PRELIMINARY

LOW SKEW, DUAL, 1-TO-2 DIFFERENTIALTO-LVDS, LVPECL FANOUT BUFFER

GENERAL DESCRIPTION

ICS

HiPerClockS™

differential input levels. The ICS854S204I is characterized to

operate from either a 2.5V or a 3.3V power supply. Guaranteed output and bank skew characteristics make the

ICS854S204I ideal for those clock distribution applications

demanding well defined performance and repeatability.

SUPPLY MODE OPERATION T ABLE

V

The ICS854S204I is a l ow skew, high performance

dual, 1-to-2 Differential-to-LVDS, LVPECL Fanout

Buffer and a member of the HiPerClockS™ fam-

ily of High Performance Clock Solutions from IDT.

The CLKx, nCLKx pairs can accept most standard

noitarepOV3.3noitarepOV5.2

V3.3=V

DD

V

cn=V

PAT

V5.2=

DD

V5.2=

PAT

ICS854S204I

FEATURES

• Two differential LVDS or LVPECL output banks

• Two differential clock input pairs

• CLKx, nCLKx pairs can accept the following differential

input levels: LVDS, LVPECL, LVHSTL, SSTL, HCSL

• Maximum output frequency: >3GHz

• Translates any single ended input signal to LVDS levels

with resistor bias on nCLKx inputs

• Output skew: <25ps (typical) design target

• Bank skew: <50ps (typical) design target

• Propagation delay: TBD

• Additive phase jitter, RMS: 0.15ps (typical)

• Full 3.3V or 2.5V power supply

• -40°C to 85°C ambient operating temperature

• Available in both standard (RoHS 5) and lead-free (RoHS 6)

packages

SEL_OUT FUNCTION TABLE

TUO_LESleveLtuptuO

0SDVL

1LCEPVL

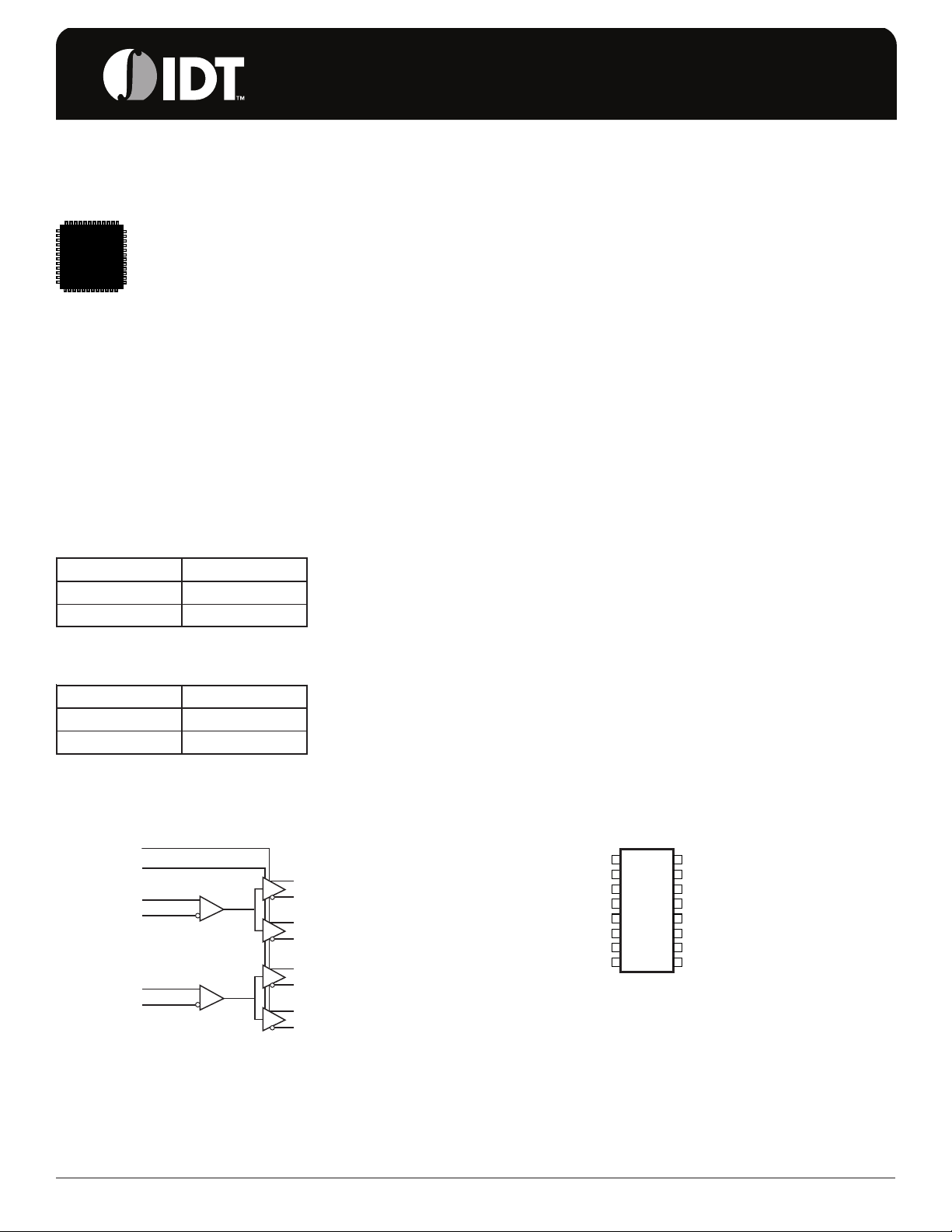

BLOCK DIAGRAM PIN ASSIGNMENT

V

TAP

CLKA

nCLKA

CLKB

nCLKB

Pulldown

Pulldown

Pullup

Pulldown

Pullup

QA0

nQA0

QA1

nQA1

QB0

nQB0

QB1

nQB1

nCLKA

4.4mm x 5.0mm x 0.92mm package body

SEL_OUT

The Preliminary Information presented herein represents a product in prototyping or pre-production. The noted characteristics are based on initial product

characterization. Integrated Device Technology, Incorporated (IDT) reserves the right to change any circuitry or specifications without notice.

1

CLKA

QA0

nQA0

QA1

nQA1

V

TAP

GND

16

2

15

3

14

4

13

5

12

6

11

7

10

8

9

ICS854S204I

16-Lead TSSOP

G Package

Top View

nCLKB

CLKB

QB0

nQB0

QB1

nQB1

V

DD

SEL_OUT

IDT™ / ICS™ LVDS, LVPECL FANOUT BUFFER 1 ICS854S204AGI REV A AUGUST 14, 2006

ICS854S204I

LOW SKEW, DUAL, 1-TO-2 DIFFERENTIAL-TO-LVDS, LVPECL FANOUT BUFFER PRELIMINARY

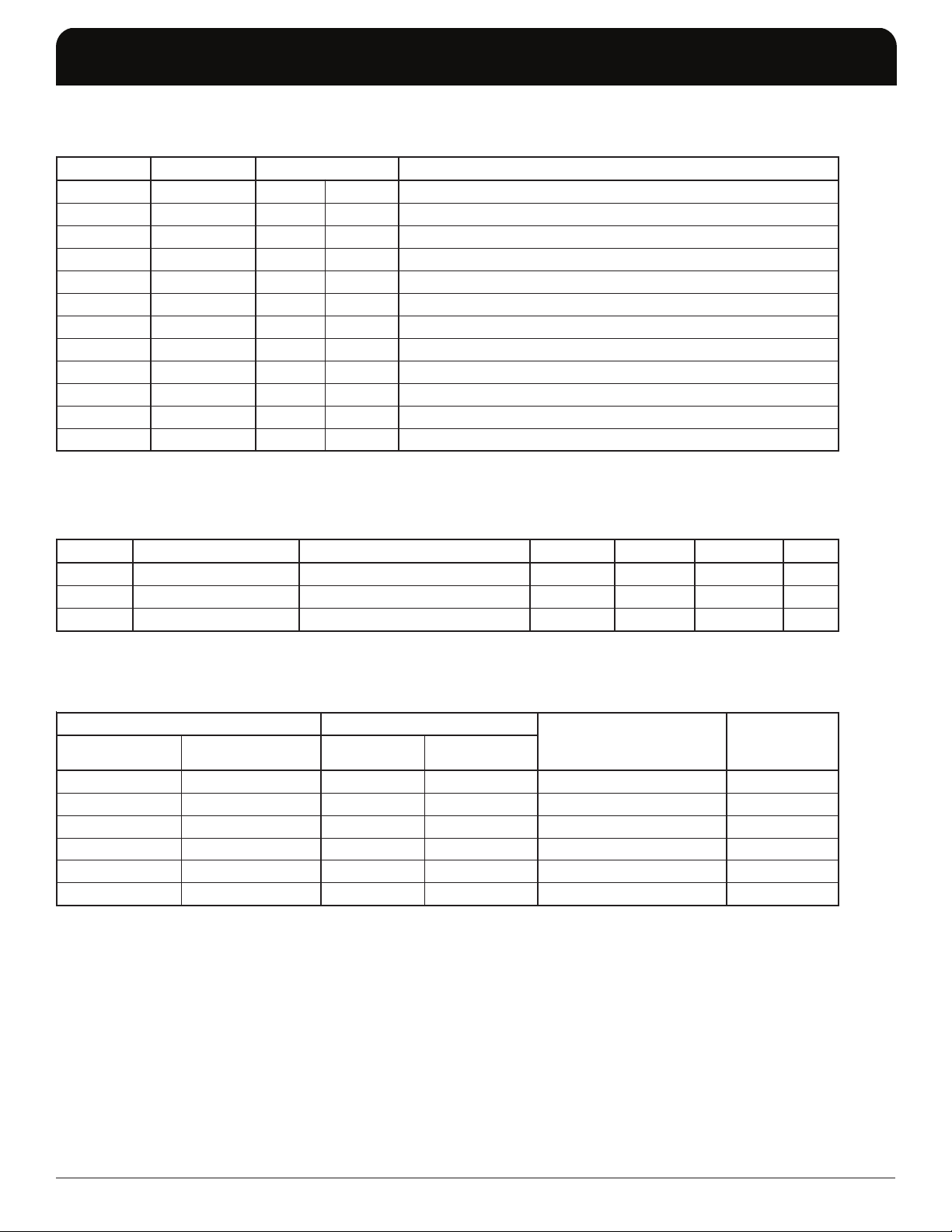

TABLE 1. PIN DESCRIPTIONS

rebmuNemaNepyTnoitpircseD

1AKLCtupnInwodlluP.tupnikcolclaitnereffidgnitrevni-noN

2AKLCntupnIpulluP.tupnikcolclaitnereffidgnitrevnI

4,30AQn,0AQtuptuO .slevelecafretniLCEPVLroSDVL.riaptuptuolaitnereffiD

6,51AQn,1AQtuptuO .slevelecafretniLCEPVLroSDVL.riaptuptuolaitnereffiD

7V

PAT

rewoPVoteiT.nipylppusrewoP

8DNGrewoP.dnuorgylppusrewoP

9TUO_LEStupnInwodlluP.stuptuoLCEPVLroSDVLneewtebstceleS

01V

DD

rewoP.nipylppusrewoP

21,111BQ,1BQntuptuO .slevelecafretniLCEPVLroSDVL.riaptuptuolaitnereffiD

41,310BQ,0BQntuptuO .slevelecafretniLCEPVLroSDVL.riaptuptuolaitnereffiD

51BKLCtupnInwodlluP.tupnikcolclaitnereffidgnitrevni-noN

61BKLCntupnIpulluP.tupnikcolclaitnereffidgnitrevnI

pulluP

:ETON

dna

nwodlluP

DD

.noitarepoV5.2rof

.seulavlacipytrof,scitsiretcarahCniP,2elbaTeeS.srotsisertupnilanretniotrefer

TABLE 2. PIN CHARACTERISTICS

lobmySretemaraPsnoitidnoCtseTmuminiMlacipyTmumixaMstinU

C

NI

R

PULLUP

R

NWODLLUP

ecnaticapaCtupnI 4Fp

rotsiseRpulluPtupnI 15kΩ

rotsiseRnwodlluPtupnI 15kΩ

TABLE 3. CLOCK INPUT FUNCTION TABLE

stupnIstuptuO

BKLCroAKLCBKLCnroAKLCn

01WOLHGIHlaitnereffiDotlaitnereffiDgnitrevnInoN

10 HGIHWOLlaitnereffiDotlaitnereffiDgnitrevnInoN

01ETON;desaiBWOLHGIHlaitnereffiDotdednEelgniSgnitrevnInoN

11ETON;desaiBHGIHWOLlaitnereffiDotdednEelgniSgnitrevnInoN

1ETON;desaiB0HGIHWOLlaitnereffiDotdednEelgniSgnitrevnI

1ETON;desaiB1WOLHGIHlaitnereffiDotdednEelgniSgnitrevnI

,1AQ,0AQ

1BQ,0BQ

,1AQn,0AQn

1BQn,0BQn

edoMtuptuOottupnIytiraloP

."sleveLdednEelgniStpeccAottupnIlaitnereffiDehtgniriW",noitamrofnInoitacilppAehtotreferesaelP:1ETON

IDT™ / ICS™ LVDS, LVPECL FANOUT BUFFER 2 ICS854S204AGI REV A AUGUST 14, 2006

ICS854S204I

LOW SKEW, DUAL, 1-TO-2 DIFFERENTIAL-TO-LVDS, LVPECL FANOUT BUFFER PRELIMINARY

ABSOLUTE MAXIMUM RATINGS

Supply Voltage, V

Inputs, V

Outputs, I

I

O

(LVPECL)

DD

4.6V

-0.5V to V

+ 0.5 V

DD

Continuous Current 50mA

Surge Current 100mA

Outputs, I

(LVDS)

O

Continuous Current 10mA

Surge Current 15mA

Package Thermal Impedance, θ

Storage Temperature, T

(Junction-to-Ambient)

STG

89°C/W (0 lfpm)

JA

-65°C to 150°C

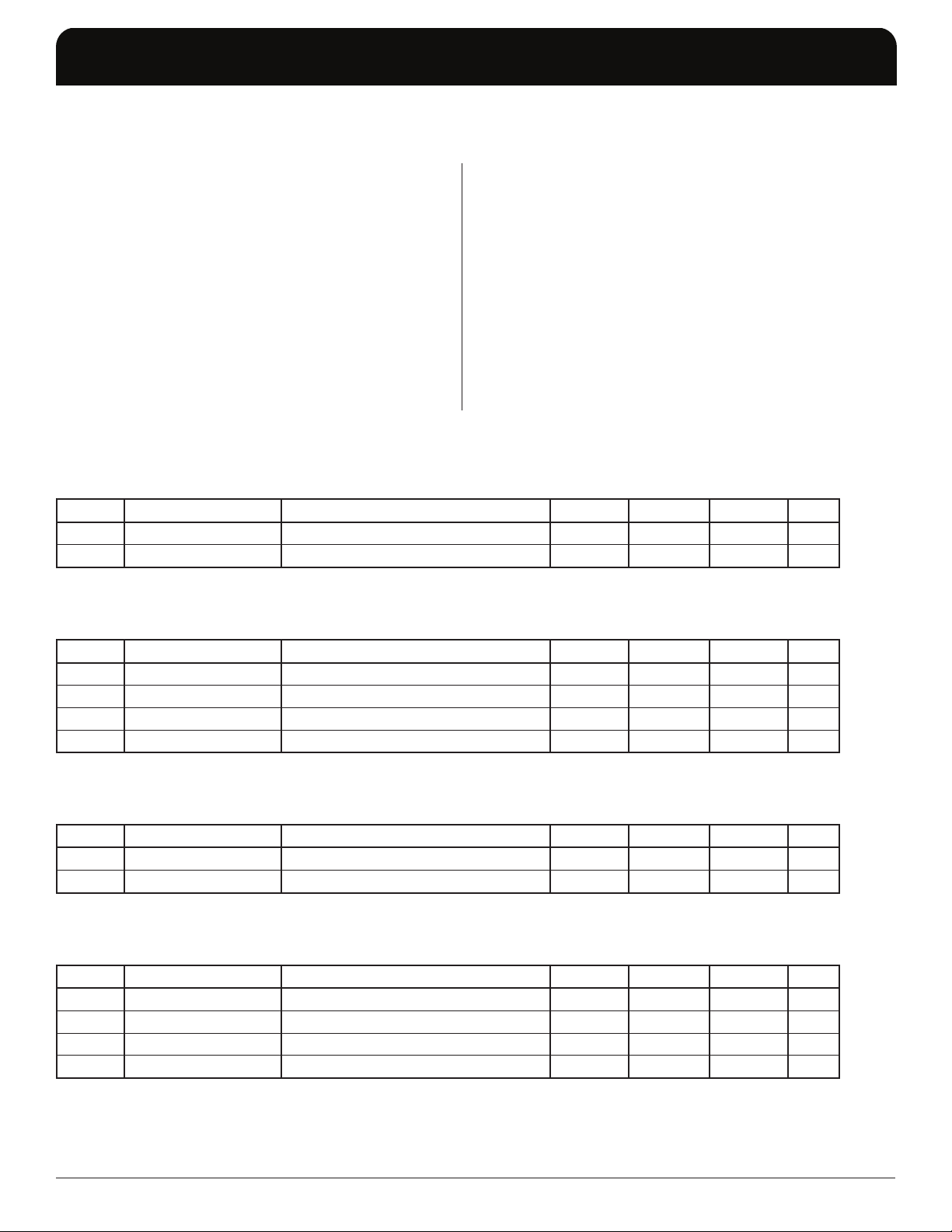

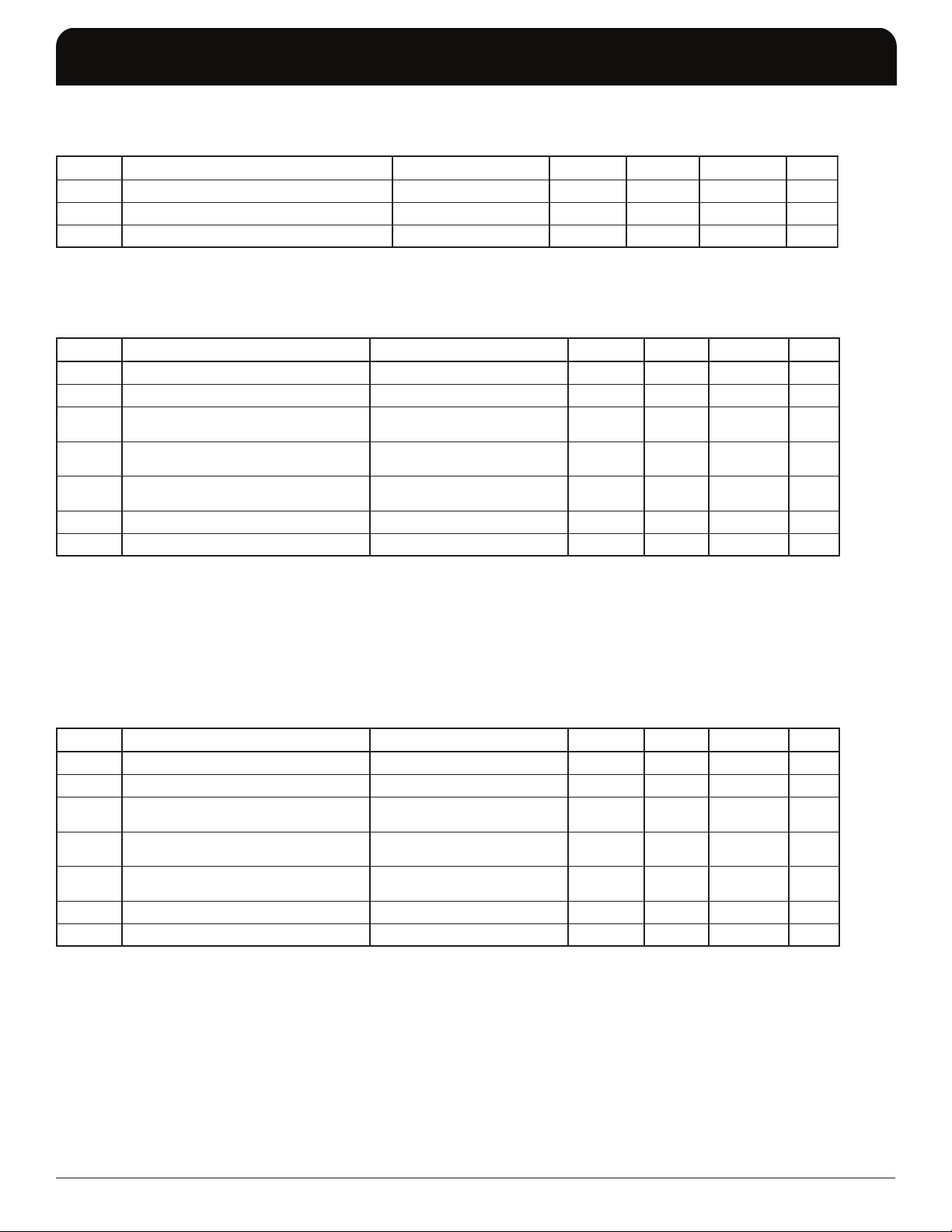

TABLE 4A. LVDS POWER SUPPLY DC CHARACTERISTICS, V

lobmySretemaraPsnoitidnoCtseTmuminiMlacipyTmumixaMstinU

V

DD

I

DD

egatloVylppuSrewoP 531.33.3564.3V

tnerruCylppuSrewoP 001Am

NOTE: Stresses beyond those listed under Absolute

Maximum Ratings may cause permanent damage to the

device. These ratings are stress specifications only. Functional operation of product at these conditions or any conditions beyond

those listed in the

implied. Exposure to absolute maximum rating conditions for extended periods may affect product reliability.

= 3.3V±5%, TA = -40°C TO 85°C

DD

DC Characteristics

or

AC Characteristics

is not

TABLE 4B. LVDS POWER SUPPLY DC CHARACTERISTICS, V

DD

lobmySretemaraPsnoitidnoCtseTmuminiMlacipyTmumixaMstinU

V

DD

V

PAT

I

DD

I

PAT

egatloVylppuSrewoP 573.25.2526.2V

egatloVylppuSrewoP 573.25.2526.2V

tnerruCylppuSrewoP 59Am

tnerruCylppuSrewoP 5Am

TABLE 4C. LVPECL POWER SUPPLY DC CHARACTERISTICS, V

lobmySretemaraPsnoitidnoCtseTmuminiMlacipyTmumixaMstinU

V

DD

I

DD

egatloVylppuSrewoP 531.33.3564.3V

tnerruCylppuSrewoP 001Am

TABLE 4D. LVPECL POWER SUPPLY DC CHARACTERISTICS, V

lobmySretemaraPsnoitidnoCtseTmuminiMlacipyTmumixaMstinU

V

DD

V

PAT

I

DD

I

PAT

egatloVylppuSrewoP 573.25.2526.2V

egatloVylppuSrewoP 573.25.2526.2V

tnerruCylppuSrewoP 59Am

tnerruCylppuSrewoP 5Am

= V

= 2.5V±5%, TA = -40°C TO 85°C

TAP

= 3.3V±5%, TA = -40°C TO 85°C

DD

= V

DD

= 2.5V±5%, TA = -40°C TO 85°C

TAP

IDT™ / ICS™ LVDS, LVPECL FANOUT BUFFER 3 ICS854S204AGI REV A AUGUST 14, 2006

ICS854S204I

LOW SKEW, DUAL, 1-TO-2 DIFFERENTIAL-TO-LVDS, LVPECL FANOUT BUFFER PRELIMINARY

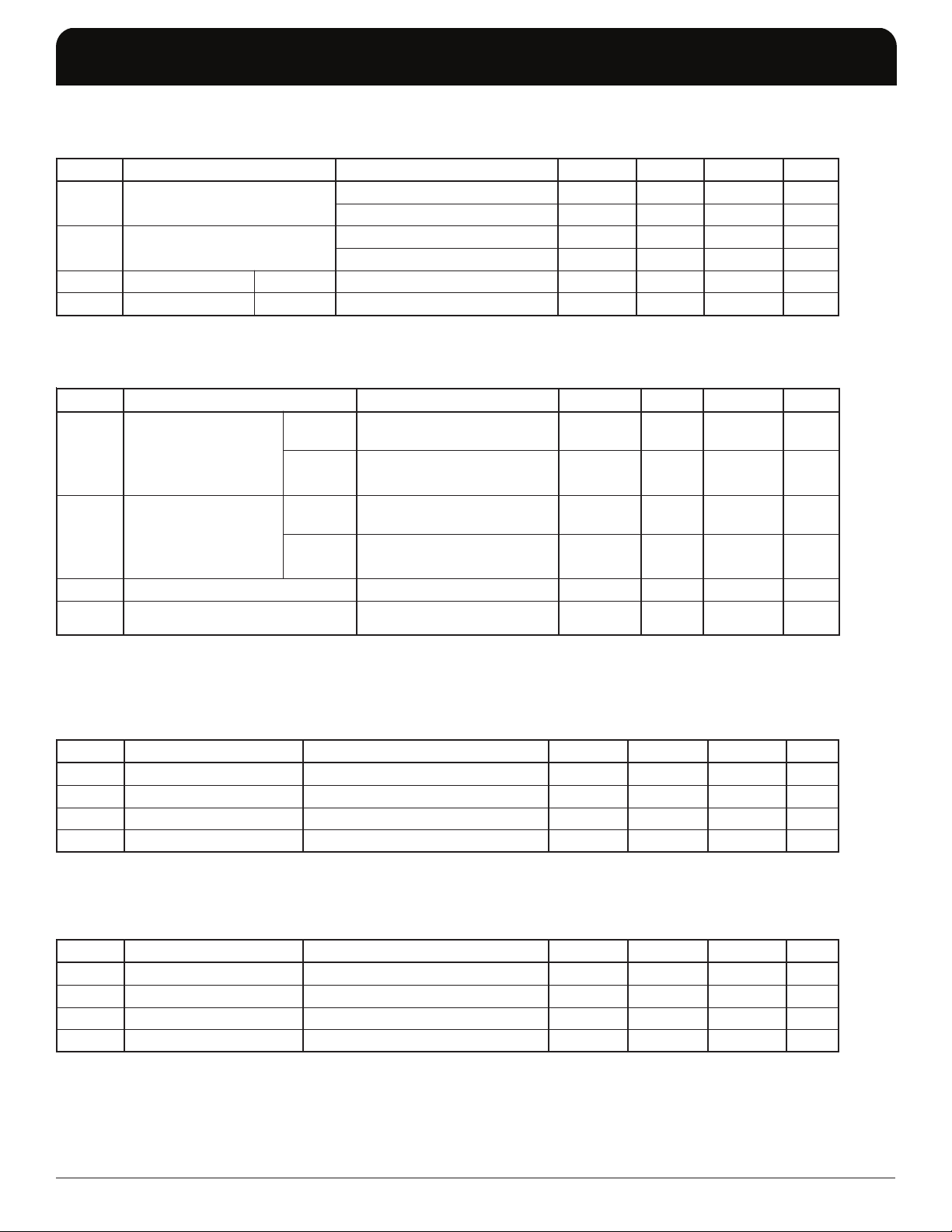

TABLE 4E. LVCMOS / LVTTL DC CHARACTERISTICS, V

lobmySretemaraPsnoitidnoCtseTmuminiMlacipyTmumixaMstinU

V

HI

V

LI

I

HI

I

LI

TABLE 4F. DIFFERENTIAL DC CHARACTERISTICS, V

lobmySretemaraPsnoitidnoCtseTmuminiMlacipyTmumixaMstinU

I

HI

I

LI

V

PP

V

RMC

2,1ETON

egatloVhgiHtupnI

egatloVwoLtupnI

tnerruChgiHtupnITUO_LESV

tnerruCwoLtupnITUO_LESV

V=

DD

DD

= 3.3V±5% OR VDD = V

DD

,AKLC

BKLC

tnerruChgiHtupnI

,AKLCn

V

BKLCn

,AKLC

BKLC

tnerruCwoLtupnI

,AKLCn

V

BKLCn

egatloVtupnIkaeP-ot-kaeP 51.03.1V

;egatloVtupnIedoMnommoC

.

VsadenifedsiegatlovedomnommoC:1ETON

HI

= 3.3V±5% OR VDD = V

DD

V

V

DD

V

V

DD

NI

V

DD

V3.3=2V

DD

V526.2=7.1V

V3.3=3.0-8.0V

DD

V526.2=3.0-7.0V

V,V526.2ro564.3=

NI

V=

NI

V564.3=

V526.2ro

DD

V

V0=

NI

V=

V

DD

NI

V564.3=

V526.2ro

DD

V0=

V

NI

= 2.5V±5%, TA = -40°C TO 85°C

TAP

3.0+V

CC

3.0+V

CC

V526.2roV564.3=051Aµ

V0=5-Aµ

= 2.5V±5%, TA = -40°C TO 85°C

TAP

051Aµ

,V526.2roV564.3=

5Aµ

5-Aµ

,V526.2roV564.3=

051-Aµ

5.0+DNGV

VsixKLCn,xKLCrofegatlovtupnimumixameht,snoitacilppadedneelgnisroF:2ETON

.V3.0+

58.0-V

DD

TABLE 4G. LVDS DC CHARACTERISTICS, V

= 3.3V±5%, TA = -40°C TO 85°C

DD

lobmySretemaraPsnoitidnoCtseTmuminiMlacipyTmumixaMstinU

V

∆ V

V

∆ V

DO

V

DO

SO

SO

DO

egatloVtesffO0=TUO_LES53.1V

V

SO

egatloVtuptuOlaitnereffiD0=TUO_LES004Vm

egnahCedutingaM0=TUO_LES04Vm

egnahCedutingaM0=TUO_LES05Vm

.noitamrofnituptuorofnoitamrofnItnemerusaeMretemaraPotreferesaelP:ETON

TABLE 4H. LVDS DC CHARACTERISTICS, V

DD

= V

= 2.5V±5%, TA = -40°C TO 85°C

TAP

lobmySretemaraPsnoitidnoCtseTmuminiMlacipyTmumixaMstinU

V

∆ V

V

∆ V

DO

V

DO

SO

SO

DO

egatloVtesffO0=TUO_LES3.1V

V

SO

egatloVtuptuOlaitnereffiD0=TUO_LES073Vm

egnahCedutingaM0=TUO_LES04Vm

egnahCedutingaM0=TUO_LES05Vm

.noitamrofnituptuorofnoitamrofnItnemerusaeMretemaraPotreferesaelP:ETON

IDT™ / ICS™ LVDS, LVPECL FANOUT BUFFER 4 ICS854S204AGI REV A AUGUST 14, 2006

ICS854S204I

LOW SKEW, DUAL, 1-TO-2 DIFFERENTIAL-TO-LVDS, LVPECL FANOUT BUFFER PRELIMINARY

TABLE 4I. LVPECL DC CHARACTERISTICS, V

= 3.3V±5% OR VDD = V

DD

= 2.5V±5%, TA = -40°C TO 85°C

TAP

lobmySretemaraPsnoitidnoCtseTmuminiMlacipyTmumixaMstinU

V

HO

V

LO

V

GNIWS

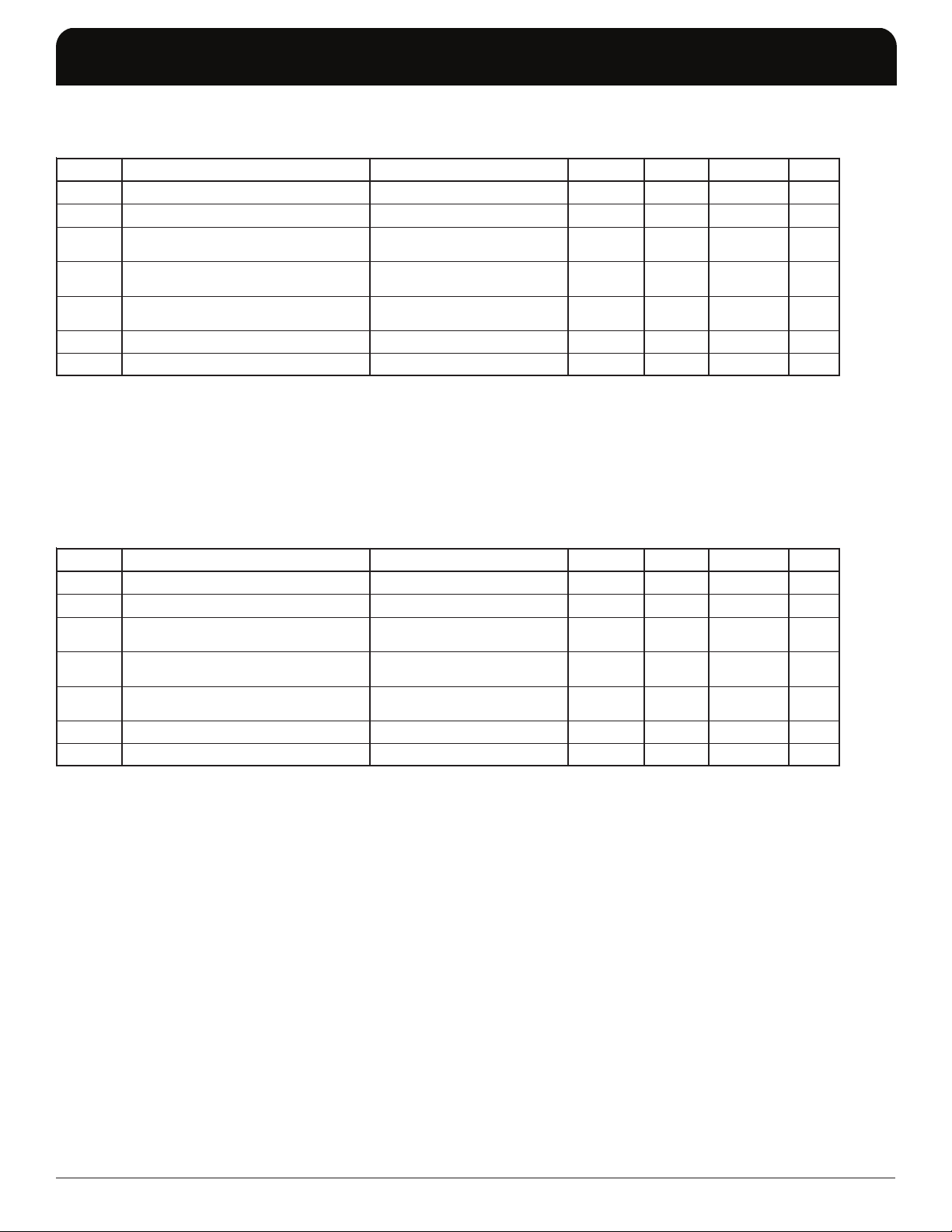

TABLE 5A. LVDS AC CHARACTERISTICS, V

1ETON;egatloVhgiHtuptuO1=TUO_LESV

1ETON;egatloVwoLtuptuO1=TUO_LESV

4.1-V

DD

0.2-V

DD

gniwSegatloVtuptuOkaeP-ot-kaeP1=TUO_LES6.00.1V

05htiwdetanimretstuptuO:1ETON Ω Vot

.V2-

DD

= 3.3V ± 5%, TA = -40°C TO 85°C

DD

9.0-V

DD

7.1-V

DD

lobmySretemaraPsnoitidnoCtseTmuminiMlacipyTmumixaMstinU

f

t

t

t

t

t

R/tF

XAM

DP

)o(ks4,2ETON;wekStuptuO

)b(ks4,3ETON;wekSknaB

tij

ycneuqerFtuptuO 3>zHG

1ETON;yaleDnoitagaporP DBTsn

52<

tegrat

05<

tegrat

;SMR,rettiJesahPevitiddAreffuB

noitceSrettiJesahPevitiddAotrefer

51.0sp

emiTllaF/esiRtuptuO%08ot%02052sp

sp

sp

cdoelcyCytuDtuptuO 05%

.esiwrehtodetonsselnuzHM005taderusaemsretemarapllA

.tniopgnissorctuptuolaitnereffidehtottniopgnissorctupnilaitnereffidehtmorfderusaeM:1ETON

.snoitidnocdaollauqehtiwdnaegatlovylppusemasehttastuptuoneewtebwekssadenifeD:2ETON

.stniopssorclaitnereffidtuptuoehtmorfderusaeM

.snoitidnocdaollauqehtiwdnaegatlovylppusemasehttastuptuofoknabanihtiwwekssadenifeD:3ETON

.56dradnatSCEDEJhtiwecnadroccanidenifedsiretemarapsihT:4ETON

TABLE 5B. LVDS AC CHARACTERISTICS, V

DD

= V

= 2.5V ± 5%, TA = -40°C TO 85°C

TAP

lobmySretemaraPsnoitidnoCtseTmuminiMlacipyTmumixaMstinU

f

t

t

t

t

t

R/tF

XAM

DP

)o(ks4,2ETON;wekStuptuO

)b(ks4,3ETON;wekSknaB

tij

ycneuqerFtuptuO 3>zHG

1ETON;yaleDnoitagaporP DBTsn

52<

tegrat

05<

tegrat

;SMR,rettiJesahPevitiddAreffuB

noitceSrettiJesahPevitiddAotrefer

31.0sp

emiTllaF/esiRtuptuO%08ot%02052sp

sp

sp

cdoelcyCytuDtuptuO 05%

.esiwrehtodetonsselnuzHM005taderusaemsretemarapllA

.tniopgnissorctuptuolaitnereffidehtottniopgnissorctupnilaitnereffidehtmorfderusaeM:1ETON

.snoitidnocdaollauqehtiwdnaegatlovylppusemasehttastuptuoneewtebwekssadenifeD:2ETON

.stniopssorclaitnereffidtuptuoehtmorfderusaeM

.snoitidnocdaollauqehtiwdnaegatlovylppusemasehttastuptuofoknabanihtiwwekssadenifeD:3ETON

.56dradnatSCEDEJhtiwecnadroccanidenifedsiretemarapsihT:4ETON

IDT™ / ICS™ LVDS, LVPECL FANOUT BUFFER 5 ICS854S204AGI REV A AUGUST 14, 2006

ICS854S204I

LOW SKEW, DUAL, 1-TO-2 DIFFERENTIAL-TO-LVDS, LVPECL FANOUT BUFFER PRELIMINARY

TABLE 5C. LVPECL AC CHARACTERISTICS, V

= 3.3V ± 5%, TA = -40°C TO 85°C

DD

lobmySretemaraPsnoitidnoCtseTmuminiMlacipyTmumixaMstinU

f

t

t

t

t

t

R/tF

XAM

DP

)o(ks4,2ETON;wekStuptuO

)b(ks4,3ETON;wekSknaB

tij

ycneuqerFtuptuO 3>zHG

1ETON;yaleDnoitagaporP DBTsn

52<

tegrat

05<

tegrat

;SMR,rettiJesahPevitiddAreffuB

noitceSrettiJesahPevitiddAotrefer

21.0sp

emiTllaF/esiRtuptuO%08ot%02052sp

sp

sp

cdoelcyCytuDtuptuO 05%

.esiwrehtodetonsselnuzHM005taderusaemsretemarapllA

.tniopgnissorctuptuolaitnereffidehtottniopgnissorctupnilaitnereffidehtmorfderusaeM:1ETON

.snoitidnocdaollauqehtiwdnaegatlovylppusemasehttastuptuoneewtebwekssadenifeD:2ETON

.stniopssorclaitnereffidtuptuoehtmorfderusaeM

.snoitidnocdaollauqehtiwdnaegatlovylppusemasehttastuptuofoknabanihtiwwekssadenifeD:3ETON

.56dradnatSCEDEJhtiwecnadroccanidenifedsiretemarapsihT:4ETON

TABLE 5D. LVPECL AC CHARACTERISTICS, V

DD

= V

= 2.5V ± 5%, TA = -40°C TO 85°C

TAP

lobmySretemaraPsnoitidnoCtseTmuminiMlacipyTmumixaMstinU

f

t

t

t

t

t

R/tF

XAM

DP

)o(ks4,2ETON;wekStuptuO

)b(ks4,3ETON;wekSknaB

tij

ycneuqerFtuptuO 3>zHG

1ETON;yaleDnoitagaporP DBTsn

52<

tegrat

05<

tegrat

;SMR,rettiJesahPevitiddAreffuB

noitceSrettiJesahPevitiddAotrefer

70.0sp

emiTllaF/esiRtuptuO%08ot%02052sp

sp

sp

cdoelcyCytuDtuptuO 05%

.esiwrehtodetonsselnuzHM005taderusaemsretemarapllA

.tniopgnissorctuptuolaitnereffidehtottniopgnissorctupnilaitnereffidehtmorfderusaeM:1ETON

.snoitidnocdaollauqehtiwdnaegatlovylppusemasehttastuptuoneewtebwekssadenifeD:2ETON

.stniopssorclaitnereffidtuptuoehtmorfderusaeM

.snoitidnocdaollauqehtiwdnaegatlovylppusemasehttastuptuofoknabanihtiwwekssadenifeD:3ETON

.56dradnatSCEDEJhtiwecnadroccanidenifedsiretemarapsihT:4ETON

IDT™ / ICS™ LVDS, LVPECL FANOUT BUFFER 6 ICS854S204AGI REV A AUGUST 14, 2006

ICS854S204I

SCOPE

Qx

nQx

LVDS

2.5V±5%

POWER SUPPLY

+–

Float GND

LOW SKEW, DUAL, 1-TO-2 DIFFERENTIAL-TO-LVDS, LVPECL FANOUT BUFFER PRELIMINARY

PARAMETER MEASUREMENT INFORMATION

SCOPE

3.3V±5%

POWER SUPPLY

+–

Float GND

V

DD

LVDS

Qx

nQx

V

DD,

V

TAP

2V

V

DD

LVPECL

V

EE

-1.3V±0.165V

V

DD

nCLKA, nCLKB

CLKA, CLKB

GND

2.5V LVDS OUTPUT LOAD AC TEST CIRCUIT3.3V LVDS OUTPUT LOAD AC TEST CIRCUIT

2V

Qx

nQx

SCOPE

V

DD,

V

TAP

LVPECL

V

EE

-0.5V±0.125V

Qx

nQx

SCOPE

2.5V LVPECL OUTPUT LOAD AC TEST CIRCUIT3.3V LVPECL OUTPUT LOAD AC TEST CIRCUIT

nQXx

QXx

V

PP

Cross Points

V

CMR

nQXy

QXy

t

sk(b)

Where X = A or B

DIFFERENTIAL INPUT LEVEL

IDT™ / ICS™ LVDS, LVPECL FANOUT BUFFER 7 ICS854S204AGI REV A AUGUST 14, 2006

BANK SKEW

ICS854S204I

LOW SKEW, DUAL, 1-TO-2 DIFFERENTIAL-TO-LVDS, LVPECL FANOUT BUFFER PRELIMINARY

nQx

Qx

nQy

Qy

OUTPUT SKEW

nQAx,

nQBx

QAx,

QBx

t

sk(o)

tPW

odc = x 100%

t

PERIOD

t

t

PERIOD

PW

nCLKA,

nCLKB

CLKA,

CLKB

nQAx,

nQBx

QAx,

QBx

PROPAGATION DELAY

Clock

Outputs

20%

t

PD

80%

t

R

80%

t

F

20%

V

SWING

OUTPUT RISE/FALL TIMEOUTPUT DUTY CYCLE/PULSE WIDTH/PERIOD

DC Input

V

DD

LV DS

out

➤

out

➤

VOS/∆ V

➤

OS

V

DD

➤

out

➤

DC Input

LVDS

100

DIFFERENTIAL OUTPUT VOLTAGE SETUP

IDT™ / ICS™ LVDS, LVPECL FANOUT BUFFER 8 ICS854S204AGI REV A AUGUST 14, 2006

out

V

/∆ V

OD

OD

➤

OFFSET VOLTAGE SETUP

ICS854S204I

LOW SKEW, DUAL, 1-TO-2 DIFFERENTIAL-TO-LVDS, LVPECL FANOUT BUFFER PRELIMINARY

APPLICATION INFORMATION

WIRING THE DIFFERENTIAL INPUT TO ACCEPT SINGLE ENDED LEVELS

Figure 1

single ended levels. The reference voltage V_REF ~ VDD/2 is

generated by the bias resistors R1, R2 and C1. This bias circuit

should be located as close as possible to the input pin. The ratio

shows how the differential input can be wired to accept

Single Ended Clock Input

of R1 and R2 might need to be adjusted to position the V_REF in

the center of the input voltage swing. For example, if the input

clock swing is only 2.5V and V

and R2/R1 = 0.609.

VDD

R1

1K

CLKx

= 3.3V, V_REF should be 1.25V

DD

V_REF

C1

0.1u R2

FIGURE 1. SINGLE ENDED SIGNAL DRIVING DIFFERENTIAL INPUT

RECOMMENDATIONS FOR UNUSED INPUT AND OUTPUT PINS

INPUTS:

CLK/nCLK INPUT:

For applications not requiring the use of the differential input,

both CLK and nCLK can be left floating. Though not required,

but for additional protection, a 1kΩ resistor can be tied from CLK

to ground.

nCLKx

1K

OUTPUTS:

LVDS OUTPUT

All unused LVDS output pairs can be either left floating or

terminated with 100Ω across. If they are left floating, there should

be no trace attached.

LVPECL O

All unused LVPECL outputs can be left floating. We recommend

that there is no trace attached. Both sides of the differential output

pair should either be left floating or terminated.

UTPUT

IDT™ / ICS™ LVDS, LVPECL FANOUT BUFFER 9 ICS854S204AGI REV A AUGUST 14, 2006

ICS854S204I

LOW SKEW, DUAL, 1-TO-2 DIFFERENTIAL-TO-LVDS, LVPECL FANOUT BUFFER PRELIMINARY

DIFFERENTIAL CLOCK INPUT INTERFACE

The CLK /nCLK accepts LVDS, LVPECL, LVHSTL, SSTL, HCSL

and other differential signals. Both V

V

PP

and V

input requirements. Figures 2A to 2E show interface

CMR

and VOH must meet the

SWING

examples for the HiPerClockS CLK/nCLK input driven by the most

common driver types. The input interfaces suggested here are

examples only. Please consult with the vendor of the driver

component to confirm the driver termination requirements. For

example in

Figure 2A,

the input termination applies for ICS

HiPerClockS LVHSTL drivers. If you are using an LVHSTL driver

from another vendor, use their termination recommendation.

1.8V

LVHSTL

ICS

HiPerClockS

LVHSTL Driver

Zo = 50 Ohm

Zo = 50 Ohm

R1

50

3.3V

CLK

nCLK

HiPerClockS

Input

R2

50

FIGURE 2A. HIPERCLOCKS CLK/nCLK INPUT DRIVEN BY

ICS HIPERCLOCKS LVHSTL DRIVER

3.3V

LVPECL

Zo = 50 Ohm

Zo = 50 Ohm

3.3V

R3

125

R4

125

R1

84

3.3V

CLK

nCLK

HiPerClockS

Input

R2

84

FIGURE 2B. HIPERCLOCKS CLK/nCLK INPUT DRIVEN BY

3.3V LVPECL DRIVER

3.3V

3.3V

LVDS_D river

3.3V

Zo = 50 Ohm

Zo = 50 Ohm

LVPECL

Zo = 50 Ohm

Zo = 50 Ohm

HiPerClockS

Input

CLK

nCLK

Receiv er

3.3V

R1

100

CLK

nCLK

R1

R2

50

50

FIGURE 2C. HIPERCLOCKS CLK/nCLK INPUT DRIVEN BY

3.3V LVPECL DRIVER

3.3V

CLK

nCLK

3.3V

HiPerClockS

Input

3.3V

LVPECL

R5

100 - 200

R5,R6 locate near the driver pin.

Zo = 50 Ohm

Zo = 50 Ohm

R6

100 - 200

R3

R4

125

C1

C2

125

R2

R1

84

84

FIGURE 2D. HIPERCLOCKS CLK/nCLK INPUT DRIVEN BY

3.3V LVDS DRIVER

R3

50

FIGURE 2E. HIPERCLOCKS CLK/nCLK INPUT DRIVEN BY

3.3V LVPECL DRIVER WITH AC COUPLE

IDT™ / ICS™ LVDS, LVPECL FANOUT BUFFER 10 ICS854S204AGI REV A AUGUST 14, 2006

ICS854S204I

LOW SKEW, DUAL, 1-TO-2 DIFFERENTIAL-TO-LVDS, LVPECL FANOUT BUFFER PRELIMINARY

3.3V, 2.5V LVDS DRIVER T ERMINATION

A general LVDS interface is shown in

differential transmission line environment, LVDS drivers

require a matched load termination of 100Ω across near

Figure 3.

In a 100Ω

the receiver input. For a multiple LVDS outputs buffer, if only partial

outputs are used, it is recommended to terminate the

unused outputs.

VDD

LVDS_Driv er

100 Ohm Differential Transmission Line

FIGURE 3. TYPICAL LVDS DRIVER T ERMINATION

TERMINATION FOR 3.3V LVPECL OUTPUTS

The clock layout topology shown below is a typical termination

for LVPECL outputs. The two different layouts mentioned are

recommended only as guidelines.

FOUT and nFOUT are low impedance follower outputs that generate ECL/LVPECL compatible outputs. Therefore, terminating

resistors (DC current path to ground) or current sources must

be used for functionality. These outputs are designed to drive

50Ω transmission lines. Matched impedance techniques should

2.5V or 3. 3V

+

R1

100

-

be used to maximize operating frequency and minimize signal

distortion.

Figures 4A and 4B

show two different layouts which

are recommended only as guidelines. Other suitable clock layouts may exist and it would be recommended that the board

designers simulate to guarantee compatibility across all printed

circuit and clock component process variations.

Z

= 50Ω

o

FOUT

= 50Ω

Z

o

RTT = Z

((V

OH

1

+ VOL) / (VCC – 2)) – 2

50Ω 50Ω

o

RTT

FIN

VCC - 2V

125Ω 125Ω

= 50Ω

Z

o

FOUT FIN

= 50Ω

Z

o

3.3V

84Ω 84Ω

FIGURE 4B. LVPECL OUTPUT TERMINATIONFIGURE 4A. LVPECL OUTPUT TERMINATION

IDT™ / ICS™ LVDS, LVPECL FANOUT BUFFER 11 ICS854S204AGI REV A AUGUST 14, 2006

ICS854S204I

LOW SKEW, DUAL, 1-TO-2 DIFFERENTIAL-TO-LVDS, LVPECL FANOUT BUFFER PRELIMINARY

TERMINATION FOR 2.5V LVPECL OUTPUT

Figure 5A

LVPECL driver. These terminations are equivalent to terminating

50Ω to V

and

Figure 5B

- 2V. For V

CC

show examples of termination for 2.5V

= 2.5V, the V

CC

- 2V is very close to ground

CC

level. The R3 in Figure 5B can be eliminated and the termination

is shown in

Figure 5C.

VCC O=2.5V

2,5V LVPECL

Driver

Zo = 50 Ohm

Zo = 50 Ohm

2.5V

R1

250

R2

62.5

R3

250

R4

62.5

2.5V

+

-

FIGURE 5A. 2.5V LVPECL DRIVER TERMINATION EXAMPLE

VCC O=2.5V

2,5V LVPECL

Driver

Zo = 50 Ohm

Zo = 50 Ohm

R2

R1

50

50

2.5V

+

-

VCCO=2. 5V

2,5V LVPEC L

Driver

Zo = 50 Ohm

Zo = 50 Ohm

R150R2

50

R3

18

2.5V

+

-

FIGURE 5B. 2.5V LVPECL DRIVER TERMINATION EXAMPLE

FIGURE 5C. 2.5V LVPECL TERMINATION EXAMPLE

IDT™ / ICS™ LVDS, LVPECL FANOUT BUFFER 12 ICS854S204AGI REV A AUGUST 14, 2006

ICS854S204I

LOW SKEW, DUAL, 1-TO-2 DIFFERENTIAL-TO-LVDS, LVPECL FANOUT BUFFER PRELIMINARY

RELIABILITY INFORMATION

TABLE 6. θ

VS. AIR FLOW TABLE FOR 16 LEAD TSSOP

JA

θθ

θJA by Velocity (Linear Feet per Minute)

θθ

Single-Layer PCB, JEDEC Standard Test Boards 137.1°C/W 118.2°C/W 106.8°C/W

Multi-Layer PCB, JEDEC Standard Test Boards 89.0°C/W 81.8°C/W 78.1°C/W

NOTE: Most modern PCB designs use multi-layered boards. The data in the second row pertains to most designs.

TRANSISTOR COUNT

The transistor count for ICS854S204I is: 454

0 200 500

IDT™ / ICS™ LVDS, LVPECL FANOUT BUFFER 13 ICS854S204AGI REV A AUGUST 14, 2006

ICS854S204I

LOW SKEW, DUAL, 1-TO-2 DIFFERENTIAL-TO-LVDS, LVPECL FANOUT BUFFER PRELIMINARY

PACKAGE OUTLINE - G SUFFIX FOR 16 LEAD TSSOP

T

ABLE 7. PACKAGE DIMENSIONS

LOBMYS

N61

A--02.1

1A50.051.0

2A08.050.1

b91.003.0

c90.002.0

D09.401.5

ECISAB04.6

1E03.405.4

eCISAB56.0

L54.057.0

α

aaa--01.0

Reference Document: JEDEC Publication 95, MO-153

muminiMmumixaM

°0°8

sretemilliM

IDT™ / ICS™ LVDS, LVPECL FANOUT BUFFER 14 ICS854S204AGI REV A AUGUST 14, 2006

ICS854S204I

LOW SKEW, DUAL, 1-TO-2 DIFFERENTIAL-TO-LVDS, LVPECL FANOUT BUFFER PRELIMINARY

TABLE 8. ORDERING INFORMATION

rebmuNredrO/traPgnikraMegakcaPgnigakcaPgnippihSerutarepmeT

IGA402S458SCIIA402S45POSSTdael61ebutC°58otC°04-

TIGA402S458SCIIA402S45POSSTdael61leer&epat0052C°58otC°04-

FLIGA402S458SCILIA402S4POSST"eerF-daeL"dael61ebutC°58otC°04-

TFLIGA402S458SCILIA402S4POSST"eerF-daeL"dael61leer&epat0052C°58otC°04-

.tnailpmocSHoReradnanoitarugifnoceerF-bPehterarebmuntrapehtotxiffus"FL"nahtiwderedroeratahtstraP:ETON

While the information presented herein has been checked for both accuracy and reliability, Integrated Device Technology, Incorporated (IDT) assumes no responsibility for either its use or for

infringement of any patents or other rights of third parties, which would result from its use. No other circuits, patents, or licenses are implied. This product is intended for use in normal commercial and

industrial applications. Any other applications such as those requiring high reliability or other extraordinary environmental requirements are not recommended without additional processing by IDT. IDT

reserves the right to change any circuitry or specifications without notice. IDT does not authorize or warrant any IDT product for use in life support devices or critical medical instruments.

IDT™ / ICS™ LVDS, LVPECL FANOUT BUFFER 15 ICS854S204AGI REV A AUGUST 14, 2006

ICS854S204I

LOW SKEW, DUAL, 1-TO-2 DIFFERENTIAL-TO-LVDS, LVPECL FANOUT BUFFER PRELIMINARY

Innovate with IDT and accelerate your future networks. Contact:

www.IDT.com

For Sales

800-345-7015

408-284-8200

Fax: 408-284-2775

Corporate Headquarters

Integrated Device Technology, Inc.

6024 Silver Creek Valley Road

San Jose, CA 95138

United States

800 345 7015

+408 284 8200 (outside U.S.)

© 2006 Integrated Device Technology, Inc. All rights reserved. Product specifications subject to change without notice. IDT, the IDT logo, ICS and HiPerClockS are trademarks

of Integrated Device Technology, Inc. Accelerated Thinking is a service mark of Integrated Device Technology, Inc. All other brands, product names and marks are or may be

trademarks or registered trademarks used to identify products or services of their respective owners.

Printed in USA

For Tech Support

netcom@idt.com

480-763-2056

Asia Pacific and Japan

Integrated Device Technology

Singapore (1997) Pte. Ltd.

Reg. No. 199707558G

435 Orchard Road

#20-03 Wisma Atria

Singapore 238877

+65 6 887 5505

Europe

IDT Europe, Limited

321 Kingston Road

Leatherhead, Surrey

KT22 7TU

England

+44 (0) 1372 363 339

Fax: +44 (0) 1372 378851

Loading...

Loading...