits the output power. This feature protects the amplifier

from being over driven and causing damage to the power transistors.

It is important to note that this feature only operates when the Forward and Reverse Sample Ports on

the amplifier have 50 Ohm Terminations installed.

IMPORTANT NOTE:

The S251-250 Sample RF Output connector must be terminated with the supplied 50 Ohm

load if the output is not being used. Should the S251-250 be operated without a termination

on the Sample RF Output connection will jeopardize the accuracy of the metering and output

protection; which are based on the Forward Power Readings, which may result in damaging

the amplifier and voiding the unit’s warranty.

Page

Page 9

9

4.3.4 Power Supply Faults

The Power Supply Fault circuit monitors the 50 VDC, ± 12 VDC and 5 VDC power supplies and

produces a fault indication should any voltage level deviate from normal operating parameters. Each

power supply voltage output is monitored and displayed to indicate the power supplies are operating

within design parameters. Some units may have Green Status LED Indicators in addition to the

Controller Display. Should any power supply voltage deviate from the design parameters, the

corresponding power supply fault will be displayed

4.3.5 Mismatch Protection

The S251-250 is designed to operate with a tuned 50 Ohm load and should any mismatching of the 50

Ohm load occur, the Reverse Power, also called Reflective Power, will increase producing a high

VSWR. The S251-250 microprocessor monitors the Reverse Power levels by utilizing a Dual

Directional Coupler and begins to turn down the gain of the preamplifier when the Reflected Power

exceeds 40%. The Reverse Power is also displayed on the LCD Display for operator monitoring for

any mismatched load.

4.3.6 Short Circuit Protection

The S251-250 utilizes three different power supply voltages, + 32 VDC, ± 12 VDC and the

+ 5 VDC, each of the power supplies are designed with a short circuit and overload protection

device.

Page

Page 10

10

Local/Remote Switch

AC PWR, IEC Power Connector

Amp ON / OFF Switch

ALC INPUT, BNC Type (Optional)

Operate / Standby Switch

INTERLOCK, BNC Type (Optional)

Fault/Reset Switch

IEEE-488, Connector

Color Touchscreen Display

RS232 Connector

RF Input, N Type, Female

RF Input, N Type, Female

FWD Sample Port,’N’ Type Female

FWD Sample Port,’N’ Type Female

RF Output, N Type, Female

RF Output, N Type, Female

4.4 STATUS INDICATORS, CONTROLS AND CONNECTORS

The S251-250 has various controls and status indicators, which are identified below and can be

visually located on Figure 1.0, S251-250 Illustration and Figure 2.0, S251-250 Rear Panel Illustration.

A narrative description for the function and purpose of each control and status indicator is provided

within paragraphs 4.4.1 and 4.4.2.

S251-250 RF AMPLIFIER

Front Panel: Rear Panel:

FIGURE 2.0

S251-250 REAR PANEL ILLUSTRATION

Page

Page 11

11

4.4.1 S251-250 PANEL STATUS INDICATORS

INDICATOR FUNCTION

FAULT INDICATOR The Fault indicator displays a fault when either a Thermal, Power

Supply or Module Fault occurs on Front panel display. Some units may

have Green Status LED Indicators in addition to the Controller Display.

A Thermal Fault occurs when the amplifier is operating outside design

temperatures. Should an excessive temperature condition occur, the

+50 VDC Supply is shut down and a Power Supply fault is indicated.

Once the thermal condition returns to the operational limits, the

+50VDC Supply will activate.

A Power Supply Fault is displayed when the +50 VDC Power Supply

voltage shuts down.

Hi VSWR When the Hi VSWR fault is displayed; the amplifier is subjected to a

condition where the Reflected Power exceeds 40%. The

microprocessor turns down the gain of the preamplifier and displays the

Reverse Power on the LCD Display.

RMT /LCL When remote displays on the front panel the amplifier is in the remote

control mode of operation via the IEEE-488 GBIP Bus. The address

selection can be done through the front panel using the Control Knob.

Follow instructions on the LCD display.

TOTL/OPRT HOUR Elapsed time Indication on the LCD display, presents total hours of the

amplifier or operate hours that it has been energized.

Page

Page 12

12

4.4.2 S251-250 CONTROLS

CONTROL FUNCTION

Local When depressed, the amplifier is restored to the local control from the

GPIB mode of control.

ALC Switch The optional Automatic Leveling Control (ALC) is a feature, which

selects the method for leveling, either internal, external or manual.

Power ON/OFF The Power On/Off switch is a circuit breaker that is used as an

On/Off switch as well as a circuit protection device. This switch

turns the driver either on or off.

Control Level Adjust Knob The optional Level Adjust control is a ten-turn pot, which allows a

minimum of a 30 dB range of gain. Turning the control Counter

Clockwise (CW) produces a minimum gain.

Important Note: If the amplifier is not equipped with this option, the

display will still indicate a GAIN percentage (refer to Figure 5.0). This

percentage indication is still controlled by Level Adjust Control but the

both the Level Adjust Control and the corresponding GAIN percentage

indication has no effect on the amplifier gain.

FLT/RST The Reset/Fault (FLT/RST) is a reset switch that resets the fault

indication. If a fault indication is present, the fault indication can

remove the by depressing this switch.

OPR/STB The Operate/Standby (OPR/STB) switch which when the switch is set

in the Standby mode, the Power Supply is turned off to the amplifier

circuitry. When set in the Operate mode, the Power Supply delivers

voltage to the amplifier circuitry.

Page

Page 13

13

4.5 OPERATING INSTRUCTIONS

4.5.1 Power On

FIGURE 3.0 – FRONT PANEL DISPLAY (START-UP MENU)

Apply power to the unit using the front panel ON/OFF switch. When the circuit breaker or AC

Power On switch is energized, An IFI Splash Screen will be displayed after the Microprocessor

(MPU) booting cycle this whole process will be about 45 seconds. The Screen in Figure 3.0 will

appear after the booting process

Page

Page 14

14

4.5.3 - Entering the GPIB Address

FIGURE 4.0 - GPIB ADDRESS

The GPIB Address can be changed by selecting the GPIB Button . Pressing the Button will scroll

through the numbers There are 31 numbers 1 through 31 .

Page

Page 15

15

4.5.4 Turning ON the Amplifier

FIGURE 5.0 – MAIN MENU AND STATUS DISPLAY (Typical)

The amplifiers status can be monitored using the Main Menu. The Gain (GAIN), Total Hours Operating Hours, Amplifier and Base Plate Temperature, STATUS and Faults, Forward (FWD) and Reflected (RFL) Status are continuously displayed.

FIGURE 6.0 – TURNING ON THE AMPLIFIER (Typical)

1. From the MAIN MENU in Figure 6.0, press the STBY /OPRT Soft Key and the color of the

button will change to Green

2. The display will show the Main DC power supply Voltage and current as per AMPLIFIER

operating data sheet (enclosed in the manual).

Page

Page 16

16

4.6 DATA SHEETS

Provided with each S251-250 are specific Amplifier Data Sheets measured from the amplifier using a

calibrated 50 Ohm Pad to assist the operator in maximizing the performance of the Wide Band

Amplifier.

The Amplifier Data Sheets are provided with each amplifier exhibiting the actual metering indication

required to produce rated power output as indicated on the data sheet. The actual metering values

were derived by measuring the power output of the amplifier using a calibrated Power Meter and a

calibrated 30 dB Attenuator Pad by inducing an appropriate input signal level to obtain rated power

output. Once the appropriate signal level has been determined to obtain the desired power level, the

actual Front Panel Metering Indication correlates to that power level.

The amplifier data sheets provide the operator with the over all frequency response of the amplifier in

perspective to the amplifier operating frequency ranges. The amplifier data sheets provide the

operator with the actual gain of the amplifier over the frequency band.

The Amplifier Data Sheets are located within Appendix A

Page

Page 17

17

SECTION 5.0

PRINCIPLES OF OPERATION

5.1 PROPER USAGE AND WARNINGS

5.1.1 Controlling Power Output

With a nominal 50 ohm resistive load and an input signal appropriate to produce a power output

within the limitations specified above, the amplifier may be placed in operation. To interrupt the

output, simply interrupt the input signal or increase the input attenuation setting to produce

commensurate output level reduction. The amplifier may be run indefinitely at rated output. Output

power is usually measured with a power meter and suitable power attenuators.

5.1.2 Input Signal Levels

The S251-250 is designed to operate with less than a 0 dBm ( 1.0 mW ) input signal however, to

prevent over driving the amplifier, the Input Protection circuit will activate if the input signal exceeds

3 dBm ( 2.0 mW ) and will automatically compensate for the increased input signal by reducing the

gain of the preamplifier.

It is not advisable to overdrive any amplifier and depend on protection circuits to maintain proper

gain control. IFI makes available with each shipped amplifier, specific amplifier data so the operator

will know the proper input signal levels to more efficiently operate the amplifier. Refer to the test

data sheets information located in Paragraph 4.6 herein.

5.1.3 Sample RF Output Cautions

The S251-250 Sample RF Output connector located on the rear panel must be terminated with the

supplied 50 Ohm load if the output is not being used. Should the S251-250 be operated without a

termination on the Sample RF Output connection, the lack of loading will jeopardize the accuracy of

the metering and output protection; which are based on the Forward Power Readings.

Important Note: If the amplifier is operated without the 50 Ohm termination, damage to the

amplifier may occur which would void the units warranty.

Page

Page 18

18

5.2 FEATURES OF THE S251-250 AMPLIFIER

The S251-250 amplifier is intended for applications requiring high gain and power output to 200

Watts, over a wide range of frequencies, without tuning adjustments. The S251-250 amplifies an

input signal source over the frequency range from 800 MHz to 2500M Hz and at a minimum gain of

53dB

FIGURE 7.0

S251-250 SCHEMATIC DIAGRAM

5.2.1 Preamplifier or Optional Preamplifier/Attenuator

The S251-250 amplifier has a preamplifier with approximately 10dB gain; which is powered from an

independent low voltage power supply.

If the amplifier is equipped with the Optional Preamplifier/Attenuator, it provides the amplifier with

remote level control and leveling capability over the entire operating frequency range. With the front

panel level control set at maximum output it has a nominal 4 dB gain and can be adjusted with the

front panel level control over a greater than 30 dB range.

Page

Page 19

19

5.2.2 Power Amplifier - continued

This amplifier consists of four amplification sections, the final stage having four cascaded highpower, push-pull devices operating in parallel and combined through a transmission type impedance

transformer.

5.3 MANUAL LEVEL CONTROL

Manual level control is accomplished by adjusting the front panel ten-turn potentiometer, located on

the power supply control unit, to a reference voltage setting between 0 to 5 volts.

5.3.1 Automatic Level Control

In this mode, the S251-250 serves as the voltage comparator and variable gain stage. It will enable

the maintenance of a constant RF voltage vs. frequency at the input to an imperfect load or a virtually

constant E-Field at a measurement point in space. For further information regarding the ALC

operation, refer to Section 6.0.

5.4 OPTIONAL FEATURES

5.4.1 Interlock Feature

The Interlock Feature is an option for the S251-250 that utilizes an Electro Magnetic Interference

(EMI) Testing Room door switch that is mounted to the door in such a manner that when opened, the

switch will automatically induce an ordered shut down of the amplifier and produce a STAND-BY

MODE indication on the LCD Metering Display. When the door is closed, the amplifier resumes

previous testing conditions.

The advantage to this feature is providing an additional safety feature for the growing concerns for

potential hazards due to exposure to EMI Fields. With the Interlock option, all Testing Personnel will

be protected from accidental exposure to EMI Fields. Should the operator desire this optional feature,

the amplifier can be returned to IFI for installation. Refer to Section 8.0 for Equipment Return

Procedure.

Page

Page 20

20

SECTION 6.0

AUTOMATIC LEVELING CONTROL

6.1 ALC FEATURES

The Automatic Leveling Control (ALC) switch located on the front panel has three positions, 'INT',

'OFF' and 'EXT'. Described below are the features of each position

Important Note: Figures 5.0 and 6.0 indicates the display for a typical amplifier and the ALC option

is indicated however if the amplifier is not equipped with this option, the ALC option will not be

displayed.

6.1.1 The 'INT' Position

The 'INT' or Internal position enables the amplifier to automatically level on an RF power level

selected by an operator displayed on the Forward Power reading located on the Front Panel LCD

display. Using the 'INT' feature, no external sources are required for leveling control and the operator

determined power level will be automatically maintained even though the frequency or input signal

levels might change. Refer to Paragraph 6.2 for the procedure to operate the amplifier in the 'INT'

mode.

6.1.2 The 'OFF' Position

The 'OFF' position enables the amplifier to operate in a passive mode with no automatic features

controlling input drive levels or output power levels. In this mode, the operator has full manual

control of the amplifier including the input signal gain, frequency and power output. As a result, the

operator must be fully knowledgeable of the effects of these variables in relationship to the operating

characteristics of the amplifier. With this in mind, the two most important factors are the dB flatness

of the amplifier over the operating frequency range and the rated output power of the amplifier.

Depending on the response curve provided on the S21 Parameter Plot for the amplifier flatness,

which is located within Appendix A, and the size of the frequency steps of the signal generator can

increase or decrease the power level by as much as 4 dB. This is the result of the design tolerance of

the amplifier to operate within a ± 2 dB over the rated frequency range. A ± 2 dB tolerance means

that the maximum deflection from minimum to maximum of the flatness curve can represent a delta

change up to 4 dB. With this factor in mind, it is advisable to identify the specific frequencies that

represent the greatest change from the nominal 0 dB level and adjust the input signal accordingly in

so that the amplifier is not over driven beyond the rated power specification. Taking these

precautions will prolong the reliability on the amplifier.

Page

Page 21

21

6.1.3 The 'EXT' or External Position

The S251-250 serves as the voltage comparator and variable gain stage. It will enable the

maintaining of a constant RF voltage vs. frequency at the input to an imperfect load or a virtually

constant E-Field at a measurement point in space.

The front panel, ALC control, switches direct level control from the front panel Level Control

potentiometer to the output of a linear comparator. The comparator output level is dependent on the

reference input from the front panel Level Control and the input from the aforementioned detected

voltage or E-Field. The total gain of the leveling loop serves to maintain the output of the comparator

virtually constant and thus maintain the desired test level at the remote detector or remote E-Field

sensor.

The 'EXT' position enables the amplifier to automatically control an operator determined power level

by means of an external 0.0 to 5.0 VDC reference source connected to the External Source connector.

An example of a 0.0 to 5.0 VDC external input would be the output of a LDI or an EFS. Refer to

Paragraph 6.3 for procedures on leveling with an external voltage level.

6.2 LEVELING USING THE 'INT' MODE

When in the INT position, no outside controls are required. The only equipment required is a

frequency generator and the intended load. The procedure to use Internal ( 'INT' ) Leveling is

described below:

1) Turn the RF Level Potentiometer fully counter clockwise to Full Attenuation.

2) Set the ALC Switch to the 'INT' position.

3) Set the Signal Generator to the proper input drive level to obtain the desired power level. Identify

the desired testing parameters and determine the required input drive levels from the Amplifier

Data Sheets provided within Appendix A It is important to determine that sufficient signal drive

signal is generated to obtain and maintain the desired programmed power level. An adequate

load capable to operate within the power requirements should also be selected.

4) Adjust the RF Level Potentiometer until the desired Forward Power Level is displayed on the

front panel LCD display.

5) The amplifier is now ready to sweep a frequency range and automatically maintain the desired

power level with no further adjustments required. The power level will be maintained at the

operator set level and remain independent of changes to the input frequency or input signal level.

6) When sweeping the frequency range, best results are obtained at a sweep rate that is slower than

500 ms.

Page

Page 22

22

6.3 LEVELING USING THE 'EXT' MODE

When operating the amplifier in the External (EXT) mode, it is important to understand that the

power output levels are determined by the external voltage reference source. The applicable

Amplifier Data Sheets should be reviewed to determine the appropriate drive signal level so that the

amplifier does not exceed the specified power output rating. As described in paragraph 6.1.2, due to

the flatness curve tolerances at certain frequencies, the rated power output power could be exceeded

by an additional 40% and that will jeopardize the longevity of the amplifier. The amplifier should

not be over driven and should a particular application require additional power beyond the rated

power of the S251-250, contact IFI's Customer Service for additional high powered amplifiers.

Detailed below are specific applications for using the External ( EXT ) Mode with a variety of

external inputs.

6.3.1 Constant RF Voltages Verses Frequency At A Remote Load

With remote detectors suitably rated for power and frequency, the S251-250 provides the means for

feeding a mismatched load with constant RF drive voltage over the entire frequency range. Full

leveling, at half the S251-250 rated output power, is realizable with most reasonable load variations.

Extremely mismatched loads, particularly those presenting near short circuit conditions to the

amplifier, will reduce the maximum voltage leveling capability of the system. Load impedance

variation from 50 Ohms to an open circuit will permit peak voltage leveling within the VSWR

capability of the amplifier. Variations in impedance from 50 Ohms down to a short circuit will

rapidly diminish the peak voltage leveling capability toward zero. Amplifier VSWR limitations will,

of course, further limit the maximum leveled voltage into mismatched low impedance loads.

To operate in this mode, after selecting the desired band, place the ALC switch in the EXT position.

Connect the ALC on the rear panel to the detected output port on the remote detector. Connect the

remote detector in series with the S251-250 output and at the input to the load. The system is now

ready for operation. Amplitude adjustments can be made with the level control as in manual

operation.

NOTE: When the S251-250 is used as a driver for higher power amplifiers, automatic level control

can be accomplished in the same manner but at the power and frequency limitations of the driven

amplifier.

Page

Page 23

23

SECTION 7.0

IEEE-488.2 INTERFACE

7.1 INTRODUCTION

The Instruments For Industry, Inc. (IFI) Amplifiers can be operated remotely from a personal computer having an IEEE488 interface. This interface allows the amplifier to be remotely controlled over the General Purpose Interface Bus

(GPIB) by sending commands to the amplifier. Additionally, amplifier status and forward and reverse power readings may

be read over the GPIB. All functions can be controlled by coded messages sent over the interface bus via the 24-pin

socket connector on the rear panel of the unit. IEEE-488.2 Standard is implemented, which defines the protocols and

syntax of commands. The GPIB command codes for the IFI Amplifier series are discussed on subsequent pages and, for

ease of identification; the command codes are identified within the text by bold capital characters. For full information on

the IEEE protocols and syntax the IEEE-488.2 Standard should be consulted.

7.2 REMOTE IN I TIA LIZATION

When the amplifier receives a command over the GPIB, it automatically switches to REMOTE operation, pressing the

LOCAL key on the front panel returns the unit to normal manual local operation. The initial state of the amplifier after

power-on is the full attenuation condition. The ZEROATT command must be sent in order for the amplifier to be able to

generate output power.

7.3 GPIB ADDRESS

The GPIB address o f the amplifier is set by via the Front panel using the Control knob at the start up menu..

NOTES ON USING NATIONAL INSTRUMENTS' GPIB CONTROLLERS:

In order for the amplifier to operate co rrectly with a National Instruments GPIB controller card, the following must be

done: (Items 1-5 are done in the IBCONF program.)

1. Set "Terminate reads on EOS" to yes.

2. Set "Set EOI with EOS on Writes" to yes.

3. Set the EOS byte to 0Ah (an ASCII line feed character).

4. Set "Send EOI at end of writes" to yes.

5. Set "Enable repeat addressing" to yes at the board level.

6. When sending co mmand st rings to the amplifier, a carriage return character (0Dh) followed by a line feed character

(0Ah), must always be appended to the command, otherwise the amplifier will wait indefinitely for the CR-LF

combination. If this happens the unit will have to be powered off and back on to reset this condition. (The interface

device will automatically assert the EOI line during the LF if items 2 - 4, above, are set to yes in the IBCONF

program.) As an example, when issuing the zer o attenuation command using the IBIC or WIBIC program, the

command string would look like this: "ZA\r\n". (The \r is National Instruments' notation for the carriage return, and

the \n is the line feed or 'new line' character.) Notice that the commands are upper case only.

Page

Page 24

24

Code

Amplifier F unction

STBY

Standby & Returns ‘SB’

OPRT

Operate & Returns ‘ON’

RESET

Fault Reset & Returns ‘STANDBY’

ATTUxx

Increase Attenuation (xx- # of steps) [Response with Gain value, ‘GAIN: XXXXX %’]

ATTDxx

Decrease Attenuation (xx- # of steps) [Response with Gain value, ‘GAIN: XXXXX %’]

Code

AMPLIFIER STATUS

STATUS

STANDBY

OPERATE

FAULT

FAULT

DETIALED MESSAGE

THERMAL FAULT

PWR SUPPLY 1 FAULT

PWR SUPPLY 2 FAULT, [ If Applicable ]

PWR SUPPLY 3 FAULT, [ If Applicable ]

PWR SUPPLY 4 FAULT, [ If Applicable ]

NO FAULTS

Commands for Solid State Amplifier

REQUEST STATUS

Page

Page 25

25

CODE

Amplifier FUNCTION

POWERFWD

Returns Forward Power Value in Watts, ‘POWER FWD: XXXXX W’

POWERRFL

Returns Reflected Power Value in Watts, ‘POWER RFL: XXXXX W’

PS1V

Returns Power Supply 1 Volts Value in Volts, ‘PWRSPLYV1: XXXXX V’

PS1I

Returns Power Supply 1 Current Val ue in Amps, ‘PWRSPLYI1: XXXXX A’

PS2V

Returns Power Supply 2 Volts Value , [ If Applicable ]

PS2I

Returns Power Supply 2 Current Value [ If Applicable ]

PS3V

Returns Power Supply 3 Volts Value , [ If Applicable ]

PS3I

Returns Power Supply 3 Current Value [ If Applicable ]

PS4V

Returns Power Supply 4 Volts Value , [ If Applicable ]

PS4I

Returns Power Supp ly 4 Current Value [ I f Applica ble ]

TOTALH

Returns Total hours unit is on, ‘ TOTAL HRS: XXXXX’

OPERATEH

Returns Operation Hours Val ue, ‘OPERATE HRS: XXXXX’

BAND1

Selects Band 1 of Operat ion [ In Dual Ba nd units only ]

BAND2

Selects Band 2 of Operation [ In Dual Band units only ]

NOLEV

Selects NO Leveling [ Optional ]

INTLEV

Selects INTERNAL Leveling [ Optional ]

EXTLEV

Selects EXTERNAL Leveling [ Optional ]

QUIETOFF

Selects QUIETING to OFF [ Optional ]

QUIETAUTO

Selects QUIETING to AUTO mode [ Optional ]

QUIETSTATUS

Returns Quieting mode of operation [ Optional ]

‘QUIETING AUTO’

ZEROATT

Sets the Amplifier for ZERO Attenuation & Returns, ‘GAIN: 00100 %’

FULLATT

Sets the Amplifier for FULL Attenuation & Returns, ‘GAIN: 00000 %’

GAIN

Returns Gain Value in percentage, ‘GAIN: XXXXX%’

MODEL

Returns Mode l number of the unit

SN

Returns Serial number of the unit

*IDN?

Returns ASCII response comprising of four data fields in the format

<Manufacturer>, <Model>, <Serial Number>, <Firmware Version>

*RST

Reset Command, Sets the Amplifier to the factory default power up state (reboots MPU)

REQUEST AMPLIFIER STATU S

(POWER AND METERING)

‘QUIETING OFF’

NOTES:

1. ALL GPIB COMMANDS AND REQUESTS MUST CONSIST ENTIRELY OF UPPER CASE ALPHANUMERIC

CHARACTERS.

2. WHEN SENDING COMMAND STRINGS TO THE AMPLIFIER, A CARRIAGE RETURN CHARACTER (0Dh)

FOLLOWED BY A LINE FEED CHARACTER (0Ah), MUST ALWAYS BE APPENDED TO THE COMMAND, and

OTHERWISE THE AMPLIFIER WILL WAIT INDEFINITELY FOR THE CR-LF COMBINATION.

Page

Page 26

26

RS-232 or USB

Operation of Serial Port on RF Amplifier

1 – Connect serial port of amplifier to computer using a null modem cable

or a standard serial cable with a null modem adapter.

2 – Use a program such as Hyperterm to communicate with the amplifier.

(To reach “Hyperterm” on windows ’98 go to Start Programs

Accessories Communications Hyper Terminal. In Hyper terminal

double click on

In Hyperterm do the following:

2.1 Enter a name and choose an icon.

2.2 In the connect using box select “Direct to Com1”.

2.3 Click OK.

2.4 Select 9600 baud.

2.5 In Data Bits select 8

2.6 In Parity Select “None”

2.7 In Stop bits select “1”.

2.8 In Flow control select “None”

2.9 Press enter.

3 – If you use Hyperterm steps 2.1 to 2.9 will set up Com1 to

communicate at 9600 baud, 8 bit s , and no parity with 1 st op bit.

4 – Turn amplifier line power ON.

To place the amplifier in remote operation type in a valid command such as

“STATUS”. The amplifier will then go into remote operation and the status

will be displayed on the computer. The same commands as above.

Page

Page 27

27

5 – When used with an RS-232 or RS-422 interface each character that is

sent to the amplifier is echoed back.

RS-422

Communication Interface

Communication Standard RS422

Communication Baud Rate 19200

Communication Update Rate 50 Hz

Average Data Latency 100 mSec

Data Latency Variation 100 mSec

Control Functions Status Request, Mode Selection, BIT activation

Report Data Amplifier Status, BIT results

Data rate is 9600 baud, 1 or 2 stop bits, no parity.

Example

The commands are the same as above.

Command: Place unit in operate mode

ASCII String sent to amplifier: ON(cr)(lf)

Hex equivalent of string: 0x4f, 0x4e,0x0d,0x0a

Response: None

Response String from amplifier: None

Example of response: N/A

Hex value of example: N/A

Command: Read forward power

ASCII String to amplifier: POWERFWD(cr)(lf)

Hex equivalent of string: 0x50,0x4f,0x57,0x45,0x52,0x46,0x57,0x44,0x0d,0x0a

Action: None

Response: Responds with forward power

Response String from amplifier: POWER FWD: xxxxx W(cr)(lf)

Where xxxxx is the value of the power

Example of response : POWER FWD: 09005 W(cr)(lf)

Hex value of example :

0x50,0x4f,0x57,0x45,0x52,0x20,0x46,0x57,0x44,0x3a,0x20,0x30,0x39,0x30,0x30,0x35,0x20,0x57,

0x0a,0x0d

Page

Page 28

28

PROBLEM

CAUSE

SOLUTION

COMMENTS

Touchscreen display blank

No service voltages

Check line power.

Connect AC line to

Refer to S/N tag on unit

Amp will not go to Operate

Door interlock open,

Check that door interlock BNC

Power Supply fault

Main Power supply faulty

Check either for 32VDC

Check on the LCD dis play

for the fault description.

Thermal fault

Over-heating

Make sure airflow is adequate

the limit.

Meter Inaccuracy

Un-terminated Forward

Ports

Use 50 Termination on Forward

SECTION 8.0

MAINTENANCE AND SERVICING

8.1 PERIODIC MAINTENANCE

The only periodic maintenance required on the S251-250 amplifier system is ensuring that the cooling

vents are not obstructed in such a manner that the airflow is restricted. Periodic cleaning of the vents

may be required depending on the degree of dust in the atmosphere.

8.2 SERVICING THE AMPLIFIER

Servicing of the amplifier by the operator is not recommended. Most of the internal circuitry requires

special and unique test instruments to trouble shoot, align and calibrate the circuits. Should servicing

be required, refer to Paragraph 8.3.

8.2.1 TROUBLESHOOTING

mode

Page

and/or Reverse Sample

Check service voltages,

+12VDC, -12Vdc, 5VDC

connector is terminated with

either 50 Ohms or short.

and ambient temperature within

and Reverse Sample Ports

specified Prime power

source.

Page 29

29

Page

Page 30

30

8.3 EQUIPMENT RETURN PROCEDURE

Should the S251-250 require repair or it is recommended that the reader follow the Equipment Return

Procedure so the equipment can be repaired or calibrated and returned in an efficient and timely

manner.

8.3.1 Request a RMA Number

Contact the IFI Service Department either in writing or by calling (631) 467-8400 and request a

Return Material Authorization ( RMA ) Number.

The RMA Number is the method IFI uses to prepare its services for returned material in transit and

acts as a tracking document for the returned material through the repair or process.

The RMA also documents the customer’s specific instructions or reason related to the return of the

material.

8.3.2 Return All Accessories

In the interest of saving time and expediting the repair or process, return all the associated

accessories described in Section 1.0 when returning the equipment for repair.

In many cases, a faulty accessory could give the illusion that the equipment itself has failed. For this

reason it is important to return all the accessories with the equipment. It is also IFI's policy to verify

performance of all associated accessories of Section 1.0 before returning the equipment to service.

8.3.3 Packaging The Equipment

When returning equipment to the manufacturer, always wrap each accessory separately, and provide

sufficient protective material around each item to prevent damage from handling and shipping

conditions. It is strongly recommended the equipment be returned in its original wooden crate (or

equivalent) for maximum protection. Cardboard boxes do not provide sufficient protection of the

equipment.

8.3.4 Reference The RMA Number

As detailed in Paragraph 8.3.1, always reference the IFI assigned RMA Number on your Packing List

and Purchase Order and when any inquiries are made.

Page

Page 31

31

APPENDIX A

AMPLIFIER DATA SHEETS

Page

Page 32

32

APPENDIX B

DRAWINGS

BOM S251-250 BILL OF MATERIALS (BOM)

901031 INTERCONNECT, S251-250

Page

Page 33

Bill of Materials

Fiished Good Product Description Rev LtrBuild Qty

S251-300 SSA, 0.8-2.5 GHz, 300W

Product Code Component Product Description Qty Req'd Revision Designation Manufactor Info / NotesLevel Seq#

S251-300 0I-901014 INTERCONNECT DIAGRAM - S2505-300, 200 0 A1

S251-300 0O-850052 OUTLINE DRAWING - SMX100 0 C1 85

S251-300 302352 SIDE - CHANNEL, 24 inch LONG 3 G1 21

S251-300 302355 PARTITION 2 A 1

S251-300 302372 PARTITION - LOW BAND 1 B1

S251-300 302456 COVER - 7in. CHASSIS 2 B 1 27

S251-300 302464 PAN - POWER SUPPLY 1 L1 39

S251-300 302470 BRACKET - MPU BD 1 I1 29

S251-300 302511 PANEL - FRONT - 7in. H 1 I1 20

S251-300 302511-G-S PANEL - FRONT - SCREENED AND PAINTED GREY 1 F1 32

S251-300 302512 PANEL - BACK - 7in. H 1 F1 31

S251-300 302512-S PANEL - BACK - SCREENED ONLY NO PAINT 1 E 1 97

S251-300 302601 BRACKET - COUPLER 1 E1 34

S251-300 303186 BRACKET, POWER SUPPLY RQ65 MOUNTING 1 B W/ pow-rq65d1 92

S251-300 400359 TOP HEATSINK LAYOUT - HIGH BAND 1 R1 11

S251-300 400365 BOTTOM HEATSINK LAYOUT - LOW BAND 1 G1 84

S251-300 500499-1 SWITCH/LED BOARD ASSY 1 A 1 3

S251-300 500523-48 SS - HALLEFFECT/PS SENSING BD, for 48V PS 1 A1

S251-300 500536 BOARD ASSY - MPU MICROCHIP 8680 PROCESSOR 1 B1 97

S251-300 500540 PS -ENABLE XSTR BD ASS`Y 1 B 1

S251-300 500699-5 VOLTAGE ATTENUATOR ASSY 500MHz to 3000MHz Low

Gain

S251-300 500710-1000 EQUALIZER, S21 1 B1

S251-300 700543-40 RIBBON CABLE - IEEE-488 - A1P10-GPIB 11 93

S251-300 700544-08 MPU-DISPLAY RIBBON CABLE 11

S251-300 700545-08 MPU-500499-1 RIBBON CABLE 11

S251-300 700589-32 MPU-RS232 RIBBON CABLE 11

S251-300 700589-40 MPU-RS232 RIBBON CABLE 1 A1-J41

S251-300 700823 ASSY, PREAMP MODULE, 100 - 3500 MHz 2W P1dB-38 dB

Gain 4W SAT 28V, 1.5A, no regulators

S251-300 700862 DO NOT USE AMPLIFIER MODULE, 800 to 3000 MHz 45W

CREE X4 100Watts 32VDC.

S251-300 700863 ASSY, 20W 800-3000 MHz 2 X Cree 45W +32VDC 1 A1

S251-300 700900 RF MODULE, 500-2500MHZ 300W 4-GAN +50V 2 B1

S251-300 800100-07 CABLE - RF - .141 FLEX - SMA/MALE - N/MALE 1 A1

6/22/2016 7:16:22 AM Page 1 of 4

Lot#

A

0

1B1

1B1

1G1

Page 34

Bill of Materials

Fiished Good Product Description Rev LtrBuild Qty

S251-300 SSA, 0.8-2.5 GHz, 300W

Product Code Component Product Description Qty Req'd Revision Designation Manufactor Info / NotesLevel Seq#

S251-300 800101-06 CABLE - RF - EZ FLEX .141 - SMA/M-SMA/M 31 89

S251-300 800101-07 CABLE - RF - EZ FLEX .141 SMA/M SMA/M 11

S251-300 800101-12 CABLE - RF - EZ FLEX .141 SMA/M SMA/M 31

S251-300 800101-8 CABLE - RF - EZ FLEX .141 SMA/M SMA/M 11 90

S251-300 800102-12 CABLE - RF - .141 FLEX - SMA/M-N/F PRECISION

BULKHEAD

S251-300 800102-30 CABLE - RF - .141 FLEX - SMA/M-N/F PRECISION

BULKHEAD

S251-300 800134-72 CABLE - RF ASSY - CABLE RG-174A - BNC/F BLKHD 21 97

S251-300 ATT-VAT6G-3 ATTEN - FIXED COAX SMA M/F - DC-6 GHZ - 2W - 3DB 21 84

S251-300 ATT-VAT6G-4 ATTEN - FIXED COAX SMA M/F - DC-6 GHZ - 2W - 4DB 2 1

S251-300 CBR-R112P12A BREAKER - CKT - SINGLE POLE - ROCKER - 12 AMPS -

GREY

S251-300 CON-08500114 CONN - PIN - CONTACT 0.100 SERIES 141 14

S251-300 CON-102387-2 CONN - IDC FEMALE WIRE APPLIED HOUSING - 14 PIN - . 1 A1-P51 15

S251-300 CON-102387-3 CONN - IDC FEMALE WIRE APPLIED HOUSING - 16 PIN - . 1 A1-P81 16

S251-300 CON-102387-8 CONN - IDC FEMALE WIRE APPLIED HOUSING - 34 PIN - 1 A1-P91 17

S251-300 CON-2201-12 CONN - 12 PIN - MOLEX 0.100in. 1 A4-P11 18

S251-300 CON-2201-2 CONN - 0.100in. HOUSING WITH LOCKING RAMP - 2

POSITIO

S251-300 CON-39-01-2020 CONN - 2 PIN MOLEX - FEMALE 21 70

S251-300 CON-39-01-2060 CONN - 6 PIN - FEMALE - MOLEX 1 A8P11 38

S251-300 CON-39-01-2100 CONN - SOCKET HOUSING 10 PIN - FEMALE - DUAL ROW 11 62

S251-300 CON-39-01-3023 CONN - 2 PIN - MALE - MOLEX 11 63

S251-300 CON-553636 CONN - GPIB - ACCESSORY - MTG HDW, IEEE-488 11 64

S251-300 CON-553636 CONN - GPIB - ACCESSORY - MTG HDW, IEEE-488 1 w/ W111

S251-300 CON-554349-1 CONN - 554349-1 GPIB AMP - TWT/SST # W/F 1 w/ W111

S251-300 CON-87523-6 CONN - CONTACT - SNAP IN - PINS 64 A1,P9,A1P8,A1P51 65

S251-300 CON-B52C4U02T CONN - PLUG - 5MM - R/A - 2 POS. 1 A1P21 66

S251-300 CON-COA-UG657/U CONN - BNC BULKHEAD RECEPTACLE COAX 1 Interlock rear panel1

S251-300 COR-17602 VOLEX AC LINE CORD 16AWG 6` 7in. 11 85

S251-300 COU-BDC6265N/SMA COUPLER BIDIRECTIONAL - 500-3000MHz - 50dB -

500W -N/F MAINLINE - SMA PORTS

S251-300 DIS-DMF5005 DISPLAY - MODULE - LCD - 240X64 DO 11 48

S251-300 DIV-2W500M2500M200 POWER DIVIDER/COMBINER - 2 WAY - COAXIAL - 500-

2500MHZ - 200W CW , N/out, SMA/ins, IL=0.4dB

6/22/2016 7:16:22 AM Page 2 of 4

Lot#

A

3

11 92

11 93

11 91

2 PS1,A9P21 41

1A1

1 1

Page 35

Bill of Materials

Fiished Good Product Description Rev LtrBuild Qty

S251-300 SSA, 0.8-2.5 GHz, 300W

Product Code Component Product Description Qty Req'd Revision Designation Manufactor Info / NotesLevel Seq#

S251-300 DIV-2W500M2500M500 POWER DIVIDER/COMBINER - 2 WAY - COAXIAL - 500-

2500MHZ - 500W CW , N FEMALE, IL=0.4dB

S251-300 DIV-ZFRSC-42+ DIVIDER, 0.75W, DC TO 4200 MHz 2 A1

S251-300 FAN-03245 FAN - GUARD - 6in. OR 08126 11 68

S251-300 FAN-4 FAN - 4 INCH GUARD 11 42

S251-300 FAN-JQ24B2 FAN - 6in. - 24VDC (12-28VDC) - 250CFM - 0.8 Static

Pressure, 54.3 dB(A)

S251-300 FER-T502525T FERRITE CORES - TOROID - CN20 MATERIAL - SIZE

0.5in. OD - 0.25in. ID

S251-300 FER-T7325 FERRITE CORES - TOROID - CN20 MATERIAL - SIZE

0.75in. OD - 0.375in.

S251-300 FER-ZW-43813TC FERRITE -TOROID 1.5in.OD 0.75ID 11 96

S251-300 FIL-5110.1533.1 FILTER - LINE - IEC EMI - 15A - 115/230 SINGLE PHASE 11 85

S251-300 FLT-HP800MSMA FILTER HIGH PASS - COAXIAL - Fco=710MHz - SMA M/F 1 1

S251-300 HAN-245-26 HANDLE - 6.0 in. x 1.5 in. OVAL, BLACK OXIDE - 10-32

THD, SS

S251-300 HDW-HOL-3092 HDW - PLUG - BLACK 1/2 HOLE H.H. SMI, 1/8 PANEL THK 21 87

S251-300 HDW-HOL-790-3158 HDW - PLUG - HOLE - 5/8 BLACK PLASTIC, 1/8 PANEL

THK

S251-300 HDW-PLA-FTH-1 HDW - RICHO WIRE TIE HOLDER 01 59

S251-300 HDW-SC-21005 HDW - MOUNTING - RS232 11 95

S251-300 KNO-RKP3SB KNOB - SKIRTED - BLACK TEXTURE 11 40

S251-300 POW-RQ65D PS, QUAD OUTPUTS, 5V @ 8A, 12V @ 3A, 24V @ 1.5A, -

12V @ 1A

S251-300 POW-RSP1500-48 PWR SPLY,1500W,48V 32A,PFC, MEANWELL, Size, 5inch

x 11inch x 3.3inch

S251-300 POW-RSP-150-24 PS - 150 WATT - 24VOLT RSP-150-24 NOT SP-150-24 1 1

S251-300 POW-SP300W27V PS - 27VDC OUT -300W - 85-264VAC INPUT LINE - SIZE

9in.X4

S251-300 RES-MO2-10K RESISTOR - 10K - 2 W - METAL OXIDE - METAL OX 11 96

S251-300 SWI-67F065 SWITCH - THERMAL 65 C - NO - CLOSE ON RISE - TO220 21 54

S251-300 TER-333 SOLDER LUG ZERICK 2 w/ TS1,TS21

S251-300 TER-35559 16-14 WIRE -#6 NYLON INS.BLOC 01 55

S251-300 TER-572-4863-01-0516 CAMBION TERMINAL EG & G OBS 3 w/ D3,D41

S251-300 TER-S05305FN MIDLAN ROSS BLUE QUICK DISCONNECT - 16/14 -

FULLY INSULATED

Lot#

A

1

1 1

1A 1 43

2 HB PA 500516 x 21 44

5 1

21 46

21 47

1 NR W/ 3031861 93

1NR1

1 1

51 56

6/22/2016 7:16:22 AM Page 3 of 4

Page 36

Bill of Materials

Fiished Good Product Description Rev LtrBuild Qty

S251-300 SSA, 0.8-2.5 GHz, 300W

Product Code Component Product Description Qty Req'd Revision Designation Manufactor Info / NotesLevel Seq#

S251-300 TER-STR-8-141 TERMINAL STRIP-BLOCK DOUBLE - 0.438 SPACING -

20A - #14 AWG - 8 POS. -6-32

S251-300 TER-STR-MS-8-141 MARKER - TERMINAL STRIP 11 58

S251-300 TRM-BNC50ITLK TERMINATION 5OHMS - 1W - BNC MALE WITH GROUND

CABLE

S251-300 TRM-CXDC18GN2WC TERMINATION RF - 50 OHMS - COAXIAL - 2W - DC-18

GHZ - N MALE CONN WITH

S251-300 TYR-08461 SMALL TYWRAP PADS 01 61

S251-300 Y-CLIP-L CLIP - CABLE - RIBBON - LARGE 11 92

Lot#

A

1

11 57

1 w/ con-coa-ug6571

1 w/ W41

6/22/2016 7:16:22 AM Page 4 of 4

Page 37

5

D D

RF INPUT

RF INPUT

TYPE N

TYPE N

C C

+32V PS3

-12V PS5

B B

U1

U1

A A

SIT SIT

ATT1

ATT1

. .

ATT-VAT6G-3

ATT-VAT6G-3

[2x#16]

CON-AMP-1-480699-0

CON-AMP-1-480699-0

[2x#14]

CON-AMP-1-480699-0

CON-AMP-1-480699-0

[1x#20][1x#20]

CON-AMP-1-480699-0

CON-AMP-1-480699-0

+48V

1

3

2

2

3

1

LM35DT

LM35DT

750061

750061

W1

W1

EQ1

EQ1

IN OUT

500710-1000

500710-1000

P1-1

P1-2

P1-3

P1-4

P1-5

P1-6

S1-1

1

S1-2

2

S1-3

3

S2-1

S2-2

S2-3

S3-1

S3-2

S3-3

S4-1

S4-2

S4-3

5

J123

J123

1

2

J124

J124

1

2

J125

J125

1

2

A9

A9

500878-1

500878-1

ATT2

ATT2

. .

ATT-VAT6G-3

ATT-VAT6G-3

-12V PS2

+12V PS2

Vc

J126

J126

1

2

CON-AMP-1-480698-0

CON-AMP-1-480698-0

J127

J127

1

2

CON-AMP-1-480698-0

CON-AMP-1-480698-0

J128

J128

1

2

CON-AMP-1-480698-0

CON-AMP-1-480698-0

POWER 1

POWER 1

+48VDC IN1

GND1

48VDC IN2

GND2

+48VDC IN3

GND3

SENSOR 1

SENSOR 1

+5V OUT1

GND4

TEMP IN1

SENSOR 2

SENSOR 2

+5V OUT2

GND5

TEMP IN2

SENSOR 3

SENSOR 3

+5V OUT3

GND6

TEMP IN

SENSOR 4

SENSOR 4

+5V OUT4

GND7

TEMP IN3

VVA1

VVA1

RF IN RF OUT

FL4

-12V

FL3

+12V

FL2

Vc

FL1

GND

500699-5

500699-5

+32V PRE1

+32V DRV1

+50V PA1+50V PS1

+50V PA2

-12V PA1

J1 FAN 1

J1 FAN 1

+48VDC1

GND8

FG SIG1

PWM1

J2 FAN 2

J2 FAN 2

+48VDC2

GND9

FG SIG2

PWM2

J3 FAN 3

J3 FAN 3

+48VDC3

GND10

FG SIG3

PWM3

J1-1

J1-2

J1-3

J1-4

CON-39-01-2040

CON-39-01-2040

J2-1

J2-2

J2-3

J2-4

J3-1

J3-2

J3-3

J3-4

J105

J105

4

SIT

ATT3

ATT3

. .

ATT-VAT6G-3

ATT-VAT6G-3

+32V PRE1

J103

J103

1

2

3

4

1

2

3

4

CON-39-01-3043

CON-39-01-3043

+50V PS1 RTN

+32V PS3 RTN

-12V PS5 RETURN

4

1

2

3

4

5

6

7

8

9

RED

BLACK

BLUE

YELLOW

PREAMP1

PREAMP1

. .

AMP1039

AMP1039

FWD

VVA

CURRENT

TEMP

SHUTDOWN

29VDC

29VDC

GND

GND

DSUB

DSUB

FAN1

FAN1

1

+48VDC

2

GND

3

FG SIGNAL

4

PWM

FAN-THB1548AG

FAN-THB1548AG

3A @ MAX RPM

[2x#14]

[2x#16]

[1x#20]

+32V DRV1

DRV1

DRV1

NQ_H

. .

32V

700862

700862

#14

#14

#16

#16

#20

3

DIV1

DIV1

0 DEG

SUM

0 DEG

DIV-2W500M2500M200W

DIV-2W500M2500M200W

+5V PS2

1

3

5

7

9

GND LUG

ATTACHED

TO HTSK

3

TS1

TS1

SWI-67F065

SWI-67F065

-12V PA1

+50V PA1

-12V PA1

+50V PA1

TS2

TS2

SWI-67F065

SWI-67F065

A11

A11

+5V1

TEMP VOUT1

+5V2

TEMP VOUT2

GND1

GND2

GND3

500871

500871

APPROVALS

APPROVALS

APPROVALS

DRAWN BY:

DRAWN BY:

DRAWN BY:

CHECKED BY:

CHECKED BY:

CHECKED BY:

APPROVED BY:

APPROVED BY:

APPROVED BY:

REVISED BY:

REVISED BY:

REVISED BY:

THERM FAULT

PA1

PA1

NQ_H

. .

-12V

+50V

700900

700900

PA2

PA2

NQ_H

. .

-12V

+50V

700900

700900

THERM FAULT

2

4

6

NC1

8

NC2

10

NC3

J CAMPANELLA

J CAMPANELLA

J CAMPANELLA

TBD

TBD

TBD

TBD

TBD

TBD

2

0 DEG

0 DEG

DIV-2W500M2500M500W

DIV-2W500M2500M500W

BASEPLATE TEMP

A10

A10

500734

500734

DATE

DATE

DATE

6/5/2017

6/5/2017

6/5/2017

TBD

TBD

TBD

TBD

TBD

TBD

2

DIV2

DIV2

COU1

COU1

COU-BDC6265N/SMA

COU-BDC6265N/SMA

SUM

ATTENUATOR CTRL

FLT PIN DIODE CTRL

1 2

-50 dB -50 dB

GND FROM uP

RFL PWR MON

VSWR FLT OUT

+5V FROM uP

FWD PWR MON

Size

Size

Size

B

B

B

Scale

Scale

Scale

3

DIV3

DIV3

DIV-ZFRSC-42+

DIV-ZFRSC-42+

FWD IN

RFL IN

J3

J3

GND

GND

GND

+5V OUT

-12V

N.C.

+12V

CAGE Code DWG NO

CAGE Code DWG NO

CAGE Code DWG NO

1

REVISION HISTORY

REVISION HISTORY

REVISION HISTORY

DATE REV DESCRIPTION

DATE REV DESCRIPTION

DATE REV DESCRIPTION

6/5/2017 1 INITIAL RELEASE

RF OUTPUT

RF OUTPUT

4

DET1

DET1

RF-IN

.

DET-DZM185AA

DET-DZM185AA

ATT6

ATT6

-6dB

SUM

-6dB

1

2

3

RFL PWR MON

4

VSWR INDICATOR

5

6

7

8

9

10

11

-12V PS2

12

13

FWD PWR MON

14

+12V PS2

903 S. 2ND STREET, RONKONKOMA, NY. 11779

903 S. 2ND STREET, RONKONKOMA, NY. 11779

903 S. 2ND STREET, RONKONKOMA, NY. 11779

TITLE

TITLE

TITLE

01105

01105

01105

Tuesday, June 06, 2017

Tuesday, June 06, 2017

Tuesday, June 06, 2017

. .

ATT-VAT6G-2

ATT-VAT6G-2

INSTRUMENTS FOR INDUSTRY

INSTRUMENTS FOR INDUSTRY

INSTRUMENTS FOR INDUSTRY

S251-250 PA, RF BLOCK

S251-250 PA, RF BLOCK

S251-250 PA, RF BLOCK

ATT7

ATT7

..

ATT-VAT36-2

ATT-VAT36-2

RF-IN

901097

901097

901097

Sheet

Sheet

Sheet

1

FWD SAMPLE

FWD SAMPLE

DET2

DET2

.

DET-DZM185AA

DET-DZM185AA

12

12

12

TYPE N

TYPE N

DC OUT

.

DC OUT

.

of

of

of

TYPE N

TYPE N

Rev

Rev

Rev

1

1

1

Page 38

5

110-220VAC UNIVERSAL 1PH, 3 WIRES

CB1

FL1

FL1

LINE

NEUT

GND

D D

+50V PS1

C C

+50V PS1 RTN

B B

A A

Line

Neut

Gnd

FIL-5110.1533.1

FIL-5110.1533.1

LINE

NEUT

GND

Load

Neut

Gnd

[2x#14]

[2x#14]

[2x#14]

PS1

PS1

1

DA

2

DA

3

DB

4

DB

5

GND

6

GND

LINE

NEUT

GND

POW-RSP-2000-48

POW-RSP-2000-48

NOTE: SET TO 50V

CN502

CN502

5

CB1

.1.

CBR-R112P15A

CBR-R112P15A

A2

A2

Vout1 PS1, V-IN

Vin1

500523-48

500523-48

RTN

+12V-AUX

TB1

TB1

2

1

2

3

4

TER-STR-4-142

TER-STR-4-142

+48V

CN501

CN501

+SENSE

-SENSE

PV

GND

DC-OK

T-ALARM

ON/OFF

GND-AUX

GND-AUX

GND-AUX

+5V-AUX

1

.

.

2

.

.

3

.

.

4

.

.

J1

J1

PS1, V-MON

PS1, FLT

PS1, I-MON

GND

+12v

-12V

GND

+32V PS3

+32V PS3 RTN

1

2

3

4

5

6

7

8

9

10

11

12

LINE

NEUT

PS ON

1

+50V PS1

2

PS1 VMON

3

PS1 FAULT

4

PS1 IMON

5

6

+12V PS2

7

-12V PS2

8

[2x#16]

[2x#16]

A4

A4

1

GND1

2

GND2

3

FROM MPU

4

RC 0 OHM

5

RC 270 OHM

500540-1

500540-1

NOTE: CHANGE R2 TO 270 OHM

4

PS2

PS2

LINE

NEUT

PS3

PS3

V+

V+

VV-

POW-RSP-500-27

POW-RSP-500-27

NOTE: SET TO 32V

LINE

NEUT

GND

POW-RQ65D

POW-RQ65D

34

34

12

12

+48V

DRIVING 1 FAN

@ 3A MAXIMUM

4

CN100

CN100

+5V, 4A

-12V, 0.5A

+12V, 1.5A

+24V, 1A

FAN2

FAN2

FAN-4715KL-05W-B40-E (0.5A)

FAN-4715KL-05W-B40-E (0.5A)

1

-S

2

+S

3

RC-

4

RC+

L

N

G

PS4

PS4

V+

V+

VV-

POW-RSP-200-48

POW-RSP-200-48

-12V PS5 RETURN

RET

PS ON

+5V PS2

LINE

NEUT

-12V PS5

+5V PS2

-12V PS2

+12V PS2

+24V PS2

GND

+24V

BNCBNC

INTERLOCK

A3

A3

1

GND1

2

GND2

3

FROM MPU

4

RC 0 OHM

5

RC 270 OHM

500540-1

500540-1

NOTE: CHANGE R2 TO 270 OHM

LINE

L

NEUT

N

G

PS5

PS5

J2

J2

1

+12V

2

+12V

3

RET

4

RET

POW-ECS45US12

POW-ECS45US12

3

PS1 FAULT

VSWR INDICATOR

THERM FAULT

Vc

J1

J1

1

L

2

N

3

G

3

PS ON

RG188

+12V PS2

LINE

NEUT

A1

A1

J9

J9

J9-1

PS1 FAULT

J9-2

PS2 FAULT

J9-3

FUTURE USE25

J9-4

PRF FAULT

J9-5

DUTY FAULT

J9-6

PW FAULT

J9-7

VSWR INDICATOR

J9-8

VSWR FAULT

J9-9

THERMAL FAULT

J9-10

INTERLOCK

J9-11

FUTURE USE1

J9-12

FUTURE USE2

J9-13

FUTURE USE3

J9-14

FUTURE USE4

J9-15

FUTURE USE5

J9-16

FUTURE USE6

J9-17

FUTURE USE7

J9-18

FUTURE USE8

J9-19

FUTURE USE9

J9-20

FUTURE USE10

J9-21

PULSE IN

J9-22

PULSE OUT

J9-23

BAND 1 HIGH I DRVR

J9-24

PULSE/CW OUTPUT

J9-25

ENABLE PS1

J9-26

ENABLE PS2

J9-27

BAND 2 HIGH I DRVR

J9-28

OPERATE

J9-29

GND1

J9-30

GND2

J9-31

GND3

J9-32

GND4

J9-33

GND5

J9-34

GND6

J8

J8

J8-1

BAND 1 SWITCH

J8-2

BAND 2 SWITCH

J8-3

ON

J8-4

FUTURE USE15

J8-5

FUTURE USE16

J8-6

FUTURE USE17

J8-7

FUTURE USE18

J8-8

FUTURE USE19

J8-9

GND7

J8-10

GND8

J8-11

GND9

J8-12

GND10

J8-13

Vc

J8-14

Vc INVERTED

J8-15

GND11

J8-16

GND12

J2

J2

J2-1

+12V

J2-2

GND13

500865

500865

APPROVALS

APPROVALS

APPROVALS

DRAWN BY:

DRAWN BY:

DRAWN BY:

CHECKED BY:

CHECKED BY:

CHECKED BY:

APPROVED BY:

APPROVED BY:

APPROVED BY:

REVISED BY:

REVISED BY:

REVISED BY:

J CAMPANELLA

J CAMPANELLA

J CAMPANELLA

TBD

TBD

TBD

TBD

TBD

TBD

2

P1

P1

RS422

U3

U3

ETHERNET

J4

J4

RS232

J10

J10

IEEE

J17

J17

USB1

J18

J18

USB2

J11

J11

CAN1

J12

J12

CAN2

J5

J5

FWD PWR

RFL-PWR

PS1 CURRENT

PS2 CURRENT

FUTURE USE20

FUTURE USE21

FUTURE USE22

PA 1 CURRENT

PA 2 CURRENT

PA 3 CURRENT

PA 4 CURRENT

PA 5 CURRENT

PA 6 CURRENT

PA 7 CURRENT

PA 8 CURRENT

IPA 1 CURRENT

IPA 2 CURRENT

BASEPLATE TEMP

FUTURE USE23

PS1 V

PS2 V

RF DRIVE IN

ALC EXT IN

AUTO LIMIT IN

GND14

GND15

GND16

GND17

DATE

DATE

DATE

6/1/2017

6/1/2017

6/1/2017

TBD

TBD

TBD

TBD

TBD

TBD

2

J6

J6

J5-1

J5-2

J5-3

J5-4

J5-5

J5-6

J5-7

J5-8

J5-9

J5-10

J5-11

J5-12

J5-13

J5-14

J6-1

J6-2

J6-3

J6-4

J6-5

J6-6

J6-7

J6-8

J6-9

J6-10

J6-11

J6-12

J6-13

J6-14

Size

Size

Size

B

B

B

Scale

Scale

Scale

DATE REV DESCRIPTION

DATE REV DESCRIPTION

DATE REV DESCRIPTION

6/1/2017 1 INITIAL RELEASE

REAR PANELREAR PANEL

RJ45

REAR PANEL2REAR PANEL2

RS232

REAR PANEL1REAR PANEL1

GPIB

REAR PANEL3REAR PANEL3

USB

A5A5

750055

FWD PWR MON

RFL POW MON

PS1 VMON

PS1 IMON

ALC (BNC)ALC (BNC)

BASEPLATE TEMP

CAN USB

INSTRUMENTS FOR INDUSTRY

INSTRUMENTS FOR INDUSTRY

INSTRUMENTS FOR INDUSTRY

903 S. 2ND STREET, RONKONKOMA, NY. 11779

903 S. 2ND STREET, RONKONKOMA, NY. 11779

903 S. 2ND STREET, RONKONKOMA, NY. 11779

TITLE

TITLE

TITLE

S251-250 PS INTERCONNECT

CAGE Code DWG NO

CAGE Code DWG NO

CAGE Code DWG NO

01105

01105

01105

Tuesday, June 06, 2017

Tuesday, June 06, 2017

Tuesday, June 06, 2017

Sheet

Sheet

Sheet

1

700967-1

A7A7

USB

HDMI

+5V PS2

1

REVISION HISTORY

REVISION HISTORY

REVISION HISTORY

A6A6

USB USB

HDMIUSB

+5V

.

GND

750062750062

901097

901097

901097

Rev

Rev

Rev

1

1

1

of

of

22

22

22

of

Loading...

Loading...