Page 1

2016.9.1

SMART-70

User Manual

Page 2

Copyright Notice

Users must respect the copyright laws applicable in their country. This manual must not be photocopied,

translated, reproduced or transmitted in whole or in part for any reason and by the means that might be,

albeit electronic or mechanical, without the express, written authorization of IDP Corp., LTD.

All information contained herein may be subject to modification without prior notice. IDP Corp., Ltd. accepts

no liability for any possible errors herein, nor for any accidental damage or damage caused through the

dissemination or the use of this manual.

Trademarks

SMART-70 is a trademark and IDP is a registered trademark of IDP Corp., LTD. Windows is registered

trademark of Microsoft Corp. All other trademarks or registered trademarks are marks of their respective

holders. SMART-70 Design is a trademark of IDP Corp., Ltd.

Return Materials Authorization

In order to make a warranty claim you must contact an IDP Reseller. You will be responsible for packaging the

printer for shipment and the costs of shipping and insurance of the printer from the point of use of the printer

to the IDP Reseller. The IDP Reseller will bear the costs of shipping and insuring the printer from the repair

location to the address from which the printer was shipped.

Before returning any equipment for in-warranty or out-of warranty repair, contact an IDP Reseller or an IDP

Service Center for a Return Materials Authorization (RMA) number.

Repack the equipment in the original packing material and mark the RMA number clearly on the outside of

the box. For more information about RMA or IDP warranty statements, refer to the Warranty booklet on the

quick install guide.

2

Page 3

Table of Contents

1. INTRODUCTION ............................................................................................................................................................................................... 11

1.1 OVERVIEW ....................................................................................................................................................................................................... 11

1.2 MODULES ........................................................................................................................................................................................................ 14

1.2.1 Input Hopper

1.2.2 Printer

1.2.3 Hybrid Flipper

1.2.4 Laminator

1.2.5 Output Hopper

1.2.6 Stacker

2. INSTALLATION AND OPERATION ............................................................................................................................................................ 28

2.1 HARDWARE INSTALLATION ........................................................................................................................................................................... 28

2.1.1 Placement of Modules

2.1.2 Module fastening

2.1.3 Module connection

2.1.4 Power connection

2.1.5 Print ribbon and laminating film installation

2.1.6 Disposable cleaning roller installation

................................................................................................................................................................................................... 16

..................................................................................................................................................................................... 14

................................................................................................................................................................................... 20

............................................................................................................................................................................................ 21

................................................................................................................................................................................. 25

.................................................................................................................................................................................................. 27

.................................................................................................................................................................. 28

............................................................................................................................................................................ 28

........................................................................................................................................................................ 29

............................................................................................................................................................................ 30

..................................................................................................................... 30

................................................................................................................................... 34

2.1.7 Cards Loading

2.1.8 Loading card cartridge into Output Hopper

2.1.9 Power on

2.1.10 Module combination setting

2.1.11 System status check

2.1.12 Sample card printing

2.2 ADVANCED HARDWARE INSTALLATION ...................................................................................................................................................... 47

2.2.1 Module ID of SMART-70

2.2.2 System configuration of SMART-70

2.2.3 Cable connection of SMART-70

2.3 SOFTWARE INSTALLATION (WINDOWS VISTA/7/8/10) .......................................................................................................................... 53

3. DRIVER CONFIGURATION ........................................................................................................................................................................... 58

3.1 PRINTING PREFERENCES ................................................................................................................................................................................ 58

3.1.1 Printing Preferences

................................................................................................................................................................................... 37

...................................................................................................................... 41

............................................................................................................................................................................................. 41

................................................................................................................................................... 42

.................................................................................................................................................................... 44

................................................................................................................................................................... 44

.............................................................................................................................................................. 47

....................................................................................................................................... 49

............................................................................................................................................... 51

....................................................................................................................................................................... 58

3.2 ADVANCED SETUP .......................................................................................................................................................................................... 61

3.3 OTHER SETTINGS ............................................................................................................................................................................................ 63

3

Page 4

3.3.1 Sharing

................................................................................................................................................................................................. 63

3.3.2 Ports

3.3.3 Advanced

3.3.4 Color Management

3.3.5 Security

3.3.6 Printer status check

4. SMART-70 UTILITIES ...................................................................................................................................................................................... 67

4.1 PRINTER SETTING ........................................................................................................................................................................................... 67

4.1.1 CardPrinter70Setup

4.1.2 Basic Setup

4.1.3 Advanced Setup

4.2 PRINTER TEST .................................................................................................................................................................................................. 75

4.2.1 Printer selection and basic control

4.2.2 Print Test

4.2.3 Batch Job

....................................................................................................................................................................................................... 64

............................................................................................................................................................................................. 64

......................................................................................................................................................................... 65

................................................................................................................................................................................................. 65

........................................................................................................................................................................ 66

......................................................................................................................................................................... 67

......................................................................................................................................................................................... 68

............................................................................................................................................................................... 72

......................................................................................................................................... 76

............................................................................................................................................................................................. 76

............................................................................................................................................................................................. 76

4.2.4 Monitor

4.2.5 Printer status

4.3 FIRMWARE UPGRADE ..................................................................................................................................................................................... 79

4.3.1 Printer connection

4.3.2 Module Firmware Upgrade

5. TROUBLESHOOTING ...................................................................................................................................................................................... 82

5.1 PRINTING QUALITY ......................................................................................................................................................................................... 82

5.1.1 Unprinted or wrong colors printed spot

5.1.2 Unprinted horizontal line

5.1.3 Blurry or unstable print

5.1.4 Not aligned color print

5.1.5 Unplanned color print

5.2 CARD SUPPLY .................................................................................................................................................................................................. 84

5.2.1 Card is not supplied or 2 cards are supplied from Input Hopper

................................................................................................................................................................................................ 76

...................................................................................................................................................................................... 77

........................................................................................................................................................................... 80

......................................................................................................................................................... 80

.............................................................................................................................. 82

............................................................................................................................................................. 82

................................................................................................................................................................ 82

................................................................................................................................................................. 83

................................................................................................................................................................... 83

........................................................................ 84

5.3 CARD JAM ....................................................................................................................................................................................................... 84

5.3.1 Card jam in Input Hopper

5.3.2 Card jam in Printer

5.3.3 Card jam in Hybrid Flipper

5.3.4 Card jam in Laminator

5.3.5 Card jam in Output Hopper

......................................................................................................................................................................... 86

........................................................................................................................................................... 84

......................................................................................................................................................... 88

.................................................................................................................................................................. 89

....................................................................................................................................................... 91

4

Page 5

5.4 CLEANING ....................................................................................................................................................................................................... 92

5.4.1 Input Hopper cleaning

5.4.2 Printer cleaning

................................................................................................................................................................................ 94

5.4.3 Hybrid Flipper cleaning

5.4.4 Laminator cleaning

5.4.5 Output Hopper cleaning

.................................................................................................................................................................. 92

................................................................................................................................................................. 95

.......................................................................................................................................................................... 95

............................................................................................................................................................... 96

5.5 TPH (THERMAL PRINT HEAD) REPLACEMENT .......................................................................................................................................... 97

5.6 LAMINATOR HEAD REPLACEMENT ............................................................................................................................................................... 99

6. SMART-70 SPECIFICATIONS ..................................................................................................................................................................... 102

6.1 SMART-70 INPUT HOPPER ...................................................................................................................................................................... 102

6.2 SMART-70 PRINTER .................................................................................................................................................................................. 102

6.3 SMART-70 HYBRID FLIPPER .................................................................................................................................................................... 103

6.4 SMART-70 LAMINATOR ........................................................................................................................................................................... 103

6.5 SMART-70 OUTPUT HOPPER .................................................................................................................................................................. 104

5

Page 6

Table of Figures

FIGURE 1 COMBINATION OF SMART-70 ............................................................................................................................................................. 11

FIGURE 2 FRONT SIDE OF INPUT HOPPER ............................................................................................................................................................. 15

FIGURE 3 REAR SIDE OF INPUT HOPPER ................................................................................................................................................................ 15

FIGURE 4 FRONT SIDE OF PRINTER ......................................................................................................................................................................... 17

FIGURE 5 REAR SIDE OF PRINTER ........................................................................................................................................................................... 17

FIGURE 6 CONTROL PANEL OF PRINTER ................................................................................................................................................................ 18

FIGURE 7 FRONT SIDE OF HYBRID FLIPPER ........................................................................................................................................................... 20

FIGURE 8 REAR SIDE OF HYBRID FLIPPER .............................................................................................................................................................. 21

FIGURE 9 FRONT SIDE OF LAMINATOR .................................................................................................................................................................. 22

FIGURE 10 REAR SIDE OF LAMINATOR ................................................................................................................................................................... 23

FIGURE 11 CONTROL PANEL OF LAMINATOR........................................................................................................................................................ 23

FIGURE 12 FRONT SIDE OF OUTPUT HOPPER ...................................................................................................................................................... 26

FIGURE 13 REAR SIDE OF OUTPUT HOPPER ......................................................................................................................................................... 27

FIGURE 14 STACKER .................................................................................................................................................................................................. 27

FIGURE 15 SMART-70 PLACEMENT OF MODULES ............................................................................................................................................ 28

FIGURE 16 MODULE FASTENING ............................................................................................................................................................................. 29

FIGURE 17 MODULE CONNECTION ........................................................................................................................................................................ 29

FIGURE 18 POWER CONNECTION ........................................................................................................................................................................... 30

FIGURE 19 RIBBON / FILM CARTRIDGE UNLOCKING ............................................................................................................................................ 30

FIGURE 20 PULLING OUT RIBBON / FILM CARTRIDGE .......................................................................................................................................... 31

FIGURE 21 PRINT RIBBON / LAMINATING FILM MOUNTING ............................................................................................................................... 31

FIGURE 22 PRINT RIBBON MOUNTING ................................................................................................................................................................... 32

FIGURE 23 LAMINATING FILM MOUNTING ............................................................................................................................................................ 32

FIGURE 24 PRINT RIBBON / LAMINATING FILM ALIGNMENT .............................................................................................................................. 33

FIGURE 25 RIBBON / FILM CARTRIDGE INSERTION ............................................................................................................................................... 33

FIGURE 26 RIBBON / FILM CARTRIDGE LOCKING .................................................................................................................................................. 34

FIGURE 27 DETACHMENT OF DISPOSABLE CLEANING ROLLER HOLDER ............................................................................................................ 34

FIGURE 28 USED DISPOSABLE CLEANING ROLLER REMOVAL .............................................................................................................................. 35

FIGURE 29 NEW DISPOSABLE CLEANING ROLLER MOUNTING............................................................................................................................ 35

FIGURE 30 REMOVAL OF NEW DISPOSABLE CLEANING ROLLER PROTECTOR.................................................................................................... 36

FIGURE 31 INSTALLATION OF DISPOSABLE CLEANING ROLLER HOLDER ............................................................................................................ 36

FIGURE 32 CARD CARTRIDGE RELEASE FROM INPUT HOPPER ........................................................................................................................... 37

FIGURE 33 CARDS THICKNESS ADJUSTMENT ........................................................................................................................................................ 37

FIGURE 34 CARD CARTRIDGE OPEN ....................................................................................................................................................................... 38

FIGURE 35 REMOVAL OF THE TAPE FOR FIXING THE WEIGHT ............................................................................................................................. 38

6

Page 7

FIGURE 36 CARD CARTRIDGE’S WEIGHT FIXING .................................................................................................................................................... 39

FIGURE 37 CARD LOADING ...................................................................................................................................................................................... 39

FIGURE 38 PUTTING DOWN THE CARD CARTRIDGE’S WEIGHT ........................................................................................................................... 40

FIGURE 39 LOADING CARD CARTRIDGE INTO INPUT HOPPER............................................................................................................................ 40

FIGURE 40 LOADING CARD CARTRIDGE INTO OUTPUT HOPPER ....................................................................................................................... 41

FIGURE 41 POWER ON ............................................................................................................................................................................................. 41

FIGURE 42 MODULES COMBINATION CHECKING ................................................................................................................................................. 42

FIGURE 43 EXISTING MODULES COMBINATION .................................................................................................................................................... 42

FIGURE 44 ADJUSTED MODULES COMBINATION .................................................................................................................................................. 43

FIGURE 45 SAVED MODULE COMBINATION ........................................................................................................................................................... 43

FIGURE 46 COMPLETED MODULE COMBINATION ................................................................................................................................................. 43

FIGURE 47 SYSTEM STATUS CHECKING ................................................................................................................................................................... 44

FIGURE 48 PRINTER MENU ...................................................................................................................................................................................... 44

FIGURE 49 PRINTER MENU (SYSTEM CONFIG) ..................................................................................................................................................... 45

FIGURE 50 PRINTER MENU (NETWORK CONFIG) ................................................................................................................................................. 45

FIGURE 51 PRINTER MENU (PRINTER CONFIG) .................................................................................................................................................... 45

FIGURE 52 PRINTER MENU (OPERATION) .............................................................................................................................................................. 46

FIGURE 53 PRINTER MENU (PRINT SAMPLE) ........................................................................................................................................................ 46

FIGURE 54 SAMPLE CARD ........................................................................................................................................................................................ 46

FIGURE 55 DIP SWITCH LOCATION OF SMART-70 MODULE ........................................................................................................................... 48

FIGURE 56 SYSTEM CONFIGURATION OF SMART-70 ........................................................................................................................................ 49

FIGURE 57 CABLE CONNECTION OF SMART-70 IPHLO .................................................................................................................................. 51

FIGURE 58 CABLE CONNECTION OF SMART-70 IPP ........................................................................................................................................ 51

FIGURE 59 CABLE CONNECTION OF SMART-70 IPHLO .................................................................................................................................. 52

FIGURE 60 CABLE CONNECTION OF SMART-70 IPHPO ................................................................................................................................. 52

FIGURE 61 PRINTER DRIVER INSTALLATION 1 ....................................................................................................................................................... 53

FIGURE 62 PRINTER DRIVER INSTALLATION 2 ....................................................................................................................................................... 53

FIGURE 63 PRINTER DRIVER INSTALLATION 3 ....................................................................................................................................................... 53

FIGURE 64 PRINTER DRIVER INSTALLATION 4 ....................................................................................................................................................... 53

FIGURE 65 PRINTER DRIVER INSTALLATION 5 ....................................................................................................................................................... 54

FIGURE 66 PRINTER DRIVER INSTALLATION 6 ....................................................................................................................................................... 54

FIGURE 67 PRINTER DRIVER INSTALLATION 7 ....................................................................................................................................................... 54

FIGURE 68 PRINTER DRIVER INSTALLATION 8 ....................................................................................................................................................... 54

FIGURE 69 PRINTER DRIVER INSTALLATION 9 ....................................................................................................................................................... 55

FIGURE 70 PRINTER DRIVER INSTALLATION 10 ..................................................................................................................................................... 55

FIGURE 71 PRINTER DRIVER INSTALLATION 11 ..................................................................................................................................................... 55

7

Page 8

FIGURE 72 PRINTER DRIVER INSTALLATION 12 ..................................................................................................................................................... 55

FIGURE 73 PRINTER DRIVER INSTALLATION 13 ..................................................................................................................................................... 56

FIGURE 74 PRINTER DRIVER INSTALLATION 14 ..................................................................................................................................................... 56

FIGURE 75 APPLICATION INSTALLATION 1 ............................................................................................................................................................. 56

FIGURE 76 APPLICATION INSTALLATION 2 ............................................................................................................................................................. 57

FIGURE 77 APPLICATION INSTALLATION 3 ............................................................................................................................................................. 57

FIGURE 78 APPLICATION INSTALLATION 4 ............................................................................................................................................................. 57

FIGURE 79 APPLICATION INSTALLATION 5 ............................................................................................................................................................. 57

FIGURE 80 APPLICATION INSTALLATION 6 ............................................................................................................................................................. 58

FIGURE 81 PRINTER PROPERTIES WINDOW ........................................................................................................................................................... 58

FIGURE 82 LAYOUT ................................................................................................................................................................................................... 59

FIGURE 83 INPUT / OUTPUT SETTINGS .................................................................................................................................................................. 59

FIGURE 84 PRINTING SETTINGS ............................................................................................................................................................................... 60

FIGURE 85 LAMINATING SETTINGS ......................................................................................................................................................................... 60

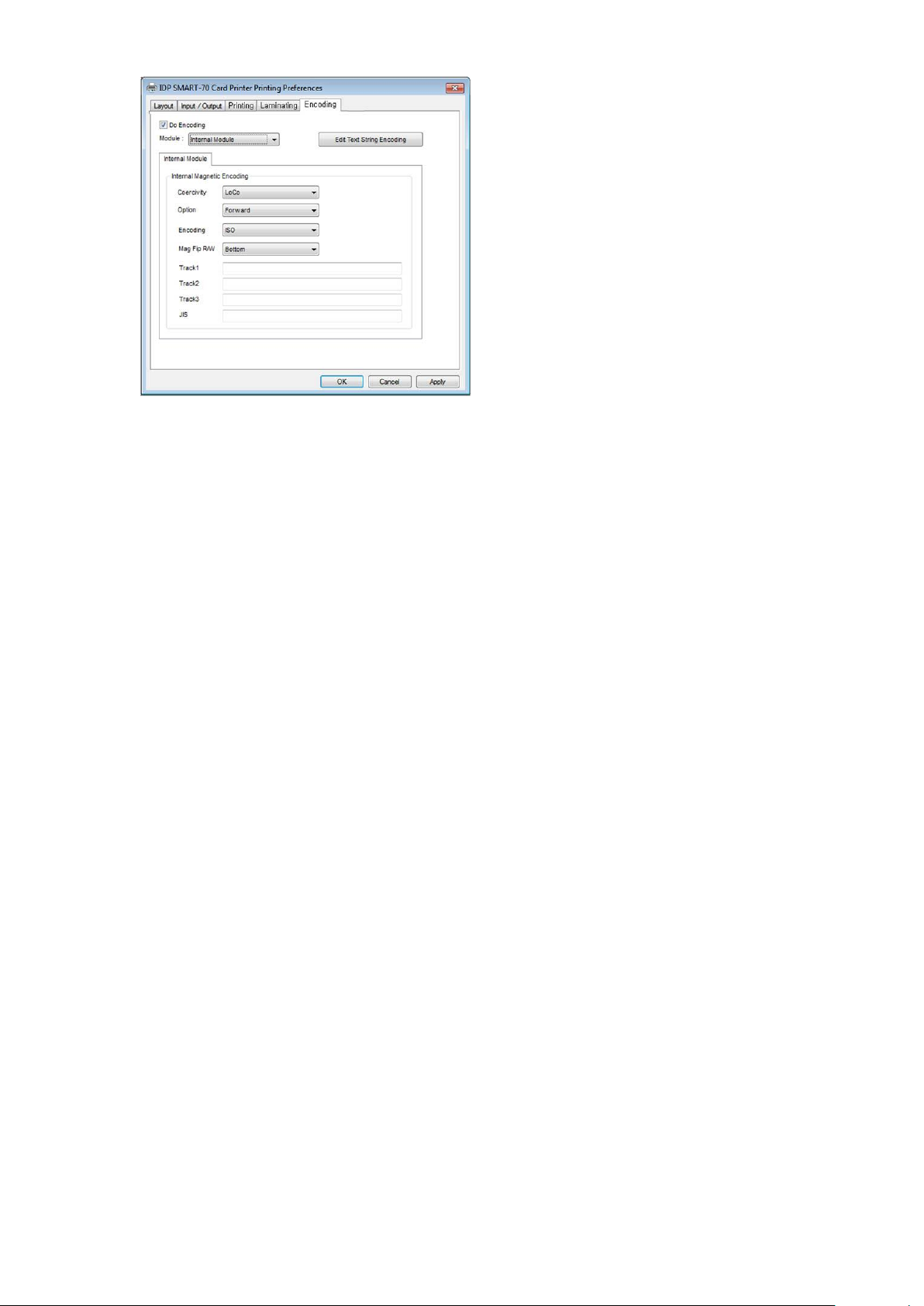

FIGURE 86 ENCODING SETTINGS ............................................................................................................................................................................ 61

FIGURE 87 PRINTER SHARING SETTINGS ................................................................................................................................................................ 63

FIGURE 88 PORTS SETTING ...................................................................................................................................................................................... 64

FIGURE 89 ADVANCED SETTINGS ............................................................................................................................................................................ 64

FIGURE 90 COLOR MANAGEMENT SETTINGS ....................................................................................................................................................... 65

FIGURE 91 SECURITY SETTING ................................................................................................................................................................................. 65

FIGURE 92 PRINTER STATUS CHECK ........................................................................................................................................................................ 66

FIGURE 93 CARDPRINTER70SETUP LOG-IN ......................................................................................................................................................... 67

FIGURE 94 CARDPRINTER70SETUP START ............................................................................................................................................................ 68

FIGURE 95 BASIC SETUP OF CARDPRINTER70SETUP .......................................................................................................................................... 68

FIGURE 96 COLOR DENSITY ..................................................................................................................................................................................... 70

FIGURE 97 RESIN BLACK DENSITY .......................................................................................................................................................................... 71

FIGURE 98 OVERLAY DENSITY ................................................................................................................................................................................. 71

FIGURE 99 ADVANCED SETUP ................................................................................................................................................................................. 72

FIGURE 100 ARDPRINTER70TEST ........................................................................................................................................................................... 75

FIGURE 101 MONITOR ............................................................................................................................................................................................. 76

FIGURE 102 CARDPRINTER70FIRMWARE .............................................................................................................................................................. 79

FIGURE 103 MODULES OF SMART-70 SYSTEM (PRINTER, HYBRID FLIPPER) ............................................................................................... 80

FIGURE 104 READY FOR FIRMWARE UPGRADE ..................................................................................................................................................... 80

FIGURE 105 MANUAL FIRMWARE UPGRADE ......................................................................................................................................................... 81

FIGURE 106 PRINTING QUALITY TROUBLE 1 ......................................................................................................................................................... 82

FIGURE 107 PRINTING QUALITY TROUBLE 2 ......................................................................................................................................................... 82

8

Page 9

FIGURE 108 PRINTING QUALITY TROUBLE 3 ......................................................................................................................................................... 82

FIGURE 109 PRINTING QUALITY TROUBLE 4 ......................................................................................................................................................... 83

FIGURE 110 PRINTING QUALITY TROUBLE 5 ......................................................................................................................................................... 83

FIGURE 111 CARD SUPPLY PROBLEM 1 ................................................................................................................................................................. 84

FIGURE 112 CARD JAM IN INPUT HOPPER 1 ....................................................................................................................................................... 84

FIGURE 113 CARD JAM IN INPUT HOPPER 2 ....................................................................................................................................................... 85

FIGURE 114 CARD JAM IN INPUT HOPPER 3 ....................................................................................................................................................... 85

FIGURE 115 CARD JAM IN INPUT HOPPER 4 ....................................................................................................................................................... 85

FIGURE 116 CARD JAM IN INPUT HOPPER 5 ....................................................................................................................................................... 86

FIGURE 117 CARD JAM IN PRINTER 1 ................................................................................................................................................................... 86

FIGURE 118 CARD JAM IN PRINTER 2 ................................................................................................................................................................... 86

FIGURE 119 CARD JAM IN PRINTER 3 ................................................................................................................................................................... 87

FIGURE 120 CARD JAM IN PRINTER 4 ................................................................................................................................................................... 87

FIGURE 121 CARD JAM IN PRINTER 5 ................................................................................................................................................................... 87

FIGURE 122 CARD JAM IN HYBRID FLIPPER 1 ...................................................................................................................................................... 88

FIGURE 123 CARD JAM IN HYBRID FLIPPER 2 ...................................................................................................................................................... 88

FIGURE 124 CARD JAM IN HYBRID FLIPPER 3 ...................................................................................................................................................... 88

FIGURE 125 CARD JAM IN HYBRID FLIPPER 4 ...................................................................................................................................................... 89

FIGURE 126 CARD JAM IN LAMINATOR 1 ............................................................................................................................................................. 89

FIGURE 127 CARD JAM IN LAMINATOR 2 ............................................................................................................................................................. 89

FIGURE 128 CARD JAM IN LAMINATOR 3 ............................................................................................................................................................. 90

FIGURE 129 CARD JAM IN LAMINATOR 4 ............................................................................................................................................................. 90

FIGURE 130 CARD JAM IN LAMINATOR 5 ............................................................................................................................................................. 90

FIGURE 131 CARD JAM IN OUTPUT HOPPER 1 ................................................................................................................................................... 91

FIGURE 132 CARD JAM IN OUTPUT HOPPER 2 ................................................................................................................................................... 91

FIGURE 133 CARD JAM IN OUTPUT HOPPER 3 ................................................................................................................................................... 91

FIGURE 134 CARD JAM IN OUTPUT HOPPER 4 ................................................................................................................................................... 92

FIGURE 135 CARD JAM IN OUTPUT HOPPER 5 ................................................................................................................................................... 92

FIGURE 136 INPUT HOPPER CLEANING 1 ............................................................................................................................................................. 92

FIGURE 137 INPUT HOPPER CLEANING 2 ............................................................................................................................................................. 93

FIGURE 138 INPUT HOPPER CLEANING 3 ............................................................................................................................................................. 93

FIGURE 139 INPUT HOPPER CLEANING 4 ............................................................................................................................................................. 93

FIGURE 140 PRINTER CLEANING 1 ......................................................................................................................................................................... 94

FIGURE 141 PRINTER CLEANING 2 ......................................................................................................................................................................... 94

FIGURE 142 PRINTER CLEANING 3 ......................................................................................................................................................................... 94

FIGURE 143 HYBRID FLIPPER CLEANING 1 ............................................................................................................................................................ 95

9

Page 10

FIGURE 144 HYBRID FLIPPER CLEANING 2 ............................................................................................................................................................ 95

FIGURE 145 LAMINATOR CLEANING 1 ................................................................................................................................................................... 95

FIGURE 146 LAMINATOR CLEANING 2 ................................................................................................................................................................... 96

FIGURE 147 LAMINATOR CLEANING 3 ................................................................................................................................................................... 96

FIGURE 148 OUTPUT HOPPER CLEANING 1 ......................................................................................................................................................... 96

FIGURE 149 OUTPUT HOPPER CLEANING 2 ......................................................................................................................................................... 97

FIGURE 150 OUTPUT HOPPER CLEANING 3 ......................................................................................................................................................... 97

FIGURE 151 TPH REPLACEMENT 1 ........................................................................................................................................................................ 97

FIGURE 152 TPH REPLACEMENT 2 ........................................................................................................................................................................ 98

FIGURE 153 TPH REPLACEMENT 3 ........................................................................................................................................................................ 98

FIGURE 154 TPH REPLACEMENT 4 ........................................................................................................................................................................ 98

FIGURE 155 TPH REPLACEMENT 5 ........................................................................................................................................................................ 99

FIGURE 156 TPH REPLACEMENT 6 ........................................................................................................................................................................ 99

FIGURE 157 LAMINATOR HEAD REPLACEMENT 1 ................................................................................................................................................ 99

FIGURE 158 LAMINATOR HEAD REPLACEMENT 2 .............................................................................................................................................. 100

FIGURE 159 LAMINATOR HEAD REPLACEMENT 3 .............................................................................................................................................. 100

FIGURE 160 LAMINATOR HEAD REPLACEMENT 4 .............................................................................................................................................. 100

FIGURE 161 LAMINATOR HEAD REPLACEMENT 5 .............................................................................................................................................. 100

FIGURE 162 LAMINATOR HEAD REPLACEMENT 6 .............................................................................................................................................. 101

10

Page 11

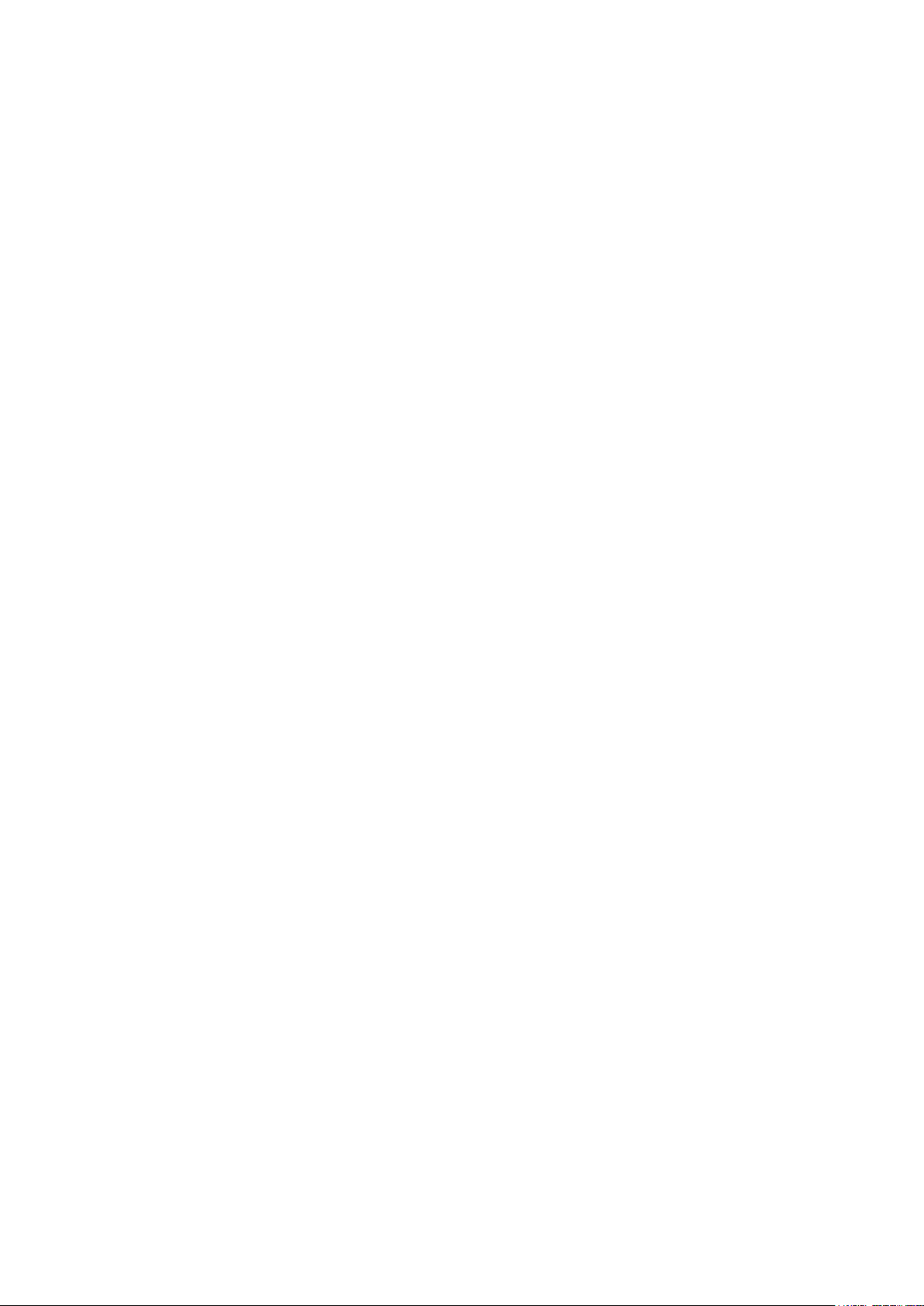

1. Introduction

①

②

③

⑤

④

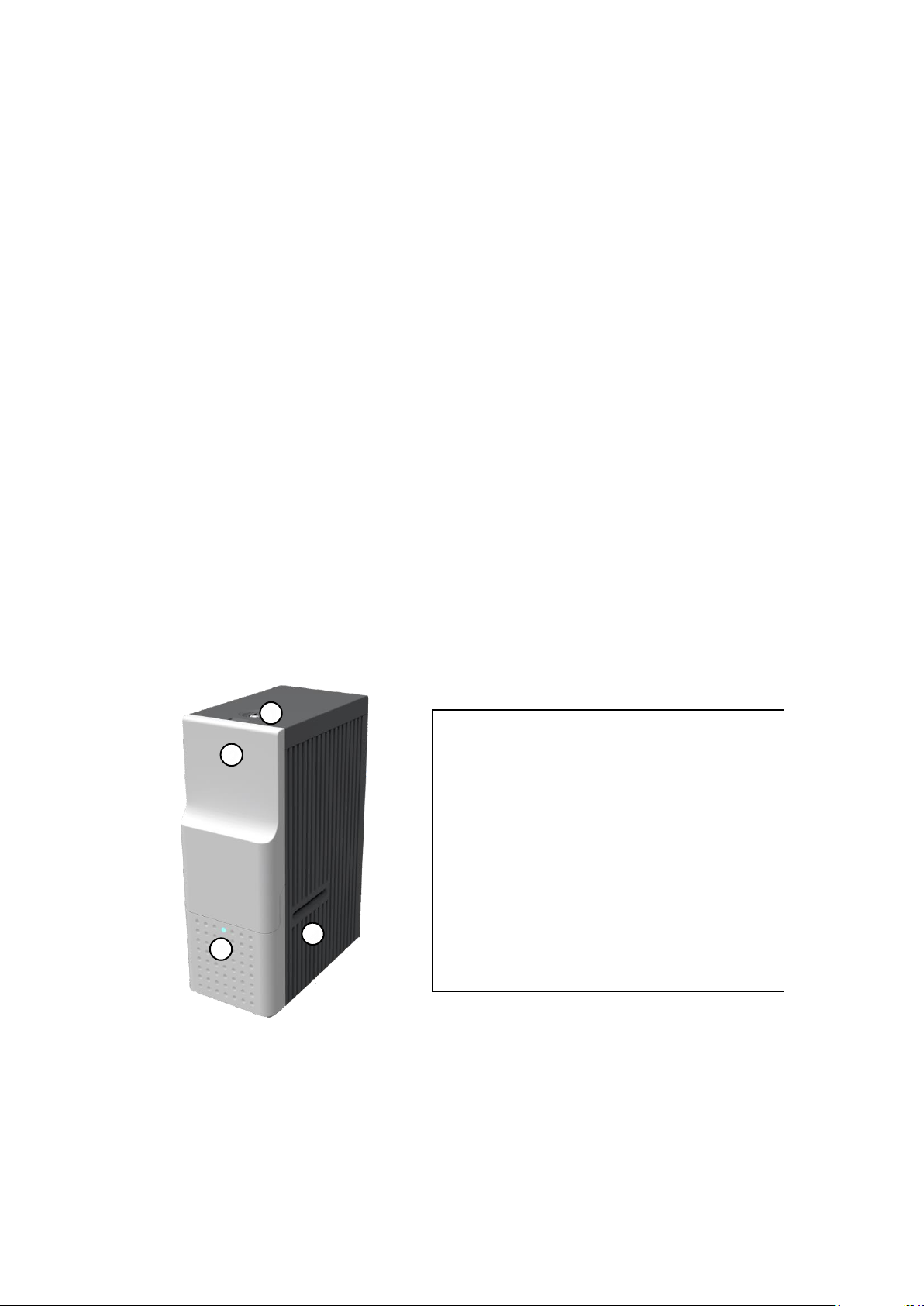

1.1 Overview

SMART-70 is a high-performance large capacity ID card printer designed by the unique

modular concept that can support various printer configurations to meet different user

requirements. 500 cards can continuously be printed, laminated and encoded on various card.

SMART-70 consists of 5 different modules (① Input Hopper, ② Printer, ③ Hybrid Flipper, ④

Laminator, ⑤ Output Hopper) that can be configured in various combinations according to

different customer requirements. Required modules can easily be added to extend functions

depending on your needs.

Figure 1 Combination of SMART-70

Key features of SMART-70 are as follows.

Convenience

SMART-70 is sleekly designed, such as modern household appliances, to provide

user-friendly environment with the maximum convenience. Status LED on all

modules can indicate the status of each module at all times. Also, LCD and buttons

on Printer and Laminator are for user to check the status and set the configuration.

Card, print ribbon and other consumables can be changed in intuitive way.

11

Page 12

Flexibility

SMART-70 is designed to organize the combination of SMART-70 by user

requirements and easy to add necessary modules or remove unnecessary modules.

After purchasing and installing SMART-70 Input Hopper and Printer module for

printing, the Laminator can be additionally added when the laminating function is

needed.

Security

For preventing the theft and leakage of cards, ribbons and consumables, physical

locking mechanism and Kensington lock are designed and applied on every module.

For high-level security, authenticated user can only print, encode and laminate cards

by using SMAR-70.

Clear Printing

SMART-70 can print clear images on card by using IDP’s FINE Technology that can

exquisitely control the heat of print head depending on the picture.

High Speed

SMART-70 can print 200 cards/hour for color (YMCKO) and 1,000 cards/hour for

monochrome. Since each module can independently work, multiple cards can be

simultaneously printed, encoded and laminated by the pipeline processing for

enhancing issuance speed.

Reasonable Cost

SMART-70 Series enables a Mass card issuance system to be built by the reasonable

cost compared with competitive products. When multi systems built by SMART-70

Series are used, the systems can be substituted for large equipment for card

issuance by reasonable cost.

High Capacity

SMART-70 is designed to support 500 cards capacity in Input Hopper, Printer,

Laminator and Output Hopper. Once card, print ribbon and laminating film are

replaced, 500 cards can be continuously issued. Also, cards can be loaded and

stacked the up to 3000 cards by using multiple Input / Output Hopper.

12

Page 13

Encoding

SMART-70 can encode the magnetic stripe cards and contact/contactless smart

cards by using the encoding options, images or 1D/2d barcodes on card can be also

read by using image scanner. The magnetic stripe encoder and contactless smart

card encoder can be installed into SMART-70 Printer, and the contact/contactless

smart card encoder and both-side image scanner can be installed into SMART-70

Hybrid Flipper.

Energy Saving

SMART-70 is designed to minimize unnecessary power consumption when the

system doesn’t work. Since SMART-70 Laminator uses the instant direct heating

mechanism developed by IDP, it requires no warming-up for laminating and no

additional power consumption for maintaining the temperature of the laminate head

while on standby.

Reliability

Since the metal frame, stainless steel shaft and ball bearing is used for the high

durability, SMART-70 can be stably operated under the harsh environments of the

massive issuance environment.

Scratch Free

SMART-70 can protect a card surface while the card is in SMART-70 for printing and

encoding. 500 cards can be loaded in Input Hopper but the cards can be taken out

from Input Hopper without scratch by using the patented load distribution structure

of IDP. Also, it is designed that inserted cards don’t get in contact with any other

components except the rollers for card feeding in Printer, Laminator and other

module. In Output Hopper, the stacked cards are lifted up for preventing scratch

when a new card is inserted into Output Hopper.

Software

Since the card design and DB (Database) software for card issuance as well as the

printer driver is provided free of charge, users will not need to purchase additional

software. Utility programs for adjusting the configuration and checking the status of

Printer and powerful SDK (Software Development Kit) for easily developing

customized applications are also provided without cost.

13

Page 14

1.2 Modules

SMART-70 can organize the card issuing system by combining the 5 different modules. In this

case, Printer communicates with the PC and controls the other modules. If Laminator is used

without Printer, Laminator will control other modules. This chapter shows the features of each

module.

1.2.1 Input Hopper

SMART-70 Input Hopper can be loaded up to 500 cards and supply a card at a time. SMART-

70 Input Hopper has the following features.

LED Indicator on the front side of Input Hopper displays the status of Input Hopper

by using the color, so user can intuitionally check the status of Input Hopper

Cards can be conveniently loaded by using large capacity card cartridge which 500

CR80 cards (card thickness 0.8mm) can be loaded.

The gate of card cartridge can be easily adjusted depending on the thickness of card.

When card cartridge is taken out from Input Hopper, the gate of cartridge is

automatically closed for preventing the loss of cards.

In order to prevent the theft of cards, physical locking mechanism can prevent card

cartridge from being taken out from Input Hopper.

For solving the problem caused by dust, both sides of card are cleaned when the

card is supplied.

The cleaning device is easily managed by changing the disposable cleaning roller

included in new print ribbon package whenever print ribbon is changed.

Since cards in cartridge pushed by special structure of IDP’s patented technology,

cards are stably supplied even if the cards are stuck by the static.

500 cards are loaded, but the loaded cards don’t make scratch because the weight of

loaded cards is dispersed when the lowest card has to be supplied.

When card cartridge is empty, Input Hopper can automatically check and notify the

status.

14

Page 15

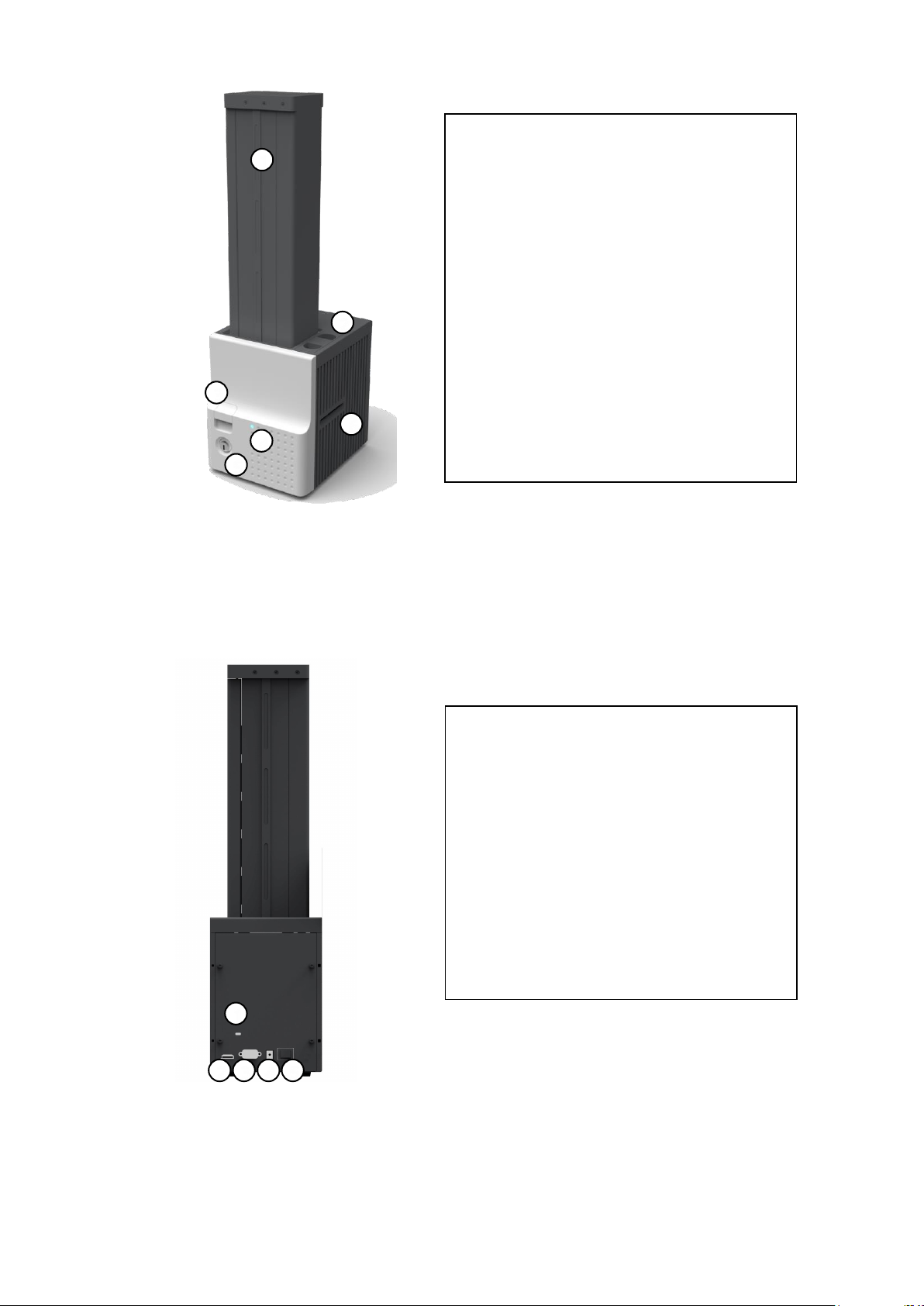

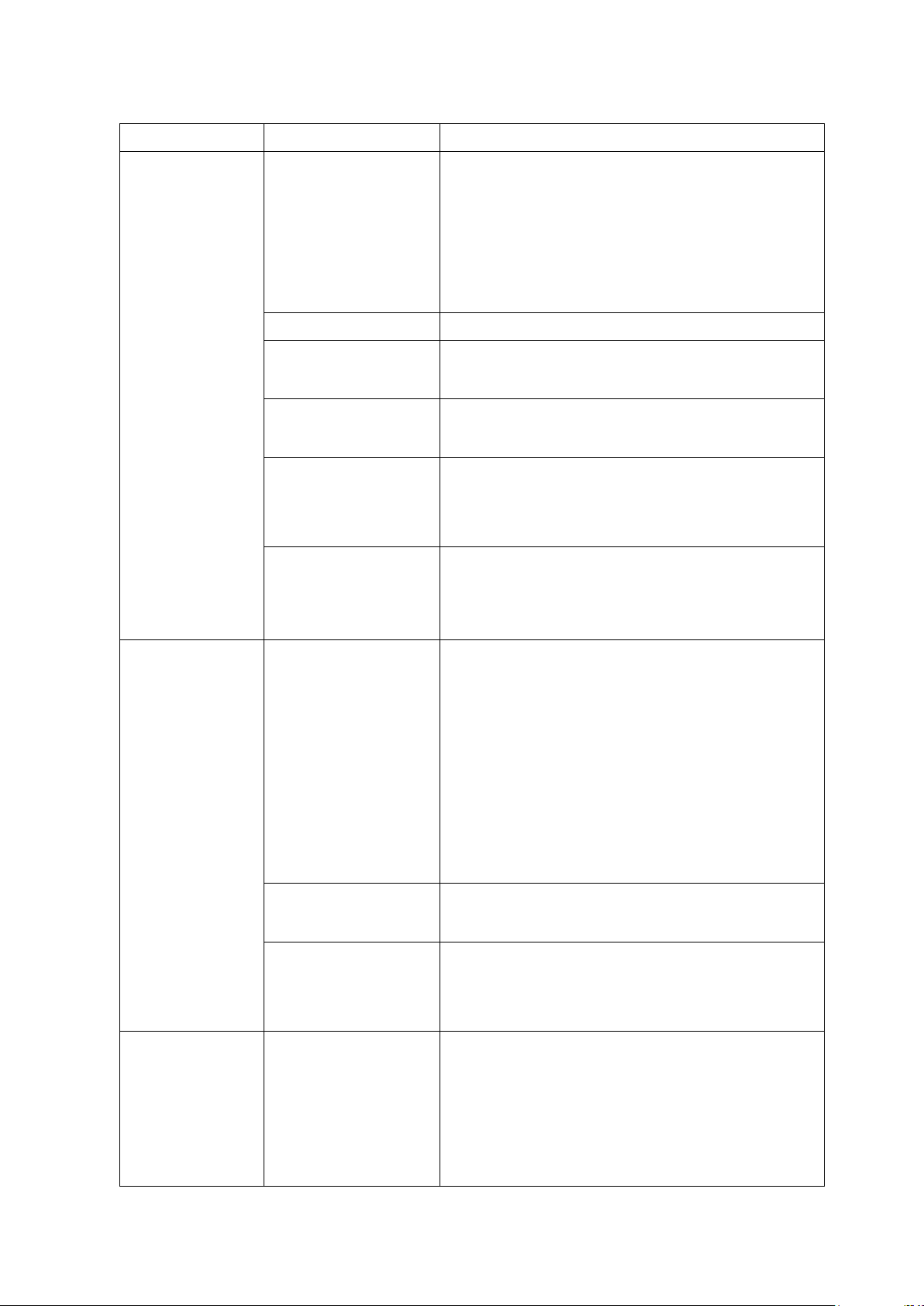

① Card cartridge

500 cards can be loaded.

② Disposable cleaning roller holder

Please install the disposable cleaning roller

included with new ribbon.

③ Cartridge release button

Please pull up card cartridge while pressing

cartridge release button.

④ Indicator LED

The status of Input Hopper is displayed by the

color.

⑤ Physical lock

Card cartridge is locked and can’t be taken out

from Input Hopper.

⑥ Card gate

Card is supplied to other module.

1

2

3

4 5 6

1

2 3 4

5

① Kensington lock

Kensington lock is usable.

② Communication port

To communicate between SMART-70 modules,

please connect to an adjacent module.

③ Serial communication port

This port is used when an external device

controls Input Hopper.

④ Power port

Please connect the 24V DC power adaptor

provided with Input Hopper.

⑤ Power switch

Turn On/Off

Figure 2 Front side of Input Hopper

Figure 3 Rear side of Input Hopper

15

Page 16

1.2.2 Printer

SMART-70 Printer is the high-end printer which the IDP’s printing technologies are

concentrated. SMART-70 Printer can continuously print 500 cards of color or 3000 cards of

mono, and the magnetic stripe and contactless encoding option can be installed.

SMART-70 Printer has the following features.

LCD and 4 buttons on the control panel of Printer are for user conveniences and

users can easily check the status of Printer and adjust the configuration.

Indicator LED on the front side of Printer displays the status of Printer by using the

color, so user can intuitionally check the status of Printer.

For improving the convenience of changing print ribbon, ribbon cartridge is

designed as the drawer type and the print ribbon can easily be changed.

By using ribbon cartridge lock lever, ribbon cartridge can easily be locked and print

head can be moved up and down for the convenience of maintenance.

For the prevention of thefts, physical locking mechanism and Kensington lock are

designed and applied to Printer.

Ethernet port is installed by default and user can print and encode cards via network.

For massive card issuance, metal frame, stainless steel shaft, ball bearing and high

quality materials are used to increase the stability and reliability of Printer.

In order to prevent scratch on cards, Printer is designed that cards don’t get in

contact with any other components except rollers when cards are being fed in Printer.

High printing speed and improved printing algorithm can guarantee a more vivid

and fine printing quality.

Since card design and DB (Database) software for card issuance as well as printer

driver and utility programs are provided free of charge, additional software is not

needed to purchase.

16

Page 17

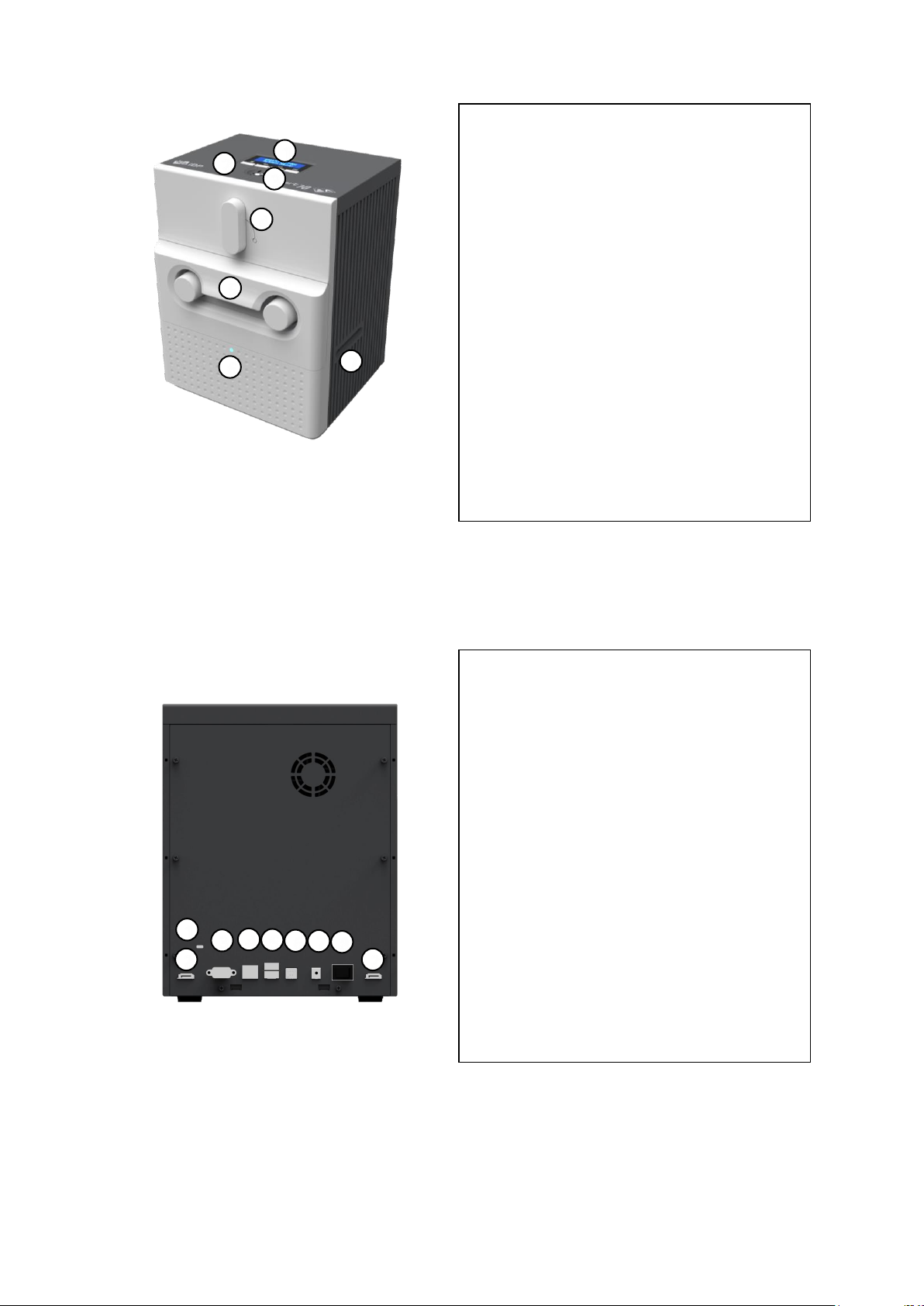

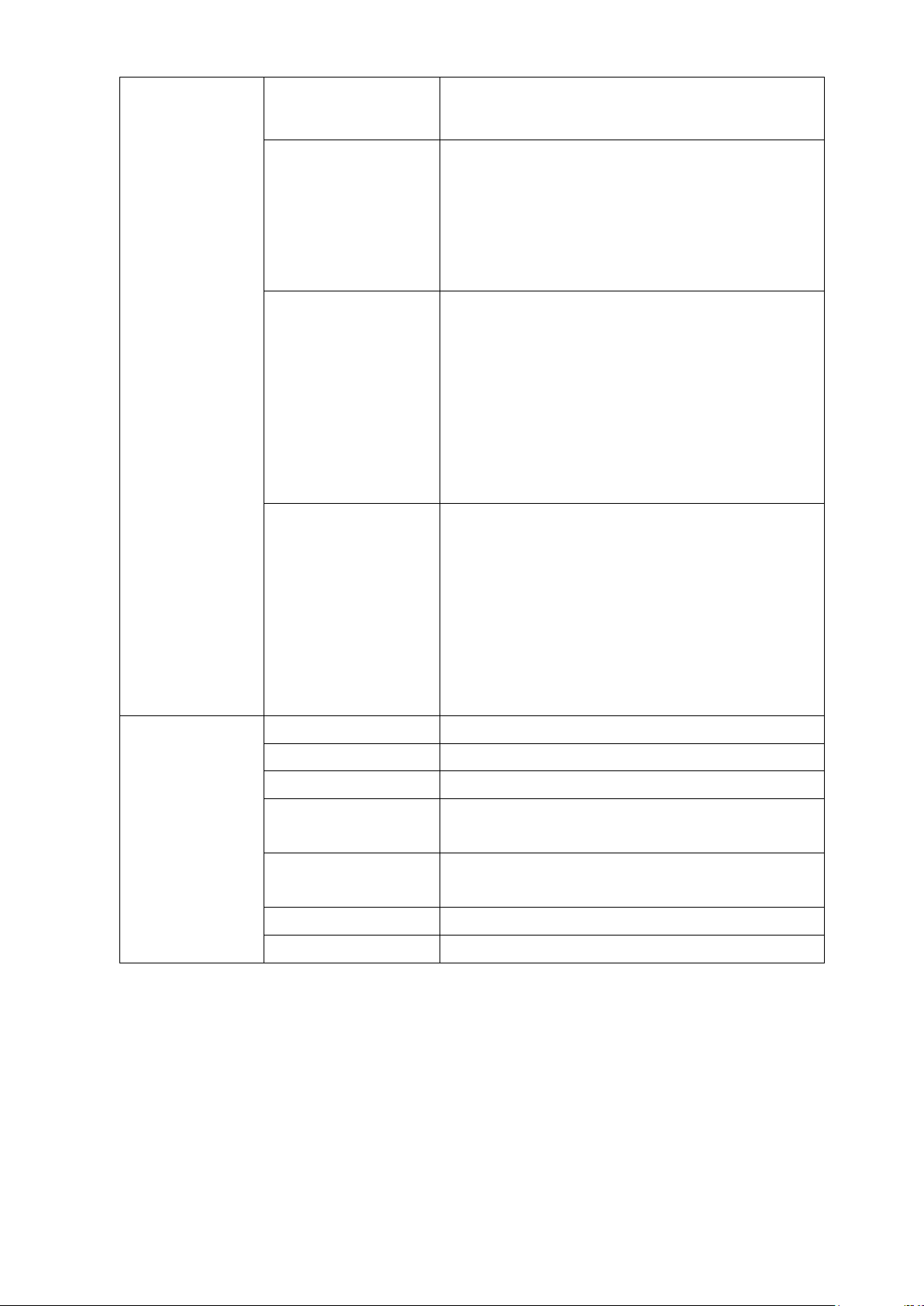

1

① Kensington lock

Kensington lock is usable.

② Communication port

To communicate between SMART-70 modules,

please connect to an adjacent module.

③ Serial communication port

This port is to communicate with external

device except SMART-70 modules.

④ Ethernet port

This port is for network communication.

⑤ USB host communication port

⑥ USB device port

To communicate with PC, please connect to PC.

⑦ Power port

Please connect the 24V DC power adaptor

provided with Input Hopper.

⑧ Power switch

Turn On/Off.

2

3

5

7 4 6

1 2 3 4 5 2 6 7 8

① Control panel LCD

The status of Printer is displayed.

② Control panel buttons

Buttons are used to adjust configuration and

check status.

③ Physical lock

Physical lock is to lock Printer and ribbon

cartridge.

④ Ribbon cartridge lock lever

To pull out ribbon cartridge, please turn lever

to the right 90 degrees for taking.

⑤ Ribbon cartridge

Color ribbon for 500 cards or mono ribbon for

3000 cards is loaded into ribbon cartridge.

⑥ Indicator LED

The status of Printer is displayed by the color.

⑦ Card gate

Card gate is to convey cards from module to

module.

Figure 4 Front side of Printer

Figure 5 Rear side of Printer

17

Page 18

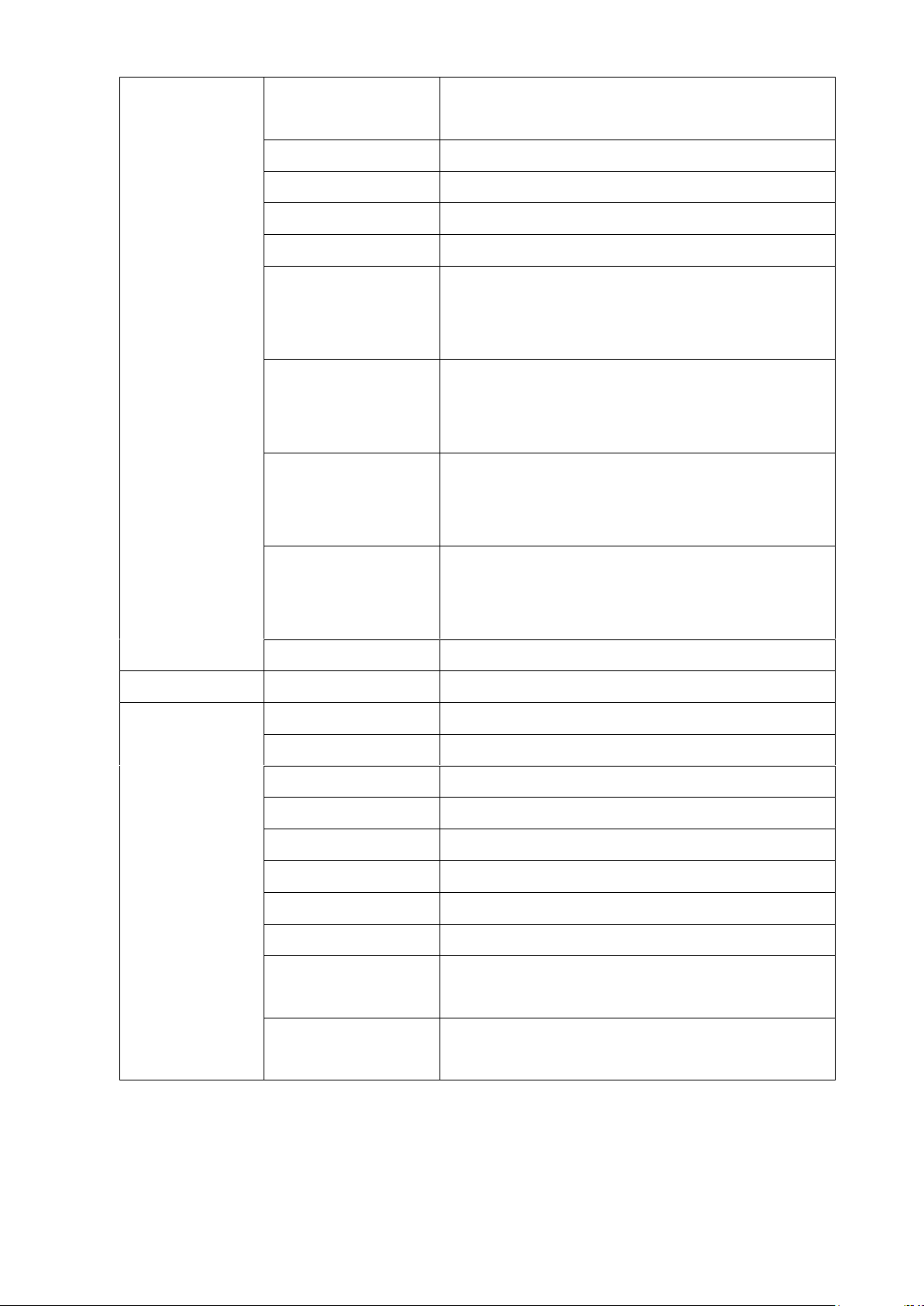

Control panel of Printer consists of 2 lines LCD and 4 buttons. The 4 buttons have the functions

Menu

Submenu

Description

>System Config.

>>Combination

To set module combination. Refer to the chapter

2.1.10 for modules combination setting.

>>Operation Mode

To set Printer as a Master device. Default is Master.

>>Insert Dir

To set the direction of Card In. Default is the left.

>>Eject Dir

To set the direction of Card Out. Default is the right.

>>Auto Card In

To set the automatic card feeding when the card is

detected at the direction of Card In. Default is OFF.

>>UserCounterClear

To reset user issue count.

>Network Config.

>>DHCP

To set whether to use DHCP function. Default is On.

>>IP Address

IP address to be used when DHCP is OFF.

>>Network Mask

Network Mask to be used when DHCP is OFF.

>>Gateway

Gateway address to be used when DHCP is OFF.

>Print Config.

>>XStartPosition

To set the start position of the printing on the card’s

X-axis (shorter side).

>>YStartPosition

To set the start position of the printing on the card’s

Y-axis (longer side).

>>YEndPosition

To set the end position of the printing on the card’s

Y-axis.

Menu/Cancel

Left/Up

Right/Down

Select/OK

as shown in the figure 6.

Figure 6 Control panel of Printer

The menus of the control panel of Printer are as below table.

18

Page 19

>>YScale

To set the length of printed image on the card’s Y-

axis.

>>TotalDensity

To set the total printing density.

>>ColorDensity

To set the color density

>>BlackDensity

To set the resin black density.

>>OverlayDensity

To set overlay density.

>>RMP+

To adjust the force for pulling print ribbon during

printing when the residual quantity of print ribbon is

in its maximum quantity.

>>RMP-

To adjust the force for pulling print ribbon during

printing when the residual quantity of print ribbon is

in its minimum quantity.

>>RMM+

To adjust the force for pulling print ribbon during

alignment when the residual quantity of print ribbon

is in its maximum quantity.

>>RMM-

To adjust the force for pulling print ribbon during

alignment when the residual quantity of print ribbon

is in its minimum quantity.

>>HeadResister

To set resistance value of TPH (Thermal Print Head).

>Operation

>>Print Sample

To print a sample card.

>Information

>>Printer Serial

To show the serial number of Printer.

>>Firmware Ver.

To show the firmware version of Printer.

>>Head Serial

To show the serial number of TPH.

>>Ribbon Balance

To show the print ribbon type and balance.

>>IP Address

To show the current IP address of Printer.

>>Network Mask

To show the current Network mask of Printer.

>>Gateway

To show the current Gateway of Printer.

>>MAC Address

To show the MAC address of Printer.

>>User Count

To show the number of issued cards that user can

reset.

>>Factory Count

To show the number of accumulated issued cards

after factory shipment.

19

Page 20

1.2.3 Hybrid Flipper

1

2

3

① Physical Lock

Physical lock is to lock Flipper cover.

② Flipper cover

To take out error cards or fix problem, please

open Flipper cover by pulling out.

③ Indicator LED

The status of Flipper is displayed by the color.

④ Card gate

Card gate is to convey cards from module to

module.

4

SMART-70 Hybrid Flipper can flip over a card for dual sided printing and laminating. And,

encoding option and image scanner can be installed into the Hybrid Flipper b option. When

the encoder or/and scanner is not installed, the error card bin to collect encoding failed cards is

installed by default. After removing the error card bin, the encoder or/and scanner can be

installed.

SMART-70 Hybrid Flipper has following features.

LED Indicator on the front side of Hybrid Flipper displays the status of Hybrid Flipper

by using the color, so user can intuitionally check the status of Hybrid Flipper.

30 error cards (encoding failed cards) can be collected in the error bin.

The contact/contactless smart card encoder and both-side image scanner option can

be installed instead of the error card bin.

For the prevention of thefts, physical locking mechanism and Kensington lock

are designed and applied to Hybrid Flipper.

Figure 7 Front side of Hybrid Flipper

20

Page 21

① Kensington lock

Kensington lock is usable.

② Communication port

To communicate between SMART-70 modules,

please connect to an adjacent module.

③ Power port

Please connect the 24V DC power adaptor

provided with Flipper.

④ Power switch

Turn On/Off

⑤ USB host communication port

To communicate with SMART-70 Printer via USB

when encoder or/and scanner is installed.

2 4 3

2

1

5

Figure 8 Rear side of Hybrid Flipper

1.2.4 Laminator

SMART-70 Laminator is the high performance laminator which cards are can be laminated with

high quality without warming-up by using the patented technology of the IDP’s “Instant direct

heating mechanism”. One roll of the holographic or clear laminating film can laminate 500 cards.

SMART-70 Laminator has following features.

LCD and 4 buttons on the control panel are for user conveniences and users can easily

check the status of Laminator and adjust configuration.

Indicator LED on the front side of Laminator displays the status of Laminator by using

the color, so user can intuitionally check the status of Laminator.

For improving the convenience of changing a laminating film, film cartridge is

designed as the drawer type and laminating film can easily be changed.

By using film cartridge lock lever, film cartridge can easily be locked and laminate

head can be moved up and down for the convenience of maintenance.

For the prevention of thefts, physical locking mechanism and Kensington lock are

designed and applied to Laminator.

21

Page 22

For massive card issuance, metal frame, stainless steel shaft, ball bearing and high

1 2 3

5

7

4

6

① Control panel LCD

The status of Laminator is displayed.

② Control panel buttons

Buttons are used to adjust configuration and

check status.

③ Physical lock

Physical lock is to lock Laminator and film

cartridge.

④ Film cartridge lock lever

To pull out film cartridge, please turn lever to

the right 90 degrees.

⑤ Film cartridge

Laminating film for 500 cards is loaded into

cartridge. Ribbon cartridge in Printer can’t be

used for Laminator.

⑥ Indicator LED

The status of Laminator is displayed by the

color.

⑦ Card gate

Card gate is to convey cards from module to

module.

quality materials are used to increase the stability and reliability of Laminator.

Conventional laminators must be needed warming-up time before laminating, but

SMART-70 Laminator can immediately laminate without having to wait by using IDP’s

Instant direct heating mechanism.

Instant direct heating mechanism of IDP uses bar-type laminate head to instantly

increase the temperature of laminate head and to reduce energy consumption to one-

seventh level compared with conventional method and to increase the lifespan of

laminate head.

In order to prevent scratch on cards, Laminator is designed that cards don’t get in

contact with any other components except rollers when cards are being fed in

Laminator.

Figure 9 Front side of Laminator

22

Page 23

1 2 3

2

4

5

6

① Kensington lock

Kensington lock is usable

② Communication port

To communicate between SMART-70 modules,

please connect to an adjacent module.

③ Serial communication port

This port is to communicate with external

device except SMART-70 modules.

④ USB device port

When Laminator is used without the Printer,

this port is to communicate with PC.

⑤ Power port

Please connect the 24V DC power adaptor

provided with Laminator.

⑥ Power switch

Turn On/Off

Menu/Cancel

Left/Up

Right/Down

Select/OK

Figure 10 Rear side of Laminator

Control panel of Laminator consists of 2 lines LCD and 4 buttons. The 4 buttons have the

functions as shown in the figure 11

Figure 11 Control panel of Laminator

23

Page 24

The menus of the control panel of Laminator are as below table.

Menu

Submenu

Description

>System Config.

>>Operating Mode

To determine whether Laminator is used as the

main control device of SMART-70 system or not.

When Laminator is used with Printer, this mode is

set to Slave. When Laminator is used alone, this

mode is set to Master.

Default is Slave.

>>UserLami.Count

To initialize the user issue laminating count.

>>In Direction

To set the direction of Card In.

Default is the left.

>>Out Direction

To set the direction of Card Out.

Default is the right.

>>Auto Card In

The Laminator draws in a card automatically when

the card is detected at the gate of Card In.

Default is On.

>> Laminate Side

To select the laminating side of the card when

Operating Mode is Master.

Default is Null Side.

>Lamination

Cfg

>>Lami.StartPOS.

To adjust the position of patch to be attached on a

card[0 ~ 200].

When the value of Lami.StartPOS is bigger, the

laminating patch is attached on more back side of

card. When the value of Lami.StartPOS is smaller,

the laminating patch is attached on more front side

of card.

Default is 52.

>>Lami.Temp

To adjust the temperature for laminating[90 ~ 200].

Default is 160.

>>Head Resister

The resistance of temperature sensor is registered

when Laminator Head Ver.2 is used

[39.0 ~ 56.0].

>Extra Config

>>Lami Width

To adjust the distance that Laminator Head

attaches the patch from Head Down to Up[5500 ~

6500].

As the value of Lami Width is bigger, the distance

of attached patch is longer. As the value of Lami

24

Page 25

Width is smaller, the distance of attached patch is

shorter. Default is 5950.

>>Lami Speed

To adjust the Laminating Speed[400 ~ 800].

As the value of Lami Speed is bigger, the

laminating speed is faster. As the value of Lami

Speed is smaller, the laminating speed is slower.

Default is 550.

>>Lami Torque+

To adjust the torque of motor to move a patch

when the residual quantity of patch is in its

maximum quantity [400 ~ 1000].

As the value of Lami Torque+ is bigger, the motor

moves with big force. As the value is smaller, the

motor moves with small force.

Default is 600.

>>Lami Torque-

To adjust the torque of motor to move a patch

when the residual quantity of patch is in its

minimum quantity [400 ~ 1000].

As the value of Lami Torque- is bigger, the motor

moves with big force. As the value is smaller, the

motor moves with small force.

Default is 700.

>Information

>>Lami. Version

To display the firmware version of Laminator.

>> Serial Number

To display the serial number of Laminator.

>>Film Type

To display the film type installed in Laminator.

>>Fac.Lami.Count

To display the laminating count after shipping

from factory.

>>UserLami.Count

To display the laminating count after user

initializes

>>User Count

To display the firmware version of Laminator.

>>Factory Count

To display the serial number of Laminator.

1.2.5 Output Hopper

SMART-70 Output Hopper can stack with 500 cards after printing, laminating and encoding.

SMART-70 Output Hopper has the following features.

25

Page 26

LED Indicator on the front side of Output Hopper displays the status of Output

1

2

3 4 5

① Card cartridge

500 cards can be loaded.

② Cartridge release button

Please pull up card cartridge while pressing

cartridge release button.

③ Indicator LED

The status of Output Hopper is displayed by

the color.

④ Physical lock

Card cartridge is locked and can’t be taken out

from Output Hopper.

⑤ Card gate

Card is inserted from other module.

Hopper by using the color, so user can intuitionally check the status of Output Hopper.

Cards can be conveniently collected by large capacity cartridge which 500 CR80 cards

(card thickness 0.8mm) can be loaded.

When card cartridge is taken out from Output Hopper, the gate of card cartridge is

automatically closed for preventing the loss of cards.

In order to prevent the theft of cards, physical locking mechanism can prevent card

cartridge from being taken out from Output Hopper.

When card cartridge is full, Output Hopper can automatically check and notify the

status.

When a card is inserted into Output Hopper, stacked cards are lifted up by the

support beam what is operated by internal CAM to protect card from scratch.

Same card cartridge is used for Input Hopper and Output Hopper, so card cartridge

can be shared.

Figure 12 Front side of Output Hopper

26

Page 27

1

2 3 4

5

① Kensington lock

Kensington lock is usable.

② Serial communication port

This port is used when external device needs to

control Output Hopper.

③ Power port

Please connect the 24V DC power adaptor

provided with Output Hopper.

④ Power switch

Turn On/Off.

⑤ Communication port

To communicate between SMART-70 modules,

please connect to an adjacent module.

Figure 13 Rear side of Output Hopper

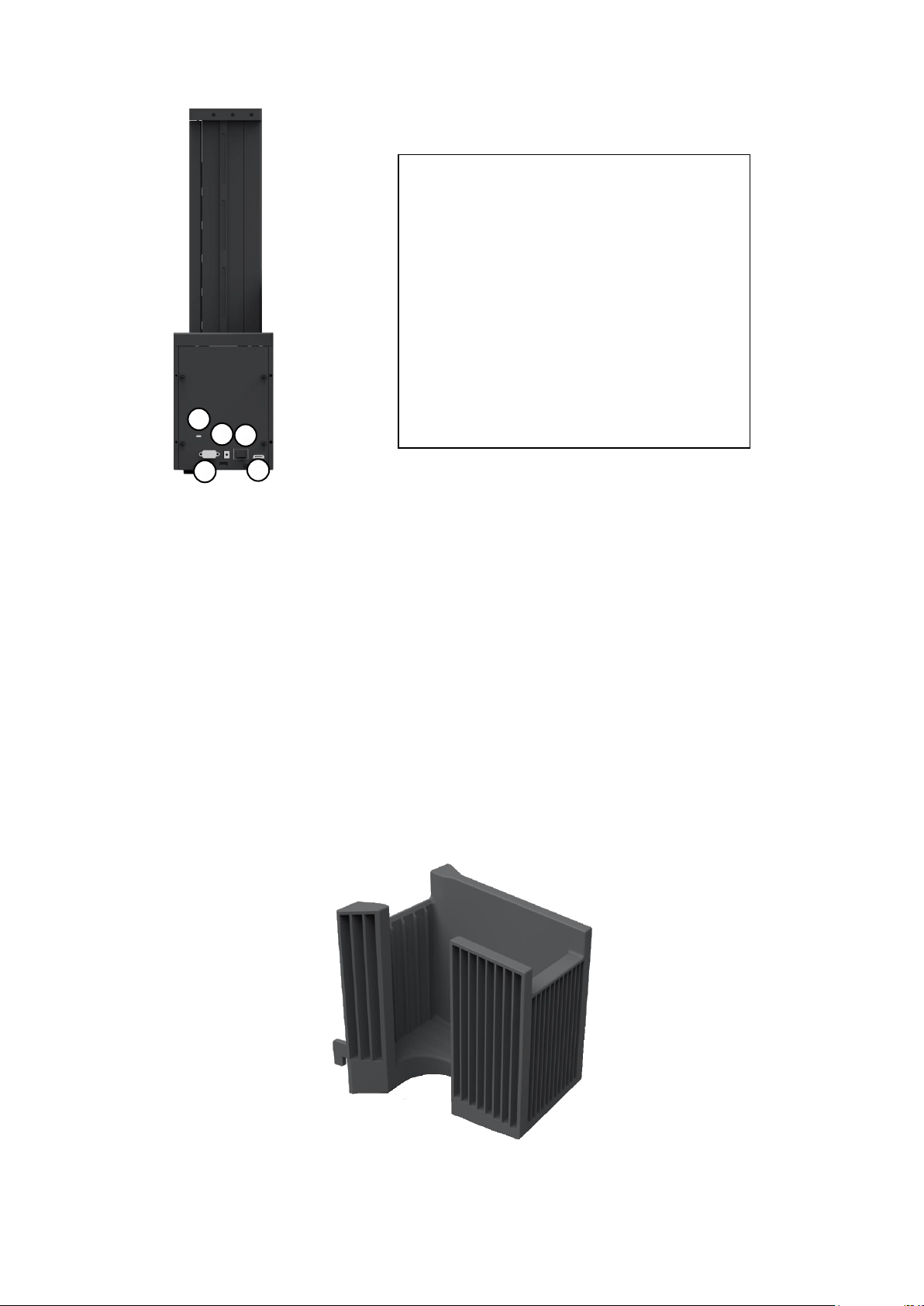

1.2.6 Stacker

If Output Hopper is not needed, 100 cards can be ejected and loaded by using the Stacker

provided with Input Hopper.

Figure 14 Stacker

27

Page 28

2. Installation and operation

2.1 Hardware installation

2.1.1 PLACEMENT OF MODULES

SMART-70 modules need to be placed on a flat table. Order of placing modules from left to

right is Input Hopper, Printer, Laminator and Output Hopper. When some module is not

required, please remove unnecessary modules from above placing order. For example, when

Laminator is not needed, Input Hopper, Printer, Hybrid Flipper and Output Hopper can be

placed.

When more than one same modules are needed or encoding option ins installed into Hybrid

Flipper, please refer to 2.2 Advanced Hardware Installation.

Figure 15 SMART-70 Placement of modules

2.1.2 MODULE FASTENING

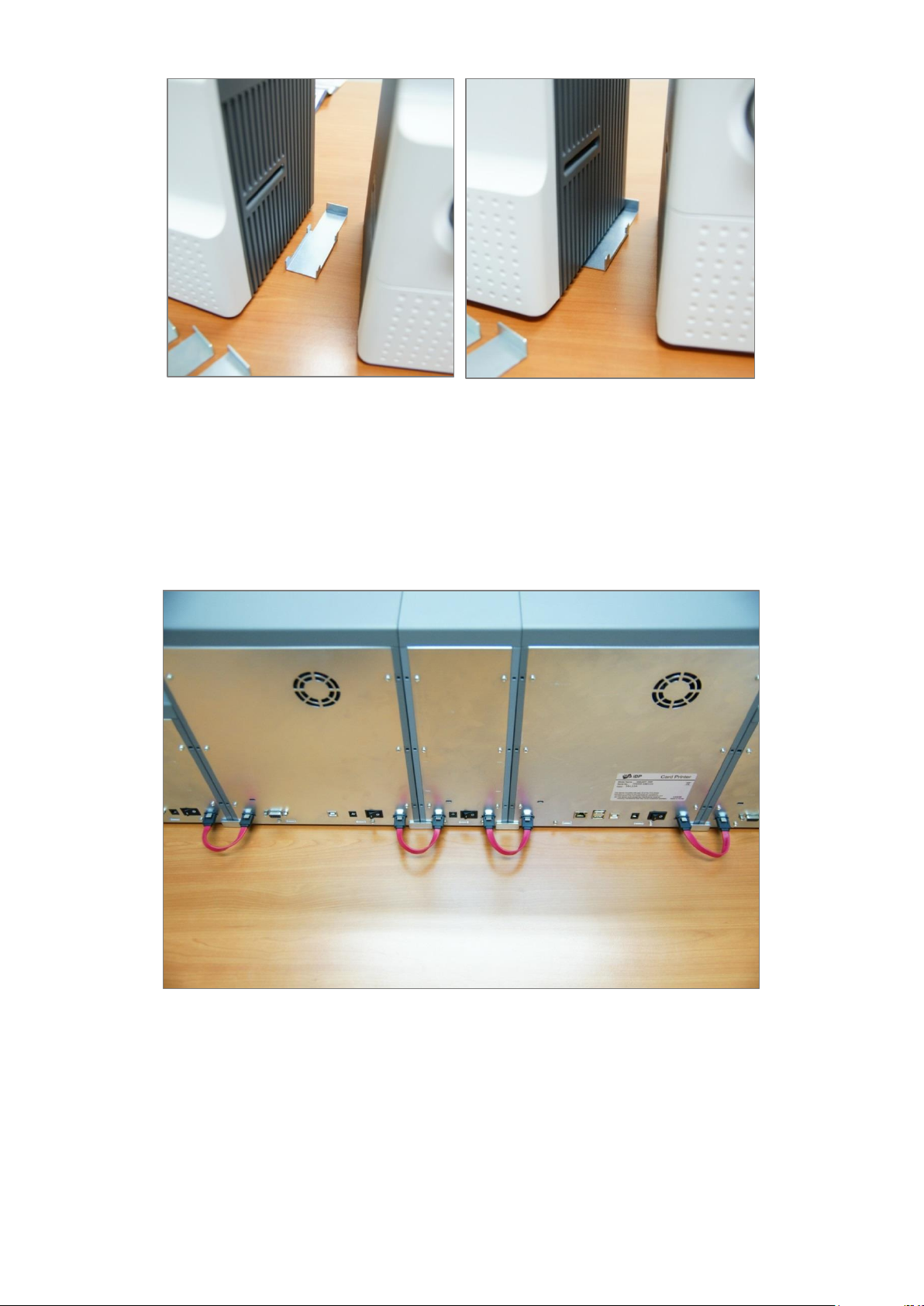

모든 모듈들을 그림과 같이 클램프를 사용해서 고정합니다. 클램프를 바닥에 놓고 모듈의 뒤쪽

을 클램프의 꺾인 부분에 맞춰서 내려 놓으면 됩니다.

28

Page 29

Figure 16 Module fastening

2.1.3 MODULE CONNECTION

Please connect the red communication cables provided with the modules to each module.

Figure 17 Module connection

29

Page 30

2.1.4 POWER CONNECTION

Please connect the 24V DC power adaptors provided with each module to all modules. Printer

must be connected to the 24 DC power adaptor provided with Printer.

Figure 18 Power connection

2.1.5 PRINT RIBBON AND LAMINATING FILM INSTALLATION

A. Please turn ribbon / film cartridge lock lever to the clockwise 90 degrees.

Figure 19 Ribbon / film cartridge unlocking

30

Page 31

B. Please pull out ribbon / film cartridge.

Figure 20 Pulling out ribbon / film cartridge

C. Please mount print ribbon / laminating film by pushing cores into cartridge from the side of