Page 1

FC9Y-B644-04

FC4A SERIES

Micro Programmable

Logic Controller

FC4A-AS62M

AS-Interface Master Module

User’s Manual

Page 2

Warning

Warning notices are used to emphasize that improper operation may cause

severe personal injury or death.

Caution

Caution notices are used where inattention might cause personal injury or

damage to equipment.

SAFETY PRECAUTIONS

• Read this user’s manual to make sure of correct operation before starting installation, wiring, operation, maintenance, and

inspection of the MicroSmart AS-Interface master module.

• All MicroSmart AS-Interface master modules are manufactured under IDEC’s rigorous quality control system, but users

must add a backup or failsafe provision to the control system using the MicroSmart AS-Interface master module in applications where heavy damage or personal injury may be caused in case the MicroSmart AS-Interface master module should

fail.

• In this user’s manual, safety precautions are categorized in order of importance to Warning and Caution:

• Turn off the power to the MicroSmart before starting installation, removal, wiring, maintenance, and inspection of the

MicroSmart AS-Interface master module. Failure to turn power off may cause electrical shocks or fire hazard.

• Special expertise is required to install, wire, program, and operate the MicroSmart AS-Interface master module. People

without such expertise must not use the MicroSmart AS-Interface master module.

• Emergency stop and interlocking circuits must be configured outside the MicroSmart. If such a circuit is configured inside

the MicroSmart, failure of the MicroSmart may cause disorder of the control system, damage, or accidents.

• Install the MicroSmart AS-Interface master module according to the instructions described in this user’ s manual. Improper

installation will result in falling, failure, or malfunction of the MicroSmart AS-Interface master module.

• The MicroSmart AS-Interface master module is designed for installation in a cabinet. Do not install the MicroSmart AS-

Interface master module outside a cabinet.

• Install the MicroSmart AS-Interface master module in environments described in this user’s manual. If the MicroSmart

AS-Interface master module is used in places where the MicroSmart AS-Interface master module is subjected to high-temperature, high-humidity, condensation, corrosive gases, excessive vibrations, and excessive shocks, then electrical shocks,

fire hazard, or malfunction will result.

• The environment for using the MicroSmart AS-Interface master module is “Pollution degree 2.” Use the MicroSmart AS-

Interface master module in environments of pollution degree 2 (according to IEC 60664-1).

• Prevent the MicroSmart AS-Interface master module from falling while moving or transporting the MicroSmart AS-Inter-

face master module, otherwise damage or malfunction of the

• Prevent metal fragments and pieces of wire from dropping inside the MicroSmart AS-Interface master module housing.

Put a cover on the

chips may cause fire hazard, damage, or malfunction.

• Use a power supply of the rated value. Use of a wrong power supply may cause fire hazard.

• Use an IEC 60127-approved fuse on the power line outside the MicroSmart. This is required when equipment containing

MicroSmart is destined for Europe.

the

• Use an IEC 60127-approved fuse on the output circuit. This is required when equipment containing the MicroSmart is destined for Europe.

• Use an EU-approved circuit breaker. This is required when equipment containing the MicroSmart is destined for Europe.

• Make sure of safety before starting and stopping the MicroSmart or when operating the MicroSmart to force outputs on or

off. Incorrect operation on the MicroSmart may cause machine damage or accidents.

• Do not connect the ground wire directly to the MicroSmart. Connect a protective ground to the cabinet containing the

MicroSmart using an M4 or larger screw. This is required when equipment containing the MicroSmart is destined for

Europe.

• Do not disassemble, repair, or modify the MicroSmart modules.

• When disposing of the MicroSmart modules, do so as an industrial waste.

MicroSmart AS-Interface master module during installation and wiring. Ingress of such fragments and

MicroSmart AS-Interface master module will result.

MICROSMART AS-INTERFACE MASTER MODULE USER’S MANUAL PREFACE-1

Page 3

About This Manual

This user’s manual describes brief information about the AS-Interface and the entire functions, installation, and programming of the MicroSmart AS-Interface interface module.

Note: WindLDR Ver. 4.21 and higher are compatible with the AS-Inter face master module. This manual describes procedures

for using WindLDR Ver. 4.30.

CHAPTER 1: AS-INTERFACE

General information about of the Actuator-Sensor-Interface, abbreviated AS-Interface.

CHAPTER 2: MODULE SPECIFICATIONS

Specifications of the AS-Interface master module and applicable cables.

CHAPTER 3: INSTALLATION AND WIRING

Methods and precautions for installing and wiring the AS-Interface master module.

CHAPTER 4: OPERATION BASICS

General information about simple operating procedures for the basic AS-Interface system from programming WindLDR on

a computer to monitoring the slave operation.

CHAPTER 5: PUSHBUTTONS AND LED INDICATORS

Operation of pushbuttons PB1 and PB2 on the AS-Interface master module to change operation modes, and also the functions of address and I/O LED indicators.

CHAPTER 6: AS-INTERFACE OPERANDS

AS-Interface operands, or internal relays M1300 through M1997 and data registers D1700 through D1999, assigned in the

CPU module to control and monitor the AS-Interface bus. Provides detailed description about internal relays allocated to

SwitchNet™ control units for use as slaves in the AS-Interface network. Also describes ASI commands used to update ASInterface operands in the CPU module or to control the AS-Interface master module.

CHAPTER 7: USING WINDLDR

Procedures to use WindLDR ver. 4.30 for the AS-Interface system.

INDEX

Alphabetical listing of key words.

TM

SwitchNet is an IDEC trademark for pushbuttons, pilot lights, and other control units

capable of direct connection to the AS-Interface. SwitchNet devices are completely

compatible with AS-Interface Ver. 2.1.

Note: In this manual, “ASI” is shor t for “AS-Inter face” and is not intended to represent any par ticular product.

IMPORTANT INFORMATION

Under no circumstances shall IDEC IZUMI Corporation be held liable or responsible for indirect or consequential damages

resulting from the use of or the application of IDEC PLC components, individually or in combination with other equipment.

All persons using these components must be willing to accept responsibility for choosing the correct component to suit their

application and for choosing an application appropriate for the component, individually or in combination with other equipment.

All diagrams and examples in this manual are for illustrative purposes only. In no way does including these diagrams and examples in this manual constitute a guarantee as to their suitability for any specific application. To test and approve all programs,

prior to installation, is the responsibility of the end user.

PREFACE-2 MICROSMART AS-INTERFACE MASTER MODULE USER’S MANUAL

Page 4

TABLE OF CONTENTS

HAPTER 1: AS-INTERFACE

C

Applicable Sensors and Actuators for AS-Interface . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

AS-Interface System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Main Features of AS-Interface V2 with Slave Expansion Capability . . . . . . . . . . . . . . 1-3

Slave Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Slave Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Quantities of Slaves and I/O Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

AS-Interface Bus Topology and Maximum Length . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

AS-Interface Bus Cycle Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

High Reliability and Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

HAPTER 2: MODULE SPECIFICATIONS

C

Parts Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Applicable Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

HAPTER 3: INSTALLATION AND WIRING

C

Installation Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Assembling Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Disassembling Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Mounting on DIN Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Removing from DIN Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Direct Mounting on Panel Surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Terminal Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

AS-Interface Cable Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

HAPTER 4: OPERATION BASICS

C

AS-Interface System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Selecting the PLC Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Function Area Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Assigning a Slave Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Configuring a Slave . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Monitoring Digital I/O, and Changing Output Status and Parameters . . . . . . . . . . . . 4-6

Troubles at System Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

HAPTER 5: PUSHBUTTONS AND LED INDICATORS

C

Pushbutton Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Transition of AS-Interface Master Module Modes Using Pushbuttons . . . . . . . . . . . . 5-1

AS-Interface Master Module Operation Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Address LEDs and I/O LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

MICROSMART AS-INTERFACE MASTER MODULE USER’S MANUAL i

Page 5

TABLE OF CONTENTS

HAPTER 6: AS-INTERFACE OPERANDS

C

AS-Interface Operand Allocation Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

I/O Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Status Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Slave List Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Slave Identification Information (Slave Profile) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

SwitchNet Data I/O Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Internal Relays for SwitchNet Slaves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

ASI Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

HAPTER 7: USING WINDLDR

C

Configure AS-Interface Master . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Change Slave Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Monitor AS-Interface Slave . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

NDEX

I

ii MICROSMART AS-INTERFACE MASTER MODULE USER’S MANUAL

Page 6

1: AS-INTERFACE

Introduction

This chapter describes general information about the Actuator-Sensor-Interface, abbreviated AS-Interface.

AS-Interface is a type of field bus that is primarily intended to be used to control sensors and actuators. AS-Interface is a

network system that is compatible with the IEC62026 standard and is not proprietary to any one manufacturer. A master

device can communicate with slave devices such as sensors, actuators, and remote I/Os, using digital and analog signals

transmitted over the AS-Interface bus.

The AS-Interface system is comprised of the following three major components:

• One master, such as the MicroSmart AS-Interface master module (FC4A-AS62M)

• One or more slave devices, such as sensors, actuators, switches, and indicators

• Dedicated 30V DC AS-Interface power supply (26.5 to 31.6V DC)

These components are connected using a two-core cable for both data transmission and AS-Interface power supply. ASInterface employs a simple yet efficient wiring system and features automatic slave address assignment function, while

installation and maintenance are also very easy.

Applicable Sensors and Actuators for AS-Interface

AS-Interface Compatible Sensors and Actuators

AS-Interface compatible sensors and actuators communicate using the built-in AS-Interface function, and serve as ASInterface slaves when connected directly to the AS-Interface bus via a branch unit or a T-junction unit.

Sensors/Actuators Not Compatible with AS-Interface

Conventional sensors and actuators that are not compatible with the AS-Interface can also be connected to the AS-Interface bus using a remote I/O slave and be handled in the same way as devices that are compatible with the AS-Interface.

T-junction Unit

AS-Interface Bus

AS-Interface Compatible Sensors/Actuators

•••• 62 slaves maximum

•••• 434 I/O points maximum (248 inputs and 186 outputs)

•••• Maximum Communication Distance

Without repeater: 100m

With 2 repeaters: 300m

Remote I/O Type SlaveBranch Unit

AS-Interface Non-compatible

Sensors/Actuators

MICROSMART AS-INTERFACE MASTER MODULE USER’S MANUAL 1-1

Page 7

1: AS-INTERFACE

AS-Interface System Requirements

Master

The AS-Interface master controls and monitors the status of slave devices connected to the AS-Interface bus.

Normally, the AS-Interface master is connected to a PLC (sometimes called ‘host’) or a gateway. For example, the

AS-Interface master module is connected to the MicroSmart CPU module.

Smart

Micro-

Slim Type CPU Module

MicroSmart

FC4A-D20RK1

FC4A-D20RS1

FC4A-D40K3

FC4A-D40S3

AS-Interface Master Module

FC4A-AS62M

Slaves

Various types of slave devices can be connected to the AS-Interface bus, including sensors, actuators, and remote I/O

devices. Analog slaves can also be connected to process analog data.

Slaves are available in standard slaves and A/B slaves. Standard slaves have an address of 1 trough 31 in the standard

address range. A/B slaves have an address of 1A through 31A in the standard address range or 1B through 31B in the

expanded address range. Among the A/B slaves, slaves with an address of 1A through 31A are called A slaves, and slaves

with an address of 1B through 31B are called B slaves.

AS-Interface Power Supply

The AS-Interface bus uses a dedicated 30V DC power supply (AS-Interface power

supply), which is indicated with the AS-Interface mark. General-purpose power supply units cannot be used for the AS-Interface bus.

Caution

• Use a VLSV (very low safety voltage) to power the AS-Interface bus.

The normal output voltage of the AS-Interf ace po wer supply is 30V DC.

AS-Interface Marks

Cables

The AS-Interface bus uses only one cable to transmit signals and power. Use one of the following cable types (the wire

does not have to be stranded).

• Standard yellow unshielded AS-Interface cable (with polarity)

• Ordinary two-wire flat cable

AS-Interface Cable Two-wire Flat Cable

1-2 MICROSMART AS-INTERFACE MASTER MODULE USER’S MANUAL

Page 8

1: AS-INTERFACE

Main Features of AS-Interface V2 with Slave Expansion Capability

The AS-Interface is a reliable bus management system in which one master periodically monitors each slave device connected on the AS-Interface b us in sequence. The master manages the I/O data, parameters, and identification codes of each

slave in addition to slave addresses. The management data depends on the type of the slave as follows:

Standard Slaves

• A maximum of four inputs and four outputs for each slave

• Four parameters for setting a slave’s operation mode (P3, P2, P1, P0)

• Four identification codes (ID code, I/O code, ID2 code, and ID1 code)

A/B Slaves

• A maximum of four inputs and three outputs for each slave

• Three parameters for setting a slave’s operation mode (P2, P1, P0)

• Four identification codes (ID code, I/O code, ID2 code, and ID1 code)

Note 1: Parameters P3 through P0 are used to set an operation mode of the slave. For details, see the user’s manual for

the slave.

Note 2: The slaves connected to the AS-Interface bus are distinguished from each other by the ID code and I/O code contained in each slave. Some slaves have ID2 code and ID1 code to indicate the internal functions of the slave. For example,

analog slaves use the ID2 code to represent the channel number of the slave.

Note 3: The MicroSmart AS-Interface master module is also compatible with AS-Interface ver. 2.1 and earlier slaves.

Slave Addresses

Each standard slave connected to the AS-Interface bus can be allocated an address of 1 through 31. Each A/B slave can be

allocated an address of 1A through 31A or 1B through 31B. All sla ves are set to address 0 at factory before shipment. The

address of a slave can be changed using the “addressing tool.” Using WindLDR, the addresses of slaves connected to the

AS-Interface master module can be changed (see page 7-1).

When a slave fails during operation and needs to be replaced, if the auto addressing function is enabled on the master module, just replace the slave with a new one (with address 0 and the same identification codes). The new slave will automatically be allocated the same address as the slave that was remov ed, and you do not ha v e to set the address again. F or details

of the ASI command to enable auto addressing, see page 6-17.

Slave Identification

Slaves have the following four identification codes. The master checks the identification codes to determine the type and

feature of the slave connected on the AS-Interface bus.

ID Code

The ID code consists of 4 bits to indicate the type of the slave, such as sensor, actuator, standard slave, or A/B slave. For

example, the ID code for a standard remote I/O is 0, and that for an A/B slave is A (hex).

I/O Code

The I/O code consists of 4 bits to indicate the quantity and allocation of I/O points on a slave.

I/O Code Allocation I/O Code Allocation I/O Code Allocation I/O Code Allocation

0h I, I, I, I 4h I, I, B, B 8h O, O, O, O Ch O, O, B, B

1h I, I, I, O 5h I, O, O, O 9h O, O, O, I Dh O, I, I, I

2h I, I, I, B 6h I, B, B, B Ah O, O, O, B Eh O, B, B, B

3h I, I, O, O 7h B, B, B, B Bh O, O, I, I Fh (reser ved)

I: input, O: output, B: input and output

ID2 Code

The ID2 code consists of 4 bits to indicate the internal function of the slave.

ID1 Code

The ID1 code consists of 4 bits to indicate additional identification of the slave. Standard slaves can have an ID1 code of

0000 through 1111 (bin). A/B sla ves use the MSB to indicate A or B slave, and can have a unique value only for the lower

three bits. The MSB of A slaves is set to 0, and that of B slaves is set to 1.

MICROSMART AS-INTERFACE MASTER MODULE USER’S MANUAL 1-3

Page 9

1: AS-INTERFACE

Quantities of Slaves and I/O Points

The quantity of slaves that can be connected to one AS-Interface bus is as follows.

• Standard slaves: 31 maximum

• A/B slaves: 62 maximum

The limits for slave quantities given above apply when the slaves are either all standard slaves or are all A/B slaves.

When 62 A/B sla v es (with four inputs and three outputs) are connected, a maximum of 434 I/O points (248 inputs and 186

outputs) can be controlled over the bus.

When using a mix of standard slaves and A/B slaves together, the standard slaves can only use addresses 1(A) through

31(A). Also, when a standard slave takes a certain address, the B address of the same number cannot be used for A/B

slaves.

AS-Interface Bus Topology and Maximum Length

The AS-Interface bus topology is flexible, and you can wire the bus freely according to your requirements.

When repeaters or extenders are not used, the bus length can be 100m (328 feet) at the maximum.

AS-Interface Bus Cycle Time

The AS-Interface bus cycle time is the amount of time required for a master to cycle through every slave on the bus.

The information for each slave is continuously transmitted over the bus in sequence, so the AS-Interface bus cycle time

depends on the quantity of active slaves.

• When up to 19 slaves are active, the bus cycle time is 3 msec.

• When 20 to 31 slaves are active, the bus cycle time is 0.156 × (1+N) msec where N is the number of slaves.

When A slave and B slave have the same address number (e.g. 12A and 12B), the two slaves are alternately updated each

cycle. Therefore, when the system consists of 31 A slaves and 31 B sla v es, then the AS-Interface b us c ycle time will be 10

msec.

Maximum AS-Interface Bus Cycle Time

• When 31 slaves are connected, the maximum bus cycle time is 5 msec.

• When 62 slaves are connected, the maximum bus cycle time is 10 msec.

High Reliability and Security

The AS-Interface employs a transfer process of high reliability and high security. The master monitors the AS-Interface

power supply voltage and data transmitted on the bus, and detects slave failures and data errors.

Even when a slave is replaced or a new slave is added during operation, the AS-Interface master module need not be shut

down and can continue uninterrupted communication with other active slaves on the bus.

1-4 MICROSMART AS-INTERFACE MASTER MODULE USER’S MANUAL

Page 10

2: MODULE SPECIFICATIONS

Introduction

This chapter describes specifications of the MicroSmart AS-Interface master module and applicable cables.

AS-Interface Master Module Type Number

Module Name Type No.

AS-Interface Master Module FC4A-AS62M

The AS-Interface master module can connect a maximum of 62 digital I/O slaves. A maximum of seven analog I/O sla ves

can also be connected to the AS-Interface master module (compliant with AS-Interface ver. 2.1 and analog slave profile

7.3).

The AS-Interface master module can be used with the 20-I/O relay output slim type CPU modules (FC4A-D20RK1 and

FC4A-D20RS1) and the 40-I/O slim type CPU modules (FC4A-D40K3 and FC4A-D40S3). Use a CPU module version of

201 or higher. When using WindLDR, use ver. 4.21 or higher.

Caution

• The AS-Interface master module cannot be used with the all-in-one type CPU modules and the

20-I/O transistor output slim type CPU modules.

• Only one AS-Interface master module can be connected to the slim type CPU module. If more

than one AS-Interface master module is connected, an error occurs and special data register

D8037 (quantity of expansion I/O modules) stores error code 40 (hex).

• Normally, a maximum of seven expansion I/O modules can be connected to the slim type CPU

module. But when the AS-Interface master module is connected, only a total of six expansion

modules can be connected, including the AS-Interface master module. Do not connect more than

six expansion modules due to the amount of heat generated. If more than six expansion modules,

including the AS-Interface master module, are connected, an error occurs and special data register D8037 (quantity of expansion I/O modules) stores error code 20 (hex).

• The AS-Interface master module can connect a maximum of se v en analog I/O sla ves. When more

than seven analog I/O slaves are connected, the AS-Interface system will not operate correctly.

MICROSMART AS-INTERFACE MASTER MODULE USER’S MANUAL 2-1

Page 11

2: MODULE SPECIFICATIONS

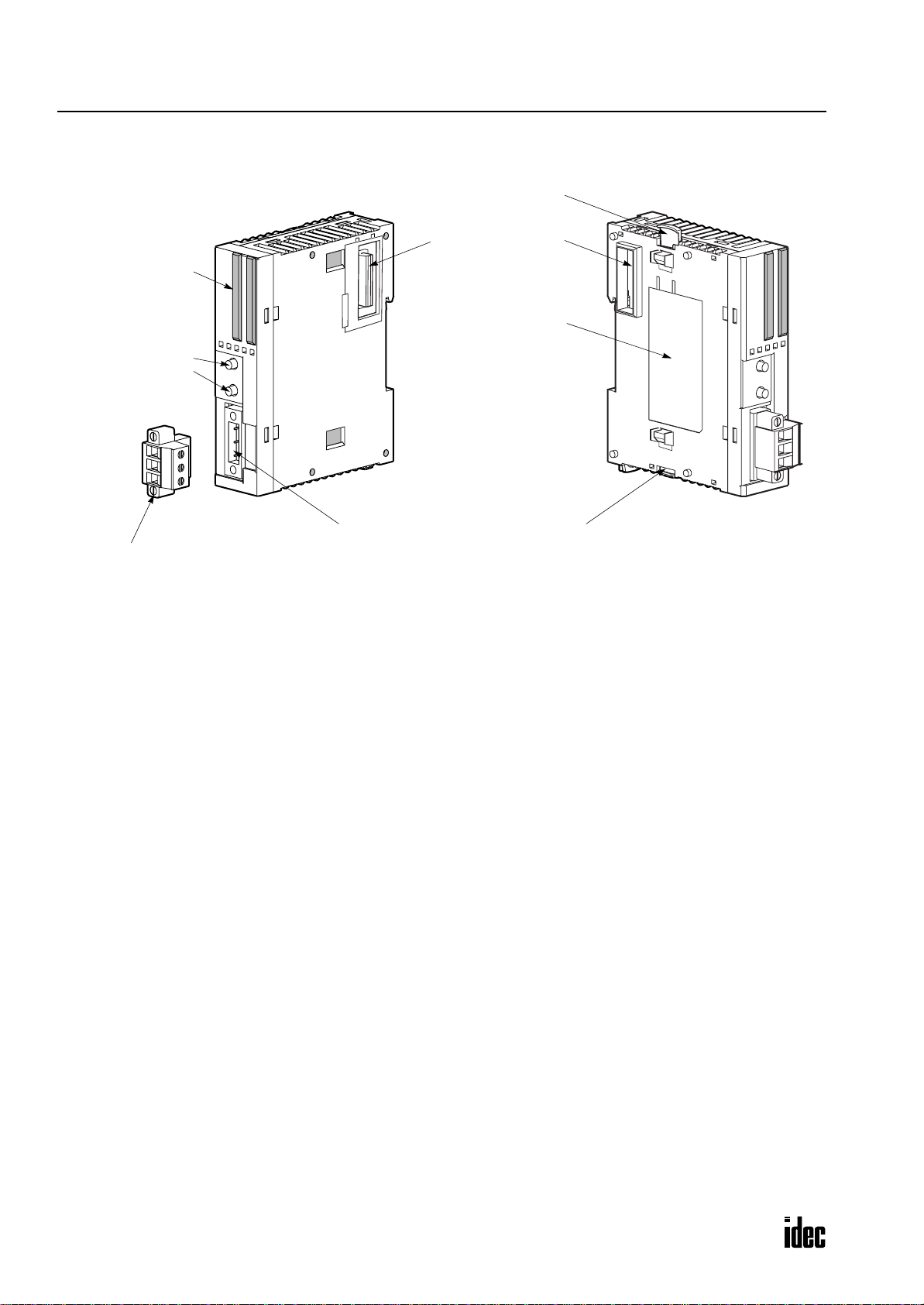

Parts Description

(1) LED Indicators

(2) Pushbuttons

PB1

PB2

(5) Unlatch Button

(6) Expansion Connector

(7) Module Label

(4) AS-Interface Cable Connector

(3) AS-Interface Cable Terminal Block

(supplied with the AS-Interface master module)

(5) Unlatch Button

(1) LED Indicators Status LEDs: Indicate the AS-Interface bus status.

I/O LEDs: Indicate the I/O status of the slave specified by the address LEDs.

Address LEDs: Indicate slave addresses.

(2) Pushbuttons Used to select slave addresses, change modes, and store configuration.

(3) AS-Interface Cable Terminal Block

Connects the AS-Interface cable.

One terminal block is supplied with the AS-Interface master module.

When ordering separately, specify Type No. FC4A-PMT3P and quantity

(package quantity: 2).

(4) AS-Interface Cable Connector

Installs the AS-Interface cable terminal block.

(5) Unlatch Button Used to unlatch the AS-Interface master module from the CPU or I/O module.

(6) Expansion Connector Connects to the CPU and other I/O modules.

(Applicable CPU modules are 20-I/O relay output and 40-I/O slim types.)

(7) Module Label Indicates the AS-Interface master module Type No. and specifications.

2-2 MICROSMART AS-INTERFACE MASTER MODULE USER’S MANUAL

Page 12

2: MODULE SPECIFICATIONS

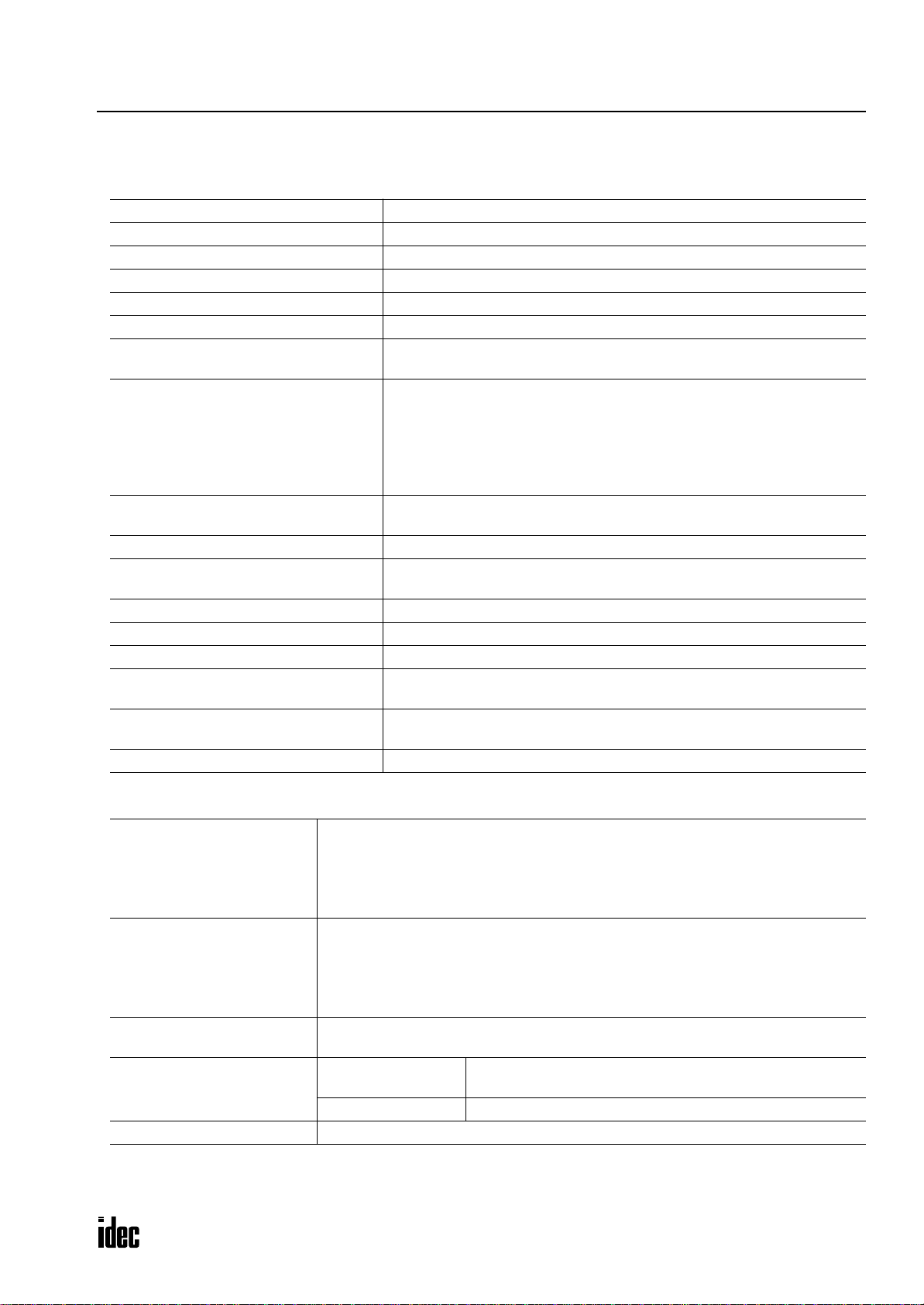

Specifications

General Specifications

Operating Temperature 0 to 55°C (operating ambient temperature, no freezing)

Storage Temperature –25 to +70°C (no freezing)

Relative Humidity Level RH1, 30 to 95% (non-condensing)

Pollution Degree 2 (IEC 60664)

Degree of Protection IP20

Corrosion Immunity Free from corrosive gases

Altitude

Vibration Resistance

Shock Resistance

External Power Supply AS-Interface power supply, 29.5 to 31.6V DC

AS-Interface Current Draw

Effect of Improper Input Connection No damage

Connector on Mother Board MSTB2.5/3-GF-5.08BK (Phoenix Contact)

Connector Insertion/Removal Durability 100 times minimum

Internal Current Draw

AS-Interface Master Module

Power Consumption

Weight 85g

Operation: 0 to 2,000m (0 to 6,565 feet)

Transport: 0 to 3,000m (0 to 9,840 feet)

When mounted on a DIN rail:

10 to 57 Hz amplitude 0.075 mm, 57 to 150 Hz acceleration 9.8 m/s

2 hours per axis on each of three mutually perpendicular axes

When mounted on a panel surface:

2 to 25 Hz amplitude 1.6 mm, 25 to 100 Hz acceleration 39.2 m/s

90 minutes per axis on each of three mutually perpendicular axes

2

147 m/s

dicular axes (IEC 61131)

65 mA (normal operation)

110 mA maximum

80 mA (5V DC)

0 mA (24V DC)

540 mW (24V DC)

, 11 msec duration, 3 shocks per axis, on three mutually perpen-

2

2

Communication Specifications

When 1 through 19 slaves are connected: 3 msec

When 20 through 62 slaves are connected: 0.156 × (1 + N) msec

Maximum Bus Cycle

Maximum Slaves

Maximum I/O Points

Maximum Cable Length

Rated Bus Voltage 30V DC

where N is the number of active slaves

5 msec maximum when 31 standard or A/B slaves are connected

10 msec maximum when 62 A/B slaves are connected

Standard slaves: 31

A/B slaves: 62

When using a mix of standard slaves and A/B slaves together, the standard slaves can

only use addresses 1(A) through 31(A). Also, when a standard slave takes a cer tain

address, the B address of the same number cannot be used for A/B slaves.

Standard slaves: 248 total (124 inputs + 124 outputs)

A/B slaves: 434 total (248 inputs + 186 outputs)

AS-Interface Cable

2-wire Flat Cable

Single Wires 200 mm

MICROSMART AS-INTERFACE MASTER MODULE USER’S MANUAL 2-3

When using no repeater or extender: 100m

When using a total of 2 repeaters or extenders: 300m

Page 13

2: MODULE SPECIFICATIONS

Applicable Cables

The AS-Interface cable transfers data and supplies power to the sensors and actuators connected to the bus. The following

cables can be used with the AS-Interface master module.

Applicable Cable Specifications

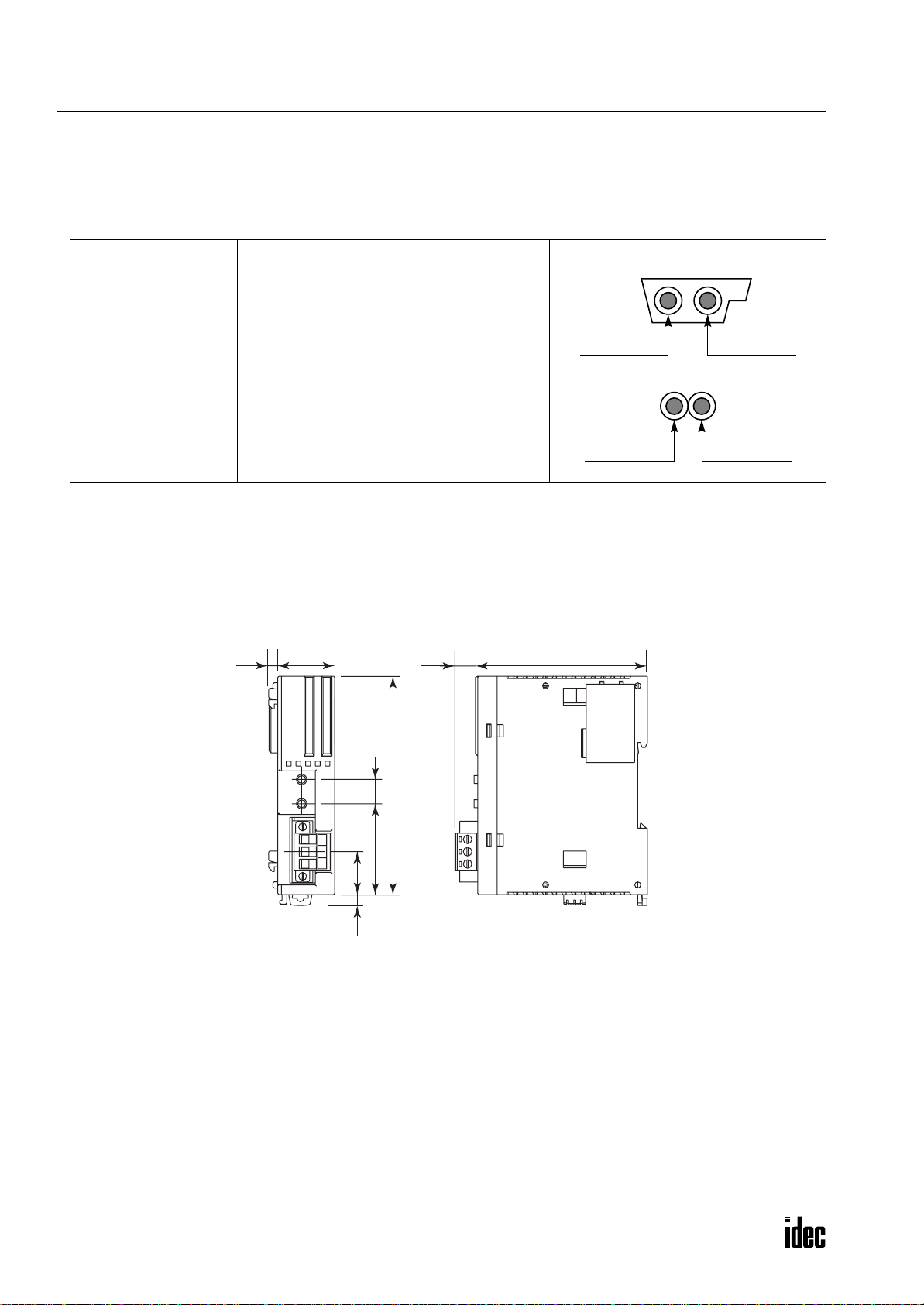

Cable Type Cable Size/Manufacturer Cross-sectional View

Cable sheath color: Yellow

Conductor cross section: 1.5 mm

2

AS-Interface

Standard Cable

2-wire Flat Cable

or

Single Wires

(See Note)

LAPP’s Cables

Type No: 2170228 (sheath material EPDM)

Type No: 2170230 (sheath material TPE)

Conductor cross section

Stranded wire: 0.5 to 1.0 mm

Solid wire: 0.75 to 1.5 mm

2

2

AWG: 20 to 16

AS-Interface – AS-Interface +

(blue) (brown)

AS-Interface – AS-Interface +

(blue) (brown)

Note: When using single wires, the maximum cable length is 200 mm. See “Maximum Cable Length” on page 2-3.

Dimensions

The AS-Interface master module has the same profile as all other MicroSmart modules for consistent mounting on a DIN

rail.

3.8

23.5

9.4 70.0

90.0

10

37.5

17.7

*8.5 mm when the clamp is pulled out.

4.5*

All dimensions in mm.

2-4 MICROSMART AS-INTERFACE MASTER MODULE USER’S MANUAL

Page 14

3: INSTALLATION AND WIRING

Introduction

This chapter describes the methods and precautions for installing and wiring the AS-Interface master module.

Before starting installation and wiring, be sure to read “Safety Precautions” in the beginning of this manual and under-

stand precautions described under Warning and Caution.

Warning

Caution

• Turn off the power to the AS-Interface master module before starting installation, removal, wiring, maintenance, and inspection of the AS-Interface master module. Failure to turn power off

may cause electrical shocks or fire hazard.

• Emergency stop and interlocking circuits must be configured outside the

circuit is configured inside the MicroSmart, failure of the MicroSmart may cause disorder of the

control system, damage, or accidents.

• Special expertise is required to install, wire, program, and operate the MicroSmart. People with-

out such expertise must not use the MicroSmart.

• Prevent metal fragments and pieces of wire from dropping inside the MicroSmart housing. Put a

cover on the MicroSmart modules during installation and wiring. Ingress of such fragments and

chips may cause fire hazard, damage, or malfunction.

• Do not touch the connector pins with hand, otherwise electrostatic discharge may damage the

internal elements.

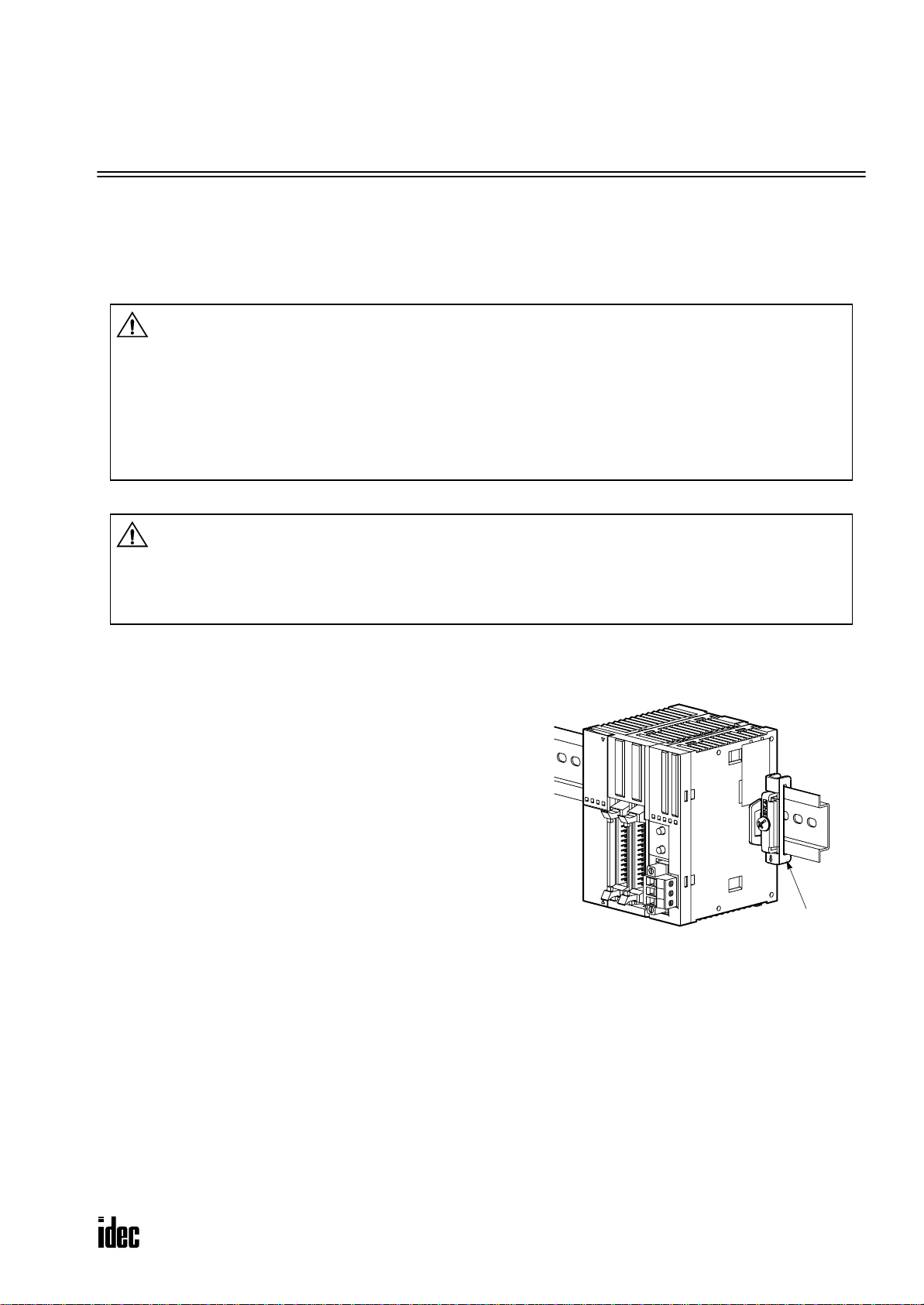

Installation Location

The MicroSmart modules must be installed correctly for optimum

performance.

The MicroSmart is designed for installation in a cabinet. Do not

install the MicroSmart outside a cabinet.

The environment for using the

Use the MicroSmart in environments of pollution degree 2 (according to IEC 60664-1).

Make sure that the operating temperature does not drop below 0°C

or exceed 55°C. If the temperature does exceed 55°C, use a fan or

cooler.

Mount the

To eliminate excessive temperature build-up, provide ample venti-

lation. Do not install the MicroSmart near, and especially above,

any device which generates considerable heat, such as a heater,

transformer, or large-capacity resistor. The relati ve humidity should

be above 30% and below 95%.

The

direct sunlight, vibrations, or shocks. Do not use the MicroSmart in

an area where corrosive chemicals or flammable gases are present.

The modules should not be exposed to chemical, oil, or water

splashes.

MicroSmart on a vertical plane as shown at right.

MicroSmart should not be exposed to excessi v e dust, dirt, salt,

MicroSmart is “Pollution degree 2.”

MicroSmart. If such a

Mounting Clip

BNL6P

MICROSMART AS-INTERFACE MASTER MODULE USER’S MANUAL 3-1

Page 15

3: INSTALLATION AND WIRING

Assembling Modules

Caution

The following example demonstrates the procedure for assembling the 40-I/O type CPU module and the AS-Interface

master module together. When assembling the 20-I/O relay output type CPU module, take the same procedure.

1. When assembling an AS-Interface master mod-

ule, remove the expansion connector seal from

the 40-I/O type CPU module.

2. Place the CPU module and AS-Interface master module

side by side. Put the expansion connectors together for easy

alignment.

• Assemble MicroSmart modules together before mounting the modules onto a DIN rail. Attempt

to assemble modules on a DIN rail may cause damage to the modules.

• Turn off the power to the MicroSmart before assembling the modules. Failure to turn power off

may cause electrical shocks.

3. With the expansion connectors aligned correctly and the

blue unlatch button in the down position, press the CPU

module and AS-Interface master module together until the

latches click to attach the modules together firmly. If the

unlatch button is in the up position, push down the button to

engage the latches.

Note: When assembling other I/O modules with the AS-Interface

master module, take the same procedure.

Disassembling Modules

Caution

1. If the modules are mounted on a DIN rail, first remove the

modules from the DIN rail as described on page 3-3.

2. Push up the blue unlatch button to disengage the latches,

and pull the modules apart as shown.

Note: When disassembling other I/O modules from the AS-Interface master module, take the same procedure.

• Remove the MicroSmart modules from the DIN rail before disassembling the modules. Attempt

to disassemble modules on a DIN rail may cause damage to the modules.

• Turn off the power to the MicroSmart before disassembling the modules. Failure to turn power

off may cause electrical shocks.

Unlatch Button

Unlatch Button

3-2 MICROSMART AS-INTERFACE MASTER MODULE USER’S MANUAL

Page 16

Mounting on DIN Rail

35-mm-wide DIN Rail

Clamp

(A)

(B)

Direct Mounting Strip

FC4A-PSP1P

3: INSTALLATION AND WIRING

Caution

• Install the MicroSmart modules according to instructions described in this user’s manual.

Improper installation will result in falling, failure, or malfunction of the MicroSmart.

• Mount the MicroSmart modules on a 35-mm-wide DIN rail or a panel surface.

Applicable DIN rail: IDEC’s BAA1000NP or BAP1000NP (1000mm/39.4” long)

1. Fasten the DIN rail to a panel using screws firmly.

2. Pull out the clamp from each MicroSmart module,

and put the groove of the module on the DIN rail.

Press the modules towards the DIN rail and push in

the clamps as shown on the right.

3. Use BNL6P mounting clips on both sides of the

MicroSmart modules to prevent moving sideways.

Removing from DIN Rail

1. Insert a flat screwdriver into the slot in the clamp.

Groove

35-mm-wide DIN Rail

Clamp

2. Pull out the clamps from the modules.

3. Turn the MicroSmart modules bottom out.

Direct Mounting on Panel Surface

MicroSmart modules can also be mounted on a panel

surface inside a console. When mounting a slim type

CPU module, AS-Interface master module, and other

expansion modules, use optional direct mounting strip

FC4A-PSP1P as described below.

Installing the Direct Mounting Strip

1. Remove the clamp from the module by pushing the

2. Insert the direct mounting strip into the slot where the

clamp inward.

clamp has been removed (A). Further insert the direct

mounting strip until the hook enters into the recess in

the module (B).

MICROSMART AS-INTERFACE MASTER MODULE USER’S MANUAL 3-3

Page 17

3: INSTALLATION AND WIRING

Removing the Direct Mounting Strip

(A)

1. Insert a flat screwdriver under the latch of the direct

mounting strip to release the latch (A).

(B)

2. Pull out the direct mounting strip (B).

Caution

• Reusing the Direct Mounting Strip

When you attempt to reuse a direct mounting strip, the hook may not catch on the recess sufficiently and may come out easily. When using a direct mounting strip again, be certain to push the

hook deeply into the recess.

Mounting Hole Layout for Direct Mounting on Panel Surface

Make mounting holes of ø4.3 mm as shown below and use M4 screws (6 or 8 mm long) to mount the AS-Interf ace master

module on the panel surface.

6.3

23.5

3.0

2-ø4.3

90.0

103.0

113.0±0.2

Direct Mounting Strip

FC4A-PSP1P

3-4 MICROSMART AS-INTERFACE MASTER MODULE USER’S MANUAL

Page 18

Terminal Connection

3: INSTALLATION AND WIRING

Caution

• Make sure that the operating conditions and environments are within the specification values.

• Be sure to connect the ground terminal on the CPU module to a proper ground, otherwise electri-

cal shocks may be caused.

• Do not touch live terminals, otherwise electrical shocks may be caused.

• Do not touch terminals immediately after power is turned off, otherwise electrical shocks may be

caused.

• When using ferrules, insert a wire to the bottom of the ferrule and crimp the ferrule.

• When connecting a stranded wire or multiple solid wires to a screw terminal block, use a ferrule.

Otherwise the wire may slip off the terminal block.

Ferrules, Crimping Tool, and Screwdriver for Phoenix Terminal Blocks

The screw terminal block for the AS-Interface cable can be wired with or without using ferrules on the end of the cable.

Applicable ferrules for the Phoenix terminal blocks and crimping tool for the ferrules are listed below. The screwdriver is

used for tightening the terminal screws and mounting screws on the terminal block. These ferrules, crimping tool, and

screwdriver are made by Phoenix Contact and are available from Phoenix Contact.

Type numbers of the ferrules, crimping tool, and screwdriv er listed below are the type numbers of Phoenix Contact. When

ordering these products from Phoenix Contact, specify the Order No. and quantity listed below.

Ferrule Order No.

Quantity of Cables Cable Size Phoenix Type Order No. Pcs./Pkt.

2

AWG20 AI 0,5-8 WH 32 00 01 4 100

2

AWG18 AI 0,75-8 GY 32 00 51 9 100

2

AWG16 AI 1,5-8 BK 32 00 04 3 100

2

AWG20 AI-TWIN 2 x 0,5-8 WH 32 00 93 3 100

2

AWG18 AI-TWIN 2 x 0,75-8 GY 32 00 80 7 100

For 1-cable connection

For 2-cable connection

0.5 mm

0.75 mm

1.5 mm

0.5 mm

0.75 mm

Crimping Tool and Screwdriver Order No.

Tool Name Phoenix Type Order No. Pcs./Pkt. Tightening Torque Description

Crimping Tool CRIMPFOX ZA 3 12 01 88 2 1 — For crimping ferrules

Screwdriver SZS 0,6 x 3,5 12 05 05 3 10

0.5 to 0.6 N·m For tightening terminal screws

0.3 to 0.5 N·m For tightening mounting screws

MICROSMART AS-INTERFACE MASTER MODULE USER’S MANUAL 3-5

Page 19

3: INSTALLATION AND WIRING

AS-Interface Cable Wiring

Before wiring the AS-Interface cable, remo ve the AS-Interface cable terminal block from the AS-Interface cable connector

on the AS-Interface master module.

AS-Interface specifies use of brown cables for the AS-Interf ace + line, and blue cables for the AS-Interface – line. Connect

the cables to match the color labels on the terminal block. Tighten the terminal screws to a torque of 0.5 to 0.6 N·m.

Insert the terminal block to the connector on the AS-Interface master module, and tighten the mounting screws to a torque

of 0.3 to 0.5 N·m.

Use a ferrule.

Brown AS-Interface +

Brown Label

Blue AS-Interface –

Use a ferrule. Blue Label

Power Supply

Caution

Power Supply Wiring Diagram

A recommended power supply wiring diagram is shown below. Use a common power switch for both the CPU module

power supply and AS-Interf ace power supply to make sure that both power supplies are turned on and of f at the same time.

AC Power

Power Switch

• When turning off the power to the CPU module, also turn off the AS-Interface power supply. If

the CPU module is powered down and up while the AS-Interface po wer remains on, AS-Interface

communication may stop due to a configuration error, resulting in a communication error.

• Turn on the AS-Interface power supply no later than the CPU module power supply , e xcept when

slave address 0 exists on the network. The two power supplies may be turned off in any order.

Slim Type CPU Module

FC4A-D40K3

AS-Interface Master Module

FC4A-AS62M

AS-Interface Cable Connector

CPU Module Power Supply

AS-Interface Power Switch (Note)

AS-Interface Power Supply

VLSV (very low safety voltage)

Note: A failed slave can be replaced with a new slave with address 0 without turning of f the power to the CPU module and

the AS-Interface line. But, if power has been turned off before replacing the slaves, install a new slave with address 0 and

take one of the following steps, because the AS-Interface master module has to be initialized to enable communication.

24V DC

Slave 2

30V DC

Slave 1

• Disconnect the AS-Interface cable connector and turn on both power supplies. Five seconds later, connect the AS-Interface

cable connector.

• Turn on the CPU module power supply first. Five seconds later, turn on the AS-Interface power supply.

3-6 MICROSMART AS-INTERFACE MASTER MODULE USER’S MANUAL

Page 20

4: OPERATION BASICS

Introduction

This chapter describes general information about simple operating procedures for the basic AS-Interface system from programming WindLDR on a computer to monitoring the slave operation.

AS-Interface System Setup

The sample AS-Interface system consists of the following devices:

Name Type No. Description

MicroSmart Slim Type CPU Module FC4A-D20RK1 System program version 201 or later

MicroSmart AS-Inter face Master Module FC4A-AS62M —

WindLDR FC9Y-LP2CDW Version 4.21 or higher

1 unit

AS-Interface Standard Slave —

AS-Interface Power Supply PS2R-Q30ABL Output 30.5V DC, 2.4A (73W)

Connect the devices as shown below.

Address 0

ID: 0, I/O: 7, ID2: F, ID1: 7

Computer Link Cable 4C

FC2A-KC4C

3m (9.84 ft.) long

Slim Type CPU Module

FC4A-D20RK1

AS-Interface Power Supply

Standard Slave

Address 0

ID: 0, I/O: 7, ID2: F, ID1: 7

AS-Interface Master Module

FC4A-AS62M

Standard

AS-Interface Cable

MICROSMART AS-INTERFACE MASTER MODULE USER’S MANUAL 4-1

Page 21

4: OPERATION BASICS

Selecting the PLC Type

Start WindLDR on a computer.

1. From the

2. Select MicroSmart-20Ry.

3. Click OK to save changes and return to the ladder editing screen.

WindLDR menu bar, select Configure > PLC Selection. The PLC Selection dialog box appears.

Function Area Settings

Use of the AS-Interface master module must be selected in the Function Area Settings dialog box.

1. From the WindLDR menu bar, select Configure > Function Area Settings. The Function Area Settings dialog box

appears.

2. Select the Others tab.

3. Make sure of a check mark in the check box on the left of Use AS-Interface Master Module.

This check box is checked as default. Since this setting relates to the user program, download the user program to the CPU

module after changing any of these settings.

If the ERR LED on the CPU module goes on when the AS-Interface master module is connected, download the user program to the CPU module after making the above setting.

4-2 MICROSMART AS-INTERFACE MASTER MODULE USER’S MANUAL

Page 22

4: OPERATION BASICS

Assigning a Slave Address

AS-Interface compatible slave de vices are set to address 0 at f actory. Connect the sla v e to the AS-Interface master module

as shown on page 4-1. Do not connect two or more slav es with slave address 0, otherwise the AS-Interface master module

cannot recognize slave addresses correctly.

1. Power up the

Note: When slave address 0 is not mounted on the AS-Interface bus, the CPU module power supply and the AS-Interface

power supply can be turned on at the same time. See page 3-6.

MicroSmart CPU module first. Approximately 5 seconds later, turn on the AS-Interface power supply.

2. From the WindLDR menu bar, select Configure > AS-Interface Master to open the Configure AS-Interface Master

dialog box. Press Refresh to collect slave information and update the screen display. (When configuration in the master module is complete, you do not have to press Refresh since the screen display is updated automatically.)

On the Configure AS-Interface Master dialog box, slave address 0 is shaded with yellow. This means that the master module has found slave address 0 on the AS-Interface bus. The CDI for address 0 shows 07F7 (ID: 0, I/O: 7, ID2: F, ID1: 7).

3. Click the slave address “00” to open the Change Slave Address dialog box for slave 0. To assign slave address 1 to the

slave, enter 1 in the New Address field and click OK.

Yellow Shade

Click slave address 0 to open the

Change Slave Address dialog box.

CDI: Configuration Data Image

PCD: Permanent Configuration Data

The new address “01” is shaded with

yellow to indicate that the address

assignment is complete.

4. When changing slave addresses on

other slaves, continue from step 3 if

it is possible to wire the slave without turning off power, or from step

1 if the CPU module is shut down.

MICROSMART AS-INTERFACE MASTER MODULE USER’S MANUAL 4-3

Yellow Shade

Page 23

4: OPERATION BASICS

Configuring a Slave

Next, you have to set the sla ve con figuration in the AS-Interface master module, either by using pushbuttons PB1 and PB2

on the AS-Interface master module or WindLDR.

Configuration Using Pushbuttons PB1 and PB2

Shut down and

power up again.

Press PB1 and PB2. Press PB2. Press PB1.

1. Check that PWR LED and CMO LED on the AS-Interface master module are on (normal protection mode).

2. Press pushbuttons PB1 and PB2 together for 3 seconds. CMO LED turns off and LMO LED turns on (protected mode).

3. Press pushbutton PB2 for 3 seconds. CNF LED flashes (configuration mode).

4. About 5 seconds later, press pushbutton PB1 for 3 seconds. All I/O LEDs blink once to complete configuration.

5. Shut down the CPU module and AS-Interface master module, and power up again. Check that FLT LED is off, which

indicates that configuration is complete.

6. Use

WindLDR to view slav e information on the Configure AS-Interface Master dialog box and check that all slaves are

recognized correctly.

4-4 MICROSMART AS-INTERFACE MASTER MODULE USER’S MANUAL

Page 24

Configuration Using WindLDR

4: OPERATION BASICS

Slave configuration can be set using

WindLDR in two ways; using the Auto Configuration or Manual Configuration but-

ton on the Configure AS-Interface Master dialog box.

1. Click the A

uto Configuration button to store the configuration information (LDS, CDI, PI) of the connected slaves to

the EEPROM (LPS, PCD, PP) in the AS-Interface master module. For details, see page 7-3.

The auto configuration automatically stores the information of slaves found on the AS-Interf ace bus to the EEPROM in the

master module, and this completes configuration. Another method of configuration is manual configuration as follows.

2. Click the PCD value “FFFF” of slave address 01 to open the Configure Slave 01A dialog box.

3. Enter the same value as CDI “07F7” to the PCD field. (Set FFFF to PCD values of all unused slaves.)

4. Select initial settings of parameters 0 through 3, if required.

Yellow Shade

5. Click the M

anual Configuration button to store the selected PCD and parameter values to the master module.

6. Check that the blue shade appears at slave address 01. Now, configuration is complete.

Blue Shade

MICROSMART AS-INTERFACE MASTER MODULE USER’S MANUAL 4-5

Page 25

4: OPERATION BASICS

Monitoring Digital I/O, and Changing Output Status and Parameters

While the MicroSmart is communicating with AS-Interface slaves through the AS-Interface bus, operating status of ASInterface slaves can be monitored using WindLDR on a PC. Output statuses and parameter image (PI) of slaves connected

to the AS-Interface master module can also be changed using WindLDR.

1. From the

tor AS-Interface Slaves in the pull-down menu. The Monitor AS-Interface Slaves dialog box appears.

Active slaves are indicated with blue shade.

Next step is to change output status of the active slave.

2. Click the output of slave address 01 to open the Slave Status 01A dialog box.

3. Click the On or Off button to change the statuses of outputs O0 through O3 and parameters (PI) P0 through P3 as

required.

WindLDR menu bar, select Online > Monitor. From the WindLDR menu bar, select Online, and select Moni-

Blue Shade

The selected parameters (PI) are in effect until the CPU module is shut down. When the CPU module is po wered up again,

the parameter values (PP) selected in the slave configuration procedure (page 4-4) will take effect. To store the changed

parameter values to the AS-Interface master module EEPROM, execute the Copy PI to PP command by storing 0306,

0100, 0000, 0000, 0001 to data registers D1941 through D1945. See page 6-17.

4-6 MICROSMART AS-INTERFACE MASTER MODULE USER’S MANUAL

Page 26

4: OPERATION BASICS

Troubles at System Start-up

The following table summarizes possible troubles at system start-up, probable causes and actions to be taken.

Trouble Cause and Action

• AS-Interface power is not supplied to the AS-Interface master module. Check that

PWR LED is off.

(power)

FLT LED is on.

(fault)

LMO LED is on.

(local mode)

wiring is correct and AS-Inter face power is supplied.

• Power is not supplied from the CPU module to the AS-Interface master module.

Check the connection between the CPU module and the AS-Interface master module.

• Slave configuration on the bus is incorrect. Use the WindLDR slave monitor function

to check that slaves are connected correctly. Perform configuration, if necessar y. For

the configuration method, see page 7-1.

If FLT LED remains on even though slaves are connected correctly and configuration is

completed, either disconnect and reconnect the AS-Interface connector, or turn off and

on the AS-Interface power supply.

The CPU module fails to communicate with the AS-Interface master module. Check the

following points.

• Is the CPU module compatible with AS-Interface? Check the Type No. of the CPU

module.

• Is the system program of the CPU module 201 or higher? Check the system program

version in the Online > PLC Status dialog box in WindLDR.

• Is a check mark put in the check box “Use AS-Interface Master Module” in WindLDR

Function Area Settings? The box is checked as default. If not, put a check mark and

download the user program to the CPU module.

OFF LED is on.

(offline)

Slave operation is unstable.

• While a slave of address 0 was connected, power was turned on. After changing the

slave address, power up again. For the address changing method, see page 7-2.

• Check if there are two or more slaves with the same address. Each slave must have

a unique address. If two slaves have the same address and same identification

codes (ID, I/O, ID2, ID1), the AS-Interface master module may fail to detect an error.

When changing the duplicate slave address using WindLDR, remove one of the

slaves from the bus.

MICROSMART AS-INTERFACE MASTER MODULE USER’S MANUAL 4-7

Page 27

4: OPERATION BASICS

4-8 MICROSMART AS-INTERFACE MASTER MODULE USER’S MANUAL

Page 28

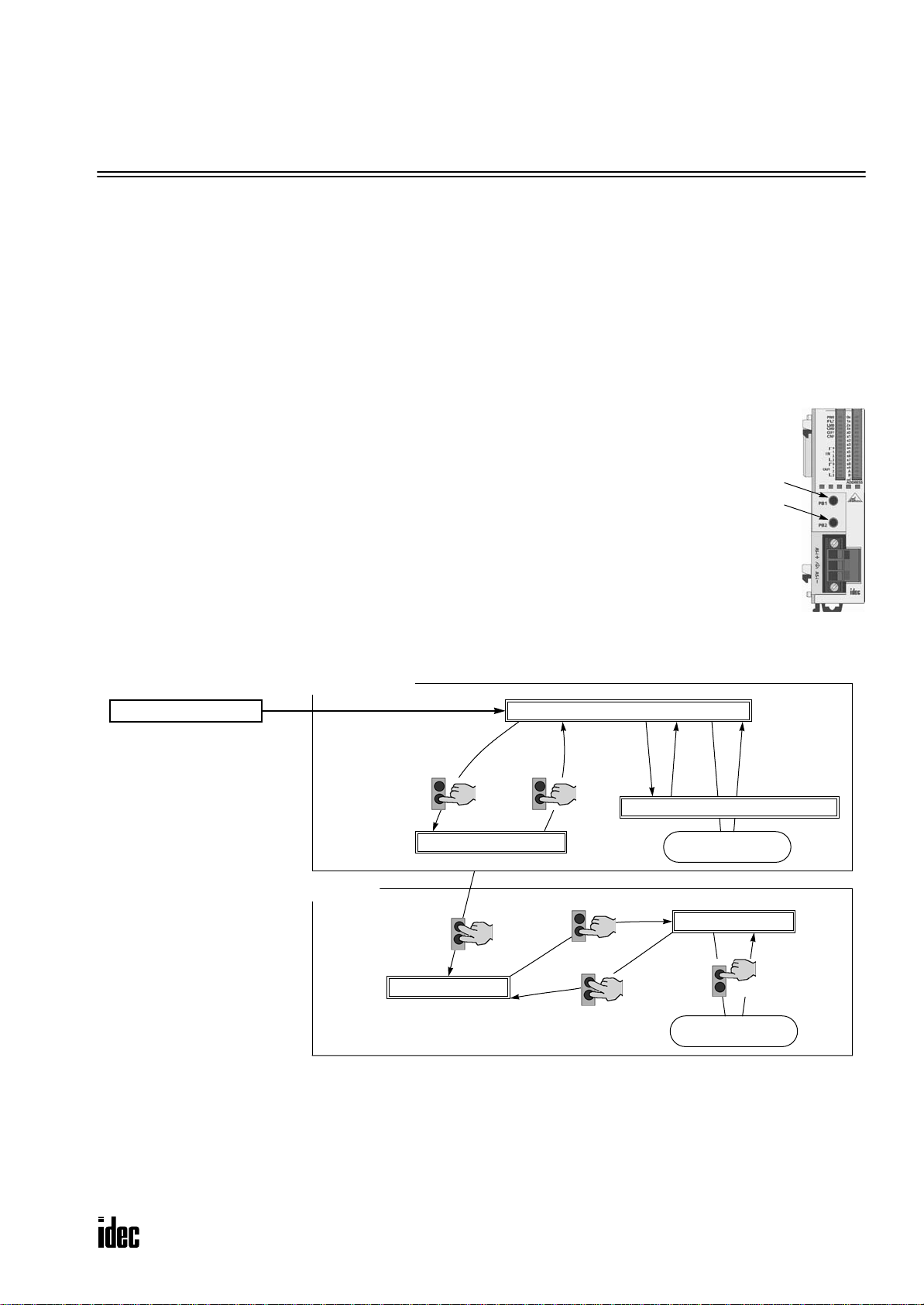

5: PUSHBUTTONS AND LED INDICATORS

PB1

PB2

Introduction

This chapter describes the operation of pushbuttons PB1 and PB2 on the AS-Interface master module to change operation

modes, and also explains the functions of address and I/O LED indicators.

Pushbutton Operation

The operations performed by pushbuttons PB1 and PB2 on the front of the AS-Interface master module depend on the

duration of being pressed. A “long press” switches the operation mode, and a “short press” switches the slave being monitored on the I/O LEDs. If the duration of pressing PB1 or PB2 does not correspond to either of these, the status of the ASInterface master module does not change.

Long Press

A “long press” takes effect when you press either pushbutton PB1 or PB2 or both for 3 seconds or

more. Use the long press to change the operation mode of the AS-Interface master module or to

save the configuration data to the AS-Interface master module EEPROM.

Short Press

A “short press” takes effect when you press either pushbutton PB1 or PB2 for 0.5 second or less.

Use the short press to change the slave address when monitoring slave I/O status on the AS-Interface master module LED indicators.

Transition of AS-Interface Master Module Modes Using Pushbuttons

Connected Mode

MicroSmart Power ON

PB2 PB2

Normal Protected Offline

Note:

All pushbutton operations

for changing modes are

“long press.”

*1 Pushbutton operation or execution of the ASI command Go to Normal Protected Of fline.

*2 Pushbutton operation or execution of the ASI command Go to Normal Protected Mode.

*3 Execution of the ASI command Prohibit Data Exchange.

*4 Execution of the ASI command Enable Data Exchange.

*5 Configuration is done by clicking the Auto Configuration or Manual Configuration button in WindLDR. The configuration

data is saved to the AS-Interface master module EEPROM.

Local Mode

PB1

PB2

Protected Mode

Normal Protected Mode

*2*1

Normal Protected Data Exchange Off

PB2

PB1

PB2

*5*4*3

Store Configuration

Data to EEPROM

Configuration Mode

PB1

Store Configuration

Data to EEPROM

MICROSMART AS-INTERFACE MASTER MODULE USER’S MANUAL 5-1

Page 29

5: PUSHBUTTONS AND LED INDICATORS

AS-Interface Master Module Operation Modes

The AS-Interface master module has tw o modes of operation: connected mode is used for actual operation, and local mode

is used for maintenance purposes.

Connected Mode

In connected mode, the CPU module communicates with the AS-Interface master module to monitor and control each

slave. Connected mode is comprised of the following three modes.

Normal Protected Mode

When the CPU module is powered up, the AS-Interface master module initially enters normal protected mode of connected mode if no error occurs. This is the normal operation mode for the AS-Interface master module to perform data

communication with the connected slaves.

If the configuration data stored in the AS-Interface master module do not match the currently connected slave configuration, the FL T LED on the front of the AS-Interface master module goes on. Execute con figuration using the pushbuttons on

the AS-Interface master module. Configuration can also be done using WindLDR. See page 7-3.

Normal Protected Offline

The AS-Interface master module stops communication with all slaves and enables offline operation (initialization of the

master module). In this mode, the CPU module cannot monitor the slave status.

To enter normal protected offline from normal protected mode, either long-press the PB2 button or execute the ASI command Go to Normal Protected Offline. To return to normal protected mode and resume data communication, either longpress the PB2 button again or execute the ASI command Go to Normal Protected Mode. For details about the ASI commands, see page 6-17.

Normal Protected Data Exchange Off

Data communication with all slaves is prohibited. To enter this mode, execute the ASI command Prohibit Data Exchange.

To return to normal protected mode and resume data communication, execute the ASI command Enable Data Exchange.

For details about the ASI commands, see page 6-17.

When auto configuration or manual configuration is executed on WindLDR, the AS-Interface master module enters this

mode during configuration.

Local Mode

In local mode, the CPU module does not communicate with the AS-Interface master module. Local mode is used to carry

out maintenance operations such as checking the configuration and slave inputs. Use the input LEDs to check the slave

input data during operation.

When the CPU module is powered up, the AS-Interface master module initially enters normal protected mode of connected mode if no error occurs. T o switch from an y of connected mode to local mode (protected mode), long-press the PB1

and PB2 buttons simultaneously. It is not possible to switch from local mode back to connected mode using the pushbuttons. To return to connected mode, shut down the CPU module and power up again.

Local mode is comprised of two modes: protected mode and configuration mode.

Protected Mode

This mode operates the slaves in accordance with the slav e configuration data stored in the AS-Interface master module. If

the configuration data stored in the AS-Interface master module does not match the currently connected slave configuration, the FLT LED on the front of the AS-Interface master module goes on, and slaves are not operated correctly.

To enter protected mode from any of connected mode, long-press the PB1 and PB2 buttons simultaneously.

Configuration Mode

This mode switches all currently connected slaves to active, regardless of the slave configuration data stored in the ASInterface master module. To store the current slave configuration data to the AS-Interface master module EEPROM, long

press the PB1 button. This way, configuration is executed.

To enter configuration mode from protected mode, long-press the PB2 button. To return to protected mode, long-press the

PB1 and PB2 buttons simultaneously.

5-2 MICROSMART AS-INTERFACE MASTER MODULE USER’S MANUAL

Page 30

5: PUSHBUTTONS AND LED INDICATORS

LED Indicators

The LED indicators on the AS-Interface master module consist of status LEDs, I/O LEDs, and address LEDs.

Address LEDs (0x to 3x)

Status LEDs

Address LEDs (x0 to x9)

Input LEDs

Output LEDs

Address LEDs (A and B)

LED Indicators Description

PWR

(AS-Interface power supply)

FLT (Fault)

Status LEDs

Input LEDs IN0-IN3

Output LEDs OUT0-OUT3

Address LEDs

LMO (Local mode)

CMO (Connected mode)

OFF (Offline)

CNF (Configuration)

0x-3x (place of 10)

x0-x9 (place of 1)

A, B (A or B slave)

Indicates the status of the AS-Interface power supply for the AS-Interface

master module.

Goes on when the AS-Interface power is supplied sufficiently.

Indicates the AS-Interface configuration status.

Goes on when the permanent configuration data (PCD) stored in the ASInterface master module EEPROM does not match the current slave configuration, or configuration data image (CDI). Then, configuration is not

complete or an error was found on the AS-Inter face bus.

Indicates the mode of the AS-Interface master module.

Goes on when the AS-Interface master module is in local mode.

Goes off when the AS-Inter face master module is in connected mode.

Indicates the mode of the AS-Interface master module.

Goes on when the AS-Interface master module is in connected mode.

Goes off when the AS-Inter face master module is in local mode.

Indicates the operating status of the AS-Interface master module.

Goes on when the AS-Interface master module is in normal protected

offline.

Indicates the configuration status of the AS-Interface master module.

Flashes when the AS-Interface master module is in configuration mode.

Indicates the operating status of four inputs at the address indicated by

the address LEDs.

Goes on when the corresponding input at the indicated address is on.

Indicates the operating status of four outputs at the address indicated by

the address LEDs.

Goes on when the corresponding output at the indicated address is on.

Indicates the slave address of 0A through 32B.

Goes on when the selected address exists.

Flashes when the selected address does not exist.

MICROSMART AS-INTERFACE MASTER MODULE USER’S MANUAL 5-3

Page 31

5: PUSHBUTTONS AND LED INDICATORS

Status LEDs

The operation modes of the AS-Interface master module can be changed by pressing the pushbuttons on the front of the

AS-Interface master module or by executing ASI commands. The operation modes can be confirmed on the six status

LEDs on the AS-Interface master module. For details about the ASI commands, see page 6-17.

Status LED Indication

Status LED PWR FLT LMO CMO OFF CNF

Normal Protected Mode ON

Connected Mode

Local Mode

*1: Goes off when AS-Inter face power is not supplied.

*2: Goes on when an error is found on the AS-Inter face bus.

Normal Protected Offline ON

Normal Protected

Data Exchange Off

Protected Mode ON

Configuration Mode ON

ON

*1

*1

*1

*1

*1

*2

OFF

ON OFF ON ON OFF

ON OFF ON OFF OFF

*2

OFF

*2

OFF

OFF ON OFF OFF

ON OFF OFF OFF

ON OFF OFF Flash

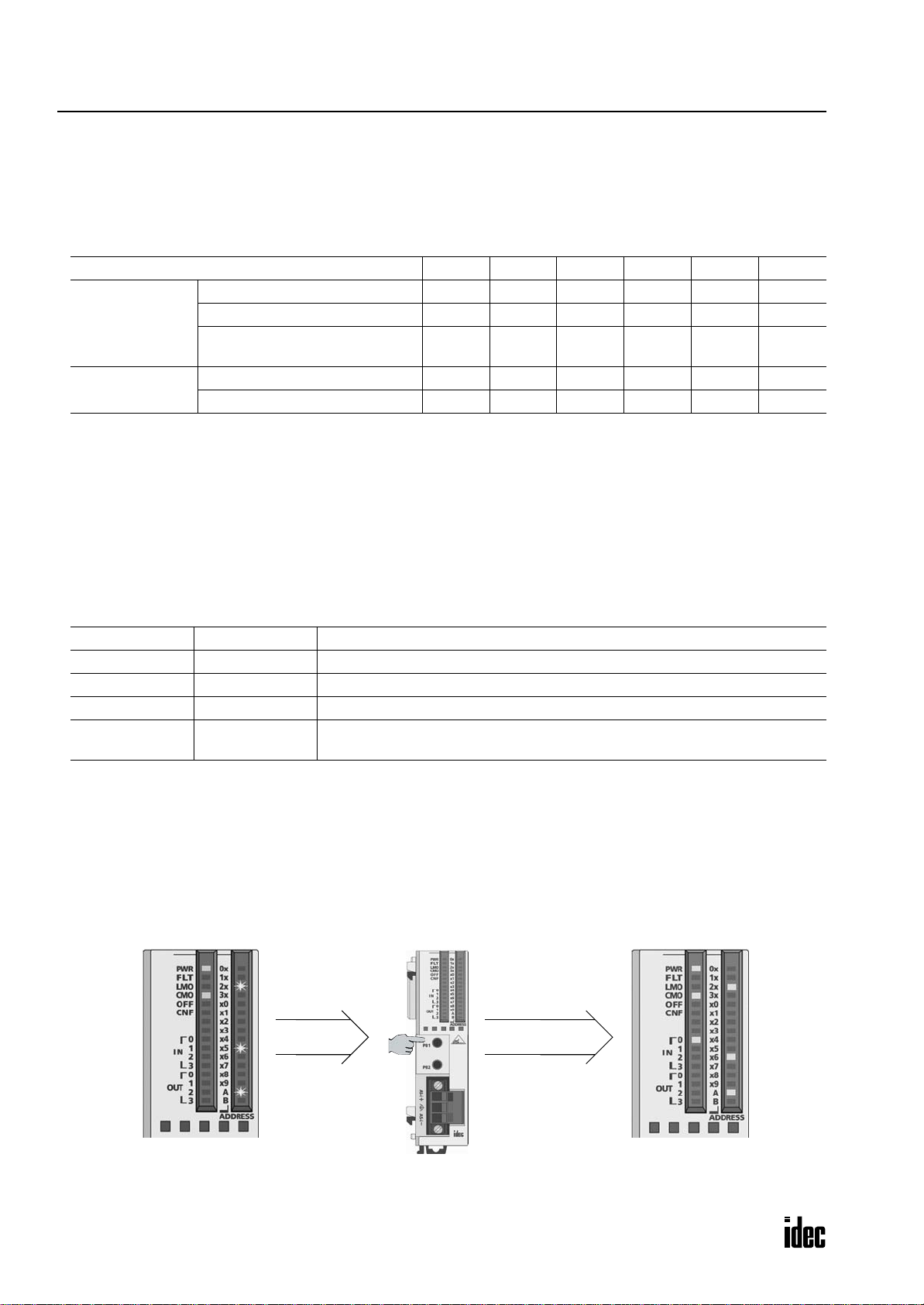

Address LEDs and I/O LEDs

The operating status and I/O status of each slave can be monitored on the address LEDs and I/O LEDs on the front of the

AS-Interface master module.

Slave Operating Status

The operating status of each slave can be determined by viewing the address LEDs and I/O LEDs.

Address LED I/O LED Description

ON ON or OFF The slave at this address is active.

ON Flash The slave at this address is active, but has an error.

Flash OFF This address is not assigned a slave.

OFF OFF

The AS-Interface bus communication is disabled because the AS-Interface power

is not supplied or the AS-Interface master module is in normal protected of fline.

Slave I/O Status

The I/O status of each slave can be monitored on the address LEDs and I/O LEDs. Use the short press to change the slav e

address when monitoring slave I/O status on the AS-Interface master module. A short press on PB1 increments the

address. At the last address (31B), another short press will return to the first address (0A). A short press on PB2 decrements the address. At the first address (0A), another short press will return to the last address (31B).

The figures below illustrate what happens when you press the PB1 button while the address LEDs indicate 25A. The

address LEDs increment to 26A where a slave is assigned. Note that the address LEDs flash if no slave is assigned.

Short press

on PB1

I/O LEDs

indicate statuses

Monitoring Slave Address 25A

Address LEDs are flashing since

no slave is assigned.

5-4 MICROSMART AS-INTERFACE MASTER MODULE USER’S MANUAL

Monitoring Slave Address 26A

Address LEDs go on and I/O

LEDs indicate the statuses.

Page 32

6: AS-INTERFACE OPERANDS

Introduction

This chapter describes AS-Interface operands, or internal relays M1300 through M1997 and data registers D1700 through

D1999, assigned in the CPU module to control and monitor the AS-Interface bus, and provides detailed description about

internal relays allocated to SwitchNet™ control units for use as slaves in the AS-Interface network. Also describes ASI

commands used to update AS-Interface operands in the CPU module or to control the AS-Interface master module.

AS-Interface Operand Allocation Numbers

The I/O data and parameters of slaves on the AS-Interface bus, the status of the AS-Interface bus, and various list information of the slaves are allocated to the AS-Interface master module EEPROM. This information is called AS-Interface

objects, which can be accessed through the AS-Interface operands. The allocation is shown in the table below.

MicroSmart CPU Module

Operand Allocation No. AS-Interface Object

AS-Interface

Internal

Relays

M1300-M1617 3.0 R

M1620-M1937 3.0 W

M1940-M1997 1.0 R Status information

Precessing

Time (msec)

*1

Read/

Write

*2

*2

D1700-D1731 5.2 R Analog input

D1732-D1763 5.2 W Analog output

*2

*2

*2

*2*3

*2

*2

AS-Interface

Data

Registers

D1764-D1767 1.0 R

D1768-D1771 1.0 R

D1772-D1775 1.0 R

D1776-D1779 1.0 R/W

D1780-D1843 10.4 R

D1844-D1907 10.4 R/W

D1908-D1923 3.0 R

D1924-D1939 3.0 R/W

AS-Interface Master Module EEPROM

Digital input (IDI)

Digital output (ODI)

*4

*4

*5

*5

List of active slaves (LAS)

List of detected slaves (LDS)

List of peripheral fault slaves (LPF)

List of projected slaves (LPS)

Configuration data image (CDI)

*2*3

Permanent configuration data (PCD)

Parameter image (PI)

*2*3

Permanent parameter (PP)

Operand

Updated

Every scan

Each time ASI

command is

executed

D1940 0.7 R/W Slave 0 ID1 code

D1941-D1945 — R/W For ASI command description —

D1946-D1999 — — (reserved) —

*1: The time required to update the operand data. When using the AS-Inter face master module, the scan time increases by

a minimum of 10 msec.

*2: These AS-Inter face operand data can be read or written using WindLDR. For details, see page 7-1.

*3: The LPS, PCD, and PP are set and downloaded to a PLC using WindLDR. For details, see page 7-3.

*4: IDI (input data image), ODI (output data image)

*5: The analog I/O data is updated only when an analog slave is connected to the AS-Inter face bus.

Processing Time

AS-Interface internal relays for digital I/O and status information, and data registers for LAS, LDS, LPF are updated

in every scan. Data registers for analog I/O operands are

also updated in every scan only when analog I/O are connected to the AS-Interface bus. The processing times for

these AS-Interface operands are shown in the table above.

Other AS-Interface data registers are updated when an

ASI command is executed in the CPU module. For the

processing times of the ASI commands, see page 6-17.

MICROSMART AS-INTERFACE MASTER MODULE USER’S MANUAL 6-1

Ladder

Processing

AS-Interface

Processing

Other

Processing

MicroSmart CPU Module

AS-Interface Operands

Constantly

Updated Operands

M1300-M1997

D1700-D1775

ASI Command

D1941-D1945

ASI Command

Updated Operands

AS-Interface

Master Module

AS-Interface Objects

IDI, ODI

Status Information

Analog I/O

LAS, LDS, LPF

LPS, CDI, PCD

PI, PP

Slave 0 ID1D1776-D1940

Page 33

6: AS-INTERFACE OPERANDS

I/O Data

The AS-Interface master module can process digital I/O data and analog I/O data. Digital I/O data can be a maximum of 4

digital inputs and 4 digital outputs per slave. Analog I/O data consists of 4 channels of 16-bit analog input or output data

per slave.

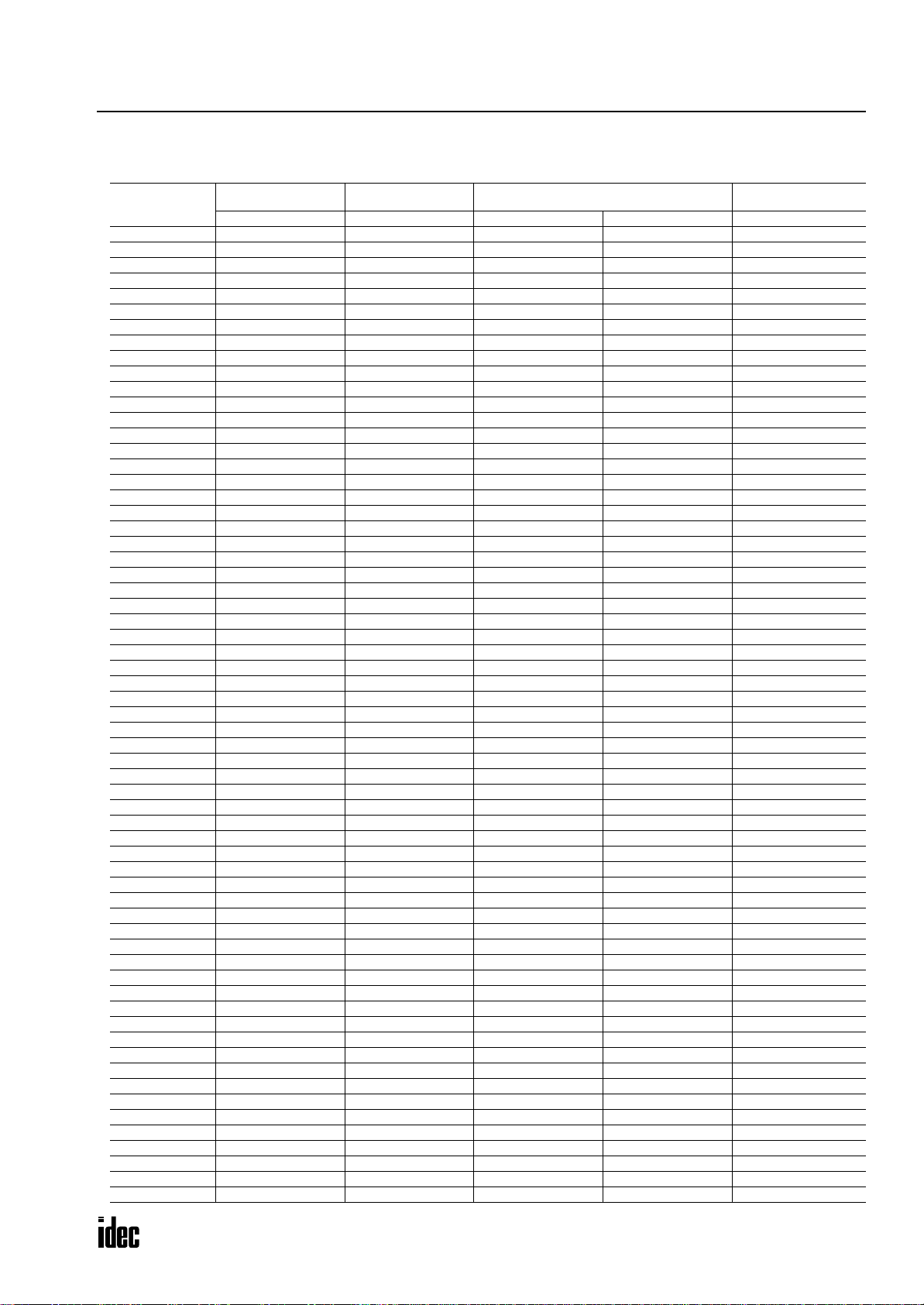

Digital I/O Data of Standard Slaves and Expansion Slaves

The digital I/O data for standard slaves and A/B slaves (sensors and actuators) on the AS-Interface bus are allocated to the

AS-Interface internal relays in the ascending order starting with slave 0. The input data image (IDI) for each slave is allocated to M1300 through M1617, and the output data image (ODI) is allocated to M1620 through M1937. For example, in

the case of slave 3A, the input data is allocated to M1314 (DI0) through M1317 (DI3), and the output data is allocated to

M1634 (DO0) through M1637 (DO3).

•

Digital Input Data Image

Data Format

Input Data Image (IDI)

M1300 Byte 0 Slave 1(A) (Slave 0)

M1310 Byte 1 Slave 3(A) Slave 2(A)

M1320 Byte 2 Slave 5(A) Slave 4(A)

M1330 Byte 3 Slave 7(A) Slave 6(A)

M1340 Byte 4 Slave 9(A) Slave 8(A)

M1350 Byte 5 Slave 11(A) Slave 10(A)

M1360 Byte 6 Slave 13(A) Slave 12(A)

M1370 Byte 7 Slave 15(A) Slave 14(A)

M1380 Byte 8 Slave 17(A) Slave 16(A)

M1390 Byte 9 Slave 19(A) Slave 18(A)

M1400 Byte 10 Slave 21(A) Slave 20(A)

M1410 Byte 11 Slave 23(A) Slave 22(A)

M1420 Byte 12 Slave 25(A) Slave 24(A)

M1430 Byte 13 Slave 27(A) Slave 26(A)

M1440 Byte 14 Slave 29(A) Slave 28(A)

M1450 Byte 15 Slave 31(A) Slave 30(A)

M1460 Byte 16 Slave 1B —

M1470 Byte 17 Slave 3B Slave 2B

M1480 Byte 18 Slave 5B Slave 4B

M1490 Byte 19 Slave 7B Slave 6B

M1500 Byte 20 Slave 9B Slave 8B

M1510 Byte 21 Slave 11B Slave 10B

M1520 Byte 22 Slave 13B Slave 12B

M1530 Byte 23 Slave 15B Slave 14B

M1540 Byte 24 Slave 17B Slave 16B

M1550 Byte 25 Slave 19B Slave 18B

M1560 Byte 26 Slave 21B Slave 20B

M1570 Byte 27 Slave 23B Slave 22B

M1580 Byte 28 Slave 25B Slave 24B

M1590 Byte 29 Slave 27B Slave 26B

M1600 Byte 30 Slave 29B Slave 28B

M1610 Byte 31 Slave 31B Slave 30B

7

(DI3)

6

(DI2)

5

(DI1)

4

(DI0)

3

(DI3)

2

(DI2)

1

(DI1)

(DI0)

0

6-2 MICROSMART AS-INTERFACE MASTER MODULE USER’S MANUAL

Page 34

6: AS-INTERFACE OPERANDS

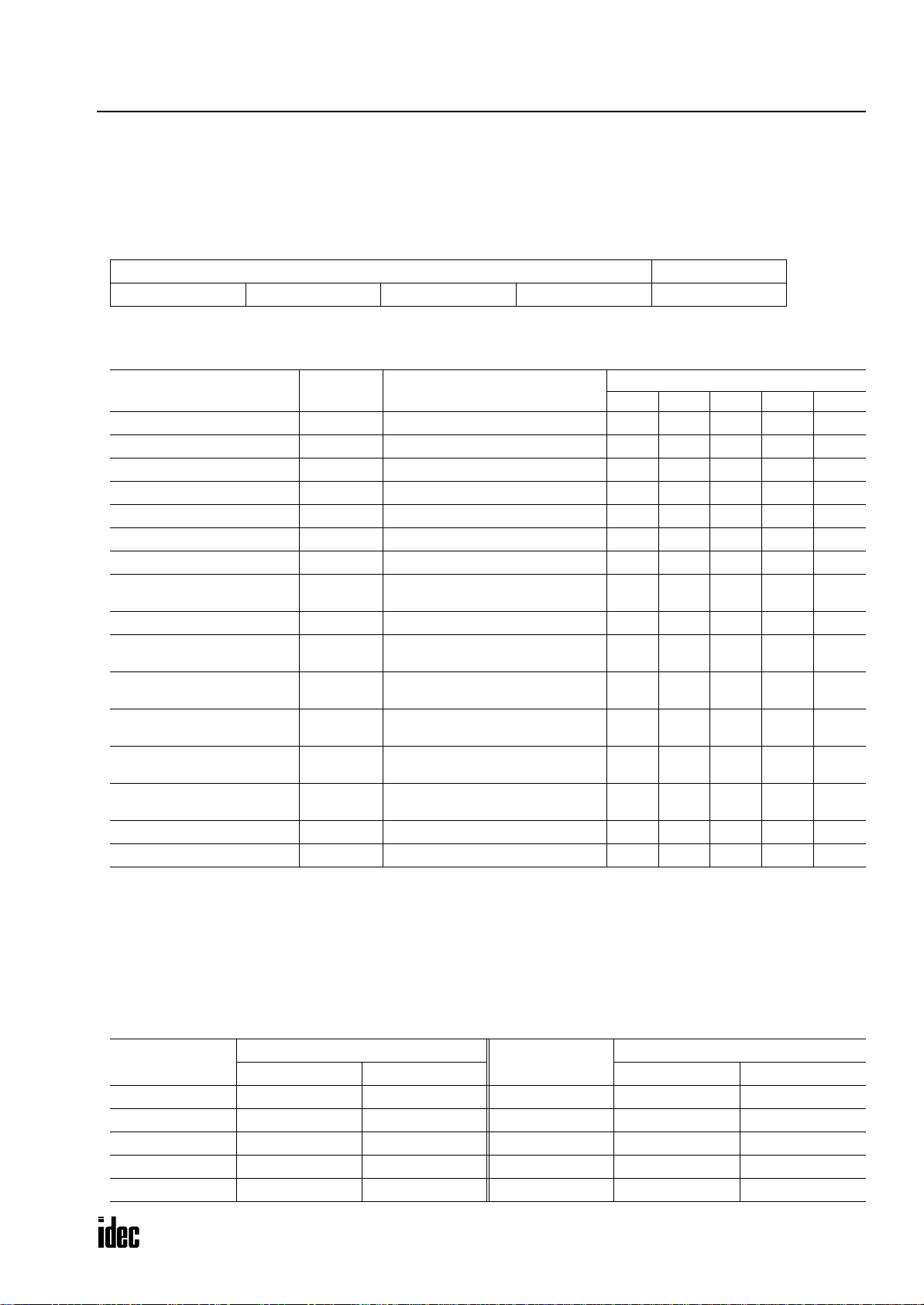

• Digital Output Data Image

Data Format

Output Data Image (ODI)

M1620 Byte 0 Slave 1(A) (Slave 0)

M1630 Byte 1 Slave 3(A) Slave 2(A)

M1640 Byte 2 Slave 5(A) Slave 4(A)

M1650 Byte 3 Slave 7(A) Slave 6(A)

M1660 Byte 4 Slave 9(A) Slave 8(A)

M1670 Byte 5 Slave 11(A) Slave 10(A)

M1680 Byte 6 Slave 13(A) Slave 12(A)

M1690 Byte 7 Slave 15(A) Slave 14(A)

M1700 Byte 8 Slave 17(A) Slave 16(A)

M1710 Byte 9 Slave 19(A) Slave 18(A)

M1720 Byte 10 Slave 21(A) Slave 20(A)

M1730 Byte 11 Slave 23(A) Slave 22(A)

M1740 Byte 12 Slave 25(A) Slave 24(A)

M1750 Byte 13 Slave 27(A) Slave 26(A)

M1760 Byte 14 Slave 29(A) Slave 28(A)

M1770 Byte 15 Slave 31(A) Slave 30(A)

M1780 Byte 16 Slave 1B —

M1790 Byte 17 Slave 3B Slave 2B

M1800 Byte 18 Slave 5B Slave 4B

M1810 Byte 19 Slave 7B Slave 6B

M1820 Byte 20 Slave 9B Slave 8B

M1830 Byte 21 Slave 11B Slave 10B

M1840 Byte 22 Slave 13B Slave 12B

M1850 Byte 23 Slave 15B Slave 14B

M1860 Byte 24 Slave 17B Slave 16B

M1870 Byte 25 Slave 19B Slave 18B

M1880 Byte 26 Slave 21B Slave 20B

M1890 Byte 27 Slave 23B Slave 22B

M1900 Byte 28 Slave 25B Slave 24B

M1910 Byte 29 Slave 27B Slave 26B

M1920 Byte 30 Slave 29B Slave 28B

M1930 Byte 31 Slave 31B Slave 30B

7

(DO3)6(DO2)5(DO1)4(DO0)3(DO3)2(DO2)1(DO1)0(DO0)

Caution

• Immediately after power up, the digital I/O data of standard slaves and expansion slaves cannot

be accessed. Data communication between the CPU module and the connected slaves starts when

special internal relay M1945 (Normal_Operation_Active) turns on. Make sure that M1945 is on

before starting to access the slave I/O data.

MICROSMART AS-INTERFACE MASTER MODULE USER’S MANUAL 6-3

Page 35

6: AS-INTERFACE OPERANDS

Analog I/O Data of Analog Slaves

The I/O data for a maximum of seven analog slaves (four channels for each slave) on the AS-Interface bus is stored to ASInterface data registers in the CPU module. The analog slav e addresses (1 to 31) are in the ascending order. The input data

for each analog slave is allocated to data registers D1700 to D1731, and the output data is allocated to D1732 to D1763.

The AS-Interface master module is compliant with analog slave profile 7.3.

Caution

• The maximum number of analog slaves that can be connected to the AS-Interface bus is seven. Do

not connect eight or more analog slaves to one bus, otherwise the slaves will not function correctly.

• When data registers D1700 through D1731 allocated to analog inputs contain 7FFF, do not use this

data for programming, because this value is reserved for a special meaning as follows:

Unused channel on a slave allocated to analog slave. (For a channel on a slave not allocated an

analog slave, the corresponding data register holds an indefinite value.)

Data overflow.

Communication between the master and analog slave is out of synchronism.

• When using analog slaves, read the user’s manual for the analog slave to process the data properly.

•

Analog Input Data

Analog Input Channel No. Data Format

D1700 Bytes 0 and 1 Channel 1

D1701 Bytes 2 and 3 Channel 2

D1702 Bytes 4 and 5 Channel 3

D1703 Bytes 6 and 7 Channel 4

D1704 Bytes 8 and 9 Channel 1

D1705 Bytes 10 and 11 Channel 2

D1706 Bytes 12 and 13 Channel 3

D1707 Bytes 14 and 15 Channel 4

D1708 Bytes 16 and 17 Channel 1

D1709 Bytes 18 and 19 Channel 2

D1710 Bytes 20 and 21 Channel 3

D1711 Bytes 22 and 23 Channel 4

D1712 Bytes 24 and 25 Channel 1

D1713 Bytes 26 and 27 Channel 2

D1714 Bytes 28 and 29 Channel 3

D1715 Bytes 30 and 31 Channel 4

D1716 Bytes 32 and 33 Channel 1

D1717 Bytes 34 and 35 Channel 2

D1718 Bytes 36 and 37 Channel 3

D1719 Bytes 38 and 39 Channel 4

D1720 Bytes 40 and 41 Channel 1

D1721 Bytes 42 and 43 Channel 2

D1722 Bytes 44 and 45 Channel 3

D1723 Bytes 46 and 47 Channel 4

D1724 Bytes 48 and 49 Channel 1

D1725 Bytes 50 and 51 Channel 2

D1726 Bytes 52 and 53 Channel 3

D1727 Bytes 54 and 55 Channel 4

D1728 Bytes 56 and 57 —

D1729 Bytes 58 and 59 —

D1730 Bytes 60 and 61 —

D1731 Bytes 62 and 63 —

1st data

(AI0)

2nd data

(AI1)

3rd data

(AI2)

4th data

(AI3)

5th data

(AI4)

6th data

(AI5)

7th data

(AI6)

(reserved)

6-4 MICROSMART AS-INTERFACE MASTER MODULE USER’S MANUAL

Page 36

• Analog Output Data

Analog Output Channel No. Data Format

D1732 Bytes 0 and 1 Channel 1