Page 1

SMART Series

SMART-30S, SMART-30R, SMART-30D,

SMART-50S, SMART-50D, SMART-50L

User Manual

1

Page 2

Copyright Notice

Users must respect the copyright laws applicable in their country. This manual must not be

photocopied, translated, reproduced or transmitted in whole or in part for any reason and by

the means that might be, albeit electronic or mechanical, without the express, written

authorization of the company IDP card printer.

All information contained herein may be subject to modification without prior notice.

IDP card printer accepts no liability for any possible errors herein, nor for any accidental

damage or damage caused through the dissemination or the use of this manual.

Trademarks

SMART-50 is a trademark and IDP is a registered trademark of IDP card printer. Windows is

registered trademarks of Microsoft Corp. All other trademarks or registered trademarks are

marks of their respective holders. SMART-50 Design is a trademark of IDP.

Return Materials Authorization

In order to make a warranty claim you must contact an IDP Reseller. You will be responsible

for packaging the printer for shipment and the costs of shipping and insurance of the printer

from the point of use of the printer to the IDP Reseller. The IDP Reseller will bear the costs of

shipping and insuring the printer from the repair location to the address from which the printer

was shipped.

Before returning any equipment for in-warranty or out-of warranty repair, contact an IDP

Reseller or an IDP Service Center for a Return Materials Authorization (RMA) number.

Repack the equipment in the original packing material and mark the RMA number clearly on

the outside of the box. For more information about RMA or IDP warranty statements, refer to

the Warranty booklet on the quick install guide.

2

Page 3

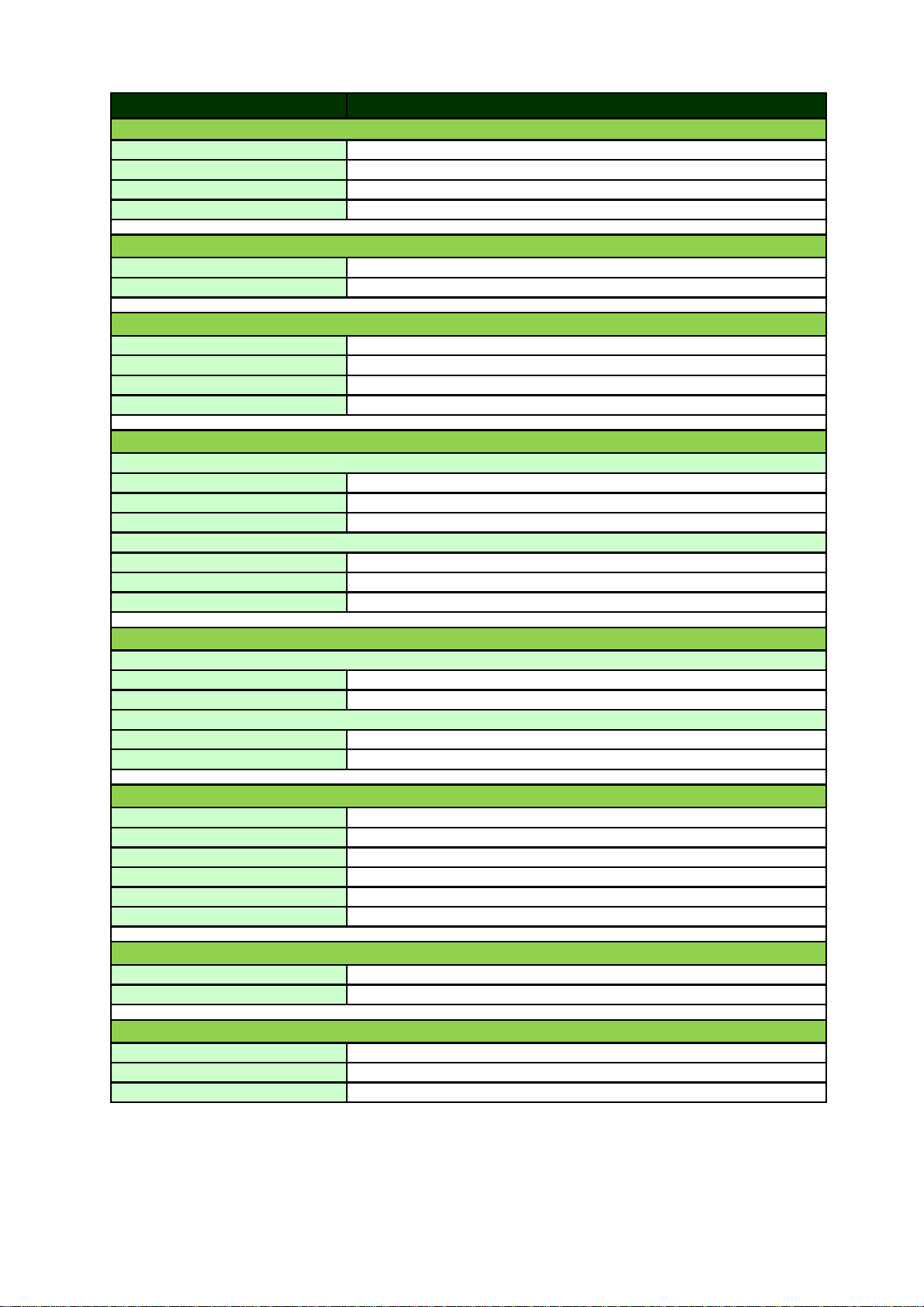

Table of Contents

1. Introduction ........................................................................ 7

1.1 Printer outside features ........................................................................... 7

1.1.1 SMART-30 outside feature. ...................................................................... 7

1.1.2 SMART-50 outside feature. ...................................................................... 8

1.2 Printer inside features .................................................................................. 11

1.2.1 SMART-30 inside feature. ..................................................................... 11

1.2.2 SMART-50 inside feature. ..................................................................... 12

1.3 Ribbon cartridge features ............................................................................. 13

1.4 LCD panel display & button operation ......................................................... 14

2. Printer installation .............................................................. 18

2.1. Fitting the ribbon ......................................................................................... 18

2.2. Loading the cards ........................................................................................ 21

2.3. The withdrawal of printed cards. .............................................................. ... 23

2.4. Driver installation (Windows XP, 2000, 2003) .............................................. 24

2.5. Driver installation (Windows Vista, 7, 8) ...................................................... 31

2.5. Network configuration ................................................................................. 37

3. Driver configuration ........................................................... 46

3.1. Checking printer properties ........................................................................ 46

3.2. Changing printer properties ........................................................................ 46

3.3. Other settings .............................................................. ................................ 51

4. Utilities ............................................................................... 54

4.1. Card Printer Setup ....................................................................................... 54

4.2. Card Printer Test ......................................................................................... 64

4.3. Firmware upgrade ....................................................................................... 70

5. Optional device driver installation ..................................... 73

5.1. Contact smartcard reader ............................................................................ 73

6. Troubleshooting ................................................................. 78

6.1. Cleaning the printer ..................................................................................... 78

6.2 TPH (Thermal Print Head) replacement ........................................................ 82

6.3. Card movement ........................................................................................... 83

6.4. Printing quality ............................................................................................ 84

6.5. Magnetic stripe encoding ............................................................................ 85

6.6. General operation ........................................................................................ 85

7. Printer specification ........................................................... 87

3

Page 4

Table of Pictures

Pic.1 SMART-30 front features .............................................................................................. 7

Pic.2 SMART-30 back features .............................................................................................. 7

Pic.3 SMART-50 front features .............................................................................................. 9

Pic.4 SMART-50 rear features ............................................................................................... 9

Pic.5 SMART-50S ................................................................................................................ 10

Pic.6 SMART-50D ................................................................................................................ 10

Pic.7 SMART-50L ................................................................................................................. 10

Pic.8 SMART-30 Inside features ............................................................... ........................... 11

Pic.9 SMART-50 Inside features ............................................................... ........................... 12

Pic.10 Ribbon cartridge features ........................................................................................ 13

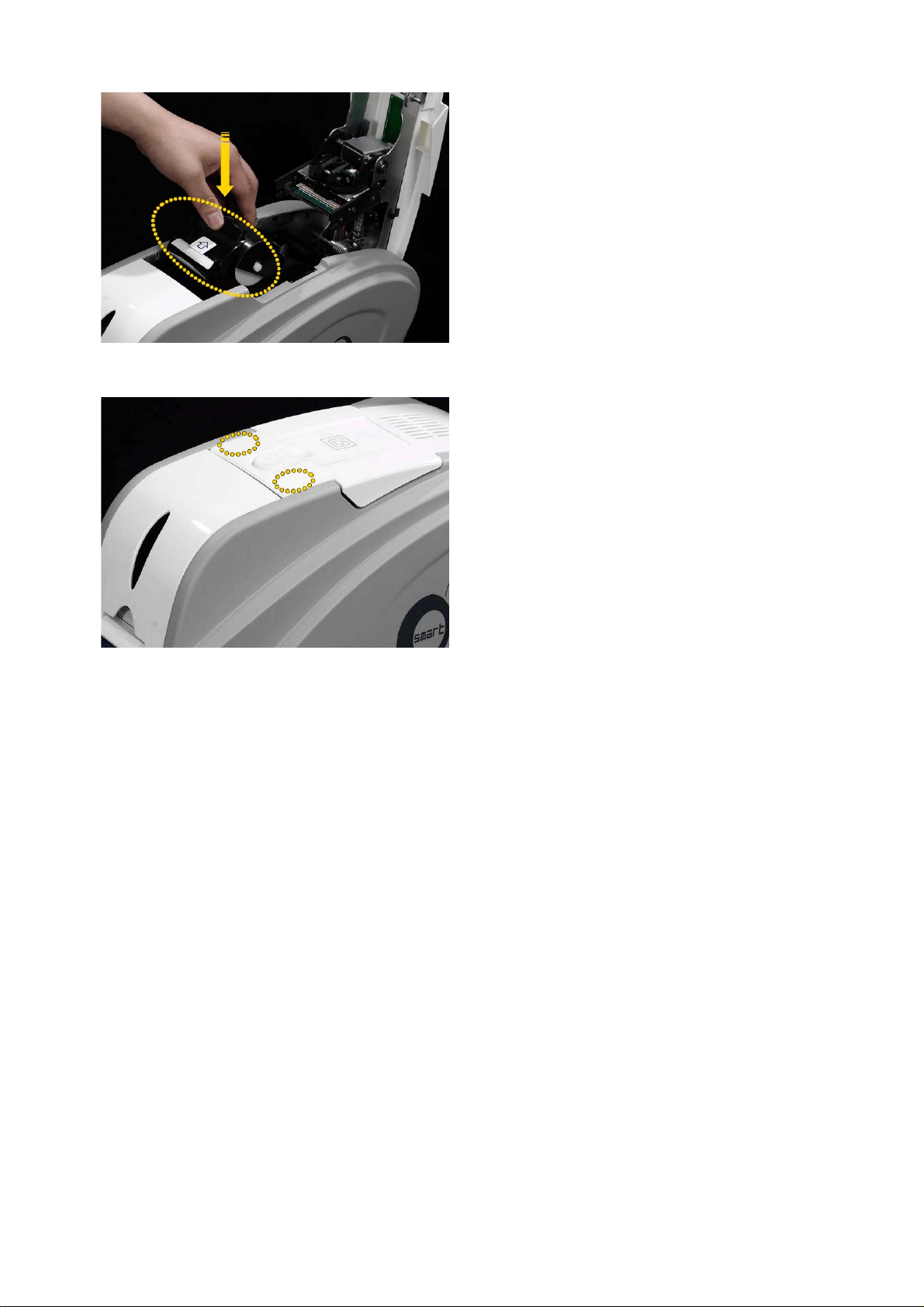

Pic.11 Top Cover open .............................................................. .......................................... 18

Pic.12 Take out the ribbon cartridge ............................................................... .................... 18

Pic.13 Loading the ribbon 1 ................................................................................................ 19

Pic.14 Loading the ribbon 2 ................................................................................................ 19

Pic.15 Installing the cleaning roller .................................................................................... 19

Pic.16 Peeling the protective wrapper ................................................................................ 19

Pic.17 Installing the ribbon cartridge ............................................................... ................... 20

Pic.18 Close Top Cover ............................................................... ........................................ 20

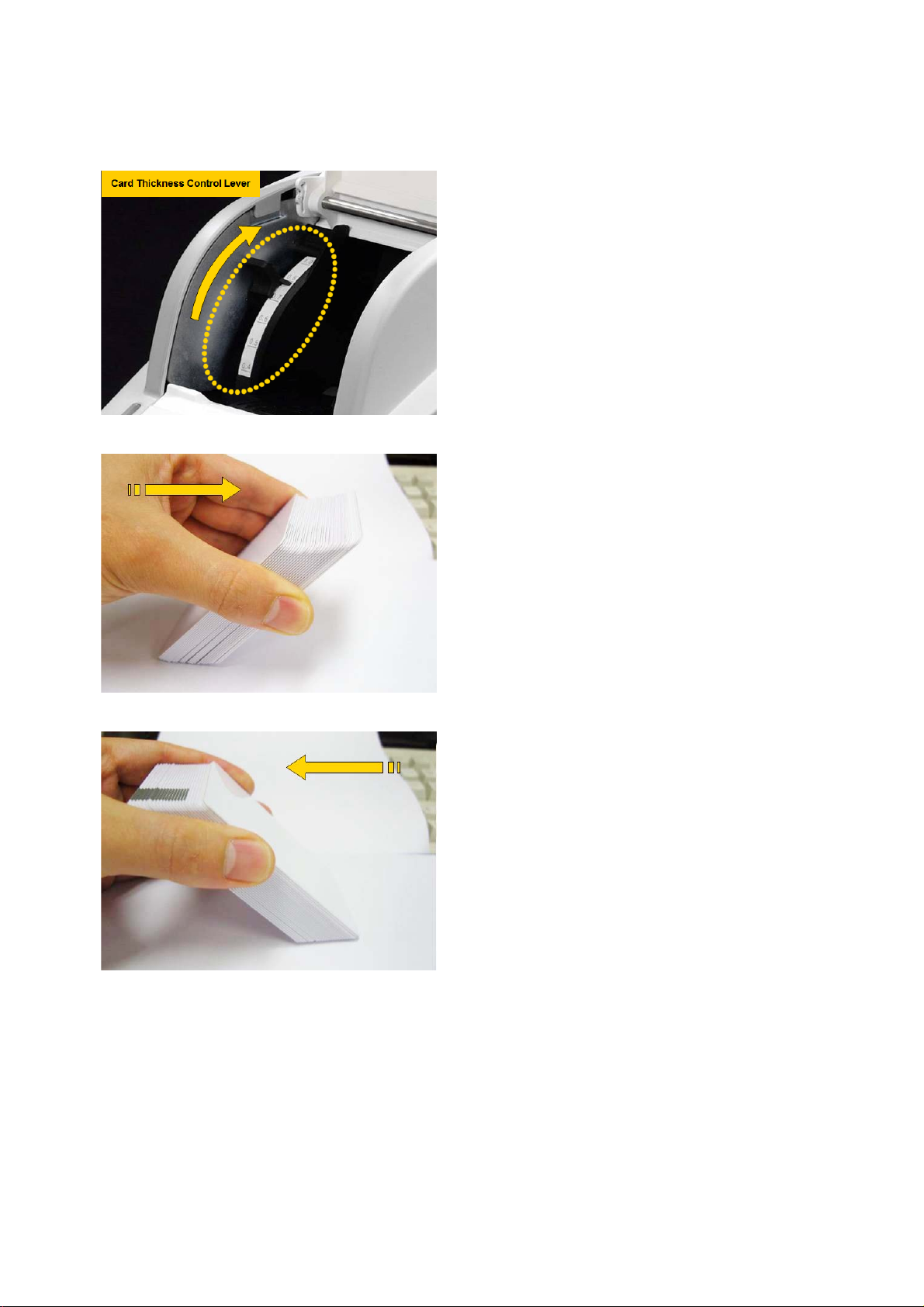

Pic.19 Adjusting the card thickness lever ..............................................................

Pic.20 Preparing the card 1 ................................................................................................. 21

Pic.21 Preparing the card 2 ................................................................................................. 21

Pic.22 Loading the cards 1 ................................................................................................. 22

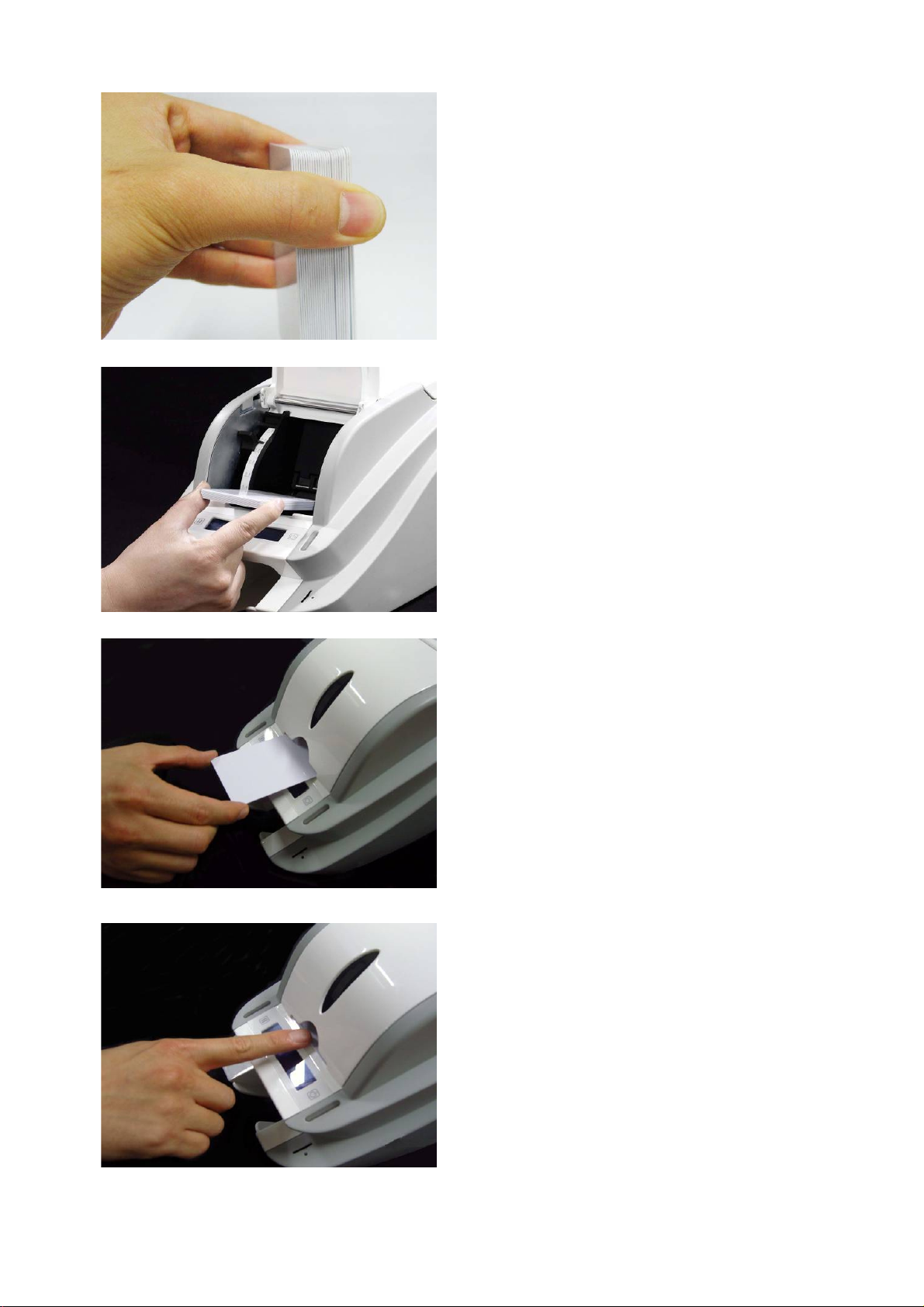

Pic.23 Loading the cards 2 ................................................................................................. 22

Pic.24 Loading the cards 3 ................................................................................................. 22

Pic.25 Loading the cards 4 ................................................................................................. 22

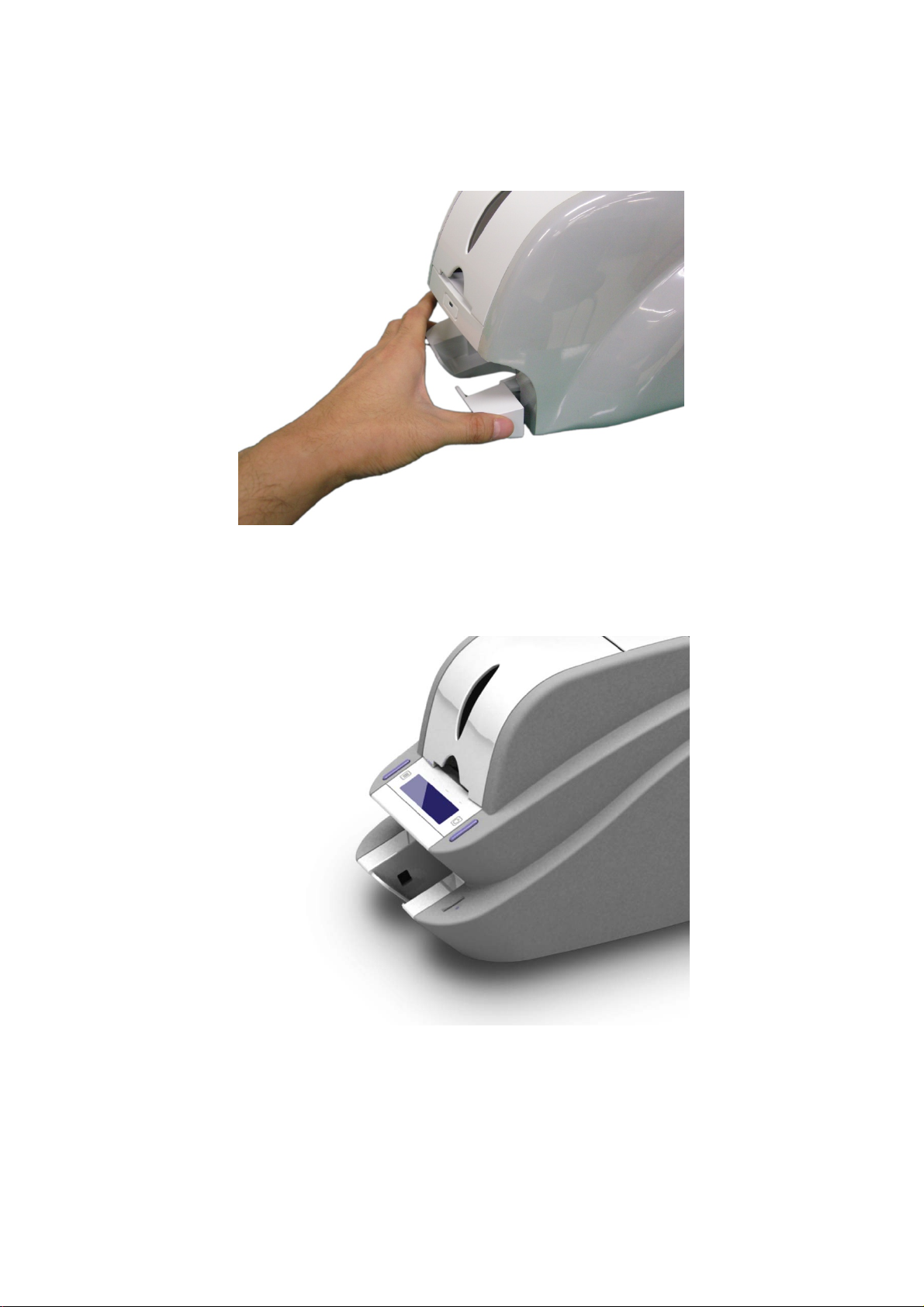

Pic.25 SMART-30 Stacker ................................................................................................... 23

Pic.25 SMART-50 Stacker ................................................................................................... 23

Pic.26 Install XP printer driver 1 ......................................................................................... 24

Pic.27 Install XP printer driver 2 ......................................................................................... 24

Pic.28 Install XP printer driver 3 ......................................................................................... 24

Pic.29 Install XP print driver 4 ............................................................................................. 24

Pic.30 Install XP print driver 5 ............................................................................................. 25

Pic.31 Install XP print driver 6 ............................................................................................. 25

Pic.32 Install XP printer driver 7 ......................................................................................... 25

Pic.33 Install XP printer driver 8 ......................................................................................... 25

Pic.34 Install XP printer driver 9 ......................................................................................... 26

Pic.35 Install XP printer driver 10 ....................................................................................... 26

Pic.36 Install XP printer driver 11 ...............................................................

Pic.37 Install XP printer driver 12 ....................................................................................... 27

Pic.38 Install XP printer driver 13 ....................................................................................... 27

Pic.39 Install XP printer driver 14 ....................................................................................... 27

Pic.40 Install XP printer driver 15 ....................................................................................... 27

Pic.41 Install XP printer driver 16 ....................................................................................... 28

Pic.42 Install XP printer driver 17 ....................................................................................... 28

Pic.43 Install XP printer driver 18 ....................................................................................... 28

Pic.44 Install XP printer driver 19 ....................................................................................... 29

Pic.45 Install XP printer driver 20 ....................................................................................... 29

Pic.46 Install XP printer driver 21 ....................................................................................... 29

Pic.47 Install XP printer driver 22 ....................................................................................... 29

Pic.48 Install XP printer driver 23 ....................................................................................... 30

......................... 26

............ 21

4

Page 5

Pic.49 Install XP printer driver 24 ....................................................................................... 30

Pic.50 Install XP printer driver 25 ....................................................................................... 30

Pic.51 Install Win7 driver 1 ................................................................................................. 31

Pic.52 Install Win7 driver 2 ................................................................................................. 31

Pic.53 Install Win7 driver 3 ................................................................................................. 31

Pic.54 Install Win7 driver 4 ................................................................................................. 31

Pic.55 Install Win7 driver 5 ................................................................................................. 32

Pic.56 Install Win7 driver 6 ................................................................................................. 32

Pic.57 Install Win7 driver 7 ................................................................................................. 32

Pic.58 Install Win7 driver 8 ................................................................................................. 32

Pic.59 Install Win7 driver 9 ................................................................................................. 33

Pic.60 Install Win7 driver 10 ............................................................... ................................. 33

Pic.61 Install Win7 driver 11 ................................................................................................ 33

Pic.62 Install Win7 driver 12 ............................................................... ................................. 33

Pic.63 Install Win7 driver 13 ............................................................... ................................. 34

Pic.64 Install Win7 driver 14 ............................................................... ................................. 34

Pic.65 Install Win7 driver 15 ............................................................... ................................. 34

Pic.66 Install Win7 driver 16 ............................................................... ................................. 35

Pic.67 Install Win7 driver 17 ............................................................... .................................

Pic.68 Install Win7 driver 18 ............................................................... ................................. 35

Pic.69 Install Win7 driver 19 ............................................................... ................................. 35

Pic.70 Install Win7 driver 20 ............................................................... ................................. 36

Pic.71 Install Win7 driver 21 ............................................................... ................................. 36

Pic.72 Install Win7 driver 22 ............................................................... ................................. 36

Pic.73 Install Win7 driver 23 ............................................................... ................................. 36

Pic.74 Rear view of SMART-50 printer 1 ............................................................................. 37

Pic.75 Rear view of SMART-50 printer 2 ............................................................................. 37

Pic.76 Running the NetAdmin ............................................................................................. 38

Pic.77 Network printer is not found .................................................................................... 38

Pic.78 Connecting to USB port ........................................................................................... 39

Pic.79 NetAdmin Log-in ...................................................................................................... 39

Pic.80 Dynamic IP configuration ............................................................... .......................... 40

Pic.81 Static IP configuration.............................................................................................. 40

Pic.82 Network service configuration ................................................................................. 41

Pic.83 OCP configuration ............................................................... ..................................... 41

Pic.84 Network user configuration ..................................................................................... 42

Pic.85 USB port state .......................................................................................................... 42

Pic.86 Rebooting the network module ................................................................................ 43

Pic.87 Reset to default .............................................................. .......................................... 43

Pic.88 Upgrading the firmware 1 ......................................................................................... 44

Pic.89 Upgrading the firmware 2 ......................................................................................... 44

Pic.90 Upgrading the firmware 3 ......................................................................................... 45

Pic.91 Printer properties 1 .................................................................................................. 46

Pic.92 Printer properties 2 .................................................................................................. 46

Pic.93 Layout ...................................................................................................................... 47

Pic.94 Advanced Setup ....................................................................................................... 48

Pic.95 Paper / Ribbon / Printing .......................................................................................... 49

Pic.96 Side / Media .............................................................................................................. 50

Pic.97 Laminator ................................................................................................................. 50

Pic.98 Printer sharing ......................................................................................................... 51

Pic.99 Ports ......................................................................................................................... 51

Pic.100 Advanced ............................................................................................................... 52

Pic.101 Color Management .............................................................. ................................... 52

Pic.102 Service .................................................................................................................... 52

Pic.103 Laminator .............................................................. ................................................. 53

35

5

Page 6

Pic.104 CardPrinterSetup Log-in ........................................................................................ 54

Pic.105 CardPrinterSetup start ........................................................................................... 54

Pic.106 CardPrinterSetup – Card Printer Basic Setup ........................................................ 55

Pic.107 SMART-30 R density ............................................................................................... 56

Pic.108 Color density .......................................................................................................... 57

Pic.109 Resin Black density................................................................................................ 57

Pic.110 Overlay density....................................................................................................... 57

Pic.111 CardPrinterSetup – Card Printer Advanced Setup ................................................. 59

Pic.112 CardPrinterSetup – Laminator Basic Setup ........................................................... 61

Pic.113 CardPrinterSetup – Laminator Advanced Setup .................................................... 62

Pic.114 CardPrinterTest ...................................................................................................... 64

Pic.115 Magnetic stripe encoding ....................................................................................... 66

Pic.116 Contact smartcard encoding .................................................................................. 67

Pic.117 Contactless smartcard encoding .............................................................. ............. 68

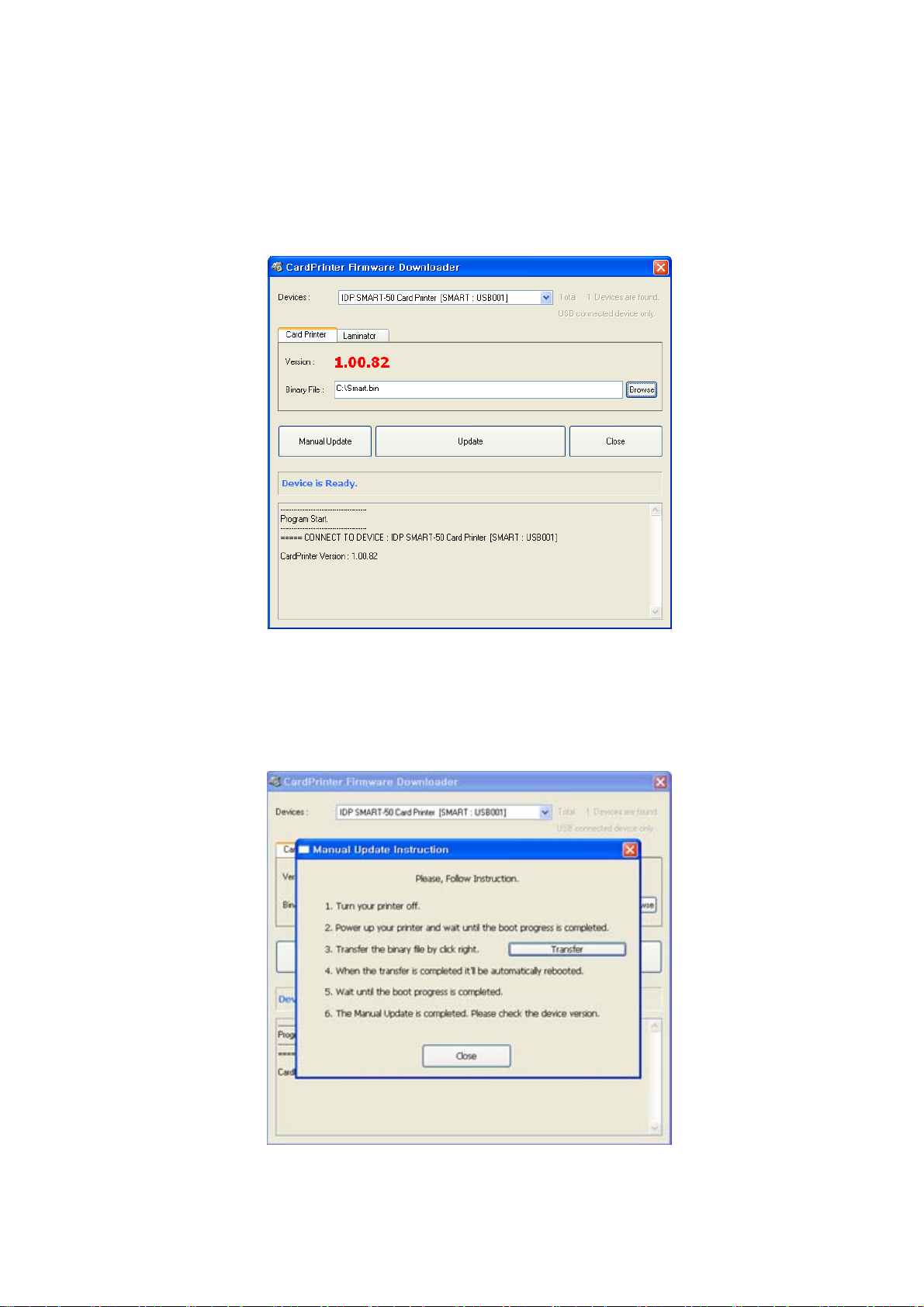

Pic.118 Upgrading printer firmware .............................................................. ...................... 70

Pic.119 Ready for firm-ware upgrade .................................................................................. 71

Pic.120 Firm-ware manual upgrade .................................................................................... 71

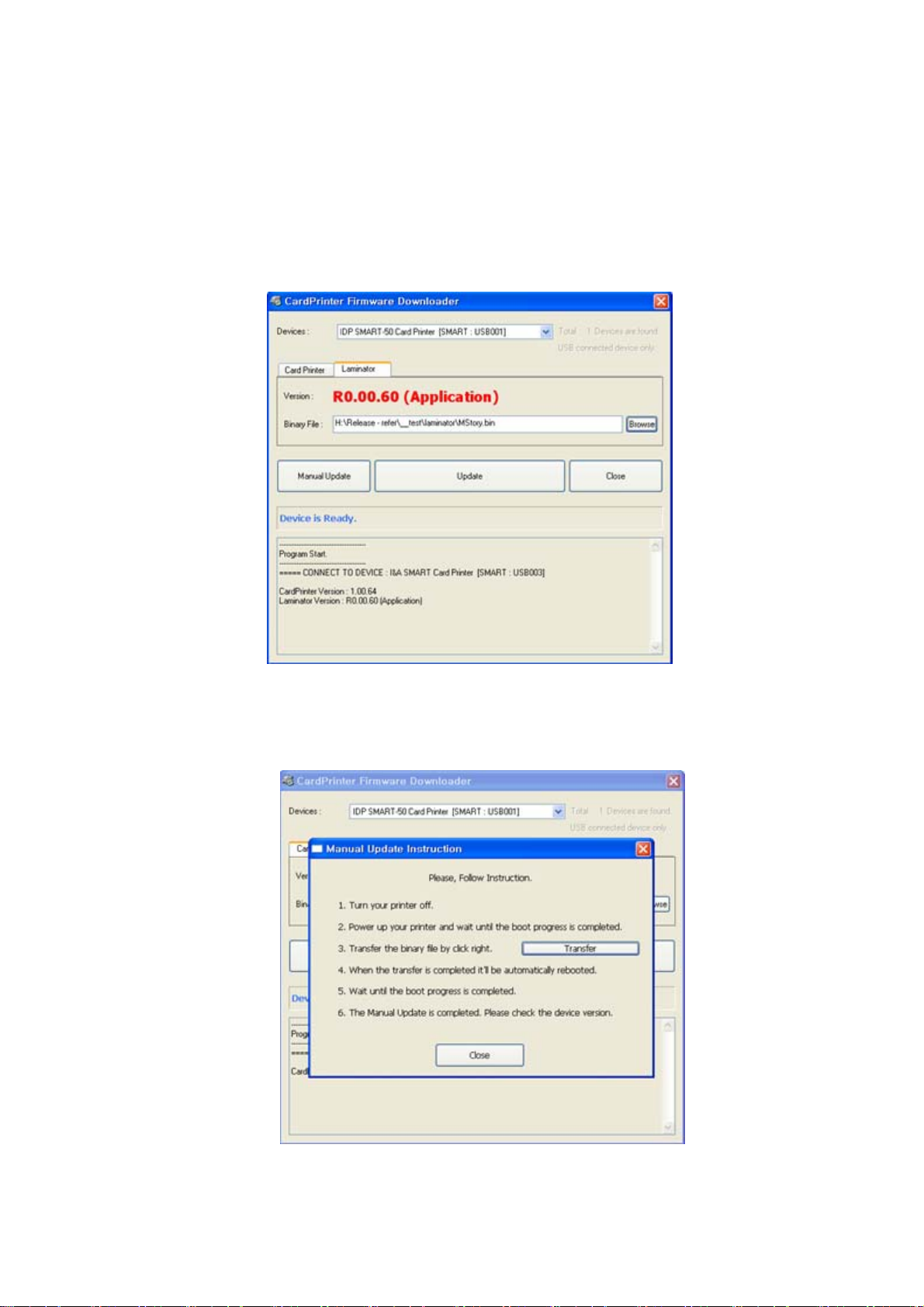

Pic.121 Ready for laminator firm-ware upgrade ................................................................. 72

Pic.122 Firm-ware manual upgrade .................................................................................... 72

Pic.123 Contact smartcard reader d river installation ......................................................... 73

Pic.124 License agreement ..............................................................

Pic.125 Installing the contact smartcard reader driver....................................................... 74

Pic.126 Completing the smartcard reader driver installation ............................................. 75

Pic.127 Found New Hardware Wizard ................................................................................. 76

Pic.128 Installation method selection ............................................................... .................. 76

Pic.129 Driver location ........................................................................................................ 77

Pic.130 Completing the driver installation ............................................................... ........... 77

Pic.131 Exclusive cleaning card for SMART-50 printer ...................................................... 78

Pic.132 Printer cleaning start .............................................................................................. 78

Pic.133 Printer cleaning Step 1 ........................................................................................... 79

Pic.134 Printer cleaning Step 2 ........................................................................................... 79

Pic.135 Printer cleaning Step 3 ........................................................................................... 80

Pic.136 Printer cleaning Step 4 ........................................................................................... 80

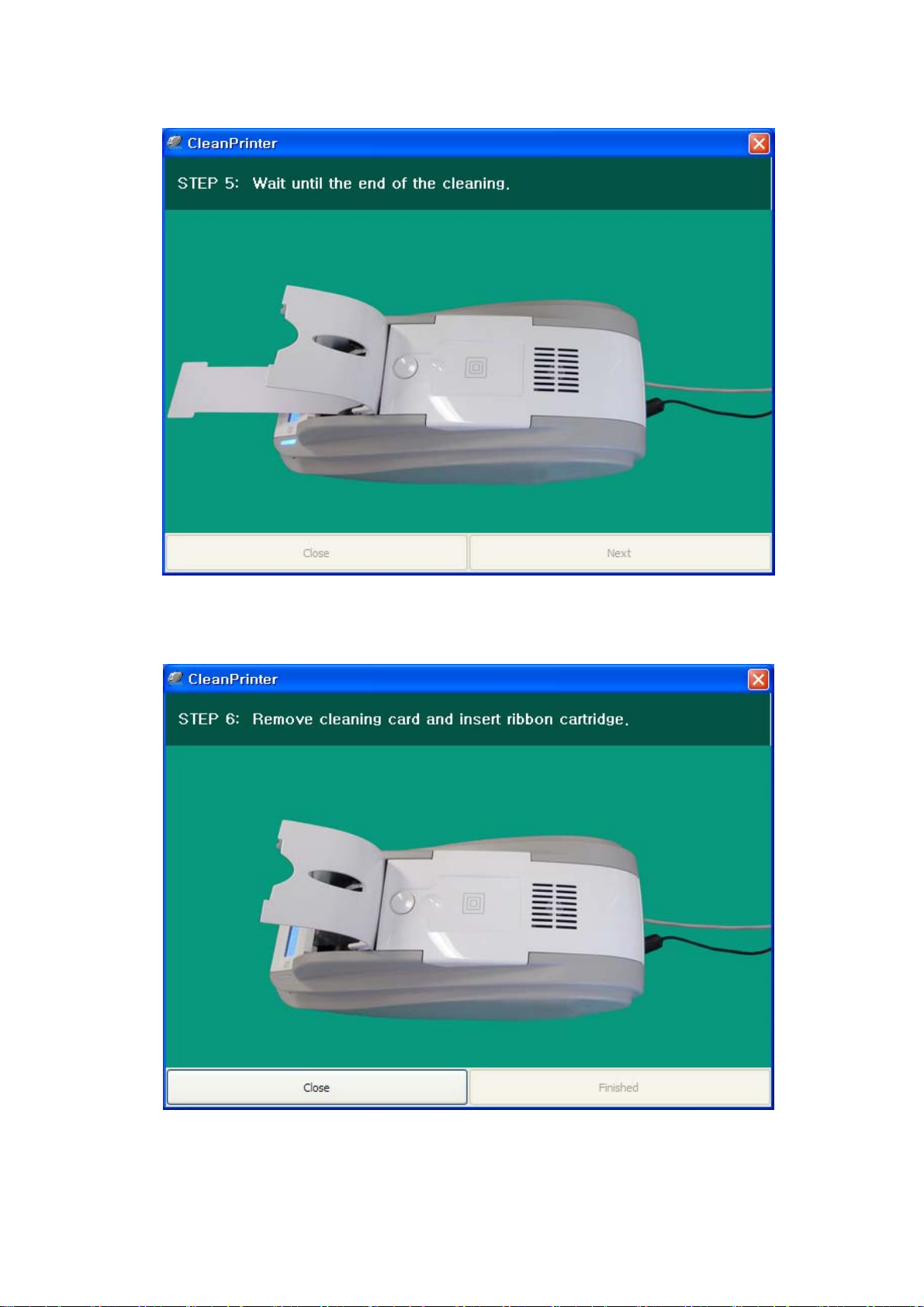

Pic.137 Printer cleaning Step 5 ........................................................................................... 81

Pic.138 Printer cleaning Step 6 ........................................................................................... 81

Pic.139 Thermal Print Head ................................................................................................ 82

Pic.140 Print head setup ..................................................................................................... 82

Pic.141 Print head replacement .......................................................................................... 83

Pic.142 Print head angle ..................................................................................................... 83

Pic.142 Printing quality trouble 1 ........................................................................................ 84

Pic.143 Printing quality trouble 2

Pic.144 Printing quality trouble 3 ........................................................................................ 84

Pic.145 Printing quality trouble 4 ........................................................................................ 85

Pic.146 Printing quality trouble 5 ........................................................................................ 85

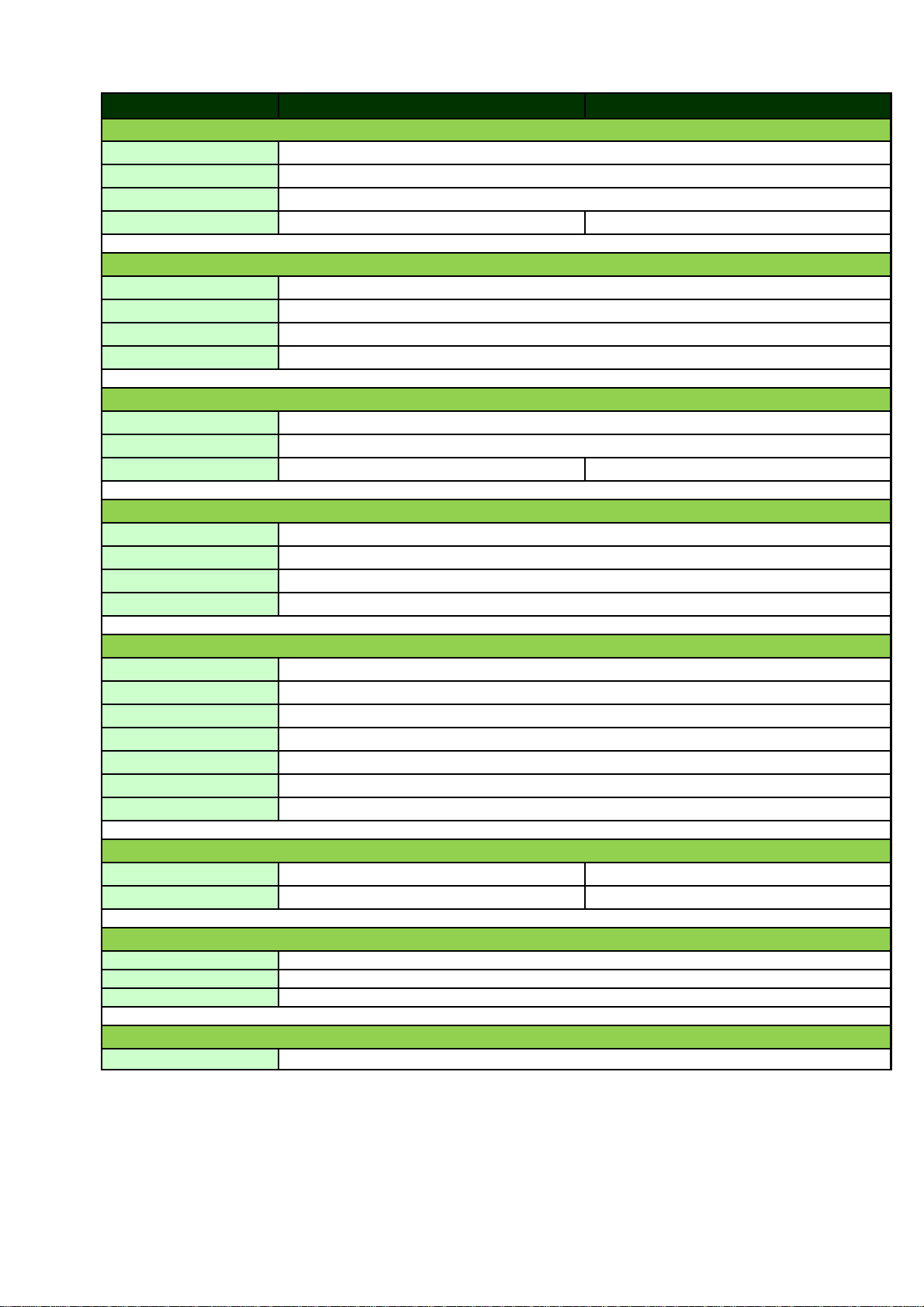

Pic.148 Printer Specification 1 ............................................................................................ 87

Pic.149 Printer Specification 2 ............................................................................................ 89

Pic.150 Printer Specification 3 ............................................................................................ 90

........................................................................................ 84

................................... 74

6

Page 7

1. Introduction

1.1 Printer outside features

1.1.1 SMART-30 outside feature.

For the user’s convenience, SMART-30 status can be seen through LED and the printer can be

controlled by a button. It takes a power via the 24V adaptor provided with the printer. Using USB

and Network port, it is communicated with the user’s PC

The following shows the outside functional features found on the printer.

②

①

③

④

① Top cover open button

② External contactless

Smartcard encoding

position

③ Input hopper

④ LED buttons

⑤ Dividing Stacker

⑤

⑦

Pic.1 SMART-30 front features

⑥

⑧ ⑨

⑩

① Backside card outlet

② Power switch

③ 24V power connector

④ Network port

In case there is no

network option, it is

closed.

⑤ USB port

There are five models in SMART-50 card printer series such as SMART-50S, SMART-50D, SMART50L.

Pic.2 SMART-30 back features

7

Page 8

SMART-30S (Pic.5) is the standard card printer. It can be printed in single side with the encoding. This

manual is prepared based on SMART-30S.

SMART-30R (Pic.6) is the rewritable card printer. It can rewrite on rewritable card in single side with

encoding.

SMART-30D (Pic.7) have a flipper which can enable to print in both side. SMART-30D can print the both

side of the card with the encoding.

Pic.3 SMART-30S (Standard)

Pic.5 SMART-30D (Dual)

1.1.2 SMART-50 outside feature.

For the user’s convenience, SMART-50 status can be seen through LCD with LED and the printer

Pic.4 SMART-30R (Rewritable)

8

Page 9

can be controlled by two LED buttons. It takes a power via the 24V adaptor provided with the

printer. Using USB and Network port, it is communicated with the user’s PC

The following shows the outside functional features found on the printer.

③

① Top cover open button

② External contactless

Smartcard encoding

position

③ Fan

④ Input hopper

⑤ LED buttons

⑥ LCD show the process

status

⑦ Internal SIM reader

⑤

⑥

④

⑦

①

②

Pic.6 SMART-50 front features

⑧

⑨ ⑩ ⑪

Pic.7 SMART-50 rear features

⑫

⑥ Backside card outlet

⑦ Power switch

⑧ 24V power connector

⑨ Network port

In case there is no

network option, it is

closed.

⑩ USB port

9

Page 10

There are five models in SMART-50 card printer series such as SMART-50S, SMART-50D, SMART50L.

SMART-50S (Pic.5) is the standard card printer. It can be printed in single side with the encoding. This

manual is prepared based on SMART-50S.

SMART-50D (Pic.6) have a flipper which can enable to print in both side. SMART-50D can print the both

side of the card with the encoding.

SMART-50L (Pic.7) produces long-life cards for ID and access control with customizable security features

and ability to print smart cards. To cater to expanding requirement in card security, SMART-50L’s

DLW(Direct to Laminating in a Wink) technology provides the most stable & fast laminating solutions.

Pic.8 SMART-50S

Pic.10 SMART-50L

Pic.9 SMART-50D

10

Page 11

1.2 Printer inside features

1.2.1 SMART-30 inside feature.

In SMART-30 printer, the ribbon is installed by a ribbon cartridge which can be used

semipermanently. The following shows the inside functional features found on your SMART-30

printer.

① Output hopper(Stacker)

② Input hopper

③ Card thickness control lever

④ Ribbon cartridge

Install the ribbon and the disposable cleaning roller.

⑤ Thermal Print Head

③

Pic.11 SMART-30 Inside features

Collect the printed card and/or encoded cards.

Load the cards for printing.

Adjust the cards thickness.

This enables the cards to be printed.

(Caution

with fingers or a sharp metal object to avoid degrading print quality or damaging printer head

permanently.)

!: This is very hot after printing. Do not contact the surface of the Thermal Print Head

②

①

⑤

④

11

Page 12

1.2.2 SMART-50 inside feature.

In SMART-50 printer, the ribbon is installed by a ribbon cartridge which can be used

semipermanently. The following shows the inside functional features found on your SMART-50

printer.

⑤

③

②

④

①

Pic.12 SMART-50 Inside features

② Output hopper(Stacker)

Contactless smartcard encoder.

Collect the printed card and/or encoded cards.

② Input hopper

Load the cards for printing.

③ Card thickness control lever

Adjust the cards thickness.

④ Ribbon cartridge

Install the ribbon and the disposable cleaning roller.

⑤ Thermal Print Head

This enables the cards to be printed.

(Caution!: This is very hot after printing. Do not contact the surface of the Thermal Print Head

with fingers or a sharp metal object to avoid degrading print quality or damaging printer head

permanently.)

⑥ External contactless encoder

⑥

① Output hopper

② Input hopper

③ Card thickness

control lever

④ Ribbon cartridge

⑤ Thermal Print Head

⑥ External contactless

encoder

12

Page 13

1.3 Ribbon cartridge features

②

③

①

④

① Ribbon cartridge

② Take up parts

③ Supply parts

④ Disposable cleaning

roller

① Ribbon cartridge

-. Install a ribbon and a disposable cleaning roller provided with the ribbon.

-. In the case of SMART-30 R model, a ribbon is not used, and a disposable cleaning

roller is only installed and used.

-. This semi-permanent ribbon cartridge is a component of the printer. Printer does not operate

if it is broken or damaged. In this case, please contact printer reseller.

② ③ Take up & Supply parts

-. Ribbon is wrapped to the supply parts as the Pic. 10. It should be installed as the Pic.10.

④ Disposable cleaning roller

-. It removes dust on the surface of card to improve print quality before the card is printed.

It should be changed together with the ribbon.

-. After installing the disposable cleaning roller to the ribbon cartridge, peel off the protective

film.

-. It is provided with the ribbon.

-. In the case of SMART-30 R model, you have to purchase the disposable cleaning roller

from the reseller.

Pic.13 Ribbon cartridge features

13

Page 14

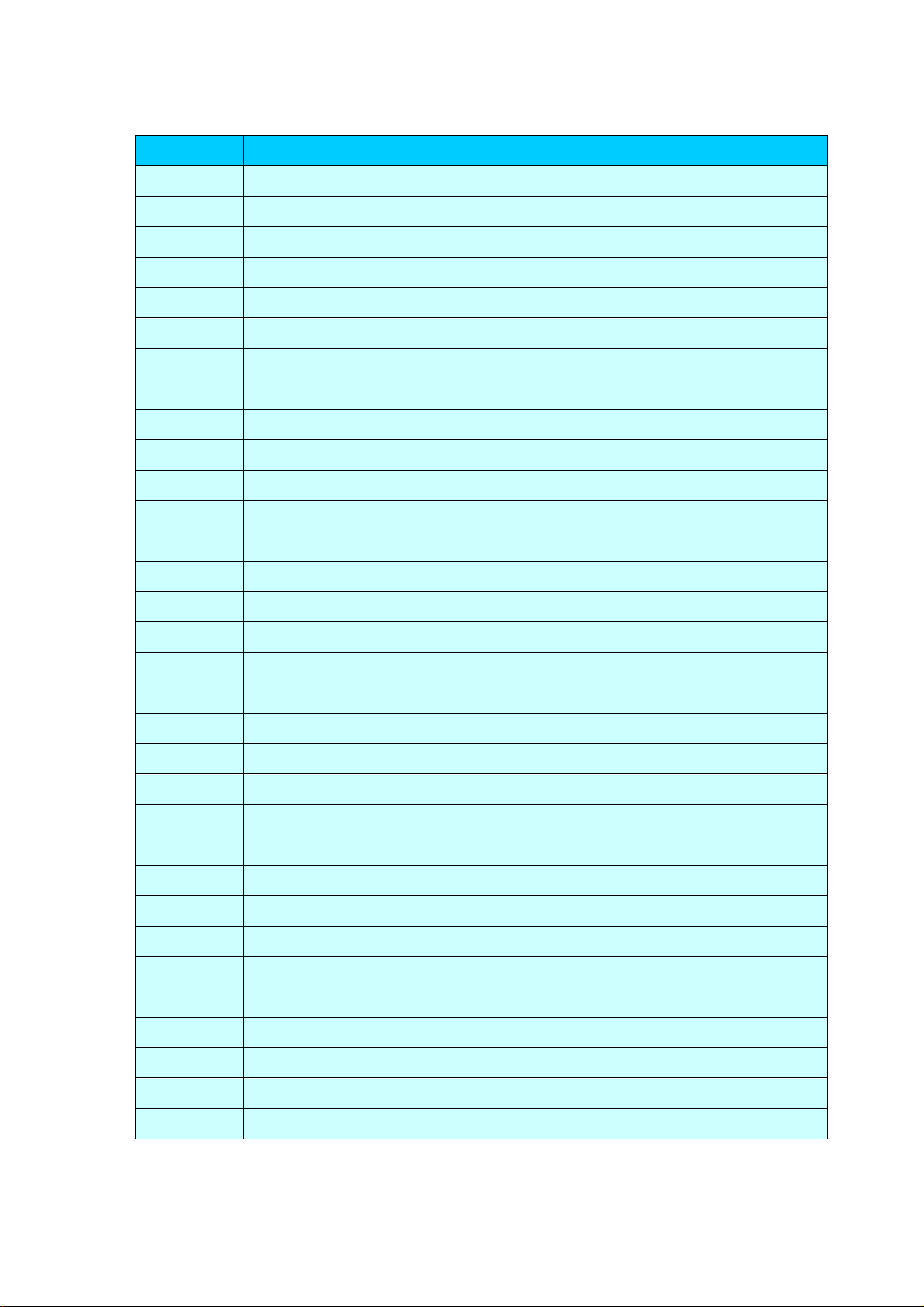

1.4 LCD panel display & button operation

SMART-50 printer can show the real-time process status to user. SMART-30’s status is displayed in windows tray.

No LCD Display

1

2

3

Ver X.XX…

Initialize…

INIT Error xx

<Replay Replay>

S m a r t

Auto Ribbon Set

LED Button

Left Right Left Right

On On Initializing Initializing with the indication of SMART-50 firmware version

Blinking Blinking Repeat Repeat Error during initializing

On On Automatic ribbon setting

State Description

Showing error no. in case of failure of normal initializing while

SMART-50 is initialized. (Refer to page13). Press any keys for reinitializing process.

It optimizes the ribbon position setting automatically in case of the

replacement of color ribbon(YMCKO or YMCKOK).

4

5

6

7

8

9

10

11

Auto Ribbon Set

Fail!!!!

Auto Ribbon Set

Color=xxx(xxx)

S M A R T

System Ready

Wait.. 1”C

Temperature=xxx

S m a r t

Unlock Please..

S m a r t

Verify your PC

Ribbon Balance

Type / Remains

S M A R T

Printing!

Blinking Blinking

Blinking Blinking

Installed

On On

Blinking Blinking

On On Printer is locked

On On PC is not authenticated

On On Card out

On On Printing Under printing.

ribbon

information

Soft power

ON/OFF

Fail to optimize the

ribbon setting

Fail to optimize the

ribbon setting and

display the ribbon’s color

value

Standby

Printer’s operating

temperature is under

1℃

Display the ribbon type

and remains

Display these messages when the auto ribbon setting is failed and

it shows the ribbon detecting level.

Printer is ready for printing and you can check the installed ribbon

information by pressing the left button. Printer turns off by pressing

the right button. Printer turns on by pressing the right button when it

turns off.

Shown it when printer’s operating temperature falls down under

1℃. Normal operating temperature is 15℃~35℃.

Physical key option is active using the CardPrinterSetup utility and

it shows the locked state. Unable to print.

Authentication option is active using the CardPrinterSetup utility.

When use the printer with an unauthenticated PC, it is shown.

Printer is not working.

Display the installed ribbon’s type and the remains. It can be shown

by pressing the left LED button on the system ready mode.

14

Page 15

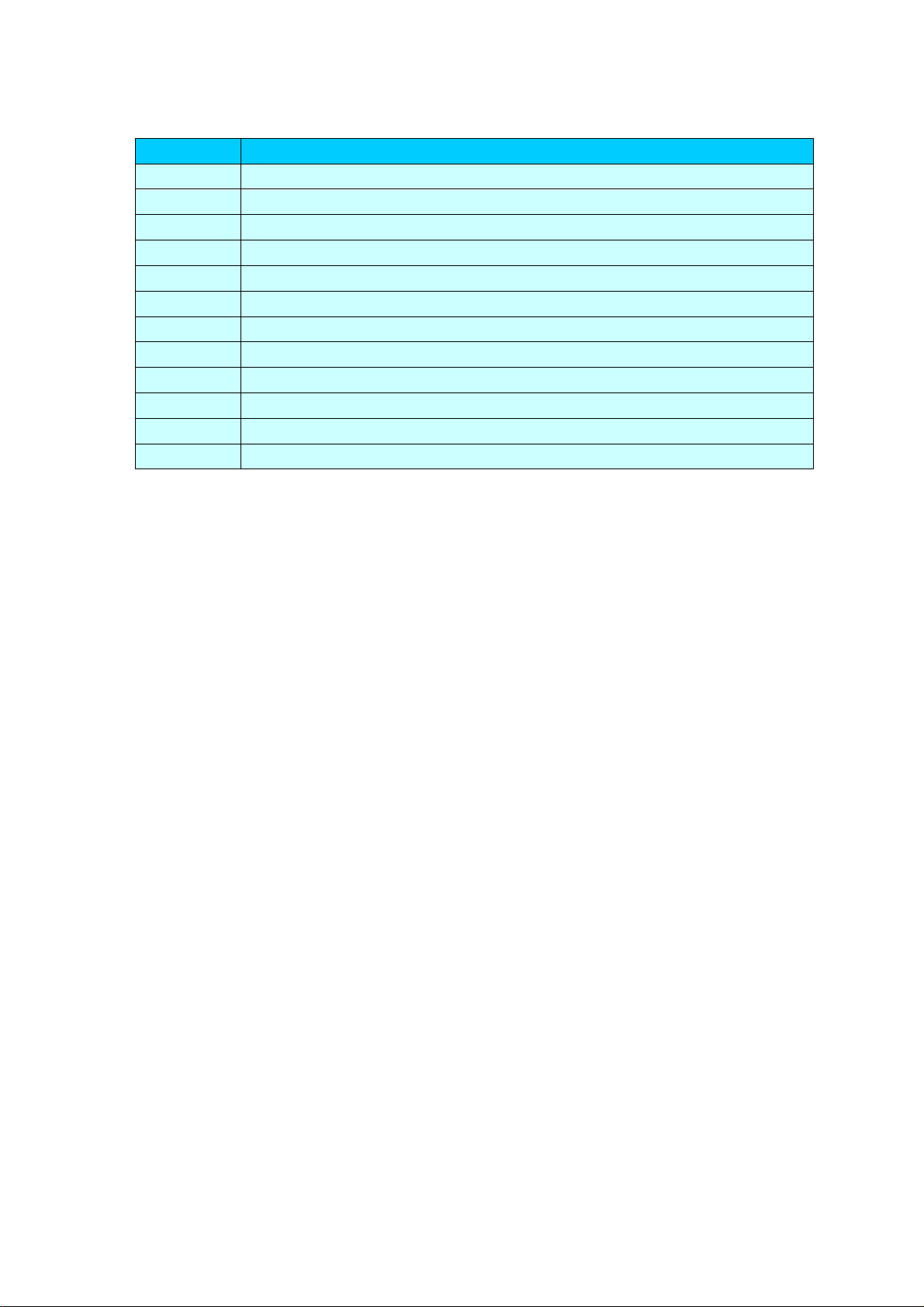

No LCD Display

12

13

14

15

S M A R T

Mag R/W

Spool Error!

<-Any Key Push->

Print Error xx

<Replay Cancel>

Top Cover Open

<-Card Moving ->

LED Button

Left Right Left Right

On On

Blinking Blinking

Blinking Blinking Repeat

Blinking Blinking

Cancel &

Initialize

Move a

card to the

back side

Cancel &

Initialize

Cancel &

Initialize

Move a card

to the front

side

State Description

Reading or writing the

Magnetic stripe

Printing data is not

transmitted properly

Error in printing or

moving a card

Top cover open

Magnetic encoder is reading or writing the magnetic stripe

information.

Shown it when error occurs in a printing data transmission. Press

any keys to delete the spooled data and to return the ready state.

Error in the printing or the transmission. Retry by pressing the left

button or cancel the command by pressing the right button.

Top cover is open. The card in the printer can be moved by

pressing the left or right LED button. If press both buttons at the

same time, the print head will be up and down. (Flipper will be flip

over if it is installed)

16

17

18

19

20

21

22

Check Please..

Ribbon Not Found

Check Please..

Ribbon Zero

Check Please..

TPH Not Found

Print Error xx

Top Cover Open

Card Out Error

<Replay Cancel>

Board Test Mode

S M A R T

Download...

Wait

Blinking Blinking

Blinking Blinking

Blinking Blinking

Blinking Blinking

Blinking Blinking Repeat

On On Firmware downloading

Test mode state

Ribbon

redetecting

Ribbon

redetecting

Ribbon

redetecting

Ribbon

redetecting

Cancel &

Initialize

There is no ribbon in the

printer or fail to detect

The installed ribbon has

run out

Thermal Print head is not

installed

Fail to move the card out

(Check the card in the

printer)

Fail to move the card out

(Check the card in the

printer)

Table1 Status display

Fail to detect the ribbon. Check the ribbon installed state. If there

is no ribbon, install the ribbon. If there is a ribbon, pull out it and

install again. Press the left or right button to redetect the ribbon.

It is displayed when the installed ribbon is all used up. Replace

with new ribbon. Press the left or right button to redetect the

ribbon.

Thermal Print Head is not installed or there is a misconnection of

the cable. Open the top cover to check the print head installed

state or turn off the printer and check the cable connecting state.

The card in the printer will be come out when the initialization or

top cover close. If it is not come out, this message will be

displayed. Remove the card and close the top cover.

After an error occurs in printing, the error card is not come out

even though "Replay" or "Cancel" button is pressed.

The printer is downloading the firmware. Do not turn off the power

until it is rebooting. It takes about 20 seconds.

Test mode which can test the sensors or motors of the printer.

User can set the LED status.

15

Page 16

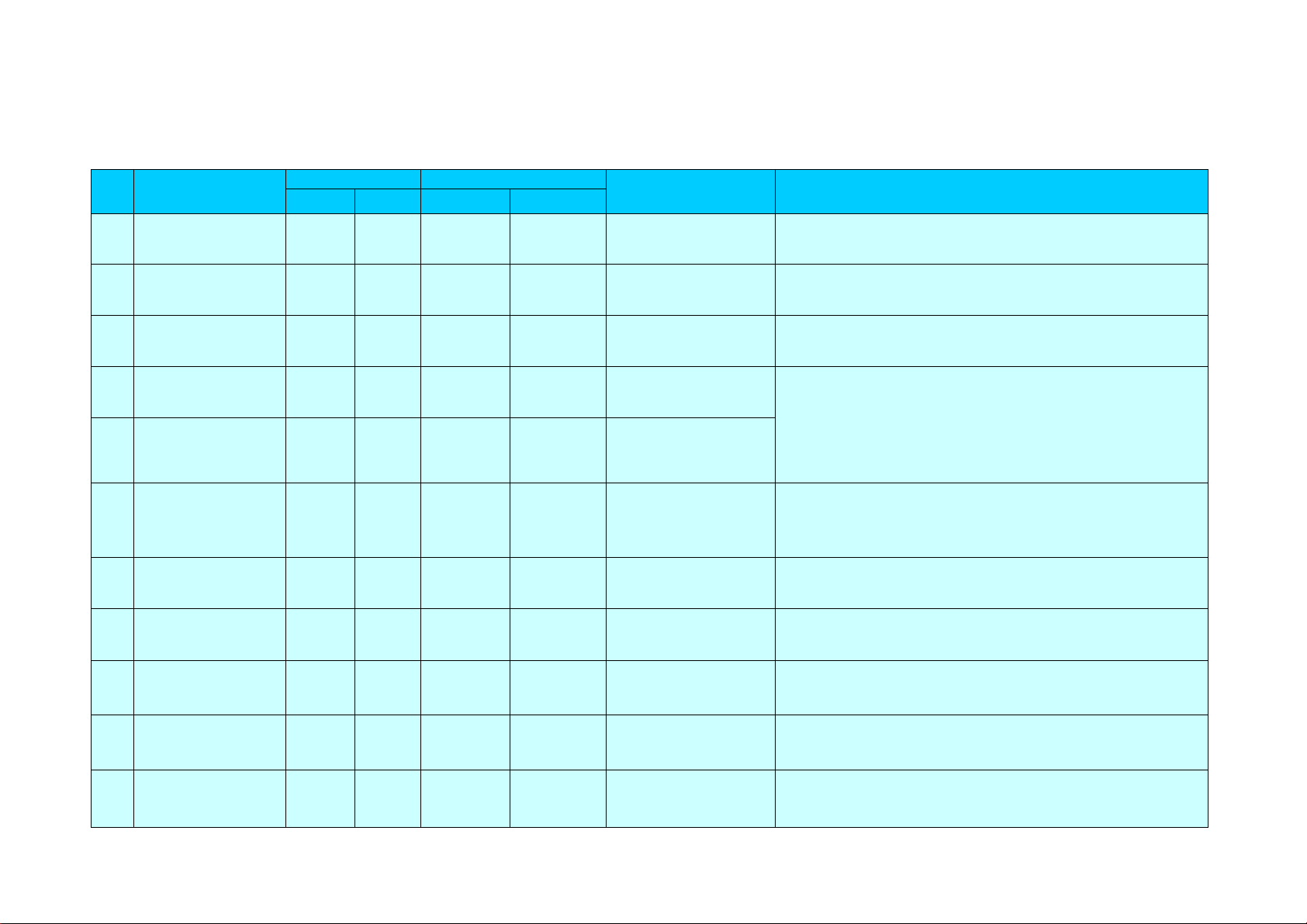

Description of printer error code

Error code Description

0 Card in error

1 Card move center error

2 Card out error

3 Card move magnetic error

4 Card move contact encoder error

5 Card move contactless encoder error

6 Card move error from the printer to the flipper

7 Card move error form the flipper to the printer

8 Print head up error

9 Print head down error

10 IC Contactor up

11 IC Contactor down

12 Flipper top error

13 Flipper bottom error

14 Error in printing

15 Magnetic stripe read/write error

16 Ribbon search error

17 Ribbon move error

18 No print head installed

19 Print head overheating

20 No ribbon

21 Printing data error

22 Card back out error

23 Magnetic data erasing error

24 Printer password is not correct

25 Magnetic stripe track 1 read error

26 Magnetic stripe track 2 read error

27 Magnetic stripe track 3 read error

28 Printer locked state

29 Printer spool full state

30 No defined

31 No defined

16

Page 17

Description of laminator error code

Error code Description

0 Laminator head up error

2 Laminator head down error

4 Laminator card in error

6 Laminator card move error

8 Laminator card front out error

9 Laminator card rear out error

10 Flipper error

13 Error while laminating

15 Laminator initializing error

16 Laminator film zero error

17 Laminator film search error

31 No laminating film

17

Page 18

2. Printer installation

2.1. Fitting the ribbon

Before printing, prepare the related items such as a card, a ribbon and a cleaning roller. In this

section we invite you to know the proper method of installing the ribbon and the cleaning roller

into the printer. In the case of SMRT RW model, the ribbon is no needed so skip 2.1.4 and

2.1.5 process.

2.1.1. Turn off the printer

2.1.2. Open the printer top cover by

pressing the top cover open

button.

Pic.14 Top Cover open

Pic.15 Take out the ribbon cartridge

2.1.3. Take out the ribbon cartridge.

18

Page 19

2.1.4. Install a ribbon into the ribbon

cartridge as left Pic. 13.

Pic.16 Loading the ribbon 1

①

②

Pic.17 Loading the ribbon 2

③

2.1.5. Insert the supply side of the ribbon

to no.1 hole and press the opposite

(no.2). Insert the take-up side of the

ribbon same method to no.3 and

no.4. After inserting, tighten the

ribbon.

(Caution! If the ribbon is not tightened, a

④

rolling up error might be happened.)

2.1.6. Install the disposable cleaning

roller to the ribbon cartridge.

Pic.18 Installing the cleaning roller

Pic.19 Peeling the protective wrapper

2.1.7. Peel the protective wrapper from

the cleaning roller.

After removing the protective wrapper, the

cleaning roller should be kept clean from

fingerprints, dust and foreign substances to

avoid contamination because it is adhesive.

(Caution! Do not use without peeling off the

protective wrapper because the cleaning

roller cannot perform its function.)

19

Page 20

2.1.8. Install the ribbon cartridge into the

printer after installing the ribbon

with a cleaning roller to the

cartridge.

Pic.20 Installing the ribbon cartridge

Pic.21 Close Top Cover

2.1.9. Close the top cover

(If it is not closed properly, check the installation

state of the ribbon cartridge.)

20

Page 21

2.2. Loading the cards

This section shows how to load the plastic cards.

2.2.1. Open the input hopper cover.

2.2.2. Adjust the card thickness with the

card thickness control lever.

(Caution! If the adjustment is not correct, it will

make some error. Use the type of cards in the

specification of this manual. Always keep the

card surface clean state.)

Pic.22 Adjusting the card thickness lever

Pic.23 Preparing the card 1

2.2.4. To separate cards from each other,

push a stack of cards back and

forth to an angle about 45 degrees

vertically.

(Static charge makes cards stuck with

significant adhesive force. These cards must be

physically separated from each other before

inserted into the feeder. If not separated,

feeding or printing problems may occur.)

Pic.24 Preparing the card 2

21

Page 22

2.2.5. Stand the stack of cards vertically

after separating.

Pic.25 Loading the cards 1

2.2.6. Load the cards on the input hopper

properly and close the hopper

cover.

Pic.26 Loading the cards 2

2.2.7. When insert each one card, insert

the card to the end as the Pic. 24

and 25.

Pic.27 Loading the cards 3

Pic.28 Loading the cards 4

22

Page 23

2.3. The withdrawal of printed cards.

Printed cards are passed out to the stacker of rear bottom side of SMART printer. SMART-30’s stacker

can be divided as following image.

Pic.29 SMART-30 Stacker

SMART-50’s stacker sticks out of the device so you can withdraw the printed

cards easily.

Pic.30 SMART-50 Stacker

23

Page 24

f

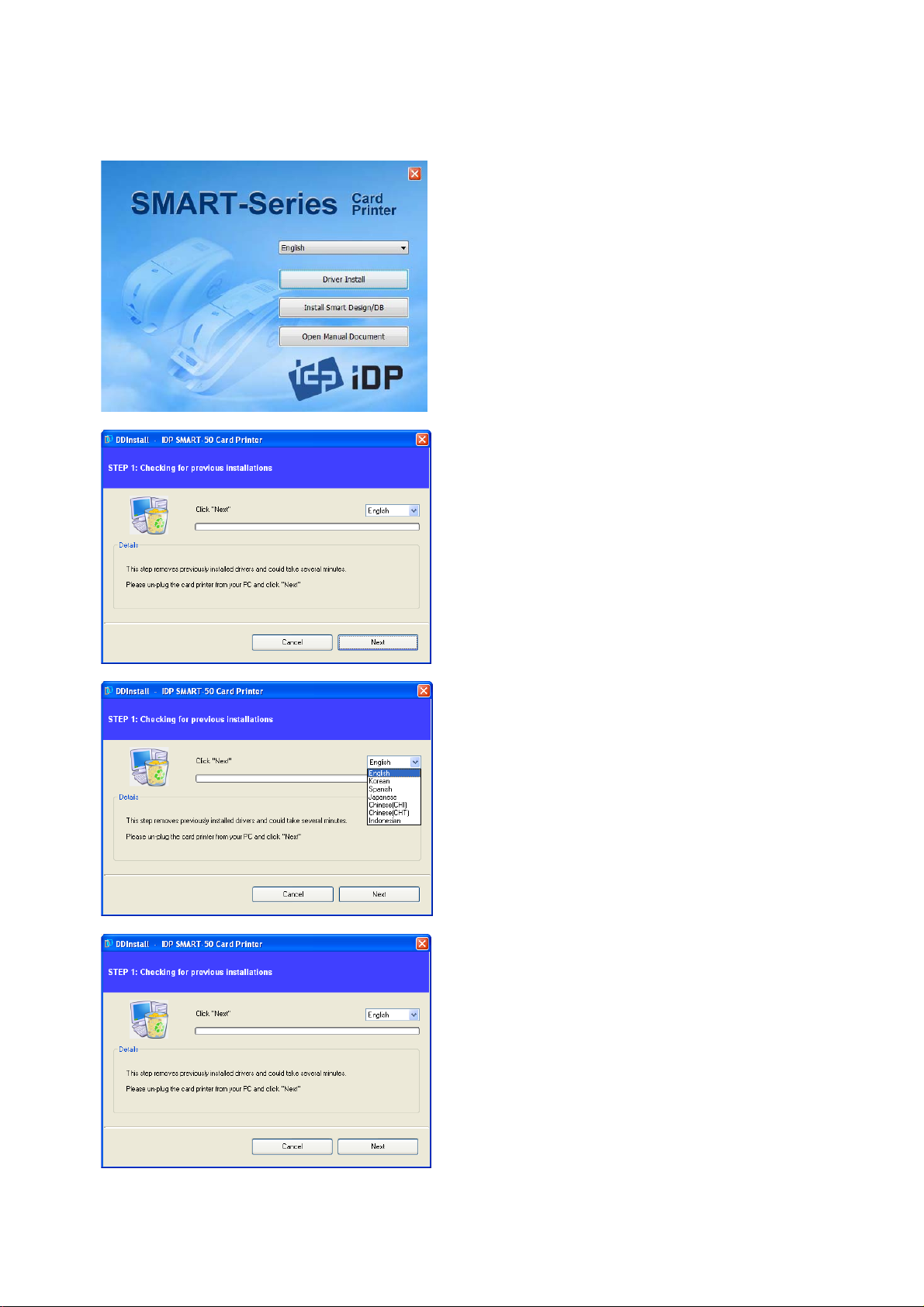

2.4. Driver installation (Windows XP, 2000, 2003)

2.4.1. Insert the installation CD provided

with the printer.

2.4.2. Choose the language and click

“Driver Install”.

Pic.31 Install XP printer driver 1

Pic.32 Install XP printer driver 2

2.4.3. STEP 1:

If the printer is connected to the PC

and turned on, turn off the power o

the printer.

Click “Next”. The existing installed

printer driver will be removed.

If the printer driver is already installed, it will

be removed automatically but it may take

times.

Choose the language as shown on the Pic.29

and 27.

Pic.33 Install XP printer driver 3

Pic.34 Install XP print driver 4

24

Page 25

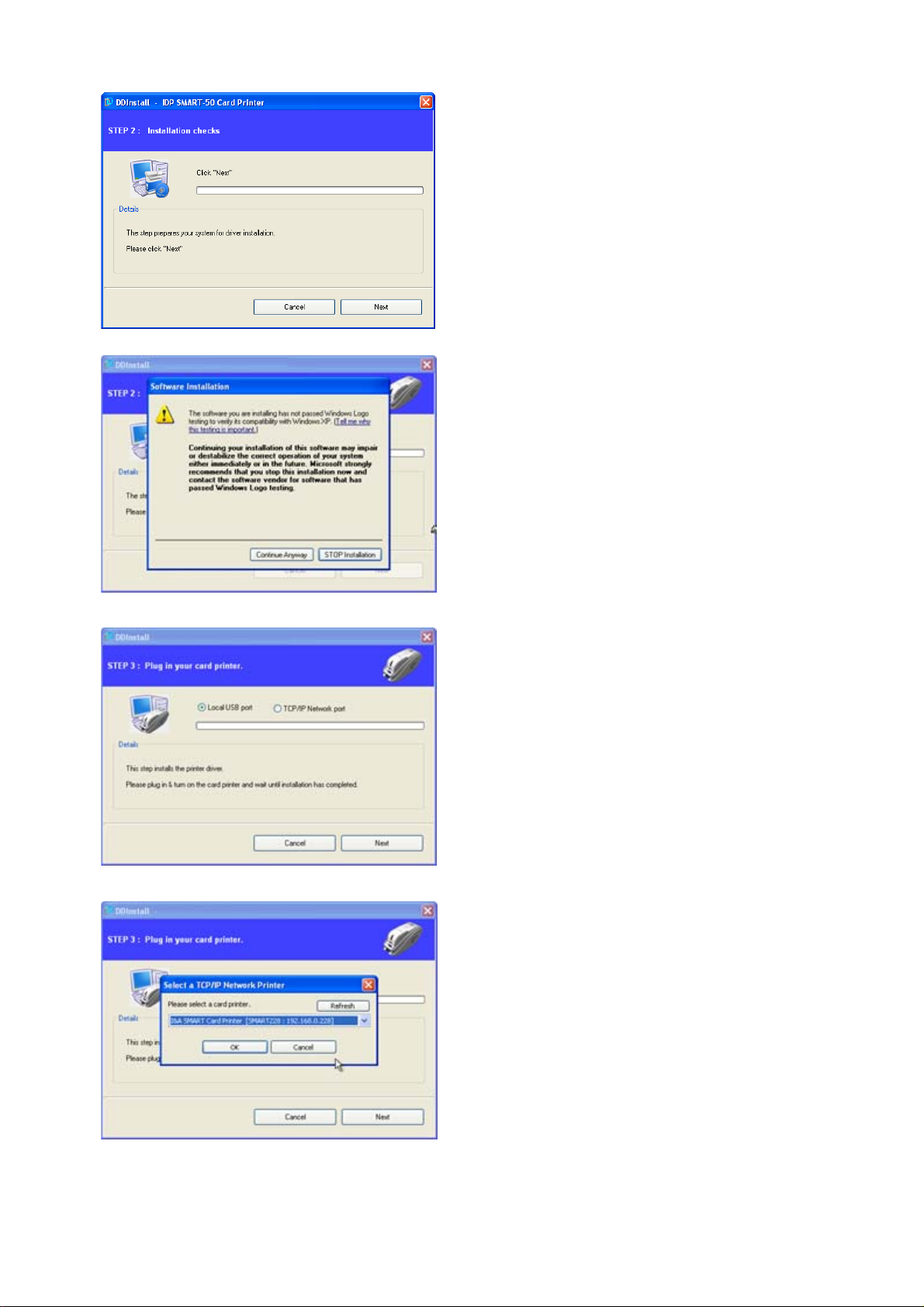

2.4.4. STEP 2:

Click “Next” to ready the

installation of the printer driver.

Pic.35 Install XP print driver 5

2.4.5. If there is a pop-up window for the

software installation, click

“Continue Anyway”.

Pic.36 Install XP print driver 6

2.4.6. STEP 3:

Click “Next” to use USB port.

Click “TCP/IP Network port” to use

the printer as network printer and

choose the printer as shown on the

Pic.34.

(If there is no information on the window for

the network printer list, it means that the

printer is not connected to the network. Check

“2.5 Network Printer” section.)

Pic.37 Install XP printer driver 7

Pic.38 Install XP printer driver 8

25

Page 26

2.4.7. Please connect a power supply to

the printer.

(For the network printer, refer to “2.5 Network

Printer” section.)

Pic.39 Install XP printer driver 9

Pic.40 Install XP printer driver 10

2.4.8. Please connect USB cable provided

with the printer to PC and the

printer.

(For the network printer, refer to “2.5 Network

Printer” section.)

2.4.9. Turn on the printer to boot up it.

Pic.41 Install XP printer driver 11

26

Page 27

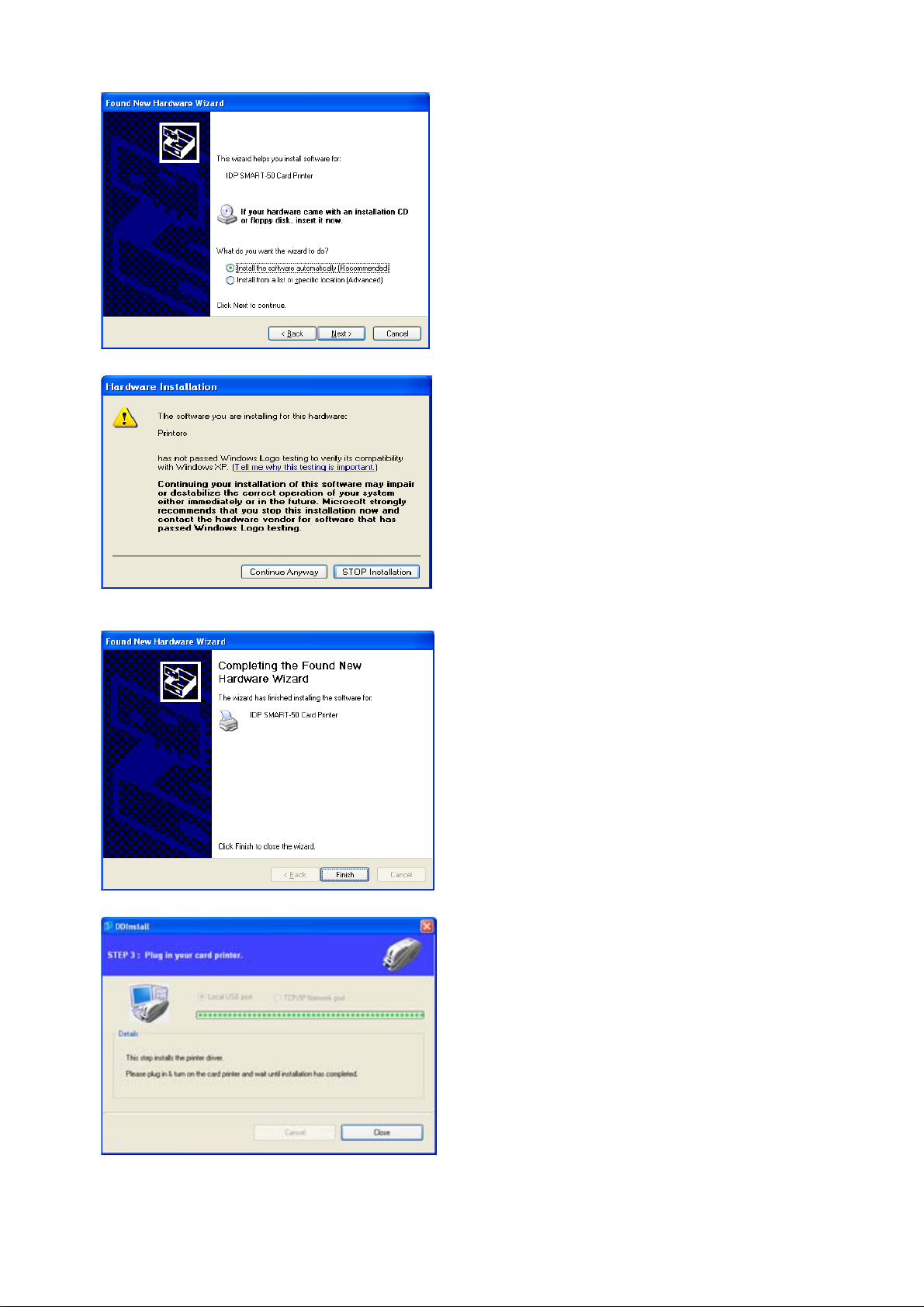

2.4.10. Select “Install the software

automatically (Recommended)”and

click “Next”.

Pic.42 Install XP printer driver 12

2.4.11. Click “Continue Anyway” in

Software Installation window.

Pic.43 Install XP printer driver 13

2.4.12. Click “Finish” in Completing the

Found New Hardware Wizard

window.

Pic.44 Install XP printer driver 14

Pic.45 Install XP printer driver 15

2.4.13. When the printer driver installation

is completed. Click “Close”.

27

Page 28

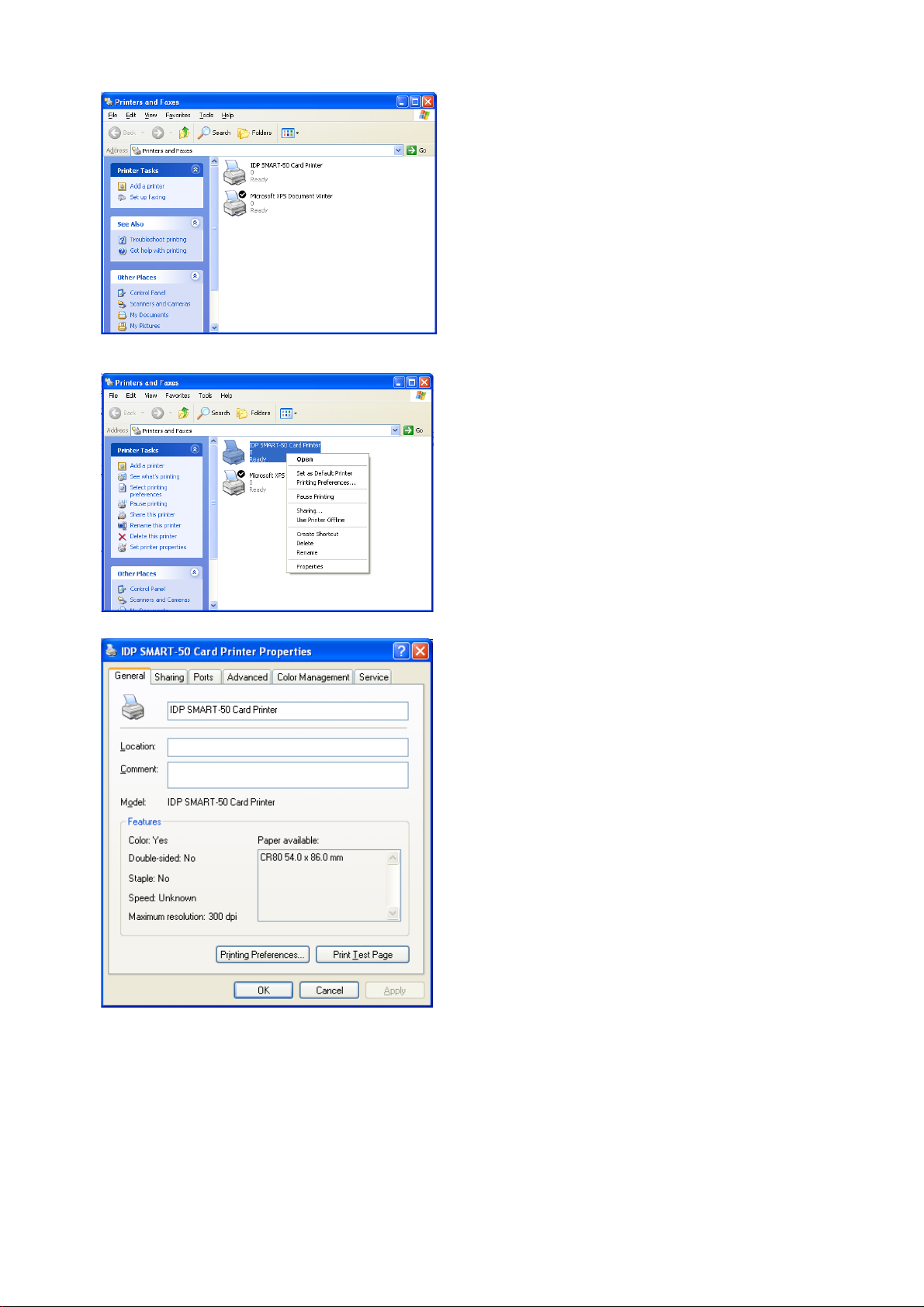

2.4.14. Check “IDP SMART-50 Card

Printer” is generated in Printers

and Faxes window.

Pic.46 Install XP printer driver 16

Pic.47 Install XP printer driver 17

2.4.15. After selecting the icon of “IDP

SMART-50 Card Printer”, click the

right mouse button and select the

“Properties”.

2.4.16. Select “General” tap and click

“Print Test Page” button on the IDP

SMART-50 Card Printer Properties

window.

Pic.48 Install XP printer driver 18

28

Page 29

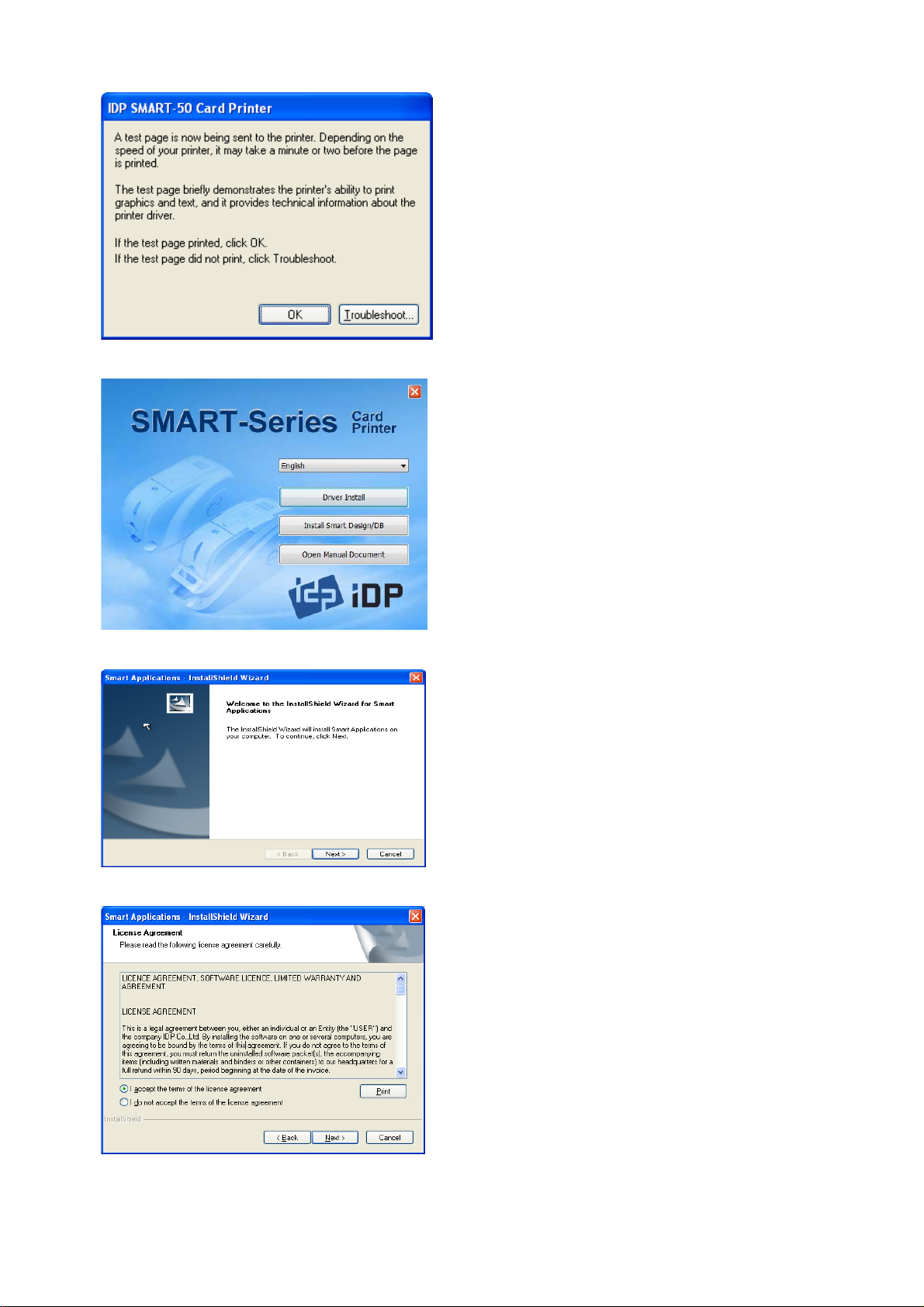

2.4.17. Printer will start the printing and

there will be the window which asks

the printing success. If the printing

is normal, click the “OK”

(If the printing is abnormal or the printer error

is occurred, remove the problem refer to

“Trouble Shooting” section and execute test

printing again.)

Pic.49 Install XP printer driver 19

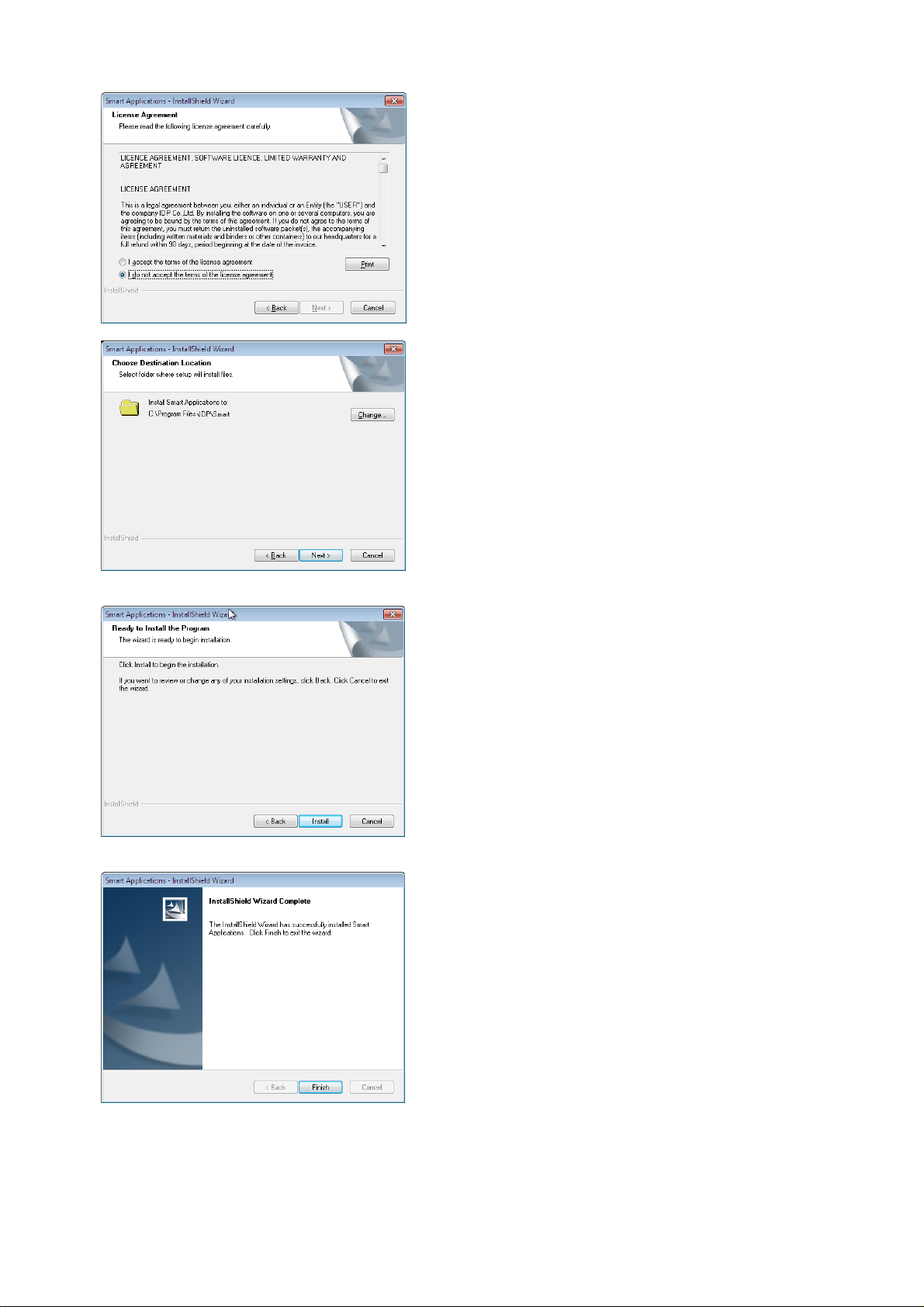

2.4.18. Please install “Smart Application”

program after installing the printer

driver.

Pic.50 Install XP printer driver 20

2.4.19. Click “Next” on the “Smart

Applications - InstallShield Wizard”

window.

Pic.51 Install XP printer driver 21

2.4.20. Select “I accept the terms of the

license agreement” and click

“Next”.

Pic.52 Install XP printer driver 22

29

Page 30

2.4.21. Choose the destination location

and click “Next”.

Pic.53 Install XP printer driver 23

2.4.22. Click “Install” to begin the

installation.

Pic.54 Install XP printer driver 24

2.4.23. Smart Design/DB program is

installed successfully.

Pic.55 Install XP printer driver 25

30

Page 31

2.5. Driver installation (Windows Vista, 7, 8)

r

2.5.1. Please insert the installation CD.

2.5.2. Please choose language and click

“Driver Install”.

Pic.56 Install Win7 driver 1

2.5.3. When “User Account Control”

window is opened, click “Yes”

Pic.57 Install Win7 driver 2

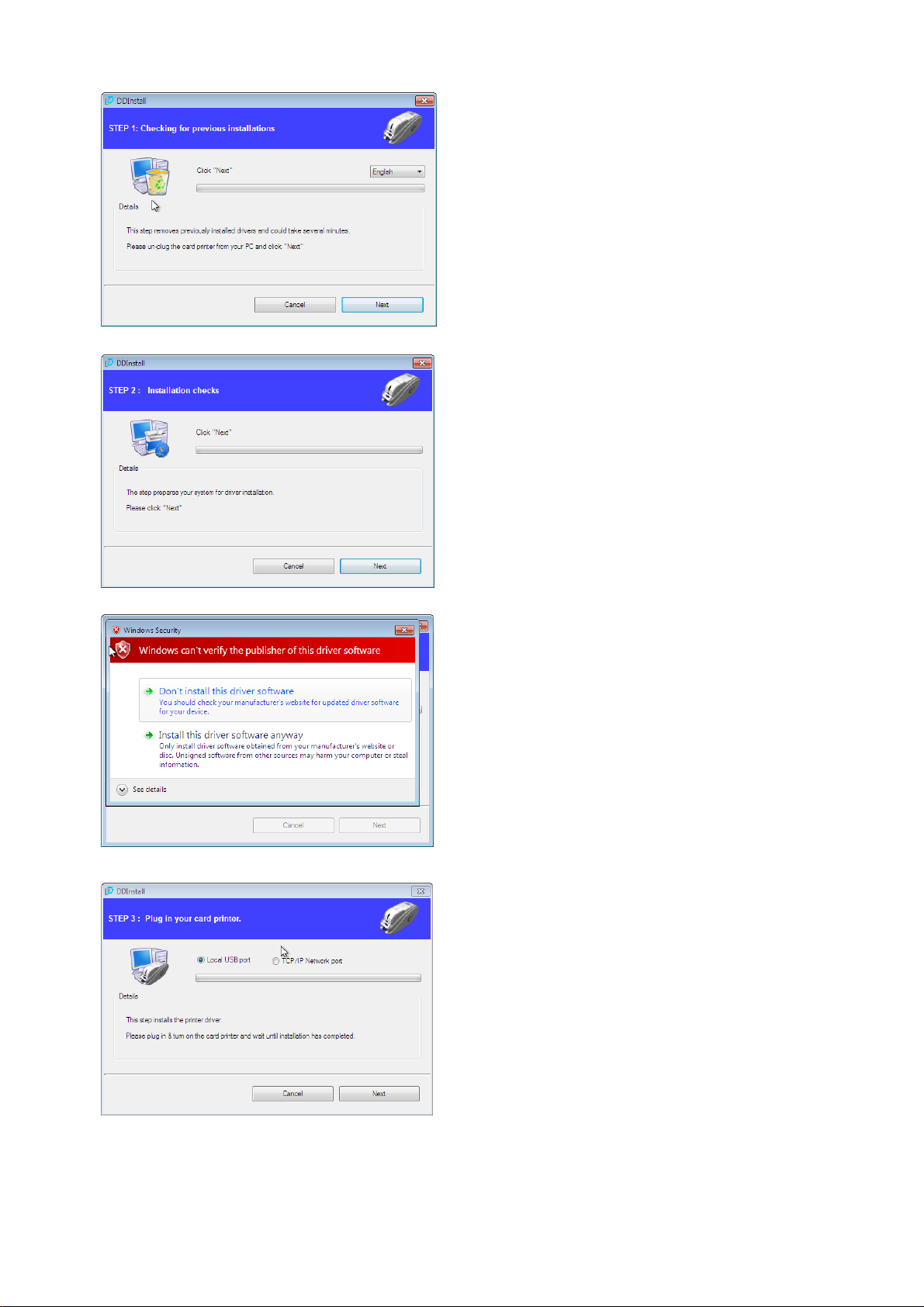

2.5.4. STEP 1:

Please turn off printer if it is

connected to PC. Please click

“Next”.

When you click “Next”, older drive

will be removed automatically.

This process will take several minutes to

remove older driver.

You can select the languages by selecting the

Pic.58 Install Win7 driver 3

combo box as shown on the Pic.55.

Pic.59 Install Win7 driver 4

31

Page 32

r

r

Pic.60 Install Win7 driver 5

2.5.5. STEP 2:

When you click “Next”, the drive

installation will be ready.

Pic.61 Install Win7 driver 6

2.5.6. Please click “Install this driver

software anyway” in case

“Windows Security” window comes

out.

Pic.62 Install Win7 driver 7

2.5.7. STEP 3:

Please click “Next” if printer is

connected to USB only.

If you want to install the driver for a

printer connected to network,

please select the “TCP/IP Network

port” and select the proper printe

as shown on the Pic.60.

(If no printer comes out on the window, please

check the connection. Please refer “2.5

Pic.63 Install Win7 driver 8

Network Printer Setup”.)

32

Page 33

Pic.64 Install Win7 driver 9

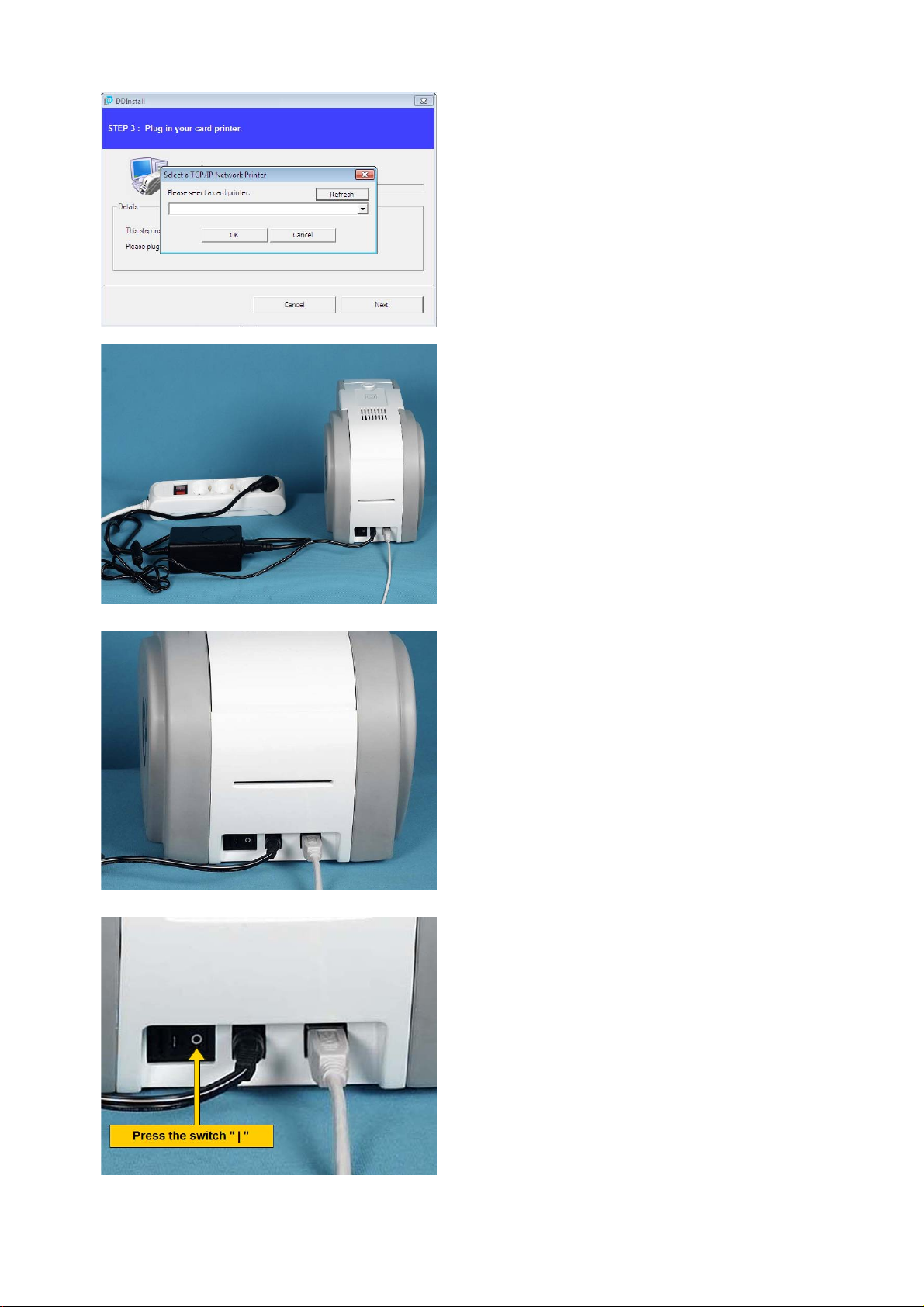

2.5.8. Please connect a power supply to

the printer.

(If your printer is for network, please refer “2.5

Network Configuration”.)

Pic.65 Install Win7 driver 10

2.5.9. Please connect USB cable to the

printer.

(If your printer is for network, please refer “2.5

Network Configuration”.)

Pic.66 Install Win7 driver 11

2.5.10. Please turn on the printer.

Pic.67 Install Win7 driver 12

33

Page 34

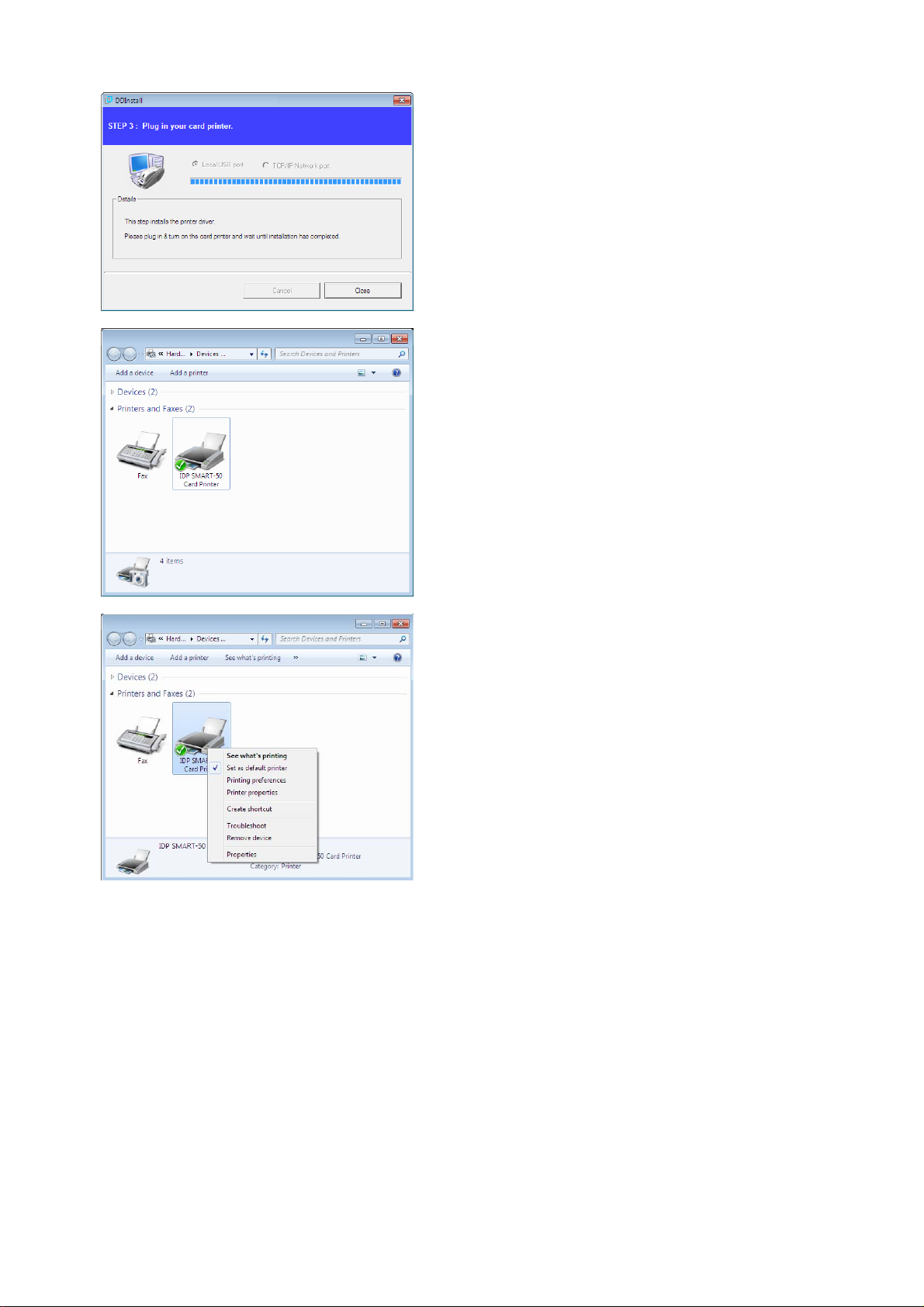

2.5.11. When driver installation is

completed, please click “Close”.

Pic.68 Install Win7 driver 13

Pic.69 Install Win7 driver 14

2.5.12. Please open “Devices and

Printers” from “Hardware and

Sound”. Please check if “IDP

SMART-50 Card Printer” is created.

2.5.13. Please click the right mouse button

after cursor is placed on “IDP

SMART-50 Card Printer” icon. Click

“Printer properties”.

Pic.70 Install Win7 driver 15

34

Page 35

2.5.14. Please select “general” tab and

click “Printer test page” in “IDP

SMART-50 Card Printer Properties”

window.

Pic.71 Install Win7 driver 16

Pic.72 Install Win7 driver 17

2.5.15. Please check test card if it is

printed properly and click “Close” if

a card is printed properly.

(If card is not printed or error comes out,

please refer “Trouble Shooting”.)

2.5.16. Please install “Smart Design/DB”

by clicking “Smart Design/DB

Installation”.

Pic.73 Install Win7 driver 18

Pic.74 Install Win7 driver 19

2.5.17. Please click “Next” when “Smart

Application Install Shield Wizard”

comes out.

35

Page 36

2.5.18. Please agree “I accept the terms of

the license agreement” and click

“Next”.

Pic.75 Install Win7 driver 20

2.5.19. Please select directory for

program installation and click

“Next”.

Pic.76 Install Win7 driver 21

2.5.20. Please click “Installation”.

Pic.77 Install Win7 driver 22

2.5.21. Please click “Finish”.

Pic.78 Install Win7 driver 23

36

Page 37

2.5. Network configuration

k

2.5.1 Connecting network port

① ② ③ ④

The printer which installed with

network option has a port for network

connection as shown in the Pic.76 - ③.

① Power Switch

② Power Supply Connector

③ Network Port

④ USB Port

Pic.79 Rear view of SMART-50 printer 1

Please connect network cable (RJ45)

to a printer.

(Network cable is not supplied. Please as

network administrator for more questions.)

Pic.80 Rear view of SMART-50 printer 2

37

Page 38

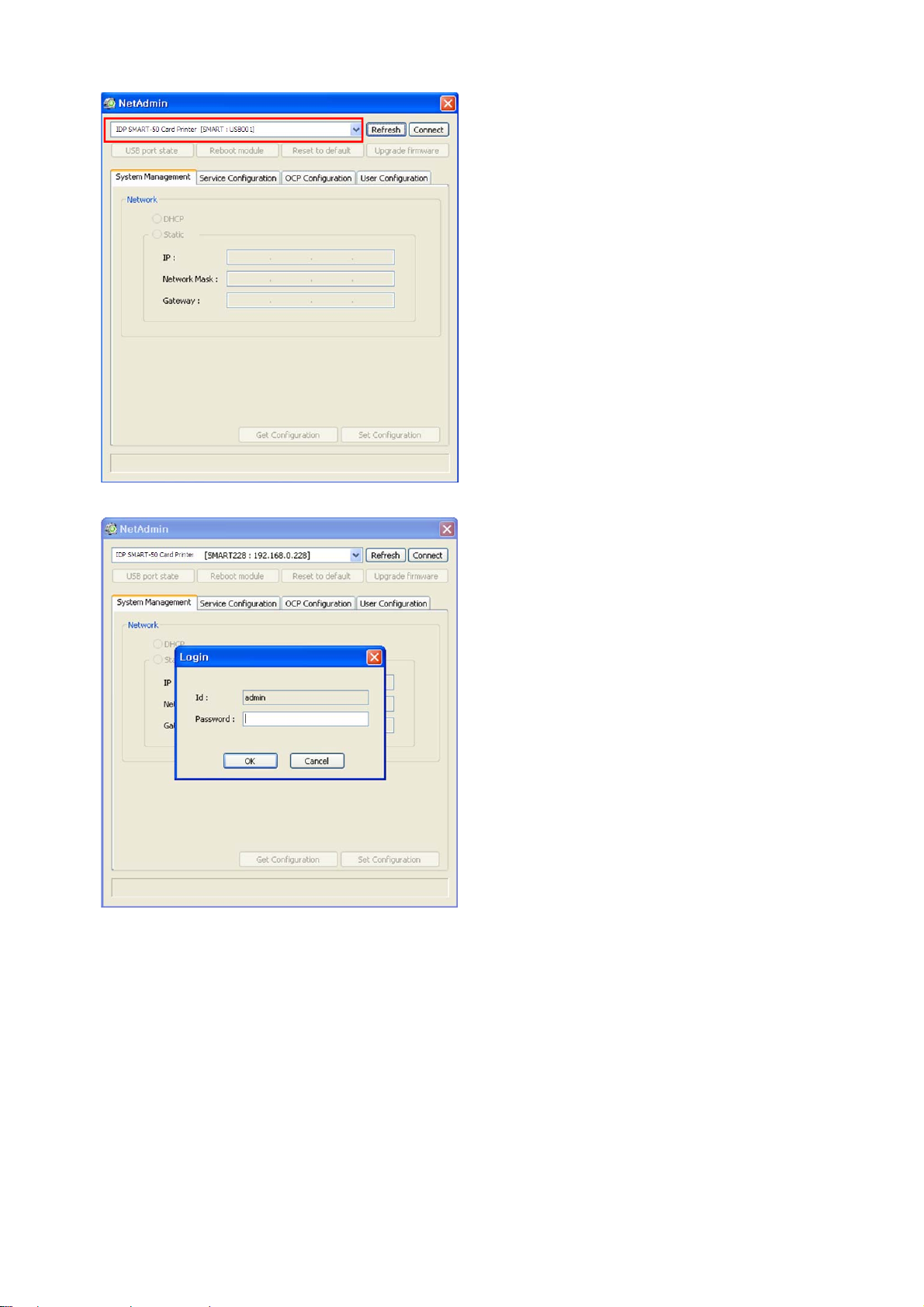

2.5.2 Network configuration

DHCP (Dynamic Host Configuration Protocol) which automatically assigns IP address to the SMART-50

network printer on the same network is default for IP configuration. If you don’t have DHCP server, you

need to set static IP.

Please run NetAdmin.exe in the SMART-50 installation CD to set or change network configuration.

①

②

③

NetAdmin is run as the Pic74 after

turning on SMART-50 network printer.

① Printer Connection Status

Searches local network, finds and shows

available network printer.

② Network Module Management

Searches connected encoder on network

module. Reboots, Resets network module.

Firmware upgrade available

③ Printer Configuration

Sets detailed system configuration.

④ Network Information

Shows firmware version of network module

④

Pic.81 Running the NetAdmin

When no printer is connected to

network, there is no printer shown on

the box.

Please click “Refresh”. If no printer shown, please

check as below,

1. Please check the printer is turned on.

2. Please check network cable is connected to

network hub and works properly (LED lamp

blinking).

3. Please check if there is DHCP server in the

local network. When DHCP server is not in

your local network, you need to set Static IP.

4. If Static IP is used, please check the IP

configuration. If another device uses same IP

address, it doesn't work.

Pic.82 Network printer is not found

38

Page 39

Pic.83 Connecting to USB port

r

r

If you are unable to find printer in local

network, please connect printer by

USB. You can setup network by USB.

When you click Refresh, you can find a printer

connected by USB as shown in the Pic.80.

z You don’t need to install device driver fo

network configuration by USB. Please ignore

messages related to device installation.

z You can change values of “System

Management” only when you connect a printe

by USB. Please connect a printer by network to

use all of the functions of Netadmin.exe.

Please select a proper printer and click

“connect”. Please enter password and

click “OK”.

Default password is “admin”.

Pic.84 NetAdmin Log-in

39

Page 40

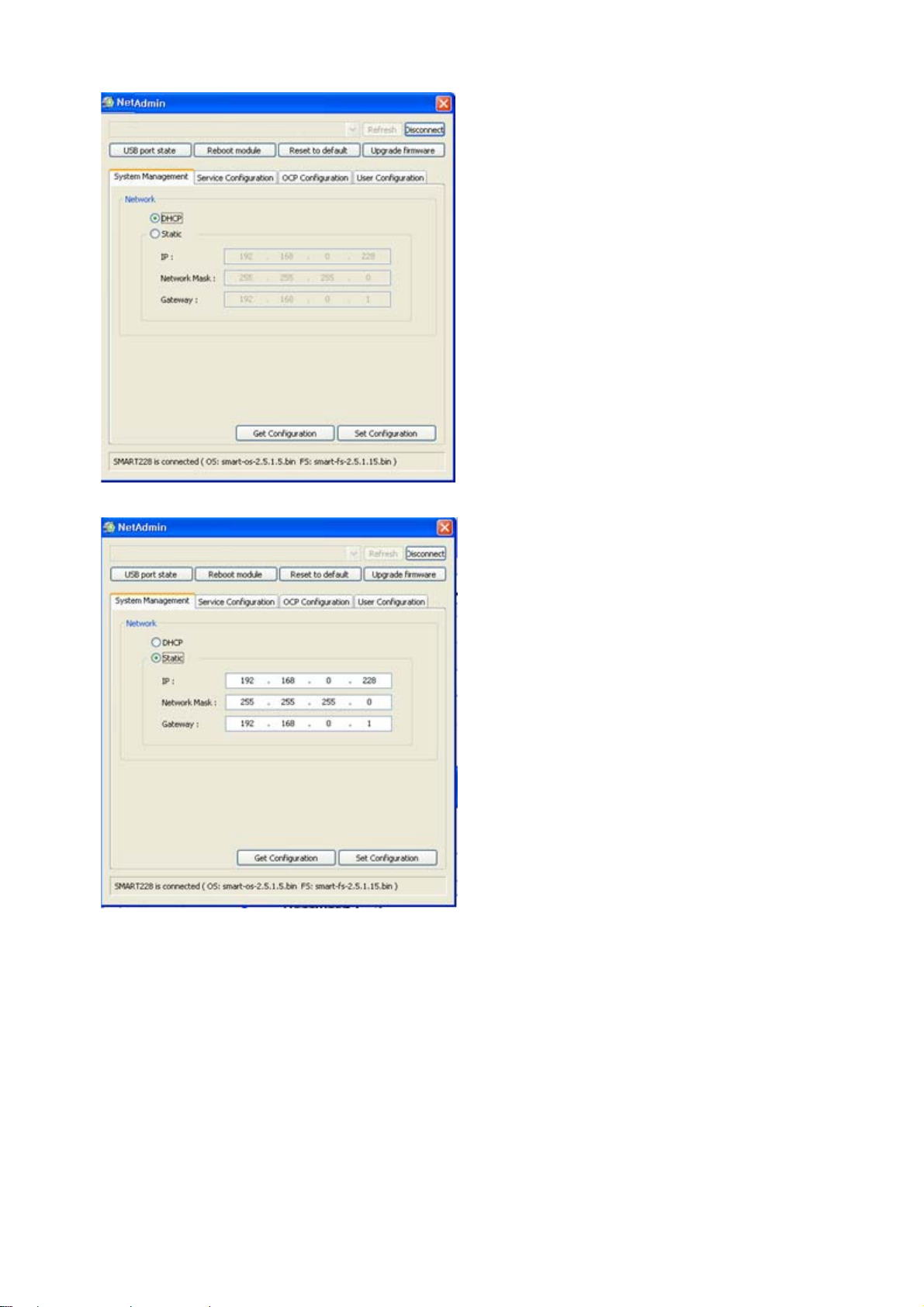

Pic.85 Dynamic IP configuration

r

If you setup network automatically,

please choose DHCP.

z Please select DHCP and click “Set

Configuration”.

z “DHCP” is default for SMART-50 printer.

z DHCP server should be in local network to use

DHCP function.

z Static IP is recommended. DHCP serve

assigns IP address automatically but this IP

address is temporary, so the IP address may be

changed. In this case, the network error may

occur in connecting to SMART-50 network

printer.

Please select “Static” for Static IP

configuration.

z Please enter values for “IP”, “Network Mask”,

and “Gateway”. Click “Set Configuration”.

z Please check IP address properly which does

not conflict with other devices.

z If you are not aware of static IP, please ask

network administrator for Static IP.

z We recommend using Static IP because it is

more stable for using SMART-50 network

printer.

Pic.86 Static IP configuration

40

Page 41

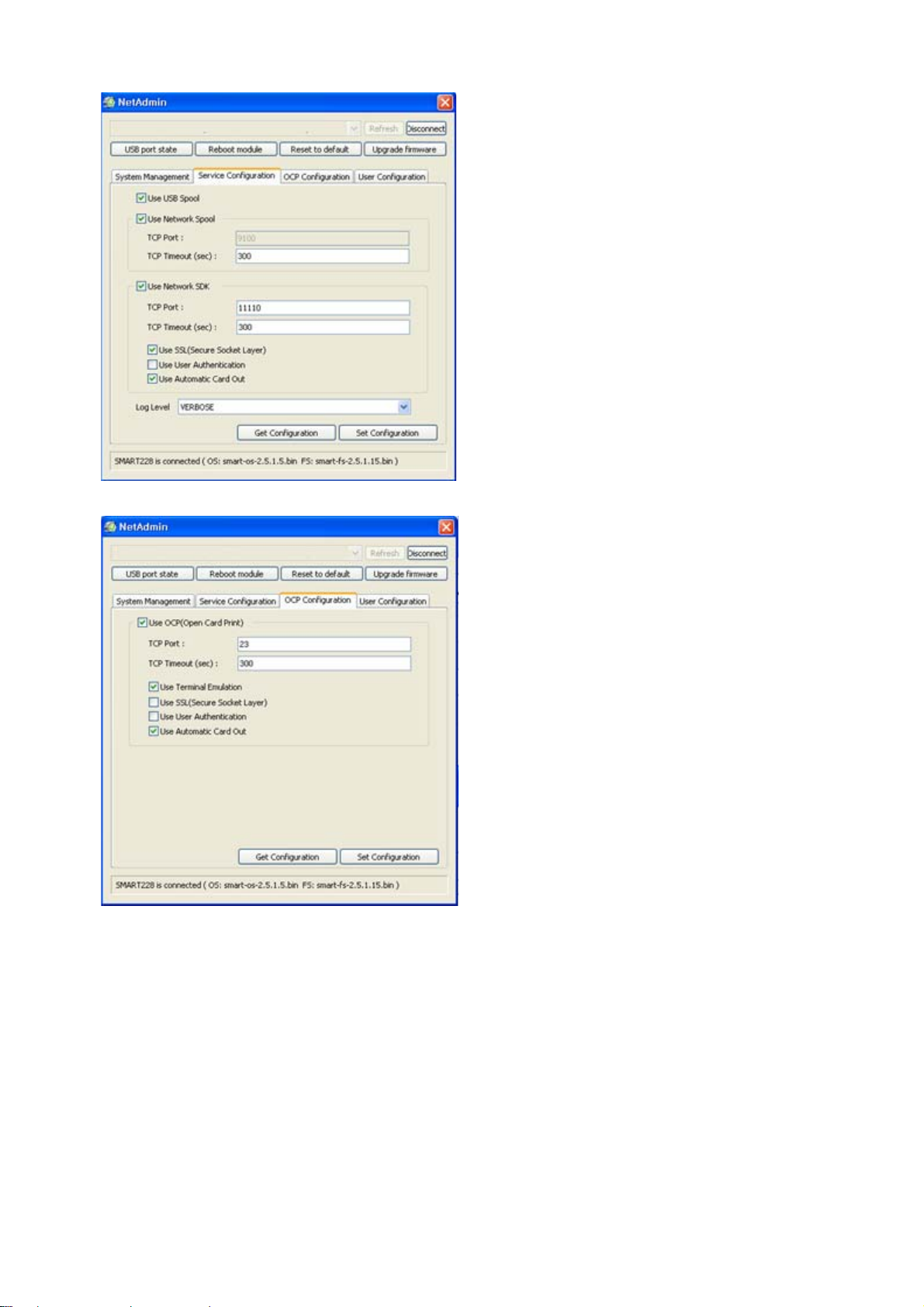

Pic.87 Network service configuration

r

r

r

You can change Service Configuration.

z SMART-50 network printer provides 3 kinds of

service (change “USB Spool”, “Network Spool”

and “Network SDK”). You can select and

change the service according to the need.

z In “Network SDK”, you can control the printe

and print a card well, and the printer supports

SSL (Secure Sockets Layer) and Use

Authentication for security.

z Please use default and ask technician fo

details.

You can use Open Card Print function.

z This function is for send commands and

print through network card regardless of OS

z Click check box “Use OCP”

z “Use Terminal Emulation” is value for

getting echo according to the commands

through terminal. For security, it supports

SSL and User Authentication.

z Please do not change default value except

special case..

Pic.88 OCP configuration

41

Page 42

Pic.89 Network user configuration

r

2.5.3 Network module management

You can add, change, delete User and

change its password.

z “admin” is administrator and you can’t delete

this account. Please don’t forget password fo

“admin”

z “Get User”: shows available users

z “Add User”: makes new user

z “Del User”: deletes selected user

z “Change Password”: changes password

“USB port state” shows USB device

status connected on network module.

z Network module has 4 USB ports.

z Network module supports PC/SC. When you

install the encoders that support PC/SC on

network module, you can recognize the status

of encoders.

Pic.90 USB port state

42

Page 43

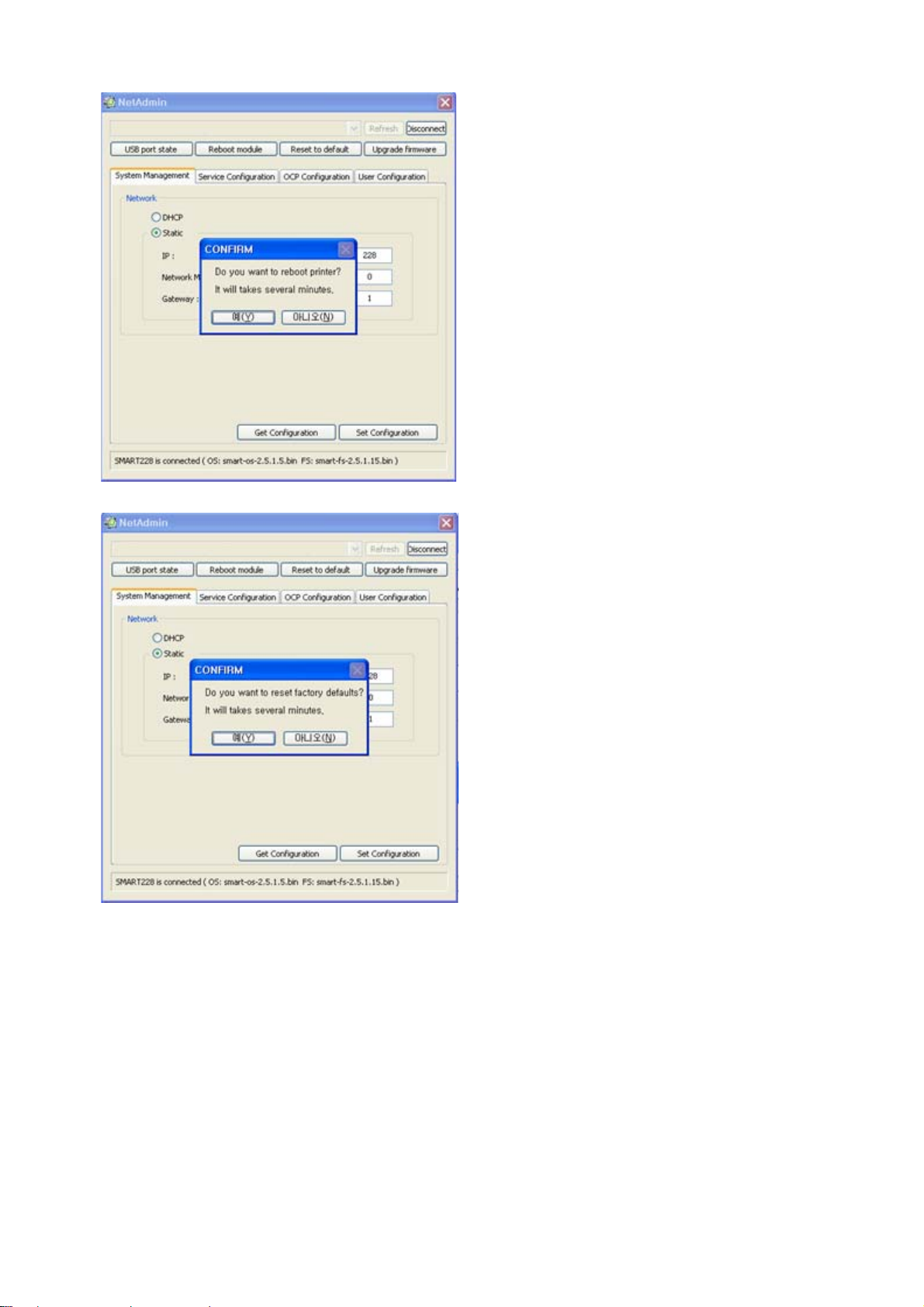

Pic.91 Rebooting the network module

“Reboot module” reboots network

module.

z Please click “Yes” when pop-up window comes

out for reboot.

z It takes 1 minute to reboot.

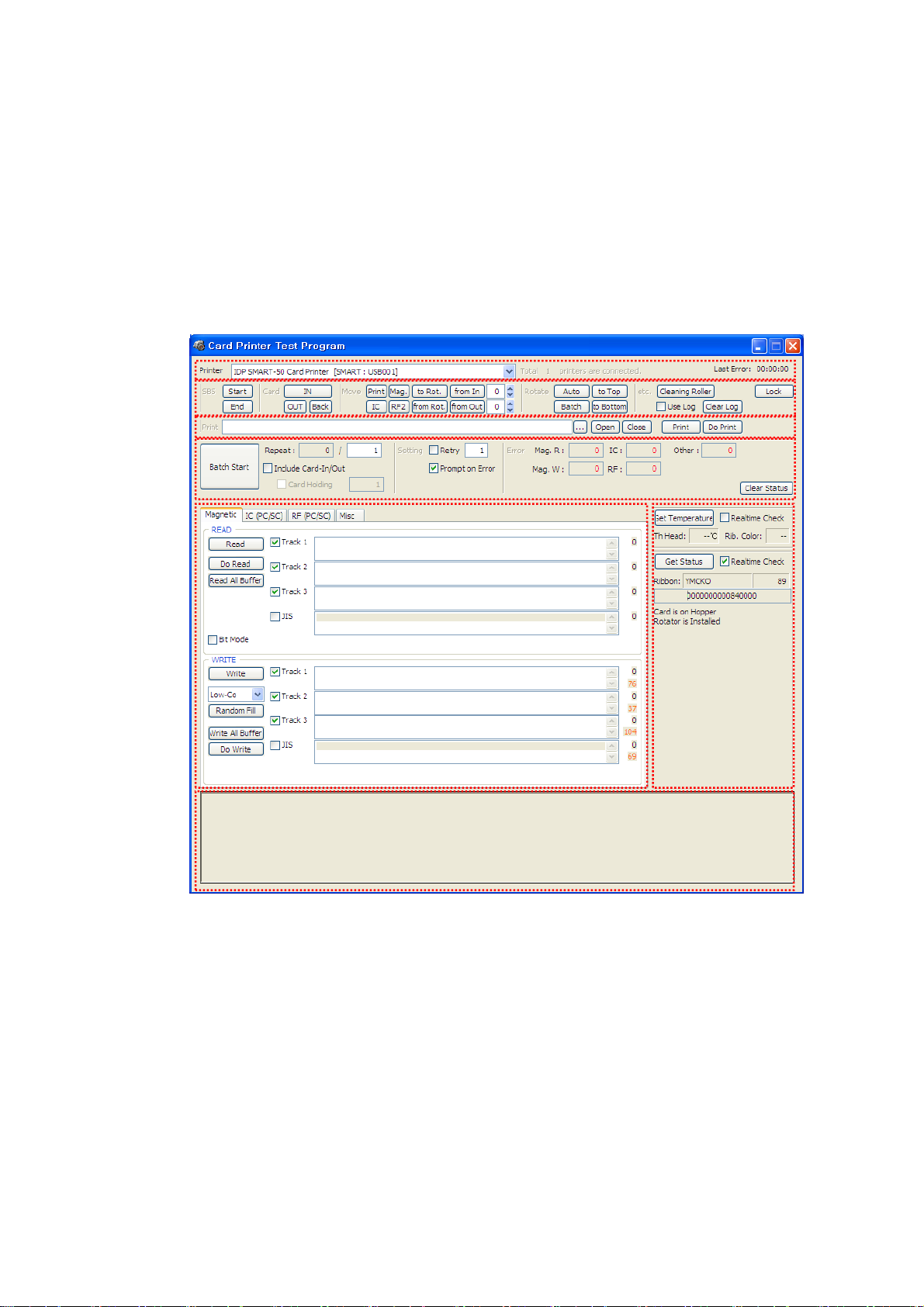

z Please click “Refresh” after reboot. When

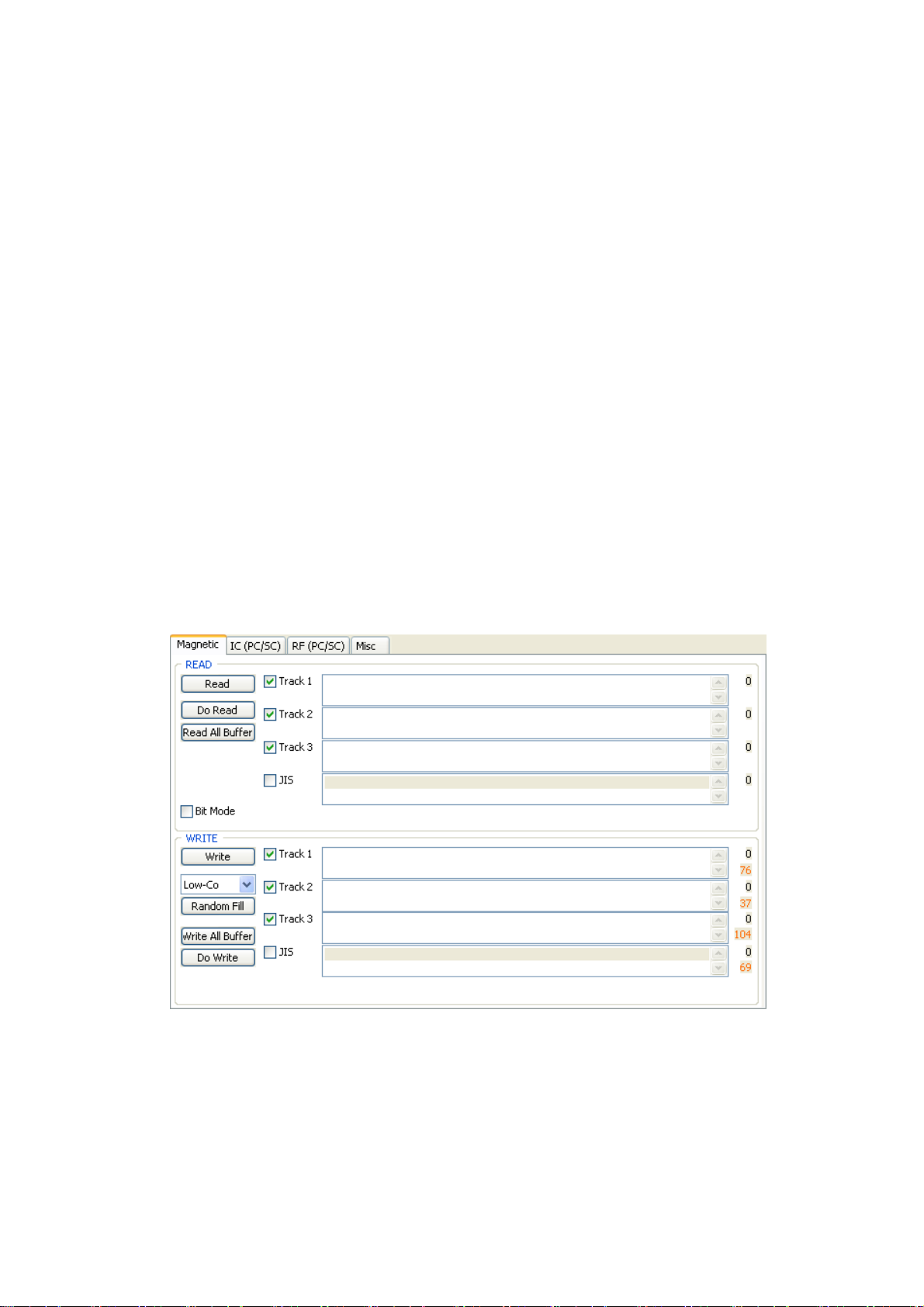

proper printer shown, please connect printer by

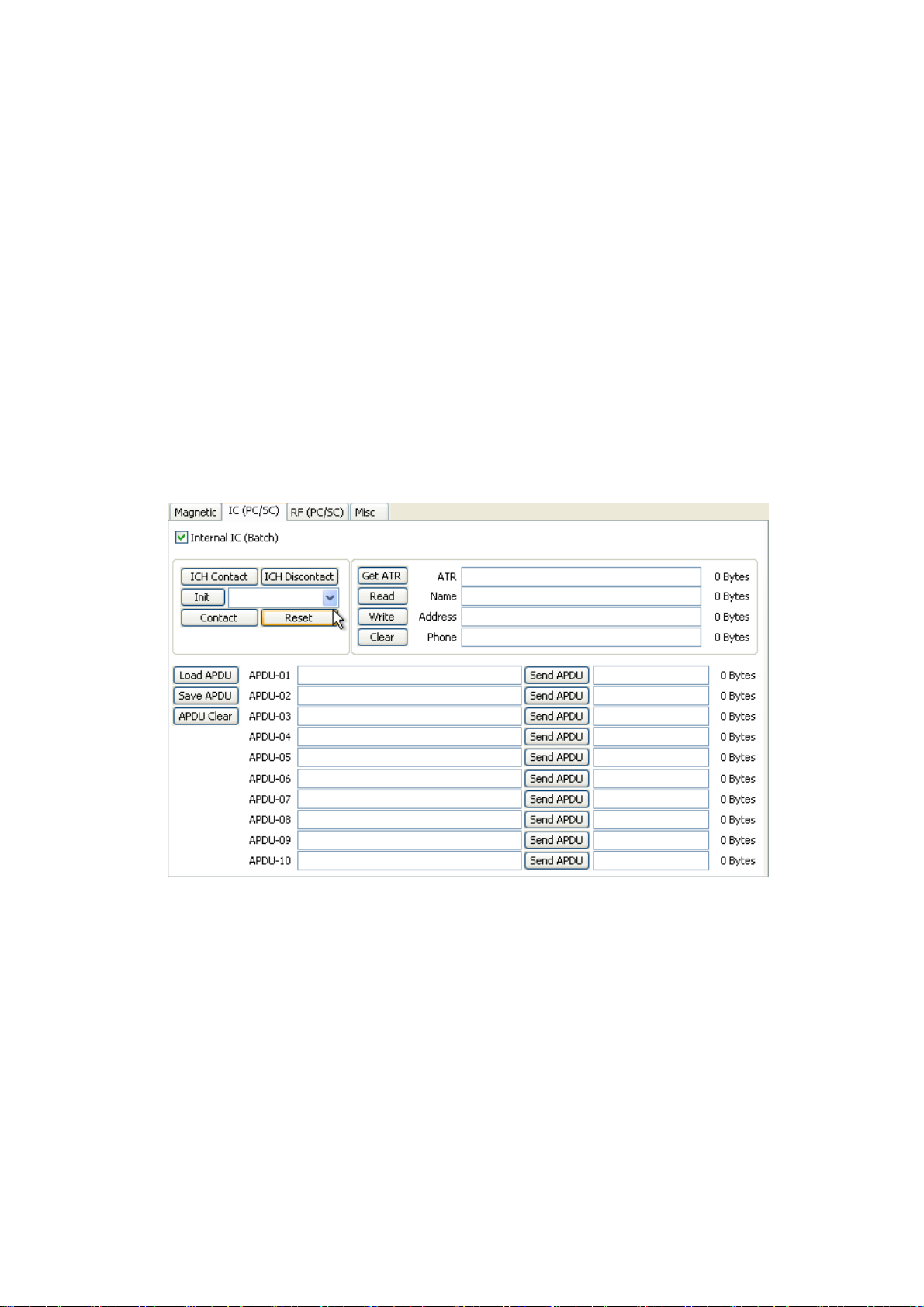

clicking “Connect”.

“Reset to default” resets to default and

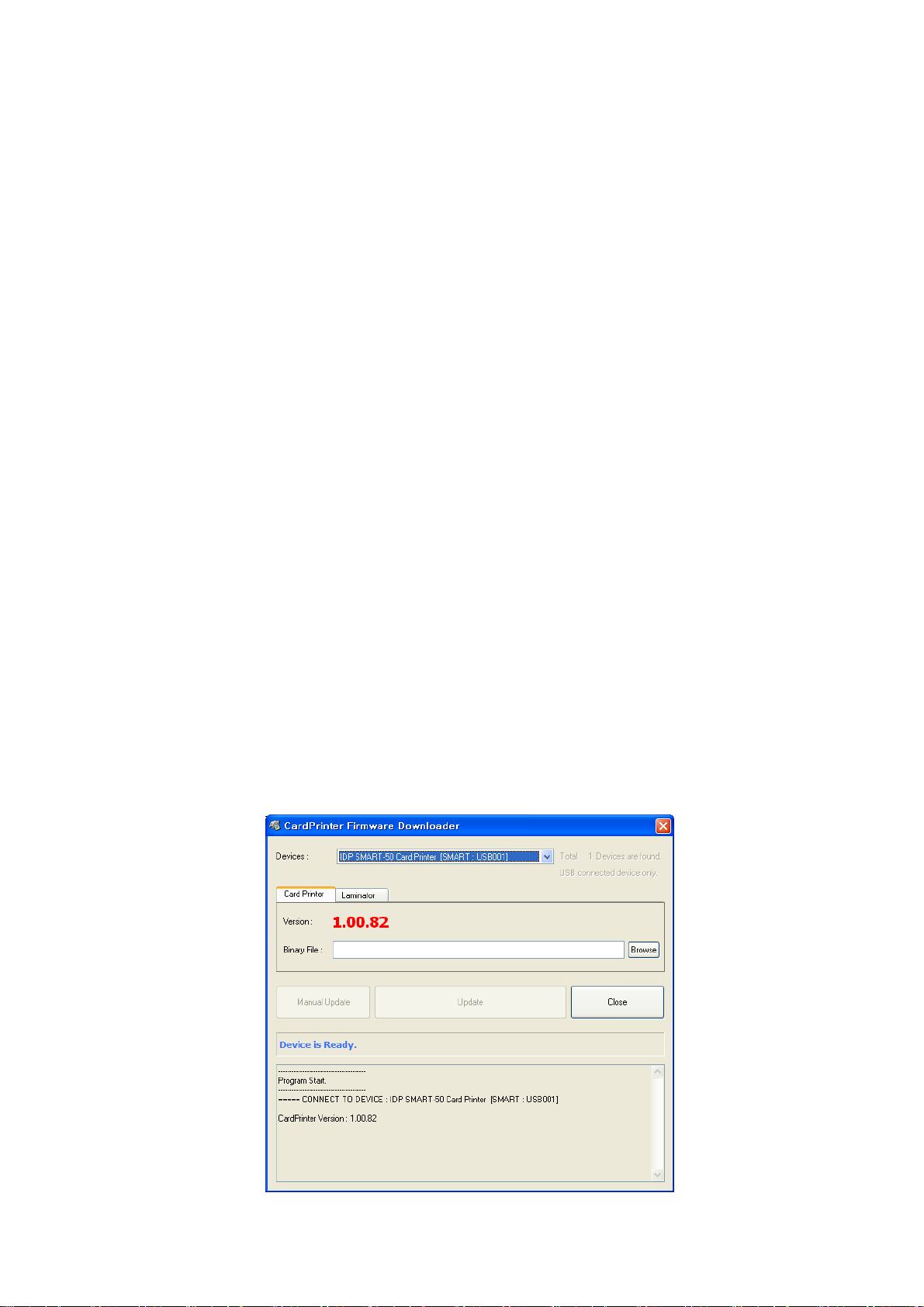

reboot network module.

z Please click “Yes” when pop-up window comes

out for reset.

z It takes 1 minute to reboot.

z Please click “Refresh” after reboot. When

proper printer shown, please connect printer by

clicking “Connect”.

Pic.92 Reset to default

43

Page 44

Pic.93 Upgrading the firmware 1

“Upgrade firmware” enables to

upgrade firmware of network module.

z You can choose a firmware file.

z Warning box will be shown during firmware

upgrade for network module.

z It is recommended not to do other work during

firmware upgrade for system reliability.

z Please do not turn off a printer until the

upgrade is completed.

Pic.94 Upgrading the firmware 2

44

Page 45

Pic.95 Upgrading the firmware 3

z When firmware upgrade is completed, pop-up

comes out for reboot. Please click “Yes”.

z It takes 1 minute to reboot.

z Please click “Refresh” after reboot. When

proper printer shown, please connect printer by

clicking “Connect”.

45

Page 46

3. Driver configuration

/

3.1. Checking printer properties

To check printer properties, you need to open printer driver. Please open “Drivers

and Printers” and right-click “IDP SMART-50 Card Printer”. Click “Properties”. For

Windows 7 or 8, please click “Printer Properties”.

When you click “Printer Properties” as like

Pic.88, a device driver of “IDP SMART-50

Card Printer” is shown.

Pic.96 Printer properties 1

3.2. Changing printer properties

In the general tab shown as Pic.94, you can check the printer model and

specifications.

3.2.1. Printing Preferences

Please click “Printing Preferences” shown on the

bottom of Pic.95.

There are 3 tabs of “Layout”, “Paper/Ribbon

and “Side/Media”.

(You can set the options for printing shown on

Pic.95.)

Quality”

Pic.97 Printer properties 2

46

Page 47

3.2.1.1. Layout

- You can select either horizontal or vertical printing

direction. To apply your selection, click “OK”.

Pic.98 Layout

47

Page 48

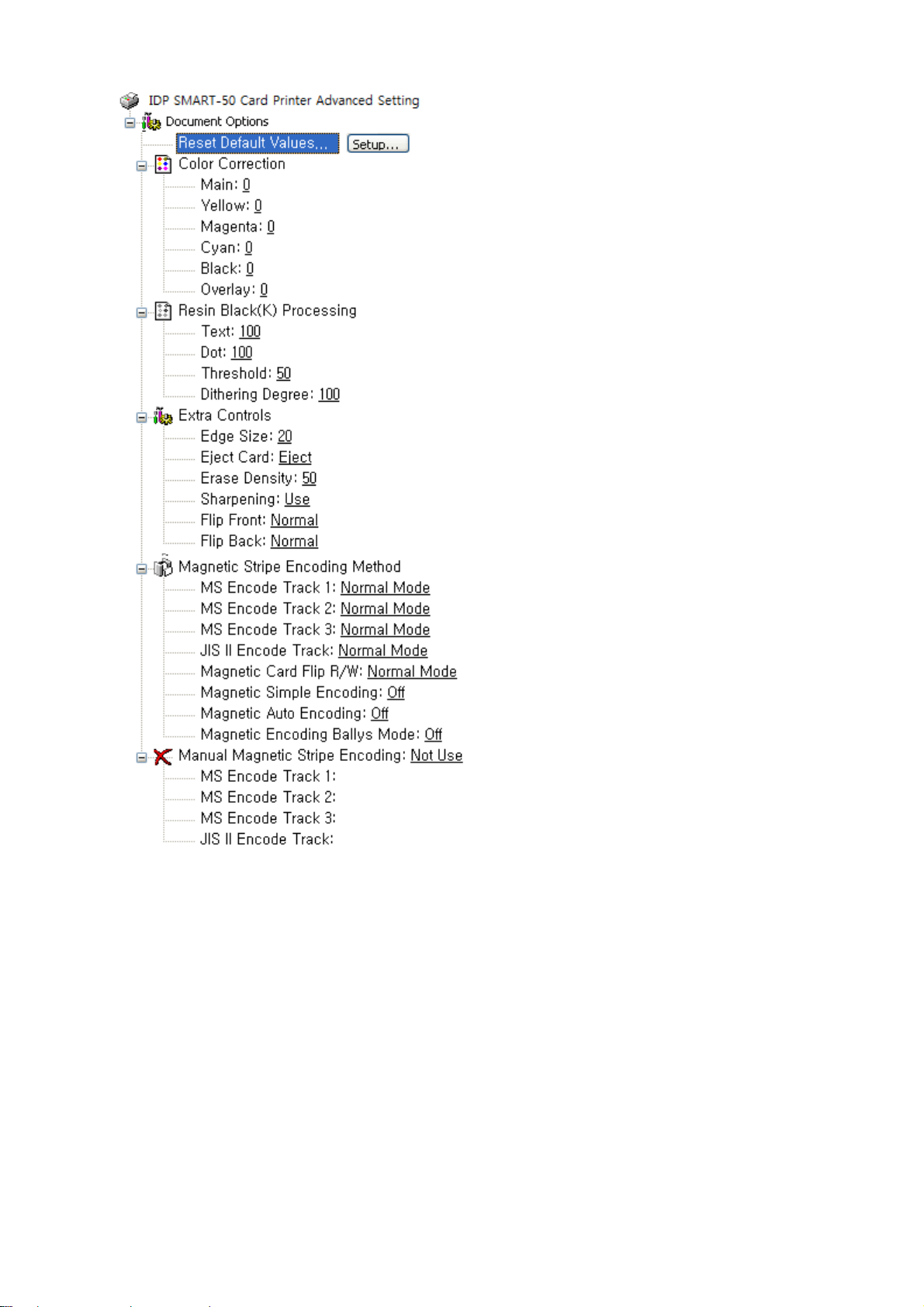

3.2.1.2. Advanced setup

r

t

r

Reset Default Values: Reset to default.

Color Correction: You can correct gamma fo

colors. You need to use CardPrinterSetup to adjus

color densities.

Resin Black (K) Processing: Set criteria for resin

black processing.

Text: to set density criteria for extracting black

objects

Dot: to set density criteria for extracting black

dots

Threshold: to set density criteria on dithering

Dithering Degree: to set sharpness on dithering

Extra Controls :

Edge Size: to set not printed area in case of not

using Edge-To-Edge

Eject Card: to set if eject a card after printing

Erase Density : to set erase density fo

SMART-30 R Erase

Sharpening: to calibrate image sharpened

Flip Front: to set printed direction of image on

front side.

Flip Back: to set printed direction of image on

back side.

Magnetic Strip Encoding Method: to set magnetic

stripe encoding method for each track

Normal: to encode on LoCo Card forwards

Reverse: to encode on LoCo Card backwards

Bit: to encode on LoCo Card in Bit

HiCo Normal: to encode on HiCo Card forwards

HiCo Reverse: to encode on HiCo Card

backwards

HiCo Bit: to encode on HiCo Card in Bit

Magnetic Card Flip R/W: to set back side

image printing when magnetic encoding

Magnetic Simple Encoding: Set fast encoding

and printing

Magnetic Auto Encoding: Set auto coercivity.

Pic.99 Advanced Setup

Magnetic Encoding Ballys mode: Set Ballys

mode

Manual Magnetic Stripe encoding: to put in data

on magnetic stripe manually

Not Use: not to use magnetic stripe encoding

Encoding and Printing: to print after magnetic

stripe encoding

Encoding or Laminating only: encoding

magnetic or laminating. without printing

48

Page 49

3.2.1.3. Paper / Ribbon / Printing

Pic.100 Paper / Ribbon / Printing

z Supply Tray

Supply

Please select “CR-80” because SMART-50 has 1 input hopper.

Tray

Please select “Auto” because SMART-50 supports CR80 cards only.

z Ribbon

Ribbon

It shows the type of installed ribbon. You don’t need to select this option as SMART-50

recognizes ribbon automatically with RF Tag.

Resin

You can set the method to extract resin black when you use design programs. (If you use

Smart Design, you don’t need to select this option.) It will be set automatically.

Black Objects: to extract resin black automatically for text, line, box, circle, binary images,

etc.

Black T ex ts: to extract resin black for text only

Black Dots: to extract resin black for all of black

Not Use: not to extract resin black

Split

You can set the both sides (Front:YMCO, Back:K) to save color ribbon(YMCKO, HYMCKO,

BYMCKO). It is only activated while printing both sides option is set.

z Printing

Mode

Set printing mode

Standard: Default print mode. Prints all area of priniting

Partial: Partial print mode. It is printed partially for the print area only. Printing speed can

be faster than standard mode.

Speed

Set printing speed and quality.

Standard: Default print mode and best quality setting option of printing

High: Fast print mode. This option can be used with only K and KO ribbo. Printing quality

might be lower than Standard.

Color

You can select color or black&white print. (“Color” option is available only with color ribbon.)

Dither

There are 3 possible selections, Threshold, Random, and Diffusion Dither. It is performed

with K and KO ribbon only. (Please select “Diffusion Dither” for high quality.)

49

Page 50

Pic.1

0

a

e

n

c

p

n

c

e

M

(

k

t

n

e

e

m

c

s

e

c

u

m

s

c

e

0

m

c

b

m

n

e

o

M

d

n

y

e

r

o

2

5

,

0

a

r

P

e

n

g

h

s

m

l

r

r

d

a

n

h

n

s

o

e

w

p

o

p

a

w

t

p

p

c

n

s

o

T

a

o

n

a

w

e

d

i

n

e

g

k

n

s

r

0

d

e

e

s

s

y

-

s

Pic.1

1 Side / M

02 Lamin

edia

tor

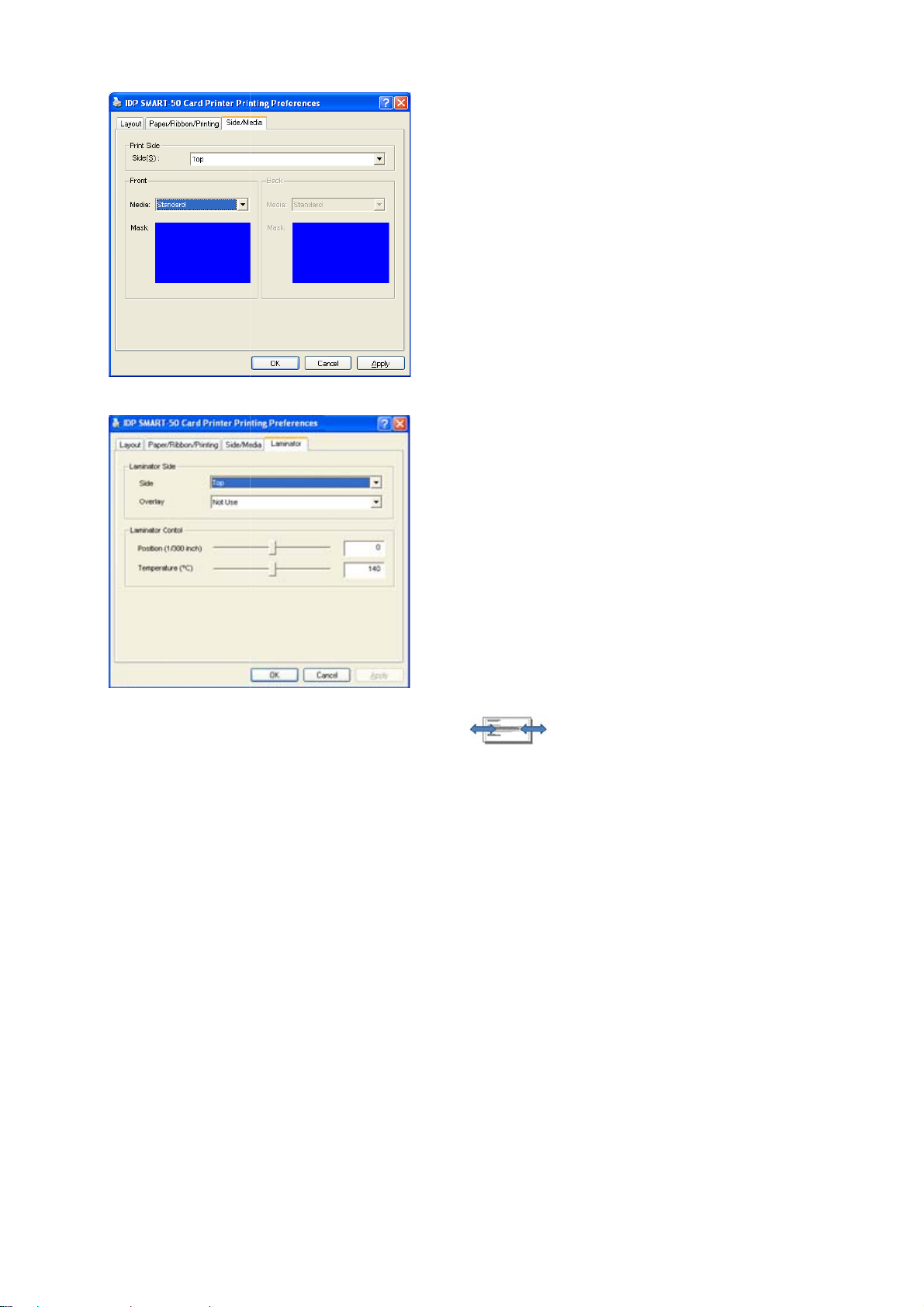

3.2.1

To s

- Pri

You

(It is

- Fro

You

(whit

front

You

can define

BIT

Blue

(RGB(0,0,2

Pink

Blac

3.2.1

This

is co

Print

To s

- La

You

both

- Ov

You

Defa

reco

- Po

.4. Side /

t printing si

t Side

an select o

ossible onl

t / Back

an use a pr

card, sma

r back side

AP file (101

RGB(255,0

(RGB(0,0,

.5. Lamin

ap will be c

nected to

r, this tap w

t Laminator

inator Sid

an select

ides printin

rlay

an select w

lt setting is

mend to us

ition

edia

e and printi

e side printi

when you

defined ma

tcard, Mag

.

a mask. U

X 636 pixe

5)): Print an

255)): Print

)): Print, Ov

tor

eated only

C. In the ca

ll be not dis

rinting opti

ot use, to

ether overl

no overlay

e the defaul

g mask.

ng or both

ave a flippe

sk or user d

etic stripe c

er defined

ls).

d Overlay

only

rlay and Fl

hen SMAR

se of norm

layed.

ns.

side, bott

y prints or

hen lamin

value.

ides printin

r.)

efined mas

ard, etc.) o

mask use

rescent

-50L printe

l SMART-5

m side an

ot.

ting and w

You

valu

1/30

an set Lami

s can be

inch.

nating start

et from -50

position of

to 50. Th

idth and th

number i

- Te

perature

You

can

- La

You

setti

Print

Enco

“Enc

an set La

e set from 1

inating On

can skip p

g a value in

r setup - P

ing and

ding and L

inating tem

00℃ to 180

y

inting and

int preferen

Laminating

minating O

erature an

℃.

do laminat

ces - Adva

- Set th

ly”

the value

ng only b

ced Setup

value a

50

Page 51

3.3. Other settings

3.3.1. Sharing

You can share a printer with Sharing tab via Network.

Default is “Not sharing”

Pic.103 Printer sharing

3.3.2. Ports

Port tab shows which port is connected with SMART-

50. SMART-50 has connection with USB Virtual

printer port as Pic.101 because SMART-50 uses USB

connected to PC.

(Caution! This port is selected automatically. It is

recommended to maintain default.)

Pic.104 Ports

51

Page 52

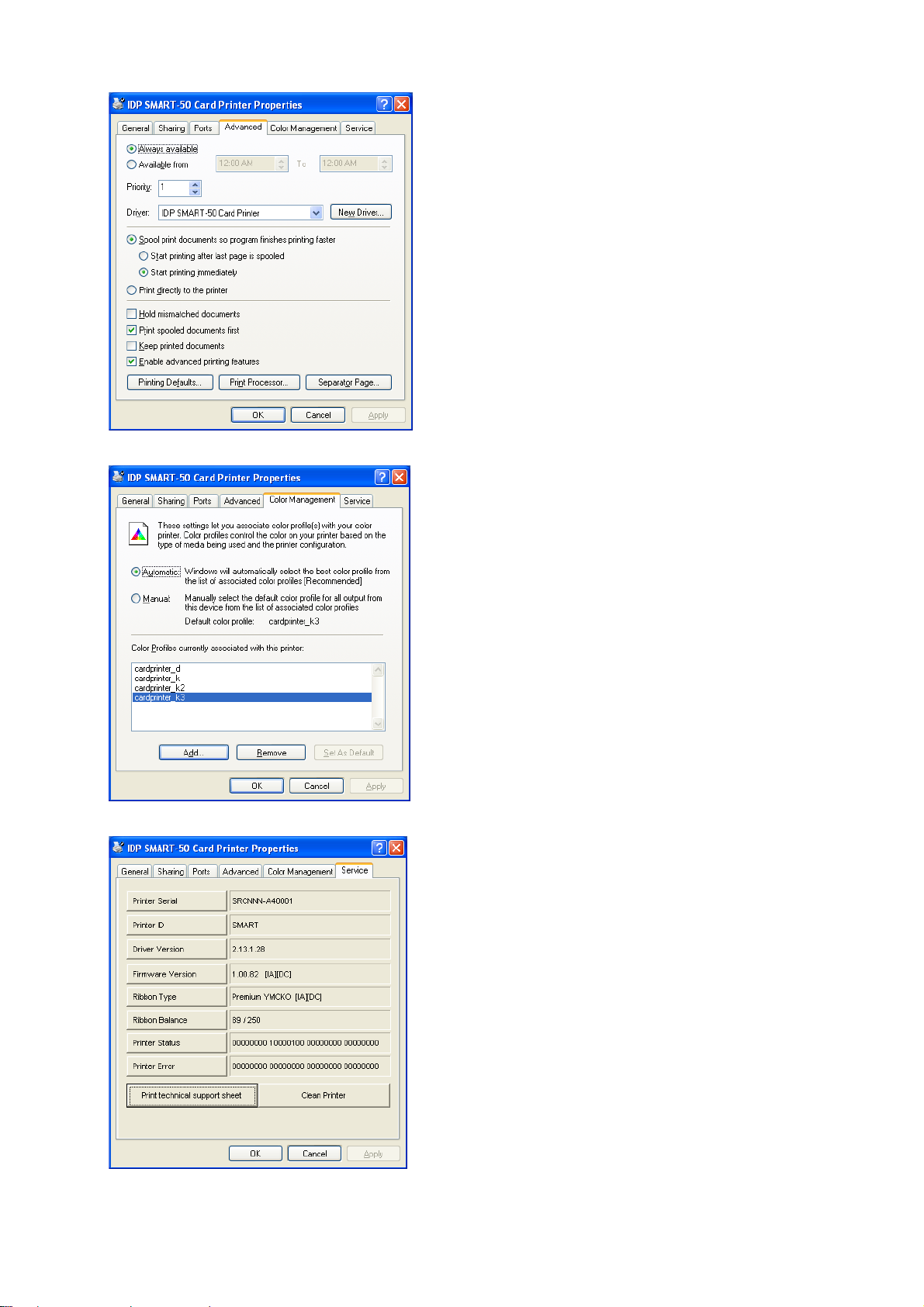

3.3.3. Advanced

r

f

It is available for Working Time setting, Priority order,

Spool print etc. in “Advanced” tab. “Advanced” setting

follows MS Windows standard. If you want to change

the setting, please refer to the Window manual.

(It is recommended to maintain default.)

Pic.105 Advanced

3.3.4. Color Management

In “Color management” tab, you can select colo

management profile fit to the printer.

SMART-50 uses color profile to express optimal color.

The driver selects color profile automatically to fit

each ribbon.

(It is recommended to maintain default.)

Pic.106 Color Management

3.3.5. Service

You can recognize printer serial, printer ID, driver

version, firmware version, type of ribbon & balance

and printer’s status.

You can print the “technical support sheet” on a card

to check printer’s setup value.

To clean printer, please insert a cleaning card in a

hopper and click “Clean Printer”. For further details,

please refer “6.1. Cleaning Printer”.

Please refer “4.2.6 Printer Status” for numbers o

“Printer Status” and “Printer error”

Pic.107 Service

52

Page 53

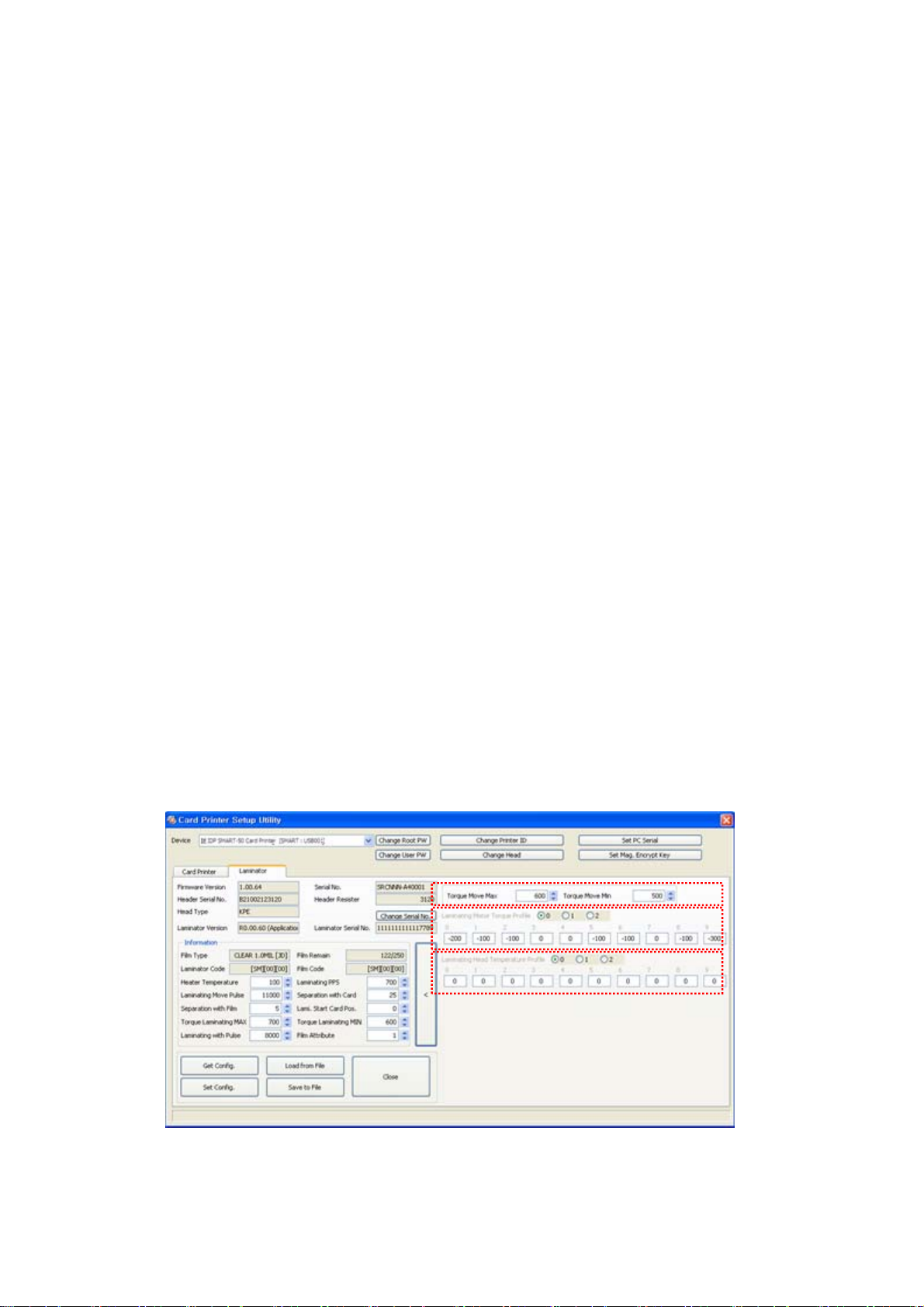

3.3.6. Laminator

r

This tap will be shown only when SMART-50L printer

is connected to PC. You can recognize laminato

film’s type, balance, laminator’s version, serial

number status.

Pic.108 Laminator

53

Page 54

4. Utilities

4.1. Card Printer Setup

SMART-50 is produced with optimized setting. You need to adjust setting value if required or spare parts

are replaced using CardPrinterSetup in our Installation CD. You can adjust following settings with

CardPrinterSetup.

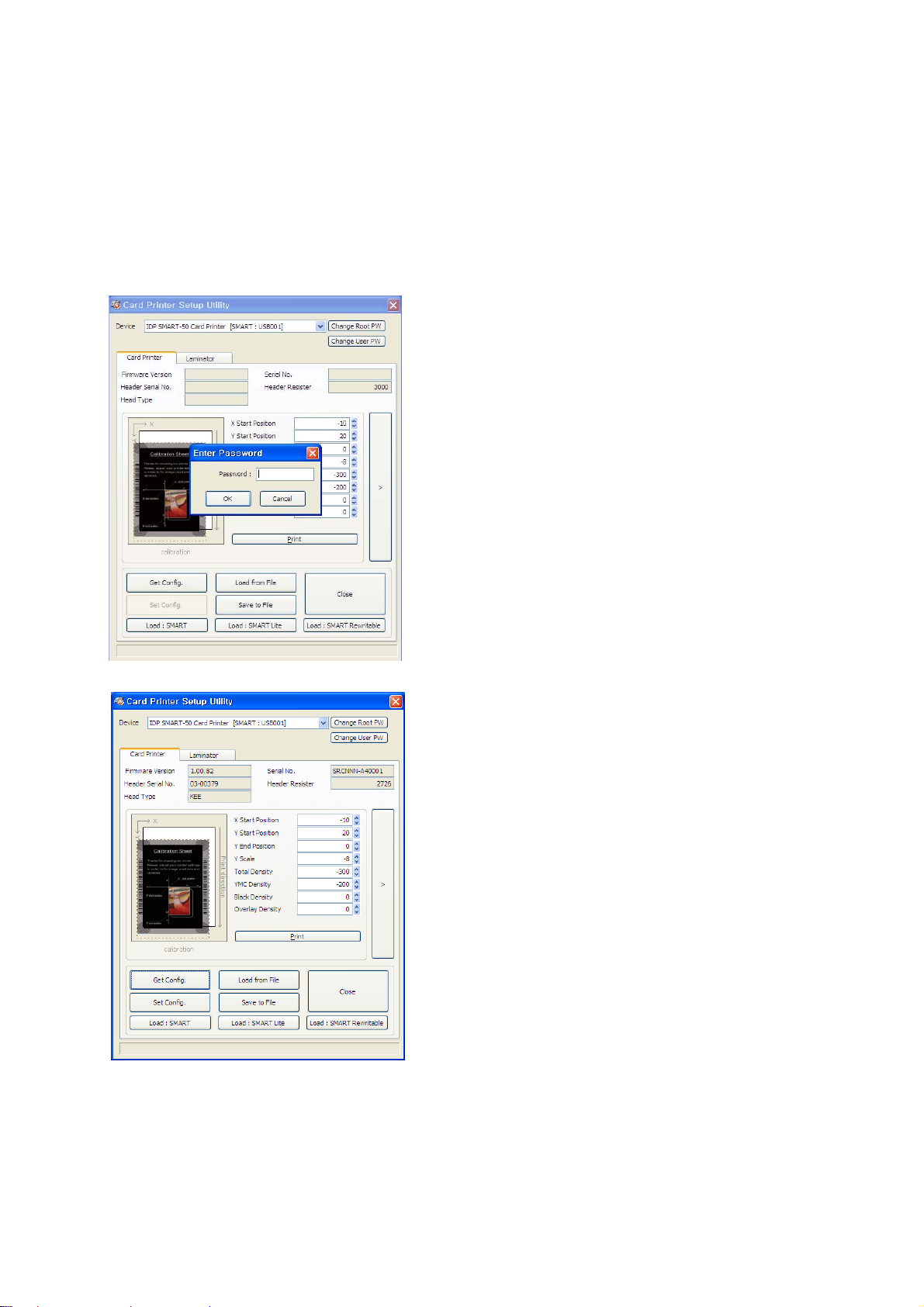

4.1.1. Run CardPrinterSetup

Password input window is displayed when you run

this program. If you input the correct password, the

recorded setup value will be shown and you can

change values. The password is saved to SMART-50

printer. If you use another PC with same printer,

previous password is required to run this program.

(Default password is none. Please press OK if you

have not set password.)

Pic.109 CardPrinterSetup Log-in

Pic.110 CardPrinterSetup start

When you are successful to log-in, you can set values

shown as Pic.107.

54

Page 55

4.1.2. Card Printer

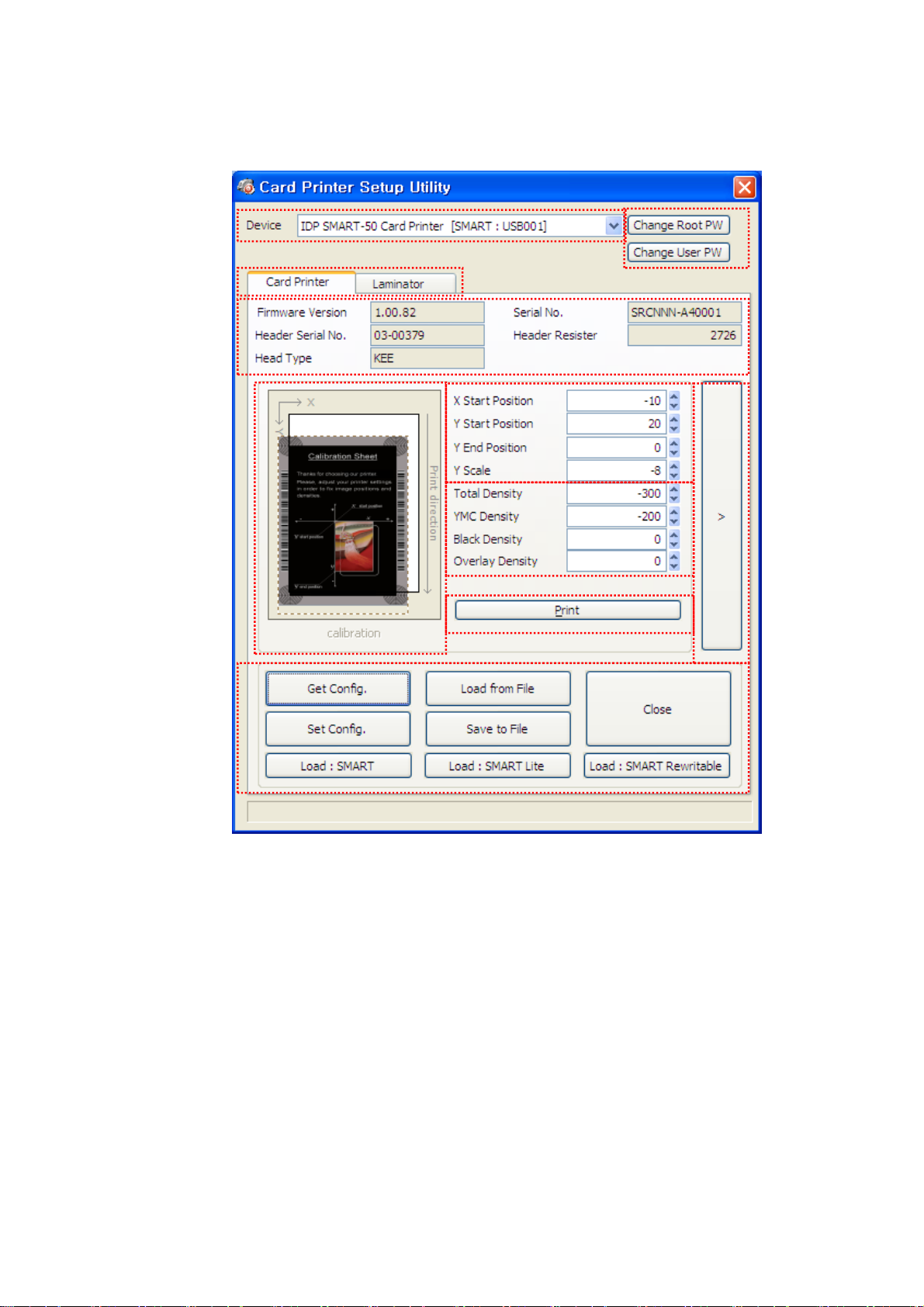

4.1.2.1. Basic Setup

①

③

④

②

⑤

⑥

⑦

⑧

⑩

⑨

Pic.111 CardPrinterSetup – Card Printer Basic Setup

① To show connected printers

Device: You can select a printer using pull-down menu. “IDP SMART-50 Card Printer” is a

name of printer. “SMART228” is printer ID, “USB001” is connected port.

② To set administrator password and user password.

Change Root PW: To set administrator (root) password. This password is used to verify

user authority for CardPrinterSetup and User Authentication. Also it is required for User

password management. (Please set password for security use.)

Change User PW: To set user password for User Authentication.

③ Click “Card Printer” tap.(If laminator is installed, you can setup laminator setting value by

“Laminator” tap.

④ To show firmware version, serial number o f printer and serial number, resistor & type of print

head.

⑤ To show print area. It shows

exaggeratingly for user convenience.

55

Page 56

⑥ To set print area. Please set it properly to print on an entire card because SMART-50 is a

direct thermal card printer. When you click “⑦ Print”, a card is printed as like “④ example”.

Please set values properly that all circles of each corner are printed and blank spaces are

0.4mm ~ 0.5mm in the top and the bottom of a card. Please set values by following order.

X Start Position: Please set right and left properly by adjusting X position.

Y Start Position: Please set the start position of printed example image and blank space in

the top is 0.4mm ~ 0.5mm.

Y End Position: Please set the end position of printed example image and blank space in

the bottom is 0.4mm ~ 0.5mm. It is recommended to set bigger value for “Y scale” than

default.

Y Scale: Please set to show circles in the bottom.

⑦ To set density. SMART-50 enables to set different density for each color, resin black and

overlay. So, please set each density for high quality. Please optimize the quality by

adjusting each value. To optimize, you repeatedly adjust the density and print a Calibration

card and check the print state until you get the optimum.

If your printer is SMART-30 R model, please do not install ribbon. You can set density

with Rewritable cards. Please adjust total density only.

Total Density: To set all of the density (Color, Black and Overlay) at one time.

If your printer is SMART-30 R model, when the density is too strong, you will have

darker background color. (Background color may vary depending on card type.)

When density is proper, texts and images are printed clearly and there is no

background color. When density is too low, texts and images are printed dull.

Pic.112 SMART-30 R density

YMC Density: To set color density. Please maximize YMC density as you can, which

enables to express range of color and vivid images. If it is too strong, green or red marks

are appeared. If it is too weak, the print quality will be dull. (Please refer Pic.109.)

56

Page 57

Pic.113 Color density

Black Density: To set resin black density. In Pic.111, barcode is printed to express density.

When density is too strong, barcode is printed too thick. When density is too weak, barcode

is too thin. Please adjust resin black density to express clear barcode. Please refer

following pictures.

Pic.114 Resin Black density

Overlay Density: To set overlay density. Please set it when overlay is printed on surface

regularly. If it is too strong, it is hazy and marks are appeared. If it is too weak, overlay panel

is not printed edge areas. You can check it with printed card under the light.

Pic.115 Overlay density

⑧ To print calibration card.

⑨ To show advanced Setup.

(It is recommended not to set advanced setup.)

⑩ To load or save values.

Get Config.: to get values from current printer

57

Page 58

Set Config. : to set values to current printer

Load from File: to load values from file

Save to File : to save values to file

Load Default : to load default. Please adjust values again after load default.

Close : to close CardPrinterSetup

58

Page 59

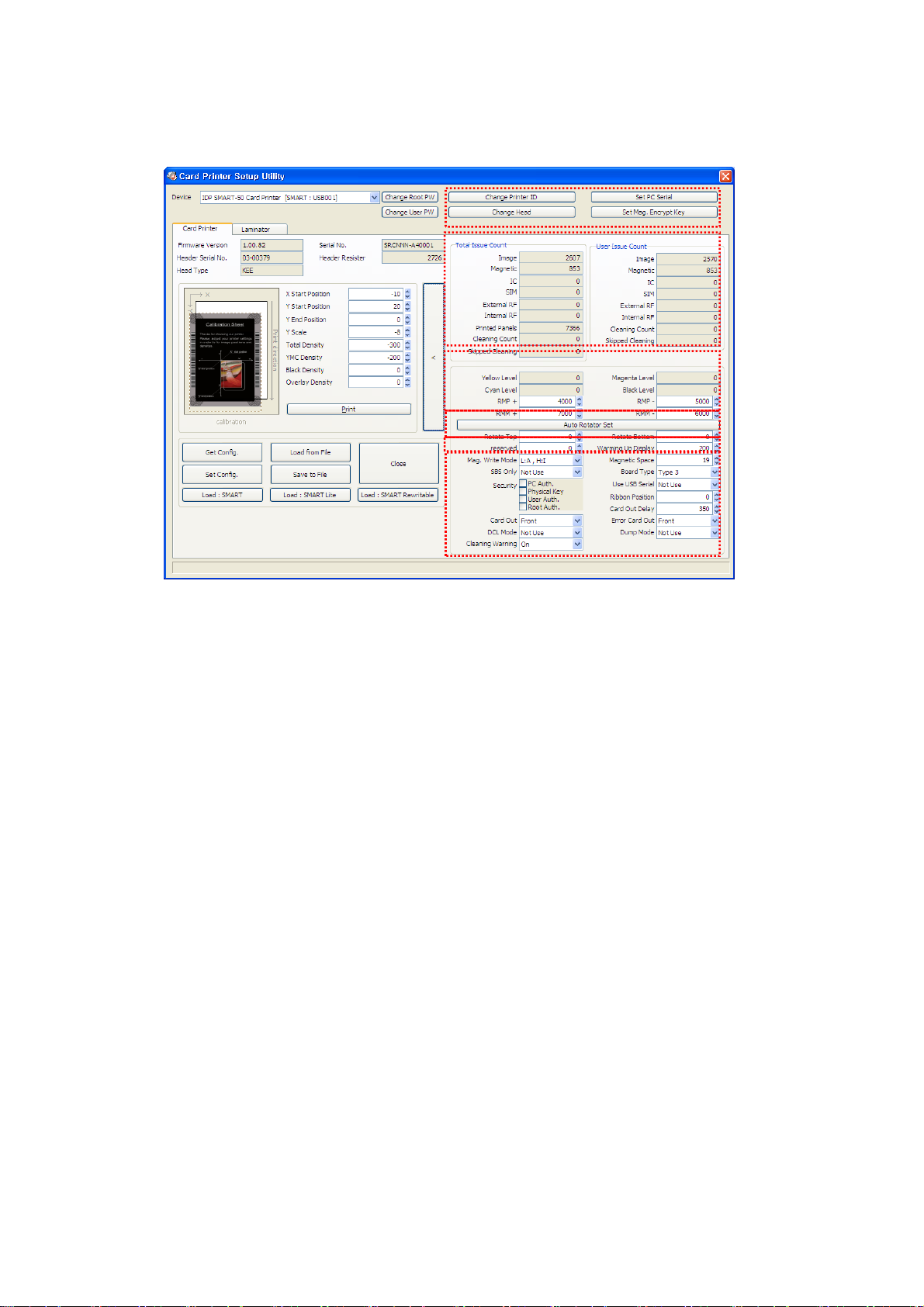

4.1.2.2. Advanced Setup

You can set more values.

①

②

③

④

⑥

① You can set Printer ID, PC serial, Print head and Magnetic encryption key.

Change Printer ID: When SMART-50 is used by SDK, you can set unique ID for SMART-50

printer regardless of whether it is connected by USB or what IP address is. It is useful to

connect and use several printers. Default is “SMART-50”.

Set PC Serial: One of security function. You can use a printer with specific PC.

It is activated when you click “Set PC Serial” after “PC Authentication” of ⑥ is ticked and

rebooted. At that time, the specific information of used PC is saved to SMART-50 printer.

Change Head: When you replace thermal print head, you must change head information for

optimal quality. Please change head serial number, resistor and type of head in the Change

Head Dialog window after click “Change Head”.

Set Mag. Encrypt Key: One of security function. When you use SDK, you can encrypt

magnetic stripe encoding data transmitted by USB. You can define and save the encryption key

to SMART -5 0 using “Set Mag. Encrypt Key”.

② To show how many cards are issued with SMART-50 printer. “Total Issue Count” is the number

of issued cards from factory shipment, “User Issue Count” is the number of issued cards from

replacing head. When you replace a head, please initialize the number by ticking “Reset User

Issue Count”.

③ To show color and motor management. SMART-50 recognizes ribbon color automatically and

controls motor by ribbon remaining. “Yellow Level”, “Magenta Level”, “Cyan Level”, “Black Level”

are default value for ribbon and user does not change values. “RMP+”, “RMP-“, “RMM+”, “RMM“ are necessary variables to control ribbon motor. Please do not change values for them as it

affects card quality.

④ SMART-50D is made by attaching a flipper in SMART-50, so you need to adjust it to be tuned in

the horizontal. “Rotate Top” is a value when the card of top side is in line. “Rotate Bottom” is a

value when card of bottom side is in line. Please click “Auto Rotator Set” when error is occurred

during a card moved to or from a flipper.

Pic.116 CardPrinterSetup – Card Printer Advanced Setup

⑤

59

Page 60

⑤ Please refer as below for other values.

Reserved: Not used

Warming Up Display: If you use SMART-30 R, LED buttons are blinked during print head is

warming up. You can adjust the timing of LED blinking by adjusting values of “Warming Up

Display”. It becomes faster as the value is smaller.

Mag. Write Mode: You can order the way how to encode magnetic stripe.

“L:A, H:I”: encodes 3 tracks at once for LoCo card and encodes at twice by dividing 1,3 and 2

track for HiCo cards.

Magnetic Space: The distance of magnetic stripe when you encode.

SBS Only: Please enable it when you issue cards with software programed by SDK. This option

disables printer device driver.

Board Type: to choose they type of mainboard. Please do not change it.

Security: There are several ways to set a security function for SMART-50.